1295

1296

Instruction manual

296-12-18 135

Betriebsanleitung engl. 08.98

This Instruction manual is valid for all models and subclasses listed in the

chapter „Specifications“.

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or in

part, is only permitted with our previous permission and with written reference to the

source.

G.M. PFAFF

Aktiengesellschaft

Postfach 3020

D - 67653 Kaiserslautern

Königstr . 154

D - 67655 Kaiserslautern

Editing/Illustrations

V erlag - TD

D - 77901 Lahr

Index

Contents .................................................................................Chapter-Page

1 Safety ........................................................................................................................ 1 -1

1.01 Regulations ................................................................................................................ 1 -1

1.02 General notes on safety............................................................................................. 1 - 1

1.03 Safety symbols .......................................................................................................... 1 - 2

1.04 Important notes for the user...................................................................................... 1 - 2

1.05 Notes for operating and technical staff ...................................................................... 1 - 3

1.05.01 Operating staff ...........................................................................................................1- 3

1.05.02 Technical staff............................................................................................................ 1 - 3

1.06 Danger warnings........................................................................................................ 1 - 4

2 Proper use ................................................................................................................ 2 - 1

3 Specifications ........................................................................................................... 3 - 1

3.01 PFAFF 1295, PFAFF 1296.......................................................................................... 3 - 1

3.02 Possible versions and subclasses .............................................................................. 3 - 2

3.03 Maximum speeds of the PFAFF 1295 ....................................................................... 3 - 2

3.04 Maximum speeds of the PFAFF 1296 ....................................................................... 3 - 2

4 Disposal of the machine .......................................................................................... 4 - 1

5 Transportation, packing and storage...................................................................... 5 - 1

5.01 Transportation to the customer’s premises ............................................................... 5 - 1

5.02 Tansportation inside the customer’s premises .......................................................... 5 - 1

5.03 Disposal of packing materials..................................................................................... 5 - 1

5.04 Storage ......................................................................................................................5- 1

6 Explanation of symbols ........................................................................................... 6 - 1

7 Controls ..................................................................................................................... 7- 1

7.01 On/off switch ............................................................................................................. 7 - 1

7.02 Pedal (on machines without subclass -917/97) .......................................................... 7 - 1

7.03 Pedal (on machines with subclass -917/97) ............................................................... 7 - 2

7.04 Knee lever (on machines without subclass -911/97 ................................................... 7 - 2

7.05 Key on machine head (on machines with subclass -911/97)...................................... 7 - 3

7.06 Presser bar lifter ........................................................................................................ 7 - 3

7.07 Feed regulator/reverse sewing .................................................................................. 7 - 4

7.08 Feed regulator (on machines with subclass -911/97) ................................................. 7 - 4

7.09 Adjusting nut for the top feed stroke ......................................................................... 7 - 5

8 Installation and commissioning.............................................................................. 8 - 1

8.01 Installation.................................................................................................................. 8 - 1

8.01.01 Adjusting the table height .......................................................................................... 8 - 1

8.01.02 Tensioning the v-belt.................................................................................................. 8 - 2

8.01.03 Fitting the upper belt guard........................................................................................ 8 - 2

8.01.04 Fitting the lower belt guard........................................................................................ 8 - 3

8.01.05 Fitting the synchroniser ............................................................................................. 8 - 3

Index

Contents .................................................................................Chapter-Page

8.01.06 Assembling the reel stand ......................................................................................... 8 - 4

8.02 Commissioning .......................................................................................................... 8 - 4

8.03 Switching the machine on/off .................................................................................... 8 - 4

9 Setting up ................................................................................................................. 9 - 1

9.01 Inserting the needle on the PFAFF 1295 ................................................................... 9 - 1

9.02 Inserting the needle on the PFAFF 1296 ................................................................... 9 - 2

9.03 Winding the bobbin thread, regulating the winder tension ........................................ 9 - 3

9.04 Changing the bobbin .................................................................................................. 9 - 4

9.05 Threading the bobbin thread and regulating the bobbin thread tension......................... 9 - 4

9.06 Threading needle thread/adjusting needle thread tension on the PFAFF 1295 .................... 9 - 5

9.07 Threading needle thread/adjusting needle thread tension on the PFAFF 1296 .................... 9 - 6

10 Care and maintenance........................................................................................... 10 - 1

10.01 Cleaning ................................................................................................................... 10- 1

10.02 General oiling ........................................................................................................... 10 - 2

10.03 Oiling the sewing hook ............................................................................................ 10 - 3

10.04 Oiling the needle-head parts .................................................................................... 10 - 4

10.05 Lubricating the top-feed drive eccentric................................................................... 10 - 4

10.06 Checking/regulating the air pressure........................................................................ 10 - 5

10.07 Emptying/cleaning the water bowl of the air filter/regulator .................................... 10 - 5

11 Adjustment ............................................................................................................. 11 - 1

11.01 Tools, gauges and other equipment for adjusting .................................................... 11 - 1

11.02 Notes on adjustment ............................................................................................... 11 - 1

11.03 Abbreviations ........................................................................................................... 11 - 1

11.04 Adjusting the basic machine .................................................................................... 11 - 2

11.04.01 Position of the bottom feed dog crosswise to sewing direction.............................. 11 - 2

11.04.02 Adjusting the bottom feed dog in sewing direction ................................................. 11 - 3

11.04.03 Bottom feed dog height........................................................................................... 11 - 4

11.04.04 Needle height (preliminary adjustment) ................................................................... 11 - 5

11.04.05 Needle in needle-hole centre ................................................................................... 11 - 6

11.04.06 Bottom feed dog lifting motion ................................................................................ 11 - 7

11.04.07 Feeding stroke of bottom and top feeds.................................................................. 11 - 8

11.04.08 Hook clearance, needle rise, needle height and needle guard................................. 11 - 9

11.04.09 Top feed stroke........................................................................................................ 11 -11

11.04.10 Top feed lifting motion............................................................................................. 11 -12

11.04.11 Bobbin case opener ................................................................................................. 11 -13

11.04.12 Slip coupling.............................................................................................................11 -14

11.04.13 Needle-thread tension release ................................................................................. 11 -15

11.04.14 Thread check spring, without subclass -900/56 ....................................................... 11 -16

11.04.15 Thread check spring on the PFAFF 1296 with subclass -900/56.............................. 11 - 17

11.04.16 Bobbin winder.......................................................................................................... 11 -18

11.04.17 Pressure of the lifting presser.................................................................................. 11 - 19

Index

Contents .................................................................................Chapter-Page

11.05 Adjusting the thread trimmer -900/56 ...................................................................... 11 - 20

11.05.01 Engaging solenoid.................................................................................................... 11 -20

11.05.02 Control cam (preliminary adjustment) ...................................................................... 11 -21

11.05.03 Control lever spring action ....................................................................................... 11 -22

11.05.04 Control lever stroke.................................................................................................. 11 -23

11.05.05 Thread-trimmer drive linkage ................................................................................... 11 -24

11.05.06 Linkage bar (only on the PFAFF 1296) ..................................................................... 11 - 25

11.05.07 Thread catcher height .............................................................................................. 11 -26

11.05.08 Thread catcher resting position................................................................................ 11 - 27

11.05.09 Knife pressure.......................................................................................................... 11-28

11.05.10 Bobbin thread trapping spring.................................................................................. 11 - 29

11.05.11 Control cam (final adjustment) ................................................................................. 11 - 30

11.05.12 Release lever ........................................................................................................... 11-31

11.05.13 Release rod.............................................................................................................. 11 -32

11.05.14 Adjusting the synchroniser ...................................................................................... 11 - 33

Safety

1 Safety

1.01 Regulations

1.02 General notes on safety

This machine has been made according to the European regulations indicated in the

conformity and manufacturer’s declarations.

In addition to this instruction manual, please also observe all generally accepted statutory

and other legal requirements, including those of the user’s country, and the valid pollution

control regulations!

The locally valid regulations of the social insurance institution responsible for occupational

accidents, or other supervisory authorities, must be strictly adhered to!

● The machine must only be operated when the instruction manual has been fully read and

understood, and only by operators who have had the necessary training!

● All notes on safety and the instruction manual of the motor manufacturer must be read

before the machine is put into operation!

● All notices on the machine referring to danger and safety must be observed!

● The machine must be used for the purpose it is intended for and must not be operated

without its safety devices; all regulations relevant to safety must be adhered to.

● When part sets are changed (e.g. needle, presser foot and needle plate), during

threading, when the workplace is left unattended and during maintenance work, the

machine must be isolated from the power supply by pressing the on/off switch or

removing the plug from the mains!

● Daily maintenance work must only be carried out by appropriately trained persons!

● Repairs and special maintenance work must only be carried out by qualified technical

staff or persons with the appropriate training! Exceptions to this are only allowed for

adjustment and function checks by appropriately trained personnel!

● Repair work and special maintenance work must only be carried out by technical

personnel or by persons with the appropriate training!

● Work on the electrical equipment must only be carried out by technical staff who are

qualified to do so!

1 - 1

● Work on parts or equipment connected to the power supply is not permitted! The only

exceptions to this are specified in regulations EN 50110.

● Conversion or modification of the machine must only be carried out under observation of

all relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We draw

!

special attention to the fact that spare parts and accessories not supplied by us have not

been subjected to testing nor approval by us. Fitting and/or use of any such parts may

cause negative changes to the design properties of the machine. We shall not accept

any liability for damage caused by the use of non-original parts.

1.03 Safety symbols

Danger!

!

Special points to observe.

Danger of injury to operating or technical staff!

Safety

1.04 Important notes for the user

● This instruction manual is part of the equipment of the machine and must be available to

the operating staff at all times.

● The instruction manual must be read before the machine is operated for the first time.

● Both operating and technical staff must be instructed on the safety devices of the

machine and on safe working methods.

