Page 1

®

CC4600 Series

1/3-inch Color Cameras

Installation/Operation Manual

C1902M (11/96)

Pelco • 3500 Pelco Way, Clovis, CA 93612-5699 • USA • (800) 289-9100 or (1-559) 292-1981

FAX (800) 289-9150 or (1-559) 292-3827

International Customers call (1-559) 292-1981 or FAX (1-559) 348-1120

Page 2

TABLE OF CONTENTS

Section Page

1.0 IMPORTANT SAFEGUARDS.............................................................................................................1

1.1 FCC INFORMATION ................................................................................................................2

1.2 SAFETY PRECAUTIONS.........................................................................................................2

1.3 UNP ACKING.............................................................................................................................2

2.0 DESCRIPTION...................................................................................................................................3

2.1 LOCATION AND FUNCTION OF PARTS.................................................................................4

2.1.1 Top/Front/Side (Illustration A) .........................................................................................4

2.1.2 Rear (Illustration B).........................................................................................................5

3.0 POWER SUPPLY CONSIDERATIONS..............................................................................................6

4.0 LENSES .............................................................................................................................................8

4.1 LENS LIMITS............................................................................................................................8

4.2 LENS COMPATIBILITY ............................................................................................................8

4.3 LENS INSTALLATION ..............................................................................................................9

4.3.1 Auto Iris...........................................................................................................................9

4.3.2 Manual Iris ......................................................................................................................9

5.0 CAMERA INSTALLATION ................................................................................................................14

5.1 CONNECTIONS (Illustration F) ..............................................................................................14

5.2 PHASE ADJUSTMENT (Illustration G) ...................................................................................14

5.3 VERTICAL PHASE (Illustration H)..........................................................................................14

6.0 CCD CHARACTERISTICS...............................................................................................................15

7.0 HOUSEKEEPING.............................................................................................................................15

7.1 OPERATION AND STORAGE LOCATIONS ..........................................................................15

7.2 CARE OF THE UNIT ..............................................................................................................15

8.0 MAINTENANCE ...............................................................................................................................15

9.0 SPECIFICATIONS............................................................................................................................16

10.0 WARRANTY AND RETURN INFORMATION...................................................................................18

LIST OF FIGURES AND ILLUSTRATIONS

Figure Page

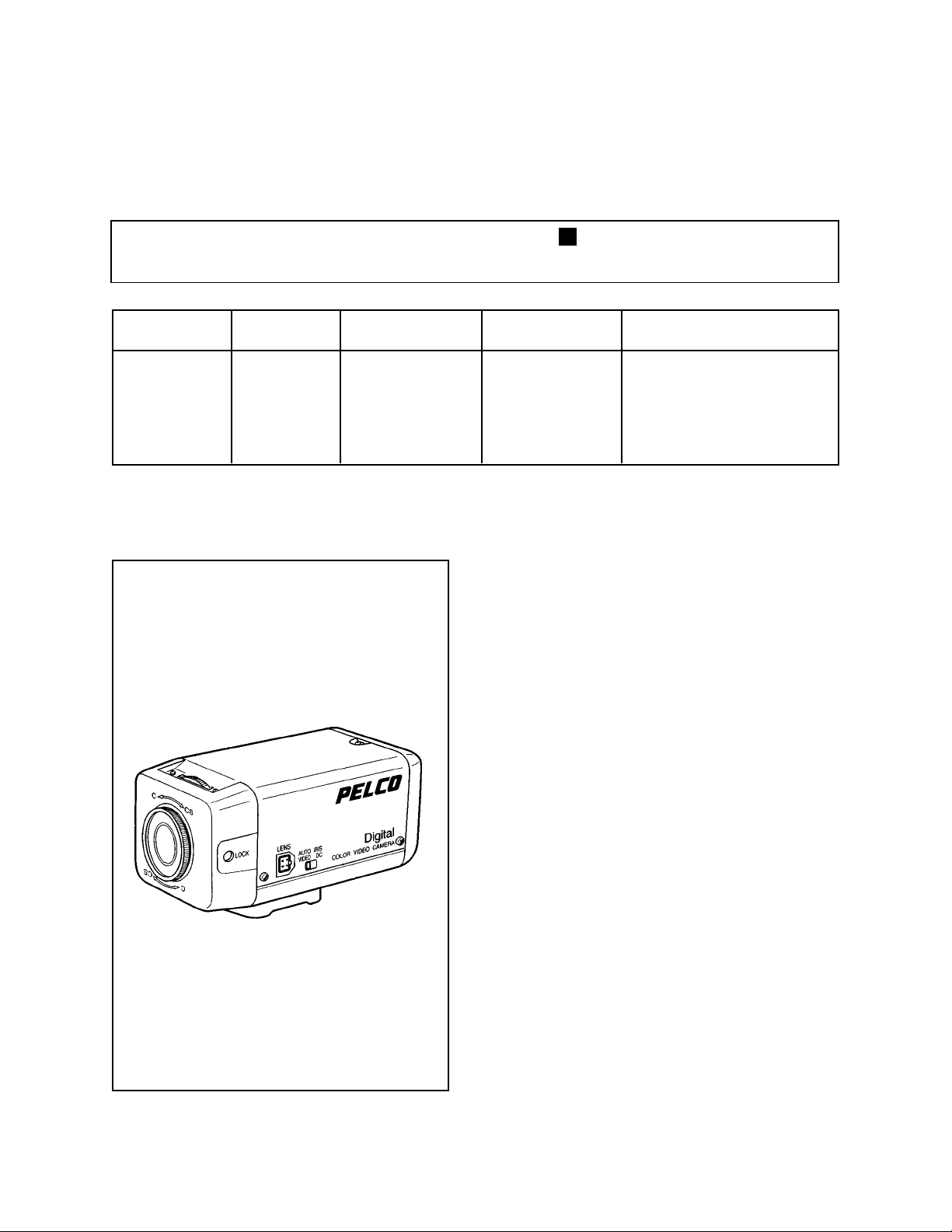

1 The CC4600 Series Camera ....................................................................................................3

