Page 1

®

CM9760-MXB/

CM9760-MXBL

System 9760

®

Matrix Bay

Installation/

Operation Manual

C543M-A (7/03)

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

Page 2

CONTENTS

Section Page

1.0 GENERAL ......................................................................................................5

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ................................... 5

1.2 CERTIFICATIONS ................................................................................. 5

1.3 UNPACKING INSTRUCTIONS .............................................................. 6

1.4 RECOMMENDED TOOLS .....................................................................6

2.0 GENERAL DESCRIPTION ............................................................................ 7

2.1 OVERVIEW ............................................................................................ 7

2.1.1 Models ........................................................................................ 7

2.1.2 Optional Equipment .................................................................... 7

2.2 PHYSICAL LAYOUT .............................................................................. 8

2.2.1 Matrix Bay Card Cage ................................................................ 8

2.2.2 Video Output Card ..................................................................... 16

2.2.3 Video Input Card ........................................................................20

2.2.4 Rear Panel Input/Output Cards ................................................. 24

2.2.5 Power Supply ............................................................................ 30

3.0 INSTALLATION ............................................................................................32

3.1 MOUNTING INSTRUCTIONS ............................................................. 32

3.2 CONNECTING POWER TO THE MATRIX BAY ..................................33

3.3 CONNECTING THE MATRIX BAY TO THE CONTROLLER ............... 34

3.4 LED DIAGNOSTICS ............................................................................ 35

3.4.1 Performing a Diagnostic LED Check ........................................ 35

3.5 CONNECTING VIDEO INPUTS/OUTPUTS ........................................ 35

4.0 FUNCTIONAL CIRCUIT DESCRIPTION ..................................................... 36

5.0 SYSTEM CONFIGURATION–FRAMING..................................................... 38

5.1 DOWNFRAMING .................................................................................39

5.2 SIDEFRAMING .................................................................................... 42

5.3 DOWNFRAMING/SIDEFRAMING ....................................................... 44

6.0 PROGRAMMING NOTES–ODDS AND ENDS ............................................ 47

7.0 SYSTEM TROUBLESHOOTING ................................................................. 53

8.0 SPECIFICATIONS ....................................................................................... 54

9.0 WARRANTY AND RETURN INFORMATION .............................................. 55

2 Pelco Manual C543M-A (7/03)

Page 3

LIST OF ILLUSTRATIONS

Figure Page

1 Front of Matrix Bay ............................................................................ 8

2 Matrix Bay Card Cage ....................................................................... 9

3 Matrix Bay Connection Geometry .....................................................10

4 Rear of Matrix Bay ............................................................................ 11

5 Power Supply Section of Rear Matrix Bay ........................................11

6 Alarm Connector ...............................................................................12

7 Matrix Bay and Rear Input Cards ..................................................... 13

8 Rear Input Card Mounting ................................................................ 14

9 Rear Input Power Supply Connector ................................................ 15

10 Video Output Card with 16 Monitor Outputs (CM9760-VMC16) .......16

11 Video Output Card Installation .......................................................... 17

12 Location of DIP Switches, Jumpers and Fuses ................................18

13 Video Input Card ...............................................................................20

14 Video Input Card Installation ............................................................. 22

15 Input Card LED and Fusing Locations ..............................................23

16 CM9760-RPC Rear Panel BNC Input Card ...................................... 24

17 Installation of RPC Input Card .......................................................... 25

18 DFC Card .......................................................................................... 27

19 RPL Card .......................................................................................... 28

20 CM9760-RPM Video Output Card .................................................... 29

21 Power Supply Installation ................................................................. 30

22 Jumper Position on Bottom of Power Supply ................................... 31

23 Mounting the Matrix Bay ................................................................... 32

24 Replacing Power Supply Fuses ........................................................33

25 Connecting the Matrix Bay to the CM9760-CC1 Controller .............. 34

26 Video Signal Flow–Block Diagram .................................................... 36

27 Video Signal Flow–Graphical Representation .................................. 37

28 System Configuration–Reference Conventions ................................38

29 Single Bay Configuration–256 Cameras x 16 Monitors .................... 39

30 Single Bay Downframe–256 Cameras x 32 Monitors ....................... 40

31 Downframe Configuration–256 Cameras x 128 Monitors .................41

32 Single Sideframing–496 Cameras x 16 Monitors ............................. 42

33 Sideframe Configuration–976 Cameras x 16 Monitors .....................43

34 Sideframe/Downframe Configuration–496 Cameras x

35 Sideframe/Downframe Configuration–976 Cameras x

36 Sideframe/Downframe Configuration–2048 Cameras x

37 Setup File Dialog Box with Comms Tab Opened ..............................48

38 Configuration File Dialog Box ........................................................... 48

39 Camera Files and Logical Numbers ................................................. 50

40 Physical and Logical Numbers Compared ........................................ 51

41 Physical/Logical Numbers, Sideframed Bays and Camera Files ...... 52

32 Monitors ....................................................................................... 44

128 Monitors ..................................................................................... 45

128 Monitors ..................................................................................... 46

LIST OF TABLES

Table Page

A Alarm Port Pin Definition................................................................... 12

B Output Card S2 Functions ................................................................ 19

C X55 Jumper Definitions .....................................................................19

DVideo Output Card LED Assignments ............................................... 20

E Physical Input Range per Slot Position............................................. 21

FVideo Input Card LED Assignments.................................................. 23

G Matrix Bay LED Assignments ........................................................... 35

Pelco Manual C543M-A (7/03) 3

Page 4

REVISION HISTORY

Manual # Date Comments

C543M 9/97 Original version.

2/98 Removed references that a second power supply is

6/98 Added Section 1.2, Certifications.

1/99 Revised Figures 4, 5, 6, 7, 8, and 24 per ECO #98-4147.

6/99 Running change. Revised Table B for NTSC and PAL

C543M-A 7/03 Revised manual for System 9760 support of 2048

recommended if the number of input cards exceeds 10.

Changed manual pagination.

models.

cameras and 512 monitors. Also updated graphics of

video input, video output, and DFC cards and revised

text as necessary. Included other miscellaneous

changes.

4 Pelco Manual C543M-A (7/03)

Page 5

Please thoroughly familiarize yourself with the

information in this manual

prior to installation and

operation.

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should be done only by qualified service personnel

and conform to all local codes.

2. Unless the unit meets NEMA Type 3, 3R, 3S, 4, 4X, 6 or 6P standards, it is

designed for indoor use only and it must not be installed where exposed to

rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

The product and/or manual may bear the following marks:

NOTE:

This device complies with

part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not

cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired

operation.

Radio and Television

Interference

This equipment has been tested

and found to comply with the limits

of a Class A digital device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy

and, if not installed and used in

accordance with the instruction

manual, may cause harmful interference to radio communications.

Operation of this equipment in a

residential area is likely to cause

harmful interference in which case

the user will be required to correct

the interference at his own expense.

NOTE:

The CM9760-MXBL does

not require power; therefore, certification is not required.

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

CAUTION:

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

1.2 CERTIFICATIONS

The products identified below have been tested and certified for agency compliance as noted.

Agency Compliance Certification

Model CE FCC UL cUL

CM9760-MXB X X X

CM9760-MXB-X X

Applicable CE, FCC, UL, and cUL directives/standards:

• 93/68/EEC–CE Mark Directive

89/336/EEC, 92/31/EEC–Electromagnetic Compatibility (EMC) Directives

• FCC–47 CFR, Part 15, Subpart B, Class A

Pelco Manual C543M-A (7/03) 5

Page 6

1.3 UNPACKING INSTRUCTIONS

Unpack and inspect all parts carefully.

The matrix bay you receive should be populated with all the boards and associated

cables needed for your particular installation. In addition, jumper settings, board

installation locations specific to your order should already be completed.

Be sure to save the shipping box and any packing material, at least until it has been

determined that the equipment you have received is working properly. It is best to

keep the material anyway in case future problems warrant return of any equipment.

If an item has been damaged in shipment, replace it in its box and contact the

factory at 1-800-289-9100 or 1-559-292-1981. (International customers fax 1-559348-1120 for authorization and instructions.)

If an item needs to be returned to the factory for repair, consult the WARRANTY

AND RETURN section of this manual for instructions.

1.4 RECOMMENDED TOOLS

Pelco does not supply basic tools for the installation process. The following tools,

however, may be needed to install the product depending on your installation

geometry:

Crimp tools

Wire stripper

Straight and Phillips screwdrivers

Coaxial cable stripper

Wire cutter

BNC crimp tool

6 Pelco Manual C543M-A (7/03)

Page 7

2.1 OVERVIEW

The matrix bay is a peripheral product that is part of the System 9760® family. The

matrix bay provides all video input and output connections for the system. Each unit is

capable of accepting up to 256 camera inputs in 16 input increments and provides

up to 16 monitor outputs in 4 output increments. If more than 256 camera inputs are

needed, sideframing is required (see Section 5.2); if more than 16 monitor outputs

are needed, downframing is required (see Section 5.1). Version 8.03.006 and later

of CM9760-CC1 operational software enables sideframing and downframing to extend the number of inputs and outputs allowed to 2048 cameras and 128 monitors.

With the addition of CM9760-MDA (Master Distribution Amplifier) units, a maximum

of 2048 cameras and 512 monitors is supported. Note that the term

any device that can transmit a video signal and the term

device that can receive a video signal. VCRs and multiplexers are examples of

devices that can transmit or receive video signals.

All connections are made on the rear of the matrix bay and utilize standard BNC-type

connectors for video connections. All video inputs leave the factory terminated with

75 ohms (standard default). Non-termination (where applicable) is jumper selectable.

2.1.1 Models

2.0 GENERAL DESCRIPTION

camera

monitor

includes

includes any

CM9760-MXB Video matrix bay equipped with CM9760-MPS power supply.

CM9760-MXB-X Same as CM9760-MXB except 230 VAC, 50 Hz. (CE)

CM9760-MXBL Video matrix bay for video loop-out connections. Uses

120 VA, 60 Hz. (UL; cUL; FCC, Class A)

downframe looping cards (CM9760-DFL). No power required.

2.1.2 Optional Equipment

CM9760-MPS Matrix bay power supply (spare). Operates on 120 VAC, 60 Hz.

CM9760-MPS-X Matrix bay power supply (spare). Operates on 230 VAC, 50 Hz.

CM9760-VCC Video input (camera) card capable of accepting up to 16

CM9760-RPC Rear panel (BNC) card provides 16 BNC connectors used to

CM9760-DFC Downframe card and cable assembly used to connect multiple

CM9760-DFL Same as CM9760-DFC except has looping inputs.

CM9760-RPL Double wide rear panel card for single bay looping. Maximum

CM9760-VMC4 Video output (monitor) card providing 4 monitor outputs. Requires

CM9760-VMC8 Video output (monitor) card providing 8 monitor outputs. Requires

CM9760-VMC12 Video output (monitor) card providing 12 monitor outputs.

CM9760-VMC16 Video output (monitor) card provides 16 monitor outputs.

CM9760-VMM Video output module for expanding CM9760-VMC4, CM9760-

CM9760-RPM Rear Panel (BNC) Card provides 16 BNC connectors used to

camera inputs. Also requires a rear panel card (CM9760-RPC,

CM9760-RPL, CM9760-DFC, or CM9760-DFL).

connect camera inputs to matrix bay.

matrix bays together for output expansion purposes.

number of inputs per bay reduced to 128.

CM9760-RPM.

CM9760-RPM.

Requires CM9760-RPM.

Requires CM9760-RPM.

VMC8 or CM9760-VMC12 by one monitor output.

connect monitor to matrix bay.

