Pentax ME 23900 Service Manual

PRODUCT No.23900

ASAHI PENTAX

SERVICE MANUAL ENGLISH

23900 ME

Disassembly Procedure

1. Self-timer charge lever assembly (0-A118)—Self-timer screw left-handed (A122)

— 231K-H50

2. Body Covering, left and right (A19, A20)

3. Install self-timer lever assembly (0-A118) temporarily.

4. Bottom cover assembly (A400) — CSS 1.7 x 2.8 x 3

Connector seat (A23), R button (C117)

5. Winding lever assembly (0-C69)

Cover screw (C139) — 23600K-C135-A (left handed)

Winding lever nut (C8) — 23600K-C134-A2

Cover ring (A321)

6. Shutter dial

Shutter dial at AUTO

Loosen set screw (A319) — Shutter dial (A316)

Release pin (A313) — Release button (A317)

7. Rewinding knob

R Rewinding knob assembly (0-D6) — Nut (D15) - Washer (D21)

- ASA dial assembly (0-D11-01)

23600k-D4-A2

8. Top cover assembly (A300) - 4 screws - cover frame (A131)

9. Unsolder 12 lead wires and one contact piece

Take out lead wires from cord holder

Lead wire No. 21 (K100), No. 24 (T100), No. 22 and No. 23 (T100),

No. 19 and No. 20 (N4), No. 15, No. 16, No. 17, No. 18 and one

Contact piece (A129), No. 26 and No. 27 (0-A21).

10. ASA volume assembly (R100) - Top cover screw (A16) - CNL-d 1.7 x 2.5

11. Hot shoe contact piece (N4)

12. P.C. board retainer (I1) - W14

13. P.C. board retainer plate (N5) - T-CNS 1.7 x 5

14. LED retainer screw - CNL-D 1.4 x 2 - W31

15. P.C. board assembly (T100)

16. Front board and mirror housing

Cocking the shutter

Removing 5 screws - W14

Shutter light seal cover (A8)

17. Bulb actuator plate (A504) - CNL-D 1.4 x 2

18. Cocked indicator assembly (0-C23)

SW actuator lever shaft (C49)

