Page 1

MOLECULAR SPECTROSCOPY

FRONTIER IR SINGLE-RANGE SYSTEMS

User’s Guide

Page 2

Release History

Part Number Release Publication Date

L1050101 B July 2013

Any comments about the documentation for this product should be addressed to:

User Assistance

PerkinElmer Ltd

Chalfont Road

Seer Green

Beaconsfield

Bucks HP9 2FX

United Kingdom

Or emailed to: info@perkinelmer.com

Notices

The information contained in this document is subject to change without notice.

Except as specifically set forth in its terms and conditions of sale, PerkinElmer makes no

warranty of any kind with regard to this document, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose.

PerkinElmer shall not be liable for errors contained herein for incidental consequential damages in

connection with furnishing, performance or use of this material.

Copyright Information

This document contains proprietary information that is protected by copyright.

All rights are reserved. No part of this publication may be reproduced in any form whatsoever or

translated into any language without the prior, written permission of PerkinElmer, Inc.

Copyright © 2013 PerkinElmer, Inc.

Produced in the UK.

Trademarks

Registered names, trademarks, etc. used in this document, even when not specifically marked as such,

are protected by law.

PerkinElmer is a registered trademark of PerkinElmer, Inc.

Spectrum, AssureID and Frontier are trademarks of PerkinElmer, Inc.

Page 3

Table of Contents

Introduction ............................................................................................... 5

About This Manual ............................................................................................ 6

Conventions Used in this Manual ........................................................................ 7

Notes, Cautions and Warnings ..................................................................... 7

Warnings and Safety Information ........................................................... 11

Safety Summary ...............................................................................................12

General Safety .................................................................................................13

Location and Ventilation ...................................................................................14

To allow for adequate cooling ....................................................................14

To allow any nitrogen used to disperse .......................................................14

Use of flammable solvents and samples ......................................................15

Electrical Safety ...............................................................................................16

Laser Safety Regulations...................................................................................17

Radiation Hazards and their Classification ..........................................................18

Laser radiation ..........................................................................................18

Radiation emitted by the Frontier FT-NIR ....................................................18

Labels .............................................................................................................19

Warning Signs on the Instrument ......................................................................21

EMC Compliance ..............................................................................................22

European EC Directive ...............................................................................22

FCC rules and regulations...........................................................................22

An Overview of the Frontier IR Single-Range Spectrometers ................. 23

A Guided Tour of the Frontier IR Single-Range Spectrometers ............................24

Optical system ...........................................................................................25

Top panel controls .....................................................................................26

The sample compartment ..........................................................................26

Internal accessories ...................................................................................27

External accessories ...................................................................................28

Imaging systems .......................................................................................29

Storage compartment ................................................................................29

Power switch and communication ports ......................................................29

Accessories ......................................................................................................30

Frontier IR Sytems Upgrades ............................................................................31

Unpacking and Installation ...................................................................... 33

Requirements ..................................................................................................34

Electrical requirements ...............................................................................34

Environment ..............................................................................................34

Unpacking the Spectrometer .............................................................................35

Opening the shipping container ..................................................................35

The Desiccant Indicator ....................................................................................37

Connecting up the Spectrometer .......................................................................38

Connecting to the PC .................................................................................38

Other connectors .......................................................................................39

Connecting the spectrometer to the electrical supply ...................................40

Installing the Instrument in the Software ...........................................................42

Installing the software ...............................................................................42

The Instrument Install Wizard ....................................................................42

Using the Spectrometer with Spectrum .................................................. 43

Basics of Software Control ................................................................................44

Starting Spectrum software ........................................................................44

Scanning samples ......................................................................................45

Working with the instrument display and Go button .....................................46

Changing the beam path ............................................................................46

Using the Spectrum on-screen Help system .................................................47

Page 4

Atmospheric (CO2/H2O) Suppression ................................................................. 48

What is atmospheric suppression? .............................................................. 48

What does atmospheric suppression do? .................................................... 48

AVI Correction ................................................................................................. 50

What is AVI correction? ............................................................................. 50

What does AVI correction do? .................................................................... 50

Look Ahead ..................................................................................................... 51

What is Look Ahead? ................................................................................. 51

What does Look Ahead do? ....................................................................... 51

Quality Checks ................................................................................................. 52

What are Quality Checks? .......................................................................... 52

What do Quality Checks do? ...................................................................... 52

Routine Maintenance ............................................................................... 53

Cleaning the Spectrometer ............................................................................... 54

Cleaning the display .................................................................................. 54

Moving the Spectrometer ................................................................................. 55

Condensation ............................................................................................ 55

The Desiccant Indicator in Detail ...................................................................... 56

Changing the Desiccant.................................................................................... 57

Renewing the instrument desiccant ............................................................ 58

Installing rechargeable desiccant in the instrument ..................................... 59

Purging the Spectrometer ................................................................................ 60

Changing the External Fuse .............................................................................. 63

Cooling the MCT Detector (If Fitted) ................................................................. 65

Advanced Maintenance ............................................................................ 69

Opening the Main Cover ................................................................................... 70

Replacing the Source ....................................................................................... 74

Replacing the Beamsplitter ............................................................................... 76

Installing/Replacing Windows ........................................................................... 78

Installing Filters in the Filter Wheel ................................................................... 80

Replacing the Laser and Power Supply .............................................................. 84

Replacing the laser and power supply (External Beam Pack option fitted) ..... 86

Appendices ............................................................................................... 89

Appendix 1: Changing the Sampling Accessory .................................................. 90

Appendix 2: Instrument Self-Checks ................................................................. 92

Appendix 3: Instrument Performance Validation Kits .......................................... 94

Appendix 4: Decontamination and Cleaning ....................................................... 95

Appendix 5: WEEE Instructions for PerkinElmer Products ................................... 96

Index .............................................................................................................. 97

Page 5

Introduction

Page 6

6 . Frontier IR Single-range Spectrometers User's Guide

About This Manual

This manual contains the following sections:

• Introduction

• Warnings and Safety Information

• An Overview of the Frontier IR Single-Range Spectrometers

• Unpacking and Installation

• Using the Spectrometer with Spectrum

• Routine Maintenance

• Advanced Maintenance

• Appendices.

For further information on collecting, viewing and processing spectra using Spectrum

software, refer to the help file that you can access from the Help menu, or by clicking Help

on a dialog.

NOTE: This manual shows details for using your instrument with the Spectrum software

package (version 10 or later). If you have Spectrum ES or AssureID software, please

refer to the Administrator’s Guide for your software which can be found on the

IR & Raman Manuals CD

(L1050002), or refer to the on-screen Help.

Page 7

Introduction . 7

Conventions Used in this Manual

Normal text is used to provide information and instructions.

Bold text refers to text that is displayed on the screen.

UPPERCASE text, for example ENTER or ALT, refers to keys on the PC keyboard. '+' is

used to show that you have to press two keys at the same time, for example, ALT+F.

All eight digit numbers are PerkinElmer part numbers unless stated otherwise.

The term ‘instrument’ refers to the mid- or near-infrared Frontier IR spectrometers, and any

sampling accessory fitted.

Notes, Cautions and Warnings

Three terms, in the following standard formats, are also used to highlight special

circumstances and warnings.

NOTE: A note indicates additional, significant information that is provided with some

procedures.

Page 8

8 . Frontier IR Single-range Spectrometers User's Guide

警告

警告

We use the term WARNING to inform you about situations that could result in

personal injury to yourself or other persons. Details about these

circumstances are in a box like this one.

WARNING

Warning (Warnung)

Bedeutet, daß es bei Nichtbeachten der genannten Anweisung zu einer

Verletzung des Benutzers kommen kann.

Warning (Advarsel)

Betyder, at brugeren kan blive kvæstet, hvis anvisningen ikke overholdes.

Warning (Peligro)

Utilizamos el término WARNING (PELIGRO) para informarle sobre

situaciones que pueden provocar daños personales a usted o a otras

personas. En los recuadros como éste se proporciona información sobre este

tipo de circunstancias.

Warning (Danger)

Nous utilisons la formule WARNING (DANGER) pour avertir des situations

pouvant occasionner des dommages corporels à l'utilisateur ou à d'autres

personnes. Les détails sur ces circonstances sont données dans un encadré

semblable à celui-ci.

Warning (Pericolo)

Con il termine WARNING (PERICOLO) vengono segnalate situazioni che

potrebbero provocare incidenti alle persone. Troverete informazioni su tali

circostanze in un riquadro come questo.

Warning (Waarschuwing)

Betekent dat, wanneer de genoemde aanwijzing niet in acht wordt genomen,

dit kan leiden tot verwondingen van de gebruiker.

Warning (Aviso)

Significa que a não observância da instrução referida poderá causar um

ferimento ao usuário.

Warning (

我们使用“警告”这一术语来通知您有关可能会对您自己或他人造成人

)

身伤害的情况。

有关这些情况的详细信息可在此类方框中找到。

Warning (

使用者及びその他周辺に危害が及ぶ恐れがある場合は、

この様なボックスの中に注意事項が表示されています。

)

Page 9

CAUTION

小心

本仪器或其它设备造成严重损害

注意

Introduction . 9

We use the term CAUTION to inform you about situations that could result in

serious damage to the instrument or other equipment. Details about these

circumstances are in a box like this one.

Caution (Achtung)

Bedeutet, daß die genannte Anleitung genau befolgt werden muß, um einen

Geräteschaden zu vermeiden.

Caution (Bemærk)

Dette betyder, at den nævnte vejledning skal overholdes nøje for at undgå en

beskadigelse af apparatet.

Caution (Advertencia)

Utilizamos el término CAUTION (ADVERTENCIA) para advertir sobre

situaciones que pueden provocar averías graves en este equipo o en otros. En

recuadros éste se proporciona información sobre este tipo de circunstancias.