Pelco Manual C543M-A (7/03) 7

Page 8

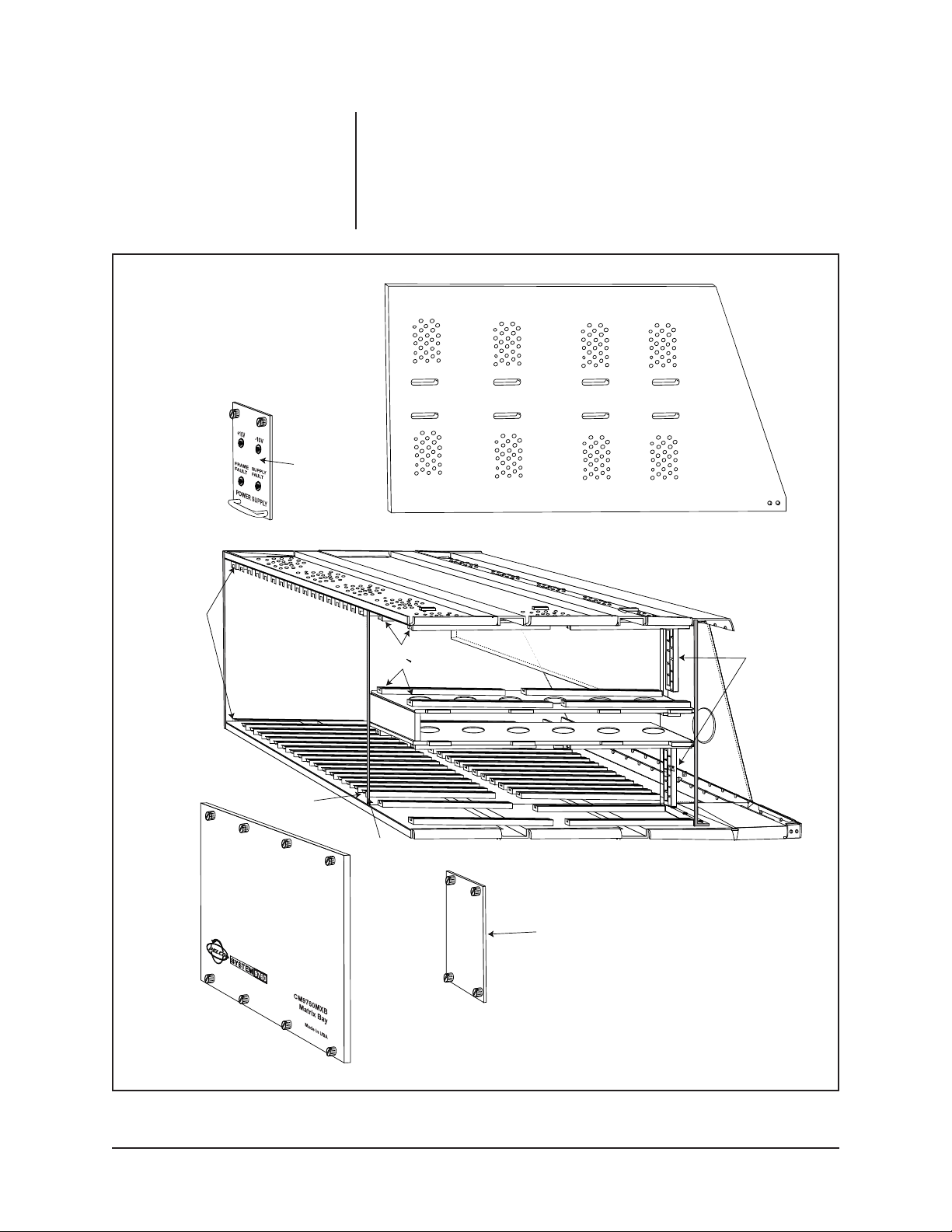

2.2 PHYSICAL LAYOUT

The matrix bay consists of the following items:

• Matrix Bay Card Cage

•Video Output Card (the 17

12 or 16 outputs and front loading)

•Video Input Cards (up to 16 total; all identical and front loading)

• Rear Panel Input Cards (there are, at present, four types of Rear Panel Input

cards that can plug into any one of 16 rear loading Video Input Card positions)

• Rear Panel Output Card (at present, there exists only one type of Rear Panel

Output card)

• Power Supply (shipped as 120 or 230 VAC).

The following paragraphs illustrate and describe the function of each of the bulleted

items just mentioned.

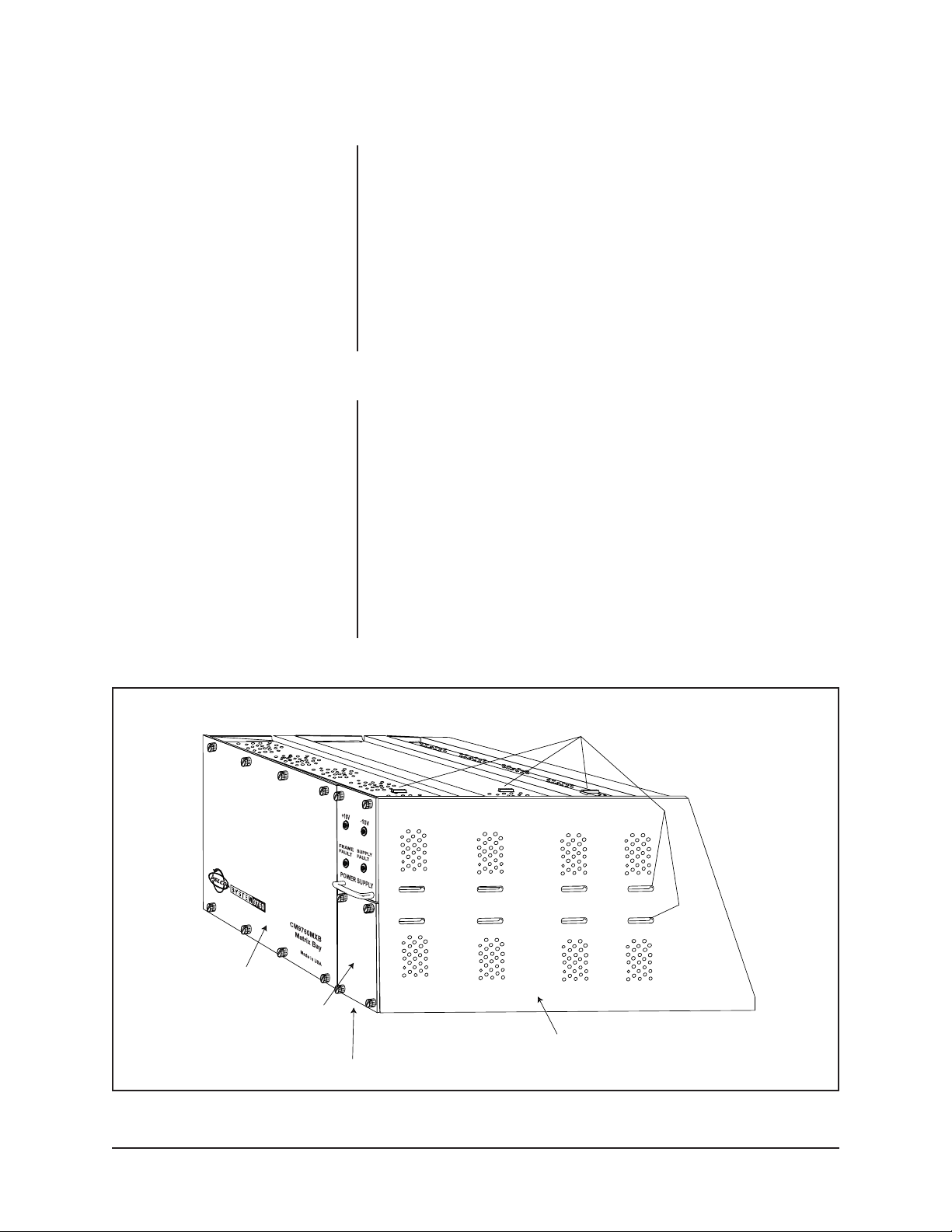

2.2.1 Matrix Bay Card Cage

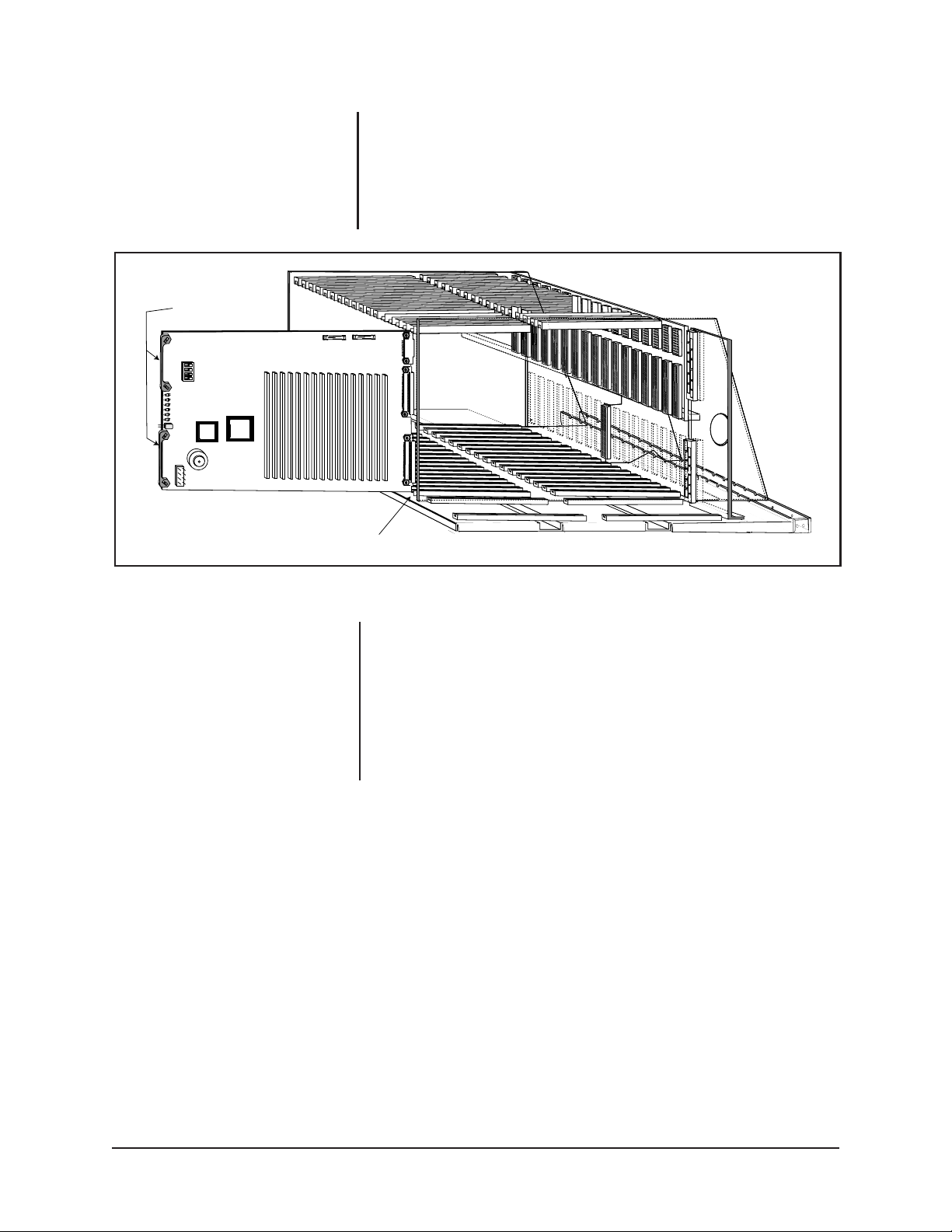

The matrix bay is pictured in Figure 1. The right side panel (power supply side), and

the top and bottom panels of all units are perforated with circular cut-outs to facilitate air circulation. Even though the matrix bay is a low power device and contains

no separate circulation fans, it is a good idea, if possible, to leave 1 RU (1.75")

between it and other installed bays. A fully loaded matrix bay, like all electrical

devices, does generate some heat.

The Cage of the matrix bay provides the skeleton into which all the bulleted items

listed in Section 2.2 fit. Figure 1 illustrates a matrix bay populated with one power

supply (the panel with the handle on it); the covered opening immediately below that

has a blank-off plate installed where a second power supply is installed if needed.

