Page 1

Page 2

ASAHI PENTAX KX

Product No.

KX

camera is fundamentally based upon SP type camera except

23700

Mirror housing and other exterior parts, therefore assembly and

disassembly procedures or some of the adjustments which are

included in SP type camera are not mentioned here.

In this manual, exclusive adjustments for KX are mentioned.

Items

A.

Preface

B.

f-stop indicator adjustment

C.

Blue needle adjustment

D. Main SW adjustment

E.

Light metering adjustment

F.

Galvanometer installation

KX~~)J~~~~$A~JIISP%FIJ~/~I-

BTLXTL>Q.

fia~a~1.i

BM,

&Cljtvflf;*?

%2$:h

C?-=ZL

b>TJ!!L-T&5ho

ID

L

:

?-A

,?

XI~V.

K

X$%~~,@I$$'#-,

S

P%"rl]h A 71-

6~1iZldLT2~1.

7

/b?iL

K

X$ifeC&j$F1:r,

TL

6.

A.

Preface

0

Lubricant

(G

21) is applied thinly on the mount surface of KX

and KM to prevent it from being scratched by a lens, when it

is mounted or dismounted.

Material of the mount for

KX

and

KM

is brass and that for

is stainless.

And mount ring of all interchangeable lenses are brass materials

except f 1.2/50mm lens of stainless mount.

Therefore, it

is

not allowed

to

wipe off the lubricant

(G

from the mount surface of camera.

0

Fleon

TF

(Dupont made or Mitsui chemical) is used for cleaning

exterior parts especially platstic materials.

If ether or alcohol is used on plastic materials, the plastic will

change

0

Do not push aperture-reader window from outside, because it

color.

falls into camera inside.

K2

21)

Page 3

B.

f-stop indicator adjustment

1.

Optics

B.

1.

