Page 1

Visit RepairManualClub.com for more

motorcycle manuals

Buy Motorcycle Gear and

Equipment

Buy Helmets, Jackets, Pants

Buy Everything Motorcycle at

Amazon.com

Visit RepairManualClub.com for more

motorcycle manuals

Page 2

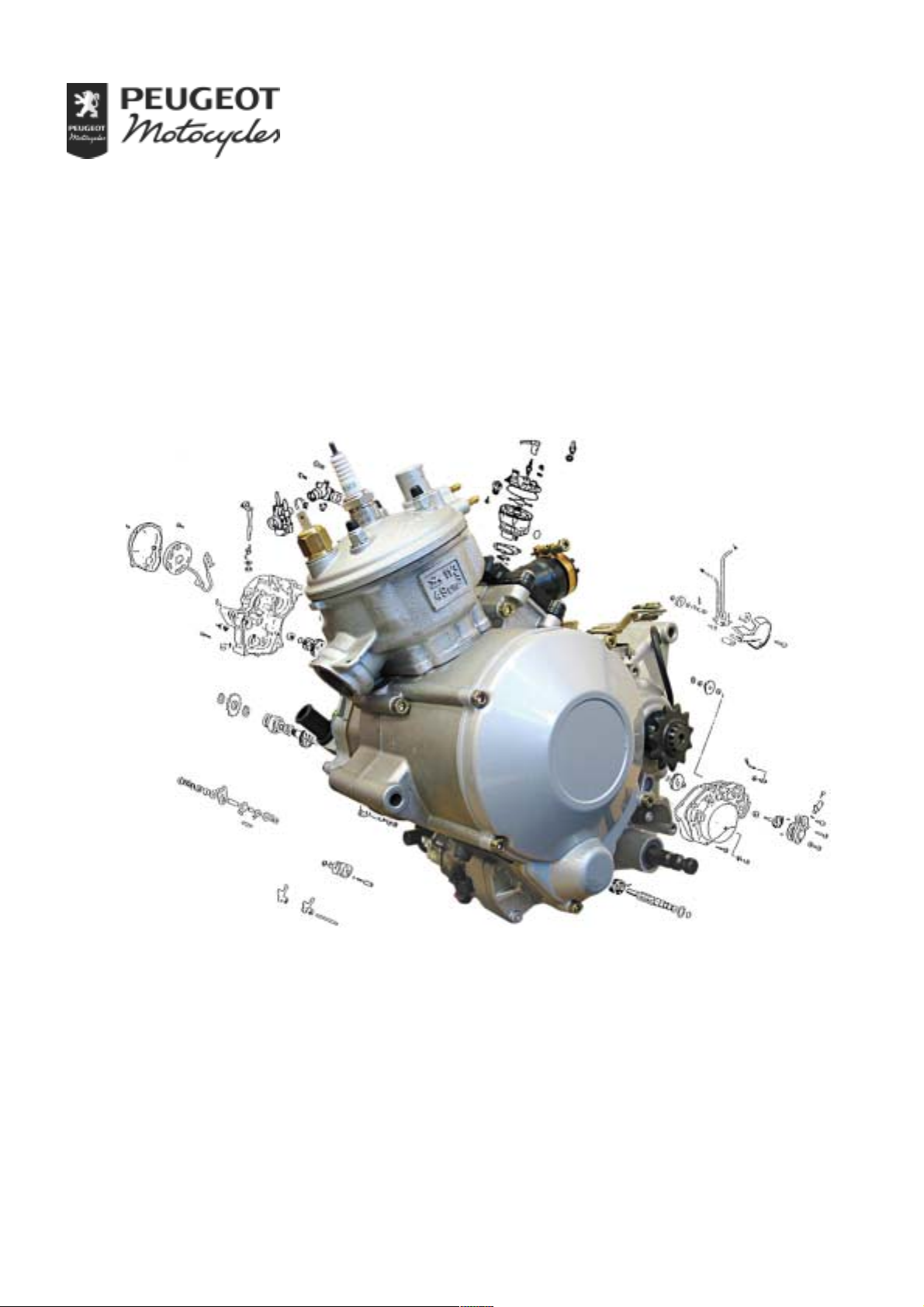

SALES DIVISION

NETWORK TECHNICAL INFORMATION

WORKSHOP

MANUAL

50 cc ENGINE

MULTI-SPEED

Page 3

CONTENTS

CONTENTS

CONTENTS..........................................................................................................................................2

CHARACTERISTICS.........................................................................................................................4

Characteristics.................................................................................................................................................4

Capacities........................................................................................................................................................4

Engine markings.............................................................................................................................................4

SPECIAL IMPORTANT POINTS.....................................................................................................5

Oil and fuel.....................................................................................................................................................5

TIGHTENING TORQUES.................................................................................................................6

Tightening torques..........................................................................................................................................6

SPECIAL TOOLS................................................................................................................................7

DISASSEMBLY ...................................................................................................................................9

Putting the engine on the stand.......................................................................................................................9

To remove the magneto flywheel...................................................................................................................9

To remove the stator.....................................................................................................................................10

To remove the starter motor (depending on model).....................................................................................10

To remove the gearbox output pinion...........................................................................................................10

To remove the clutch cover ..........................................................................................................................11

To remove the clutch....................................................................................................................................12

To remove the crank assembly and balance shaft pinions............................................................................14

To remove the inlet manifold and valve.......................................................................................................14

To remove the cylinder head/cylinder assembly..........................................................................................15

To remove the piston....................................................................................................................................15

Removal of the thermostat............................................................................................................................16

Removal of the temperature sensor ..............................................................................................................16

To open the engine casings...........................................................................................................................17

To remove the gearbox and the selector system...........................................................................................18

To remove a primary or secondary shaft pinion...........................................................................................20

To remove the balance shaft.........................................................................................................................21

To remove the crank assembly.....................................................................................................................21

Checking the crank assembly .......................................................................................................................22

REFITTING SPECIFIC COMPONENTS......................................................................................23

To fit the crank assembly bearings...............................................................................................................23

To fit the box output seal..............................................................................................................................24

To fit the selector shaft seal..........................................................................................................................24

To fit the clutch lever seal ............................................................................................................................24

To fit the balance shaft .................................................................................................................................25

To fit the crank assembly..............................................................................................................................25

To fit the gearbox..........................................................................................................................................25

To fit the left side casing ..............................................................................................................................27

To check the piston.......................................................................................................................................29

To check the piston rings..............................................................................................................................29

To fit the piston.............................................................................................................................................29

To fit the cylinder .........................................................................................................................................30

To fit the cylinder head.................................................................................................................................30

To fit the right side O-ring............................................................................................................................31

To fit the crank assembly and balance shaft pinions....................................................................................31

To fit the clutch.............................................................................................................................................33

To adjust the clutch control lever .................................................................................................................35

Page 2

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 4

CONTENTS

To fit the starter system (depending on model) and the clutch cover...........................................................35

To fit the magneto flywheel..........................................................................................................................36

MISCELLANEOUS OPERATIONS ...............................................................................................37

To remove the water pump...........................................................................................................................37

To fit the water pump ...................................................................................................................................37

To remove the oil pump and its drive pinions..............................................................................................38

To fit the oil pump........................................................................................................................................38