The card cage cutouts indicated in Figure 1 accept the tabbed appendages of the

panels that form the interior walls of the top and bottom power supply bays and

anchor them in place. If the installed power supply, the blank-off panel, the right side

panel and the large front-cover panel are removed from the unit in Figure 1, one can

see the layout of just the cage itself as show in Figure 2.

th

card, consists of one card type; available in 4, 8,

FRONT COVER

PANEL

BLANK OFF

PLATE

POWER

SUPPLY

RIGHT SIDE

PANEL

Figure 1. Front of Matrix Bay

TAB INSERTS PROVIDE

SUPPORT FOR SIDE, FLOOR

AND CEILING OF POWER SUPPLY BAYS

8 Pelco Manual C543M-A (7/03)

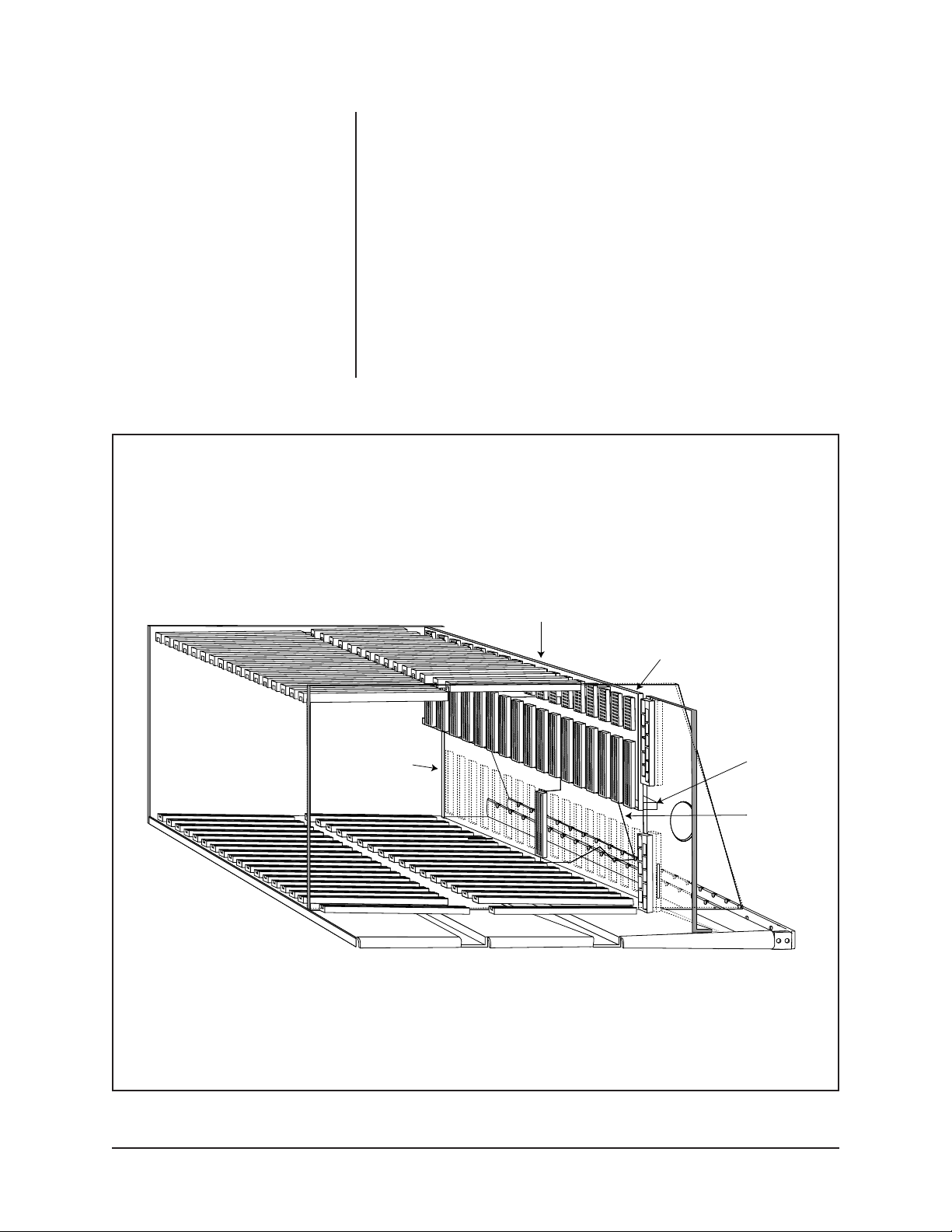

Page 9

POWER SUPPLY

COVER

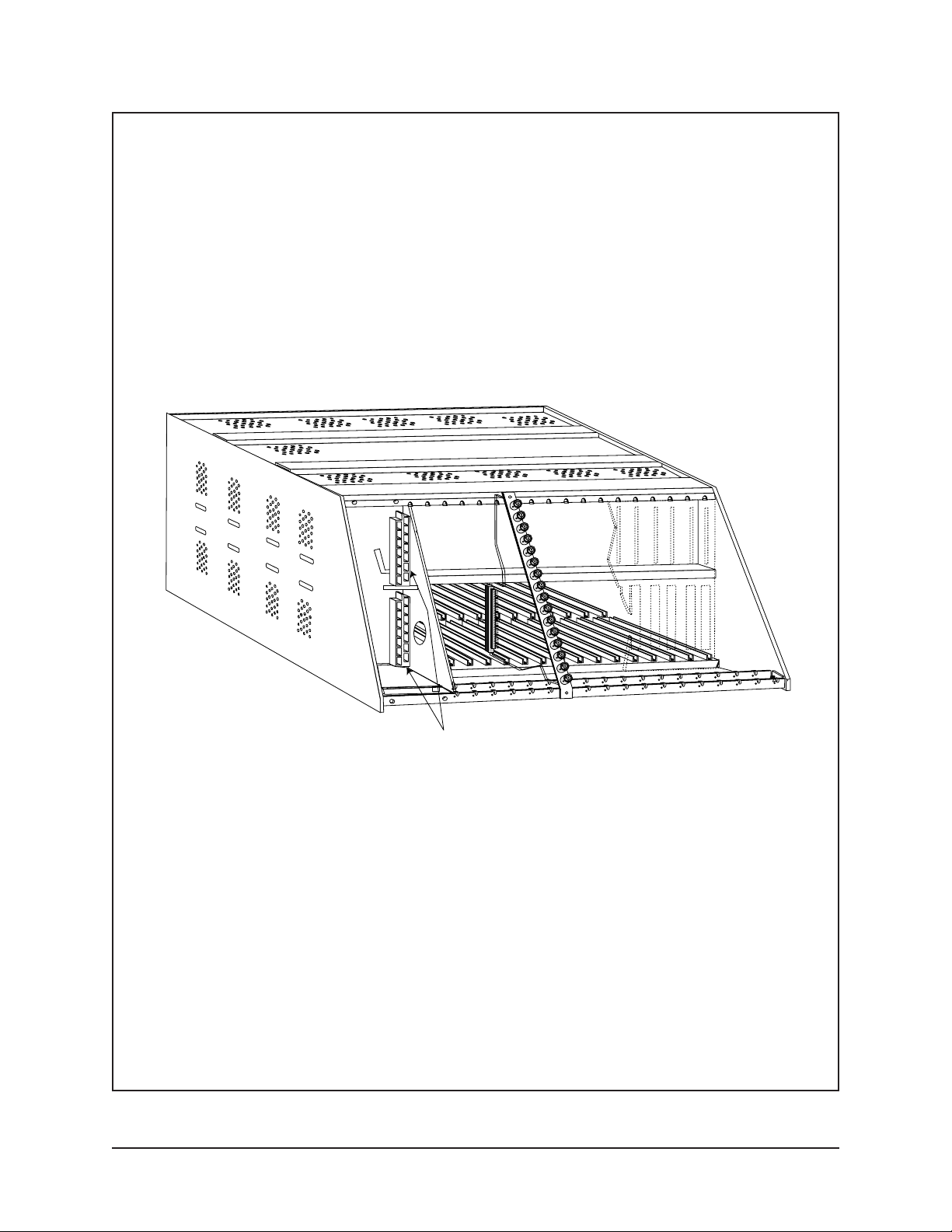

As already mentioned, room is made on the right side of the unit for the installation

of up to two power supplies. Two guide rails situated at the top and bottom of each

power supply bay exist to accept the power supply units. Seventeen sets of guide

rails (top & bottom) located to the left of the power supply provide for the installation

of up to sixteen Video Input Cards and one Video Output Card. The empty positions

are labeled left to right, 1 through 16. The seventeenth position (next to the power

supply bays) is the Video Output Card position. The Video Output card is slot specific and must always be installed in this slot position.

GUIDE RAILS

VIDEO OUTPUT

CARD POSITION

POWER SUPPLY

GUIDE RAILS

LEFT WALL

OF POWER SUPPLY

HOUSING

BLANK OFF

PLATE

POWER

SUPPLY

CONNECTORS

Figure 2. Matrix Bay Card Cage

Pelco Manual C543M-A (7/03) 9

Page 10

NOTE:

There are three (3) connectors into which any Video Input or

Output Card plugs into: the two on

the backplane and one on the appropriate rear panel card (see Figure 3).

This connection geometry holds true

for all installed front loaded Video Input and Video Output cards.

Further disassembly allows one to see the backplane upon which are located two

of the three connectors into which all installed Video Input and Video Output cards

plug into (refer to Figure 3). The back plane is held in place by rectangular bar stock

(top and bottom) which runs the width of the bay between the left side panel and

the power supply plate which secures it in place. Power supply units, Video Input

and Video Output Cards are all installed from the front of the unit. All other cards

are installed from the rear of the unit (refer to Figure 4).

Also note in Figure 3 the baffle plate installed for CE purposes with appropriate

openings for Rear Panel cards and their connectors to fit through. The baffle plate

itself, extends the width and height of the matrix bay itself (excluding power supply

sections).

The three connectors (consisting of two on the backplane and a single connector

provided by a Rear Panel card as indicated in Figure 3) constitute the connection

geometry for all Video Input and Output Cards. For any given card position an

associated Rear Panel card (card type dependent on the function of the matrix bay

into which it fits) must be installed FIRST.

REPRESENTS CE

BAFFLE PLATE

NOTE EXAMPLE OF VERTICAL ALIGNMENT

ORIENTATION INTO WHICH ALL VIDEO/OUTPUT

CARDS PLUG INTO (OUTPUT CARD SPECIFIC

TO SLOT 17)

BACKPLANE

BAR STOCK

REAR PANEL

CARD

Figure 3. Matrix Bay Connection Geometry

10 Pelco Manual C543M-A (7/03)

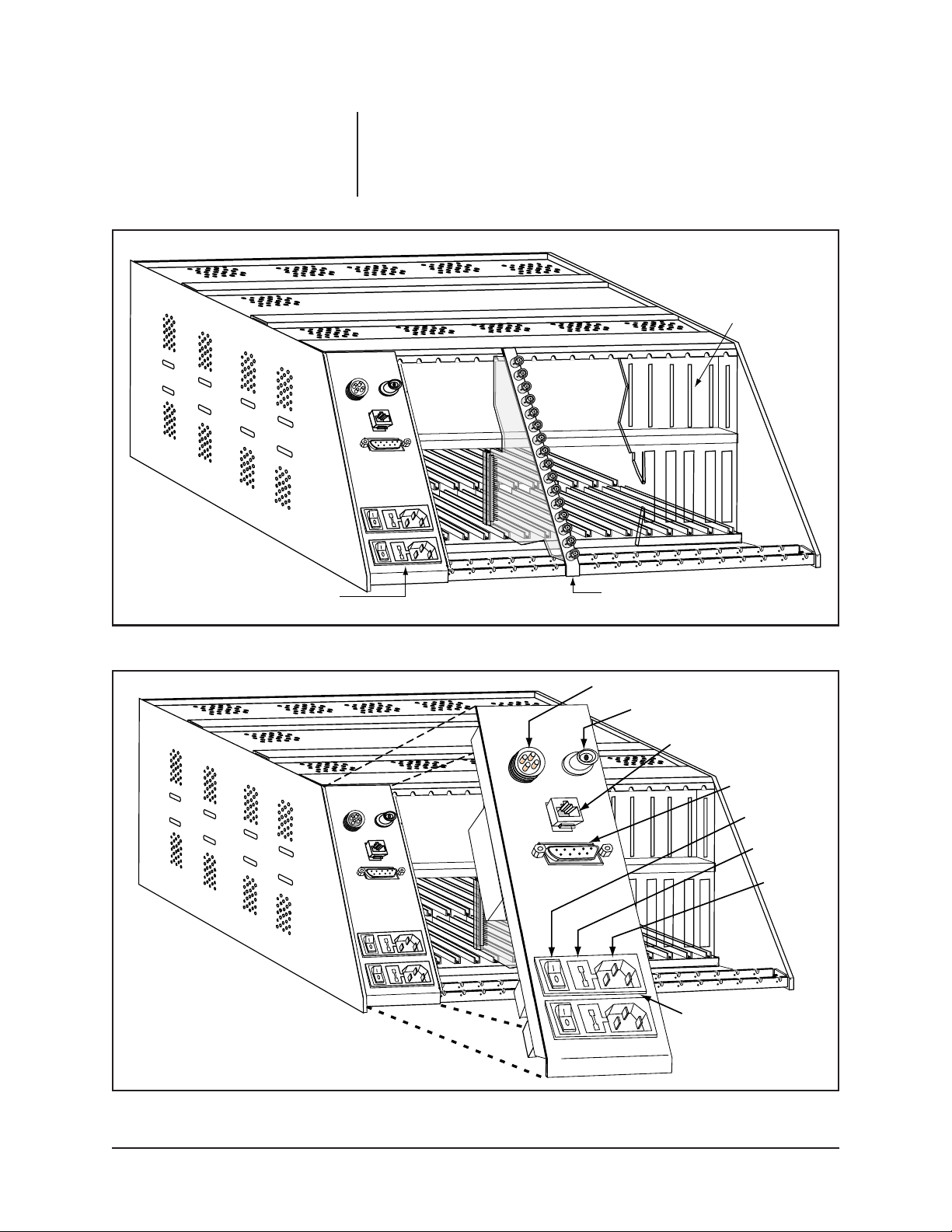

Page 11

A rear view of an empty matrix bay is shown in Figure 4.

