Page 1

Perkins 4000 Series

4006-23 TAG1A, TAG2A and TAG3A Inline diesel engine

WORKSHOP MANUAL

6 cylinder turbo charged diesel eng ine for electric pow er

applications

Publication TPD 1511E, Issue 1.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in September 2004 by Technical Publications.

Perkins Engine Company Limited, Peterborough PE1 5NA England

i

Page 2

This publication is written in

Perkins A pp rove d C lea r En glish

Chapters

1 General information

2 Specifications

3 Cylinder head assembly

4 Piston and connecting rod assemblies

5 Crankshaft assembly

6 Timing case and drive assembly

7 Cylinder block assembly

8 Engine timing

9 Aspiration system

10 Lubrication system

11 Fuel system

12 Cooling system

13 Flywheel and housing

14 Electrical equipment

15 Auxiliary equipment

16 Special tools

The following pages contain a detailed table of contents

ii

Page 3

4000 Series

Contents

1 General information

Introduction .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1

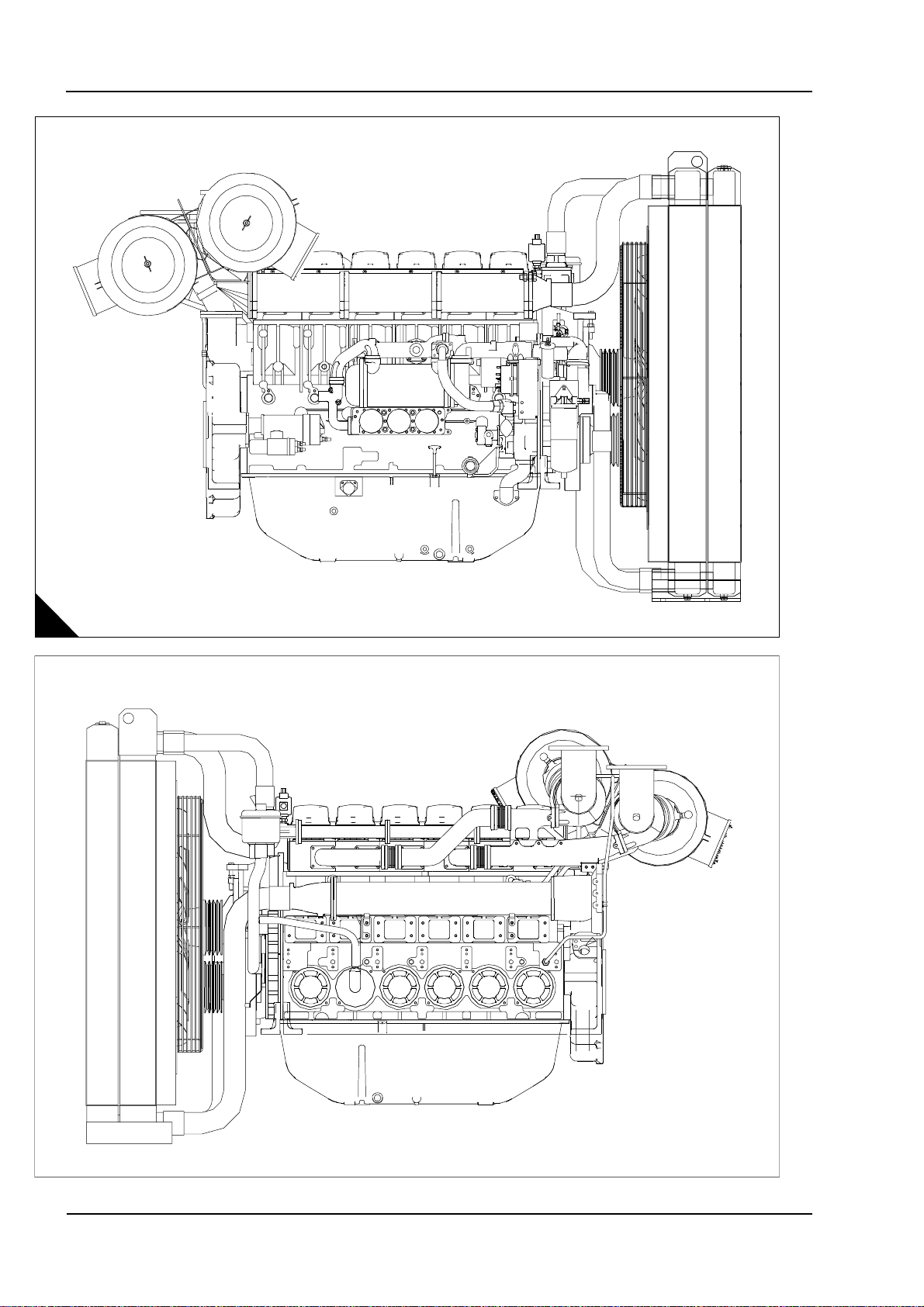

Engine views ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2

Engine identification . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 3

General safety precautions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

Viton seals . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 5

Engine lift equipment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

POWERPAR T reco mmen ded consu ma ble pr od uct s ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7

2 Spec if ic at i o ns

Basic engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9

Data and dimensions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..10

3 Cylinder head assembly

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..17

Rocker box and valve gear

Operation 3-1 To remove and fit the rocker box and valve gear ... ... ... ... ... ... ... ... ... ... ... ..18

Valve gear

Operation 3-2 To inspect rockers, bridge pieces and rocker shaft ... ... ... ... ... ... ... ... ... ... ..20

Workshop Manual, TPD 1511E, issue 1 iii

Page 4

4000 Series

Operation 3-3 To replace the bridge piece pressure pad .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 21

Cylinder head

Operation 3-4 To remove and fit the cylinder head . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 22

Valves and springs

Operation 3-5 To remove and fit the valve and the valve springs .. ... ... ... ... ... ... ... ... ... ... 24

Operation 3-6 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 26

Valves seats

Operation 3-7 To remove and fit, and reface the valve seats .. ... ... ... ... ... ... ... ... ... ... ... ... 27

Valves guides

Operation 3-8 To remove and fit the valve guides ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

Fuel injector bush

Operation 3-9 To remove and fit a fuel injector bush .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

Cylinder head

Operation 3-10 To inspect and pressure test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 33

Manifolds

Operation 3-11 To remove and fit the induction manifold . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 34

Operation 3-12 To remove and fit the exhaust manifold ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 35

4 Piston and connecting rod assemblies

General description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 39

Piston and connecting rod

Operation 4-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 40

Operati on 4-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 43

Piston rings

Operation 4-3 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 45

Operati on 4-4 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 46

Piston and connecting rod assembly

Operation 4-5 To dismantle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 47

Operation 4-6 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 47

Piston and piston rings

Operation 4-7 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 49

Connecting rod

Operation 4-8 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50

iv Workshop Manual, TPD 1511E, issue 1

Page 5

4000 Series

Small end bush

Operation 4-9 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..51

Operation 4-10 To remove and fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..51

Piston cooling jets

Operation 4-11 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..52

Operation 4-12 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..53

5 Crankshaft assembly

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..55

Crankshaft pulley and adaptor

Operation 5-1 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..56

Operation 5-2 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 57

Crankshaft vibration damper assembly

Operation 5-3 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..58

Operation 5-4 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 59

Crankshaft

Operation 5-5 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..60

Operation 5-6 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 61

Operation 5-7 To check the crankshaft end float ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..63

6 Gearcase and drive assembly

General description ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..65

Gearcase

Operation 6-1 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..66

Operation 6-2 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 67

Front oil seal

Operation 6-3 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..68

Operation 6-4 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 68

Camshaft gear

Operation 6-5 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..69

Operation 6-6 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 70

Idler gear

Operation 6-7 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..71

Operation 6-8 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 72

Operation 6-9 To check the hub and renew the idler gear bush ... ... ... ... ... ... ... ... ... ... ... ..73

Workshop Manual, TPD 1511E, issue 1 v

Page 6

4000 Series

Cam followers

Operation 6-10 To remove and fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 74

Operation 6-11 To check ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 75

Camshaft

Operation 6-12 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 76

Operation 6-13 To check the camshaft .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 77

Operation 6-14 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78

Operation 6-15 To remove and fit the camshaft bush ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 79

Crankshaft gear

Operation 6-16 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 80

Operation 6-17 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 81

Back Plate

Operation 6-18 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 82

Operation 6-19 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

7 Crankc as e

General Description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 85

Crankcase

Operation 7-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 86

Operati on 7-2 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 87

Operation 7-3 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 87

Cylinder Liner

Operation 7-4 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

Operation 7-5 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 89

Operati on 7-6 To fit liner .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 90

8 Engine timing

Operation 8-1 To set number 1 piston to Top Dead Centre (TDC) ... ... ... ... ... ... ... ... ... ... 91

Operation 8-2 Calibrating fuel injectors .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92

Operation 8-3 Setting governor on zero fuel . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 94

Operation 8-4 Applying pressure to the timing pin .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 95

Operation 8-5 Timing the fuel injectors ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 96

9 Aspiration system

General description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 99

vi Workshop Manual, TPD 1511E, issue 1

Page 7

4000 Series

How to check the air restriction indicator

Operation 9-1 To check and reset . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 100

Air filter element

Operation 9-2 To remove and fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 101