● It is the duty of the user to operate the machine in perfect running order only.

● The user must ensure that none of the safety devices are removed nor put out of

working order.

● The user must ensure that only authorized persons operate and work on the machine.

For further information please refer to your PFAFF agency.

1 - 2

Safety

1.05 Notes for operating and technical staff

1.05.01 Operating staff

Operating staff are the persons responsible for setting up, operating and cleaning the

machine and for removing any disturbances in the sewing area.

The operating staff must be sure to observe the following items:

● always observe the notes on safety in this instruction manual in their work!

● refrain from any working methods which adversely effect the safety of the machine!

● avoid wearing loose clothing or jewelry such as necklaces or rings!

● also make sure that only authorised persons are allowed near the danger area of the

machine

● immediately report to the user any changes to the machine that may affect its safety!

1.05.02 Technical staff

Technical staff are persons who have been trained in electrical engineering, electronics,

pneumatics and mechanical engineering. They are responsible for lubricating, servicing,

repairing and adjusting the machine.

The technical staff must be sure to observe the following items:

● always observe the notes on safety in this instruction manual in their work!

● press the on/off switch before carrying out adjustment and repair work, and ensure it

cannot be switched on again unintentionally, or isolate the machine from the power

supply by removing the mains plug!

● never work on parts or equipment still connected to the power supply! Exceptions to

this are only permissible according to regulations EN 50110;

● replace all safety covers after carrying out maintenance or repair work and, if applicable,

close the electrical control box again!

1 - 3

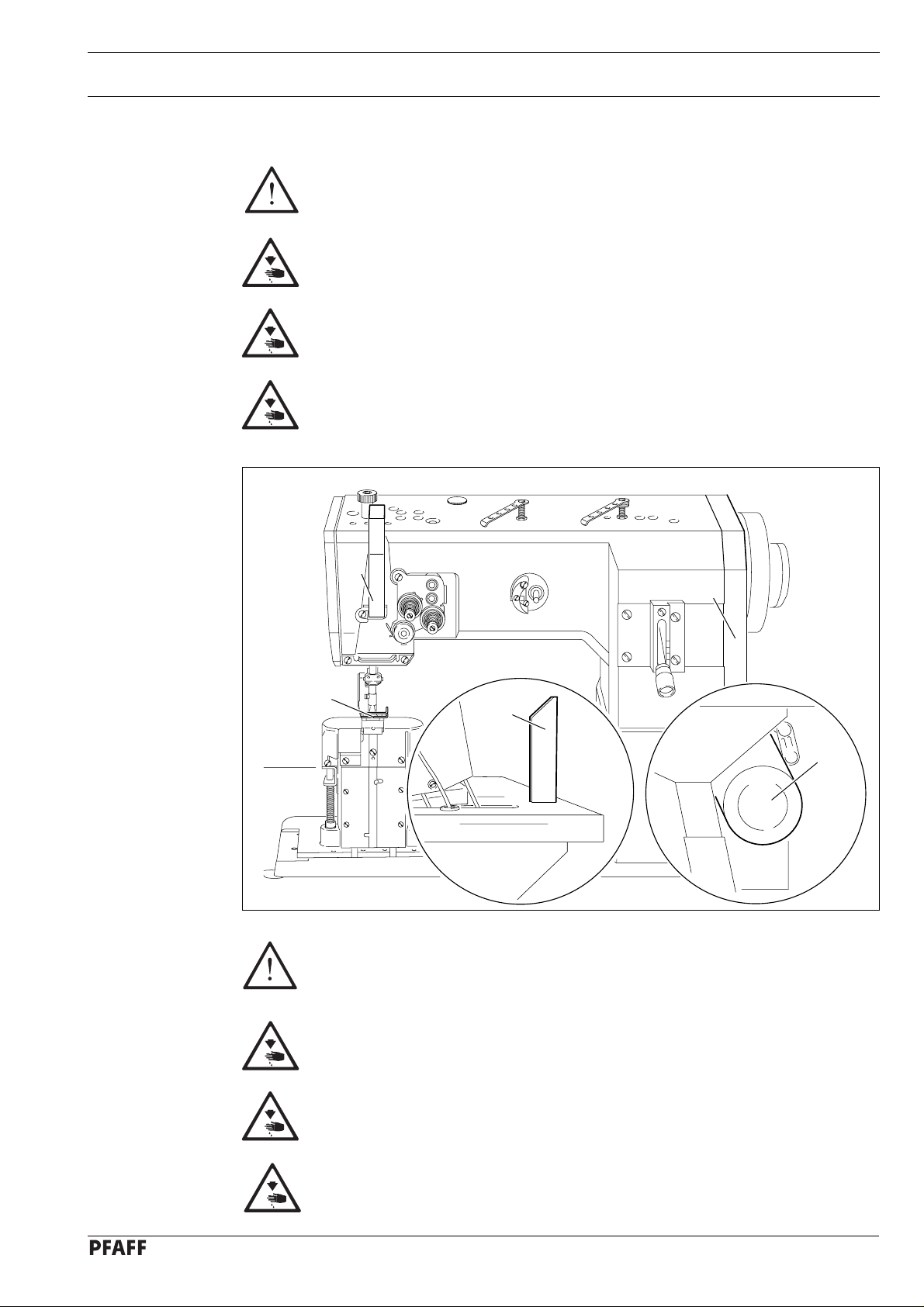

1.06 Danger warnings

A working area of 1 m must be kept free both in front of and behind the

machine, so that easy access is possible at all times.

Never put your hands or fingers in the sewing area during sewing!

Danger of injury by the needle!

While setting or adjusting the machine do not leave any objects on the table

nor in the needle plate area! Objects may be trapped or flung out of the

machine!

When a mechanically operated clutch motor without actuation lock is switched

off, alwys wait until the motor has stopped! Danger of injury!

