Panasonic UJ35 Installation Manual

LED UV Curing System Aicure SPOT Type

UJ30/35 Series

User’s Manual

ARCT1F510E-2

2011.9 |panasonic-electric-works.net/sunx

LED product safety precautions

LED Product Classification

The light source of the LED head connected to this product is classified as 3B under the

JIS C6802 “Safety of laser products.”

Max output: 780mW Wavelength: 365±5 nm

Class 3B LED Product JIS C6802: 2005

Max output: 940mW Wavelength: 385±5 nm

Class 3B LED Product JIS C6802: 2005

DANGER

Controlling or calibrating this product by other than the procedures stipulated here could

cause exposure to dangerous LED radiation.

・ Do not look directly at LED-UV light, or at LED-UV light reflected in a mirror or

other reflective surface. Doing so could cause eye damage.

・ Install the main unit so that humans are not exposed to LED-UV light.

Exposure could injure the skin or cause other injury.

・ Always turn off the key switch before cleaning the LED head.

Cleaning the head while the switch is on could cause eye damage or injury to the skin.

・ Never disassemble this product.

Disassembling this product could cause exposure to LED-UV light, causing eye

damage or injury to the skin.

・ If there is a risk of the LED-UV light being exposed to UV reflective light, place the

product inside a cover with proper reflectance and heat characteristics to block that

reflected light.

・ When operating the controller, set up the system so that the path of the LED-UV light

is not at eye level.

・ It is strongly recommended that a protective barrier be placed around the product,

so that people cannot approach it while it is operating.

・ Always wear the UV protective goggles when using this product.

・ Never operate this product in a manner not described in this manual. Doing so risks

exposure to LED-UV light.

Safety Precautions for Users

JIS C6802 stipulates user guidelines pertaining to safety precautions to be taken by users

and management standards.

In the case of this product, please implement safety precautions for a class 3B LED

product. See JIS C6802, “Safety of laser products” for details. In the abroad, see the

standard according each country.

ii

LED product safety precautions

Laser products Preventive safety measures for users (summary)

[from JIS “Safety of laser products”]

Required item/

Article

Laser

safety manager

10.1

Remote

interlock

10.2

Key control

10.3

Beam attenuator

10.4

Emission

indication device

Warning

indication

10.5

Beam path

10.6

Specular

reflection

10.7

Eye protection

10.8

Protective

clothing

10.9

Training

10.10

Classification

Class 1 Class 1M

Not necessary, but it is recommended that one be

appointed in the case of applications where laser beams

can be directly observed

Not necessary

Same as

Not necessary

No necessary

items

No necessary

items

Class 3B for

Class 1M

Same as

Class 3B for

Class 1M

Same as

Class 3R for

Class 1M

Class 2 Class 2M

Not necessary

Not necessary Remove the key when not in use

Not necessary

Not necessary

Same as

Not necessary

No necessary

items

No necessary items

No necessary items

No necessary

items

Class 3B for

Class 2M

Same as

Class 3R for

Class 2M

Same as

Class 3B for

Class 2M

Class 3R Class 3B Class 4

Not necessary in

the case of

visible light

beams.

Necessary in the

case of invisible

light beams.

Avoid careless irradiation during

Indicates that

laser is operating

at an invisible

wavelength.

Terminate beam at end of effective length

Necessary for all operators and maintenance

Indicates that laser is operating

Avoid unintended reflection

Necessary if it is not possible to

execute technical and management

permissible exposure) is exceeded

Necessary

Connected to a room or door

circuit

use

Follow warning indication

preventive measures

procedures, and if MPE (max.

Sometimes

necessary

personnel

instructions are

Specific

necessary

iii

LED product safety precautions

Safety features

This product is equipped with the following safety features, based on JIS C6802 “Safety of laser

products.”

■Remote interlock

UV irradiation can be stopped by opening the INPUT terminal “INTERLOCK (11)” on the rear of the

controller. It is shorted with a shorting bar as a factory default.

■Control by a key switch

The controller unit of this product is started via a key switch. Ensure that the key is removed while this

product is not in use.

■LED radiation emission warning

Turning ON the key switch enables the irradiation of LED UV light, which turns on the irradiation

warning indicator on the front panel of the controller. If the LED connection cable is longer than 2 m, or if

the controller unit is installed in an invisible part of the equipment, another warning indicator needs to be

provided in a visible location around the LED head.

(OUTPUT terminals “+5V” (23) and “COM” (24) on the rear of the controller output signals when the

key switch is turned ON.)

Stays on during irradiation

The emitting channels are indicated by a red light, either still

or flashing.

■Emergency reset

If an error occurs, eliminate the cause and then hold down “SET” for more than one second to clear the error.

iv

LED product safety precautions

Emission hole

Labels

The LED irradiation warning labels (shown below specified by JIS C6802) shown below are attached to

the LED heads before this product is shipped from the factory. Warning labels in Chinese that comply

with GB standards and those in English that comply with IEC/EN standards are also included.

■Warning labels in Japanese (JIS)

Description

Warning mark Emission hole location indication label

■Description

Description and mark label

Emission hole location indication label

LED head

■Warning labels in Chinese (GB standards)

If this product is used in China, apply the labels shown below over the Japanese labels.

■Warning labels in English (IEC/EN standards)

If this product is used outside Japan or China, attach the labels shown below over the Japanese

labels.

v

Safety precautions

DANGER

The purpose of the following caution indications is to ensure the safe and correct use of this product,

in order to protect users from injury and prevent property damage.

The caution indications to prevent possible human injury and property damage caused by incorrect use are

classified by “DANGER” and “WARNING” depending on their degree and severity.