Caution (Attention)

Nous utilisons le terme CAUTION (ATTENTION) pour signaler les situations

susceptibles de provoquer de graves détériorations de l'instrument ou

d'autre matériel. Les détails sur ces circonstances figurent dans un encadré

semblable à celui-ci.

Caution (Attenzione)

Con il termine CAUTION (ATTENZIONE) vengono segnalate situazioni che

potrebbero arrecare gravi danni allo strumento o ad altra apparecchiatura.

Troverete informazioni su tali circostanze in un riquadro come questo.

Caution (Opgelet)

Betekent dat de genoemde handleiding nauwkeurig moet worden opgevolgd,

om beschadiging van het instrument te voorkomen.

Caution (Atenção)

Significa que a instrução referida tem de ser respeitada para evitar a

danificação do aparelho.

Caution (

我们使用“小心”这一术语来通知您有关可能会对

)

的情况。

有关这些情况的详细信息可在此类方框中找到。

Caution (

分光器や他の機材等に深刻なダメージを与える恐れがある場合は、

この様なボックスの中に表示しています。

)

Page 10

10 . Frontier IR Single-range Spectrometers User's Guide

Page 11

Warnings and Safety

Information

Page 12

12 . Frontier IR Single-range Spectrometers User's Guide

Safety Summary

The Frontier IR spectrometers have been designed to comply with a wide variety of

international standards governing the safety of laboratory equipment. In routine use, the

instruments pose virtually no risk to you. If you take some simple, common-sense

precautions, you can make sure that you maintain the continued safe operation of your

instrument:

DO make sure that the instrument is properly connected to the electrical supply; in particular

make sure that the ground (earth) is securely connected.

DO disconnect the electrical power cable before opening the main cover of the instrument.

DO keep the instrument dry. Avoid spilling liquid into the instrument. Clean all external spills

immediately. If anything that is spilled enters the main body of the instrument, switch off the

power and contact a PerkinElmer Service Engineer.

DO NOT stare into the internal laser beam under the instrument cover. The instrument

contains a low power, visible (red) laser; momentary exposure to the beam is not dangerous,

but deliberate, direct viewing of the beam along its axis could damage your eye.

DO NOT use a flammable gas to purge the instrument. The instrument contains a hot source,

and a fire or explosion will result. Only use clean, dry, oil-free nitrogen or air to purge the

instrument.

DO read the more detailed information on warnings and safety in the following pages to

ensure the safe operation of the instrument.

Page 13

Warnings and Safety Information . 13

General Safety

The Frontier IR spectrometers have been designed and tested in accordance with

PerkinElmer specifications and in accordance with the safety requirements of the

International Electrotechnical Commission (IEC). The instruments conform to IEC publication

61010-1 (“Safety requirements for electrical equipment for measurement, control, and

laboratory use”) as it applies to IEC Class 1 (earthed) appliances and therefore meets the

requirements of EC low voltage directive 2006/95/EC.

If the instrument is used in a manner not specified by the manufacturer, the protection

provided by the instrument may be impaired. Only use the instrument indoors and under the

following conditions:

Temperature 15 °C to 35 °C

Relative Humidity 80% maximum (non-condensing)

If possible, avoid any adjustment, maintenance and repair of the opened, operating

instrument. If any adjustment, maintenance and repair of the opened, operating instrument

is necessary, this must only be done by a skilled person who is aware of the hazard involved.

Whenever it is likely that the instrument is unsafe, make it inoperative. The instrument may

be unsafe if it:

• Shows visible damage

• Fails to perform the intended measurement

• Has been subjected to prolonged storage in unfavorable conditions

• Has been subjected to severe transport stresses.

If the equipment is used in a manner not specified herein the protection

provided by the equipment may be impaired.

WARNING

The instrument has been designed to be safe under the following environmental conditions:

• Indoor use

• Altitude up to 2000 m (above mean sea level)

• Ambient temperatures of 5 °C to 40 °C

• A maximum ambient relative humidity of 80% for temperatures up to 31 °C, decreasing

linearly to 50% relative humidity at 40 °C

• Mains supply fluctuations not exceeding ±10% of the nominal voltage.

Page 14

14 . Frontier IR Single-range Spectrometers User's Guide

Location and Ventilation

Make sure that the switch at the electrical supply inlet on the rear of the

instrument is not obstructed.

WARNING

To allow for adequate cooling

Do not site the instrument near to room heating equipment, for example, central heating

radiators.

During operation, there should be a minimum gap of:

• 15 cm (6 inches) between any surface and the cooling louvers at the rear of the

instrument.

• 7 cm (3 inches) between the instrument and adjacent equipment.

• 45 cm (18 inches) between any surface and the top surface of the closed sample area lid

(to allow for the lid to be opened fully).

To allow any nitrogen used to disperse

Do not site the instrument in a poorly ventilated area if nitrogen will be

used as a purge gas, or if liquid nitrogen will be used to cool a detector.

WARNING

The spectrometer includes a coupling that enables the instrument body, and another

coupling that enables the sample compartment, to be purged using clean, dry, oil-free air or

nitrogen. The recommended flow rate to each connector is 10 l/min, and both the instrument

and the sample compartment vent to their surroundings.

If the instrument is fitted with an MCT detector, this is cooled using liquid nitrogen. A risk

assessment should include personal protection protocols, and proper actions in the event of

accidental spillage. 1 l (2 US pints) of liquid nitrogen evolves to 700 l (approximately

25 cubic feet) of nitrogen gas, and the cold vapor can pool at floor level.

Oxygen depletion in an enclosed space does not trigger a gasping reflex,

and errors of judgment, confusion, or unconsciousness can occur in

seconds and without warning.

Page 15

Warnings and Safety Information . 15

Use of flammable solvents and samples

The instrument contains a hot source and contact with flammable vapors

may cause an explosion. When working with flammable solvents or

samples, particularly during unattended operation with flow-cells, it is

WARNING

WARNING

recommended that the instrument optics area should be continuously

purged with dry air or nitrogen to maintain a positive pressure and

prevent flammable vapor from entering the instrument.

If flammable solvents or samples are spilled on the instrument and there

is any possibility that they have entered the interior (by coming into

contact with cover gaskets, for example) then the instrument must be

switched off immediately and disconnected from the power supply. The

optics area should then be thoroughly purged with dry air or nitrogen, or

the main cover should be opened to thoroughly ventilate the optics area

before proceeding.

WARNING

WARNING

Flammable solvents or samples should not be stored on or near the

instrument. Handling of such materials during preparation should be

performed in a safe area away from the instrument such as a fume

cabinet.

Do not use a flammable gas to purge the Frontier IR instruments. Use

only clean, dry, oil-free nitrogen or air.

Page 16

16 . Frontier IR Single-range Spectrometers User's Guide

Electrical Safety

• Connect the instrument to a power supply line that includes a switch or other means of

disconnection from the electricity supply.

• Only plug the instrument into an electricity-supply socket that is provided with a

protective earth connection.

• When fuses need replacing, use only those with the required current rating and of the

specified type. Do not use makeshift fuses and do not short-circuit fuse holders.

• When the instrument is connected to its electricity supply, terminals may be live and the

removal of covers other than those which can be removed by hand is likely to expose

live parts.

• Capacitors inside the instrument may still be charged even if the instrument has been

disconnected from all voltage sources.

• The instrument must be disconnected from all voltage sources before it is opened for

any adjustment, replacement, maintenance or repair.

Any interruption of the protective earth conductor inside or outside the

instrument or disconnection of the protective earth terminal can make the

instrument dangerous.

WARNING

The instrument has an IEC Insulation Class I rating for external circuits – only connect other

equipment that meets the requirements of IEC 61010-1, IEC 60950 or equivalent standards.

Page 17

Warnings and Safety Information . 17

Laser Safety Regulations

The Frontier IR spectrometers are Class 1 laser products as defined by IEC 60825-1. The

optical module contains a Class 2 Helium Neon (HeNe) laser, which emits visible, continuous

wave radiation at a wavelength of 633 nm and has a maximum output power of 1 mW. Some

diffuse HeNe laser radiation, within Class 1 limits, emerges from:

• The window in the left hand side of the sample compartment when an internal beam

path is selected.

• An external beam port when the beam port cover is removed, no accessory is fitted at

the port, and the beam path to the port is selected.

Do not stare into any laser beam. Staring into a laser beam (intrabeam

viewing) can cause permanent damage to your eyes.

WARNING

The laser is automatically shut down when the main cover of the instrument is raised.

Do not attempt to override or modify the interlock system.

Use of controls or adjustments or performance of procedures other than

WARNING

The instrument complies with the following laser safety regulations:

1. 21 CFR Part 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No.50

dated 24 June 2007. Administered by the Center for Devices and Radiological Health,

U.S. Department of Health and Human Services.

2. European Standard EN 60825-1:2007 – “Safety of laser products – Part 1: Equipment

classification and requirements”.

those specified herein may result in hazardous radiation exposure.

Page 18

18 . Frontier IR Single-range Spectrometers User's Guide

Radiation Hazards and their Classification

Laser radiation

Indirect observation of the laser beam radiation in the optical path is not hazardous. Directly

viewing the laser beam along its axis (allowing the laser beam radiation to pass into the eye)

can be hazardous, depending upon the power of the beam, the length of time that the eye is

exposed to the beam and the optical efficiency of the exposed eye. Direct viewing of a laser

beam along its axis is termed

Protection of the eye during accidental, momentary intrabeam viewing of a Class 2 laser

beam is normally given by the eye’s aversion response, including the blink reflex, which limits

exposure of the eye to less than 0.25 seconds.

Class 1 levels of laser radiation are not considered to be hazardous.

intrabeam

Radiation emitted by the Frontier FT-NIR

The Frontier IR FT-NIR quartz halogen bulb, which produces the near infra-red beam, emits

ultraviolet, visible and infrared radiation. The majority of this radiation is in the infrared

region. Do not stare into the beam produced by this bulb.

viewing.

