Page 1

INSTALLATION MANUAL

MANUEL DINSTALLATION

INSTALLATIONS-HANDBUCH

MANUALE DI INSTALLAZIONE

MANUAL DE INSTALACIÓN

MANUAL DE INSTALAÇÃO

INSTALLATIEHANDLEIDING

ЕГЧЕЙСЙДЙП ЕГКБФБУФБУЗУ

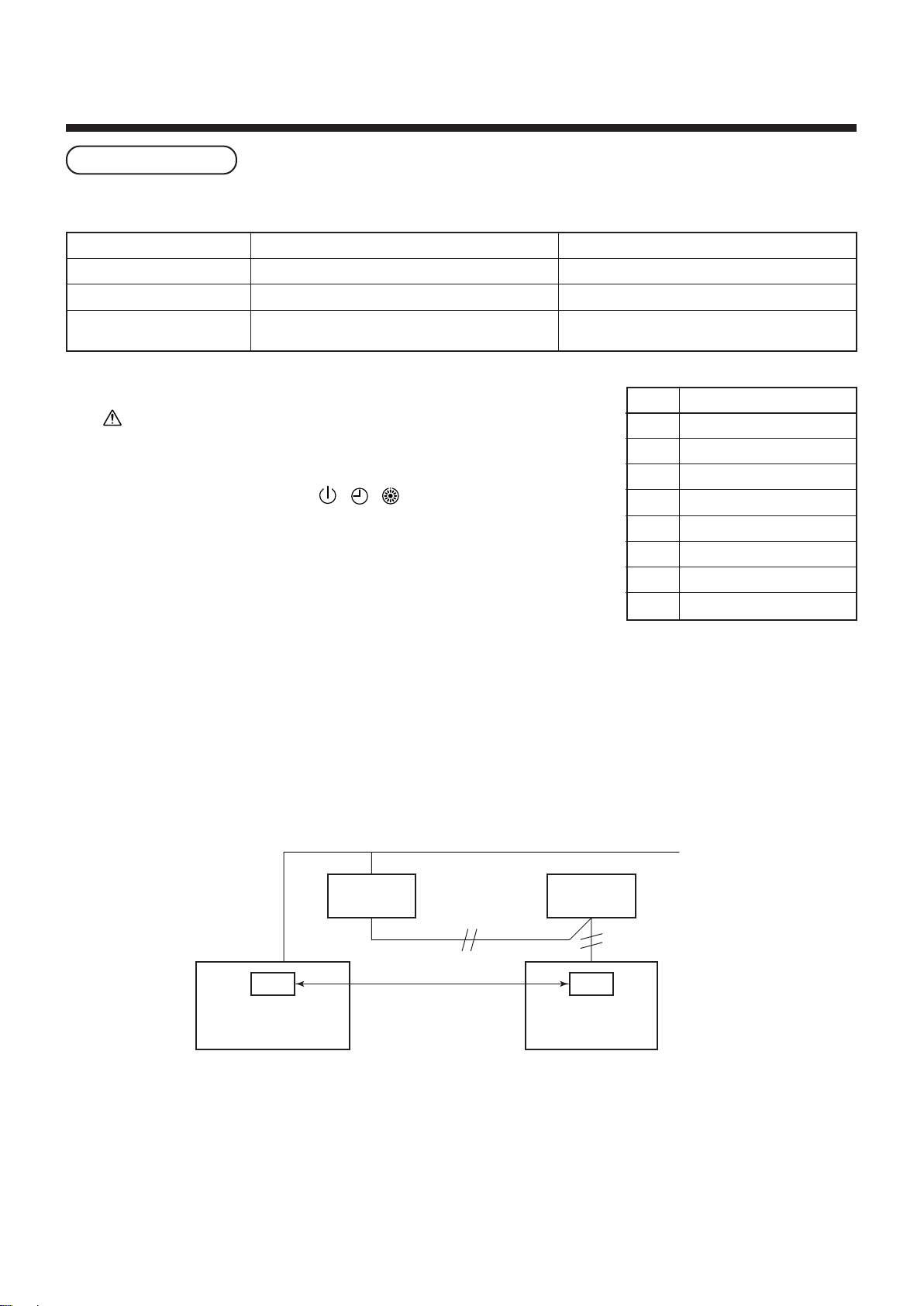

SUPER MODULAR MULTI SYSTEM

SMMS

SMMS

SMMS

SMMS

SMMS

SMMS

CLIMATISEUR

KLIMAGERÄT

CONDIZIONATORE D'ARIA

APARATO DE AIRE ACONDICIONADO

AR CONDICIONADO

AIRCONDITIONER

SMMS КЛЙМБФЙУФЙКП

SMMS

Indoor Unit

Unité intérieure

Raumeinheit

Unità interna

Unidad interior

Unidade interior

Voor commercieel gebruik (niet geschikt voor huishoudelijk gebruik)

Binnenunit

ЕущфесйкЮ mпнЬдб

AIR CONDITIONER

For commercial use

Pour usage commercial

Nur für gewerbliche Nutzung

Per uso commer ciale

Para uso comercial

Para uso comercial

Гйб емрпсйкЮ чсЮуз

<High-Wall Type>

<Type mural haut>

<Wandmodell>

<Tipo per mura alte>

<Tipo montaje en pared alta>

<Tipo Mural>

<Hogewandmodel>

<Фэрпт енфпйчйжьменпх шзлЬ>

MMK-AP0071H, AP0091H,

MMK-AP0121H, AP0151H,

MMK-AP0181H, AP0241H

Page 2

ADOPTION OF NEW REFRIGERANT

This Air Conditioner is a new type which adopts a new

refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the

ozone layer.

Thank you very much for purchasing TOSHIBA Air Conditioner.

Please read this owner's manual carefully before using your Air

Conditioner.

• Be sure to obtain the “Owner’s manual” and “Installation manual” from

constructor (or dealer).

Request to constructor or dealer

Please clearly explain the contents of the Owner’s manual and hand over it.

UTILISATION DU NOUVEAU REFRIGERANT

Ce climatiseur est d’un type inédit qui utilise le nouveau

réfrigérant HFC (R410A) au lieu du réfrigérant

traditionnel R22, afin d’éviter la destruction de la couche

d’ozone.

EINFÜHRUNG EINES NEUEN KÜHLMITTELS

Dies ist ein neuartiges Klimagerät. Anstatt des

herkömmlichen Kühlmittels R22 verwendet es das neue

ozonschicht-schonende HFC Kühlmittel R410A.

ADOZIONE DI UN NUOVO REFRIGERANTE

Questo condizionatore d'aria è di un tipo nuovo che

adotta un nuovo refrigerate HFC (R410A) al posto del

refrigerante convenzionale R22, per prevenire la

distruzione dello strato di ozono dell'atmosfera terrestre.

ADOPCIÓN DE NUEVO REFRIGERANTE

Este aparato de aire acondicionado es un modelo

reciente que incorpora el nuevo refrigerante HFC

(R410A) en lugar del refrigerante convencional R22

para así evitar daños en la capa de ozono.

Nous vous remercions pour avoir choisi un climatiseur TOSHIBA.

Veuillez lire attentivement ce Manuel du propriétaire avant d’utiliser votre

climatiseur.

• Assurez-vous que le constructeur (ou le revendeur) vous remette le

“Manuel du propriétaire” et le “Manuel d’installation”.

Demande au constructeur ou au revendeur

Veuillez expliquer clairement le contenu du Manuel du propriétaire et le

remettre au client.

Wir danken Ihnen, dass Sie sich für ein TOSHIBA Klimagerät entschieden

haben.

Bitte lesen Sie diese Betriebsanleitung, bevor Sie Ihr Klimagerät benutzen, sorgfältig.

• Lassen Sie sich die “Betriebsanleitung” und das “Installations-Handbuch”

unbedingt vom Installateur oder vom Lieferanten aushändigen.

Eine Bitte an den Installateur oder Lieferanten:

Bitte erklären Sie dem Käufer den Inhalt der Betriebsanleitung und händigen

sie ihm aus.

Grazie di aver acquistato un condizionatore d'aria TOSHIBA.

Prima di usare il condizionatore d'aria, leggere con attenzione questo

manuale del proprietario.

• Si raccomanda di tenere a portata di mano il “Manuale del proprietario”

e il “Manuale di installazione” ricevuti dal produttore (o dal rivenditore).

Richiesta al produttore o al rivenditore

Spiegare chiaramente il contenuto del Manuale del proprietario e

consegnarne una copia all'utente.

Muchas gracias por haber adquirido el aparato de aire acondicionado TOSHIBA.

Lea atentamente este manual del propietario antes de utilizar el aparato de aire

acondicionado.

• Asegúrese de que el fabricante (o distribuidor) le proporcione el “Manual del

propietario” y el “Manual de instalación”.

Solicitud al fabricante o distribuidor

Explique con claridad el contenido del Manual del propietario y entréguelo al

cliente.

ADOPÇÃO DO NOVO REFRIGERANTE

Este ar condicionado é um modelo novo que adopta um

novo refrigerante HFC (R410A) em vez do refrigerante

convencional R22 para evitar a destruição da cama de

ozono.

TOEPASSING VAN EEN NIEUW KOELMIDDEL

Deze airconditioner is een nieuwe type dat werkt met

een nieuw koelmiddel HFC (R410A) in plaats van met

het conventionele koelmiddel R22, als bijdrage om de

aantasting van de ozonlaag te reduceren.

ХЙПИЕФЗУЗ НЕПХ ШХКФЙКПХ

Фп рбсьн Клймбфйуфйкь еЯнбй нЭпт фэрпт рпх хйпиефеЯ нЭп

шхкфйкь HFC (R410A) уфз иЭуз фпх ухмвбфйкпэ

шхкфйкпэ R22 рспкеймЭнпх нб впзиЮуей уфзн рспуфбуЯб

фпх ьжпнфпт.

HFC

R410A R22

Muito obrigada por adquirir o Ar Condicionado TOSHIBA.

Leia atentamente este manual do utilizador antes de utilizar o seu ar

condicionado.

• Não se esqueça de receber o “Manual do utilizador” e o “Manual de

inslatação” do fabricante (ou agente).

Pedido ao fabricante ou agente

Explique por favor o conteúdo do Manual do utilizador e entregue-o.

Hartelijk dank voor uw keuze voor een airconditioner van TOSHIBA.

Lees deze gebruiksaanwijzing zorgvuldig door voordat u de

airconditioner gaat gebruiken.

• Zorg ervoor dat u zowel de ‘gebruiksaanwijzing’ als de

‘installatiehandleiding’ van de installateur (of leverancier) krijgt.

Verzoek aan de installateur of de leverancier

Leg de inhoud van de gebruiksaanwijzing duidelijk uit en overhandig de

gebruiksaanwijzing nadien aan de klant.

Убт ехчбсйуфпэме рплэ рпх рспфймЮубфе гйб фзн бгпсЬ убт Энб

Клймбфйуфйкь TOSHIBA.

Рбсбкблпэме дйбвЬуфе рспуечфйкЬ фйт пдзгЯет чсЮузт рсйн брь фз чсЮуз

фпх Клймбфйуфйкпэ.

• ВевбйщиеЯфе ьфй п кбфбукехбуфЮт (Ю п рщлзфЮт) убт рбсЭдщуе кбй фйт

“ПдзгЯет ЧсЮузт” кбй фп “ЕгчейсЯдйп ЕгкбфЬуфбузт”.

РбсЬклзуз гйб фпн кбфбукехбуфЮ Ю фпн рщлзфЮ

Рбсбкблю еозгЮуфе ме убцЮнейб фб ресйечьменб фщн Пдзгйюн ЧсЮузт кбй

рбсбдюуфе фп.

Page 3

CONTENTS

Accessory parts and Parts to be procured locally ........................... 1

1

PRECAUTIONS FOR SAFETY ........................................................2

2

SELECTION OF INSTALLATION PLACE ........................................ 3

3

INSTALLATION OF INDOOR UNIT ................................................. 5

4

DRAIN PIPING WORK .....................................................................8

SOMMAIRE

Pièces accessoires et pièces non fournies ........................................ 23

1

MESURES DE SECURITE .............................................................. 24

2

SELECTION DU LIEU D’INSTALLATION .. ........ ....... ....... ........ ....... .. 25

3

INSTALLATION DE L’UNITE INTERIEURE ...................................... 27

4

INSTALLATION DES TUYAUX D’EVACUATION ...............................30

INHALT

Zubehör und bauseits bereitzustellende Teile ..................................... 45

1

SICHERHEITSVORKEHRUNGEN................................................... 46

2

AUSWAHL DES AUFSTELLUNGSORTES ...................................... 47

3

INSTALLATION DER RAUMEINHEIT .............................................. 49

4

INSTALLATION DES KONDENSWASSER-ABLAUFS ..................... 52

INDICE

Accessori e parti da acquistare sul posto .......................................... 67

1

PRECAUZIONI PER LA SICUREZZA .............................................. 68

2

SCELTA DEL POSTO D’INSTALLAZIONE ....................................... 69

3

INSTALLAZIONE DELL’UNITÀ INTERNA . ...... ....... ....... ....... ............71

4

LAVORO PER LA TUBAZIONE DI SCARICO .................................. 74

5

REFRIGERANT PIPING................................................................... 9

6

ELECTRIC WORK ..........................................................................11

7

APPLICABLE CONTROLS ............................................................ 14

8

TEST RUN ......................................................................................16

9

TROUBLESHOOTING ................................................................... 18

5

TUYAUX DE RÉFRIGÉRANT ..........................................................31

6

TRAVAUX D’ÉLECTRICITÉ .............................................................33

7

COMMANDES UTILISABLES ......................................................... 36

8

ESSAI DE FONCTIONNEMENT ...................................................... 38

9

DÉPANNAGE ..................................................................................40

5

KÜHLMITTELLEITUNGEN ..............................................................53

6

ELEKTROARBEITEN ......................................................................55

7

STEUERUNGSMÖGLICHKEITEN ................................................... 58

8

TESTLAUF ...................................................................................... 60

9

FEHLERSUCHE ..............................................................................62

5

TUBAZIONI DEL REFRIGERANTE ................................................. 75

6

COLLEGAMENTI ELETTRICI .......................................................... 77

7

COMANDI APPLICABILI ................................................................. 80

8

FUNZIONAMENTO DI PROVA ......................................................... 82

9

RISOLUZIONE DEI PROBLEMI ....................................................... 84

ENGLISH

FRANCAIS

DEUTSCH

ITALIANO

CONTENIDO

Componentes accesorios y componentes de suministro local ......... 89

1

PRECAUCIONES PARA SU SEGURIDAD ...................................... 90

2

SELECCIÓN DEL LUGAR DE INSTALACIÓN ................................. 91

3

INSTALACIÓN DE LA UNIDAD INTERIOR...................................... 93

4

INSTALACIÓN DE LA CANALIZACIÓN DE DESAGÜE ................... 96

ÍNDICE

Acessórios e peças adquiridas localmente ......................................111

1

PRECAUÇÕES DE SEGURANÇA ................................................ 112

2

SELECÇÃO DO LOCAL DE INSTALAÇÃO ................................... 113

3

INSTALAÇÃO DA UNIDADE INTERIOR ....................................... 115

4

INSTALAÇÃO DA TUBAGEM DE DRENAGEM ............................. 118

INHOUD

Accessoires en niet meegeleverde onderdelen ............................... 133

1

VOORZORGSMAATREGELEN VOOR UW VEILIGHEID ................. 134

2

KEUZE VAN DE LOCATIE VOOR DE INSTALLATIE .......................135

3

INSTALLATIE VAN DE BINNENUNIT ............................................ 137

4

AFVOERLEIDINGEN ..................................................................... 140

РЕСЙЕЧПМЕНБ

Рбселкьменб бнфбллбкфйкЬ кбй ЕобсфЮмбфб брь фзн фпрйкЮ бгпсЬ .. . 1 55

1 РСПЦХЛБОЕЙУ БУЦБЛЕЙБУ ......................................................... 156

2 ЕРЙЛПГЗ ФПХ ЧЩСПХ ЕГКБФБУФБУЗУ ....................................... 157

3 ЕГКБФБУФБУЗ ФЗУ ЕУЩФЕСЙКЗУ МПНБДБУ .............................. 159

4 ЕСГБУЙБ УЩЛЗНЩУЗУ БРПУФСБГГЙУЗУ ..................................... 162

5

TUBERÍA DE REGRIGERANTE ...................................................... 97

6

INSTALACIÓN ELÉCTRICA ............................................................ 99

7

CONTROLES APLICABLES ......................................................... 102

8

PRUEBA DE FUNCIONAMIENTO ................................................. 104

9

RESOLUCIÓN DE PROBLEMAS .................................................. 106

5

TUBAGEM DE REFRIGERANTE ................................................... 119

6

TRABALHOS DE ELECTRICIDADE ............................................. 121

7

CONTROLOS APLICÁVEIS .......................................................... 124

8

TESTE DE FUNCIONAMENTO ...................................................... 126

9

RESOLUÇÃO DE PROBLEMAS ................................................... 128

5

KOELMIDDELLEIDINGEN ............................................................ 141

6

ELEKTRISCHE BEDRADING ....................................................... 143

7

BEDIENINGSELEMENTEN ........................................................... 146

8

WERKINGSTEST .......................................................................... 148

9

STORINGEN VERHELPEN ............................................................ 150

5 УЩЛЗНЩУЗ ШХКФЙКПХ МЕУПХ ................................................... 163

6 ЗЛЕКФСЙКЗ ЕСГБУЙБ .................................................................... 165

7 ЕЦБСМПУЙМПЙ ЕЛЕГЧПЙ .............................................................. 168

8 ДПКЙМЗ ЛЕЙФПХСГЙБУ .................................................................. 170

9 БНФЙМЕФЩРЙУЗ РСПВЛЗМБФЩН ................................................ 172

ESPAÑOL

PORTUGUÊS

NEDERLANDS

ЕЛЛЗНЙКБ

....................................................................... 177

1

2

3

4

............................................................................. 178

......................................................................... 179

............................................................................. 181

................................................................................. 184

5

6

7

8

9

................................................................................. 185

..................................................................................... 187

..................................................................................... 190

......................................................................................... 192

..................................................................................... 194

