Page 1

OilExpress System

MOLECULAR SPECTROSCOPY

User’s Gui de

Page 2

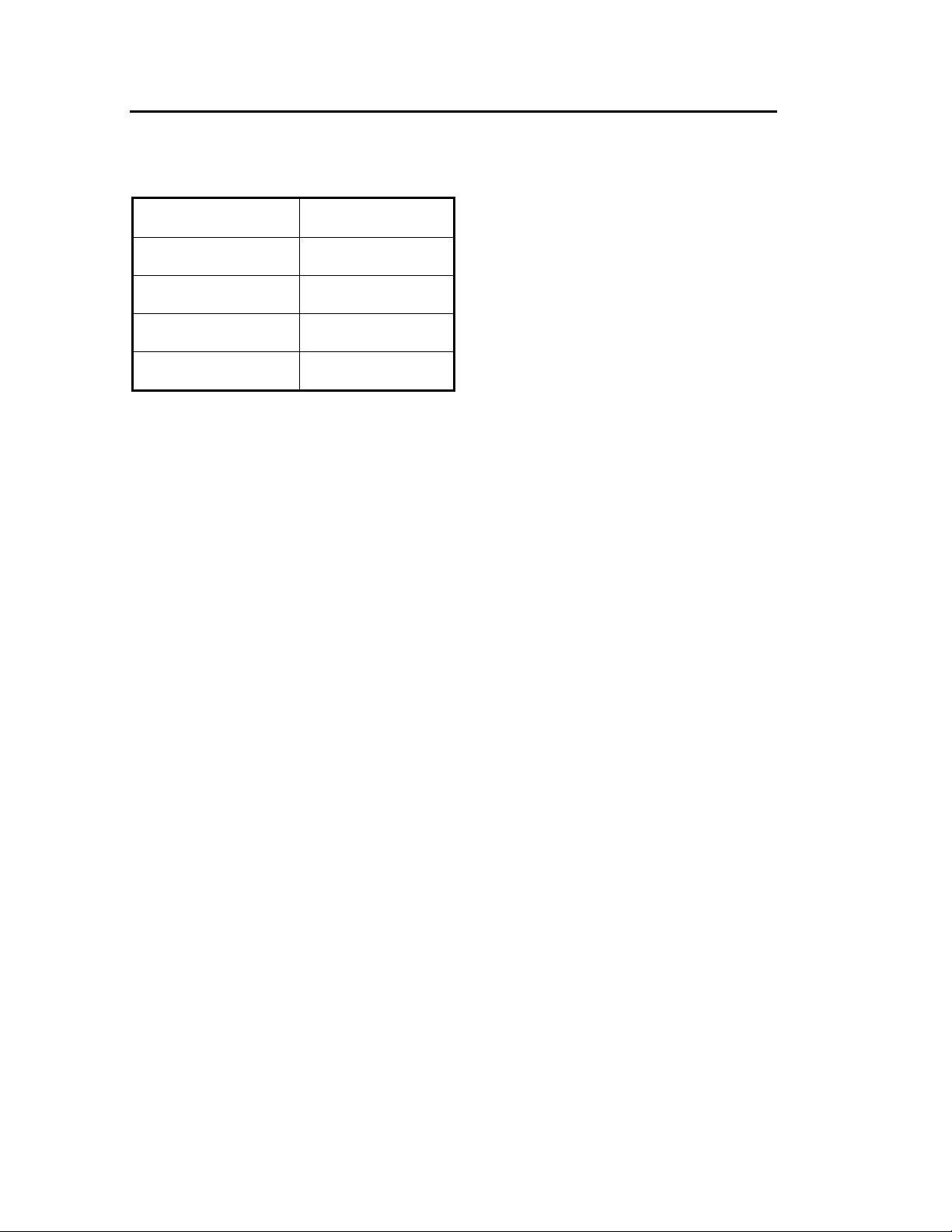

Release History

Part Number Release Publication Date

L1050039 J December 2010

Any comments about the documentation for this product should be addressed to:

User Assistance

PerkinElmer Ltd

Chalfont Road

Seer Green

Beaconsfield

Bucks HP9 2FX

United Kingdom

Or emailed to: info@perkinelmer.com

Notices

The information contained in this document is subject to change without notice .

Except as specifically set forth in its terms and conditions of sale, PerkinEl me r mak es no

warranty of any kind with regard to this document, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose.

PerkinElmer shall not be liable for errors contained herein for incidental consequential damages in

connection with furnishing, performance or use of this material.

Copyright Information

This document contains proprietary information that is protected by copyright.

All rights are reserved. No part of this publication may be reproduced in any form whatsoever or

translated into any language without the prior, written permission of PerkinElmer, Inc.

Copyright © 2010 PerkinElmer, Inc.

Produced in the UK.

Trademarks

Registered names, trademarks, etc. used in this document, even when not specifically marked as such,

are protected by law.

PerkinElmer is a registered trademark of PerkinElmer, Inc.

Frontier and Spectrum are trademarks of PerkinElmer, Inc.

Page 3

Contents

Introduction ............................................................................................... 5

About this Manual ............................................................................................. 6

Using this Guide ......................................................................................... 6

Conventions ...................................................................................................... 7

Conventions Used in this Manual ................................................................. 7

Part Numbers ............................................................................................. 7

Notes, Warnings and Cautions ..................................................................... 7

The OilExpress System .....................................................................................10

A Guided Tour of the OilExpress System ............................................................11

Power Switch and Communications Ports ....................................................12

The Liquid Autosampler ....................................................................................13

X – Y – Z Arm ............................................................................................14

Pumps ......................................................................................................14

Sample Injection/Wash Port .......................................................................15

Sampling Probe/Needle ..............................................................................15

Sample Rack .............................................................................................16

Solvent Bottle ............................................................................................16

Overview of the Sampling Procedure ..........................................................17

Analyzer Measurement .....................................................................................20

Analyzer Sample Compartment ...................................................................20

2-Port Flowcell ..........................................................................................21

FT-IR Liquid Autosampler for Oils: Specifications ................................................22

Warnings and Safety Information ........................................................... 23

OilExpress System Safety Summary ...................................................................24

General Safety .................................................................................................25

Location and Ventilation .............................................................................26

Mechanical Hazards ...................................................................................26

Electrical Safety .........................................................................................26

Samples and Waste ...................................................................................27

Laser Safety Regulations...................................................................................28

Warning Labels ................................................................................................29

Autosampler Labels ...................................................................................29

Warning Signs on the Instrument ...............................................................30

EMC Compliance ..............................................................................................31

EC Directive ..............................................................................................31

FCC Rules and Regulations .........................................................................31

Use of Flammable Solvents and Samples ...........................................................32

Heptane ....................................................................................................33

Material Safety Data Sheets ..............................................................................35

Unpacking and Installation ...................................................................... 37

Overview .........................................................................................................38

Instrument Requirements .................................................................................39

Unpacking .......................................................................................................40

Unpacking the Autosampler ........................................................................40

Unpacking and Installing the Sample Shuttle ...............................................41

Positioning the OilExpress System .....................................................................42

Installing the Liquid Autosampler ......................................................................43

Electrical Connections ................................................................................43

Installing the Fluid Line Suppor t Arm ..........................................................44

Installing Racks (if ordered) .......................................................................45

Autosampler Tubing Connections ......................................................................46

Fluid Tubing System ..................................................................................46

Installing the Flowcell in the Sample Shuttle ................................................49

Waste Container ........................................................................................49

Installing the Syringe .................................................................................50

Page 4

PC Software and Hardware Requirements ......................................................... 51

Software Requirements ............................................................................. 51

Hardware Requirements ............................................................................ 51

Upgrading from a Previous Version of OilExpress ............................................... 52

Upgrading from OilExpress v3.x ................................................................. 52

Upgrading from earlier versions ................................................................. 52

Installing the OilExpress Software ..................................................................... 54

Default Users for OilExpress ............................................................................. 58

Starting up OilExpress and Configuring your Instrument .................................... 59