Measurements of the infrared radiation emitted from the sample area show that exposure

limits recommended by the American Conference of Governmental Industrial Hygienists

(ACGIH) and International Commission on Non-Ionizing Radiation Protection (ICNIRP) will

not be exceeded during normal operation.

Page 19

Warnings and Safety Information . 19

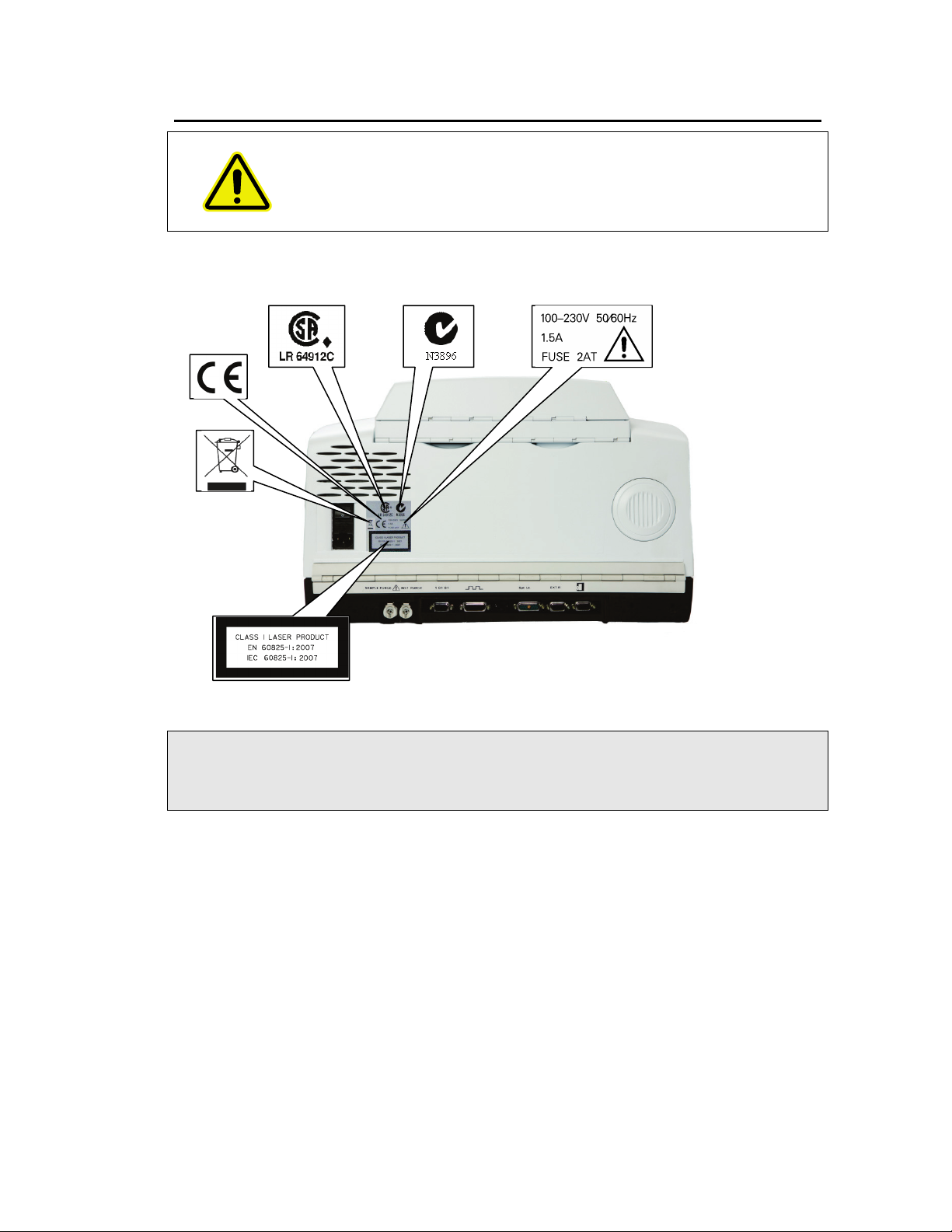

Labels

When this label is attached to an instrument it means ‘Caution, risk of

danger’. Refer to the manual to find out the nature of the potential

hazard and any actions that have to be taken.

The product identification label is on the front of the instrument. Other labels are fixed to the

Frontier IR spectrometers in the locations shown in Figure 1 and Figure 2:

Figure 1 Labels (rear of instrument)

NOTE: The label with a crossed-out wheeled bin symbol and a rectangular bar indicates that

the product is covered by the Waste Electrical and Electronic Equipment (WEEE)

Directive.

page 96.

Refer to Appendix 5: WEEE Instructions for PerkinElmer Products

on

Page 20

20 . Frontier IR Single-range Spectrometers User's Guide

Serial number, part

number and date of

manufacture

NOTE: There is a second copy of the CAUTION label inside the sample compartment cover.

Figure 2 Labels (sample compartment)

Page 21

Warnings and Safety Information . 21

have

Warning Signs on the Instrument

Caution, hot surface.

Caution, risk of electric shock.

Caution, laser radiation hazard.

Caution, risk of danger.

Refer to accompanying documents in all cases where this symbol is used

to find out the nature of the potential hazard and any actions which

to be taken.

Page 22

22 . Frontier IR Single-range Spectrometers User's Guide

EMC Compliance

European EC Directive

The Frontier IR spectrometers have been designed and tested to meet the requirements of

the EC Directive 2004/108/EC.

FCC rules and regulations

These products are classified as digital devices used exclusively as industrial, commercial, or

medical test equipment. They are exempt from the technical standards specified in Part 15 of

the FCC Rules and Regulations, based on Section 15.103(c).

Page 23

An Overview of the

Frontier IR Single-Range

Spectrometers

Page 24

24 . Frontier IR Single-range Spectrometers User's Guide

A Guided Tour of the Frontier IR Single-Range Spectrometers

PerkinElmer Frontier IR single-range spectrometers are bench-top FT-IR instruments.

Figure 3 Frontier IR Systems spectrometer

• Frontier FT-IR spectrometers:

– The optical system enables you to collect data over a total range of

8300 to 350 cm

– A LiTaO

MIR detector.

3

−1

with a best resolution of 0.4 cm−1.

– Optional gold optics.

– Optional MCT detector.

• Frontier Performance Pack Systems FT-IR spectrometers:

– The optical system enables you to collect data over a total range of

8300 to 350 cm

−1

with a best resolution of 0.4 cm−1.

– A DTGS (deuterated triglycine sulfate) MIR detector as standard for enhanced

signal-to-noise.

– Optional gold optics.

– Optional MCT detector.

• Frontier Extended Range Performance Pack FT-IR spectrometers:

– The optical system with CsI beamsplitter enables you to collect data over a total

range of 7800 to 225 cm

−1

with a best resolution of 0.4 cm−1.

– A DTGS (deuterated triglycine sulfate) MIR detector as standard.

– Optional gold optics.

– Optional MCT detector.

• Frontier FT-NIR spectrometers:

– The optical system enables you to collect data over a total range of

14700 to 2000 cm

−1

with a best resolution of 0.5 cm−1.

– An NIR DTGS (deuterated triglycine sulfate) detector.

– Gold optics as standard.

The instrument can operate in ratio, single-beam, or interferogram mode.

Page 25

An Overview of the Frontier IR Single-Range Spectrometers . 25

The instrument is connected to a PC, either point-to-point or over a network. The Spectrum

software package supplied enables you to control the instrument and to manipulate the

spectra that you collect.

Optical system

The optical system is under the main cover of the system. Usually the main cover of the

instrument is closed, but to perform most maintenance tasks the cover has to be open. When

you do this, a safety interlock automatically switches off the power. Nevertheless, the

instrument should be disconnected from the mains before opening the main cover for

maintenance.

Consistent, reliable performance is achieved by having few moving or adjustable parts, and

by extensive insulation of the optical system from the effects of humidity and vibration.

Stability of the optical system

The entire optical system is purged and sealed at the factory. A supply of desiccant placed

within the system removes any water vapor and carbon dioxide that may enter. A desiccant

indicator is fitted in the top cover, which warns you when the desiccant needs changing (an

internal humidity sensor is available as an option).

In Frontier FT-IR spectrometers, KBr or CsI windows separate the sample compartment from

the purged optical system. For Frontier FT-NIR spectrometers, these windows are CaF

NOTE: Before you select the MCT detector (optional) in Spectrum software, fit one of the

attenuators supplied (Attenuator Set – L1160560) to the window to the right of the

sample compartment to prevent the detector from overloading. See

Replacing Windows

You can purge the sample compartment with clean, dry, oil-free air or nitrogen. Either one

removes water vapor; however, nitrogen is preferable because it also removes atmospheric

carbon dioxide.

on page 78 for more information.

Installing/

.

2

Do not use a flammable gas to purge Frontier IR Systems. The

instruments contain a hot source, and a fire or explosion will result. Only

use clean, dry, oil-free nitrogen or air to purge the instrument.

WARNING

The optics are kinematically mounted to ensure accurate positioning and to make them

rugged. The interferometer is enclosed and mounted on anti-vibration mounts to guard

against air and bench borne disruptions. The interferometer uses very low-friction point

bearings and a frictionless electromagnetic drive to ensure long life.

Page 26

26 . Frontier IR Single-range Spectrometers User's Guide

Display

Go button

Sample compartment lid

Baseplate

Top panel controls

Figure 4 Top panel controls

The display on the front right of the top of your instrument has two purposes:

• To display messages generated by the instrument’s firmware, such as those that monitor

initialization and diagnostics when the instrument is switched on.

• To display prompts and other messages generated by Spectrum software.