Page 4

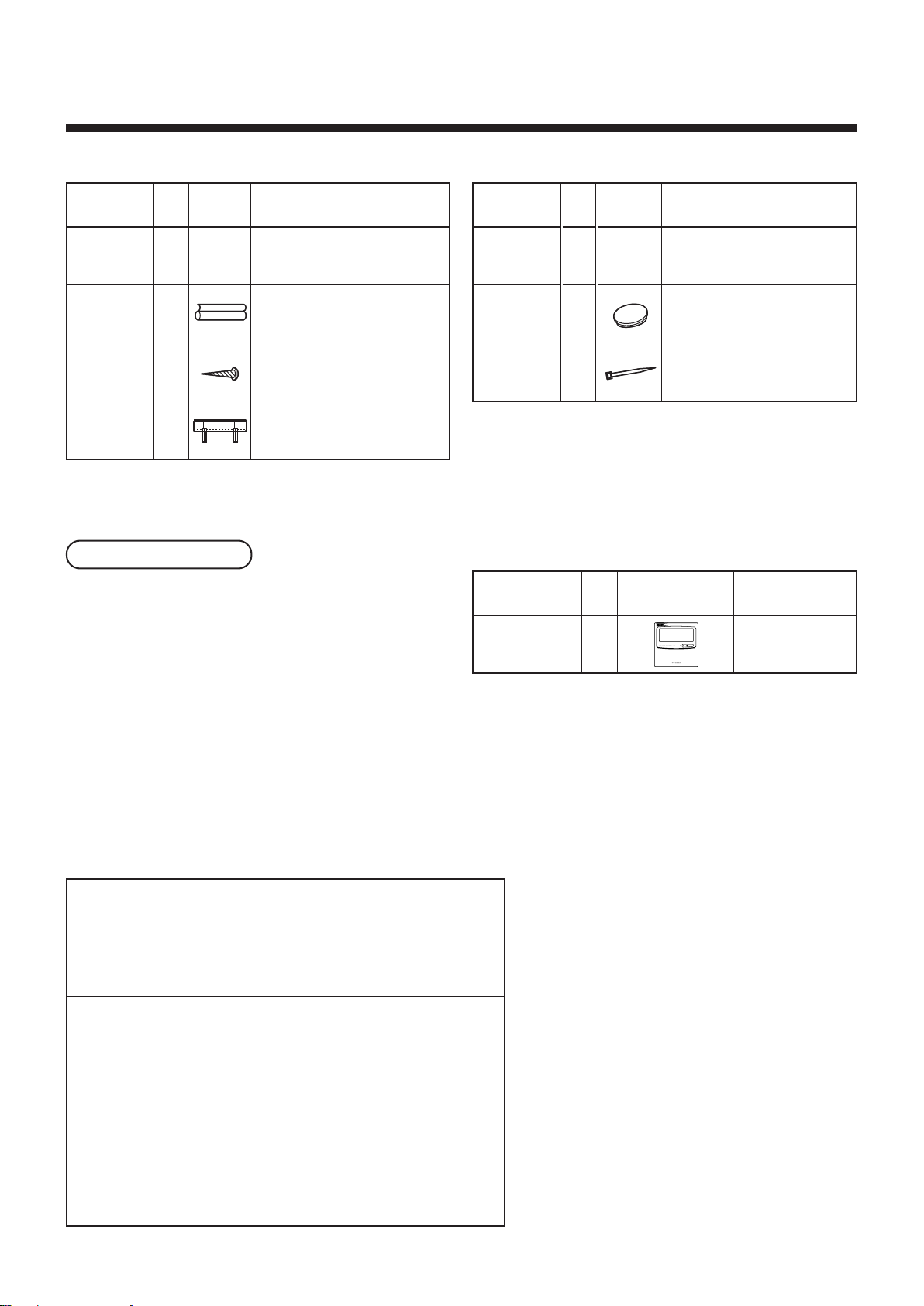

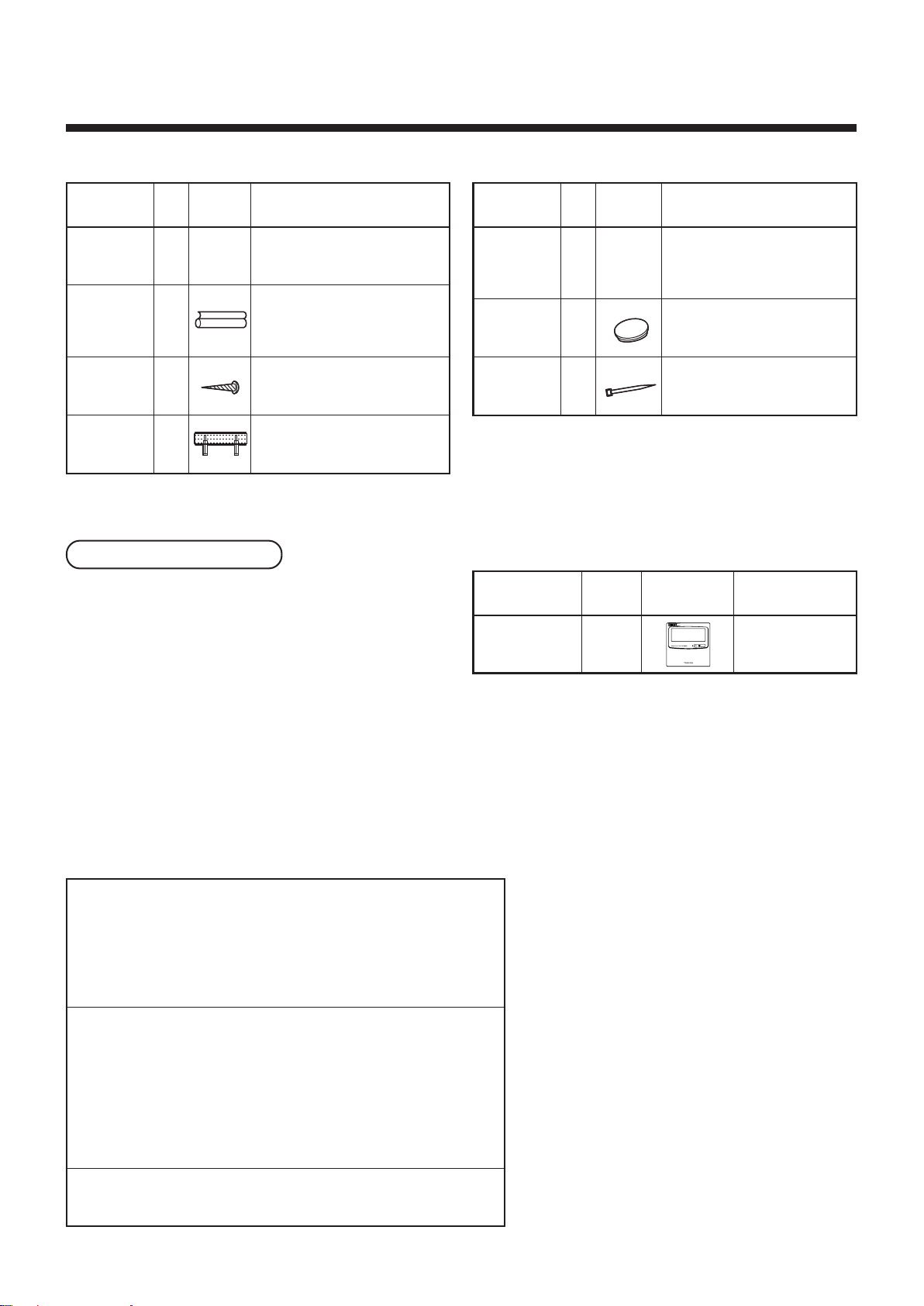

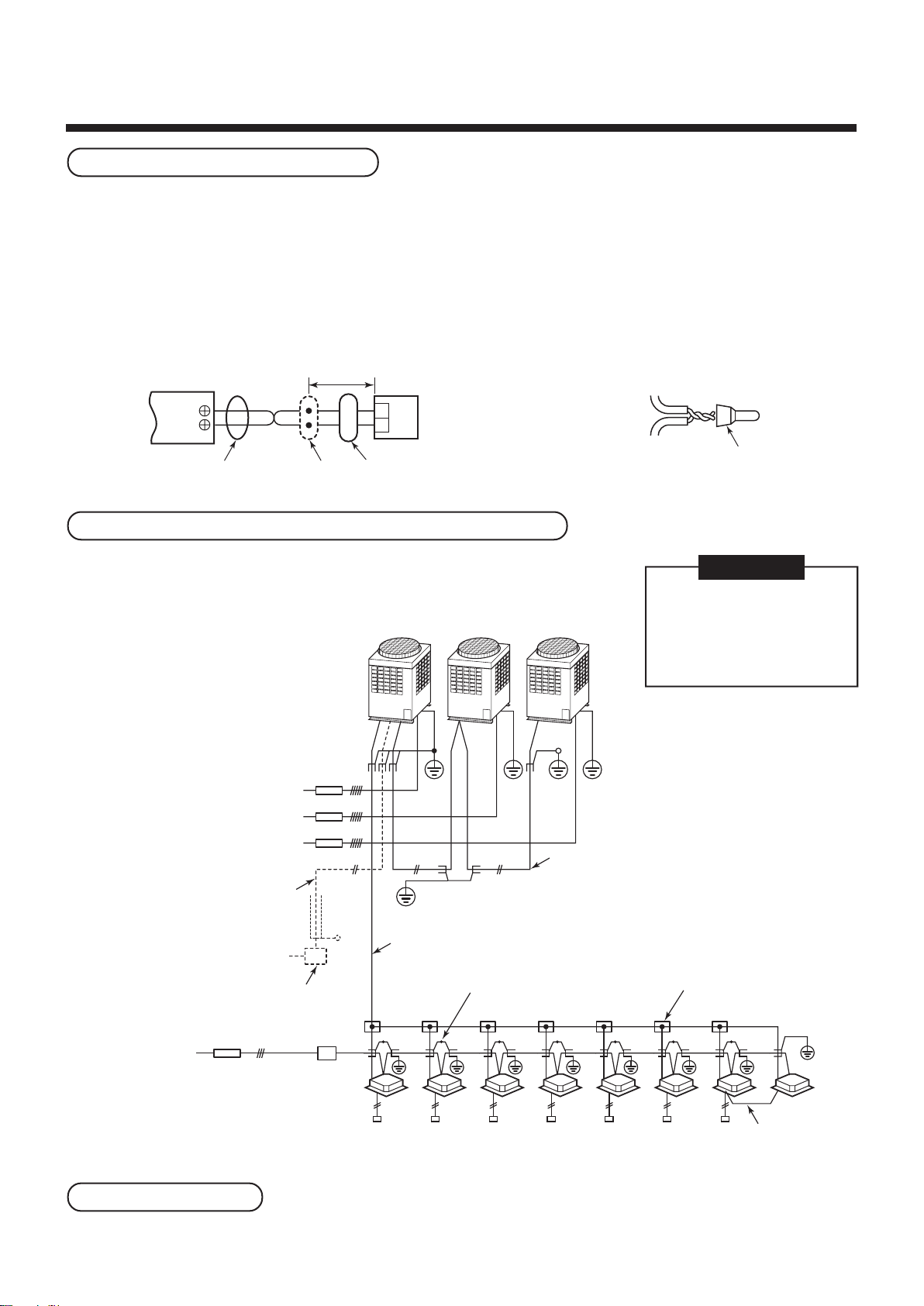

Accessory parts and Parts to be procured locally

Accessory parts

Part name

Installation

Manual

Heat

insulating pipe

Wood screw

M4 × 35L

Installation

plate

Q’ty

1

2

12

1

Shape

This

manual

(Be sure to hand over to customers)

For heat insulation of pipe

connecting section

For attach the installation plate

Used install indoor unit wall unit

Usage

Refrigerant piping

• Piping material used for the conventional refrigerant

cannot be used.

• Use copper pipe with 0.8 mm or more thickness for

Ø6.4, Ø9.5, Ø12.7.

Use copper pipe with 1.0 mm or more thickness for

Ø15.9.

• Flare nut and flare works are also different from those

of the conventional refrigerant. Take out the flare nut

attached to the indoor unit of the air conditioner, and

use it.

Part name

Installation

pattern

Screw cap

Banding band

Q’ty

1

4

4

Shape

—

<Separate sold parts>

Part name

Standard wired

remote controller

Q’ty

1

Usage

For confirmation of piping hole

and indoor unit position

Cover on fixing screw at side plate

Used to fix attached pipe heat

insulating material

Shape Usage

Model

RBC-AMT21E

Parts to be procured locally

Connecting pipe (Liquid side)

(6.4mm (diam.), Nominal (diam.) 1/4” thick 0.8mm)

MMK-AP0071H to MMK-AP0181H

(9.5mm (diam.), Nominal (diam.) 3/8” thick 0.8mm)

MMK-AP0241H

Connecting pipe (Gas side)

(9.5mm (diam.), Nominal (diam.) 3/8” thick 0.8mm)

MMK-AP0071H to MMK-AP0121H

(12.7mm (diam.), Nominal (diam.) 1/2” thick 0.8mm)

MMK-AP0151H to MMK-AP0181H

(15.9mm (diam.), Nominal (diam.) 5/8” thick 1.0mm)

MMK-AP0241H

Power supply cord

Cable 3-core 2.5mm2, in conformity with Design 60245 IEC57

1

Page 5

1

PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

CAUTION New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil

does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are charged from those for the conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does

not enter. Moreover, do not use the existing piping because there are problems with pressure-resistance force and

impurity in it.

ENGLISH

CAUTION To Disconnect the Appliance from Main Power Supply.

This appliance must be connected to the main power supply by means of a switch with a contact separation of at

least 3 mm.

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not to

enter any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally

high and it as a result causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety

interlock switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of

electrical parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that

the concentration of refrigerant leakage occur in the room does not exceed the critical level.

2

Page 6

1

PRECAUTIONS FOR SAFETY

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation

Manual. Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix. To prevent external forces

applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

2

SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner where there is sufficient strength to weight of the unit.

If strength is insufficient, the unit may fall down resulting in human injury.

• Perform a specified installation work to guard against an earth quake.

An incomplete installation can cause accidents by the units failing and dropping.

CAUTION

• Do not install the air conditioner in a location subject to a risk of exposure to combustible gas.

Should the combustible gas leak and collect near the unit, fire may occur.

Upon approval of the customer, install the air conditioner in a place that satisfies the following

conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be ensured for safe maintenance and check.

• Place where drained water will not cause any problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside area), or place exposed to large quantities of sulfide gas

(hot spring). (Should the unit be used in these places, special protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place near door or window where may come to contact with the outside air of high humidity. (Dewing may be caused.)

• Place where special spray is frequently used.

• Place with poor ventilation.