Safety

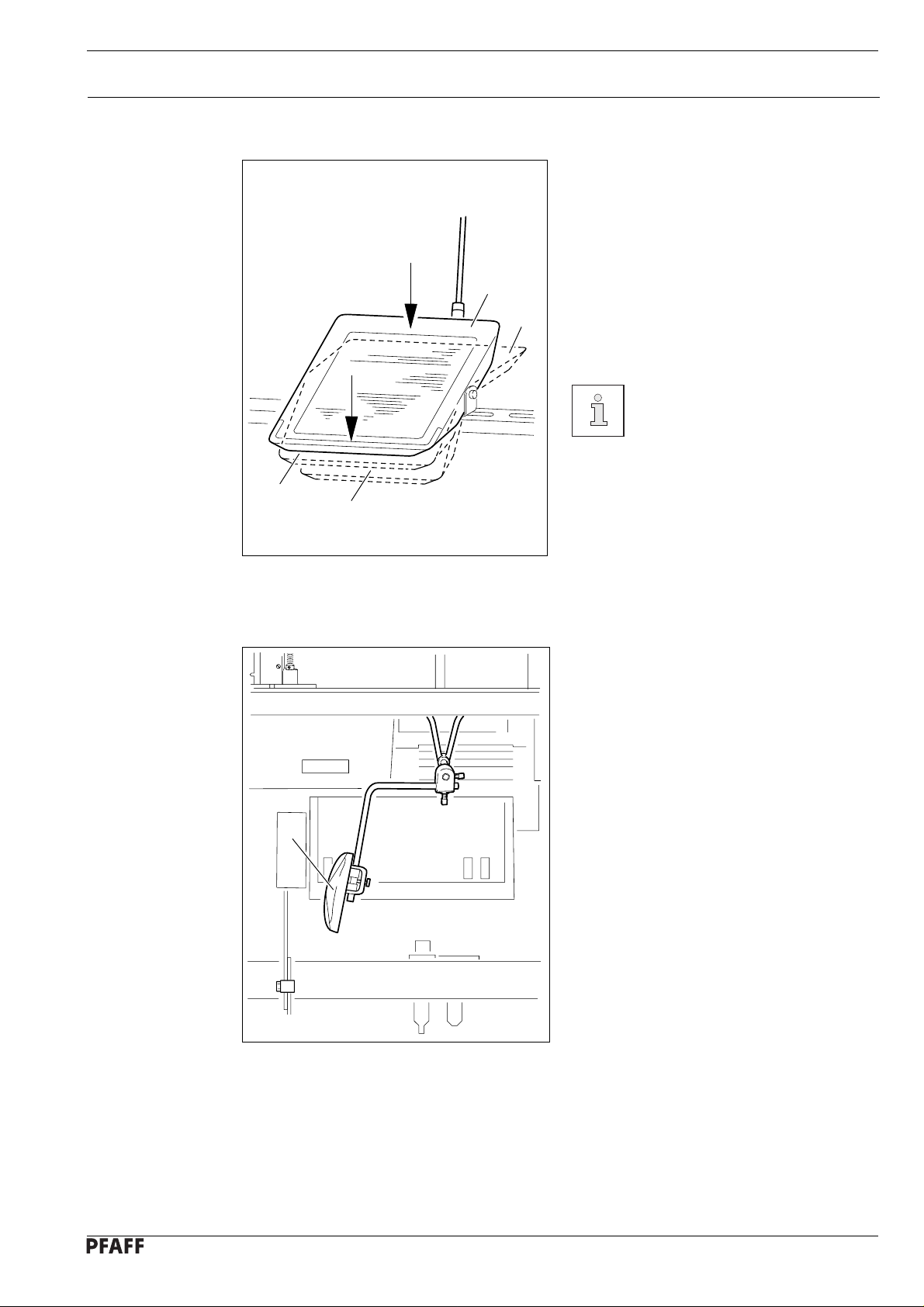

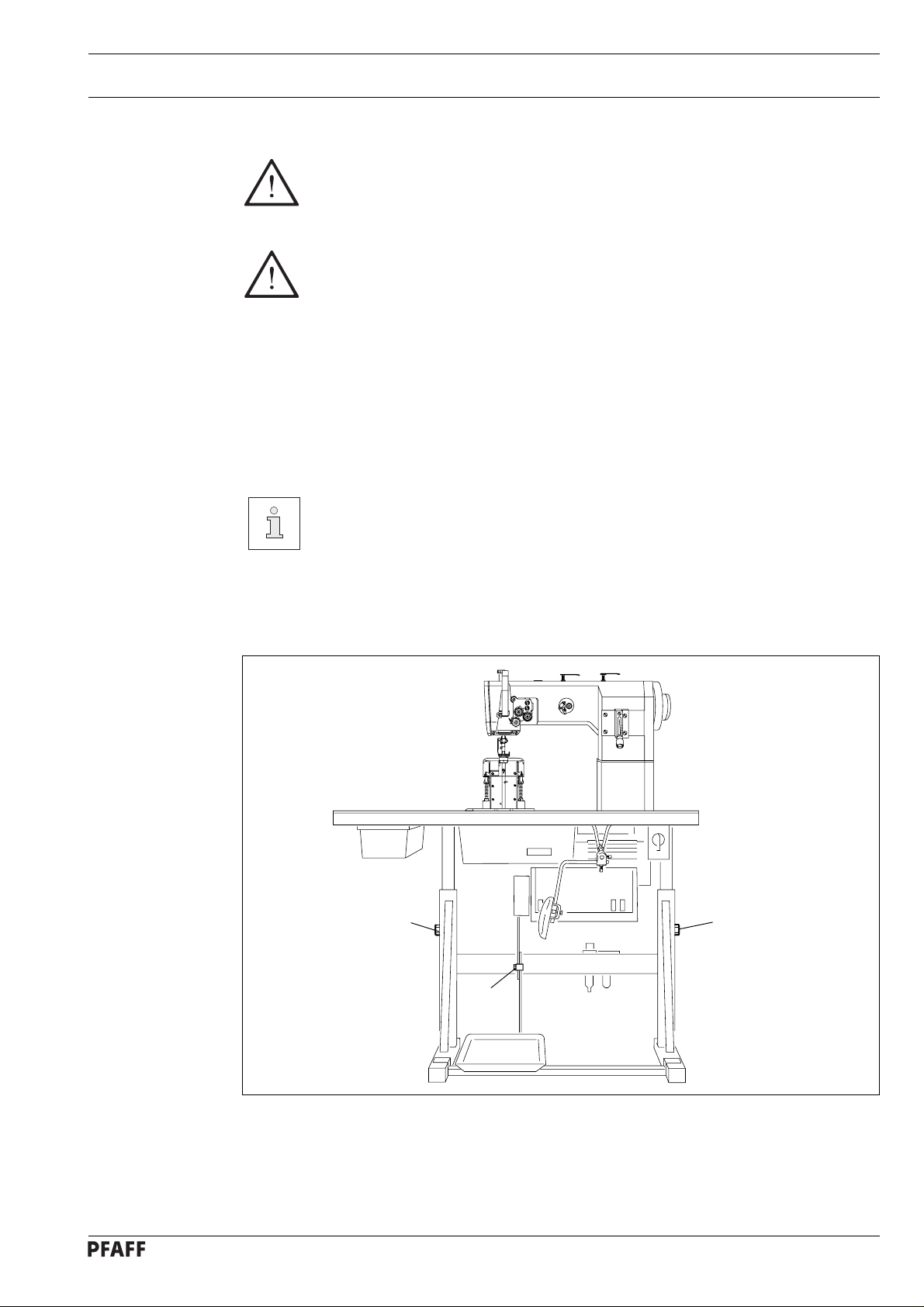

Fig. 1 - 01

2

3

1

Do not run the machine without support 1.

Danger due to top-heavy sewing head!

Machine may tip over backwards when tilted!

4

0

1

2

3

5

Do not run the machine without take-up lever guard 2!

Danger of injury by moving take-up lever!

Do not run the machine without finger guard 3!

Danger of injury by up and down movement of needle!

Do not run the machine without belt guards 4 and 5!

Danger of injury by rotating v-belt!

1 - 4

Proper use

2 Proper use

The PFAFF 1295 is a single-needle lockstitch postbed sewing machine with unison feed and

large vertical sewing hook.

The PFAFF 1296 is a two-needle lockstitch postbed sewing machine with unison feed and

large vertical sewing hooks.

These machines are for sewing lockstitch seams in the textile industry.

Any use of this machine which is not approved by the manufacturer shall be

considered as improper use! The manufacturere shall not be held liable for any

damage arising out of improper use! Proper use shall also be considered to

include compliance with the operation, adjustment, service and repair

measures specified by the manufacturer!

2 - 1

3 Specifications

Specifications

3.01 PFAFF 1295, PFAFF 1296

Stitch type:.................................................................................................. 301 (lockstitch)

Needle system....................................................................................................... 134 - 35

Needle size in 1/100 mm:

Version B : ............................................................................................................. 80 - 100

Versiong CN : ....................................................................................................... 110 - 140

▲

Max. thread size (synthetic

Version B : ................................................................................................................... 40/3

Version CN :................................................................................................................. 20/3

Max. stitch length:

Version BN :............................................................................................................ 6,0 mm

Version CN :............................................................................................................ 6,0 mm

Effective dia. of balance wheel: ............................................................................... 90 mm

Dimensions of the machine:

Length:...................................................................................................... approx. 530 mm

Breadth:: ................................................................................................... approx. 177 mm

Height (above table): ................................................................................. approx. 440 mm

):

◆

Clear workspace length: ........................................................................................ 265 mm

Clear workspace height: ........................................................................................ 115 mm

Fabric clearance (with presser foot raised): ............................................................. 14 mm

Postbed height:...................................................................................................... 165 mm

Net weight (sewing head):..........................................................................................55 kg

Mains voltage:...................................................................see instruction manual of motor

Max. power input:.............................................................see instruction manual of motor

Power supply fuse: ...........................................................see instruction manual of motor

Working pressure:....................................................................................................... 6 bar

Air consumption:............................................................................. ~0,8 l litres/work cycle

Ambient noise level:

Workplace noise level, PFAFF 1295, at a speed of 1,600 r.p.m.............................77 dB(A)

Workplace noise level, PFAFF 1296, at a speed of 1,500 r.p.m.............................76 dB(A)

Noise measurement according to DIN 45 635-48-A-1

◆

Subject to technical alterations

▲

Or comparable sizes of other thread types

3 - 1

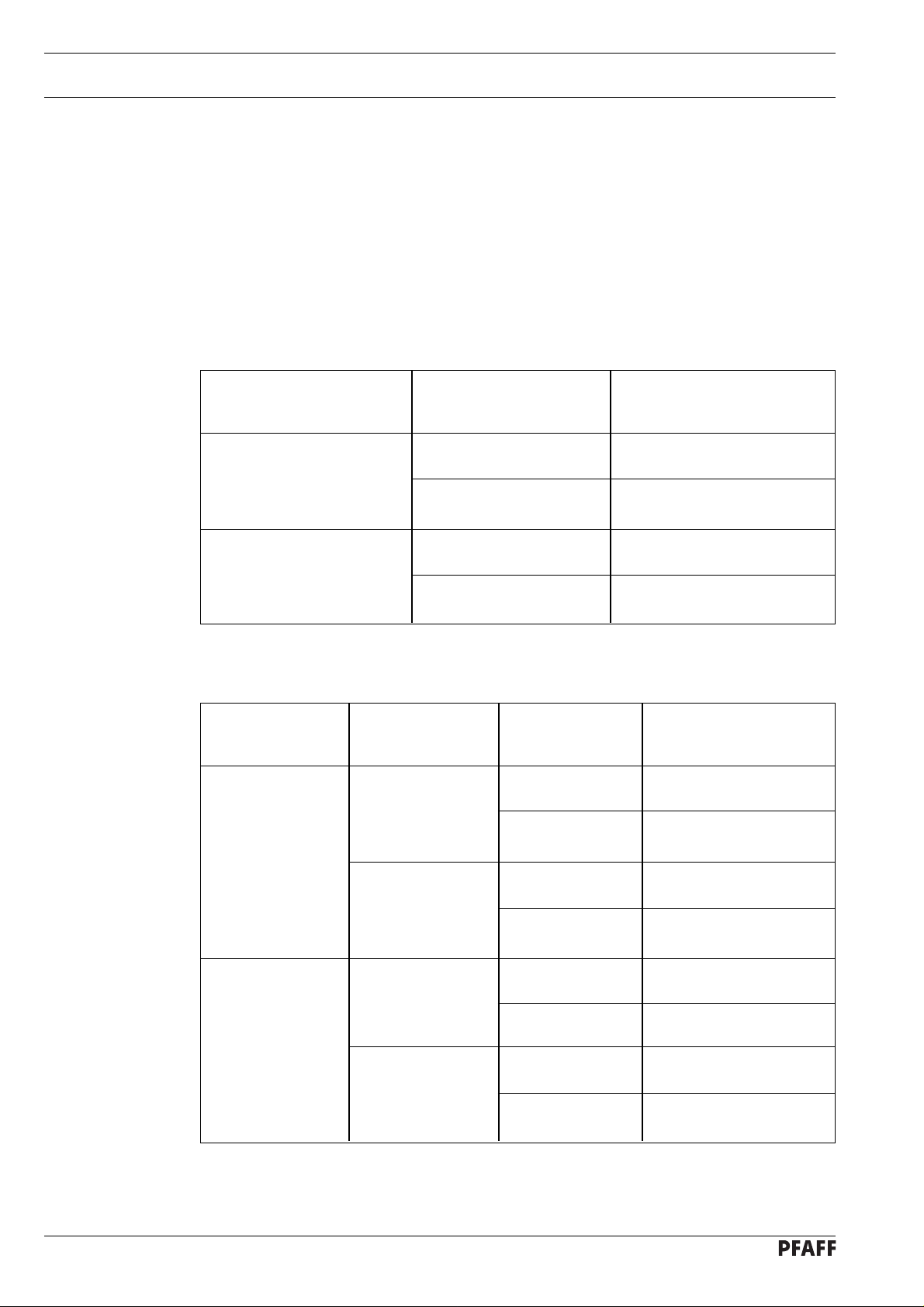

Specifications

3.02 Possible versions and subclasses

Version B (only on 1296): ..................................................... For sewing medium materials

Version CN:................................................................ For sewing medium-heavy materials

Work aids:

Subclass -900/56.........................................................................................Thread trimmer

Subclass -911/97................................Automatic presser foot lift with backtacking system

3.03 Maximum speeds of the PFAFF 1295

Top feed stroke

Up to 5.5 mm

over 5.5 mm to 7 mm

Version

3.04 Maximum speeds of the PFAFF 1296

Top feed stroke

up 5.5 mm

Needle gauge

up 10 mm

Max. speed (s.p.m.)

