Page 1

PRESSURE WASHER PHD 100 A1

PRESSURE WASHER

Translation of original operation manual

6

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

GB / IE Translation of original operation manual Page 5

Page 3

B

A

3

14

14

4 5

7621

13

12

11

1 2

3

15

8

9

10

11

13

12

10

10

Page 4

E

C

D

F

G

13

18

12

17

10

11

10

16

9

16

8

9

Page 5

GB IE

Content

Notes on Safety .................................... 5

Explanation of symbols ..................... 5

Symbols in the manual ..................... 6

General notes on safety .................... 6

Areas of Application ............................. 8

General Description ............................. 8

Overview ........................................... 8

Functional description ....................... 8

Scope of Delivery .............................. 9

Start-up .................................................. 9

Setting up .......................................... 9

Mains connection .............................. 9

Operation ........................................ 10

Interrupting operation ...................... 10

Ending operation ............................. 10

Using detergents ............................. 10

Fixing the Wheels ......................... 10

Removing the Chassis ....................11

Cleaning and Maintenance .................11

Cleaning ...........................................11

Maintenance ....................................11

Storage .................................................11

Waste Disposal and Environmental

Protection ............................................ 12

Guarantee Notes ................................. 12

Technical data ..................................... 13

Trouble shooting ................................ 14

Spare Parts Order ............................... 14

EU declaration of conformity ............ 15

Exploded Drawing ............................. 16

Grizzly Service-Center ....................... 17

Notes on Safety

This Section is concerned with the basic

safety rules when working with the pressure washer.

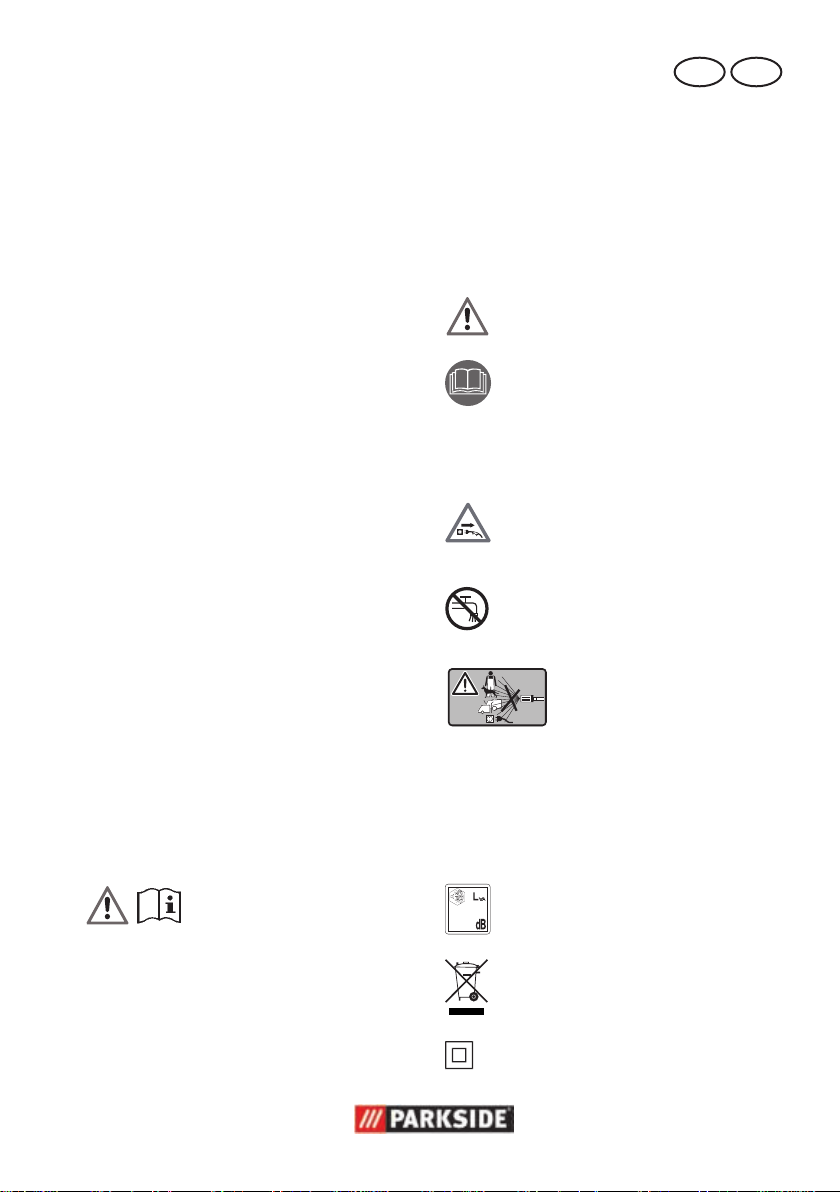

Explanation of symbols

Attention!