3

Page 7

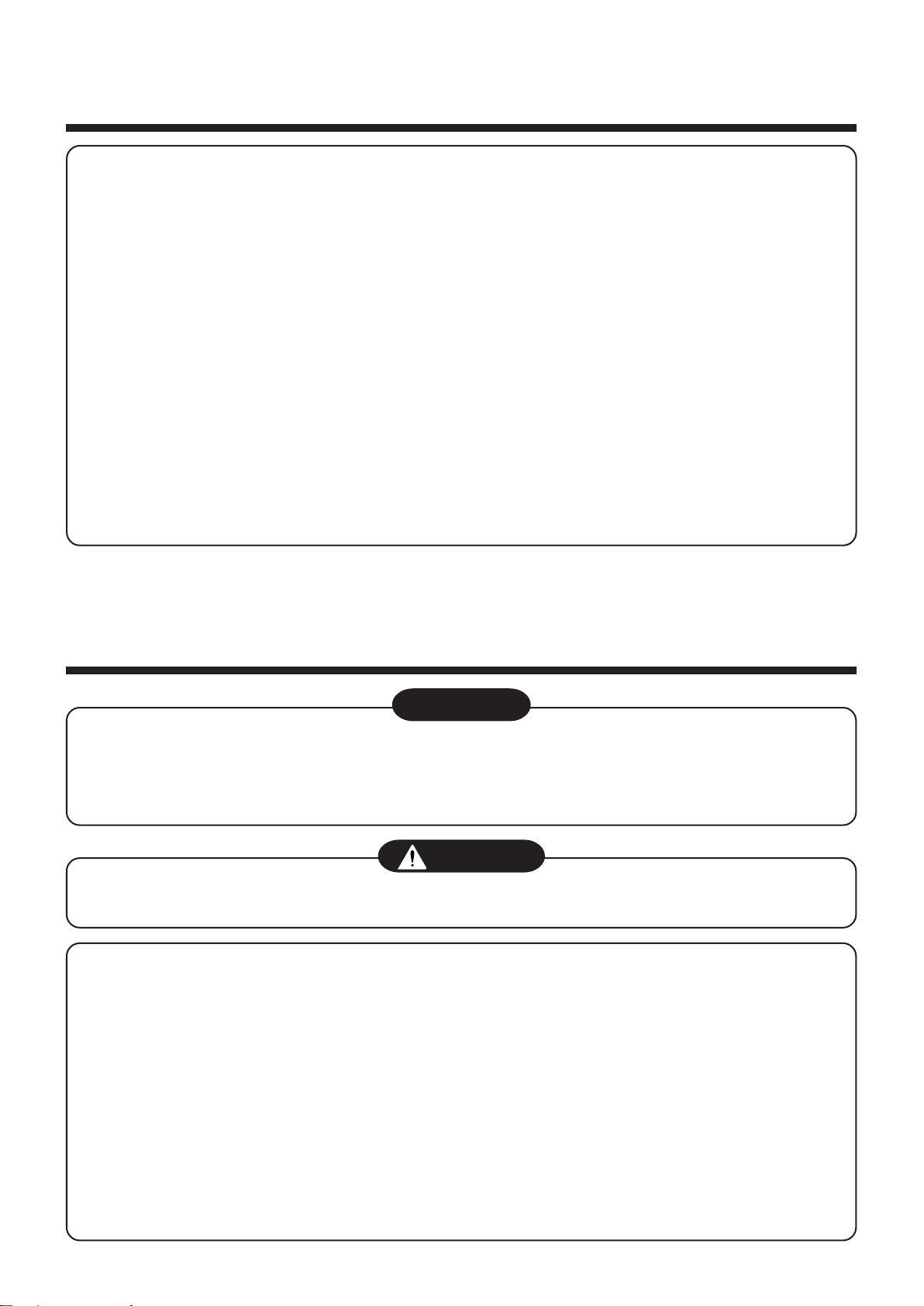

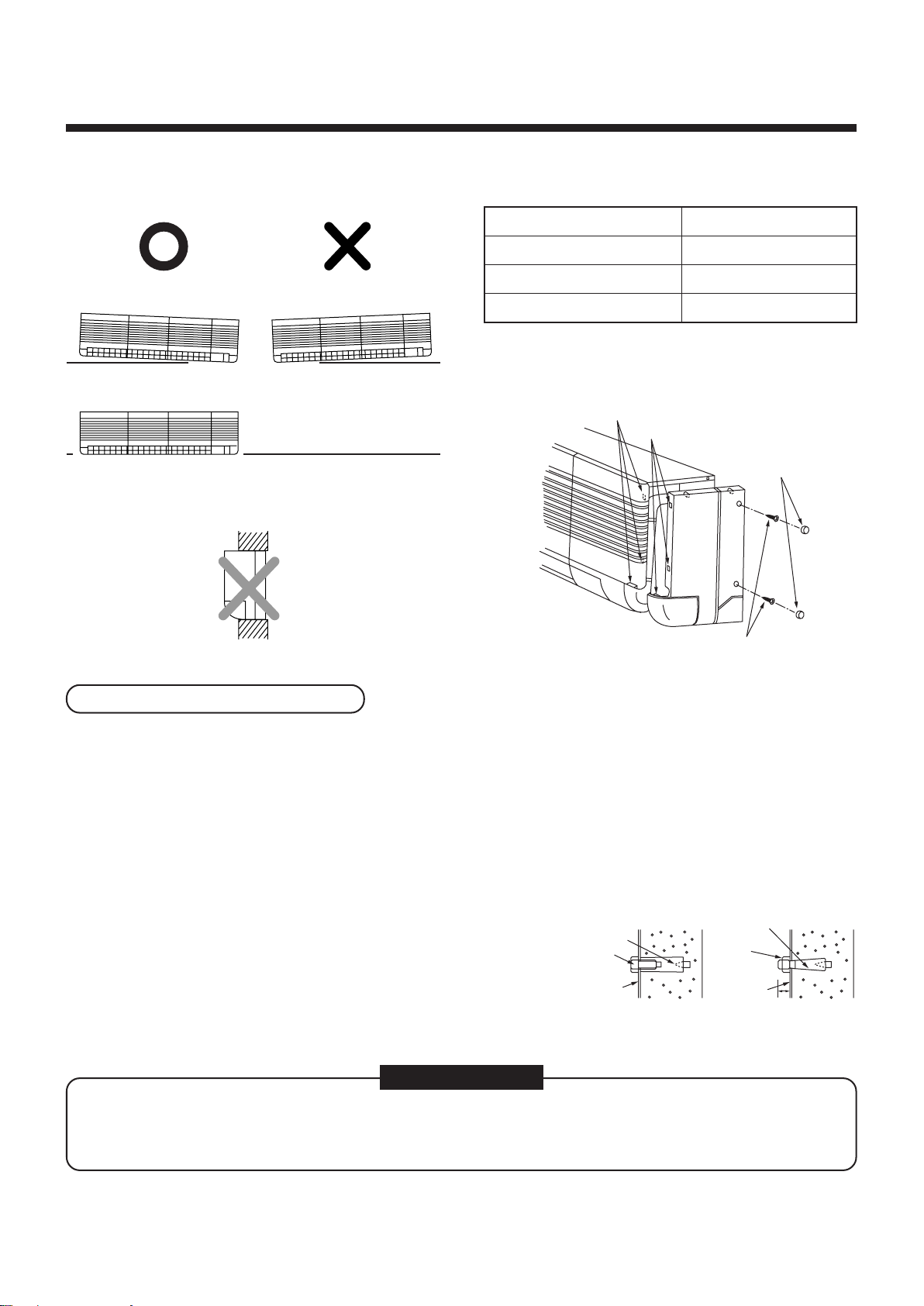

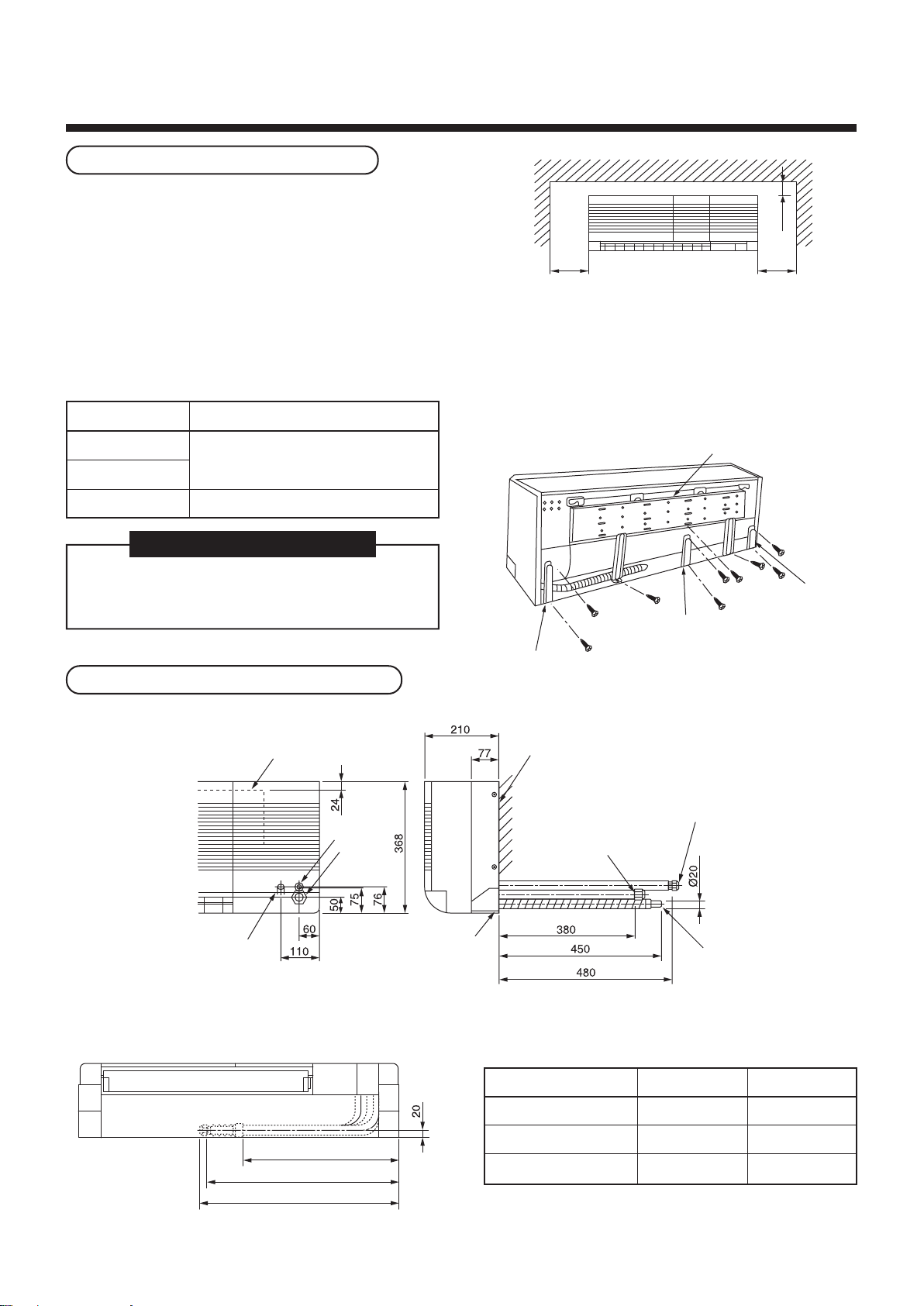

Installation space

300 or more300 or more

300 or more

Transport bracket

(Right)

Installation plate

Transport bracket

(Left)

Transport bracket

(Center)

(Including installation plate)

Installation plate (Accessory)

Refrigerant pipe connecting port

gas side A

Refrigerant pipe connecting port

liquid side B

Drain pipe

connecting port

Left and

right side piping

(Knockout hole)

24

60

110

50

75

76

368

Ø20

210

77

450

480

380

Top end of installation plate

Liquid side

Gas

side

Drain pipe

Liquid pipe 540

Drain pipe 560

Gas pipe 440

20

Shipping from factory (Left side piping)

Reserve space required to install the indoor unit and

for service work.

Keep 300mm or more for clearance between top plate

of the indoor unit and the ceiling surface.

The transport brackets are provided. Following to the table, remove the brackets according to direction of pipe.

(Left, right, center) (For AP0071H to AP0181H, (left) and (right) transport brackets only are provided.)

Pipe side piping

Parts to be removed

Right side piping

Remove transport bracket (right) only.

Rear side piping

Left side piping

Remove all transport brackets.

REQUIREMENT

After removing of the transport brackets, do not

apply force on the lower cabinet. It is to prevent

deformation and breakage.

Pipe connecting position

<Front view>

• Remove the installation plate.

<Bottom view>

4

Model MMK-

AP0071H to AP0121H

AP0151H, AP0181H

AP0241H

AB

Ø9.5 Ø6.4

Ø12.7 Ø6.4

Ø15.9 Ø9.5

Page 8

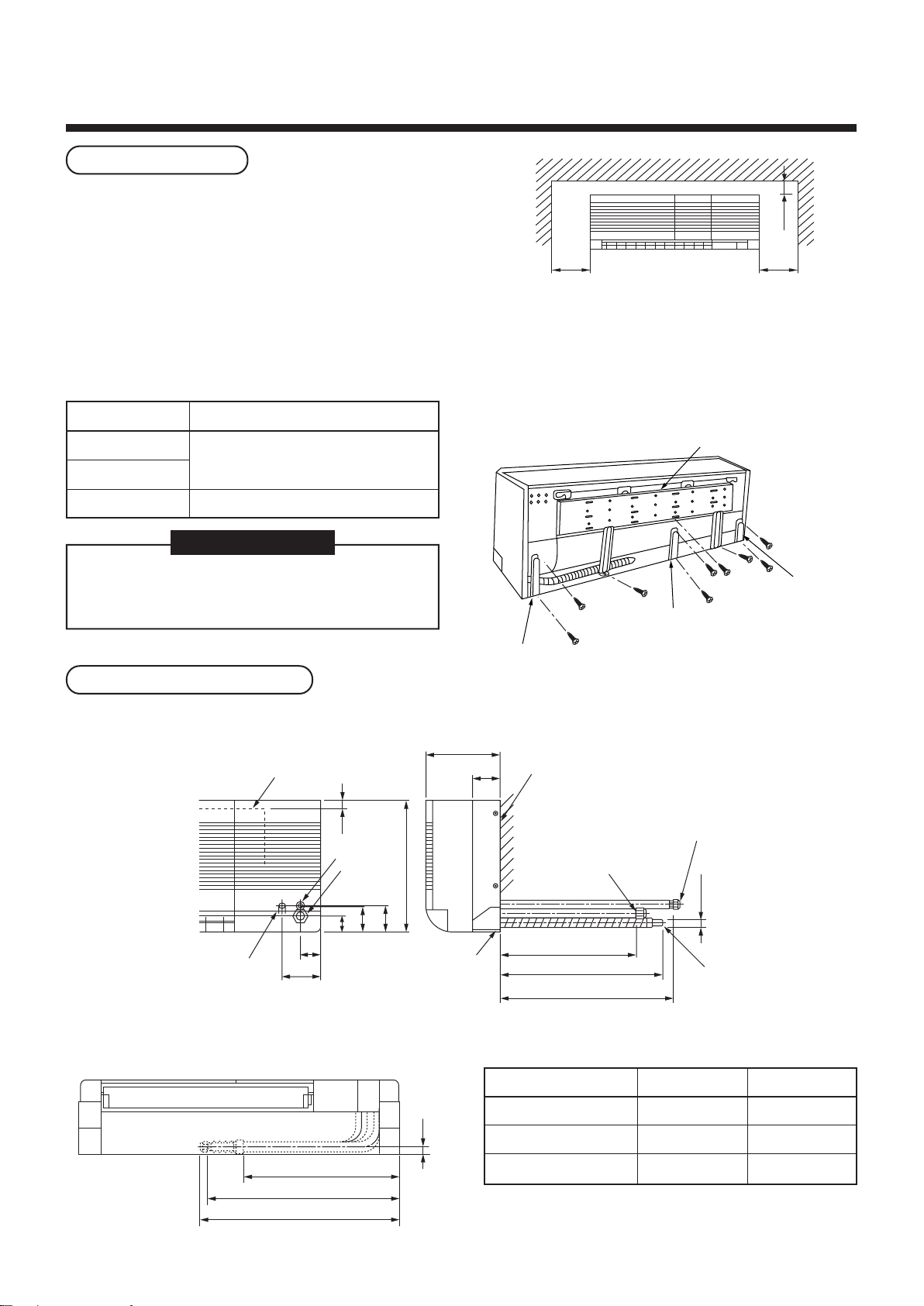

2

8m or less

Screen

Good installation place

Cooled well all over.

Bad installation place

: Not cooled well.

SELECTION OF INSTALLATION PLACE

The lighting time setup of the filter sign (Notification of filter cleaning) of the remote controller can be changed

according to the condition of installation. If the room is not heated due to the installation place or construction of the

room, the detection temperature of heating can be raised.

For setup method, refer to “Change of lighting time of filter sign” and “To secure better effect of heating” in the

Applicable controls of this Manual.

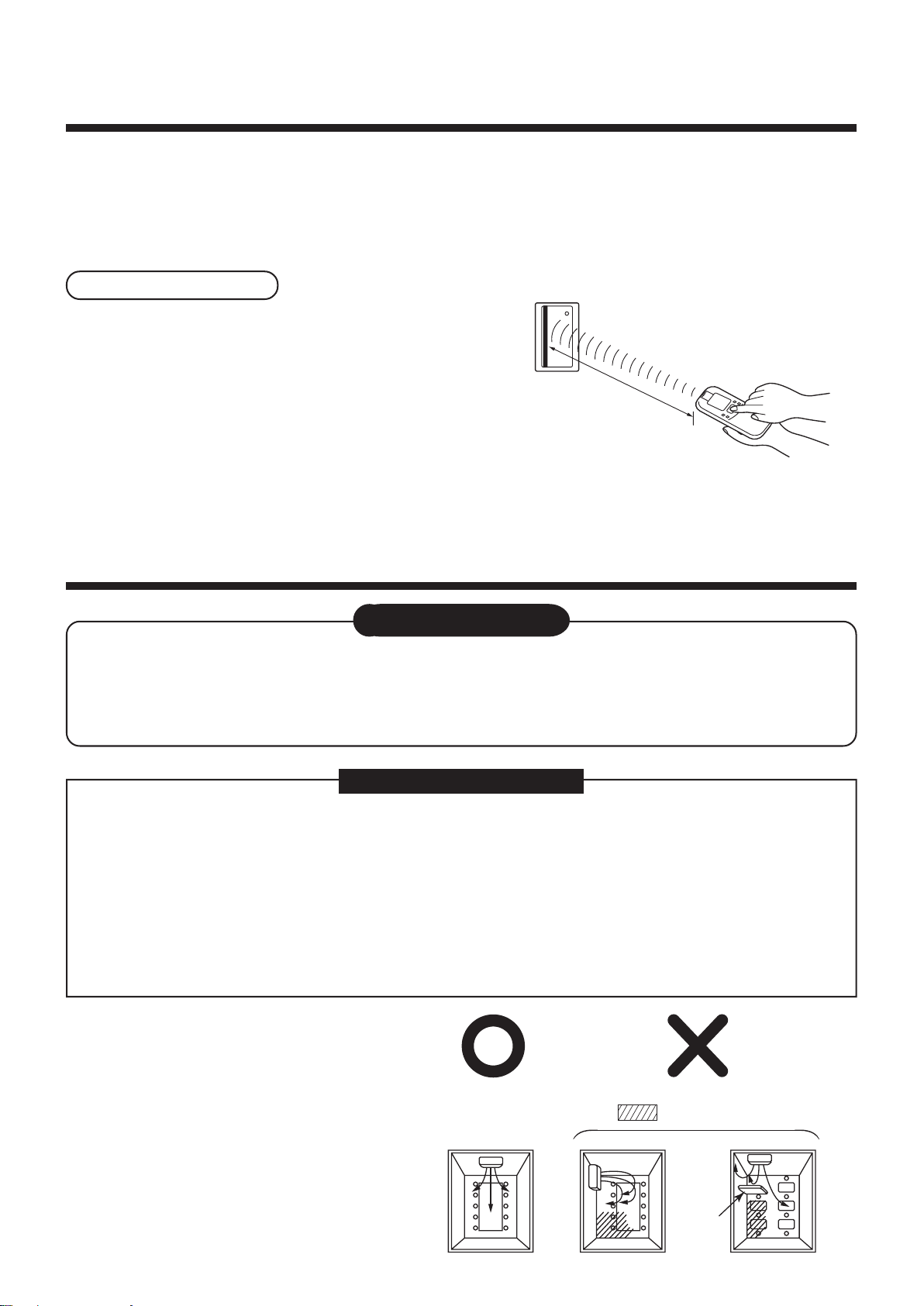

In case of wireless type

The sensor of indoor unit with wireless remote controller can

receive a signal within approx. 8m. Based upon it, determine

a place where the remote controller is operated and the

installation place of the indoor unit.

• To prevent a malfunction, select a place where is not

influenced by a florescent light or direct sunlight.

• Two or more (Up to 6 units) indoor units with wireless

remote controller can be installed in the same room.

3

Install the air conditioner certainly to sufficiently withstand the weight.

If the strength is insufficient, the unit may fall down resulting in human injury.

Perform a specified installation work to guard against strong wind or earthquake.

An incomplete installation can cause accidents by the units falling and dropping.

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by necessity, be

• To move the indoor unit, do not apply force to the refrigerant pipe, drain pan, foamed parts, or resin parts, etc.

• Carry the package by two or more persons, and do not bundle it with PP band at positions other than specified.

Be careful to the following items when

installing the unit.

• Considering air discharge direction, select

an installation place where discharge air can

circulate evenly in a room. Avoid to install

the unit at place with × mark in the

following figure.

INSTALLATION OF INDOOR UNIT

sure to use buffering cloth, etc. to not damage the unit.

WARNING

REQUIREMENT

5

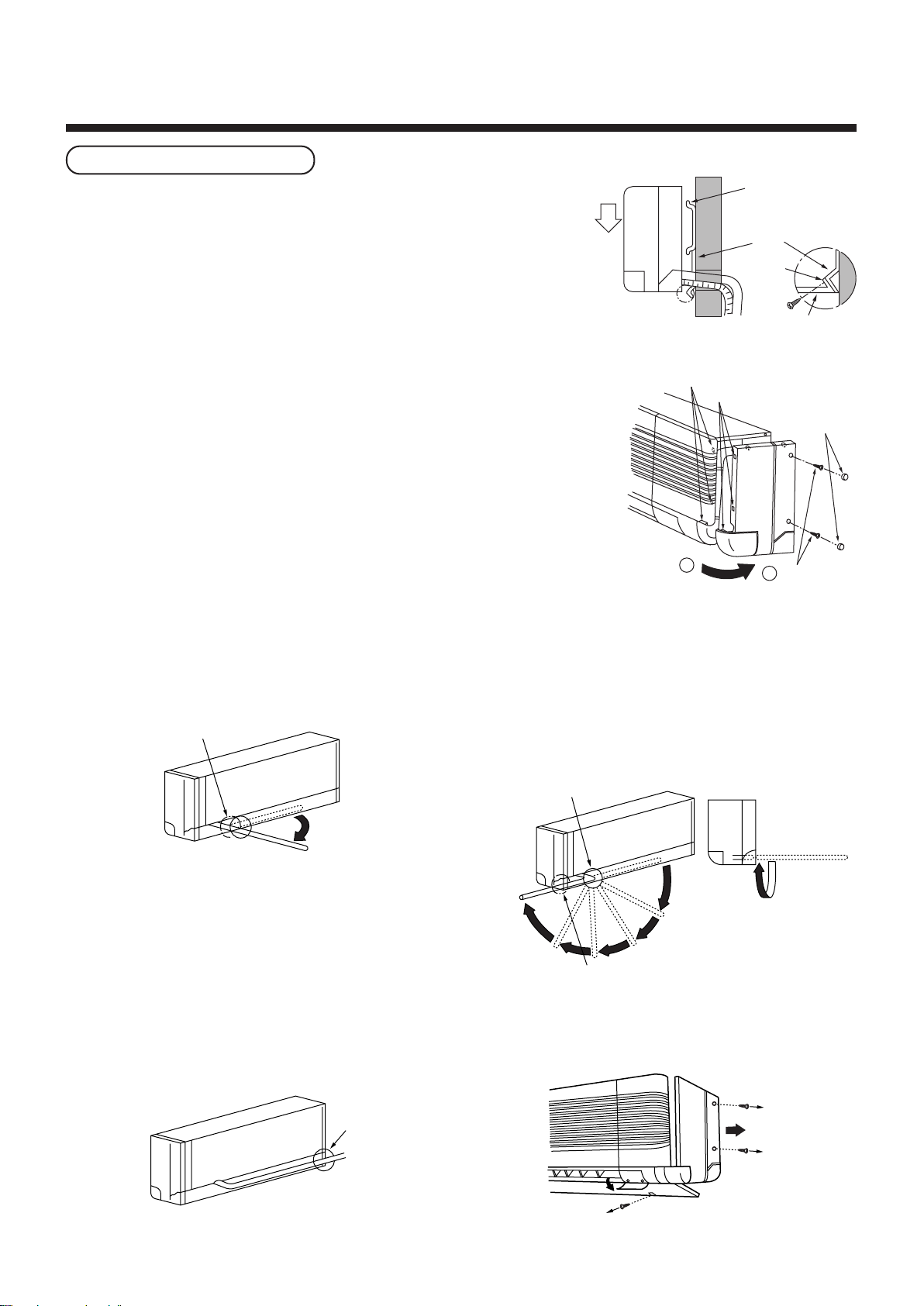

Page 9

• To increase effect of drain, confirm the unit is

Lowering rightward viewed

from the front side

Lowering leftward viewed

from the front side

Horizontal installation

Indoor unit

Side plate fixing screws

Square hole

Hook

Screw cap

Grip anchor

Hole-in anchor

Bolt

Installation plate

Installation

plate

Concrete

wall

Concrete

wall

Nut

screw

dia. Ø8

10mm

or less

installed horizontally or slightly lowering rightward

viewed from the front side.

• The mass including installation plate of the indoor

unit is shown in the following table. Check whether

the wall has sufficient intensity.

• Do not install the unit by plugging in the wall.

Model MMK-

0071H to 0121H

0151H to 0181H

0241H

Mass (kg)

20

22

29

• When installing the side plate, check the status that

hook is inserted in square hole. Push in the side

plate until it is stuck closely to the indoor unit.

Installation of installation plate

• Using the installation pattern, determine the installation position of the indoor unit, and drill the pipe hole matching

with the position indicated in the installation pattern. When passing the refrigerant pipe through wall using metal

mesh, be sure to use insulation sleeve such as polyvinyl chloride pipe.

In case of wooden construction (Wide wall)

(1) Determine vertical position of the installation plate by interval (height) between the indoor unit and the ceiling.

(2) Determine the position so that screw hole of installation plate locates at the center of pillar or stud by adjusting

left/right position without changing height of the installation plate.

(3) Tighten the screws (accessory parts) after bore preholes with a gimlet in the stud to prevent the crack.

In case of reinforced concrete construction

(1) After drilling holes with interval by 150mm at the selected

positions on the concrete wall, strike in grip anchor or

hole-in anchor.

(2) Fix the installation plate to the anchor with bolt or nut.

However, when using hole-in anchor, adjust drilling depth

so that screw head-out is 10mm or less.

• Conduit tube may be buried in the concrete wall. Ask the constructor it.

• Before installation of the indoor unit, be sure to check whether the installation plate has been completely

installed.

REQUIREMENT

In case of rear direction piping

Using the installation pattern, determine the pipe hole position, and drill a pipe hole slightly lowering downward.

6

Page 10

Lower cabinet

Hang up

Installation

plate

Screwing

1

2

Side plate

fixing screws

Square hole

Screw cap

Hook

A

Be sure to support A part with

hands while pipe is formed.

Knockout of right side plate

Be sure to support A part with

hands while pipe is formed.

Side face

Do not turn

horizontally.

Turn it upward/downward.

Knockout of

left side plate

Open

3

INSTALLATION OF INDOOR UNIT

Installation of indoor unit

In case of rear and right direction piping

(1) Pass the drain pipe through the wall hole, and hang the indoor unit

to the top end of the installation plate.

(2) Check that top end of the installation plate is inserted in by moving

the indoor unit to left and right sides.

(3) Fix bottom end of the installation plate and the lower cabinet with

screw so that the indoor unit does not move.

Removing of indoor unit right side plate

Remove the right side plate as the following procedure.

(1) Remove two side plate fixing screws.

