Page 1

Motor FB-0-1-2-4

GB

WORKSHOP MANUAL 50 cm3

Page 2

CONTENTS

ENGINE PART

Designation Page

- Contents, ............................................................. 1

- Main characteristics, ............................................ 2

- Maintenance plan,................................................ 3

- Putting into service, ............................................. 4

- Special tools,........................................................ 5

- Tightening torques............................................... 5

Dismantling

Designtation Page

- Removing the engine from the vehicle, ............... 6

- Placing the engine on the support, ...................... 6

- Removing the cooling system,............................. 6

- Removing the flywheel,........................................ 6

- Removing the oil pump, ....................................... 7

- Removing the starter motor, ................................. 7

- Removing the carburettor and choke, ................. 7

- Removing the intake valve and connecting part,. 7

- Removing the complete primary drive assy, ........ 7

- Removing the kick starter system,....................... 8

- Removing the relay unit, ...................................... 8

- Removing the cylinder head, ............................... 8

- Removing the cylinder piston assy,...................... 9

- Removing the RH housing,.................................. 9

- Removing the crankshaft from the LH housing, .. 9

- Replacing the crankshaft bearings and seals,...... 9

- Checking the crankshaft ...................................... 9

CYCLE PART

Designation Page

- Contents, ..............................................................1

- Main characteristics, ............................................ 2

- Maintenance plan,................................................ 3

- Putting into service, ..............................................4

- Tightening torques, ...............................................5

- Disc brake...........................................................14

RECOMMENDATIONS

Designation Page

- Spark plug.............................................................2

- Fuel ...................................................................... 4

- Separate lubrication..............................................4

- Relay unit ............................................................. 4

Refitting

Designation Page

- Refitting the crankshaft,..................................... 10

- Closing the engine housings,............................. 10

- Refitting the piston, ............................................ 10

- Refitting the cylinder, ......................................... 11

- Refitting the cylinder head, ................................ 11

- Refitting the relay unit, ........................................ 11

- Refitting the kick starter system,........................ 12

- Checking the driven pulley clutch, ..................... 12

- Checking the drive pulley variator,..................... 12

- Refitting the primary drive,................................. 12

- Refitting the intake valve and connecting part,.. 13

- Refitting the carburettor, .................................... 13

- Refitting the starter motor, ................................. 13

- Refitting the oil pump and setting, ..................... 14

- Refitting the flywheel,......................................... 14

- Refitting the cooling system............................... 14

ELECTRIC EQUIPMENT

Designation Page

- Electronic ignition,...............................................15

- Circuits supplied with alternative current, ........... 15

. lighting,............................................................. 15

. choke, .............................................................. 16

- Resistance check of stator,................................ 16

- Circuits supplied with direct current, .................. 17

. battery charge, ................................................. 17

. fuel gauge, ........................................................18

. oil gauge, ......................................................... 18

. horn,..................................................................18

. indicators,..........................................................18

. starter motor circuits, ....................................... 19

- Functional diagrams for electric circuits,. 20 and 21

- Key to electric circuits ........................................ 22

Trekker - Squab

1

Page 3

TECHNICAL DA TAS

Main spécifications

ENGINE MARKING

Number

Type

FB2 ENGINE

Forced-air cooled 2 stroke engine :

- Bore and stroke : ................................................ 40 x 39.1

- Cylinder capacity : ............................................. 49.13cm3

- Compression ratio : ...................................................6.6:1

- Maximum power (ISO) : ..........................................3.1 kw

Distribution :

- Exhaust port : ...........................................................160c°

- Scavenging port : .......................................................1 10 °

- Air intake : .....................................by reed valve induction

- Ignition :.......................CDI (capacitive-discharge ignition)

- Spark advance : ....................................... 13° before TDC

- Spark plug ...................................................Resistive 5KÙ

..................................................................... NGK - BR7HS

.................................................................. EYQUEM R 850

................................................................. BOSCH WR4AC

- spark plug gap :.....................................................0.6mm

Carburettor :..........................................GURTNER P A350

- Idling speed :....................................1800 rpm ± 1 00 rpm

- Initial position of the pilot air adjusting screw :

- Anticlockwise rotation : ..................................... 1/2 to 13/4

- Needle with 3 levels :.................................. clips at the top

- Main jet :........................................................................74

Flywheel magneto :

- Number of poles :............................................................6

- Power : .......................................................... 2500t = 55w

........................................................................ 5000t = 85w

Starter.motor : .................................................... MITSUBA

................................................................ 2000w SM10 129

................................................................. 1500w SM10254

Oil pump :.............................................................. MIKUNI

flow 24cm3 ± 1.7cm3 / hour at 3800 rpm, wide open

throttle. 1CM3 = 0.031 cubic inch

XXXXXXXX

FB2

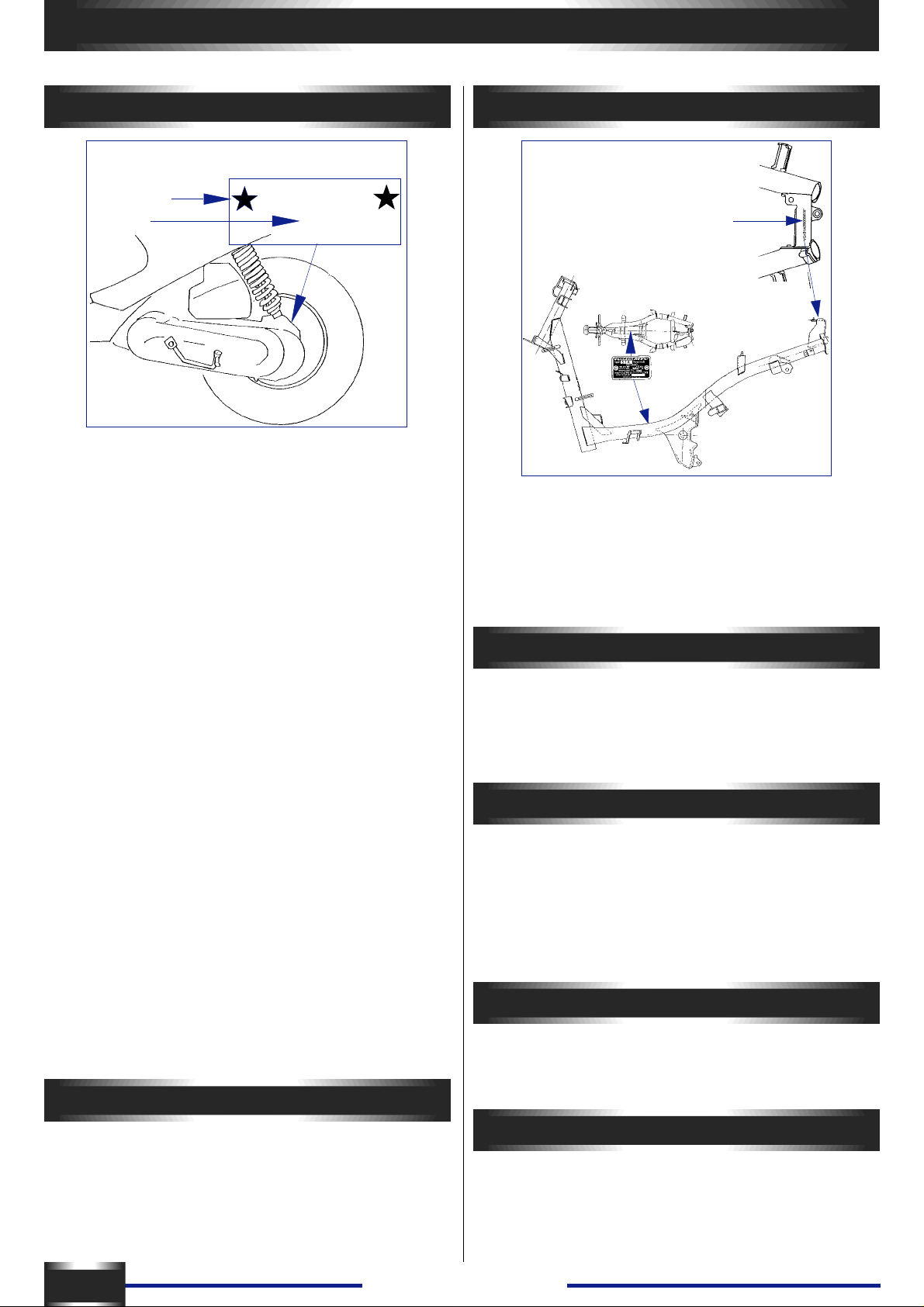

Frame

IDENTIFICA TION MARK

Identification

plate

Identification : VGAS1A . . . . . . . . . . .

