Page 1

SERVICE MANUAL

Page 2

23800 MX

Disassembly procedure

1. Peel off Body coverings (A19 & A20)

2. Remove Bottom cover (A400), Connector seat (A34) and Tripod screw (All).

CSS 1.7 x 2.2 x 3, CSM 1.7 x 3.5 x 2

3. Remove Top cover (A300)

a.) Retainer screw (Left handed)

Winding lever assembly (C300)

Cover ring B (A329)

b.) Shutter dial— ASA100, 1/1000

Shutter dial screw (E231) — 23800K-E321A

Shutter dial assembly (0-E223), Hook pin (E228)

Speed dial assembly (0-E229)

c.) Knob assembly (0-D1)

Nut (D12)—23110-D16-1-A

Cover ring (D7)

• d.) Top cover retainer screw (A15 x 2)

CSS 1.7 x 2.2 x 2

Top cover assembly (A300)

4. Unsolder 7 lead wires

5. Front board plate assembly (A100)

— Not necessary to cock self-timer.

Cover (A24)

0.1mm washers are underneath the Front board plate.

6. Sv resistor assembly (J300)— Retainer screws (E208 x 2)

7. Hot shoe contact (3204) — Hot shoe contact screw (3209 x 2)

8. P.C.board retainer plate (J205) — P.C.board retainer screw (J208), Spring (J206)

23800 /361

Page 3

9. P.C.board assembly (J500) — CNM 1.7 x 2.5 x 2

Base plate screw (A41-01)

10. Unsolder lead wires. 8 pcs

11. Mirror housing complete assembly (B000)

a.) After loosening Screw (M75), disconnect Idle gear assembly (0-M74) and Supporter plate

assembly (0-M53).

b.) Remove Mirror housing complete assembly (B000) together with Prism seat assembly

(0-M1), Penta prism assembly (0-L3) and Cell frame (J201).

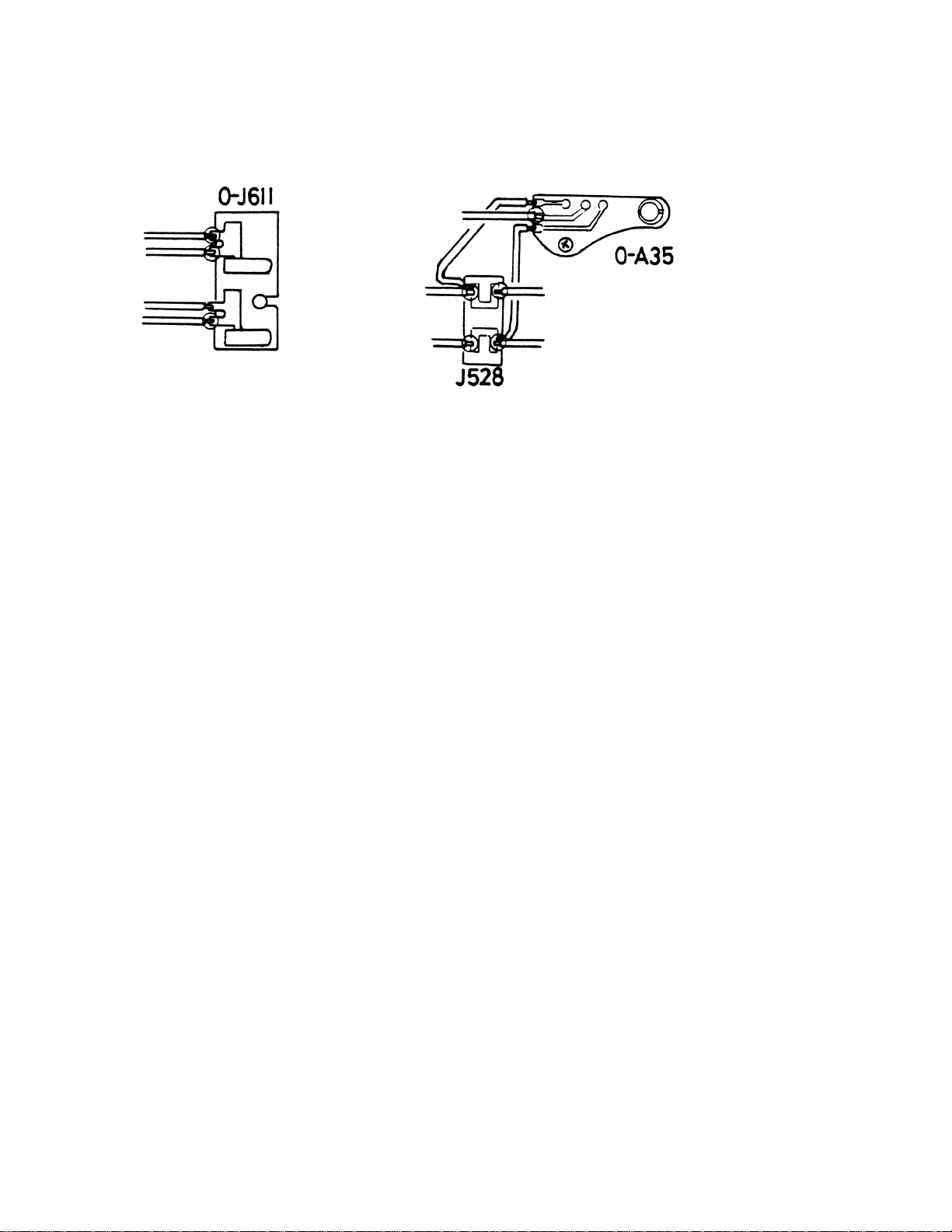

12. Terminal contact assembly (0-J611) — CNS 1.7 x 2.5

13. Battery seat assembly (0-A8) — CNS 1.7 x 2.5 x 2

14. Restitution spring assembly (0-M62)

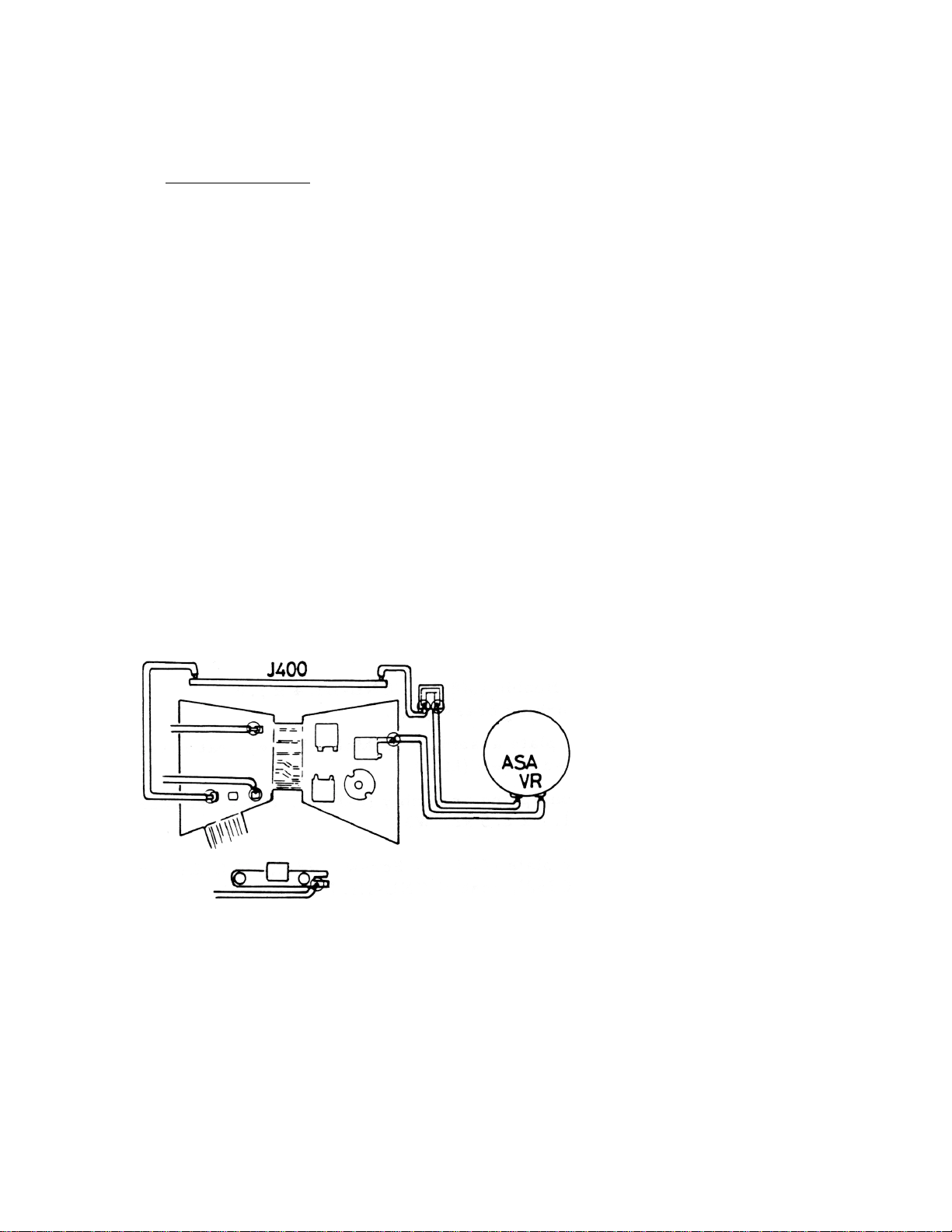

a.) Idle gear assembly (0-M74), Idle gear supporter plate (M73)

Screw (M75)

b.) Remove Bobbin (M85) — CNL-B 1.4 x 2.0

Without turning brass gear.

c.) Adjusting plate assembly (0-M68), Pulley seat assembly (0-M76)

Left handed screw (M72)

d.) Restitution spring.assembly (0-M62), Hinge retainer spring (A5)

— CNM 1.7 x 2.5 x 2, W3

15. Governor actuator plate (C252) — Screw (C253), CNL-E 1.7 x 2.5

After removing (C252), install CNL-E 1.7 x 2.5 again.

