TM

ENGLISH

PRODUCT No. 76180

PENTAX Corporation

Service Planning Section

03:04 H.Y.

[TABLE OF CONTENTS]

PREPARATION ............................................................................................................................... 2

Preparation of Digital Adjustment.............................................................................................. 2

DISASSEMBLY AND ASSEMBLY................................................................................................. 3

Outline of Disassembly and Assembly........................................................................................ 3

1. Caution ................................................................................................................................. 3

2. Chart for Assemble, Adjustment and Confirmation........................................................... 3

DISASSEMBLY AND ASSEMBLY PROCEDURES .................................................................. 6

I. Disassembly procedure of main body ...................................................................................... 6

II. Assembly procedures of Front Housing Block..................................................................... 15

Ⅲ Assembly procedure of main body ....................................................................................... 26

FW FIRMWAR............................................................................................................................... 56

1. Checking Firmware Version.................................................................................................. 56

2. Updating Firmware Version (1) ............................................................................................ 56

3. Updating Firmware Version (2) ............................................................................................ 57

TECHNICAL INFORMATION ..................................................................................................... 58

Battery consumption current .................................................................................................... 58

Block diagram ............................................................................................................................ 59

Circuit diagram.......................................................................................................................... 60

Table of Error Code (Digital adjustment) ................................................................................. 61

AE Program line and APEX chart ............................................................................................ 62

76180 PROGRAM SOFTWARE FLOW CHART ...................................................................... 63

INFORMATION FOR PREPATION............................................................................................. 70

Table of Jigs, Tools and Testers for *istD.................................................................................. 70

Method for marking power adapter .......................................................................................... 72

Method for making temporally bottom cover ........................................................................... 72

AF confirmation chart and scale............................................................................................... 73

76180 EM -1/73-

PREPARATION

The following preparations are required before disassembling and assembling the camera.

1. Prepare the Jigs, tools and testers. (Refer to the Table of Jigs, tools and testers.)

2. Make the preparation for the digital adjustment. (Refer to the Preparation of digital adj.)

Preparation of Digital Adjustment

[Required equipment]

Programmed software 76180 (for Digital adjustment, contained 95901 P401-00B)

Computer (for Digital adjustment)

CF card 6 pieces (8MB or above)

CF card reader

1. Preparation for the adjustment and confirmation of CF cards (6pcs.)

1) Product FW (Firmware) of *istD (2 pieces): use for service and updating FW

2) Switch function checking

3) Default setting

4) FW version check [ON]: use for service

5) FW version check [OFF]: use for service

2. Installing procedure of the Adjustment Software (Setting of the Computer)

① Turn on the test computer.

② Place the Programmed software of 76180 (95901 P401-00B) into the CD-ROM drive.

③ Copy the [76180] folder from the Programmed software contained in the CD-ROM to [C:

drive] as shown in the picture below.

④ Copy the file from each folder (01~04) of [ModeSET] to each CF card.

[CAUTION] Since the name of all files is same, you should distinguish them by name label etc.

⑤ Copy the file from [GM_FW] to two CF cards (for FW).

[CAUTION] You should use latest firmware whenever creating the CF cards for updating.

⑤ Rename one of two CF cards which were created for updating firmware from [kb321b.bin]

◆ The CF card named [kb321b.bin] should be used for repairing the camera.

◆ The CF card named [fwdc112b.bin] should be used for updating FW of customer’s camera.

to [fwdc112b.bin].

76180 EM -2/73-

DISASSEMBLY AND ASSEMBLY

Outline of Disassembly and Assembly

1. Caution

1) Be sure to use the conductive mat and wrist strap to prevent static failure of circuits.

2) Do not stress to the connector terminals and flexible boards because they are very delicate

parts. And, we recommend marking to the flexible board before disconnecting them. This will

be helpful to reconnect the flexible board to the connector terminal properly.

2. Chart for Assemble, Adjustment and Confirmation

I. Disassembly procedure of main body ...................................................................................... 6

II. Assembly procedures of Front Housing Block..................................................................... 15

1. Front Housing Block....................................................................................................... 15

2. 0-B52・B62 ....................................................................................................................... 15

3. 0-M22............................................................................................................................... 15

4. 0-G100 ............................................................................................................................. 16

5. [CONF] Checking the Mirror Function ......................................................................... 17

6. A104................................................................................................................................. 18

7. [ADJ] Positioning 1st and 2

8. 0-J201・A163.................................................................................................................. 19

9. 0-L3・L2.......................................................................................................................... 19

10. M301.............................................................................................................................. 20

11. [ADJ] Viewfinder Focus・Parallax .............................................................................. 20

11-1. Parallax...................................................................................................................... 20

11-2. Viewfinder Focus ....................................................................................................... 20

12. 0-J100 ............................................................................................................................ 21

13. M51................................................................................................................................ 21

14. [ADJ] Positioning 0-O170 (SI-LED) ................................................................................ 21

15. 0-O100 ........................................................................................................................... 22

16. 0-M100........................................................................................................................... 22

17. 0-S300............................................................................................................................ 22

18. [ADJ/CONF] AF Joint stroke....................................................................................... 23

19. 0-T100 (1) ...................................................................................................................... 23

20. [ADJ] Viewfinder Indications....................................................................................... 23

20-1. Preparation ................................................................................................................ 23

20-2. Adjustment................................................................................................................. 24

21. 0-T100 (2) ...................................................................................................................... 24

Ⅲ Assembly procedure of main body ....................................................................................... 26

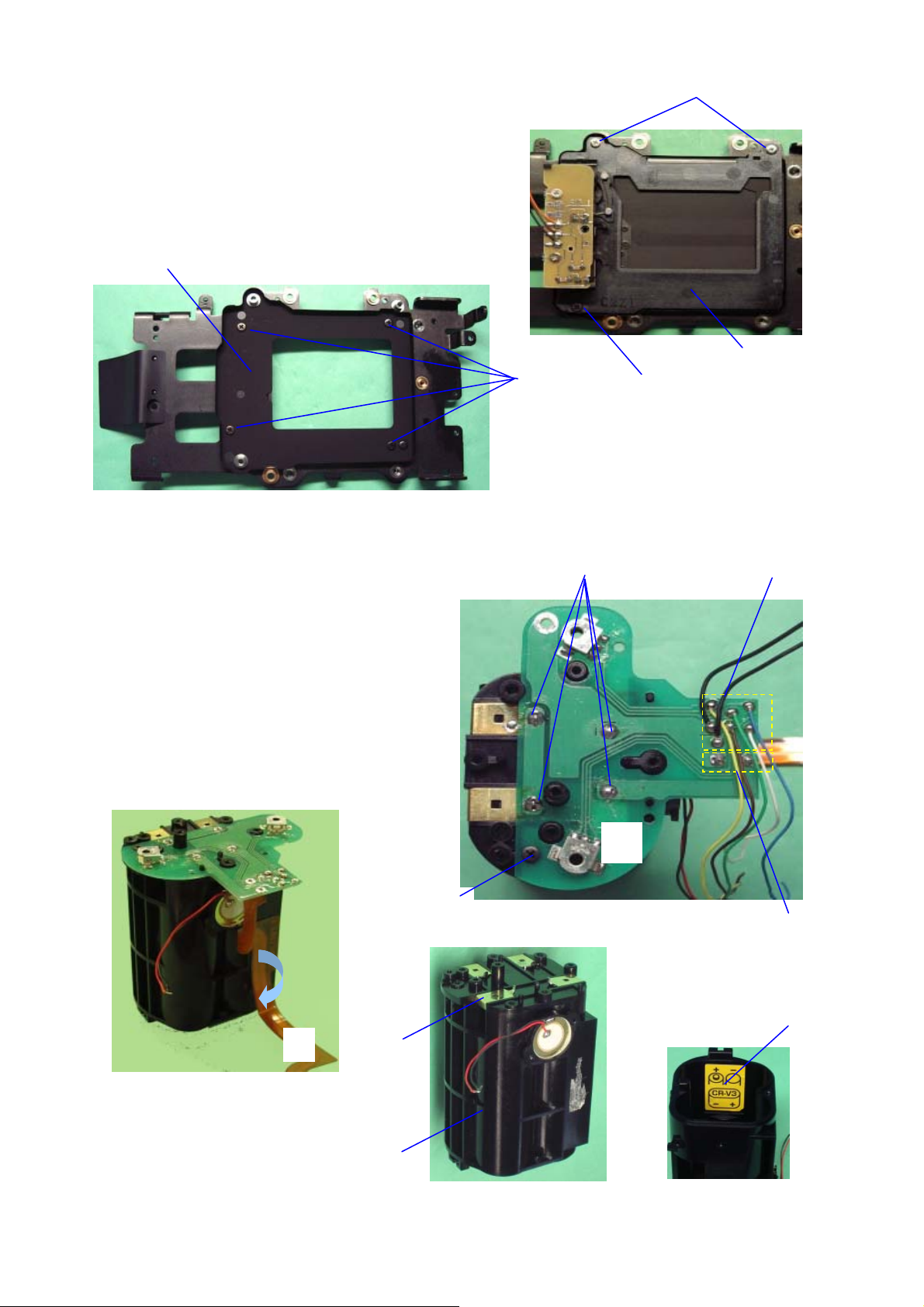

1. Battery Chamber and Related Parts ............................................................................. 26

2. 0-E000 (Shutter Block)................................................................................................... 26

3. Front Housing Block....................................................................................................... 27

4.T903 (Tv/Av dial) .............................................................................................................27

5. 0-A3 (Bottom Plate assy.) ............................................................................................... 28

nd

Mirror.............................................................................. 18

76180 EM -3/73-

6. Around Pentaprism (2)................................................................................................... 28

7. 0-Q200・0-T800 (Flash P.C. Board assy.・Power P.C. Board assy.) ............................ 29

8. A49 (Remote Control Base Plate)................................................................................... 30

9. A5 (Right Shoulder Plate) .............................................................................................. 30

10. Around Pentaprism (1)................................................................................................. 31

11. [CONF] Function Check Ⅰ.......................................................................................... 31

11-1. Preparation (The following preparation is required checking the function.)......... 31

11-2. Function Check.......................................................................................................... 32

11-3. Exposure・Release .................................................................................................... 32

11-4. Mode dial.................................................................................................................... 32