- Front tyre :...................................................... 120/90 x 10

- Rear tyre : ......................................................130/90 x 10

Pressure :

- Front :.................................................................... 1,3 bar

- Rear : .................................................................... 1,6 bar

Capacities

- Fuel tank : .............................................................. 6 litres

- Oil tank : .............................................................. 1.3 litres

- Transmission case : ............................................0.12 litre

- Under-seat storage compartment :............................. 3 kg

Dimensions

- Overall length : ....................................................1760mm

- Overail width :........................................................670mm

Excluding rear view mirror :

Overall height : ...................................................... 1110mm

Excluding rear view mirror :

Wheelbase : ..........................................................1250mm

Weight

- Complete vehicle dry weight :....................................82kg

- Vehicie weight with t anks full : ...................................88kg

T ransmission

- Clutch : .................................... centrifugai, automatic type

- Primary réduction gear : ........................ by a ribbed V-beit

- Life of belt :...................................................... 1 0 000 km

- Reducer equipped with 2 gearsets.

2

Trekker - Squab

Markings 49cc

- Left hand casing (under the starter motor)

- Cylinder head (front right)

- Cylinder (exhaust flange left hand side)

- Intake pipe (on the front «49»)

Page 4

MAINTENANCE

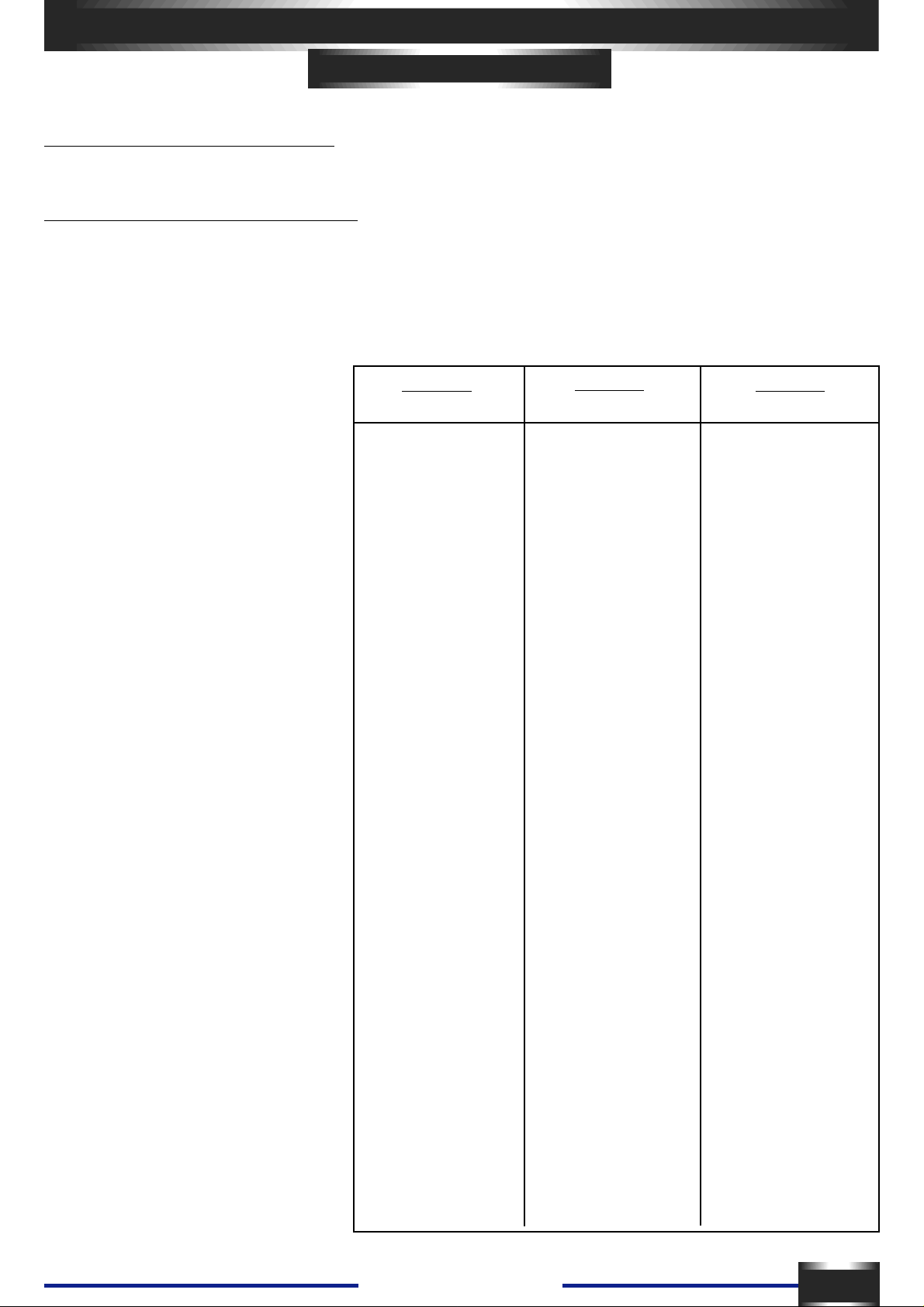

MAINTENANCE PLAN

Depending on how the scooter is used, it is recommended to apply either - The normal maintenance plan or

- The reinforced maintenance plan.

The normal maintenance plan includes:

- Visit at 500 km or 3 months Plan A

- Periodic maintenance every 5000 km Plan B

- Periodic maintenance every 10000 km Plan C

The reinforced maintenance plan includes:

- Visit at 500 km Plan A

- Periodic maintenance every 2500 km Plan B

- Periodic maintenance every 5000 km Plan C

The reinforced maintenance is intended for vehicles used in so-called “severe” conditions: door to door sales, intensive urban

use (courrier), short journeys engine cold, areas with dusty atmospheres, frequent use of vehicles at an ambient temperature

above 30°C.

500 km or 3 mois

PLAN B

5000 km or 2500 km* 10000 km or 5000 km*

PLAN CPLAN A

CHECK :

Idle speed adjustment XXX

Throttle XXX

Oil pump control XXX

Functioning of the electric equipment XXX

Front and rear brake control XXX

Fuel pipes XXX

Oil pipes XXX

Front brake fluid pipes XXX

State and pressure of tyres X

State, pressure and wear of tyres XX

Brake fluid level XXX

Level of battery electrolyte XXX

Tightening of nuts and bolts XXX

REPLACE :

Relay unit oil XX

Spark plug XX

Filter element of the intake silencer XX

Front brake pads (if necessary) X

Rear brake linings (if necessary) XX

Drive pulley rollers (if necessary) XX

Transmission belt X

CHECK AND UNCLOG

Piston X

Cylinder head X

Exhaust port X

CHECK AND LUBRICATE

Driven pulley :

movable driven face and needle bearing X

Drive pulley :

movable drive face and rollers X

Kick : driven gear and link ring X

CLEAN AND ADJUST

Carburettor X

VEHICLE TEST

Road test XXX

* reforced maintenance

Trekker - Squab

3

Page 5

INSTRUCTIONS FOR MAKING OPERATIONAL

1. Preparation of the battery

(dry charged)

- Remove the battery .

- Remove the six cell caps and the breather tube cap.

- Fill the battery with électrolyte up to the level marked

UPPER LEVEL (35% sulphuric acid 1.28 g/CM3),

Ref :........................................................... 1 litre : 752740

................................................................ 5 litres : 752741

- Leave the battery to settle for half an hour. Top up the

level if necessary .

- Charge the battery for 1 to 2 hours with a current of

400m.A (0.4A).

- Replace the battery and connect the breather tube.

- Connect up the red positive leads to the battery positive

terminal, then the green negative lead to the battery earth

terminal.

- From then on, the battery can be topped up if necessary ,

using distilled water only .

