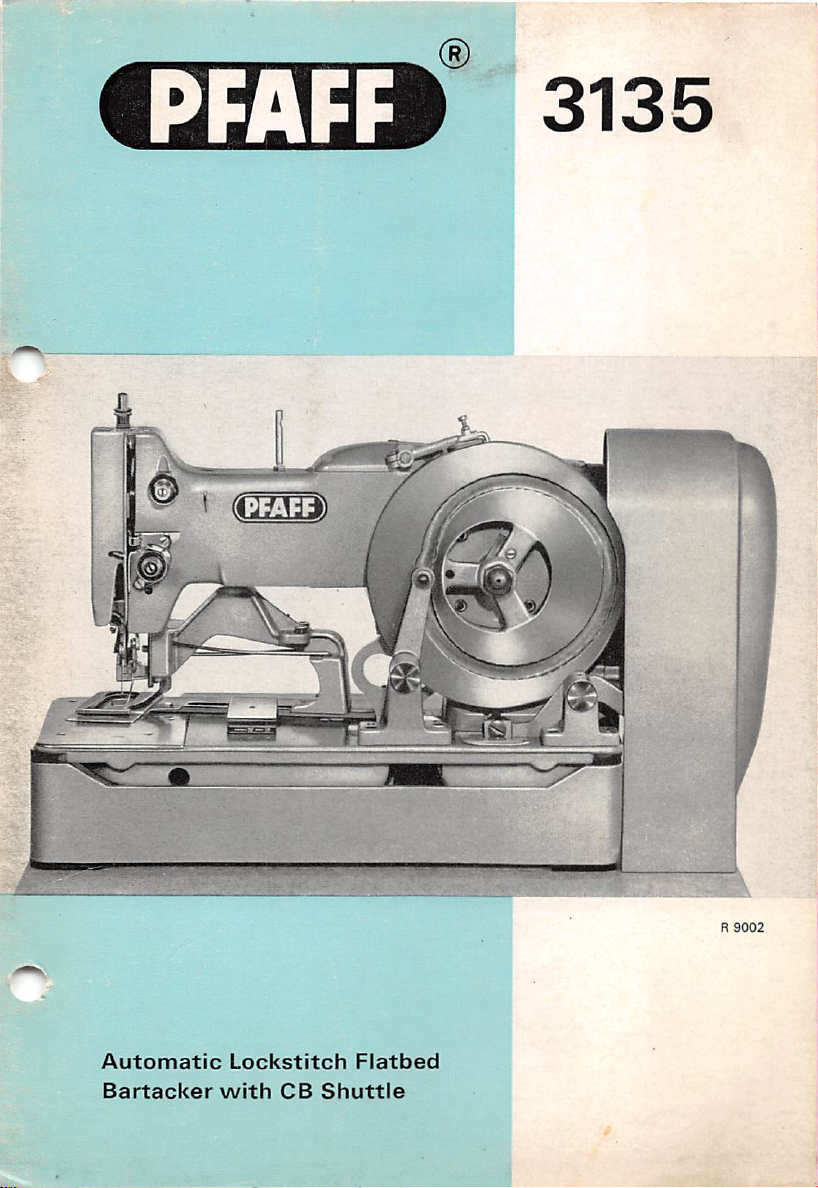

Page 1

CEza)

3135

Automatic

Bartacker

Lockstitch

with

CB

Flatbed

Shuttle

Ft

9002

Page 2

h-

§

R

8795

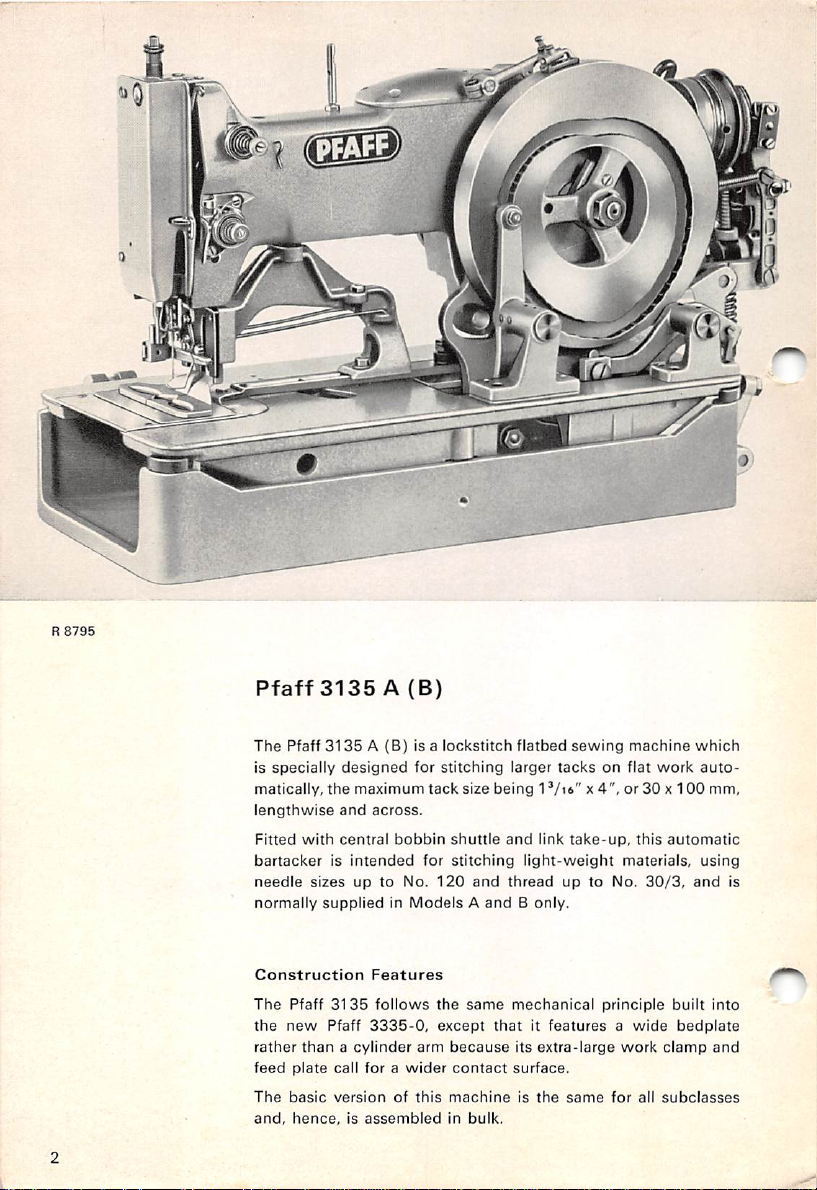

Pfaff3135A(B)