11-5. AF ............................................................................................................................... 33

12. [ADJ.] Shutter Speed (1/4000sec.) ............................................................................... 33

12-1. Preparation for the shutter adjustment................................................................... 33

12-2. Adjustment................................................................................................................. 34

13. [CONF] CCD Base Plate Support Pillar...................................................................... 34

14. 0-T600 (CCD Block) ...................................................................................................... 34

15. 0-T700 (CF P.C. Board assy.)........................................................................................ 35

16. [CONF] Function Check II........................................................................................... 36

16-1. Battery・DC Power Input, Connection between 0-T100 and 0-T600..................... 36

16-2. Writing FW ................................................................................................................37

17. A102 (Front Cover) ....................................................................................................... 37

18. A153 (Front Cover, Left)............................................................................................... 38

19. A201 (Back Cover) ........................................................................................................ 38

20. [ADJ] Positioning 0-J100 ............................................................................................. 39

21. 0-A301 (Top cover) ........................................................................................................ 39

22. [CONF] Function check Ⅲ .......................................................................................... 40

22-1. Preparation ................................................................................................................ 40

22-2 [CONF] Static Current............................................................................................... 41

22-3 [CONF] Preview・LCD panel illumination .............................................................. 41

22-4 [CONF] Switch Function............................................................................................ 41

22-5. [CONF] AF・SI (Superimpose) Function................................................................. 42

22-6. [CONF] Shooting・Playback Function .................................................................... 42

22-7. [CONF] Flash Function............................................................................................. 42

22-8. [CONF] Aperture Control・CCD.............................................................................. 42

22-9. [CONF] CF card cover SW ........................................................................................ 43

23. [ADJ] Adjustment with Programmed Software (SLR operation)............................... 43

24. [ADJ.] Adjustment with programmed Software (Digital operation).......................... 44

24-1. Installing Adjustment Software................................................................................ 44

24-2. Setting of *istD ..........................................................................................................44

24-3. Procedure of adjustment ........................................................................................... 45

24-4. Procedure of WDC adjustment. ................................................................................ 45

25. Arranging the lead wires for CE marking................................................................... 48

26. A401 (Bottom Cover)..................................................................................................... 48

27. [CONF] Checking the back-up function ...................................................................... 48

76180 EM -4/73-

28. [CONF] Final function check ....................................................................................... 49

28-1. Confirmation of the Metering function ................................................................... 49

28-2. Confirmation of the Exposure value (for reference) ................................................ 49

28-3. Confirmation of White Balance ................................................................................ 49

28-4. Confirmation of the Battery Exhaustion Warning .................................................. 51

28-5. Confirmation of AF Focus Position by FI (Focus Indicator).................................... 51

28-7. Cleaning the CCD...................................................................................................... 53

28-8. Default setting...........................................................................................................55

76180 EM -5/73-

DISASSEMBLY AND ASSEMBLY PROCEDURES

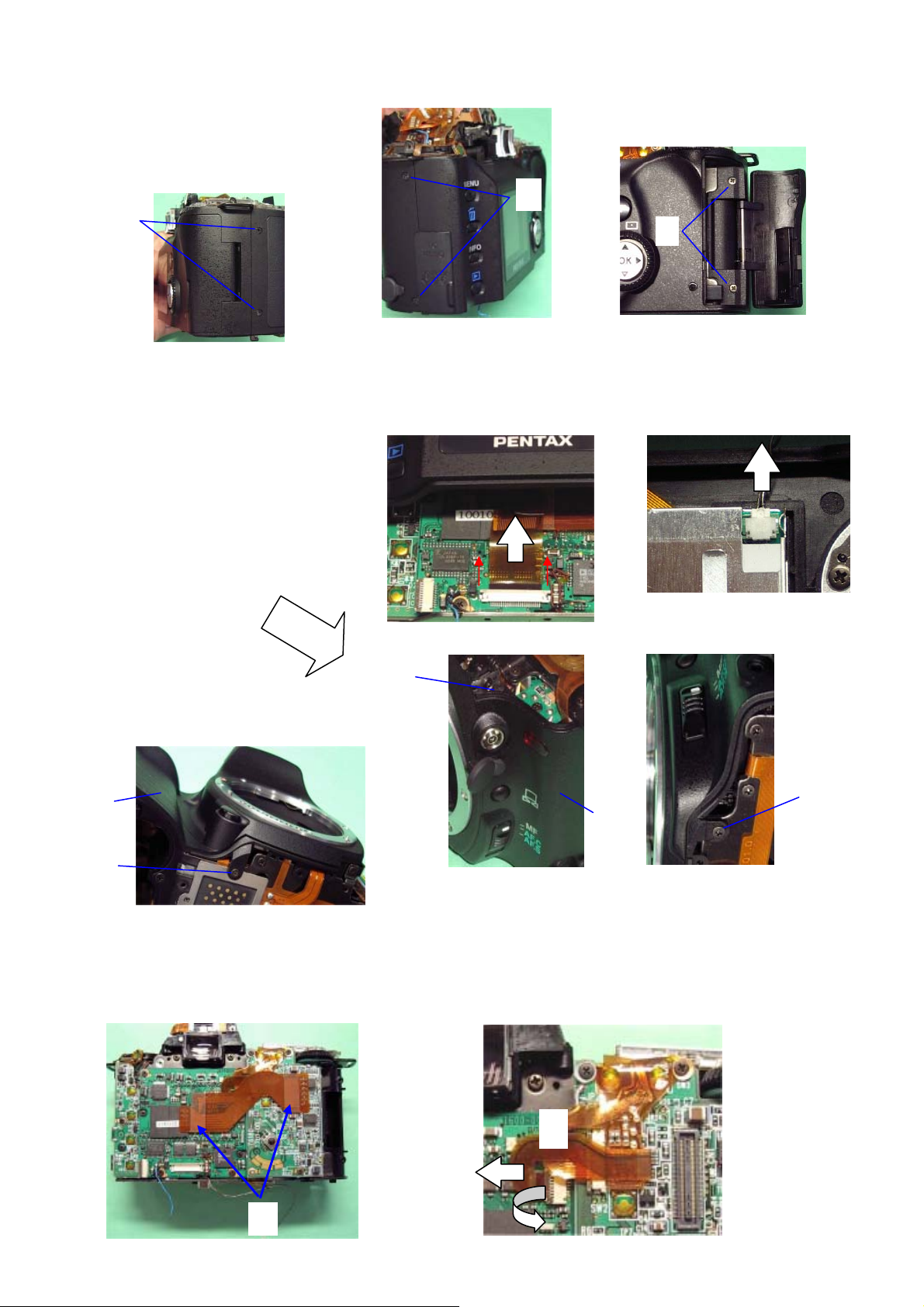

I. Disassembly procedure of main body

[Preparation] Remove the Hot shoe cover FK, Eye cap FL and Battery from the main body.

1. A401 (Bottom Cover)

① A431・・・Remove the cover by using a coin.

② A61 (Screw, 2mm)

③ A67 x6 (Screw)・・・Do not remove the bottom cover yet.

④ Open the battery cover, and then lift up A401 from rear side as shown in the figure below.

⑤ 0-A412, A419 (Battery cover shaft)

⑥ Unsolder a blue wire, and then remove A401 from the main body.

⑦ A421

⑧ Peel off PT x6.

⑨ A434

⑩ CNL-B1.4x1.6, A424 (Reset switch)

⑪ Unsolder two lands.

2. 0-A301 (Top Cover)

① TY-CNS1.4x2.5・・・Pop-up the built-in flash.

② A70 (Screw (Ni), Inside the battery chamber)

③ A61 (Screw, 2.5mm)

④ A62 (Screw, 3.5mm)

⑤ A63 (Screw, 4.2mm)

⑥ A69 (Screw (TY), 3.5mm)

⑦ A64 x2 (Screw, 11mm)

⑩

⑪

④

⑤

②

④

⑤

③

⑦

⑥

③

①

②

⑨

①

③

⑥

⑦

76180 EM -6/73-

⑧ Lift up the top cover, and then discharge the main capacitor at the following positions.

-1. Between a brown lead wire and a blue lead wire.

[NOTE] If the above position is not available for discharging proceed as follows.

-2. Between a brown lead wire and a land behind a black wire as shown in the figure below.

[CAUTION] Be careful short and electric shock when handling the camera.

⑨ Unsolder 4 lead wires (Blue, Black, Brown, Green)・・・Q100

⑩ Peel off T72 (20x15).

⑪ Unsolder 6 lands.・・・ T51

⑫ Unsolder a black lead wire.・・・ A330

⑬ Remove the top cover (0-A301) from the main body.

⑭ M311・・・ DT

⑭

3. A201 (Back Cover)

① Insert the CF card to the camera to remove T691.

② T691・・・Pull out T691with care to prevent damage.

③ Remove the CF card with pressing the CF card eject lever.

[NOTE] Do not touch the CF card switch pin because it is very delicate part.

⑧-1

⑩

⑪

⑧-2

~1kΩ

⑨

⑫

①

②

76180 EM -7/73-

③

Pin

④ A62 x2 (Screw, 3.5mm)

⑤ A68 x2 (Screw (TY), 6mm)

⑥ A69 x2 (Screw (TY), 3.5mm)

⑤

⑦ Lift up A201while opening the terminal cover.

⑧ Disconnect the flexible board of 0-O301from the connector terminal.

⑨ Disconnect the connector terminal of T905 from 0-O301by using the tweezers with care to

prevent damage.

⑩ A201

4. A153 (Front Cover, Left)

① CNL-D1.7x2.5 (2pcs.)