ygl~

&,~;tfig

%y.%

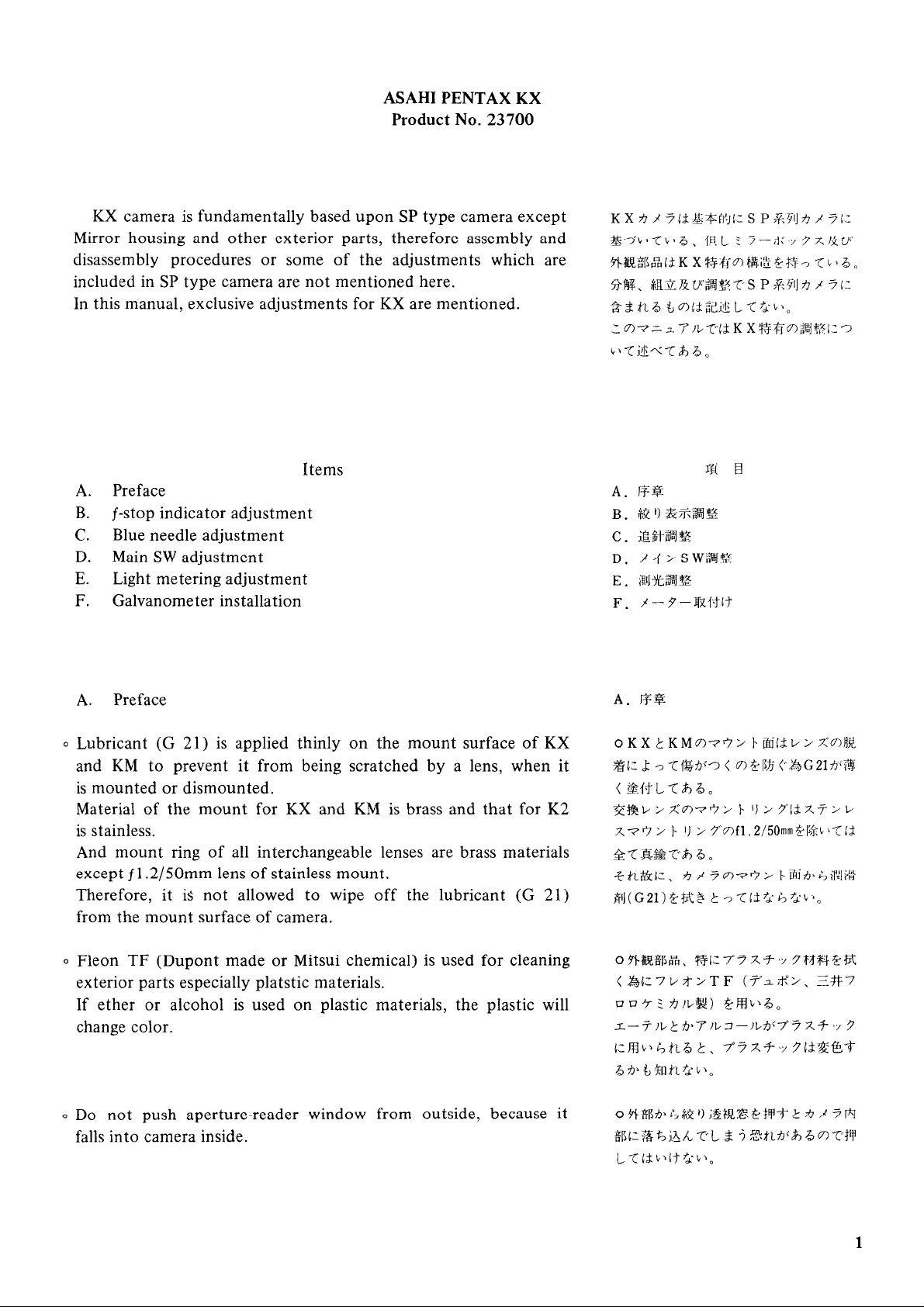

Optical ray reflects rather complicatedly as shown in Figure

therefore adjustment is very severe and critical.

k

Diaphragm

scale

ring

X

a:

b:

c:

X

X

X

=

63mm

=

62.5mrn-

=

64mm

1,

-t

-,

*#$lLFig.

1

mku

<

~:Fg#iz

$jw~i#-$~:.i%tll~:~h

XiM

Y

-8mm

Y

-8.5rnm

Y

-7mm

Fig.

I

i

Q

Ji~jjT

6

X3.

c:

X=

64mm

1.8185

(Not available lenses for f-stop indicator system)

6.71 135 - 600, 5.61400, 4.5/500, 8/ 1000

2.