The

Pfaff

3135A(B)

is

specially

matically,

lengthwise

Fitted

bartackerisintended

needle

normally

Construction

The

the

rather

feed

The

and,

designed

the

maximum

and

across.

with

central

sizesupto

suppliedinModelsAandBonly.

Features

Pfaff

3135

follows

new

Pfaff

3335-0,

thanacylinder

plate

call

forawider

basic

version

hence,isassembled

is a

for

bobbin

for

No.

arm

of

this

lockstitch

stitching

tack

size

shuttle

stitching

120

the

except

because

contact

machine

in

flatbed

sewing

machine

larger

tacksonflat

being1Vi*"x4".or30x100

and

link

take-up,

light-weight

and

thread

uptoNo.

same

mechanical

thatItfeaturesawide

its

extra-large

surface.

is

the

bulk.

same

materials,

principle

work

for

this

30/3,

all

work

automatic

and

built

bedplate

clamp

subclasses

which

auto

mm,

using

is

Into

and

Page 3

Machines having

the

feed

cam

slot,

This

far-reaching

accurately

feed

3135

designs

The

for

Since

junction

not

suchasfeed

both

tacks

closely.

This

simplifies

machine

When

only

material

Pfaff

cam

machines,

of all

fixed

all

Cl.

all

with

only

their

basic

made

generous

for

considering

question

to be

3135

calculated

and

one

subclasses

points

3135

subclasses

the

control

cam,

models,

with up to No.

storekeeping

the

that

sewn

fitted

whichisequipped

heavier

materials.

the

same

gear

the

feed

plate

standardization

fixed

pointsonthe

setofcontrol

regardlessoftheir

measuringupto 1

usedtocontrol

and

3125

bartackers.

of

the

Pfaff

Pfaff

3125,

both

elements,

arch

clamp

with

the

only

limitation

18/3

standardization

and

enables

production

the

mustbedecided

of a

employmentofan

canbehandled

with

central

bobbin

with

beak

shuttle

ratio differ only in

and

the

clamp

was

achievedbyestablishing

machinesothat

elements

gear

is

ratio, to

needed

^ht"x4".

the

feed

motions

3135

can

alsobeusedincon

machines

but

thread

and

also

clamp

are

their

organizational

feet

being

that

must

notbespaced

interchangeability

userstoquickly

new

line.

automatic

beforehandiswhether

more

successfully

shuttleoron

and

intended

the

design of

feet.

