CORDLESS ANGLE GRINDER PWSA 20-Li B2

CORDLESS ANGLE GRINDER

Translation of the original instructions

AKKU-WINKELSCHLEIFER

Originalbetriebsanleitung

IAN 290756

ΕΠΑΝΑΦΟΡΤΙΖΟΜΕΝΟΣ

ΓΩΝΙΑΚΟΣ ΤΡΟΧΟΣ

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τις δυο σελίδες με τις εικόνες και εξοικειωθείτε με όλες τις

λειτουργίες της συσκευής.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / CY Translation of the original instructions Page 1

GR / CY Μετάφραση των αυθεντικών οδηγιών λειτουργίας Σελίδα 19

DE / AT / CH Originalbetriebsanleitung Seite 39

A

B

DC

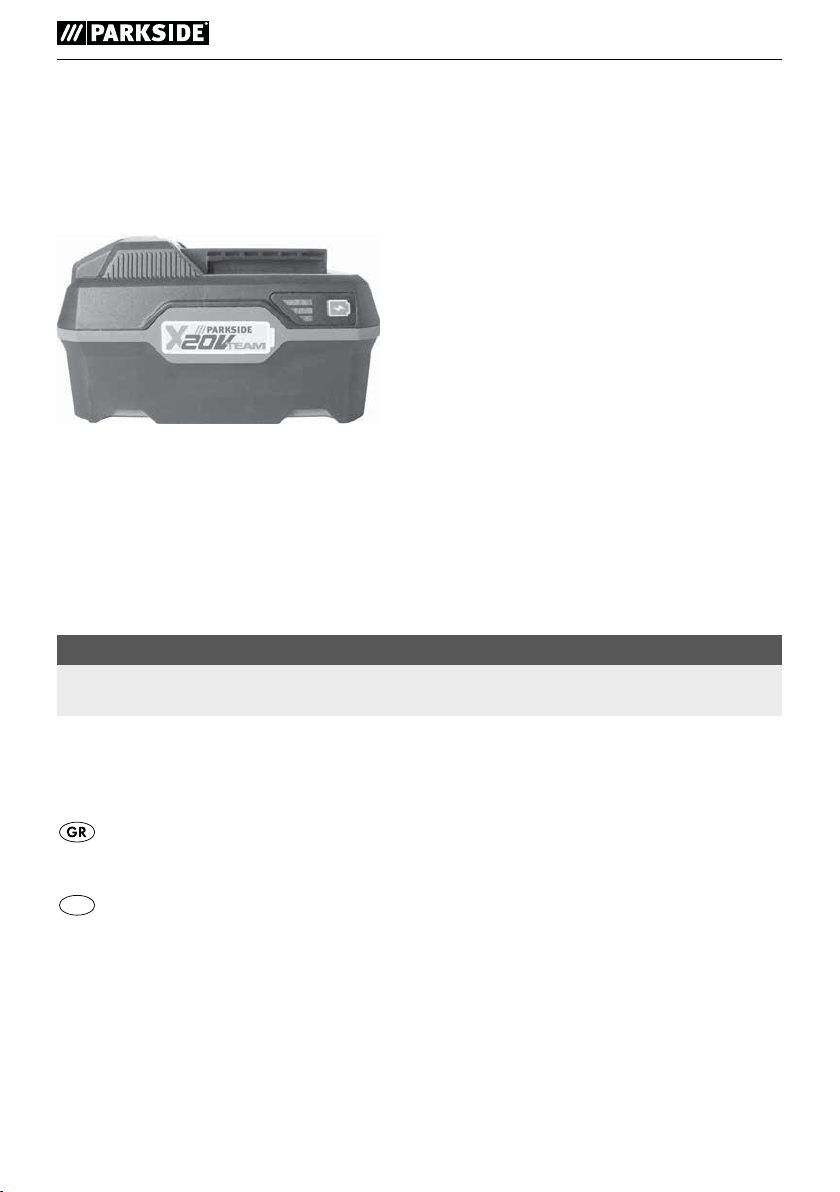

BATTERY COMPATIBLE WITH ALL DEVICES OF THE SERIES

„PARKSIDE X 20V TEAM“

20V max.

18V

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 3

Technical details ............................................................. 3

General Power Tool Safety Warnings ................................4

1. Work area safety .......................................................... 4

2. Electrical safety ........................................................... 4

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 5

5. Use and handling of the cordless electrical power tool ............................. 5

6. Service .................................................................. 6

Safety instructions for all applications ............................................ 6

Kickback and corresponding safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Special safety instructions for grinding and abrasive cutting ........................... 8

Additional special safety instructions for abrasive cutting ............................. 8

Safety guidelines for battery chargers ............................................. 9

Permissible accessories .......................................................10

Storage and handling of the recommended accessory tools ..........................10

Working procedures ......................................................... 11

Before use ......................................................12

Charging the battery pack (see fig. A) ........................................... 12

Attaching/disconnecting the battery pack to/from the appliance ...................... 12

Checking the battery charge level ..............................................12

Fitting the blade guard with quick release ........................................12

Fitting the additional handle ................................................... 13

Fitting/changing the roughing/cutting disc .......................................13

Operation ......................................................14

Switching on and off ........................................................14

Adjusting the rotational speed ................................................. 14

Maintenance and cleaning .........................................14

Disposal ........................................................15

Kompernass Handels GmbH warranty ..............................15

Service .........................................................16

Importer .......................................................16

Translation of the original Conformity Declaration .....................17

Ordering a replacement battery ....................................18

Online ordering ............................................................ 18

Telephone ordering .........................................................18

PWSA 20-Li B2

GB│CY

│

1 ■

CORDLESS ANGLE GRINDER

PWSA 20-Li B2

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

The appliance is intended for cutting, rough cutting

and brushing metal, concrete or tiles without the

use of water. Any other usage or modification of

the appliance is deemed to be improper and carries

a significant risk of accidents. The manufacturer

accepts no responsibility for damage(s) resulting

from improper usage. The appliance is not intended

for commercial use.

Explanation of the symbols used:

Before using the device for

the first time, read the original

operating instructions and

safety instructions.

Using damaged cutting or

roughing discs is dangerous

and may cause serious injury!

Disc diameter

Cordless angle grinder

Wear protective goggles!

Wear hearing protection!

Wear safety shoes!

Wear protective gloves!

Wear a dust mask!

Not approved for wet grinding

Not approved for side grinding

Intended for metal grinding

Features

ON/OFF switch

Release button for the battery pack

Battery pack

Battery charge level button

Battery display LED

Adjusting wheel for speed preselection

Additional handle

Blade guard

Spindle locking button

Screw thread (3 x) for the additional handle

Clamping lever

Coding pin

Adjusting nut

High-speed battery charger (see fig. A)

Red charge control LED (see fig. A)

Green charge control LED (see fig. A)

Clamping nut (see fig. C)

Mounting spindle (see fig. C)

Mounting flange (see fig. C)

Coding groove (see fig. C)

Two-hole mounting spanner (see fig. D)

■ 2 │ GB

│

CY

PWSA 20-Li B2

Package contents

1 cordless angle grinder PWSA 20-Li B2

1 high-speed battery charger PLG 20 A2

1 battery pack PAP 20 A3

1 additional handle

1 blade guard (pre-assembled)

1 two-hole mounting spanner

1 cutting disc (pre-assembled)

1 set of operating instructions

Technical details

Cordless angle grinder: PWSA 20-Li B2

Rated voltage: 20 V

Rated idle speed: n 2500–10000 rpm

Disc width: Ø 115 mm

Thread size: M14

Use the following battery to operate the

cordless tool: PAP 20 A3

Type: LITHIUM ION

Rated voltage: 20 V

Capacity: 4 Ah

Cells: 10

To charge the battery pack rapidly use the

following high-speed battery charger:

PLG 20 A2

INPUT:

Rated voltage: 230–240 V ~, 50 Hz

Rated power

consumption: 85 W

Fuse (internal): 3.15 A

OUTPUT:

Rated voltage: 21.5 V

Rated current: 3.5 A

Charging time: approx. 80 min

Protection class: II /

(DC)

(DC)

(AC)

T3.15A

(DC)

(double insulation)

Noise and vibration data:

Noise measurement value determined in accordance with EN 60745. The A-rated noise level of

the power tool is typically as follows:

Noise emission value:

Sound pressure level: LPA = 84 dB(A)

Uncertainty: K = 3 dB

Sound power level: L

= 95 dB(A)

WA

Uncertainty: K = 3 dB

Wear hearing protection!

Total vibration value:

Surface grinding main

handle: a

= 1.83m/s

h, AG

Uncertainty: K = 1.5 m/s

Surface grinding additional

handle: a

= 1.224 m/s

h, AG

Uncertainty: K = 1.5 m/s

2

2

2

2

NOTE

► The vibration level specified in these instruc-

tions has been measured in accordance with

a standardised measuring procedure and

can be used for equipment comparisons. The

specified vibration emission value can also be

used to make an initial exposure estimate.

WARNING!

► The vibration level varies depending on the

use of the power tool and may be higher

than the value specified in these instructions

in some cases. Regular use of the power tool

in this way may cause the user to underestimate the vibration. Try to keep the vibration

loads as low as possible. Measures to reduce

the vibration load are, e.g. wearing gloves

and limiting the working time. Wherein all

states of operation must be included (e.g.

times when the power tool is switched off and

times where the power tool is switched on but

running without load).

PWSA 20-Li B2

GB│CY

│

3 ■

General Power

Tool Safety Warnings

WARNING!

► Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

d)

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e)

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b)

Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

■ 4 │ GB

│

CY

PWSA 20-Li B2

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many acci-

dents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed.

Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5. Use and handling of the cordless

electrical power tool

a) Charge a rechargeable battery unit using

only the charger recommended by the manufacturer. Chargers are often designed for a

particular type of rechargeable battery unit.

There is the danger of fire if other types of

rechargeable battery units are used.

b) Only the rechargeable battery units supplied

are to be used with an electrical power tool.

The use of other rechargeable batteries may

lead to a risk of injury or fire.

c) When they are not being used, store re-

chargeable battery units away from paperclips, coins, keys, nails, screws or other small

metal objects that could cause the contacts

to be bridged. Short-circuiting the contacts of

a rechargeable battery unit may result in heat

damage or fire.

d) Fluids may leak out of rechargeable battery

units if they are misused. If this happens,

avoid contact with the fluid. If contact occurs,

flush the affected area with water. Seek additional medical help if any of the fluid gets into

your eyes. Escaping battery fluid may cause

skin irritation or burns.

PWSA 20-Li B2

GB│CY

│

5 ■

CAUTION! RISK OF EXPLOSION!

Never charge non-rechargeable

batteries.

Protect the rechargeable battery from

heat, for example from continuous

exposure to sunlight, fire, water and

moisture. There is a risk of explosion.

6. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Safety instructions for all applications

Special safety instructions for grinding and

abrasive cutting:

a) This power tool is to be used as a grinder and

abrasive cutting appliance. Please follow all

safety instructions, instructions, diagrams and

data that you receive with the appliance.

If you do not observe the following instructions,

this can lead to an electrical shock, fire and/or

serious injuries.

b) This power tool is not suitable for sandpaper

sanding, working with a steel brush or burnishing. Using the power tool for applications for

which it is not designed can lead to hazards

and injuries.

c) Do not use any accessories that have not

been specifically provided or recommended

by the manufacturer for this power tool. Just

because you can attach the accessories to your

power tool does not guarantee they are safe to

use.

d) The maximum speed of the accessory tool

used must be at least as high as the maximum

speed specified for the power tool. Accessories

that rotate faster than the permissible rate can

break and throw pieces into the air.

e) The external diameter and thickness of the

accessory tool used must comply with the

dimensions of the power tool. Incorrectly di-

mensioned accessory tools cannot be sufficiently shielded or controlled.

f) Attachment tools with a thread insert must

match the thread of the grinding spindle exactly. For attachment tools that are mounted

using a flange, the diameter of the hole on

the attachment tool must correspond to the

width of the fitment on the flange. Accessory

tools that cannot be fitted precisely to the power

tool rotate unevenly, vibrate severely and can

lead to a loss of control.

g) Never use damaged attachment parts. Check

accessory tools such as grinding discs before

each use for chips or cracks, grinding plates

for cracks, wearing or excessive wear and

tear and wire brushes for loose or broken

wires. If the power tool or the accessory tool

in use is dropped, check to see if it is damaged or use an undamaged accessory tool.

When you have checked and inserted the

accessory tool, ensure that you and any other

people in the vicinity remain outside of the

level of the rotating accessory tool and allow

the tool to rotate at maximum speed for one

minute. Damaged accessories usually break

during the test period.

h) Wear personal protective equipment.

Depending on the application, ensure that

you use full face protection, eye protection

or goggles. Use a dust mask, hearing protection, protective gloves or special apron to

protect yourself from grindings and material

particles as required. Protect your eyes from

flying debris that may be created during certain

applications. Dust or filter masks must be used

to filter any dust created by the application. If

you are exposed to loud noise for any length of

time, you can suffer a hearing loss.

■ 6 │ GB

│

CY

PWSA 20-Li B2

i) Ensure that other people remain at a safe dis-

tance to your workspace. Anyone who enters

the workspace must wear personal protective

equipment.

Fragments of the workpiece or broken accessory tools can fly off and cause injury – even

outside the immediate working area.

j) Hold the power tool only by the insulated

handles when you are carrying out work in

which the accessory tool may come into

contact with concealed power cables.

Contact with a live wire may make exposed

metal parts of the power tool live and could

give the operator an electric shock.

k) Keep the power cord away from any rotating

accessories. If you lose control of the appliance,

the cord may get caught or cut and your hand or

arm could get caught in the rotating accessory

tool.

l) Never put the power tool down until the

accessory tool being used has come to a

complete standstill. The rotating accessory tool

could come into contact with the surface and

cause you to lose control of the power tool.

m) Do not leave the power tool running whilst

carrying it. Accidental contact between your

clothing and the rotating accessory tool could

lead to a physical injury.

n) Clean the ventilation slits of your power tool

regularly. The engine fan draws dust into the

housing and a strong accumulation of metal

dust can cause electrical hazards.

o) Never use the power tool in the vicinity of

inflammable materials. Sparks can ignite these

materials.

p) Do not use any accessory tools which require

liquid coolant. The use of water or other liquid

coolants may lead to an electric shock.

Kickback and corresponding safety

instructions

Kickback is a sudden reaction caused when a

rotating accessory tool, e.g. grinding disc, grinding

plate, wire brush, etc., catches or jams. Catching or

jamming leads to an abrupt stop of the rotating accessory tool. If this happens, an uncontrolled power

tool turns rapidly against the direction of rotation of

the accessory tool caught in the blockage.

If, for example, a grinding disc catches or jams in a

workpiece, the edge of the grinding disc projecting

into the workpiece can get caught and break off

the grinding disc or cause a kickback. The grinding

disc can then fly in the direction of the operator

or away from him, depending on the direction of

rotation of the disc at the blockage. This can also

break grinding discs.

A kickback is caused by improper or incorrect use

of the power tool. This can be avoided by taking

proper precautions as given below.

a) Hold the power tool firmly in both hands and

position your body and arms so they can

absorb the force of a kickback. Always use

the additional handle, if available, so that

you have the maximum possible control over

the kickback force or reaction forces at full

speed. By taking adequate precautions, the

operator can stay in control of the kickback

and reaction torques.

b) Never hold your hand close to a rotating

accessory tool. The accessory tool could hit

your hand in the event of a kickback.

c) Avoid having any part of your body in the

region in which the power tool is likely to

move in event of a kickback. The kickback will

force the power tool in the opposite direction to

the direction of rotation of the grinding disc at

the blockage.

d) Take special care when working near corners,

sharp edges, etc. Avoid allowing the accessory tool to bounce back from the workpiece

or jam. The rotating accessory tool is more

likely to jam in corners or sharp edges or if it

rebounds off them. This can cause a loss of

control or kickback.

PWSA 20-Li B2

GB│CY

│

7 ■

e) Do not use chains or toothed saw blades.

Such accessories often cause a kickback or

loss of control over the power tool.

Special safety instructions for

grinding and abrasive cutting

a)

Use only the grinding accessories approved

for your power tool and the appropriate

blade guard for these grinding tools. Grinding

tools which are not designed for the power tool

cannot be sufficiently shielded and are unsafe.

b)

Offset grinding discs must be fitted so that the

grinding surface does not protrude over the

level of the blade guard edge. An improperly

fitted grinding disc which protrudes over the level

of the blade guard edge cannot be properly

guarded.

c) The blade guard must be securely mounted

on the power tool and adjusted to ensure

maximum safety so that the smallest possible

amount of the grinding tool is open to the

operator. The blade guard is designed to

protect the operator from fragments, accidental

contact with the grinding tool and sparks that

could ignite clothing.

d) Grinding tools should only be used for the

recommended applications.

For example: Never grind with the side surface of a cutting disc. Cutting discs are de-

signed to remove material with the edge of the

disc. Any lateral application of force on these

grinding tools can lead to a breakage.

e) Always use an undamaged clamping flange

of the correct size and shape for the selected

grinding disc. Suitable flanges support the

grinding disc and reduce the risk of disc breakage. Flanges for cutting discs can be different

to flanges for other grinding discs.

f) Do not use worn grinding discs from larger

power tools. Grinding discs for larger power

tools are not designed for the higher rotational

speeds of smaller power tools and can break.

Additional special safety instructions

for abrasive cutting

a) Avoid any blockage to the cutting disc or

high contact pressure. Do not make any

excessively deep cuts. Overloading the cut-

ting disc increases the stress and likelihood of

canting or blocking and thus the possibility of a

kickback or a breakage of the grinding tool.

b) Avoid the area in front of and behind the

rotating cutting disc. When you move the cutting disc away from yourself in the workpiece, it

is possible, in the event of a kickback, that the

electrical tool along with the rotating disc is

thrown out directly towards you.

b) If the cutting disc jams or you stop working,

switch the tool off and hold it steadily in

the workpiece until the disc has completely

stopped turning. Never attempt to pull a

rotating cutting disc out of a cut. This could

lead to kickback. Identify and remove the

cause of the jam.

d) Do not switch the power tool back on while

it is located in the workpiece. Allow the cutting disc to reach its full speed before you

carefully continue the cut. Otherwise, the disc

can jam, jump out of the workpiece or cause a

kickback.

e) Support boards or large workpieces to re-

duce the risk of the cutting disc jamming and

causing a kickback. Large workpieces can

bend under their own weight. The workpiece

must be supported on both sides of the disc:

both in the vicinity of the cutting disc and also

at the edge.

f)

Be particularly careful when making pocket

cuts into existing walls or other obscured areas.

The inserted cutting disc may cut into gas or

water pipes, electrical wiring or other objects

that can cause kickback.