Calibration ....................................................................................................... 60

Calibrating the Autosampler ....................................................................... 60

Calibrating the Pathlength of the Flowcell ................................................... 66

Installing the Arm Shield ........................................................................... 67

Background to Used Oil Analysis ............................................................. 69

Background to Used Oil Analysis ....................................................................... 70

Infrared Absorption ................................................................................... 70

Why Analyze Used Oils? ............................................................................ 70

Methods of Analysis .................................................................................. 71

Degradation Products ................................................................................ 72

Common Contaminants ............................................................................. 73

Analysis Methods ...................................................................................... 73

Sample Preparation ......................................................................................... 74

Filtering the Oil ......................................................................................... 74

Sample Presentation Requirements ............................................................ 74

Routine Maintenance and Troubleshooting ............................................. 75

Maintenance Schedule ..................................................................................... 76

Autosampler Maintenance Procedures ............................................................... 77

Flushing the Syringe Pump ........................................................................ 77

Cleaning the Syri nge Seal .......................................................................... 77

Cleaning the Sampling Probe ..................................................................... 77

Cleaning the Sample Rack ......................................................................... 77

Cleaning the Injection and Wash Port ......................................................... 77

Cleaning the Z-Rack .................................................................................. 77

Cleaning the Splas h Guard/Safety S hields ................................................... 78

Cleaning the Lead Screw and Lead Screw Encoder ...................................... 78

Cleaning X-Y-Z Mechanis m ........................................................................ 78

Inspecting the Insulation Block/ALIDUM Cable Asse mbly ............................. 79

Checking the Fluid Path (Tubing) ............................................................... 79

Replacing the Sample Probe/Needle ........................................................... 79

Replacing the Syring e Seal ........................................................................ 80

Replacing a Syringe ................................................................................... 80

Replacing the Rea gent Syringe Seal ........................................................... 80

Replacing the 3-port Valve ......................................................................... 82

Replacing the Insulation Block/ALIDUM Cable Assembly .............................. 82

Lubrication ............................................................................................... 84

Changing the Autosampler Fuses ............................................................... 84

Replacing the Tubing ................................................................................ 85

Replacing Reagent and Needle or Cell Tubing ............................................. 85

Replacing Waste Tubing ............................................................................ 86

Maintenance of the Flowcell ............................................................................. 87

Routine Cleaning of the Flowcell, Using Software Utilities ............................ 87

Deep Cleaning the Flowcell, Involving Disassembly ..................................... 88

Warranty Exclusions and Limitations ................................................................. 91

Spares and Consumables ................................................................................. 92

Troubleshooting .............................................................................................. 93

Appendices ............................................................................................... 97

Appendix 1: Decontamination ........................................................................... 98

Appendix 2: WEEE Instructions for PerkinElmer Products ................................... 99

Index ............................................................................................................ 100

Page 5

Introduction

Page 6

6 . OilExpress System User's Guide

About this Man ual

This manual contains the following sections :

• Introduction

• Warnings and Safety Information

• Unpacking and Installation

• Background to Used Oil Analysis

• Routine Maintenance and Troubleshooting

• Index

Using this Guide

This guide tells you how to install and maintain the OilExpress System; we recommend that

you use it as follows:

1. Read

2. Read

3. Follow the procedures in

4. Read the

5. Read

You should use this guide in conjunction with the docume ntation supplied wit h your

spectrometer.

Warnings and Safety Information

OilExpress System.

The OilExpress System

on page 10, to learn about the analyzer.

Unpacking and I nstallation

Maintenance Schedule

System requires.

Background to Used Oil Analysis

and the information that can be obtai ned by analyzing used oils.

on page 23 and this section before usi ng your

on page 37.

on page 76 to learn what maintenance the OilExpress

on page 69 to learn about sample preparation

Page 7

Introduction . 7

Conventions

Conventions Used i n this Manua l

Normal text is used to provide information and instructions.

Bold text refers to text that is displayed on the screen.

UPPERCASE text refers to keys on the PC keyboard. ‘+’ is used to show that you have to

press two keys at the same time, for example, ALT+F.

Part Numb ers

All eight-digit numbers are PerkinElmer part numbers unless stated otherwise.

Notes, Warnings and Cautions

Three terms, in the following standard formats, are also used to highlight special

circumstances and warnings.

NOTE: A note indicates additional, significant information that is provided with some

procedures.

Page 8

8 . OilExpress System User's Guide

einen Geräteschaden zu vermeiden.

undgå en beskadigelse af apparatet.

este tipo de circunstancias.

We use the term CAUTION to inform you about situations that could

CAUTION

result in serious damage to the instrument or other equipment. Details

about these circumstances are in a box like this one.

Caution (Achtung)

Bedeutet, daß die genannte Anleitung genau befolgt werden muß, um

Caution (Bemærk)

Dette betyder, at den nævnte vejledning skal overholdes nøje for at

Caution (Advertencia)

Utilizamos el término CAUTION (ADVERTENCIA) para advertir sobre

situaciones que pueden provocar averías graves en este equipo o en

otros. En los recuadros como éste se proporciona información sobre

Caution (Attention)

Nous utilisons le terme CAUTION (ATTENTION) pour signaler les

situations susceptibles de provoquer de graves détériorations de

l'instrument ou d'autre matériel. Les détails sur ces circonstances

figurent dans un encadré semblable à celui-ci.

Caution (Attenzione)

Con il termine CAUTION (ATTENZIONE) vengono segnalate situazioni

che potrebbero arrecare gravi danni allo strumento o ad altra

apparecchiatura. Troverete informazioni su tali circostanze in un

riquadro come questo.

Caution (Opgelet)

Betekent dat de genoemde handleiding nauwkeurig moet worden

opgevolgd, om beschadiging van het instrument te voorkomen.

Caution (Atenção)

Significa que a instrução referida tem de ser respeitada para evitar a

danificação do aparelho.

Page 9

Verletzung des Benutzers kommen kann.

overholdes.

este tipo de circunstancias.

dans un encadré semblable à celui-ci.

informazioni su tali circostanze in un riquadro come questo.

genomen, dit kan leiden tot verwondingen van de gebruiker.

WARNING

We use the term WARNING to inform you about situations that could

result in personal injury to yourself or other persons. Details about

these circumstances are in a box like this one.

Introduction . 9

Warning (Warnung)

Bedeutet, daß es bei Nichtbeachten der genannten Anweisung zu einer

Warning (Advarsel)

Betyder, at brugeren kan blive kvæstet, hvis anvisningen ikke

Warning (Peligro)

Utilizamos el término WARNING (PELIGRO) para informarle sobre

situaciones que pueden provocar daños personales a usted o a otras

personas. En los recuadros como éste se proporciona información sobre

Warning (Danger)

Nous utilisons la formule WARNING (DANGER) pour avertir des

situations pouvant occasionner des dommages corporels à l'utilisate u r

ou à d'autres personnes. Les détails sur ces circonstances sont données

Warning (Pericolo)

Con il termine WARNING (PERICOLO) vengono segnalate situazioni

che potrebbero provocare incidenti alle persone. Troverete

Warning (Waarschuwing)

Betekent dat, wanneer de genoemde aanwijzing niet in acht wordt

Warning (Aviso)

Significa que a não observância da instrução referida poderá causar um

ferimento ao usuário.

Page 10

10 . OilExpress System User's Guide

The OilExpress Sys tem

The OilExpress System is optimized for the determination of lubricant degradation products.

Based on infrared spectroscopy, the system is capable of measuring the following parameters

in lubricants:

• Soot loading

• Anti-wear additive depletion

• Glycol

• Water

• Nitration

• Oxidation

• Sulfonation

• Fuel contamination

Page 11

Introduction . 11

A Guided Tour of the OilExpress System

Figure 1 The OilExpress System

The PerkinElmer OilExpress System (Figure 1) is a bench-top instrument that provides all the

following in one self-contained unit:

• A spectrometer, fitted with a sample shuttle.