B

C

B

C

Version

B

C

2200

1900

1800

1800

Max. speed (s.p.m.)

2100

1800

3 - 2

over 5.5 mm

from 10.4 mm

up 10 mm

from 10.4 mm

B

C

B

C

B

C

1900

1600

1800

1600

1500

1400

4 Disposal of the machine

● Proper disposal of the machine is the responsibility of the user.

● The materials used for the machine are steel, aluminium, brass and various plastics.

The electrical equipment comprises plastic materials and copper.

● The machine must be disposed of according to the locally valid pollution control

regulations; if necessary, a specialist will have to be contracted.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

Disposal of machine waste

4 - 1

Transportation, packing and storage

5 Transportation, packing and storage

5.01 Transportation to the customer’s premises

Within the Federal Republic of Germany, complete machines (with table and motor) are

delivered without packing.

Machines without table (sewing heads only) and machines intended for exports are packed.

5.02 Tansportation inside the customer’s premises

The manufacturer cannot be made liable for transportation inside the customer’s premises

nor to other operating locations. Care must be taken that the machines are only transported

in an upright condition.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fibre. Proper

disposal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but

after that it should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a film of oil.

5 - 1

6 Explanation of symbols

In this instruction manual, work to be carried out, or important information, is accentuated

by symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Explanation of symbols

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

6 - 1

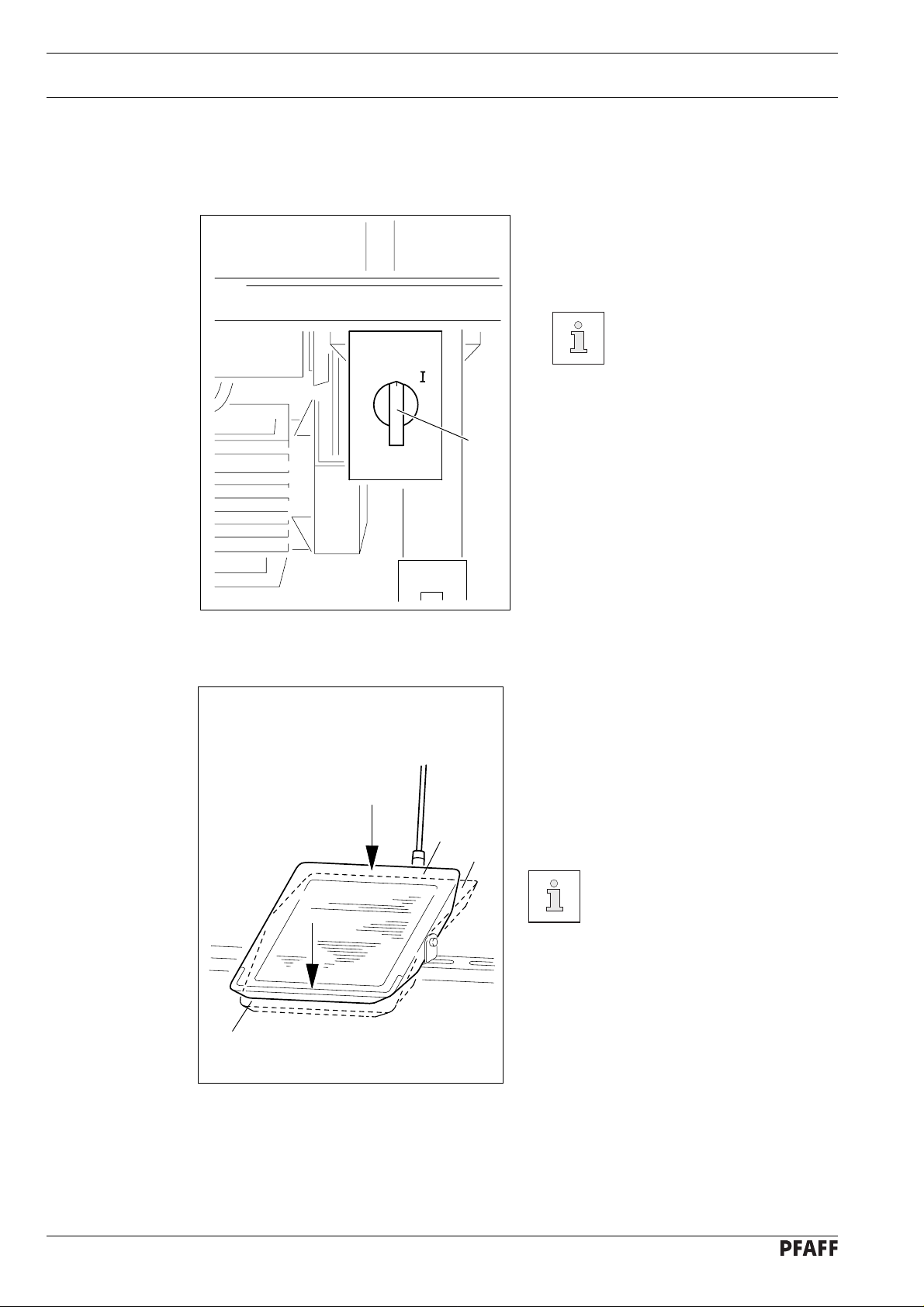

Controls

7 Controls

7.01 On/off switch

● The power supply to the machine is

switched on or off by turning switch 1.

The illustrated on/off switch is

fitted to machines with Quick

motors. If other motors are

O

used, a different switch may

be fitted.

1

Fig. 7 - 01

7.02 Pedal (on machines without subclass -911/97)

0 = Neutral position

+1 = Sewing

-1 = Thread trimming (on machines with

0

+1

-1

thread trimmer)

For further pedal functions

please refer to the instruction

manual of the motor

manufacturer.

7 - 1

Fig. 7 - 02

7.03 Pedal (on machines with subclass -911/97)

0 = Neutral position

+1 = Sewing

-1 = Raise presser foot

0

Controls

+1

-2 = Thread trimming (on machines with

thread trimmer)

-1

-2

Fig. 7 - 03

7.04 Knee lever (on machines without subclass -911/97)

● The presesr foot is raised by pressing

knee lever 1.

For further pedal functions

please refer to the instruction

manual of the motor

manufacturer.

1

Fig. 7 - 04

7 - 2

Controls

7.05 Key on machine head (on machines with subclass -911/97)

● If key 1 is pressed during sewing, the

machine will switch to reverse sewing.

1

Fig. 7 - 05

7.06 Presser bar lifter

1

● The presser foot is lifted by raising

presser bar lifter 1.

7 - 3

Fig. 7 - 06

7.07 Feed regulator/reverse sewing

0

1

2

3

Controls

● The stitch length is adjusted by turning

the knurled nut on lever 1.

● To reverse the sewing direction press

lever 1 fully upwards.

1

Fig. 7 - 07

7.08 Feed regulator (on machines with subclass -911/97)

● Turn knurled screw 1 to adjust the stitch

length for sewing forwards.

● Turn knurled screw 2 to adjust the stitch

length for sewing backwards.

2

Reverse stitches can be set as

long as required, independently

of forward stitches.

For adjustment of automatic

start- and finish backtacks

please refer to the instruction

book of the motor

1

manufacturer.

Fig. 7 - 08

7 - 4

Controls

7.09 Adjusting nut for the top feed stroke

Switch off the machine!

2

● Loosen screw 1 at the back of the

machine.

● Open cover 2.

● Loosen screw 3 and adjust lever

3

-

+

1

accordingly.

● Close cover 2 and tighten screw 1.

Fig. 7 - 09

7 - 5

8 Installation and commissioning

The machine must only be installed and commissioned by qualified personnel!

All relevant safety regulations must be strictly adhered to!

If the machine is delivered without a table, be sure to use a stand and table

that will reliably support the weight of the machine with its motor.

It is very important to ensure that the stand of the machine is firm and steady,

also during sewing.

8.01 Installation

The site where the machine is installed must be provided with suitable connections for

electric current and compressed air. It must be ensured that the standing surface of the

machine site is firm and horizontal and that sufficient lighting is available.

For packing and transportation reasons the table top is in the lowered position.

The table height is adjusted as described below.

Installation and commissioning

8.01.01 Adjusting the table height

1

1

2

Fig. 8 - 01

● Loosen screws 1 and 2 and set the table at the required height.

● Fully tighten screw 1.

● Set the required pedal position and tighten tighten screw 2.

8 - 1

Installation and commissioning

8.01.02 Tensioning the v-belt

2 cm

1

● Loosen nuts 1.

● Tension v-belt by adjusting bracket 2.

● Tighten nuts 1.

Fig. 8-02 shows a Quick motor.