■ 8 │ GB

│

CY

PWSA 20-Li B2

Safety guidelines for battery chargers

■ This appliance may be used by

children aged 8 years and above

and by persons with limited physical,

sensory or mental capabilities or

lack of experience and knowledge,

provided that they are under supervision or have been told how to use

the appliance safely and are aware

of the potential risks. Do not allow

children to use the appliance as a

toy. Cleaning and user maintenance

tasks must not be carried out by

children unless they are supervised.

■ To avoid potential risks, damaged

mains cables should be replaced

by the manufacturer, their customer

service department or a similarly

qualified person.

The charger is suitable for indoor use

only.

WARNING!

■ To avoid potential risks, damaged mains

cables should be replaced by the manufacturer, their customer service department or a

similarly qualified person.

PWSA 20-Li B2

GB│CY

│

9 ■

Permissible accessories

Max.

circum-

ferential

speed

(m/s)

Tool Blade guard

Two-hole

mounting

spanner

Two-hole

mounting

spanner

Yes

Yes

Cutting disc

Roughing disc

Max.

diameter

Ø (mm)

115 3 M14 13300 80

115 6 M14 13300 80

Max.

thickness

(mm)

Thread

size (mm)

Max

speed

(rpm)

Storage and handling of the recommended accessory tools

■ Grinding tools are to be treated with care and transported carefully.

■ Grinding tools should be stored in such a way that they are not exposed to mechanical damage or

environmental influences (e.g. moisture).

■ 10 │ GB

│

CY

PWSA 20-Li B2

Working procedures

NOTE

► Grinding tools should only be used for the

recommended applications. Otherwise, they

can break, be damaged or cause injuries.

Rough grinding:

■ While applying moderate pressure, move

the angle grinder back and forth over the

workpiece.

■ For soft material, move the rough grinding

disc at a shallow angle over the workpiece;

for hard material at a slightly steeper angle.

Abrasive cutting:

■ Use only tested fibre-reinforced cutting or

grinding discs that are approved for a circum-

ferential speed of not less than 80 m/s.

CAUTION!

The grinder continues running after being turned

off. Do not try to brake it by applying lateral

counterpressure.

■ Secure the workpiece. Use clamps/a vice to

hold the workpiece firmly in place. This is much

safer than simply holding it in your hand.

■ Always switch off the appliance before put-

ting it down and wait for the appliance to

come to a complete standstill.

■ Use the appliance only for dry cutting or

sanding.

■ The additional handle

on the appliance for all work.

■ Materials containing asbestos may not be

processed. Asbestos is a known carcinogen.

Never use cutting discs for rough

grinding!

Never use roughing discs for

cutting!

must be mounted

Tip! This symbol indicates proper

behaviour.

HAZARD! ALWAYS GUIDE THE

APPLIANCE THROUGH THE WORKPIECE IN REVERSE ROTATION.

► In the opposite direction there is a risk of

kickback. The appliance can be pushed out

of the cut.

■ Always switch the appliance on before apply-

ing it to the workpiece. After completing the

task, lift the appliance from the workpiece and

then switch it off.

■ Always hold the appliance firmly with two

hands while working. Ensure that your stance

is secure and stable.

■ For an optimum grinding effect, move the ap-

pliance evenly at an angle of 15° to 30° (between grinding disc and workpiece) backwards

and forwards.

■ When working on angled surfaces, do not

exert great force on the workpiece. If the

rotational speed drops significantly, you must

reduce the pressure exerted to allow safe and

effective working. If the appliance suddenly

brakes completely or jams, it must be switched

off immediately.

■ Cutting: Work at a moderate feed rate and

do not tilt the cutting disc.

■ Roughing and cutting discs become very

hot – let them cool down completely before

touching them.

■ Never use the appliance for purposes other

than the ones for which it was designed.

■ Always make sure that the appliance is

turned off before inserting the battery into it.

■ Switch the appliance off and remove the

battery immediately in hazardous situations.

Ensure that the appliance is easily and quickly

accessible in the event of an emergency.

PWSA 20-Li B2

GB│CY

│

11 ■

■ Always remove the battery during work

breaks, when servicing the appliance and

when it is no longer in use. The appliance must

be kept clean, dry and free of oil and grease at

all times.

■ Remain alert at all times! Always pay attention

to what you are doing and act with common

sense. Do not use the appliance if you are

distracted or feeling unwell.

WARNING!

Always wear safety goggles.

WARNING!

Always wear a dust mask!

Before use

Charging the battery pack (see fig. A)

CAUTION!

► Always unplug the appliance before you

remove the battery pack

the battery pack to the charger.

■ Never charge the battery pack

ambient temperature is below 10°C or above

40°C.

♦ Connect the battery pack

battery charger (see fig. A).

♦ Insert the power plug into the socket.

The control LED

♦ The green charge control LED

the charging process is complete and the battery pack

ATTENTION!

♦ If the red charge control LED

means that the battery pack has overheated and cannot be charged.

♦ If the red and green charge control LEDs

both flash, this means that the battery

pack is defective.

♦ Switch off the charger for at least 15 minutes

between successive charging sessions. Also

disconnect the power plug from the mains

power socket.

lights up red.

is ready.

from or connect

when the

to the high-speed

indicates that

flashes, this

Attaching/disconnecting the battery

pack to/from the appliance

Attaching the battery pack:

♦ Push the battery pack

clicks into place.

Removing the battery pack:

♦ Press the release button

battery pack

.

into the handle until it

and remove the

Checking the battery charge level

♦ Press the battery charge level button to

check the status of the battery (see also main

diagram).

The status/remaining charge will be shown on

the battery display LED

♦ RED/ORANGE/GREEN = maximum charge

RED/ORANGE = medium charge

RED = low charge – charge the battery

as follows:

Fitting the blade guard with quick

release

WARNING! RISK OF INJURY

► Always switch the appliance off and remove

the battery before carrying out any work on

the appliance.

RISK OF INJURY

► Always use the angle grinder with the blade

guard

securely. Set this so that the highest possible

degree of safety is achieved, i.e. the smallest

possible part of the grinding disc is open to

the operator. The blade guard is designed

to protect the operator from fragments and

accidental contact with the grinding tool.

. The blade guard should be fitted

■ 12 │ GB

│

CY

PWSA 20-Li B2

RISK OF INJURY

12

► Make sure that the blade guard

is fitted

at least at the same angle as the additional

handle (see fig. B). Otherwise, you could

cut injure yourself on the roughing disc or

cutting disc.

♦ Open the clamping lever .

♦ Place the blade guard

with the coding pin

in the coding groove .

♦ Turn the blade guard to the required position

(working position). The closed side of the blade

guard must always be toward the operator.

♦ Close the clamping lever to clamp the blade

guard into position. If necessary, the clamping force of the lock can be changed by loosening or tightening the adjusting nut . Ensure

that the blade guard sits firmly on the neck

of the spindle.

Fitting the additional handle

CAUTION!

► For safety reasons, this appliance may only

be used with the additional handle

. Failure

to do so can lead to serious injury. The

additional handle can be screwed onto

the left, the right or the top, depending on the

job at hand.

Fitting/changing the roughing/

cutting disc

Always wear protective gloves when changing

cutting/rough grinding discs.

Pay attention to the dimensions of the roughing/

cutting disc. The diameter of the hole must fit the

mounting flange

a reducer or adapter.

NOTE

► Use only discs which are free of dirt.

without any play. Do not use

■ Use only grinding discs whose permissible

speed rating is at least as high as that on the

type plate on the power tool.

■ RISK OF INJURY! Press the spindle locking

button

only when the mounting spindle

is at a complete standstill.

♦ Press the spindle locking button to lock the

motor.

♦ Undo the clamping nut

using the two-hole

mounting spanner (see fig D).

♦ Place the rough grinding or cutting disc with

the label side towards the appliance on the

mounting flange

♦ Then replace the clamping nut

.

with the raised

side facing up on the mounting spindle .

With thin grinding discs (see fig. 1):

♦ The collar of the clamping nut faces upwards

so that a thin grinding disc can be fitted safely.

≤ 3,2 mm

Fig. 1

♦ Press the spindle locking button

to lock the

motor.

♦ Tighten the clamping nut

using the two-hole

mounting spanner .

With thick grinding discs (see fig. 2):

> 3,2 mm

Fig. 2

The collar of the clamping nut

faces downwards

so that the grinding disk can be fitted securely onto

the mounting spindle .

PWSA 20-Li B2

GB│CY

│

13 ■

♦ Lock the mounting spindle

♦ Tighten the clamping nut

rection using the two-hole mounting spanner .

NOTE

If the disc does not turn smoothly or vibrates

►

after the change, the disc must be replaced

immediately.

♦ For safety's sake, run the appliance at maximum

speed for 60 seconds after every disc change.

Be aware of unusual noises and sparks.

♦ Check whether all the fastening elements are

correctly fitted.

♦ Make sure that the arrow showing the direction

of rotation (if any) on the cutting or rough grinding discs (including diamond cutting discs) and

the direction of rotation of the appliance (arrow

showing the direction of rotation on the head)

match.

.

in a clockwise di-

Operation

Switching on and off

Check the inserted tool to ensure that all mounting

parts are correctly attached before use.

NOTE

Always switch on the angle grinder before

►

making contact with the material, then apply

it to the workpiece.

Switching on:

♦ First press the ON/OFF switch to the right so

that you can then press it forwards.

Switching off:

♦ Let go of the ON/OFF switch

Switching to continuous operation:

♦ First press the

that you can then press it forwards. Then press

the

ON/OFF switch forwards and down

until it engages.

ON/OFF switch to the right so

.