2 Rear Panels: CC4600-2/-2X and CC4600-3 ............................................................................6

3 Typical 120 VAC to 24 VAC (60Hz) Power Supply ...................................................................7

4 Typical 230 VAC to 24 VAC (50 Hz) Power Supply ..................................................................7

5 Standard Acceptable Lens Dimensions....................................................................................8

6 CC4600 Series Dimension Drawing .......................................................................................16

Illustrations Page

A Top/Front/Side View of CC4600 Series Cameras.....................................................................4

B Rear View of CC4600 Series Cameras ....................................................................................5

C Compatible Lenses ...................................................................................................................8

D Changing the Plug on an Auto Iris Lens Cable.........................................................................9

E Fitting the Lens .......................................................................................................................13

F Connecting the CC4600 Cameras..........................................................................................14

G Phase Adjustment...................................................................................................................15

H Vertical Phase.........................................................................................................................15

®Pelco and the Pelco logo are registered trademarks of Pelco.

©Copyright 1996, Pelco. All rights reserved.

20 Pelco Manual C1902M (11/96)

ii

Page 3

1.0 IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating instructions should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating instructions should be adhered to.

4. Follow Instructions - All operating and use instructions

should be followed.

5. Cleaning - Unplug the unit from the outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

6. Attachments - Do not use attachments not recommended

by the product manufacturer as they may cause hazards.

7. Water and Moisture - Do not use this unit near water - for

example, near a bath tub, wash bowl, kitchen sink, or

laundry tub, in a wet basement, near a swimming pool, in

an unprotected outdoor installation, or any area which is

classified as a wet location.

8. Accessories - Do not place this unit on an unstable stand,

tripod, bracket, or mount. The unit may fall, causing serious injury to a person and serious damage to the unit.

Use only with a stand, tripod, bracket, or mount recommended by the manufacturer, or sold with the product.

Any mounting of the unit should follow the manufacturer’s

instructions, and should use a mounting accessory recommended by the manufacturer.

An appliance and cart combination should be

moved with care. Quick stops, excessive force,

and uneven surfaces may cause the appliance

and cart combination to overturn.

9. Ventilation - Openings in the enclosure, if any, are provided for ventilation and to ensure reliable operation of

the unit and to protect it from overheating. These openings must not be blocked or covered. This unit should not

be placed in a built-in installation unless proper ventilation is provided or the manufacturer's instructions have

been adhered to.

10. Power Sources - This unit should be operated only from

the type of power source indicated on the marking label.

If you are not sure of the type of power supply you plan to

use, consult your appliance dealer or local power company. For units intended to operate from battery power,

or other sources, refer to the operating instructions.

11. Grounding or Polarization - This unit may be equipped

with a polarized alternating-current line plug (a plug having one blade wider than the other). This plug will fit into

the power outlet only one way. This is a safety feature. If

you are unable to insert the plug fully into the outlet, try

reversing the plug. If the plug should still fail to fit, contact

your electrician to replace your obsolete outlet. Do not

defeat the safety purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-wire

grounding-type plug, a plug having a third (grounding)

pin. This plug will only fit into a grounding-type power

outlet. This is a safety feature. If you are unable to insert

the plug into the outlet, contact your electrician to replace

your obsolete outlet. Do not defeat the safety purpose of

the grounding-type plug.

12. Power-Cord Protection - Power supply cords should be

routed so that they are not likely to be walked on or pinched

by items placed upon or against then, paying particular

attention to cords and plugs, convenience receptacles,

and the point where they exit from the appliance.

13. Power Lines - An outdoor system should not be located

in the vicinity of overhead power lines or other electric

light or power circuits, or where it can fall into such power

lines or circuits. When installing an outdoor system, extreme care should be taken to keep from touching such

power lines or circuits as contact with them might be fatal. U.S.A. models only - refer to the National Electrical

Code Article 820 regarding installation of CATV systems.

14. Overloading - Do not overload outlets and extension cords

as this can result in a risk of fire or electric shock.

15. Object and Liquid Entry - Never push objects of any kind

into this unit through openings as they may touch dangerous voltage points or short-out parts that could result

in a fire or electric shock. Never spill liquid of any kind on

the unit.

16. Servicing - Do not attempt to service this unit yourself as

opening or removing covers may expose you to dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

17. Damage Requiring Service - Unplug the unit from the outlet and refer servicing to qualified service personnel under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into

the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate normally by following the

operating instructions. Adjust only those controls that

are covered by the operating instructions, as an im-

proper adjustment of other controls may result in

damage and will often require extensive work by a

qualified technician to restore the unit to its normal

operation.

e. If the unit has been dropped or the cabinet has been

damaged.

f. When the unit exhibits a distinct change in perfor-

mance - this indicates a need for service.