If a different motor is used,

please refer to the instruction

manual of the motor

manufacturer.

2

Fig. 8 - 02

8.01.03 Fitting the upper belt guard

6

4

2

5

6

8

4

If a large balance wheel is in

use, break off corner 1 of belt

guard part 3.

● Screw stop piece 2 onto belt guard part 3.

● Screw on belt guard part 3 with screws 4.

3

8

7

● Screw on belt guard part 5 with screws 6.

● Secure belt guard part 7 to the table top

using woodscrews 8.

8

8 - 2

Fig. 8 - 03

8.01.04 Fitting the lower belt guard

Installation and commissioning

● Position belt guard 1 so that motor pulley

and v-belt can run freely.

Fig. 8-04 shows a Quick

motor. If a different motor is

used, please refer to the

instruction manual of the motor

manufacturer.

1

Fig. 8 - 04

8.01.05 Fitting the synchroniser

2

● Push synchroniser 1 onto the shaft.

● Tighten screws 2 a little.

● Connect the synchroniser plug at the

control box.

● Adjust the synchroniser (see Chapter

11.05.14, Adjusting the synchroniser).

1

Fig. 8 - 05

8 - 3

Installation and commissioning

8.01.06 Assembling the reel stand

● Assemble the reel stand as shown in

Fig. 8-06.

● Afterwards insert the stand in the hole in

the table top and secure it with the nuts

provided.

Fig. 8 - 06

8.02 Commissioning

● Check the machine, particularly its electrical wiring and pneumatic tube connections, for

any damage.

● Clean the machine thoroughly and afterwards fill it with oil and oil the machine (see

Chapter 10, Care and maintenance).

● Have a mechanic check whether the motor of the machine can be used with the

available power supply and that the motor is correctly connected to the junction box. Do

not run the machine if there is any discrepancy.

● When the machine is running, the balance wheel must turn towards the operator. If it

does not, have the motor connection changed by a mechanic.

● Connect the machine to the compressed air supply. When it is connected, the gauge

should show a pressure of approx. 6 bar. If necessary, have this reading correctly set

(see Chapter 10.06, Checking/adjusting the air pressure).

8.03 Switching the machine on/off

8 - 4

● Switch the machine on/off (see Chapter 7.01, On/off switch).

● Carry out a running test.

9 Setting up

All instructions and regulations in this manual must be observed. Special

attention must be given to all safety regulations!

All setting-up work must only be done by personnel with the necessary

training. For all setting-up work the machine must be isolated from the power

supply by turning off the on/off switch or removing the machine plug from the

electric power socket!

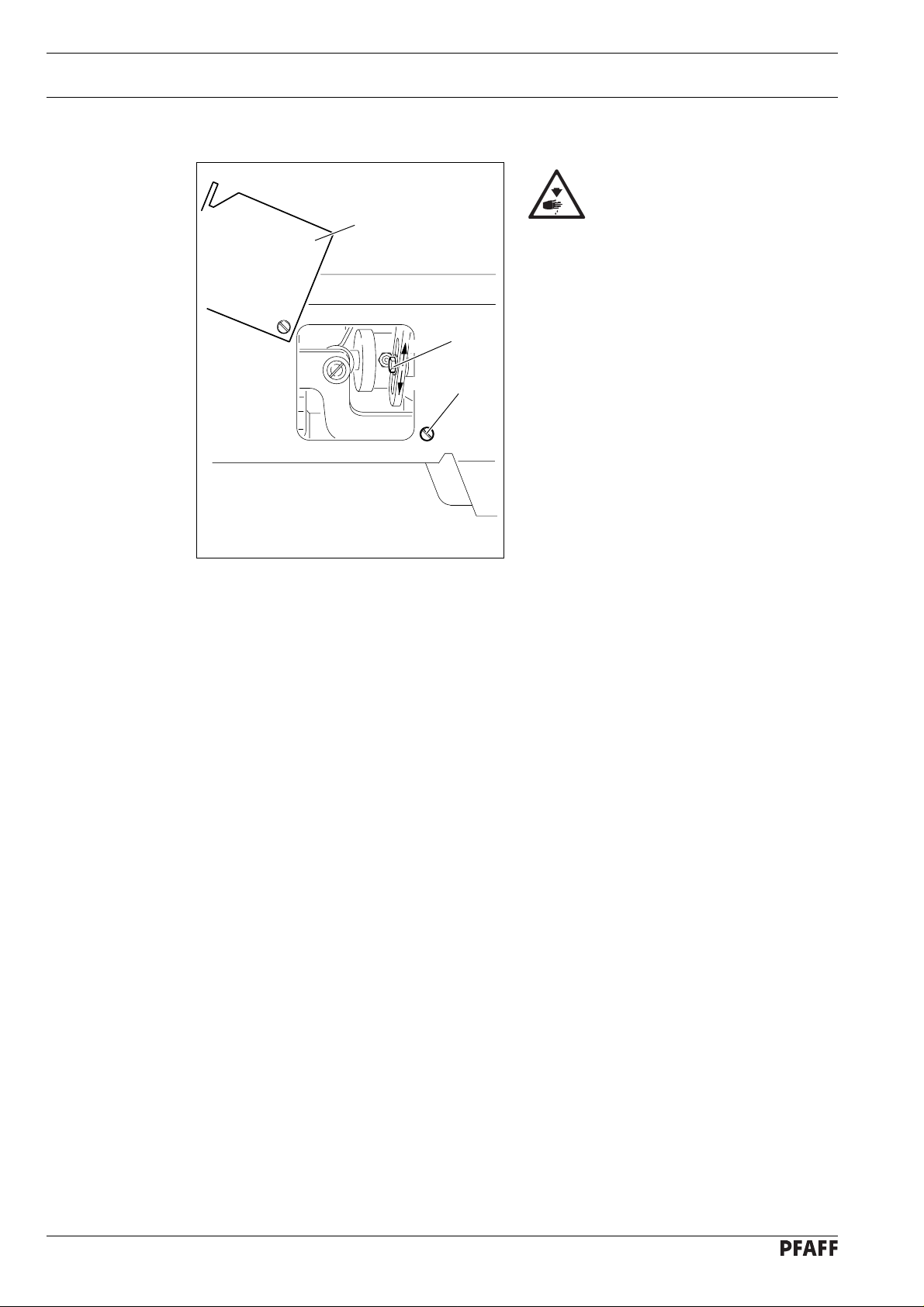

9.01 Inserting the needle on the PFAFF 1295

Setting up

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

Fig. 9 - 01

Only use needles of system 134-35.

● Set needle bar at top position and loosen

screw 1.

● Push needle 2 fully in (the long needle

groove must face to the left).

● Tighten screw 1 again..

1

2

The choice of needle depends on the version of the machine and the sewing

thread and material in use (see Chapter 3, Specifications).

9 - 1

Setting up

9.02 Inserting the needles on the PFAFF 1296

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

Only use needles of system 134-35.

● Set needle bar at top position and loosen

screws 1.

● Push needles 2 fully in (the long groove

of the left needle must face to the right

and that of the right needle to the left).

● Tighten screws 1 again.

1

Fig. 9 - 02

2

The choice of needle depends on the version of the machine and the sewing

thread and material in use (see Chapter 3, Specifications).

9 - 2

9.03 Winding the bobbin thread, regulating the winder tension

4

Setting up

-

+

6

1

3

5

2

Fig. 9 - 03

● Place an empty bobbin 1 on winder spindle 1.

● Thread up as shown in Fig. 9-03 and wind the thread a few ttimes clockwise around

bobbin 1.

● Engage the bobbin winder by pressing spindle 2 and lever 3 simultaneously

The bobbin is wound during sewing.

● The tension of the thread wound onto bobbin 1 is set on knurled screw 4.

● The bobbin winder will stop when sufficient thread is wound onto bobbin 1.

If the thread is wound on unevenly:

● Loosen nut 5.

● Turn thread guide 6 as required.

● Tighten nut 5 again.

9 - 3

Setting up

9.04 Changing the bobbin

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

2

Removing the bobbin case:

● Set the take-up lever at its highest point.

● Remove the post cover, lift latch 1 and

1

take out bobbin case 2.

Inserting the bobbin case:

● Insert bobbin case 2 so that you feel it

snap in place.

● Push latch 1 down and close the post

cover.

Fig. 9 - 04

Do not run the machine with the post cover open!

Danger of injury by moving parts!

9.05 Threading the bobbin thread and regulating the bobbin thread tension

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

5 cm

● Thread the bobbin as shown in Fig. 9-05.

● When the thread is pulled, the bobbin

must rotate as shown by the arrow.

● Regulate the bobbin thread tension on

srew 1.

9 - 4

Fig. 9 - 05

+

1

-

Setting up

9.06 Threading needle thread/adjusting needle thread tension on the PFAFF 1295

1

Fig. 9 - 06

Switch off the machine!

Danger of injury due to unintentional starting of the machine!

● Thread needle thread as shown in Fig. 9-06. Be sure to thread the needle from the left.

● Regulate the needle thread tension by turning knurled screw 1.

9 - 5

Setting up

9.07 Threading needle thread/adjusting needle thread tension on the PFAFF 1296

2

1

9 - 6

Fig. 9 - 07

Switch off the machine!

Danger of injury due to unintentional starting of the machine!

● Thread needle threads as shown in Fig. 9-07. Be sure to thread the right needle from

the left and the left needle from the right.

● Regulate the needle thread tensions by turning knurled screw 1 (right needle) or 2 (left

needle).

10 Care and maintenance

Check air pressure ........................................................ daily, each time before operation

Clean hook area ............................................ daily, in continuous operation several times

Check water bowl of air filter/regulator.......................................... daily, before operation

Oil hook...................................................................................................................... daily

General oiling ............................................................................................... twice a week

Oil needle-head parts ................................................................................... twice a week

Clean hook .................................................................................................... once a week

Lubricate top-feed drive eccentric ................................................................ once a week

The maintenance intervals in the table refer to the average machine running

time in single-shift operation. If the machine running time is longer than this, it

is advisable to shorten these intervals.