only

for

all

produce

are

the

the

designedsothat

parts,

and

feed plate, fit

the

stitches

greatly

convert

bartacker,

on

the

Pfaff

for

stitching

one

Pfaff

tack

same

in

too

the

the

the

the

3125

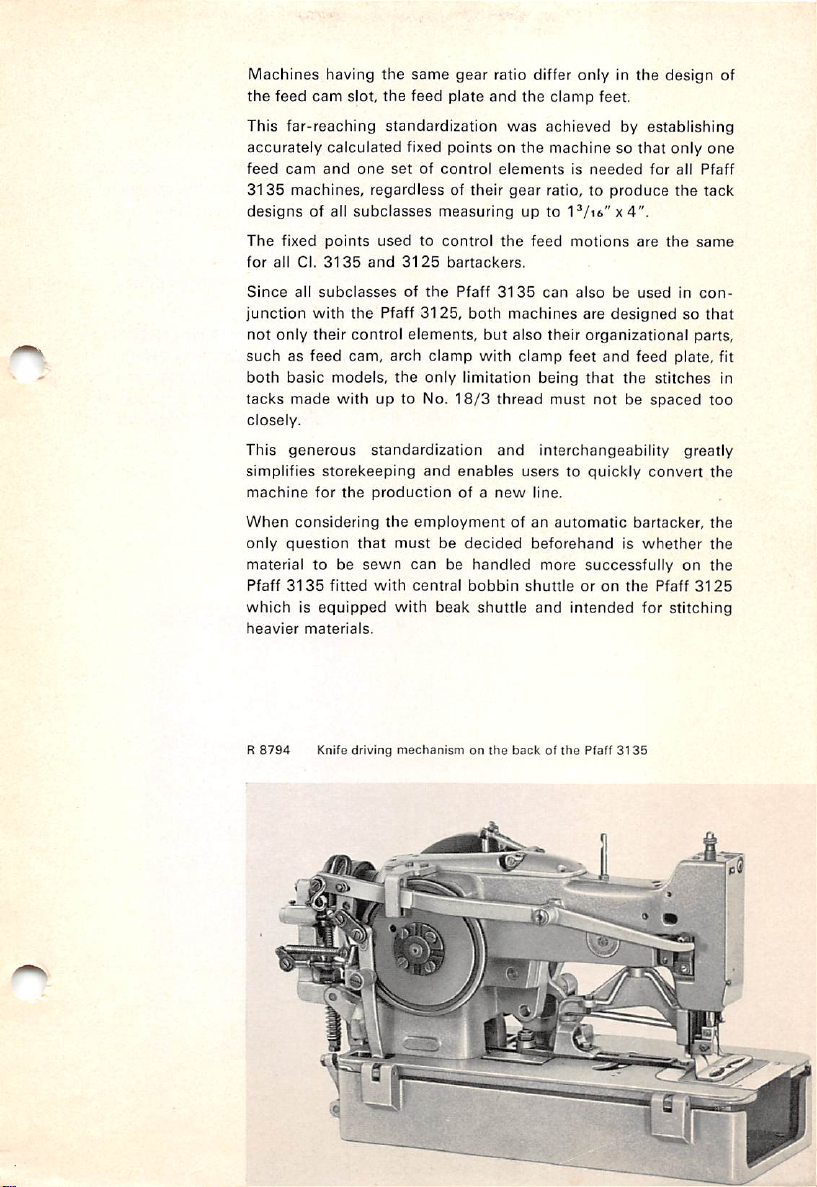

R

8794

» V-

Knife

driving

mechanismonthe

backofthe

Pfaff

3135

Page 4

The machine can be easily converted from one subclass to another

which

produces

the

same

number of stitches per tack. This job can

even be done by the operator herself because all she has to do is

exchange

Another possibility is to convert

into a similar

one

knife

All

different

and

Minor

the

inevitable

studs

through

tilting

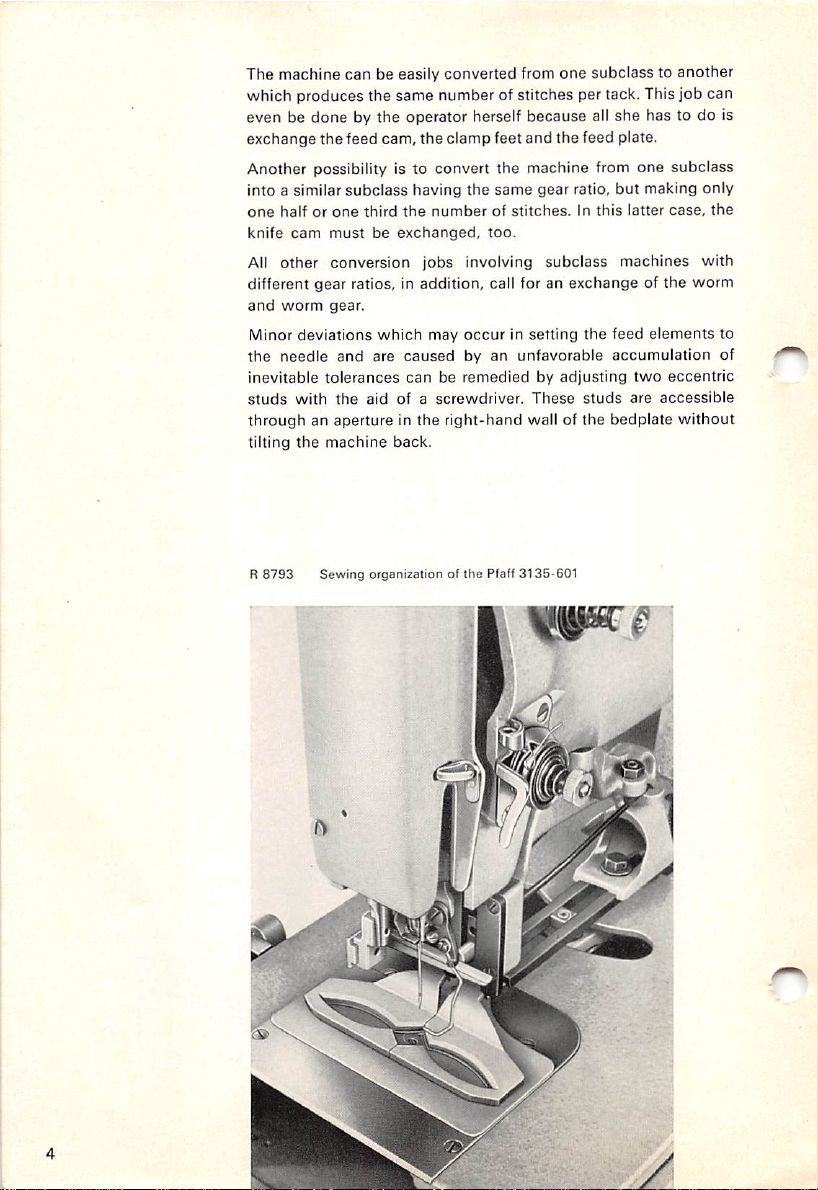

R

halforone

cam

other

worm

deviations

needle

with

the

8793

the

feed cam,

subclass

mustbeexchanged,

third

having

the

conversion

gear

ratios, in

gear.

which

and

are

caused

tolerances

the

an aperture in

machine

Sewing

canberemediedbyadjusting

aidofa

the

back.

organizationofthe

the

clamp feet and the feed plate.

the

machine from

the

same

gear

ratio,

numberofstitches.Inthis

too.

jobs

involving

addition,

may

occurinsetting

by an

screwdriver.