18. Replacement Parts - When replacement parts are required, be sure the service technician has used replacement parts specified by the manufacturer or have the same

characteristics as the original part. Unauthorized substitutions may result in fire, electric shock or other hazards.

19. Safety Check - Upon completion of any service or repairs

to this unit, ask the service technician to perform safety

checks to determine that the unit is in proper operating

condition.

20. Coax Grounding - If an outside cable system is connected

to the unit, be sure the cable system is grounded. U.S.A.

models only-Section 810 of the National Electrical Code,

ANSI/NFPA No.70-1981, provides information with respect

to proper grounding of the mount and supporting structure, grounding of the coax to a discharge unit, size of

grounding conductors, location of discharge unit, connection to grounding electrodes, and requirements for the

grounding electrode.

21. Lightning - For added protection of this unit during a lightning storm, or when it is left unattended and unused for

long periods of time, unplug it from the wall outlet and

disconnect the cable system. This will prevent damage to

the unit due to lightning and power-line surges.

Pelco Manual C1902M (11/96) 1

Page 4

1.1 FCC INFORMATION

1.2 SAFETY PRECAUTIONS

For USA customers

WARNING - This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

- Consult the dealer or an experienced audio/TV technician for help.

Intentional or unintentional changes or modifications not expressly approved by the party responsible for compliance shall

not be made. Any such changes or modifications could void

the user’s authority to operate the equipment.

The user may find the following booklet prepared by the Federal

Communications Commission helpful: “How to Identify and Resolve Radio-TV Interference Problems”. This booklet is available from the U.S. Government Printing Office, Washington, DC

20402, Stock No. 004-000-00345-4.

CAUTION

RISK OF ELECTRIC

SHOCK. DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRICAL SHOCK DO NOT OPEN COVERS. NO USER

SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This label may appear on the bottom of the unit due to space

limitations.

The lightning flash with an arrowhead symbol,

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated “dangerous voltage” within the product’s enclosure

that may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to presence

of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

Warning

To prevent fire or shock hazard, do not expose units

not specifically designed for outdoor use to rain or

moisture.

For United Kingdom customers

WARNING

THIS APPARATUS MUST BE EARTHED

IMPORTANT

The wires in the power supply lead are colored in accordance

with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colors of the wires in the power lead of this apparatus

may not correspond with the colored markings identifying the

terminals in your plug proceed as follows:

The wire which is colored green-and-yellow must be connected

to the terminal in the plug which is marked by the letter E or by

the safety earth symbol or colored green or green-andyellow.

The wire which is colored blue must be connected to the terminal which is marked with the letter N or colored black.

The wire which is colored brown must be connected to the

terminal which is marked with the letter L or colored red.

WARNING: Electrostatic-sensitive device. Use proper

CMOS/MOSFET handling precautions to avoid electrostatic discharge.

NOTE: Grounded wrist straps must be worn and proper

ESD safety precautions observed when handling the

electrostatic-sensitive printed circuit boards.

1.3 UNPACKING

The shipping carton is the safest container in which the unit

may be transported. Save it for possible future use.

Supplied

Accessories: 4-pin plug for auto iris lens (1); Operating

Instructions (1)

2 Pelco Manual C1902M (11/96)

Page 5

2.0 DESCRIPTION

The CC4600 series cameras are compact, rugged, full performance general purpose color CCD cameras. Contemporary styling and concealed controls allow these cameras to blend naturally into the most modern installation sites.

These cameras are 1/3-inch image format and are available in the following models:

NOTE: The alphanumeric reference designations (of the form A ) used in this manual, are keyed to the

reference designations used in the instruction sheets shipped with the product received by the customer.

Model # Voltage Voltage Range Nominal Power Color

CC4600-2 24 VAC 21 to 28 4.5 W NTSC/EIA (60 Hz) 470TVL

CC4600-2X 24 VAC 21 to 28 4.5 W PAL/CCIR (50 Hz) 470TVL

CC4600-3 230 VAC 198 to 264 5.5 W PAL/CCIR (50 Hz) 470TVL

These model cameras all have the following features in

common:

• High sensitivity (minimum illumination: 1.9 lux,

F1.2)

• CCD camera with electronic iris function

• Automatic white balance tracking and adjustment

(normal/PRO)

• Compatibility with DC controlled or video signal

controlled auto iris lenses

• Automatic backlight compensation and automatic

flicker reduction (operates when AGC switch is in

the “ON” position)