Care and maintenance

10.01 Cleaning

Fig. 10 - 01

Switch off the machine!

Danger of injury due to

3

5 mm

2

1

● Clean hook area with a brush daily, in

continuous operation several times daily.

● Clean the hook thoroughly once a week.

● Open post cover.

● Set needle bar at its highest position.

● Remove top of bobbin case together

with bobbin

● Unscrew and remove hook gib 1.

● Turn balance wheel until point of bobbin

case 2 has entered into the groove of the

hook race by about 5 mm.

● In this position remove bobbin case 2.

● Clean hook race with petroleum spirit.

unintentional starting of the

machine!

● When inserting the bobbin case, make sure that bobbin case position finger 3 enters the

slot in the needle plate.

● Screw on hook gib 1.

● Insert bobbin case and close post cover.

10 - 1

Care and maintenance

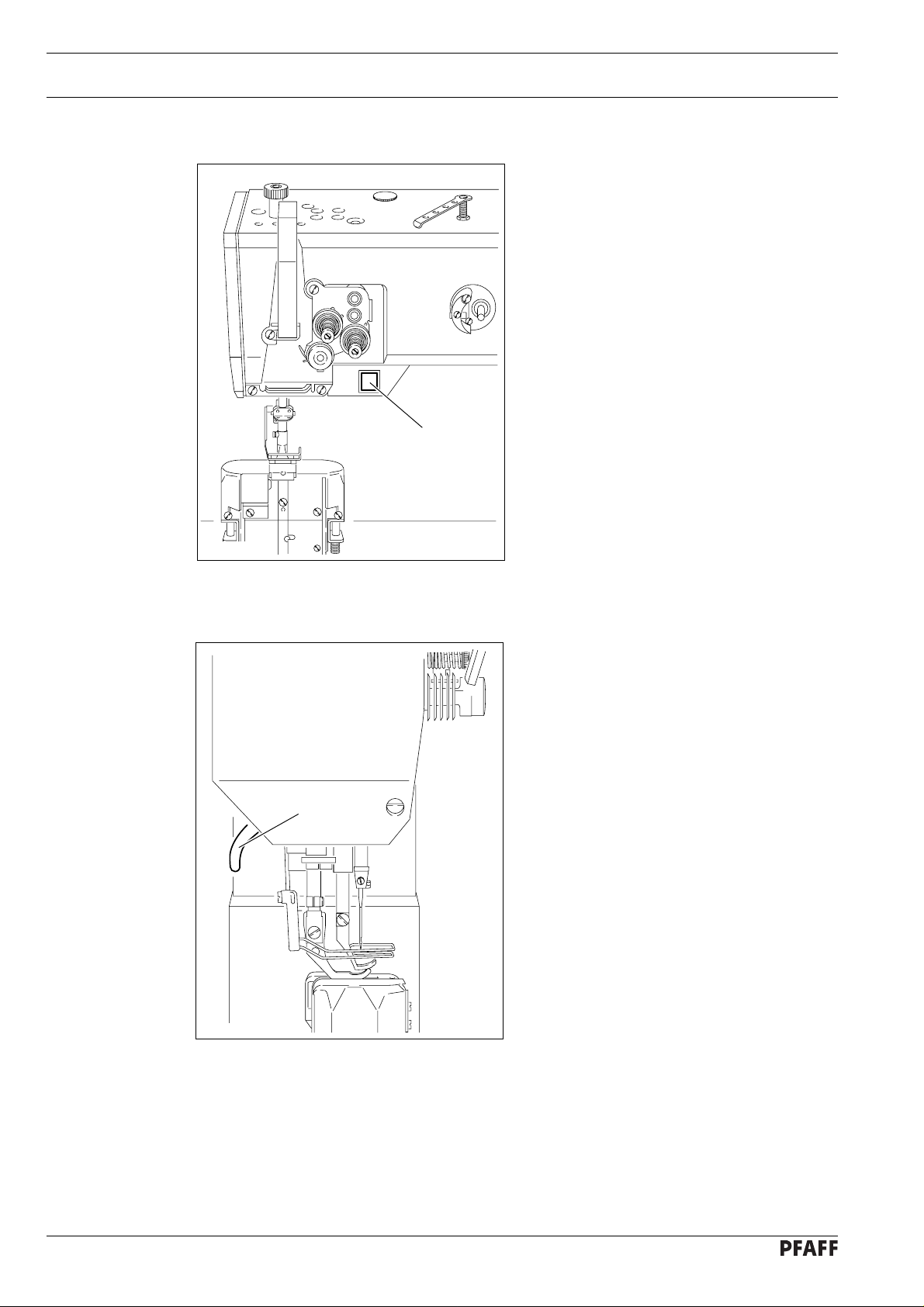

1

2

3

0

10.02 General oiling

10 - 2

Fig. 10 - 02

● Apply oil at all bearing points above the table (see arrows) twice a week.

Switch off machine! Danger of injury!

● Pull knee lever out to the front and tilt machine backwards.

● Apply oil at all bearing points beneath the table (see arrows) twice a week.

Set the machine upright with both hands! Danger of crushing between sewing

head and table!

Care and maintenance

Only use oil with a medium viscosity of 22.0 mm²/s at 40° C and a density of

0.865 g/cm³ at 15°C!

We recommend PFAFF sewing-machine oil, part No. 280-1-120 144.

10.03 Oiling the sewing hook

Fig. 10 - 03

1

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

● Open the post cover.

● Set the needle bar at its highest position.

● Apply 1 or 2 drops of oil in hole 1 of the

hook gib.

● Apply a few drops of oil to the hook race

(see arrow)

Only use oil with a medium

viscosity of 22.0 mm²/s at 40°

C and a density of 0.865 g/cm³

at 15°C!

We recommend PFAFF

sewing-machine oil, part

No. 280-1-120144.

10 - 3

Care and maintenance

10.04 Oiling the needle-head parts

Fig. 10 - 04

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

● Remove the faceplate.

● Oil all moving parts and bearing points

(see arrows) twice a week.

● Refit the faceplate.

Only use oil with a medium

viscosity of 22.0 mm²/s at 40°

C and a density of 0.865 g/cm³

at 15°C!

We recommend PFAFF

sewing-machine oil, part

No. 280-1-120144.

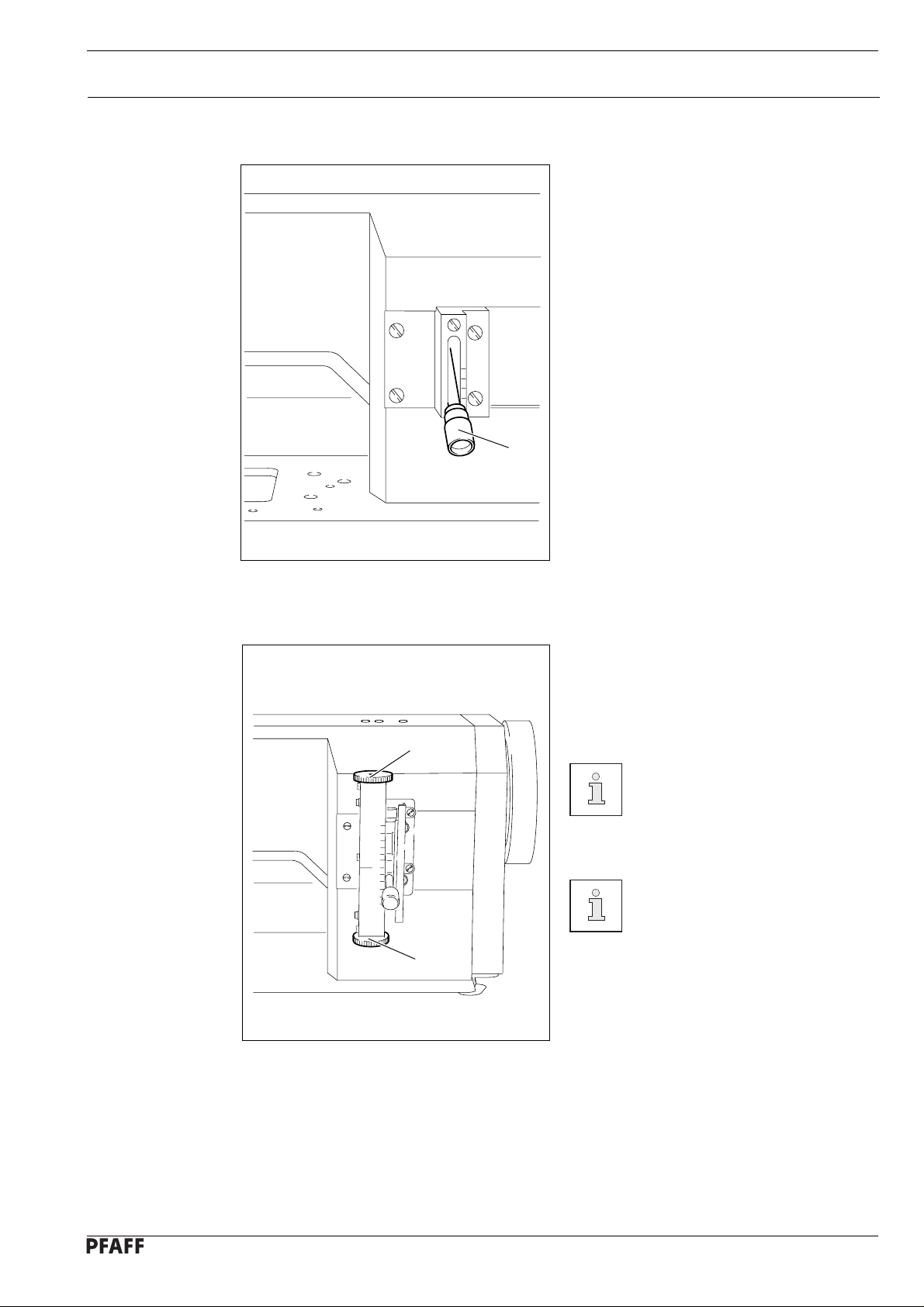

10.05 Lubricating the top-feed drive eccentric

2

● Loosen screw 1 and open cover 2 on the

● Apply a little grease at nipple 3 at least

● Close cover 2 and tighten screw 1.