Adjustment procedures

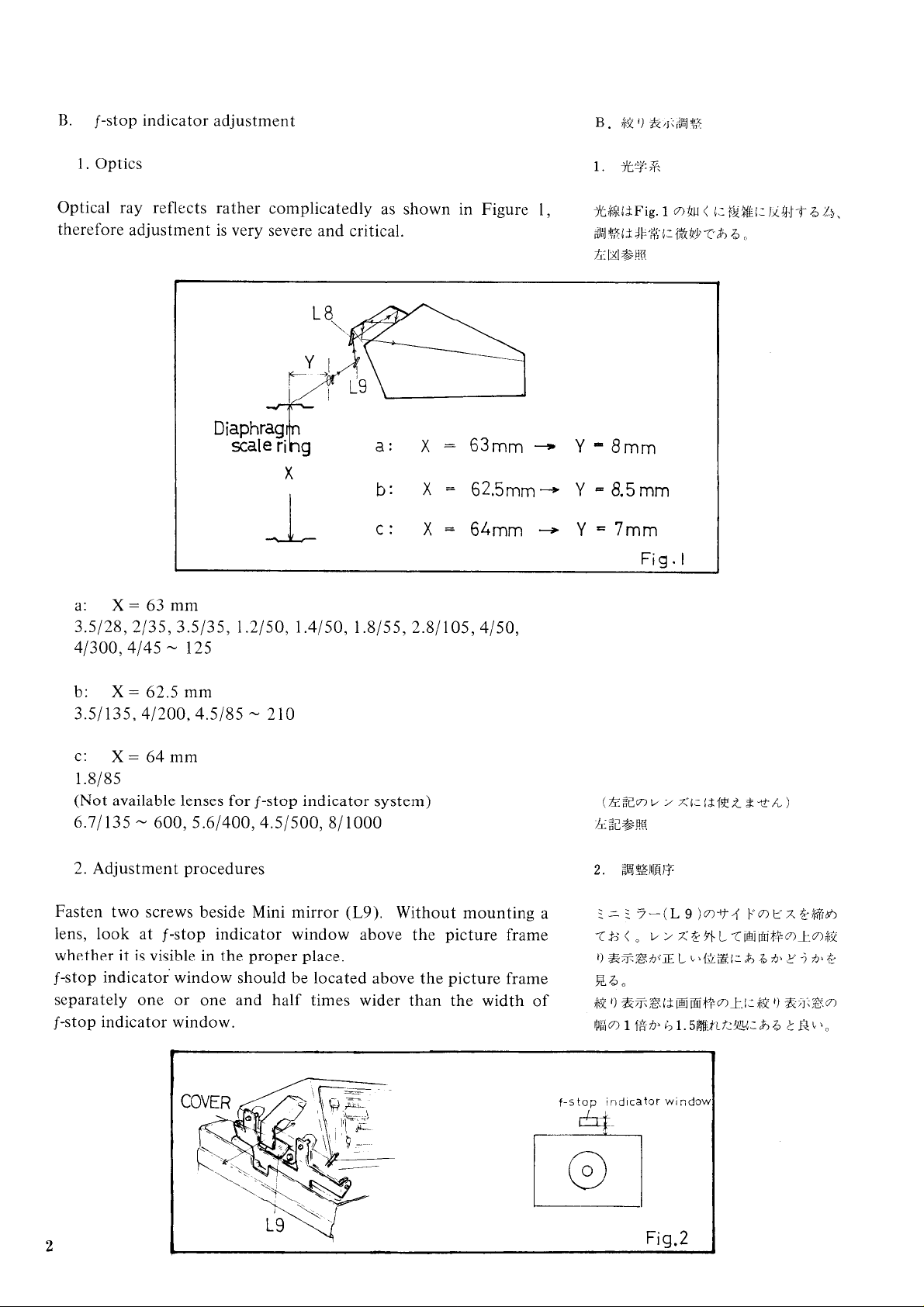

Fasten two screws beside Mini mirror

(L9).

Without mounting a

lens, look at f-stop indicator window above the picture frame

whether it is visible in the proper place.

f-stop indicator window should be located above the picture frame

separately one or one and half times wider than the width of

f-stop indicator window.

t

f-s

top

ind~cator window

+

Fig.2

Page 4

Adjust mini-mirror

(L8)

position bending the cover of it with

finger or tweezers so that f-stop indicator window might come

in the correct position.

(Caution:

Every corners of picture frame must be visible during

this adjustment.)

After attaching the lens (standard lens etc.), each f-stop should

be clearly visible in the center part of f-stop indicator window.

If each f-stop is not visible clearly in the center portion, for

instance visible in upper or down part, adjust Mini mirror

(L9)

position loosening two screws evenly beside of it and pulling

it with tweezers so that f-stop might come just in the center.

And if f-stop deviates either left or right from the center portion,

loosen or fasten one of the two screws.

$29

&7k~h~~xLL~i2El:*Q@iz

:

3-(L

TFmLBCfT%Et

(

Z~~%H~B~C~@~~#C?Z?--

-zEk-c~.a#ETQIjfiim

v>z*

i&h*@') $;%%C~1&3

If2

;t

L&f ii&h'P~i\l~JL,t2~~~+, VlJ,tiB

km3t

7-(L

LTIB,BM>T Y7t.r

LT~

&f

3-(L

KB, @KBh.T8%$QQ

B)O,*.~--+)$-?Y>+.~

6.

(t$@v>x%)

r;

2Lro

&~Tm%l:JLkTQP~l&

9

)my4 pa2

+9i-j-T,

3

'1

t

&O,k+2+4i$

/.

