Page 1

INSTRUCTION

BOOK

PFAFF

130-6

Page 2

PFAFF

best

For

licularly

leoving

tested,

follow

enjoy

through-out

finest

and

the

your

sewing

Instruction

Sewing

results,

ports

those

factory

the

found

simple

PFAFF...

years

the

machine

Machine

these

study

the

on

PFAFF

your

perfect

be

to

suggestions

find

be

the

in

book

instructions

core

endlessly

it

glad

world.

for

(Model

the

of

adjusted,

was

every

in

outlined

your

that

the

130)

carefully—par

machine.

respect.

here,

useful

choice

Before

carefully

If

you

...

is

you

will

and,

the

help

to

fine

Use

ordinary

For

place

seams,

should

threads

the

fabric.

Use

for

yarn

smoother

are

glazed

protecting

Skipping

Needle

1.

Using

2.

Needle

3.

for

when

so

and

be

unglazed

cotton,

tension

tension

takes

buttonholes,

I.

the

get

you

and

thread

sewing

lock

interlacing

the

that

the

in

stitching

hemstitching,

somewhat

interlock

and

the

stitches

not

other

being

thread

thread

more

they

seams

having

than

embroidering,

of

the

Useful

best

a

thin,

stitch

center

on

tight,

more

assure

when

may

the

bent

used.

hinis

results

needle

fine

fabrics.

light

zigzag

or

upper

of

the

of

buttons,

tension

the

since

toward

ordinary

for

darning,

flexible

than

well-drawn-in

fabric

the

caused

be

inserted

been

recommended

wrong

by

with

adjusted

seams,

and

stitching.

eyeletting,

of

desirable

is

it

the

Since

etc.

the

is

by:

handling,

your

regulate

under

under

the

underside

sewing,

hard

stitches,

washed.

properly.

PFAFF

for

For

these

and

or

PFAFF

loose

threads

making

rolling

thread

hove

to

of

and

yarns

brittle

Needles.

too

the

the

soft

thus

fine

Page 3

Thread

1.

2.

3.

Bad

1.

2.

3.

breaking

of

Any

Tension

Using

stitches

Tensions

should

Using

thickness

the

should

Fluff

discs,

case.

the

too

bad

may

being

be

needles

be

having

underneath

or

be

may

three

tight.

knotty

or

caused

be

too

equal.

and

the

of

same.

the

accumulated

caused

reasons

thread.

loose

threads

fabric.

the

by:

mentioned

result

as

a

too

or

that

Top

between

tension

tight.

do

and

the

spring

above.

of:

Both

not

bottom

upper

of

tensions

conform

thread

tension

bobbin

the

to

Heavy

1.

2.

3.

4.