16. Slow governor assembly (C100) at 1/125 shutter speed.

— CNM 1.4 x 2.0, CNM 1.7 x 2.0

17. Governor restitution plate (E407), (E408), (E409), W3

18. Slow speed cam assembly (0-E402), Nut (E406) — 23800K-E406-A

Caution:

a.) Remove Nut (E406) grabbing slow speed cam shaft (E401) with plier, without turning

(E401).

b.) Remove (0-E402) by loosening two set screw, at 1 sec shutter speed.

23800 /362

Page 4

19. Pinion coupler gear assembly (0-C249) — CNL-E 1.7 x 2.5

20. Pinion coupler lever assembly (0-C254), (C257) (C 137)

21. Coupler lever spring (C266).Coupler lever spring hook screw (C214), Cord holder (J525).

22. Coupler lever assembly (0-C244), Coupler lever retainer screw (C248) — left handed.

23. Installing seat assembly (0-A508) — CSS 1.7 x 2.2 x 2

24. SW plate assembly (0-J521) — CNL-D 1.7 x 3.5

25. Bulb coupler lever spring (C263)

26. Install Winding lever assembly (C300) with Retainer screw (C305) temporarily, and cock the shutter.

27. Shutter seat plate assembly (E200) — CSS 1.7 x 3.0 x 3

High speed cam assembly (E210)

Selector gear collar (E123)

28. Slow speed cam shaft (E401)

LW 17, W70

29. Winding seat assembly (C100) — Nut B (E144).CNM 1.7 x 3.0, CSS 1.7 x 2.5

30. Release plate assembly (0-A502) — CNL-D 1.4 x 2.0

Shutter actuator plate A assembly (0-A504)

31. Shutter rod spring (A514)

Shutter rod assembly (0-A501)

32. Self-timer (H100) — CNM 2.0 x 9.0, CNM 1.7 x 3.0

33. X contact seat assembly (0-J621) — CNS 1.7 x 2.5 x 2

34. High speed lever assembly (0-E126)

a.) Indication spring (E134)

b.) Nut A (E133)

c.) (0-E126) Indication plate assembly (0-E132)

35. Bottom winding mechanism

a.) Bottom main gear screw (C265) — left handed

b.) Winding transmission plate (C221)

c.) Bottom main gear retainer plate (C220)

d.) Bottom main gear (C219)

e.) Bottom main gear retainer (C269)

f.) Winding shaft supporter plate (C270) — W24

g.) Winding shaft receptacle (C218)

h.) Spool gear assembly (0-C216) — W16 (0.3t)

23800 /363

Page 5

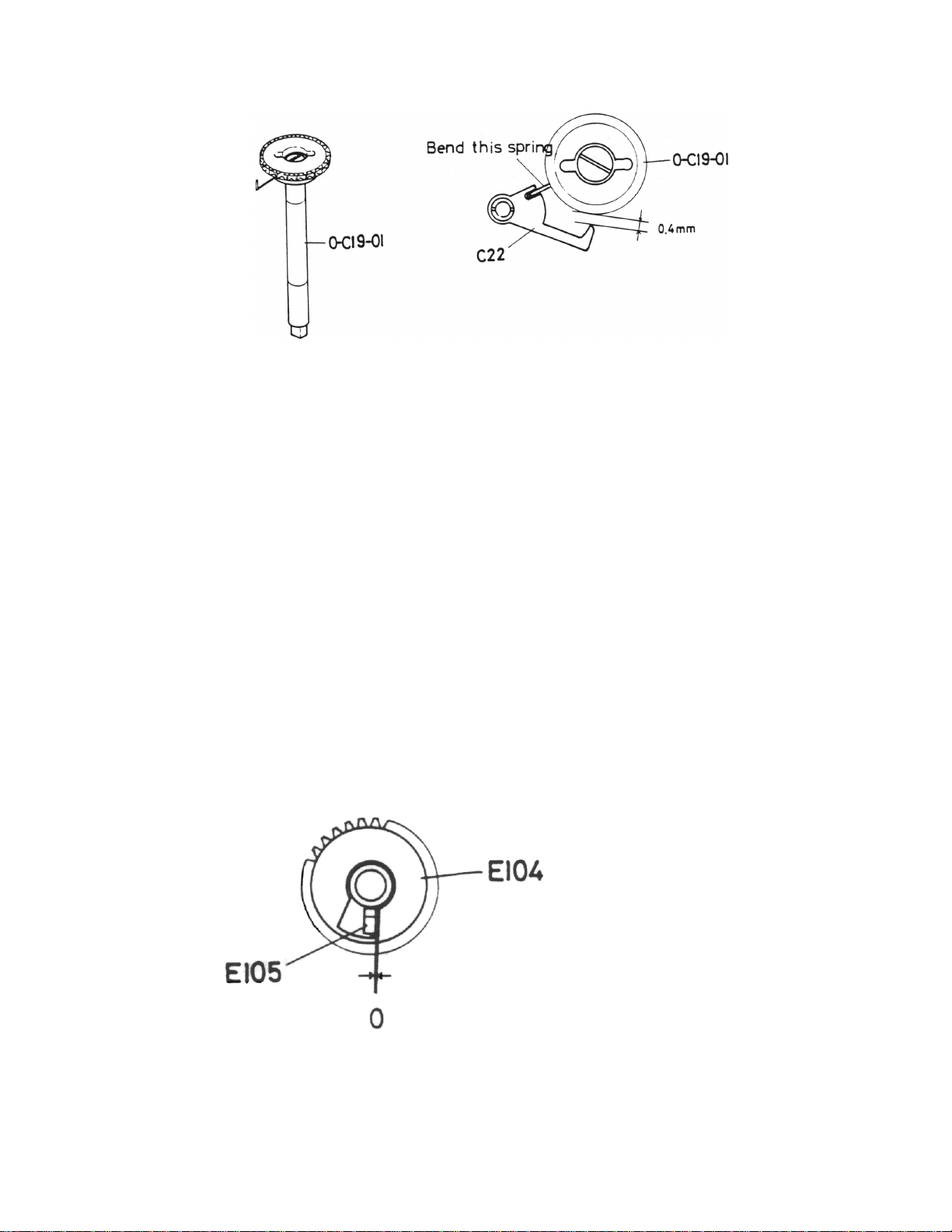

36. Winding shaft assembly (0-C19)

37. Restitution retainer lever (C22)

a.) Supporter screw (C24)

b.) (C22)

c.) Restitution lever spring (C25)

d.) Collar (C23)

38. Coupler pinion (E11) — Retainer screw (E12)

39. Reversing plate (E111)

a.) C137 — b.) E111 — c.) E112 — W6

40. Intermediate gears

a.) E107 — b.) E106 — c.) E104 — d.) E105 — e.) 0 E101

41. Hook plate (E153)

a.) E154 — b.) E155 — c.) E153 — W1

42. Top 2

nd

gear assembly (0-C9)

Top 2nd gear shaft retainer nut (C11)

231K-E111-A or 234K-B83-A

• 43.Bounce stopper (E145)

a.) E147 — b.) E146 — c.) E145 — W3 — d.) E152

44. Shutter curtain light seal (A17)

After releasing the shutter, remove (A17)