subclass

call for an

unfavorable

These

exchangeofthe

the

studs

right-hand wall of the bedplate

Pfaff

3135-601

one

subclass

but

making

latter

case,

machines

feed

elements

accumulation

two

eccentric

are

accessible

without

only

the

with

worm

to

of

Page 5

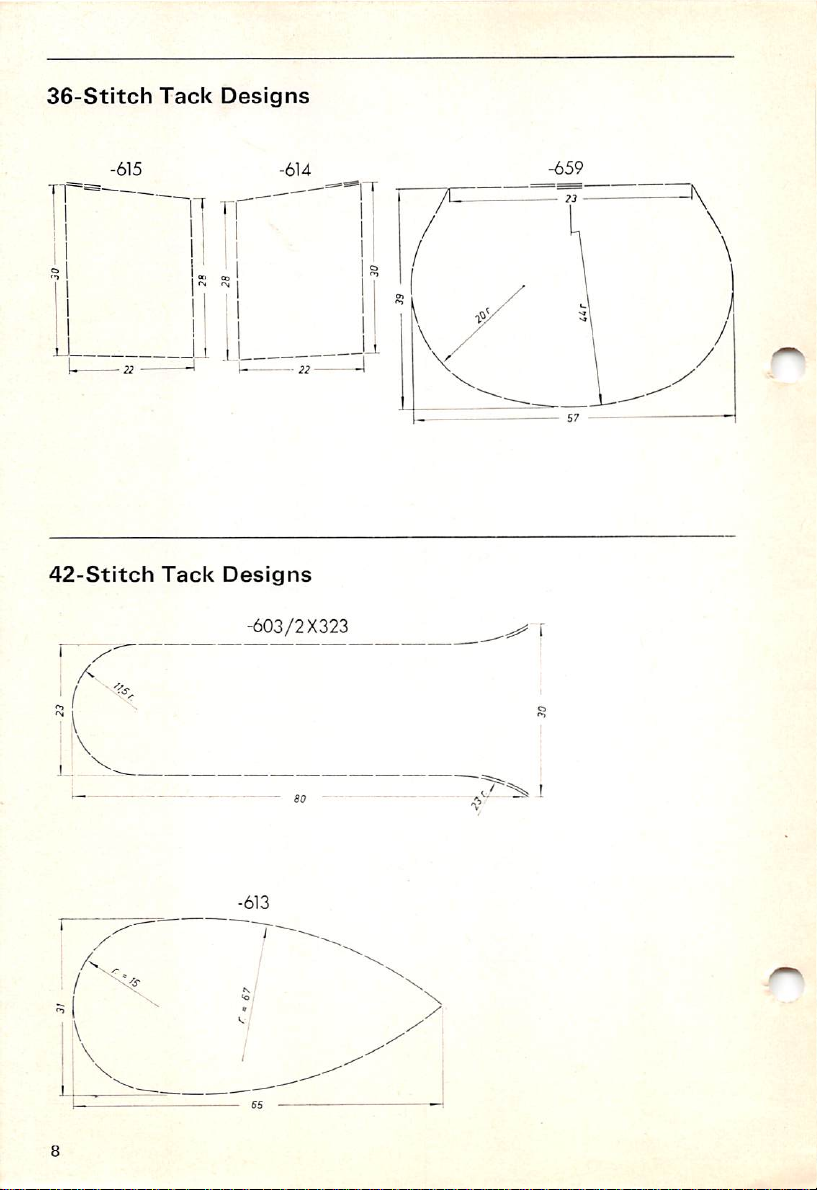

Operation

The machine is

of

the

table, it is

mounted

on a cast-iron base

startedbydepressing

the

and

right

set

up crosswise

treadle.

Since

the

needle bar is of the rigid type, it does not swing sideways.

Hence,

the

material is moved under

the

different

The

workisheld

feed

The

principal

seam

which

machine

The right, or feed,

the

grooveonthe

oneonthe

Both

the

bedplatebymeansofvertical

The

lengthwise

on

the

cylinder

of

the

emanates

andisconveyedtothe

by a

two-armed

The

feed

ference

nipper

tack

designs.

between,

plate.

motions

and

the

trimmingofthe

are

carriedona

arm.

cam

outside

inside

produces

motions

are

feed

back

sideofthe

armbymeans

feed

cam.

from

the

conveyedtothe

The

channel

lever

cam,inaddition,

which

servetostop

when

additional thread is pulled

and

required for

joint

has

controls

motionistransmitted

feed

of a

crosswise

trackonthe

feed

and

two

and both threads are trimmed at the completion of

cycle.

The

left,orknife,

knives

and

last

stitchisbeing

of

thread

to be

to

start

the

backsofthe

At

the

completionofthe

matically. Only

operator

both

During

depress

threads.

the

knife cam so

cam

actuates

swings

them

forwardtothe

formed.

This

pulled

from

next

stitch,

both

knives,toobtainaclean

sewing

after

the

machine

the

left treadle to raise

sewing

that

action,

the

work clamp

the

needle in order to

guided

by,

the

clamp

the

automatic

threads

are

transverse

two

the

shaftoneither

pattern-forming grooves. While

the

crosswise

lengthwise

feeding

two-armed

camtothe

two-armed

feed

motion,onthe

front

driving

mechanisminthe

ball-joint

carries tripping

the

machine

down

the

needle

productionofthe

derived

from

feed

feed

motion.

mechanism

levers.

from

the

driving

lever

locatedatthe

sideofthe

connections,

points

andtoactuate

through

and

operative

action

causesasufficient

the

spool

and

the

bobbin

threads

the

being

cut.

action,

the

has

come

the

lifting lever is

cannot

be raised inadvertently.