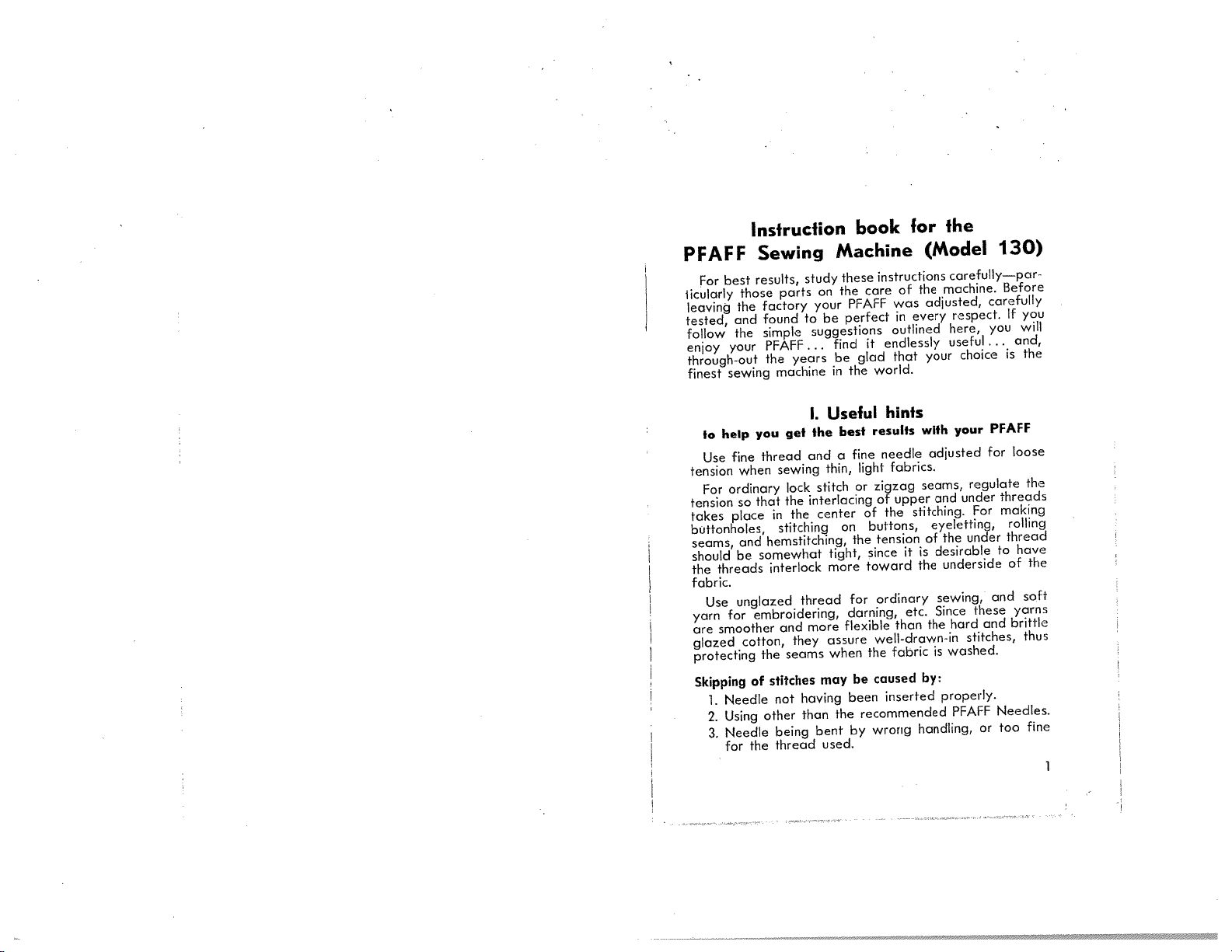

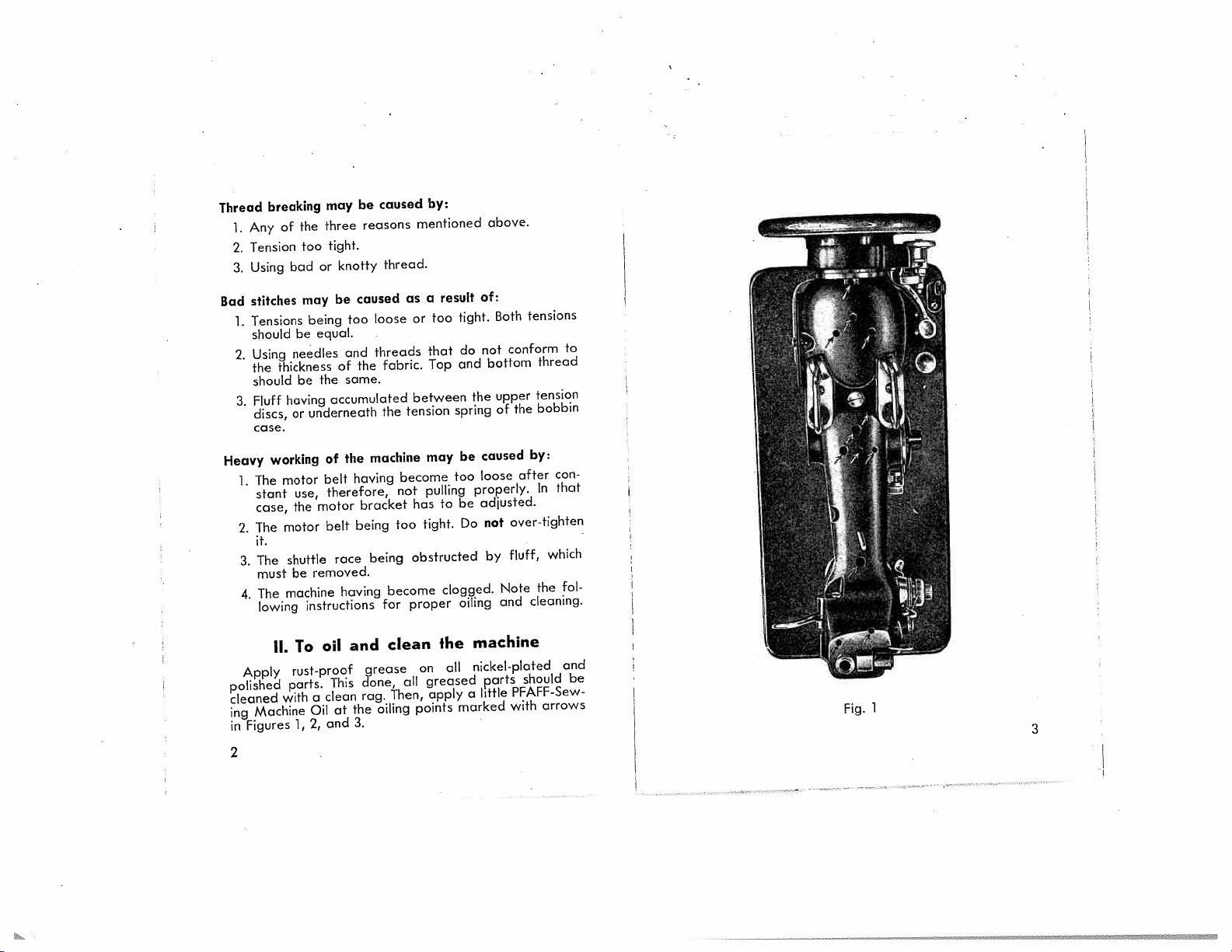

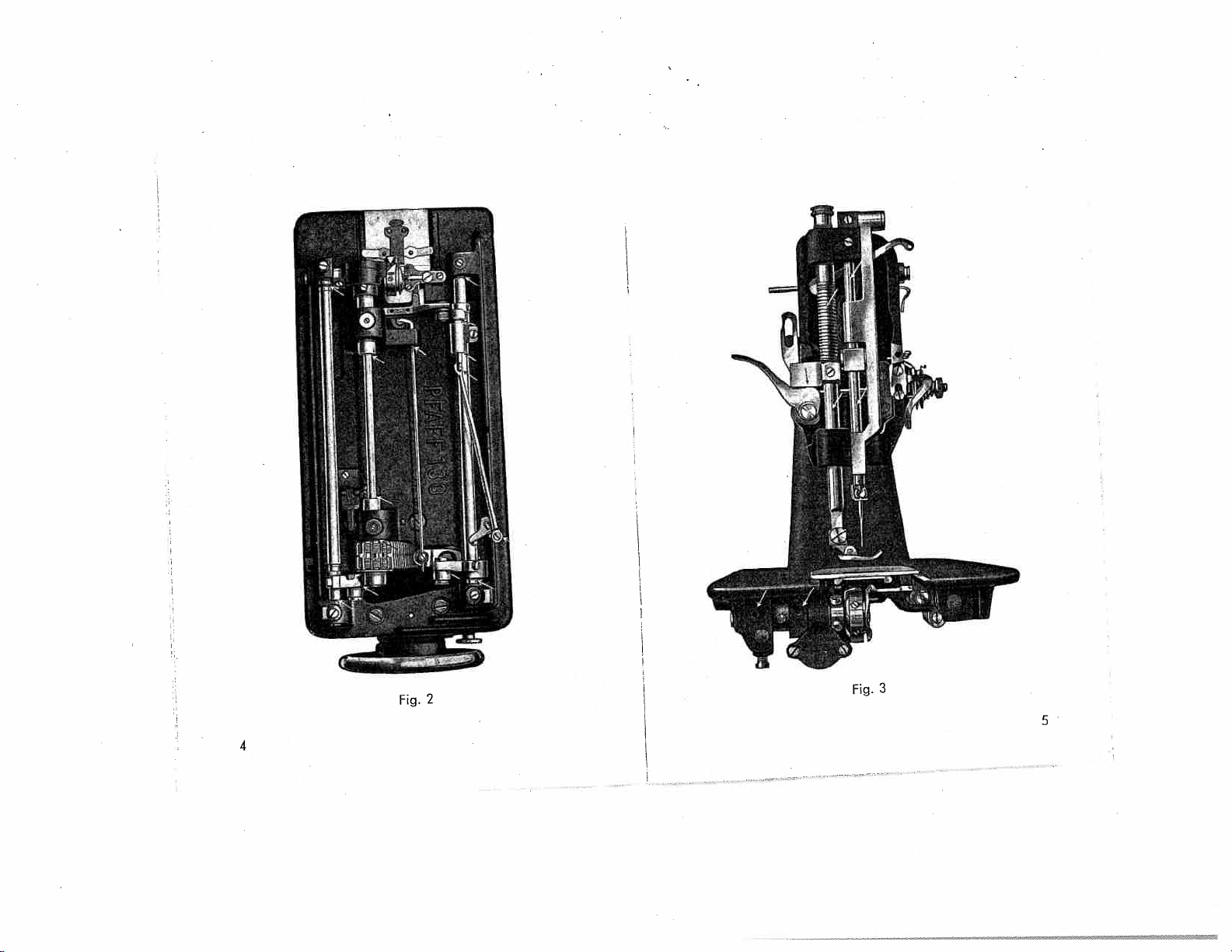

Apply

polished

cleaned

ing

Figures

in

2

working

motor

The

stant

case,

motor

The

it.

shuttle

The

must

machine

The

lowing

IL

ports.

with

Machine

of

belt

therefore,

use,

motor

the

belt

race

removed.

be

instructions

oil

To

rust-proof

This

clean

a

at

Oil

and

2,

1,

the

having

bracket

being

having

and

grease

done,

rag.

the

3.

machine

become

not

too

being

become

for

clean

all

Then,

oiling

may

pulling

to

has

tight.

obstructed

clogged.

proper

the

all

on

greased

apply

points

caused

be

loose

too

properly.

adjusted.

be

not

Do

by

oiling

machine

nickel-plated

parts

little

a

marked

by:

after

In

over-tighten

which

fluff,

the

Note

cleaning.

and

should

PFAFF-Sew

arrows

with

con

that

fol

and

be

g.

3

Page 4

2

Fig.

4

1

Fig.

3

5.

Page 5

raising

After

little

and

oil

points

all

clean

when

ci

for

VERY

first

Machine

Keep

The

cleaned

If

will

the

lift.

In

for

If

pressure

There

presser

Too

and

When

IMPORTANT—When

that

you

then

in

sible

6

without

while

apply

where

oil

and

has

it

time.

long

IMPORTANT:

apply

time,

Oil.

the

needle

of

needle

the

in

jam

needle

general,

thread

finer

material

the

screw

should

bar—use

much

foot.

in

needle

the

slide

to

tighten

way,

this

needle

a

the

been

oil

plate

accumulated

the

with

is

follow

pressure

doubt,

the

it

breakage.

the

drop

can

hook,

and

be

the

will

presser

thread,

of

there

machine

constant

in

Before

the

to

clean.

should

Ill.

inserted

is

and

the

this

a

IV.

does

the

to

little

as

just

call

thumb

needle

thumb

cause

PFAFF

is

from

hook

fluff

The

tear.

of

flat

simple

heavier

Feeding

not

right

enough

causes

in

inserting

screw

all

screw.

SKIPPING

run

foot,

off

wipe

Sewing

friction.

time

use,

using

drop

a

token

be

the

on

needle

incorrectly,

The

shank

the

rule:

needle

(move),

feed

to

pressure

feed

to

excessive

qualified

a

loose

is

way

the

the

If

the

the

Make

to

has

or

the

of

off

underside.

correct

Use

for

increase

as

the

PFAFF

new

up

needle

of

machine

down-dripping

Machine

time,

machine

the

toward

turn

possible

needle,

enough

stitches,

rule

a

it

especially

been

not

for

PFAFF

frequently

top

to

way

the

finer

a

heavier

presser

pressure.

the

material.

in

wear

mechanic.

make

to

stop

the

to

not

is

and

Sewing

a

for

to

Oil

to

used

the

and

thread

install

hand

needle

thread.

bar

the

on

feeder

sure

permit

pin,

inserted

pos

spool

Put

circular

spring

check

of

hole

above

guide

back.