Air filter and pipe connection

Operation 9-3 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 102

Operation 9-4 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 103

Air filter bracket

Operation 9-5 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 104

Operation 9-6 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 104

Turbocharger ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 105

Operation 9-7 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 106

Operation 9-8 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 108

Air pipe connection

Operation 9-9 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 110

Operation 9-10 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 111

Engine breather

Operation 9-11 To remove breather system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1 12

Operation 9-12 To fit the breather system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 113

10 Lubrication system

General Description .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 115

Filter Canister

Operation 10-1 To renew .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 117

Filter head

Operation 10-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 118

Lubricating oil sump

Operation 10-3 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 119

Operation 10-4 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 120

Dipstick tube

Operation 10-5 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 121

Oil strainer and suction pipe

Operation 10-6 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 122

Workshop Manual, TPD 1511E, issue 1 vii

Page 8

4000 Series

Lubricating oil pump

Operation 10-7 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..123

Operation 10-8 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..124

Operation 10-9 To dismantle . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..125

Operation 10-10 To assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..126

Operation 10-11 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 128

Relief Valve

Operation 10-12 To dismantle and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..129

Operation 10-13 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 130

Fuel lift pump drive unit

Operation 10-14 To renew .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..131

Rotor end float

Operation 10-15 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 132

Drive shaft bearings

Operation 10-16 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..133

11 Fuel syste m

General description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..135

Fuel filter

Operation 11-1 To remove and fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..136

Fuel injector unit

Operation 11-2 To remove the fuel injector unit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 137

Operation 11-3 To disassemble and to check a fuel injector unit ... ... ... ... ... ... ... ... ... ... .. 139

Operation 11-4 To assemble the fuel injector unit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..143

To test and set the fuel injector

Operation 11-5 To test and set ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..146

Operation 11-6 To fit a fuel injector .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..151

Fuel Lift pump

Operation 11-7 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..152

Fuel control shaft

Operation 11-8 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..153

Operation 11-9 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..154

Operation 11-10 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..155

viii Workshop Manual, TPD 1511E, issue 1

Page 9

4000 Series

12 Cooli ng syst e m

Coolant pipework

Operation 12-1 To remove and fit the coolant pipework . ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1 58

Thermostat

Operation 12-2 To remove the thermostat .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 159

Operation 12-3 To fit the thermostat . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 160

Operation 12-4 To test . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 161

Thermostat housing

Operation 12-5 To remove and fit the thermostat housing . ... ... ... ... ... ... ... ... ... ... ... ... ... 162

Coolant pump

Operation 12-6 To remove the coolant pump . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 164

Operation 12-7 To fit the coolant pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 166

Operation 12-8 To disassemble the coolant pump ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 168

Operation 12-9 To assemble the coolant pump . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1 69

Fan Guards

Operation 12-10 To remove and fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 171

Fan

Operation 12-11 To remove and fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 171

Fan drive belts

Operation 12-12 To check the fan drive belts . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 172

Operation 12-13 To adjust the fan drive belts ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1 72

Operation 12-14 To remove and fit the drive belts ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 173

Fan drive

Operation 12-15 To remove and fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 174

Lubricating oil cooler

Operation 12-16 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 176

Operation 12-17 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 177

Operation 12-18 To disassemble and clean the oil cooler tube stack . ... ... ... ... ... ... ... ... 178

Operation 12-19 To assemble the oil cooler tube stack .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 179

Operation 12-20 To pressure test the oil cooler ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 180

Radiator

Operation 12-21 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 181

Operation 12-22 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 182

Workshop Manual, TPD 1511E, issue 1 ix

Page 10

4000 Series

13 Flywheel and housing

General description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..183

Flywheel

Operation 13-1 To remove and to fit the flywheel ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..184

Gear ring

Operation 13-2 To remove and to fit the gear ring .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..186

Flywheel Housing

Operation 13-3 To remove and to fit the flywheel housing ... ... ... ... ... ... ... ... ... ... ... ... ... ..187

Flywheel housing oil seal

Operation 13-4 To remove and to fit the flywheel housing oil seal . ... ... ... ... ... ... ... ... ... .. 189

14 Electrical equipment

General description . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..191

Alternator . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..192

Operation 14-1 To check the drive belts . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..192

Operation 14-2 To adjust the drive belt tension ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..193

Operation 14-3 To remove the alternator ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..193

Operation 14-4 Remove the alternator drive pulley ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..194

Operation 14-5 To fit the alternator drive pulley ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..195

Operation 14-6 To fit the alternator .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..196

Operation 14-7 To maintain ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..196

Starter motor .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..197

Operation 14-8 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 197

Operation 14-9 To Fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 197

The air starter motor system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..198

Operation 14-10 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..201

Operation 14-11 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..201

Stop solenoid

Operation 14-12 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..202

Operation 14-13 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..202

Digital Electronic Governor . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..203

Description of System ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..206

Block diagram of the governor system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..207

x Workshop Manual, TPD 1511E, issue 1

Page 11

4000 Series

Magnetic pick-up

Operation 14-14 To clean the magnetic pick-up ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2 08

Operation 14-15 To remove the actuator . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 209

Operation 14-16 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2 10

Specification of Governor system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2 11

Operation 14-17 To remove the digital control box ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 211

Operation 14-18 To Fit the digital control box ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2 11

Feedback Setting

Operation 14-19 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 212

Configuration ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 216

External Speed Control Input ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 216

Changing the governor configuration ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 217

Operation 14-20 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 217

Single/Parallel Generator (Non Heinzmann Load Sharing)

Operation 14-21 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 218

Single/Parallel Generator with Droop

Operation 14-22 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 219

Parallel Generator Heinzmann (SyG02/LMG10-01)

Operation 14-23 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 220

Parallel Generator Heinzmann Digital Theseus

Operation 14-24 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 221

Parallel Generator Variable Speed in Droop Range

Operation 14-25 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 222

Other settings

Operation 14-26 Load Control Settings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 223

PID parameters

Operation 14-27 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 226

PID Maps

Operation 14-28 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 227

Speed Ramps ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2 28

Sectional Speed Ramp

Operation 14-29 To adjust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 229

Workshop Manual, TPD 1511E, issue 1 xi

Page 12

4000 Series

External connections – Control box connector ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..234

Alternative Connections for Speed Setting Inputs . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..235

Wiring detail, digital control box in IP enclosure – production engines ... ... ... ... ... ..236

Fault Tracing ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..237

Error Codes . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..239

Low oil High water temperature switch ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..242

Operation 14-30 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..242

Operation 14-31 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..242

Switch connections

Operation 14-32 To remove and fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..243

Switch setting ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..243

15 Auxiliary equipment

Operation 15-1 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..246

Operation 15-2 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..247

Operation 15-3 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..249

Operation 15-4 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..250

16 Special tools

List of special tools ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 252

xii Workshop Manual, TPD 1511E, issue 1

Page 13

4000 Series

1

General information 1

Introduction

This Workshop Manual has been written to provide assistance in the service and overhaul of

Perkins 4006-23, TAG1A, TAG2A and TAG3A engines. It should be used in conjunction with normal workshop

practise and information contained in current service bulletins. Mention of certain accepted practices therefore,

has been purposely omitted in order to avoid repetition. For overhaul procedures the assumption is made that

the engine is removed from the application.

The engine conf orms with USA (EPA/CARB) stage 2 and EEC stage 2 emissions legislation for agriculture,

construction and industrial applications.

Most of the general information which is included in the relevant User's Handbook has not been repeated in

this workshop manual and the two publications should be used together.

Where the information applies only to certain engine types, this is indicated in the text.

When reference is made to the "left" or "right" side of the engine, this is as seen from the flywheel end of the

engine.

When not working on the engine, ensure that all covers, blank flanges, doors, etc., are refitted to openings to

prevent the ingress of dirt, etc.

Please quote the engine type and serial number with all your enquiries. This will help us to help you. The type

and serial number are on a plate fitted to the crankcase.

If any doubt exists regarding the installation, use or application of the engine, the Installation Manual should

be consulted for further advice contact Applications Department at Perkins Engines (Stafford) Ltd.

Oil change intervals may be changed according to operating experience by agreement with Perkins Engines

(Stafford) Limited and subject to oil analysis being carried out at regular intervals.

Special tools have been made available and a list of these is given in Chapter 16, Special tools. Reference to

the relevant special tools is also made at the beginning of each operation.

POWERPART recommend ed consumab le products are listed under "P OW E RPART recomm ended

consumable products" on page 7. Reference to the relevant consumable products is also made at the

beginning of each operation.

Data and dimensions are included in Chapter 2, Specifications.

Read and remember the "General safety precautions" on page 4. They are given for your protection and must

be used at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Workshop Manual, TPD 1511E, issue 1 1

Page 14

1

Engine views

4000 Series

JC

A

D1001

D1367

2 Workshop Manual, TPD 1511E, issue 1

Page 15

4000 Series

Engine identification

The 4006-23 engine consists of a range of six cylinder engines. This range has three basic engine types,

TAG1A, TAG2A and TAG3A.