pulled

machine

to a

work clamp and trim

interlockedbythe

produce

feet

and

the

two

cams

sideofthe

motion,

channel

the

underneath

track

blockinthe

back

other

hand,

feed

cam

cylinder

on its

each

bobbin

the

circum

the

material

sewing

arm

thread

thread

positionasthe

amount

with

which

taut

over

the

stops

auto

stop

can

the

Page 6

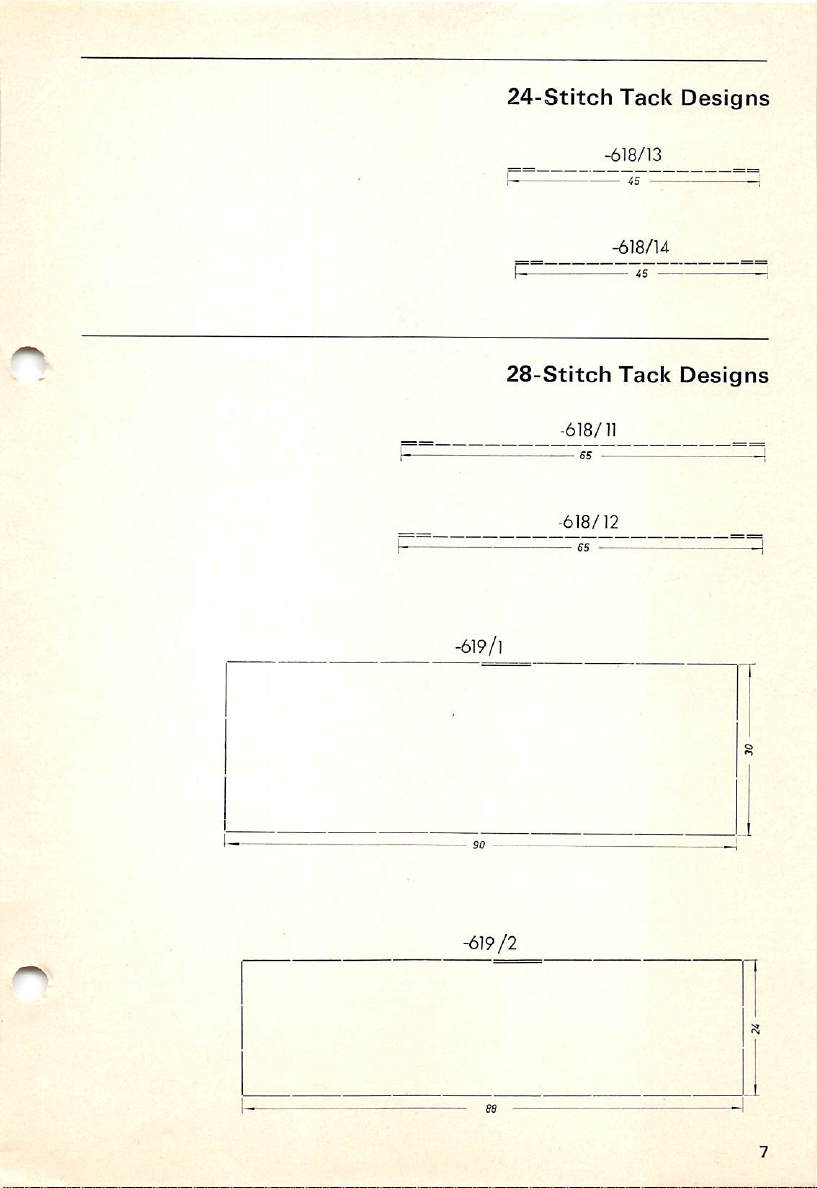

Double buffer springs absorb the momentum of the machine at

sudden

stops.

The Pfaff

motor and, if desired, can be fitted with a belt

3135

is driven by a Va-HP squirrel-cage Induction

take-up

hanger

which greatly simplifies the regulation of the belt tension.

Machines

driving

If

desired,

control.Inthis

control

pressed

lowered

fitted

withabelt

belt.

the

Pfaff

case,

switch

with

downtothe

onto

the

3135

canbeequipped

the

operator

two

switch

first position,

goods.

At this stage,

take-up

hanger

has

merely to

positions.

the

two-part

may

useanendless

with

electromagnetic

operateafoot

When

the

work clamp is

the

work can still be

switch

repositioned after releasing the foot control again. The machine

is started by depressing the switch all

second

At the completion of

and

The

enables

without

position.

the

work

remarkable

the

operatortoboost

any

difficulty.

clamp

work

the

sewing cycle, both

is raised

simplification

completely

her

the

way

downtothe

threads

are trimmed

automatically.

accomplishedbythis

outputby10

to 15 per

machine

cent

is

Pfaff

3135A(B)

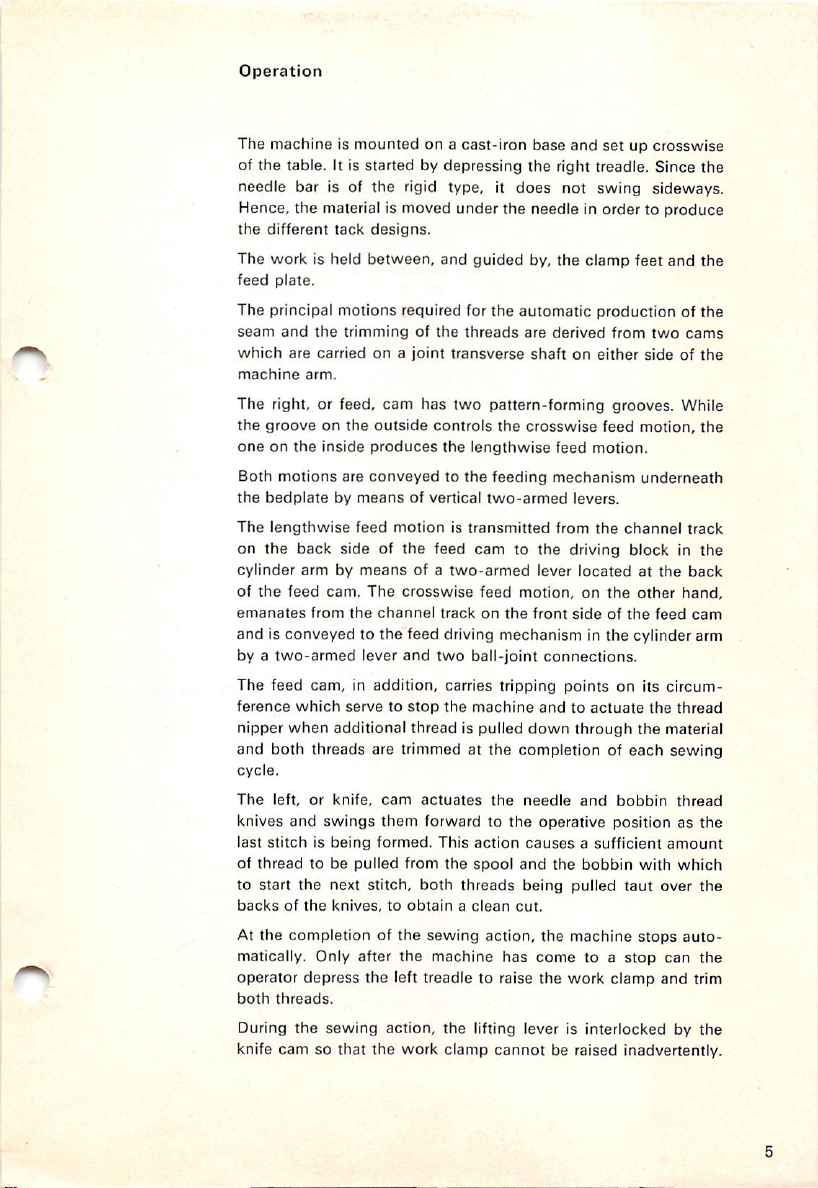

The

following

size,

indicating

Owing to

diagrams

the

large variety of designs, their diagrams are

accordingtothe

group,

the

diagrams

Since

each

tack

possibilities are

Subclasses

show

the

various

their

dimensions

in millimeters.

