Page 1

1245

1246

ADJUSTMENT MANUAL

This adjustment manual applies to machines

from the following serial numbers onwards:

# 6 500 124

296-12-19 200/002

Justieranleitung engl. 01.12

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Adjustment ........................................................................................................................... 4

1.01 Tools, gauges and other accessories for adjusting ............................................................... 4

1.02 Abbreviations ......................................................................................................................... 4

1.03 Explanation of the symbols .................................................................................................... 4

1.04 Adjusting the basic machine .................................................................................................. 5

1.04.01 Positioning the feed dog across the direction of sewing ....................................................... 5

1.04.02 Positioning the feed dog in the direction of sewing .............................................................. 6

1.04.03 Height of the bottom feed-dog ............................................................................................. 7

1.04.04 Pre-adjusting the needle height ............................................................................................. 8

1.04.05 Centering the needle in the needle hole ................................................................................ 9

1.04.06 Lifting motion of the bottom feed-dog. ................................................................................ 10

1.04.07 Driving motion of the bottom and top feeds ........................................................................ 11

1.04.08 Hook-to-needle clearance, needle rise, needle height and needle guard ............................ 12

1.04.09 Top-feed stroke .................................................................................................................... 14

1.04.10 Lifting motion of the top feed ............................................................................................. 15

1.04.11 Bobbin-case opener ............................................................................................................. 16

1.04.12 Safety clutch ........................................................................................................................ 17

1.04.13 Needle thread tension release ............................................................................................. 18

1.04.14 Bobbin winder ...................................................................................................................... 19

1.04.15 Presser-foot pressure ...........................................................................................................20

3

Page 4

Adjustment

1 Adjustment

Notes on adjustment

Please observe all notes from Chapter 1 Safety of the instruction manual!

In particular care must be taken to see that all protective devices are refi tted

properly after adjustment, see Chapter 1.06 Danger warnings of the instruction

manual!

If not otherwise stated, the machine must be disconnected from the electrical

power supply. Danger of injury due to unintentional starting of the machine!

The illustrations in this section show the PFAFF 1245 single-needle machine.

For the PFAFF 1246 two-needle machine, various adjustments must be made

twice, i.e. to the left- and right-hand sewing hooks. This will be pointed out in

the respective sections, whereby it is often possible to apply the mirror image

of the illustrations.

All following adjustments are based on a fully assembled machine and may only be carried

out by expert staff trained for this purpose.

Machine covers, which have to be removed and replaced to carry out checks and adjustments, are not mentioned in the text.

The order of the following chapters corresponds to the most logical work sequence for

machines which have to be completely adjusted. If only specifi c individual work steps are

carried out, both the preceding and following chapters must be observed.

Screws, nuts indicated in brackets ( ) are fastenings for machine parts, which must be

loosened before adjustment and tightened again afterwards.

1.01 Tools, gauges and other accessories for adjusting

● Screwdrivers withi blade widths from 2 to 10 mm

● Spanners (wrenches) in sizes from 7 to 14 mm

● Allen keys from 1.5 to 6 mm

● Metal rule (part No. 08-880 218-00)

● Needle-rise gauge (part No. 61-111 600-01)

● Gauge, (top feed stroke 7 mm) (Part No. 61-111 633-61)

● Screw clamp (part No. 61-111 600-35)

1.02 Abbreviations

t.d.c. = top dead centre

b.d.c. = bottom dead centre

1.03 Explanation of the symbols

In this adjustment manual, symbols emphasize operations to be carried out or important in-

formation. The symbols used have the following meaning:

Note, information

Service, repair, adjustment, maintenance

(work to be carried out by qualifi ed staff only)