(2) Remove the side plate by turning the gray colored part counter-

clockwise to remove hooks in the square hole of the suction grille.

(3) When piping is in direction from right side, cut off the knockout of

the side plate with knife, etc, and finish the end face.

In case of rear direction piping

In case of left direction piping

Work after removing the lower cabinet.

(1) Remove the left/right side plates.

(2) Remove two screws of the lower cabinet.

(3) Pull the lower cabinet toward you lowering a little.

In case of right direction piping

• Insert the right side plate observing click of the side

plate. (Refer to right side plate installation drawing.)

• Fix the side plate, and cover the screw head with

attached cap.

7

Page 11

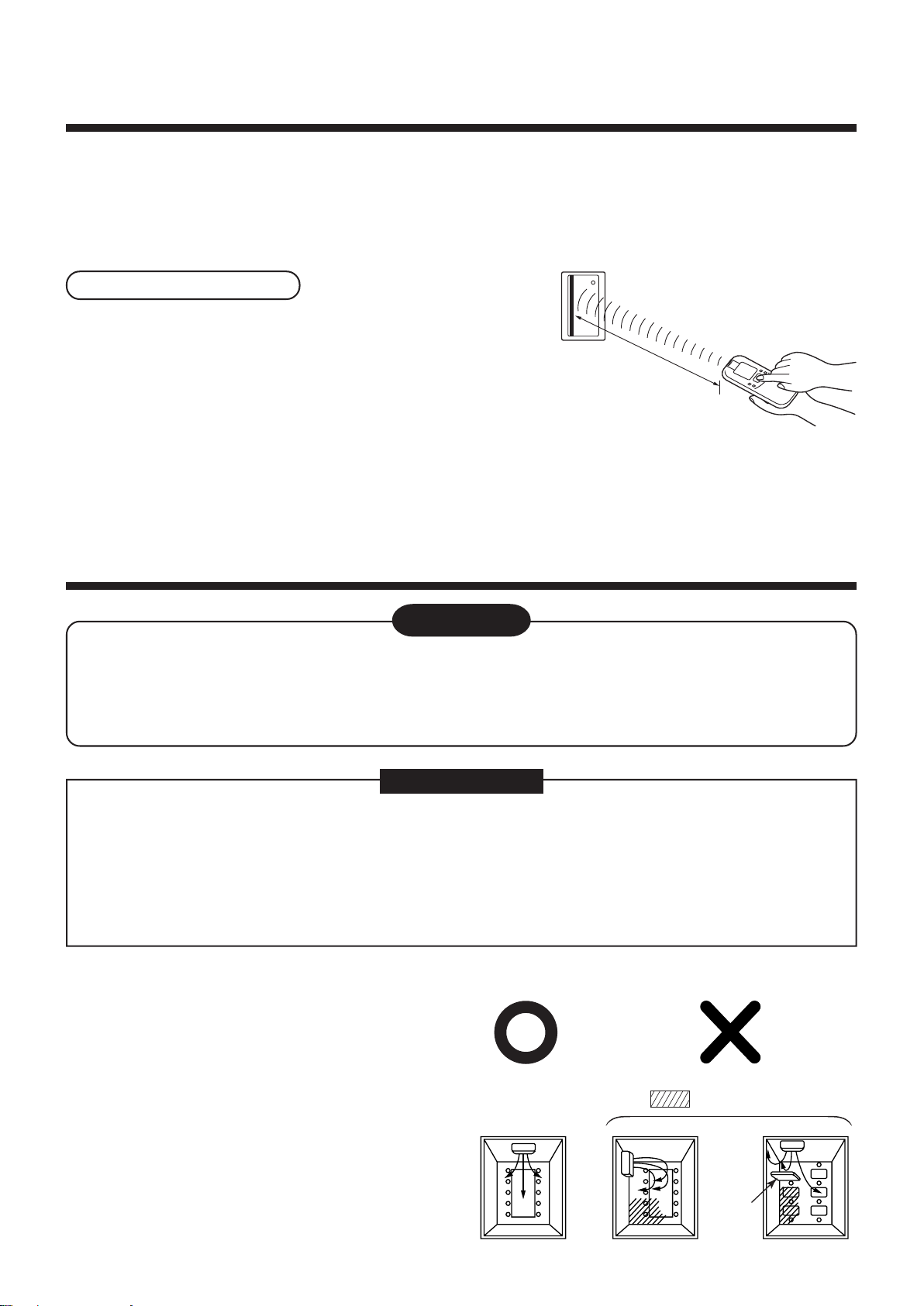

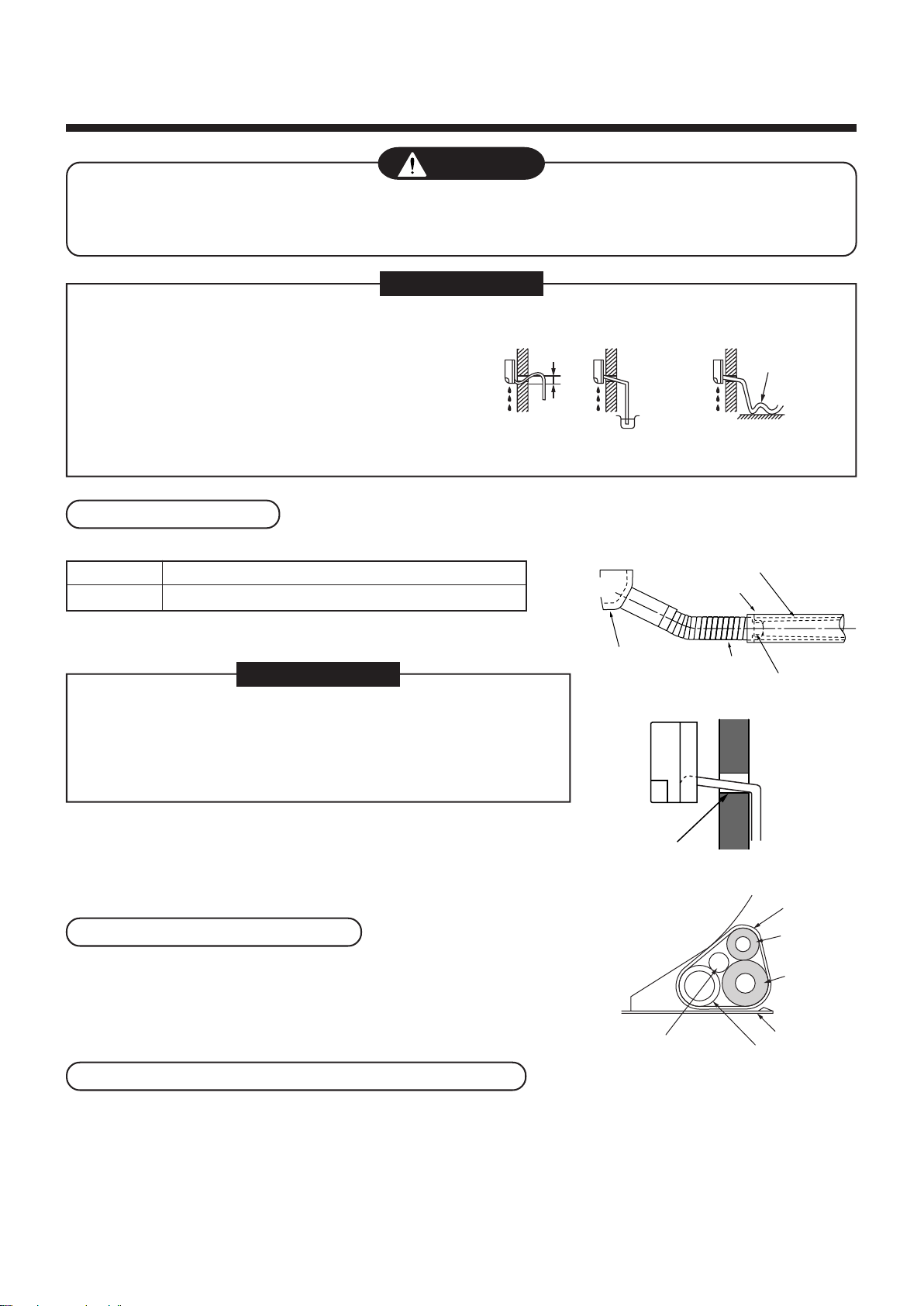

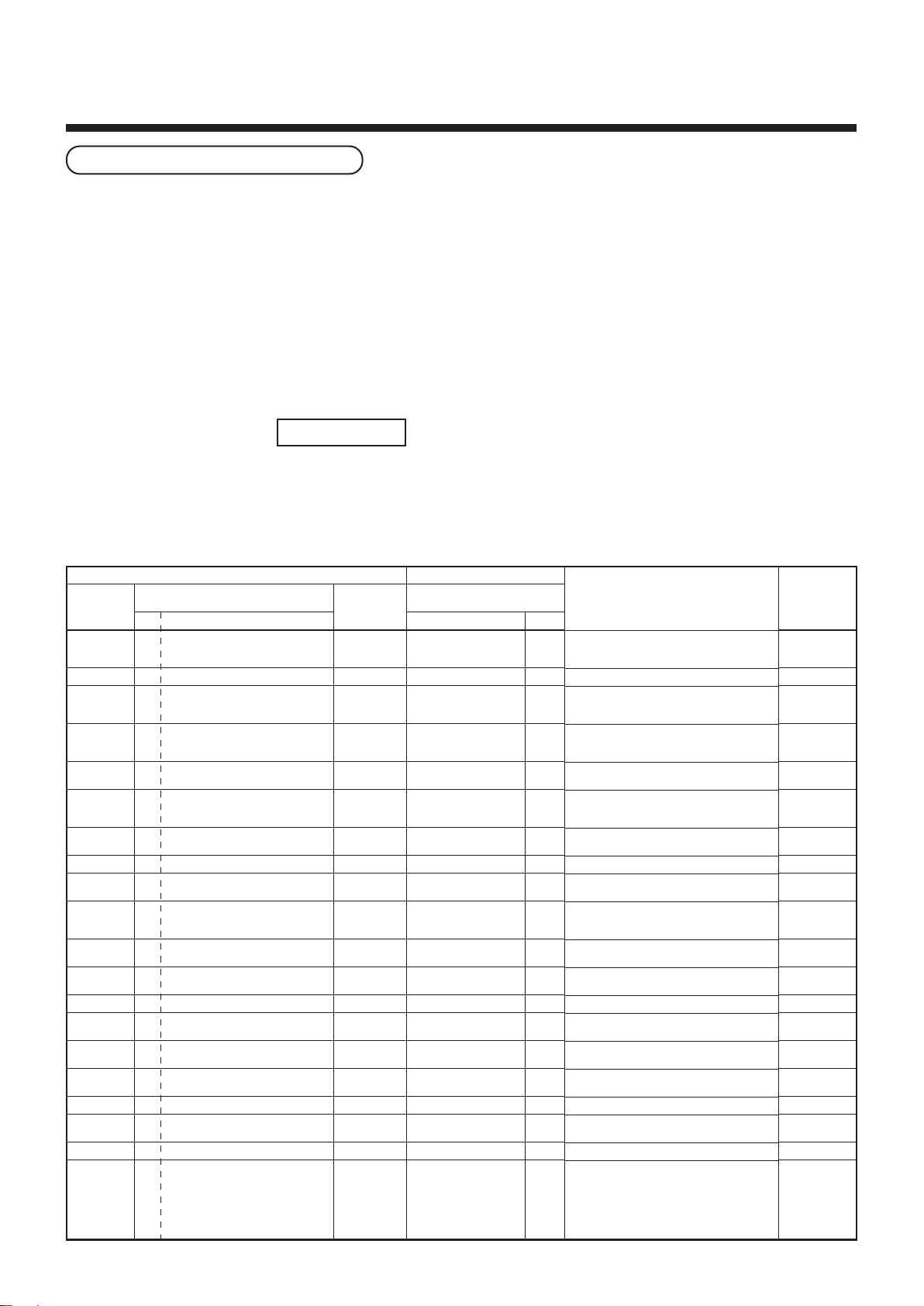

4

Do not leave any

undulations in the

drain pipe.

Do not let the drain

pipe slope upwards.

Do not leave the

end of the drain

hose in water.

NG

NG

NG

Heat insulator

Hard polyvinyl chloride pipe

Drain pan

Adhesion for hard polyvinyl

chloride pipe used

Drain hose

Pipe hole

(Grading downward to outdoor side)

Indoor

side

Outdoor side

Communication

wires for control

Pipe

(Liquid side)

Tape

Pipe

(Gas side)

Lower cabinet

Drain hose

DRAIN PIPING WORK

CAUTION

Install the drain pipe in accordance with the Installation Manual so that the water is drained completely, and

insulate the pipes so that no condensation forms them.

Improper pipe installation could result in water leaking indoors on furniture, etc.

REQUIREMENT

• Insulate indoor drain pipes completely.

• Insulate the connection with the indoor unit. Incomplete

insulation could result in condensation forming.

• Make sure that the drain pipe slopes downwards at a

rate of 1/100 or more, do not route the drain pipe

over another pipe, and do not create a trap.

These can all cause unusual sounds.

• Do not apply undue force to the drain pipe connection.

Piping and Insulation

Arrange for the following materials on site for the pipe installation and insulation work.

Piping

Heat insulator

• When extending the drain hose, make the connection as shown in the

figure at right.

Hard polyvinyl chloride pipe :nominal dia. (inner dia.) ; Ø20mm

Vesicant polyethylene : Thickness ; 10mm

REQUIREMENT

• Using adhesive agent for vinyl chloride, connect the hard vinyl

chloride pipes certainly so that water does not leak.

• It requires several times to dry and harden the adhesive agent.

(Refer to Guide Manual of the adhesive agent.) In this time, be sure

not to apply force to the connecting section with the drain pipes.

• Because the drain is a gravity drain, the pipes outside of the unit must

have a downward slope.

• Once the piping work is complete, pour water in the drain pan and make

sure that the water drains completely.

Pipe and Drain hose formation

The drain pipe can be routed out of the rear, left, or right side of the unit.

When routing the drain pipe out the left or right side, align the pipe

and drain hose as shown in the figure at right.

Make sure that the hose does not stick out the rear of the unit.

Installation of remote controller (Sold separately)

For installation of the wired remote controller, follow the Installation Manual attached with the remote controller.

For installation of the wireless remote controller, follow to the Installation Manual attached to the remote controller.

• Do not put the woreless remote controller on the place where is exposed to direct sunlight or near a stove, etc.

• Operate the remote controller, check the indoor unit surely receives the signal, and then install the remote

controller. (Wireless type)

• Install the remote controller 1m apart from the devices such as TV or stereo.

(Image may be disturbed or noise may be output.) (Wireless type)

8

Page 12

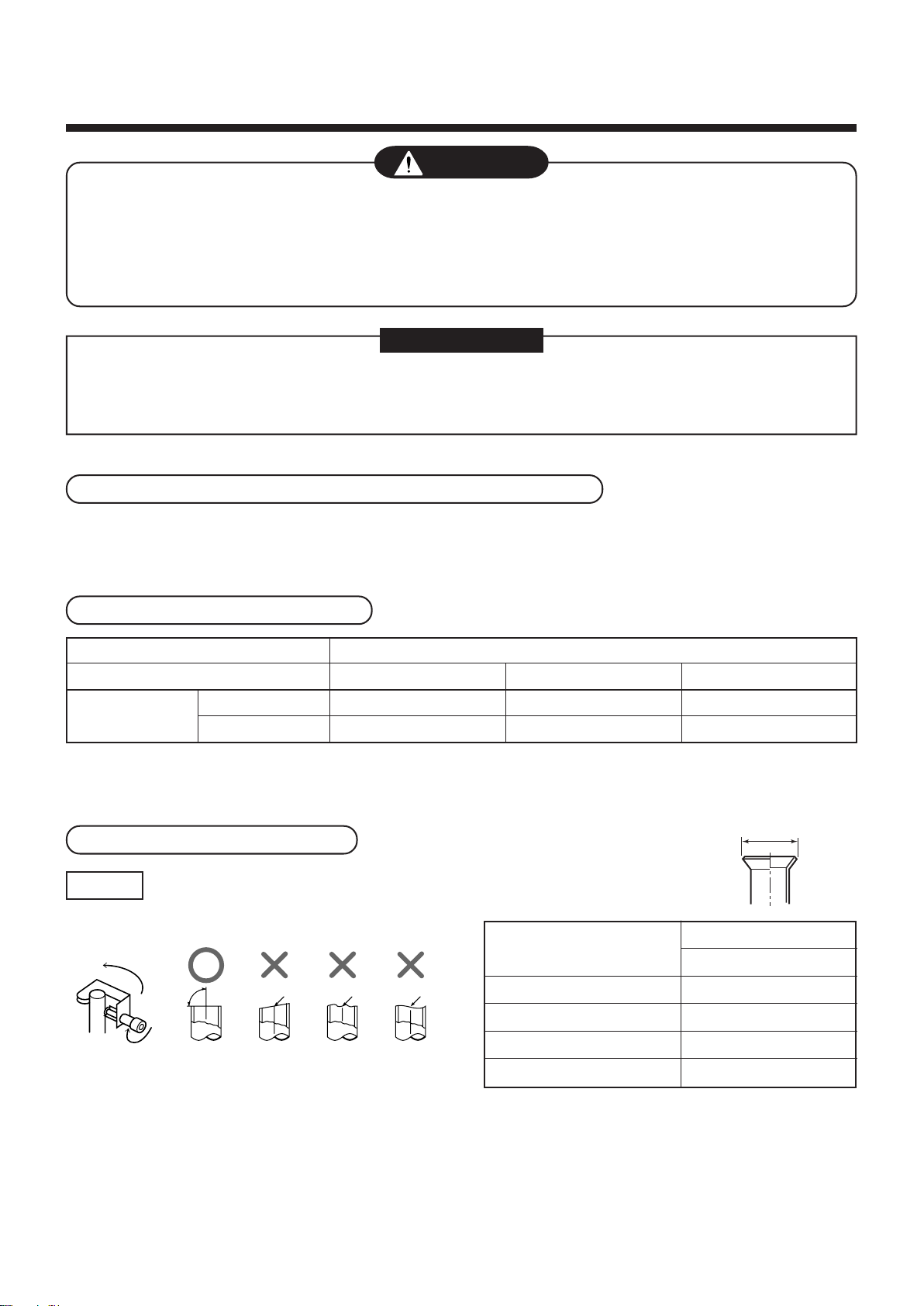

5

A

90˚

Obliquity Roughness Warp

REFRIGERANT PIPING

WARNING

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

• If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

• If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas may

generate.

REQUIREMENT

When the refrigerant pipe is long, set the support brackets to fix the pipe with 2.5 to 3m intervals. If the pipe is

not fixed, abnormal sound may generate.

Be sure to use the flare nuts attached to the indoor unit or those for R410A.

Permissible pipe length and permissible height difference

They are different according to the used outdoor unit. For details, refer to the Installation Manual attached to the

outdoor unit.

Piping material and dimensions

Piping material

Model MMK-

Pipe size (mm)

• Use a clean and new pipe, and check that impurity such as dust, oil, moisture, etc. does not adhere in the pipe.