The plate covering the rear section of the matrix bay dedicated to the power supply

bays is shown on the left in Figure 4. This panel is populated with several items of

importance, refered to in Figure 5. Located at the top left corner of the panel is the

Alarm Port connector.

CE BAFFLE

PLATE (PARTIAL)

POWER SUPPLY COVER

Figure 4. Rear of Matrix Bay

REAR PANEL CARD

ALARM PORT

VIDEO BLACK LEVEL

OUTPUT BNC

RJ-45 DATA PORT

DB9 PORT

POWER

SWITCH

FUSE

HOLDER

VOLTAGE

IN

INPUTS AND CONTROLS

FOR TOP POWER SUPPLY

Figure 5. Power Supply Section of Rear Matrix Bay

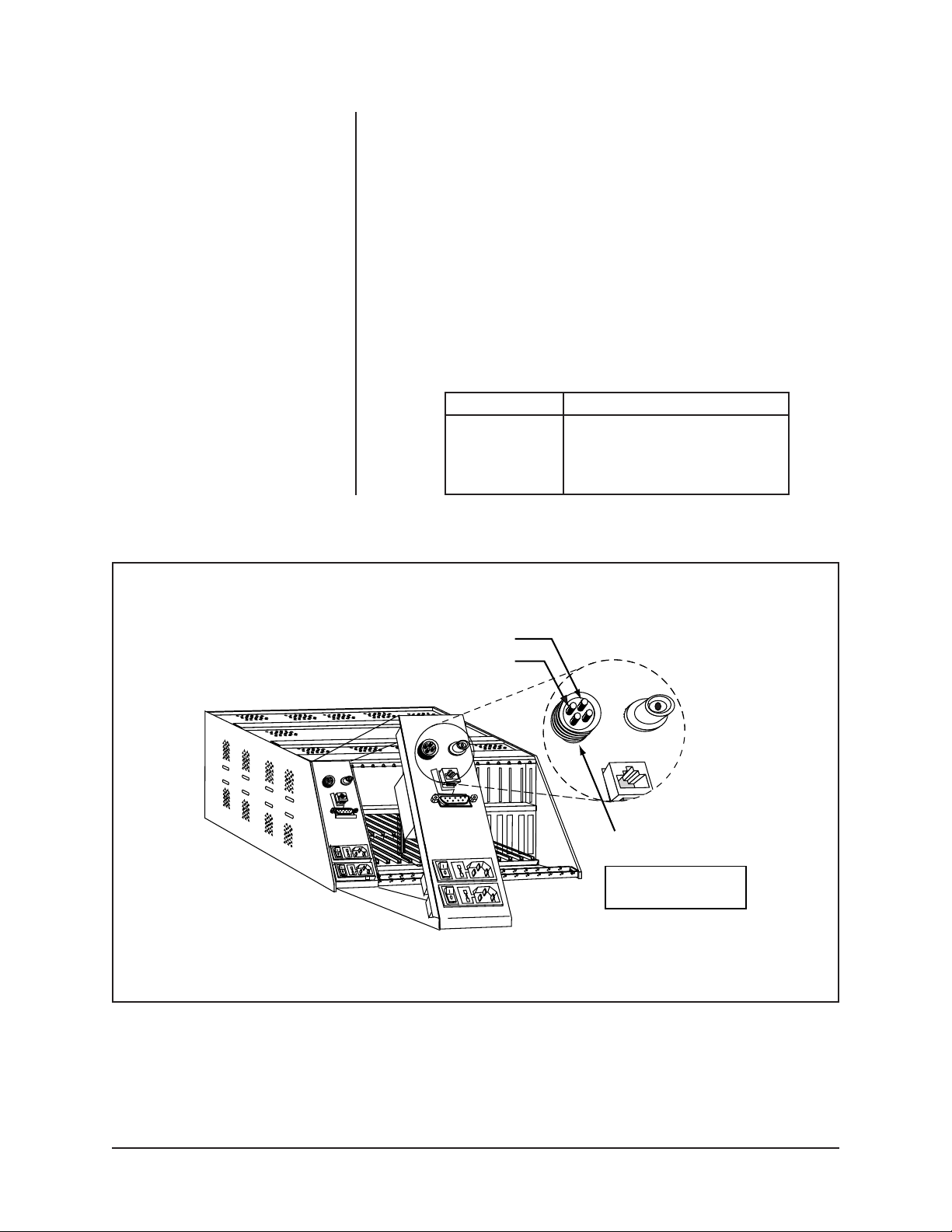

Pelco Manual C543M-A (7/03) 11

Page 12

A single Alarm port is provided with each matrix bay which facilitates a relay output

(contact closure) to operate remote alarm circuitry in the event of a system malfunction. The relay operates in conjunction with the front panel fault LEDs (discussed

later in Section 3.4) to notify personnel when a hardware problem occurs. The

Alarm Relay contact closure will activate (close) if there is:

1. A power supply failure.

2. A frame fault including fuse failure on the Input card.

3. An Output card failure.

4. A communication fault with an Input or Output card.

If wiring to this port, use the 4-pin audio connector supplied with the unit (refer to

Figure 6 and Table A).

Table A. Alarm Port Pin Definition

Pin Description

1 Relay One Common

2 Relay One Normally Open

3 Not Used

4 Not Used

NORMALLY OPEN

COMMON

Figure 6. Alarm Connector

ALARM PORT

4-PIN DIN SOCKET

ON THE REAR LEFT PANEL

OF THE VMB

12 Pelco Manual C543M-A (7/03)

Page 13

To the right of the Alarm Connector is a Video Black Level Output BNC which can

be used as a reference sync output to allow for genlocking of peripheral devices.

The signal level for this output is 300 mV. The connection for this output is a standard BNC connector. The output has a 75-ohm termination. The Video Black Level

BNC can be seen in Figure 5.

Below the two connectors just discussed is the RJ-45 connector or data port, which

provides the main RS-422 communication path between the matrix bay and an

appropriate SerCom port on the rear of a CM9760-CC1.

Power supply input terminal plugs, ON/OFF switches, and power supply input fuses

for both power supply positions (whether the power supply is installed or not) are

located at the bottom of the power supply panel. The top set of this twin configuration is for the top power supply; the bottom for the bottom (refer to Figure 5). Further

details of power supply configuration are discussed in Section 2.2.5 and 3.2.

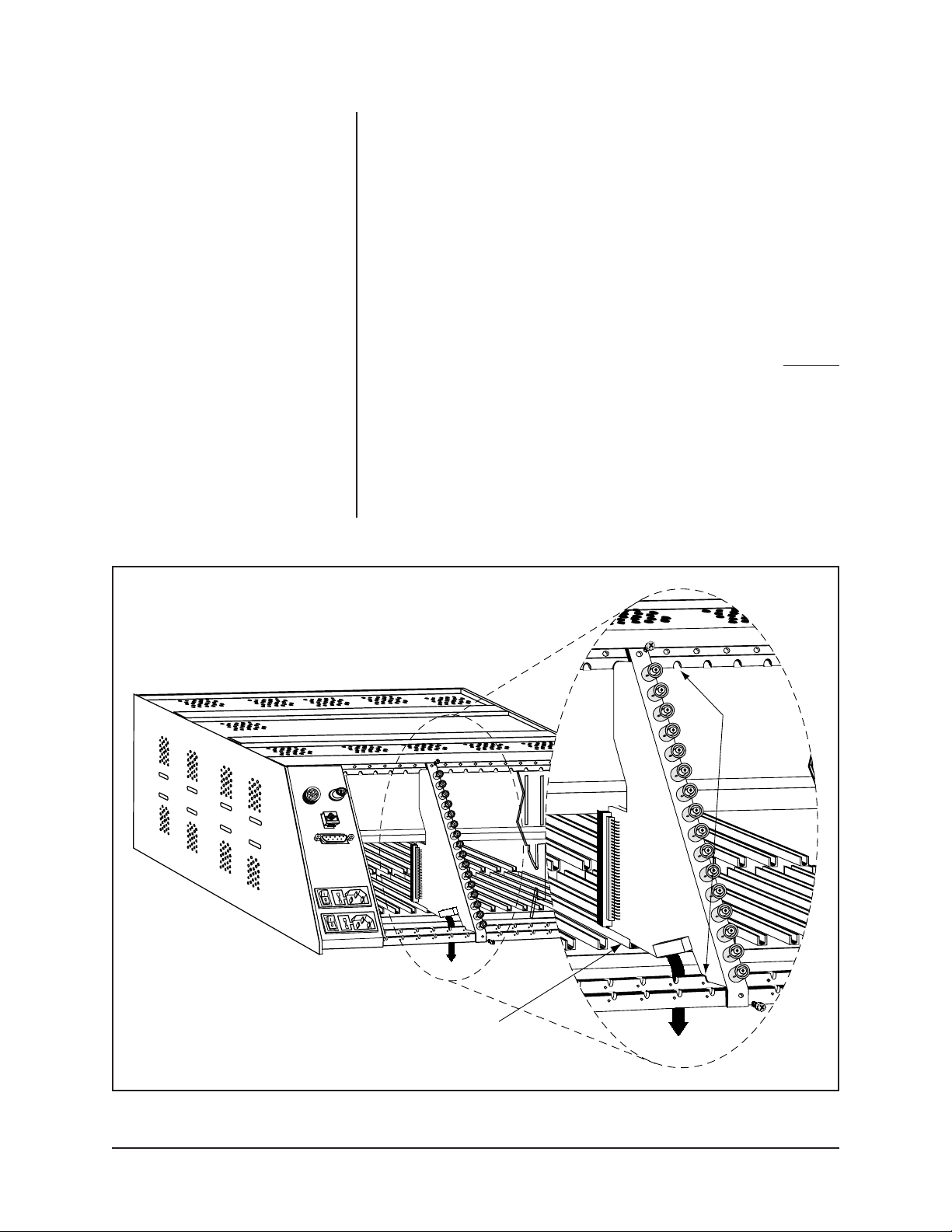

To the right of the power supply bays are the openings for installing the

rear panel

Input and Output cards. These cards provide a video signal path for the Video Input

and Output cards that plug into the matrix bay from the front. These unique, triangular shaped cards are held laterally in place by top and bottom notched rails and

a small rear portion of the guide rail into which the cards fit (refer to Figure 7).

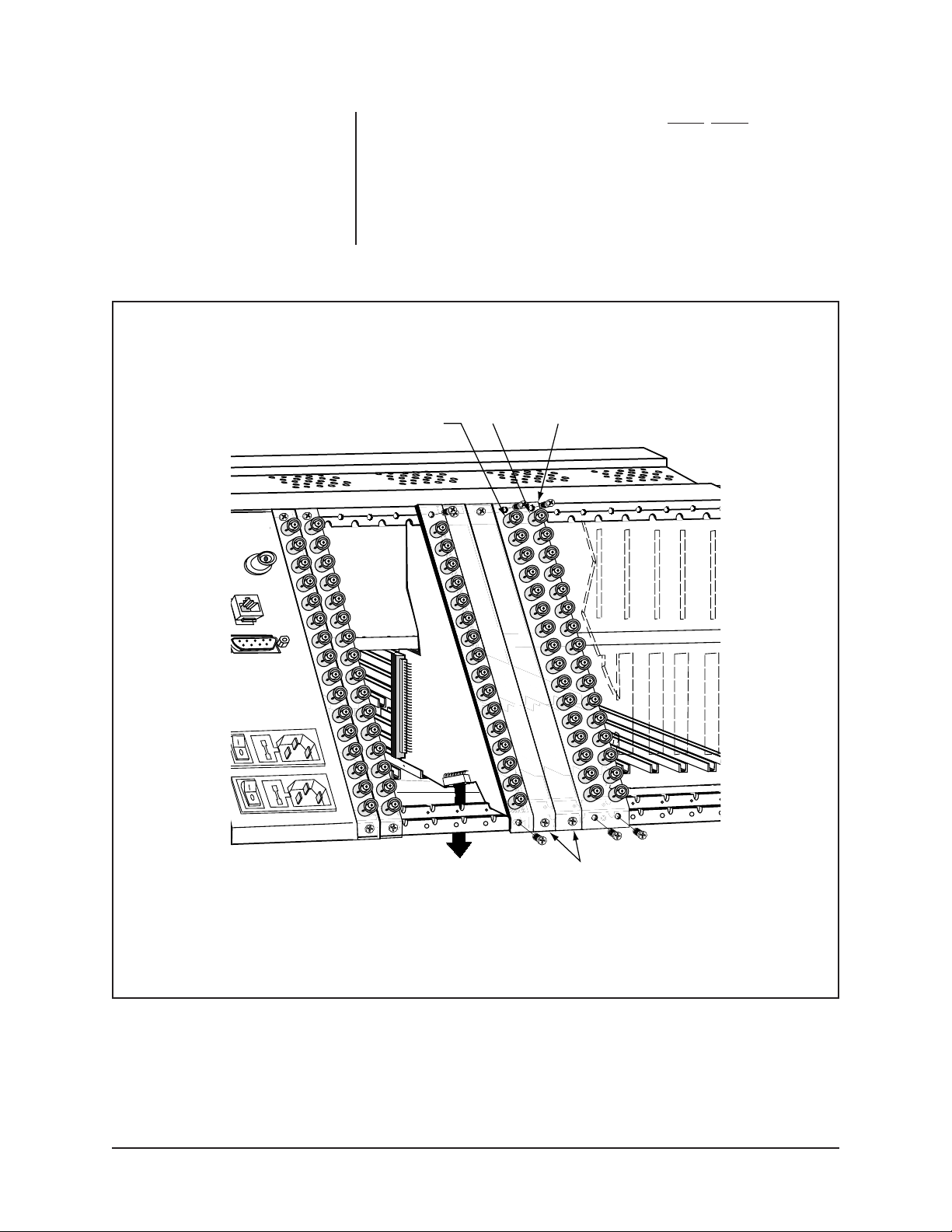

In addition, the cards are snugly secured to the matrix bay frame by screws which

hold the top and bottom of each card’s faceplate to the frame of the matrix bay

(refer to Figure 8). The dual BNC Rear Input card discussed in Section 2.2.4 is held

in place with four screws, two at top and two at bottom. Unused rear openings are

covered by appropriately sized blank plates.