Switching off continuous operation:

♦ Press the

ON/OFF switch to the rear and

downwards and release it.

Adjusting the rotational speed

You can use the adjusting wheel for speed preselection to preselect the rotational speed:

(1 = slower speed, 6 = faster speed).

We recommend you carry out practice tests to

determine the correct speed.

The speed can also be changed during operation.

Maintenance and cleaning

WARNING! RISK OF INJURY!

Always switch the appliance off and

remove the battery before carrying

out any work on the appliance.

The battery angle grinder is maintenance-free.

■ Do not use any sharp objects for cleaning

the appliance. Never allow any liquids to

penetrate inside the appliance. Otherwise the

appliance could be damaged.

■ Clean the appliance regularly, preferably im-

mediately after completion of the work.

■ Clean the housing with a dry cloth – do NOT

use petrol, solvents or cleaners which can attack

the plastic.

■ A vacuum cleaner is required for thorough

cleaning of the appliance.

■ Ventilation openings must never be obstructed.

■ Remove any sanding dust stuck to the appliance

with a brush.

NOTE

► Replacement parts not listed (such as carbon

brushes, switch) can be ordered via our

service hotline.

■ 14 │ GB

│

CY

PWSA 20-Li B2

Disposal

The packaging consists of environmentally

friendly material. It can be disposed of in

the local recycling containers.

Do not dispose of power tools in

your normal domestic waste!

European Directive 2012/19/EU requires that

worn-out power tools be collected separately and

recycled in an environmentally compatible manner.

Do not dispose of batteries in your

normal household waste!

Remove the batteries from the appliance before

disposal.

Defective or worn-out rechargeable batteries must

be recycled according to Directive 2006/66/EC.

Take the battery pack and/or appliance to a nearby collection facility.

Please consult your local authorities regarding

suitable disposal of worn out power tools/battery

packs.

Note the labelling on the packaging

and separate the packaging material

components for disposal if necessary.

The packaging material is labelled

with abbreviations (a) and numbers

(b) with the following meanings:

1–7: Plastics,

20–22: Paper and cardboard,

80–98: Composites

Your local community or municipal

authorities can provide information on

how to dispose of the worn-out

product.

Kompernass Handels GmbH

warranty

Dear Customer,

This appliance has a 3-year warranty valid from

the date of purchase. If this product has any faults,

you, the buyer, have certain statutory rights. Your

statutory rights are not restricted in any way by the

warranty described below.

Warranty conditions

The validity period of the warranty starts from the

date of purchase. Please keep your original receipt

in a safe place. This document will be required as

proof of purchase.

If any material or production fault occurs within

three years of the date of purchase of the product,

we will either repair or replace the product for you

at our discretion. This warranty service is dependent

on you presenting the defective appliance and

the proof of purchase (receipt) and a short written

description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product

will either be repaired or replaced by us. The repair

or replacement of a product does not signify the

beginning of a new warranty period.

Warranty period and statutory claims for

defects

The warranty period is not prolonged by repairs

effected under the warranty. This also applies to

replaced and repaired components. Any damage

and defects present at the time of purchase must

be reported immediately after unpacking. Repairs

carried out after expiry of the warranty period shall

be subject to a fee.

PWSA 20-Li B2

GB│CY

│

15 ■

Scope of the warranty

This appliance has been manufactured in accordance

with strict quality guidelines and inspected meticulously prior to delivery.

The warranty covers material faults or production

faults. The warranty does not extend to product parts

subject to normal wear and tear or fragile parts such

as switches, batteries, baking moulds or parts made

of glass.

The warranty does not apply if the product has been

damaged, improperly used or improperly maintained.

The directions in the operating instructions for the

product regarding proper use of the product are

to be strictly followed. Uses and actions that are

discouraged in the operating instructions or which

are warned against must be avoided.

This product is intended solely for private use and

not for commercial purposes. The warranty shall be

deemed void in cases of misuse or improper handling,

use of force and modifications/repairs which have

not been carried out by one of our authorised

Service centres.

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

■ Please have the till receipt and the item number

(e.g. IAN 12345) available as proof of purchase.

■ You will find the item number on the type plate,

an engraving on the front page of the instructions

(bottom left), or as a sticker on the rear or

bottom of the appliance.

■ If functional or other defects occur, please

contact the service department listed either by

telephone or by e-mail.

■ You can return a defective product to us free of

charge to the service address that will be provided

to you. Ensure that you enclose the proof of

purchase (till receipt) and information about

what the defect is and when it occurred.

NOTE

► For Parkside and Florabest tools, please send

us only the defective item without the accessories (e.g. battery, storage case, assembly

tools, etc.).

You can download these instructions

along with many other manuals,

product videos and software on

www.lidl-service.com.

Service

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

CY

Service Cyprus

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

IAN 290756

Importer

Please note that the following address is not the

service address. Please use the service address

provided in the operating instructions.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

DE - 44867 BOCHUM

GERMANY

www.kompernass.com

■ 16 │ GB

│

CY

PWSA 20-Li B2

Translation of the original Conformity Declaration

We, KOMPERNASS HANDELS GMBH, document officer: Mr Semi Uguzlu, BURGSTR. 21,

DE - 44867 BOCHUM, GERMANY, hereby declare that this product complies with the following

standards, normative documents and EC directives:

Machinery Directive

(2006/42/EC)

EC Low Voltage Directive

(2014/35/EU)

EMC (Electromagnetic Compatibility)

(2014/30/EU)

RoHS Directive

(2011/65/EU)*

*The manufacturer bears the full responsibility for compliance with this conformity declaration. The object of the

declaration described above complies with the requirements of the Directive 2011/65/EU of the European

Parliament and Council of 8 June 2011 on the limitations of use of certain dangerous substances in electrical

and electronic appliances.

Applied harmonised standards:

EN 60745-1:2009+A11

EN 60745-2-3:2011+A2+A11+A12+A13

EN 55014-1:2006+A1+A2

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 60335-2-29:2004+A2

EN 60335-1:2012+A11

EN 62233:2008

EN 50581:2012

Type designation of machine:

Cordless angle grinder PWSA 20-Li B2

Year of manufacture: 12 - 2017

Serial number: IAN 290756

Bochum, 06/12/2017

Semi Uguzlu

- Quality Manager We reserve the right to make technical changes in the context of further product development.

PWSA 20-Li B2

GB│CY

│

17 ■

Ordering a replacement battery

If you want to order a replacement battery for your appliance, you can do so easily via the Internet on

www.kompernass.com or by telephone.

The price of the replacement battery (PAP 20 A3) is €27.99 incl. VAT and shipping. Due to limited stocks,

this item may sell out in a relatively short time.

Online ordering

To order a replacement battery from the Accessories Shop:

■ Use your Internet browser to visit www.kompernass.com.

■ Click on the corresponding flag at the top left of the page to select the desired country and language.

■ Under the heading "Brands", click on "Parkside" and select your appliance to select a suitable replace-

ment battery.

■ After you have placed the rechargeable battery in the shopping basket, click the "Checkout" button

and follow the on-screen instructions to complete the ordering process.

NOTE

► Online ordering of replacement parts might not be possible in some countries. If this is the case,

please contact the Service hotline.

■ The promotion is limited to one battery per customer/appliance and also to a timeline of two months

after the promotion period. Thereafter, the replacement battery can be ordered as a replacement part

under other conditions.

Telephone ordering

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

CY

Service Cyprus

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

To ensure fast processing of your order, have the article number of your appliance to hand

(e.g. IAN 290756) in case of questions. The article number can be found on the type plate

or the title page of these instructions.

■ 18 │ GB

│

CY

PWSA 20-Li B2

Περιεχόμενα

Εισαγωγή .......................................................20

Προβλεπόμενη χρήση ....................................................... 20

Εξοπλισμός ............................................................... 20

Παραδοτέος εξοπλισμός ..................................................... 21

Τεχνικά χαρακτηριστικά ...................................................... 21

Γενικές υποδείξεις ασφαλείας για ηλεκτρικά εργαλεία ...................22

1. Ασφάλεια στο χώρο εργασίας ............................................... 22

2. Ηλεκτρική ασφάλεια ....................................................... 22

3. Ασφάλεια ατόμων ........................................................23

4. Χρήση και χειρισμός του ηλεκτρικού εργαλείου .................................23

5. Χρήση και χειρισμός του επαναφορτιζόμενου εργαλείου ..........................24

6. Σέρβις ................................................................. 24

Υποδείξεις ασφαλείας για όλες τις χρήσεις .......................................24

Αντεπιστροφή και αντίστοιχες υποδείξεις ασφαλείας ...............................26

Ειδικές υποδείξεις ασφαλείας για λείανση και αποκοπή με λείανση ....................27

Περισσότερες ειδικές υποδείξεις ασφαλείας για αποκοπή με λείανση .................. 27

Υποδείξεις ασφαλείας για φορτιστές ............................................ 28

Επιτρεπόμενα αξεσουάρ ..................................................... 29

Φύλαξη και χειρισμός των προτεινόμενων εργαλείων εφαρμογής ...................... 29

Υποδείξεις εργασίας ........................................................30

Πριν από τη θέση σε λειτουργία .....................................31

Φόρτιση συστοιχίας συσσωρευτών (βλ. Εικ. Α) .................................... 31

Τοποθέτηση/Απομάκρυνση συστοιχίας συσσωρευτών στη/από τη συσκευή ............. 31

Έλεγχος κατάστασης συσσωρευτών ............................................. 31

Συναρμολόγηση του προστατευτικού καλύμματος με ταχυσύνδεσμο ...................32