② A153

5. A102 (Front Cover)

① CNL-D1.7x3.0

② A102

②

①

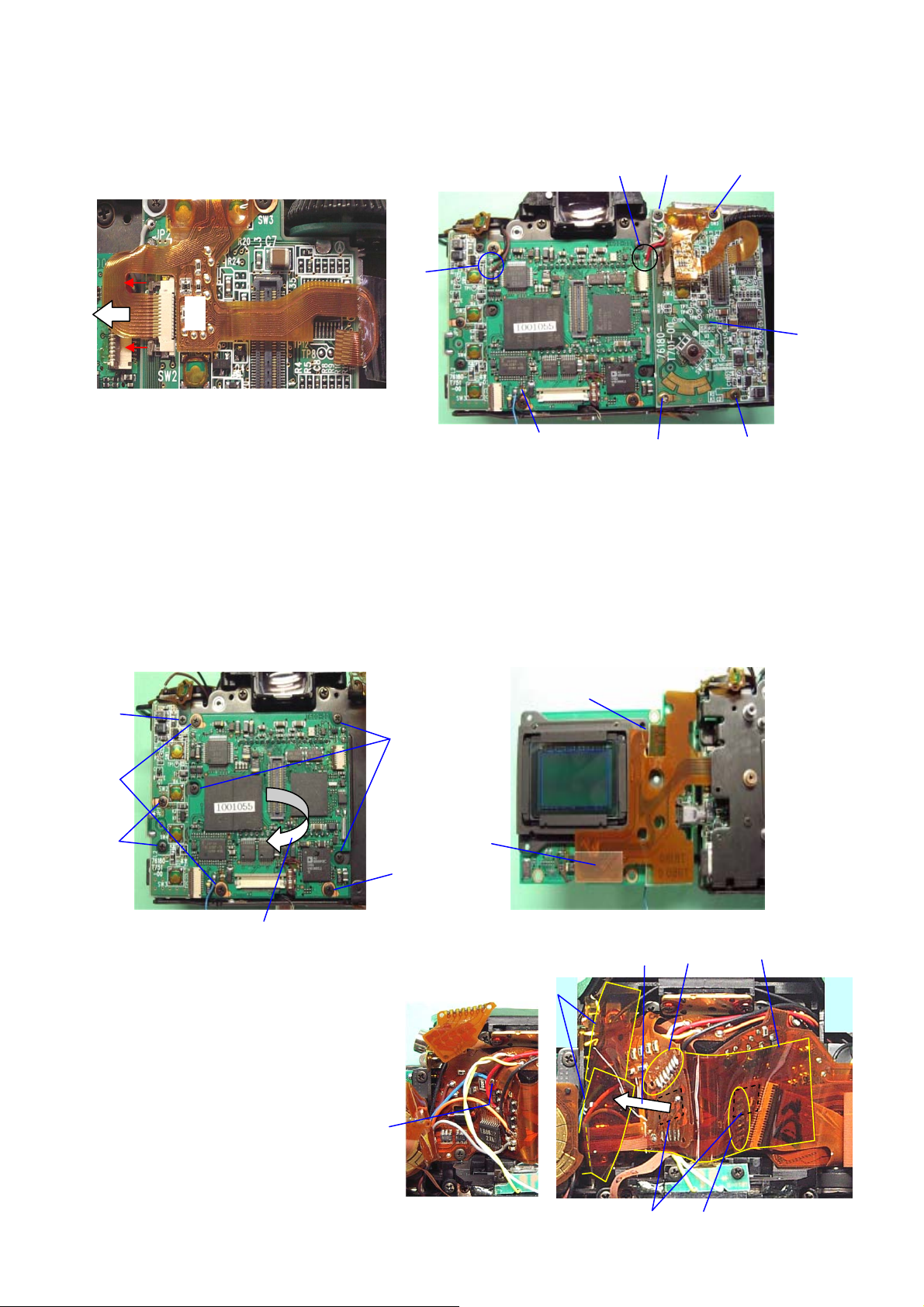

6. 0-T700 (CF P.C. Board assy.)

① 0-T950・・・Disconnect both connector terminals of 0-T950 from 0-T600 and 0-T700.

② Disconnect the flexible board of T100 from the connector terminal of T600.

⑧

①

④

⑥

⑨

①

②

②

①

76180 EM -8/73-

③ Disconnect the flexible board of T100 from the connector terminal of T700.

④ Unsolder 5 lead wires on T600. (Brown, Black (T800), Red, Gray (T700), Black (A433))

⑤ CNL-D1.7x2.5 (4pcs.)

⑥ 0-T700

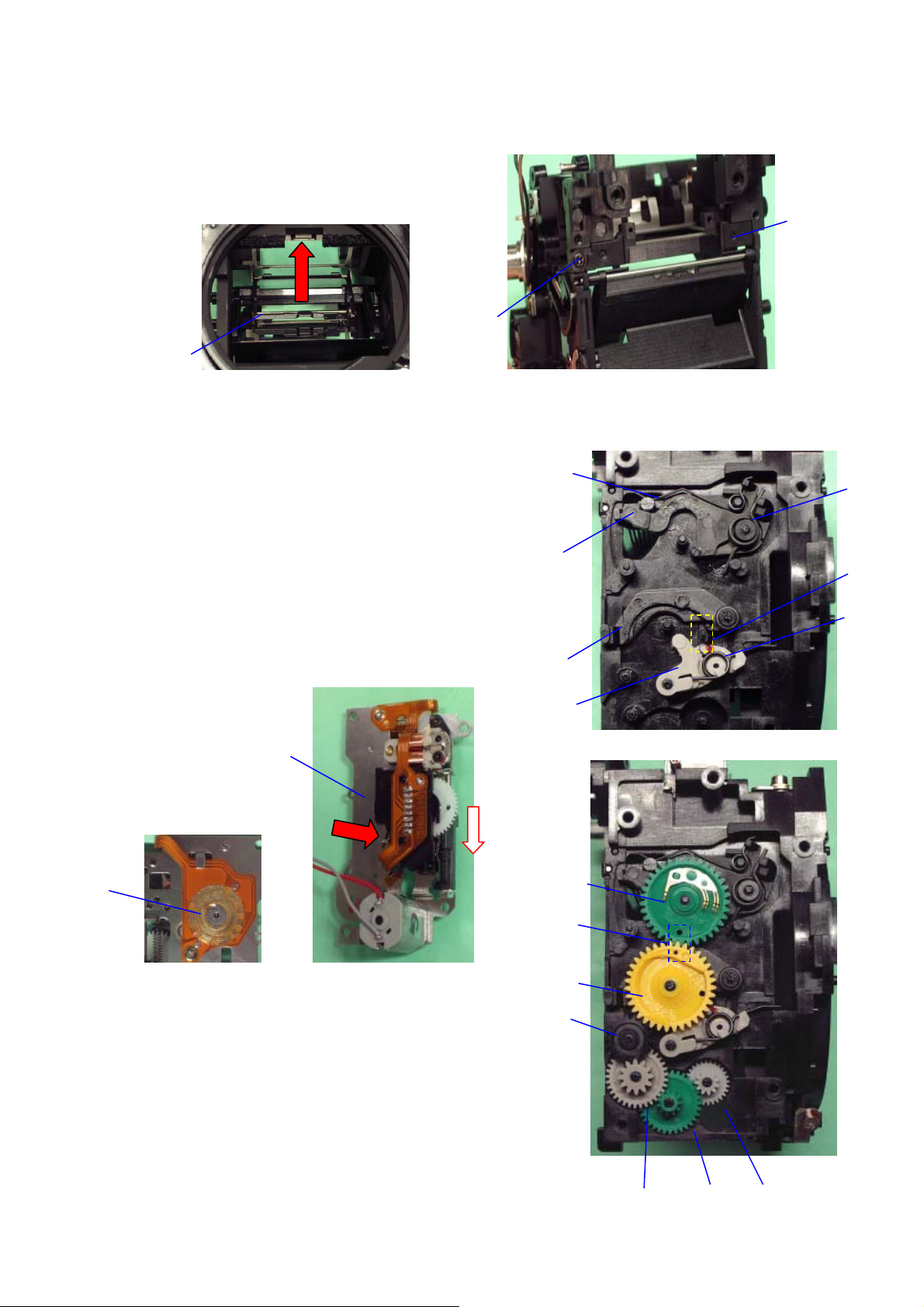

7. 0-T600 (CCD BLOCK)

① A60 x3 (Shoulder screw)

② TY-CNL-D1.7x2.5 (3pcs.)

③ TY-CNL-D1.7x2.5 (3pcs.)・・・ There are two washers at the USB part underneath 0-T750.

④ Turn up 0-T600, 0-T750 and T960 from left side as shown in the figure below.

⑤ 0-T600・・・ Disconnect the connector terminal of 0-T960 from 0-T600. (CCD side)

⑥ 0-T750・・・ Disconnect the flexible board of 0-T960 from the connector terminal of 0-T750.