Before beginning work, familiarise

yourself thoroughly with all the operating elements, particularly with

how they function and operate. Ask

a specialist if necessary.

Attention: Remove the plug from

the socket as soon as the power

lead is damaged or cut.

The pressure washer is not suit-

able for direct connection to the

drinking water supply system.

CAUTION. pressure wash-

ers can be dangerous if

they are not operated correctly! The jet must never

be directed at people, animals, electric equipment

connected to the power

supply or against the actual pressure washer.

For your own safety, and for

the safety of others, please read these

Operating Instructions carefully before

you use the pressure washer for the rst

time! Keep the manual in a safe place and

pass it on to any subsequent owner to ensure that the information contained therein

is available at all times.

Information of the acoustic power

level L

95

Electric appliances should not be

disposed of in the domestic garbage.

Safety class II

WA

in dB.

5

Page 6

GB IE

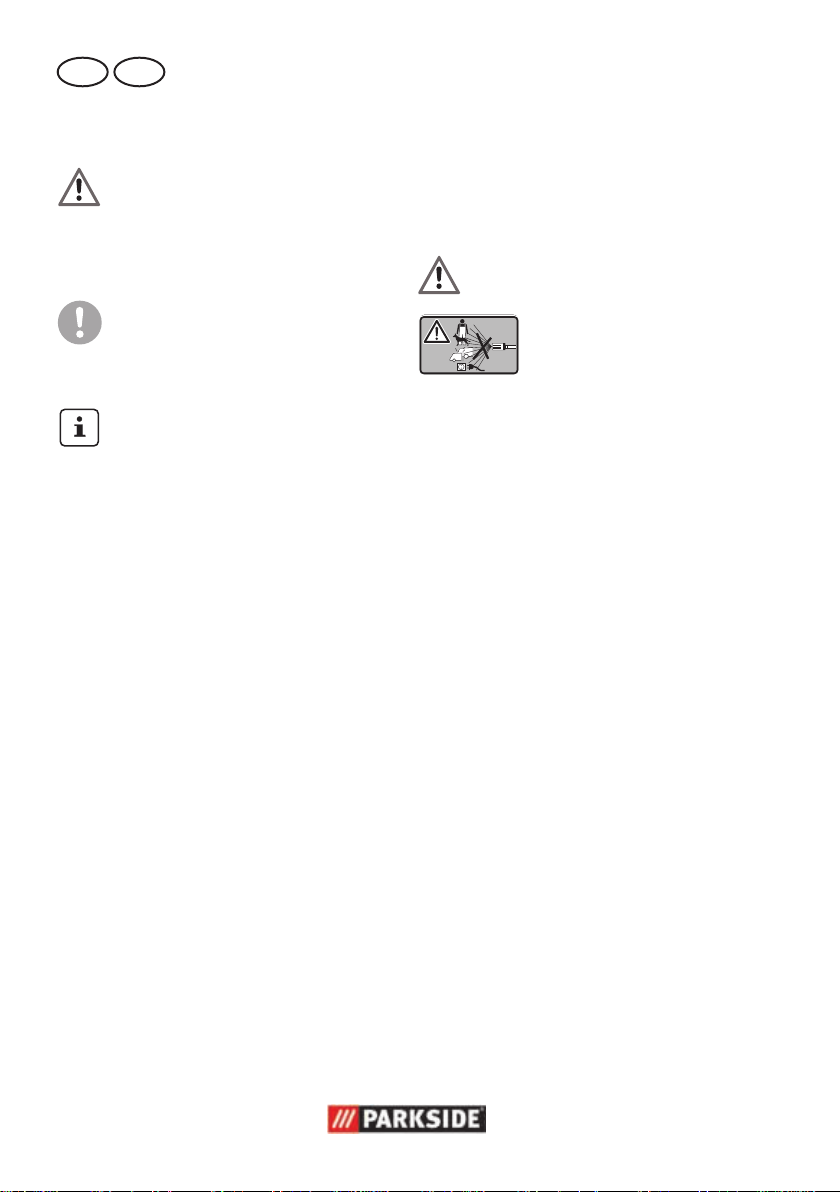

Symbols in the manual

Warning symbols (the danger

can be explained at the place of

the exclamation mark) with information on damage and injury

prevention.