to

LOOSEN

flat

with

to

ready

Turn

bobbin

finger

bobbin

release

Practice

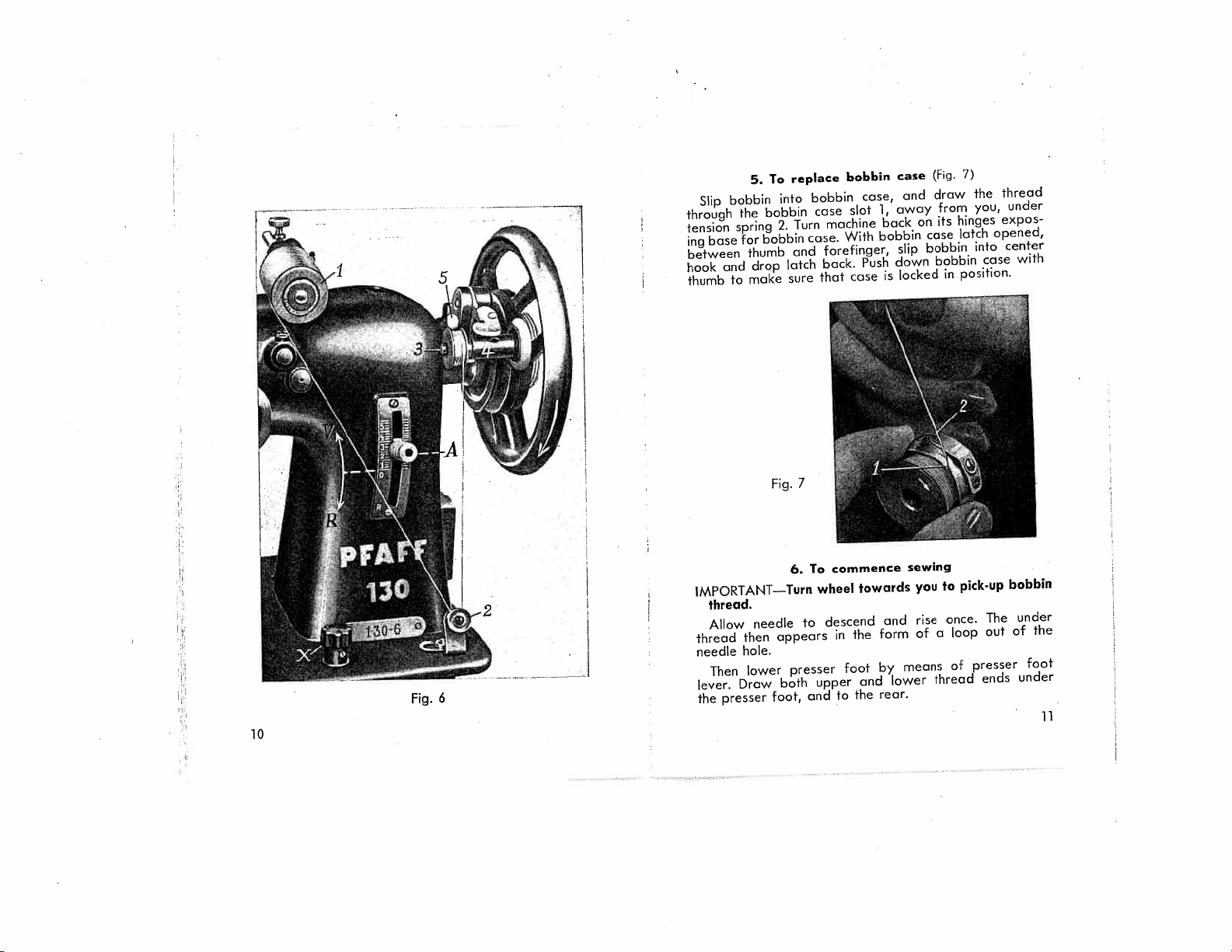

beginners

For

disconnected

be

experienced

connected

while

bobbin

winder

on

the

in

Place

Draw

placed

lock

to

4

wind

to

do

you

winder

automatic.

is

on

guide

4,

take-up

the

the

(Fig.

lock

shank

sew.

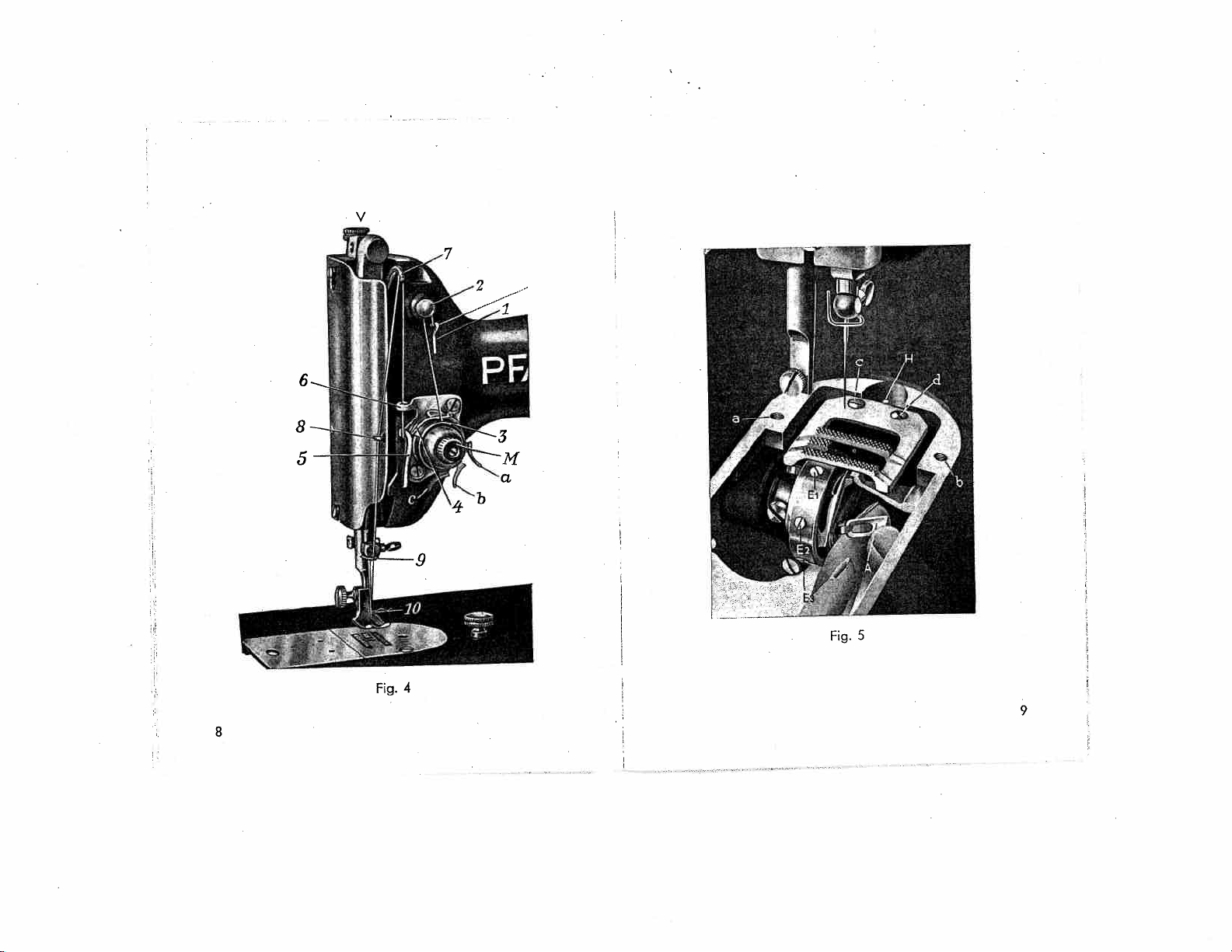

3.

machine

the

by

case

is

(it

case

latch

few

a

4.

if

sewing

couple

a

spindle

of

side

spool

thread

winder

on

bobbin

bobbin.

not

disconnect

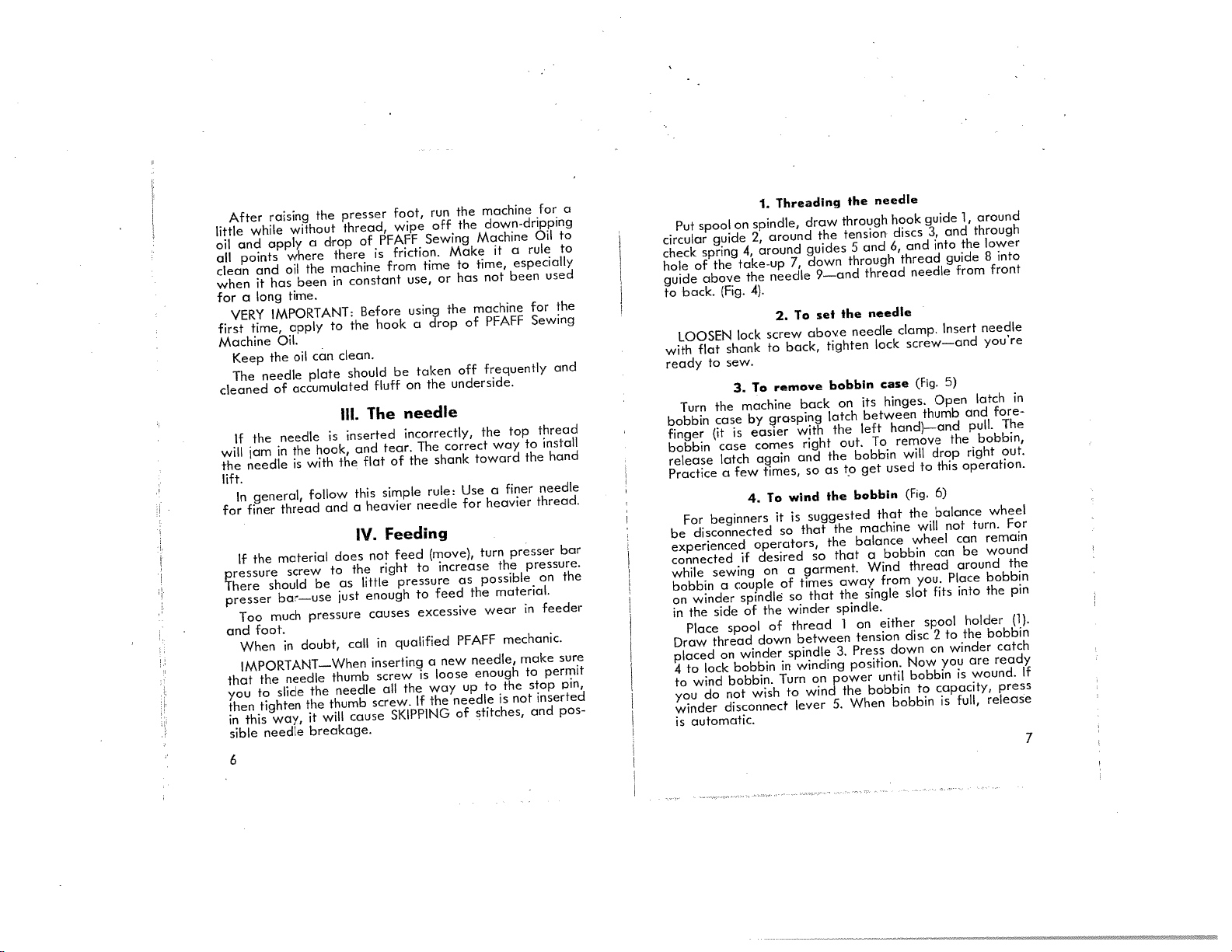

Threading

1.

spindle,

around

2,

around

7,

needle

4).