③

①

③

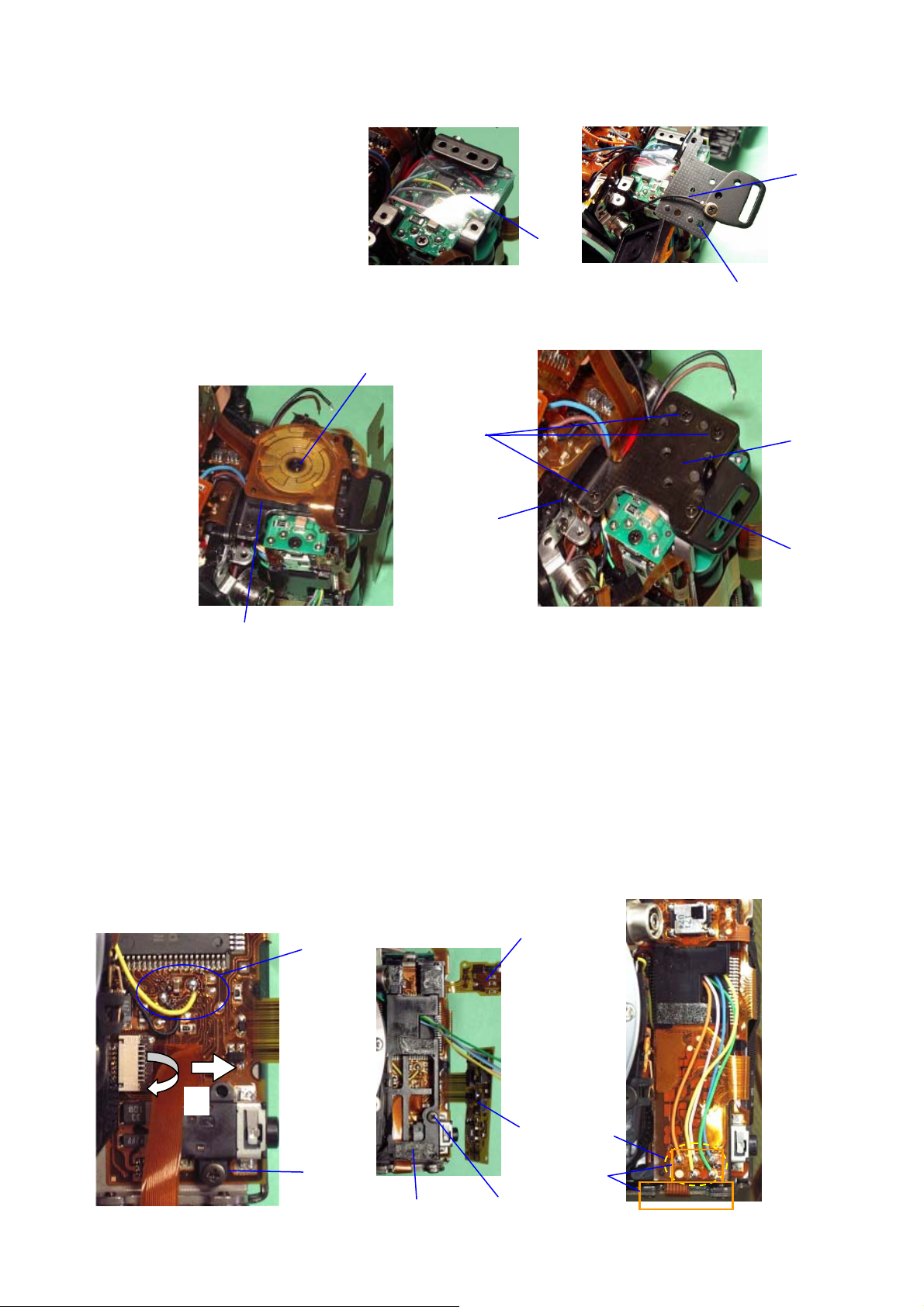

8. Around Pentaprism (1)

① Unsolder 7 lands.・・・ 0-O170.

② Peel off T74 x2 (20x10).

③ Peel off T100 from DT.

④ Peel off T64 (20x50).

⑤ Unsolder 7 lands.・・・ 0-J100.

⑥ Unsolder a blue wire.・・・ T800

③

④

④

④

⑥

②

⑤

①

②

⑥

④

⑤

③

DT(5x5)

⑤

①

⑤

⑤

⑥

⑤

④

76180 EM -9/73-

9. A5 (Right shoulder plate)

① CNL-D1.7x2.5

② A338

③ CNL-D1.7x2.5 (3pcs.)

④ CNL-D1.7x3.5

⑤ TY-CNL-D1.7x3.5 (PT 15x8)

⑥ Unsolder a black wire.

・・・ for CE mark

⑦ A5

⑧ T62

10. A49 (Remote control base plate)

① Peel off A427 (8x10) and A425 (10x20). (for CE mark)

② Unsolder 5 lead wires.

③ Peel off the flexible board of remote control.

④ Peel off the flexible board of T100.

⑤ CNL-D1.4x5.0

⑥ A49

⑦ Unsolder 2 lead wires. (Yellow, Black)

⑧ Disconnect the flexible board of T301from 0-T100.

⑨ CNL-D1.4x4.0・・・ Cable release socket

⑧

②

⑦

⑨

①

③

⑤

③

⑤⑥

④

⑥

⑧

⑦

⑦

④

②

①

76180 EM -10/73-

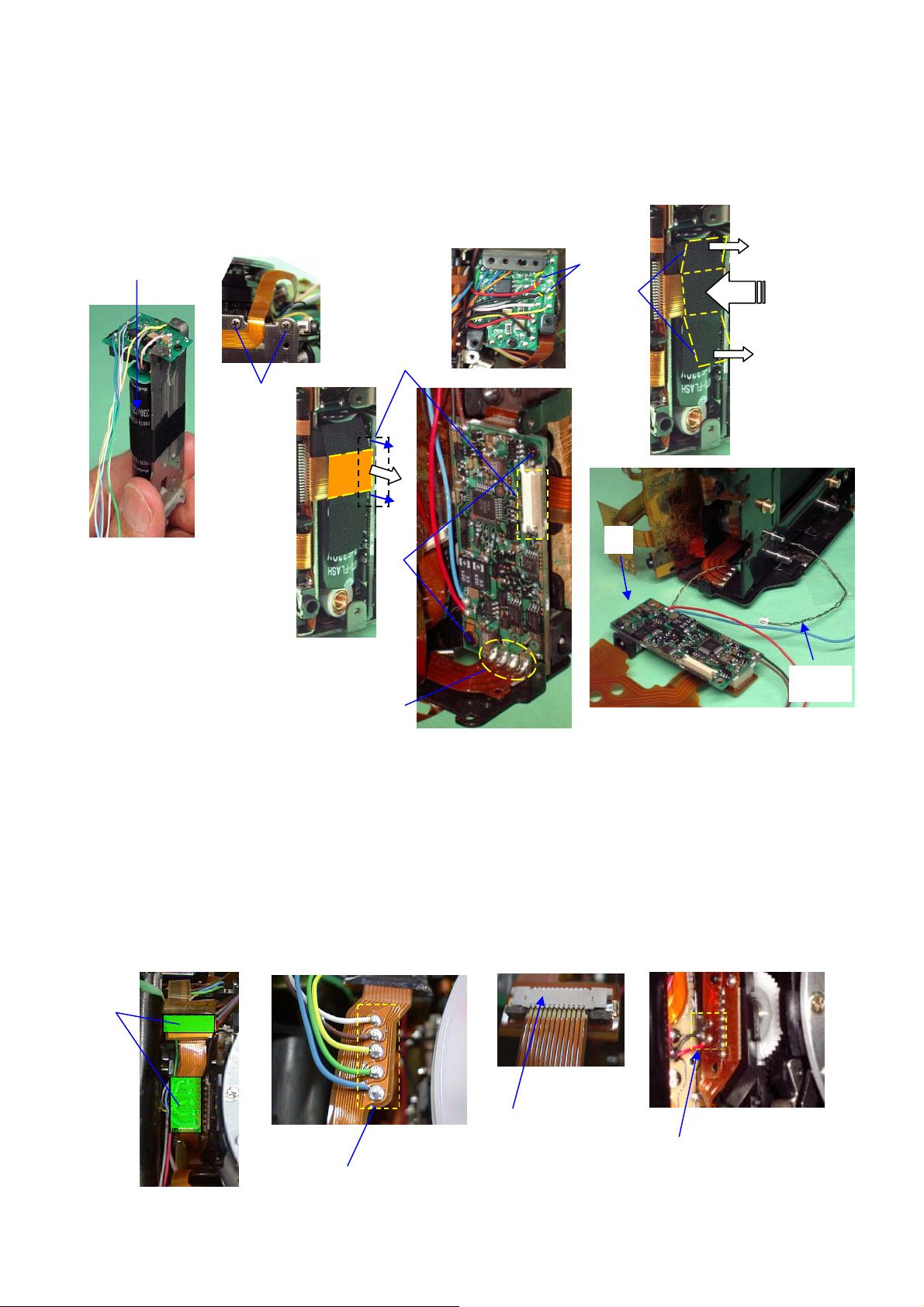

11. 0-Q200・0-T800 (Flash P.C. Board assy., Power P.C. Board assy.)

① Unsolder 2 lead wires. (Red, Black)

② Peel off BT (25x10) while holding 0-T100 with care to avoid breaking the flexible board.

③ Disconnect the flexible board of T100 from the connector terminal of 0-T800.

④ Peel off the flexible board of the cable release socket from DT.

⑤ CNL-D1.7x2.5 (2pcs.)

⑥ 0-Q200

⑦ CNL-D1.7x2.5 (2pcs.)

⑧ Unsolder 4 lands.

⑨ 0-T800・・・ 0-T800 is removed with T905 (Power supply cable).

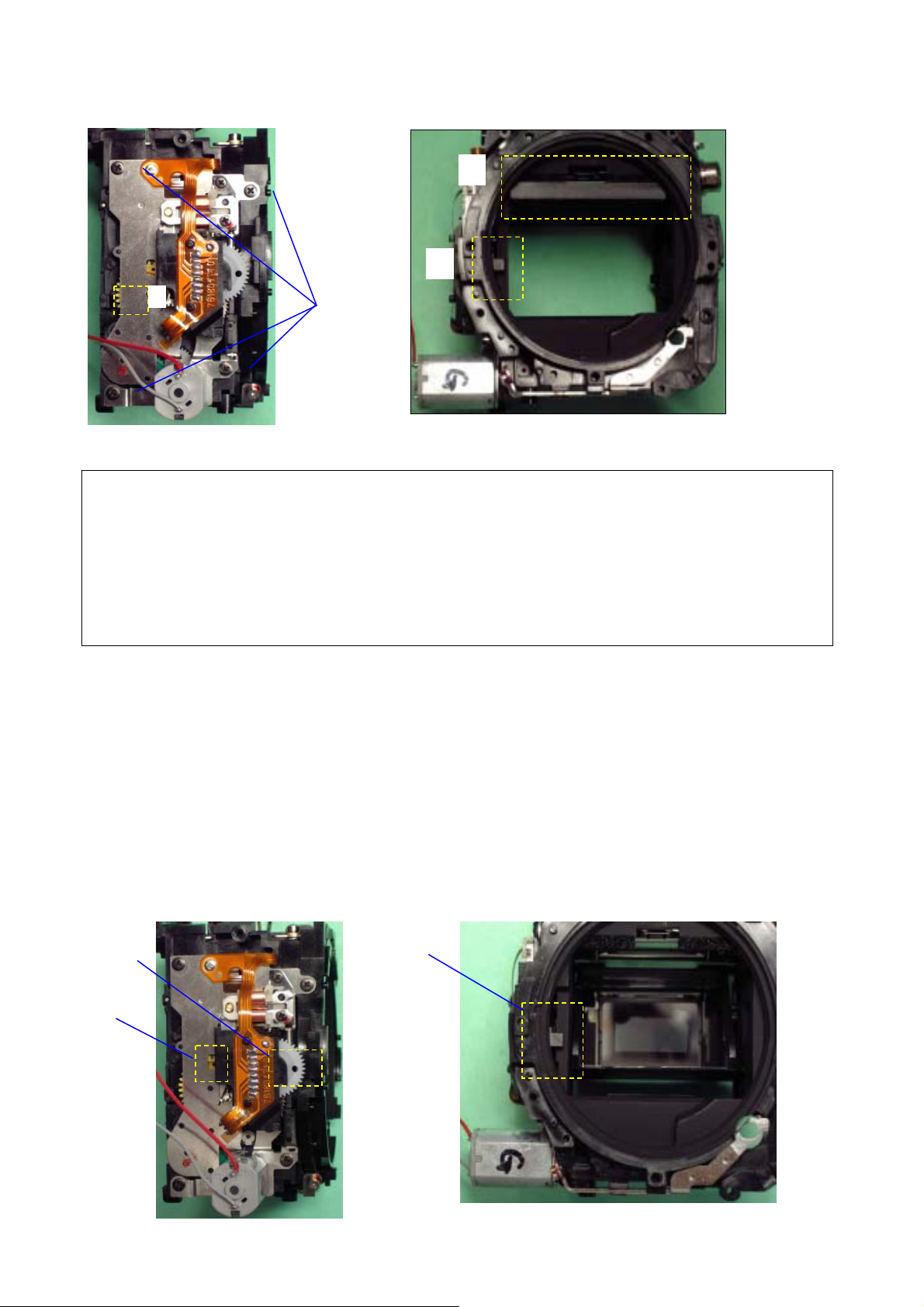

12. T301 (Mount P.C. Board)

① Peel off T69 (8x15) x2 from T301.