Instruction symbols (the instruction

can be explained at the place of

the exclamation mark) with information on preventing damage.

Help symbols with information on

improving tool handling.

General notes on safety

• This appliance is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience

and knowledge, unless they have

been given supervision or instruction

concerning use of the appliance by a

person responsible for their safety.

• Children should be supervised to

ensure that they do not play with the

appliance.

• People who are unfamiliar with the operating instructions are not permitted

to use the equipment. The operation

of the equipment is not authorised for

people under the age of 16.

• Use the equipment only on a at, stable surface.

• For your safety, it is recommended

that you wear safety glasses, safety

boots and gloves and, if necessary,

ear protection.

• In the event of a fault or defect during operation, immediately switch off

and unplug the equipment. Then read

page 14 of the operating instructions

for possible fault causes or contact

our service centre.

Working with the equipment

Caution: to avoid accidents and

injuries:

CAUTION. pressure wash-

ers can be dangerous if

they are not operated correctly! The jet must never

be directed at people, animals, electric equipment

connected to the power

supply or against the actual pressure washer.

• Do not direct the jet at yourself or

others in order to clean clothes and

shoes.

• Do not operate the pressure washer

when other people are in the immediate vicinity, other than they are also

wearing protective clothes.

• Take appropriate measures to keep

children away from the equipment

whilst it is running.

• Dispose of the packaging material

correctly.

• Do not use the equipment in the vicinity of ammable liquids or gases. Nonobservance will result in a risk of re

or explosion.

• Do not spray combustible liquids. Risk

of explosion.

• Store the equipment in a dry place

and out of reach of children.

• Children must be supervised in order

to ensure that they do not play with

the equipment.

• Ensure that no exhaust emissions oc-

6

Page 7

GB IE

cur within the vicinity of air inlets.

Caution! To avoid damage to the

equipment and any possible

person injury resulting from this:

• Do not work with damaged or incom-

plete equipment, or with equipment

that has been converted without the

approval of the manufacturer. Before

initial operation, have a specialist

check that the required electrical protection measures are in place.

• Never operate the pressure washer

if the power supply cable or other important parts, such as the high-pressure hose or the gun, are damaged.

• Protect the pressure washer from frost

and dry running.

• Use only original accessories and do

not carry out conversion work on the

equipment.

• Please read the notes in the operating

instructions on the topic of “maintenance and cleaning”. Any measures

above and beyond these, particularly

opening the equipment, are to be carried out by an electrician. In the case

of repairs, always contact our service

centre.

• The washer was designed for opera-

tion with a neutral detergent based on

a biologically decomposable anionic

tenside. Other detergents or chemical

substances could impair the safety of

the washer and damage it.

• If you come into contact with cleaning

agents, rinse with plenty of clean water.

• Water that has passed through a

backow preventer is classied as undrinkable.

• High-pressure hoses, ttings and

couplings are important for machine

safety. Use only high-pressure hoses,

ttings and couplings recommended

by the manufacturer.

• To ensure machine safety, use only

original replacement parts from the

manufacturer or replacement parts

authorised by the manufacturer.

Electrical safety:

Caution: to avoid accidents and

injuries from electric shocks:

• The plug and socket of an extension

cable must be water-tight!

Unsuitable extension cables can

be dangerous as people can be

harmed by an electric shock!

• Protect the electric plug connections

against moisture.

• If there is a risk of ooding, x the

plug connections in an area that is

safe from ooding.

• Ensure that the mains voltage matches the specications on the rating

plate.

• The electrical installation shall be according to national wiring rules.

• Connection to the mains must be carried out by an experienced electrician

and meet the requirements of IEC

60364-1.

• The device must only be connected to

a mains socket via a residual-current

circuit breaker (RCD) with a rated

leakage current of not more than

30 mA. Fuse: at least 13 ampere.

• Before each use, check the equipment, cable and plug for damage.

• If the power cable for this equipment

7

Page 8

GB IE

A

is damaged, it must be replaced by

the manufacturer, a customer service

agent of the same or a similarly qualied person in order to prevent hazards.