2.

screw

back,

to

remove

To

grasping

easier

comes

again

times,

wind

To

is

it

so

operators,

desired

a

on

of

so

winder

the

thread

of

down

spindle

in

Turn

to

wish

draw

the

guides

down

9—and

set

To

above

tighten

back

with

right

and

as

so

the

suggested

that

so

garment.

times

that

between

winding

on

wind

lever

the

through

tension

through

the

bobbin

on

latch

the

out.

the

to

the

the

that

away

the

spindle.

1

3.

position.

power

the

When

5.

needle

and

5

thread

needle

needle

lock

case

its

between

left

To

bobbin

get

bobbin

that

machine

balance

a

Wind

from

single

either

on

tension

Press

until

bobbin

guide

hook

3,

discs

and

6,

thread

needle

clamp.

screw—and

(Fig.

hinges.

thumb

hand)—and

remove

drop

will

to

used

(Fig.

the

will

wheel

bobbin

thread

you.

slot

spool

disc

on

down

Now

bobbin

to

bobbin

1,

and

the

into

guide

from

Insert

5)

Open

and

the

right

operation.

this

6)

balance

not

can

be

can

around

Place

into

fits

holder

the

to

2

winder

you

is

capacity,

full,

is

around

through

lower

8

front

needle

youre

latch

fore

pull.

bobbin,

wheel

turn.

remain

wound

bobbin

the

bobbin

ready

are

wound.

release

into

in

The

out.

For

the

pin

(1).

catch

If

press

7

Page 6

I

a

(

\

‘4

5

Fig.

4

Fig.

9

8

Page 7

Slip

through

tension

base

ing

between

hook

thumb

bobbin

the

spring

for

and

to

To

5.

bobbin

bobbin

thumb

drop

make

into

2.

Fig.

replace

Turn

case.

and

latch

sure

7

bobbin

case

machine

With

forefinger,

back.

that

bobbin

case,

slot

Push

case

case

and

away

1,

bock

bobbin

slip

down

locked

is

(Fig.

draw

on

case

bobbin

bobbin

from

its

in

7)

the

you,

hinges

latch

into

case

position.

thread

under

expos

opened,

center

with

10

Fig.

and

form

by

lower

rear.

sewing

you

rise

of

means

to

once.

loop

a

of

thread

pick-up

The

out

presser

ends

bobbin

under

the

of

foot

under

commence

To

6.

towards

IMPORTANT—Turn

wheel

thread.

descend

appears

presser

both

foot,

to

and

in

upper

to

the

foot

and

the

needle

Allow

Then

lever.

the

then

hole.

lower

Draw

presser

thread

needle

6

11

Page 8

To

protect

machine

the

With

turn

the

a

slight

give

control—or

models.

Stop

the

its

tension

rear

8.

The

tension

tension

the

highest

Raise

To

tension

until

at

stitch.)

the

the

material

of

the

clockwise,

Having

thread,

pulling

(you

the

threaded

at

glance

sion

nut,

upper

If

the

down

pull

as

shown

thread

under

the

shows

the

material,

tensions.

12

without

cloth

balance

against

machine.

take-up

is

of

on

the

regulate

nut

will

it will

adjusted

con

thread

the

the

and

the

in

Fig.

locking

as a

presser

placing

inserted

wheel

pressure

with

the

remove

7.

To

Turn

(see

point.

presser

section

(Or

foot.

automatically

the

needle.

thread

cutter.

the

of

the

upper

(Fig.

(M),

become

become

the

judge

best

gently

machine

number

note

tension

upper

is

its

8.

If

drawn

in

marked

relative

is

thread,

the

the

result

foot

fabric

and

toward

foot

the

turn

(On

Cut

tension

thread

Turning

4).

tighter.

looser.

tension

with

through

too

upper

up,

as

two

of

the

and

feed,

under

the

presser

you.

your

knee

control

the

balance

on

threading

the

wheel

lifting

released.)

the

of

the

is

Unscrewing

for

this

tension

your

the

in

the

position.

loose,

forming

tension

illustrated

threads

proper

the

At

against

on

work

wheel

to

the,

Draw

thread

upper

regulated

this

screw

a

certain

hand

tension

bell

the

under

little

is

in

adjustment

never

presser

foot

the

same

some

toward

the needle)

complete

presser

the

close

thread

by

clockwise,

it,

yourself

for

when

you

spring),

behind

thread

knots

tight,

too

in

Fig.

center

the

operate

foot.

lowered,

time,

the

knee

portable

you

foot,

cloth

to

means

counter

kind

have

lust

the

ten

will

or

loops

the

9

Fig.

both

of

the

the

of

by

of

to

10

is

9

Fig.

10

Fig.

under

bobbin

small

aid

of

below

thread

case

tension

of

the

counter

it

a

in

stitch

the

by

neutral)—

above

for

out

screw

screw

stitch

posi

zero

reverse

of

9.

If

the

machine

the

(Z)

in

a

driver.

clockwise

length

The

regulator

there

tion,

for

ore

regulate

To

tension

clockwise

the

If

direction.

10.

screw.

is

forward

is

(Fig.

tension

To

of

feeding

no

tension

too

loose,

and

5),

direction

is

(Fig.

regulate

stitches

the

6).

(Fig.

stitching;

tighten

too

11).

In

at

tight,

the

the

all.

the

of

take

with

length

is

zero—(or

The

space

the

the

the

the

unscrew

regulated

numbers

stitching.

13

Page 9

Fig.

11

dial

is

straight

buttons.

the

If

should

should

wise,

set.

sewing,

machine

not

not

the

This

be

be

needle

is

useful

embroidery,

is

made,

changed,

might

not

running,

the

or

unless

bent

be

applique,

for

buttonholes,

size

needle

the

or

shifting

the

of

broken.

the

fancy

and

is

raised.

sewing

procedure

zigzag

stitching,

on

stitch

Other

from

have

regulator

1

to

chosen

Loosen

tion

you

screw.Tosew

downward,

same

the

If

on

point

straight

machine

zag

left,

maximum

If

machine,

chine

mal

right,

the

14

size

nose

the

zeroofthe

stitch.

is

stitch

bringing

of

lever

and

sew

will

posifion.

continuing

below

doing

is

H

screw,

5.

Position

size

the

in

reverse,

position

stitchinreverse.

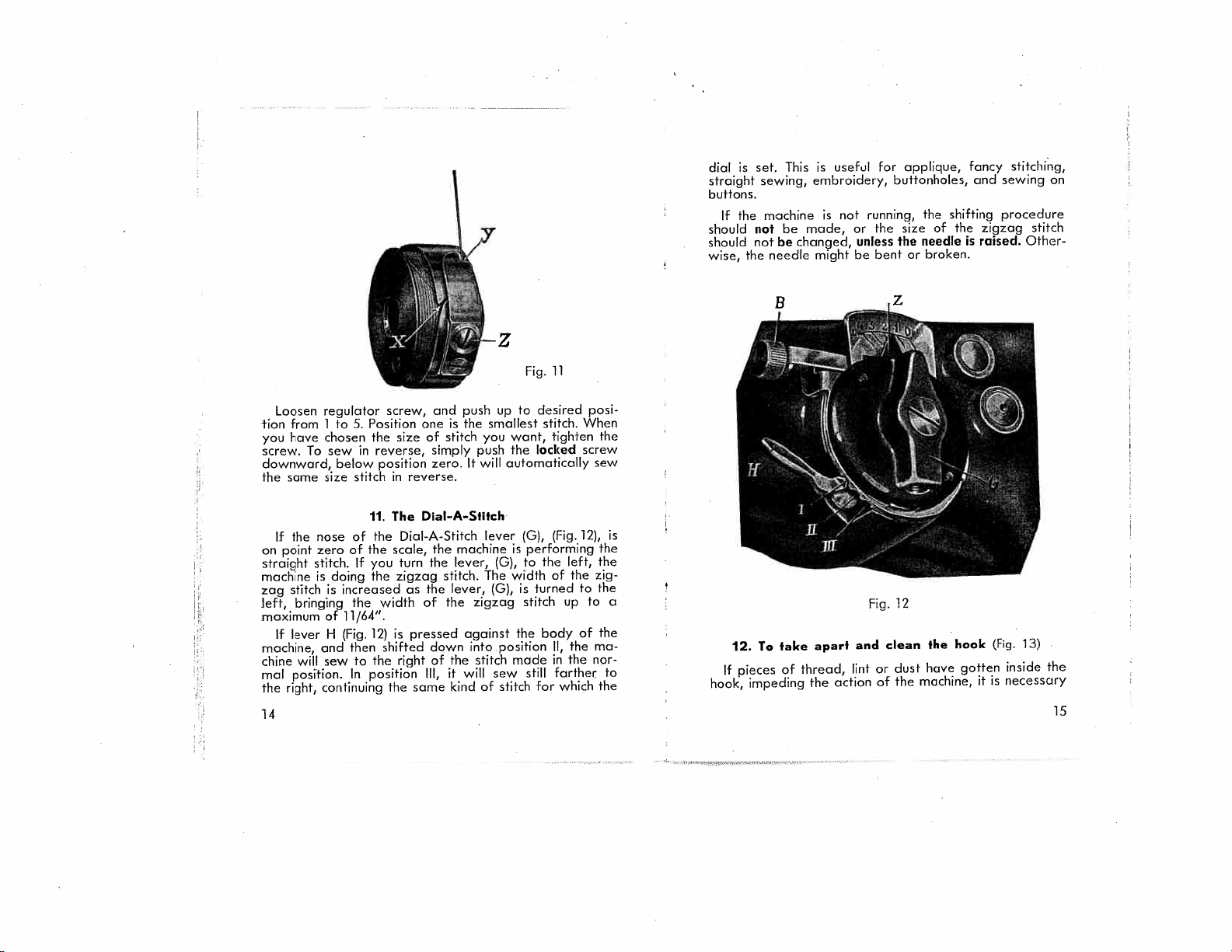

11.