The different engines are identified by their engine number and their type as shown below:

A typical example of an engine number: DGB 060081 U0017 B

Engine number identification

D Made in Stafford

G Application code

B Engine type

06 Number of cylinders

0081 Fixed build number

U United Kingdom

0017 Number of engines bui lt

B Year that the engine was built

Engine type

A 4006-23TAG1A

B 4006-23TAG2A

D 4006-23TAG3A

1

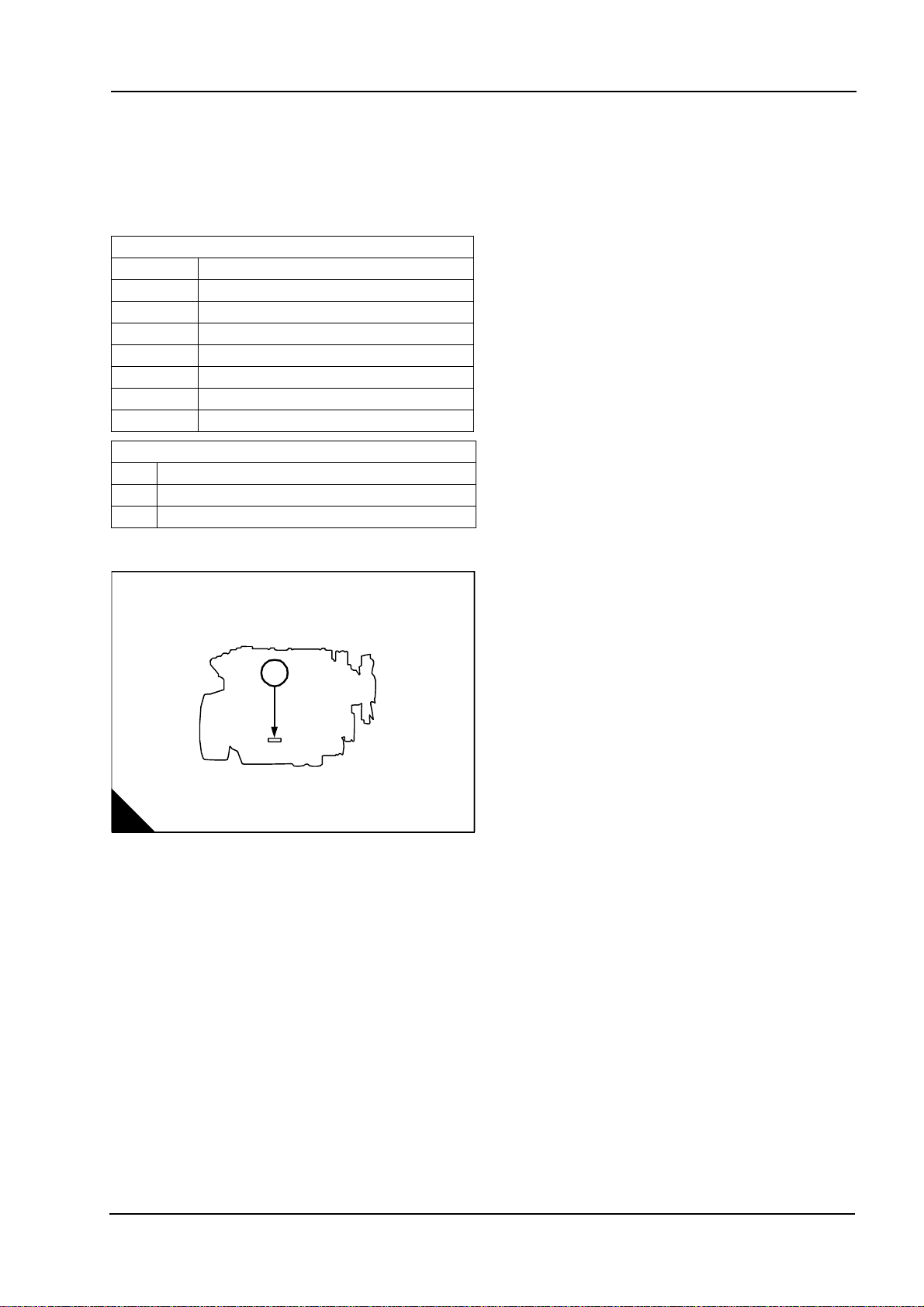

The position of the plate for the engine number (A1).

1

A

D1104

Workshop Manual, TPD 1511E, issue 1 3

Page 16

1

4000 Series

General safety precautions

These safety precautions are important. You must refer also to the local regulations in the country of use.

Some items only refer to specific applications.

Only use these engines in the type of application for which they have been designed.

Do not change the specification of the engine.

Do not smoke when you put fuel in the tank.

Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

Do not put fuel in the tank while the engine runs (unless it is absolutely necessary).

Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the e yes.

Do not smoke when you are in the working area of the engine.

Isolate the engine and disconnect the battery before a repair is made to the electrical system.

Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training,

even then extreme care must be used to prevent injury).

Do not make adjustments that you do not understand.

Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

Ensure that the exhaust system from the engine is supported.

Other persons must be kept at a safe distance while the engine or auxiliary equipment is in operation.

Do not permit loose clothing or long hair near moving parts.

Keep away from moving parts during engine operation.

Warning! Some moving parts cannot be seen clearly while the engine runs.

Do not operate the engine if a safety guard has been removed.

Do not remove the filler cap or any component of the cooling system while the engine is hot and while the

coolant is under pressure, because dangerous hot coolant can be discharged.

Only one person must control the engine.

Ensure that the engine is operated only from the control panel or from the operator’s position.

If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

Ensure that all personal protection equipment for your head, ears, eyes and feet etc, are used when you

are in the working area of the engine.

Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets of clothing.

Discard used lubricating oil in accordance with local regulations to prevent contamination.

Ensure that the control lever of the transmission drive is in the "out-of-drive" position before the engine is

started.

Use extreme care if emergency repairs must be made in adverse conditions.

The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes.

Always use a safety cage to protect the operator when a component is to be pressure tested in a container

of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to

be pressure tested.

Continued

4 Workshop Manual, TPD 1511E, issue 1

Page 17

4000 Series

C

Do not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help

immediately.

Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from

the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces.

Fit only genuine Perkins parts, failure to do so can damage the engine and may effect the warranty.

Do not wash an engine while it runs or while it is hot. If cold cleaning fluids are applied to a hot engine,

certain components on the engine could be damaged.

Always use lift equipment of the approved type and of the correct capacity to lift heavy engine components.

Never work alone when you operate lift equipment.

1

Viton seals

Viton is used by many manufacturers and is a safe material under normal conditions of operation.

Some seals used in engines and in components fitted to these engines are made of Viton.

If Viton is burned, a product of this burnt material is an acid which is extremely dangerous. Never allow this

burnt material to come into contact with the skin or with the eyes.

If it is necessary to come into contact with components which have been burnt, ensure that the precautions

which follow are used:

Ensure that the components have cooled.

Use neoprene gloves and discard the gloves safely after use.

Wash the area with calcium hydroxide solution and then with clean water.

Disposal of components and gloves which are contaminated must be in accordance with local regulations.

If there is contamination of the skin or eyes, wash the affected area with a continuous supply of clean water or

with calcium hydroxide solution for 15 to 60 minutes. Obtain immediate medical attention.

Safety cautions when an engine is cleaned

Care should be taken, when an engine is cleaned with a high pressure cleaning system.

autions:

Do not wash an engine while it runs or while it is hot. If cold cleaning fluids are applied to a hot engine,

certain components on the engine could be damaged.

Leave the engine to cool for at least one hour and disconnect the battery connections before cleaning.

Do not wash any part of the fuel injection pump (FIP), cold start device, electrical shut off solenoid (ESOS)

or electrical connectors.

Ensure that the alternator, starter motor and any other electrical components are shielded and not directly

cleaned by the high pressure cleaning system.

If these cautions are ignored, the engine or certain components could be damaged, fail to operate and also

make the manufacturer’s warranty invalid.

Workshop Manual, TPD 1511E, issue 1 5

Page 18

1

4

4000 Series

Engine lift equipment

When lifting engine or generating sets, special lifting equipment is required. It is recommended that a spreader

lifting beam of the correct lifting load capacity is used and that chains, hooks, shackles and eye bolts etc. are

checked that they are well within their safe working loads. The load should be secure, stable and balanced

when lifting.

The lifting chains etc must be firmly secured to the load by means of hooks etc on to the purpose-designed

lifting points, and that included angle is not exceeded (A).

In order to accommodate the chains for lifting it may be necessary to have to remove engine components such

as air filters etc to prevent damage, but this should be avoided where the chains can be clear by nondetrimental means.

Warning! Lifting equipment should be used by trained personnel only. Generating sets mu st be lifted using

the lifting lugs on the engine frame and a spreader lifting beam. The engine lifting brackets and alternator lifting

lugs must not be used.

A

6 Workshop Manual, TPD 1511E, issue 1

D114

Page 19

4000 Series

1

POWERPAR T reco mmen ded consu ma ble pr od uct s

Perkins have made available the products recommended below in order to assist in the correct operation,

service and maintenance of your engine and your machine. The instructions for the use of each product are

given on the outside of each container. These products are available from your Perkins distributor.

POWERPART ELC (Extended Life Coolant).

ELC is pre-mixed and protects the cooling system against frost and corrosion. Part number 21820181.

POWERPART Easy flush

Cleans the cooling system. Part number 21825001.

POWERPART Gasket and flange sealant

To seal flat faces of components where no joint is used. Especially suitable for aluminium components.