NOTCHED

RAILS

INTO

WHICH

CARDS

FIT

REAR INPUT CARDS

SLIDE PARTIALLY INTO

BACK PORTION OF

CARD GUIDE

DOWNFRAMING

PATH

Figure 7. Matrix Bay and Rear Input Cards

Pelco Manual C543M-A (7/03) 13

Page 14

These rear input cards should always be installed

FIRST

, before the correspond-

ing Video Input and/or Output cards in the front of the unit are installed.

If we remove the left rear power supply panel with its associated connectors, you

can better visualize the backside of the power supply connectors into which the

individual power supplies inserted from the front of the matrix bay are located.

External power connected to the rear power supply input panels is routed and

attached to these connectors to provide input power for the power supply itself

(refer to Figure 9).

VIDEO OUT

(LOOPING)

VIDEO IN CM9760-RPL

DOWN FRAME

PATH

BLANK

PLATES

Figure 8. Rear Input Card Mounting

14 Pelco Manual C543M-A (7/03)

Page 15

REAR VIEW

OF POWER

SUPPLY CONNECTORS

Figure 9. Rear Input Power Supply Connector

Pelco Manual C543M-A (7/03) 15

Page 16

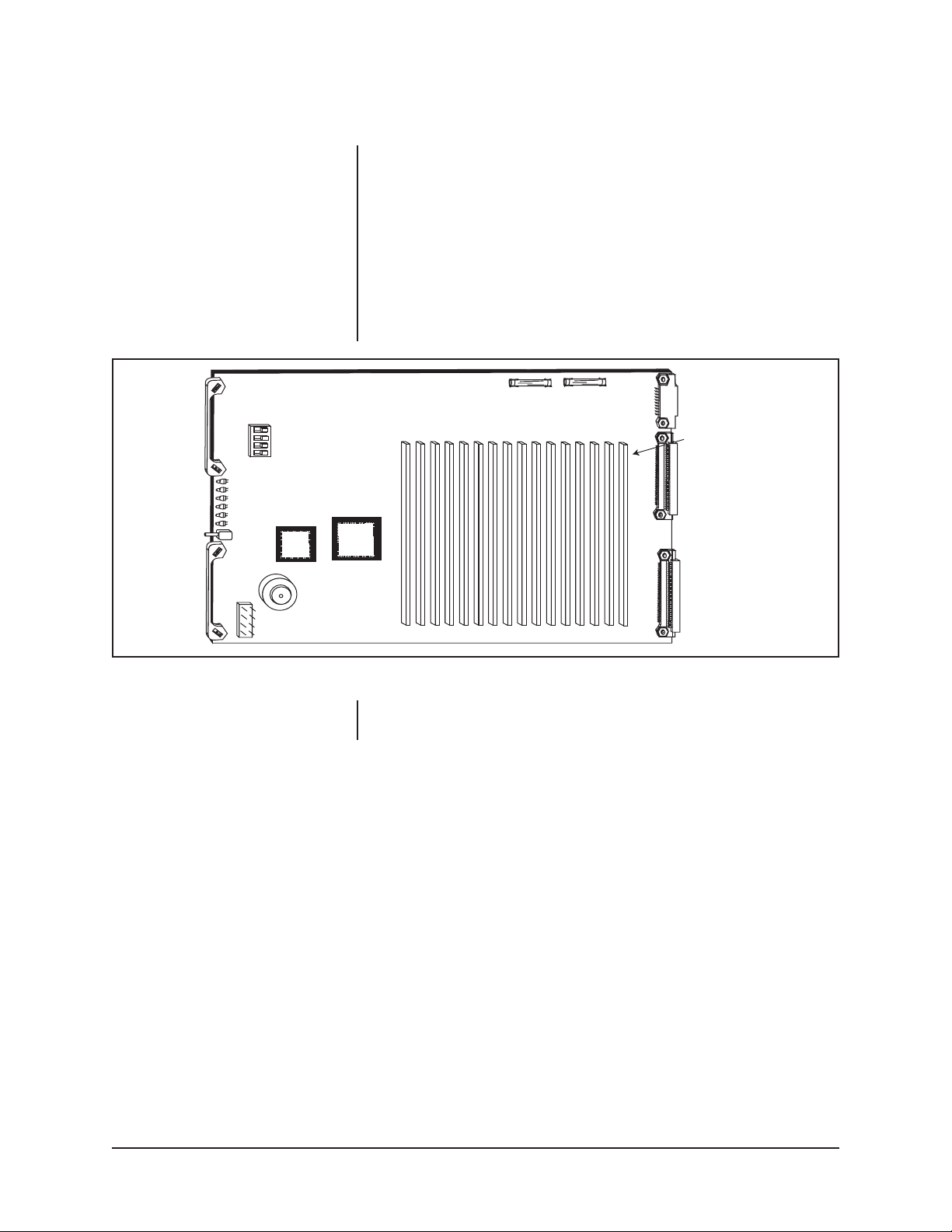

2.2.2 Video Output Card

Pelco Part Number Designation (CM9760-VMC)

What Does It Look Like?

The Video Output Card can contain up to 16 monitor outputs with titling. The card

may be purchased with 4, 8, 12, or 16 monitor outputs:

• CM9760-VMC4—provides 4 monitor outputs.

• CM9760-VMC8—provides 8 monitor outputs.

• CM9760-VMC12—provides 12 monitor outputs.

• CM9760-VMC16—provides 16 monitor outputs.

Figure 10 illustrates the CM9760-VMC16 Video Output Card.

MONITOR

OUTPUTS

WITH TITLING

Figure 10. Video Output Card with 16 Monitor Outputs (CM9760-VMC16)

Note that a CM9760-VMM video output module can expand the number of monitor

outputs on a CM9760-VMC4, CM9760-VMC8, and CM9760-VMC12 Video Output

Card. Each CM9760-VMM video output module provides one monitor output.

16 Pelco Manual C543M-A (7/03)

Page 17

CARD HANDLES

SLOT SPECIFIC

TH

SLOT

17

Where Is It Installed?

The Video Output Card is located behind the front cover of the matrix bay. It is the

only card that is slot specific in the matrix bay (slot 17, to be specific). Refer to Figure

11. To install, simply line up the edges of the card with the top and bottom card

guides, slide the card in toward the rear of the unit until it is seated firmly with the

connectors on the back plane as well as with any associated rear panel card connector. To remove, grab the handles on the front card edge and firmly pull straight out.

Figure 11. Video Output Card Installation

What Are Its Functions?

The Video Output Card handles several functions; the most important of which are:

1. Routes regular video from the internal input bus, adds idents (if applicable)

and routes the signal through the system to the output monitors.

2. In the case of video loss, the output card will maintain video reference levels

and route black video for ident purposes.

3. Video loss compensation throughout the system via the video output amplifier.

Pelco Manual C543M-A (7/03) 17

Page 18

Other Important Items

DIP Switch and Jumper Settings

The matrix bay has a DIP switch (S2) and jumpers (JP2 and X55) located on the

Video Output Card that enable the selection of different options. These are normally

set in the proper position upon leaving the factory. However, it is recommended that

the settings be checked prior to operating the system (the other “front loading”

Video Input Cards have no DIP switches or jumpers to verify). Refer to the following

paragraphs for a complete description of the switches and jumpers on the Video

Output Card.

Refer to Figure 12. Switch S2 determines the communications baud rate, how the

system will operate on power up and whether video loss detection is enabled or

disabled. Refer to Table B for S2 switch assignments.

RED DS6

GREEN DS5

GREEN DS4

DS3

AMBER DS2

DS1

RESET

SWITCH

1

23

4

ON

S2

(SEE TABLE B)

FUSES, BOTH .7ASB

F6

F7

JP2

X55

(SEE TABLE C)

Figure 12. Location of DIP Switches, Jumpers and Fuses

18 Pelco Manual C543M-A (7/03)

Page 19

DIP switch 2 has the following functions:

S2

1 234

Table B. Output Card S2 Functions

S02

Description 1234

2400 Baud OFF OFF

4800 Baud OFF ON

9600 Baud ON OFF

19.2 K Baud ON ON

NTSC* OFF

PAL* ON

Default setting OFF

Must be ON for VIDEO LOSS

feature to operate ON

*X55 jumpers (refer to Table C) need to be set per Table C.

Setting the Jumpers on the Video Output Card

There are two jumper locations on the Video Output Card (refer to Figure 12 inset).

JP2 and X55. JP2 is used to control the program loading sequence and must always

have a jumper installed for proper operation. X55 is an eight-position header used

to set the standard required for video black generator operation. Refer to Table C

for a complete list of the available standards and the jumper location.

JP2 is a two-pin header used to control the program loading sequence and

must always have a jumper installed for proper operation.

X55 is an eight-pin header used to set the video standard for the video black

generator.

Table C. X55 Jumper Definitions

STANDARD OSC. FREQ. 1-2 3-4 5-6 7-8

SECAM1 5.0 MHz ON ON ON ON

SECAM2 5.0 MHz ON ON OFF ON

624 5.0 MHz ON OFF ON ON

PAL/CCIR 5.0 Mhz ON OFF OFF ON

NTSC1 5.034964 MHz ON ON ON OFF

NTSC2 5.034964 MHz ON ON OFF OFF

524 5.034964 MHz ON OFF ON OFF

PAL-M 5.034964 MHz ON OFF OFF OFF

Pelco Manual C543M-A (7/03) 19

Page 20

Video Output Card LEDs

The Video Output Card is equipped with six LEDs labeled DS1, DS2, DS3, DS4,

DS5, and DS6. Refer to Table D for a complete description of the Video Output

Card LEDs. Refer to Section 3.4.1 for further information regarding LED diagnostic

checks.

Table D. Video Output Card LED Assignments

LED COLOR WHEN LED IS ON

DS1 to DS3 Amber Always ON, No assignment

DS4 Green -10 VDC is OK

DS5 Green +10 VDC is OK

DS6 RED Communications failure with the CM9760-CC1

2.2.3 Video Input Card

Pelco Part Number Designation (CM9760-VCC)

What Does It Look Like?

The Video Input Card is illustrated in Figure 13

There can be from 1 to 16 Video Input Cards installed in a matrix bay. Your particular matrix bay has been shipped from the factory with the specified cards installed.

Figure 13. Video Input Card

20 Pelco Manual C543M-A (7/03)

Page 21

Where Is It Installed?

The Video Input Card is located behind the front panel of the matrix bay and is

found in any one or all of the available 16 slots provided there. Video Input cards

are not slot specific (any card can go into any slot) but there are some items to keep

in mind. The first and most important is the fact that, although the board can be put

into any position, each slot position does correspond to a specific range of physical

inputs; i.e. slot position 1 (on the far left of the matrix bay) corresponds to physical

inputs 1-16; slot 2 corresponds to physical inputs 17-32, and so on. If you do not

install the cards in sequential order, this must be taken into account when programming the system. Table E gives a quick reference for determining the range of

inputs for any slot position (also refer to Figure 14).