Gas side

Liquid side

Pipe Forming/End Positioning

Phosphor deoxidization joint-less pipe for air conditioner

AP0071H to AP0121H AP0151H, AP0181H AP0241H

Ø9.5 Ø12.7 Ø15.9

Ø6.4 Ø6.4 Ø9.5

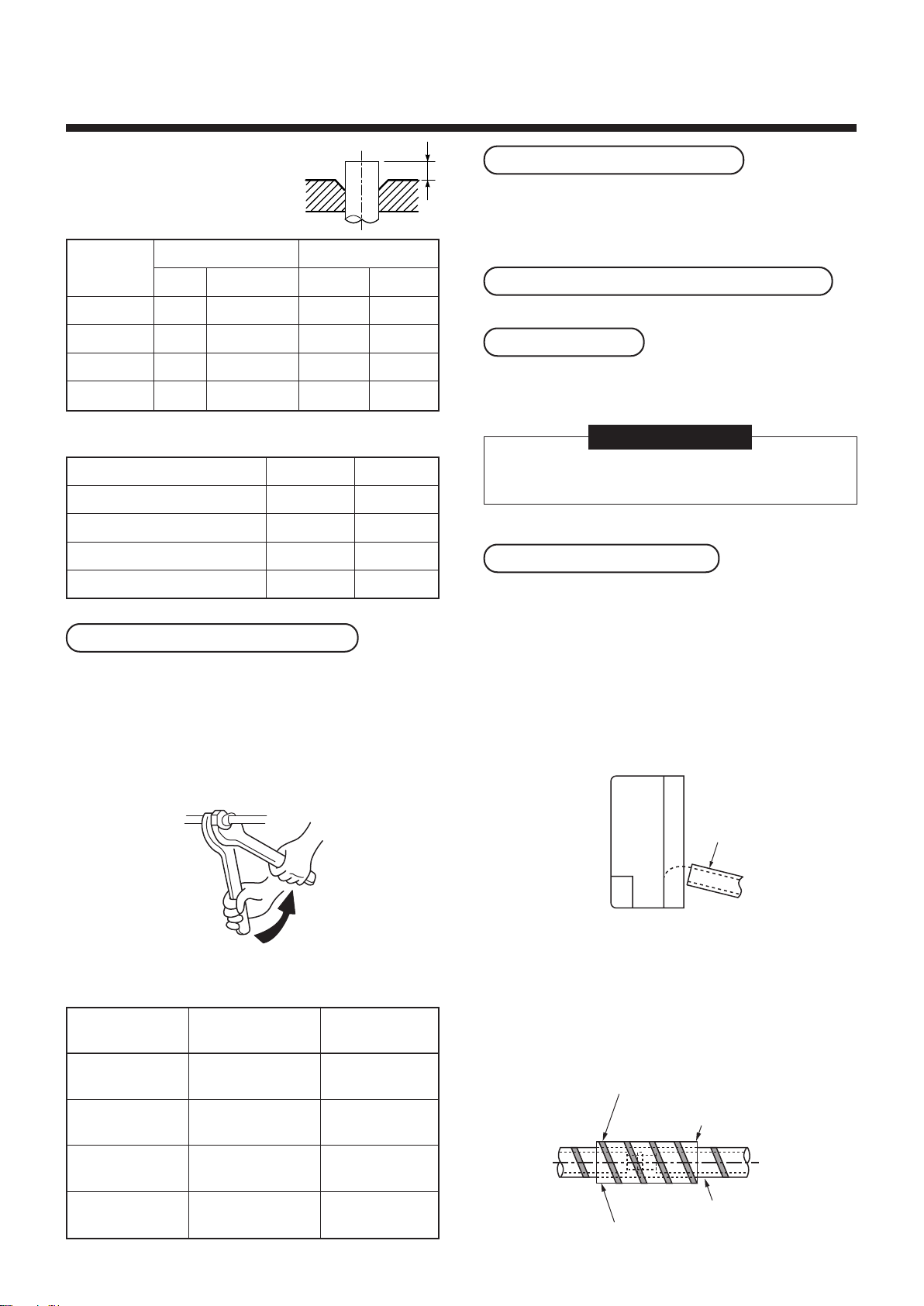

• Flaring diam. meter size :

A (Unit : mm)

Flaring

1. Cut the pipe with a pipe cutter.

Outer diam. of copper pipe

6.4

9.5

12.7

+0

A

- 0.4

R410A

9.1

13.2

16.6

2. Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools can be used by

adjusting projection margin of the copper pipe.

15.9

In case of flaring for R410A with the conventional

*

flare tool, pull it out approx. 0.5 mm more than that

for R22 to adjust to the specified flare size.

The copper pipe gauge is useful for adjusting

projection margin size.

9

19.7

Page 13

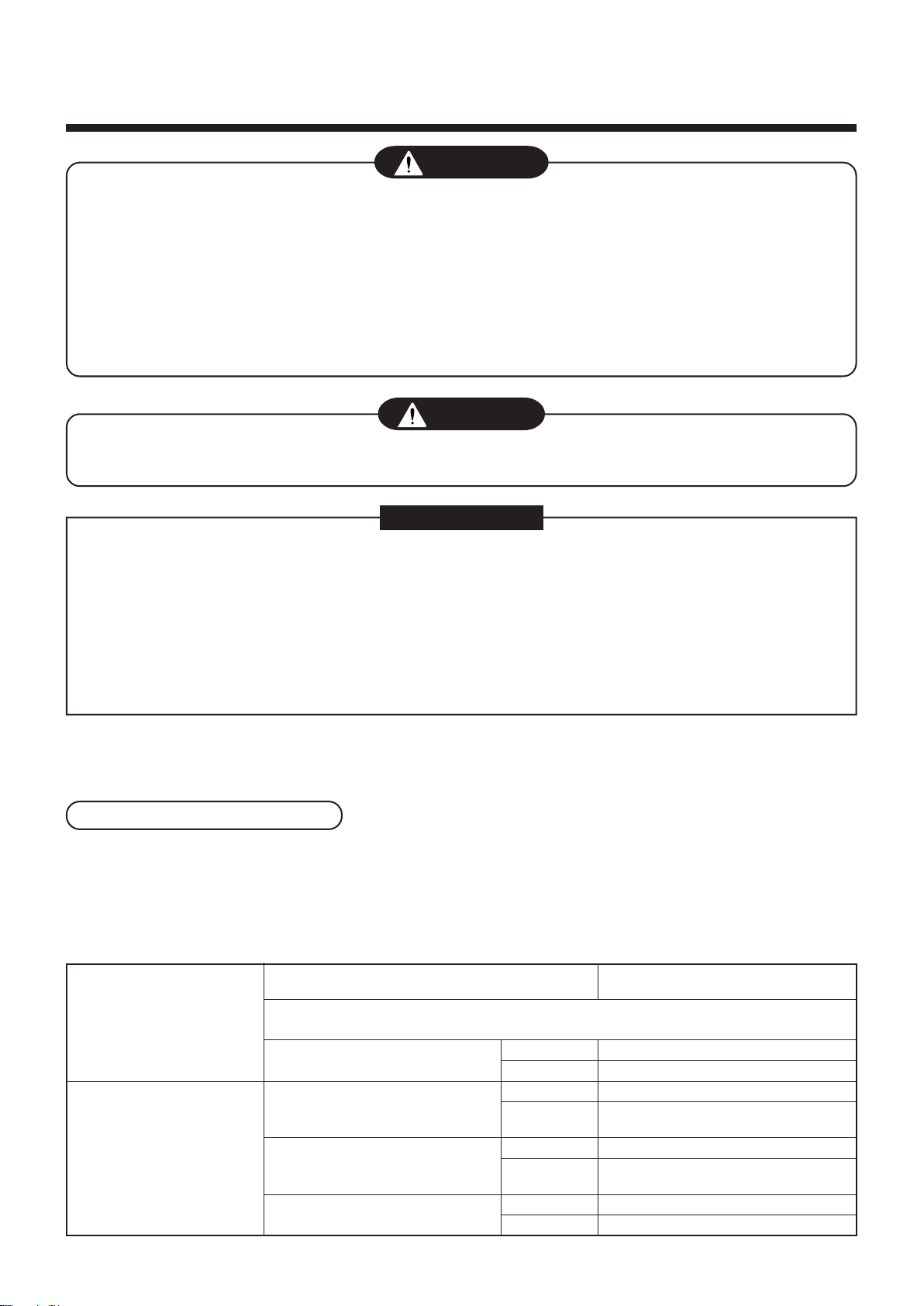

Work using double spanner

• Projection margin in flaring :

Fix the pipe with vinyl tape.

Set the notched part to upper side.

Attached thermal insulation pipe

Field-supplied pipe side

B

Indoor

unit

Heat

insulator

B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

6.4

R410A tool used

R410A R22

0 to 0.5 (Same as left)

Conventional tool used

R410A R22

1.0 to 1.5 0.5 to 1.0

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant, and

gas leak check, follow the Installation Manual attached

to the outdoor unit.

Open fully valves of the outdoor unit

9.5

12.7

15.9

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

0 to 0.5 (Same as left)

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

1.0 to 1.5 0.5 to 1.0

Imperial (Wing nut type)

Outer diam. of copper pipe

6.4

9.5

12.7

15.9

R410A R22

1.5 to 2.0 1.0 to 1.5

1.5 to 2.0 1.0 to 1.5

2.0 to 2.5 1.5 to 2.0

2.0 to 2.5 1.5 to 2.0

Connection of refrigerant pipe

Connect all the refrigerant pipes with flare connecting

work.

• Since the atmospheric pressure only is sealed as the

sealing gas, it is not abnormal that “Pushu…” sound

is not heard when the flare nut is removed.

• Be sure to use a double spanner for pipe connecting

work of the indoor unit.

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap

of the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for

HFC refrigerant (R410A, R134a, etc.).

Heat insulating process

Perform heat insulating for pipes at liquid side and gas

side separately.

In cooling time, temperature at both liquid and gas

sides becomes lower.

Therefore, perform heat insulating process sufficiently

to avoid dewing.

• Apply heat insulator from the outside of the indoor

unit. (In cases of drawing pipes from the rear side

and from the right side)

• Refer to the following table for tightening torque.

Connecting pipe

outer dia. (mm)

Ø6.4

Ø9.5

Ø12.7

Ø15.9

Tightening torque

(N•m)

14 to 18

(1.4 to 1.8 kgf•m)

33 to 42

(3.3 to 4.2 kgf•m)

50 to 62

(5.0 to 6.2 kgf•m)

68 to 82

(6.8 to 8.2 kgf•m)

Re-tightening

torque (N•m)

18

(1.8 kgf•m)

42

(4.2 kgf•m)

50

(5.0 kgf•m)

68

(6.8 kgf•m)

• For heat insulator of pipe at gas side, be sure to use

one with heat-resisting temp.120°C or more.

• Using the attached heat insulating pipe, perform heat

insulating process securely for pipe connecting part

of the indoor units without clearance.

10

Page 14

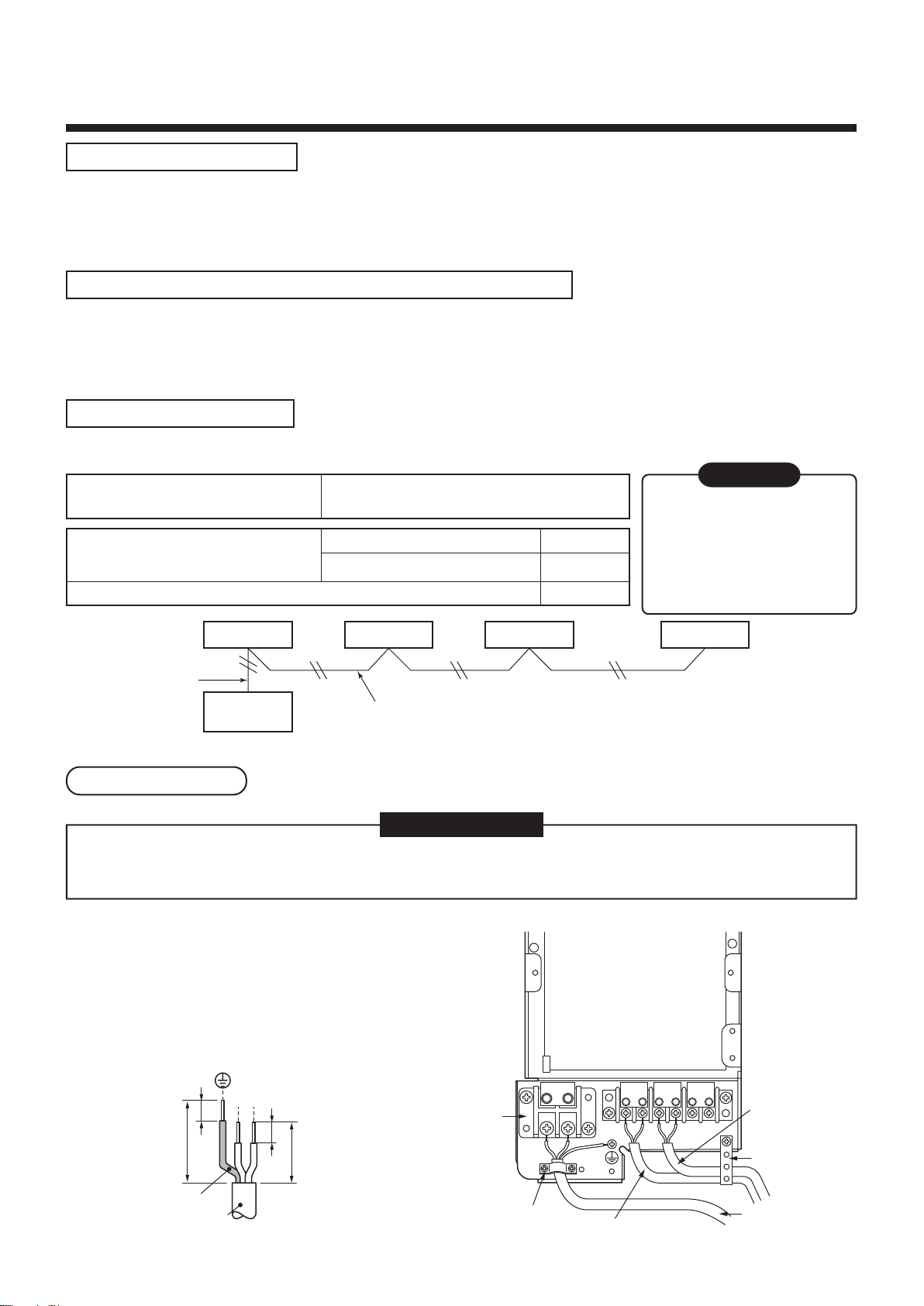

6

ELECTRIC WORK

WARNING

1. Using the specified wires, ensure to connect the wires, and fix wires securely so that the

external strength of the wires do not transmit to the connecting part of the terminals.

Incomplete connection or fixation may cause a fire, etc.

2. Be sure to connect earth wire. (Grounding work)

Do not connect the earth wire to gas pipe, city water pipe, lightning rod, or the earth wire of telephone.

Incomplete grounding causes an electric shock.

3. For electric work, strictly follow to the Local Regulation in each country and the Installation

Manual, and use an exclusive circuit.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

CAUTION

Be sure to install an earth leakage breaker.

If an earth leakage breaker is not installed, an electric shock may be caused.

REQUIREMENT

• For power supply wiring, strictly conform to the Local Regulation in each country.

• For wiring of power supply of the outdoor units, follow to the Installation Manual of each outdoor unit.

• Never connect 220–240V power to the terminal blocks (A, B, U1, U2, X, Y, etc.) for control wiring.

(Otherwise, the system will be failed.)

• Perform the electric wiring so that it does not come to contact with the high-temperature part of the pipe.

The coating may melt resulted in an accident.

• After connecting wires to the terminal blocks, provide a trap and fix wires with the wire clamp.

• Store the refrigerant piping line and control wiring line in the same line.

• Do not turn on the power of the indoor unit until vacuuming of the refrigerant pipes completes.

Power supply specifications

Cables and remote controller wires are procured locally.

For the power supply specifications, follow to the table below. If capacity is little, it is dangerous because overheat or

seizure may be caused.

For specifications of the power capacity of the outdoor unit and the power supply cables, refer to the Installation

Manual attached to the outdoor unit.

220–240V ~ 50Hz

220V

Twist wire : 2.0 mm²

Twist wire : 3.5 mm²

Twist wire : 0.5 to 2.0 mm²

~ 60Hz

2

2

2

Indoor unit power supply (*1)

Communication line

Power supply

Power supply switch/Earth leakage breaker or power supply wiring/fuse rating for

indoor units should be selected by the accummulated total current values of the indoor units.

Power supply wiring

Indoor/Outdoor inter-unit wiring (*2)

Central control line wiring (*3)

Remote controller wiring (*4)

20m or less

50m or less

Q’ty

Wire size

Q’ty

Wire size

Q’ty

Wire size

(Up to 1000m) Twist wire : 1.25 mm²

(Up to 2000m) Twist wire : 2.00 mm²

(Up to 1000m) Twist wire : 1.25 mm²

(Up to 2000m) Twist wire : 2.00 mm²

11

Page 15

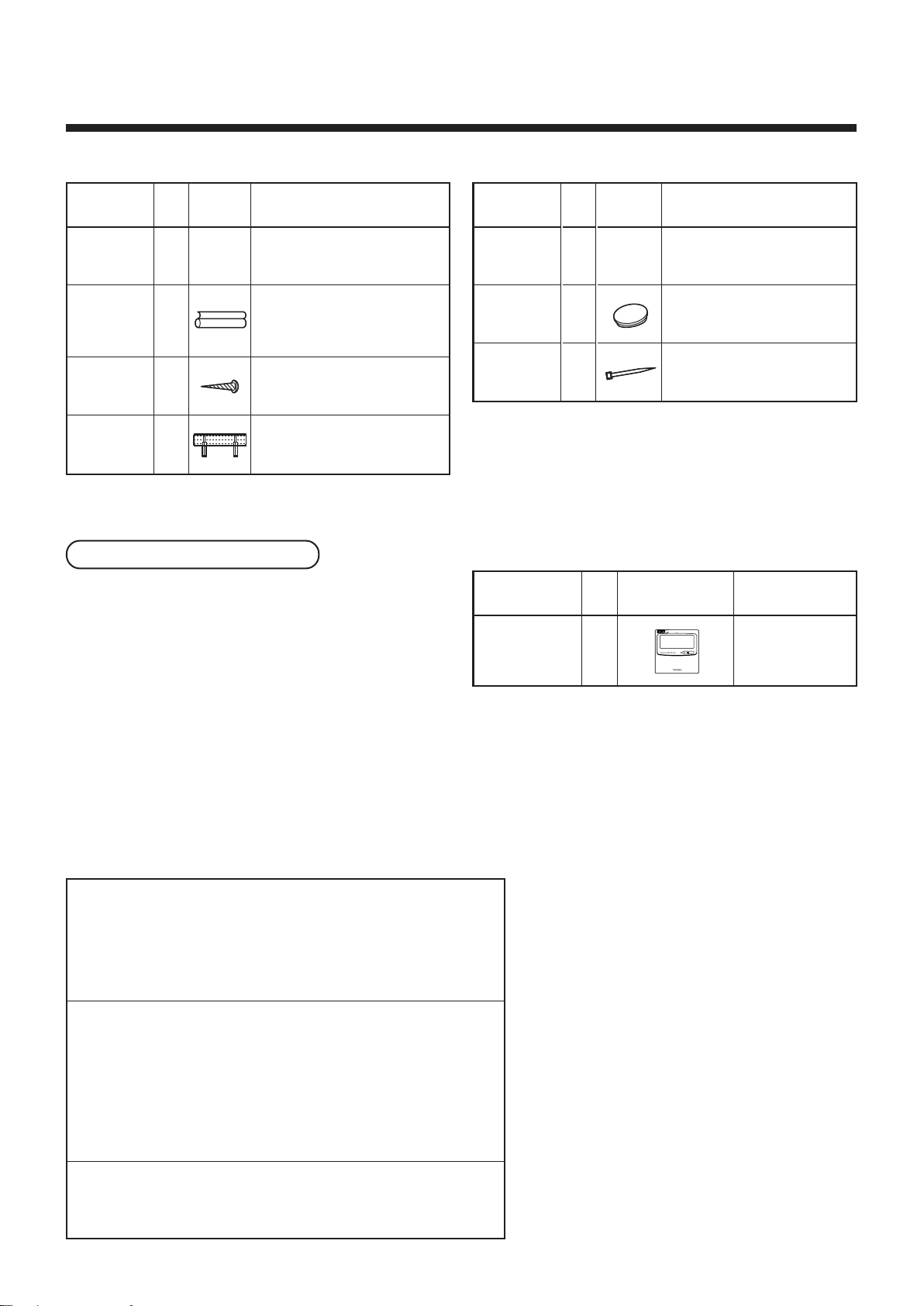

Indoor unit power supply (*1)

Remote controller inter-unit wiring

Indoor unit

Remote

controller

Indoor unit

L1 L2 Ln

(Max. 8 units)

Indoor unit Indoor unit

Remote

controller

wiring

R

(L)

S

(N)

10

10

50

70

Earth line

Connecting

cord

R(L)

R(L)

S(N)

S(N)

Main P.C. board

Power supply

terminal block

2P

Cord clamp

Inter-unit cable between indoor and outdoor units

A B X Y

U1 U2

Cord clamp

Power supply cable

Remote controller

cable

• For the power supply of the indoor unit, prepare the exclusive power supply separated from that of the outdoor unit.

• Arrange the power supply, earth leakage breaker, and main switch of the indoor unit connected to the same

outdoor unit so that they are commonly used.

• Power supply cord specification : Cable 3-core 2.5mm², in conformity with Design 60245 IEC 57.