— CNS 1.7 x 2.5 x 2

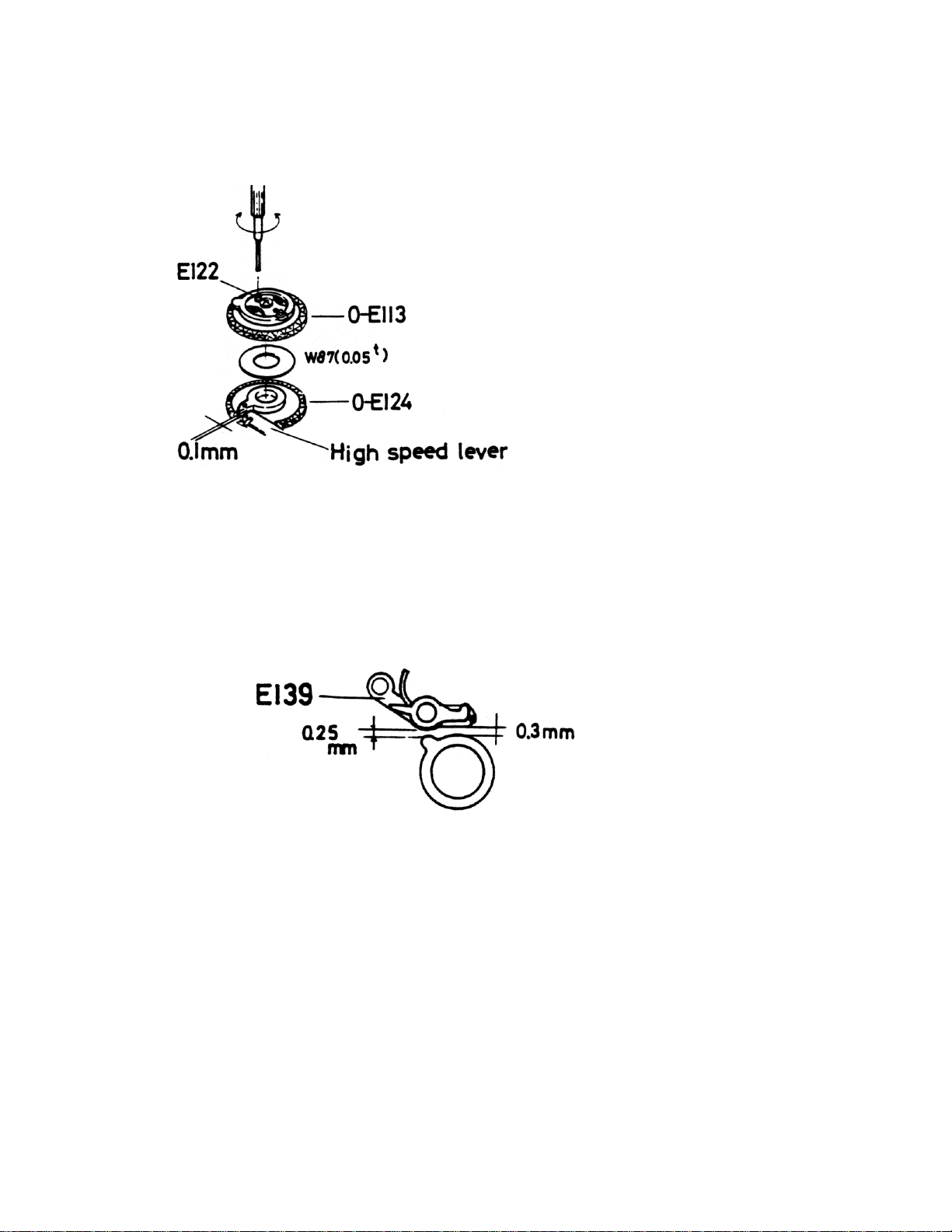

45. Curtain stopper (E139)

a.) After releasing curtain tension, remove Worm (E41 x 2)

b.) Worm wheel (E42 x2) — left handed.

c.) Curtain stopper screw (E143) — 23800K-E143-A

d.) Curtain stopper retainer screw (E142)

e.) (E140), (E141)

f.) Not removing Curtain stopper (E139), retain it with (E142)

46. Shutter curtains

a.) (C27) & (C28)

b.) Curtain plate assembly (0-A25)

c.) Shutter curtain mechanism

0-C1, 0-E36, 0-E38, etc.

47. Top shaft receptacle (C17)

Stopper retainer screw (C18) — CNS 1.7 x 1.8 x 2

48. Idle gear (C624) — CNL-F 1.7 x 1.8

49. Bottom shaft receptacle (C202)

W73, CNS 1.7 x 1.6 x 2, CNS 1.7 x 2.5

23800 /364

Page 6

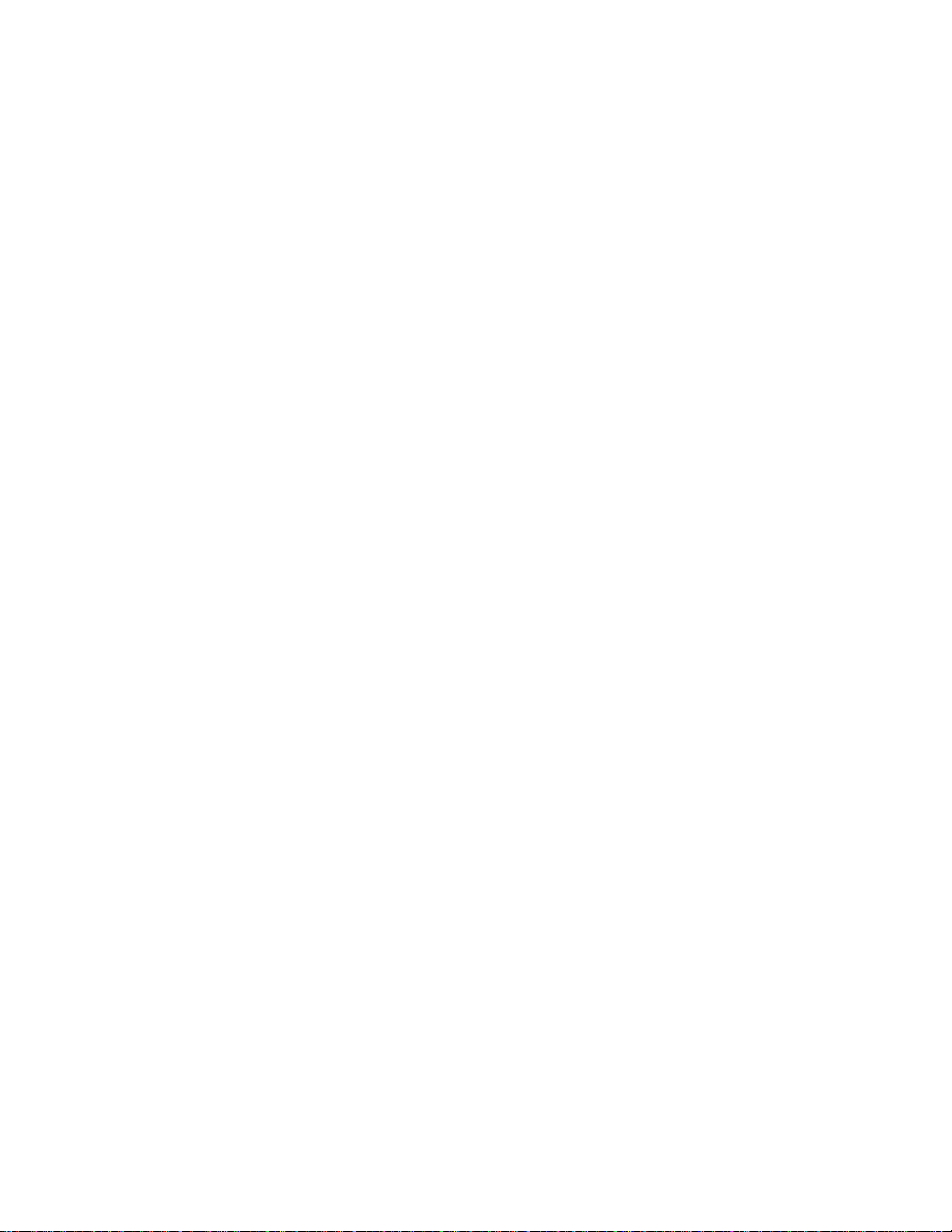

50. Coupler gear assembly (0-C222)

Coupler gear retainer screw (C226) — left handed

51. Rewinding actuator lever assembly (0-C241)

a.) CNL-B 1.4 x 2.0

b.) Spring retainer.(C243)

c.) Rewinding actuator lever spring (C242)

d.) 0-C241

52. Bottom mec.plate assembly (C200)

a.) Stopper pole (C267) — CNS 1.7 x 2.5

b.) Coupler guide (C268)

c.) C200

d.) Sprocket (C236)

23800 /365

Page 7

Assembly procedure

1. Bottom mec.plate assembly (C200)

a.) Sprocket (C236)

b.) Bottom mec.plate assembly (C200) — positioning with (C202)

c.) C268, C267, CNS 1.7 x 2.5

2. Spool

a.) Install spool (0-C20) and Spacer (C29)

b.) Top shaft receptacle (C17-01)

c.) Bottom shaft receptacle (C202)

Vertical clearance of Spool is adjusted with W73

(t=0.5 or 0.6mm)

d.) Idle gear (C264)

3. Rewinding actuator lever assembly (0-C241)

As shown in Parts list

4. Coupler gear assembly (0-C222) — (C226) = left handed

a.) Sprocket teeth is positioned as shown in Figure

b.) When installing Coupler gear assembly (0-C222), it should be positioned as shown below,

besides sprocket teeth should not be moved.

5. Shutter curtains

a.) Top mec.plate assembly (0-C1) — C27, C28

Curtain strings should not be off from rollers.

b.).Curtain plate assembly (0-A25)

Arrangement of both curtains is opposite from SP type camera.

6. Worm (E42) and Worm wheel (E41)

Turn worm wheel two rounds to give the tension to both curtains.