Page : 3

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 5

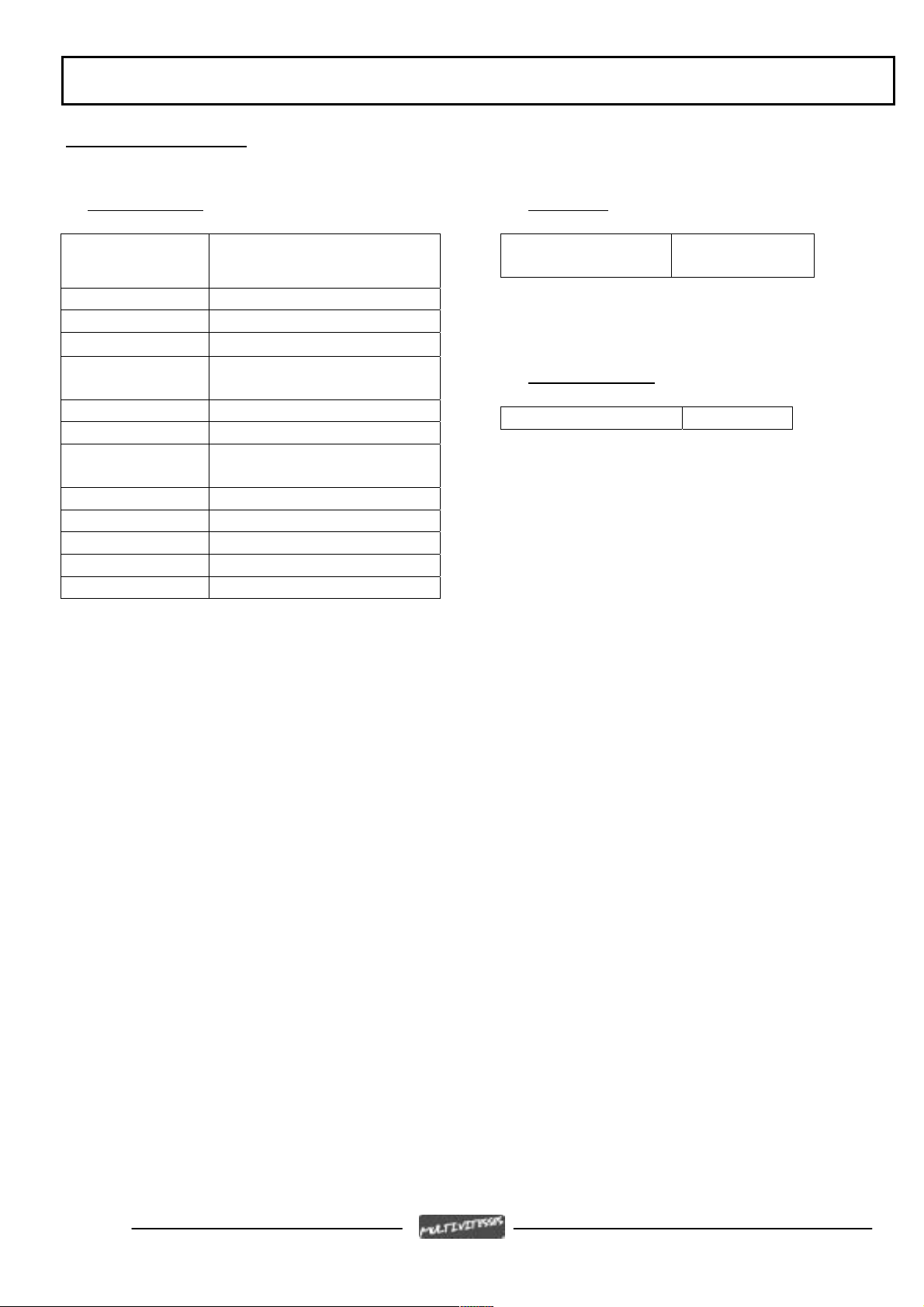

CHARACTERISTICS

Characteristics

Engine

Single cylinder 2-stroke with

balance shaft

Cooling Liquid

Bore x stroke 40.3 x 39 mm

Cubic capacity 49.7 cc

Max. power

output

1.82 kW at 5250 rpm

Max. torque at 5250 rpm

Gearbox 6-speed

Clutch Oil bath multi-disc with

manual control

Oil pump Mikuni ESOP-03

Spark plug NGK BR9ES

Magneto flywheel Ducati 85 W

Starter motor Ducati

Carburettor Dell'orto PHBN 12

CHARACTERISTICS

Capacities

Gearbox 0.75 L.

Engine markings

Engine type AM6

SAE 10W30

Page 4

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 6

SPECIAL IMPORTANT POINTS

SPECIAL IMPORTANT POINTS

Oil and fuel

This engine is designed to run on 95 or 98 unleaded

fuel only

The separate lubrication system oil to use is Esso 2T Spécial recommended by the manufacturer.

Note:

Petrol is highly inflammable, do not smoke in the working area and avoid proximity to flames or sparks.

Work in a clear and well-ventilated area.