numberofstitchesineach

are

arrangedbysubclass

canbeusedinmany

not

listed in

this

different

table.

tack

designsinactual

tack. Within

numbers.

ways,

its

grouped

each

application

Page 7

24-Stitch

Tack

-618/13

-618/14

Designs

45 —,

-619/1

-619/2

28-Stltch

-618/11

-618/12

—

55

Tack

Designs

Page 8

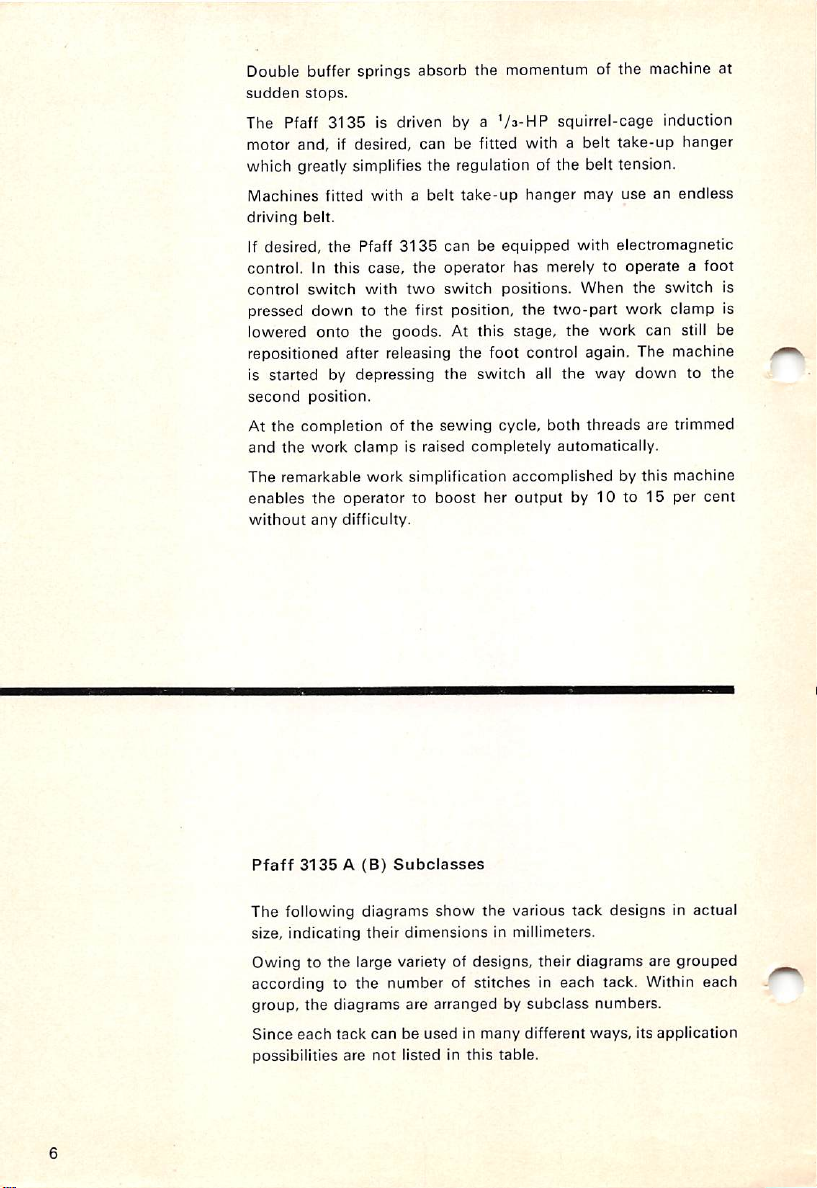

36-Stitch

Tack

Designs

-615 -614

42-Stltch

i A ,

I / •-%

i*j I *

n

Tack

"T

-659

1-

Designs

-603/2X323

-613

"~~"T

/

\

\

\

\

\

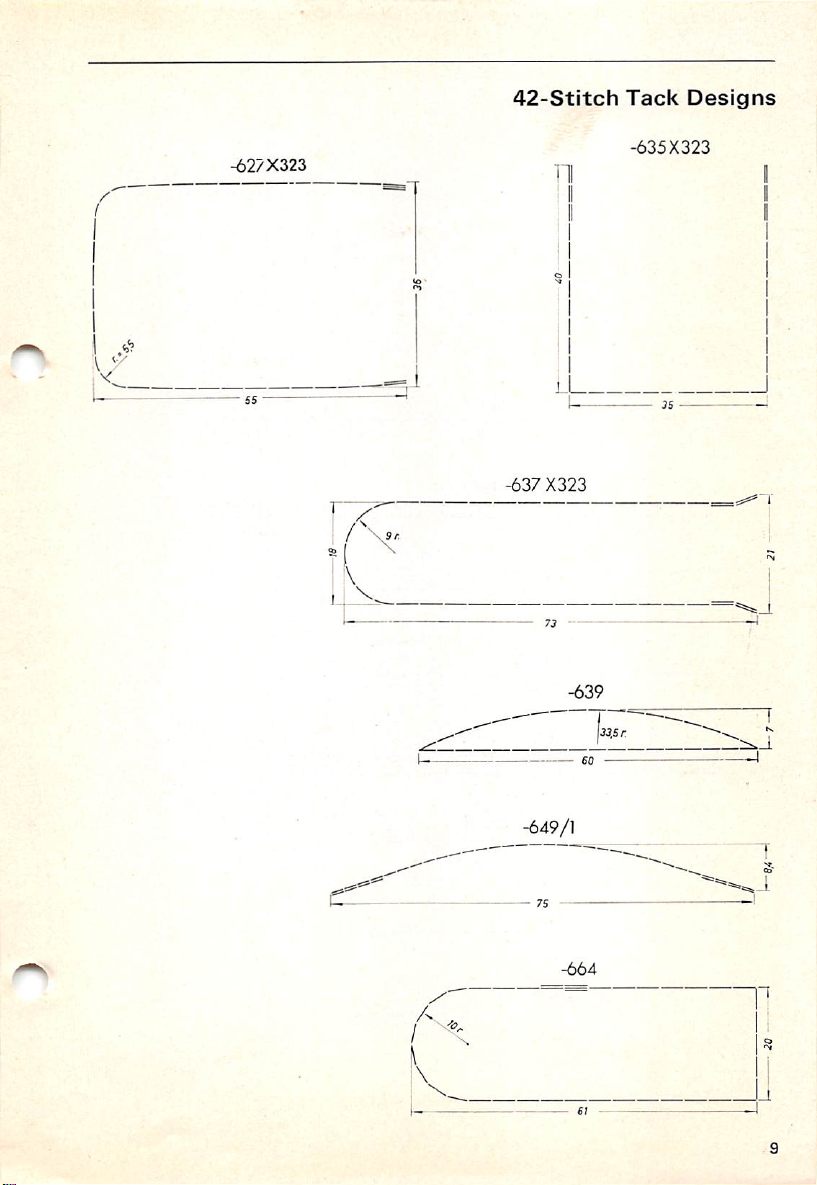

Page 9

42-Stitch

Tack

Designs

H527X323

/\s/:

V

-635X323

-637

J_

X323