NOTE: The spectrometer may be a Frontier IR System, Spectrum 100 or 400 Series, or

Spectrum One instrument. For full details on how to install and use your

spectrometer, refer to the documentation supplied with your instrument.

• A Liquid Autosampler designed to analyze up to 60 samples an hour.

• A water-resistant flowcell.

The system is controlled by dedicated oil analysis OilExpress software resident on a PC.

NOTE: See the help system available from the Help menu in the OilExpress software, which

includes a tutorial and full information on using the software.

Page 12

12 . OilExpress System User's Guide

Power Switch and Communications Ports

The power switch, AC power cable connector, and communications ports are o n the rear of

the spectrometer. The power switch is marked I/O (on/off).

The power switch, AC power cable connector, and communications ports are located on the

left-hand side of the Autosampler (see Figure 2).

Power switch

Figure 2 Location of the Autosampler power switch

The spectrometer is connected to a PC, either point-to-point or over a network.

The Liquid Autosampler module is connected to the same PC via an RS232 link.

Page 13

Introduction . 13

The Liquid Autosampler

The OilExpress System uses a Liquid Autosampler to enable the rapid sampling of up to 60

oil samples per hour. Figure 3 shows a general view of the Liquid Autosampler.

The Liquid Autosampler provides:

• Minimal sample carry-over by flus hing the needle and flowcell with solvent.

• A 2-port flowcell that is designed for the analysis of viscous liquids.

• Flexible sample presentation: a rack that holds 30 sample bottles, or test tube racks

with a capacity of 240.

• Solvent bottle.

• Two high-resolution syringe pumps to provide robust, reliable liquid handling.

Figure 3 The liquid autosampler

Page 14

14 . OilExpress System User's Guide

X-frame

Arm

Insulation Block

Z- rack

Coax Cable

CCU-9000

ADRI-9 Board

ADRI-9 Board Cover

X-slide

X – Y – Z Arm

Figure 4 X – Y – Z arm mechanism

The X – Y – Z arm movements are controlled by stepper motors linked by drive belts.

Pumps

The Autosampler uses two syringe pumps. These pumps are located on the back panel of the

auto stepper motor driven syringe pump (Figure 5). The pump consists of a syringe drive, a

valve drive, and control electronics. The head of the syringe is attached to the valve

assembly that controls the input and output of the fluid path. The plunger of the syringe is

attached to the syringe drive that moves the plunger up and down.

Figure 5 The sample pump

Page 15

Introduction . 15

Injection port

Sample Injection/Wash Port

The Sample Injection/Wash Port (Figure 6 and Figure 7) consists of a waste transfer and

port. After completion of a liquid handling function, the excess sample is discarded in the

waste port. The probe is then moved to the wash port for cleaning. Washing is accomplished

by pumping wash fluid through the probe. The fluid then flows around the outside of the

probe and overflows into the waste port. The waste fluid then travels by gravity out of the

waste tubing to a waste reservoir located below the instrument.

Sample injection &

wash ports

Waste exit port

Interconnect

tubing port

Figure 6 Sample injection and wash ports (s ide v iew)

v2

v3

Wash station

Waste position

v1

Bolt

Figure 7 Sample injection and wash ports (top view)

The transfer port is used to transfer the sample to the flowcell located in the sample

compartment of the spectrometer. The transfer port consists of a nylon fitting into which the

sample probe is lowered.

Sampling Probe/Needle

The sample is drawn through the stainless steel needle and delivered to the flowcell via the

transfer port. The needle is cleaned in the wash por t: the solvent flows down inside the

needle, and then is forced up around the outside and to waste.

Page 16

16 . OilExpress System User's Guide

Sample Rack

A 30-bottle sample rack is supplied as shown in Figure 8.

Figure 8 Autosampler sample rack

Solvent Bottle

In the event of a solvent spillage, isolate the power to the OilExpress

System immediately and then clean up the solvent spill. The system can

then be powered up but the spectrometer should be allowed to stabilize

WARNING

The recommended solvent for the OilExpress System is heptane. This should be aspirated

from a supply adhering to laboratory safety standa r d s that advise on its safe storage,

handling, use and disposal.

If using the solvent bottle supplied with the OilExpress System (Figure 9), the following is

recommended:

• The solvent bottle should be re-filled away from the OilExpress System, in a

well-ventilated area, and precautions should be taken against static discharge.

• The bottle lid should be used at all times. The solvent bottle lid should be correctly

fitted to the bottle during operation of the OilExpress System.

• The bottle should be stored to the rear of instrumentation at a location where it will not

be knocked accidentally.

for at least two hours before measurements are taken.

Page 17

Introduction . 17

Solvent bottle lid

Solvent bottle

Figure 9 Solvent bottle

Overview of the Sampling Procedure

1. At the start of an ana lysis, the wash volume of solvent is drawn up by each pump.

2. The sample pump valve switches to the needle and the cell pump switches to the cell,

and the solvent is dispensed.

3. The needle is lowered into the sample and the sample is aspirated by the drawing down

of the sample pump.

The default volume aspirated is 3.5 ml.

Page 18

18 . OilExpress System User's Guide

4. The needle then moves to the transfer port.

5. The sample pump dispenses the sample to the cell.

Only 2.1 ml of sample is dispensed to the cell.

To aid the transfer of the viscous liquid and prevent pressure build up, the cell pump is

simultaneously drawn back by the same volume.

6. The OilExpress software performs a sample det ection.

7. When the sample has been successfully detected the needle moves to the waste port to

dispense the remaining sample.

8. The sample pump valve switches position so that the pump is connected to the solvent

reservoir.

9. The pump aspirates the solvent.

10. The sample pump valve then switches back to the needle.

11. The needle moves and lowers into the wash port.

Page 19

Introduction . 19

12. The sample pump dis penses the solvent to flush out the tubing and the needle.

When the needle has been flushed the next sample can be aspirated.

13. When OilExpress has completed scanning the sample, the cell pump valve switches to

the cell and the pump moves to push the sample back through the cell and back

through the trans fer port where it then flows to the adjacent wash port.

14. The cell pump valve switches to the reservoir and aspirates solvent.

15. The cell pump valve then switches back to the cell and the pump moves up to flush the

cell and the tubing.

Waste from this process flows back through the cell and the transfer port to waste.

Page 20

20 . OilExpress System User's Guide

Analyzer Measurement

Analyzer Sample Compartment

DO NOT use the OilExpress System when the sample compartment lid is

fitted. Flammable vapor may seep through instrument seals and gasket s

and accumulate under the lid, where it could cause a fire or explosion

WARNING

CAUTION

hazard.

The sample compartment windows may be composed of a hygroscopic

material, such as KBr; which, although coated, can be damaged by high

levels of humidity. Refer to the documentation supplied with your

spectrometer for details.

If you spill liquid in the sample compartment, wipe it up quickly.

Relative humidity higher than 80 % can damage the windows of the

CAUTION

The sample compartment (Figure 10) is located at the front of the instrument.

Figure 10 Sample compartment of a Frontier IR System

sample compartment.

• The infrared beam enters the compartment through an aperture on the left. After

passing through the sample, it enters the detector area through an aperture on the

right side of the sample compartment.

• A sample shuttle is installed in the sample compartment. The sample shuttle is used to

move the flowcell of the Liquid Autosampler in and out of the beam.

Page 21

Introduction . 21

2-Port Flowcell

The 2-port flowcell (Figure 11) is used in a sample shuttle so that a background spectrum

can be collected regularly if sampling times are long, or to compensate for changing

environmental co nditions. The sample shuttle moves the flowcell in and out of the beam

between collecting a background and sample spectrum.

Flowcells are fitted with zinc selenide (ZnSe) windows for use with mid infrared

spectrometers. Each flowcell is fitted with two windows.

Figure 11 The 2-port flowcell

Filling and emptying the flowcell

In the 2-port flowcell, the sample enters the flowcell at the bottom of the cell. When the cell

is emptied, the sample is pushed back out of the bottom of the flowcell, up through the

transfer port and evacuates to waste by gravity.