Page : 5

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 7

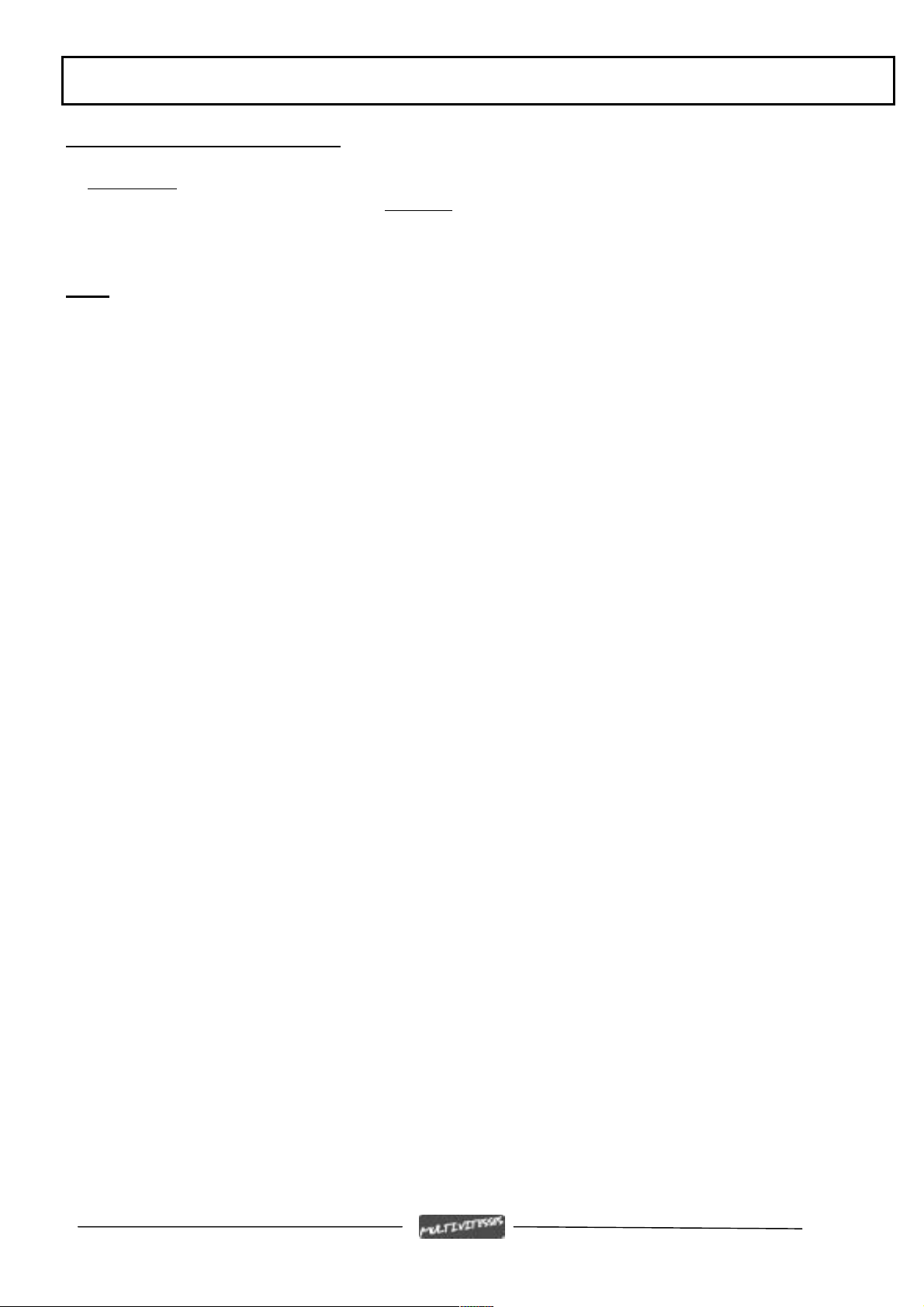

TIGHTENING TORQUES

TIGHTENING TORQUES

Tightening torques

Cylinder head 1.8 m.daN

Cylinder casings 1.1 m.daN

Transmission cover 1.1 m.daN

Water pump 1.1 m.daN

Inlet manifold 1.1 m.daN

Crank assembly pinion 7.5 m.daN

Balance shaft pinion 6 m.daN

Clutch cover 7.5 m.daN

Clutch pressure plate 0.5 m.daN

Clutch thrust bearing locknut 2.7 m.daN

Starter motor 1.1 m.daN

Rotor 5.2 m.daN

Stator 0.3 m.daN

Magneto flywheel cover 0.4 m.daN

Gearbox drain plug 1.8 m.daN

Spark plug 2.5 m.daN

Page 6

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

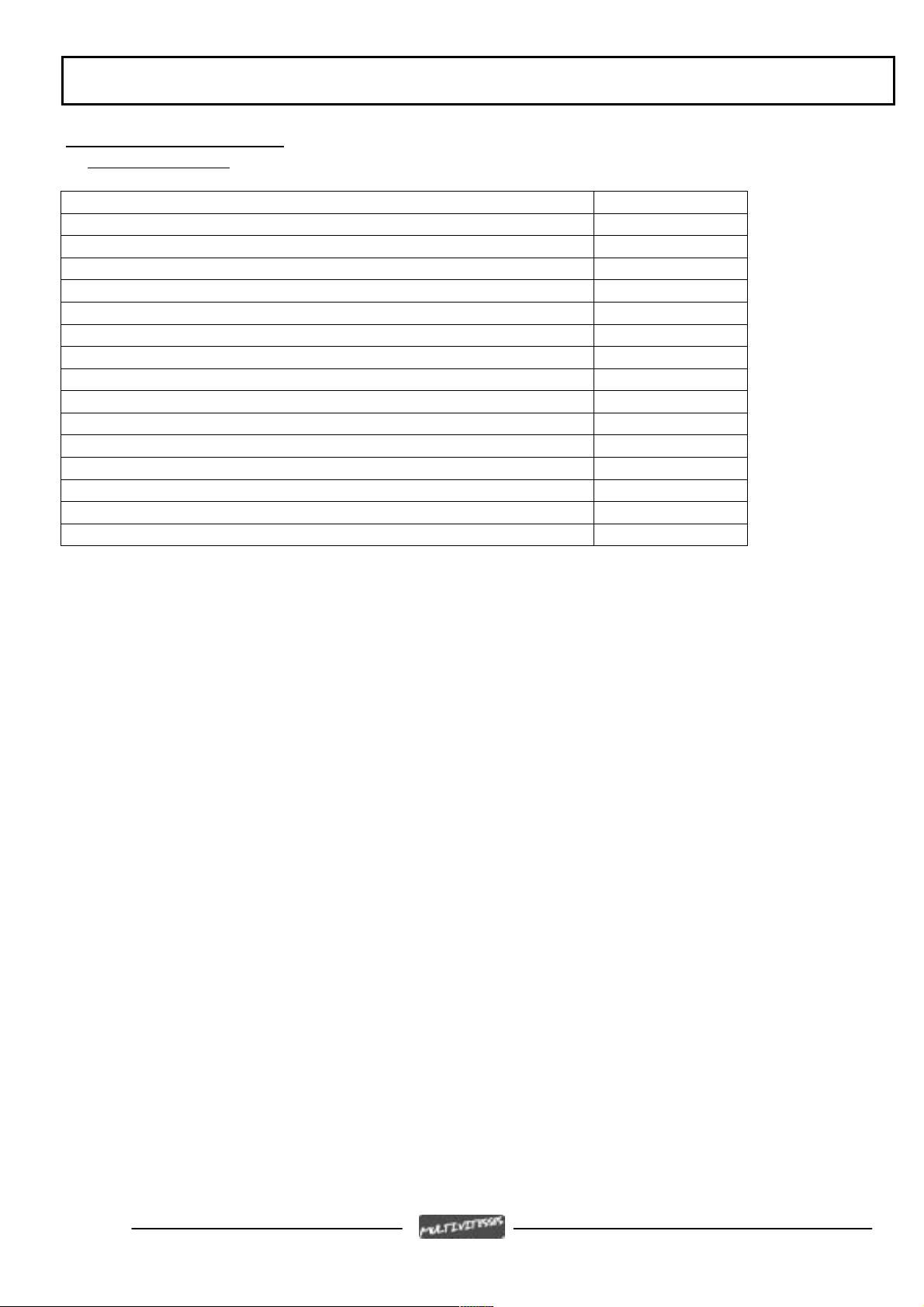

Page 8

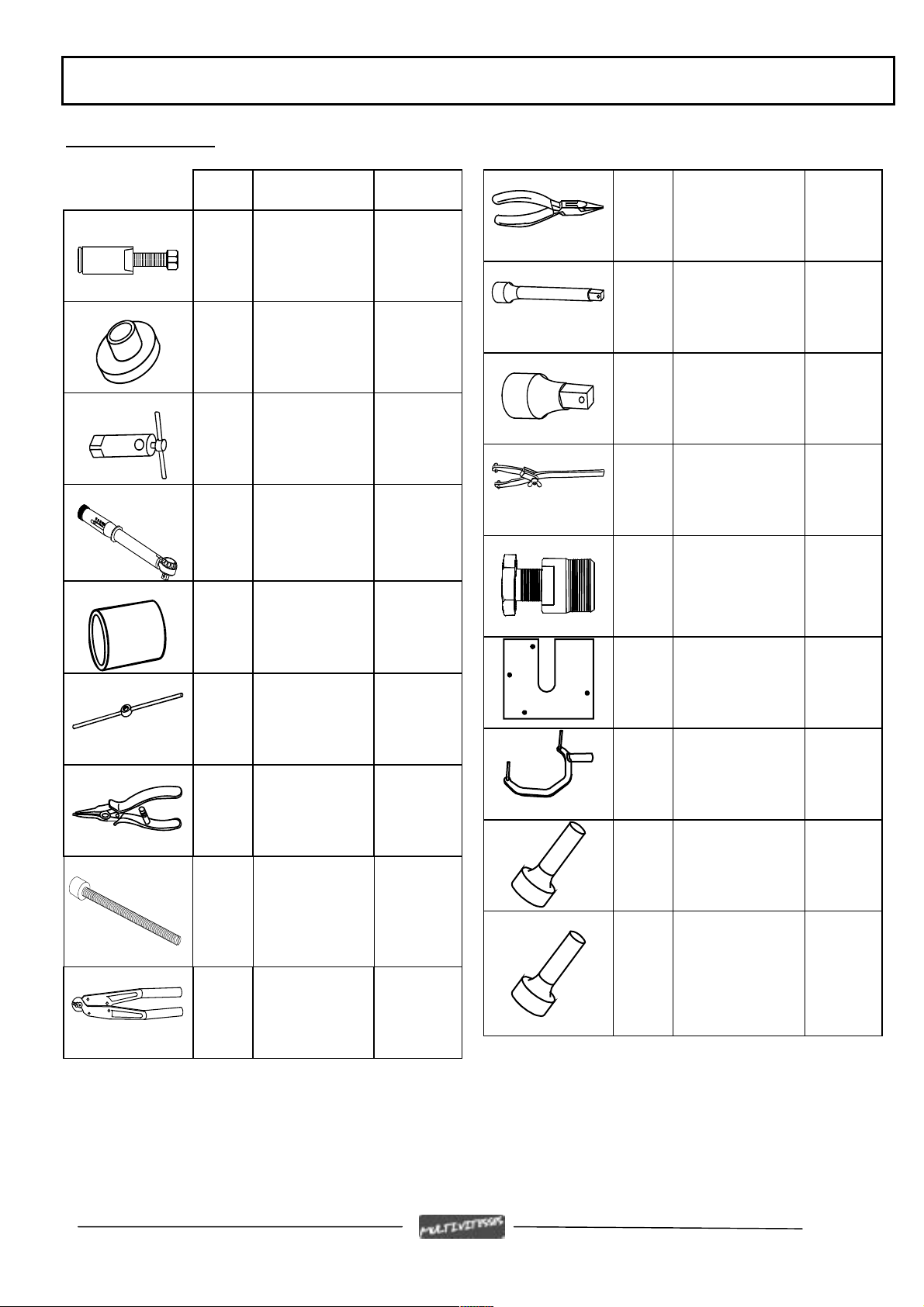

SPECIAL TOOLS

. Tool N° Description Used with

SPECIAL TOOLS

752000 Piston circlip pliers

64706 Casing extractor

and opening tool

64710 Shoulder locator 64706

64765 Engine support

68994 Torque wrench 8

Nm to 54 Nm

69098 Protective cap

large model

69104 Wing nut

69117 Exterior circlip

pliers

750069 +

Casing

opening

plate + pin

Engine

support

adapter

Extension

752235