2. Fuel

Capacity : ..............................................................6 litres

- Conventional 4-star petrol.

- Lead free petrol 98 octanes.

3. Separate lubrication:

4. Putting fuel and oil circuits into

opération:

- Put one litre of fuel mixture with 4% oil into the fuel tank.

- Fill up the oil tank.

- Start the engine: make sure that the oil circuit is

completely primed. Remove the oil bleed screw from the

pump to allow air in the circuit to escape. When a

continuons stream of oil issues from this hole, replace the

bleed screw with its fiber washer.

For this : disconnect the oil intake hose to the carburettor

and check that it drips, frequency depending on the

engine’s speed.

- Top up the fuel tank with pure 4 star petrol.

5. Checking the oil level in the

transmission case:

- Unscrew and remove the oil filler hole screw A and

make sure that the oil level is flush with the level of the

filling hole. The vehicle must be positioned on its stand

and on a level surface.

Esso Oil SAE 80 W 90

REF : .................................................................... 753009

capacity 0. 1 2 litre

A = 1.2m.daN.

Capacity : ..........................................................1.3 litres.

- Fill up the oil tank with semi-synthetic engine oil for 2stroke engines with separate lubrication,

- T ype TC (API standard), type TSC3 (ASTM standard), -

- T ype FC (JASO st andard) or a synthetic oil.

PEUGEOT MOTOCYCLES recommends :

.......................................ESSO : 2T Special performance

.........................................................ESSO : 2T Synthetic

6. Checks before delivery to the

customer:

- In particular , check the tightening of the Wheel nut s ... -

front : .................................................................... 6m daN

- rear :.............................................................. 1Om daN

- Check the tightness of the nuts and bolts.

- Check brake adjustment and eff iciency.

- Cold tyre pressure:

FRONT

- pressure : ......................................................... 1.3 bar

- size :..........................................................120/90 x 10

REAR

- pressure : ......................................................... 1.6 bar

- size :..........................................................130/90 x 10

- Make sure all lights and signals operate correctly

(taillight, turnsignals, stop light, horn), and various

warning lights.

- vehicle road test.

4

Trekker - Squab

Page 6

Engine

TIGHTENING TORQUES AND SPECIAL TOOLS

TIGHTENING TORQUES SPECIAL TOOLS

Assembly screws for :

- Housings : ........................................................ 1m.daN

- Covers :............................................................ 1m.daN

- Intake connecting part : .................................... 1m.daN

- Starter motor : .................................................. 1m.daN

- Stator :.............................................................. 1m.daN

- Sensor :............................................................ 1m.daN

- Fan : ................................................................. 1m.daN

- Carburettor : .................................................. 0.8m.daN

- Oil pump :...................................................... 0.8m.daN

- Cylinder head : .............................................. 1.2m.daN

- Drive pulley :..................................................... 4m.daN

- Driven pulley :................................................ 4.5m.daN

- Rotor : .............................................................. 4m.daN

- Oil plug : ........................................................ 1.2m.daN

- Spark plug : ...................................................... 2m.daN

Frame

- Front wheel axis nut : ........................................ 6m.daN

- Rear wheel nut : ............................................. 10m.da N

- Engine joint on rod :........................................... 6m.daN

- Rod joint on chassis : ..................................... 2.2m.daN

- Rear shock absorber upper fixation :.............. 1.6m.daN

- Rear shock absorber lower fixation : .............. 1.6m.daN

- Exhaust nuts on cylinder : .............................. 1.6m.daN

- Handlebar nut :.................................................. 4m.daN

- Steering lock nut :.............................................. 7m.daN

- Service cradle mount............................................... 64765

- Adjustable adapter for engine service cradle......... 752026

- Flywheel holder ....................................................... 68570

- Snap ring pliers ..................................................... 752000

- Protective end, small model for flywheel magneto remover

.................................................................................. 68007

- Puiler tool ................................................................ 64706

- Crankshaft end protector......................................... 69098

- Shouldered centring tool.......................................... 64710

- Screw on torque handle........................................... 69104

- Compresser tool, ail types of clutch....................... 752127

- Tubular socket wrench 39 ..................................... 752361

- Adjustable pin type face wrench ............................ 752237

- Set of half sheils 0 52 .............................................. 64709

- Puiler tool .............................................................. 750807

- Support washer .....................................................750808

- Surface plate 250 x 160 x 50................................. 750541

- Comparator (adapts to pattern plate accessory..... 750969

- Torque wrench + extension + reducer .....................69802

- Flywheel puller supplied with 68007 protector ....... 750806

- Blooking tool.......................................................... 752370

- Pliers for circlips ...................................................... 69117

- Spindle .................................................................. 750069

- Steering tools ........................................................ 752948

Standard

- Screw and nut ø 5mm : ...................... 0.45 to 0.6m.daN

- Screw and nut ø 6mm : ........................ 0.8 to 1.2m.daN

- Screw and nut ø 8mm : ........................ 1.8 to 2.5m.daN

- Screw and nut ø 1Omm : ...........................3 to 4m.daN

- Screw and nut ø 12mm : ............................ 5 to 6m.daN

Trekker - Squab

5

Page 7

REMOVAL

Removal of the engine

- Remove :

- All side casings

- Disconnect :

- Fuel line from the carburettor,

- Fuel tap vacuum hose,

- Oil pump control cable

- Throttle control cable,

- Oil iniet piping at the pump (large

hose)

- Radio interference suppressor cap

- Rear brake control cable

Disconnect :

- The wiring harness on the frame’s

right tube: located at the outlet of the

Flywheel magneto (under the foot

board), choke, starter motor .

Remove :

- The lower anchor bolt of the shock

absorber and the front anchor pin of

the engine.