Συναρμολόγηση της πρόσθετης χειρολαβής ..................................... 32

Συναρμολόγηση/Αλλαγή δίσκου τορναρίσματος/κοπής ........................... 32

Θέση σε λειτουργία ...............................................33

Ενεργοποίηση/απενεργοποίηση ...............................................33

Ρύθμιση αριθμού στροφών ...................................................34

Συντήρηση και καθαρισμός ........................................34

Απόρριψη ......................................................34

Εγγύηση της Kompernass Handels GmbH ............................35

Σέρβις. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Εισαγωγέας .....................................................36

Μετάφραση της Πρωτότυπης Δήλωση συμμόρφωσης ...................37

Παραγγελία εφεδρικού συσσωρευτή ................................38

Ηλεκτρονική παραγγελία .....................................................38

Τηλεφωνική παραγγελία ...................................................... 38

PWSA 20-Li B2

GR│CY

│

19 ■

ΕΠΑΝΑΦΟΡΤΙΖΟΜΕΝΟΣ

ΓΩΝΙΑΚΟΣ ΤΡΟΧΟΣ

PWSA 20-Li B2

Εισαγωγή

Συγχαρητήρια για την αγορά της νέας σας

συσκευής. Το προϊόν που αποκτήσατε είναι ένα

προϊόν υψηλής ποιότητας. Οι οδηγίες χρήσης

αποτελούν τμήμα αυτού του προϊόντος. Περιλαμβάνουν σημαντικές υποδείξεις για την ασφάλεια,

τη χρήση και την απόρριψη. Πριν από τη χρήση

του προϊόντος, εξοικειωθείτε με όλες τις υποδείξεις

χειρισμού και ασφάλειας. Χρησιμοποιείτε το προϊόν αποκλειστικά όπως περιγράφεται και για τους

αναφερόμενους τομείς χρήσης. Παραδίδετε όλα

τα έγγραφα σε περίπτωση παράδοσης του προϊόντος σε τρίτους.

Προβλεπόμενη χρήση

Η συσκευή ενδείκνυται για κοπή, προλείανση

και βούρτσισμα μετάλλου, τσιμέντου ή πλακιδίων

χωρίς χρήση νερού. Κάθε άλλη χρήση ή μετατροπή της συσκευής θεωρείται μη σύμφωνη με τους

κανονισμούς και ενέχει σημαντικούς κινδύνους

ατυχημάτων. Για βλάβες που προέρχονται από

ακατάλληλη χρήση δεν αναλαμβάνουμε καμία

ευθύνη. Η συσκευή δεν προορίζεται για επαγγελματική χρήση.

Επεξήγηση των συμβόλων:

Διαβάστε τις πρωτότυπες οδηγίες λειτουργίας και τις υποδείξεις

ασφαλείας πριν τη θέση σε

λειτουργία.

Η χρήση φθαρμένων δίσκων

κοπής ή τορναρίσματος είναι επικίνδυνη και μπορεί να οδηγήσει

σε σοβαρούς τραυματισμούς!

Διάμετρος δίσκου

Επαναφορτιζόμενος γωνιακός

τροχός

Φοράτε γυαλιά προστασίας!

Φοράτε προστασία για την

ακοή!

Φοράτε υποδήματα προστασίας!

Φοράτε προστατευτικά γάντια!

Φοράτε μάσκα προστασίας από

τη σκόνη!

Δεν επιτρέπεται για υγρό

τρόχισμα

Δεν επιτρέπεται για πλευρικό

τρόχισμα

Προβλέπεται για τρόχισμα

μετάλλου

Εξοπλισμός

Διακόπτης ON/OFF

Πλήκτρο για την απασφάλιση της συστοιχίας

συσσωρευτών

Συστοιχία συσσωρευτών

Πλήκτρο κατάστασης συσσωρευτή

LED ένδειξης συσσωρευτή

Τροχίσκος για την προεπιλογή αριθμού στροφών

Πρόσθετη χειρολαβή

Προστατευτικό κάλυμμα

Πλήκτρο ασφάλισης ατράκτου

Σπείρωμα (3 x) για πρόσθετη χειρολαβή

Μοχλός τάνυσης

Προεξοχή κωδικοποίησης

Παξιμάδι ρύθμισης

Ταχυφορτιστής (βλ. Εικ. Α)

Κόκκινη λυχνία LED ελέγχου φόρτισης (βλ. Εικ. Α)

Πράσινη λυχνία LED ελέγχου φόρτισης

(βλ. Εικ. Α)

■ 20 │ GR

│

CY

PWSA 20-Li B2

Περικόχλιο συγκράτησης (βλ. Εικ. C)

Άτρακτος υποδοχής (βλ. Εικ. C)

Φλάντζα υποδοχής (βλ. Εικ. C)

Σφηναύλακα (βλ. Εικ. C)

Κλειδί συναρμολόγησης δύο οπών (βλ. Εικ. D)

Παραδοτέος εξοπλισμός

1 ΕΠΑΝΑΦΟΡΤΙΖΌΜΕΝΟΣ ΓΩΝΙΑΚΌΣ

ΤΡΟΧΌΣ PWSA 20-Li B2

1 Ταχυφορτιστής συσσωρευτών PLG 20 A2

1 Συστοιχία συσσωρευτών PAP 20 A3

1 Πρόσθετη χειρολαβή

1 Προστατευτικό κάλυμμα (προμονταρισμένο)

1 Κλειδί συναρμολόγησης δύο οπών

1 Δίσκος κοπής (προμονταρισμένος)

1 Οδηγίες χρήσης

Τεχνικά χαρακτηριστικά

Επαναφορτιζόμενος γωνιακός τροχός:

PWSA 20-Li B2

Τάση μέτρησης: 20 V

Αριθμός στροφών

μέτρησης: n 2500 - 10000 / min

Διάσταση δίσκου: Ø 115 mm

Διάσταση σπειρώματος: M14

Για τη λειτουργία του επαναφορτιζόμενου

εργαλείου, χρησιμοποιείτε τον ακόλουθο

συσσωρευτή: PAP 20 A3

Τύπος: ΛΙΘΙΟΥ-ΙΟΝΤΩΝ

Τάση μέτρησης: 20 V

Απόδοση: 4 Ah

Στοιχεία: 10

Για τη γρήγορη φόρτιση της συστοιχίας

συσσωρευτή χρησιμοποιείτε τον ακόλουθο

ταχυφορτιστή συσσωρευτών:

PLG 20 A2

ΕΙΣΟΔΟΣ / Input:

Τάση μέτρησης: 230 - 240 V ~, 50 Hz

Κατανάλωση μέτρησης: 85 W

Ασφάλεια (εσωτερικά): 3,15 A

ΕΞΟΔΟΣ / Output:

Τάση μέτρησης: 21,5 V

(συνεχές ρεύμα)

(συνεχές ρεύμα)

(εναλλασσόμενο ρεύμα)

T3.15A

(συνεχές

ρεύμα)

Ονομαστικό ρεύμα: 3,5 A

Διάρκεια φόρτισης: περ. 80 λεπτά

Κατηγορία προστασίας: II /

(διπλή μόνωση)

Πληροφορίες θορύβου και κραδασμών:

Τιμή μέτρησης για θόρυβο διακριβωμένη σύμφωνα

με το EN 60745. Το επίπεδο θορύβου Α-στάθμισης του ηλεκτρικού εργαλείου ανέρχεται συνήθως:

Τιμή εκπομπής θορύβου:

Στάθμη ηχητικής πίεσης: L

PA

Αβεβαιότητα: K = 3 dB

Στάθμη ηχητικής απόδοσης: L

WA

Αβεβαιότητα: K = 3 dB

Φοράτε προστασία για την ακοή!

Συνολική τιμή κραδασμών:

Λείανση επιφανειών, βασική

λαβή: a

= 1,83 m/s

h, AG

Αβεβαιότητα: K = 1,5 m/s

Λείανση επιφανειών Πρόσθετη

χειρολαβή: a

-1

= 1,224 m/s

h, AG

Αβεβαιότητα: K = 1,5 m/s

ΥΠΟΔΕΙΞΗ

► Το αναφερόμενο σε αυτές τις οδηγίες επίπεδο

κραδασμών έχει μετρηθεί σύμφωνα με μια

τυποποιημένη διαδικασία μέτρησης και

μπορεί να χρησιμοποιείται για τη σύγκριση

συσκευών. Η αναφερόμενη τιμή εκπομπής

κραδασμών μπορεί επίσης να χρησιμοποιείται για μια αρχική εκτίμηση της έκθεσης.

= 84 dB (A)

= 95 dB (A)

2

2

2

2

PWSA 20-Li B2

GR│CY

│

21 ■

ΠΡΟΕΙΔΟΠΟΙΗΣΗ!

► Το επίπεδο κραδασμών αλλάζει ανάλογα με

τη χρήση του ηλεκτρικού εργαλείου και σε

ορισμένες περιπτώσεις μπορεί να βρίσκεται

πάνω από την αναφερόμενη σε αυτές τις

οδηγίες τιμή. Το φορτίο κραδασμών θα

μπορούσε να υποτιμηθεί, εάν το ηλεκτρικό

εργαλείο χρησιμοποιείται τακτικά με αυτό τον

τρόπο. Προσπαθείτε να διατηρείτε την επιβάρυνση λόγω δονήσεων σε όσο το δυνατόν

χαμηλότερα επίπεδα. Παραδειγματικά μέτρα

μείωσης της επιβάρυνσης λόγω δονήσεων

είναι η χρήση γαντιών κατά τη χρήση του

εργαλείου και ο περιορισμός του χρόνου

εργασίας. Εδώ πρέπει να συνυπολογίζονται

όλα τα μέρη του κύκλου εργασίας (παραδείγματος χάριν χρόνοι, κατά τους οποίους το

ηλεκτρικό εργαλείο είναι απενεργοποιημένο,

και χρόνοι, κατά τους οποίους είναι μεν ενεργοποιημένο, αλλά λειτουργεί χωρίς φορτίο).