adapter

752236

754003

64711 +

64712 +

64754

752235 1/2 extension

752236 1/2-3/8 adapter

752237 Adjustable pin

wrench

753411 Magneto flywheel

extractor

753708 Casing opening

plate

753709 Engine mount

adapter

69802 or

753977

69802 or

753978

68007

64706

750069 Stud Ø10 pitch

125

69104

753726 Crank assy lip seal

fitting tool for

primary

transmission side

753728 Selector shaft lip

seal fitting tool

750539 Tie-wrap pliers

Page : 7

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 9

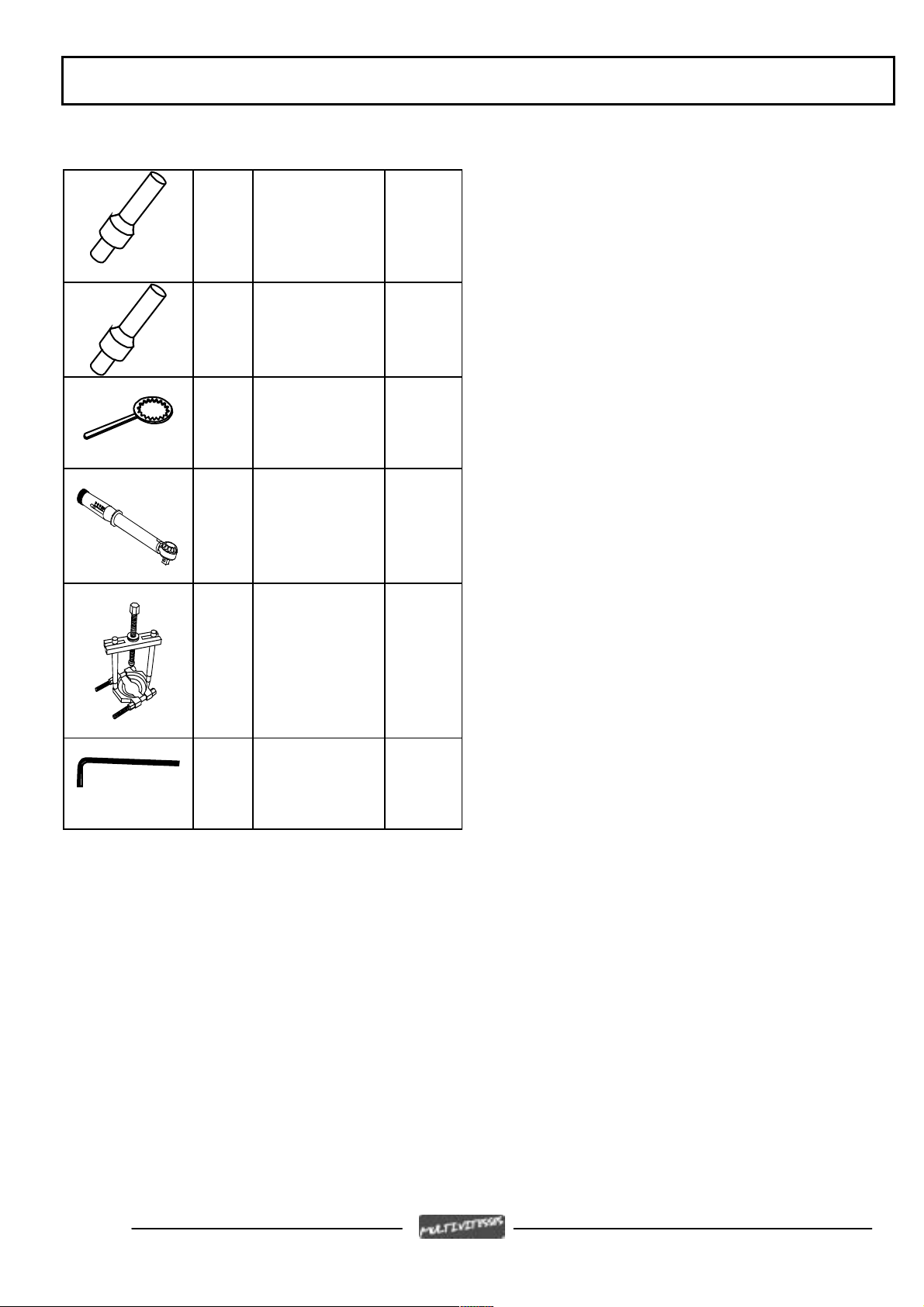

TOOLS

753729 Water pump lip seal

fitting tool

753730 Clutch lever lip seal

fitting tool

753731 Clutch locking tool

753977 Torque wrench 30

Nm to 150 Nm

Extension

752235

adapter

752237

755585 Bearing extractor

tool

755813 Valve unit safety

Allen key

Page 8

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 10

DISASSEMBLY

DISASSEMBLY

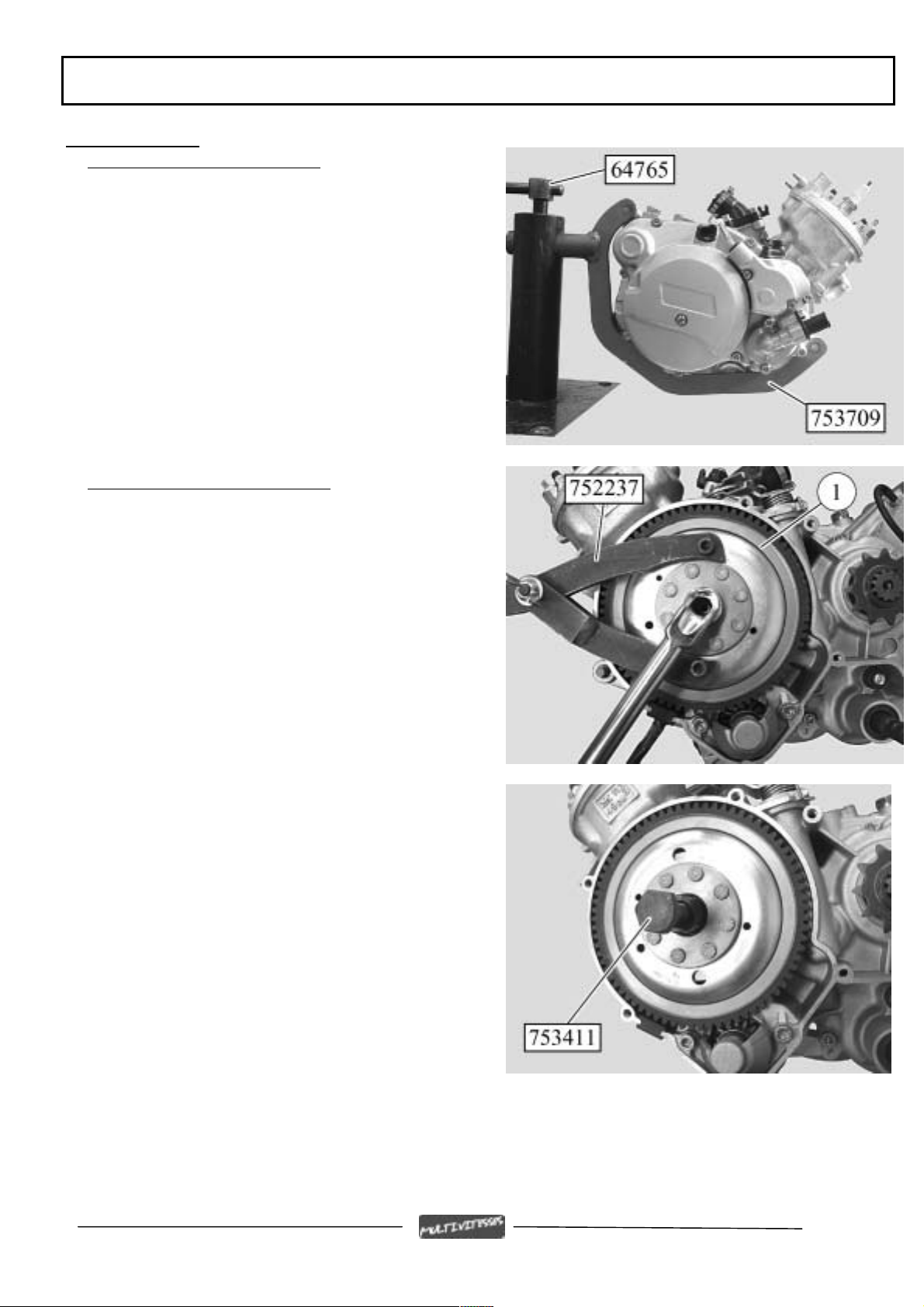

Putting the engine on the stand

- Fit the engine to adapter P/N 753709

- Lock the engine to the adapter using the 2 spring

pins

- Put the assembly on stand P/N 64765 clamped in

the jaws of a vice