4

Page 5

Adjustment

1.04 Adjusting the basic machine

1

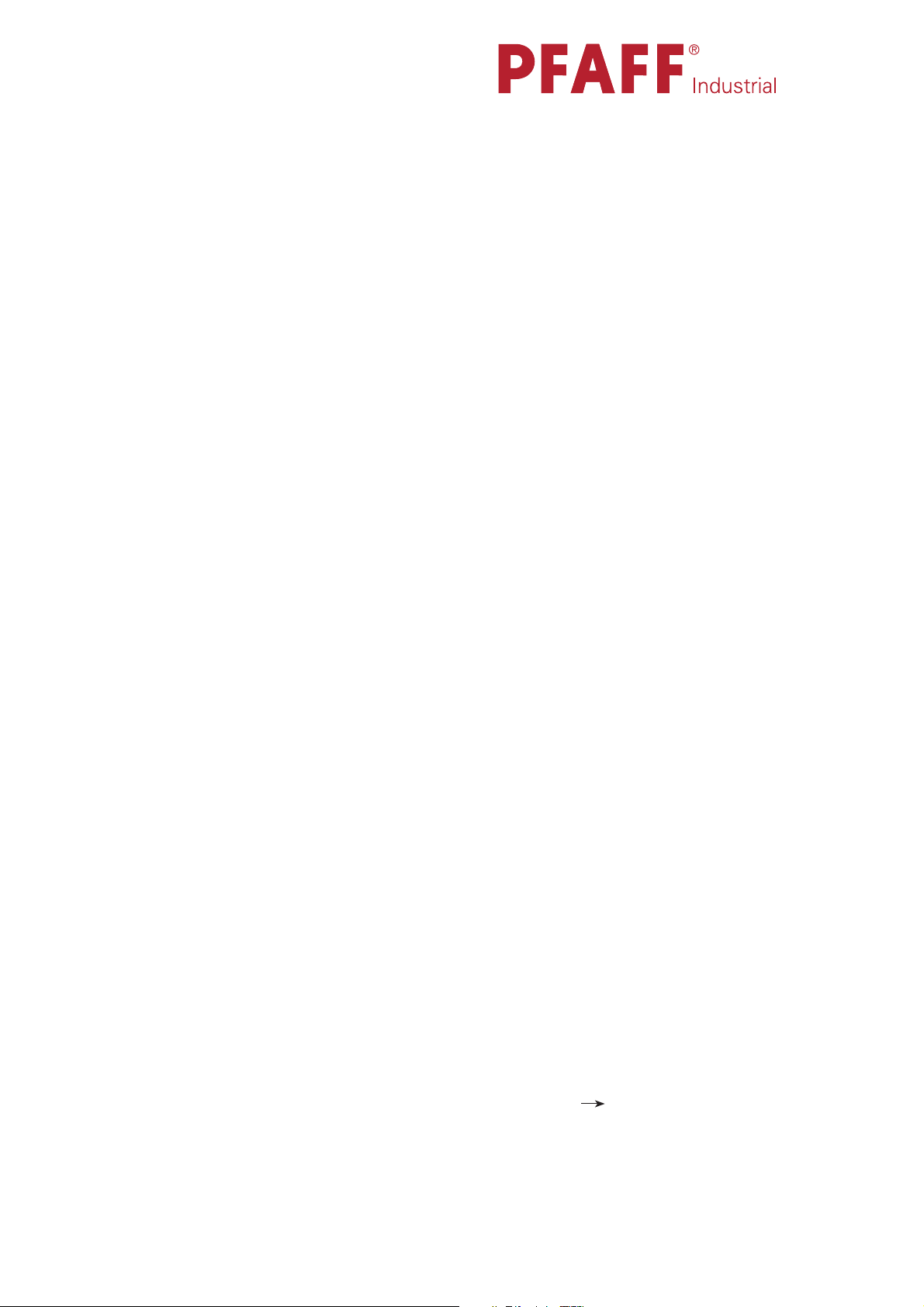

.04.01 Positioning the feed dog across the direction of sewing

Requirement

The bottom feed dog must be the same distance from the left and right side of the need-

le-plate cutout.

3

4

Fig. 1 - 01

● Loosen screws 1 and 2.

● Laterally align rock shaft 3 in accordance with the requirement.

● Now tighten screws 1.

● Screws 2 remain loose for the following adjustments..

1

The fl at sides of pins 4 must be opposite the fl at sides of screws 1 and rock

shaft 3 must exhibit neither play nor stiffness.