7. Check 2nd curtain position after releasing 1st curtain

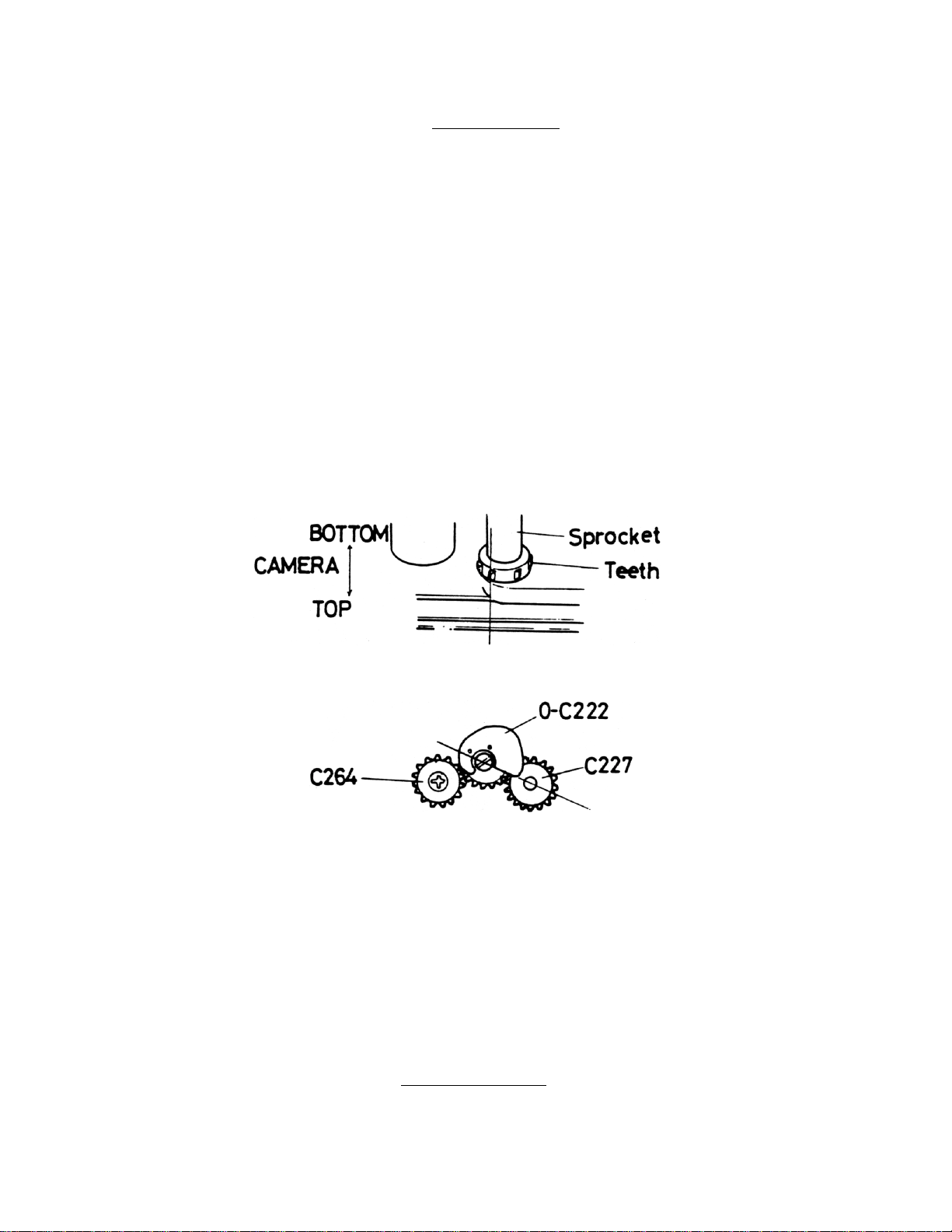

a.) Install High speed lever assembly (0-E126) temporarily.

Cock the shutter, and release 1st curtain, 2nd curtain should be staying at 5mm distant

from picture frame.

Shutter cocking tool — 23800K-E113, E124-A.

23800 /366

Page 8

b.) When both curtains are wound and hooked with 1st curtain ratchet assembly (0-E135), adjust the

clearance at 0.1mm between high speed.lever and Bottom selector gear assembly (0-E124) with

turning Adjusting stud (E122).

8. Curtains overlapping

After cocking the shutter, both curtains should be overlapping completely or within ± 0.1mm

deviation.

9. Bounce stopper (E152)

E152 — W3 — E145 — E146

10. Curtain stopper (E139)

E139 — E140 — E142 — E143 — 23800K — E143-A — E147

11. Top 2nd gear assembly (0-C9)-C11

12. Coupler pinion (E11) — E12 before cocking the shutter.

13. Restitution retainer lever (C22)

C23 — C25 — C22 — C24

14. Winding shaft assembly (0-C19-01)

a.) Clearance between (C22) and (0-C19-01) should be 0.4mm

23800 /367

Page 9

b.) Bottom winding mechanism

W16 — 0-C216 — C218 — W24 — C270 — C269 — C219 — C220 — C221 — C265

(left-handed)

Caution;

* W16 should be installed first separately from (C216), otherwise (C216) can not be installed

together with W16.

* When (C219) is installed, sprocket teeth should be positioned correctly as mentioned before.

Perforation is adjusted definitely here.

15. Reversing plate (E111) and hook plate

a.) E112 — C26 — W6 — E111 — C137

Check the function and play of (E111), the play should be

within 0.1mm

b.) W1-E153 — E155 — E154

16. Intermediate gears — Shutter cocked

a.) Sprocket teeth should be positioned correctly as mentioned before.

b.) b.) 0-E101

c.) Spill (E105)

d.) E104

Clearance between (E104) and (E105) should be desirably closer to (0), but (E105) must move up and

down smoothly without catching (E104).

23800 /368

Page 10

17. High speed lever assembly (0-E126)

— 0-E126 — 0-E132 — E133 — E134

* After installing the above parts, 1st curtain ratchet assembly (0-E135) functions

automatically.

18. X contact seat assembly (0-J621) — CNS 1.7 x 2.5

19. Self-timer (H100) — CNM 2.0 x 9.0, CNM 1.7 x 3.0

* Install self-timer pushing upper left.

20. Shutter actuator plate A assembly (0-A501)

0-A501 — A514 — 0-A502 — 0-A504 — CNL-D 1.4 x 2.0 x 3

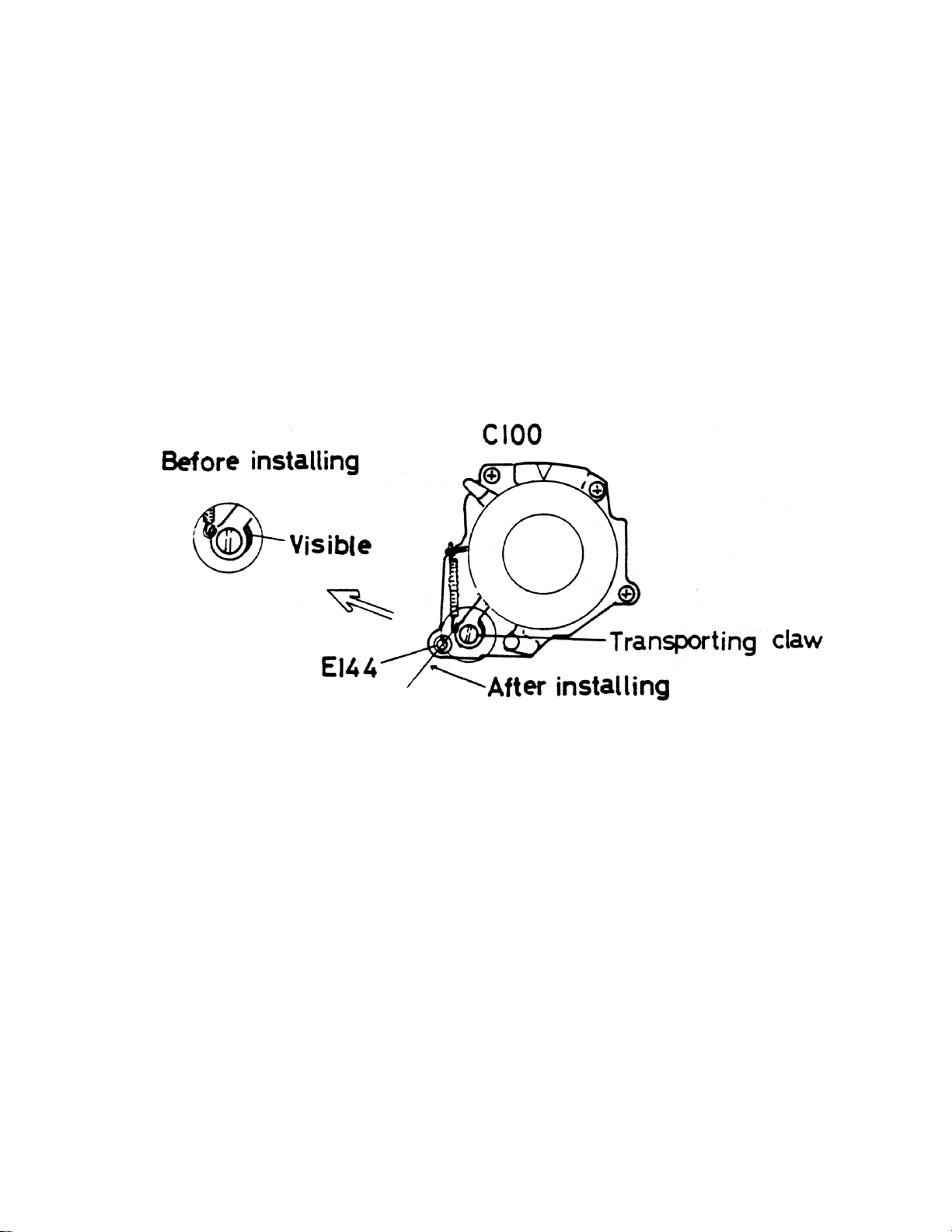

21. Winding seat assembly (C100) — together with winding lever

— Back cover open.

* Confirm the position of transporting claw before installing as shown in figure.

* Straight parts of transporting claw should align with the center of Nut B (E144) with shutter

cocked and back cover close.

* Check counter dial movement, counter dial should be transported till 37 point, not 38. If

counter dial proceeds till 38 point, reinstall Winding seat assembly (C100) as mentioned

above.

* After cocking shutter, check the clearance between Curtain stopper (E139) and Top selector

gear assembly (0-E113), 0.1mm is enough.

23800 /369

Page 11

22. Slow speed cam shaft (E401)

E401 — E405 — LW17 x 3 — W70

* Up and down play of (E401) should be within 0.1mm.