To remove the magneto flywheel

- Remove the magneto flywheel cover

- Remove the paper gasket

- Hold the rotor (1) with the pin wrench

P/N 752237

- Remove the nut

Depending on the model, the rotor acts as the

starter ring

- Tighten flywheel extractor P/N 753411 on the

rotor

- Lock the flywheel extractor and turn the thrust

bolt until the rotor is released

Page : 9

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 11

DISASSEMBLY

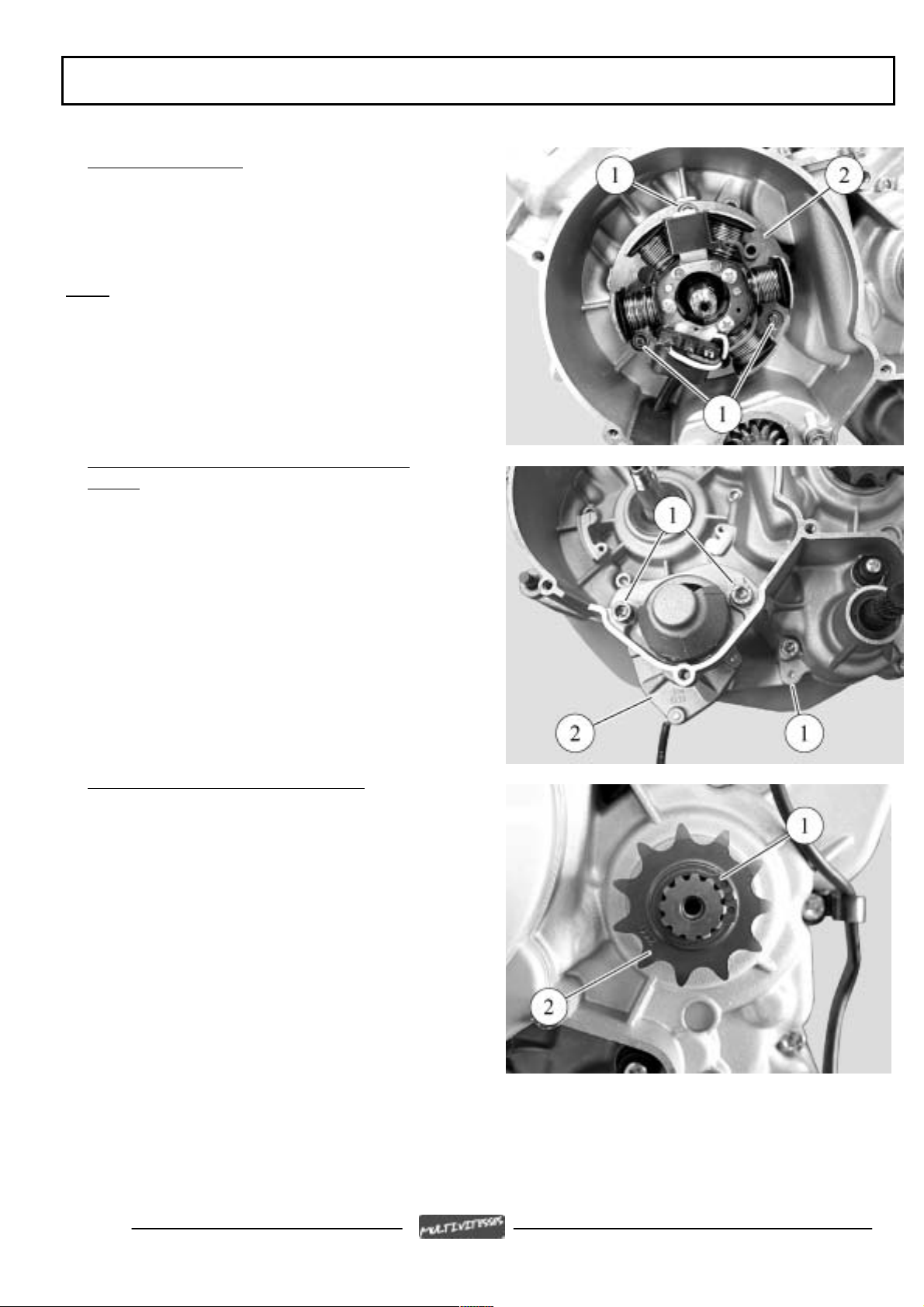

To remove the stator

- Remove the three fixing bolts (1) from the stator

plate and stator

- Remove the stator plate and stator assembly

Note:

We recommend tapping the bolts with a

hammer and drift to facilitate slackening

The 3 bolts must be renewed once removed

To remove the starter motor (depending on model)

- Remove the starter motor (2) three fixing

bolts (1)

- Remove the 2 spring pins

which lock the engine to the adapter

- Move the engine along the adapter guides to

remove the starter motor

- Re-fit the 2 spring pins

To remove the gearbox output pinion

- Remove the circlip (1) using pliers P/N

69117

- Remove the pinion (2)