4

2

1

5

Page 6

Adjustment

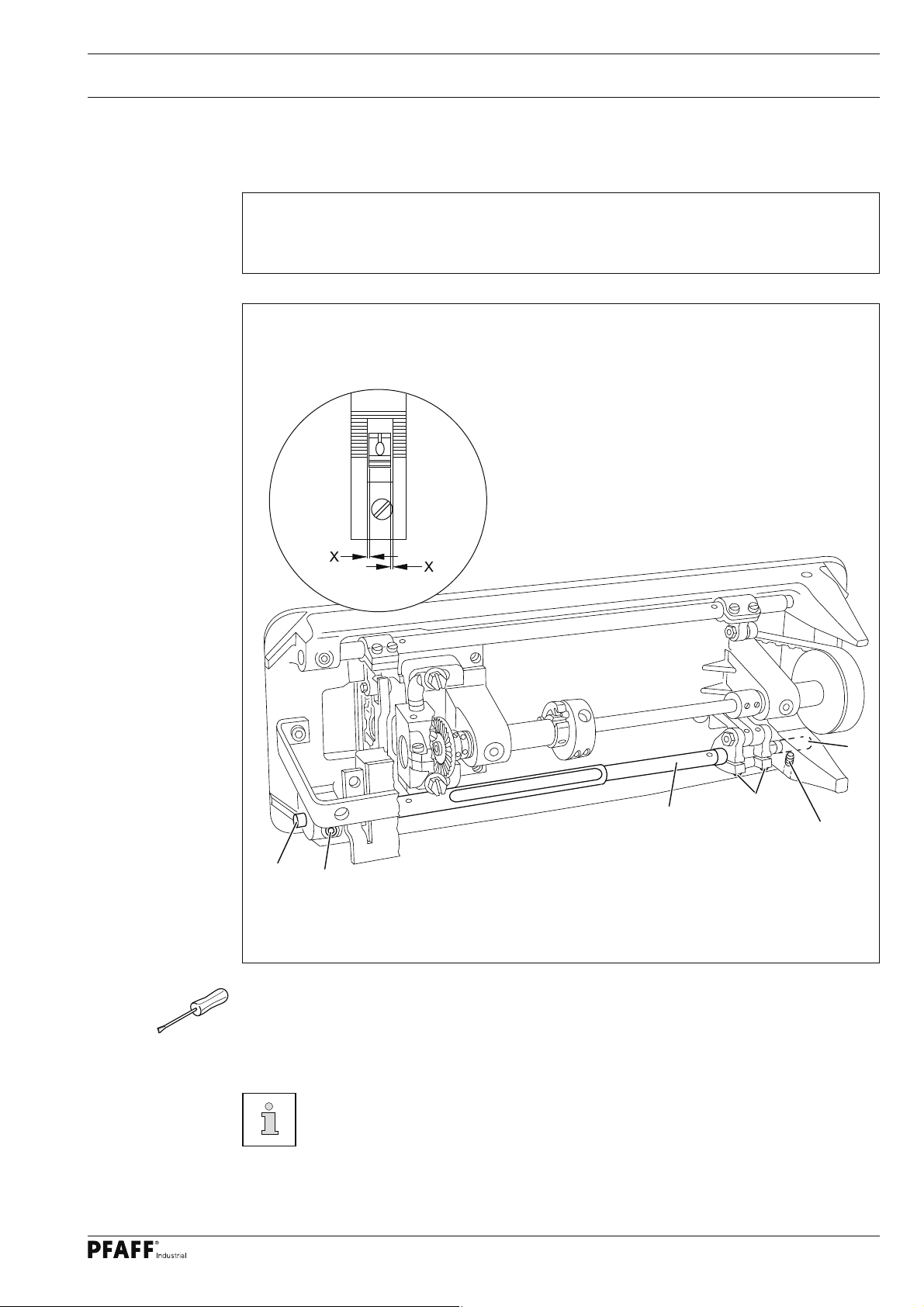

1.04.02 Positioning the feed dog in the direction of sewing

Requirement

With the longest stitch set, the bottom feed dog must have the same clearance the front

and the back with respect to the needle-plate cutout when feeding both forwards and

backwards.

1

2

Fig. 1 - 02

● Set the longest stitch.

● Adjust rock shaft 1 in accordance with the requirement and tighten screws 2.