Part number 21820518.

POWERPART Gasket remover

An aerosol for the removal of sealants and adhesives. Part number 21820116.

POWERPART Griptite

To improve the grip of worn tools and fasteners. Part number 21820129.

POWERPART Hydraulic threadseal

(1)

To retain and seal pipe connections with fine threads. Especially suitable for hydraulic and pneumatic systems.

Part number 21820121.

POWERPART Industrial grade super glue

Instant adhesive designed for metals, plastics and rubbers. Part number 21820125.

POWERPART Lay-Up 1

A diesel fuel additive for protection against corrosion. Part number 1772204.

POWERPART Lay-Up 2

Protects the inside of the engine and of oth er closed systems. Part number 1762811.

POWERPART Lay-Up 3

Protects outside metal parts. Part number 1734115.

POWERPART Metal repair putty

Designed for external repair of metal and plastic. Part number 21820126.

POWERPART Pipe sealant and sealant primer

To retain and seal pipe connections with coarse threads. Pressure systems can be used immediately.

Part number 21820122.

Continued

Workshop Manual, TPD 1511E, issue 1 7

Page 20

1

POWERPART Radiator stop leak

For the repair of radiator leaks. Part number 21820127.

POWERPART Retainer (high strength)

To retain components which have an interference fit. Part number 21820638.

POWERPART Retainer (oil tolerant)

To retain components which have an interference fit, but are in contact with oil. Part number 21820608.

POWERPART Safety cleaner

General cleaner in an aerosol container. Part number 21820128.

POWERPART Silicone adhesive

4000 Series

An RTV silicone adhesive for application where low pressure tests occur before the adhesive sets. Used for

sealing flange where oil resistance is needed and movement of the joint occurs. Part number 21826038.

POWERPART Silicone RTV sealing and jointing compound

Silicone rubber sealant which prevents leakage through gaps. Part number 1861108.

POWERPART Stud and bearing lock

To provide a heavy duty seal to components that have a light interference fit. Part number 21820119 or

21820120.

POWERPART Threadlock and nutlock

To retain small fasteners where easy removal is necessary. Part number 21820117 or 21820118.

POWERPART Universal jointing compound

Universal jointing compound which seals joints. Part number 1861117.

(1) Powerpart (ELC) is not recommended for the 1300 Series.

(2) These product must not be used for the 4006-23 engine.

(2)

(2)

(2)

8 Workshop Manual, TPD 1511E, issue 1

Page 21

4000 Series

2

Specifications 2

Basic engine data

Number of cylinders. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

Cylinder arrangement.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Ver ti c a l, in-l ine

Cycle ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Four stroke

Induction system.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Turbocharged, air cooled C.A. in radiator (air to air)

Combustion system. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Direct injection

Nominal bore... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .160 mm

Nominal stroke. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .190 mm

Compression ratio ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...13:1

Cubic capacity . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .22,92 litres

Firing order.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1, 5, 3, 6, 2, 4

Direction of rotation . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Anti-clockwise viewed on flywheel

Lubricating oil capacity:

Total system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 122,7 litres (27 gallons)

Sump maximum ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . 113, 7 litres (25 gallons)

Sump minimum ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...90,9 litres (20 gallons)

Lubricating oil pressure:

At rated speed (Min) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 200 kPa (29 lb/in

Typical coolant capacity of engine... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 36 litres (8 gallons)

Typical coolant capacity of engine and radiator .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 105 litres (23 gallons)

2

)

Workshop Manual, TPD 1511E, issue 1 9

Page 22

2

4000 Series

Data and dimensions

Rocker assembly

Rocker shaft diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 39,975 / 39,950 mm

Valve rocker lever bore.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 40,025 / 40,000 mm

Clearance between valve rocker levers and shaft. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,025 to 0,075 mm

Unit fuel injecto r ro cke r leve r bore. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 40,025 / 40,000 mm

Valves

Diameter of valve stem.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 11,0236 / 11,0109 mm

Diameter of valve head:

Inlet valve... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 52,12 / 52,00 mm

Exhaust valve. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 52, 12 / 52,00 mm

Angle of face of valve:

Inlet valve... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30°30’ / 30°00’

Exhaust valve. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. . 30°30’ / 30°00’

Thickness of valve lip:

Inlet valve and exhaust valve. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2,1 / 1,9 mm

Exhaust valve and inlet valve minimum “outside diameter: land” thickness .. ... ... ... ... ... ... ... ... ... ... ...1 mm

Length of valve:

Inlet ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 170,0 / 169,5 mm

Exhaust. . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 170,0 / 169,5 mm

Valve guides

Bore of valve guide when installed ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 11, 118 / 11,082 mm

Do not use a combination of a valve and valve guide which have a difference of 0,20 mm or more.

Height from cylinder head to top of valve guide. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9 mm

Valve springs

Assembled length .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..42,545 mm

Load at assembled length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...399,6 N

Minimum operating length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..31,369 mm

Load at minimum operating length. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 695 ,1 N

Free length after test. . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..57,658 mm

Outside diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..33,934 mm

Minimum free length.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..55,6 mm

10 Workshop Manual, TPD 1511E, issue 1

Page 23

4000 Series

Valve seat inserts

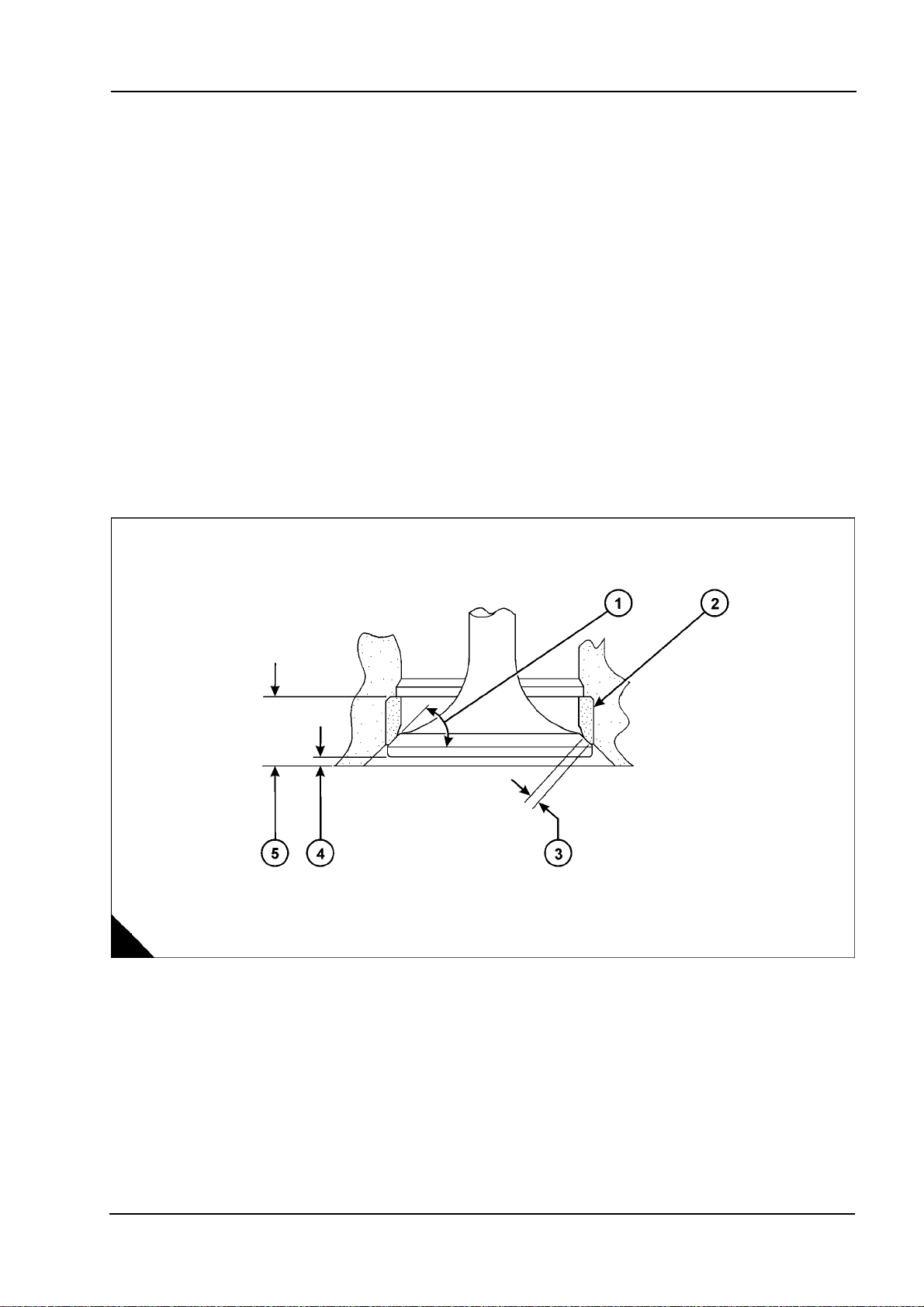

Depth of bore in cylinder head for valve seat insert (A5):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..11,10 / 11,00 mm

Exhaust valve.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..11,10 / 11,00 mm

Diameter of valve seat insert (A2):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..56,119 / 56,094 mm

Exhaust valve.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..56,620 / 56,595 mm

Bore in cylinder head for valve seat insert (A2):

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..56 mm H7

Exhaust valve.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .56,50 mm H7

Angle of face of valve seat insert (A1):

Inlet valve insert... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...30°30’ / 30°00’

Exhaust valve insert ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30° 30’ / 30°00’

Valve recess (A4):

Inlet valve (new parts) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Flush

Exhaust valve (new parts)... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... . Flush

Inlet valve ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Maximum: 1 mm

Exhaust valve.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... Maximum: 1 mm

2

A

Workshop Manual, TPD 1511E, issue 1 11

D1366

Page 24

2

Cylinder head

Thickness of cylinder head (new) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 140,075 / 139,925 mm

Minimum thickness for a used cylinder head. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 139,773 mm

Flatness of cylinder head: The cylinder head flame face must be flat within a maximum of 0,03 mm (0.001

in) with the rocker box face parallel within 0,076 mm.