- Remove the second circlip

Page 10

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 12

DISASSEMBLY

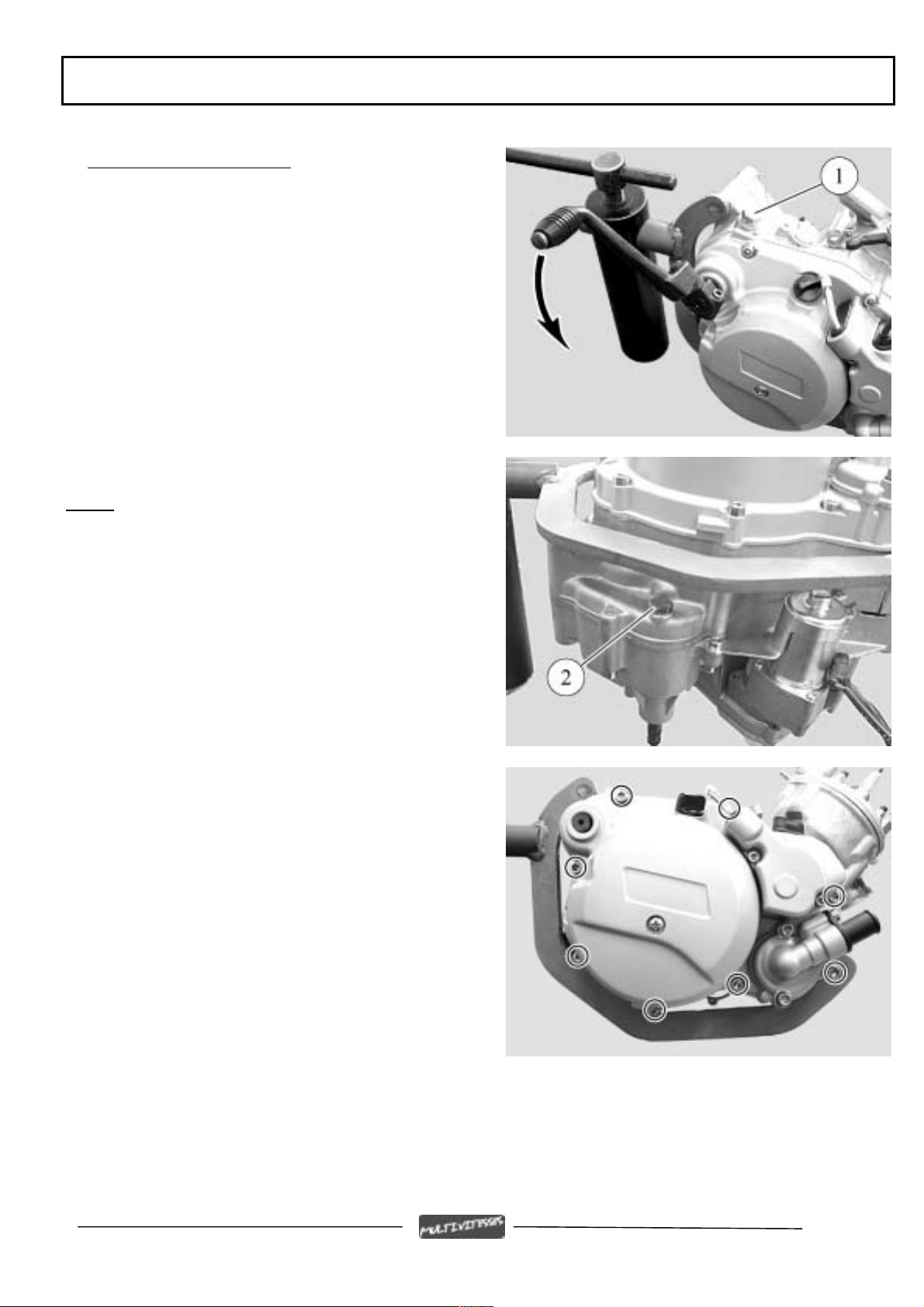

To remove the clutch cover

- Remove the kickstart pedal securing bolt

(depending on model)

- Lightly operate the kickstart pedal and hold it in

position

- Slacken off the kickstart shaft thrust bearing (1)

and release the kickstart pedal to relax the spring

- Remove the kickstart pedal

Note:

Use a recipient to recover the box oil

- Remove the bolt (2) in order to drain off the

gearbox

- Remove the cover 8 fixing bolts

- Remove the cover

- Remove the two centring pillars and the paper

gasket

Page : 11

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 13

DISASSEMBLY

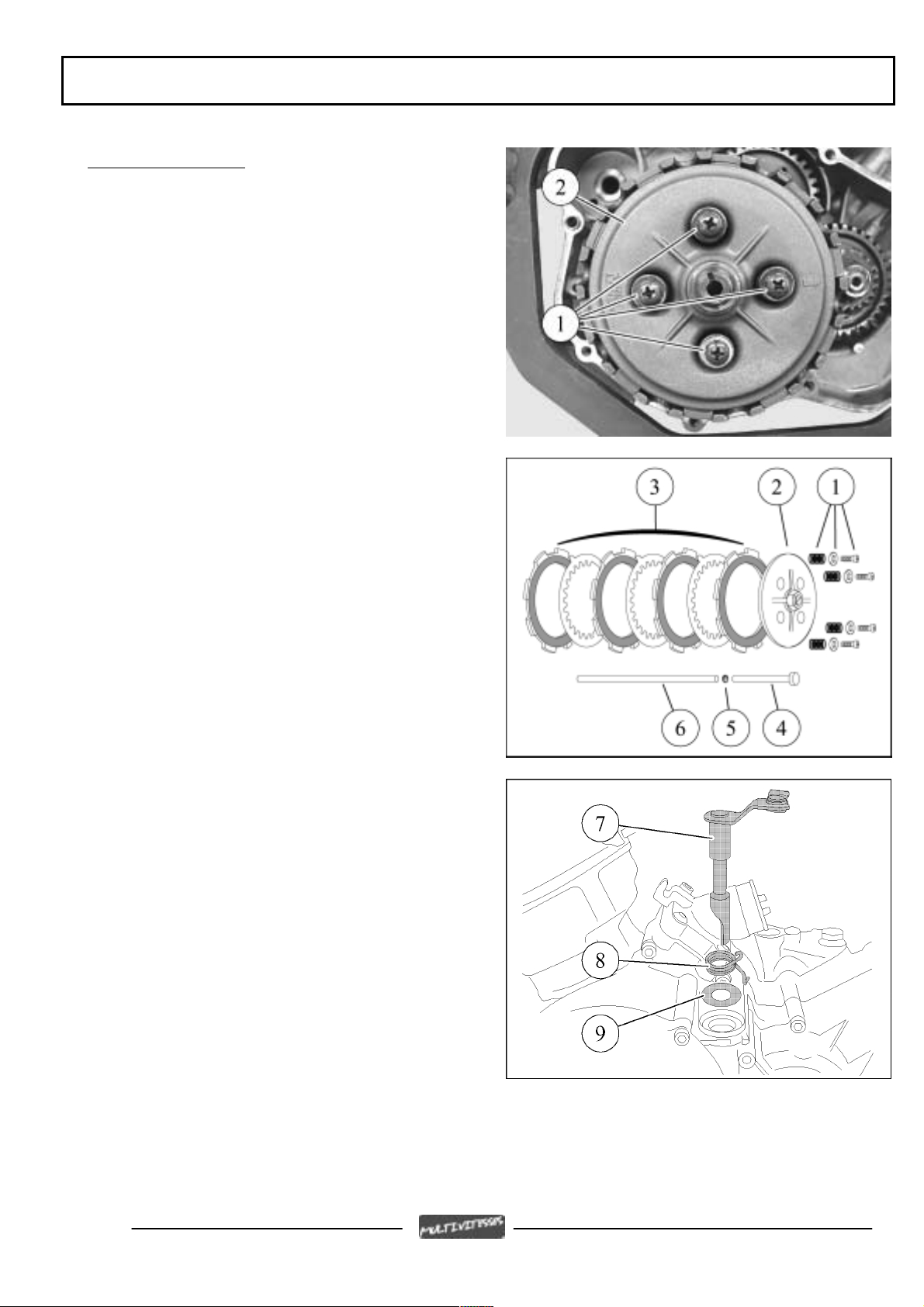

To remove the clutch

- Remove the four bolts and spring (1) from the

pressure plate (2)

- Remove the pressure plate

- Remove the assembly (3) of 4 lined discs and 3

smooth discs

- Withdraw the primary shaft:

- the piston (4)

- the ball (5)

- the thrust rod (6)

- Remove the clutch operating lever (7) with its

spring (8) and its washer (9)

Page 12

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 14

DISASSEMBLY

- Fold down the clutch nut (10) lockwasher tab

(11)

- Lock the clutch main shaft (12) with tool P/N

753731

- Remove the nut and the washer

- Remove the clutch main shaft (12), the splined

bush (13), the cover (14), the plain washer (15) and

the tapered washer (16)

Page : 13

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 15

DISASSEMBLY

To remove the crank assembly and balance shaft pinions

- Lock the balance shaft using a bolt (A) inserted

into one of the threaded holes

- Turn the balance shaft pinion (1) to bring the bolt

into contact with a ribbing in the case

- Remove the crank assembly nut (2)