U

-639

35

1

£!

33,5/7

60

J

u

-649/1

-664

\

J_l

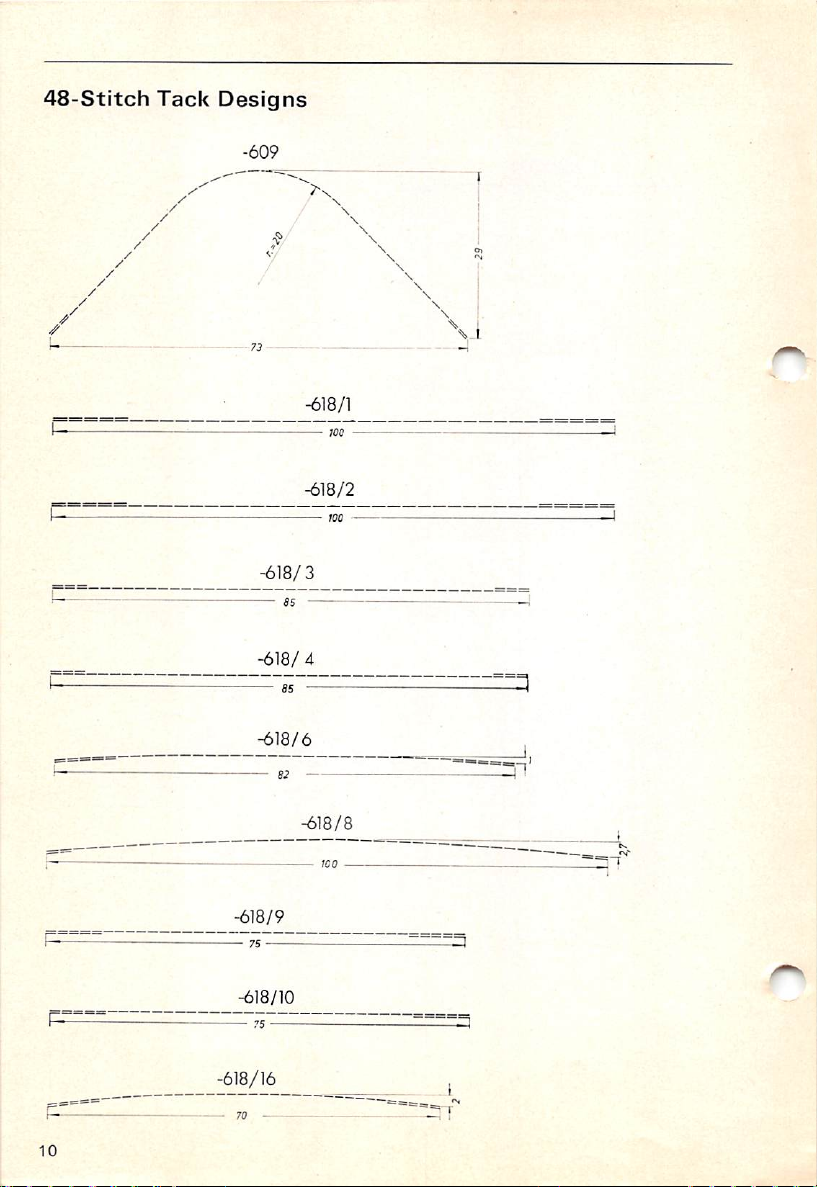

Page 10

48-Stitch

Tack

Designs

-609

/ \

-618/1

-618/2

mo

-618/3

55

—

^518/4

55

.1

1

10

r"""

-618/6

-618/9

75

-618/10

—~?i

-618/16

82

4l'

-618/8

11

Z\

===»==,

...1

Page 11

48-Stitch

Tack

Designs

-618/17

c

-618/18

c:

309r

-618/19

85

-618/20

85

-618/21

—

too

-618/22

-643X323

/

11

Page 12

48-Stitch

/

/

/\

\

\

Tack

Designs

-646

-649/2

56-Stltch

Tack

68.3

Designs

-601

•

92

-603/1X323

a

•1

12

Page 13

V

56-Stitch

-606

-607

-605

T

Tack

Designs

-608X323

/

A.