23. Shutter seat plate assembly (E200)

a) Cock the shutter

b) Put on selector gear collar (E123)

c) High speed cam assembly (0-E210)

d) Install (E200) taking care of jointing part with slow speed cam shaft.

24. Bulb coupler lever spring (C263)

25. Switch plate assembly (0-J521) Main SW

— CNL-D 1.7 x 3.5 x 2

* When installing it, take care of shortage or leakage to camera body.

26. Installing seat assembly (0-A508) — CSS 1.7 x 2.2 x 2

27. Coupler lever assembly (0-C244)

a) Cord holder (J525) — Coupler lever spring hook screw (C214)

b) (0-C244) — Coupler lever retainer screw (C248) — left handed

c) Coupler lever spring (C266)

d) Check the function of (0-C244)

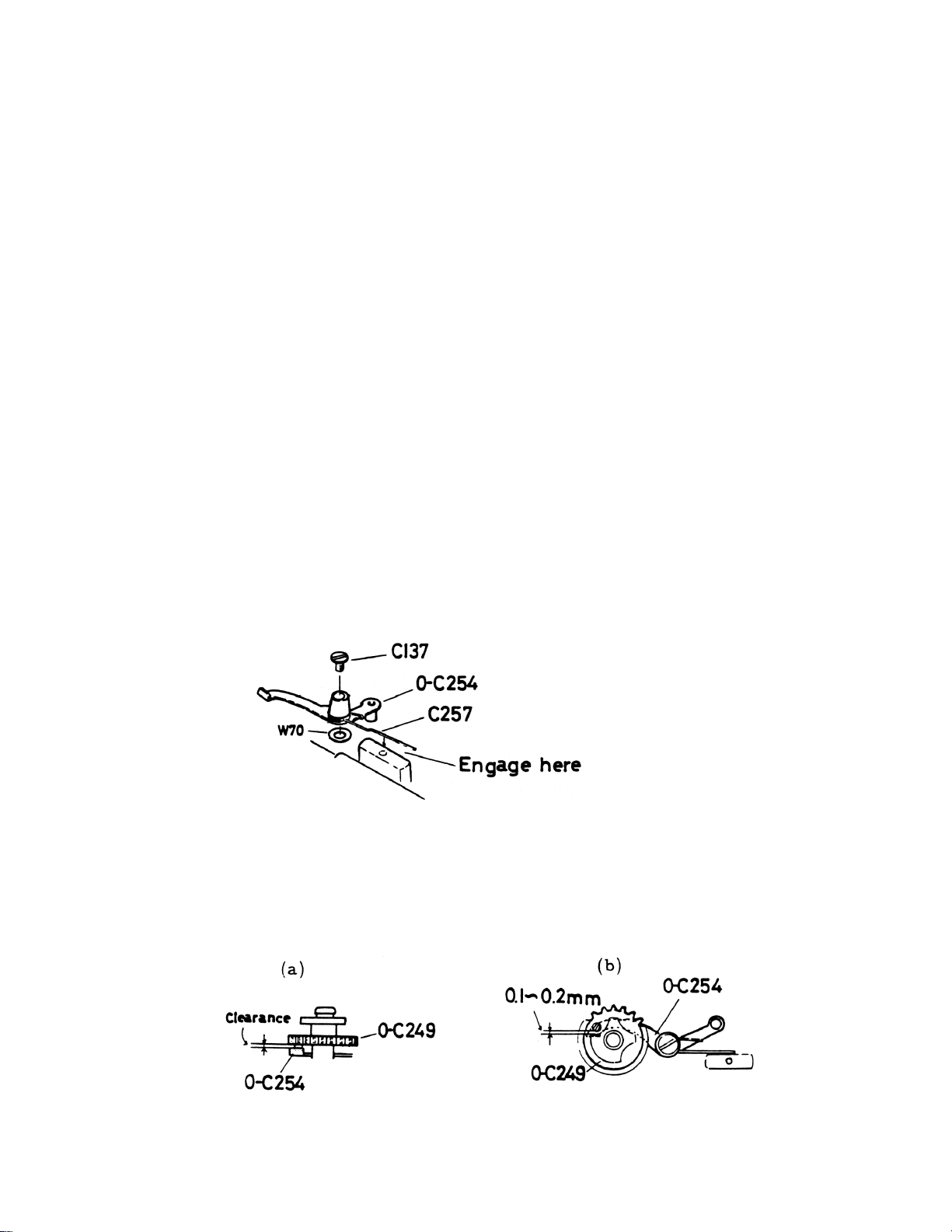

28. Pinion coupler lever assembly (0-C254)

W70 — 0-C254 — C257 — C137

29. Pinion coupler gear assembly (0-C249)

* After installing (0-C249), (0-C254) should not touch to (0-C249).

* After winding up, the least clearance (0.1 — 0.2) is necessary between the rivet of

(0-C249) and the lever of (0-C254).

See Figure (a)

See Figure (b)

23800 /3610

Page 12

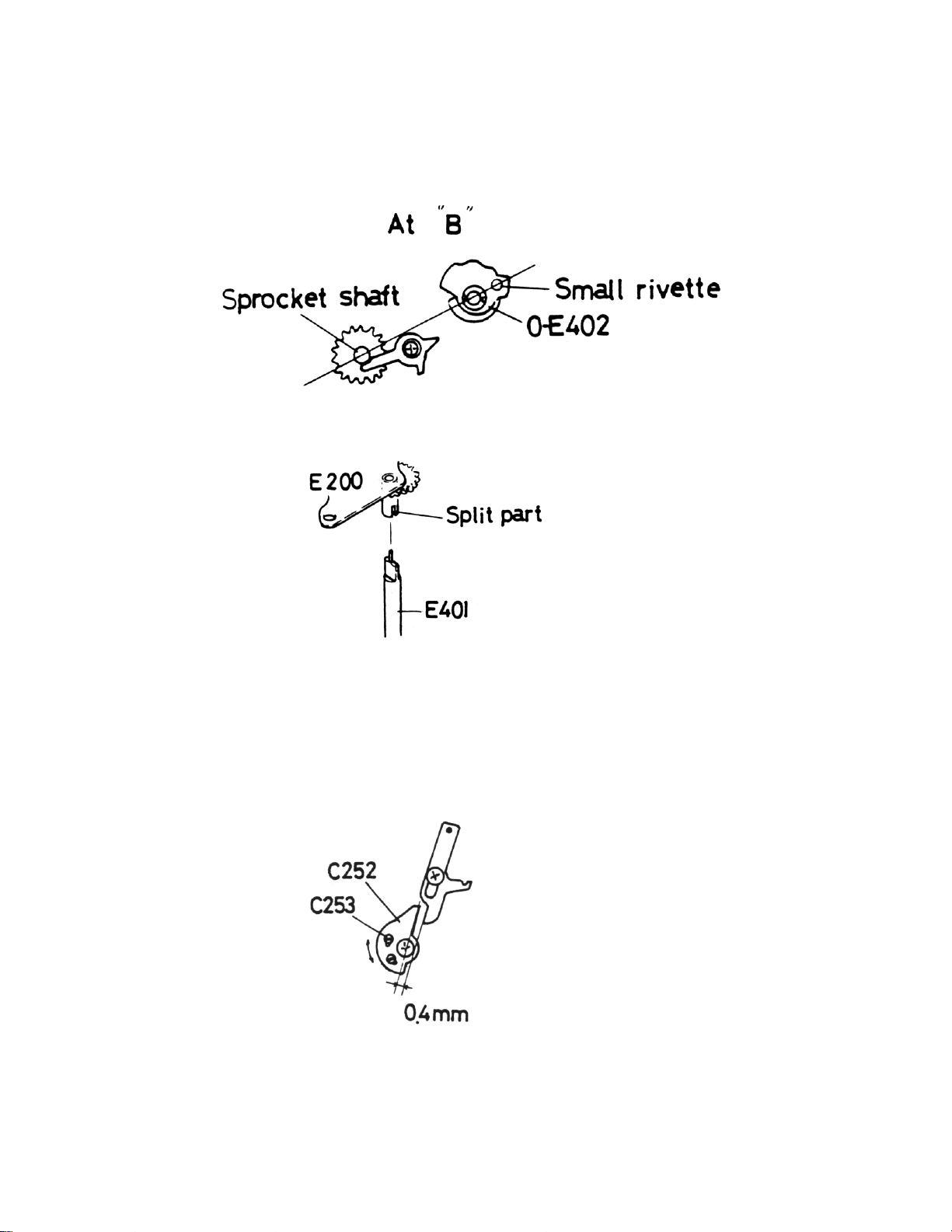

30. Slow speed cam assembly (0-E402)

a) Shutter speed at B

b) Small rivet of (0-E402) should align straight with the center of (E401) and sprocket shaft

as shown in Figure, and fasten Nut (E406) catching (E401) with pliers.

Fasten set screws also.

* When (E406) is fastened without catching (E401) with pliers, jointing split part underneath (E200)

spreads with revolving power of (E401), and slower shutter speed will be affected.

31.Governor (G100) — CNM 1.7 x 2.0, CNM 1.4 x 2.0

a) Shutter speed at 1/125

b) Install (G100) without bending small levers (such as angle lever etc).