The

Dial-A-Stitch

the

of

scale,

turn

you

If

the

zigzag

increased

the

as

width

11/64”.

pressed

is

12)

(Fig.

shifted

then

the

right

to

position

In

the

same

push

and

the

is

one

stitch

of

simply

you

push

zero.Itwill

Dial-A-Stitch

machine

the

lever,

the

stitch.

lever,

the

the

of

zigzag

against

into

down

stitch

the

of

it

will

Ill,

kind

of

to

up

smallest

want,

the

automatically

lever

(G),

performing

is

to

(0),

width

The

is

(0),

stitch

the

position

made

still

sew

stitch

desired

stitch.

tighten

locked

(Fig.

the

of

turned

body

II,

in

farther

which

for

left,

up

the

the

the

posi

When

screw

sew

12),

zig

to

to

of

ma

nor

the

the

the

the

the

the

is

a

apart

To

pieces

impeding

fake

of

thread,

the

action

12.

to

If

hook,

and

lint

Fig.

or

of

12

clean

dust

the

hook

the

have

machine,

gotten

it

(Fig.

inside

necessary

is

13)

the

15

Page 10

to

remove

Turn

the

E-2,

and

NOTE:

necessary

Grasp

the

turn

Clear

out.

on

the

bobbin

Replace

the

balance

E-3.

Since

to

center

balance

out

running

case.

the

upper

wheel

Unscrew

these

use

great

hook

wheel

the

surface

not

Do

bow,

hook

and

screws

dirt

force

lower

so

these,

caresoas

between

gently

with

under

and

as

a

ii,

screw

to

and

are

thumb

until

cloth,

the

as

parts

see

take

extremely

not

the

and

case.

will

it

the

of

the

clearly

off

to

and

lower

put

damage

three

bobbin

screws

the

hook

small,

lose

them.

forefinger,

case

drop

a

Replace

the

screws

case.

E-1,

bow.

it

and

slips

oil

of

lower

part.

back

force

will

presser

4),

and

controller

tension

the

in

materials,

tension,

4.

Fig.

embroidering;

and

thick

it—call

to

to

the

not

bushing

presser

used.

the

of

little

thick

tighten

To

as

for

position;

for

do

by

of

the

(V),

thread

ease

more

or

shown

darning

sewing

force

(Fig.

foot,

than

hard

the

in

position.

into

mechanic.

your

replaced

is

13.

Screw

decrease

or

the

for

it

14.

Adjusting

For

thread

sewing.

tension

of

lever

indicating

a)

indicating

b)

indicating

c)

If

of

free

regulate

To

or

unscrew

pressure

of

type

the

embroidering

controller

working

When

be

should

tension

the

the

the

the

Parts

charge.

the

material

tension

and

spring

tighter.

sleeve

position

normal

position

damaged

pressure

the

of

darning,

a

on

difficult,

is

this

not

foot

increase

regulate

spring

of

case

turn

and

for

be

the

of

the

the

hard

materials.

“L”

by

for

The

direction

loose

(light),

for

and

turning

“F”

for

the

fast

lever

is

(tight).

indicated

16

Fig.

13

Make

for

your

machined,

able

in

sewing.

darning

For

by

turning

of

side

left

it

turn

you

that

sure

machine—Needle

tempered

11,

7

to

sizes

16.

embroidering,

and

knob

the

plate.

bed

the

to

raise

the

15.

for

To

(X),

and

The

use

polished

the

lower

(Fig.

Turn

feed.

needle

the

Series

most

6),

it

PFAFF

130

delicate

the

the

on

right

R.

steel,

feed

feed

the

to

needles

These

and

to

can

front

lower

designed

are

are

heaviest

the

lowered

be

right-hand

the

finely

avail

feed;

Page 11

NO

ATTACHMENTS

and

most

with

used

lift

44088

types

a

hinged

for

these

most

presser

17.

foot

No.

for snaps,

of

Sewing

ped

is

machine

and

n

45037

Use

buttons,

46120

18 19

of

fancy

presser

purposes.

the

foot

44088

46120

ARE

time.

out

on

hooks

sewing.

To

to

buttons

for

and

NEEDED

foot.

No.

This

remove

the

left.

back

firmly

thumb

right

screw.

Fig.

For

dard

No.

ded

use

Fig.

sewing

small

(Fig.

the

tion

the

right

the

feed.

Fig.

for

all

The

PFAFF

44088

should

remain

it,

loosen

To

replace

into

position,

in

place

and

forefinger

hand

and

14

plain

sewing

type

of

45037,

(Fig.

for

those

it.

15

(Fig.

16

and

on

two-

boneormetal

Lower

18).

Dial-A-Stitch

Ill

with

dial

as

possible.

16

normal

comes

(Fig.

14),

on

the

it,

holding

between

tighten

the

presser

15),isinclu

who

prefer

17)

or

four-hole

ever

into

setasfar

sewing

equip

which

your

screw,

slip

the

of

the

the

stan.

foot,

rings.

H

posi

Lower

it

it

Fig

17

to

Fig.

18

button

With

on

fabric,

through

zigzag

through

To

of

to

fix

stitches

holes,

necessary

too.

At

adjust

sufficetolock

will

regulator

stitch

under

centerofright

stitch

with the

the

center

the

button

will

do.

place

the

to permit

last

the

the

stitch,

machine

button

of

When

fabric

for

the

set

between

foot,

hole

dial

the left

to

the

stitching

with

fastening

leave

straight

stitch.

1

so

of

so

fcsbric,

the

that

the

button.

that

of

hole

four or

buttons

on

button

the

second

the

needle

stitchesofwhich

and

the

the

as

at

place

2,

needle

Then

needle

button.

five

having

far

pair

the

passes

adjust

passes

double

back

of

right

four

holes,

and

few

a

the

as

Page 12

be

varied,

Pearl

in

the

a

well

The

on

With

stitch

ness

Screw

made

Cotton

For

corded

the

buttonhole

upper

drawn-in

length

the

fabric.

Dial-A-Stitch

regulator

of

18.

on

buttonhole

with

depending

No.

buttonhole,

and

under

of

the

zigzag

Buttonholes

or

without

on

5).

foot,

thread

stitch.

the

buttonhole

lever

between

stitch

foot,

cord.

your

draw

towards

must

H

in

zero

with

(F)g.

No.

choice,

the

the

should

position

-and

screw

19

and

42297.

The

from

cord

rear.

be

tightened

be

one.

20)

(Buttonholes

cord

used

the

through

The

marked

I,

(Fig.

12),

Adjust

B,

to

the

con

finest

the

tension

to

obtain

in

pencil

adjust

the

left

hole

fine

can

be

to

of

of

the

dial,

zigzag

cordings.

right

that

excess

the

stitch

according

is

these

length.

side

bar

and

the

edge

with

cord.

presser

to

the

most

f

After

marked

the

presser

so

parallel

off

lower

more

to

set

at

number

preparations,

When

of

this

edge

swing

now

the

cord

This

bar

left.

and

the

the

this

the

lies

guide.

makes

allow

heaviness

two,

the

first

is

done,

in

the

fabric

at

the

Keep

neater

the

this

edge

leave

fabric.

half

right

the

needle

of

carding

is

adequate

is

sewn

the

Now,

araund,

buttonholes.

of

work

clockwise,

the

clean.

to

make

used.

to

needle

raise

needle,

If

for

the

at

the

Cut

Then

one

t

I

20

Fig.

19

Fig.

20

21

Page 13

The

Raise

by

turning

stitch

to

five

these,

forward

leave

needle

in

the

sew

edge

to

make

is

raised

bar

tack

back

plain

The

hole

knife.

damaging

row

or

tightening

For

presser

with

ruler,

and

zigzag

make

teresting

An

additional

noting

sew

left

ter,

push

Colored

of

the

22

needle

the

for

zigzag

the

feeding.

the

up

position

the

made,

to

the

stitches

cutting

the

plain

foot.

any

as

seams

of

lever

work.

needle

it

the

fabric

needle

and

two.

second

before

farthest

to

of

This

the

broad

the

and

No.

stitches

number

dress

to

center,

thread

is

now

and

to

the

first

bar

stitches

must

On

in

the

push

in

which

Readjust

bar

switching

again

position

lock

the

buttonhole

must

buttonhole

blade

screw.