Rinsing the flowcell

When the flowcell is rinsed, the solvent enters the flowcell at the top of the cell, and leaves it

at the bottom, then passes through the transfer/wash port to waste.

Page 22

22 . OilExpress System User's Guide

FT-IR Liquid Autosampler for Oils: Specifications

Sample Viscosity Range 4–1000 cSt (centiStokes)

Sample Throughput Approximately 50 per hour for 200 cSt samples

Sample Carry-over <0.1%

Wash Solvent Carry-over 1% typical

Capacity 30 × 4 oz bottles / 240 × 16 mm vials

Minimum Sample Vo lume 4 ml

Flowcell – mid infrared Flow-through trans mission with ZnSe windows:

0.1 mm pathlength

Page 23

Warnings and Saf et y

Information

Page 24

24 . OilExpress System User's Guide

OilExpress System Safety Summary

The PerkinElmer OilExpress System has been designed to comply with a wide variety of

international standards governing the safety of laboratory equipment. In routine use, the

OilExpress System poses virtually no risk to you. If you take some simple, common sense

precautions, you can make sure that you maintain the continued safe oper ation of the

OilExpress System.

DO make sure that the OilExpress System is properly connected to the electrical supply; in

particular make sure that the ground (earth) is securel y connected.

DO take care with solvents: heptane is highly flammable. Remove the solvent bottle and

move it away from the OilExpress System before you fill it. Always keep the lid on the solvent

bottle.

DO disconnect the electrical power cable before opening the main cover of the spectrometer.

DO keep the OilExpress S ystem dry. Avoid spilling liquid into the OilExpress System. Clean all

external spills immediately. If anything that is spilled enters the main body of the OilExpress

System, switch off the power and call a PerkinElmer Service Engineer.

DO NOT stare into the laser beam. The spectrometer contains a low power, visible (r ed)

laser; momentary exposure to the beam is not dangerous, but deliberate, direct viewing of

the beam along its axis could damage your eye.

DO NOT use the OilExpress System when the sample compartment lid is fitted. Flammable

vapor under the lid could be a fire or explosion hazard.

DO NOT use a flammable gas to purge the spectrometer. The spectrometer contains a hot

source, and a fire or explosion will result. Only use clean, dry, oil-free nitrogen or air to purge

the instrument.

DO NOT place hands b eyond the line at the front of the Autosampler enclosure whilst

operating the OilExpress Sy stem.

Read the more detailed information on warnings and safety in the following pages, and in

the documentation supplied with your spectrometer, to ensure the safe operation of the

instrument.

Page 25

Warnings and Safety Information . 25

General Safety

The OilExpress System has been designed and tested in accordance with PerkinElmer

specifications and in accordance with the safety requirements of the International

Electrotechnical Commission (IEC). The spectrometer conforms to IEC publication 61010-1

(“Safety requirements for electrical equipment for measurement, control, and laboratory

use”) as it applies to IEC Class 1 (earthed) appliances and therefore meets the requirements

of EC low voltage directive 2006/95/EC.

If the instrument is used in a manner not specified by the manufacturer, the protection

provided by the instrument may be impaired. Only use the OilExpress System indoors and

under the following conditions:

Temperature: 15 °C to 35 °C

Relative Humidity: 80% maximum (non–condensing)

If possible, avoid any adjustment, maintenance and re pair of the opened, operating

instrument. If any adjustment, maintenance and repair of the opened, operating instrument

is necessary, this must only be done by a skilled person who is aware of the hazard involved.

Whenever it is likely that the OilExpress System is unsafe make it inoperative. The OilExpress

System may be unsafe if it:

• Shows visible damage.

• Fails to perform the intended measurement.

• Has been subjected to prolonged storage in unfavorable conditions.

• Has been subjected to severe transport stresses.

Use of controls or adjustments or performance o f p rocedures other than

those specified herein may result in hazardous radiat ion exposure.

WARNING

The OilExpress System has been designed to be safe under the following environmental

conditions:

• Indoor use.

• Altitude up to 2000 m (above mean sea level).

• Ambient temperatures of 5 °C to 40 °C.

If the equipment is used in a manner not specified her ein the protection

provided by the equipment may be impaired.

• A maximum ambient relative humidity of 80% for temperatures up to 31°C, decreasing

linearly to 50% relative humidity at 40 °C.

• Mains supply fluctuations not exceeding ±10% of the nominal voltage.

Page 26

26 . OilExpress System User's Guide

Location and Ventilation

To allow for adequate cooling, t he OilExpress System should not b e sited near to room

heating equipment, for example, central heating radiators.

During operation, there should be a minimum gap of:

• 6 inches (15 cm) between any sur face and the cooling louvers at the rear of the

spectrometer.

• 3 inches (7 cm) between the OilExpress System and adjacent equipment.

• 1 inch (2.5 cm) between any wall or obst ructing surface and the ventilation panel on

the back of the Auto sampler.

Make sure that the switches at the electrical supply inlet on the rear and

.

side of the OilExpress System are not obstructed

WARNING

Mechanical Hazards

Whenever the autosampler is in operation there is the risk of injury from

moving mechanical parts. The autosampler is de signed for automatic

hands-off operation only. Never reach into the autosampler workspace

WARNING

when the autosampler is in operation

.

Electrical Safety

• Connect both units comprising the OilExpress System to a power supply line that

includes a switch or other means of disconnection from the electricity supply.

• Only plug the OilExpress System into an electricity supply socket that is provided with a

protective earth connection.

• When fuses need replacing, use only those with the requi red current rating and of the

specified type. Do not use makeshift fuses and do not short-circuit fuse holders. On the

Autosampler, replace both fuses if one blows as the second one will be weakened.

• When the OilExpress System is connected to its electricity supply, terminals may be live

and the removal of covers other than those that can be removed by hand is likely to

expose live parts.

• Capacitors inside the OilExpress System may still be c harged even if the instrument has

been disconnected from all voltage sources.

Page 27

Warnings and Safety Information . 27

• The OilExpress System must be disconnected from all voltage sources before it is

opened for any adjustment, replacement and maintenance, or cleaning up of any major

liquid spills.

• Do not touch any swi tches or outlets with wet hands.

Any interruption of the protective earth conductor inside or outside of any

components comprising the OilExpress System or disconnection of the

protective earth terminal can make the instrument dangerous.

WARNING

The OilExpress System has:

• An IEC Pollution Degree 2 classification – usually only non-conductive atmospheric

pollution of the equipment occurs; occasionally, however, a temporary conductivity

caused by condensation must be expected.

• An IEC Insulation class I rating for external circuits – only connect equipment that

meets the requirements of IEC 61010-1, IEC 60950 or equivalent st andards.

The instrument is designed to be safe under transient overvoltages typically present on the

MAINS supply.

NOTE: The normal level of transient overvoltages is impulse withstand (Overvoltage)

category II of IEC 60364-4-443.

Samples and Waste

Samples

When using the flowcell, to ensure that the sample will flow through the flowcell the

maximum particle diameter must not exceed 50 µm.

Solvent

The recommended solvent for use in the OilExpress System is heptane. Observe the

warnings in

Use of Flammable Solvents and Samples

Waste

DO position the waste container on a surface that is at l east 90 cm (36 inches) below the

bench on which the OilExpress System is located because the flow of waste relies on gravity.

DO NOT immerse the ends of the tubes in the waste.

on page 32 when using hep t a ne.

Disposal of waste

Observe local and national regulations when disposing of waste from the OilExpress System .

Page 28

28 . OilExpress System User's Guide

Laser S afe ty Reg ula tio ns

The OilExpress System is a CDRH Class I, BS EN 60825-1/IEC 60825-1 Class 1 laser product

as defined by IEC 60825-1. The optical module contains a Class 2 Helium Neon (HeNe) laser,

which emits visible, continuous wave radiation at a wavelength of 633 nm and has a

maximum output power of 1 mW. Some diffuse HeNe laser radiation, within Class 1 limits,

emerges from:

• The window in the left hand side of the sample compartment when an internal

beampath is selected.