32. Governor actuator plate (C252)

a) Shutter speed at B

b) Cock the shutter

c) (C252) — (C253) x 2 as shown in Figure

33. Shutter curtain light seal (A17)— CNS 1.7 x 2.5 x 2

23800 /3611

Page 13

34. Tv indication

a) Shutter speed at 1/1000

b) Lower pulley of Pulley seat assembly (0-M76) should be in parallel with camera.

c) Adjusting plate assembly (0-M68) — (M72) = left handed

d) Restitution spring assembly (0-M62) — (A5) — (M85)

* Turn wire 1 turn counter-clockwise around the pulley of (0-M62)

* After installing (0-M62), Tv wire should not be loose.

•If it is loose, give tension by moving (0-M68), but too much tension makes it harder to

adjust the position of Indication plate (M61).

e) (M73) — (0-M74) — (M75)

* Gear of (0-M62) and (0-M74) should be gearing not too deep, and check the function.

35. Mirror housing complete assembly (B000)

a) Battery seat assembly (0-A) — CNS 1.7 x 2.5 x 2

b) (B000) should be installed taking care of coupling two gears (M74) and (0-M53).

c) (E407) — (E408) — (E409) — W3

23800 /3612

Page 14

36. Terminal contact assembly (0-J611)

Soldering lead wires 8 pcs.

37. Shutter speed adjustment

a) Curtain speed 12.2 — 12.3ms

Same way with SP camera.

b) High speed adjustment 1/1000 — 1/60ms

Same way with SP camera

c) Slow speed adjustment 1/30 — l sec

1 Loosen screw

2 Adjust with eccentric screw

3 Fasten screw

4 Apply red lacquer on screw

38. Shutter stroke — Shutter dial at B

a) Install Top cover assembly (A300) and Winding lever assembly (C300) temporarily.

b) Depressing shutter button gradually, shutter starts working at 2.1 ± 0.2mm from origina1

position.

c) Self-timer exposure time adjustment at B.(Around 1000ms)

39. Main SW keep adjustment

40. Tv indication

a) Shutter speed at 1/1000

b) Positioning adjustment of Supporter plate assembly (0-M53).

Main SW stroke

±

— 0.6

0.2mm

23800 /3613

Page 15

41. Front board plate assembly (A100).

Mechanical back 45.46mm

1 Tv indication dial should be set just

center portion of viewing finder.

2 Tv indication (1000) should be set as

shown in Figure.

3 Three jointing gears (0-M53), (0-M62)

and (0-M74) must function well.If they

do not, adjust the position of Idle gear

supporter plate (M73) with eccentric

A

screw

4 Each figure of Tv indication must come

in the center portion, adjusting eccentric

B

screw

42. Sv resistor assembly (J300) — (E208)

43. P.C.board assembly (H500)

a.) LED

(A41-01) — W3 — CNM 1.7 x 2.5 — CNL-D 1.4 x 2.5

b.) GPD

(J205) — (J206) — (J208)

c.) Bonding (J500) to Penta prism cover

d.) (J204) — (J209) x 2

44. Soldering lead wires — 7pcs

45. Bottom cover assembly (A400) — CSS 1.7 x 2.2 x 3

Tripod screw (All) — CSM 1.7 x 3.5 x 2

46. Adjustment of LED indication place

23800 /3614

Page 16

47. Light measurement

a.) Temporary setting — Top cover tool, shutter dial, winding lever

b.) Battery checker — VR

EV12, f8, 1/60, ASA100

2.6V Light off

2.7V Light on

c.) Light measurement — VR

EV12, f8, 1/60, ASA 100, 2.8V

When shutter dial is turned 1EV step (1/60 — 1/30 and A/60 — 125), and both red LED

(over and under) light on, it shows within 0.1EV difference.

d.) Confirmation of voltage reliability

EV12, f8, 1/60, ASA100

When voltage is dropped down from 2.8V to 2.7V, LED indication should not change.

e.) When mirror stays up, LED should not light on.Check it at B.

A

B

or VR

C

48. Focusing adjustment

a.) Removing Top cover tool and others

b.) Adjust focusing with Focusing screw (M6) x 4

49. Adjustment of Focusing plate holder assembly (0-B101)

If vertical play is felt on (0-B101), remove Cover plate (B109) and adjust the position of

Hook metal assembly (0-M107) with eccentric screw.

50. Top cover assemb1y (A300)

Winding lever, shutter dial, rewind knob and other small parts.

Tools — 23110K-D16-1-A

23800K-E231-A

23600K-C135-A

51. Bonding Coverings (A19 & A20)

23800 /3615

Page 17

ASAHI PENTAX MX (23800)

Curtain assembly

1. Curtain inspection

Check if Aron-alpha is applied to curtain string as shown in

Figure.

Aron-alpha is applied to increase durability.Curtain string

should be, bent parallel with shutter curtain.

2. Install 1st and 2nd pinion shafts (0-E2, 0-E7), (0-E118), (0-E108), (0-E135) and 2nd curtain assembly

(0-E38) to Top mec.plate assembly (0-C1).

3. Install Top mec.plate assembly (0-C1) to camera body temporarily.

4. Give slight tension to 2nd curtain.

5. Install 1st curtain assembly (0-E36) and Curtain plate assembly (0-A25).

Give slight tension to 1st curtain.

Arrangement of both curtains is opposite from SP type

camera.

Install 1st curtain (0-E36) engaging 2nd curtain string

with the rollers.

6. Removing Top mec.plate assembly (0-C1) from camera body for a while, engage 1st curtain string with

the 2nd curtain pinion rollers and re-install Top mec.plate assembly (0-C1) to camera body without

slipping off the string from rollers.

7. 2nd curtain hold position — with shutter cocked 2nd curtain should stay at 5mm distant from picture

frame when High speed lever hooks Bottom selector gear assembly (0-E124).

Adjust the position of 2nd curtain with changing the coupling between 2nd pinion gear and (0-E124).

8. Install Top selector gear assembly (0-E113) with shutter released, facing the retainer screws of 1st

curtain pinion 45

°

forward.

23800 /3616

Page 18

9. Install adjusting plate (E120) and other parts.

Adjusting plate (E120) is installed after

turning Top selector gear and Selector

retainer (0-E118) to cocked position.

10. Install 1

st

curtain string to bobbin (E3).

Confirm curtain overlapping and slit parallel, with adjusting the

length of 1st curtain string.Aron-alpha is applied to curtain string

and its retainer screw (CNS 1.4 x 1.6) after adjustment is finished,

and cut the curtain string after turning around the Bobbin one time

on the other way.

11. Clearance between Bottom selector gear assembly (0-E124) and High speed lever assembly (0-E126)

should be adjusted at 0.1mm with cocked position by turning Adjusting plate (E120).

After adjustment, apply aron-alpha to Retainer screw (E121).

23800 /3617

Page 19

Page 20

Page 21

Page 22

Page 23

LIST OF SERVICE PARTS

Product No.23800

ASAHI PENTAX MX

Note: 1. The parts with numbers starting ‘0-’ are assemblies.

2. 0nly available parts are listed below.

Parts No. Description Quantity Interchangeability

A1 Body proper 1

A2 Hinge 1

A3 Hinge collar 2

A4 Hinge retainer plate 1

A5 Hinge retainer spring 1

A6 Back cover guide screw 1

A7 Cassette receptacle 1

0-A8 Battery seat assembly 1

(A8, A9, A10 x 2)

A11 Tripod screw 1 23602-A23

0-A13-01 Strap hook assembly 1

(A13-01, A14)

A15 Top cover retainer screw 2

A16 Mirror box retainer screw 2

A17 Shutter curtain light seal 1

A18 Light seal 1

A19 Body covering, left 1

A20 Body cuvering, right 1

A24 Cover 1

0-A25 Curtain plate assembly 1

(A25, M7 1 x2)

A27 Sprocket shaft receptacle 1

A31 Light seal A 1

A32 B 1

A33 C 2

A34 Connector seat 1

0-A35 Connector base plate assembly 1

(A35, A36 x3)

A37 Insulation plate 1

23800 /3622

Page 24

Parts No. Description Quantity Interchangeability

A38 Connector retainer screw 1

A41-01 Base plate screw 1

A42 Spacer 1

A43-01 Light seal curtain 2

A44 Light seal D 2

A45 Light seal E 2

A46 Light seal F 1

A47 Light seal G 1

A48 Strap hook retainer screw 2

A49 Light seal tape 1

A100 Front board plate assembly 1

(A101 — A149, 0-J401, 0-J601 x 2)

A104 Mount ring 1

A105 Mount spring 1 23602-A105

A106 Mount screw 6 23602-A106

0-A108 Mount lock button assembly 1

(A108, A107, A109)

A110 Collar 1

A111 Lock button spring 1

A112 Lock pin supporter plate 1

A113-01 Front board retainer screw 4 23602-A159

A114 Front board light seal 1 23701-A120

A116-01 Front board light seal 2

A121-01 Base plate 1

0-A123 Charge lever assembly 1

(A123, A122-01, A124)

A125-01 Charge lever shaft A 1

0-A127-01 Charge lever shaft B assembly 1

(A127-01, A145)

A130-01 Button cover 1

A132 Start button 1

A134 Spring B 1

0-A135 Diaphragm coupler ring assembly 1

(A135, A136 x 5, A137 x 5, A138, A140)

A139-01 Diaphragm coupler ring spring 1

0-A143 Supporter plate assembly 1

(A143, A144, A146, A147, A148-01)

23800 /3623

Page 25

Parts No. Description Quantity Interchangeability

A148-01 Restitution spring 1

A149 Front board light seal 1

A200 Back cover assembly 1

(A201, A203, A207, A208 x 2, A209, A210 x4, A211,

A212, A213, A214, A215, A216 x 4, A217 x 2, A218

A219, A221, A222-01 x 4, A225, A226, A227)