② Unsolder 5 lead wires.

③ Disconnect the flexible board of T301 from the connector terminal of 0-T100.

④ Unsolder 2 lead wires. (Red, Black N300)

①

⑤

③

⑦

⑧

③

①

②

⑨

T905

④

②

76180 EM -11/73-

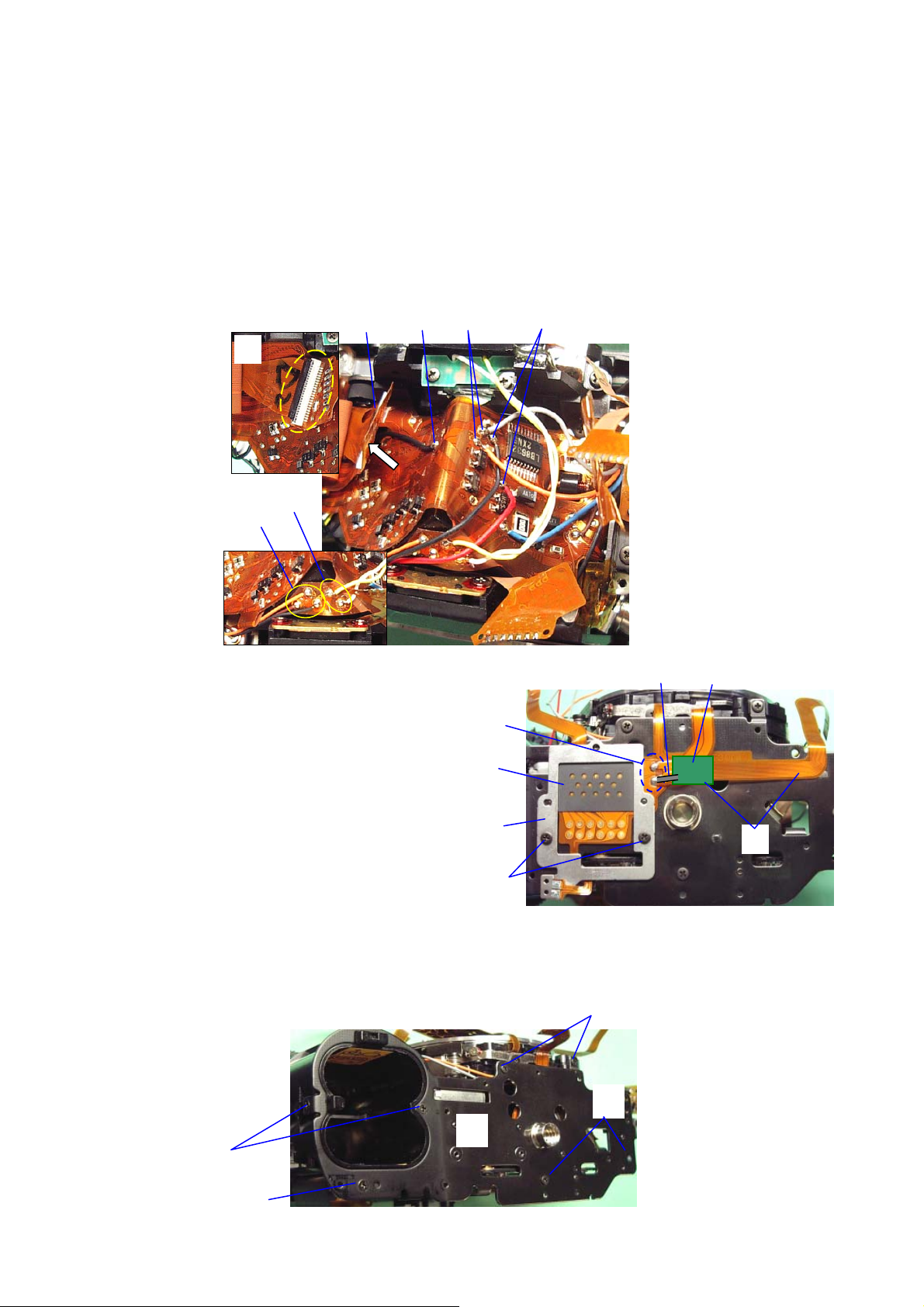

13. Around Pentaprism (2)

① Disconnect the flexible board of O100 from the connector terminal of 0-T100.

② Peel off the flexible board of T100 from DT.

③ Unsolder a black lead wire. (T900)

④ Unsolder 2 lead wires. (Orange, Gray S300)

⑤ Unsolder 2 lead wires. (Red, Black S250)

⑥ Unsolder 2 lead wires. (Yellow, White T970)

⑦ Unsolder 3 lead wires. (Orange, Brown, Black E000)

14. 0-A3 (Bottom Plate assy.)

① CNL-D1.7x2.0 (2pcs.)

② A422

③ A423

④ Unsolder 2 lands. (T301, T907)

Unsolder a gray lead wire. (T81, for CE mark)

⑤ Peel off T301 and T81 from bottom plate.

(T81 will remove with a lead wire.)

⑥ TY-CSM1.7x4.0 (2pcs.)

⑦ TY-CNL-D1.7x4.0 (2pcs.) ・・・ A429 lug-plate for CE mark

⑧ CSM1.7x2.5

⑨ CNL-D1.7x2.5 (2pcs.)

⑩ 0-A3

①

⑥

⑦

②

③

④

③

②

⑤

Gray T81

④

①

⑦

⑤

⑥

⑨

⑩

⑧

76180 EM -12/73-

15. T903 (TV/AV Dial)

① CNL-D1.7x2.5

② TY-CNL-D1.7x9.0 (3pcs.)

③ Peel off the flexible board from the LCD frame.

④ TY-CNL-D2.0x9.0

・・・ Underneath the flexible board of 0-T100.

⑤ Lift up the LCD frame of 0-T100.

(If there is a lug-plate, remove it by loosening screw.)

⑥ T903 (2pcs.)

⑦ BO1.5 (2pcs.)

⑧ A17 (2pcs.)

⑨ CSM1.7x2.5

⑩ TY-CSM1.7x4.0・・・ A429 lug-plate for CE mark

⑪ TY-CNL-D1.7x4.0 (2pcs.)

⑫ A6 ・・・ If there is a lug-plate, remove it by loosening screw.)

⑦

⑨

⑩

A429

④

③

②

⑧

16. Front Housing Block

A429

⑫

⑪

⑦

⑧

④

① TY-CNL-D2.0x9.0

② TY-CNM2.0x6.0 (2pcs.)

