PEUGEOT XP6 50 User Manual

PEUGEOT XP6 50

Manuel d'atelier (EN ANGLAIS)

G.H.E. MOTORHISPANI

A, S.L

.

GARAGE HANDBOOK

INTRODUCTION

This garage manual refers to the AM6 engine, equipping the following vehicles:

- Furia 6V Cross

- Furia 6V Supermotard

MOTORHISPANIA RECOMMENDS

2 stroke engine:

• MOTUL POWERLUBE SEMI-SYNTHETIC 2T

Gearbox oil:

• TRANSOIL 10W30

Grease:

• GREASE 100

ADVICE

A good repairer acts with order and methodically

Use the appropiate tools, gaining time and a professional image.

Página 2 de 34

CONTENTS

TECHNICAL FEATURES REPLACEMENT

Engine part .................................................. 2 Water pump .............................................. 24

Cycle part .................................................... 2 Oil pump .................................................. 25

Capacities and types ................................... 3

Tightening motor and cycle......................... 3

Special tools ................................................ 3 IGNITION AND ELECTRICAL CIRCUIT

Maintenance...................………………….. 4

Electronic ignition .................................... 28

DISASSEMBLY

Disassembly of engine ................................ 5 Neutral gauge........................................… 28

Disassembly of magneto ............................. 6 Cooling system temperature gauge.......... 28

Disassembly of clutch cover ....................... 7 Min. oil level gauge...............................… 28

Disassembly clutch ..................................... 7 Horn ......................................................... 28

Disassembly of crankshaft pinions Socket ....................................................... 28

and camshaft ..............................…………. 8 Indicators .................................................. 29

Disassembly of inlet pipe and Principle scheme....................................... 30

plate valve ...................................………… 8 Scheme legend.......................................... 31

Disassembly cylinder head ......................... 9 Cable plan ................................................ 32

Disassembly of cylinder ............................. 9

Disassembly of piston ................................ 9

Disassembly of exhaust pinion ................... 9 CONTROL

Openin

g of cases .................................... 10

Disassembly of stick and gearbox ............. 11 Elements of the gearbox ........................... 13

Disassembly of camshaft ........................... 11 Connecting rod/crankshaft set................... 15

Disassembly of crankshaft .......................... 11 Piston ........................................................ 17

ASSEMBLY

Replacement of bearings/joints ............…... 12 Clutch ....................................................... 22

Assembly of gearbox .................................. 13 Ignition advance ....................................... 26

Assembly of selector shaft ......................... 14 Oil level of gearbox ................................. 27

Assembly of camshaft.... .................……… 15

Assembly of connecting rod/crankshaft

in right case ................................................. 15

Closing of left case ..................................... 16 ADJUSTMENTS

As

sembly of the piston ............................... 17

Assembly of the cylinder ............................ 17 Engine clutch lever...................………… 24

Assembly of the cylinder head ................... 18 Ignition advance ....................................... 26

Assembly of plate valve and inlet

pipe ............................................................. 19

Assembly of crankshaft right joint ............. 20

Assembly pinions crankshaft and cam

shaft ............................................................ 20

Assembly of the clutch ............................... 22

Clutch lever regulation ............................... 24

Starting shaft/clutch cover .......................... 25

Assemblyof magneto .........................……. 26

Principle and regulator ............................. 28

Lights ....................................................... 28

Cylinder .................................................... 17

Segments .................................................. 17

Thermostat valve ..................................... 18

Plate valve .......................................... 19

Oil pump .................................................. 25

Página 3 de 34

Assembly of exhaust pinion ....................... 27

Filling of gearbox ....................................... 27

TECHNICAL FEATURES

ENGINE PART

Name of

Type: ........................................FU01

Engine marking: only engine type is inscribed, not

num

ENGINE: MOTORI MINARELLI type AM6

2 stroke monocylindrical type, with separate

greasing and liquid cooling by means of circulation

pump.

Diameter and distance: ......... Ø40.3x39mm

Cylinder capacity: ................. 49.7 cc

B compression relation ......... 12:1

R compression relation ......... 6.86:1

Transmission:

Exhaust pipe: ............ 177º

Transfer: ................... 125º

Admission: ..........…. plate valve

Idling pattern: .............….. 1800 rpm +/- 200

Power: .......... 1.82Kw ISO at 5250 rpm

Max. Par.: ….. 3.23 mdaN ISO at 5250 rpm

IGNITION: Type CDI

-Electronic type by means of condensator discharg

(tyristor)

-Advance .......... 1.4 mm before PMS (20º)

-Spark plug ....... Resisting 5 Kohm

Type: ..NGK BR8ES or EYQUEM R1000 L

Electrode space: .................... 0.6 mm

the manufacturer: ......Furia6V

bered.

-Gearing down relation: 3.55 (20x

CH: Multidisc in oil coating with manual

CLUT

control.