Γενικές υποδείξεις

ασφαλείας για

ηλεκτρικά εργαλεία

ΠΡΟΕΙΔΟΠΟΙΗΣΗ!

► Διαβάστε όλες τις υποδείξεις ασφαλείας και

τις οδηγίες. Σε περίπτωση μη τήρησης των

υποδείξεων ασφαλείας και των οδηγιών, ενδέχεται να προκληθεί ηλεκτροπληξία, πυρκαγιά

ή/και σοβαροί τραυματισμοί.

Φυλάξτε όλες τις υποδείξεις ασφαλείας και τις

οδηγίες για να μπορείτε να ανατρέξετε σε αυτές

μελλοντικά.

Ο χρησιμοποιούμενος σε αυτές τις υποδείξεις

ασφαλείας όρος «Ηλεκτρικό εργαλείο» αναφέρεται

σε ηλεκτρικά εργαλεία (με καλώδιο) που λειτουργούν με ρεύμα και σε ηλεκτρικά εργαλεία (χωρίς

καλώδιο) που λειτουργούν με συσσωρευτή.

1. Ασφάλεια στο χώρο εργασίας

α) Διατηρείτε το χώρο εργασίας σας καθαρό

και φροντίζετε για επαρκή φωτισμό. Η ακα-

ταστασία και οι μη φωτισμένοι χώροι εργασίας

μπορούν να οδηγήσουν σε ατυχήματα.

β) Μην εργάζεστε με το ηλεκτρικό εργαλείο σε

εκρήξιμα περιβάλλοντα με εύφλεκτα υγρά,

αέρια ή σκόνη. Κατά τη χρήση των ηλεκτρικών

εργαλείων δημιουργούνται σπινθήρες, από τους

οποίους μπορούν να αναφλεγούν η σκόνη ή οι

ατμοί.

γ) Κρατάτε τα παιδιά και άλλα άτομα μακριά

κατά τη χρήση του ηλεκτρικού εργαλείου.

Εάν αποσπαστεί η προσοχή σας, μπορείτε να

χάσετε τον έλεγχο της συσκευής.

2. Ηλεκτρική ασφάλεια

α) Το βύσμα σύνδεσης του ηλεκτρικού εργαλεί-

ου πρέπει να ταιριάζει στην πρίζα. Το βύσμα

δεν επιτρέπεται να τροποποιηθεί με κανέναν

τρόπο.

Μην χρησιμοποιείτε βύσματα προσαρμογέων

μαζί με γειωμένα ηλεκτρικά εργαλεία.

Τα βύσματα που δεν έχουν τροποποιηθεί και

οι κατάλληλες πρίζες μειώνουν τον κίνδυνο

ηλεκτροπληξίας.

β) Αποφεύγετε τη σωματική επαφή με γειωμένες

επιφάνειες, όπως σωλήνες, θερμαντικά σώμα-

τα, εστίες και ψυγεία. Παρατηρείται αυξημένος

κίνδυνος ηλεκτροπληξίας όταν το σώμα σας

είναι γειωμένο.

γ) Κρατάτε τα ηλεκτρικά εργαλεία μακριά από

βροχή ή υγρασία. Η διείσδυση νερού σε μια

ηλεκτρική συσκευή αυξάνει τον κίνδυνο ηλε-

κτροπληξίας.

Μη χρησιμοποιείτε το καλώδιο άσκοπα, π.χ.

δ)

για να μεταφέρετε το ηλεκτρικό εργαλείο, να

το κρεμάσετε ή για να τραβήξετε το βύσμα

από την πρίζα. Κρατάτε το καλώδιο μακριά

από υψηλές θερμοκρασίες, λάδια, αιχμηρές

άκρες ή κινούμενα τμήματα της συσκευής.

Τα φθαρμένα ή μπερδεμένα καλώδια αυξάνουν

τον κίνδυνο ηλεκτροπληξίας.

ε)

Όταν εργάζεστε με ένα ηλεκτρικό εργαλείο σε

εξωτερικό χώρο, χρησιμοποιείτε αποκλειστικά

εγκεκριμένα για εξωτερικούς χώρους καλώδια

προέκτασης. Η χρήση κατάλληλου για εξωτερι-

κούς χώρους καλωδίου προέκτασης μειώνει τον

κίνδυνο ηλεκτροπληξίας.

■ 22 │ GR

│

CY

PWSA 20-Li B2

στ) Εάν δεν μπορεί να αποφευχθεί η λειτουργία του

ηλεκτρικού εργαλείου σε υγρό περιβάλλον,

χρησιμοποιείτε διακόπτη ασφαλείας. Η χρήση

διακόπτη ασφαλείας μειώνει τον κίνδυνο ηλεκτροπληξίας.

3. Ασφάλεια ατόμων

α) Να είστε πάντα προσεκτικοί. Προσέχετε τι

κάνετε και χρησιμοποιείτε τη λογική όταν

εργάζεστε με ένα ηλεκτρικό εργαλείο. Μην

χρησιμοποιείτε ηλεκτρικά εργαλεία εάν είστε

κουρασμένοι ή υπό την επήρεια ναρκωτικών,

αλκοόλ ή φαρμάκων. Ένα μόνο λεπτό απροσε-

ξίας κατά τη χρήση του ηλεκτρικού εργαλείου

αρκεί για να οδηγήσει σε σοβαρούς τραυματισμούς.

Φοράτε μέσα ατομικής προστασίας και πάντα

β)

γυαλιά προστασίας. Όταν φοράτε μέσα ατομικής προστασίας, όπως μάσκα για τη σκόνη,

αντιολισθητικά υποδήματα ασφαλείας, κράνος

ή προστασία για την ακοή, ανάλογα με το είδος

και τη χρήση του ηλεκτρικού εργαλείου, μειώνεται

ο κίνδυνος τραυματισμών.

γ) Αποφεύγετε τυχόν ακούσια έναρξη λειτουργί-

ας. Βεβαιώνεστε ότι το ηλεκτρικό εργαλείο έχει

απενεργοποιηθεί, προτού το συνδέσετε στην

τροφοδοσία ρεύματος και/ή το συσσωρευτή,

το σηκώσετε ή το μεταφέρετε. Όταν μεταφέρετε

το ηλεκτρικό εργαλείο και έχετε το δάχτυλο στο

διακόπτη ή εάν έχετε συνδέσει την ήδη ενεργοποιημένη συσκευή στην παροχή ρεύματος,

αυτό μπορεί να οδηγήσει σε ατυχήματα.

δ) Απομακρύνετε εργαλεία ρύθμισης ή μηχανικά

κλειδιά πριν ενεργοποιήσετε το ηλεκτρικό

εργαλείο. Ένα εργαλείο ή κλειδί, το οποίο

βρίσκεται σε ένα περιστρεφόμενο εξάρτημα της

συσκευής, μπορεί να οδηγήσει σε τραυματισμούς.

ε) Αποφεύγετε τυχόν μη φυσιολογικές στάσεις

του σώματος. Φροντίζετε για ασφαλή στάση

και διατηρείτε πάντα την ισορροπία. Έτσι,

μπορείτε να ελέγχετε το ηλεκτρικό εργαλείο

καλύτερα σε μη αναμενόμενες καταστάσεις.

στ) Φοράτε κατάλληλο ρουχισμό. Μην φοράτε

μακριά ρούχα ή κοσμήματα. Κρατάτε τα

μαλλιά, τα ρούχα και τα γάντια μακριά από

κινούμενα εξαρτήματα. Τα χαλαρά ρούχα, τα

κοσμήματα ή τα μακριά μαλλιά μπορούν να

πιαστούν σε κινούμενα εξαρτήματα.

ζ) Εάν είναι δυνατή η τοποθέτηση διατάξεων

αναρρόφησης και συλλογής σκόνης, βε-

βαιωθείτε ότι έχουν συνδεθεί και χρησιμο-

ποιούνται σωστά. Η χρήση μιας διάταξης

αναρρόφησης σκόνης μπορεί να μειώσει τους

κινδύνους από τη σκόνη.

4. Χρήση και χειρισμός του ηλεκτρικού εργαλείου

α) Μην καταπονείτε υπερβολικά τη συσκευή.

Χρησιμοποιείτε το κατάλληλο ηλεκτρικό εργαλείο ανάλογα με την εργασία. Με το κατάλλη-

λο ηλεκτρικό εργαλείο εργάζεστε καλύτερα και

ασφαλέστερα στο δοθέν πεδίο απόδοσης.

β) Μη χρησιμοποιείτε ηλεκτρικά εργαλεία, των

οποίων ο διακόπτης έχει υποστεί βλάβη. Ένα

ηλεκτρικό εργαλείο, το οποίο δεν μπορεί πλέον

να ενεργοποιηθεί ή απενεργοποιηθεί, είναι

επικίνδυνο και πρέπει να επισκευαστεί.