• Line lock function for synchronizing through AC

power source

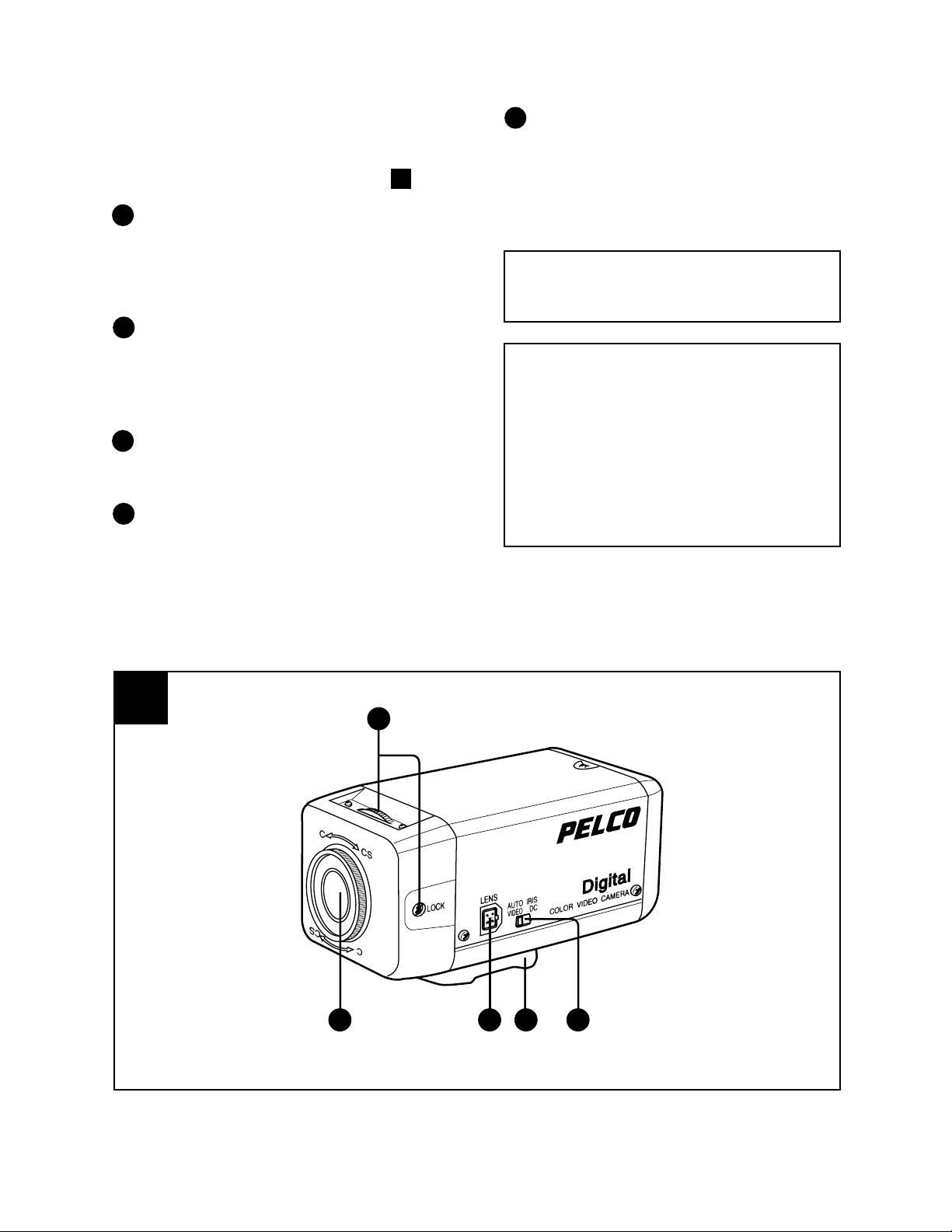

Figure 1. The CC4600 Series Camera

Pelco Manual C1902M (11/96) 3

Page 6

2.1 LOCA TION AND FUNCTION OF

PARTS

2.1.1 Top/Front/Side (Illustration A )

1

Focal length adjustment ring and locking screw

Use this ring to adjust the focal length (the distance between the lens mounting plane and the

image plane). Use the locking screw to lock the

focal length.

2

Lens mount

Use to mount an appropriate C-mount or a CSmount lens. To attach a C-mount/CS-mount lens,

turn the focal length adjustment ring to the appropriate position. The factory setting is C mount.

5

Auto iris lens selection switch (DC/Video)

Switch for selecting the control signal for the auto

iris lens.

DC: For auto iris lenses controlled by DC

signals

VIDEO: For auto iris lenses controlled by video

signals

NOTE: If you use the electronic iris function

in locations where the camera is exposed to fluorescent light, a slow color change may occur.

NOTES: When the DC/VIDEO switch is set

to VIDEO, the backlight compensation function may not work properly.

Lens connector (4 pin socket)

3

Supplies power and control signals to an auto iris

lens.

4

Camera mounting bracket

The mounting bracket can be attached to either the

top or bottom of the camera using the four attached

screws (1/4" UNC-20).

A

1

When the DC/VIDEO switch is set to VIDEO,

“hunting” may occur. If this occurs, use the

LEVEL L/H adjustment screw on the lens to

change the incident light level. When adjusting

the incident light level, set the ALC (Automatic

Light Control) adjustment screw to Av.

2 3 4 5

Top/Front/Side View of CC4600 Series Camera

4 Pelco Manual C1902M (11/96)

Page 7

2.1.2 Rear (Illustration B )

SYNC switch

6

Use this switch to set the camera synchronization

mode—line lock (L.L) or internal (INT).

AGC (automatic gain control) ON/OFF switch

7

The automatic gain function automatically adjusts

picture gain in accordance with the brightness of

the subject.

Gain up switch

8

Switching the Gain up switch to the TURBO mode

while the AGC switch is on increases gain by up

to 6dB over the NORM (normal) mode.

BLC (back lighting compensation) ON/OFF switch

9

When switched on, this function adjusts exposure

to compensate for situations where the subject is

lit from behind.

11

White balance mode switch

When set in the ATW (auto tracing white balance)

- PRO position, the camera automatically adjusts

white balance to suit the color temperature of various lighting sources, including incandescent, fluorescent and natural lighting.

When set to the ATW position, the camera automatically adjusts white balance to suit special lighting sources such as sodium lamps.

Aperture switch

12

Set in the “SHARP” mode to sharpen the outline

and produce a clearer picture.