GEARBOX: 6 gears

-Lubrication by means of chain and pinions

-Control by means of selector at right foot

GEARING DOWN

1 12X36 3 32,0 %

2 16X33 2,06 46,5 %

3 19X29 1,53 62,9 %

4 22X27 1,23 78,2 %

5 24X25 1,04 92,2 %

6 25X24 0,96 100 %

SECONDARY T

chain and pinions

-Gearing down relation: (12x52):

CYCLE PART

e

RANSMISSION: by means of

71)

4,33

CARBURETTOR: DELL ‘ORTO SHA 14-12

-Main jet: .......………………. 63

GENERATOR: magneto DUCATI

-Number of poles: .....……….. 6

-Power: ...……………………. 85 W

-Voltage: .....…………………. 12 V

REGULATOR: FACOMSA (with integrated

central integrator)

-Regulation tension: …………. 13.4VAC +/-0.5

STARTING: Starting pedal

SEPARATE GREASING: DELL ‘ORTO oil pump

-Variable flow

6 cc/H approx. (control between 0 and 10º

9 cc/h approx. (control at 15º)

25 cc/h approx. (control at 45º)

38 cc/h approx. (control at 71º)

-Gearing down relation: 2.03 (20x24 and 13x22)

PRIMARY TRANSMISSION: helical gears

)

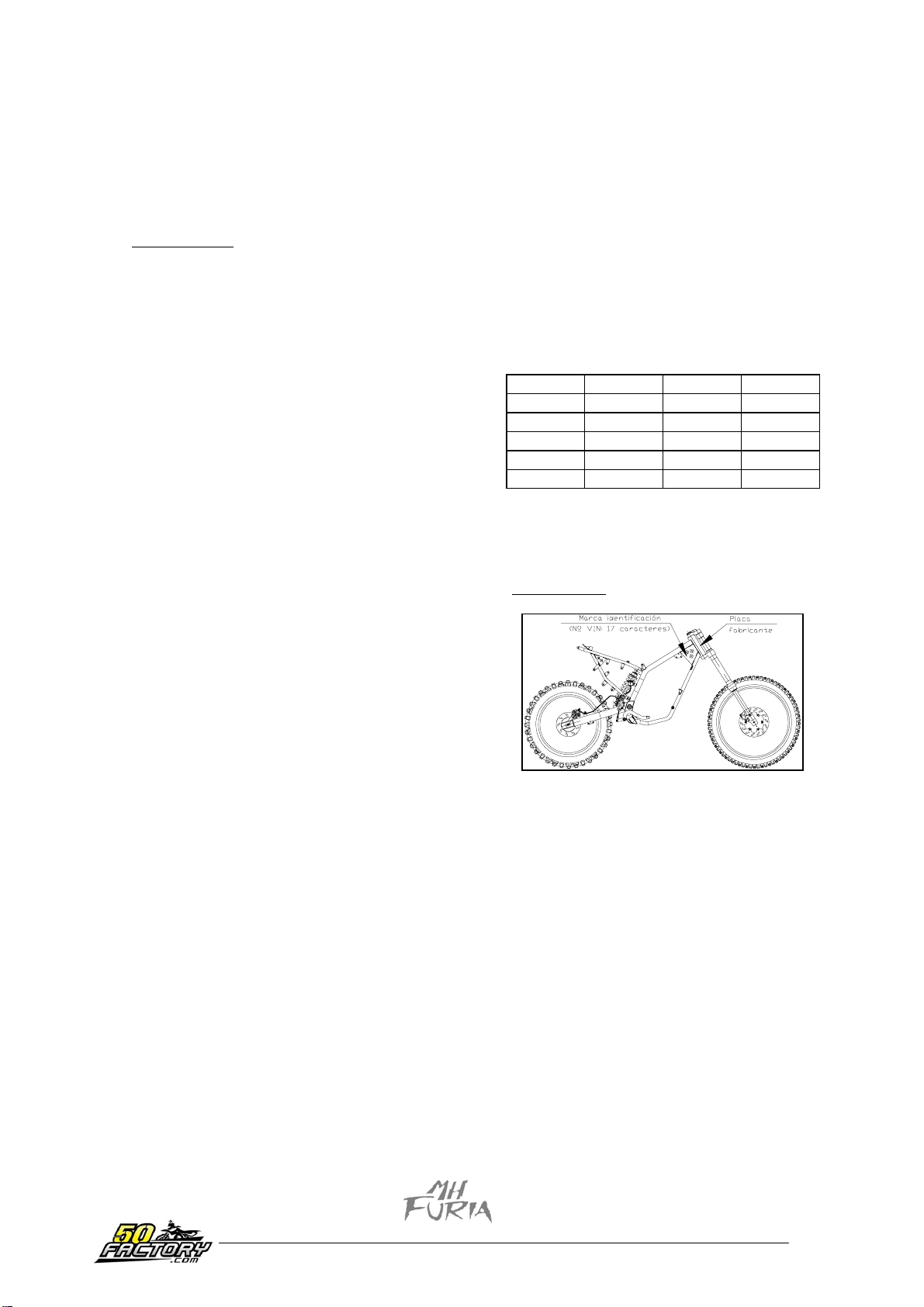

IDENTIFICATION MARK

-VIN nr. 17 characters VTVFU01A………….