Piston and connecting rod

Piston ring gaps measured with the ring fitted in a new liner with a bore size: 160,025 / 160,000 mm

Top piston ring... ... ... ... .. . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,80 mm, maximum worn 1,05 mm

Intermediate ring (second). ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,60 mm, maximum worn 0,85 mm

Oil control ring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,60 mm, maximum worn 0,85 mm

Width of groove for oil control ring in new piston... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6,065 / 6,040 mm

Thickness of a new oil con tro l ring. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. . ... ... ... ... ... 5,990 / 5,975 mm

Clearance between piston ring groove and new oil control ring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...

Maximum permissible clearance between piston

ring groove and a used oil control ring... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0, 254 mm

Piston gudgeon pin bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 63. 525 / 63,515 mm

Gudgeon pin diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 63,500 / 63,492 mm

Length of gudgeon pin... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 135,00 / 134,75 mm

Bore in connecting rod for small end bearing ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 71,450 / 71,425 mm

Bore of connecting rod small end bearing . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 63,576 / 63,551 mm

Bore in connecting rod for big end bearing shells.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 123,025 / 123,000 mm

Distance between centres of big and small end bearings.. ... ... ... ... ... ... ... ... ... ... ... ... 336,06 / 335,94 mm

Maximum worn clearance small end.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,15 mm

Conrod end float ... ... ... ... ... ... ... ... ... ... .. . ... ... ... ... ... .. . ... ... ... ... ... ... ... ... ... .. . ... ... ... 0,16 / 0,36 mm

4000 Series

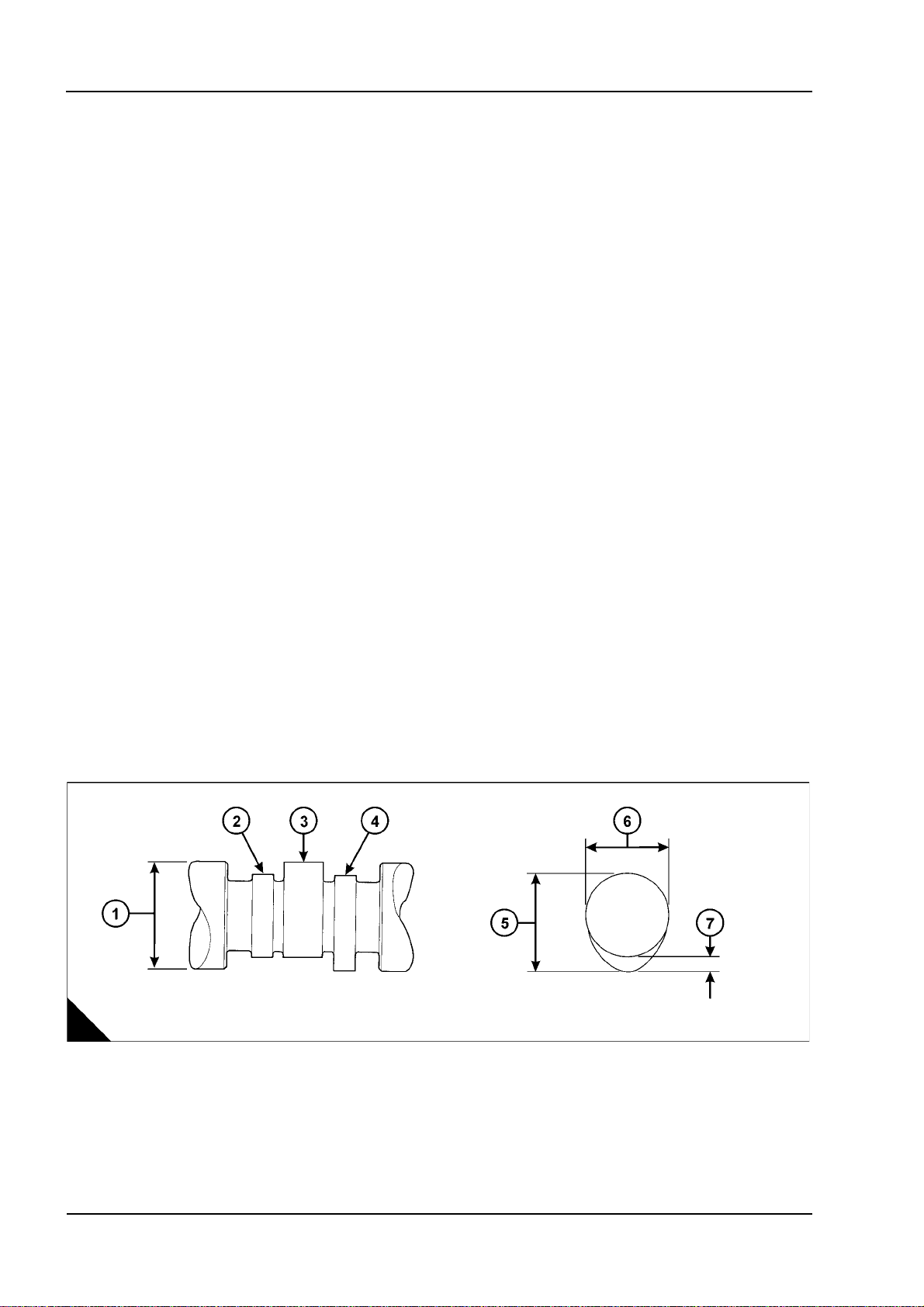

Camshaft and bearings

Diameter of camshaft journal (A3). ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 91,960 / 91,933 mm

Exhaust cam height (A5) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78,58 mm, service limit 78,1 mm

Inlet cam height (A5) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78,58 mm, service limit 78,1 mm

Injector cam height. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78,88 mm, service limit 78,4 mm

Maximum: worn clearance cam journal / bearing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,25 mm

Camshaft end float . ... ... ... ... ... ... ... ... ... ... ... ... ... ... .0,10 / 0,25 mm, maximum: worn clearance 0,30 mm

Cam follower lever assembly:

followers, pivot shaft / arms / shims end float ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,50 / 0,25 mm