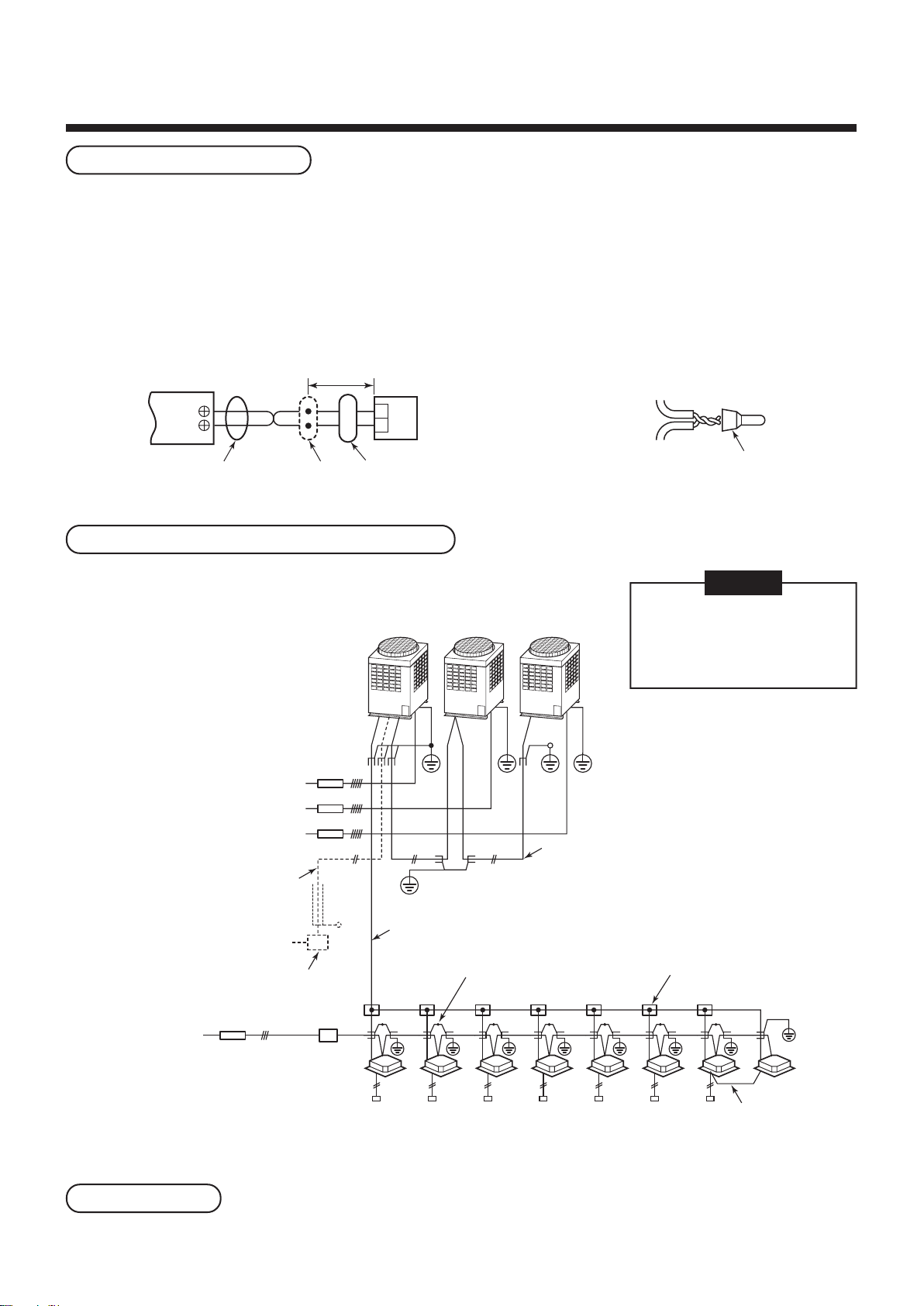

Indoor/Outdoor inter-unit wiring, Central controller wiring (*2) (*3)

• 2-core with polarity wires are used for the Indoor/Outdoor inter-unit wiring and Central controller wiring.

• To prevent noise trouble, use 2-core shield wire.

• The length of the communication line means the total length of the inter-unit wire length between indoor and

outdoor units added with the central control system wire length.

Remote controller wiring (*4)

• 2-core with non-polarity wire is used for wiring of the remote controller wiring and group remote controllers wiring.

Remote controller wiring, remote

controller inter-unit wiring

Total wire length of remote controller

wiring and remote controller inter-unit

wiring = L + L1 + L2 + … Ln

Total wire length of remote controller inter-unit wiring = L1 + L2 + … Ln

Twist wire: 0.5mm2 to 2.0mm2 × 2

In case of wired type only

In case of wireless type included

Up to 500m

Up to 400m

Up to 200m

Cable connection

REQUIREMENT

• Be sure to pass the cable through the cable connection port of the indoor unit.

• The low-voltage circuit is provided for the remote controller.

• Tighten the screws of the terminal block, and fix the cables

with cord clamp attached to the electric parts box.

(Do not apply tension to the connecting section of the

terminal block.)

CAUTION

The remote controller wire

(Communication line) and

AC220–240V wires cannot be

parallel to contact each other and

cannot be stored in the same

conduits. If doing so, a trouble

may be caused on the control

system due to noise, etc.

12

Page 16

Terminal block

for remote controller

wiring of indoor unit

A

B

Approx. 200mm

W : White

B : Black

W

B

Remote controller wire

(Local procure)

Wire from remote controller unit

or sensor

Connecting

part

Remote

controller unit

or sensor part

Wire from remote

controller or sensor

Remote controller wiring

Wire joint

Header unit Follower unit

Earth leakage breaker

Earth leakage breaker

Switch

(Earth)

(Open)

Earth

Outdoor power supply

3-phase

380–415V, 50Hz

380V, 60Hz

Central control line wire

Power supply

220–240V

~

50Hz

220V ~ 60Hz

Remote controller,

for central control, etc.

Connection of shield

wire closed terminal

Inter-unit wire between outdoor units

Indoor/Outdoor inter-unit wire

Indoor power supply

220–240V

~

50Hz

220V

~

60Hz

(Earth)

Connection of shield

wire closed terminal

(Remote controller group operation)

Pull box

Indoor unit

6

ELECTRIC WORK

Remote controller wiring

• Strip off approx. 14mm cover of the wire to be connected.

• Twist wire of the remote controller to be connected with wire of the remote controller unit (or sensor), and press-fit

them with a wire joint. (Wire joints (White: 2 pieces) are included in the accessory of the main remote controller

(sold separately) or wireless remote controller kit (sold separately).)

• As the remote controller wire has no polarity, there is no problem if connections to indoor unit terminal blocks A

and B are reversed.

<Wiring diagram>

Wiring between indoor and outdoor units

NOTE

An outdoor unit connected

with indoor/outdoor inter-unit

wire becomes automatically

the header unit.

Address setup

Set up the addresses according to the Installation Manual attached to the outdoor unit.

13

Page 17

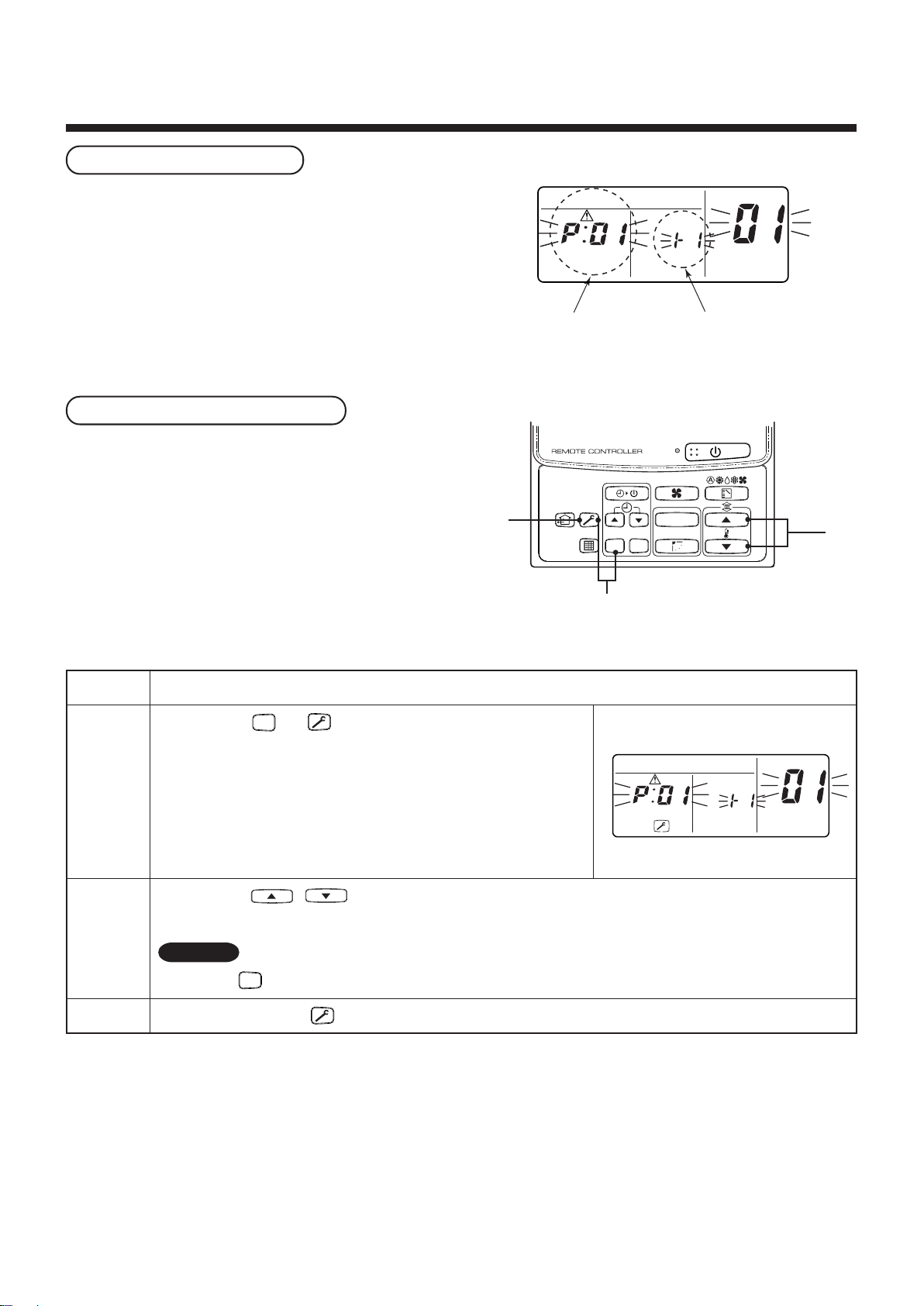

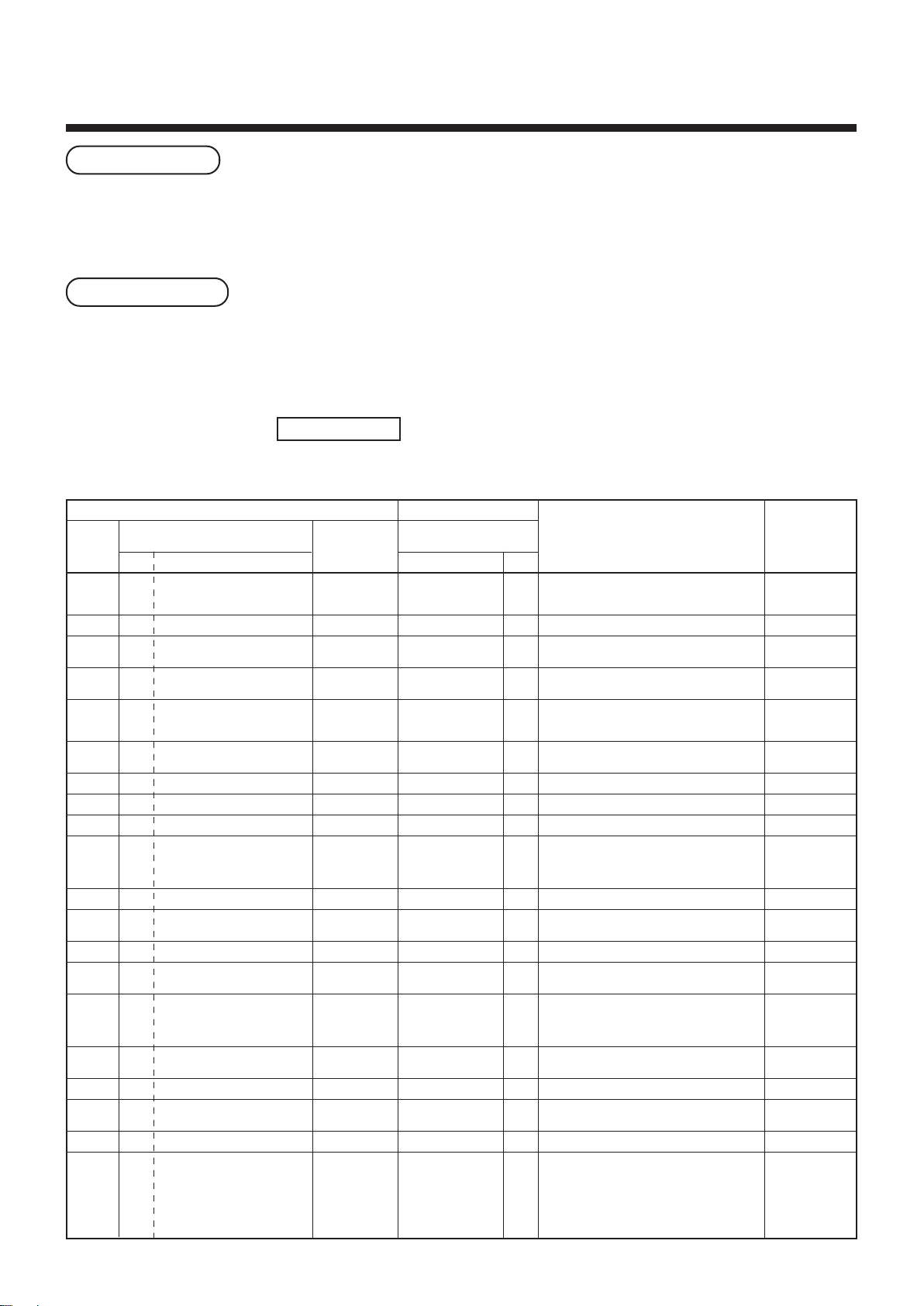

7

SET

UNIT

SET

UNIT

SET

CL

UNIT No.

CODE No.

R.C. No.

1

4

6

2

3

5

UNIT No.

CODE No.

R.C. No.

UNIT No.

CODE No.

R.C. No.

** **

** **

*

**

APPLICABLE CONTROLS

NOTIFICATION

When using the equipment at the first time, it will take a lot of time that the remote controller accepts an

operation after power was on. However, it is not a trouble.

• Automatic address

• While automatic addressing, the operation cannot be performed on the remote controller.

• For automatic addressing, Max. 10 minutes (generally, approx. 5 minutes) are required.

• When power will be turned on after finish of automatic addressing;

• It will require Max. 10 minutes (generally, approx. 3 minutes) that outdoor unit starts operation after power

was on.

As all have been set to [Standard] at the shipment, change the setup of the indoor unit if necessary.

To change the setup, use the main remote controller (wired remote controller).

* The setup change for wireless remote controller, sub remote controller, or remote controller-less system

(Central control remote controller only is provided.) is impossible. In these cases, prepare and mount a

separate main remote controller.

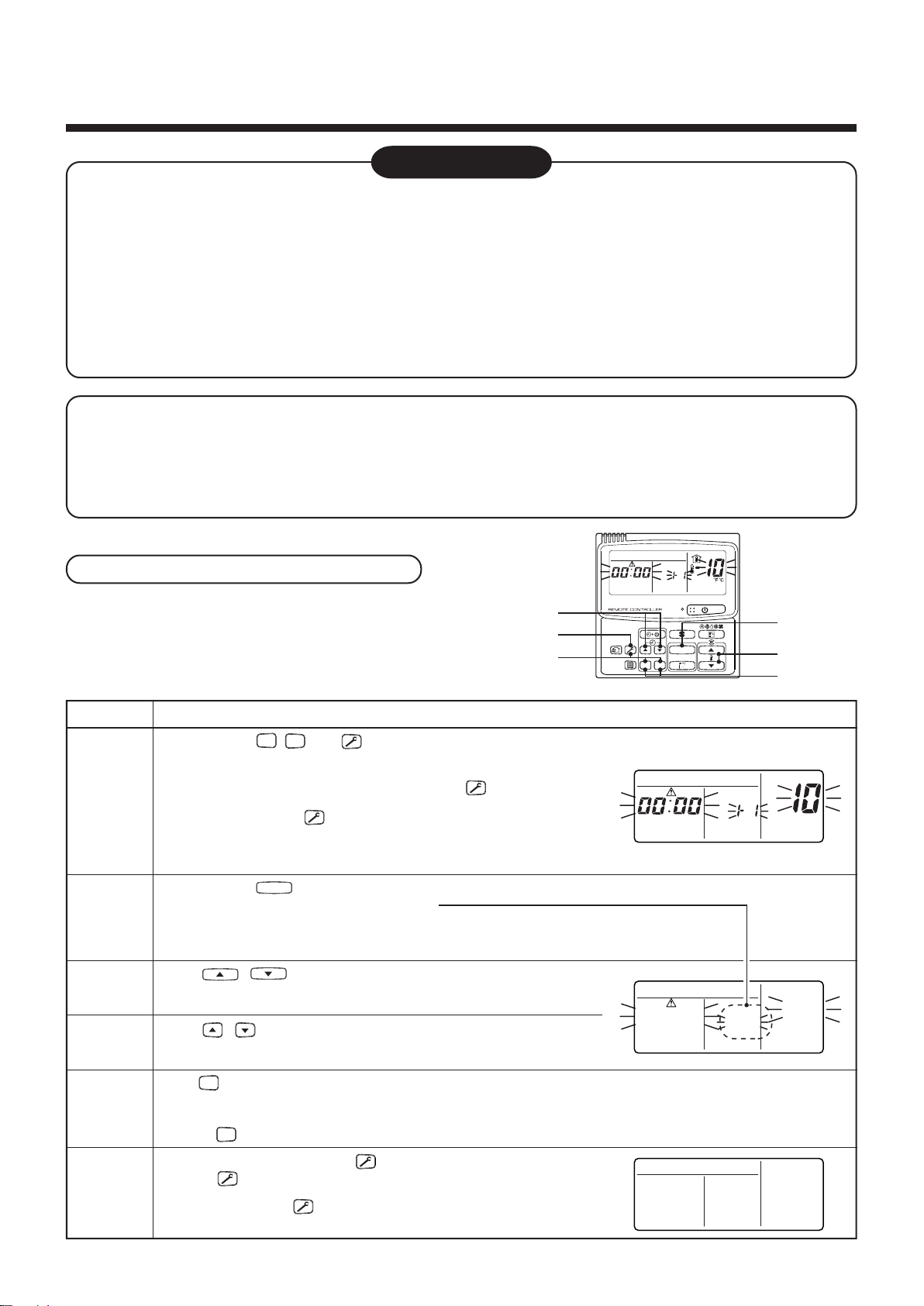

Exchange of applicable control setup

Basic operation procedure for setup exchange

Change the setup while operation of the equipment stops.

(Be sure to stop the operation of a set.)

Procedure

1

2

3

When pushing

flashes as shown in the figure.

Check that the displayed item code is [10].

• If the item code indicates other than [10], push

the display, and then retry the operation from the first step.

(For some time after button has been pushed, the operation of

the remote controller cannot be accepted.)

(In a group control, the firstly displayed

indoor unit No. becomes the header unit.)

Every pushing

indoor unit of which setup to be changed.

In this time, the position of the indoor unit of which setup to be

changed can be confirmed because the fan and the flap of the

selected indoor unit work.

Using , buttons of set temperature, specify the item

code [**].

, CL, and buttons simultaneously for 4 seconds or more, after a while, the display part

button, the indoor unit No. in the group control is displayed successively. Select an

Description

button to erase

(* The display changes according to the indoor unit model.)

4

5

6

Using , buttons of timer time, select set data [

Push

• To change the setup of an indoor unit other than the selected one, start operation from Procedure 2.

• To change the setup of another setup in the selected indoor unit, start operation from Procedure

Pushing CL button clears the set up contents which have been already set. In this case, retry from Procedure 2.

When the setup finished, push button. (The setup is determined.)

Pushing button deletes the display and returns the status to

normal stop status.

(For some time after button has been pushed, the operation of

the remote controller cannot be accepted.)

button. In this time, if the display changes from flashing to lighting, the setup completes.