The instrument’s Go button is used in concert with the displayed prompts and other

messages generated by Spectrum software. It allows you to Start and Halt data collection

while you are away from your computer.

The sample compartment

The instrument has a large purgeable sample compartment (Figure 5) located at the front of

the instrument.

Figure 5 Sample compartment

Page 27

CAUTION

CAUTION

An Overview of the Frontier IR Single-Range Spectrometers . 27

Frontier IR spectrometers are fitted with sample compartment windows

that are composed of KBr or CsI that, although coated, can be damaged

by high levels of humidity.

If you spill a liquid in the sample compartment, wipe it up quickly. When

working with water-based samples open to the air, either purge the

sample compartment or leave the cover open.

For the Frontier FT-IR, a relative humidity higher than 80% (or 45% if

your instrument is fitted with CsI optics) can damage the windows of the

sample compartment. If you expect the humidity to exceed 80% (or 45%

if your instrument is fitted with CsI optics), continually purge or desiccate

the sample compartment.

Frontier FT-NIR spectrometers are fitted with sample compartment

windows that are composed of CaF

, which is relatively resistant to

2

humidity.

Open the sample compartment by lifting the cover using the recess at the front.

The infrared beam enters the sample compartment through an aperture on the left. After

passing through the sample, it enters the detector area through an aperture on the right side

of the sample compartment.

Standard accessories are mounted on a baseplate. The standard baseplate has a sample

holder located by a knurled screw.

Internal accessories

A wide range of optional MIR or NIR accessories, such as the Universal ATR accessory, fit in

the sample compartment (Figure 6).

Figure 6 Frontier IR with Universal ATR accessory

It is easy to remove an internal accessory and to replace it with another. See

Changing the Sampling Accessory

The instrument identifies the type of accessory fitted using a coded connector on its

baseplate that plugs into a socket on the rear wall of the sample compartment.

on page 90.

Appendix 1:

Page 28

28 . Frontier IR Single-range Spectrometers User's Guide

External accessories

The external beam port on the right side of the instrument is used, for example, with the

optional External Near Infra-Red Accessory (External NIRA). Spectrum software enables you

to switch the instrument between this external accessory and another accessory fitted in the

sample compartment.

Figure 7 Frontier IR with External NIRA accessory

NOTE: To use your instrument with an external accessory, you require the optional External

Beam Pack. If you did not purchase the External Beam Pack with your spectrometer,

it is available as a field-fitted upgrade (L1280248).

For information about removing or refitting an external accessory, refer to its User’s Guide,

which is distributed on the

IR & Raman Manuals CD

(L1050002) as a .pdf file.

Do not attempt to remove the external accessory bracket mounted within

the handhold on the right of the instrument or to transfer the bracket to

CAUTION

another spectrometer.

The external accessory bracket is fitted by a PerkinElmer Service

Engineer, along with any other internal components that may be required.

Do not attempt to lift the instrument, or to move it to another location,

when an external accessory is attached.

CAUTION

For information about moving the instrument, see

The optical alignment of the accessory may be disturbed.

Moving the Spectrometer

on page 54.

Page 29

An Overview of the Frontier IR Single-Range Spectrometers . 29

Imaging systems

The external port on the left side of the instrument is used with the Spotlight Imaging

Systems and Multiscope Imaging Systems (Figure 8).

Figure 8 Spotlight 150: Microscope and Frontier FT-IR spectrometer

NOTE: To use your instrument with a microscope, you require the optional External Beam

Pack. If you did not purchase the External Beam Pack with your spectrometer, it is

available as a field-fitted upgrade (L1280248).

Storage compartment

You can store your polystyrene reference film, sample slides and other small accessories in

the storage compartment on the top of the spectrometer (Figure 9).

Figure 9 Storage compartment on top of the spectrometer

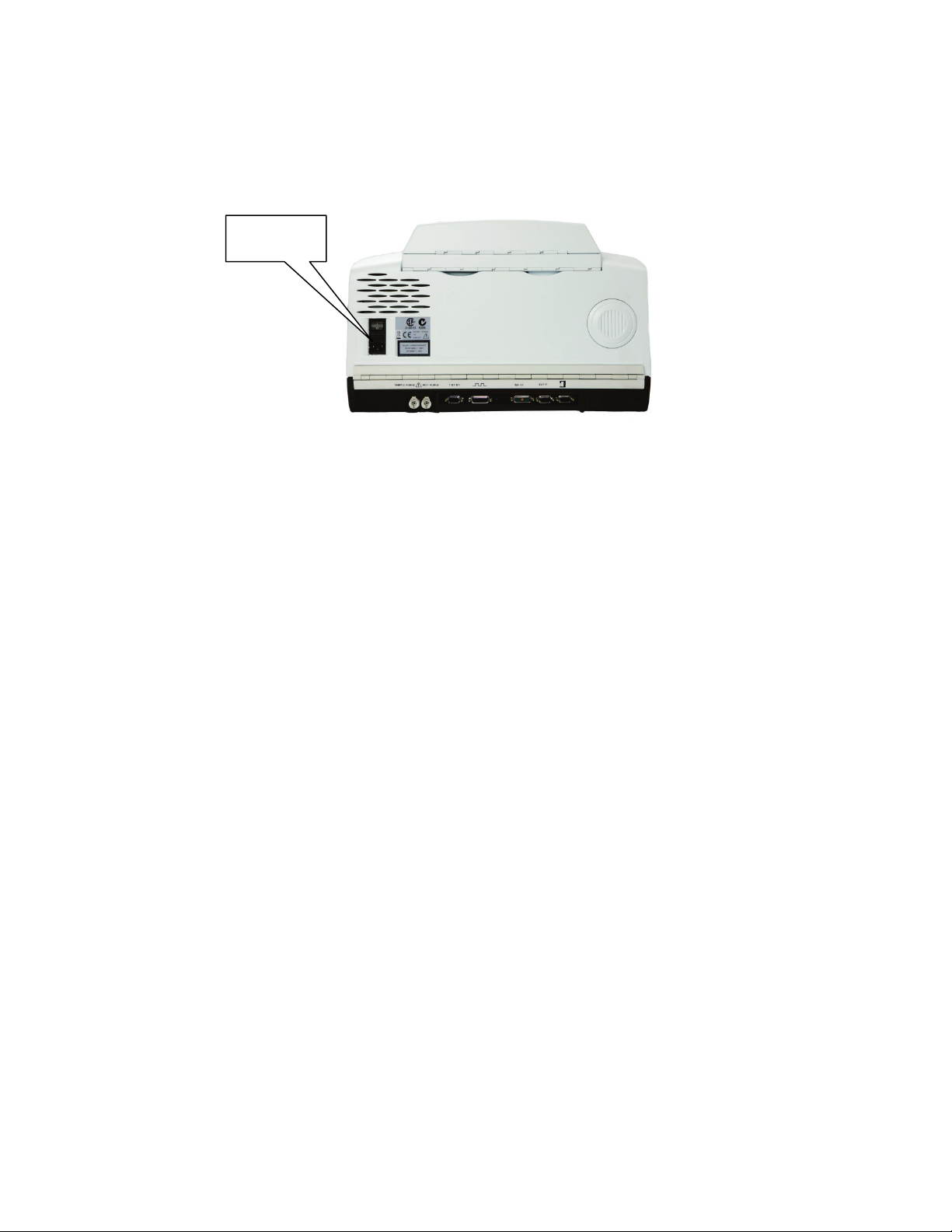

Power switch and communication ports

The power switch, AC power cable connector, and communications ports are on the rear of

the instrument. The power switch is marked I/O (on/off).

NOTE: It can take the instrument about two hours to equilibrate when switched on after

being switched off overnight. To save time, we suggest that you leave the instrument

switched on at all times.

Page 30

30 . Frontier IR Single-range Spectrometers User's Guide

Accessories

A wide range of optional accessories, such as the Universal ATR accessory (UATR), fits in the

sample compartment. In addition, a number of external accessories are available, including

the External NIRA. An external accessory can be fitted in conjunction with another internal

accessory.

Table 1 Sampling accessories for the Frontier IR instruments

Accessory MIR NIR

Sample Shuttle Yes Yes

Horizontal ATR Yes n/a

Universal ATR Yes n/a

Diffuse Reflectance Yes n/a

NIRA n/a Yes

External NIRA n/a Yes

NIR Fiber Optic Probe n/a Yes

NIR Tablet Autosampler* n/a Yes

Liquid Sipper* Yes Yes

TL 8000 EGA System (TG-IR) Yes Yes

General Purpose Optical Bench (GPOB) with External

MCT Detector**

General Purpose Optical Bench (GPOB) and External

LiTaO

*The Liquid Sipper and NIR Tablet Autosampler accessories are supported by AssureID software and

Spectrum software version 6.x. They are not supported in Spectrum software version 10.0 or later.

** For more details of the GPOB options, contact your PerkinElmer Sales Representative.

Further information about the use of these accessories can be found on the

Manuals CD

Detector**

3

(L1050002).

Yes Yes

Yes Yes

IR & Raman

Page 31

An Overview of the Frontier IR Single-Range Spectrometers . 31

Frontier IR Systems Upgrades

The Frontier IR systems as designed to be flexible, upgradable instruments, including the

ability to upgrade from a single-range to a dual-range instrument. The upgrades available for

Frontier IR Single-Range Systems are listed in Table 2.