γ) Αποσυνδέετε το βύσμα από την πρίζα ή/και

αφαιρείτε τον συσσωρευτή πριν από τη διεξαγωγή ρυθμίσεων στη συσκευή, πριν από την

αλλαγή αξεσουάρ ή πριν από την αποθήκευση της συσκευής. Αυτό το μέτρο ασφαλείας

εμποδίζει τη μη ηθελημένη εκκίνηση του ηλεκτρικού εργαλείου.

δ) Φυλάτε τα μη χρησιμοποιούμενα ηλεκτρικά

εργαλεία εκτός εμβέλειας των παιδιών. Μην

επιτρέπετε να χρησιμοποιούν τη συσκευή

άτομα τα οποία δεν έχουν εξοικειωθεί με τη

χρήση ή που δεν έχουν διαβάσει τις παρούσες οδηγίες. Τα ηλεκτρικά εργαλεία είναι επικίν-

δυνα όταν χρησιμοποιούνται από άτομα χωρίς

εμπειρία.

PWSA 20-Li B2

GR│CY

│

23 ■

ε) Φροντίζετε τα ηλεκτρικά εργαλεία με προσο-

χή. Ελέγχετε εάν τα κινούμενα εξαρτήματα

λειτουργούν σωστά και δεν μαγκώνουν,

καθώς και εάν έχουν σπάσει εξαρτήματα ή

παρουσιάζουν βλάβη που να επηρεάζει τη

λειτουργία του ηλεκτρικού εργαλείου. Τα

εξαρτήματα που έχουν υποστεί βλάβη πρέπει

να επισκευάζονται πριν από τη χρήση της

συσκευής. Πολλά ατυχήματα οφείλονται στην

κακή συντήρηση ηλεκτρικών εργαλείων.

στ) Διατηρείτε τα εργαλεία κοπής αιχμηρά και

καθαρά. Τα εργαλεία κοπής των οποίων η φροντίδα έχει εκτελεστεί με προσοχή και τα οποία

διαθέτουν αιχμηρές ακμές κοπής μαγκώνουν

λιγότερο και είναι ευκολότερα στο χειρισμό.

ζ) Χρησιμοποιείτε το ηλεκτρικό εργαλείο, τα

αξεσουάρ, τα εργαλεία, κλπ., σύμφωνα με

τις παρούσες οδηγίες. Λαμβάνετε υπόψη τις

συνθήκες εργασίας και τη δραστηριότητα

προς διεξαγωγή.

Η χρήση ηλεκτρικών εργαλείων για διαφορετικές από τις προβλεπόμενες χρήσεις μπορεί να

οδηγήσει σε επικίνδυνες καταστάσεις.

5. Χρήση και χειρισμός του επαναφορτιζόμενου εργαλείου

α) Φορτίζετε τους συσσωρευτές μόνο με προτει-

νόμενους από τον κατασκευαστή φορτιστές.

Για φορτιστές κατάλληλους για έναν καθορισμένο τύπο συσσωρευτών υπάρχει κίνδυνος

πυρκαγιάς όταν χρησιμοποιούνται με άλλους

συσσωρευτές.

β) Χρησιμοποιείτε μόνο τους προβλεπόμενους

συσσωρευτές στα ηλεκτρικά εργαλεία. Η χρήση άλλων συσσωρευτών μπορεί να οδηγήσει σε

τραυματισμούς και κίνδυνο πυρκαγιάς.

γ) Κρατάτε το μη χρησιμοποιούμενο συσσωρευ-

τή μακριά από συνδετήρες, νομίσματα, κλειδιά, καρφιά, βίδες ή άλλα μικρά μεταλλικά

αντικείμενα, τα οποία μπορούν να προκαλέσουν υπεργεφύρωση των επαφών. Ένα βραχυ-

κύκλωμα μεταξύ των επαφών του συσσωρευτή

μπορεί να έχει ως επακόλουθο εγκαύματα ή

πυρκαγιά.

δ) Σε περίπτωση εσφαλμένης χρήσης μπορεί

να εξέλθει υγρό από το συσσωρευτή. Αποφεύγετε την επαφή με το υγρό. Σε περίπτωση

επαφής, ξεπλένετε με νερό. Εάν το υγρό έλθει

σε επαφή με τα μάτια, ζητήστε επιπλέον ιατρική βοήθεια. Το εκρέον υγρό των συσσωρευτών

μπορεί να προκαλέσει δερματικούς ερεθισμούς

ή εγκαύματα.

ΠΡΟΣΟΧΗ! ΚΙΝΔΥΝΟΣ ΕΚΡΗΞΗΣ!

Μη φορτίζετε ποτέ μη επαναφορτιζόμενες μπαταρίες.

Προστατεύετε το συσσωρευτή από υψη-

λή θερμοκρασία, π.χ. και από συνεχή

ηλιακή ακτινοβολία, φωτιά, νερό και

υγρασία. Υπάρχει κίνδυνος έκρηξης.

6. Σέρβις

α) Το ηλεκτρικό εργαλείο σας πρέπει να επισκευ-

άζεται αποκλειστικά από εξειδικευμένο ειδικό

προσωπικό και μόνο με γνήσια ανταλλακτικά.

Κατά αυτόν τον τρόπο, διατηρείται η ασφάλεια

του ηλεκτρικού εργαλείου.

Υποδείξεις ασφαλείας για όλες τις

χρήσεις

Κοινές υποδείξεις ασφαλείας για λείανση και

αποκοπή με λείανση:

α) Αυτό το ηλεκτρικό εργαλείο προορίζεται ως

διάταξη λείανσης και μηχανή κοπής με λειαντικούς δίσκους τριβής. Λάβετε υπόψη σας

όλες τις υποδείξεις ασφαλείας, τις οδηγίες,

τις απεικονίσεις και τα δεδομένα, τα οποία

λαμβάνετε μαζί με τη συσκευή. Σε περίπτωση

μη τήρησης των παρακάτω οδηγιών, ίσως έρθετε

αντιμέτωποι με ηλεκτροπληξία, φωτιά και/ή

σοβαρούς τραυματισμούς.

β) Αυτό το ηλεκτρικό εργαλείο δεν ενδείκνυται

για λείανση με γυαλόχαρτο, εργασίες με συρματόβουρτσες και στίλβωση. Χρήσεις, για τις

οποίες δεν προβλέπεται το ηλεκτρικό εργαλείο,

μπορεί να προκαλέσουν κινδύνους και τραυματισμούς.

■ 24 │ GR

│

CY

PWSA 20-Li B2

γ) Απαγορεύεται η χρήση εξαρτημάτων, τα

οποία δεν προβλέπονται εκ μέρους του

κατασκευαστή ειδικά για αυτό το ηλεκτρικό

εργαλείο. Το γεγονός ότι το εξάρτημα μπορεί

να στερεωθεί σε ηλεκτρικό εργαλείο, δεν μπορεί

να διασφαλίσει την ασφαλή χρήση.

δ) Ο επιτρεπόμενος αριθμός στροφών του εργα-

λείου εφαρμογής πρέπει να είναι τουλάχιστον

ίσος με αυτόν που αναφέρεται στο ηλεκτρικό

εργαλείο ως μέγιστος αριθμός στροφών. Τα

εξαρτήματα, τα οποία περιστρέφονται πιο γρήγορα από ότι επιτρέπεται, ίσως σπάσουν και

εκτιναχθούν.

ε) Η εξωτερική διάμετρος και το πάχος του ερ-

γαλείου εφαρμογής πρέπει να ανταποκρίνονται στα στοιχεία διαστάσεων του ηλεκτρικού

εργαλείου σας. Εργαλεία εφαρμογής με λάθος

διαστάσεις δεν μπορούν να θωρακιστούν ή να

ελεγχθούν επαρκώς.

στ) Εργαλεία εφαρμογής με ένθεμα σπειρώματος

πρέπει να ταιριάζουν επακριβώς στο σπείρωμα της ατράκτου λείανσης. Σε εργαλεία εφαρμογής, τα οποία τοποθετούνται με φλάντζα,

η διάμετρος οπής του εργαλείου εφαρμογής

πρέπει να ταιριάζει στη διάμετρο υποδοχής

της φλάντζας. Τα εργαλεία εφαρμογής, τα

οποία δεν εφαρμόζουν με ακρίβεια στο ηλεκτρικό εργαλείο, περιστρέφονται ανομοιόμορφα,

δονούνται πολύ και ίσως οδηγήσουν σε απώλεια ελέγχου.

η) Απαγορεύεται η χρήση ελαττωματικών ερ-

γαλείων εφαρμογής. Πριν από κάθε χρήση,

ελέγχετε τα εργαλεία εφαρμογής, όπως τους

λειαντικούς τροχούς, για σπασίματα και

ρωγμές, τους δίσκους λείανσης για ρωγμές,

βλάβες ή σημάδια μεγάλης φθοράς, τις συρματόβουρτσες για χαλαρά ή σπασμένα σύρματα. Σε περίπτωση πτώσης του ηλεκτρικού

εργαλείου ή του εργαλείου εφαρμογής, ελέγξτε αν έχει καταστραφεί ή χρησιμοποιήστε ένα

άθικτο εργαλείο εφαρμογής. Εφόσον ελέγξετε

και τοποθετήσετε το εργαλείο εφαρμογής,

κρατηθείτε τόσο εσείς όσο και τα πλησίον

ευρισκόμενα άτομα εκτός της περιοχής του

περιστρεφόμενου εργαλείου εφαρμογής και

αφήστε τη συσκευή να λειτουργήσει για ένα

λεπτό στο μέγιστο αριθμό στροφών.

Τα κατεστραμμένα εργαλεία εφαρμογής σπάνε

συνήθως κατά το δοκιμαστικό χρόνο.