TSIc,l.fB@i:

i~~~+~~.t:~a~c:nn+~.

i~h~&h~$ii:~3TL~~~I&:

9

)my4

pu)rxmi

f

=

/.

j-7524

r,

QL>)~

&f

Hri2C+h

:

=

f

=

5

C.

Blue needle adjustment

Trun two eccentric rivets @ and O to make them face the large

chamfering toward the direction of Galvanometer

a. Set shutter dial at "B", and turn the eccentric rivet

(J

100).

@

so that

blue needle might indicate "B" in the viewfinder.

b. Set shutter dial at'

"

1

OOO", and turn the eccentric rivet @ so

that blue needle might indicate " 1000" in the viewfinder.

C. ;g$t~~

2 $ni~,~\y

r

-

9-(

a.

>-r~ 5'-9"4711.%Bl:+.:,b

ziz

b.$fi3*7

@O,%.L\P"iK

b.

>-~~YP-P~~IL%'~ooo"~:~~I

1

LTWL+~~*~

++~~&@o,IG~L~~"~K%

snk3

5

100)n%)il:TiilIfTQ6~

7

4

+

~.3mmr[x

>9"-mT"B"gg$&

H.t.

7

4

>

~-~T"~OOO~

B$.

9

3%

LT

Page 5

c. Turn shutter dial from "1000" to

needle must indicate each shutter speed correctly.

If

it doesn't, readjust the eccentric rivets @ at

"1

000".

Eccentric rivet

For adjusting blue needle

indication at

@

;

"B"

critically.

"B"

or vise versa, blue

"B"

and O at

c

.

>T

,r

9-T4

"~"~ikinig1:.

h'&x~-

k~lf

5

L);L~~~?~~atj~c~i$j?z$

?lhbt)h~i;~79

{,~,L~T~K

ZIZ

~x$tm"B "~0)gir;${$!&j?+j-6~

FS~J;$XL

2

l;

2

L>,

1

7/~$"1000"LJ.i,"

B~L~:II+,

(

?j-'j-~~$f.

+ELTL>CI?

&

j

1

12

Eccentric rivet

For adjusting movable range of blue needle.

@

;

M:?:b

-

P

Fig,

D.

Main SW adjustment

When wind lever is set at closed position, there should be

0.3 - 0.5

SW lever

If there is no proper clearance, turn the eccentric rivet

obtainning proper clearance.

@

mm

clearance between eccentric rivet

.

@

and main

@

for

6

D.

%.r;SW$jg

-&LI?~/~-$~I#IAA%~~

,i.~s@)tr

+f-710.3-00:5 mmC:W%?$B.

;ELL~Z+T~~~&$~I:~~!G,L\~'~@

@Hk-bB,

$4

2

s

~f:&$1:

w

k~q-@mgdo

>

(~6

z

Page 6

When release lever

@

must ride on the eccentric rivet

0

is depressed half way, main

contact wires of main SW must be turned

E.

Light metering adjustment

SW

@

without fail, and two

"on".

lever

Testers:

Light value correction unit

f8

set ring.

Condition: ASA 100

F.

Galvanometer installallation

2.8V

(Light metering)

2.2V

(Batt. ch.)

T

adjuster (Power source)

F.

3-9-Rxi+

When galvanometer is installed, black

needle must be completely horizontal

at

30

with using Meter tester.

(MA-00-0

1

).

/--9-??Xxrl

i+if

as$tkn~.~

$tik"30"~&~

22

tiqq~t:

&%l:BE-4-ao

3

-

9

f

29-

-00-01)

Q

--RX.r+lf

(MA

I%H,

Page 7

ASAHI PENTAX

Product

ASAHI PENTAX KM is based upon ASAHI PENTAX SPF

(23

1

10).

Therefore, the different points from SPF are mentioned here in

itemized statement.

1.

BATTERY

SPF

KM

2.

KM is not equipped with stop-down metering device but

possible for stop-down metering.

3.

Galvanometer

Movable range of the needle for KM is wider than that for SPF.

Therefore galvanometer of

that of SPF.

1.345V

1.5V

(J

100)

(Mercury battery)

(Silver oxide battery)

KM

is not interchangcable with

No.

KM

23701

Loading...

Loading...