A202 Back cover shaft receptacle 2

0-A204 Pressure plate assembly

(A204, A205, A206 x 2)

A217 Light seal A 2

A218 Light seal B 1

A220 Pressure plate cover 1 23701-A220

A300 Top cover assembly 1

(A301 — A336)

A302 Accessory shoe 1

A303 Accessory shoe spring 1

0-A304 Accessory shoe base assembly 1

(A304, A305)

A306 Contact spring A 1

A307 Contact spring B 1

A308 Collar 1

A309 Retainer screw 1

A310-01 Insulation washer 1 23602-A327

A311 SW pin 2

A312 Indication plate 1 23701-A307

A315 Cover ring A 1

0-A316 Shutter button seat assembly 1

(A316 ,A317)

A318 Guide screw A 1 23602-A317

A319 Guide screw B 1 23602-A318

A320 Spring 1 23602-A320

A322 Nut 1

0-A323 Click plate assembly 1

(A323, A324)

A325 Shutter button 1

0-A326 Shutter button core assembly 1

(A326.A327, A328)

A329 Cover ring B 1

23800 /3624

Page 26

Parts No. Description Quantity Interchangeability

A330-01 Window C 1

A332-01 Mask 1

A334-01 Pattern retainer 2

A335 Light seal 1

A336 Insulation tape 2

A400 Bottom cover 1

(A401, A406)

A403 Bottom winding cap 1

0-A405 Battery cap assembly 1 23602-0-A403

(A405, A406)

0-A501 Shutter rod assembly 1

(A501, A505, A507)

0-A502 Release plate assembly 1

(A502, A503, A506, A516)

0-A504-02 Shutter actuator plate A assembly 1

(A504-02, A515-02, A516, CNL-D 1.4 x 2.5)

0-A508 Installing seat assembly 1

(A508, A509, A510, A511, A512, A513, LW13)

A514 Shutter rod spring 1

B000 Mirror housing complete assembly 1

(B1 — B112, 0-J531-01, 0-J532-02)

0-B2 Mirror seat assembly 1

(B2, B3, B4, B5, B6 x 4, B7)

B8 Spacer 1

0-B9 Supporter, right assembly 1

(B9, B10)

0-B11 Supporter left assembly 1

(B 11, B12)

B13 Mirror seat restitution spring 1

0-B15 Mirror actuator lever, bottom assembly 1

(B15, B16, B17, B18 x 2, B19, B46)

B20 Washer 1

0-B22 Diaphragm coupler lever assembly 1

(B22, B21, B23, B24 x 2, B25-01, B26-01, B29, B30, B31-01, B32-01, B33, B34)

828 Diaphragm actuator lever connection spring 1

B35 Hook plate 1

B36 Hook plate spring 1

0-B41-01 Actuator lever plate assembly 1

(B41-01, B40-01)

23800 /3625

Page 27

Parts No. Description Quantity Interchangeability

B51-01 Stopper screw 1

B53 Diaphragm actuator lever spring 1

0-B55-01 Mirror actuator plate assembly 1

(B55-01, B56, B57, B58, B93)

0-B59 Mirror charge lever assembly 1

(B59, B60, B61, B62, B63.)

0-B64 Mirror charge lever retainer assembly 1

(B64, B65)

B66 Mirror charge lever collar screw 1

B67 Restitution spring

B68 Mirror seat spring

0-B71 Shock absorber assembly 1

(B71, B72, B73)

0-B79 Mirror charge hook plate assembly 1

(B79, B80)

B81 Hook plate spring 1

0-B83 Mirror seat receptacle assembly 1

(B83, B88)

B84 Mirror seat receptacle screw 1

0-B85-01 Mirror seat receiver assembly 1

(B85-01, B86)

B87 Mirror seat recever spring 1

B89 Light seal frame 1

B90-01 Mirror shock absorber 1

B91 Mirror adhesive tape 1

B92 Light seal A 1

B94 Light seal B 1

B95 Light seal C 1

B96 Stopper washer 1 23701-B70

0-B101 Focusing plate holder assembly 1

(B 101, B 102)

B103 Shaft receptacle 1

B104 Spacer 1

B105 Shaft 1

0-B107 Hook metal assembly 1

(B 107, B108)

B109 Cover plate 1

B110 Retainer screw 2

23800 /3626

Page 28

Parts No. Description Quantity Interchangeability

B111 Light seal curtain 1

B112 Light seal curtain B 1

0-C1 Top mec.plate assembly 1

(C1, C2, C3, C4 x 2, C5, C6, C7, C8, E5)

0-C9 Top 2nd gear assembly 1

(C9, C10)

G11 Top 2nd gear shaft retainer nut 1

C17-01 Top shaft receptacle 1

C18 Stopper retainer screw 1

0-C19-01 Winding shaft assembly 1

(C19-01, C12, C13, C14, C15-01, C16)

0-C20-01 Spool assembly 1

(C20-01, C21 x 16, C30)

C22 Restitution retainer lever 1

C23 Collar 1

C24 Supporter screw 1

C2S Restitution lever spring 1

C26 Winding plate supporter 1

C27 Top cover supporter 1

C28 Top mec. plate screw 1

C29-01 Spacer 1

C100 Winding seat assembly 1

(C101 — C142)

C200 Bottom mec.plate assembly 1

(C201 — C215, C262, E6, E15, E44)

C214 Coupler lever spring hook screw 1

0-C216 Spool gear assembly 1

(C216, C217)

C218-01 Winding shaft receptacle 1

C219-01 Bottom main gear 1

C220-01 Bottom main gear retainer plate 1

C221-01 Winding transmission plate 1

0-C222 Coupler gear assembly 1

(C222, C223, C224, C225 x 2)

C226 Coupler gear retainer screw 1

C227 Sprocket gear 1

C228 Sprocket retainer 1

C229 Sprocket shaft 1

23800 /3627

Page 29

Parts No. Description Quantity Interchangeability

C230 Clutch ring 1

C231-02 Clutch ring retainer screw 1 23602-C14

C232-01 Clutch ring retainer screw collar 1 23602-C15

C233 R button 1

C234 Sprocket spring 1 23602-C11

C235 Sprocket collar 1

C236 Sprocket 1

0-C241 Rewinding actuator lever assembly 1

(C241, C237, C238, C239, C240)

C242 Rewinding actuator lever spring 1

C243 Spring retainer 1

0-C244 Coupler lever assembly 1

(C244, C245, C246, C247)

C248 Coupler lever retainer screw 1

0-C249 Pinion coupler gear assembly 1

(C249, C250)

C252 Governer actuator plate 1

C253 Governer actuator plate screw 2

0-C254 Pinion coupler lever assembly 1

(C254, C255, C256)

C257 Pinion coupler lever spring 1

C263 Bulb coupler lever spring 1

C264 Idling gear 1

C265 Bottom main gear screw 1

C266 Coupler lever spring 1

C267 Stopper pole 1 23701-C18

C268 Coupler guide 1

C269 Bottom main gear retainer 1

C270 Winding shaft supporter plate 1

C300 Winding lever assembly 1

(C301, C302, C303 x 4, C304, TCSM 1.4 x 3.5)

C305 Retainer screw 1

0-D1 Knob assembly 1

(D1, D2, D3, D4, D5, D6)

D7 Cover ring 1

0-D8 Shaft receptacle assembly 1

(D8, D9, D11)

23800 /3628

Page 30

Parts No. Description Quantity Interchangeability

D10 Rewind shaft 1

D12 Nut 1

0-E2 1st curtain pinion shaft assembly 1

(E2, E1)

E3 Bobbin 2

E4 Retainer screw 3

0-E7-01 2nd curtain pinion shaft assembly 1

(E7-01, E1)

E11 Coupler pinion 1

E12 Coupler pinion screw 1

E15-01 Roller A 2

E24 Roller B 2

E26 1st curtain shaft collar 1

0-E36 1st curtain assembly 1

(E36, E20, E21, E22, E23, E24, E25, E35, E37)

0-E38-01 2nd curtain assembly 1

(E38-01, E4, E8, E9, E10, E27, E28, E29, E30, E31, E32, E33, E34, E35, E39)

E40-01 Bottom shaft rest 1

E41 Worm 2

E42 Worm wheel 2

E46 Collar 2

0-E101-01 Intermediate gear, bottom assembly 1

(E101-01, E102, E13)

E104 Intermediate gear, top 1

E10S Spill 1

E106 Spill retainer plate 1

E107 Intermediate gear retainer screw 1

E108 Spill spring 1

E109 Spill spring screw A

E110 Spill spring screw B 1

E111 Reversing plate 1

E112 Reversing spring 1

0-E113 Top selector gear assembly 1

(E113, E114, E115 x 2, E116, E117)

0-E118 Selector retainer assembly 1

(E118, E119)

E120 Adjustable plate 1

23800 /3629

Page 31

Parts No. Description Quantity Interchangeability

E121 Adjustable plate screw 1

E122 Adjusting stud 1

E123 Selector gear collar 1

0-E124 Bottom selector gear assembly 1

(E124,E115, E125)

0-E126 High speed lever assembly 1

(E126, E127, E128, E 129, E130, E131, E137)

0-E132 Indication plate assembly 1

(E132, E138)

E133 Nut A 1

E134 Indication spring 1

0-E135 1st curtain ratchet assembly 1

(E135, E136)