Table 2 Frontier IR Single-Range Systems Upgrades

Part Number Description

L1280247 Performance Pack Upgrade – DTGS detector upgrade

L1280248 External Pack Beam Upgrade – Microscope, GPOB, NIRA and

external beam input port ready

The kit contains KBr windows, but other windows are available. Ask

your PerkinElmer Customer Service Representative for details

L1280258 Single-Range FT-IR to Dual-Range FT-IR/FT-NIR upgrade

L1280259 Single-Range FT-NIR to Dual-Range FT-IR/FT-NIR upgrade

L1280260 Single-Range FT-IR to Dual-Range FT-IR/FT-FIR upgrade

L1280249 Narrow band 1 mm MCT FT-IR Second Detector

(adds an MCT detector in the second detector position)

FT-IR instruments only

L1280250 Medium band 1 mm MCT FT-IR Second Detector

(adds an MCT detector in the second detector position)

FT-IR instruments only

L1280251 Wide band 1 mm MCT FT-IR Second Detector

(adds an MCT detector in the second detector position)

FT-IR instruments only

L1250477 ZnSe Window Upgrade Kt

(optional ZnSe window for Single-Range FT-IR instruments)

L1200391 Electronic Humidity Sensor

Page 32

32 . Frontier IR Single-range Spectrometers User's Guide

Page 33

Unpacking and

Installation

Page 34

34 . Frontier IR Single-range Spectrometers User's Guide

Requirements

NOTE: Read the warnings and safety information at the start of this manual before you

install the instrument. They contain important information.

Electrical requirements

The Frontier IR instruments can operate on electricity supplies of 50 or 60 Hz and in the

100 V to 230 V range without any adjustment.

The nominal power consumption of the instrument is 120 VA.

The line supply must be within 10% of the nominal voltage.

If possible, do not connect the instrument to circuits that have heavy duty equipment

connected, such as large motors.

If possible, do not use photocopiers, discharge lamps, radio transmitters, and other

equipment with large or frequent transient loads on the same supply circuit.

The primary fuse (2 AT, 250 V) is in the drawer on the rear of the instrument next to the

mains inlet: the spare fuse is in the same drawer. The primary fuse is connected in the live

line.

Environment

To obtain the best performance from your instrument:

• Place the instrument in an environment that is relatively dust-free.

• Make sure that the bench top is free from vibration or mechanical shocks.

• Do not place the instrument or the PC near to room-heating equipment, such as

central-heating radiators.

• Do not position the instrument in direct sunlight, as this may cause overheating.

• Leave at least 15 cm (6 inches) from any surface and the cooling louvers at the rear of

the instrument.

• Leave at least 7 cm (3 inches) from any vertical obstacle to the sides of the instrument,

to permit an adequate flow of cooling air.

• Make sure that there are no overhanging shelves, and no water pipes or faucets that

could leak onto the instrument.

• The area near the PC must be free of strong magnetic fields, direct sunlight, and heating

or cooling units or ducts.

The instrument has been designed for indoor use and operates correctly under the following

conditions:

Ambient temperature 15 °C to 35 °C

Ambient relative humidity 80% maximum (non-condensing)

Page 35

Unpacking the Spectrometer

The spectrometer is a heavy precision instrument, so two people are

required for safe handling.

The instrument weighs approximately 34 kg unpacked (40 kg packed)

and has a lifting recess on either side. Consult the local codes of practice

WARNING

CAUTION

issued by safety advisors before attempting to lift it.

Take care not to injure yourself or others, or to drop the instrument.

Take great care when installing your Frontier IR spectrometer, and

follow the procedures described in this manual. If you require assistance,

contact your local PerkinElmer Service Engineer.

Unpacking and Installation . 35

Opening the shipping container

Your spectrometer is packed inside the box in a silver bag that protects it from condensation.

1. First remove the software box, leads, and so on from the box, and check that all the

following parts are present:

Part Number Description MIR NIR

L1202057 Polystyrene Calibration Film 1 –

L1180479 NIR Performance Validation Kit – 1

04974265 Quick Release Purge Coupling 2 2

L1200466 Ethernet Crossover Cable 1 1

04790839 2 A, 250 V Time Lag Fuse 2 2

09923433 8.0 mm Hexagonal Wrench 1 1

L1050002 IR & Raman Manuals CD 1 1

L1250230 Spectrum Configuration Disk 1 1

LX108873

OR

LX108875

L1240055 Cuvette Holder Assembly – 1

L1240056 Cell Holder Assembly & Disposable Cells (5) – 1

If any items are missing or damaged, contact your local PerkinElmer office.

Spectrum Standard Software Kit

OR

Spectrum ES Software Kit

1 1

Page 36

36 . Frontier IR Single-range Spectrometers User's Guide

2. Carefully remove the instrument from the shipping container, but not from the bag in

which it was shipped.

The spectrometer must be allowed to reach the temperature of its

CAUTION

surroundings before it is removed from the bag. This means leaving it

overnight if it has been moved from a cold area, and at least 4 hours

after removal from the shipping container.

3. When the spectrometer has been allowed to warm to the temperature of its

surroundings, remove it from the bag and place it on the bench where it is to be used.

Ensure that you can reach the rear of the spectrometer to connect the cables.

NOTE: Any accessories will be shipped in separate boxes.

Page 37

Unpacking and Installation . 37

must

Pink

Blue

Blue

The Desiccant Indicator

The optical system of the spectrometer is purged at the factory. This protects the

beamsplitter and the sample compartment windows from being damaged by humidity.

Replaceable packs of desiccant keep the optics dry and free of CO

The top panel of the instrument includes a desiccant indicator, whose sectors change

sequentially from blue to pink as the desiccant packs are exhausted (Figure 10). Change the

desiccant in the instrument when the sector marked 10 becomes pink, but while the sectors

marked 15 and 20 are still blue.

.

2

Refer to

appropriate action to take if the sectors marked 15 and 20 are pink.

Figure 10 The desiccant indicator

The Desiccant Indicator in Detail

on page 56 for more information about the

If all three sectors of the desiccant indicator are pink, then you

change the desiccant.

CAUTION

The instrument optics may be fogged. Do not switch the instrument

either ON or OFF until all sectors are blue.

Page 38

38 . Frontier IR Single-range Spectrometers User's Guide

PC or network

connection port

Connecting up the Spectrometer

Connecting to the PC

NOTE: To control your instrument from a PC, use the crossover cable supplied.

To control your instrument over your network, use a standard Ethernet cable (not

supplied).

1. Plug one end of the cable into the connector port on the right-hand side of the

instrument (Figure 11).

Figure 11 PC connection port

2. Plug the other end of the cable into the network connection on your PC (if you are using

the crossover cable) or network hub (if you are using a standard Ethernet cable).

Connector details

Description Connector

Type

10/100 Base-T Ethernet connector. This is the

standard interface between the PC and the

instrument, or between a Local Area Network

(LAN) and the instrument. If connecting directly

from the PC to the instrument use the Category 5

UTP Cross-Over cable supplied. If you are

connecting to your network, use a standard

Ethernet cable.

DO NOT USE THE CROSS-OVER CABLE TO

CONNECT TO YOUR NETWORK.

Ethernet <5 V <100 mA

Voltage Maximum

Current

Page 39

Unpacking and Installation . 39

Sample area purge

Instrument purge

10101

Spt. Lt.

EXT.R

Other connectors

The communication ports for peripheral devices are shown in Figure 12.

Figure 12 Communication ports

Icons that identify the function of each of the communications ports are printed on the hinge

molding directly above the port.

Connector details

Icon Description Connector

Type

10101

Spt.Lt

Serial port. Connects a PC to the

instrument using an RS232

interface cable. This connector is

only used for service diagnostics.

General Purpose Optical Bench

(GPOB). Allows synchronization

between the instrument and an

external accessory.

Spotlight. Used to connect the

instrument to a Spotlight Imaging

System.

9-way

D-type

26-way

high density

D-type

11-way

mixed

D-type

Voltages Maximum

Currents

+12 V <100 mA

−12 V <100 mA

+5 V <50 mA

+5 V <100 mA

±12 V 50 mA

Page 40

40 . Frontier IR Single-range Spectrometers User's Guide

Icon Description Connector

Type

EXT.R

Right external detector module.

Connects to an external detector

module. Usually the detector is

located in an accessory placed on

the right of the instrument.

Microscope external detector

module. Connects to a

PerkinElmer infrared microscope,

placed on the left of the

instrument.

15 way

high density

D-type

15 way

high density

D-type

Voltages Maximum

Currents

+12 V 0.65 A

−12 V 0.65 A

+5 V 4 A

+12 V 0.65 A

−12 V 0.65 A

+5 V 4 A

Do not attempt to connect a monitor to either the EXT.R port or the

CAUTION

MICROSCOPE port or you will cause serious damage to the instrument

when it is switched on.

Connecting the spectrometer to the electrical supply

The power cable for the electrical supply plugs into the rear of the instrument. It has a

molded socket at one end. If it is necessary to fit a plug on the power cable, use the wire

color code below:

Plug Pin Wire Color (100–120 V) Wire Color (220–240 V)

Ground (Earth) Green or Green/Yellow Green/Yellow

Live Black Brown

Neutral White Blue

To ensure safe and satisfactory operation of the instrument, it is

essential that the green or green/yellow ground (earth) wire of the

power cord is connected to a ground that complies with the regulations

WARNING

of the local electricity supply authority (or equivalent body); ground

circuit continuity is essential for safe operation of the equipment.

Page 41

Unpacking and Installation . 41

Electricity

supply inlet

Frontier IR instruments can operate on electricity supplies of 50 Hz or 60 Hz and in the 100 V

to 230 V range without any adjustment.

1. Fit the molded socket of the power cable into the electrical supply inlet (Figure 13) of

the instrument.

Figure 13 Electrical supply inlet

2. Switch on the power at the supply.

3. Switch on the instrument at the switch above the supply inlet.

I is on and O is off.

After a short diagnostic check, which takes about 2 minutes and is described in

Instrument Self-Checks

on page 90, your instrument will be ready to communicate with the

PC.

Appendix 2:

Page 42

42 . Frontier IR Single-range Spectrometers User's Guide

Installing the Instrument in the Software

Before you can use the instrument it must be set up in the software.