23900 Page 1 of 15

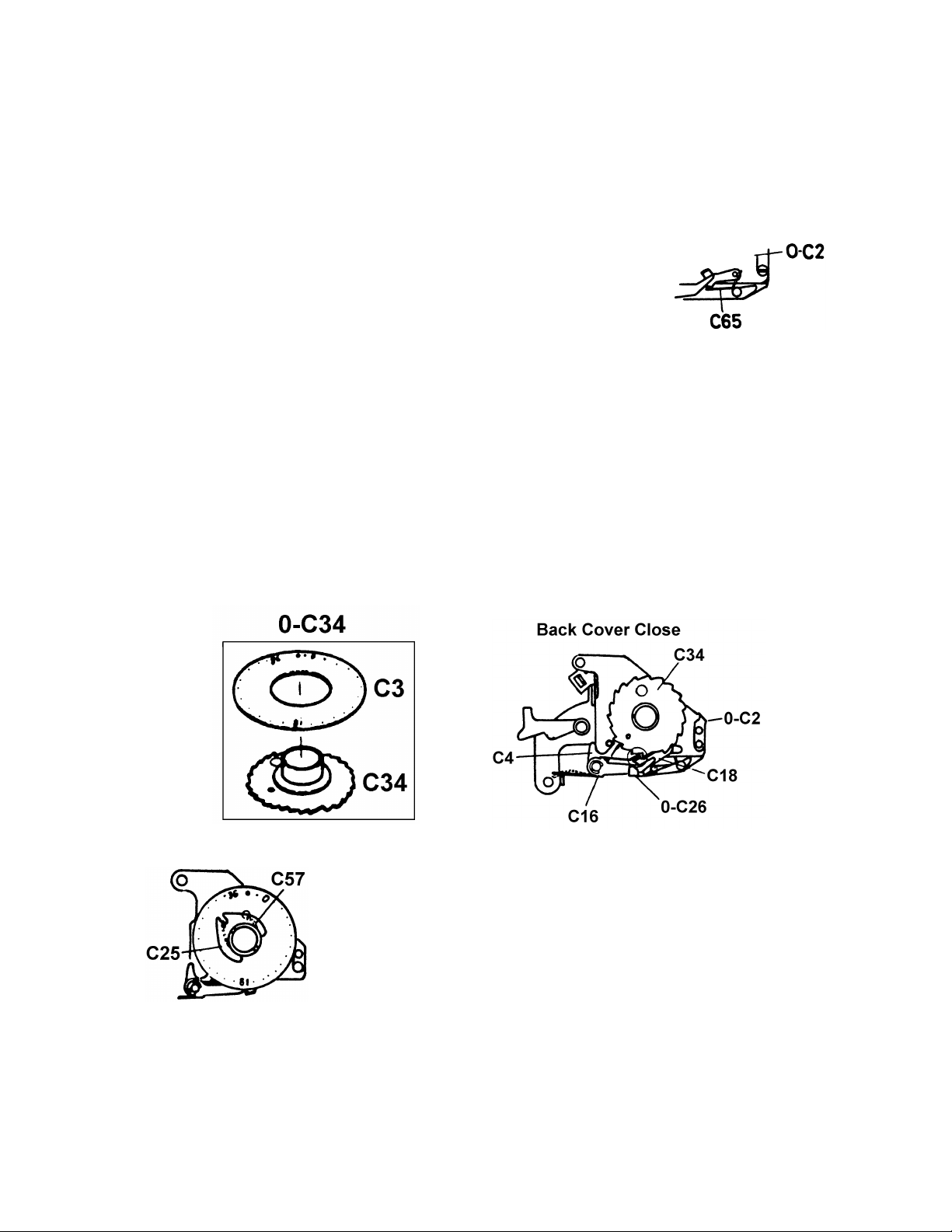

19. Counter dial Back cover open

Counter dial spring (C57) - Counter retainer plate (C25),

Counter dial assembly (0-C34)

Come off transporting claw spring (C65)

Remove (C146) (C53) and CNS 1.7 x 3

Winding seat assembly (0-C2) - (0-C5) - (C7)

20. Shutter block (S000) - CNL-D 1.7 x 3 x 3

21. Bottom release assembly (0-C147)

Winding up little from bottom part with tool (23900K-C207-A)

To remove retainer screws of (0-C147).

22. Release plate assembly (A500)

Guide screw (A507) - Release plate restitution spring (A510).

When removing (A500), detach hook lever (C108) from (A500)

23. Shutter charge lever assembly (0-C129)

Loosening joint (C207) with tool (23900K-C207-A), remove (0-C129)

and (C144).

Fasten joint (C207) again.

24. Winding guide plate assembly (0-C102)

25. R lever assembly (0-C105)

LW-13 - (0-C105) - (C126)

(C145) - LW13 - (C144) - (C107) - (C130) - W14 - (C108) - W8 - (C125)

(C207) - (0-C106) - (0-C12).