CHASSIS:

Double seat in rectangular steel tube

Attack angle: 26º

Advance: 167 mm

STEERING:

-on ball beari

FRONT SUSPENSION: SHOWA

-inverted hydraulic telescopic fork

-distance: 180 mm

-bar diameter: 32 mm

REAR SUSPENSION:

-Cantilever type with oilpneumatic mono shock

absorber with helical spring

-distance: 45 mm

ngs

Página 4 de 34

FRONT BRAKE:

-AJP brake pin

-disc O220 mm with manual hydraulic control

-thickness: 4 mm

REAR BRAKE:

-AJP brake pin

-floating disc O180 mm with hydraulic control at

the stem

-thickness: 3.5 mm

TYRES: dimensions and pressures when cold

-Cross version:

Front: 2.5x21 1.5 bars

Rear: 110/80x18 1.7 bars

-Supermotard version:

Front: 100/80x17 2.3 bars

Rear: 130/70x17 2.5 bars

DIMENSIONS:

-Total length: 1995 mm

-Total width: 750 mm

-Total height: 1350 mm

WEIGHT:

-Weight when moving: 85

-Max. authorized total weight: 235 kg

CAPACITIES AND TYPES

FUEL: Super, unleaded, 98 or 95 oct.

Capacity of the tank: 6 litres

Reserve: 0.2 litres

SEPARATE GREASING: Semi synthetic oil, or

synthetic

MOTUL Powerlube semi-synthetic 2T

Capacity of the oil tank: 1.1 litres.

kg

Contents for each bar:........... 175 cc

PARES APRIETE MOTOR

Cy

linder head nut 1,8 mdaN

Crankshaft pinion nut 7,5 mdaN

Camshaft pinion nut 6 mdaN

Magneto nut 5,2 mdaN

Clutch nut 7,5 mdaN

Pressure plate screw 0,5 mdaN

Clutch counter nut 2,7 mdaN

Engine housing case screw 1,1 mdaN

Transmission cover screw 1,1 mdaN

Magneto cover screw 0,4 mdaN

Inlet pipe screw 1,1 mdaN

Starting pedal screw 3 mdaN

Gearbox casting screw 1,8 mdaN

TIGHTENING OF THE CYCLE PART

t wheel nut 4,5 mdaN

Fron

Rear wheel nut 6,5 mdaN

Fork screw 2,5 mdaN

Steering nut 6 mdaN

Fork tube inf. T screw 1,5 mdaN

Fork tube sup. T screw 2,8 mdaN

Handlebar fixing screw 2,3 mdaN

Engine fixing screw 2,8 mdaN

Swing arm nut 6,5 mdaN

Rear chassis fixing screw 2,8 mdaN

Fixing footrest bracket screw 2,8 mdaN

Upper shock absorber screw 4,5 mdaN

Lower shock absorber screw 4,5 mdaN

Front brake pin screw 2,8 mdaN

Rear brake pin screw 2,8 mdaN

Front brake disc screw 1,2 mdaN

Rear brake disc screw 0,5 mdaN

SPECIAL TOOLS

GEARBOX: Transmission oil

MOTUL Transoil 10W30

Capacity gearbox: 0.75 litres.