6

Page 7

Adjustment

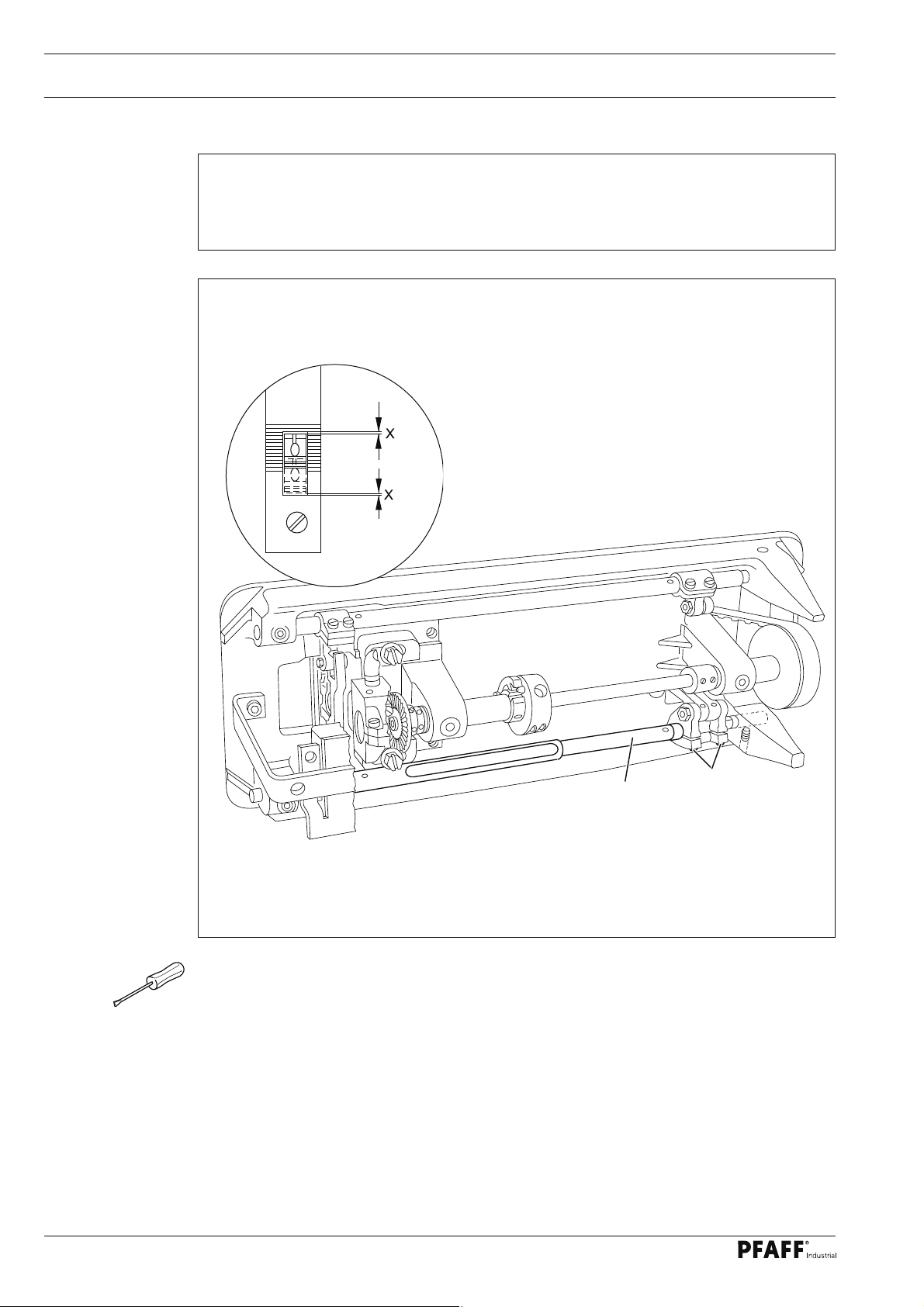

1.04.03 Height of the bottom feed-dog

Requirement

With the stitch length set at "0", the bottom feed dog must protrude over the needle plate

as high as the teeth when at TDC.

21

Fig. 1 - 03

● Set stitch length "0".

● Bring the bottom feed dog to its TDC by turning the handwheel.