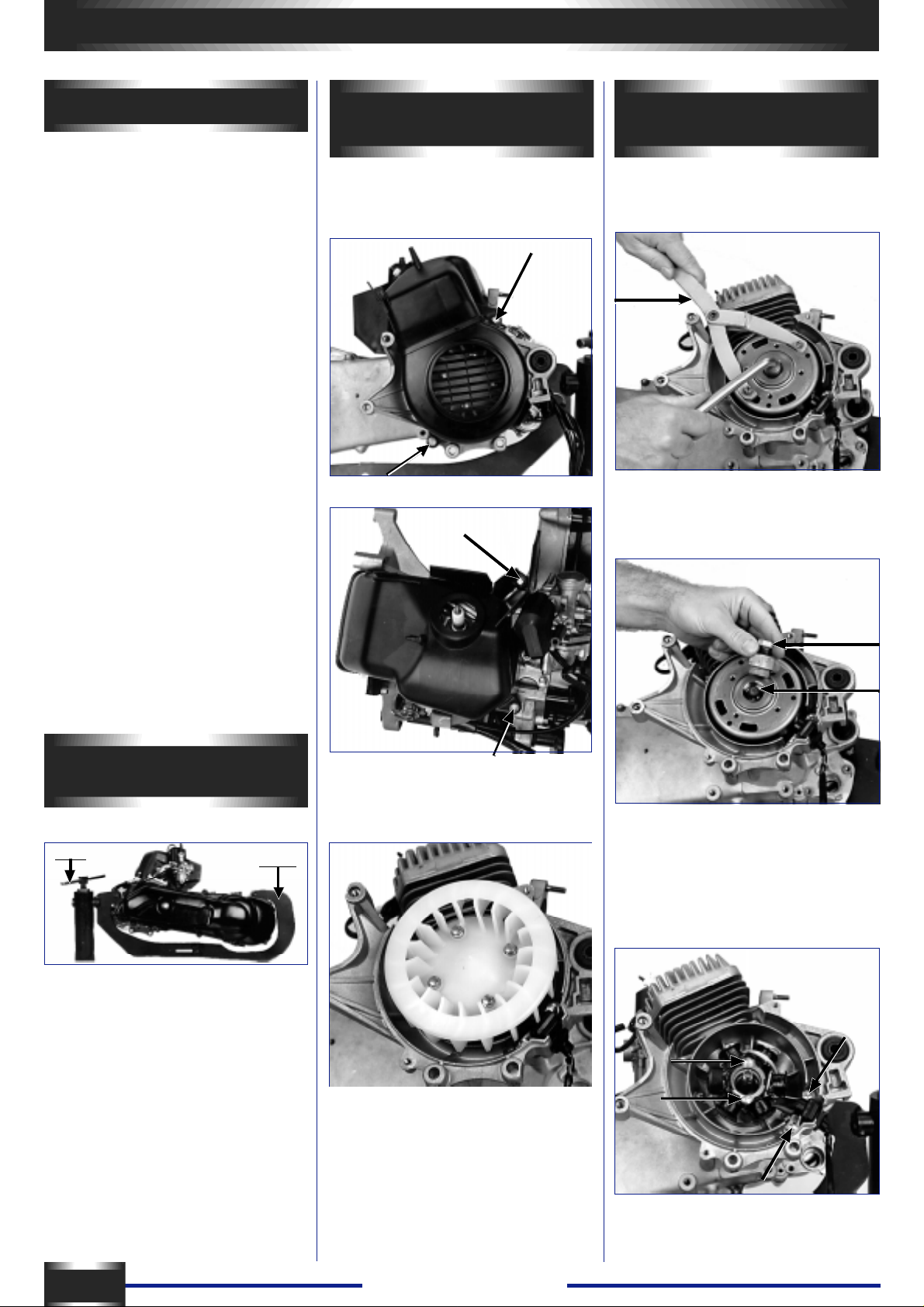

Removal of cooling

systern

- Remove the two parts of the fan

covers (4 screws).

Removal of the flywheel

magneto

- Block the rotor using a notch type pin

752237.

- Remove the nut (right-hand thread).

- Fit the crankshaft end protector

68007 onto the end of the crankshaft.

Fitting of engine on service

cradle

64765

- Place the engine onto the adapter

752026

- Place the assembly on the cradle

mount 64765 clamped in a vice

752026

- Remove the 4 fastening screws of

the fan and remove the fan.

750806

68007

- Screw the flywheel puller tool 750806

onto the rotor and tighten the centre

bolt until the rotor comes away .

- Remove the 2 fastening screws of

the sensor, as well as the 2 fastening

screws of the stator plate.

6

- Remove the coil assembly and the

sensor.

Trekker - Squab

Page 8

REMOVAL

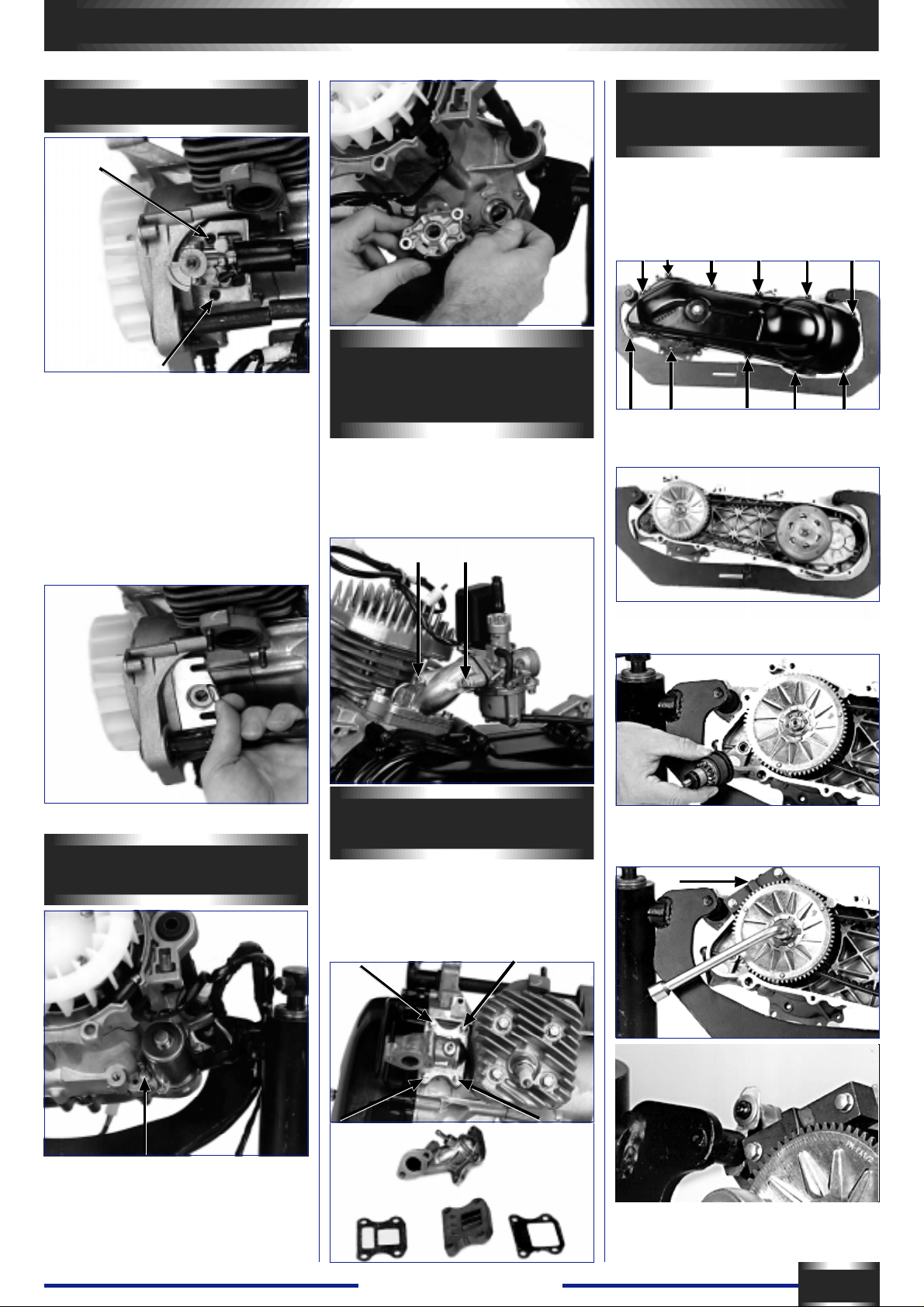

Removal of the oil pump

- Unclip the oil inlet pipe to the

carburettor.

- Unscrew the 2 hex head socket

screws.

- Remove the oil pump and the control

flange.

- Remove the 2 square fastening nuts

Q from their housings.

- Remove the flexible washer lodged

between the pump and the shaft

bearing of the oil pump.

Removal of the

carburettor / choke

assembly

- Take off the 2 fastening screws from

the carburettor and remover the

carburettor / choke

assembly , as well as the isothermal

spacer .

Removal of the primary

drive system

You do not have to remove of the kick

starter arm when removing the

crankcase cover.

- Loosen and remove the 1 1 fastening

screws of the cover.

- Remove the cover with both locating

dowls.

- Adjustment: see page N° 14

Rernoval of the starter

motor

Removal of the reed

valve and intake pipe

- Unscrew and remove the 4 fastening

screws.

- Remove the intake pipe, the gasket,

the reed valve assembly and the

second gasket.

- Remove the starter drive assembly

from the starter motor.

- Hold the starter ring gear with the

tool 752370.

752370

- Free the wire harness from the

support bracket.

- Remove the 2 fastening screws and

washers from the starter motor and

pull out together with «0» ring seal.

Trekker - Squab

7

Page 9

REMOVAL

Make careful note of where this tool

comes level with the starter ring gear

plate of the starter motor in order to

make sure, when refitting, that the

pressure plate fits correcte into the

grooves of the crankshaft.

- Loosen the fastening nut (right-hand

thread) of the gear plate of the drive

pulley .

- Remove the nut, washer and plate.

- Remove the belt.

- Remove the drive pulley assembly

(variable speed drive) and the washer

on the engine housing side (12,35 X

19,75 X 1).

Rdl 12,35x19,75x1

Removal of the kick

starter system

- Actuate the kick starter spindle with

your thumb and remove the drive

ratchet and its washer .

- Remove the kickstarter lever . Using

snipe-nosed pliers (ref. 691 17), t ake

off the circlips, the washer, then

remove the kick starter toothed

section, the pull-back spring and the

bushing.

- Removal of the drive shaft (or input

shaft) from the transmission cover is

done using a mallet.

- Remove the thrust washer from the

counter shaft (14.3x26xO.5).

- Drain the transmission case

completely before removing the final

shaft (or output shaft) in order to avoid

contamining brake linings.