• Do not pull the plug from the socket

by the cable. Protect the cable from

heat, oil and sharp edges.

• Do not carry or x the equipment by

the cable.

• Use only extension cables that are

protected from spray water and designed for outdoor use. Always fully

unroll a cable drum before use. Check

the cable for damage.

• Before any work on the equipment,

during work breaks and in the case

of non-use, remove the plug from the

socket.

• The cross-section of the power supply

cable must not be less than 2 x 1,5

mm².

Areas of Application

Only use the pressure washer in the following private home areas:

• To clean machines, vehicles, buildings, work tools, facades, terraces,

gardening tools, etc. with a high-pressure water jet.

• Only use with original accessories and

spares.

• Observe the manufacturer’s instructions for the device that is to be

cleaned.

General Description

The diagram of the most im-

portant functional elements

can be found on the foldout

side.

Overview

1 High-pressure connection on

the gun side

2 High-pressure connection on

the washer side

3 High-pressure connection

4 Carrying handle

5 ON / OFF switch

6 Accessories holder

7 Power supply cable

8 Water connection with sieve in-

sert (not visible)

9 Chassis

10 Gun

11 Jet lance

12 Adjustable at-jet nozzle

13 High-pressure nozzle

14 Cleaning agent container with

nozzle

15 Nozzle cleaning pin

Functional description

The pressure washer is to be used for

washing with a high-pressure water jet. A

detergent can be added if this is required.

For the functions of the operating elements please refer to the subsequent

description. Ensure that the safety instructions are always observed!

8

Page 9

GB IE

C

A

A

B

Scope of Delivery

Unpack the pressure washer and verify

the contents:

- Pressure washer

- Chassis

- Gun

- High-pressure hose

- Jet lance

- High-pressure nozzle

- Adjustable at-jet nozzle

- Cleaning agent container with nozzle

- Nozzle cleaning pin

Start-up

In keeping with current regulations

a pressure washer must never be

operated off the drinking water

mains supply without a controllable backow preventer. A suitable

backow preventer in conformity

with EN 12729 type BA must be

used.

Water that has passed through a backow

preventer is classied as undrinkable.

A backow preventer is available

from specialist retailers.

connecting the rapid-action water supply connector to the water connection with sieve insert

(8).

• Connect to the spray gun (10)

by inserting and screwing in the

jet tube (11).

• If the jet tube (11) is tted, connect either the adjustable fan

nozzle (12), high-pressure jet

(13) or cleaning agent container

to the nozzle (14) by screwing

together with the jet tube (11).

With using the cleaning agent

container with the nozzle (

14), pour only cleaning agent

into the container. It is sucked in

automatically.

The width of the jet can be increased by

turning the end of the nozzle to the left. To

reduce the width of the jet, turn the end of

the nozzle to the right.

Mains connection

The pressure washer you have acquired

is already tted with a mains plug. The

pressure washer must only be connected

to an earthed socket 230 V ~ 50Hz.

Setting up

• Screw the equipment side of the

high-pressure hose connection

(2) to the high-pressure hose

connection (3) on the equipment.

• Screw the gun side of the highpressure hose connection (1) to

the spray gun (10)

• Establish the water supply by

Only operate the pressure washer

after all the above points have

been observed.

• Ensure that the pressure washer is

turned off by its ON / OFF switch (

5).

• Insert the mains plug into the mains

socket

9

Page 10

GB IE

A

A

A

A

D

A

A

A

A

E

Operation

• Connect the equipment to the water

tap. Observe the regulations for the

use of a system separator.

• Turn on the water tap entirely.

Never operate the pressure wash-

er with a closed water tap. Dry running will damage the washer!

Be prepared for the recoil force

of the emitted water jet! Ensure

that you are standing rmly and

that you are holding the gun (

5) securely, otherwise you could

injure yourself or other people.

• Switch on the pressure washer with

the ON / OFF switch (

• Pull the lever of the gun (

turn on the washer.

• Hold the switch-on lever of the gun

(

10) until there is no more air in the

pressure washer.

Releasing the lever will switch

off the washer, but the pressure

within the system is retained.

• Lock / unlock the switch-on lever of the gun (10) by depressing the locking button (17).

Lock the switch-on lever to prevent the

pressure washer from being inadvertently / accidentally started.

5).

10) to

Interrupting operation

• Release the lever of the gun (A10).

• During prolonged work intervals turn

off the washer by its ON / OFF switch

(

5).