13

VIDEO OUT connector (BNC)

14

Ground terminal (screw type)

Power cable (model CC4600-3 only)

15

NOTE: When the BLC is in the “ON” posi-

tion, hunting may occur; that is, the image may

get darker and lighter as the camera “hunts”

for the best exposure level. If hunting occurs,

set the BLC switch to “OFF”.

CCD-IRIS ON/OFF switch

10

When using a manual iris lens, the CCD-IRIS function automatically adjusts the shutter speed to maintain a suitable exposure level. Set switch to OFF if

using an auto-iris lens..

B

16

24 VAC input terminals (models CC4600-2,

CC4600-2X)

17

Video level adjustment pot

Use to adjust the video level when using a DC servo

lens. If using a Video servo lens , turn the control

toward the H (high) side.

18

Vertical phase adjustment pot

Use to adjust the vertical phase of cameras synchronized by line lock.

6

7

8

9

10

11

12

13

13

14

17 18

16

17

18

15

Rear View of CC4600 Series Cameras

Pelco Manual C1902M (11/96) 5

Page 8

3.0 POWER SUPPLY CONSIDERATIONS

Use only the recommended power supplies. Improper

substitutions may damage the camera or cause a shock

or fire hazard.

CC4600-2/2X

The power runs for user supplied wiring from a 24 VAC

supply to a CC3300-2 camera should be within the following limits:

Up to 60 m (200 ft) — 1 mm2 (18 AWG) or larger.

Up to 100 m (325 ft) — 1.5 mm2 (16 AWG) or larger

• The CC3300-2 must always be operated with a 24

V AC, Class 2 (60 Hz) power supply (not supplied).

A wall transformer (as depicted in Figure 3) is an

example of a common power source.

• In the USA, use a power supply which is UL Listed.

In Canada, use a power supply which is CSA Cer tified.

• The CC4600-2X must always be operated with a

24 VAC (50 Hz) power supply.

• When connecting to the transformer, be sure to

carefully connect each lead to the appropriate terminal. Wrong connections may cause malfunction

and/or damage to video camera.

• Ground the unit or an irregular voltage may be

generated in the AC power cord and may cause

malfunction or damage to the video camera.

• 24 VAC Cameras: do not exceed 24 VAC input.

Normal input voltage is 24 VAC

Do not mistakenly attach the

GND terminal on 24 VAC

cameras to either of the power

terminal inputs. Be sure to use

the grounding lug or screw.

CC4600-3

• The CC3300-3 must be always operated with a 220240 VAC, (50 Hz) power supply.

NOTE: The CC4600-3 is supplied with an

attached main power cable cord. See Figure 2

legend for power connections.

CC4600-2 & -2X

2

CC4600-3

4

3

GND

76

5

24VAC Input

POWER CONNECTIONS:

Brown Wire - Hot or Live wire

Blue Wire - Neutral wire

Green and Yellow wire - Earth Ground or GND

Figure 2. Rear Panels: CC4600-2/-2X and CC4600-3

6 Pelco Manual C1902M (11/96)

Page 9

• 120 VAC power source: The 24 VAC CC4600-2 camera must be wired to a 60 Hz source.

Typical Power Supply

Input

120 VAC, 60 Hz

To 24 VAC Terminals

On Camera

24 V AC Output

Figure 3. Typical 120 VAC to 24 VAC (60 Hz) Power Supply

• 230 VAC power source: The 24 VAC CC4600-2X and the 230 VAC CC4600-3 must be wired to a 50 Hz source.

Typical Power Supply

#2

To 24 VAC Terminals

Input

COM

#1

On Camera

220-240 VAC, 50 HZ

With 240 VAC Input: Use #1 and COM

With 220 VAC Input: Use #2 and COM

Figure 4. Typical 230 VAC to 24 VAC (50 Hz) Power Supply

NOTE: Cameras with 220-240 VAC power

cords are double insulated. Article 250-45 of

the National Electrical Code states that listed

products protected by a system of double insulation shall not be required to be grounded.

Pelco Manual C1902M (11/96) 7

Page 10

4.0 LENSES

4.1 LENS LIMITS

Lenses exceeding the dimensions shown in Figure 5

below cannot be used.

When the lens is not mounted on the camera head, be

sure to install the dust cap to protect the internal parts

from dust or damage.

NOTE: Lenses that are suitable for a 1/3-inch

CCD should be used with this camera using C

or CS type lens mounts. Pelco 1/3" format

lenses are recommended for optimum performance. The use of other lenses may impair camera performance. When lenses for a 2/3-inch or

1/2-inch CCD are used, the viewing angle will

be slightly different.

4.2 LENS COMPATIBILITY

(Illustration C )

The lens must be either a C- or a CS-mount type weighing less than 1 kg (2.2 lbs). The protrusion behind the

mounting surface must be within the following limits:

1

C-mount lens CS-mount lens

2

9 mm or less 4 mm or less

3

4

C

1

2

3

4

Compatible Lenses

4.0 mm Max Thread

(0.16" Max.)

For CS Lens

22.4 mm Max.

(0.88" Max.)

Lens

9.0 mm Max. Thread

(0.35" Max)

For C Lens

Figure 5. Standard Acceptable Lens Dimensions

8 Pelco Manual C1902M (11/96)

Page 11

4.3 LENS INST ALLATION

4.3.1 Auto Iris

Install an auto-iris lens as follows:

(Refer to Illustration E )

1. Unscrew lens mount cap.

2. Screw in the lens.

3. Check the plug wiring on the lens cable against

Illustration and the pin-outs mentioned in the

D

Information Box below . If you need to replace the

existing plug on the lens cable, follow the instructions given.