19.

Ornamental

straight

For

parallel

41350.

of

of

decorations.

variety

the

right

push

down.

H

is

often

in

the

fabric

push

lever

left.

In

tack

are

be

held

making

fabric

lever

0

you

the

tack,

the

raise

the

threads.

be

performed

threads.

into

ornamental

seams

By

skillfully

varying

attractive

effects

of

and

lever

used

at

the

G

into

this

set.

is

necessary,

somewhat

the

to

back

sewed

lever

being

zigzag

the

needle

the

on

is

the

width

(Fig.

left

H

up;

to

enhance

its

way,

the

To

make

last

stitch

the

left.

into

the

into

the

sure

lever.

and

right

made

with

Insert

holder

seams

seams

use

the

alternating

and

patterns—especially

21).

is

produced

of

center.

to

sew

left

second

wider

the

and

to

Then,

its

first

second

that

push

and

with

care

either

and

use

edge

length,

right

the

appearance

of

while

reduce

of

first

edge.

the

This

make

the

to

fasten

the

by

(Fig.

the

groove

zigzag

bar,

doing

the

bring

groove

groove

needle

second

lever

some

button

avoid

the

it

normal

stitcher

straight

you

alter-

22).

of

cen

cord.

four

the

bar,

the

Now

nar

by

can

in

To

0

Fig.

21

20.

Overedged

and

childrens

required

edge

with

stitch

carefully

and

length

with

hems

dresses,

baste

zigzag

of

a

are

stitches,

1/16th

pair

Overedged

very

underwear,

if

necessary.

inch.

of

scissors.

popular

small

Cut

hems

for

etc.

Fold

Then

cover

to

medium-small,

the

projecting

trimming

the

the

edge

edge

ladies

folded

at

off

as

a

23

Page 14

An

adds

additional

handsome

a

ornamental

effect.

Fig.

(Fig.

22

seam,

23).

parallel

edging,

the

to

Trace

appliqued

design.

sponds

24

the

extending

Place

the

to

design

the

pattern,

Applique

21.

on

1/16th

cutting

both

and

fabrics,

inch

on

baste

the

work

with

beyond

fabric

on.

it

so

the

the

that

cloth

edge

it

to

of

corre

be

the

Fig.

23

25

Page 15

Fig.

Fig.

24

25

41621

is

This

be

to

is

With

applied

is

necessary.

zigzag

the

ln

lace

the

dane

used.

strong

1/16th

The

stitches

case

sewn

is

41621

22.

with

so,

If

fabric

edge

and

of

inch

finer

on

Running

the

use

such

from

of

the

fabrics

with

a

lf

more

a

or

use

red,

41621.

No.

at

able

26

Fig.

regular

No.

foot

linen,

as

the

lace

the

projecting

such

straight

cord

the

extra

on

sewing

41621.

edge,

stitches

to

is

raised

special

(Fig.

cast.

lace

shirting,

then

is

fabric

voile

as

26).

foot,

(Fig.

and

appliqued,

be

effect

cording

This

unless

26>.

etc.

basted

covered

off.

cut

and

above

as

desi

is

foot

avail

is

cord

lace

the

an

with

cambric,

des-

if

Follow

too

the

more

26

dense

cutting.

dense

the

zigzag

lines

Then

zigzag

the

of

stitch,

reinforce

seam.

design

and

cut

the

(See

with

the

seam

Fig.

narrow

a

projecting

with

and

24

a

edges

wider

25>.

and

not

off

and

Fig.

27

27

Page 16

cribed.

under,

and

of

the

if

sewing

41746,

of

the

holding

ders

Even

(Fig.

(Fig.

With

rolled

tight

railed

knitted

of

using

Then

the

the

projecting

fabric

special,

curtains,

is

fabric

the

can

hems

28),

29),

with

light

edge

tension

hem

thread

the

double

is

clean-edge

available

under

lace

be

shirred

are

with

or

the

ensian

of

and

obtained,

is

silk

of

the

projecting

edgeiscovered

fabric

made

cut

impossible.

lace

linens,

bed

extra

at

as

the

back,arletting

or

sewn

Even

23.

sewn

the

machine

and

fabric

broad

goonds.

different

hems

by

using

larger

medium-sized

remains

zigzag

especially

Special

shades.

edge

off.

etc.,

cost.

lace

on

hemming

set

of

In

borders

sewn

is

it

go

flat.

(flg.

hemming

for

straight

even

stitches

desirable

effects

the

fabricisfolded

with

zigzag

this

manner,

are

special

a

This

curls

on.

forward,

30)

foot,

foot,

zigzag

zigzag

smooth.

and

an

are

stitches,

opening

desired

foot,

the

(Fig.

lace

Na.

No.

stitches,

undulating

in

the

obtained

edge

27).

bor

41246,

41248,

stitch.

With

case

far

No.

By

the

by

fabric

Now

flatten

formed

lock

goods,

good

Fig.

is

infold

the

through

stitch,

which

strong

30

then

folded

the

seam,

except

require

seams.

two

the

and

feller.

for

once,

pieces

thin

a

and

sewn

of

cloth

once

more

When

or

elastic

medium-sized

as

guide

felling,

fabrics

to

the

shown

the

use

zigzag

top

the

and

in

edge

straight

stitch

piece.

Fig.

thus

knitted

for

32,

1246

Fig.

For

Place

projects

pieces

28

28

felling,

the

about

into

two

the

use

fabrics

1/4”

feller,

24.

the

on

Felling

felling

together

the

right

just

as

(Fig.

foot

so

side.

when

41248

32)

41242.

No.

that

the

Then

hemming.

lower

guide

The

Fig.

(Fig.

the

41248

29

layer

two

lower

31).

41242

Fig.

31

Fig.

32

29

Page 17

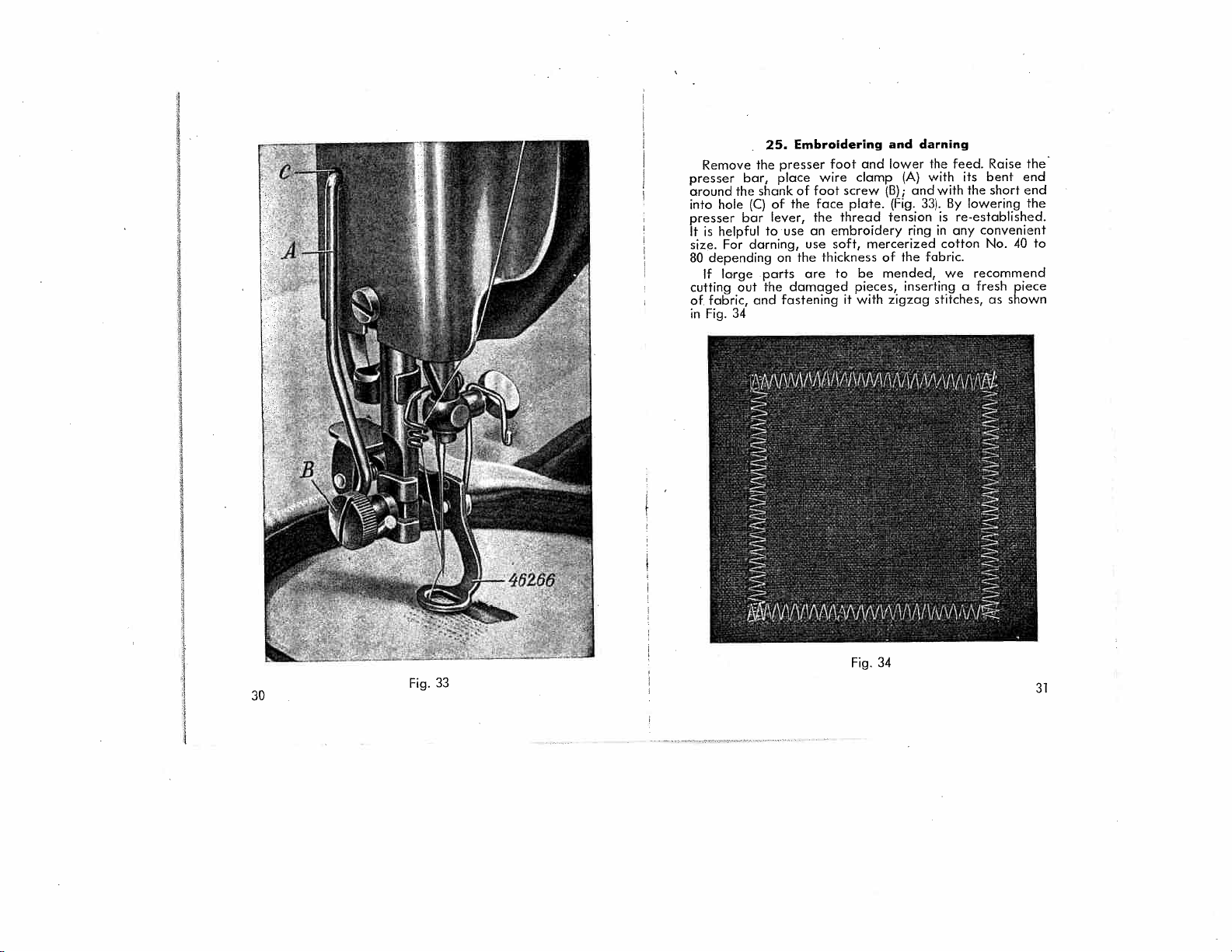

Remove

presser

around

into hole

presser

is

helpful

It

For

size.