Ending operation

• After working with cleaning agents,

run the equipment with clean water to

completely rinse the cleaning agent

from the pipes.

• Release the lever of the gun (

• Turn off the pressure by its ON / OFF

switch (

• Turn off the water tap.

• Disconnect the pressure washer from

the water mains.

• Pull the lever of the gun (

vent the pressure existing within the

system.

• Disconnect the mains plug.

5).

10).

10) to

Using detergents

The washer was designed for operation

with a neutral detergent based on a biologically decomposable anionic tenside.

Other detergents or chemical substances

could impair the safety of the washer and

damage it.

Fixing the Wheels

The back wheels on the chassis (9) can

be xed in order to secure the pressure

washer against undesired rolling away.

Locked

Open

10

• To do this push the two bolts (16) outwards and downwards.

The wheels are now no longer able to

turn.

Page 11

GB IE

F

G

A

A

• To cancel the wheel xing, push the

two bolts (16) upwards.

Removing the Chassis

The pressure washer can also be used

without the chassis (9).

• Press the release button (18) on the

front locking point. Hold the chassis

(9) securely in the front area and pull

the pressure washer upwards.

At the same time, tilt the pressure

washer slightly to the rear.

• To reinstate, insert the device into

the rear area of the chassis (9). Push

down on the device down and press

the release button (18) at the same

time. The device clicks into the chassis.

Cleaning and Maintenance

Pull out the power plug before eve-

ry maintenance operation. There

is a risk of electrocution or of injury

from moving parts.

Cleaning

Never direct the water jet

against the washer, nor clean

the washer under owing water.

This could give rise to the danger of electric shock and damage the washer! .

Always keep the washer clean. Do not

use any detergents or solvents.

• Always keep the ventilation slots

clean and free.

• Only clean the pressure washer with a

soft brush or a slightly moist cloth.

• In case a nozzle of the jet tube (12/13)

is clogged up, use the nozzle cleaning

pin (15) to remove the object from the

nozzle.

If necessary, take off the water

connection with the lter insert (8)

and clean the lter insert.

Maintenance

The pressure washer is maintenance free.

Ask our service centre to carry out

any work that is not described in

these instructions. Use only original parts.

Storage

• Drain all the water from the pressure

washer. Disconnect the unit from the

water supply. Press the On/Off switch

(

5) to turn on the pressure washer

for no longer than 1 minute until no

more water escapes from the highpressure connection (

the unit.

• Protect the pressure washer and its

accessories from frost when they

have not been completely drained of

all water.

• Store the pressure washer and its accessories in a frost-free room.

• To transport or put away the equipment, use only the carrying handle.

• Store the equipment only in a horizontal position in order to protect it from

any damage.

5). Turn off

11

Page 12

GB IE

Waste Disposal and Environmental Protection

Be environmentally friendly. Return the

tool, accessories and packaging to a recycling centre when you have nished with

them.

Electric appliances should not be

disposed of in the domestic garbage.

Hand the tool in at a recycling centre. The

plastics and metal parts can be separated

and recycled. Ask your Service Center

about this.

We can carry out a waste disposal of your

device free of charge.

Guarantee Notes

• This unit has a guarantee period of 36

months, or 12 months for units used on

a commercial basis or for replacement

units according to the statutory regulations.

• Justied guarantee claims should be

reported to our Service Centre (see

page 17 for telephone & fax no.s, and

email address). Our Service Team will

tell you more about our complaints

handling procedure.

• Damage due to natural wear and tear,

overload or incorrect use is excluded

from the guarantee. Certain components are subject to normal wear and

tear and are excluded from the guarantee. Inappropriate use will invalidate

the warranty.

• Furthermore, the prerequisite for guarantee services is that the references

indicated in the operating instructions

regarding cleaning and maintenance

have been adhered to.

• Damage, which has been caused

from material or manufacturing faults,

will be made good free of charge, by

replacement delivery or repair.

This requires that the appliance is

returned to our service center undismantled and with proof of purchase

and guarantee.

• Repairs, which are not covered by

the guarantee, can be carried out for

charge by our service center. Our

service center will be glad to provide

you with a cost estimate.

We can only process devices which

have been packaged sufciently and

which have been dispatched with correct stamping.

• Devices sent in freight collect - by

bulk freight, express or with other

special freight - are not accepted.

• We can carry out a waste disposal of

your device free of charge.