● Adjust feed dog carrier 1 (screws 2) in accordance with the requirement.

If required, the feed dog height can be reduced a little on machines without a

bottom feed lifting phase (without P).

7

Page 8

Adjustment

1.04.04 Pre-adjusting the needle height

Requirement

With the needle bar at BDC, the distance between the needle bar and the needle plate

must be 15 mm.

2

1

Fig. 1 - 04

● Move needle bar 1 (screw 2) in accordance with the requirement without moving it

laterally.

8

Page 9

Adjustment

1.04.05 Centering the needle in the needle hole

Requirement

With the stitch length set at "0", the needle must enter the needle hole exactly in the

middle.

4

3

7

5

8

9

1

2

Fig. 1 - 05

● Unscrew vibrating presser 1 and presser foot 2.

6

● Set stitch length "0" and bring the needle bar to its TDC.

● Insert a new needle. Loosen screws 3, 4, 5 and 6.

● Position the needle directly over the bottom feed dog by turning the handwheel.

● Move needle bar frame 7 in accordance with the requirement.

● Tighten screws 3, 4 and 5.

● Position stop 8 so that it is touching needle bar frame 7 and tighten screw 6.

The movement of needle bar frame 7 in guide 9 and of the top feed drive bars

must not be stiff.

9

Page 10

Adjustment

1.04.06 Lifting motion of the bottom feed-dog (This adjustment does not apply for machines

without a bottom feed lifting phase (without P)

Requirement

1. With the needle bar at its BDC, the bottom feed dog must be at its TDC.

2. With the longest stitch set, the bottom feed dog must reach the top surface of the

needle plate at the same time as the needle point when the handwheel is turned.

.

1 2

10

Fig. 1 - 06

● Bring the needle bar to its BDC.

● Turn feed lifting eccentric 1 (screws 2) in accordance with requirement 1.

● In this position, tighten the accessible screw 2 until feed lifting eccentric 1 can be turned

with diffi culty.

● Turn feed lifting eccentric 1 a little further in accordance with requirement 2.

● Tighten both screws 2.