80

depending

If

large

cutting

fabric,

of

in

Fig.

bar,

the

(C)

bar

darning,

out

34

25.

the

shank

to

parts

the

and

Embreidering

presser

place

of

the

of

lever,

use

use

on

the

are

damaged

fastening

foot

wire

foot

face

the

thread

embroidery

an

soft,

thickness

to

and

clamp

screw

plate.

mercerized

be

pieces,

with

it

and

darning

lower

the

(A)

with

and

(13);

(Fig.

tension

33). By

ring

with

is

in

cotton

the

fabric.

of

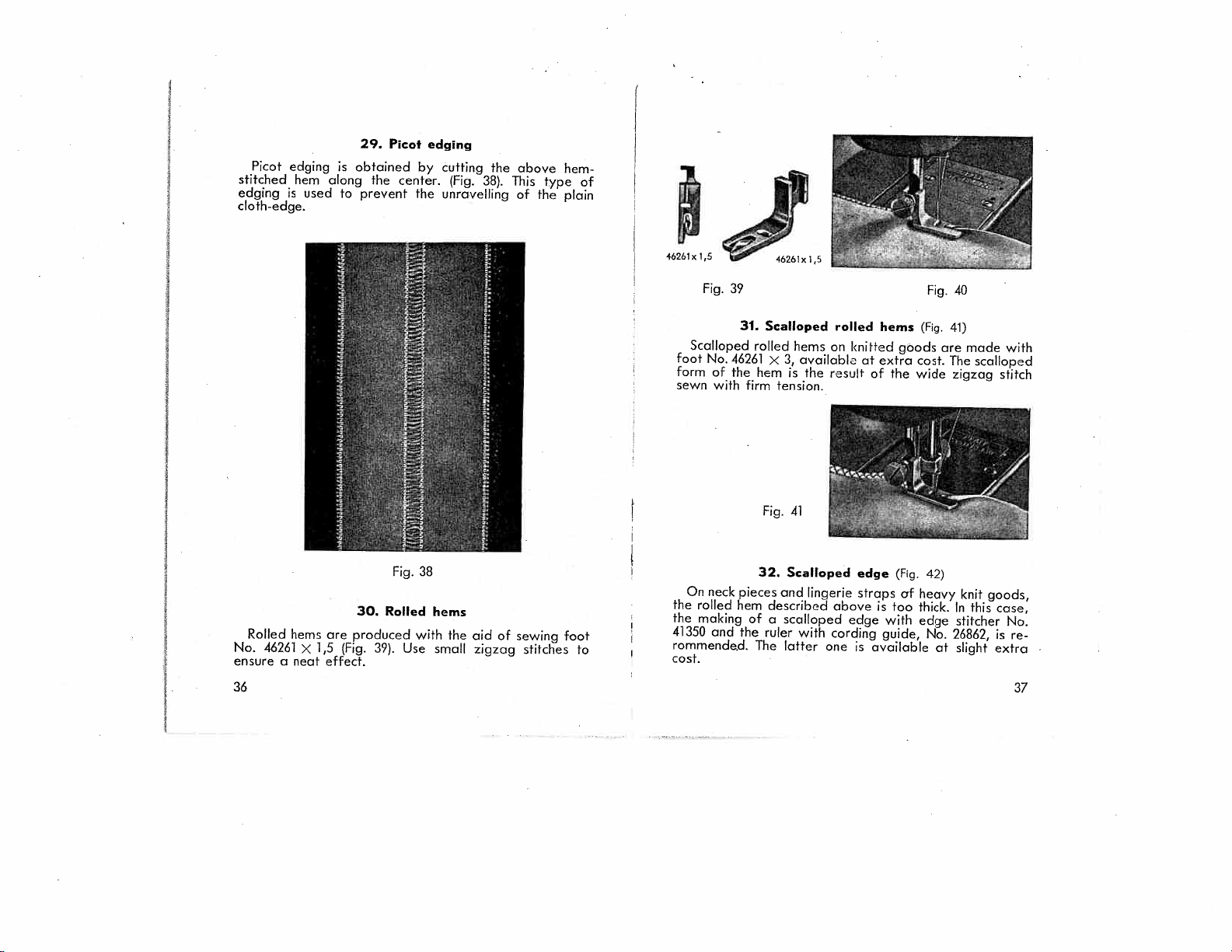

mended, we

inserting

stitches,

zigzag

Raise

feed.

bent

its

the

short

lowering

re-established.

any

convenient

40

No.

recommend

a

fresh

as

piece

shown

the

end

end

the

to

30

Fig.

33

Fig.

34

31

Page 18

Covered

and

cord

No.

41319

at

a

slight

Embroidery

ing

cotton,

serve

as

Pass

place

the

the

line

Soft

thread.

zigzag

Ruffling

tioned

Fasten

completing

together

cord

must

coming

First

as

threads

zigzag

of

draw

if

hemstitching

stitches,

stitch

sewing

threads

same

as

appearance.

useful.

32

guide

with

cord.

the

fabric

you

cording

This,

stitches.

is

above.

one

the

for

be

undone.

have

depends

the

are

covered,

an

cords

No.

extra

yarn

may

crochet

have

effects

(as

done

(See

end

sean.

uniform

fixed,

28.

the

been

using

second

the

For

26.

Covered

are

made

41842,

five

grooves.

cost.

No.

40,

be

used

yarn

under

the

traced,

can

shown

27.

with

the

Fig.

36).

of

the

filler

The

ruffling.

to

Hemsfifching

threads

by

hand.

drawn

must

the

the

regular

effect

on

edge,

and

first

this

work

cords

with

in

addition

All

sewing

Crochet

through

in

presser

with

be

Fig.

the

a

medium

obtained

35),

Ruffling

same

thread,

fabric

can

The

prevent

the

(Fig.

according to

The

two

now

be

presser

you

wish

make

the

an

embroidery

sure

length

to

that

edge,

the

to

of

these

silk,

yarn

cording

foot.

is

done

type

and

now

opposite

ruffling

37)

the

edges

sewn

to

assure

feed

the

or

No.

Sew

by

of

tighten

foot.

obtain.

that

of

cover

cording

are

available

standard

3

or

guide,

the

zig-zag

using

with

cording

be

puckered

end

from

pattern,

where

with

The

the

stitch

a

uniform

ring

is

plate

foot,

sew

5

cord

stitch.

filler

a

smaller

men

it

after

of

the

be

just

the

narrow

length

When

same

is

the

very

can

and

on

Fig.

35

33

Page 19

34

Fig

36

H

1

Fig

37

35

Page 20

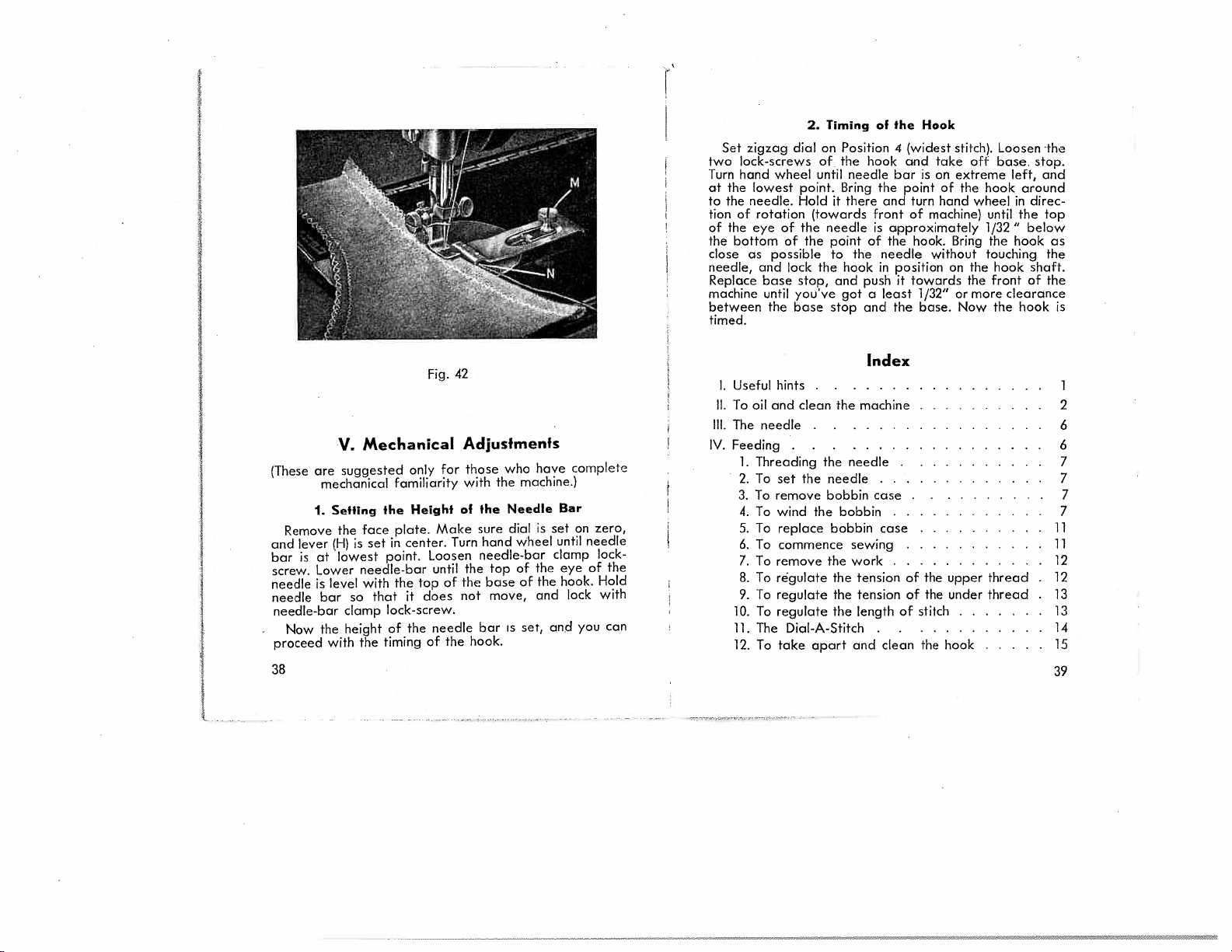

Picot

stitched

edging

is

cloth-edge.

edging

hem

used

is

along

to

Picof

29.

obtained

the

prevent

by

center.

the

edging

cutting

(Fig.

unravelling

the

38).

above

This

of

the

type

hem-

of

plain

Rolled

No.

ensure

36

46261

a

hems

x

neat

are

1,5

effect.