4. As part of lens installation, you need to adjust

backfocusing. Follow the appropriate instructions

found in the Information Boxes on pages 11 and

12. Background “General Information”, if needed,

is provided on page 10.

5. Once adjusted, tighten the backfocus LOCK screw.

(The factory setting is C-mount.)

D

2

1

3

8

7

6

5

Changing the Plug on an Auto Iris Lens Cable

42

Auto Iris Plug

Pin-out (Back of Plug)

13

4

NOTE: When attaching a C-mount type lens,

be sure to turn the C/CS adjustment ring fully

in the “C” direction. When the C/CS adjustment ring is set to “CS,” mounting any lens

with a mount projection of more than 4 mm

may damage the internal parts of the camera.

Information Box

1. Remove the plug cover and solder the lens

cable wires to the pins thru on the

2

Plug Change on Auto Iris Lens Cable

1

5

8

plug supplied. The pin assignments are as follows:

Pin # DC-servo Lens VS-servo Lens

Pin 3: DRV+ Video signal

Pin 1: CONT- Power supply

Pin 2: CONT+ Not Used

8

7

6

4.3.2 Manual Iris

Follow the instructions of the previous section but

ignore all instructions for changing the lens cable plug.

Information Box

2. Put the cover on the plug.

ILLUSTRATION D ELEMENTS

1

Cover

2

Auto-iris cable

Rib (If the cable is thick and the plug cover

3

does not seat properly, cut away this rib.)

4

Lens plug

Pin 4: DRV- Ground

5

Pelco Manual C1902M (11/96) 9

Page 12

CAMERA/LENS GEOMETRY–GENERAL INFORMATION

Incident Light

MANUAL

LENS

The lens has

a focus ring

adjustment

on it.

MOTORIZED

ZOOM LENS

Zoom lens which

can be remotely

controlled for zoom

and focus

• Iris has motor on it which

is controlled remotely by

the operator

• No automatic compen-

sation for light changes

LENS

IRIS

MANUAL IRISMOTORIZED IRIS

(STYLIZED)

CCS

• Iris adjustment ring is

on the lens

• Fixed position applica-

tions

• Indoor use

• Minimal light variations

CAMERA

CCD Iris (Electronic Shutter) CCD out-

put voltage is electronically sampled and

used to adjust for small variations in light

levels. Normally used in indoor, fixed po-

CCD

IMAGER

C/CS Adjustment (all models) conditions camera mount

for lens type being used by changing physical distance

of imager face with respect to back of lens. Adjustment

screw or ring is initially positioned at the corresponding

C or CS position (corresponding to lens type) and not

some setting in between. Factory set at C position.

Iris opening (sometimes referred to as aperture) is

defined by f/stop numbers. The higher the # the

more closed the iris is

DC CONTROL VIDEO CONTROL

• Iris operation con-

trolled by DC motor

voltages from the

camera

• Level control ON THE

CAMERA

• Only choice available

if you wish to use the

auto-iris feature with

B/W cameras

sition applications where small variations

in light levels might be encountered. CCD

iris must be turned OFF when performing camera/lens adjustments.

Used when large

variations in lighting

AUTO-IRIS

are expected (usually

outside).There are two

types of auto-iris control

• Iris operation con-

trolled by video to

voltage motor control signals from the

camera

• Level control ON

THE LENS

10 Pelco Manual C1902M (11/96)

Page 13

Information Box

Lens/Camera Setup and Backfocusing

Information Box

The purpose of backfocusing is to make the adjustments necessary for the picture to remain in focus throughout the camera‘s zoom

range, which is the case for instance, in motorized zoom, auto iris configurations. Manual Iris lens/camera combinations also need to

be backfocused. Follow the general instructions listed below to adjust backfocus appropriate to your camera/lens combination

LENS TYPE

MANUAL IRIS

VARIABLE LIGHT CONDITIONS

• Turn Manual Iris

ring so iris is fully

open and set the Focus ring for ∞ (or dis-

tant object).

• Set all other

switches on the

back of the Camera

to the left (deactivated or OFF), including the CCD

Iris switch.

A

Manual

Iris

CC3300 Series

AGC

TURBO AGC

BLC

CCD IRIS**

NOTE: We are essentially referencing indoor lighting conditions in each of the cases below. If you have occasion to use

fixed lenses in an outdoor setting, where lighting is much brighter

(not widely done with fixed lenses), you may need to filter the

light while performing these adjustments.

Generic Lens w/

Manual Iris &

Focus

STATIC LIGHT CONDITIONS

• Adjust Backfocus the

same as was done for Variable Light conditions except CCD iris is left in the

OFF position; therefore

there is no need to adjust

the LVL control; follow all

other steps, however.

Manual

Focus

CC4600 Series

Sync

AGC

Gain

BLC

CCD Iris** (OFF)

White

Aperture

AUTO IRIS

B

• Adjust the C/CS

adjustment ring

Generic example of best

setting for C mount lens.

for the best picture.

• Move CCD Iris switch

to the ON position.

• Set the Iris/Video Level

control pot to the H position.

• Adjust or set other camera switches as needed.