③ CNL-D1.7x2.5

④ Main base plate

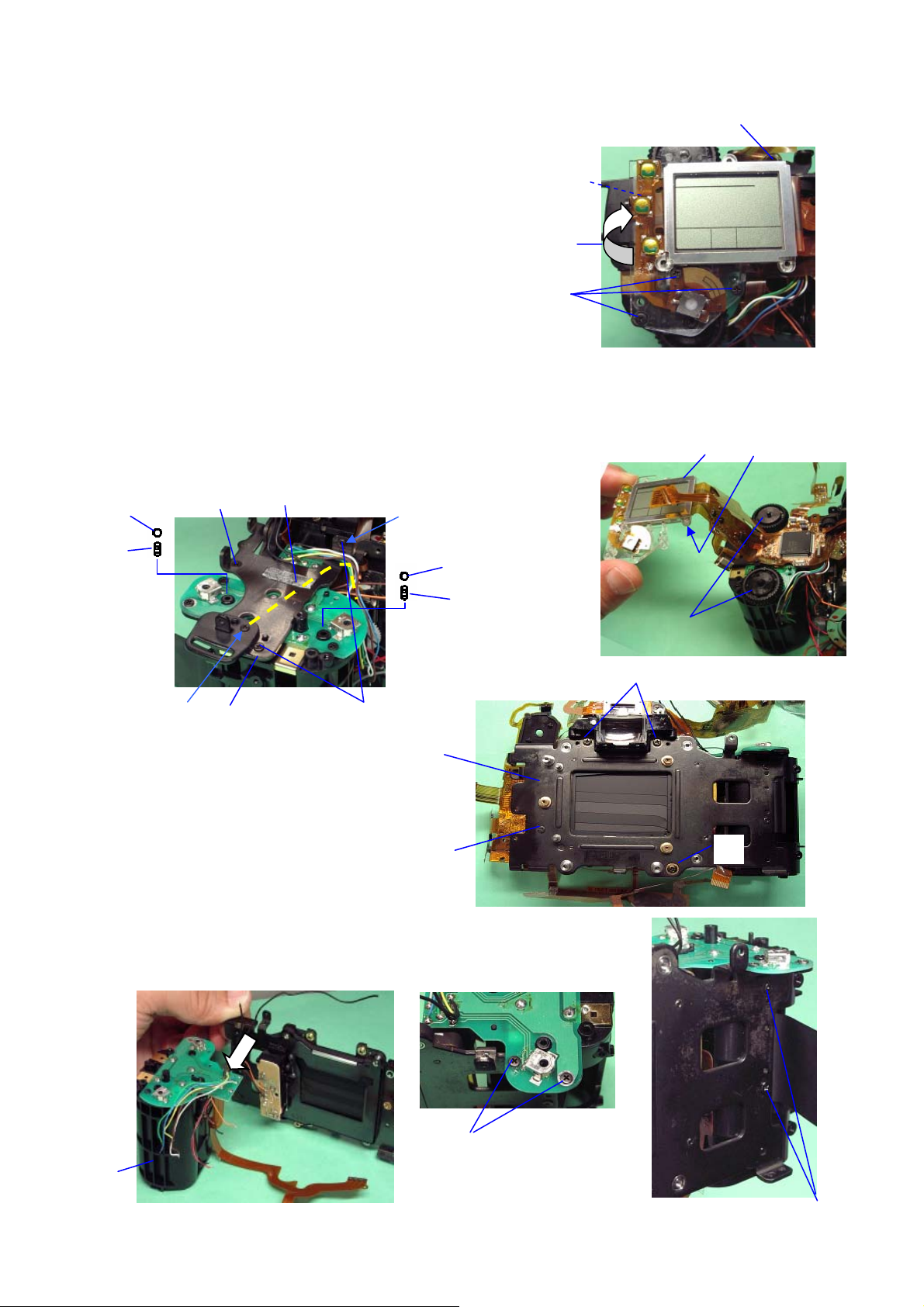

17. 0-E000 (Shutter Block)

① TY-CNL-D1.7x4.0 (2pcs.)

② CNL-D1.7x2.5 (2pcs.)

③ A13

③

②

⑥

⑤

①

A429

①

③

②

①

76180 EM -13/73-

④ A71 x2 (Shoulder screw)

⑤ TY-CNL-D1.7x2.5

⑥ 0-E000

⑦ A65 x4 (Screw)

⑧ A2

18. Battery Chamber and Related Parts

① Unsolder 7 lead wires.

② Unsolder 2 lands.

③ T907・・・DT

④ Unsolder 4 lands.

⑤ TY-CNL-D1.7x4.0

⑥ 0-T900

⑦ A13, A14 (4pcs.), A15 (2pcs.)

⑧

③

A14

⑤

⑦

④

④

⑥

⑤

①

⑥

②

A15

A13

76180 EM -14/73-

II. Assembly procedures of Front Housing Block

Disassemble the front housing block in reverse order of assembly procedures according to “Note

of disassembly”.

Assembly Procedures

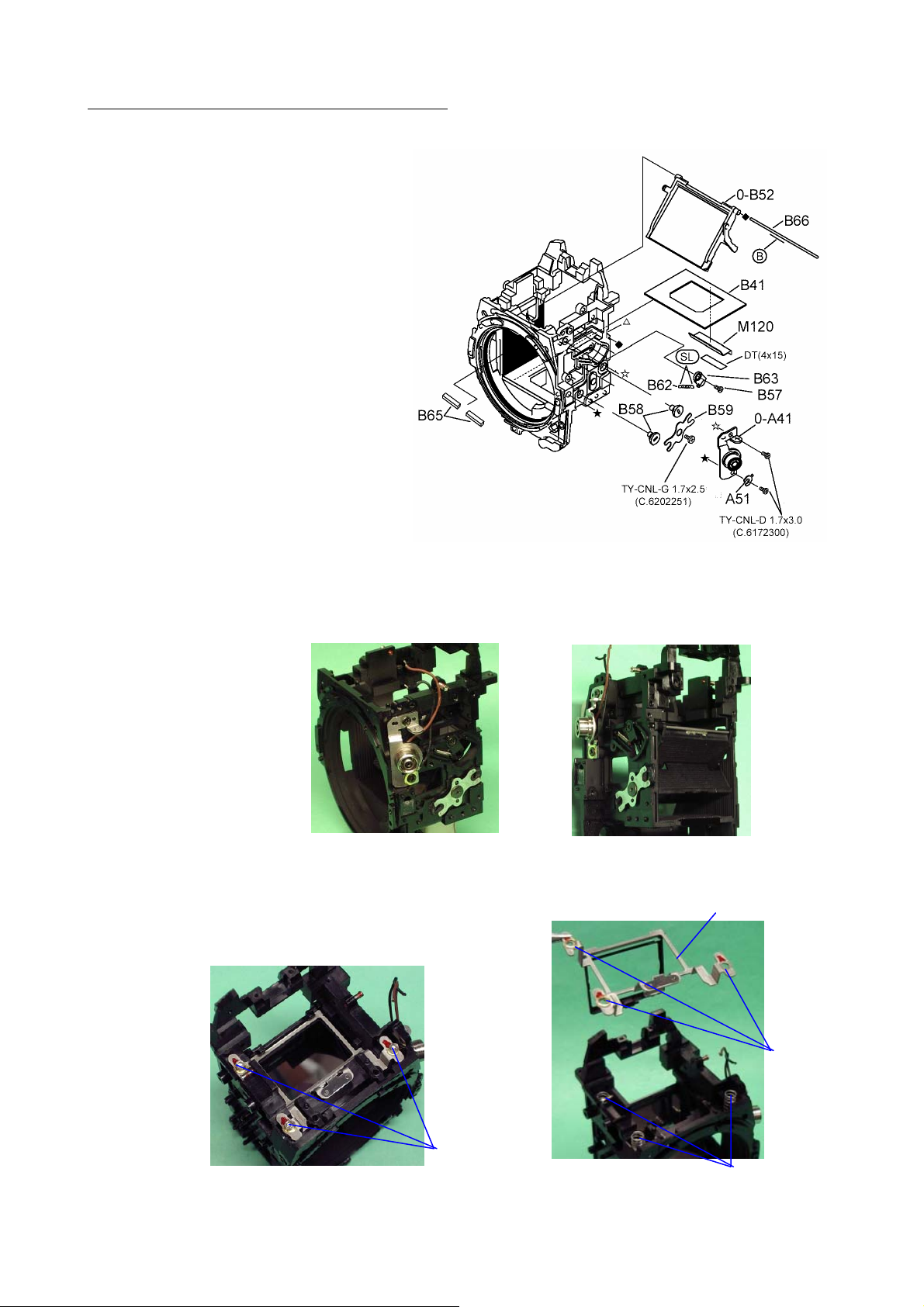

1. Front Housing Block

① B65 x2, B41, M120, B58 x2, B59

② 0-A41 (X- terminal)・・・ Brown lead wire 40mm

③ A51 (Lug plate)・・・ Black lead wire 40mm

④ TY-CNL-D1.7x3.0 (2pcs.)

2. 0-B52・B62

① 0-B52 (Mirror seat)

② B66・・・ Apply the Dia-bond 1663 in the center part of B66 and fix 0-B52.

③ B63

④ B57 (Shaft screw)

⑤ B62・・・ Apply the screw-lock agent on each end.

3. 0-M22

[Required equipment] Hexagonal screwdriver 1.5mm

① M104 (3pcs.)

② 0-M22 (0-M4, M23) ・・・ 0-M4 should be unhooked condition.

③ W65 x3 (t=0.5)

④ M103 x3 (Focus adjusting screw)

②

③

④

76180 EM -15/73-

①

⑤ [ADJ.] Pre-adjusting the Focus

Screw-in 3 adjusting screws until they stops, and then screw back two turns.

⑥ Hook 0-M4.

⑦ Install M21 while positioning the boss.

⑧ TY-CNS1.7x3.5

4. 0-G100

① B11

② B20・・・ The spring (B20) should be set on the shaft of 0-B52.

③ B19

④ B10

⑤ B9

⑥ B17

⑦ B18・・・Apply the screw-lock agent on end of spring.

⑧ 0-B8

⑨ B7

⑩ Align the both hole of 0-B8 and B7.

⑪ B3

⑫ B4

⑬ B5

⑭ B6

⑮

⑮ Clean the code plate and apply G151.

⑯ Latch the lever of G100 while pushing down

the sliding plate.

⑰ 0-G100

⑥

⑰

⑧

②

①

④

⑤

⑯

⑧

⑩

⑨

⑭

⑦

③

⑦

⑥

76180 EM -16/73-

⑬

⑫

⑪

⑱ TY-CNL-D1.7x3.5 (4pcs.)

[Note of Disassembly]

Set the mirror seat at top end position before removing 0-G100.

1. Apply DC1~3V to 0-S250 (Red lead wire: Positive) and set the mirror seat at top end

2. Push down the Sliding plate, and then latch the lever of G100.

5. [CONF] Checking the Mirror Function

[NOTE] Make sure the latch lever of G100 is unlatched.

① Confirm the following items while applying DC3V to the mirror motor. (Red wire: Positive)

-1)The mirror seat must be moved smoothly without noise.

-2)The shutter charge lever and sliding plate must be moved smoothly.

② Set the mirror seat to the down position and then confirm that the Sliding plate (A), White

③ Both mirror seats 1

(C)

②

⑱

position. (Mirror seat ① and Sliding plate ③ must be top end position, Shutter charge

lever must be bottom end position ②.)

gear (B) and Yellow gear (C) must be positioned as shown in figure below.

st

and 2nd must be returned smoothly to the original position when both

mirror seats are pressed inward about 3mm by finger pressure.

(B)

(A)

①

③

76180 EM -17/73-

6. A104

① 0-A126

⑦

⑧

②

①

② TY-CNL-D1.7x3.0

③ A133

④ 0-A121

⑤ TY-CNL-F1.4x4.0

⑥ A105

⑨

⑥

③

⑦ 0-A108

⑧ A110

⑤

3

5

1

⑩

④

⑨ A104

2

4

⑪

⑩ TY-CNS2.0x4.5Ni (5pcs.)

・・・ Tighten 5 screws in the numerical order

as shown in the figure above.