- Pull out the final shaft (output shaft).

- Block the clutch drum with the flywheel pinch bolt no.68570 or the adjustable pin type face wrench 752237.

752237

- Loosen the screw, remove the drum

and the clutch driven pulley assembly .

- Pull out the countershaft as well as

its friction washers (1 4.3 x 26 x 0.5)

and flexible washer (1 4 x 22 x 1.5).

Dismantling the

transmission case

After draining the transmission case:

- Remove the 5 screws securing the

cover.

Removing the cylinder

head

- Unscrew in a crosswise order the 4

screws securing the cylinder head and

cylinder block assembly .

- Remove the cylinder head and

gasket.

- Remove the cover with the drive

shaft (or input shaft), the gasket and

both locating dowls.

8

Trekker - Squab

Page 10

REMOVAL

Removing the cylinder

and piston

- Remove the cylinder and cylinder-tocrankcase gasket.

- Pack the crankcase mouth with

clean cloth or paper .

- Lean the engine to the left and take

out the wrist pin’s RH snap ring.

- Push the wrist pin from the left to the

right; this opération does not require

use of a strap.

- Take out the needie bearing race.

- Turn the inner thrust bolt of tool

750807 until the crankcase halves

split Hold the connecting rod so that it

does not knock against the crankcase

halves.

- Remove the RH half casing.

- Remove the gasket and both

locating dowls. Remove the drive

shaft of the oil pump and its locating

bush.

- Secure the plate to the crankcage by

tightening the 4 screws.

- Withdraw the crankshaft by turning

the inner thrust bolt of tool 64706.

Changing the bearings

and seals

- Heat the crankcase halves evenly to

90° so that they expand. The bearings

will drop out, drive out the seals.

- Fit the new bearings while the

crankcase halves are still warm.

- Fit the oil seals in place.

- The oil seal on the drive pulley side

should fit flush with the crankcase, the

lips being on the fl.ywheel housing

side. The seal on the flywheel side

should be approximately 9mm in.

Opening the crankcase

- Remove the 6 screws securing the

RH crankcase half.

- Fit the crankshaft end protector

68007 onto the end of the crankshaft.

- Position the puller tool 750807 onto

the crankcase half.

750807

Removing the crankshaft

assembly

- Fit the crankshaft end protector

69098 onto the end of the crankshaft.

64706

752168

69098

-Fit puller tool 647706 with the plate

752168 onto the crankcase.

Note:

If the crankshaft bearings remain on

the crankshaft; use the puller tool

64706 with the half shells 64709 (diam

= 52) to remove them. Do not forget

to fit the crankshaft end protector

69098 onto the ends of the crankshaft.

Checking the crankshaft

assembly

- The maximum side play of the

conrod big end should not exceed:

0.5mm.

- Check crankshaft alignement as

shown in the drawing (surface plate

750541, comparator 750969

The values measured at the ends

should not exceed 0.12mm.

Trekker - Squab

9

Page 11

REFITTING

Refitting the engine

Assembly of the crankshaft into the

left hand crankcase:

- Fit the crankshaft into the bearing.

- Screw the ex tended nut 750069

onto the end of the crankshaft.

64706

752168

750069

- Fit tool 64706 with the plate 752168

onto the extended nut and centre the

assembly onto the crankcase using 4

screws.

- Position the centring tool 64710.

69104

64710

Closing the crankcase halves

- Position both locating dowls in the

LH crankcase:

- Put the crankcase gasket in place

(no oil, no grease).

- Position the RH crankcase and fit it

on being careful not to damage the oil

seal where it meets the cotter key.

-Screw the extended nut 750069 onto

the end of the crankshaft.

- Position the washer 750808 (50 x 29

x 3mm).

-Position the tool 64706.

750808

Refitting the piston

- Check the cylinder and piston parts

are a matched pair.

- Fit the needie bearing race into the

conrod small end after having oiled it

(2-stroke engine oil).

- Screw the torque handie 69104 onto

the extended nut 750069 while

keeping the crankshaft assembly

steady . Continue turning the torque

handle until the crankshaft comes into

contact with the bearing.

Waming :

cabre in the crankcase.

do not jam the conrod

- Position the centring tool 64710.

- Turn the torque handle 69104 until

the crankcases close completely .

- Hold the crankshaft assembly steady

on the left hand side with the starter

ring gear.

- Grease the oil pump shaft and

position the shaft / seat assembly in

the crankcase.

- Make sure that the crankshaft

assembly can rotate normally and

drives the oil pump shaft correctly.

- Position the 6 fastening screws (3 =

L 45mm, 3 = L 70mm) and tighten

them to 1 m.dan.

Make sure the crankcase gasket is

level.

- Position the piston with the arrow

pointing towards the exhaust port.

-Push in the wrist pin.

-Fit the snap rings. It is essentiel that

they are new.

The opening of the snap ring will be

positioned at the top or at the bottom,

but under no

circumstances to the side.

In order to hold the crankshaft

assembly easily , use the rotor

positioned in its right hand side

woodruff key .

Make sure the crankshaft assembly is

correctly positioned in relation to the

crankcase mouth (the middle of the

conrod must correspond with the level

of the crankcase mouth).

10

Lubricate the crankshaft assembly

and bearings with 2-stroke engine oil.

Trekker - Squab

Page 12

REFITTING

Refitting the cylinder

- The parting face should be cleaned.

- Lubricate the piston and the cylinder

bore.

- Fit a new and dry cylinder base

gasket onto the cylinder.

- Make sure that the piston ring end

gaps are aligned with the positioning

slots.

- Position the cylinder and push it

down while squeezing the piston rings

bet-ween your thumb and middle

finger.

- Make sure the cylinder base gasket

is correctly positioned on the

crankcase using 2 threaded bolts.

Refitting the transmission

case

- Replace the oil seals and bearings if

necessary by the appropriate “ heating

and drift >, method.

- Check that the outlet channels are

clear :

Removal of the case.

Important

Smear the countershaft ends with

graphite grease in order to ensure

improved lubrication when putting the

vehicie into service.

- Position the countershaft.

- Position the final shaft (or output

shaft) while being careful not to

damage the oil seal.

If this seal is damaged, oit wîil flow to

the outside through the outiet siot

located in the retum

spring housing of the brake key; Photo

opposite.

Refitting the cylinder head

- Check thàt the gasket seat surface

of the cylinder head is not damaged.

-Position the 4 fastening screws onto

the cylinder head with washers.

- Position the cylinder head gasket

onto the cylinder head, the raised face

upwards.

- Push the cylinder head / screw /

gasket assembly onto the cylinder.

- Tighten the 4 screws progressively

and in a crosswise order (L = 95mm)

1.2 m.dan.

- Fit a thrust washer 14.3 x 26 x 0.5

onto the countershaft;

Outlet between the oil seal and the

rear wheel bearing.

- Fit on the countershaft:

· the flexible washer 14 x 22 x 1.5

· the thrust washer 14.3 x 26 x 0.5.

- Position 2 locating dowls and the

gasket.

- Position the primary shaft (or input

shaft) into its bearing using a mallet if

necessary .

- Position the cover and secure it

using 5 screws (L = 40) 1 m.dan.

-Fit the spark plug 2m.daN.

côté couvercle

ARBRE INTERMÉDIAIRE

rondelle souple

Trekker - Squab

rondelle métal

Make sure that the shafts can rotate.

Note

- Fill the case with 0.12 litre of SAE

80W 90 oil.

- Peugeot Motocycles recommends

ESSO GEAR OIL GX........ ref. 753009

- Oil filler screw 1.2m.daN.

11

Page 13

REFITTING / FITTING

Instailing the kick starter (LH

cover)

- Fit the spindle bushing and the nylon

spacer (mark 1).

1

- Position the return spring, fit the

longest hook onto the pin on the cover.

- Instail the spindle into the bushing

after lubrication.

- Fit the second hook of the spring

onto the toothed section.

- Wind the spring slightly so as to

position the kick starter spindle onto

the central rib of the cover.

- Install the washer and circlips onto

the axis of the toothed section.

- Position the drive ratchet:

place the washer over the boss of the

ratchet shaft housing

load the kick starter by about 1/8 of a

turn in order to position the ratchet

(after lubricating the

shaft),

position the ratchet stop in its housing.