Installing the software

NOTE: If you are supplying your own computer, make sure that it meets the minimum

requirements for hardware and software set out in the “PC Requirements” section of

the

Administrator’s Guide

Manuals CD

To install Spectrum software, insert the supplied DVD and follow the instructions on the

screen. Details of the installation program are given in the

(part number L1050002) supplied with your instrument.

The Instrument Install Wizard

After installing your software you will need to install your instrument.

If you have Spectrum software or Spectrum ES software, select Add Instrument from

the Administration group on the Setup menu.

The Instrument Install Wizard starts.

for your software, which can be found on the

Administrator’s Guide

IR & Raman

.

OR

If you have AssureID software, select Configure Instruments from the Configure

Instruments and Accessories group on the Tools menu.

The Instrument Install Wizard starts.

Details of the Instrument Install Wizard can be found in the

software, which can be found on the

supplied with your instrument.

IR & Raman Manuals CD

Administrator’s Guide

(part number L1050002)

for your

Page 43

Using the Spectrometer

with Spectrum

Page 44

44 . Frontier IR Single-range Spectrometers User's Guide

Basics of Software Control

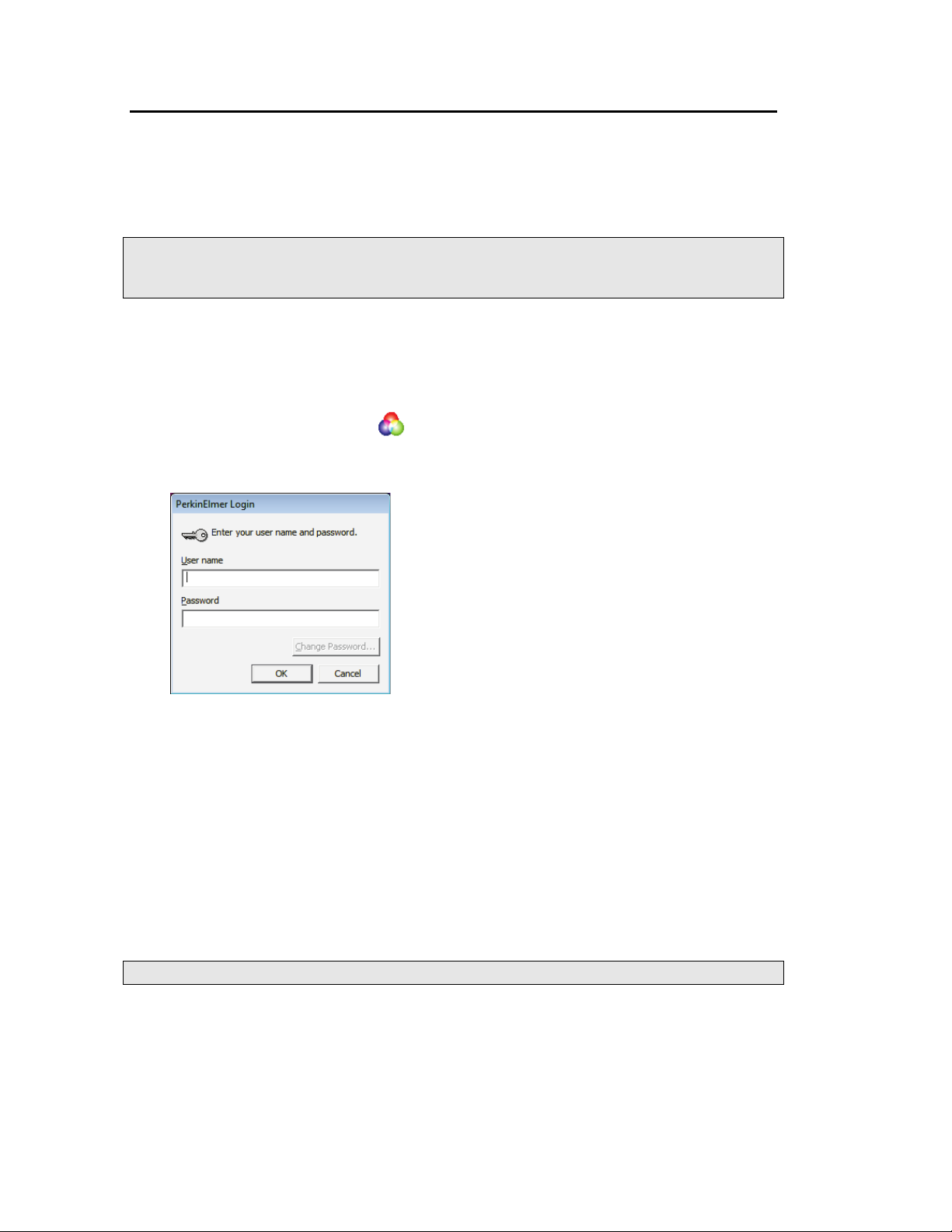

Starting Spectrum software

1. Switch on the power to the instrument using the switch on the rear of the instrument.

The instrument will initialize, which will take approximately 2 minutes.

NOTE: It can take the instrument about two hours to equilibrate when switched on after

being switched off overnight. To save time, we suggest that you leave the instrument

switched on at all times.

2. From the Start menu select Programs; the PerkinElmer Applications group; the

Spectrum sub-group and then the Spectrum application.

OR

Double-click the shortcut icon on the desktop.

The Spectrum start-up splash-screen is displayed, followed by a dialog that may require

your login details:

3. If required, enter your User name and Password, and then click OK.

If you already have an instrument set up in Spectrum or AssureID software for this user

on this PC, the Instrument Connection dialog may be displayed, unless Auto Connect is

set up for the instrument. If Auto Connect is enabled Spectrum will automatically

connect to the instrument.

4. Select the Instrument you want to use.

OR

If you want to work with data that has been collected previously, without connecting to

an instrument, select work offline.

NOTE: Working offline can free a networked instrument for use by another user.

Spectrum starts.

Page 45

Using the Spectrometer with Spectrum . 45

Scanning samples

When you connect to your spectrometer the instrument settings will default to appropriate

values for your instrument type and accessory.

The configurable Scan toolbars at the top of the workspace include the tools you need to

collect a sample spectrum (Figure 14).

Figure 14 Frontier IR Single-Range systems default scan toolbars

By default, the Measurement bar includes Scan, Halt, Background and Monitor buttons.

You can also select Scanalyze and then choose one of the scan and then process options

Scan and Compare, Scan and Search or Scan and Quant. All these commands can be

selected from the Measurement menu.

NOTE: The Scan toolbars are not displayed if you have chosen to work offline.

To scan a sample:

1. Check and set the instrument parameters.

Here you set the Start and End points of the scan range (by default in wavenumbers,

but the abscissa units can also be set to nanometers or microns on the Setup

Instrument Basic tab) and the Accumulations required, either as a number of scans,

or as a length of time. You can enter a unique Sample ID and Description for the

sample. You can also set the Resolution (in cm

(in mm) to the default for that resolution, which you can then edit.

By default, sensible values for the scan and instrument parameters are entered in the

Instrument Settings toolbar. The values applied depend on your instrument and

accessory. To amend any value, select the parameter and then enter your new value, or

select a value from the drop-down list.

2. If a background scan is required, the Scan button includes a small background flag.

Clear the instrument beam path, or insert a suitable background material, and then click

to collect a background spectrum.

The background spectrum is displayed briefly, and then the Viewing Area is prepared

for data collection from your sample.

We recommended that you run a background scan before every sample.

NOTE: If you wish to run a background scan with a filter in place, you must set the Scan

Type to Background on the Setup Instrument Basic tab, rather than using the

toolbar button. See the Spectrum on-screen Help for more information.

−1

). This will set the J-Stop size

3. Place your sample in the instrument or accessory and then click to begin scanning

your sample.

By default, during scanning the sample data is displayed on the Live tab in the Viewing

Area.

The completed spectrum is displayed on the Graph tab, and added to the current

Samples View in the Data Explorer.

4. If, for any reason, you want to stop scanning your sample, click .

Page 46

46 . Frontier IR Single-range Spectrometers User's Guide

Display

Go button

You can use the Sample Shuttle Accessory (L1200302) to set up an interleaved cycle scan so

that you do not have to open the sample compartment between the background and sample

scans. This helps to reduce changes in the concentration of carbon dioxide and water vapor

in the sample compartment. Set the Scan Type to Interleaved on the Setup Instrument

Basic tab. See the Spectrum on-screen Help for more information.

Working with the instrument display and Go button

The display on the top of your instrument is used to display prompts and other messages

generated by Spectrum software.

Simply follow the prompts in the instrument display and use the Go button located on the

instrument to complete a series of sample scans.

Figure 15 Top panel controls

Changing the beam path

Hover over the icons on the Setup Instrument BeamPath tab to identify elements in the

instrument beam path. As you click on each item, the appropriate row in the Settings Table is

highlighted.

The accessory fitted in the sample compartment is identified by a graphic element in the

beam path schematic. If an external accessory is fitted at the beam port on the right of the

instrument, or a Spotlight Imaging System is fitted, the Setup Instrument BeamPath tab

includes additional elements that enable you to redirect the beam path to the accessory you

want to use.

Page 47

Using the Spectrometer with Spectrum . 47

In Figure 16 the beam path is directed to the standard sample slide. In this example, the

additional interface elements for the Spotlight microscope are also shown.

Figure 16 Setup Instrument BeamPath tab with the beam path directed to the

Slide Holder

To direct the beam to the Spotlight microscope, select Left external from the Beam

Location drop-down list.

Figure 17 Setup Instrument BeamPath tab with the beam path directed to the

Microscope (circled)

Using the Spectrum on-screen Help system

Use the Spectrum Help system to find further information about using Spectrum software to

control, set up and adjust your instrument.

To open the Help file, select Contents from the Help menu. This menu also includes links to

on-screen tutorials (Tutorials), and information about the software (About).