The second item to keep in mind is that the rear panel BNC Input card associated

with the Video Input Card you are getting ready to install should already be in place

and matched up with your slot position choice.

The physical removal and installation for this card is the same as that discussed for

the Video Output Card.

Table E. Physical Input Range Per Slot Position

Slot Position 1 2 3 4 5 6 7 8

Physical Range 1-16 17-32 33-48 49-64 65-80 81-96 97-112 113-128

Slot Position 9 10 11 12 13 14 15 16

Physical Range 129-144 145-160 161-176 177-192 193-208 209-224 225-240 241-256

Pelco Manual C543M-A (7/03) 21

Page 22

INPUT SLOT

RANGES POSITION

1-16 1

17-32 2

33-48 3

49-64 4

65-80 5

81-96 6

97-112 7

113-128 8

129-144 9

145-160 10

161-176 11

177-192 12

193-208 13

209-224 14

225-240 15

241-256 16

VIDEO FOR OUTPUT CARD

(1 ONLY)

Figure 14. Video Input Card Installation

22 Pelco Manual C543M-A (7/03)

Page 23

What Are Its Functions?

The Video Input Card also handles several functions:

1. The card accepts up to 16 video input signals from the Rear Panel BNC Card

and switches them to the 16 lines of the video output bus.

2. Accepts and acts upon control data coming from the Video Output Card.

3. Synchronizes matrix switching with the vertical interval and reports card status.

4. Acts as a power-up configuration watchdog and monitors serial communica-

tions with the output card controller and causes the COMMS failure LED to

light as a result of any conditions that can cause a communication failure.

5. Monitors Video Loss and raises a video fail flag in the case of signal loss and

notifies the Output Card Controller.

Other Important Items

Video Input Card LEDs

Each of the 16 possible Video Input Cards is equipped with three LEDs labeled

CR1, CR2, and CR3. Refer to Table F for a complete description of the Video Input

Card LEDs. Further information regarding LED diagnostics is found in Section 3.4.

Table F. Video Input Card LED Assignments

LED COLOR WHEN LED IS ON

CR1 RED

CR2 GREEN

CR3 GREEN

CR1 Red Communications failure with the CM9760-CC1

CR2 Green +10 VDC is OK

CR3 Green –10 VDC is OK

The Video Input Card has no jumper or switch settings to worry about.

Video Input Card Fusing

Two power fuses, F1 and F2 exist on each Video Input Card. Refer to Figure 15 for

fuse locations. Both of the front panel LEDs should be lit at all times (CR2 and

CR3). If one or both are Out on any card, remove the affected card, and check the

fuses. Replace defective fuses and reinstall the card.

F1

.7ASB

F2

.7ASB

Figure 15. Input Card LED and Fusing Locations

Pelco Manual C543M-A (7/03) 23

Page 24

2.2.4 Rear Panel Input/Output Cards

Pelco Part # Designations

CM9760-RPC (Rear Panel Input BNC Card for CM9760-VCC)

CM9760-DFL (Rear Panel Input Looping Downframe Card)

CM9760-DFC (Rear Panel Downframe Card, No Looping)

CM9760-RPL (Rear Panel Localized Looping Within the Same Matrix Bay)

CM9760-RPM (Rear Panel Output BNC Card for CM9760-VMC)

CM9760-RPC (Rear Panel Input BNC Card for CM9760-VCC)

What Does It Look Like?

The Rear Panel Input BNC Card is illustrated in Figure 16.

2

3

TERMINATED

1

JP1-JP16

DOWNFRAME

CONNECTOR

UNTERMINATED

Figure 16. CM9760-RPC Rear Panel BNC Input Card

16 VIDEO INPUT BNCs

What Are Its Functions?

The RPC card handles Video Input to the matrix bay. From 1 to 16 cards can occupy a single matrix bay. Each card has 16 BNC inputs. When the multiplication is

done, up to 256 Video Inputs are available on a fully populated matrix bay. Each

front loaded Video Input Card requires that a corresponding Rear Panel Input BNC

card (CM9760-RPC) be installed.

The RPC card serves several functions:

1. Physical connection point for Coax Cable.

2. The Rear Panel BNC Input Card passes the external Video signal to the Video

Input card.

3. All 16 Input Video Signals are also made available at the 16-pin connector canted

at an angle and located toward the bottom of the board (refer to Figure 16).

4. Video Input Signals can also be terminated, if applicable, with individual jumpers

accessible on the board at each of the 16 video inputs (refer to Figure 16).

24 Pelco Manual C543M-A (7/03)

Page 25

Note the following about the termination jumpers on the RPC card:

• In a single-bay configuration (up to 256 cameras and 16 monitors), the jump-

ers on the RPC card must be set in the terminated position. Refer to Section

5.1 for an illustration of a single-bay configuration.

• In a downframe configuration, the jumpers on the RPC card must be set in the

unterminated position. Refer to Section 5.1 for information about downframing.

• In a sideframe configuration, the jumpers on the RPC card must be set in the

unterminated position. Refer to Section 5.2 for information about sideframing.

Where Is It Installed?

The Rear Panel Video Input Card is installed from the rear of the matrix bay in any

1 of 16 possible slot positions depending on your system configuration. Remember

that each RPC card is associated with a corresponding Video Input Card. Locate

the correct slot position and install the card as shown. Refer to Figure 17 for typical

installation geometry.

Figure 17. Installation of RPC Input Card

Pelco Manual C543M-A (7/03) 25

Page 26

CM9760-DFL (Rear Panel Downframe Looping Card)

What Does It Look Like?

The DFL card is essentially an RPC card with an attached downframing cable. The

card itself looks like the one pictured in Figure 16.

What Are Its Functions?

The DFL card is used in the last bay in a downframe configuration and provides the

capability to loop out video. The card contains termination jumpers that must be set

in the unterminated position when looping to another device is required. When

looping is not required, the termination jumpers must be set in the terminated position.

The DFL card can be used in the CM9760-MXB to increase the number of available

monitors whether or not looping is required. In addition, the DFL card is the only

card that can be used in the CM9760-MXBL, which is an unpowered, downframed

matrix bay that contains 16 DFL card slots for supporting 256 video loop-out connections. (When looping is required in a 9760 system that has 16 or fewer monitors

and more than 128 cameras, the CM9760-MXBL containing DFLs must be used.)

For additional information about the DFL card, refer to Section 5.1.

Where Is It Installed?

Physically (as long as function parameters are met), a DFL card can be installed in

any slot position.

26 Pelco Manual C543M-A (7/03)

Page 27

CM9760-DFC (Rear Panel Downframe Card, No Looping)

What Does It Look Like?

The DFC card is illustrated in Figure 18.

Note that instead of BNC connectors on the spine of the card there are two identical

16-pin male connectors. Note that there are termination jumpers on the board. Also

note that there is no connector located on the bottom area of the board as was the

case for previously illustrated rear panel cards. The DFC card is supplied with a

downframing cable.

What Are Its Functions?

The downframe card’s almost sole function is as its name implies — to provide a

signal path for the addition of more monitors in extended framing situations while at

the same time aiding full cross-point functionality of the downframed configuration.

For every bay between the first and last, a DFC card is used to interconnect the

associated intermediate bays. The DFC card can also be used in the last bay in a

downframe configuration. Note that when the DFC card is used in the intermediate

bays, the termination jumpers must be set in the unterminated position. When the

DFC card is used in the last bay in a downframe configuration, the termination

jumpers must be set in the terminated position.

Where Is It Installed?

It is installed in any of the 16 slot positions of any bay in a downframing configuration where it is needed. It is physically installed in the same manner as any other

rear panel card. For additional information, refer to Section 5.1 on downframing.

UNTERMINATED

3

2

1

TERMINATED

JP

1

Figure 18. DFC Card

INPUT

FROM BAY ABOVE

JP

16

OUTPUT

TO BAY BELOW

Pelco Manual C543M-A (7/03) 27

Page 28

CM9760-RPL (Rear Panel Localized Looping Within the

Same Matrix Bay)

What Does It Look Like?

The RPL card is illustrated in Figure 19.

Note the double row of BNC connectors running down the spine of the card. Also

note that the card takes up two slot positions instead of one and that the card

contains termination jumpers. The jumpers must be set in the unterminated position when looping functions are required. When looping functions are not required,

the jumpers must be set in the terminated position.

What Are Its Functions?

The RPL card provides a convenient solution for those installations where looping

functions are desired and the total number of camera or video signal inputs for

looping does not exceed 128. Since each card takes up two slot positions, you

have only half of the normally available 256 inputs available for looping. Note that

only odd slot positions (in a fully populated bay) would be occupied and that the

corresponding front loaded Video Input card would also occupy odd slot positions.

Where Is It Installed?

In the same manner as RPC cards, but where looping functions are desirable.

UNTERMINATED

TERMINATED

2

3

JP1-JP16

IN

OUT

1

16 BNC PAIRS

Figure 19. RPL Card

28 Pelco Manual C543M-A (7/03)

Page 29

CM9760-RPM (Rear Panel Output BNC Card for CM9760-VMC)

What Does It Look Like?

The CM9760-RPM rear panel output card is associated with the CM9760-VMC

card. Note that the RPM card contains termination jumpers that must always be set

in the unterminated position. The device to which the RPM card passes its signal is

the point where termination should take place (e.g., a monitor).

What Are Its Functions?

1. Provides signal path for Video Output Card

2. Provides physical BNC connection for external use of Video signal (monitor,

VCR, etc.)

Where Is It Installed?

The card is slot specific and MUST always be installed in the rear position that

corresponds to the front loaded Video Output Card position as viewed from the

front of the matrix bay, which is

slot 17 (refer to Figure 11 or 14).

UNTERMINATED

TERMINATED

2

3

1

16 VIDEO INPUT BNCs

JP1-JP16

DOWNFRAME

CONNECTOR

Figure 20. CM9760-RPM Video Output Card

Pelco Manual C543M-A (7/03) 29

Page 30

2.2.5 Power Supply

Note that the power supply bays are on the right side of the unit (one directly above

the other). An installed power supply is characteristically identified by its handle

and the four LEDs on its front plate. An unoccupied power supply bay is covered

with a blank-off plate as previously shown in Figure 1.

Installing an Additional or Redundant Power Supply

The matrix bay accepts two separate power supplies. When shipped, unless specified otherwise, the unit has one power supply installed. The other location has a

blank-off plate installed. To install an additional power supply, remove the blank-off

plate, line up the supply in the mounting rails and slide into place. Press firmly on

the front of the supply to properly seat the supply into the rear connector (refer to

Figure 21).

Figure 21. Power Supply Installation

30 Pelco Manual C543M-A (7/03)

Page 31

Setting the Jumper on the Power Supply (Beeper Enable)

Located on the power supply is a three-position header that allows the user to

enable/disable the audio beeper, which also is located on the power supply. The

beeper operates in conjunction with the fault LEDs located on the front panel. Refer

to Figure 22 for the location of X5 and how to set the jumper.

Power Supply LEDs

Each power supply is equipped with four LEDs labeled +10 V, -10 V, Frame Fault

and Supply Fault. If the unit is operating properly, the +10 V and -10 V LEDs will be

illuminated. Refer to Table H in Section 3.4.1 for a complete description of the

power supply LEDs.

X5

BEEPER ENABLED

BEEPER DISABLED

Figure 22. Jumper Position on Bottom of Power Supply

Pelco Manual C543M-A (7/03) 31

Page 32

3.0 INSTALLATION

NOTE:

Make sure the selected location has adequate power available.

The unit operates on either 120 VAC

or 230 VAC input power.

3.1 MOUNTING INSTRUCTIONS

The matrix bay communicates with the Controller via RS-422 communications and

therefore can be installed up to 4,000 feet (1,219.2 meters) away from the Controller. Determine where the matrix bay is to be located and follow the mounting and

wiring instructions below.

The matrix bay mounts in a 19-inch rack using standard mounting hardware and

occupies 6 RU (10.5 inches) of vertical space. Place the matrix bay in the desired

location and secure properly.

The matrix bay is designed for low power consumption and therefore has no internal

fans. If mounting several matrix bays together in the same location or if installing in

high temperature environments, it is highly recommended that you separate the

units by at least 1 RU (1.75 inches). In high temperature environments, it also may

be necessary to provide forced air cooling. Contact Pelco for additional information.

Once the unit has been secured into the equipment rack, remove the front panel of

the unit to gain access to the circuit cards. Ensure each card is firmly seated in the

frame.

Figure 23. Mounting the Matrix Bay

32 Pelco Manual C543M-A (7/03)

Page 33

3.2 CONNECTING POWER TO THE MATRIX BAY

WARNING:

Always

replace blown fuses

with fuses of the same

rating. Failure to do so

could result in serious

damage to the unit.