(Mark 2).

2

PRIMARY

TRANSMISSION

A. Clutch and driven puiley

assembly :

1. Dismantling:

752361

- Hold the assembly using tool 752127

in a vice and loosen the special nut

with the wrench 752361 (39) or a 34

mm wrench depending on the clutch.

- Remove in the followin’g order :

. the clutch shoe assembly

. the spring

. the spring guiding sleeve

. take out the three guide pins of the

variable speed drive,

. separate the movable driven face

from the fixed driven face.

2. Refitting

- Check the oil seals of the movable

driven face.

- Assemble the fixed and movable

driven faces.

- Refit the 3 guide pins and lubricate

the ramp of the variable speed drive.

- Position the sleeve having checked

that both «0» rings are in good

condition.

- Position the spring and the clutch

assembly .

- Using the tool 752127, compress the

spring and check that the nut is

tightened to 5m.daN.

B. Drive pulley - variator

assembly :

1. Dismantling

- Remove the thrust spacer L = 38mm

and the 3 bolts that secure the

housing and the stop (no 7 wrench).

- Remove the housing using a

screwdriver.

- Remove the stop, the ramp plate, the

3 plastic spacers and the 6 rollers, the

«0»ring (81/1.5).

2. Inspection

- After cleaning, check the rollers in

particular. Their diameter should not

show any flat spots.

3. Refitting

- Reverse opérations to dismantling

having lubricated the 6 rollers, the

ramp, and the movable

clutch plate bore with high

température grease 752093.

NOTE :

On the first generation FB engines

(Zenith, Buxy , S peedake), the rollers

of the drive pulley were assembled

without grease.

C. Refit the primary

transmission.

Fitting a variator

Warning: do not delete any piling up

element or reduce the dimensions.

This would lead to a tightening of the

nut on the grooves of the crankshaft

assembly and not on the fixes driven

face and hence would destroy the

crankshaft assembly .

- Place the washer 12.35 x 19.75 X 1

on the crankshaft assembly.

- Position the variable speed drive

while keeping the movable driven

face, the 6 rollers and the variation

ramp with the thrust spacer under

pressure.

- Fit the drive belt.

- Position the start ring gear plate

while checking that it is properly fitted

on the grooves of the crankshaft assembly , position the nut and tighten by

hand.

- Check that the ring is flush with the

tool 752370.

- Tighten the nut to 4m.da.N.

752127

12

Trekker - Squab

Page 14

FITTI NG

Fitting of the «clutch drive

pulley» assembly and the belt

- Introduce the belt to the bottom of

the groove of the driven puiley by

pulling apart the drive faces using both

hands.

- Position the belt on the drive pulley .

- Fit the «clutch / drive pulley»

assembly onto the primary shaft of the

transmission.

- Position the clutch casing and tighten

the nut to 4.5m.daN while holding it in

place with the

adjustable pin type face wrench

752237 (or the flywheel holder).

Fitting the reed valve and

intake pipe

- Check:

the condition of the petals and the

seats.

- lnstall in the following order on the

crankcase:

a gasket

a reed valve

a gasket

- Fasten all the parts using 4 screws

(L = 28mm), and tighten to 1 m.dan.

see

foolproof

device

- Fit the carburettor and tighten to 0.8

m.dan

Screw 1: air screw

Initial adjustment: screw until it seats

without forcing, then loosen by 1 1/2 to

13/4 of a turn.

Screw 2: throttle stop screw (idle

speed: 1800 rpm ± 100 rpm).

Needle : clips at the top.

2

1

1

Fitting the starter motor

NOTE

- The rollers must be checked every

50OOkm.

- The belt must be changed every

100OOkm.

Fitting the transmission

case

- Position the washer 8.5 x 16 x 0.8,

the kick starter gear assembly.

Grease its bearings.

- Position both dowel pins and the

transmission case using 1 1 screws.

Tighten to 1 m.dan.

Fitting the carburettor

- Position both carburettor holding

screws (L = 28 and 50mm) onto the

intake pipe.

- Position the isothermic spacer with

the seai on the intake pipe side. This

spacer is aimed at avoiding heat from

the engine being transferred to the

carburettor. A foolproof system on the

edge of the spacer guarantees that it

is positioned correctly (arrow pointing

towards the front).

Good

- Install the starter motor with its «0»

ring.

- The lower screw also ensures

earthing of the battery to the engine

(green wire).

- The upper screw also ensures

fixation of the cable harness clamp.

- Tighten to 1 m.dan.

No good

Trekker - Squab

13

Page 15

FITTING

Fitting of the oil pump

- Position both square nuts (Q) in their

housings.

- Place the flexible washer on the seat.

- Position the pump fitted with its

«0»ring, position the sheath stop

fastening hook and fasten the cluster

with two n».4 hex head socket screws.

- tighten to 0.8m.daN.

Adjustment of the oil purnp

1) Check the free play in the throttle

grip (2 to 5mm) and adjust if

necessary using the adjusting screw.

2) Open the throttle fully .

-Check that the alignment mark on the

pump control lever is opposite the

mark on the pump body.

Bleed screw

Mark

- Disconnect the oil input hose on the

pump and check the oil flow. Check

also :

. that there is oil in the tank,

. that the hose is not trapped,

. that the oil filter is not blocked,

. that the tank filler hole is not

blocked (atmospheric pressure hole).

- Reconnect the hose onto the pump

body .

- Open the pump bleeding screw until

ail the air bubbles have escaped and

then close again.

- Turn the engine on.

Disconnect the oil input hose on the

carburettor. Check that the oil drips

out. Dripping frequency depends on

the engine’s speed

- Reconnect the hose onto the

carburettor. OIL PUMP FLOW: 24

cm3 ± 1.7cm3 hour at 3800 rpm.

Wide open throttle.

Fitting the flywheel

- Position the stator / sensor assembly

on the crankcase.

- Fasten with 4 screws (2 screws L =

16, 2 screws L = 20). T ighten to 1

m.dan.

- Position the rotor.

- Keep the rotor in place using the adjustable pin type face wrench 752237.

- Tighten the nut at 4m.daN.

Fitting the cooling systern

- Position and fasten the fan onto the

rotor (4 screws L = 1 8). Tighten to 1

m.dan.

- Position and fasten the cylinder case

and cooling cover (4 screws M = 25).

Make sure that it is fastened correctly

around the sensor.

- Tighten to a torque of 1 m.dan.

- Adjust if necessary by turning the

pump cable abjusting nuts.

Checking the lubrication

circuit

- Supply the carburettor from a

separate tank containing 2-stroke fuel

mixture.

DISK BRAKE

Filling the circuit :

At the receiver (brake calliper),

remove the cap of the bleed screw.

Connect a flexible hose to this screw,

the other end put into an empty

container (fuel hose for example).

Loosen this bleed screw.

Remove the cover and seal, with the

tank positioned horizontally, f rom the

emitter (master cylinder). Fill the tank

with brake fluid. Activate the brake

handle gently until the liquid comes

through to the bleeding container .

Tighten the bleed screw.

Fill the emitter tank to the top.

- Make sure that the woodruff key is

indeed on the crankshaft.

PARTIE CYCLE

CYCLE PART

Activate the brake lever several times

with the cover refitted.

Loosen the bleed screw again. Air

bubbles should escape through the

flexible hose.

When there are no more air bubbles,

tighten the bleed screw with the brake

lever constantly on.

Repeat the operation until no bubbles

appear in the liquid.

Note: At the end of the opération, top

up the level.

- It is sometimes necessary to tap the

elements of the brake system lightly in

order for the air to escape.

- Certain callipers need to be

dismounted in order to place the bleed

screw in the high position.

Warning :

- The brake fluid attracts humidity.

ln certain conditions humidity may

impair braking efficiency. Y ou must

always use brake fluid from a recently

opened container (tightness cap). The

liquid recovered in the bleed container

must not be reused. Do not open the

container when there is a high degree

of hi-imidity in the atmosphère (rain,

fog .... ).

- Brake fluid is corrosive. Avoid

spillage on painted parts.

- Do not spill fluid onto the pads or the

disks.

- Use brake fluid which complies with

the DOT 3 or DOT 4 standards.