- Remove the balance shaft nut (3)

- Remove the 2 pinions (20 and 34 teeth) and the

key (4) from the crank assembly

- Remove the 34-tooth pinion and the key (5) from

the balance shaft

To remove the inlet manifold and valve

- Remove the four inlet coupling bolts, two of

which (1) are with the safety Allen key P/N

755813

- Remove the coupling and the inlet valve

Page 14

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 16

DISASSEMBLY

- Check that the valve assembly blades and

support are in perfect condition

Note:

The position of the limiter must be 7 mm from

the valve support

To remove the cylinder head/cylinder assembly

- Remove the spark plug

- Slacken off the cylinder head/cylinder 4

mounting nuts in the order shown, in 2 or 3 stages

- Remove the 4 nuts and washers

- Remove the cylinder head and the 2 O-rings

- Remove the cylinder and its bottom seal

To remove the piston

- Remove one of the circlips (1) with pliers P/N

752000

- Remove the gudgeon pin

- Remove the piston

- Remove the needle bearing race from the

connecting rod end

Page : 15

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 17

DISASSEMBLY

Removal of the thermostat

- Remove the thermostat (2) two bolts (1)

- Remove the thermostat

Note:

When refitting, ensure that the degassing

hole (A) is at the highest point

Removal of the temperature sensor

Note: The engine temperature sensor (1) seal is

provided by a steel gasket

Page 16

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 18

DISASSEMBLY

To open the engine casings

- Remove the left casing 13 securing bolts

- Fit the crank assembly protective cap P/N 68007

- Fit to casing with tool P/N 64706 fitted with

plate P/N 753708

- Fix the assembly to the casing using four bolts

(1)

- Remove the engine mount adapter 2 spring pins

- Tighten the tool centre screw until the casings

separate

Note:

When opening the casings, so that they open

evenly, use a plastic mallet to tap alternatively on

the ends of the secondary shaft and the speed

selector

Page : 17

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 19

DISASSEMBLY

- To remove the left casing

Note:

Recover the friction washers which may

have been retained by the oil in the left casing

- Remove the 2 centring pins (2)

- Refit the engine mount adapter 2 spring pins

To remove the gearbox and the selector system

- Position the selector so that the mecanindus pin

is positioned opposite the secondary shaft fork

shaft

- Remove the selector shaft (1) fitted with its 2

friction washers

Page 18

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 20

DISASSEMBLY

- Remove the fork shaft (2) from the secondary

shaft

- Remove the upper fork (3) from the secondary

shaft

- Turn the selector cylinder (4) to lower the

primary shaft fork (5) into the cylinder lower

groove

- Remove the selector cylinder

- Remove the secondary shaft 2

nd

fork (6)

- At the same time, remove the secondary shaft

and primary shaft assembly fitted with its fork

Page : 19

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 21

DISASSEMBLY

- Remove the friction washer (7) from the

secondary shaft which due to the oil may have

remained stuck in the right casing

- Remove the locking ball (8) and its thrust spring

To remove a primary or secondary shaft pinion

- Remove the circlips and pinions using circlips

pliers P/N 69117

- When refitting, ensure each part is fitted in the

right position and the right way round

1. Primary shaft with 1

rd

2. 3

3. 5

and 4th gear pinion

th

gear pinion

4. 2nd gear pinion

5. 6th gear pinion

st

gear pinion

6. Circlips

7. Secondary shaft

st

8. 1

gear pinion

rd

9. 3

gear pinion

th

10. 4

gear pinion

11. 6th gear pinion

12. 2nd gear pinion

13. 5th gear pinion

14. Circlips

15. Friction washer

Note:

When changing a pinion, we recommend

changing the opposite one on the other shaft

The circlips must be renewed each time they are

removed.

Page 20

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 22

DISASSEMBLY

To remove the balance shaft

- Remove the balance shaft (1) with the help of a

plastic mallet if necessary

To remove the crank assembly

- Remove the crank assembly (2) with its bush (3)

and its O-ring (4) by tapping it lightly on the end

with a plastic mallet if necessary

Note:

The crank assembly is a free fit in the right-

hand casing bearing

Page : 21

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 23

DISASSEMBLY

Checking the crank assembly

- Using a set of shims, check the big end side play

- The maximum side play on the connecting rod

end must not exceed: 4/10 mm

- The out-of-round values measured on the ends of

the crank assembly should not exceed 4/100 mm et

and must be measured:

-50 mm on the transmission end

-50 mm on the magneto flywheel end

Page 22

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 24

REFITTING SPECIFIC COMPONENTS

REFITTING SPECIFIC COMPONENTS

To fit the crank assembly bearings

Note:

- The crank assembly bearings and seals must be

renewed each time the engine casings are opened

- When the casings are opened, if the bearings stay

on the crank assembly, use tool

P/N 755585 to remove them

- If a bearing has stuck in the left casing, heat the

casing with a heat gun in order to remove it

This operation should be done quickly in order

to remove and refit a bearing to the casing

- Set one of the casings on its mating surface, heat

it (80 to 90°C) until the bearing drops out of its

own accord

- Remove the seal

- While the casing is expanded fit the new bearing

fully home in its housing

- Fit a new seal in the left casing using tool P/N

753726

Note:

The right hand side seal should be fitted

after closing the casings, fitting the O-ring and the

bush, in order to prevent the seal lips from being

damaged or from turning inside out.

Page : 23

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 25

REFITTING SPECIFIC COMPONENTS

To fit the box output seal

- Using tool part number 753726, fit the box

output seal

To fit the selector shaft seal

- Using tool part number 753728, fit the selector

shaft seal

To fit the clutch lever seal

- Using tool part number 753730, fit the clutch

lever seal

Page 24

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 26

REFITTING SPECIFIC COMPONENTS

To fit the balance shaft

- Fit the balance shaft (1) into the right side casing

using a plastic mallet if necessary

To fit the crank assembly

- Fit the crank assembly (2) in the right side casing

Note:

The crank assembly is a free fit in the righthand casing bearing

To fit the gearbox

- Fit the slightly greased friction washer (1) onto

the needle bearing sleeve on the secondary shaft in

the right side casing

- Fit the slightly greased thrust spring and the

locking ball (2) into their housing

- At the same time fit the secondary shaft and

primary shaft assembly with its selector fork (3)

into the right side casing

Page : 25

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 27

REFITTING SPECIFIC COMPONENTS

- Fit the elbow fork (4) and the 5th gear idler

pinion to the secondary shaft

- Fit the selector cylinder with its 2 washers

- Position the fork guide (3) in the selector

cylinder intermediate groove

- Fit the fork (5) to the 6

th

gear idler pinion

- Position the fork guide (4) in the selector

cylinder lower groove

- Position the fork guide (5) in the selector

cylinder upper groove

Page 26

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 28

REFITTING SPECIFIC COMPONENTS

- Fit the fork shaft (6)

- Position the selector cylinder in 4

th

gear, with the

mécanindus pin opposite the fork shaft

- Fit the selector shaft (7) fitted with its 2 friction

washers

To fit the left side casing

- Check the friction washers are fitted to:

- the secondary shaft (1)

- the selector drum (2)

- the selector shaft (3)

- Fit the 2 centring pins (4)

- Check the right side casing mating surface is

absolutely clean

- Coat the right side casing mating surface with

gasket compound

- Lightly grease the ends of the shafts

- Check the left side casing mating surface is

absolutely clean

- Fit the left side casing

- Tighten pin P/N 750069 on the end of the crank

assembly

Page : 27

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 29

REFITTING SPECIFIC COMPONENTS

- Fit tool P/N 64706 fitted with plate P/N 753708

to the pin

- Centre the assembly on the casing using 4

bolts (5)