30.

produced

(Fig.

Rolled

39).

Fig.

Use

38

with

hems

the

small

aid

zigzag

of

sewing

stitches

foot

46261x1,5

Fig.

Scalloped

foot

No.

form

of

sewn

with

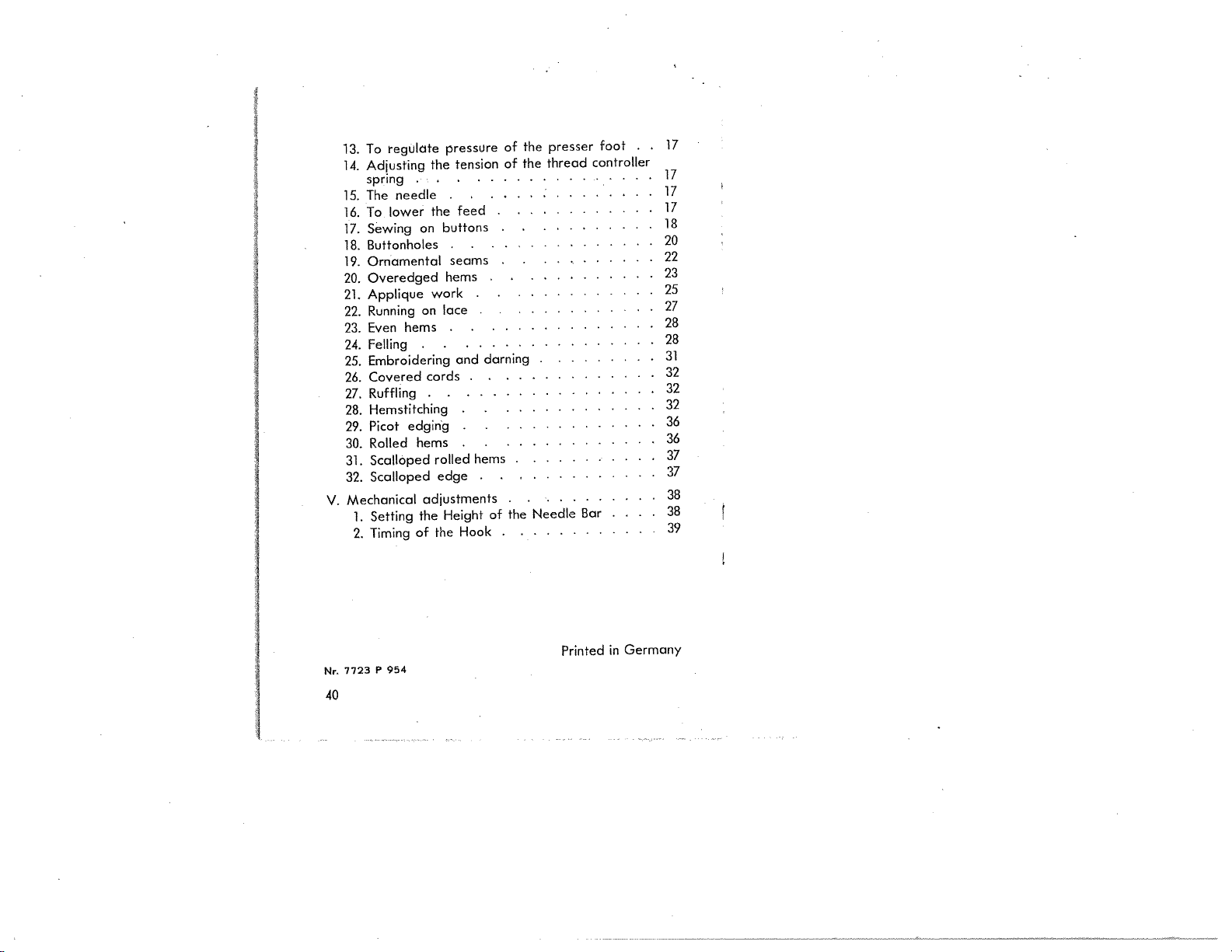

On

neck

the

rolled

the

making

41350

and

to

rommende.d.

cost.

39

31.

46261

the

firm

pieces

hem

of

the

46261x

5

Scalloped

rolled

3,

x

hem

tension.

32.

and

described

scalloped

a

ruler

The

latter

hems

available

is

the

Scalloped

lingerie

with

one

rolled

on

knitted

result

edge

straps

above

edge

cording

is

hems

at

extra

of

is

with

guide,

available

goods

the

(Fig.

of

too

Fig.

(Fig,

cost.

wide

42)

heavy

thick.

edge

No.

are

at

40

41)

made

The

zigzag

knit

In

this

stitcher

26862,

slight

with

scalloped

stitch

goods,

case,

No.

is

re

extra

37

Page 21

7

7

2.

Set

two

lack-screws

Turn

hand

at

the

the

to

tion

of

of

the

bottom

the

close

needle,

Replace

machine

between

zigzag

lowest

needle.

rotation

eye

as

and

base

until

the

dial

wheel

point.

Hold

the

of

of

the

possible

lock

stop,

you’ve

base

Timing

Position

on

of

the

until

needle

Bring

it

there

(towards

needle

point

to

the

hook

and

got

stop

hook

front

is

of

the

push

a

and

Hook

of

Ihe

4

(widest

and

take

is

bar

point

turn

of

on

machine)

the

and

approximately

hook.

the

needle

in

least

without

positiononthe

it

towards

1/32”

base.

the

stitch).

off

extreme

hook

of

the

hand wheel

until

1/32”

Bring

the

touching

hook

front

the

or

more

the

Now

Loosen

base,

left,

around

in

the

below

hook

of

clearance

hook

‘the

stop.

and

direc

top

as

the

shaft.

the

is

timed.

are

(These

1.

Remove

lever

and

at

is

bar

Lower

screw.

is

needle

needle

needle-bar

Now

proceed

38

Mechanical

V.

suggested

mechanical

SettIng

the

face

set

is

(H)

lowest

needle-bar

with

level

bar

so

clamp

height

the

the

with

only

familiarity

Height

the

plate.

center.

in

point.

the

it

that

lock-screw.

of

the

timing

Fig.

Make

Loosen

until

top

does

needle

of

for

Turn

of

the

42

Adjusiments

who

those

with

of

the

the

not

hook.

machine.)

the

Needle

the

dial

sure

wheel

hand

needle-bar

of

top

of

base

move,

is

set,

bar

have

is

the

the

and

and

complete

Bar

set

until

clamp

eye

hook.

lock

on

needle

you

zero,

lock-

of

Hold

the

with

con

II.

Ill.

lv.

I.

Useful

To

The

Feeding

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

hints

oil

and

needle

Threading

To

set

To

remove

wind

To

replace

To

To

commence

remove

To

regulate

To

regulate

To

regulate

To

The

Dial-A-Stitch

To

take

clean

the

the

apart

the

machine

the

needle

needle

bobbin

bobbin

bobbin

sewing

the

work

the tension

the

tension

the

length

and

Index

case

case

clean

of

of

of

..........

the

the

stitch

the

upper

under

hook

thread

thread

1

2

6

.6

7

7

11

11

12

12

13

13

14

15

39

Page 22

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Mechanical

V.

1.

2.

egUlcite

To

Adjusting

spring

needle

The

lower

To

Sewing

on

Buttonholes

Ornamental

Overedged

Applique

Running

Even

on

hems

Felling

Embroidering

Covered

cords

Ruffling

Hemstitching

edging

Picot

hems

Rolled

Scalloped

Scalloped

adjustments

Setting

Timing

the

of

pressure

the

the

buttons

seams

hems

work

lace

rolled

edge

Height

the

tension

feed

and

hems

Hook

of

of

darning

the

of

the

the

Needle

presser

threod

foot

controller

Bar

.

17

.

17

17

17

18

20

22

23

25

27

28

28

31

32

32

32

36

36

37

37

38

38

.

39

Nr.

40

7723

Germany

Printed

954

P

in

Loading...

Loading...