(Lockeed D55 for exam

14

Trekker - Squab

Page 16

c

a

a

a

1

10

8

7

6,7Ω 5w

9

5,9Ω 30w

11

26

B

1,2w

5/21w

12V 4Ah

A

0,75Ω 4w

13

3 x 1,2w

15w

15

14

27

IGNITION

Operating principle :

The ignition coil charges a condenser

in the CDI unit. Passage of the rotor

pad in front of the sensor authorises

the discharging of the condenser in

the primary winding of the high voltage

coil via a thyristor, in order to generate

through transformation in the

secondary , a voltage in the region of

20 000 volts at the spark plug.

ELECTRIC EQUIPMENT

a

b

1

2

3

1

on

4

3

5

off

6

15

12V 4Ah

Troubleshooting :

- Check the connections, especially

the earth connection of the starter

motor.

- Check by successively replacing with

new components: the spark plug,

radio interference suppressor, high

voltage coil, CDI unit.

- Check the key switch.

Example of a breakdown: the engine

only runs with the rear brake applied.

Cause: earth wire of the starter

motor is damaged.

The CDI unit, ref. 709205 is used on

all 50cc powered two-wheelers as well

as on the SV 80cc.

Warning :

A second CDI unit, ref. 705272

(marked CI 08) is reserved for SV 125

SC-SX models.

AL TERNA TING CURRENT

POWERED CIRCUITS

4

5kΩ

5

26

6

5kΩ

1 - Flywheel

a - ignition

b - sensor

2 - Ignition switch

3 - (CDI) ignition unit

4 - High voltage coil

5 - Interference suppresser 5 KW

6 - Spark plug resistance 5 KW

15 - Battery

26 - Starter motor

LIGHTING AND STARTER

MOTOR

Operating principle:

Three coils connected in series in the

flywheel magneto generate an

alternating current stabilised by the

regulator to give a maximum voltage

of 12V ± 0.5V .

LIGHTING

When in the < lights off > position

(Day*), current is directed from the

switch towards a résistance of 5.9 Ù

30W where it is consumed (pink wire).

When in the “ lights on ” position

(night), current is supplied to the bulbs

(brown wire); headlight, taillight, instrument panel light, headlight telltale.

1 - Flywheel

c - alternative current

7 - Regulator

a - AC regulator

8 - Choke

9 - Resistance 6,7 W 5W

10 - Lighting control

11 - Resistance 5,9 W 30w

13 - Headlamp

A - Instrument panel lighting

B - Headlamp telltale

14 - Rear and stop light

15 - Battery

26 - Starter motor

27 - Current limiter

Trekker - Squab

15

Page 17

ELECTRIC EQUIPMENT

Note :

The rear bulb is composed of 2

filaments, one 5W filament supplied

with alternating current for the taillight,

one 21 W filament supplied with direct

current for the stop light.

1/ Solving lighting faults

- Check the bulbs; power, volt age,

compliance with European standards

(El).

- Check the connections (especially

those of the regulator).

- Check the voltage

using a multimeter (MX40) set to the

AC voltmeter position.

check at the terminale of a bulb

(brown wire), that voltage does not

exceed 12 volts ± 0.5V when

accelerating the engine. If the voltage

is over 13V, check the regulator

connection (especially the green earth

wire). If necessary , change the

regulator (it is not possible to check

the regulator when static).

2/ Checking

Check the continuité capacities of the

three coils of the flywheel. Engine

stopped.

Lighting and starter: yellow wire and

earth wire = 0.4 ohm.

CHOKE

1. Operating principle

Cold starting: the choke is

automatically in opération: the

carburettor’s mixture enrichment

circuit is open.

As soon as the vehicle is switched on,

the heat résistance which is supplied

by the flywheel magneto causes the

continuons wax to expand in its

capsule. The diaphragm pushes the

master and intermediate pistons which

cause the air duct to the throttle valve

to close gradually and to progressively

block fuel flow with the needle. When

the engine is warm, with the ducts

blocked, the enriching circuit is not

operational.

2. Checking

- Average résistance value of the

choke alone - 5 ohms.

Note :

The résistance value varies depending

on résistance température: the colder

the température, the lower the

résistance value and vice versa.

1

2

14

13

1 - Yellow wire

2 - Green-black wire

3 - Heating resistance (PTC)

4- Wax

5 - Membrane

6 - Intermediate fluid

7 - Push piston

8 - Return piston

9 - Return spring

10 - Air throttle valve

11 - Needle

12 - Needle well

13 - Needle spring

14 - “O” ring seal

3

4

5

6

7

8

9

10

11

12

1 - Flywheel

a - ignition

b - sensor

c - alternative current

d - battery charge current

Value flywheel control

0,7 Ω

d

c

1

0,4 Ω

750 Ω

a

b

110 Ω

16

Trekker - Squab

Page 18

1 - Flywheel

c : alternative current

d : battery charge current

2 - Ignition switch

7 - Regulator, rectifier

b : regulator, rectifier (DC)

14 - Rear and stop light

15 - Battery

16 - 5A Fuse

17 - Horn

18 - Horn button

19 - Indicator control

21 - Indicator bulbs

D - Indicator telltale

22 - Fuel gauge

E - Fuel gauge receiver

23 - Stop contact switch

24 - Starter motor relay

25 - Starter motor control

26 - Starter motor

27 - Current limiter

28 - Low oil level contact switch

C - Low oil level telltale

ELECTRIC EQUIPMENT

DIRECT CURRENT POWERED CIRCUITS

CHARGING BATTERY - STARTER MOTOR - FUEL GAUGE -

OIL GAUGE - TURNSIGNAL LIGHTS - HORN

Operating principle:

In the flywheel, the three coils used for the alternating current circuits are

associated with two other coils to produce a regulated current increased to

14.5V ± 0.5V maximum by the current increasing regulator. (This time, it s is the

second stage of the regulator which is used),

27

14

5/21w

5A

16

23

22

10Ω

100Ω

18

17

7

2

3

1

4

5

off

on

6

19

28

D

1,2w

20

E

C

1,2w

21

4x 10w

b

d

1

c

0,75Ω 4w

15

12V 4Ah

24

25

26

BA TTERY CHARGING

This circuit consists of the following

elements connected in series: flywheel

magneto - regulator - fuse

- battery .

The voltage depends on the engine’s

speed.

While this voltage is lower than battery

voltage, it is the battery which supplies

the various circuits. As soon as this

voltage is higher than battery voltage,

it is the flywheel which supplies the

various circuits and recharges the

battery .

Putting the battery into service: see

maintenance page N° 3.

Checking the charge

Use a multimeter (MX40) set to the

DC voltmeter position (=) connected

to the terminale of the battery . Check

that the voltage varies depending on

the speed of rotation of the engine up

to a maximum of 14.5V ± 0.5V.

If the voltage at the battery terminale

exceeds 15V, the regulator is not

connected to earth or is faulty . If

there is no variation in voltage at the

battery terminale, check the fuse,

Trekker - Squab

connections, especiahy those of the

flywheel or regulator harnesses (loose

connections inversion of wires in the

connecter for example).

Checking a discharge

Engine off.

Disconnect the red wire from the

battery .

Use a multimeter (MX40) set in the

Ampmeter (1OA) position, connect the

black wire (COM) to the + terminal of

the battery and the red wire (1OA) to

the disconnected red wire of the

battery .

17

Page 19

ELECTRIC EQUIPMENT

1. Key switch to OFF

No display should appear on the

multimeter. If a value is displayed (for

example 0.5mA), either the regulator

(connection wires) or the key switch is

faulty .

2. Key switch to ON

A slight discharge can be explained by

sending a volt supply to the fuel gauge

and to the oil low level

warning light (0.9mA to 1OOmA

maximum).

A significant dischar@e indicates a

more or less earthed circuit.

Disconnect the various circuits until

the discharge disappears and locate

either the defective unit or wire

(starter , motor, stop light, fuel gauge,

oil, indicator, horn, key switch or

instrument panel circuits).

Checking the capacities of the

flywheel magneto.

Battery charge (current = )

White wire = 0.7 ohm and earth.

check way N°1 on the 9-way main

connector.

OIL GAUGE

Operating principle

Supplied with a continuons current.