θ) Φοράτε ατομικό προστατευτικό εξοπλισμό.

Φοράτε, αναλόγως της χρήσης, προστασία

ολόκληρου του προσώπου, προστασία για

τα μάτια ή προστατευτικά γυαλιά. Εφόσον

πρέπει, φοράτε μάσκα προστασίας από τη

σκόνη, ωτοασπίδες, προστατευτικά γάντια

ή ειδική ποδιά, η οποία κρατάει μακριά τα

μικρά τεμάχια λείανσης και υλικού. Τα μάτια

πρέπει να προστατεύονται από τα ξένα σωματίδια που εκτινάσσονται και τα οποία δημιουργούνται από διάφορες εφαρμογές. Οι μάσκες

προστασίας από τη σκόνη ή οι αναπνευστικές

μάσκες πρέπει να φιλτράρουν τη σκόνη που δημιουργείται κατά την εφαρμογή. Σε περίπτωση

έκθεσης επί μακρόν σε δυνατό θόρυβο, ίσως

επηρεαστεί η ακοή σας.

ι) Φροντίστε ώστε τα άλλα άτομα να βρίσκονται

σε απόσταση ασφαλείας από την περιοχή εργασίας σας. Όλα τα άτομα, τα οποία εισέρχονται μέσα στην περιοχή εργασίας, πρέπει να

φοράνε ατομικό προστατευτικό εξοπλισμό.

Τα θραύσματα των τεμαχίων επεξεργασίας ή

τα σπασμένα εργαλεία εφαρμογής ίσως εκτιναχθούν και προκαλέσουν τραυματισμούς εκτός

της άμεσης περιοχής εργασίας.

ια) Κρατάτε το ηλεκτρικό εργαλείο μόνο από τις

μονωμένες επιφάνειες λαβής κατά την πραγματοποίηση εργασιών, κατά τις οποίες το

εργαλείο εφαρμογής μπορεί να συναντήσει

κρυφούς αγωγούς ρεύματος. Η επαφή με ένα

ρευματοφόρο καλώδιο θέτει υπό τάση μεταλλικά εξαρτήματα της συσκευής προκαλώντας

ηλεκτροπληξία.

ιβ) Κρατήστε το καλώδιο δικτύου μακριά από

περιστρεφόμενα εργαλεία εφαρμογής. Σε

περίπτωση απώλειας ελέγχου της συσκευής,

υπάρχει πιθανότητα κοψίματος ή πιασίματος

του καλωδίου δικτύου και εισχώρησης της παλάμης ή του χεριού σας μέσα στο περιστρεφόμενο εργαλείο εφαρμογής.

PWSA 20-Li B2

GR│CY

│

25 ■

ιγ) Απαγορεύεται αυστηρά η απόθεση του

ηλεκτρικού εργαλείου, προτού το εργαλείο

εφαρμογής έρθει σε κατάσταση πλήρους

ακινησίας. Το περιστρεφόμενο εργαλείο εφαρ-

μογής μπορεί να έρθει σε επαφή με την επιφάνεια απόθεσης, γεγονός που ίσως οδηγήσει σε

απώλεια ελέγχου του ηλεκτρικού εργαλείου.

ιδ) Μην αφήνετε το ηλεκτρικό εργαλείο να λει-

τουργεί, ενώ το κρατάτε. Τα ρούχα σας μπορεί

να πιαστούν, λόγω τυχαίας επαφής, στο περιστρεφόμενο εργαλείο εφαρμογής, και το εργαλείο εφαρμογής μπορεί να τρυπήσει το σώμα

σας.

ιε) Καθαρίζετε τακτικά τις οπές αερισμού του

ηλεκτρικού σας εργαλείου. Ο φυσητήρας

κινητήρα τραβάει σκόνη μέσα στο περίβλημα

και η μεγάλη συγκέντρωση μεταλλικής σκόνης

μπορεί να προκαλέσει ηλεκτρικό κίνδυνο.

ιστ) Μη χρησιμοποιείτε το ηλεκτρικό εργαλείο

κοντά σε εύφλεκτα υλικά. Οι σπινθήρες

μπορεί να αναφλέξουν αυτά τα υλικά.

ιζ) Μη χρησιμοποιείτε εργαλεία εφαρμογής, τα

οποία απαιτούν υγρά ψυκτικά μέσα. Η χρήση

νερού ή άλλων υγρών ψυκτικών μέσων μπορεί

να οδηγήσει σε ηλεκτροπληξία.

Αντεπιστροφή και αντίστοιχες υποδείξεις ασφαλείας

Αντεπιστροφή είναι η ξαφνική αντίδραση λόγω

ενός μαγκωμένου ή μπλοκαρισμένου περιστρεφόμενου εργαλείου εφαρμογής, όπως είναι ο

λειαντικός τροχός, ο δίσκος λείανσης, η συρματόβουρτσα, κλπ. Μάγκωμα ή μπλοκάρισμα οδηγούν

σε απότομο σταμάτημα του περιστρεφόμενου

εργαλείου εφαρμογής. Έτσι το μη ελεγχόμενο ηλεκτρικό εργαλείο επιταχύνεται προς την κατεύθυνση

περιστροφής του εργαλείου εφαρμογής στη θέση

μπλοκαρίσματος.

Όταν π.χ. ένας δίσκος λείανσης μαγκώσει ή

μπλοκάρει στο τεμάχιο επεξεργασίας, η ακμή του

δίσκου λείανσης που βυθίζεται στο τεμάχιο επεξεργασίας μπορεί να πιαστεί και έτσι να σπάσει ο

δίσκος λείανσης ή να προκαλέσει αντεπιστροφή.

Ο δίσκος λείανσης κινείται στη συνέχεια προς

το χειριστή ή μακριά από αυτόν, ανάλογα με την

κατεύθυνση περιστροφής του δίσκου στο σημείο

μπλοκαρίσματος. Οι δίσκοι λείανσης μπορεί να

σπάσουν.

Η αντεπιστροφή είναι το επακόλουθο λάθους ή

ελλιπούς χρήσης του ηλεκτρικού εργαλείου. Μπορεί να εμποδιστεί μέσω κατάλληλων προληπτικών

μέτρων, όπως περιγράφεται κατωτέρω.

α) Κρατάτε το ηλεκτρικό εργαλείο σφιχτά και το-

ποθετείτε το σώμα και τους βραχίονες σας σε

μια θέση, στην οποία θα μπορείτε να δέχεστε

τις δυνάμεις αντεπιστροφής. Χρησιμοποιείτε

πάντα την πρόσθετη λαβή, εφόσον διατίθεται,

ώστε να έχετε το μεγαλύτερο δυνατό έλεγχο

των δυνάμεων αντεπιστροφής ή ροπών αντίδρασης κατά την εκκίνηση. Ο χειριστής μπο-

ρεί να ελέγχει τις δυνάμεις αντεπιστροφής και

αντίδρασης με κατάλληλα προληπτικά μέτρα.

β) Ποτέ μη φέρνετε τα χέρια σας κοντά σε περι-

στρεφόμενα εργαλεία εφαρμογής. Το εργαλείο

εφαρμογής μπορεί να μετακινηθεί πάνω από το

χέρι σας σε περίπτωση αντεπιστροφής.

γ) Αποφεύγετε με το σώμα σας την περιοχή,

στην οποία κινείται το ηλεκτρικό εργαλείο

σε μια αντεπιστροφή. Η αντεπιστροφή οδηγεί

το ηλεκτρικό εργαλείο αντίθετα από την κατεύθυνση κίνησης του δίσκου λείανσης στη θέση

μπλοκαρίσματος.

■ 26 │ GR

│

CY

PWSA 20-Li B2

δ) Να εργάζεστε ιδιαίτερα προσεκτικά κοντά

σε γωνίες, αιχμηρές ακμές, κλπ. Εμποδίζετε

αναπήδηση και μάγκωμα των εργαλείων

εφαρμογής από το τεμάχιο επεξεργασίας. Το

περιστρεφόμενο εργαλείο εφαρμογής τείνει να

μαγκώνει σε γωνίες, αιχμηρές ακμές ή όταν αναπηδάει. Αυτό προκαλεί απώλεια του ελέγχου ή

αντεπιστροφή.

ε) Μη χρησιμοποιείτε αλυσίδες ή λεπίδες πριο-

νιού με οδοντώσεις. Αυτά τα εργαλεία εφαρμογής προκαλούν συχνά αντεπιστροφή ή απώλεια

του ελέγχου του ηλεκτρικού εργαλείου.

Ειδικές υποδείξεις ασφαλείας για

λείανση και αποκοπή με λείανση

α)

Χρησιμοποιείτε αποκλειστικά τα εγκεκριμένα

λειαντικά σώματα για το ηλεκτρικό σας εργαλείο

και το αντίστοιχο προβλεπόμενο προστατευτικό

κάλυμμα. Λειαντικά σώματα, τα οποία δεν προ-

βλέπονται για το ηλεκτρικό εργαλείο, δεν μπορούν

να θωρακιστούν επαρκώς και δεν είναι ασφαλή.

β)

Κεκαμμένοι δίσκοι λείανσης πρέπει να τοπο-

θετούνται κατά τέτοιο τρόπο, ώστε η επιφάνεια

λείανσης να μην προεξέχει πάνω από τον τομέα του άκρου του προστατευτικού καλύμματος. Ένας ακατάλληλα τοποθετημένος δίσκος

λείανσης που προεξέχει πάνω από τον τομέα

του άκρου του προστατευτικού καλύμματος δεν

μπορεί να θωρακιστεί επαρκώς.