• An external beam port when the beam port cover is removed, no accessory is fitted at

the port, and the beampath to the port is selected.

Do not stare into any laser beam. Staring into a laser beam (intrabeam

viewing) can cause permanent damage to your eyes.

WARNING

The laser is automatically shut down when the main cover of the instrument is raised.

Do not attempt to override or modify the interlock system.

Use of controls or adjustments or performance of procedures other tha n

WARNING

The instrument complies with the following laser safety regulations:

1. 21 CFR Part 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No.50

dated 24 June 2007. Administere d by the Center for Devices and Radiological Health,

U.S. Department of Health and Human Services.

2. EN 60825-1:2007 – “Safety of laser products – Part 1: Equipme nt classification and

requirements”.

For further information on the safe use of your spectrometer, refer to the documentation

supplied with the i nstrument.

those specified herein may result in hazardous radiat ion exposure.

Page 29

Warnings and Safety Information . 29

Warning Labels

When this label is attached to an instrument it means refer to the manual

in order to find out the nature of the potential hazard and any actions

which have to be taken.

Autosampler Labels

Labels are fixed to the Autosampler in the locations shown in Figure 12 & Figure 13.

Figure 12 Autosampler labels (front)

Figure 13 Autosampler labels (rear and left side)

Page 30

30 . OilExpress System User's Guide

Warning Signs on the Instrument

Caution, hot surface

Caution, risk of electric shock

Caution, laser radiation hazard

Caution risk of danger.

Refer to accompanying documents in all cases where this symbol is used

to find out the nature of the potential HAZARD and any actions which

have to be taken.

Page 31

Warnings and Safety Information . 31

EMC Compliance

EC Directive

The OilExpress System has be e n designed and tested to meet the requirements of the EMC

Directive 2004/ 10 8/E C. The OilExpress System complies with the EMC standard EN 61326

(EMC standard for electrical equipment for measurement, control and laboratory use).

FCC Rules and Regulations

This product is classified as a digital device used exclusively as industrial, commercial, or

medical test equipment. It is exempt from the technical standards specified in Part 15 of the

FCC Rules and Regulations, based on Section 15.103 (c).

Page 32

32 . OilExpress System User's Guide

Use of Flammable Solvents and Samples

The spectrometer contains a hot source and contact with flammable

vapors may cause an explosion. When working with flammable solvents

or samples, parti cularly during unattended operation with flow-cells, it is

WARNING

WARNING

WARNING

recommended that the instrument optics area should be continuously

purged with dry air or nitrogen to maintain a positive pressure and

prevent flammable vapor entering the instrument.

DO NOT use the OilExpress System when the sample compartment lid is

fitted. Flammable vapor may seep through instrument seals and gasket s

and accumulate under the lid, where it could cause a fire or explosion

hazard.

If flammable solvents or samples are spilled on the instrument and there

is any possibility that they have entered the interior (b y coming into

contact with cover gaskets for example) then the instrument must be

switched off immediately and disconnected from the power supply. The

optics area should then be thoroug hly purged with dry air or nitrogen, or

the main cover should be opened to thoroughly ventilate the optics area

before proceeding.

WARNING

WARNING

Flammable solvents or samples should not be stored on or near the

instrument. Handling of such materials during prepa r ation should be

performed in a safe area away from the instrument such as a fume

cabinet.

Some chemicals used with this instrument may be hazardous or may

become hazardous after completion of an analysis. The responsible body

(for example, the Laboratory Manager) must take the necessary

precautions to make sure that the surrounding workplace is safe and that

the instrument operators are not exposed to hazardous level s of toxic

substances (chemical or biological) as defined in the applicable MSDS

(Material Safety Data Sheets) or OSHA (Occupational Safety and Health

Administration (United States)), ACGIH (American Conference of

Governmental Industrial Hygienists (United States)), or COSHH (Control

Of Substances Hazardous to Healt h (United Kingdom)) documents.

Venting for fumes and disposal of waste must be in accordance with all

national, state and local health and safety reg ula tions and laws.

Page 33

WARNING

before

WARNING

Warnings and Safety Information . 33

We recommend that you use heptane as the rinse solvent in the

OilExpress System. This highly flammable solvent presents no hazard

during routine use of your OilExpress System, but:

•

DO clean up leakages and spillages immediat ely and thoroughly.

•

DO move the solvent bottle away from the OilExpress System

you fill it.

•

DO always keep the lid on the solvent bottle.

•

DO NOT allow the syringe pumps to run dry; make sure that there is

always sufficient solvent in the solvent bottle.

DO make sure that the waste tubing is not blocked and that it outlets to

a suitable waste container which stands on a surface at least 90 cm

below the bench on which the OilExpress System is located.

The end of the waste tubing should not be immersed in the waste

material.

DO read and observe the information supplied with the solvent.

Heptane

Safety information for heptane is summarized below. See the Materials Safety Data Sheet

(MSDS) for heptane, s upplied by your local Safety Officer, for full details.

Physical data

Description Clear, colorless liquid with a faint gasoline-like odor

Boiling point 98 °C

Specific gravity 0.6837

Solubility in water Insoluble

Vapor pressure 40 mmHg at 20 °C

Vapor density 3.45

Page 34

34 . OilExpress System User's Guide

Fire and explosion hazard

Heptane is flammable (USA definition)/highly flammable (European definition)

Flash point -4 °C

Explosive limits 1.05 - 6.7 %

Ignition temperature 223 °C

Firefighting measures Extinguish fire with foam, dry powder, carbon dioxide or

vaporizing liquid

Storage and handling

When storing heptane, observe local and national regulations. Keep containers tightly closed.

When handling heptane, wear safety goggles and protective gloves. Do not breathe the

vapor, and avoid contact with eyes, skin and clothing.

Page 35

Warnings and Safety Information . 35

Material Safe ty Da ta Shee ts

Some of the materials described in these procedures are hazardous.

Appropriate safety equipment and clothing should be used when

handling them. See the Materials Sa fety Data Sheets (MSDS) supplied by

your local Safety Officer for details.

WARNING

You can search for up-to-date copies of safety data sheets on materials, such as ZnSe, used

in PerkinElmer products that are known to have safety issues from the Technical Resources

section of the PerkinElmer website. The MSDS information is availab le in a range of

languages, and includes data items required in specific national, supra-national and state

jurisdictions.

To obtain a safety data sheet for a particular compound, follow the steps described below.

NOTE: To read MSDS .pdf files you will need Adobe Reader 5.0 or later. An installation of

this software is available on the

They must be disposed of with care, following your laboratory

procedures.

Software Utilities CD

.

1. Launch your web browser and navigate to the PerkinElmer web site:

www.perkinelmer.com

If you are not redirected automatically you may have to select the home page

appropriate to your location.

2. Search for the term MSDS using the se arch box located at the top of the home page.

The Search for Material Safety Data Sheets (MSDS) page is displayed.

3. Enter the key words for the compound, in the Product name box, and then click Go.

A full list of all MSDS documents that refer to the compound is displayed.

4. Select the MSDS document you want to view.

Page 36

36 . OilExpress System User's Guide

Page 37

Unpacking and

Installation

Page 38

38 . OilExpress System User's Guide

Overview

Installation of the OilExpress System and OilExpress software will be performed by a

PerkinElmer Service Engineer. The installation proce d ure is summarized below.

• Unpack the Autosampler

• Unpack and install the sample shuttle in your spectrometer

• Connect the Autosampler

• Install OilExpress software

• Configure the OilExpress system

• Calibrate the OilExpress system

NOTE: For details of how to unpack and install your spectrometer, please refer to the

documentation s upplied with your instrument.

Page 39

Unpacking and Installation . 39

Instrumen t Requi reme nts

NOTE: Read the warnings and safety information at the start of this manual before installing

the OilExpress System. They contain important information.