Page 11

Adjustment

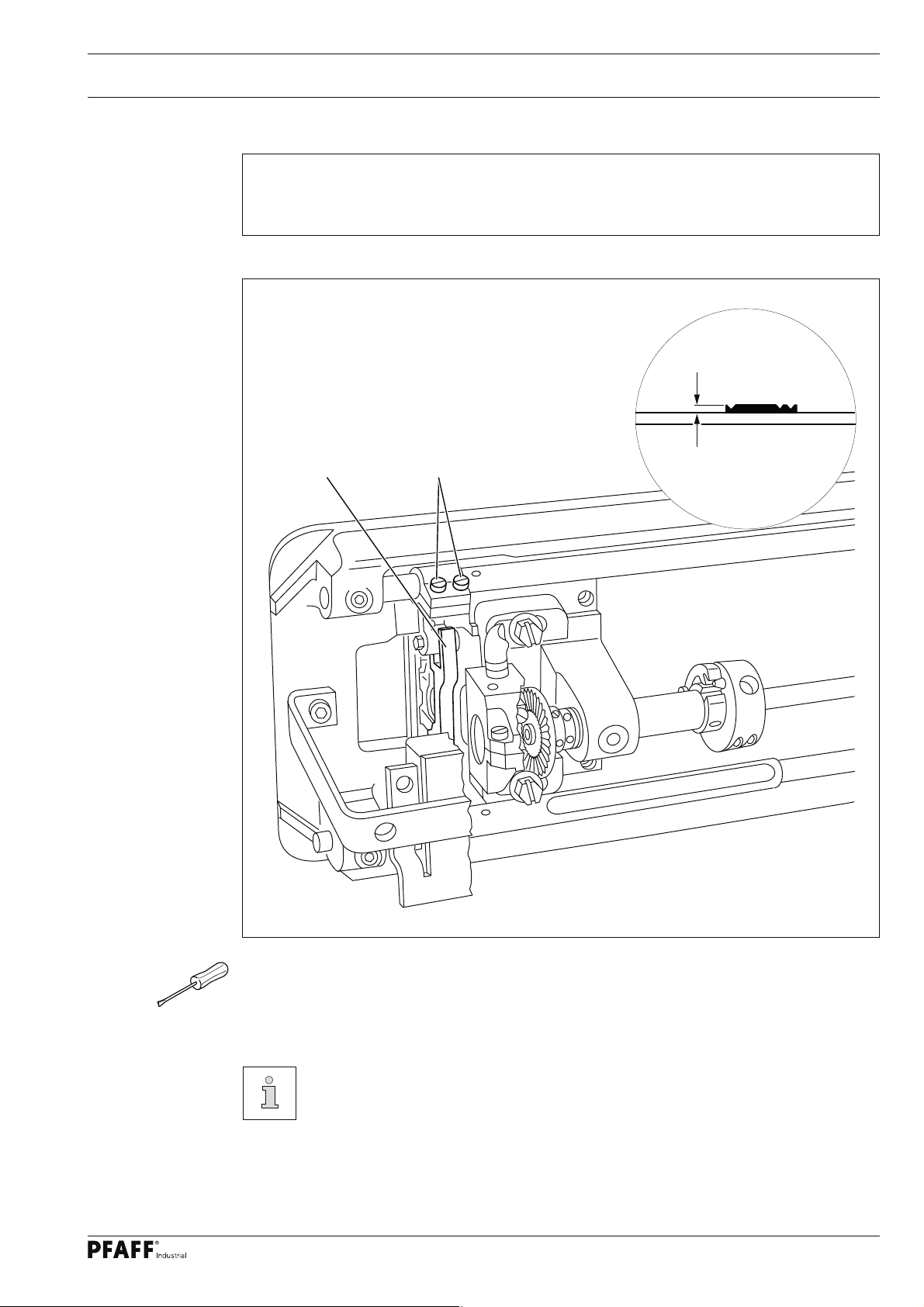

1.04.07 Driving motion of the bottom and top feeds

Requirement

With the longest stitch length set and the needle bar at its BDC, the top and bottom

feeds should not move when the reverse-feed lever is activated..

1

2

Fig. 1 - 07

● Set the longest stitch.

● Loosen screws 1 just far enough so that the feed driving eccentric 2 can be turned on the

shaft with diffi culty.

● Bring the needle bar to its BDC.

● Turn the feed driving eccentric 2 so that its eccentricity is facing downwards.

● Now turn it a little in the direction of rotation in accordance with the requirement.

● In this position, tighten screws 1.

● Carry out a check in accordance with the requirement.

11

Page 12

Adjustment

1.04.08 Hook-to-needle clearance, needle rise, needle height and needle guard

(On Model 1246 make these adjustments on both sewing hooks.)

Requirement

When the stitch length is set at "3" and with the needle rise position set (see table):

1. the hook point must be at "needle centre" with a hook-to-needle clearance of 0.05 to

0.1 mm;

2. the top of the needle eye must be 0.8 - 1,0 mm below the hook point;

3. and needle guard 5 must touch the needle just lightly..

Needle rise position:

Model C: 2,0 mm after b.d.c. off the needle bar

1

1

3

2

3

2

3

2

1

1

12

Fig. 1 - 08

● Set stitch length "3" and loosen screws 1, 2 and 3.

● Bring the needle to its BDC and slide the appropriate feeler gauge under the needle bar

bearing.

● Position the adjustable clamp against the feeler gauge and screw it tight.

● Remove the feeler gauge and turn the balance wheel in its direction of rotation until the

adjustable clamp is touching the needle bar bearing.

Page 13

Adjustment

1

1

4

3

2

7

6

3

2

6

7

3

2

4

Fig. 1 - 08

● Move hook bearing 4 in accordance with requirement 1.

● Tighten screws 1.

● Position the hook point at the needle centre, taking care to ensure that the needle is not

defl ected by needle guard 5.

1

1

5

● While ensuring that bevel gear 6 is not too close, and that the hook does not have too

much play, tighten screws 2.

● Position retaining collar 7 so that it rests on bevel gear 6 and tighten screws 3.

● Adjust the needle height in accordance with requirement 2.

● Align needle guard 5 in accordance with requirement 3.