1

3

Fig. 10 - 05

Switch off the machine!

Danger of injury due to

unintentional starting of the

machine!

rear side of the machine.

once a year.

Only use lithium grease with a

dripping point of 185°C and a

roll-penetration of 22 to 25 mm

at 25°C.

We recommend PFAFF sewing

machine grease, part

No. 280-1-120247.

10 - 4

10.06 Checking/regulating the air pressure

2

8

6

4

2

0

10

100

150

50

0

12

200

14

230

16

1

Care and maintenance

● Check the air pressure on gauge 1 every

time before operation.

● Gauge 1 must show a pressure of 6 bar.

● Regulate this pressure if required.

To do so, pull knob 2 up and turn it

accordingly.

Fig. 10 - 06

10.07 Emptying/cleaning the water bowl of the air filter/regulator

Switch off the machine.

Disconnect the air hose at the

air filter/regulating unit.

Emptying the water bowl

8

50

0

max.

10

100

150

12

200

14

230

16

2

6

4

2

0

1

● Water bowl 1 empties itself

automatically when the air hose is

disconnected from the air filter/regulator.

Cleaning the filter

● Unscrew water bowl 1 and take out filter

2.

● Clean the filter with compressed air or

with isopropyl-alcohol, part number

95-665735-91.

● Screw in filter 2 and screw on water bowl 1.

10.07

Fig. 10 - 07

10 - 5

Adjustment

11 Adjustment

11.01 Tools, gauges and other equipment for adjusting

For the adjustments in this chapter the PFAFF 1296 two-needle machine is

illustrated. On the PFAFF 1295 single-needle machines various adjustments

only have to be carried out on one side, i.e. in the right-hand hook area. This is

referred to in the different chapters.

● Screwdrivers withi blade widths from 2 to 10 mm

● Spanners (wrenches) in sizes from 7 to 14 mm

● Allen keys from 2 to 6 mm

● Metal rule (part No. 08-880218-00)

● Needle-rise gauge (part No. 61-111600-01)

● Screw clamp (part No. 61-111600-35/001)

● Needles, system 134-35

● Sewing thread and material for stitching off

11.02 Notes on adjustment

All adjustments in this instruction manual refer to a completely assembled machine and

must only be carried out by appropriately trained technical personnel. Machine covers that

have to be removed and replaced for checks and adjustment work are not mentioned in the

text.

The screws and nuts indicated in brackets () are for the fixation of machine parts that have

to be unscrewed before adjustment and tightened again afterwards.

11.03 Abbreviations

t.d.c. = top dead centre

b.d.c. = bottom dead centre

11 - 1

Adjustment

11.04 Adjusting the basic machine

11.04.01 Position of the bottom feed dog crosswise to sewing direction

Requirement

The bottom feed dog must be the same distance from the left and right side of the feed slots.

4

Fig. 11 - 01

1

X

X

3

2

4

1

● Loosen screws 1 and 2.

● Position rock shaft 3 according to Requirement..

● Tighten screw 1.

The flats of pins 4 must face screws 1 and rock shaft 3 must neither have any

play nor bind.

Leave screws 2 loose for the following adjustments.

11 - 2

Adjustment

11.04.02 Adjusting the bottom feed dog in sewing direction

Requirement

With the longest stitch length set, the bottom feed dog must not strike the feed slot at the

front or rear end of its stroke.

1

Fig. 11 - 02

● Set the longest stitch length.

● Turn rock shaft 1 according to Requirement. and tighten screws 2.

2

11 - 3

11.04.03 Bottom feed dog height

Requirement

With the stitch length set at "0" the feed dog must protrude from the needle plate by the

height of its teeth when at its highest position.

tooth height

Adjustment

2

1

Fig. 11 - 03

● Set stitch length „0“.

● Turn the balance wheel to set the bottom feed dog at its highest position.

● Adjust bracket 1 (screws 2) according to Requirement.

On machines without bottom-feed lifting phase (without "P") the feed dog

height may be reduced somewhat if necessary.

11 - 4

Adjustment

11.04.04 Needle height (preliminary adjustment)

Requirement

With the needle bar at b.d.c. the clearance between needle bar and needle plate must be

15 mm.

2

1

Fig. 11 - 04

● Re-position the height of needle bar 1 (screws 2) according to Requirement, but do not

turn it.

1

15 mm

11 - 5

1

2

3

0

11.04.05 Needle in needle-hole centre

Requirement

With the stitch length set at "0" the needle must enter exactly in the centre of the needle

hole.

Adjustment

4

3

7

5

6

8

9

1

2

Fig. 11 - 05

● Remove vibrating presser 1 and lifting presser 2.

● Set the stitch length at "0" and set the needle bar at t.d.c.

● Insert a new needle, loosen screws 3, 4, 5 and 6.

● Turn the balance wheel to set the needle immediately above the bottom feed dog.

● Shift the position of needle bar frame 7 according to Requirement.

● Tighten screws 3, 4 and 5.

● Move stop 8 up against needle bar frame 7 and tighten screw 6.

There must be no binding of needle bar frame 7 in guide 9 nor in the top-feed

drive linkages.

11 - 6

Adjustment

11.04.06 Bottom feed dog lifting motion

Requirement

1. With the needle bar at b.d.c. the feed dog must be at its highest position.

2. When the longest stitch length is set and the balance wheel is turned, the bottom feed

dog must reach the top side of the needle plate at the same time as the needle.

1

2

11 - 7

Fig. 11 - 06

This adjustment does not apply to machines without bottom-feed dog lifting

phase (without "P")

● Set needle bar at b.d.c.

● Turn eccentric 1 (screws 2) according to Requirement 1.

● In this position tighten the accessible screw 2 just enough to allow eccentric 1 to be

turned against a resistance.

● Turn eccentric 1 slightly according to Requirement 2.

● Tighten both screws 2.

11.04.07 Feeding stroke of bottom and top feeds

Requirement

With the longest stitch length set and the needle bar at b.d.c. neither the top- nor bottom

feed must make any movement when the reverse-feed lever is operated.

Adjustment

2

1

Fig. 11 - 07

● Set the longest stitch length.

● Undo screw 1 enough to allow eccentric 2 to be turned on the shaft against a resistance.

● Set needle bar at b.d.c.

● First turn eccentric 2 so that its highest eccentric point is facing "downwards."

● Now turn it slightly in rotation direction according to Requirement.

● Tighten screw 1.

11 - 8

Adjustment

11.04.08 Hook clearance, needle rise, needle height and needle guard

Requirement

With the stitch length set at "3" and in needle-rise position (= 1.8 mm past b.d.c. on version

"B" or 2.0 mm past b.d.c. on version "C")

1. The hook point must be at the "needle centre" and the clearance between hook and

needle 0.05 to 0.1 mm,

2. the top end of the needle eye must be 0.8 to 0.1 mm below the hook point, and

3. needle guard 8 must touch the needle just lightly.

0.05 - 0.1 mm

1

8

6

2

7

3

6

23

1

7

1

1

4

5

0.8 - 1 mm

11 - 9

Fig. 11 - 08

● Set the stitch length at "3" and loosen screws 1, 2 and 3.

● Loosen screws 4 at the front and rear side.

● Position posts 5 according to Requirement 1.

● Tighten screws 1 and 4.

● Set the needle bar at b.d.c. and place the 1.8 or 2.0 mm thick feeler gauge close under

the needle bar bearing, move the screw clamp up against the feeler gauge and screw it

tight.

● Remove the feeler gauge and turn the balance wheel in sewing direction until the screw

clamp is against the needle bar bearing.

Adjustment

● Set the hook point at the needle centre, making sure that the needle is not deflected by

needle guard 8.

● Making sure that bevel gear 6 is not too close, but the hook has not too much play,

tighten screws 2.

● Move fixing collar 7 up against bevel gear 6 and tighten screws 3.

● Adjust the needle height according to Requirement 2 (see also Chapter 11.04.04,

Needle height preliminary adjustment).

● position needle guard 8 according to Requirement 3.

After changing the needle clearance be sure to readjust the connecting linkage

of the thread trimmer mechanism (see also Chapter 11.05.6, Connecting

linkage).

11 - 10

Adjustment

11.04.09 Top feed stroke

Requirement

With the longest top feed stroke set and the stitch length at "0", lifting presser 1 and

vibrating presser 2 must each rise from the needle plate by 7.0 mm when the balance

wheel is turned.

4

3

7 mm

2

1

7 mm

Fig. 11 - 09

● Set the longest top feed stroke and stitch length "0".

● Lower lifting presser 1.

● Turn the balance wheel in sewing direction until vibrating presser 2 has reached its

highest point.

● Turn crank 3 (srews 4) according to Requirement.

11 - 11

11.04.10 Top feed lifting motion

Requirement

When lifting presser 1 is resting on the needle plate, vibrating presser 4 and needle point 5

must reach the needle plate at the same time at the highest top feed stroke.

Adjustment

2

3

5

1

4

Fig. 11 - 10

● Lower lifting presser 1 onto the needle plate.

● Loosen screws 2 just enough to allow eccentric 3 to be turned against a resistance on it

shaft.