⑪ Solder a black lead wire.・・・ T71

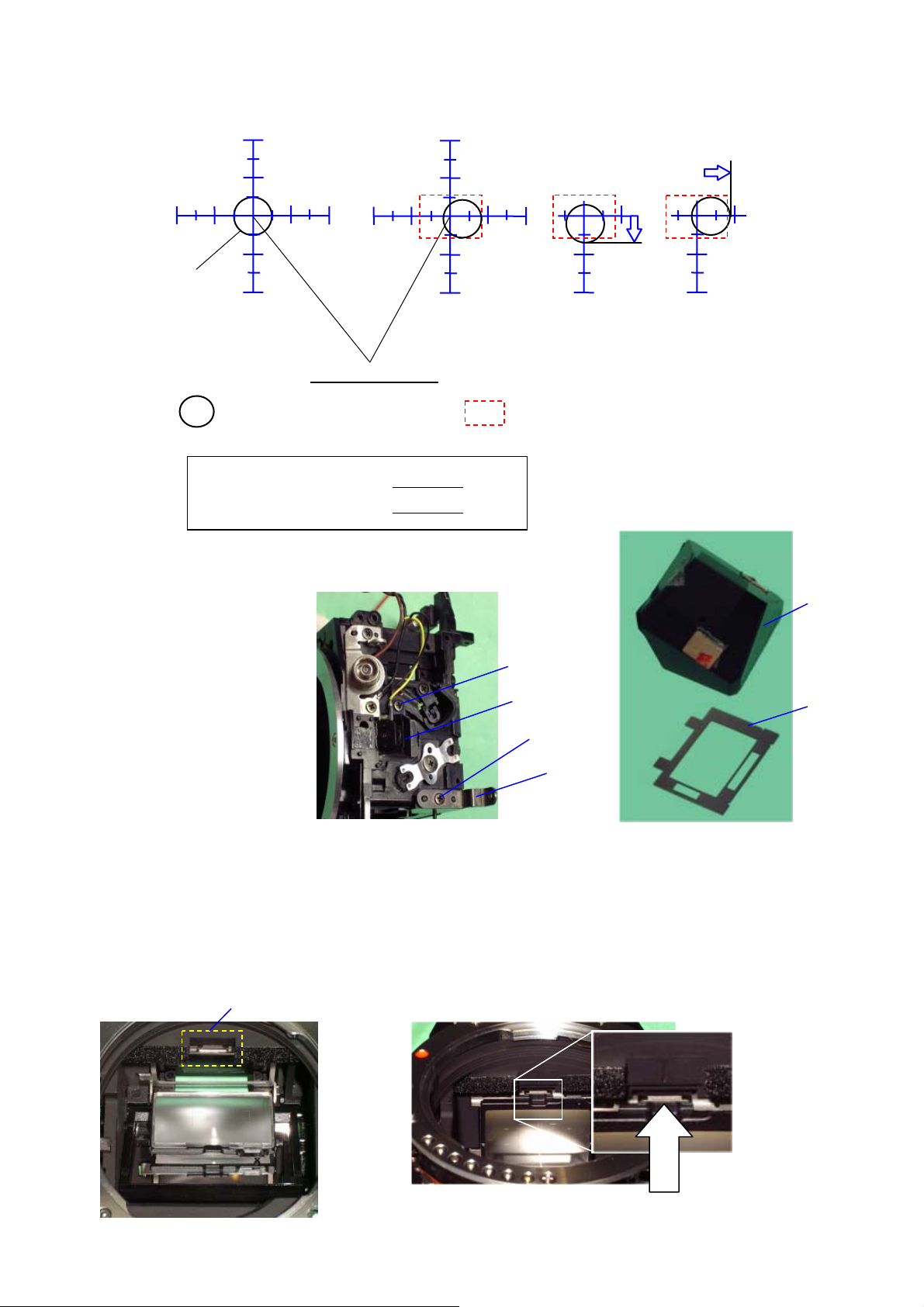

7. [ADJ] Positioning 1

st

and 2

nd

Mirror

[Required equipment] 1st Mirror angle (45°) adjusting jig, Mirror angle adjusting jig for 27830,

Mirror positioning scope

[NOTE] The manner of adjusting is the same as the other MZ-cameras. Adjust the desired

value of Y axis to ±0.

① Positioning 1st mirror: Put the 1st mirror angle (45°) adjusting jig on the camera, and then

adjust the mirror seat so that the adjusting jig touches the mirror without gap by turning

B58.

Tolerance ・・・ X-axis : ±15′

Y-axis : ±10′

② Positioning 2nd mirror: Attach the mirror positioning scope and the 2nd mirror angle

adjusting jig to the camera, and then adjust the mirror angle by turning B58 while looking

through the eyepiece lens.

1st mirror

2nd mirror

B58

76180 EM -18/73-

(

2 1

1 2

2 1

Scale

NG: 0.8(Y) or over

NG: 0.6(X) or over

- 2 - 1

1mm hole

1 2

- 1

- 2

- 2 - 1

- 1

- 2

OK OK NG NG

Standard)

Center of standard

: Tolerance of 1mm hole : (X-axis = ±0.6, Y-axis = ±0.8)

Tolerance・・・ X-axis : ±0.3mm

Y-axis : ±0.1mm

③ After adjustment is done, apply the super-glue to both B58.

8. 0-J201・A163

① 0-J201 (Yellow, Black)

② TY-CNL-D1.7x3.5

③ A163

②

①

④ TY-CNL-D1.7x3.0

④

③

9. 0-L3・L2

[CAUTION] Confirm there is neither dust nor scratch on 0-L3 and L2.

① M3・・・ DT

② 0-L3

③ Temporarily tighten M16 x2 (Screw).

④ Down the focusing screen frame (0-M4) by releasing the hook portion.

⑤ Put the focusing screen (L2) on the frame and then push it back until it locks in place.

④

②

①

⑤

76180 EM -19/73-

②

10. M301

① M301 (L5, L7, M302, 0-M307)

② TY-CNM1.7x4.5 (2pcs.)

11. [ADJ] Viewfinder Focus・Parallax

[Required equipment] Collimator, Focus master lens, Lens for checking (e.g. FA50mmF1.4)

[Preparation] Adjust the diopter by the diopter adjustment lever.

11-1. Parallax

[CAUTION] Confirm that the Pentaprism must be installed securely.

① Confirm there is neither gap nor an inclination at an upper and lower, right and left

position.

② Adjust the parallax of right and left direction by the prism retainer screws (M16 x2).

11-2. Viewfinder Focus

[CAUTION] The focus must be adjusted at the center and corners in the viewfinder.

③ Adjust the focus to within ±0.02mm

in the figure below.

1

[NOTE] One scale of the Focus master lens = 0.03mm

④ After adjustment is done, apply the screw lock agent to M16 and M103.

Standard: Right/Left 1°or less

Top/Bottom 1°50′or less

2

3

[ [NOTE] Each adjusting screw affects the focus in the

Standard: 0±0.07mm

①

by turning the adjusting screws (M103 x3) as shown

2

3

viewfinder as shown in the figure above.

1

76180 EM -20/73-

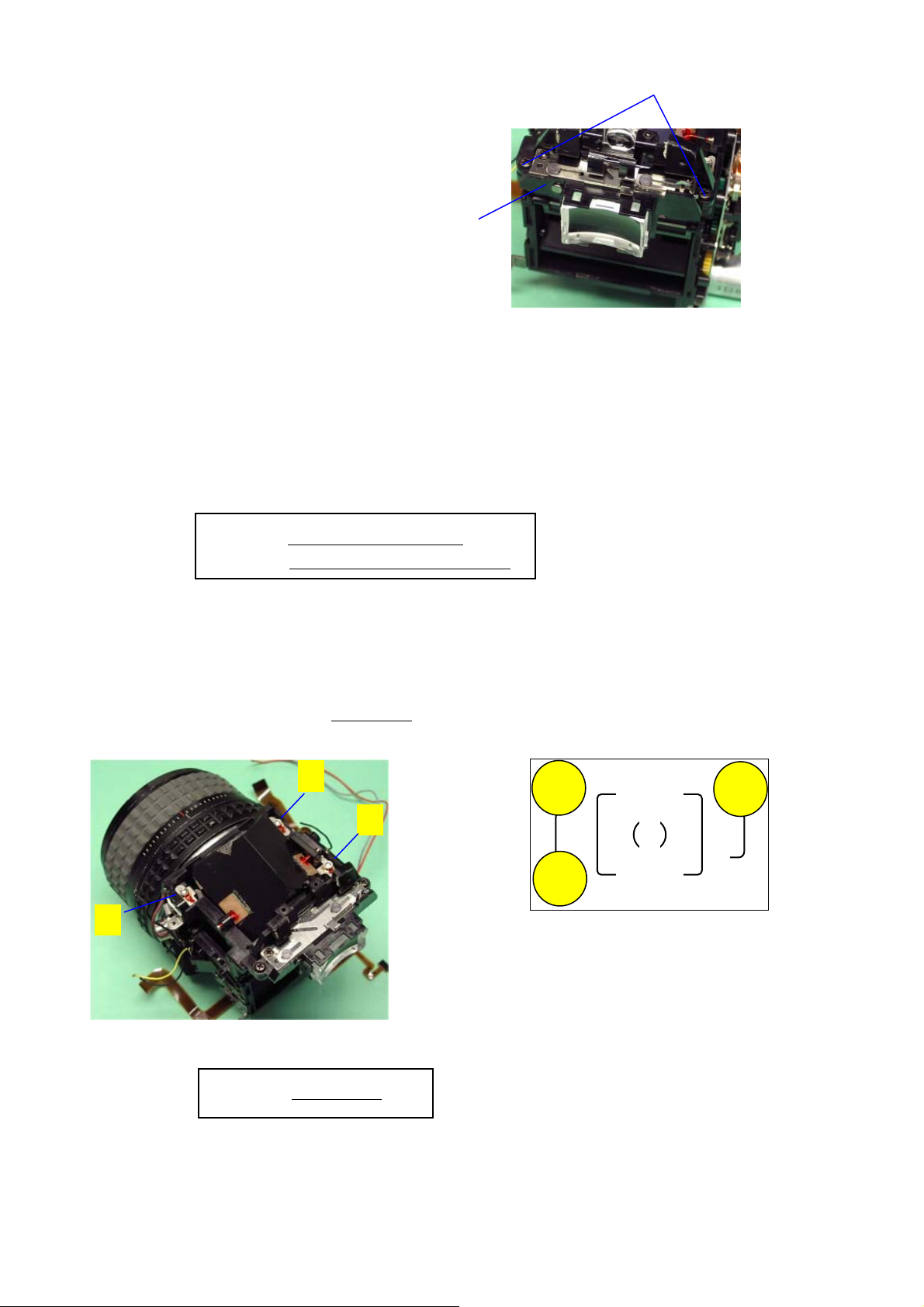

12. 0-J100

(

① M7

[Note of Disassembly]

② M5

Set the diopter adjustment lever at the

③ TY-CNL-B1.4x2.5・・・ Left side

left end to remove 0-J100.