COOLING CIRCUIT: Protection until –20ºC

Antifreeze fluid type Procor 3000 or equivalent,

change every 2 years

Capacity of the circuit: 0.7 litres

BRAKE FLUID: fluid according to the rules DOT

3 or DOT 4

HYDRAULIC FORK: Fork oil type: SAE 20

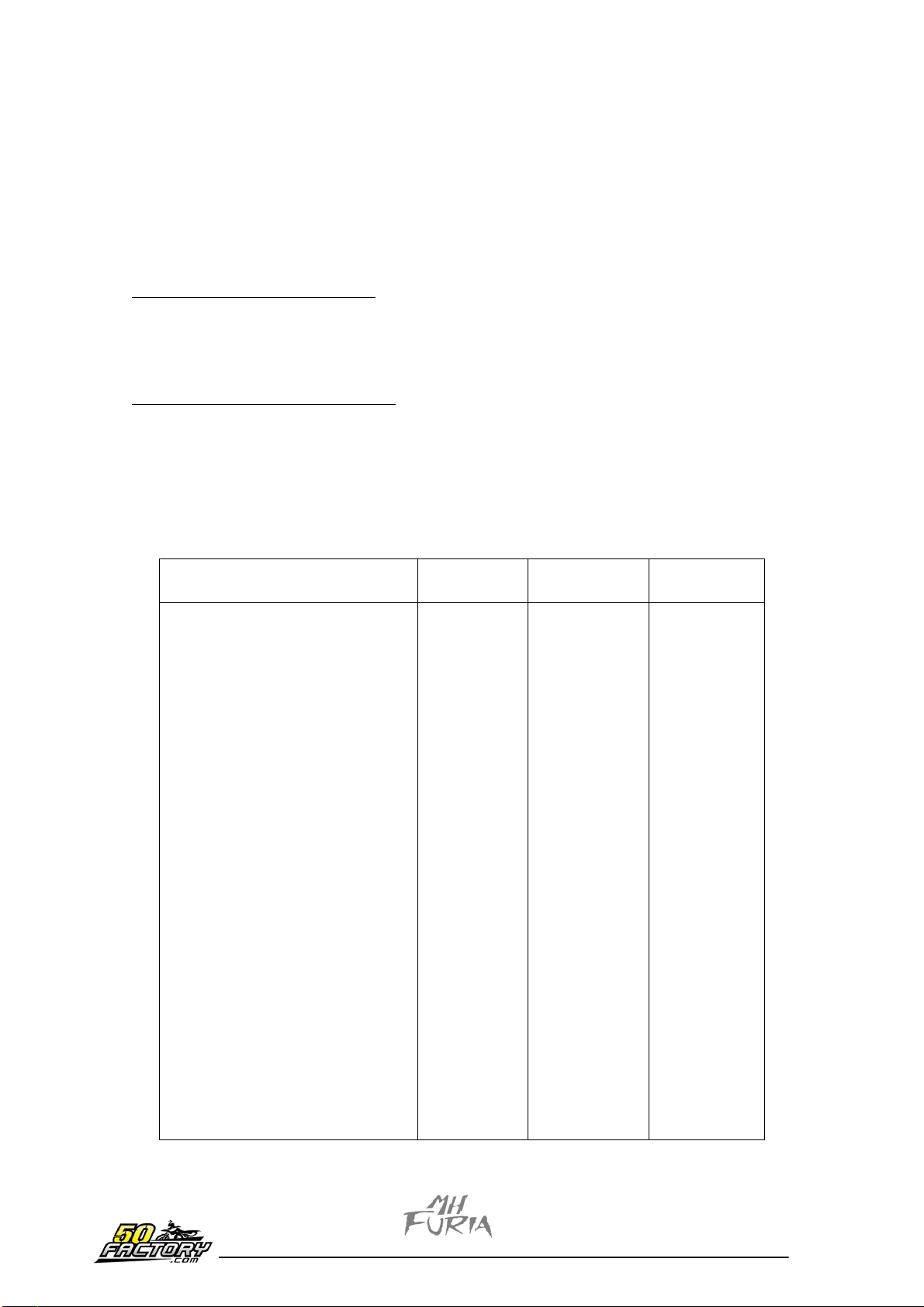

Engine bracket

Adaptation Furia 6V

VAR tool

Opening and closing plaque

Protection cap

Special 10x125 nut

Centrer

Special nut bracket

Gauge 47 set

Wheel extractor

Clutch immobil. tool

Clutch side crankshaft driver

Wheel side crankshaft driver

Selector shaft driver

Water pump driver

Clutchstick driver

Lock pin

Adjustable immobilizer

Outer circlip pin

Página 5 de 34

MAINTENANCE

Depend

ing on the use of the vehicles, we recommend that you should apply:

The normal maintenance plan

The reinforced maintenance plan

The normal maintenance plan includes:

Service after 500 km or 3 month……….…..……Plan A

Service every 5000 km......................……………Plan B

Service every 10000 km............…………………Plan C

The reinforced maintenance plan includes:

Service after 500 km..........................Plan A

Service every 2500 km......................Plan B

Service after 5000 km........................Plan C

NOTE: The replacement of certain parts is directly related to the use of the vehicle and it is also related to

“the user’s nature”.

ACTI O NS

PL AN A

500 Kms. or 3

months

PLAN B

2.500 Kms or

5.000 Kms *

PLAN C

5.000 Kms or

10.000 Kms *

Verify:

- Adjustment of the idling

- Gas control

- Clutch control

- Front and rear brake control

- Functioning the electrical equipment

- State and pressure tyres

- Petrol tube

- Oil tube

- Brake fluid tube

- Antifreeze fluid tube

- Brake fluid level

- Antifreeze fluid tube

- Regulation of tension chain and oiling

- Tightening of screws

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

X X X

Replace:

- Gearbox fluid

- Spark plug

- Filtering elements of the filter box

- Brake pads ( if necessary )

- Crown, pinion, chain ( if necessary )

- Clutch disc ( if necessary )

X X

X X

X X

X

X X

X

Clean:

- Pinion head

- Combustion chamber

- Exhaust pipe exit

X

X

X

Clean:

- Carburettor

X

Vehicle testing:

- On the road

X X X

Página 6 de 34

DISASSEMBLY OF THE ENGINE OF THE VEHICLE

-D

isassemble:

the petrol tube to the carburettor

the oil pipe to the pump

the two tubes of the cooling circuit (cylinder

head and pump)

gas control

the spark plug cap

the oil pump control

the filter box

-Disconn

the electrical installation of the magneto

the electrical installation of the neutral

-Disassemble the transmission chain (fast union

loosen nut of the swing fork

loosen and remove:

screw sup fastening of the engine and make it

pivot upwards

the other two screws of the engine

-Remove the engine and put it on the brack

adaptor (this bracket has to be screwed to a

bench)

ect:

et

)

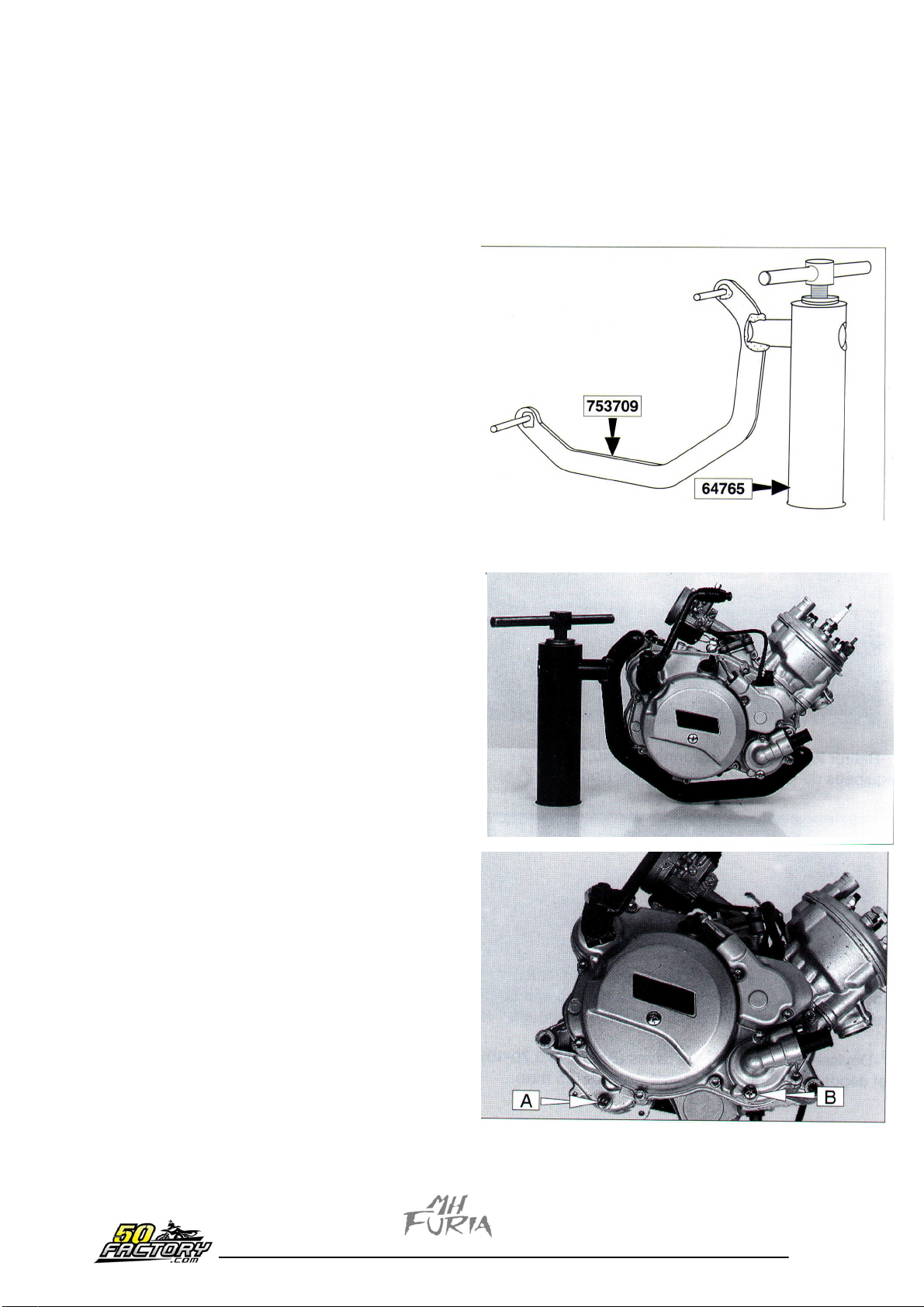

-Take the oil out of the gearbox, screw (a)

-Remove the draining screw from the water

pump (B)

to empty it.