● Turn eccentric 3 according to Requirement.

● Tighten screws 2.

11 - 12

Adjustment

11.04.11 Bobbin case opener

Requirement

The needle thread must neither be trapped between bobbin case opener 3 and hook base

4 nor between position finger 5 and the retainer on the needle plate (see arrows).

2

6

5

1

3

4

Fig. 11 - 11

● Undscrew and remove post covers 1 (on left post from the rear).

● Undo screws 2 enough to allow bobbin case opener 3 to be turned on its shaft against a

resistance.

● Thread up the machine, place sewing material in and lower the lifting presser.

● Set bobbin case opener 3 according to Requirement.

● In this position, apply pressure on the bobbin case opener from the top, move clamp

collar 6 up against it and tighten screws 2.

11 - 13

11.04.12 Slip coupling

Slip coupling 4 is adjusted at the works. When a thread jams, slip coupling 4

disengages, in order to avoid damage to the hooks. To engage the coupling

again, proceed as follows.

Adjustment

1

4

2

3

4

Fig. 11 - 12

● Remove jammed thread.

● Press plunger 1 and turn the balance wheel until pawl 2 engages groove 3.

11 - 14

Adjustment

11.04.13 Needle-thread tension release

Requirement

With the lifting presser raised, there must be a clearance of at least 0.5 mm between

tension discs 4.

2

0.5 mm

1

3

4

Fig. 11 - 13

● Position pressure plate 1 behind mounting bracket 2 according to Requirement.

The clearance of 0.5 mm is a miminum setting and may be as much as 1 mm

for heavy threads.

When the tension is engaged, release pin 3 must not be under load.

11 - 15

11.04.14 Thread check spring, without subclass -900/56

Requirement

The movement of thread check spring 5 must be finished when the needle pointe enters

the material (=spring stroke of about 7 mm).

Adjustment

7 mm

5

1

3

2

Fig. 11 - 14

● Adjust stop 1 (screw 2) according to Requirement.

● To adjust the pressure of the spring, turn screw 3 (screw 4).

For technical reasons the length of the thread check spring stroke may vary

upwards or downwards a little.

4

11 - 16

Adjustment

11.04.15 Thread check spring on the PFAFF 1296 with subclass -900/56

Requirement

The movements of thread check springs 1 and 6 must be finished when the needle points

enter the material (=spring stroke of about 7 mm).

Fig. 11 - 15

810

5

1

6

7 mm

4

2

7

9

3

11 - 17

● To adjust the pressure of spring 1, turn screw 2 (screw 3).

● Adjust stop 4 (screw 5) according to Requirement.

● To adjust the pressure of spring 6, turn screw 7 (screw 8).

● Adjust stop 9 (screw 10) according to Requirement.

For technical reasons the length of the thread check spring stroke may vary

upwards or downwards a little.

11.04.16 Bobbin winder

Requirement

1. With the bobbin winder engaged, drive wheel 1 must be driven reliably .

2. With the bobbin winder disengaged, friction wheel 5 must not run against drive wheel 1.

3. The bobbind winder must switch itself off when the filled thread is about 1 mm from

the rim of the bobbin.

Adjustment

1

Fig. 11 - 16

2

4

5

1 mm

3

● Re-position drive wheel 1 (screws 2) according to Requirements 1 and 2.

● Re-position pin 3 (screw 4) according to Requirement 3.

11 - 18

Adjustment

11.04.17 Pressure of the lifting presser

Requirement

1. The material must be properly fed, even at the highest sewing speed.

2. There must be no pressure marks on the material.

1

11 - 19

Fig. 11 - 17

● Turn screw 1 according to the Requirement.

11.05 Adjusting the thread trimmer -900/56

11.05.01 Engaging solenoid

Requirement

1. Mounting bracket 1 must be in the middle of its adjusting range and parallel with the

right-hand edge of the mounting bracket.

2. When the thread trimmer is in its resting position the core of solenoid 3 must protrude

from the solenoid housing by about 4 mm.

4 mm

Adjustment

4

3

1

2

Fig. 11 - 18

● Re-position bracket 1 (screw 2) according to Requirement 1.

● Re-position solenoid 3 (screw 4) according to Requirement 2.

11 - 20

Adjustment

11.05.02 Control cam (preliminary adjustment)

Requirement

1. Control cam 1, must be centred with the cutout of bearing mounting 5.

2. With the needle bar at t.d.c., screws 2 must be visible from the front and aligined

parallel with the bedplate.

2

4

4

3

3

1

5

Fig. 11 - 19

● Re-position control cam 1 (screws 2) and fixing collars 3 (screws 4) according to

Requirement.

11 - 21

11.05.03 Control lever spring action

Requirement

When the thread trimmer is in its resting position, it must be possible to press control lever 3

about 1 mm towards the bedplate (spring action).

Adjustment

2

3

1

Fig. 11 - 20

● Turn screw 1 (nut 2) according to Requirement.

11 - 22

Adjustment

11.05.04 Control lever stroke

Requirement

1. When engaging lever 5 is operated the pin of control lever 6 must drop freely into the

track of control cam 7.

2. After thread trimming, control lever 6 must pass freely on the right side of stop plate 3

and engage control lever 5 behind stop plate 3.

3. There must be a clearance of 0.2 mm between the pin of control cam 6 and the righthand inside of the control cam track.

0.2 mm

4

5

2

3

6

1

7

Fig. 11 - 21

● Re-position stop plate 1 (screws 2) and stop plate 3 (screws 4) according to

Requirement.

11 - 23

11.05.05 Thread-trimmer drive linkage

Requirement

1. On the PF AFF 1296 thread-catcher drive linkage 1 must have a length of 128 mm, less

half of the needle gauge.

On the PF AFF 1295, thread catcher drive linkage 1 must have a length of 128 mm

2. When the threa trimmer is in its resting position there must be a clearance of about

1 mm between plunger 5 and lever 6.

128 mm

Adjustment

6

Fig. 11 - 22

1 mm

2

1

2

4

3

5

● Turn thread-catcher drive linkage 1 (nuts 2) to adjust it according to Requirement 1.

● Re-position bracket 3 (screw 4) according to Requirement 2.

11 - 24

Adjustment

11.05.06 Linkage bar (only on the PFAFF 1296)

Requirement

The length of linkage bar 1 must be the same as the distance between the two threadcatcher drive shafts 3.

=

3

3

1

2

=

Fig. 11 - 23

● Adjust middle section 1 (nuts 2) of the linkage bar according to Requirement.

2

11 - 25

11.05.07 Thread catcher height

Requirement

There must be a clearance of 0.7 mm between the underside of thread catcher 4 and

bobbin case cap 5.

4

5

Adjustment

0.7 mm

4

2

Fig. 11 - 24

● Loosen screws 1 and 2.

● Adjust the height of shaft 3 according to Requirement.

● Tighten screws 1.

Leave screws 2 loose for the following adjustment.

3

1

11 - 26

Adjustment

11.05.08 Thread catcher resting position

Requirement

When the thread trimmer is in its resting poistion there must be a clearance of about 4

mm between the point of catcher 3 and the cutting edge of knife 4.

4 mm

3

3

4

1

2

11 - 27

Fig. 11 - 25

● Turn shaft 2 according to Requirement.

● Tighten screws 1.

When tightening screws 1 make sure that all transmission parts of the thread

catcher drive can move freely.

11.05.09 Knife pressure

Requirement

When the front edge of thread catcher 3 has passed the knife cutting edge by half, knife 1

must rest with light pressure on the edge of the catcher.

Adjustment

3

2

3

1

Fig. 11 - 26

● Adjust knife 1 (screws 2) according to Requirement

11 - 28

Adjustment

11.05.10 Bobbin thread trapping spring

Requirement

1. Bobbin thread trapping spring 3 must not be deflected by thread catcher 4 in any phase.

2. After the trimming action the bobbin thread must be securely trapped.

3. It must be possible to insert and remove the bobbin from the hook without any hindrance.

3

4

1

3

2

4

11 - 29

Fig. 11 - 27

● Re-position bracket 1 (screws 2) according to Requirements 1 and 3.

● Bend trapping spring 3 according to Requirement 2.

11.05.11 Control cam (final adjustment)

Requirement

The trimming action must be just completed when the take-up lever is at t.d.c.

Adjustment

2

Fig. 11 - 28

● Turn control cam 1 (screws 2) according to Requirement.

1

11 - 30

Adjustment

11.05.12 Release lever

Requirement

When the pin of control lever 3 has dropped into the track of control cam 4 and the needle

bar is at b.d.c. there must be a clearance of about 1 mm between control lever 3 and

release lever 5. In this position the needle thread tension must still be engaged.

4

5

3

1 mm

1

Fig. 11 - 29

● Turn eccentric 1 (screw 2) according to Requirement

2

11 - 31

11.05.13 Release rod

Requirement

1. When the lifting presser is resting on the needle plate, pin 3 must rest at the lower end

of the elongated hole in pull-rod 1.

2. The tension discs must not be moved apart in this position.

Adjustment

2

1

3

1

Fig. 11 - 30

● Re-position pull-rod 1 (screws 2) according to Requirement.

11 - 32

Adjustment

11.05.14 Adjusting the synchroniser

Requirement

1. When sewing is interrupted, the machine must position at about 4 mm past b.d.c. of

the needle bar.

2. After thread trimming the machine must position with the take-up lever at t.d.c.

● Carry out adjustment according to instruction manual of motor.

11 - 33

Notes

G.M. PFAFF

Aktiengesellschaft

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655Kaiserslautern

Telefon: (0631) 200-0

Telefax: (0631) 17202

Telex: 45753 PFAFF D

Gedruckt in der BRD

Printed in Germany

Imprimé en R.F.A.

Impreso en la R.F.A.

Loading...

Loading...