Adjustment

Ring

AGC

TURBO AGC

BLC

CCD IRIS (ON)

IRIS LEVEL

H

L

**With CCD Iris

OFF, the Video

Level control is

inactive

Best setting

Picture will be out

of focus on either

side of best setting

Sync

AGC

Gain

BLC

CCD IRIS (ON)

White

Aperture

VIDEO LEVEL

H

L

Pelco Manual C1902M (11/96) 11

Page 14

Backfocusing

Information Box

Lens/Camera Setup and Backfocusing

Information Box

The purpose of backfocusing is to make the adjustments necessary for the picture to remain in focus throughout the camera‘s zoom

range, which is the case, for instance, in motorized zoom, auto iris configurations. Manual Iris lens/camera combinations also need to

be backfocused Follow the general instructions listed below to adjust backfocus appropriate to your camera/lens combination

LENS TYPE

NOTE: Most auto-iris configurations are associated with motorized zoom

B

DC SERVO

• Make sure the Auto IrisVideo/

DC switch is in the DC position. Use a neutral density

filter or some other physical

means to decrease the

AUTO IRIS

lenses, so the instructions below are based on that assumption

CC3300 Series

CC4600 Series

AUTO IRIS

VIDEO DC

• This step is the same as the

one for DC SERVO, excpt

that the AUTO IRIS VIDEO/

DC switch is set to VIDEO,

both models.

MANUAL IRIS

VIDEO SERVO

amount of light entering the

camera lens so that the autoiris response is to open the iris

AUTO IRIS

VIDEO DC

up as wide as possible.

• Set all other switches on the

back of the Camera to the

left (deactivated or OFF), including the CCD Iris

switch.

AGC

TURBO AGC

BLC

CCD IRIS**

Sync

AGC

Gain

BLC

CCD Iris** (OFF)

White

Aperture

• This step, same as for DC

servo, both models.

A

**With CCD Iris

OFF, the Video

Level control is

inactive

BACKFOCUS ADJUSTMENT

• Adjust focus to far, zoom to

wide angle.

• Adjust C/CS adjustment

Ring on the camera for the

Generic example of best

setting for C mount lens.

Adjustment

Ring

Best setting

best picture.

• Zoom to a close object; adjust lens controller or focus

for best picture.

• Repeat above until lens remains in focus throughout

the zoom range (far to near).

Picture will be out

of focus on either

side of best setting

• Tighten the Lock Screw.

The ability of a zoom lens to remain in focus throughout its zoom range is known as Tracking

• Finally, use the IRIS/VIDEO

LEVEL adjustment on the

IRIS LEVEL

VIDEO LEVEL

REAR of the CAMERA to

adjust for best picture

• Adjust other settings on cam-

era as needed.

H

L

H

L

• This step, same as for DC

servo, both models.

• For AUTO IRIS applications

using VIDEO servo, set the

IRIS/VIDEO LEVEL on the

rear of the respective units

to H.

12 Pelco Manual C1902M (11/96)

Page 15

E

1

4

3

2

Fitting the Lens

CAUTION: When mounting the lens, loosen

the securing nut on the side and

turn the focal length adjustment

to the C position. Mounting a Cmount lens with the adjustment

ring in the CS position may damage the optical filter.

5

Pelco Manual C1902M (11/96) 13

Page 16

5.0 CAMERA INSTALLATION

ATTENTION: Installation should be per-

formed by qualified service personnel only, in

accordance with the National Electrical Code

or equivalent/applicable local codes.

When attaching the camera to a ceiling bracket or tripod, attach the supplied mounting bracket. The bracket

may be attached to either the top or bottom of the camera. Use the supplied 1/4" UNC-20 screw to attach the

camera to the tripod or ceiling bracket.

5.1 Connections (Illustration F )

Using an internal synchronization signal.

1

Set the L.L/INT switch to “INT” (internal synchronization).

Connect with VIDEO OUT connector.

2

3

75-ohm coaxial cable

4

Connect with VIDEO IN connector on a video

monitor, etc.

To AC 24V terminals 1 and 2 (CC4600-2,

7

CC4600-2X)

When using an external (L.L) synchronization signal,

set the L.L/INT switch (1) to L.L and make connections as above.

CAUTION: Be sure cable wires

are routed so as to not pinch or rub

when connected to pan/tilt units.

Frayed, pinched or broken wires

can cause fire/shock hazards or

system failure.

5.2 Phase Adjustment (Illustration G )

When using more than one camera, connect to a camera switcher and set the vertical phase range as follows:

1

Camera switcher Vertical phase

2

Monitor Adjustable range

3

4

To power supply (CC4600-2, CC4600-2X); to a

5

wall outlet (CC4600-3)

6

Power cord

F

CC4600-2 & -2X

1

CC4600-3

2

7 6

2

3

4

5

3

4

6

5

Connecting the CC4600 Series Cameras

14 Pelco Manual C1902M (11/96)

Page 17

G

-90°

+90°

In such cases, camera switching may produce what appears to be a vertical roll on the monitor between the

1 2

3

-90° 0°+90°

0°

two views. Turning the V Phase pot (while switching

rapidly as possible between the two camera views) will

adjust the relative phase angle between the two cameras and the point at which one camera synchronizes to

the AC line with respect to the other. Adjust the pot

until the switching is clean and there is no vertical roll

or flip.

6.0 CCD CHARACTERISTICS

The following conditions which may be observed when

using a CCD camera are not due to any fault within the

camera.