CAUTION: respect the environment, recover

the used oil

and antifreeze fluid in the appropiate containers.

Página 7 de 34

DISA

Remove the 5 screws (CHC M5x0.80-20) and

remove the cover.

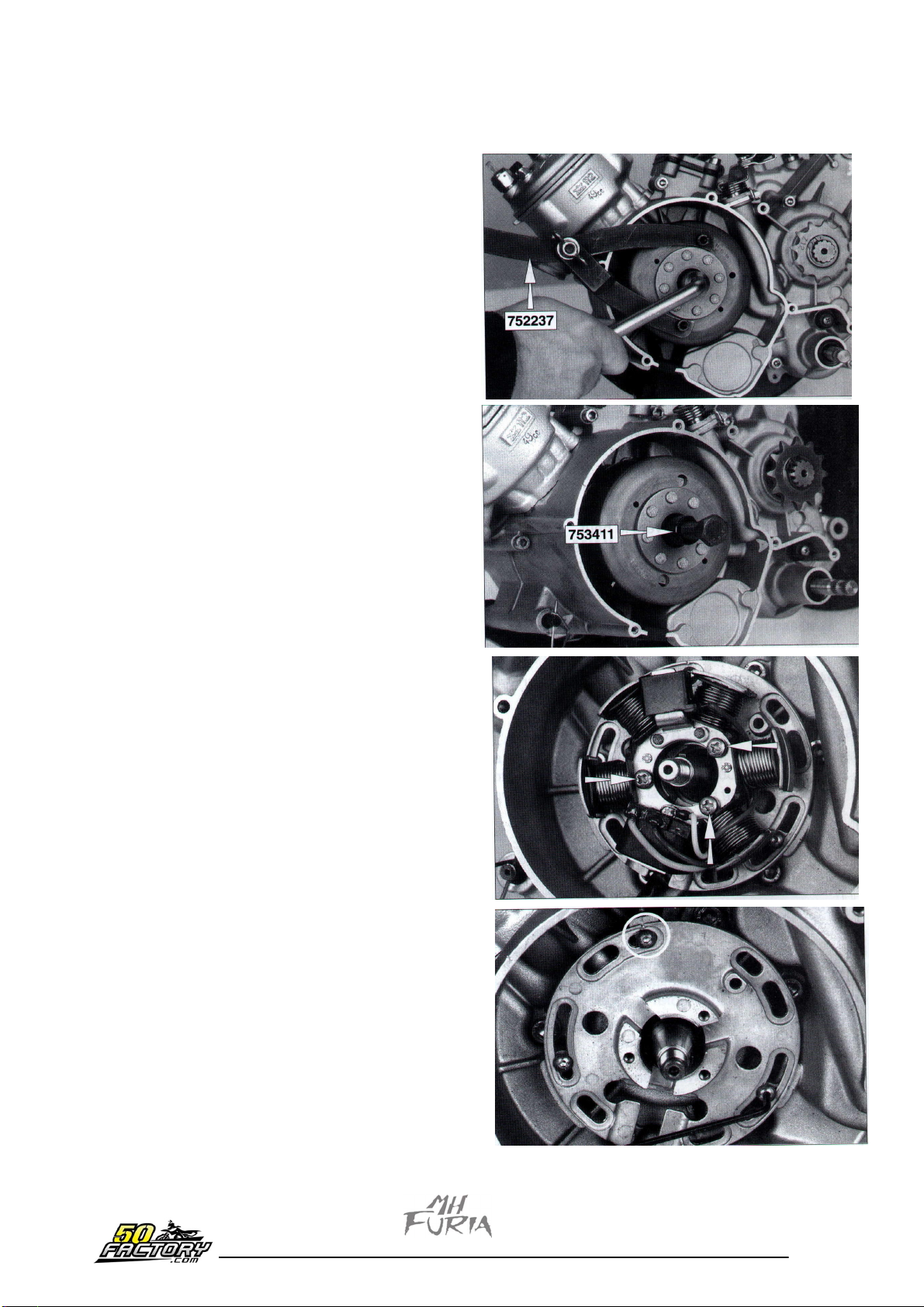

Immobilize the rotor and loosen the magneto

nut with tool.

Screw the extractor off the wheel and

act on the central part of it to take out the rotor

(assembled on conical axle with pin).

SSEMBLY OF THE MAGNETO

Remove the three screws with star head

(M4x0.70-19) and their washers.

IMPORTANT: Before removing the stator base,

leave a small mark on the housing case and on

the plaque so you can find back the initial

position during the assembly.

Loosen the three screws with allen head (BHC

M4x0.70-10) and remove the stator plaque

(Allen wrench of 2.5 mm).