Page 48

48 . Frontier IR Single-range Spectrometers User's Guide

Atmospheric (CO2/H2O) Suppression

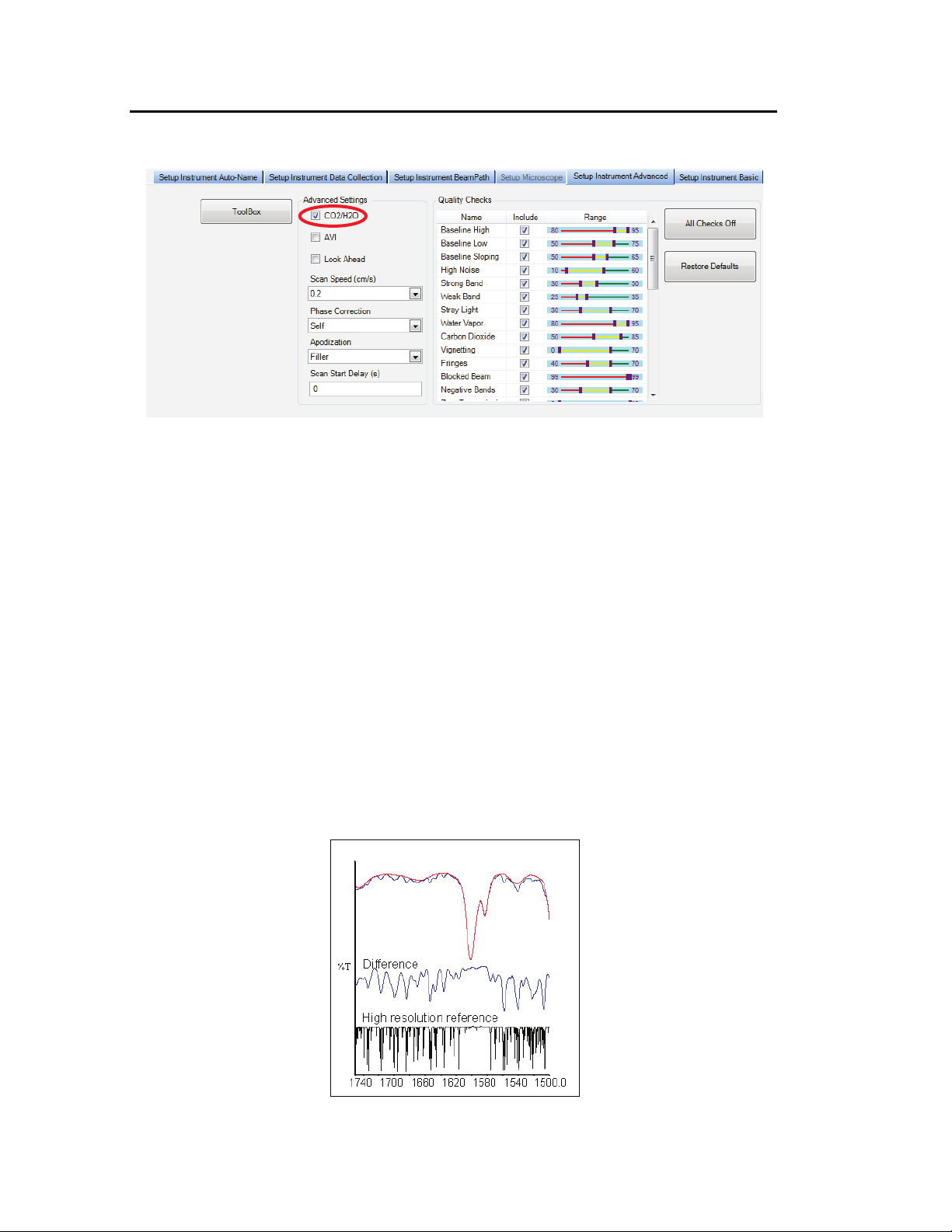

Atmospheric suppression can be selected in the Setup Instrument Advanced tab (Figure 18).

Figure 18 Setup Instrument Advanced tab in Spectrum

What is atmospheric suppression?

This is an atmospheric correction routine. This routine is more powerful than simple

subtraction, overcoming the following issues:

• Non-linearity due to resolution

• The measured spectrum is temperature dependent

• Lineshape and calibration are affected by J-stop and sample or accessory.

What does atmospheric suppression do?

When CO2/H2O is switched on, the software uses a single reference spectrum derived from

high resolution data and our understanding of the instrument to model the lineshape, then

finds the current real instrument parameters by least squares fitting to the measured

spectrum.

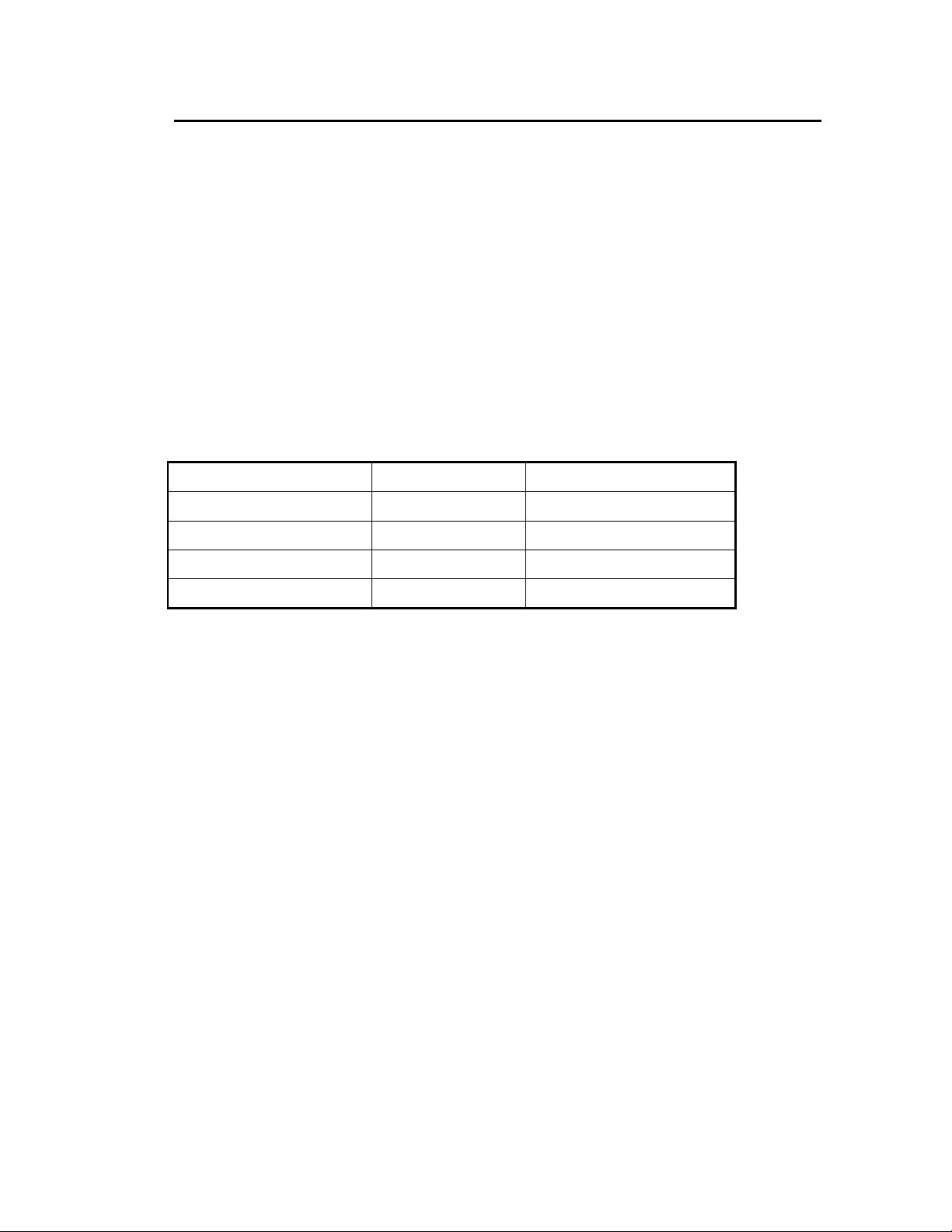

Figure 19 Correction of an MIR spectrum at 4 cm

−1

resolution

Page 49

Using the Spectrometer with Spectrum . 49

Figure 20 Atmospheric suppression

Page 50

50 . Frontier IR Single-range Spectrometers User's Guide

AVI Correction

AVI correction can be selected in the Setup Instrument Advanced tab in Spectrum

(Figure 18).

AVI correction can only be performed if an AVI Calibration has been set up for the current

configuration and resolution. Select AVI from the Adjustments Toolbox, available from the

Setup Instrument Advanced Tab. Follow the instructions on-screen. For further information,

refer to the Spectrum on-screen Help file.

NOTE: AVI correction uses a methane gas cell installed in the filter wheel.

What is AVI correction?

The objectives of Absolute Virtual Instrument (AVI) correction are:

• Consistent performance over time and between instruments

• Traceability for all measurements.

Although FT-IR spectrometers use a reference laser, the wavenumber calibration and

lineshape are affected by differences in beam divergence and uniformity. This is true for all

FT-IR spectrometers. Differences can occur between instruments, when using different

sampling accessories and when components are changed. AVI allows calibration and

lineshape to be maintained.

The Absolute Virtual Instrument is an instrument with theoretical performance, such that the

result of measuring a known sample on such an instrument can be predicted. So, if we

measure with a real instrument and calculate the software transform to match the theoretical

result, we can apply this transform to future measurements.

The Absolute Virtual Instrument is defined by wavenumber calibration, instrument lineshape

and ordinate accuracy.

What does AVI correction do?