\

13

Page 14

56-Stitch

/

\

Tack

Designs

-620

•60.B-

-62]

Ij

~T

-623

r"

\

/

5^

-625

52

/

/

/ I

His 151

\

\

\

Special

•

14

variety

Page 15

-628

56-Stitch

-634X323

Tack

Designs

-638

I-

<''

io.

I i

55

i

15

Page 16

56-Stitch

r:

V

Tack

Designs

-645

-641

-

ffi

/

/

.j:

-660

in

64-Stitch

rii

L

16

•"

Tack

-663

Designs

-642

Page 17

-670X323

j n

i B

-667

92,62

64-Stitch

Tack

-658X323

Designs

A i

(IOC'S

71

1

72-Stitch

-602

-317

-610/2

Tack

Designs

I

1 r.>" \ (

I

X

N 1

/

o>

/

_

17

Page 18

72-Stitch

.M

r*

Tack

Designs

-616

-610/1

-612

if

-317

*

Special

18

\A

-617

variety

Page 19

L.

72-Stitch

-636

r"

Tack

Designs

"H

/

/\

\

\

n

•]

-644

64

-

--

r'

i-L.

-657/3

X323

-666X323

19

Page 20

84-Stitch

/

/n.

\

Tack

Designs

"T"

-600

/\

\

/

/

/

/

,_1

7

I

I

I

_L-

_ -604/2X323

A

i6r

•iO^S-

-604/1

X323

1

J

U)

20

Page 21

84-Stitch

-622

---

-624

-317

55

Tack

Designs

--

—

r"

-630x323

/

*

Special

variety

21

Page 22

84-Stitch

P"

Tack

Designs

-633

U-

8f

n

69

-652X323

\

\

-653X323

/

/

/

\

/

•

Special

22

S2.B

variety

Page 23

84-Stitch

-654X323

-655

X323

Tack

Designs

-657/1

X323

23

Page 24

84-Stitch

Tack

Designs

-657/2X323

T

h562

r

I

h-

I

L

-665

-317

r-

I

b

24

"~l

T

IJ.

Page 25

96-Stitch

-626

--

73

-629-317

Tack

Designs

TT

-640X323

*

Special

variety

25

Page 26

96-Stitch

/

/

Tack

Designs

-647X323

-648

H550X323

X323

=. I

/

\

-651X323

/

\

26

Page 27

C

V

A

/

\

98"

L

-668X323

96-Stitch

-656/1-317

Tack

Designs

'A

95

-669X323

-9C126-

27

Page 28

Pfaff

3135

Numerical

List

of

Subclasses

Subclass

-600

-601

-602-317

-603/1

-603/2X323

-604/1

-604/2X323

-605

-606

-607

-608X323

-609

-610/1-317

-610/2

-612

-613

-614

-615

-616

-617

-618/1

-618/2

-618/3

-618/4

-618/6

-618/8

-618/9

-618/10

-618/11

-618/12

-618/13

28

X323

X323

Number

of

Stitches

perTack

84

56

72

56

42

84

84

56

56

56

56

48

72

72

72

42

36

36

72

72

48

48

48

48

48

48

48

48

28

28

24

Tack

Diagram

on

page

20

12

17

12

8

20

20

13

13

13

13

10

18

17

18

8

8

8

18

18

10

10

10

10

10

10

10

10

7

7

7

Subclass

-618/14

-618/16

-618/17

-618/18

-618/19

-618/20

-618/21

-618/22

-619/1

-619/2

-620

-621

-622-317

-623

-624

-625

-626

-627X323

-628

-629-317

-630X323

-633

-634X323

-635X323

-636

-637X323

-638

-639

-640X323

-641

-642

Number

of

Stitches

perTack

24

48

48

48

48

48

48

48

28

28

56

56

84

56

84

56

96

42

56

96

84

84

56

42

72

42

56

42

96

56

64

Tack

Diagram

on

page

7

10

11

11

11

11

11

11

7

7

14

14

21

14

21

14

25

9

15

25

21

22

15

9

19

9

15

9

25

16

16

Page 29

Pfaff3135

Numerical

List

of

Subclasses

Subclass

-643X323

-644

-645

-646

-647X323

-648X323

-649/1

-649/2

-650X323

-651

X323

-652X323

-653X323

-654X323

-655X323

-656/1-317

Number

of

Stitches

per

48

72

56

48

96

96

42

48

96

96

84

84

84

84

96

Tack

Tack

Diagram

on

page

11

19

16

12

26

26

9

12

26

26

22

22

23

23

27

Subclass

-657/1

X323

-657/2X323

-657/3X323

-658X323

-659

-660

-662

-663

-664

-665-317

-666X323

-667

-668X323

-669X323

-670X323

Number

of

per

84

84

72

64

36

56

84

56

42

84

72

64

96

96

64

Stitches

Tack

Tac

Dia

on

23

24

19

17

8

16

24

16

9

24

19

17

27

27

17

29

Page 30

Page 31

Page 32

Pfaff3135

A(B)

Automatic

designs

of

light

Technical

Maximum

Drive:

'/s-HP

fitted

Motor

Speed:

Needles;

Net

Gross

Box

Subject

System

Weights:

Head

Base

Weights:

Head

Base

Dimensions:

For

For

to

Bartacker

upto1^/i6"x4"

and

medium-weight

Data

Speed:

Sewing

alterations

1,200

squirrel-cage

with

1.400

34R,34LRor

only:88lbs

and

Accessories:

Boxed:

and

Accessories

Base:

24V2"x15^/4"

belt

r.p.m.

115

Head:

s.p.m.

take-up

lbs

2T^h"xIS^/a"x12'/^"

in

design

for

producing

on

flat

induction

44

Boxed:

motor;

hanger,ifdesired

332

lbs

66

x 10®/4"

work

materials

lbs

tack

made

No.

12299

engl.

Schn.

1064

G.

M.

PFAFF

KAISERSLAUTe^:3M

AG

BRANCH

PrintedInGermany

Loading...

Loading...