13

Page 14

Adjustment

1.04.09 Top-feed stroke

Requirement

At the largest top-feed stroke setting and stitch length "0", presser foot 1 and vibrating

presser foot 2 must lift 7.0 mm from the needle plate when the handwheel is turned.

4

3

2

1

Fig. 1 - 09

● Set the largest top-feed stroke and the stitch length at "0".

● Bring presser foot 1 to rest on the needle plate.

● Turn the handwheel in the direction of rotation until vibrating presser foot 2 has reached

its highest point.

● Turn crank 3 (screws 4) in accordance with the requirement..

14

Page 15

Adjustment

1.04.10 Lifting motion of the top feed

Requirement

When presser foot 1 is resting on the needle plate, the vibrating presser foot 4 and the

point of the needle must both reach the needle plate at the same time when the top feed

stroke is set at maximum.

2 3

1

4

Fig. 1 - 10

● Allow presser foot 1 to rest on the needle plate.

● Loosen screws 2 until feed lifting eccentric 3 can be turned on its shaft with diffi culty.

● Turn feed lifting eccentric 3 in accordance with the requirement.

● Tighten screws 2.

● Carry out a check in accordance with the requirement.

15

Page 16

Adjustment

1.04.11 Bobbin-case opener (On Model 1246 make these adjustments on both bobbin openers.)

Requirement

The needle thread must not be clamped between the bobbin-case opener 1 and the bobbin-case base 3 nor may it be clamped between projection 4 and the retaining trip of the

needle plate (see arrows).

4

2

3

1

Fig. 1 - 11

● Thread the machine, insert test material and allow the presser foot to rest on the needle

plate.

16

● Sew a few stitches by turning the handwheel and carry out a check in accordance with

the requirement.

● Turn bobbin-case opener 1 (screw 2) in accordance with the requirement.

Page 17

Adjustment

1.04.12 Safety clutch

The safety clutch is set by the manufacturer and screws 5 are sealed.

If the thread jams, the safety clutch snaps out to prevent damage to the hook.

A description of how to snap the clutch back in follows.

2

1

3

4

Fig. 1 - 12

● Remove the jammed thread.

● Press piston 1 and turn the handwheel until hook 3 of pawl 2 clicks into groove 4.

17

Page 18

Adjustment

1.04.13 Needle thread tension release

Requirement

With the presser foot raised, both of the tension discs must be at least 0.5 mm apart.

The clearance of 0.5 mm is a minimum and can increase to more than 1 mm

when using thick threads.

2

1

3

Fig. 1 - 13

● Mittels Handhebel den Stoffdrückerfuß hochstellen.

● Druckplatte 1 hinter der Spannungs-Trägerplatte 2 entprechend der Requirement richten.

If the tension is correct, release pin 3 must not be under pressure.

18

Page 19

Adjustment

1.04.14 Bobbin winder

Requirement

1. With the bobbin winder switched on, the bobbin winder spindle must engage reliably.

2. With the bobbin winder switched off, friction wheel 5 must not touch drive wheel 1.

3. The bobbin winder must switch off automatically when the thread level is approxima-

tely 1 mm from the edge of the bobbin.

2

1

5

4

3

Fig. 1 - 14

● Move drive wheel 1 (screws 2) in accordance with requirement 1 und 2.

● Move stop latch 3 (screws 4) in accordance with requirement 3.

19

Page 20

Adjustment

1.04.15 Presser-foot pressure

Requirement

The material must be fed reliably even at top sewing-speed. There mustn’t be pressure

marks on the material.

1

20

Fig. 1 - 15

● Turn screw 1 in accordance with the requirement.

Page 21

Note

Page 22

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Phone: +49 - 6301 3205 - 0

Fax: +49 - 6301 3205 1386

E-mail: info@pfaff-industrial.com

Hotlines:

Technical ser vice: +49 - 175/2243-101

Application consultance: +49 - 175/2243-102

Spare-parts hotline: +49 - 175/2243-103

Printed in Germany

© PFAFF Industriesysteme und Maschinen AG 2009, PFAFF is the exclusive trademark of VSM Group AB.PFAFF Industriesysteme und Maschinen AG is an authorized licensee of the PFAFF trademark.

Loading...

Loading...