A

D1365

12 Workshop Manual, TPD 1511E, issue 1

Page 25

4000 Series

2

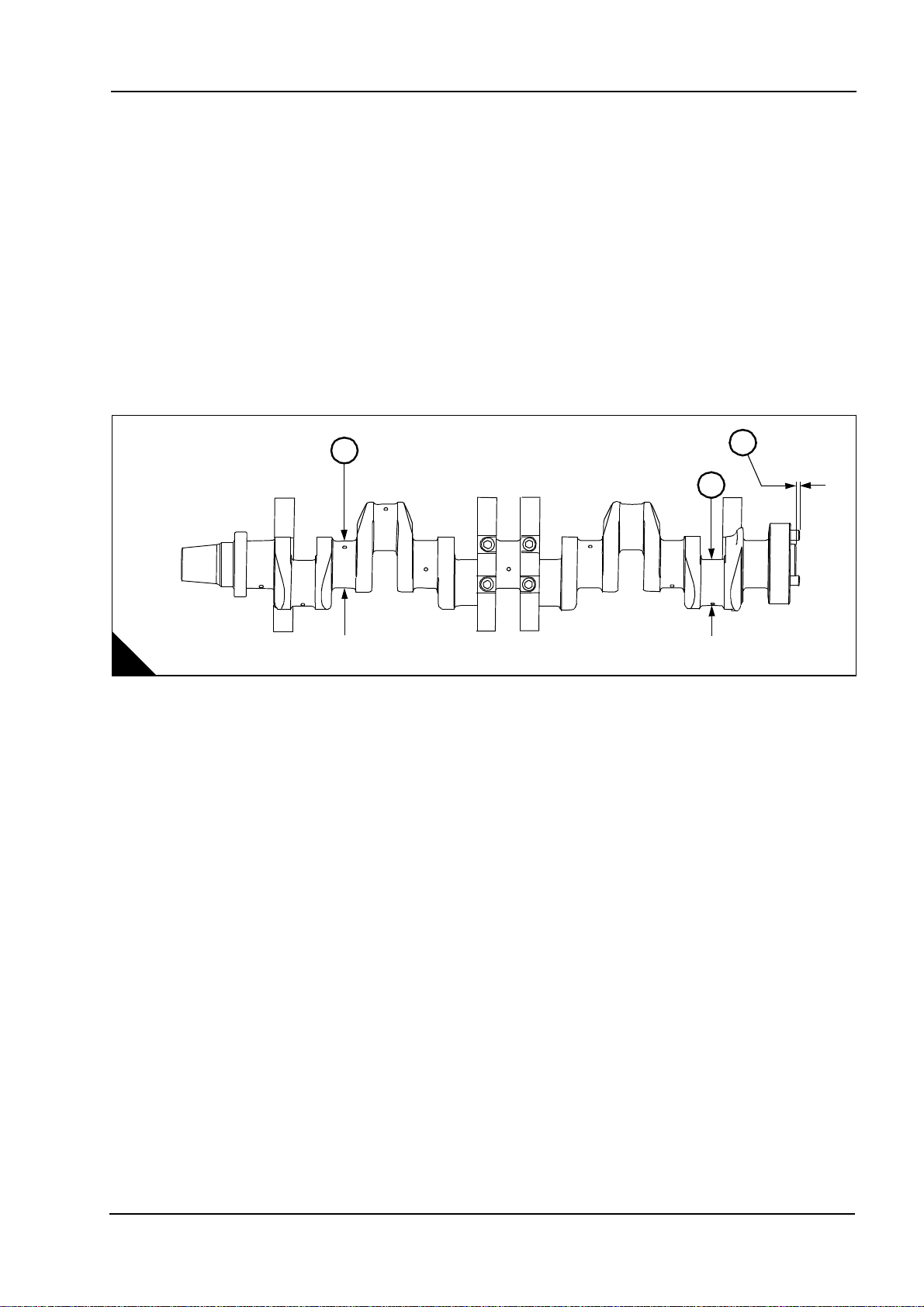

Crankshaft, main bearings and flywheel

Diameter of main bearing journal (A3). ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..120,59 / 120,57 mm

Undersize bearings by. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,254 mm

Undersize bearings by. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,508 mm

Clearance between a new bearing and the journal. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,152 / 0,089 mm

Maximum permissible clearance between the

bearing and journal.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,203 mm

Diameter of main bearing bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..120,726 / 120,675 mm

Diameter of connecting rod journal (A2).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..118 ,013 / 117,993 mm

Undersize bearings by. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,254 mm and 0.508 mm

Clearance between a new bearing and the journal. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,127 / 0,073 mm

Maximum permissible clearance between the

bearing and journal.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,203 mm

End-float of crankshaft. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,48 / 0,13 mm

Maximum permissible end-float (with used bearings) . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0, 53 mm

Protrusion of dowel (A1).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...10 mm

3

A

1

2

D1364

Crankcase and cylinder liners

Distance from top of crankcase to centre of main

bearing bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..540,15 / 540,00 mm

Block cylinder bore depth (for liner flange).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 15,20 / 15,12 mm

Distance from bottom of crankcase to centre of main

bearing bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..152,425 / 152,375 mm

Bore in new cylinder liner ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..160,025 / 160,000 mm

Thickness of liner flange .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..13,05 / 13,00 mm

Workshop Manual, TPD 1511E, issue 1 13

Page 26

2

Lubricating oil pump

Diameter of shaft ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 41,913 / 41,888 mm

Diameter of bores in bearing bushes for shaft... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 42, 039 / 41,974 mm

Length of rotors.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50,800 / 50,775 mm

Depth of bores for rotors ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50,76 / 50,72 mm

Joint O.P. body to cover. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,25 mm

Spring:

Spring rate . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .1,32 kg/mm

Load at 51 mm length ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...30 kg

Load under 30 mm comp: to assembly length... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. . ... ... ... 39,6 kg

Free length . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..73,6 mm

Outside diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..24,6 mm

Spring plunger bore ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..25,4 mm

Coolant pump

Shaft diameter at the position of the coolant seal.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25,095 / 25,087 mm

Gear train

Idler gear end float. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,2 / 0,1 mm

Idler gear maximum: worn . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..0,25 mm

Backlash:

4000 Series

Idler, camshaft, oil pump gears.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,375 / 0,125 mm

Maximum: worn.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,5 mm

Water pump gear in mesh.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 0,294 / 0,152 mm