- Fit centring tool P/N 64710 to tool P/N 64706

- Tighten pin nut P/N 69104 until the casings are

fully closed

- Fit and tighten the 13 securing bolts

- Tightening torque: 1.1 m.daN

Note: - Check the crank assembly turns freely in

the casings

- Fit the gear selector without tightening it, turn

the primary shaft manually and check the gears

change correctly

- Lightly grease the crank assembly and bearings

with 2-stroke oil

Page 28

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 30

REFITTING SPECIFIC COMPONENTS

To check the piston

- The piston should show no traces of scoring or

seizure

- The rings must be free in their grooves

To check the piston rings

- Carefully remove the piston rings

- Place a ring in the bore parallel to it and measure

the gap using a feeler gauge

- Piston ring gap: 0.15 mm to 0.30 mm

- Utilisation limit: 1 mm

To fit the piston

- Fit the needle bearing race (1) into the

connecting rod little end after lubricating it with 2stroke oil

- Fit the piston to the connecting rod, the

positioning spigots on the piston rings facing the

inlet side

- Fit the gudgeon pin

- Fit the circlips using pliers P/N 752000

Important:

- The circlips must be changed each

time they are removed

The circlip gaps must face upwards or downwards

(2), but under no circumstances to the side

Page : 29

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 31

REFITTING SPECIFIC COMPONENTS

To fit the cylinder

- Fit a new base gasket (1) do not use oil or grease

- Ensure that the piston ring gaps are opposite the

piston positioning spigots

- Fit the cylinder (2) and insert it while

compressing the piston rings by hand

- Fit the cylinder over the piston by compressing

the piston rings by hand

To fit the cylinder head

- Check the O-ring housings are absolutely clean

- Fit the new O-rings to the cylinder head

- Fit the cylinder head to the cylinder

- Tighten the cylinder head securing nuts working

diagonally in 2 or 3 steps

- Tightening torque: 1.8 m.daN

- Fit the spark plug

- Tightening torque: 2.5 m.daN

Page 30

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 32

REFITTING SPECIFIC COMPONENTS

To fit the right side O-ring

- Fit a new O-ring (1) and spacer (2) to the crank

assembly

- Using tool part number 753726, fit a new O-ring

(3), with the lip facing outwards

To fit the crank assembly and balance shaft pinions

- Fit key (1) into the crank assembly housing

- Fit the key (2) into the balance shaft housing

Page : 31

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 33

REFITTING SPECIFIC COMPONENTS

- Fit the crank assembly pinion (3), with the

marked tooth to the outside

- Fit the balance shaft pinion (4) by lining up the

tooth gap marked with two spots (A) with the mark

of on spot (A) on the crank assembly pinion

- Fit the nut but do not tighten it

- Lock the balance shaft using a bolt (B) inserted

into one of the threaded holes

- Turn the balance shaft pinion to bring the bolt

into contact with a ribbing on the casing

- Tight the balance shaft nut (5)

- Tightening torque: 6 m.daN

- Fit the pinion (6), with the spotfacing towards

the outside, and fit nut (7)

- Tighten the crank assembly pinion

- Tightening torque: 7.5 m.daN

Page 32

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 34

REFITTING SPECIFIC COMPONENTS

To fit the clutch

- Fit the following to the primary shaft:

- the tapered washer (1) with the round end

towards the bearing

- the plain washer (2)

- the clutch housing (3)

- the splined bush (4)

- the clutch main shaft (5)

- the tab washer (6) and the nut (7)

- Lock the clutch main shaft with tool P/N 753731

- Tighten the nut

- Tightening torque: 7.5 m.daN

- Fold over the clutch nut washer locking tab

- Fit the clutch control lever with its spring and

washer

- To the primary shaft, fit the piston (8), the ball

(9) and thrust rod (10)

- Fit the clutch discs starting with a lined disc (11)

and then alternate smooth and lined discs (12)

Page : 33

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 35

REFITTING SPECIFIC COMPONENTS

- When re-assembling, ensure that the marks (A)

on the smooth discs are offset by 120° from the

others

- Fit the pressure plate (13) lining up the arrow (B)

on the plate with the round imprint (C) on the

clutch main shaft

- Fit the pressure plate springs (14) and the 4 bolts

and washers (15)

- Tightening torque: 0.5 m.daN

Page 34

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 36

REFITTING SPECIFIC COMPONENTS

To adjust the clutch control lever

- Slacken the pressure plate locknut (1)

- Bring the lever into contact with the control rod

- Turn the centre bolt (2) on the pressure plate in

order to set the control lever at 30° to the magneto

flywheel cover mating surface

- Tighten the locknut without altering the

adjustment

- Tightening torque: 2.7 m.daN

To fit the starter system (depending on model) and the clutch cover

- Fit the spring (1) to the starter shaft- Fit the

spring (1) to the starter shaft

- Fit the starter dog (2), the starter release

mechanisms (A) lining up with the return spring

arm (B)

- Fit the starter motor dog (3)

- Fit the 2 locating pins and a new paper gasket

- Fit the clutch cover, turn the crank assembly by

hand, if necessary, to mesh the water pump pinion

with the crank assembly pinion

- Fit the cover 8 fixing bolts

- Tightening torque: 1.1 m.daN

- Fit and gently operate the kickstart pedal and

hold it in position

- Fit the kickstart shaft bump stop

- Tightening torque: 3 m.daN

- Release the kickstart pedal

Page : 35

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 37

REFITTING SPECIFIC COMPONENTS

To fit the magneto flywheel

- Fit the stator assembly

- Fit and tighten the stator assembly (2) two fixing

bolts (1)

- Tightening torque: 0.3 m.daN

- Fit the rotor (3) to the crank assembly ensuring it

is positioned on the key

- Lock the rotor with the adjustable pin wrench

P/N 752237

- Fit and tighten the rotor nut

- Tightening torque: 5.2 m.daN

- Fit the gasket and the magneto flywheel cover

- Tightening torque: 0.4 m.daN

Page 36

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 38

MISCELLANEOUS OPERATIONS

MISCELLANEOUS OPERATIONS

To remove the water pump

- Remove the clutch cover 8 fixing bolts

- Remove the clutch cover

- Remove the water pump cover (1) 2 fixing bolts

- Remove the cover

- Remove the two centring pillars and the paper

gasket (2)

From inside the clutch cover, remove:

- the circlip (3)

- the washer (4)

- the 30-tooth nylon pinion (5)

- the drive pin (6)

- the washer (7)

- the impeller with its shaft (8)

- the seal (9)

- Check the condition of the impeller shaft, if it is

shows signs of wear, change the impeller

To fit the water pump

- Using fitting tool P/N 753729, fit a new lightly

greased gasket (9)

- Re-assemble in the reverse order to

disassembly

Note:

A new circlip and paper gasket must be

used each time they are removed

Page : 37

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 39

MISCELLANEOUS OPERATIONS

To remove the oil pump and its drive pinions

- Remove the clutch cover 8 fixing bolts

- Remove the clutch cover

- Remove the oil pump cover

- Remove the oil pump two fixing bolts

- Remove the pump (1) with its O-ring

From inside the clutch cover, remove:

- the 2 circlips (2)

- the pinion (3)

- the drive pin (4)

- the washer (5)

- the pump shaft and its washer (6)

- the pinion with its 2 washers (7)

- Check the condition of the oil pump shaft, if it

shows signs of wear, change the shaft

To fit the oil pump

- Lubricate the 2 shafts

- Re-assemble in the reverse order to disassembly

Note:

New circlips and O-ring must be used each

time they are removed

Page 38

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 40

RECOMMENDED

REF: 757068

For reasons of continuous improvement, Peugeot Motocycles reserves the right to modify, delete or add any part number quoted

DCDC/PS/ATR printed in EU 02/2002 (photos non-contractual)

Reproduction or translation, even partial, is forbidden without prior written consent of Peugeot Motocycles

Page 41

Visit RepairManualClub.com for more

motorcycle manuals

Buy Motorcycle Gear and

Equipment

Buy Helmets, Jackets, Pants

Buy Everything Motorcycle at

Amazon.com

Visit RepairManualClub.com for more

motorcycle manuals

Loading...

Loading...