****

].

14

3

.

Page 18

7

APPLICABLE CONTROLS

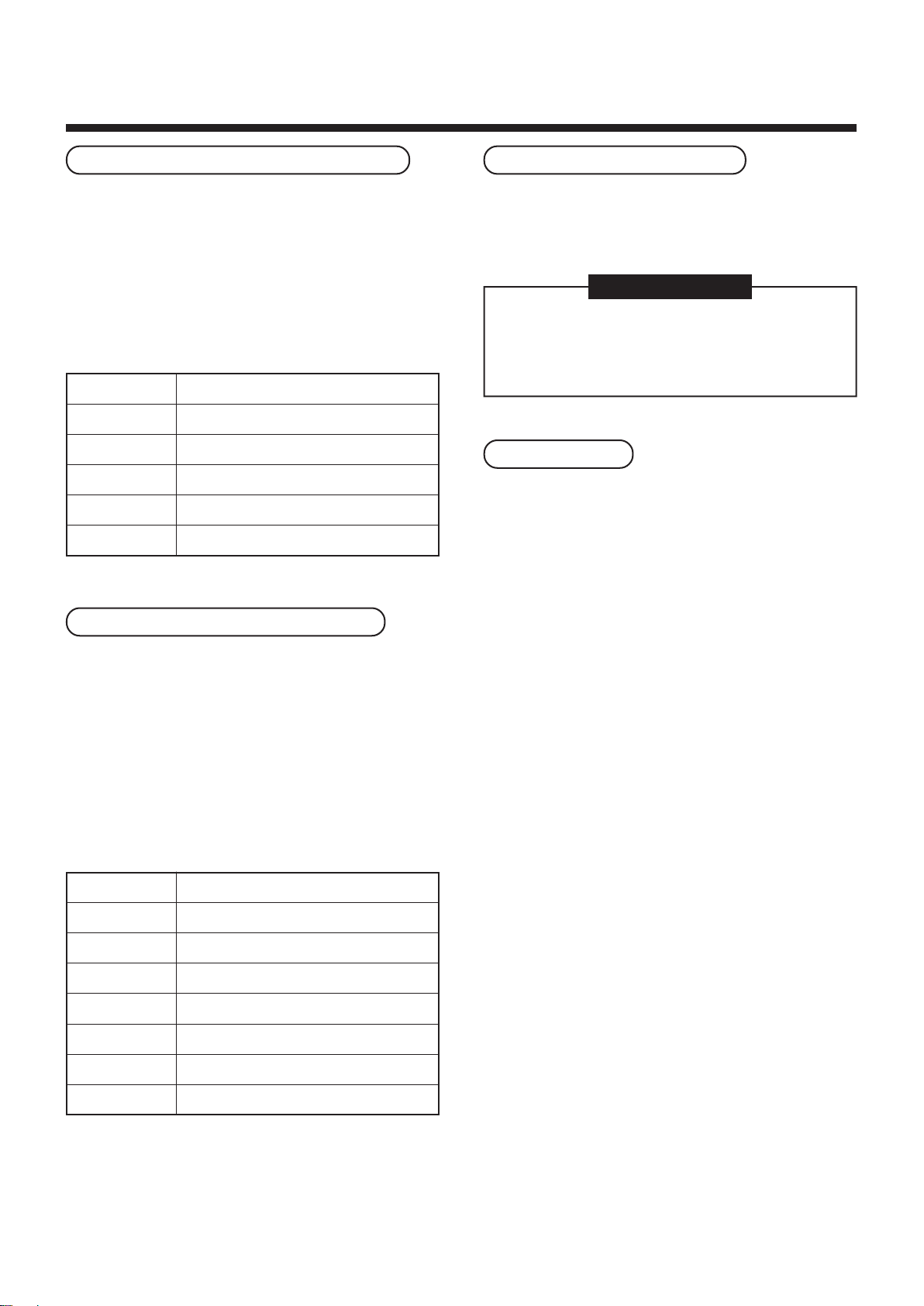

Change of lighting time of filter sign

According to the installation condition, the lighting time

of the filter sign (Notification of filter cleaning) can be

changed.

Follow to the basic operation procedure

(1 → 2 → 3 → 4 → 5 → 6 ).

• For the item code in Procedure 3 , specify [01].

• For the [Set data] in Procedure 4 , select the setup

data of filter sign lighting time from the following

table.

Setup data

0000

0001

0002

0003

0004

Filter sign lighting time

None

150H (At shipment from factory)

2500H

5000H

10000H

To secure better effect of heating

When it is difficult to obtain satisfactory heating due to

installation place of the indoor unit or structure of the

room, the detection temperature of heating can be

raised. Also use a circulator, etc. to circulate heat air

near the ceiling.

Follow to the basic operation procedure

(1 → 2 → 3 → 4 → 5 → 6 ).

• For the item code in Procedure 3 , specify [06].

• For the set data in Procedure 4 , select the setup

data of shift value of detection temperature to be set

up from the table below.

Adjustment of air direction

1. Using the remote controller switch, change the up/

down air direction by moving the horizontal flap.

2. Adjust the right/left air direction by bending the

vertical grille inside of the air outlet port with hands.

REQUIREMENT

Do not touch the horizontal flap directly with

hands; otherwise a trouble may be caused.

For handling of the horizontal flap, refer to

“Owner’s Manual” attached to the outdoor unit.

Group control

In a group control, a remote controller can control up

to maximum 8 units.

• For cabling procedure and cables of the individual

line (Identical refrigerant line) system, refer to

“Electric work” in this Manual.

• Cabling between indoor units in a group is performed

in the following procedure.

Connect the indoor units by connecting the remote

controller inter-unit cables from the remote controller

terminal blocks (A, B) of the indoor unit connected

with a remote controller to the remote controller

terminal blocks (A, B) of the other indoor unit.

(No polarity)

• For address setup, refer to the Installation Manual

attached to the outdoor unit.

Setup data

0000

0001

0002

0003

0004

0005

0006

Detection temp shift value

No shift

+1°C

+2°C (At shipment from factory)

+3°C

+4°C

+5°C

+6°C

15

Page 19

UNIT

SET

CL

1, 5

3

2, 4

TEST

8

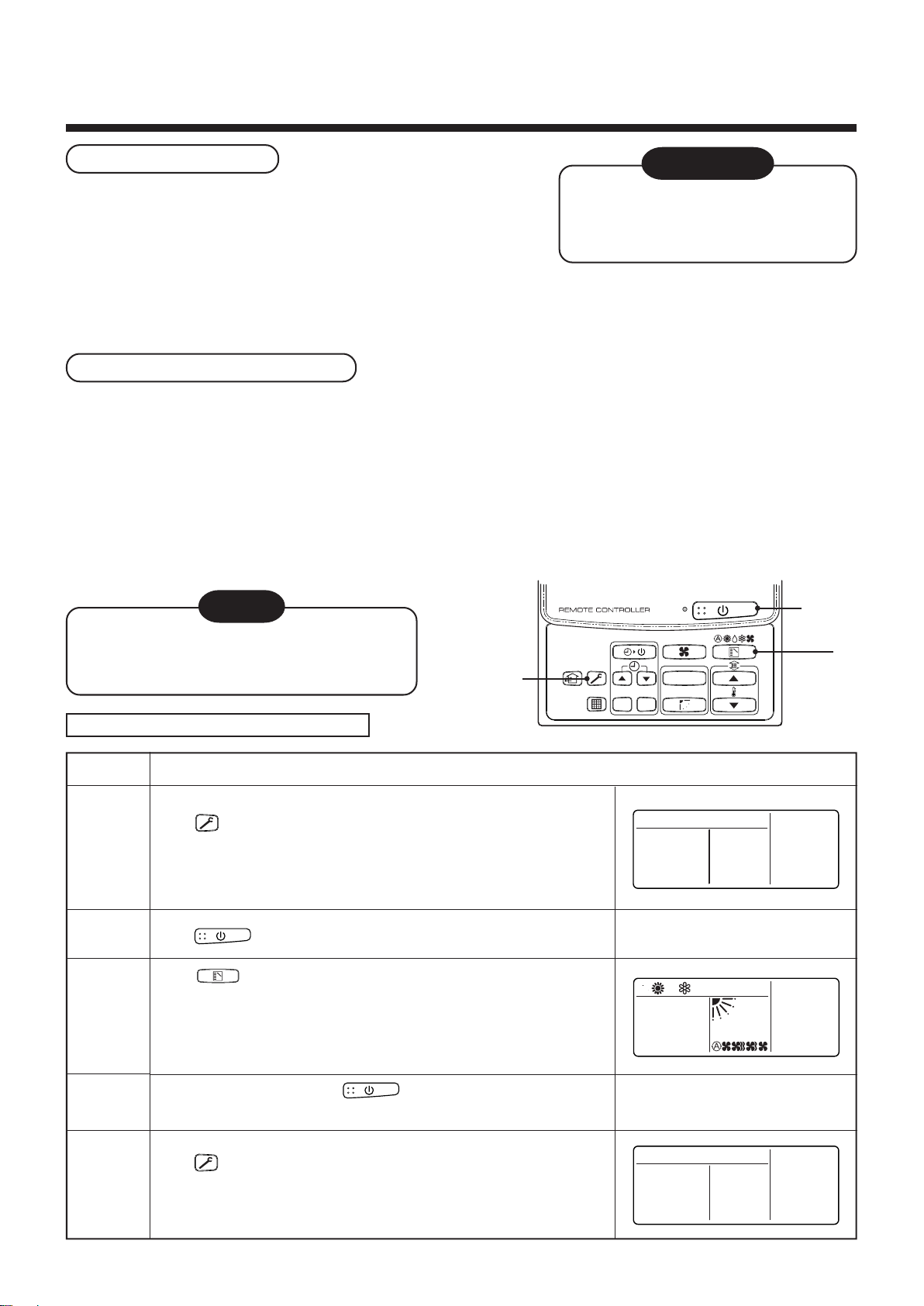

TEST RUN

Before test operation

• Before turning on the power supply, carry out the following items.

1) Using 500V-megger, check there is 1MΩ or more between the

terminal block of the power supply and the earth. If 1MΩ or less

is detected, do not run the unit.

2) Check that all the valves of the outdoor unit are fully opened.

• Never push the electromagnetic contactor to carry out a forced test operation.

(It is very dangerous because a protective device does not work.)

How to execute test operation

• To carry out a fan operation in a single indoor unit, turn off the power once, short CN72 on P.C. board, and then

turn on the power again. (Start the unit in FAN mode.) In this case, do not forget to clear short-circuit of CN72 after

test operation.

• Using the remote controller, check the operation in the usual operation. For the operation procedure, refer to the

attached Owner’s Manual.

A forced test operation can be executed in the following procedure under condition of thermo-OFF of room

temperature.

In order to prevent a serial operation, the forced test operation is released after 60 minutes and returns to the

usual operation.

To protect the compressor at

starting time, keep power-ON

condition before 12 hours or more.

WARNING

NOTE

Do not use a forced operation in cases other

than test operation because it applies an

excessive load to the air conditioner.

In case of wired remote controller

Procedure

Keep button pushed for 4 seconds or more. [TEST] is displayed

1

2

3

on the display part and the selection of mode in the test mode is

permitted.

Push button.

Using button, select the operation mode, [COOL] or [HEAT].

• Do not run the air conditioner in a mode other than [COOL] or [HEAT].

• The temperature controlling function does not work during test

operation.

• The detection of error is performed as usual.

Description

4

5

After the test operation, push button to stop the operation.

(Display part is same as procedure 1 )

Push button to cancel (release from) the test operation mode.

([TEST] disappears on the display part and the status returns to a

normal stop status.)

16

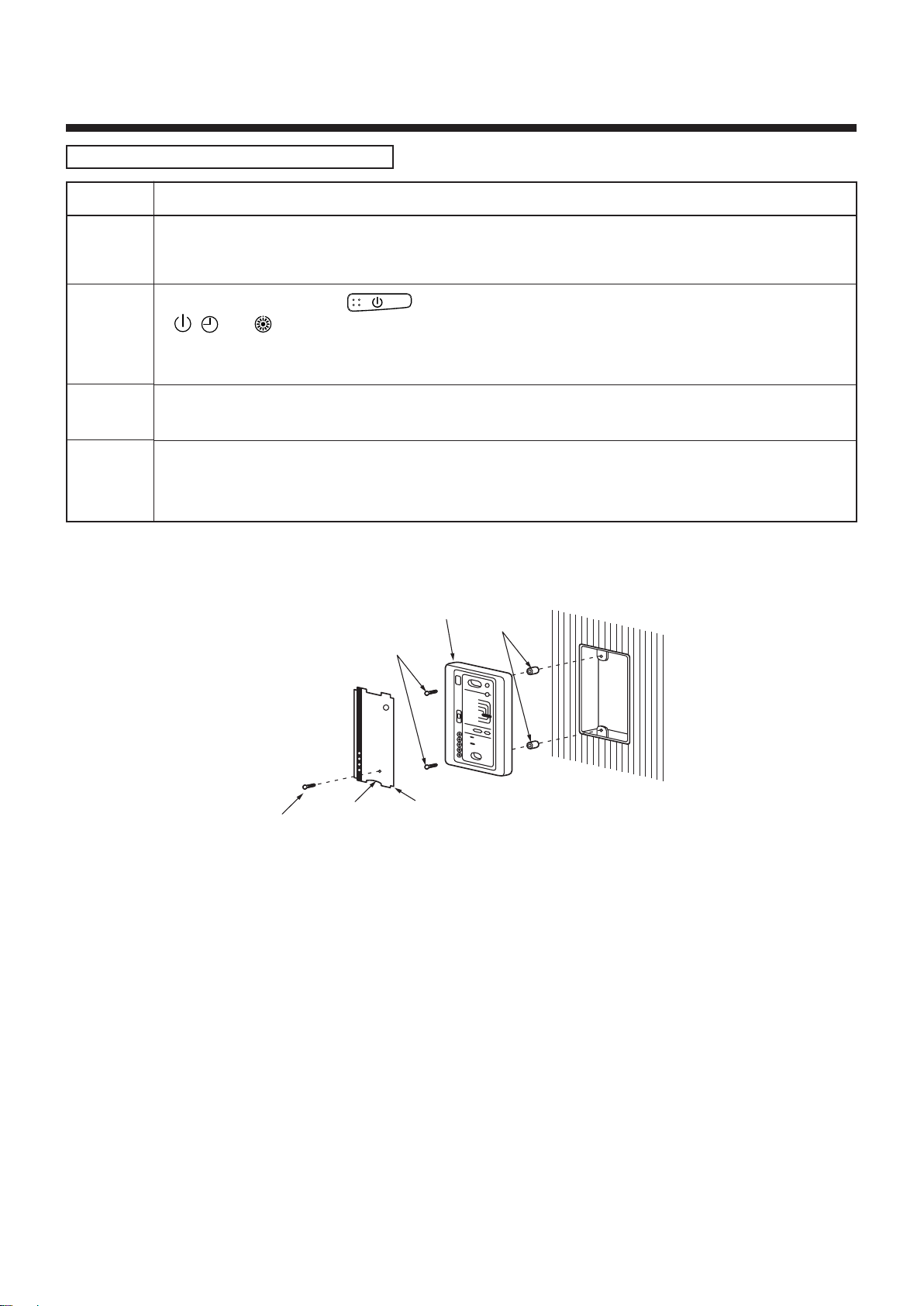

Page 20

Receiver unit

M4 × 25 screw

(2 pieces)

Small screw

Spacer

Notch

Nameplate

8

TEST RUN

In case of wireless remote controller

Procedure

1

2

3

4

Description

Remove a small screw which fixes the nameplate of the receiver unit.

Remove the nameplate of the sensor section by inserting a minus screwdriver, etc into the notch at the bottom

of the plate, and set the Dip switch to [TEST RUN ON].

Execute a test operation with button on the wireless remote controller.

• , , and LED flash during test operation.

• Under status of [TEST RUN ON], the temperature adjustment from the wireless remote controller is invalid.

Do not use this method in the operation other than test operation because the equipment is damaged.

Use either COOL or HEAT operation mode for a test operation.

* The outdoor unit does not operate approx. 3 minutes after power-ON and operation stop.

After the test operation finished, stop the air conditioner from the wireless remote controller, and return Dip

switch of the receiver section as before.

(A 60-minutes timer clearing function is attached to the receiver section in order to prevent a continuous test

operation.)

17

Page 21

9

SET

CL

UNIT No.

CODE No.

R.C. No.

Check code

Indoor unit No. in which

an error occurred

UNIT

SET

CL

3

2

1

UNIT No.

CODE No.

R.C. No.

TROUBLESHOOTING

Confirmation and check

When a trouble occurred in the air conditioner, the

check code and the indoor unit No. appear on the

display part of the remote controller.

The check code is only displayed during the operation.

If the display disappears, operate the air conditioner

according to the following “Confirmation of error

history” for confirmation.

Confirmation of error history

When a trouble occurred on the air conditioner, the

error history can be confirmed with the following

procedure.

(The error history is stored in memory up to 4 errors.)

This history can be confirmed from either operating

status or stop status.

Procedure

1

2

3

Description

When pushing

more, the right display appears.

If [Service Check] is displayed, the mode enters in the error history

mode.

• [01: Order of error history] is displayed in CODE No. window.

• [Check Code] is displayed in CHECK window.

• [Indoor unit address in which an error occurred] is displayed in

UNIT No.

Every pushing , buttons, the error history stored in the memory is displayed in order.

The numbers in CODE No. indicates CODE No. [01] (Latest) → [04] (Oldest).

CAUTION

Do not push

After confirmation, push button to return to the usual display.

and buttons simultaneously for 4 seconds or

button because all the error history of the indoor unit will be deleted.

18

Page 22

9

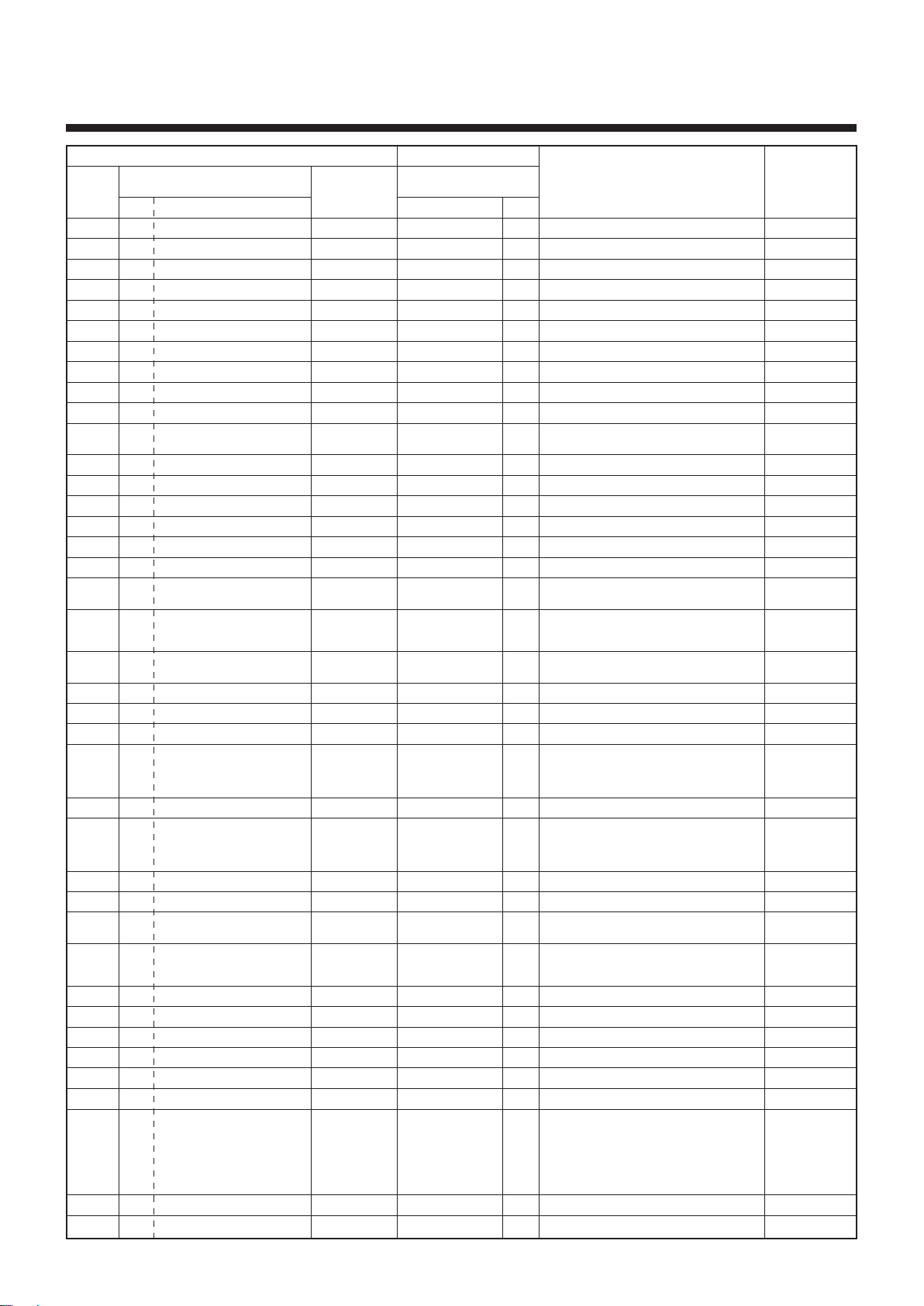

TROUBLESHOOTING

Check method

On the remote controller (Main remote controller, Central control remote controller) and the interface P.C. board of

the outdoor unit (I/F), a check display LCD (Remote controller) or 7-segment display (on the outdoor interface P.C.

board) to display the operation is provided. Therefore the operation status can be known. Using this self-diagnosis

function, a trouble or position with error of the air conditioner can be found as shown in the table below.