14 Workshop Manual, TPD 1511E, issue 1

Page 27

4000 Series

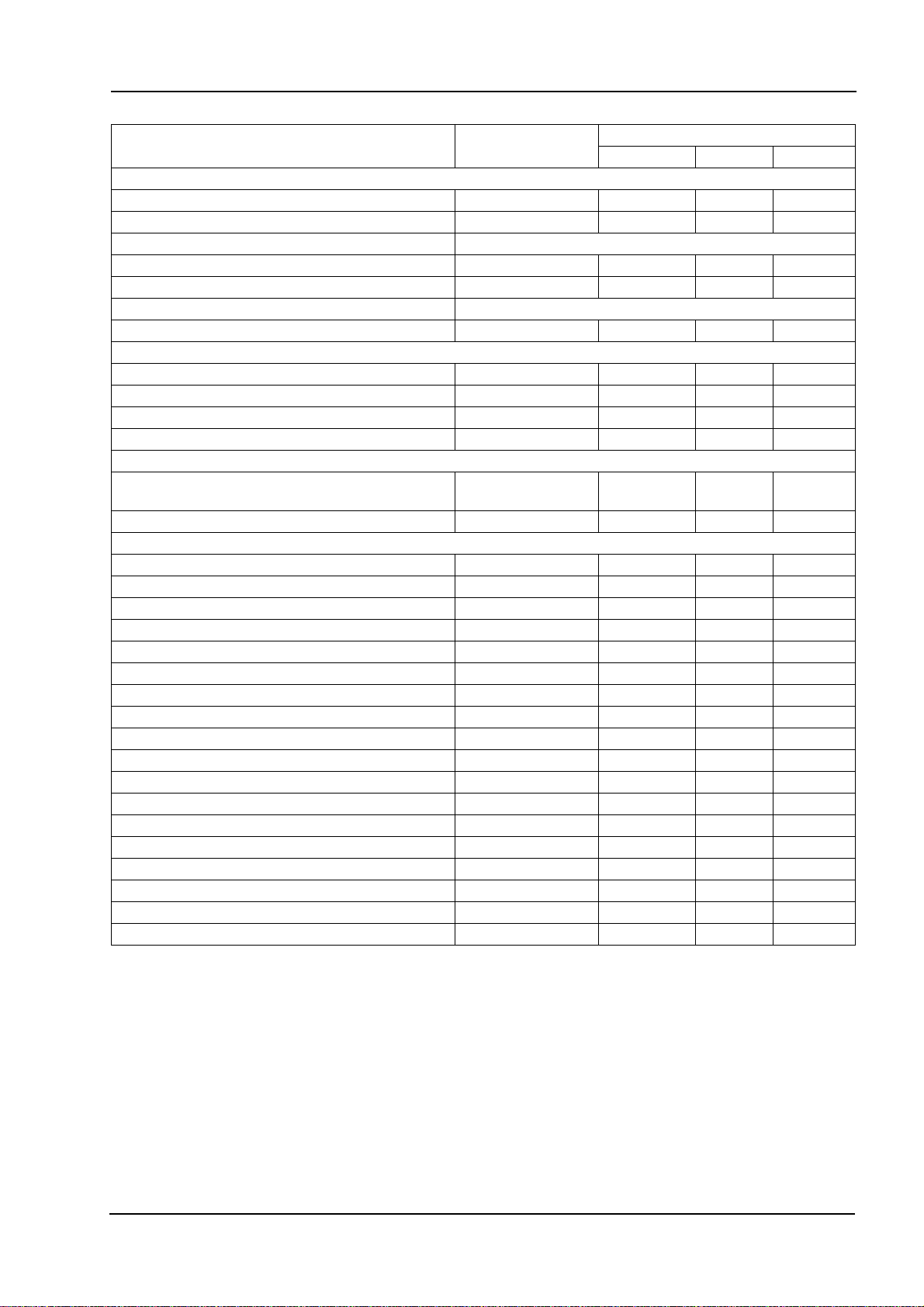

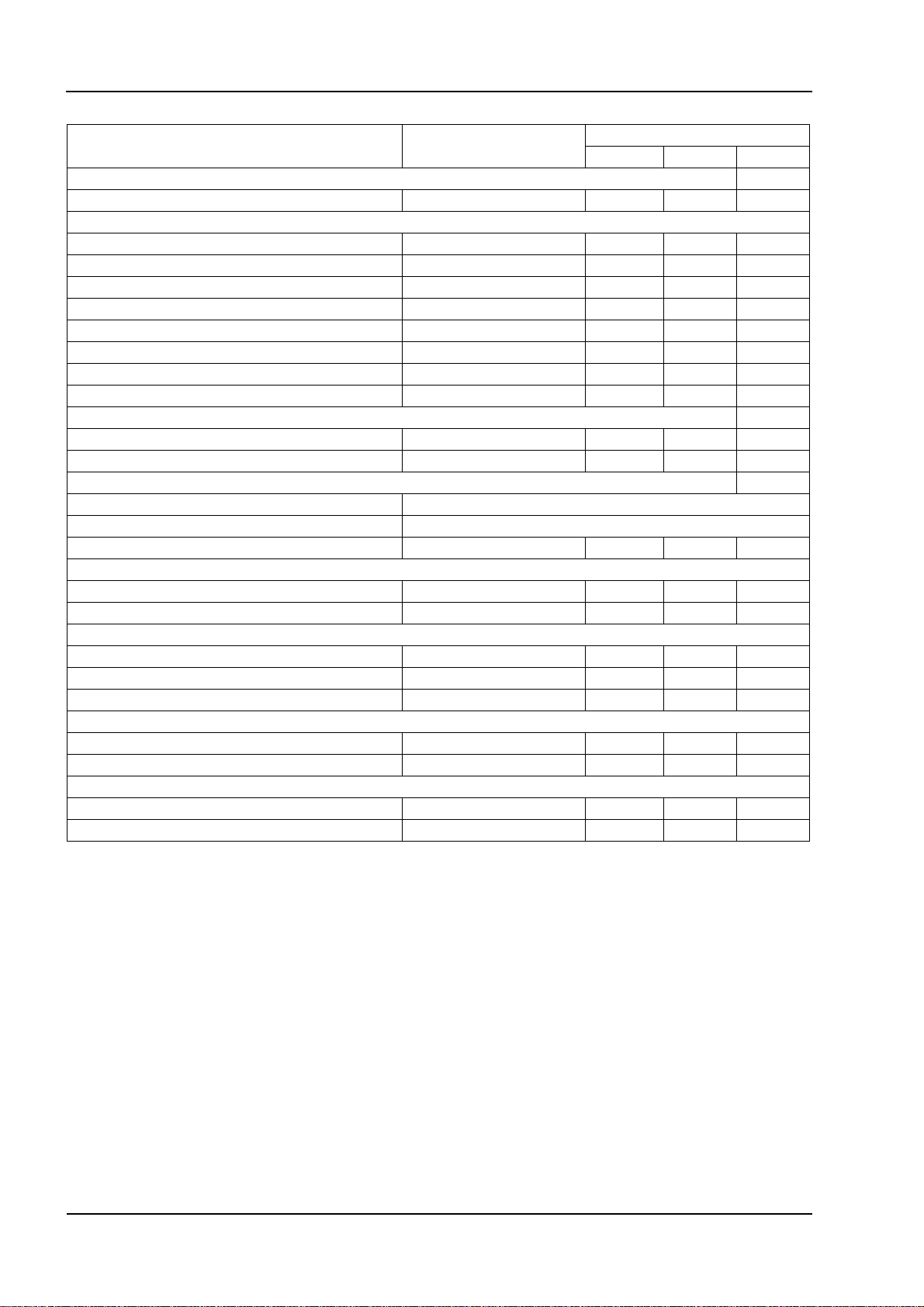

Torq ue data

2

Description Thread size

Crankcase and crankshaf t

Sump bolts into crankc a se M10 54 40 5,5

Sump bolts into gearcase (al um inium) M10 40 30 4

Main bearing cap bolts See Operation 5-6

Main bearing cap side caps crews M16 n/a n/a n/a

Oil feed block bolts M10 27 20 2,7

Connecting rod bolts See Operation 4-2

Piston cooling jet bolts M10 27 20 2,7

Camshaft

Camshaft gear bolts M12 150 110 15,2

Camshaft thrust plate bolt s M10 50 35 5,1

Idler gear hub bolts M10 50 35 5,1

Engine feet bolts M10 50 35 5,1

Cylinder head

Cylinder head bolts (Fac tory Fitted) 175 + 120°

Cylinder head bolts (Waisted) - head marked ‘W’ M24 720 530 73,4

General

M20 - Grade 8.8 steel bolts to BS3692 M20 400 290 40,7

M16 - Grade 8.8 steel bolts to BS3692 M16 210 150 21,4

M12 - Grade 8.8 steel bolts to BS3692 M12 85 60 8,6

M10 - Grade 12.9 steel bolts to BS3692 M10 70 50 7,1

M10 - Grade 8.8 steel bolts to BS3692 M10 50 35 5,1

M8 - Grade 8.8 steel bolts to BS3692 M8 25 18 2,5

M6 - Grade 8.8 steel bolts to BS3692 M6 10 7 1,0

M6 - Grade 12.9 steel capscrews to BS4168: Part 1 M6 16 12 1,6

M5 - Grade 12.9 steel capscrew to BS4168: Part 1 M5 13 10 1,3

3/8” UNF 40 30 4

5/8” UNF 200 150 20,3

1/2” UNC 90 68 9,1

7/16” UNF 66 50 6,7

5/16” UNF 22 16 2,2

Starte r motors M12 95 70 7,1

Alternator nut M24 75 55 7,6

Taper lockbush M8 20 15 2

Fuel pipes 50 35 5,1

Nm lbf ft kgf m

Torque

130 +

120°

17,8 + 120°

Workshop Manual, TPD 1511E, issue 1 15

Page 28

2

Main build

4000 Series

Description Thread size

Camshaft

Cam follower housing bolts M10 50 35 5,1

Cylinder head

Rocker box bolts-graphite joint M10 70 50 7,1

Exhaust manifol d to head bolts (Durlock) M10 70 50 7,1

Bridge piece adjuster nubs M10 35 25 3,5

Fuel injector clamp capscrews M12 95 70 9,6

Rocker shaft capscrew/nuts M16 240 180 24,9

Rocker adjuster nuts M12 50 35 5,1

Unit-fuel injector rocker adjuster nuts M14 70 50 7,1

Rocke r co v e r - plast ic M10 4 3 0,4

Water pump and oil pump

Water pump to gearcase bolts M10 50 35 5,1

Water header to oil cooler bolts M10 50 35 5,1

Crankcase and crankshaft

Flywheel bolts (Fi nal torque) See Chapter 13, Flywheel and housing

T.V. damper bolts (Fi nal torque) See Chapter 13, Flywheel and housing

Front crankshaft pulley assembly M16 340 250 34,6

Unit-fuel injector control linkage

Capscrews, unit -fuel injector cont rol lever M5 8 6 0,8

Locknut - contr ol linkage M5 8 6 0,8

Exhaust bellows

Bolts / locknu ts ( torque prevailing) M10 58 43

Durlock bolts / loc knuts M10 70 50

Setscrews M10 50 35 5,1

Unit- fuel inject ors

Nuts, fuel injec tor nozzle to nozzle holder M27 205 150 5,9

Capscrews, fuel injector clamp to cylinder head M12 95 70 9,6

Clips and clamps

Hose clips 53,50,5

V-band clamps (Mitsubishi) 9,5 7 0,96

Nm lbf ft kgf m

Torque

16 Workshop Manual, TPD 1511E, issue 1

Page 29

4000 Series

3

Cylinder head assembly 3

General description

Note: In the event of failure, valve or valve seat recession reaching the recommended limit, or when the engine

is being overhauled, service exchange cylinder heads supplied by your Perkins Dealer/Distributor are

recommended. The specialised equipm ent and liquid nitrogen are not generally available

The cast iron cylinder heads are fastened to the crankcase by flange head bolts and hardened washers. The

cylinder head gasket to crankcase consists of a stainless steel flame ring. The individual inlet and exhaust

ports are designed to assist and improve air flow. The ports for the inlet are on the right hand side of the engine

and the ports for the exhaust are on the left hand side of the engine.

The cylinder head assembly has four overhead valves for each cylinder. Each valve is held in place by a single

coil spring, cap and two collets. The cylinder head has valve seat inserts fitted for both the intake and the

exhaust. The intake valve seats are made from high speed steel casting and the exhaust valve seats are made

from Pleuco PL12 MV400 which both can be renewed. The valves move in cast iron ferrite nitro carburised

valve guides which also can be renewed.

The overhead valves are operated by a rocker shaft assembly in the rocker box. The forged steel rocker levers

are operated by forged push rods with hardened ball and sockets ends. The rockers and valve gear are

lubricated by oil from the drillings in the rocker shaft that receives oil flow from the extruded fuel/oil rail. Tappet

adjustment is achieved by adjustment screws and locknuts at the push rod end of each rocker lever.

In a diesel engine there is little carbon deposit and for this reason the number of hours run is no indication of

when to overhaul a cylinder head assembly. The factors which indicate when an overhaul is necessary are

how easily the engine starts and its general performance.