Página 8 de 34

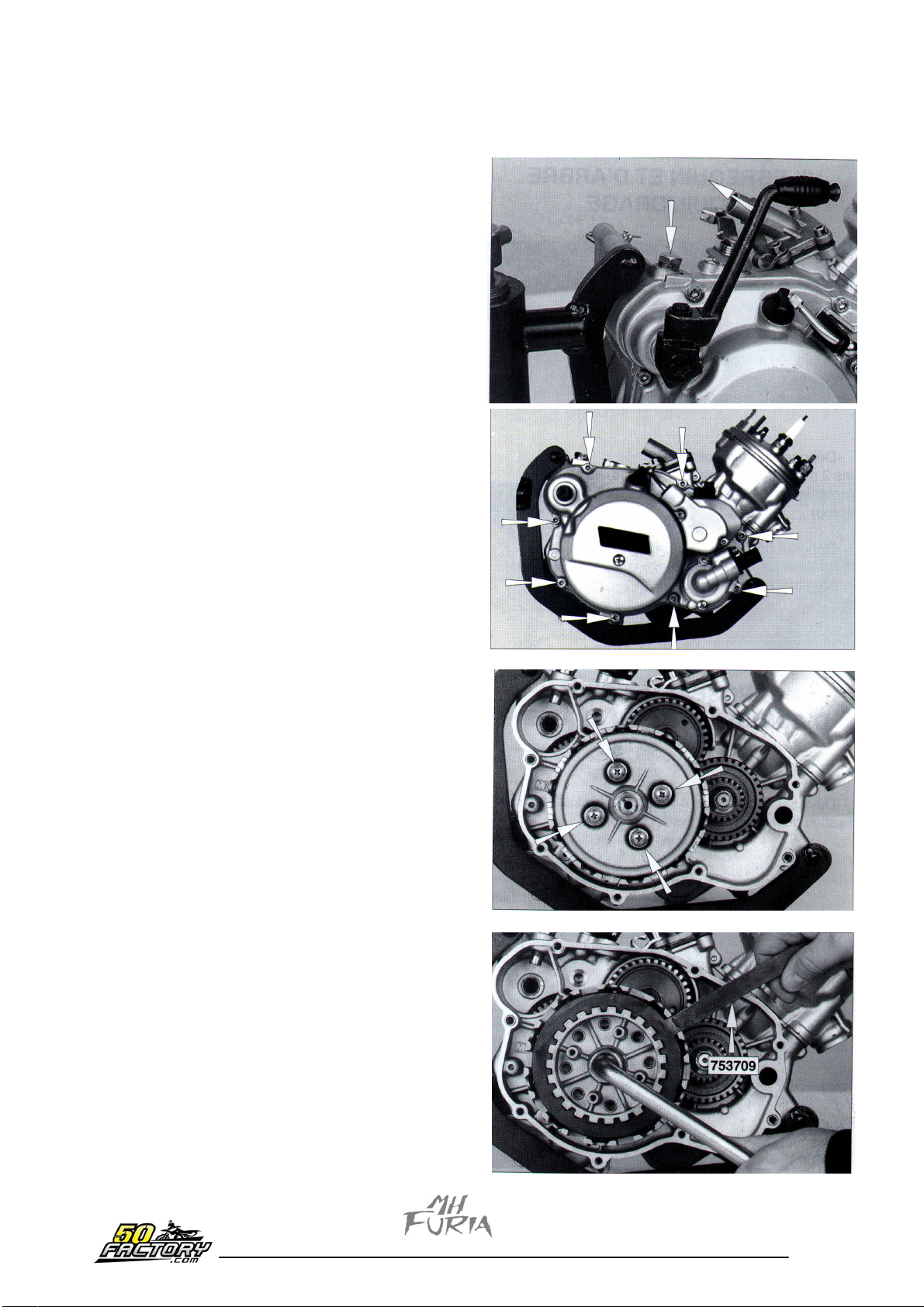

ASSEMBLY OF THE CLUTCH COVER

Activate the starting pedal slightly and keep it

in this position.

Remove the fixing screw from the pedal.

Loosen the pedal launcher screw and remove

the spring.

Loosen and remove the 8 fixing screws from the

cover (type CHC).

Remove the joint and the two centring bubbles

from the cover with the housing case.

IMPORTANT: Write down the position of the

starting pedal on the spindle to put it back

during the assembly (see page 25).

DISASSEMBLY OF THE CLUTCH

Loosen and remove the 4 screws (CB M5x0.80-

20), the washers and the springs from the

pressure plate.

Disassemble the upholstery discs and the plain

ones.

Take out the primary driving shaft, the ball and

the driving stick (see page 23 A B C).

Straighten the nut brake.

Immobilize the rotor clutch with tool.

Loosen and remove the nut (wrench 17) and the

nut brake.

Disassemble the rotor, grooved separator, the

plain washer (17.2x30x0.8) and the interior

cogged conical washer (write down its position

for the assembly).