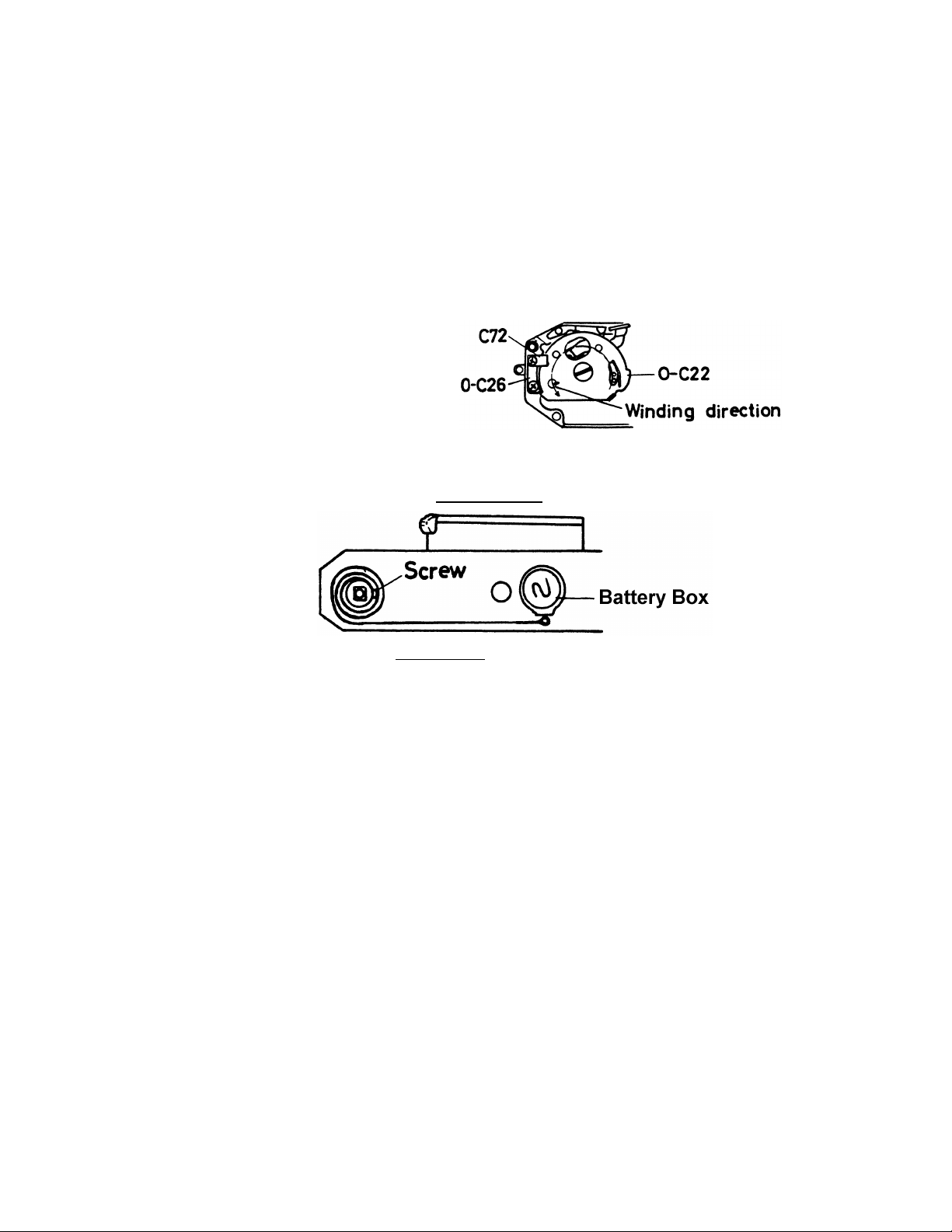

26. Back cover assembly (0-C26)

27. Winding stopper assembly (0-C26)

28. Winding shaft assembly (0-C22) - Main gear (C30)

29. Sprocket shaft pin (C40) - Loosening set T 1.7 x 1.6

30. Top mec. Plate assembly (0-C1) - (C146) x 2 - CSS 1.7 x 3

31. Spool cam assembly (0-C202) and spool assembly (0-C204)

- W17 (t=0.2mm)

23900 Page 2 of 15

Assembly Procedure

1. Spool assembly (0-C204) and spool cam assembly (0-C202)

W17 (t=0.2mm)

2. Top mec. Plate assembly (0-C1)

Pulling back transport indicator

3. Sprocket shaft pin (C40)

Apply screw lock on Set T 1.7 x 1.6

4. Winding shaft assembly (0-C22) - Main gear (C30)

5. Winding stopper assembly (0-C26)

6. Winding spring assembly (0-C12)

Proper tension of the spring is shown in figure.

After installing (0-C12), install (0-C106) and (C207) temporarily.

- 23900K-C207-A

7. Perforation adjustment - Tool 23102-C57-A

Same adjustment with K2 camera.

Choosing proper 2nd gear (C31).