The matrix bay is shipped from the factory configured for the correct input power.

The unit provides two separate power input receptacles, one for each power supply.

Each receptacle is equipped with its own On/Off switch and fuse assembly. In addition, each fuse assembly also provides a spare fuse. Refer to Figure 24. To remove

the fuse assembly, first remove the power cord from the receptacle and, using a

small screwdriver, pry the fuse holder out of the socket. The complete fuse assembly

comes out of the unit. Replace the fuse using a 1.6 ASB fuse. If using the spare,

make sure to replace the spare with one of the same rating.

STORAGE DRAWER

FOR SPARE FUSE

REPLACE IF

NECESSARY

FUSE HOLDER

Figure 24. Replacing Power Supply Fuses

Pelco Manual C543M-A (7/03) 33

Page 34

3.3 CONNECTING THE MATRIX BAY TO THE CONTROLLER

As illustrated in Figure 25, the female RJ-45 SerCom data port connector labeled

RS-422 on the rear of the matrix bay connects to a female RJ-45 SerCom port

(RS-422) on the rear of the CM9760-CC1. A 10-foot (3.05 meters) reversed cable

is supplied to connect the matrix bay to the CC1. If you must create a longer cable,

it is recommended that you use a 24-gauge twisted-pair cable.

CM9760-MXB (FULLY LOADED)

8-PIN SERCOM PORT (FEMALE)

PIN 1

PIN 8

CM9760-MXB CM9760-CC1

CONNECTOR CONNECTOR

PIN 1=Tx+

PIN 2=Tx–

.

.

.

.

PIN 7=Rx–

PIN 8=Rx+

PIN 1=Tx+

PIN 2=Tx–

.

.

.

PIN 7=Rx–

PIN 8=Rx+

REVERSED DATA CABLE (SUPPLIED)

RS-422

DATA CABLE CONNECTIONS

RJ-45 RJ-45

PIN 1=Tx+

PIN 2=Tx–

.

.

.

.

PIN 7=Rx–

PIN 8=Rx+

CM9760-CC1

Figure 25. Connecting the Matrix Bay to the CM9760-CC1 Controller

34 Pelco Manual C543M-A (7/03)

Page 35

3.4 LED DIAGNOSTICS

Each component installed in the matrix bay is equipped with diagnostic LEDs (most

of which have already been mentioned) to aid in system troubleshooting. All LED

assignments are repeated below (for convenience) in Table G.

3.4.1 Performing a Diagnostic LED Check

Prior to connecting any video input or output to the matrix bay, it is recommended

that you first power up the unit to ensure the system is operating properly. Refer to

the following checklist to ensure the matrix bay is operating correctly at this time.

1. Apply power to the unit.

2. Ensure both power LEDs on the supply (or supplies) are illuminated.

3. Ensure both the Frame Fault and the Supply Fault LEDs are OFF.

4. Remove the front panel and check the power LEDs on each of the Video

Input/Output Cards. Both LEDs should be illuminated. If any board has a problem, remove the board(s) and inspect the fuses. Replace fuse (if necessary)

and reinstall into the frame. If the condition continues, replace the defective

board with a known good board.

5. Ensure all Comm Fail LEDs are OFF. If this LED is ON on any Input card,

reseat the board. If the condition continues, replace with a known good board.

If all the Comm Fail LEDs are illuminated, press the reset button located on

the Output card. If the problem continues, replace with a known good board. If

the LED is illuminated on the Output Card only, check the communications to

the CM9750 Controller.

6. If everything is OK, install all video inputs and outputs as described in paragraph 3.5.

Table G. Matrix Bay LED Assignments

Video Output Card LEDs

LED COLOR WHEN LED IS ON

DS1 to DS3 Amber Always ON, No assignment

DS4 Green –10 VDC is OK

DS5 Green +10 VDC is OK

DS6 Red Communications failure with the CM9760-CC1

Video Input Card LEDs

LED COLOR WHEN LED IS ON

CR1 Red Communications failure with the CM9760-CC1

CR2 Green +10 VDC is OK

CR3 Green –10 VDC is OK

Power Supply Module LEDs

LED COLOR WHEN LED IS ON

+10 V Green Normal Operation

–10 V Green Normal Operation

Frame Fault Red (flashing) Failure of one or more cards

Supply Fault Red Failure of associated power supply

3.5 CONNECTING VIDEO INPUTS/OUTPUTS

NOTE:

When wiring inputs it is

always good installation practice to

label each video input. This can save

a considerable amount of time should

All video inputs and monitor outputs are connected to the Rear Panel BNC Cards.

Be sure each connection is secure and that the connectors are installed properly.

When connecting the inputs and outputs to the rear panels, allow enough slack in

the cable to act as a strain relief.

troubleshooting be required.

Pelco Manual C543M-A (7/03) 35

Page 36

4.0 FUNCTIONAL CIRCUIT DESCRIPTION

The matrix bay communicates with the Controller via an RS-422, full-duplex, asynchronous communications interface and performs all video switching functions as

directed from the Controller.

Refer to Figure 26 for a block diagram outlining the discussion in the next few

paragraphs. Refer to Figure 27 for a more graphical representation of the same

thing. The video signal enters the matrix bay through the Rear Panel BNC Card

(Input) where it is terminated with 75 ohms. The signal then proceeds to the Video

Input Card via the input buffers and is then directed to the 16 x 16 crosspoint switch.

Operation of the crosspoint switch is controlled by the Video Output Card.

The signal leaves the Video Input Card and is sent to the Video Output Card via the

video bus. When received by the Video Output Card, the signal is processed by the

Output Titling Module where the DC level of the signal is restored and the titling

message is inserted. The edited video signal leaves the matrix bay through the

Rear Panel BNC Card (Output).

The video signal path is controlled by the microprocessor located on the Video

Output Card. The Video Output Card has full control of all Video Input Cards. The

basic functional group is essentially a crosspoint switch with a variable number of

inputs and 16 outputs. The number of inputs can vary from 16 to 256, in 16 input

increments. The functional group (matrix bay) can be used as a stand alone routing

switcher or it can be connected to other matrix bays to create a larger system.

VIDEO INPUT

VIDEO OUTPUT

REAR PANEL BNC CARD

CM9760-RPC

REAR PANEL BNC CARD

CM9760-RPM

Figure 26. Video Signal Flow–Block Diagram

VIDEO INPUT CARD

INPUT

BUFFER

16 X 16

CROSSPOINT

SWITCH

CM9760-VCC

VIDEO OUTPUT CARD

VIDEO OUTPUT MODULE

CM9760-VMM

CM9760-VMC

36 Pelco Manual C543M-A (7/03)

Page 37

VIDEO INPUT CARD

5 VIDEO OUTPUT BUS

REAR PANEL VIDEO INPUT CARD

4 16x16 CROSSPOINT

3 INPUT BUFFER

2 PATH TO VIDEO CARD AND

TO DOWNFRAME CONNECTOR

1 VIDEO SIGNAL IN

7 OUTPUT TITLING MODULE

6 SIGNAL ON BACKPLANE

ON WAY TO VIDEO

OUTPUT CARD

REAR PANEL

BNC CARD

8 VIDEO

SIGNAL

OUT

Figure 27. Video Signal Flow–Graphical Representation

Pelco Manual C543M-A (7/03) 37

Page 38

CM9760-CC1

5.0 SYSTEM CONFIGURATION–FRAMING

When either more cameras and/or more monitors are needed than can be accommodated by one matrix bay (256 x 16), then one must resort to either downframing

(to increase the number of monitors available for OUTPUT) or to sideframing (to

increase the number of camera INPUTS available).

In order to accommodate these larger systems, additional matrix bays will need to

be installed and it is important to note that this requires that the physical location of

additional matrix bays be within the same rack if you are increasing

bilities, since the expansion requires that the bays be hooked together in a vertical

manner or “downframed”. For downframed configurations, leave 1 RU (1.75 inches)

of space between each matrix bay. Similarly, adding

Inputs requires that additional

matrix bays be located in nearby bays since the expansion occurs in a horizontal

manner called “sideframing”. We shall discuss each configuration separately and

follow that with a discussion of more complicated configurations which involve using

both framing methods in a multi-bay configuration.

Most of the symbolic references and conventions we shall use in our discussion of

system configurations is represented in Figure 28. Items not listed will be labeled

within the illustration itself.

CARD TYPES

MONITOR

Output capa-

CAMERA

CONTROL OR DATA CABLE

MATRIX BAY

SLOT 17

VIDEO OUT/RPM CARD

VIDEO CABLE

Figure 28. System Configuration–Reference Conventions

38 Pelco Manual C543M-A (7/03)

Page 39

5.1 DOWNFRAMING

The matrix bay can be set up in multiple configurations. When limited to 16 monitors

or less, the rear of the bay will be populated by two type of cards: the CM9760-RPC

(Rear Panel BNC card for video inputs, usually a Camera) and the CM9760-RPM

Rear Panel BNC card for Monitor output). These cards are different and are not

(

interchangeable. In addition, on single bay configurations, the jumpers on the

CM9760-RPC cards will be configured for termination–a necessary condition for

operation (refer to Figure 16). A single bay configuration is illustrated in Figure 29.

When it becomes necessary or desirable to downframe, several different scenarios,

each with different card populations, can occur.

Downframing requires that the Inputs of the first bay be electronically reflected or

mirrored in the video circuitry of all other bays downframed from the first. This will

increase, by 16, the number of monitors available for output for each additional bay

downframed.

There are two different available downframe cards, both of which have been discussed previously (refer to Section 2.2.4). One card is the CM9760-DFC (the “no

looping” downframe card) and the other is the CM9760-DFL (the “looping” downframe

card).

JUMPER

SLOT

POSITION 17

16

SLOT POSITIONS

1-16

BAY 1

CARD TYPE

Figure 29. Single Bay Configuration–256 Cameras x 16 Monitors

Pelco Manual C543M-A (7/03) 39

Page 40

Downframing requires that the Video Inputs of the first bay be connected to the

video circuitry of the bay immediately below it. If you remember the physical layout

of the CM9760-RPC card, you will recall that the 16 video inputs to the card are fed

not only to the large, front loaded Video Input Card but are also wired to an output

connector located near the bottom edge of the card. This connector is cocked at an

angle to the bottom matrix bay rear opening for easy access. A downframe cable is

used to connect the bottom connector of the RPC card to either a DFL (looping)

card or a DFC (non-looping) card.

If you are downframing to only one bay, this bay can be populated with DFL or DFC

cards. You will need as many DFL or DFC cards as there are RPC cards in the first

bay. Figure 30 represents downframing with a 256 x 32 multiple matrix bay

configuration that uses DFL cards in the second bay. In this case, the video circuitry

between the first and second bay are tied together, slot for slot, via their bottom

connectors. The termination jumpers on the DFL card in the second or last bay are

in the terminated position only if the loop outs are not connected; the RPC cards in

the first bay are unterminated. In general, termination jumpers on the last downframed

card in a series must be set to the termination setting; however, since an individual

termination jumper exists for each video line, you can route individual video signals

through the DFL card and loop to a monitor output and terminate at that point if you

wish. As a result of downframing operation just described, the Inputs in the first bay

become available to the downframed bay and any input can now be switched to the

additional 16 monitor outputs created there, increasing the total number of monitor

outputs.

JUMPER

J(NT)

J(T)

ONLY TERMINATE

THE INPUTS WHEN

LOOP OUTS ARE

NOT CONNECTED

CARD TYPE

SLOT POSITIONS

1-16

(RIBBON CABLE)

SLOT POSITIONS

1-16

256 VIDEO IN

BAY 1

BAY 2

SLOT

POSITION 17

16

16

32 MONITORS

Figure 30. Single Bay Downframe–256 Cameras x 32 Monitors

40 Pelco Manual C543M-A (7/03)

Page 41

JUMPER CARD TYPE SLOT POSITIONS

DOWNFRAME CABLES

When downframing more than one bay, the intervening bays between the first and

the last contain DFC cards. The last bay in the downframe configuration can contain DFC or DFL cards. Figure 31 illustrates a downframe configuration that uses

DFC cards rather than DFL cards in the last bay.

In Figure 31, note the following:

• The termination jumpers on the RPC cards in the first bay (bay 1) must be in

the unterminated position.

• The termination jumpers on the DFC cards in the intermediate bays (bays 2-7)

must be in the unterminated position.

• The termination jumpers on the DFC cards in the last bay (bay 8) must be in

the terminated position.