Página 9 de 34

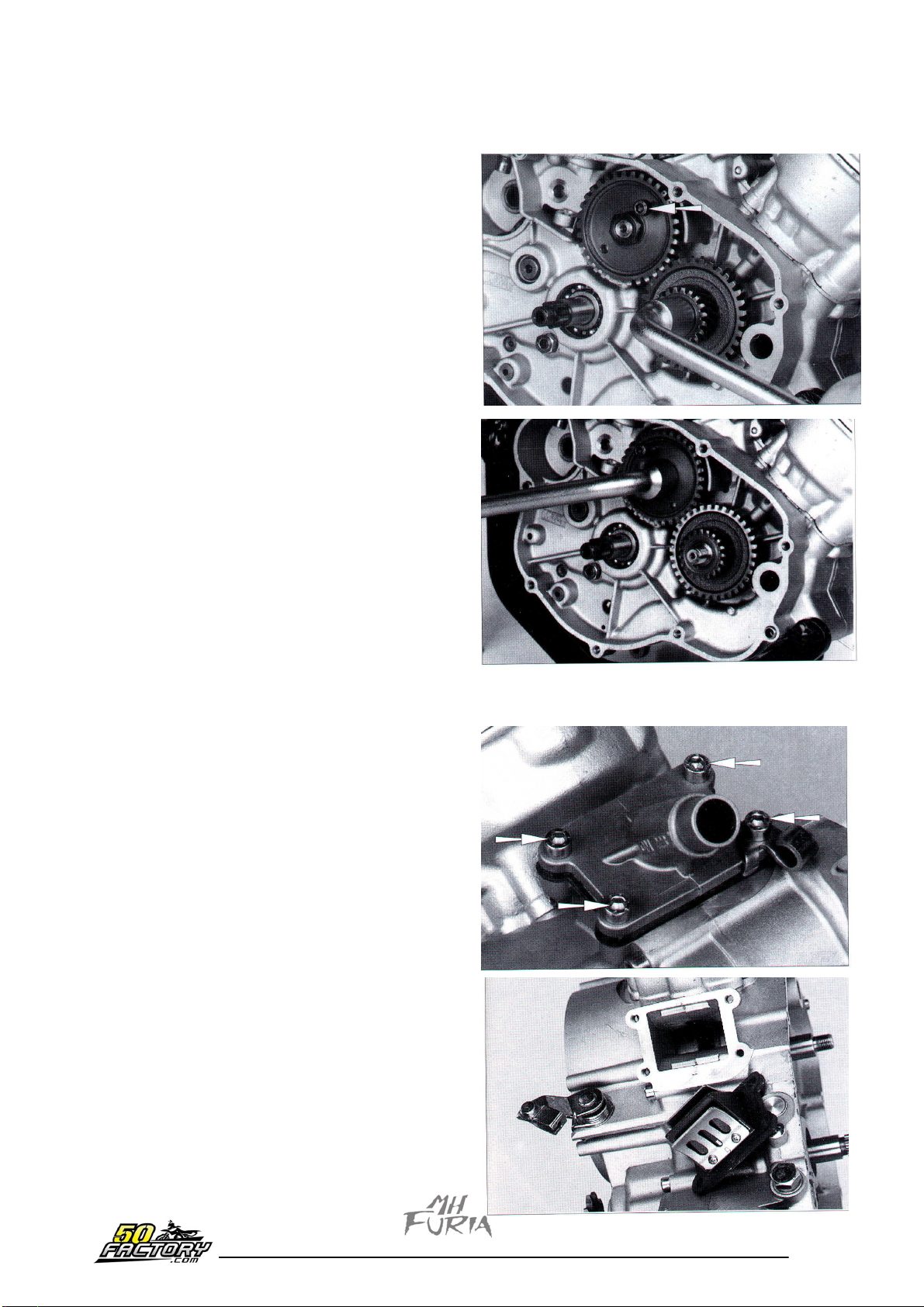

DISASSEMBLY OF THE CRANKSHAFT PINIONS

AND OF THE CAM SHAFT

Put

a screw (type CHC M6x1.00-25 for

example) into one of the thread holes of the

camshaft pinion, resting its end on the ribbing of

the housing case.

With the immobilixed pin in rotation, loosen the

crankshaft nut (wrench 17) and the cam shaft

nut (wrench 19) and remove them.

Disassembly of the crankshaft:

The two pinions (20 cogs and 34 cogs), the

in (note the direction of the pinion 20 z, mark

towards the nut).

The smooth washer (812.3x22x0.8), the pinion

(34 cogs) and the pin.

DISASSEMBLY OF THE INLET PIPE AND PLATE VALVE

Loosen and remove the 4 fixing screws (CHC

M6x1.00-20)

from the inlet pipe.

Disassemble the pipe and the plate sheet

(overhaul of

valve is in the chapter dedicated to the

assembly, page 19).

Disassemble the clutch lever with its spring and

washer.

Página 10 de 34

Loading...

Loading...