8. Bottom mechanism

a) (C125) - W8 (t=0.1) - Winding hook lever (C108) - W14 (t=0.05, 0.1) -

(C130) - Winding lever ratchet (C107) - LW13 - (C145)

b) (C126) - R lever assembly (0-C105) - LW13

c) Winding guide plate assembly (0-C102) - (C146) - CSS 1.7 x 2.5 - CNS 1.7 x 3

d) Shutter charge lever assembly (0-C129)

Loosening (C207) - (C144) - (0-C129) - fastening (C207)

When fastening (C207), winding shaft should be in the wound position, at

the same time, mirror charge lever (0-C102) should be moved to a correct

position

9. Shutter release plate

Release plate restitution spring (A510)

(Take care to install spring in correct direction)

Release plate assembly (A5000

(Take care not to bend winding hook lever (C108).)

Guide screw (A507), connection spring (A511)

(Engaging (A510) to (A500).)

10. Bottom release assembly (0-C147) - CNM 1.7 x 2.2, CNM 1.7 x 2.8

Winding shutter a little

23900 Page 3 of 15

11. Shutter block (E000) - CNL-D 1.7 x 3 x3

Light seal plate (A8)

12. Bulb actuator plate (A504) Temporary installation

- CNL-D 1.4 x 2

13. Back cover assembly (A200)

14. Winding seat assembly (0-C2) - (C53), (C146), CNS 1.7 x 3

Install (0-C2) with back cover open

Winding lever click cam assembly (0-C5)

Winding lever friction spring (C7)

Engage transporting claw spring (C65)

15. Counter transporting adjustment

a) Check the function of counter dial stopper lever (C4) and transporting

claw assembly (C18).

b) If the vertical black lever of (0-C26) is bent forward, bend it straight.

c) Adjust the counter transporting function using the temporary counter

transporting gear (C34).

When back cover is closed, receiving claw (C16) and transporting claw (C18)

should be engaged to the first tooth of (C34) simultaneously with enough

gearing portion. Bend the tip of the claw which couples with the gear (C34),

If not enough gearing portion.

When back cover is opened, claw tip of (C16) must detach from the gear (C34)

with a clearance of about 0.5mm.

If there is not enough clearance, bend the other end of (C16) opposite from

the claw as shown in the figure.

16. Counter dial

Counter dial assembly (0-C34)

Counter dial spring (C57)

Counter retainer plate (C25)

(C25) is installed in left side gutter as shown in figure.

Give the spring (C57) 1/2 or 3/4 turns of tension.

17. Bulb off adjustment (Winding lever is at pre-advance position.)

After releasing the first curtain, adjust "B" off position with eccentric

screw riveted on bulb actuator plate (A504). When shutter rod comes back,

0.2mm clearance is necessary after releasing the 2nd curtain.

23900 Page 4 of 15

18. Cocked shutter assembly (0-C23) - SW actuator lever shaft.

19. Main SW adjustment = (I200)

When shutter actuator plate is held in "ON" position, 0.2mm clearance is

necessary between longer contact piece of main SW and insulation blue

collar.

To adjust the clearance, bend the shorter contact piece.

When both contact pieces touch each other, and the shorter contact piece

is pulled down, the longer one should be down also as the shorter one does.

If there is not enough tension on the longer contact piece, it may show

uneven shutter speed.

When winding lever is at closed position, 0.2mm clearance is necessary

between both contact pieces.

20. Front board and mirror housing

When the above mentioned parts are installed, shutter block (E000) should

be cocked but not charge mirror housing.

Put on W14 (0.1mm) underneath front board and fasten it with (A132),

pushing down left. Confirm the function of self-timer, shutter mechanism

and mechanical back.

21. Parallax adjustment

22. P.C. board pattern assembly (T100)

(I1) - CNL-D 1.7 x 2.5 - (N5) - T-CNS 1.7 x 5 - (N4) - (N6 x 2)

23. ASA volume assembly (R100) - (A16) - CNL-D 1.7 x 2.5

24. Soldering 13 lead wires

25. Bottom cover assembly (A400) - (A23) - (C117)

26. LED positioning adjustment

27. Temporary top cover and installing ASA dial assembly (0-D11-01) and winding

lever temporarily.