The float acts like a switch; when it is

in a low position, it closes the circuit

which causes the warning light on the

instrument panel to come on.

Checking :

If the bulb on the instrument panel

remains permanently on, check the

float.

If the bulb remains permanently on,

check the 4-way connector on the

instrument panel (terminal 4,

the blue / white wire must not receive

a 12 volt supply while the float is in

high position).

HORN

Operating principle

Supplied with a continuons current, a

horn and a switch are fitted in series.

Check :

- If the horn does not work, check the

circuit (fuse, key switch, left-hand grip

handie switch), in order to get 12 volts

at the horn terminals.

- Check that the horn is planned for

use with continuons current (presence

of an adjustment screw, here hidden

by a plug). Horn test

FUEL GAUGE

Operating principle

Resistance from the fuel meter to the

tank varies depending on the level of

fuel from 10 to 100 ohms. On the instrument panel, the needle will vary according to this resistance from min. to

max. When the needle reaches the

reserve supply level, this indicates a

remaining riding range of about 25km.

Checks :

ignition to ON

If the fuel meter is permanently at

maximum level:

- Disconnect the gauge if the minimum

level appears, check the gauge.

- If the maximum level is still shown,

disconnect the 5-way connector on the

instrument panel. Check, using a multimeter (MX40), set in the ohm position, that the yellow / white wire is not

earthed. If this wire is earthed, check

the harness. If this wire is not earthed, change the instrument panel.

If the gauge indicator is permanently

at minimum level:

- Check that the tank gauge is

connected properly

- Check the capacities of this gauge (5

to 100 Ù)

- Check the 5-way connector on the

instrument panel: black wire to way

no.1, yellow/white wire to way N° 4.

- Check that the black wire receives a

12 volt continuons supply .

- Check that the yellow/white wire is

continuons up to the gauge. If not,

INDICA TORS

Operating principle

A direct current supplies the blinker

control unit located under the front

cover. This current is sent to the lefthand grip handle to be distributed by

the switch to the left-hand or righthand bulbs of the turnsignal lights.

The telltale on the instrument panel is

common to both sides. Its earth

return line is via the bulbs on the side

not used.

Checks :

If the central unit starts functioning

erratically , either an indicator bulb is

not working or the main connecter (9way) is not properly connected.

If the central unit makes a crackling

sound, either there is a short circuit

between an orange or blue wire and

earth or the battery is discharged.

If the central unit does not work,

before changing it, check:

- Battery voltage (it must be over 10

volts).

the 4 bulbs of the indicators and the

telltale bulb.

- that the central unit is supplied with

12 volts (if not, check the fuse, the key

switch, the connections, the black

wire).

3

2

1

off

4

on

6

2 - Ignition switch

15 - Battery

16 - 5A Fuse

19 - Turn signal relay

20 - Indicator control

21 - Indicator bulbs

D - Indicator telltale

5

5A

16

D

1,2w

21

4x 10w

15

12V 4Ah

19

20

18

Trekker - Squab

Page 20

ST ARTER MOT OR CIRCUITS

Operating principle :

The starter motor requires two circuits.

1. Control circuît :

This consists of the following elements

connected in series:

Battery , fuse, key switch, stop

switches, starter motor relay , st art

switch (ST ART).

With the ignition key in the ON

position, one or both stop switches

closed, the start switch closed, the

current supplied by the battery runs

through the coils of the relay and

closes by magnetic force, the power

circuit contact.

2. Power circuit :

This consists of the battery and starter

motor.

Activated by the relay , this circuit

consists of big wires aimed at

supporting high intensity . This circuit

is not protected by the 1OA fuse.

ELECTRIC EQUIPMENT

14

5/21w

5A

2

3

1

off

4

5

on

6

16

23

24

27

0,75Ω 4w

15

12V 4Ah

Troubleshooting :

Checks in the event of non starting.

Battery in good condition.

If the relay «clicks», check the battery

connections, the starter motor

connector, earthing of the starter

motor, the starter motor itself.

If the relay does not «click», look at

the taillight:

. if the taillight comes on, check the

relay

. if the taillight does not come on,

check: the battery , fuse, key switch,

stop lights, connectons.

Relay is good and working order

Relay at of order

Checking the starter motor :

Connect the starter motor directly to

the terminale of a 12 volt battery .

Checking the relay :

Connect a battery to the terminale of

the control circuit (small yellow / green

and purple wires). If the relay is

working correctly , it will «click» and will

make contact with the two other

terminals.

25

26

2 - Ignition switch

14 - Rear and stop light

15 - Battery

16 - 5A Fuse

23 - Stop contact switch

24 - Starter motor relay

25 - Starter motor control

26 - Starter motor

27 - Current limiter

Trekker - Squab

19

Page 21

Squab 50 without dipped headlights

13

15w

0,75Ω 4w

15

12V 4Ah

26

27

B

1,2w

14

5/21w

5A

16

24

23

25

22

10Ω

100Ω

E

A

3 x 1,2w

19

9

11

20

D

1,2w

21

4x 10w

6,7Ω 5w

5,9Ω 30w

5

2

off

3

1

7

b

a

a

6

on

4

3

b

28

18

C

17

1,2w

4

8

10

d

1

5kΩ

5

5kΩ

6

20

c

Trekker - Squab

Page 22

21

Trekker 50 all types and Squab 50 with main beam +

dipped headlights

33

5w

26

25

10Ω

22

A

B

3 x 1,2w

1,2w

H

0,75Ω 4w

27

14

5/21w

5A

15

12V 4Ah

16

24

23

E

L

13

35/35w

9

6,7Ω 5w

5,9Ω 30w

12

11

19

20

D

1,2w

5

2

off

3

1

6

on

4

28

18

C

17

1,2w

7

3

b

a

b

a

4

Trekker - Squab

21

Page 23

KEY TO ELECTRIC CIRCUITS

A Instrument panel lighting

B Headlamp telltale

C Low oil level telltale

D Indicator telltale

E Fuel gauge receiver

1 Flywheel

a ignition

b sensor

c alternative current

d battery charge current

2 Ignition switch

3 CDI ignition unit

4 High voltage coil

5 Interference suppresser 5 KW

6 Spark plug 5 KW

7 Regulator, rectifier

a regulator (AC)

b regulator, rectifier (DC)

8 Choke

9 Resistance 6,7 W - 5 W

10 Lighting control

11 Resistance 5,9 W - 30 W

12 Headlamp control

13 Headlamp bulb

14 Rear and stop light bulb

15 Battery

16 Fuse

17 Horn

18 Horn button

19 Turn signal relay

20 Indicator control

21 Indicator bulbs

22 Fuel gauge

23 Stop light contact switches

24 Starter motor relay

25 Starter motor control

26 Starter motor

27 Current limiter

28 Low oil level contact switch

33 Number* plate lighting

22

* According to the model

22

Trekker - Squab

Page 24

Note

2

Trekker - Squab

23

Page 25

INTRODUCTION

This workshop manual concerns the FB engine which is fitted on several 50cm3

vehicles on the air-cooled version:

- FB0 ............................................ ZENITH

- FB1 ............................................ BUXY - SPEEDAKE

- FB2 ............................................ SQUAB - TREKKER

- FB4 ............................................ SPEEDFIGHT - TREKKER ROAD

The electric part of this manual only concerns the TREKKER and SQUAB vehicle

ranges.

PEUGEOT MOTOCYCLES RECOMMENDS

2 STROKE OIL

- ESSO 2T SPECIAL .................1 LITRE........ Ref. : 753752

- ESSO 2T SYNTHETIC ............1 LITRE........ Ref. : 753759

TRANSMISSION CASE OIL

- GEAR OIL GX-SAE 8OW-90...2 LITRES ..... Ref. : 753009

HIGH TEMPERATURE GREASE

GREASE

- SKF LGHT 3/0.4 ............................................ Ref. : 752093

- MULTI-PURPOSE .......................................... Grease 4746

TIME SAVINGS = MONEY SAVINGS

Trekker - Squab

Page 26

recommends

Dans un souci constant d'amélioration Peugeot Motocycles se réserve le droit de modifier, supprimer ou ajouter toute référence citée

DC/PS/SH Imp. en U.E 10/07/98

N° 1 1.753784.00

Loading...

Loading...