Electrical requirements

• The OilExpress System can operate on electr icity supplies of 50 or 60 Hz and on voltage

ranges of between 100 and 120 V or between 220 and 240 V.

• The line supply must be within 10% of t he nominal voltage .

• The power rating of the Autosampler is 300 W.

• If possible, do not connect the OilExpress System to circuits that have heavy-duty

equipment, such as large motors, connected.

• If possible, do not use photocopiers, discharge lamps, radio transmitters, and other

equipment with large or frequent transient loads on the same supply circuit.

Environment

To obtain the best performance from your OilExpress System:

• Place the OilExpress System in an environment that is relatively

dust-free.

• Make sure that the bench top is free from vibrations or mechanical shocks.

• Do not place the OilExpre ss System or the PC near to room heating equipment, for

example, central-heating radiators.

• Leave at least 7 cm (3 inches) from any vertical obstacle to the sides of the OilExpress

System, to permit an adequate flow of cooling air.

• Make sure that there are no overhanging shelves, and no water pipes or faucets that

could leak onto the OilExpress System.

• The area near the PC must be free of strong magnetic fields, direct sunlight, and

heating or cooling units or ducts.

Page 40

40 . OilExpress System User's Guide

Unpacking

Unpacking the Autosampler

The Autosampler is a heavy instrument with a basic weight of

approximately 30 kg, so two people are required for safe handling.

WARNING

When you receive the instrument, look at the exterior of the container for possible

shipping damage. Check for the following items:

– Water damage or discoloration

– Cuts or gashes

– Collapsed corners

Consult the local codes of practice issued by safety advisors before

attempting to lift it.

Take care not to injure yourself or others, or to drop the Autosampler.

– Crushed top or sides

– Other physical damage

NOTE: If any of the above items are found, contact PerkinElmer and the shipping agent

immediately.

Before unpacking the Autosampler, make sure that there is sufficient space to lay out the

instrument and accessories. This makes checking the contents of the box against the packing

list easier. Follow the steps below to prevent damage to the instrument:

1. Remove the plastic shrink-wrap.

2. Cut the two (2) bands.

3. Lift off the top of the shipping carton.

4. Empty the small accessories from the end sections of the carton.

5. Gently lift the entire upper portion o f the inner container and set it aside.

6. Remove the styrofoam cushions on top of the instrument.

7. Remove instrument from the shipper and place it on a work surface.

Do not lift the Autosampler by its arm guard.

CAUTION

Page 41

Unpacking and Installation . 41

8. Inspect instrument for any physical damage.

9. Open the box of accessories and place the contents on an open surface.

10. Check to make sure that all parts have been received.

NOTE: If any parts are missing from the packing list, contact PerkinElmer immediately.

Unpacking and Installing the Sample Shuttle

The sample shuttle accessory can be simply installed into the sample compartment of the

spectrometer.

1. Unpack the sample shuttle from its box.

2. Rest the back of the sample shuttle accessory on the ledge in the sample area and slide

it into position.

Push it firmly home to ensure that the multiway connector on the rear of the sample

shuttle accessory mates properly with the spectrometer connector.

When the sample shuttle locks into place it aligns itse lf, which means

that the slide holder may move. Be careful that your fingers, tie, etc are

not trapped by the movement.

WARNING

Figure 14 Installing the sample shuttle accessory

NOTE: To remove the sample shuttle accessory, release the accessory by pulling the blue

handle under its baseplate, and then slide the accessory towards you and out of the

sample compartment.

Page 42

42 . OilExpress System User's Guide

Positioni ng the OilExpress System

The Autosampler is a heavy instrument with a basic weight of

approximately 30 kg.

WARNING

1. Position the Liquid Autosampler on the bench as shown below (Figure 15).

Leave a gap of 0.5–1 cm between the Autosampler and the spectrometer. Ensure that

you have space for the PC either to the right side of the spectrometer, or to the left side

of the Autosampler.

Two people are required for safe handling.

Consult the local codes of practice issued by safety advisors before

attempting to lift it.

Take care not to injure yourself or others, or to drop the instruments.

Figure 15 The OilExpress System positioned for use

2. Align the Autosampler and the spectrometer so that the rear of the injection wash port

and the sample shuttle are parallel.

The spectrometer protrudes approx imately 5 cm in front of the Autosampler when

correctly alig ned.

Make sure that there is access to power and a waste container.

3. Place the PC in a suitable location.

4. Remove the Velcro straps and plastic cable ties around the Z-rack.

5. Remove any additional packaging and support from the Autosampler and make sure

that the arm is able to move freely on all axes.

Page 43

Unpacking and Installation . 43

Installing the Liquid Autosampler

Electrical Connections

Power cord

1. Make sure that the Autosampler is switched off.

2. Fit the molded socket of the mains cable into the plug on the side panel of the

Autosampler (Figure 16).

3. Plug the power cord into the appropriate mains electrical supply.

Figure 16 The side panel of the autosampler

Cable to PC

1. Attach the male connector into the DB25 receptacle on the left side of the Autosampler

(Figure 16), and tighten the screws.

2. Attach the female connector of the cable to the DB9 SERIAL COMM 1 port on the back

of the PC, and tighten the screws.

If the computer has a DB25 connector, an adapter is required.

Page 44

44 . OilExpress System User's Guide

Installing the Fluid Line Support Arm

Insert the fluid line support arm into the liquid connector bl ock on the right of the

autosampler.

Figure 17 Fluid line support arm

NOTE: The Arm Shield is not installed until the remainder of the installation, including

software installation and calibration has been completed.

Page 45

Unpacking and Installation . 45

Rack installs here

Rack installs here

Installing Racks (if ordered)

1. Remove and unwrap rack.

2. Place the sample rack on the pins as shown in Figure 18.

Figure 18 Installing the sample rack

Figure 19 Sample rack

Page 46

46 . OilExpress System User's Guide

Autosample r Tubi ng Co nnec tion s

Fluid Tubing System

1. Remove the reagent tubing (L1200556) from the accessory bag. Route the ends with

the fitting throug h the black grommet hole on the right panel of the autosampler. Install

fitting on the right valve port of each of the syringe pum ps. Tighten the fitting fing er

tight and then tighten an additional quarter turn with a wrench.

2. Remove the inte rconnect tubing (L1200585) from the accessory bag. Route one end of

the tubing through t he black grommet hole on the right panel. Install the fitting on one

end to the left valve port of the right syringe pump. Connect the fitting on the other end

to the top of the 2-port flowcell. Tighten fittings as above.

3. Remove the needle tubing (L1200587) from the accessory bag. Install the end with the

fitting into the left valve port of the left syringe pump. Insert the other end through the

fluid line support arm (Figure 17), and then through the top of the Z-rack until it

extends approximately one inch out from the lower end (Figure 21).

4. Remove the interconnect tubing (L 1200557) from the accessory bag. Install the fitting

on one end to the bottom of the injection\wash port (Figure 6) and the other to the

bottom of the 2-port flowcell. Tighte n the fitting finger-tight and then tighten an

additional quarte r turn with a wrench.

From cell flush syringe

From transfer/wash port

Figure 20 Connecting tubing to the 2-port flowcell

Page 47

Unpacking and Installation . 47

Cell

Needle

Solvent

Solvent

Z-rack

Figure 21 Tubing connections from the pumps to the 2-port flowcell

5. Remove the needle from the accessory bag. Loosen the slo tted screw in the insulation

block, and then insert the shorter end of the needle through the sleeve in the insulation

block as far as the collar. Retighten the screw.

Electrostatic discharge to the sampling probe may cause damage to the

CAUTION

ALIDUM liquid level detector (see

Cable Assembly

on page 82).

Inspecting the Insulation Block/ALIDUM

Z-rack

Probe Tubing

Allen screw

Slotted screw

Needle

Insulation block

Insulation block sleeve

Needle

Figure 22 Connecting the needle tubing to needle

Page 48

48 . OilExpress System User's Guide

6. Push the needle tubing over the shorter end of the needle (to a minimum of 25 mm,

1 inch).