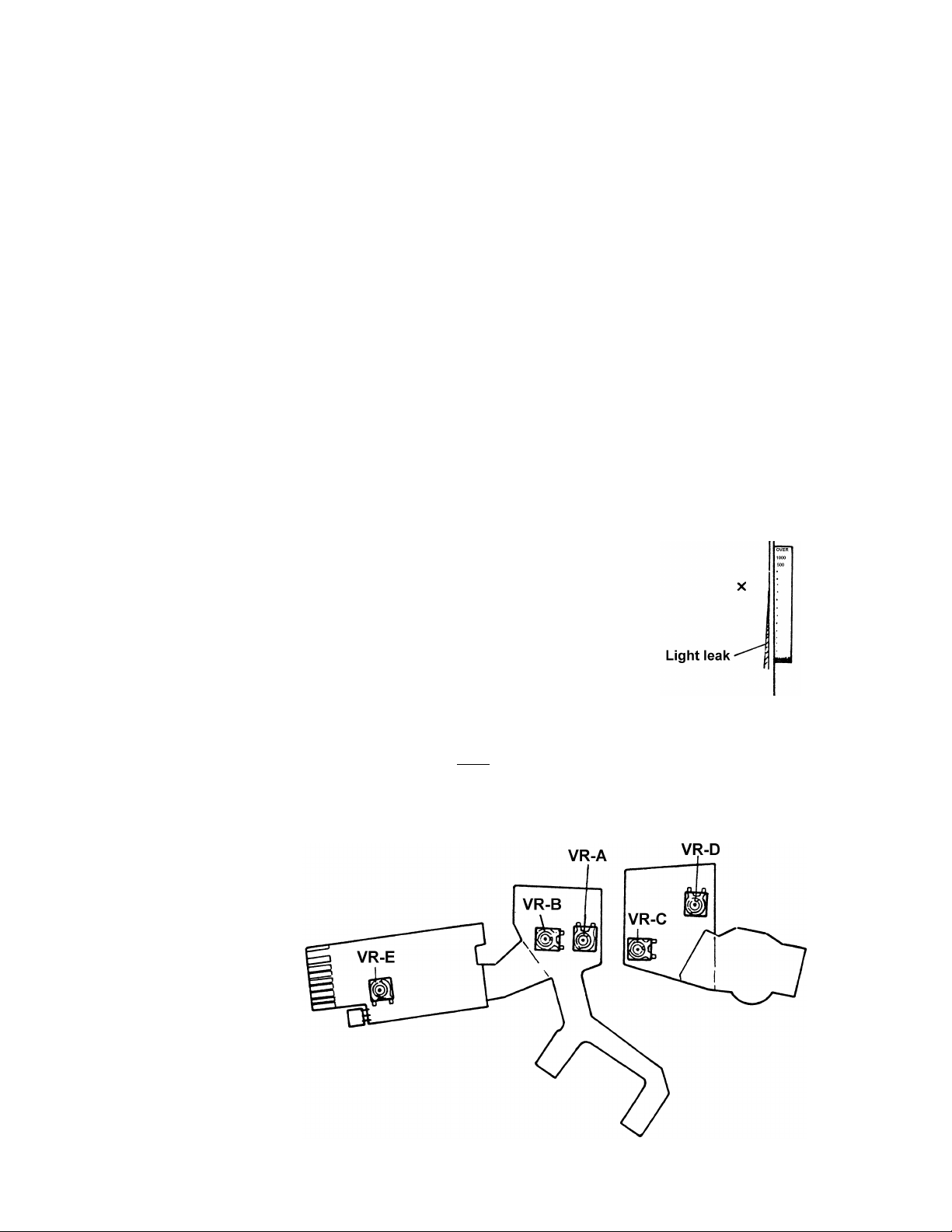

28. a) Shutter speed adjustment - VR-A

ASA 100, X1, f8, (KA-00-1A), 2.8V

EV12 - 1/60

EV16 - 1/1000

EV8 - 1/4

23900 Page 5 of 15

Loading...

Loading...