Workshop Manual, TPD 1511E, issue 1 17

Page 30

3

5

4000 Series

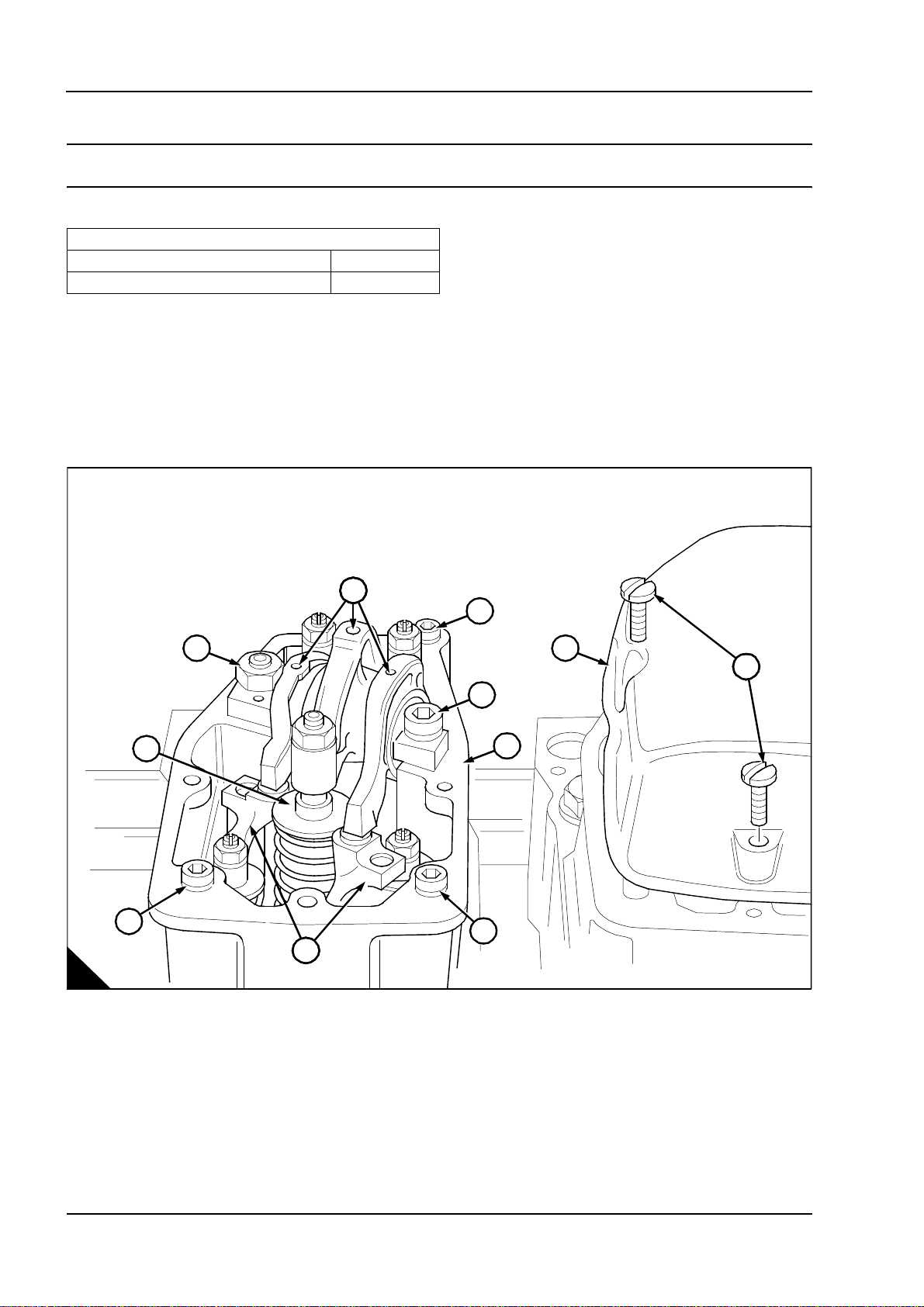

Rocker box and valve gear

To remove and fit the rocker box and valve gear Operation 3-1

Special requirements

Consumable products

Description Part number

POWERPART Hydraulic threadseal 21820121

To remove

1 Remove the retaining screws (A5) and lift off the rocker cover (A4). Remove the rocker cover joint and

discard.

2 Remove the nut (A11) and the Allen screw (A3) then lift off the rocker assembly (A1), the cup pad (A10), the

bridge pieces (A8) and the push rods.

3 Remove the retaining Allen screw (A2, A7, A9) and remove the rocker box (A6).

4 A light blow with a hide mallet may be needed to free the rocker box from its joint.

A

1

2

11

3

10

9

8

6

7

4

5

D135

Continued

18 Workshop Manual, TPD 1511E, issue 1

Page 31

4000 Series

5

3

To fit

Note: If water is found to be leaking from the rocker shaft stud, apply POWERPART Threadlock and nutlock.

1 Fit the rocker box (A6) using a new joint and ‘O’ ring, locating it on the two dowel pegs in the cylinder head

face.

2 Lub ricate the threads of the retaining Allen screw (A2,A7, A9) with clean engine oil then torque to 70 Nm

(50 lbf ft) 7,1 kgf m.

3 Lub ricate all valve gear bearing surfaces with clean engine oil then fit each item to its original position.

4 Lubricate the thread of the nut (A11) and the Allen screw (A3) with clean engine oil then torque to 250 Nm

(180 lbf ft) 25,5 kgf m.

Note: Ensure that the rocker shaft is pulled squarely onto the rocker box.

5 Set bridge piece and valve clearances, refer to the relevant User Handbook, Chapter 4, page 33.

6 Fit a new joint to the rocker cover (A4), tighten the retaining screws (A5) to a torque of

4 Nm (3 lbf ft) 0.4 kgf m.

A

1

2

11

4

5

3

10

9

6

7

8

D135

Workshop Manual, TPD 1511E, issue 1 19

Page 32

3

0

6

4000 Series

Valve gear

To inspect rockers, bridge pieces and rocker shaft Operation 3-2

1 Check the push rods (A13) are straight, the cup end (A15) and the spherical end (A12) smooth surfaced and

concentric.

2 Clean the bore and top surface on the bridge piece.

3 Check the adjuster screws and locknuts (A16) are undamaged.

4 Check the clearance between the bridge pieces (A5) and their guide pillars in the cylinder head. For the

maximum clearance, refer to the Data and dimensions for "Rocker assembly" on page 10.

5 Check the valve contact patch (A6) is not indented or chipped.

Note: A small indent on the bridge piece pressure pad can be removed with an oil stone.

6 Check the bridge piece pressure pad (A7) for indentation.

7 Check the rocker shaft (A11) for wear and the oil galleries (A9) are clear.

15

12

13

16

14

11

1

10

2

9

3

4

8

7

5

6

A

20 Workshop Manual, TPD 1511E, issue 1

D135

0000

Page 33

4000 Series

7

3

To replace the bridge piece pressure pad Operation 3-3

Special requirements

Consumable products

Description Part number

POWERPART

1 Remov e the pressure pad (A2) from the bore of the bridge piece.

Caution: There must be no POWERPART under the pressure pad area (A1).

2 Check the surfaces (A4) on each bridge piece.

3 Apply Loct ite activator ‘T’ to the pressure pad stem and the bridge piece, allow to dry.

4 Apply POWE RPA RT retainer (oil tolerant) to the bridge piece bore (A3).

5 Fit the pressure pad, then stand the assembly upright and allow to cure for two hours.

Retainer (oil tolerant) 21820603

1

A

2

4

3

D135

Workshop Manual, TPD 1511E, issue 1 21

Page 34

3

8

4000 Series

Cylinder head

To remove and fit the cylinder head Operation 3-4

Special requirements

Special tools

Description Part number

Cylinder head lif ting tool T6253/237

To remove

1 Remove the rocker box and the valve gear, see Operation 3-1, then remove the fuel injector, see Operation

11-2 and the brake-back lever.

Note: The cylinder head bolts can only be used twice. Before removal, mark each bolt head with a centre

punch dot (A5). Bolts showing two dots must be replaced.

2 Fit the cylinder head lifting tool (A2) then remove the head bolts in sequence shown (A14, A1, A15, A3). Use

a suitable hoist to remove the cylinder head from the crankcase.

3 Discard the ‘O’ rings (A6, A9, A10, A12), the flame ring (A13) and the push rod tunnel insert and ‘O’ ring

(A4) in the cylinder head, clean the surface of the crankcase.

16

5

4

2

1

15

3

6

14

13

12

8

x

7

9

10

A

22 Workshop Manual, TPD 1511E, issue 1

11

D135

Page 35

4000 Series

8

3

To fit

1 Fit the cylinder head lifting tool (A2). Locate the insert and joint (A4) into the cylinder head combustion face

secure it in position with suitable petroleum jelly.

2 Fit the flame ring (A13) to the liner flange then fit the ‘O’ rings (A6, A9, A10, A12) secure them in position

with petroleum jelly.

3 Use suitable lift equipment in order to lift the cylinder head into position. Ensure that the dowels (A8 and

A11) are aligned. Also ensure that (A7) is in the push rod tunnel. Remove the lifting tool (A2).

4 Using a suitable PBC grease (poly butyl cuprysil) apply one stripe to the bolt thread and coat both sides of

the head bolt washers. Fit the bolts and washers hand tight.

Cylinder head bolt torque sta ges

Stage Torque

1 Hand tight

2 135 Nm

3 270 Nm (200 lbf ft) 27,5 kgf m

4 540 Nm (400 lbf ft) 55,0 kgf m

5 715 Nm (530 lbf ft) 73,9 kgf m

(100 lbf ft) 13,7 kgf m

5 Torque the cylinder head bolts in the stages given, and in the same diagonal sequence (A14, A1, A15, A3).

16

5

4

x

2

1

3

7

6

14

8

9

13

15

12

10

A

11

D135

Workshop Manual, TPD 1511E, issue 1 23

Page 36

3

4000 Series

Valves and springs

To remove and fit the valve and the valve springs Operation 3-5

Special requirements

Special tools

Description Part number

Valve spring compressor T6253/243

Warning! Wear eye protection during this operation.

To remove

1 Carefully turn the cylinder head on its side (A2) and remove the push rod ‘O’ ring and insert (A1).

2 Using the spring compressor (A7), compress a valve spring and remove the split collets (A5) then release

the spring (A6) and retaining collar (A4) then pull the valve (A9) out of the cylinder head.