12

Page 13

Technical data

Pressure Washer ................PHD 100 A1

Mains connection.................230V~, 50 Hz

Power consumption ...................... 1450 W

Mains cable .........................................5 m

Weight (incl. all parts) ...................... 6,0 kg

Safety class .........................................

Degree of protection .......................... IPX5

Inow temperature t, max. .................40°C

Inow pressure p, max. ............... 0,8 MPa

Operating pressure p ................... 7,0 MPa

Max. permissible pressure p...... 10,0 MPa

Pumping rate, water .................5,67 l/min

Max. pumping rate, water ......... 6,67 l/min

Acoustic pressure level

(L

pA) .............. 76,4 dB(A); KpA=3,0 dB(A)

Sound power level (L

measured ..... 88,8 dB(A); K

WA)

WA=3,0 dB(A)

guaranteed ...............................95 dB (A)

Vibration (a

n) .........0,259 m/s

2

; K=1,5 m/s

Technical and optical changes can be carried out in the course of further development

without notice. All dimensions, references

and information of this instruction manual

are therefore without guarantee. Legal

claims, which are made on the basis of the

instruction manual, cannot thus be considered as valid.

II

GB IE

2

13

Page 14

GB IE

Trouble shooting

Problem Possible cause Remedy

Washer is

not operating

Washer

does not generate any

pressure

Severe

pressure

uctuations

ON / OFF switch (5) is turned

off

Damaged power supply cable

Mains fault

Air trapped in the pressure

washer

Drop in the water mains

pressure

High-pressure nozzle (13) is

dirty

Check ON / OFF switch

Check power supply cable (7) for

damage. If necessary have the power

supply cable (7) replaced by a qualied

electrician.

Check the electrical system for conformity with the data on the rating plate.

Turn on the washer with high-pressure

hose until bubble-free water ows out

of the high-pressure connection (3).

Check the water mains.

Rinse the high-pressure nozzle (13)

with water. If necessary clean the nozzle hole with a needle.

Spare Parts Order

When buying parts for the pressure washer, use the service address or fax number

given.

Please enter your machine type and the product number of the part you are ordering.

Item Description ........................................................................... Product No.

14 Cleaning agent container with nozzle ........................................ 91096764

13 High-pressure nozzle ................................................................. 91096765

1-2 High-pressure hose .................................................................... 91096766

12 Adjustable at-jet nozzle............................................................. 91096767

11 Jet lance .................................................................................... 91096768

10 Gun ............................................................................................ 91096769

14

Page 15

GB IE

EU declaration of conformity

We hereby conrm that the

Pressure Washer

Design Series PHD 100 A1

Serial number 201104000001 - 201104125000

conforms with the following applicable relevant version of the EU guidelines:

2004/108/EG • 2000/14/EG • 2006/42/EG

In order to guarantee consistency, the following harmonised standards as well as national standards and stipulations have been applied:

EN 60335-1/A13:2008 • EN 60335-2-79:2009 • EN 62233:2008 • EN 55014-1:2006

EN 55014-2:1997+A1:2001+A2:2008 • EN 61000-3-2:2006 • EN 61000-3-3:2008

We additionally conrm the following in accordance with the 2000/14/EC emissions guideline:

Guaranteed sound power level: 95,0 dB(A)

Measured sound power level: 88,8 dB(A)

Compliance evaluation process carried out in accordance with Appendix V,

2000/14/EC

Grizzly Gartengeräte GmbH & Co. KG

Am Gewerbepark 2

D-64823 Groß-Umstadt 10.05.2011

Andreas Gröschl

(Technical Director

and Documentation Representative)

15

Page 16

GB IE

Exploded Drawing

16

informative

Page 17

Grizzly Service-Center

DES UK Ltd.

Unit B7

Oxford Street Industrial Park

Vulcan Road

Bilston, West Midlands WV14 7LF

Tel: 0870 7876177

Tel from Ireland: 0044 870 787 6177

Fax: 0870 7876168

Fax from Ireland: 0044 870 787 6168

E-mail: grizzly@deslimited.com

GB IE

2011-03-28_rev02_gs

17

Page 18

IAN 63822

Grizzly Gartengeräte GmbH & Co. KG

Am Gewerbepark 2

D-64823 Groß-Umstadt

Last Information Update: 03 / 2011

Ident.-No.: 75041413032011-6

6

Loading...

Loading...