4

Phase Adjustment

H

Vertical Phase

5.3 Vertical Phase (Illustration H )

Vertical phase adjustment is NOT vertical ROLL adjustment. Each camera is adjusted to the AC zero crossover point at the factory. Problems arise,however, (especially in larger systems) when:

1. Switching rapidly between widely separated cameras with manual or sequential switchers.

2. Switching between cameras not operating off the

same phase of the AC line.

3. Both of the above. There are other causes too

(transformers wired backward, for instance) but

the basic symptoms described below require Vphase adjustment.

V ertical smear - This phenomenon occurs when viewing a very bright object.

Patterned noise - This is a fixed pattern which may

appear over the entire monitor screen when the camera

is operated at a high temperature.

Jagged picture - When viewing stripes, straight lines,

or similar patterns, the image on the screen may appear

jagged.

7.0 HOUSEKEEPING

Be careful not to spill water or other liquids on the units,

or allow combustible or metallic objects to fall inside

the body. If used with foreign matter inside, the unit is

liable to fail, or be a cause of fire or a shock hazard.

7.1 OPERATION AND STORAGE

LOCATIONS

Do not aim the camera at very bright objects such as

the sun or electric lights for an extended period. Avoid

operating or storing the unit in the following locations:

• Extremely hot or cold places (operating tempera-

ture — 14° to 122° F [-10° to 50° C])

• Damp or dusty places

• Exposed to rain

• Exposed to strong vibration

• Close to generators of strong electromagnetic ra-

diation such as radio or TV transmitters

• Exposed to fluorescent light reflections or unstable

(flickering) lighting conditions

Pelco Manual C1902M (11/96) 15

Page 18

7.2 CARE OF THE UNIT

• Remove dust or dirt on the surface of the lens or

CCD with a blower.

• Use a soft, dry cloth to clean the body. If it is very

dirty, use a cloth dampened with a small quantity

of a neutral detergent, then wipe dry.

• Avoid using volatile solvents such as thinner, alcohol, benzene and insecticides. They may damage the surface finish and/or otherwise impair the

operation of the camera.

CAUTION: The camera should

not be pointed at the sun, or used

for shooting very bright objects, as

the CCD imager may be permanently damaged

8.0 MAINTENANCE

These color cameras, as shipped, are factory adjusted

and tested for optimum performance in most applications. No additional camera setup procedures should

normally be required. However, improved performance

may be obtained in some applications by field setup.

Setup should be limited to the procedures described

herein.

16 Pelco Manual C1902M (11/96)

Page 19

9.0 SPECIFICATIONS

Image Device: 1/3" interline transfer type CCD

Effective Picture Elements:

CC4600-2: 768 (horizontal) x 494 (vertical)

CC4600-2X/

CC4600-3: 752 (horizontal) x 582 (vertical)

Operating

Humidity: 20 to 80%

Storage

Temperature: -40° to 140° F (-40° to 60° C)

Storage

Humidity: 20 to 80%

Lens Mount: C-mount/CS-mount adjustable

Signal System:

CC4600-2: NTSC/EIA color system

CC4600-2X/

CC4600-3: PAL/CCIR color system

Synchronization

System: Internal/line lock

Horizontal

Resolution: 470 lines

Minimum

Illumination: 1.9 lux, F1 .2 (with AGC set to ON in

TURBO mode)

Video Output: 1 Vp-p, 75 ohm, negative sync

Video S/N: 50 dB (with AGC set to OFF)

White Balance: ATW/ATW PRO (switchable)

Automatic Gain

Control (AGC): Switchable: ON/OFF with Gain up

(TURBO/NORM) switch in TURBO

position and AGC ON, a 6 dB gain

increase over NORM mode results.

Power Requirements:

CC4600-2: 24 VAC (60 Hz)

CC4600-2X: 24 VAC (50 Hz)

CC4600-3: 220-240 VAC (50 Hz)

Shock

Resistance: 70 G

Weight:

CC4600-2/

CC4600-2X: 550 g (1.20 lbs)

CC4600-3: 770 g (1.68 lbs)

Construction: Steel case

Finish: Neutral Gray

Dimensions: See Figure 6

Design and specifications are subject to change without notice.

5.50 (139.70)

1.38

1/4-20 MOUNT NUT

(TOP AND BOTTOM)

2.13 (53.97)

5.50 (139.70)

C

CS

2.75

(69.85)

CS

1.09

(27.69)

C

5.06

(128.52)

(34.93)

Power Consumption:

CC4600-2/

CC4600-2X: Less than 4.5 W

2.56

(65.09)

2.19

(55.56)

CC4600-3: 5.5 W

Operating

Temperature: 14° to 122° F (-10° to 50° C)

NOTE: VALUES IN PARENTHESES ARE MILLIMETERS;

ALL OTHERS ARE INCHES

Figure 6. CC4600 Series Dimension Drawing

Pelco Manual C1902M (11/96) 17

Page 20

10.0 WARRANTY AND RETURN INFORMATION

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

• Three years on Genex

®

Series products (multiplexers, server, and keyboard).

• Three years on Camclosure® and fixed camera models, except the CC3701H-2,

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models,

which have a five-year warranty.

•Two years on standard motorized or fixed focal length lenses.

®

•Two years on Legacy

fixed dome products.

•Two years on Spectra

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

continuous motion applications.

®

•Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product

liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused,

whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned

for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

18 Pelco Manual C1902M (11/96)

Loading...

Loading...