④ W29 (t=0.5)

⑤ 0-T970・・・ White, Yellow lead wire 55mm

⑥ TY-CNL-B1.4x3.5

⑦ 0-J100

⑧ TY-CNL-G1.7x5.0, W5 (t=0.25)

TY-CNL-B 1.4x2.5

C.6192351)

13. M51

① L12・・・ Confirm there is neither dust nor scratches on L12, and then install it to M51.

② M51 (L10, L11, M53, 0-O170)・・・ Install M51 to the Pentaprism (0-L3) without gap.

③ TY-CNL-F1.7x3.5 (2pcs.) ・・・ Apply the screw-lock agent.

②

①

③

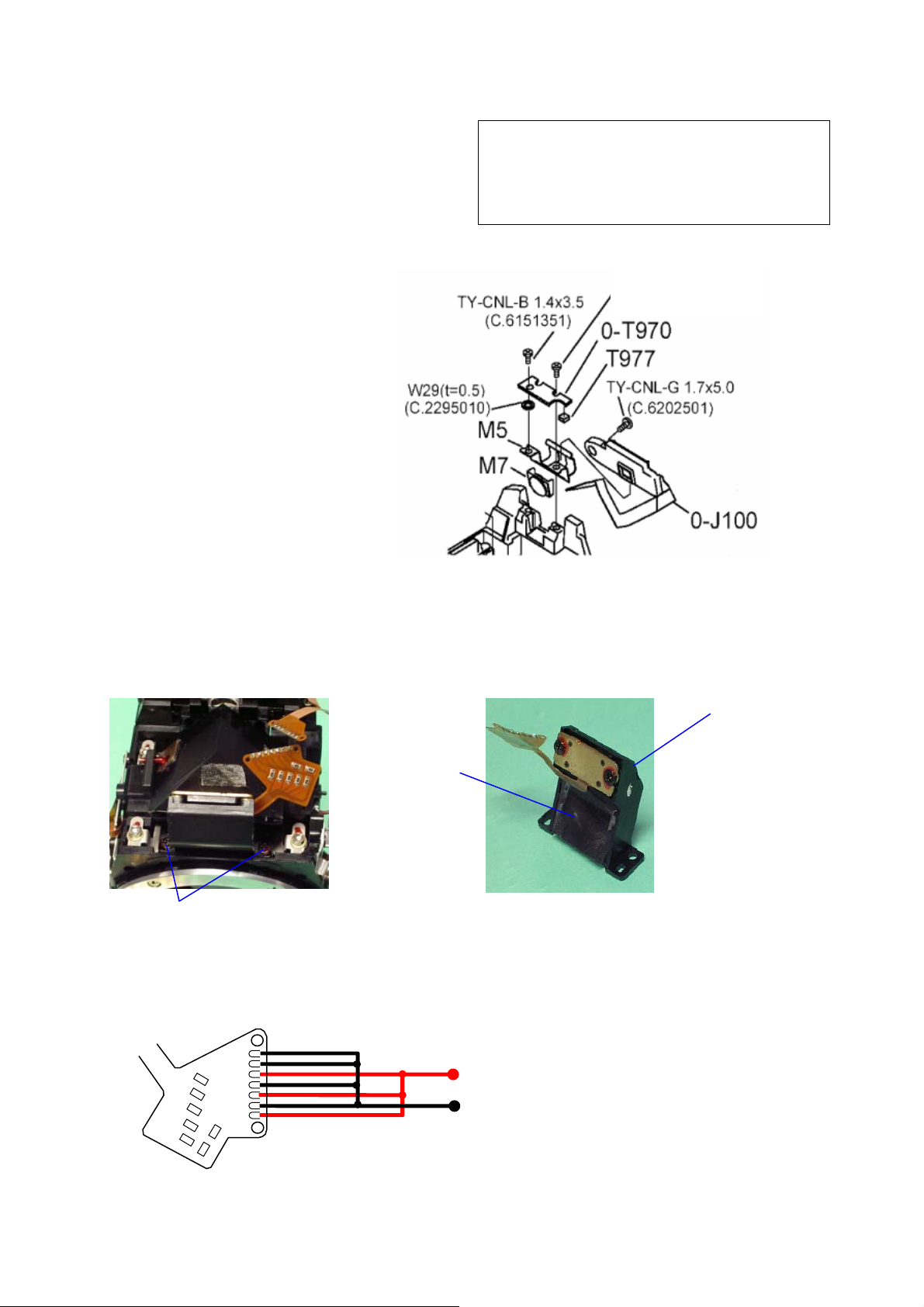

14. [ADJ] Positioning 0-O170 (SI-LED)

① Solder and arrange the lead wires on 0-O170 as shown in the figure below.

[CAUTION] Do not stress to the lands of 0-O170.

0-O170

② Apply DC3.5V to 0-O170, and confirm the positioning and lighting of SI-LED 11points.

DC3.5V

(+)

(-)

76180 EM -21/73-

③ Loosen 2 screws, and then adjust the position of 0-O170.

④ Tighten 2 screws, and then confirm the position again.

⑤ After adjustment is done, apply the screw-lock agent to both screws and remove the lead

wires from 0-O170.

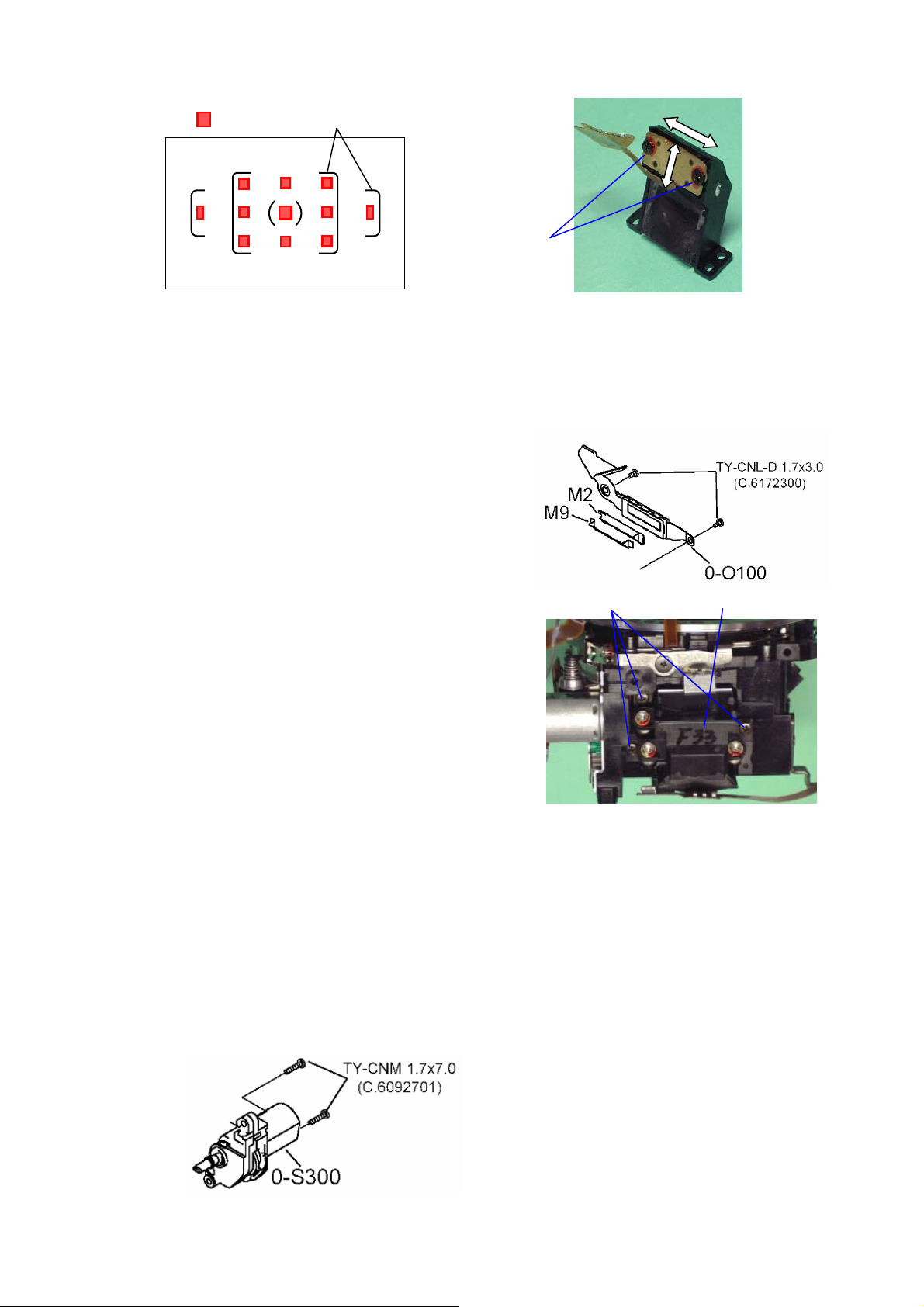

15. 0-O100

① M9

② M2

③ 0-O100

④ Temporarily tighten TY-CNL-D1.7x3.0 (2pcs.)

16. 0-M100

[Required equipment] Hexagonal screwdriver 1.5mm

① 0-M100

② TY-CNL-D1.7x3.5 (3pcs.)

③ [ADJ] Temporary adjustment of AF block・・・ Screw in 3 adjusting screws until they stops,

then screw back two turns.

[NOTE] After CCD position adjustment with programmed software is done, Apply screw-lock

agent to between the head of adjustment screws and washers.

17. 0-S300

① 0-S300

② TY-CNM1.7x7.0 (2pcs.)・・・ Apply the screw-lock agent to both screws.

: SI-LED AF frame

③

②

①

76180 EM -22/73-

Loading...

Loading...