7. Loosen the Allen screw on the insulation block. Install the insulation block on the Z-rack

with the insulation blo ck sleeve facing down and the insulatio n block (black coax) cable

on the left side. Ensure that the insulation block cable is not twisted.

8. Push the insulatio n block onto the Z-rac k until firmly seated.

9. With an Allen wrench, tighten the insulation block set screw until it makes contact with

the flat portion of the Z-rack. Do not overtighten the setscrew.

Connecting the tubing to the solvent bottle

1. Thread the tubing from top to bottom through the cap of the wash bottle as shown in

Figure 23.

Solvent bottle lid

Solvent bottle

Figure 23 Connecting the sol v en t tu bing

2. Fill the solvent bottle with solvent.

3. Screw the cap on to the solvent bottle securely.

4. Position the bottle safely, behind the instrumentation at a location where it will not be

accidentally knoc ke d.

Page 49

Unpacking and Installation . 49

Installing the Flowcell in the Sample Shuttle

DO NOT use the OilExpress System when the sample compartment lid is

fitted. Flammable vapor may seep through instrument seals and gasket s

and accumulate under the lid, where it could cause a fire or explosion

WARNING

1. Unpack the flowcell.

2. Slide the flowcell into the sample shuttle (Figure 24).

3. Make sure that the tubing cannot obstruct the optical b eampath.

hazard.

Figure 24 Sample shuttle accessory and flowcell fitted

Waste Container

We recommend that you use a waste container that is larger than the solvent bottle. Then, if

you empty the waste container whenever you refill the solvent bottle, the waste container

will not overflow.

The waste drains into the container by gravity, so the cont ainer should stand on a surface

that is at least 90 cm below the bench on which the OilExpress System is located.

Fitting waste tubing

1. Attach the waste tubing to the hose connector at the rear of the transfer/wash port.

2. Insert the waste tubing into the hole on the rear right-hand side of the base plate of the

Autosampler.

3. Adjust the routing o f the tubing so that it is not kinked.

4. Place the other end of the waste tubing in the waste container.

Ensure that the end will not be immersed in the waste.

Make sure that the ends of the tubing do not become immersed in the

CAUTION

waste or the operation of the analyzer will be impaired.

Page 50

50 . OilExpress System User's Guide

Installing the Syringe

The syringes cannot be installed until the OilExpress software has been installed.

1. Switch on the Autosampler.

2. Start the AutoSampler Utilities.

Select Start, All Programs , Pe rkinElme r Application s, OilExpress and then click

AutoSampler Utilities.

3. Log in as an Administrator.

The User Name is Administrator and the Password is Administrator.

4. Select Pump Diagnostics from the File menu.

5. Click Change Syringe.

6. Assemble the syringe (L1200552) by placing the plunger in syringe barrel and putting

the syringe clamp over the Luer lock fitting.

7. Unscrew the pin from the plunger sha ft.

8. Mount the syringe plunger on the plung er shaft. Line up the barrel with the Luer lock

fitting. Screw the barrel onto the valve fitting while pushing upward slightly.

When mounting the syringe on the val ve, you must assist the Luer lock

CAUTION

9. Replace the plunger pin.

10. Rotate the syringe clamp clockwise then tighten the clamp screw.

11. Replace the plunger screw at the base of the syringe plunger.

threads by pushi ng upward. Otherwise they may become stripped.

Page 51

Unpacking and Installation . 51

PC Software and Hardware Requirements

This section details the minimum hardware and software requirements for the PC. To ensure

successful installation of the software, please check these requirements before starting the

installation.

Only if all of these criteria are met should you start to install the OilExpress software (see

Installing the OilExpress Software

Software Requirements

The minimum software requirements for the OilExpress System are:

• Windows 7 (32-bit), Windows Vista or Windows XP with Servi ce Pack 2 must be

installed, and you must be logged on at Administra tor level.

• Internet Explorer 5.01 or later must be installed.

• Spectrum software must be installed, as described in the documentatio n supplied with

your spectrometer on the

on page 54).

IR & Raman Manuals CD

(L1050002).

Hardware Requirements

The PC you install the software on must meet the following minimum specification:

®

• Intel

• At least 256 MB of Random Access Memory (RAM).

• The capability of displaying at least High Color (16 bit) at 1024 × 768 SVGA.

• 10 GB Hard disk with at least 1 GB free space as an NTFS drive.

• CD-ROM drive.

• Ethernet network connection.

• A keyboard and PS/2

• A serial port, for autosampler connection.

Pentium 4 processor with 500 MHz or great er clock speed, or equivalent.

®

-style mouse.

Page 52

52 . OilExpress System User's Guide

Upgrading from a Previous Version of OilExpress

Upgrading from OilExpress v3.x

If you are upgrading OilExpress from version 3.x, simply uninstall the previous version of

OilExpress before installing the latest version.

All your OilExpress data is automatically retained.

Upgrading from earlier versions

If you are upgrading OilExpress from a version e arlier than 3.0, and you want to retain the

databases from the previous installation, you must copy some files from the old installation

into the new instal lation.

NOTE: The security da tabase cannot be retained. After completing the upgrade you must

recreate all users.

1. Copy the files specified in the upgrade notes that follow this procedure.

2. Uninstall OilExpress.

3. If required, uninstall Spectrum, and then install the latest version.

Follow any applicable guidance provided in the

(L1050095), which is provided on t he

4. Log in to Spectrum and install the spectrometer.

5. Install the latest version of OilExpress (see

page 54).

6. Restore any OilExpress database files you copied at step 1.

IR & Raman Manuals CD

Spectrum Administrator's Guide

(L1050002).

Installing the OilExpress Software

Upgrading from OilExpress v2.2

Before uninstalling OilExpress v2.2, make copies of these database files:

C:\Documents and Settings\All Users\Application Data \PerkinElmer\OilExpress\Local

Repository\*

C:\Documents and Settings\All Users\Application Data \PerkinElmer\OilExpress\Fuel

Calibrations\*

C:\Documents and settings\All users\Application Data\PerkinElmer\OilExpress\Local

Resultstore\resultstore.mdb

on

(where * means copy the entire contents of the folder).

Page 53

Unpacking and Installation . 53

After uninstalling OilExpress v2.2, copy the contents of the Local Repository and Fuel

Calibrations folders back to their original locations.

After installing the latest version of OilExpress (see

page 54), migrate the resultstore.mdb file:

1. Start the Database Tools utility.

Select Start, All Programs , PerkinElmer, OilExpress and then click Database Tools.

2. Select Result Stores and then click Migrate Database.

3. Open the resultstore.mdb file you copied from the previous installation.

4. Enter a short name and a file name for the migrated database.

5. Select the new database from the list and click Set Active Database.

Installing the OilExpress Software

on

Upgrading from OilExpress v1.0 or v2.0

NOTE: Make copies of these database files before uninstalling OilExpress.

• Copy the batchstore.mdb, reference spectra.mdb and repository.mdb files into

folder C:\Documents and Settings\ All Users\Application Data\PerkinElmer\OilExpress

\Local Repository.

• Copy the resultstore.mdb file into folde r C:\Documents and Settings\

All Users\Application Data\PerkinElmer\OilExpress\Local Resultstore.

• Copy the fuel calibration files into folder C:\Documents and Sett ings\

All Users\Application Data\PerkinElmer\OilExpress\Fuel Calibrations.

For OilExpress version 1.0, these files can be found in:

C:\Program Files\PerkinElmer\OilExpress\Local Repository

C:\Program Files\PerkinElmer\OilExpress\FuelCalibrations

C:\Program Files\PerkinElmer\OilExpress\Local Resultstore.

After installing the latest version of OilExpress (see

page 54), migrate the resultstore.mdb file:

1. Start the Database Tools utility.

Select Start, All Programs , PerkinElmer, OilExpress and then click Database Tools.