E139 Curtain stopper 1

E140 Lubrication tube retainer 1

E141 Lubrication tube 1 23701-E276

E142 Curtain stopper retainer screw 1

E143 Curtain stopper screw 1

E144 Nut B 1

E145 Bounce stopper 1

E146 Bounce stopper screw 1

E147 Bounce stopper spring 1

0-E148 Synchro actuator plate assembly 1

(E148, E149, E150)

E151 Synchro actuator spring 1

E152 Bounce adjusting screw 1

E153 Hook plate 1

E154 Hook plate screw 1

E155 Hook plate restitution spring 1

E200 Shutter seat plate assembly 1

(E201, E202, E203, E204, E205, E206, E207, E208, E209-01, E212, E232)

0-E210 High speed cam assembly 1

(E210, E211)

0-E223 Shutter dial assembly 1

(E223, E224)

E228 Hook pin 1

0-E229 Speed dial assembly 1

(E229, E221, E222 x3 , E225, E226 x 3, E227, E229, E230)

23800 /3630

Page 32

Parts No. Description Quantity Interchangeability

E231 Shutter dial screw 1

E401 Slow speed cam shaft 1

0-E402 Slow speed cam assembly 1

(E402, E403, E404)

E405 Spacer 1

E406 Nut 1 23723-C419

E407 Governor restitution plate 1

E408 Restitution plate shaft 1

E409 Restitution plate spring 1

G100 Governer 1

H100 Self-timer 1

J201 Cell frame 1

J203 Light metering lens 2

J204 Hot shoe contact 1

J205 P.C.board retainer plate 1

J206 Spring 1

J207 Mask 1

J208 P.C.board retainer plate screw 1

J209 Hot shoe contact screw 2 23602-N15

J300 Sv resistor assembly 1

(J301 — J307)

J400 f-volume assembly 1

(J401, J402)

J403 Collar 2

J500 P.C.board assembly 1

(J501, J502, J503, J504, J506, J507-01)

J508 Adhesive tape 1 23700-J507

0-J521 SW plate assembly 1

(J521, J522, J532-01, J524 x 2)

J525 Cord holder A 1

J526 Cord holder 4 23700-J206

J527 Relay P.C.board 1

J528 Relay P.C.board 1 23701-A157

0-J531-01 SW plate A assembly 1

(J531-01, J533-01, J535-02, J537, J613 x 4)

0-J532-02 SW plate B assembly 1

(J532-02, J534-02, 3538, 1613 x 2)

23800 /3631

Page 33

Parts No. Description Quantity Interchangeability

J539 Adhesive tape

0-J601 Synchro terminal assembly 2

(J601, 3602, J603)

0-J611 Terminal contact assembly 1

(J611, J612 x2, J613 x4)

0-J621 X contact seat assembly 1

(J621, J622, J623, J624, J625 x 4)

L1 Mirror 1

L2 Fresnel lens 1

0-L3 Penta prism assembly 1

(L3, L6-01, M11)

0-L4 Eyepiece assembly 1

(L4, L5)

0-M1 Prism seat assembly 1

(M1, M2 x 2, M3 x 2, M4 x 4, M5, M10)

M5 Ground glass mask 1

M6 Focusing screw 4

0-M7 Receptacle plate assembly 1

(M7, M8 x 4, M9 x 4)

M10 Penta mask 1

0-M12 Penta retainer plate A assembly 1

(M12, M14)

0-M13 Penta retainer plate B assembly 1

(M13, M14)

M15 Prism protector 1

M16 Penta retainer plate 2

M17 Penta retainer plate tape 2

M51 Seat 1

M52 Cover plate 1

0-M53 Supporter plate assembly 1

(M53, M54, M55, M56, M57, M58, M59, M60, M61)

M61 Indication plate 1

0-M62 Restitution spring assembly 1

(M62, M63, M64, M65, M66, M67, M82, M84, M86)

0-M68 Adjusting plate assembly 1

(M68, M69, M70)

M72 Adjusting plate screw 1

M73 Idle gear supporter plate 1

23800 /3632

Page 34

Parts No. Description Quantity Interchangeability

0-M74 Idle gear assembly 1

(M74, M83)

M75 Screw 1

0-M76 Pulley seat assembly 1

(M76, M77, M78, M79, M80, M81)

M85-00A Bobbin A 1

-00B Bobbin B

23800 /3633

Page 35

LIST OF STANDARD PARTS

Product No.23800

ASAHI PENTAX MX

Small screws:

Description Surface treatment Position of use Quantity

Set T 1.2 x 2 Black nickel M62, M67 1

Set T 1.4 x 1.8 “ E402, E401 2

Set T 1.7 x 2.2 “ E40, E41 2

Set F 1.4 x 2.5 “ E129,E137 1

Set F1.7 x 3.5 “ A1 1

CNS 1.4 x 1.4 “ E113, E120 2

CNS 1.4 x 1.6 “ A506, A501 1

1E3, E37 2

CNS 1.4 x 2 “ G100, G201 1

CNS 1.7 x 1.5 “ A17, A1 2

CNS 1.7 x 1.6 “ C202, C201 2

CNS 1.7 x 1.8 “ C17,A 1 2

CNS 1.7 x 2 “ A112, A101 2

D8, A1 3

J531, B1 2

L3M1 2

CNS 1.7 x 2.5 “ A135, A101 2

A8, A1 2

M51, B1 2

C202, A1 1

J621, A1 2

C201, A1 1

CNS 1.7 x 3.5 “ B89, B1 4

CNM 1.4 x 2.5 “ D6, D1 2

CNM 1.7 x 2 “ A61, A1 2

A25, A1 2

C100, A1 1

CNM 1.7 x 2.5 “ C201, A1 1

M62, A5, A1 2

J612, A1 1

J501, A41, A1 1

CNM1.7 x 3 “ A35, A1 1

H100, A1 1

C101, A1 1

CNM 1.7 x 4 “ B1, A1 2

CNM 2 x 9 “ H100, A1 1

23800 /3634

Page 36

Small screws:

Description Surface treatment Position of use Quantity

CSS 1.4 x 3 Black nickel A143, A125 3

CSS 1.7 x 2 “ B11, B1 2

CSS 1.7 x 2.2 Nickel A401, A1 3

A301, A1 2

Blacknickel B103, B1 2

A508, A1 2

CSS 1.7 x 2.5 “ B9, B1 2

E201, A1 2

E201, C7 1

CSS 1.7 x 2.8 “ A202, A1 4

CSS 1.7 x 3 “ A2, A3, A4, A1 2

A302, A301 2

C26, C101 1

E40, A1 2

CSS 1.7 x 6.5 “ A302, A301 2

CNM 1.7 x 3.5 “ A11, A1 2

T-CSM 1.4 x 3.5 Nickel C304, C301 1

CNL-B 1.4 x 1.5 Black nickel B107, B1 2

M53, B51 2

CNL-B 1.4 x 2 “ M85, E209 1

C241, C206 1

Small screws:

CNL-D 1.4 x 1.6 “ E135, C6 1

A515, A504 1

C134, C101 1

CNL-D 1.4 x 2 “ C142, C101 1

A504, A501 2

CNL-D 1.4 x 2.5 “ A502, A501 1

“ J501, M75 1

CNL-D 1.4 x 3 “ B15, B20 1

B46, B45 1

B79, B74 1

CNL-D 1.7 x 2 B83, B1 1

CNL-D 1.7 x 2.5 M12, B1 1

“ M13, B1 1

CNL-D 1.7 x 3 “ J521, A1 2

CNL-D 1.7 x 4 “ J403, J401, A101 2

CNL-E 1.7 x 2.5 “ C249, C210 1

CNL-E 1.7 x 3.5 A127, A123 1

23800 /3635

Page 37

Small screws:

Description Surface treatment Position of use Quantity

CNL-F 1.7 x 1.8 Black nickel C264, C205 1

CNL-F 1.7 x4 J201,B1 2

CRSS 1.4 x 1.6 “ (PB-5) E229, E230 3

Washers:

Description Material Thickess Position of use Quantity

W1 Brass 0.07, 0.1mm M57, M60 1

0.3, 0.4 E153, A1 1

W2 0.1, 0.15 B83, B85 1

W3 “ 0.3 A135, A101 2

Steel 0.3 E145, A1 1

Brass 0.15, 0.2, 0.25, 0.3 AS, M62 2

0.2 J501, A41 1

W6 Stainless 0.03, 0.05, 0.07,

0.01, 0.15, 0.2 C136, C105, 1

C126, C128 1

C134, C101 1

E111, C4 1

A143, A144 1

E402, E401 1

0.1 M62, M63 1

W7 Brass 0.05, 0.1, 0.15, 0.2 A101, A1 1

W14 “ 0.03, 0.05, 0.1 M62, M63 1

0.1, 0.15 B41, B39 1

W16 0.3 C202, C216 1

W22 “ 0.2, 0.3, 0.4 C204, C227 1

0.1, 0.15, 0.2, 0.3 C141, C112 1

W24 “ 0.1, 0.15, 0.2 C270, C218 1

W28 “ 0.3 C229 1

W40 “ 0.1, 0.15 B74, B75 1

W62 “ 0.1, 0.15, 0.2 B103, B1 1

0.1 M73, M74 1

W63 “ 0.05, 0.1 B22, B30 1

W70 “ 0.02, 0.03, 0.05

0.1, 0.15, 0.2 C254, C201 2

0.3 E401 1

W73 “ 0.5, 0.6 C20 1

W77 “ 0.05, 0.07, 0.1 E201, E232 1

23800 /3636

Loading...

Loading...