SLOT POSITION

17

(VIDEO IN)

BAY 1

BAY 2

BAY 3

BAY 4

BAY 5

BAY 6

BAY 7

BAY 8

128 MONITORS

Figure 31. Downframe Configuration–256 Cameras x 128 Monitors

Pelco Manual C543M-A (7/03) 41

Page 42

5.2 SIDEFRAMING

Factory Configured Systems

When the number of video inputs required exceeds 256, then a method known as

sideframing is used to increase camera input population. This involves tying the

monitor outputs of the first bay to the first 16 video inputs of the sideframed bay.

Figure 32 illustrates one matrix bay sideframed to another.

1-256 IN

257-496 IN

Figure 32. Single Sideframing–496 Cameras x 16 Monitors

42 Pelco Manual C543M-A (7/03)

Page 43

If more video inputs are required than are available with two matrix bays, then, in a

similar manner, additional bays can be sideframed up to a maximum of eight (physically there are nine bays; eight are sideframed to the last bay which is referred to as

the OUTPUT bay). Figure 33 illustrates three sideframed matrix bays and one output bay. When you order an entire system from the factory, all the matrix bays with

their associated boards and connecting cables are tested and properly configured

for your system.

Figure 33. Sideframe Configuration–976 Cameras x 16 Monitors

A Word About Adding Additional Matrix Bays to Existing Field

Installations

If expanding your existing system by sideframing, decouple the monitors connected

to the original bay (leaving the cables connected to the output card, if possible) and

connect these open cables to the first 16 video inputs of the new bay, having it now

become the OUTPUT bay.

This way, the already programmed video inputs for the

original bay can be left alone and all you have to program are the new video inputs.

The same type of scenario applies to any additional matrix bays that are to be

sideframed. As a general rule, to minimize programming time as new bays are

added to a system configuration, they should be installed and configured as the

OUTPUT bay. For example, to continue adding bays to the two bay-configuration

just discussed, decouple the monitor outputs of the existing OUTPUT bay (second

bay) and input them to the second 16 video inputs of the new bay which now becomes

the OUTPUT bay (third bay). Also detach the monitor out cables of the original bay

from the first 16 inputs of the second bay and route them to the first 16 inputs of the

new bay. Doing this, minimizes the amount of reprogramming within your configuration.

Pelco Manual C543M-A (7/03) 43

Page 44

1-256 IN

5.3 DOWNFRAMING/SIDEFRAMING

Combined Sideframing and Downframing

Figure 34 illustrates a matrix bay configuration containing sideframed and downframed bays.

MONITOR 1-16

257-496 IN

*

MONITOR 17-32

*

Figure 34. Sideframe/Downframe Configuration–496 Cameras x 32 Monitors

44 Pelco Manual C543M-A (7/03)

Page 45

TO SLOT 1

TO SLOT 1

TO SLOT 1

Figure 35 illustrates a sideframe/downframe configuration that provides support for

976 cameras and 128 monitors. The configuration consists of a total of 32 matrix

bays.

Figure 36 illustrates a sideframe/downframe configuration that provides support for

2048 cameras and 128 monitors. The configuration consists of a total of 72 matrix

bays.

TO SLOT 2

TO SLOT 2

TO SLOT 2

TO SLOT 3

TO SLOT 3

TO SLOT 3

TO SLOT 1

TO SLOT 1

TO SLOT 1

TO SLOT 1

TO SLOT 1

TO SLOT 2

TO SLOT 2

TO SLOT 2

TO SLOT 2

TO SLOT 2

TO SLOT 3

TO SLOT 3

TO SLOT 3

TO SLOT 3

TO SLOT 3

Figure 35. Sideframe/Downframe Configuration–976 Cameras x 128 Monitors

Pelco Manual C543M-A (7/03) 45

Page 46

1 2 3 4 5 6 7 8

Bay 1

RPCs 1-16

RPM 17

Bay 9

RPCs 1-16

RPM 17

Bay 17

RPCs 1-16

RPM 17

Bay 25

RPCs 1-16

RPM 17

Bay 33

RPCs 1-16

RPM 17

Bay 41

RPCs 1-16

RPM 17

Bay 49

RPCs 1-16

RPM 17

Bay 57

RPCs 1-16

RPM 17

Output

Bay 65

RPM 17

Output

Bay 66

RPM 17

Output

Bay 67

RPM 17

Output

Bay 68

RPM 17

Output

Bay 69

RPM 17

Output

Bay 70

RPM 17

Output

Bay 71

RPM 17

Output

Bay 72

RPM 17

1 2 3 4 5 6 7 8

Bay 2

DFCs 1-16

RPM 17

Bay 10

DFCs 1-16

RPM 17

Bay 18

DFCs 1-16

RPM 17

Bay 26

DFCs 1-16

RPM 17

Bay 34

DFCs 1-16

RPM 17

Bay 42

DFCs 1-16

RPM 17

Bay 50

DFCs 1-16

RPM 17

Bay 58

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

Bay 3

DFCs 1-16

RPM 17

Bay 11

DFCs 1-16

RPM 17

Bay 19

DFCs 1-16

RPM 17

Bay 27

DFCs 1-16

RPM 17

Bay 35

DFCs 1-16

RPM 17

Bay 43

DFCs 1-16

RPM 17

Bay 51

DFCs 1-16

RPM 17

Bay 59

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

Bay 4

DFCs 1-16

RPM 17

Bay 12

DFCs 1-16

RPM 17

Bay 20

DFCs 1-16

RPM 17

Bay 28

DFCs 1-16

RPM 17

Bay 36

DFCs 1-16

RPM 17

Bay 44

DFCs 1-16

RPM 17

Bay 52

DFCs 1-16

RPM 17

Bay 60

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

Bay 5

DFCs 1-16

RPM 17

Bay 13

DFCs 1-16

RPM 17

Bay 21

DFCs 1-16

RPM 17

Bay 29

DFCs 1-16

RPM 17

Bay 37

DFCs 1-16

RPM 17

Bay 45

DFCs 1-16

RPM 17

Bay 53

DFCs 1-16

RPM 17

Bay 61

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

Bay 6

DFCs 1-16

RPM 17

Bay 14

DFCs 1-16

RPM 17

Bay 22

DFCs 1-16

RPM 17

Bay 30

DFCs 1-16

RPM 17

Bay 38

DFCs 1-16

RPM 17

Bay 46

DFCs 1-16

RPM 17

Bay 54

DFCs 1-16

RPM 17

Bay 62

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

Bay 7

DFCs 1-16

RPM 17

Bay 15

DFCs 1-16

RPM 17

Bay 23

DFCs 1-16

RPM 17

Bay 31

DFCs 1-16

RPM 17

Bay 39

DFCs 1-16

RPM 17

Bay 47

DFCs 1-16

RPM 17

Bay 55

DFCs 1-16

RPM 17

Bay 63

DFCs 1-16

RPM 17

1 2 3 4 5 6 7 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

TO

SLOT 1

TO

SLOT 2

TO

SLOT 3

TO

SLOT 4

TO

SLOT 5

TO

SLOT 6

TO

SLOT 7

TO

SLOT 8

Bay 8

DFCs 1-16

RPM 17

Bay 16

DFCs 1-16

RPM 17

Bay 24

DFCs 1-16

RPM 17

Bay 32

DFCs 1-16

RPM 17

Bay 40

DFCs 1-16

RPM 17

Bay 48

DFCs 1-16

RPM 17

Bay 56

DFCs 1-16

RPM 17

Bay 64

DFCs 1-16

RPM 17

** ******

1 - 256

256 IN

257 - 512

256 IN

513 - 768

256 IN

769 - 1024

256 IN

1025 - 1280

256 IN

128 1 - 1536

256 IN

1537 - 1792

256 IN

1793 - 2048

256 IN

*Can also use DFL

Input

Logical

Number

16

16

16

16

16

16

16

16

46 Pelco Manual C543M-A (7/03)

Figure 36. Sideframe/Downframe Configuration–2048 Cameras x 128 Monitors

Page 47

6.0 PROGRAMMING NOTES–ODDS AND ENDS

The following programming notes are brief and are put here only as an indication of

the areas of programming that affect the matrix bay or as a “memory check” for

those already familiar with programming. The following should not be used as a

substitute for the programming manual itself, which should be consulted whenever

any programming changes or additions of substance are made.

Video Loss

Alarm and video modes of Video loss will not be activated unless the fourth switch

position of the S2 switch on the Output card for the matrix bay in which the associated

camera is located is set to ON. It is-by default-in the OFF position.

Video Matrix Bay Numbering (Sideframing)

The Current operating software allows sideframing, of up to eight additonal matrix

bays besides the first, making the total available input capacity of sideframed matrix

bays, 2048. This input capacity increases via the networking of multiple systems.

When programming the COMMS Setup dialog box (.SCP file) as part of programming

your configuration files, there is an entry field for Equipment numbers to be entered

for all devices tied to SerCom ports on the CM9760-CC1. The matrix bay is no

exception; therefore, each matrix bay used in a system must be attached to a communication port on the CC1. Whenever only “one” video matrix bay is attached to a

CC1, you must assign an equipment number of 2 to the port where it’s connected.

If another bay is attached to a different port on the CC1 and is the first sideframed

bay, the port where its connected is assigned an equipment number of 12 in the

equipment field. Likewise, a second and third sideframing bay are assigned Equipment Numbers of 22 and 32, respectively.

Adding a Video Matrix Bay Directly to an Existing System

The following is a quick reference for using 9760 Configuration Setup files to add a

matrix bay to a 9760 System.

1. Click on the Setup icon on the toolbar so that the Configuration files dialog box

appears on the screen (refer to Figure 37).

2. Select the node you wish to edit.

3. Click on “Setup Files” and the Setup File dialog box should appear on screen;

select COMMS (refer to Figure 38).

4. In the Comms Setup dialog box that appears on screen, type the appropriate

Equipment number in the Equipment Number Box (in our example, we entered

the number 2), depending on what you plan to do with the matrix bay (i.e.,

downframe, sideframe).

5. Type in the baud rate and parity.

6. Enter any descriptive information you wish and click on Save.

7. Make sure directly and indirectly associated setup file Dialog boxes are also

configured to reflect the changes made. In most cases these would be Camera

Pelco Manual C543M-A (7/03) 47

Page 48

Configuration Files

PELCO

Node 1

Update Hard Drive

Config Name

Pelco

Setup Files

Close

Node Number

1

Add Node

Figure 37. Setup File Dialog Box with Comms Tab Opened

Figure 38. Configuration File Dialog Box

48 Pelco Manual C543M-A (7/03)

Page 49

Logical Numbering

It can be difficult and confusing to track large numbers of video input and output

signals in a 9760 system. The “logical number” programming field that exists within

the input/output configuration files of affected devices exists as an aid to minimize

this problem for the programmer as well as for the operator of the system. A logical

number is a user selectable, variable number, and is always associated with an

actual physical input, while physical input numbers, in turn, represent an actual

BNC input on the rear of the matrix bay and each input has a given, fixed number

associated with it. However,

level

, it is the logical number that is used for reference; therefore, a judicious

choice for logical numbers can help minimize camera/monitor tracking.

Example 1:

As an example of “logical number” use, let’s assume that on each floor of a 5-story

building there exists a camera population ranging from a minimum of 5 to a maximum

of 10 cameras. The camera population might be as follows:

Floor 1: 5 Cameras

Floor 2: 7 Cameras

Floor 3: 10 Cameras

Floor 4: 6 Cameras

Floor 5: 5 Cameras

Can logical numbers be assigned to each of the camera inputs connected to the

matrix bay in the above list a way that would help the operator to track cameras

location?

Let’s assume that logical numbers for the above are assigned according to the

following rules:

within the programming environment and at the operator

(1) Each logical number that references a camera input consists of three digits.

(2) The first digit gives the floor level of the camera location.

(3) The next two digits identify the camera location on the referenced floor accord-

ing to some previously agreed upon sequence.

Looking at floor 4, for example, the physical inputs for the 6 cameras might be

assigned sequential logical numbers 401, 402, 403, 404, 405 and 406; however, if

one wished to allow for future expansion between existing camera locations, the

assigned logical numbers might be assigned with a 5 unit spacing between numbers

and end up with assigned logical numbers of 401, 405, 410, 415, 420, and 425,

respectively. To put a different twist on logical number assignment, let’s assume

that each floor covered a large area, then our “rule three” above might be modified

to let the last two digits represent a division of the floor area into zones; with the

second digit being one of 9 possible zones and the third digit being 1 of 9 possible

cameras within any given zone. The point of all this is, is that there are many and

varied ways to assign logical numbers-it just should be done in a way that makes

sense for your installation.

Pelco Manual C543M-A (7/03) 49

Page 50

Example 2:

At other times, it might be useful to define the logical number of a camera input as

being the same as that of the actual physical, fixed input that the camera is attached

to. Since physical inputs and their associated numbers are fixed, it seems like a

natural choice, under some circumstances, to use this scheme. Figure 39 shows a