2. Select Result Stores and then click Migrate Database.

3. Open the resultstore.mdb file you copied from the previous installation.

4. Enter a short name and a file name for the migrated database.

5. Select the new database from the list and click Set Active Database.

Installing the OilExpress Software

on

Page 54

54 . OilExpress System User's Guide

Installing the OilExpre ss Software

The Liquid AutoSampler software CD contains an Installation Wizard to help you install

OilExpress on your PC.

NOTE: The Spectrum software must be installed

documentation s upplied with your spectrometer, on the

(L1050002) for details.

Once the Spectrum software has been installed, det ails of how to administer it can be

found in the

the Manuals CD.

To install OilExpress:

1. Place your Liquid AutoSampler software CD into your CD-ROM drive.

2. If the CD does not auto-run, select Run from the Start menu.

The Run dialog is displayed.

3. Enter d:\Setup.exe and clic k OK.

Replace d:\ with the drive letter for your CD-ROM drive.

After preparing to install, the InstallShield Wizard Welcome dialog is displayed.

Spectrum Administrator's Guide

before

OilExpress. Consult the

IR & Raman Manuals CD

(L1050095), which is also provided on

Page 55

Unpacking and Installation . 55

4. Click Next.

The License Agreement dialog is displayed.

5. Read the agreement, select I accept the terms in the license agreement, and then

click Next.

The Product Selection dialog is displayed.

Page 56

56 . OilExpress System User's Guide

6. Select the OilExpress option and enter your license key; then click Next.

The Instrument Selection dialog is displayed.

7. Select PerkinElmer FT-IR with Autosampler and click Next.

Your software can now be installed.

Page 57

Unpacking and Installation . 57

8. Click Install.

The installation will start.

When the installation is complete, the following dialog will be displayed:

9. Click Finish.

Page 58

58 . OilExpress System User's Guide

Default Users fo r OilExpress

The default passwords for the default user groups in OilExpress are the same as the name of

the group, as follows:

Login Name Password

Administrator administrator

Advanced Analyst advanced analyst

Analyst analyst

Supervisor supervisor

You should immediately change these passwords to stop any unauthorized access to the

software.

For further information see

Setup Users and Groups

in the on-screen Help.

Page 59

Unpacking and Installation . 59

Starting up OilExpres s and Configu ring your Instrument

The first time you start the OilExpress system, if you have not already installed instruments

using the Spectrum software, the Instrument Configuration dialog is displayed.

Use the Add/Edit button to add one or more instr uments. See the on-screen help for

details.

NOTE: Subsequently, if you want other instruments to be made available, you can use the

menu option System Settings > Instruments Settings > Configure Instrument.

Click OK.

NOTE: If you make more than one instrument available for use wi th OilExpress, or a single

instrument capable of operating in both nea r- and mid-infrared, you are prompted to

select which instrument and mode is to be used each time you start OilExpress.

OilExpress should only be used with a spectromet er operating in mid-infrared.

Page 60

60 . OilExpress System User's Guide

Calibration

Before using the OilExpress System two calibration tasks must be performed:

• Calibrate the Autosampler

• Calibrate the flowcell

Calibrating the Autosampler

The Autosampler must be calibrated to correct for any differences in the X-Y-Z zero

alignment and any differences in the injection/wash port positioning.

1. From the Start menu select: Programs > PerkinElmer > Applications > OilExpress >

Autosampler Utilities.

The login screen (PerkinElmer or Windows, as appropriate) is displayed.

2. Enter a User name and Password.

The Autosampler Utilities dialog is displayed.

Page 61

3. From the File menu select WorkTable Editor.

The following dialog is displayed.

Unpacking and Installation . 61

4. Right-mouse click on the Waste Port, and from the drop-down menu displayed select

Properties.

The following dialog is displayed.

5. Select the Calibrate tab.

Page 62

62 . OilExpress System User's Guide

6. Click Position Evaluation.

The following dialog is displayed.

7. Separate the three dialogs on your desktop as shown below.

8. On the Moving Arm Dialog click Open Com.

The Autosampler initializes.

Page 63

Unpacking and Installation . 63

9. In the Anchor Point section of the User-defined Rack Properties dialog, click Go.

10. Click the down button

close as possible to the top of the injection/wash port without actually touching it.

on the Moving Arm Dialog to lower the needle so that it is as

Do not constantly press as this will cause the needle to accelerate.

CAUTION

Take care not to ram the needle into the injection/wash port as this may

cause the needle to bend.

11. Use the left and right arrow buttons

anchor point.

to move the needle so that it is at the

Page 64

64 . OilExpress System User's Guide

Needle position

Needle position

v1 v2 v3

The anchor point depends on the version of your wash st ation. Examine the

injection/wash port fitted, then use the appropriate needle position anchor point, as

shown in Figure 25.

anchor point

anchor point

10 mm

Needle position

anchor point

Figure 25 Injection wash port anchor positions

12. Once the needle has been aligned with the anchor point, click the Anchor Point Insert

button

.

The new numbers appear in the X= and Y= fields.

13. Record the Anchor Point X and Y values in your labora tory notebook as the numbers

can be used in the calibration of other worktables.

14. Click OK.

Page 65

Unpacking and Installation . 65

15. Right-mouse click within the worktable area of the Autosampler Utilities dialog and from

the menu select Save Worktable.

NOTE: The worktable changes are not automatically saved. If you do not select Save

Worktable, the changes will be lost.

NOTE: The procedure described above must be repeated for all worktables used by the

OilExpress software as anchor points are not app lied universally. Follow steps 16 to

20 to calibrate all additional worktables.

16. Right-mouse click within the worktable area of the Autosampler Utilities dialog and from

the menu select Load Existing Worktable.

17. Select the required worktable, PerkinElmer BOTTLES or PerkinElmer VIALS.

18. Repeat steps 4 to 7.

19. Enter the values you previously record ed in your laboratory notebook into the X= and

Y= fields of the User-defined Rack Properties dialog.

Page 66

66 . OilExpress System User's Guide

20. Repeat steps 14 and 15.

21. If the syringes have not yet been installed, comple te the hardware installation on

page 50.

Calibrating the Pathlength of the Flowcell

The OilExpress software calculates the cell pathlength by using a Partial Least Squares multicomponent calibration on heptane. A default calibrat ion file is provided and stored as

c:\quant\pls1\methods\cellpath.md, where c:\ is the drive to whic h the OilExpress software

has been installed. Heptane must be used as the solvent within the OilExpress System for

accurate cell calibration.

1. Log in to OilExpress.

2. Select System Settings > Instrument Settings > System Checks Setup.

The Check Scheduling Properties dialog is displayed.

3. Select Pathlength and click OK.

4. Click the System Checks thumbnail

OilExpress dialog.

The System Checks dialog is displayed.

on the left-hand panel in the main

Page 67

Unpacking and Installation . 67

5. Click Start.

The Autosampler pumps are primed when the system is initialized to ensure that the

cell is filled with heptane. (To prime the pumps manually, refer to

in the online help). The check will be performed.

NOTE: If additional system checks are selected, these will be performed in addition to the

pathlength check in the order that they appear on the screen.

On completion of the pathlength check, Passed or Failed will appear in the dialog. If the

pathlength falls between the limits expected for the ZnSe cell, then the pathlength will be

automatically stored for future use in OilExpress analyses.

If the pathlength check fails, checks the following and then repeat the steps described

above:

• The correct solvent was used

• The solvent was delivered to the cell correctly and there were no leaks

• The beam of the spectrometer is not obstructed

Autosampler Control

• The cell is in the correct position within the sample shuttle

• The limits within the pathlength setup are correct

Installing the Arm Shield

1. Remove the clear rectangular arm shield from the accessory box.

2. Remove the three screws (Figure 26).

3. Position the arm shield under the arm and adjust the shie ld so that the holes in the

shield are aligned with the screw holes on the side of the arm cover.

Page 68

68 . OilExpress System User's Guide

4. Insert the socket head screws through t he holes and tighte n by turning the screw

clockwise.

CAUTION

Do not over tighten the screws as this may crack the plastic shield.

screw

screw

Figure 26 Installing the arm shield

screw

Page 69