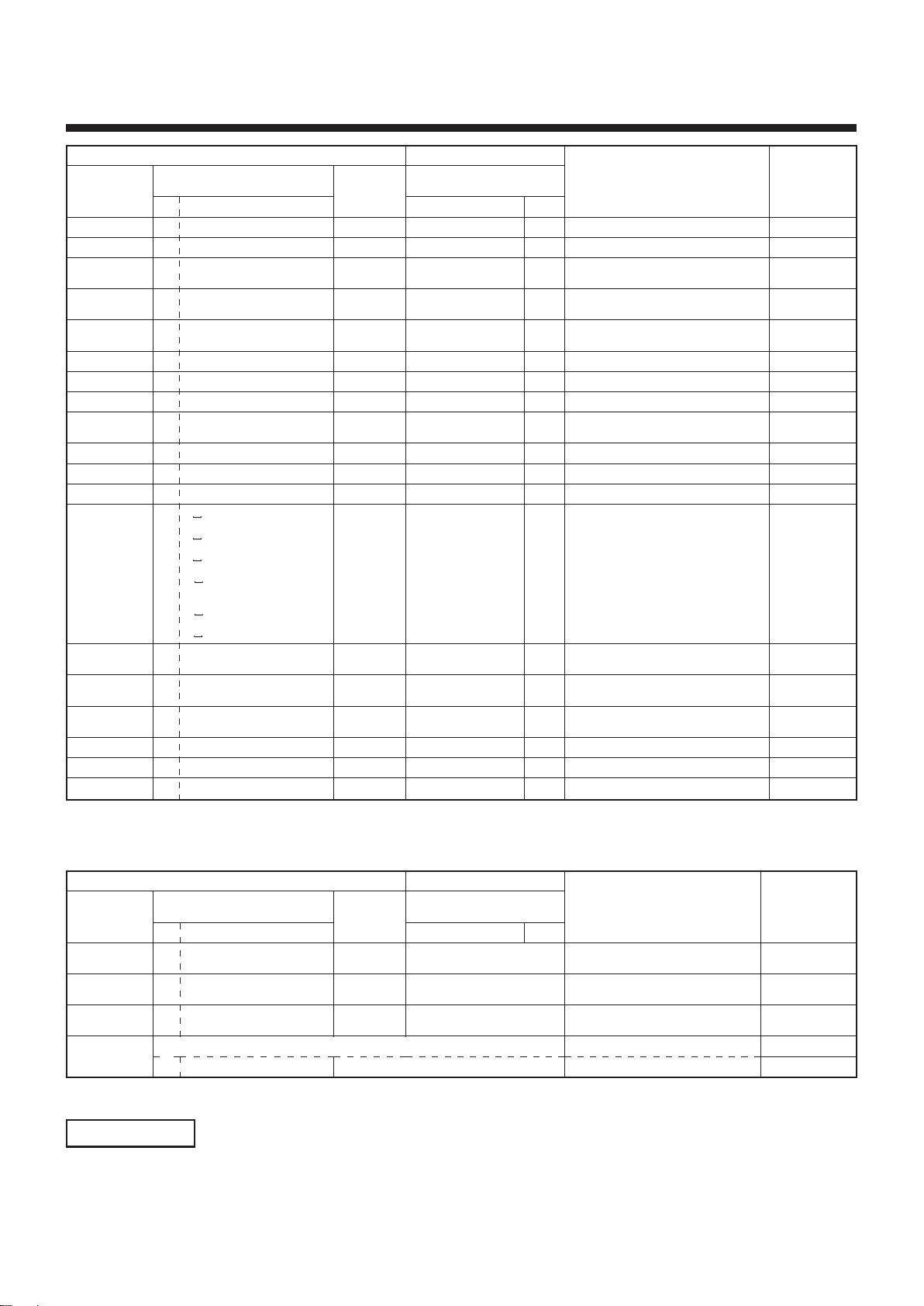

Check code list

The following list shows each check code. Find the check contents from the list according to part to be checked.

• In case of check from indoor remote controller: See “Main remote controller display” in the list.

• In case of check from outdoor unit: See “Outdoor 7-segment display” in the list.

• In case of check from AI-NET central control remote controller: See “AI-NET central control display” in the list.

• In case of check from indoor unit with wireless remote controller: See “Sensor block display of receiving unit” in the list.

AI-NET : Artificial Intelligence.

IPDU : Intelligent Power Drive Unit

{ : Lighting,

ALT. : Flashing is alternately when there are two flashing LED.

: Flashing, z : Goes off

¤

SIM : Simultaneous flashing when there are two flashing LED.

Wireless remote controller

Sensor block display

of receiving unit

Operation

Timer Ready Flash

zz

¤

zz

¤

zz

¤

zz

zz

zz

zz

¤

zz

¤

zz

¤

zz

¤

zz

zz

zz

¤

zz

zz

zz

zz

zz

zz

zz

Communication error between indoor and

remote controller

(Detected at remote controller side)

Remote controller transmission error

Communication error between indoor and

remote controller (Detected at indoor side)

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

Communication circuit error between indoor/

outdoor (Detected at indoor side)

Decrease of No. of indoor units

Communication circuit error between indoor/

outdoor (Detected at outdoor side)

Duplicated indoor addresses

Duplicated main remote controllers

Communication error between indoor MCU

Automatic address start error

Indoor is nothing during automatic addressing

Capacity over / No. of connected indoor units

Communication error between indoor units

Outdoor header units quantity error

Other line connected during automatic

address

Sending error in communication between

outdoor units

Duplicated follower outdoor addresses

Decrease of No. of connected outdoor units

Follower outdoor unit error

IPDU communication error

Check code name

Judging device

Remote controller

Remote controller

Indoor

Indoor

I/F

I/F

Indoor / I/F

Remote controller

Indoor

I/F

I/F

I/F

Indoor

I/F

I/F

I/F

I/F

I/F

I/F

I/F

Main

remote

controller

display

E01

E02

E03

E04

E06

—

E08

E09

E10

E12

E15

E16

E18

E19

E20

E23

E25

E26

E28

E31

Terminology

Check code

Outdoor 7-segment display

Auxiliary code

——

——

——

——

No. of indoor units in which

E06

sensor has been normally

received

E07 —

E08 Duplicated indoor addresses

——

——

01: Indoor/Outdoor

E12

E15 —

E16

E19

E20

E23 —

E25 —

E26

E28 Detected outdoor unit number

E31 04: Fan IPDU error

communication

02: Communication between

outdoor units

00: Capacity over

~:No. of connected units

01

——

00: Header is nothing

02: Two or more header units

01: Outdoor of other line

connected

02: Indoor of other line

connected

No. of outdoor units which

received signal normally

01: IPDU1 error

02: IPDU2 error

03: IPDU1, 2 error

05: IPDU + Fan IPDU error

06: IPDU2 + Fan IPDU error

07: All IPDU error

AI-NET central

control display

—

—

97

04

04

—

96

99

CF

42

42

89

97, 99

96

42

15

15

15

d2

CF

19

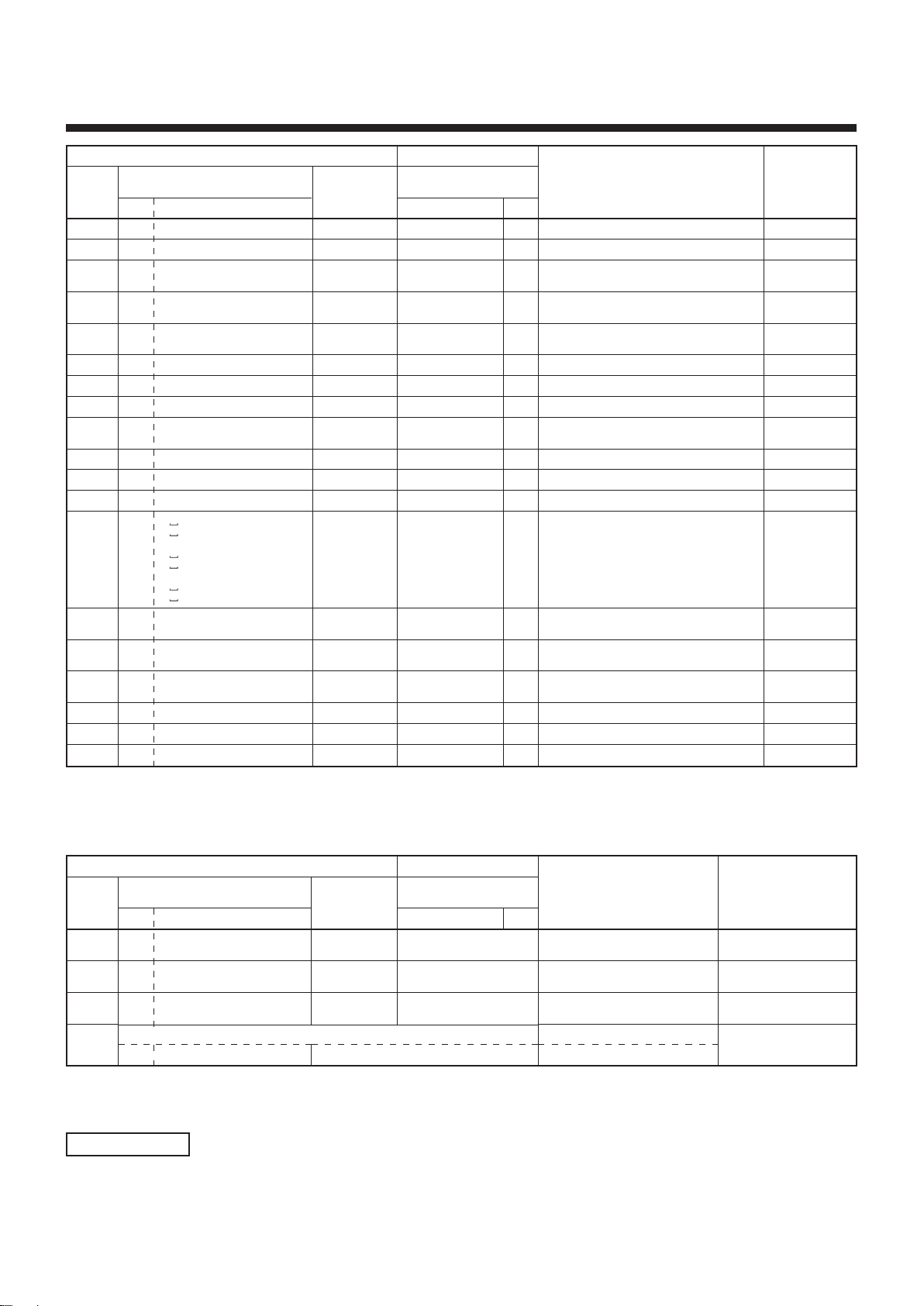

Page 23

Main

remote

controller

display

F01

F02

F03

F04

F05

F06

F07

F08

F10

F12

F13

F15

F16

F23

F24

F29

F31

H01

H02

H03

H04

H06

H07

H08

H14

H16

L03

L04

L05

L06

L07

L08

L09

L10

L20

L28

L29

L30

—

Check code

Outdoor 7-segment display

Auxiliary code

——

——

——

F04 —

F05 —

F06 —

F07 —

F08 —

——

F12 —

01: Comp. 1 side

F13

02: Comp. 2 side

F15 —

F16 —

F23 —

F24 —

——

F31 —

01: Comp. 1 side

H01

02: Comp. 2 side

01: Comp. 1 side

H02

02: Comp. 2 side

01: Comp. 1 side

H03

02: Comp. 2 side

H04 —

H06 —

H07 —

01: TK1 sensor error

02: TK2 sensor error

H08

03: TK3 sensor error

04: TK4 sensor error

H14 —

01: TK1 oil circuit system error

02: TK2 oil circuit system error

H16

03: TK3 oil circuit system error

04: TK4 oil circuit system error

——

L04 —

——

L06 No. of indoor units with priority

——

L08 —

——

L10 —

L20 —

L28 —

01: IPDU1 error

02: IPDU2 error

03: IPDU3 error

L29 04: Fan IPDU error

05: IPDU1 + Fan IPDU error

06: IPDU2 + Fan IPDU error

07: All IPDU error

L30 Detected indoor address

L31 —

AI-NET central

control display

0F

0d

93

19

A1

18

18

1b

OC

A2

43

18

43

43

43

12

1C

IF

1d

17

44

20

d7

d4

44

d7

96

96

96

96

99

99

46

88

98

46

CF

b6

—

Wireless remote controller

Sensor block display

of receiving unit

Operation

Timer Ready Flash

ALT

¤

¤

¤

¤

¤

¤

¤

¤

¤

z

{

z

z

z

z

z

{

{

{

{

{

z

ALT

z

ALT

z

ALT

{

ALT

{

ALT

{

ALT

{

ALT

{

ALT

z

ALT

{

ALT

{

ALT

{

ALT

{

ALT

{

ALT

{

SIM

z

SIM

{

z

z

z

z

z

z

z

z

z

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

SIM

¤

—

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

¤¤

z

z

z

z

z

z

z

z

z

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

¤

Check code name

Indoor TCJ sensor error

Indoor TC2 sensor error

Indoor TC1 sensor error

TD1 sensor error

TD2 sensor error

TE1 sensor error

TL sensor error

TO sensor error

Indoor TA sensor error

TS1 sensor error

TH sensor error

Outdoor temp. sensor miscabling (TE, TL)

Outdoor pressure sensor miscabling (Pd, Ps)

Ps sensor error

Pd sensor error

Indoor other error

Indoor EEPROM error

Compressor break down

Magnet switch error

Overcurrent relay operation

Compressor trouble (lock)

Current detect circuit system error

Comp 1 case thermo operation

Low pressure protective operation

Oil level down detective protection

Oil level detective temp sensor error

Comp 2 case thermo operation

Oil level detective circuit error

Magnet switch error

Overcurrent relay operation

Indoor center unit duplicated

Outdoor line address duplicated

Duplicated indoor units with priority

(Displayed in indoor unit with priority)

Duplicated indoor units with priority

(Displayed in unit other than indoor unit with

priority)

Group line in individual indoor unit

Indoor group/Address unset

Indoor capacity unset

Outdoor capacity unset

Duplicated central control addresses

Over No. of connected outdoor units

No. of IPDU error

Indoor outside interlock

Extended I/C error

Judging device

Indoor

Indoor

Indoor

I/F

I/F

I/F

I/F

I/F

Indoor

I/F

IPDU

I/F

I/F

I/F

I/F

Indoor

I/F

IPDU

MG-SW

Overcurrent relay

IPDU

IPDU

I/F

I/F

I/F

I/F

I/F

I/F

MG-SW

Overcurrent relay

Indoor

I/F

I/F

I/F

Indoor

Indoor, I/F

Indoor

I/F

AI-NET, Indoor

I/F

I/F

Indoor

I/F

20

Page 24

9

TROUBLESHOOTING

Main

remote

controller

display

P01

P03

P04

P05

P07

P10

P12

P13

P15

P17

P19

P20

P22

P26

P29

P31

—

—

—

Check code

Outdoor 7-segment display

Auxiliary code

——

P03 —

01: Comp. 1 side

P04

02: Comp. 2 side

01: Phase-missing detection

P05

02: Phase error

01: Comp. 1 side

P07

02: Comp. 2 side

P10 Detected indoor address

——

P13 —

01: TS condition

P15

02: TD condition

P17 —

P19 Detected outdoor unit number

P20 —

0 : IGBT short

: Fan motor position

1

detective circuit error

: Fan motor trouble

3

P22

P26

P29

P31 —

——

——

——

: TH sensor temp. error

C

(Heat sink overheat)

: TH sensor error

D

: Vdc output error

E

01: Comp. 1 side

02: Comp. 2 side

01: Comp. 1 side

02: Comp. 2 side

AI-NET central

control display

11

1E

21

AF

IC

Ob

11

47

AE

bb

O8

22

1A

14

16

47

b7

97

99

Wireless remote controller

Sensor block display

of receiving unit

Operation

Timer Ready Flash

z

¤¤

z

¤

z

¤

z

¤

z

¤

z

¤¤

z

¤¤

z

¤¤

z

¤

z

¤

z

¤

z

¤

z

¤

z

¤

z

¤

z

¤

By alarm device ALT

—

—

ALT

ALT

¤

ALT

¤

ALT

¤

ALT

¤

ALT

ALT

ALT

ALT

¤

ALT

¤

ALT

¤

ALT

¤

ALT

¤

ALT

¤

ALT

¤

ALT

¤

Check code name

Indoor fan motor error

Discharge temp. TD1 error

High-pressure SW system operation

Phase-missing detection /Phase error

Heat sink overheat error

Indoor overflow error

Indoor fan motor error

Outdoor liquid back detection error

Gas leak detection

Discharge temp. TD2 error

4-way valve inverse error

High-pressure protective operation

Outdoor fan IPDU error

G-TR short protection error

Comp position detective circuit system error

Other indoor unit error

(Group terminal unit error)

Error in indoor group

AI-NET communication system error

Duplicated network adaptors

Judging device

Indoor

I/F

IPDU

I/F

IPDU, I/F

Indoor

Indoor

I/F

I/F

I/F

I/F

I/F

IPDU

IPDU

IPDU

Indoor

AI-NET

AI-NET

AI-NET

Error detected by TCC-LINK central control device

Central

control

device

indication

C05

C06

C12

P30

Check code

Outdoor 7-segment display

Auxiliary code

——

——

——

Differs according to error contents of unit with occurrence of alarm

——

AI-NET central

control display

—

—

—

Wireless remote controller

Sensor block display

of receiving unit

Operation

Timer Ready Flash

(L20 is displayed.)

Terminology

TCC-LINK : TOSHIBA Carriea Cominication Link.

21

Check code name

—

—

—

Sending error in TCC-LINK central

control device

Receiving error in TCC-LINK central

control device

Batch alarm of general-purpose

equipment control interface

Group control branching unit error

Duplicated central control addresses

Judging device

TCC-LINK

TCC-LINK

General-purpose equipment

I/F

TCC-LINK

Page 25

New check code

AI-NET WORK bus

Indoor unit

AI-NET central control

remote controller

Main

remote controller

OC

F10

Network

adaptor

1. Difference between the new check code and the current system

The displaying method of the check code changes in this model and after.

Used characters

Characteristics of code classification

Block display

Check code in current system

Hexadecimal notation, 2 digits

Few classification of communication/incorrect setup system

Indoor P.C. board, Outdoor P.C. board, Cycle, Communication

Alphabet + Decimal notation, 2 digits

Many classification of communication/incorrect setup system

Communication/Incorrect setup (4 ways), Indoor protection,

Outdoor protection, Sensor, Compressor protection, etc.

New check code

<Display on wired remote controller>

•[ ] goes on.

• [UNIT No.] + Check code + Operation lamp (Green) flash

<Display on sensor part of wireless>

• Block display of combination of [ ] [ ] [ ]

<Display on indicater on wireless remote controller

receiver part>

• Unit No. and check code are displayed.

→

Display

A

C

E

F

H

J

L

Classification

Unused

Central control system error

Communication system error

Each sensor error (Failure)

Compressor protective system error

Unused

Setup error, Other errors

• In a case of error with auxiliary code, check code and

P

auxiliary code are displayed alternately.

Protective device operation

2. Special mention