When AVI is switched on, the software measures the current instrument profile relative to an

absolute standard (the methane cell) and an ideal lineshape function, and applies a

correction (Figure 21). If you have an automated, internal filter wheel, this can provide

correction for any sampling configuration.

Figure 21 Spectra of methane at 4 cm

AVI (bottom)

−1

resolution as measured (top) and with

Page 51

Using the Spectrometer with Spectrum . 51

Look Ahead

Look Ahead can be selected in the Setup Instrument Advanced tab (Figure 18).

What is Look Ahead?

Look Ahead is a novel system where the spectrometer scans continuously and uses the

properties of the measured spectrum to identify changes corresponding to sample removal,

sample insertion, or sample change, automatically.

This information is used to identify the scans that are being collected, and to accumulate

sample scans. This can decrease the overall scanning time required for those samples that

require scan accumulation.

What does Look Ahead do?

If Look Ahead has been enabled, the spectrometer scans continuously. When you request a

sample scan, the scan collected is compared to the scans that have already been collected. If

identical scans are found, the number of scans requested is decreased by the number of

scans found, so decreasing the overall scanning time.

Page 52

52 . Frontier IR Single-range Spectrometers User's Guide

Quality Checks

Quality Checks can be selected in the Setup Instrument Advanced tab (Figure 18).

What are Quality Checks?

Quality checking is a tool for less experienced IR users that identifies possible problems in

the spectrum being collected and suggests ways of improving the measurement.

What do Quality Checks do?

Simply select the Quality Checks that you want to perform from the list in the Setup

Instrument Advanced tab and, if required, adjust the threshold range using the slider bars.

To display more information about an individual test, double-click on its name in the list.

When you collect your spectrum, the selected tests are performed as the data is collected

and a signal light (green , amber , or red ) indicates the result.

The results from the Quality Checks imply:

Okay ( ) – the quality of the spectra is satisfactory.

Caution ( ) – the software has identified a problem that you may want to investigate in

order to improve the quality of the spectra you are collecting.

Warning ( ) – the software has identified a serious problem that you should attempt to

cure before collecting further spectra.

Page 53

Routine Maintenance

Page 54

54 . Frontier IR Single-range Spectrometers User's Guide

Cleaning the Spectrometer

Clean the outside of the instrument using a damp cloth. If necessary, a mild detergent may

be used. Before you clean the entire instrument, always perform a patch test on an

inconspicuous area.

Avoid spilling liquid into the instrument. Clean all external spills immediately. If anything that

is spilled enters the main body of the spectrometer, switch off the power and contact a

PerkinElmer Service Engineer.

Do not touch or attempt to clean any optical surface in the instrument,

CAUTION

Cleaning the display

Clean grease and dirt off the display using a soft damp cloth and a mild detergent.

because this will impair its performance and may easily damage the

component.

Page 55

Routine Maintenance . 55

Lifting handhold,

Moving the Spectrometer

The spectrometer is a heavy precision instrument, so two people are

required for safe handling.

WARNING

WARNING

The spectrometer can be lifted using the shaped handholds on its sides, as shown in

Figure 22. Two people are needed to lift it because its basic weight is approximately 34 kg.

Consult the local codes of practice issued by safety advisors before

attempting to lift it.

Take care not to injure yourself or others, or to drop the spectrometer.

Before moving the spectrometer, switch off the power supply, wait

60 seconds, and disconnect the power cable.

(repeated on left

of the instrument)

Figure 22 Lifting a Frontier IR spectrometer

Condensation

Be aware that condensation caused by moving your spectrometer from a cooler environment

to a warmer one can damage the windows of the sample compartment. To prevent this

damage from occurring:

• Make sure that the windows are protected by placing fresh bags of desiccant in the

sample compartment.

• Leave the spectrometer to reach the temperature of the surroundings before removing

the desiccant.

Page 56

56 . Frontier IR Single-range Spectrometers User's Guide

must

Desiccant change is recommended.

Pink

Blue

Blue

The Desiccant Indicator in Detail

The optical system of the spectrometer is purged at the factory. This protects the KBr (or

) beamsplitters, sample compartment windows, or external port windows from being

CaF

2

damaged by humidity. Replaceable packs of desiccant maintain the purge.

The top panel of the instrument includes a desiccant indicator (Figure 23), whose sectors

change sequentially from blue to pink as the desiccant becomes exhausted. Change the

desiccant packs in the instrument when the sector marked 10 becomes pink, but while the

sectors marked 15 and 20 are still blue. These numbers correspond to the approximate

% Relative Humidity in the instrument.

Figure 23 The desiccant indicator: when desiccant packs should be changed

If all three sectors of the desiccant indicator are pink, then you

CAUTION

the desiccant.

The instrument optics may be fogged. Do not switch the instrument either ON

or OFF until all sectors are blue.

Sector Action Required

All sectors blue None.

The humidity levels in the instrument are below approximately 10%

Relative Humidity.

Sector 10 pink

If the instrument has been switched OFF for an extended period, do not

switch ON until you have changed the desiccant and all sectors are

blue.

Sector 10 & 15

pink

Replace desiccant the immediately to avoid instrument damage.

Do not switch the instrument ON or OFF until you have changed the

desiccant and all sectors are blue.

change

Page 57

Changing the Desiccant

Routine Maintenance . 57

CAUTION

Expect to change the desiccant

Old, used desiccant releases moisture.

in the

spectrometer every six months.

In regions experiencing high humidity levels we recommend that you

change the desiccant more often.

The desiccant change interval is set in the Desiccant change due in (days) option on the

Setup Instrument BeamPath tab in Spectrum software (Figure 24).

Figure 24 Setup Instrument BeamPath tab in Spectrum

If an instrument desiccant change is overdue, a warning will be displayed in the Status Bar

and in the Setup Instrument BeamPath table.

The warning is displayed until you tell the software that the desiccant has been changed. To

reset the desiccant change interval, select the current value, click Changed to clear any

warning messages, and then enter the number of days before the next desiccant change is

due.

Page 58

58 . Frontier IR Single-range Spectrometers User's Guide

Screw

Screw

Sample cover

Renewing the instrument desiccant

Old, used desiccant releases moisture and can cause catastrophic failure

CAUTION

You can purchase disposable desiccant kits from PerkinElmer (part number N0171159). A kit

contains two packs of desiccant, and three kits are required.

1. Inspect the humidity indicator card in the plastic bags in which the spare desiccant

packs are packed. If the card indicates humidity in the bag, discard the desiccant pack.

2. Remove the sample area cover, if fitted, by opening the cover, pressing the clip and

pulling the cover vertically to remove (Figure 25).

of KBr optics.

Do not use damaged packs of desiccant. Make sure that the packs you

use have not been left in contact with the air.

release clip

Figure 25 Removing the sample compartment cover

3. Undo the two captive screws securing the desiccant cover (Figure 26).

Figure 26 Captive screws securing the desiccant cover

Page 59

Routine Maintenance . 59

Desiccant

4. Open the cover and remove all the exhausted desiccant packs (Figure 27), noting how

they are installed.

compartment

(empty)

Figure 27 Desiccant removed

5. Place the first three packs of desiccant upright in the recess on the right of the

desiccant holder then, one at a time, lay the three remaining packs flat in the upper

part of the holder (Figure 28).

Figure 28 Stowing the desiccant packs

Ensure that when the packs have been installed they do not rise above the level of the

black rubber purge seal.

6. Close the cover and tighten the screws.

7. Refit the sample area cover.

Installing rechargeable desiccant in the instrument

There is also a rechargeable desiccant kit available (part number L1250311).

To install rechargeable desiccant packs follow the

procedure starting on page 58.

The instrument requires two rechargeable desiccant packs; the packs are sized to fit into the

left (70 mm × 78 mm × 33 mm) or right (102 mm × 78 mm × 84 mm) of the desiccant

container.

The standard kit contains two pairs of rechargeable desiccant packs. This is so you can

immediately replace the desiccant in the instrument with re-activated packs.

Renewing the instrument desiccant

The desiccant packs can be re-activated by baking them in an oven at 250 °C for

approximately 8 hours. They should be cooled in a dry atmosphere. For optimum results,

re-activate the packs immediately before re-use.

Page 60

60 . Frontier IR Single-range Spectrometers User's Guide

Purging the Spectrometer

Under most circumstances, you do not need to purge the optical system. However, after

performing any maintenance tasks that involved opening the main cover, you may purge the

optical system to remove water vapor and CO

that entered while the system was open.

2

Purge the sample compartment if you need to make sure that no residual water vapor or CO

peaks are visible in the spectrum.

There are two separate sets of connectors for purge gas lines, one for the sample

compartment and one for the optical system. You can purge with either dry air or nitrogen.

Both remove water vapor; however, nitrogen is preferable because it also removes

atmospheric carbon dioxide.

3

A typical cylinder of dry nitrogen (or dry air) stores 6.26 m

2200 lbf/in

2

). Make sure that the gas is free of oil, water, or dirt particles larger than 25 µm

at 1.4 × 104 kPa (220 ft3 at

(0.001 inch).

Do not site the instrument in a poorly ventilated area if nitrogen will be

used as a purge gas.

WARNING

Oxygen depletion in an enclosed space does not trigger a gasping reflex,

and errors of judgment, confusion, or unconsciousness can occur in

seconds and without warning.

Do not use a flammable gas to purge the instrument. The spectrometer

contains a hot source, and a fire or explosion will result. Only use clean,

dry, oil-free nitrogen or air to purge the instrument.

WARNING

2

Never connect the purge tubing directly to a gas cylinder or other high

pressure supply; always use a pressure regulator and set the pressure to

a maximum of 1 lbf/in

2

(6.9 kPa) before you start the flow.

WARNING

A length of clear plastic tubing (4 mm internal diameter) will be required to transfer the gas

from the gas bottle to the instrument purge connectors.

Page 61

Routine Maintenance . 61

Instrument purge

Sample purge