All caution indications are critical for ensuring safety and must be strictly observed.

DANGER

WARNING

Symbol examples

Prohibited

Mandatory

Mandatory

Do not disassemble

Failure to observe the instructions can result in death or serious injury.

Failure to observe the instructions can result in injury or property damage.

This symbol denotes a

The left-hand example denotes “Do not disassemble”.

●

This symbol denotes a

The left-hand example denotes “Mandatory”.

●Do not use this product in a space in which combustible gases may be present.

(To avoid the risk of explosion.)

●Do not dispose of this product in a fire.

(To avoid the risk of batteries or electronic parts exploding.)

●While the LED is lit do not look at direct or reflected radiation, and do not allow anyone

to approach.

(To avoid the risk of injury or inflammation to eyes and skin.)

●Always wear UV protective goggles and protective gear when using this product.

(To avoid the risk of risk of injury or inflammation to eyes and skin.)

●Never try to disassemble or modify this product.

(To avoid the risk of generating abnormal heat or smoke. Also, disassembling the LED head

may expose eyes and skin to LED-UV radiation, resulting in injury or inflammation.)

●To prevent the generation of abnormal heat or smoke, always use this product with an

adequate margin of safety with respect to its guaranteed characteristics and performance

values.

●Do not touch the terminals while they are electrically powered.

(To avoid the risk of electric shock.)

●Make sure to connect the power cable and connectors securely.

(To avoid the risk of generating abnormal heat or smoke.)

●Make sure to plug in the AC adapter securely.

(To avoid the risk of generating abnormal heat or smoke.)

Prohibited

action.

Mandatory

WARNING

action or an

Instruction

.

vi

Prohibited

●Never insert any foreign substances such as liquid, flammable materials, or metals inside

the product. (To avoid the risk of generating abnormal heat or smoke.)

●Never perform any setup work (e.g., connection, disconnection) with the power cable

plugged in. (To avoid the risk of electric shock.)

●Never place anything on top of the product or obstruct the ventilation openings in any

way. (To avoid the risk of burning due to overheating.)

Precautions for use

■ General precautions

・ Never connect any LED head, connection cable, AC adapter, or UV sensor to the main unit, other

than those designated by Panasonic. Otherwise, any failure, loss, or damage that may occur will not

be covered under warranty.

・ Never try to disassemble or modify the product, or to alter its internal settings. Any failure or

damage that occurs after disassembling or modifying the product will not be covered under

warranty.

■ Installation environment

・ Ambient temperature Controller: 0 to +35°C (with no condensation)

LED head: +5 to +35°C (with no condensation)

・ Ambient humidity: 30 to 85% RH (at 25°C, with no condensation)

・ A location free of dirt, smoke or soot, conductive dust, and corrosive or flammable gases, where

there is no risk of exposure to water, oil, or chemicals

・ A location not subject to sudden temperature changes, or to vibration and physical shock

・ A location not exposed to direct sunlight

■ Power supply

・ Supply electric power of 100 to 240 V AC (frequency: 50/60 Hz).

・ Supply electric power of 5 to 28 V DC to the input/output terminals.

・ The supplied power cable is for use in Japan, at 100 V. If using this product outside Japan, make

sure to use a suitable cable with the appropriate plug, certified for use in the particular country.

・ Do not connect this product to a power supply that is shared with equipment that includes an electric

motor or other high-power usages. Use a separate power supply and make sure to provide a

protection circuit (e.g., a fuse).

・ Take care to prevent excessive static electricity accumulation.

・ If using multiple units of this product, do not tie their AC adapters together in a bundle. Otherwise,

the AC adapters may overheat, resulting in failure.

・ If the product is to remain unused for any length of time, disconnect the power plug from the power

socket.

■ Wiring

・ If any device connected to this product is connected to a DC induction load (motor or relay), connect

a noise absorption device (e.g., noise suppressor) on the side of the load.

・ When connecting an external power source to the input/output terminals, make sure that the polarity

is correct.

・ Make sure to perform wiring so that no physical or electrical load is added to the connection cable.

Also, avoid bending too close (less than 80 mm) to the base (connector part) and make sure that the

radius of bends is at least 33 mm.

・ Make sure to hold the connector (plug) part while connecting or disconnecting the power plug.

■

If the connection cable is longer than 2 m, or if the product is installed inside a larger item of

equipment, set up a display near the LED head so that the “LED radiation warning” can be readily

seen. If you use OUTPUT terminals “+5V” (23) and “COM” (24) at the rear of the controller, these

will output a signal when the power is switched ON.

vii

Precautions for use

■ Setup

・ Check that the rubber feet of the product are always horizontally level. Never incline the product,

or position it on its side, or upside down. Otherwise, overheating may occur, resulting in failure

and damage.

・ Never place anything on top or below the product, or obstruct the ventilation openings in any way.

Otherwise overheating and burning may occur. Provide for sufficient ventilation space around the

product: Top: 50 mm; Sides: 20 mm; Rear: 80 mm.

■ Precautions when powering ON

・ Check that all connections are correct before powering ON.

■ Other precautions

・ When disposing of this product, it should be treated as industrial waste.

Warranty Period

・ The Warranty Period for this product (excluding LED head) is 3 years from either the date

of purchase or the date on which the product is delivered to the location specified by the

Buyer. However, the Warranty Period shall be valid only until 42 months from the date of

manufacture which includes a maximum of 6-month distribution period. The warranty

period for the LED head extends until one year from the time of delivery, or until 5,000

hours of cumulative irradiation, whichever is sooner.

Extent of Warranty

・ In the event of any failure or defect in the product or non-conformity of specifications due

to the reasons solely attributable to the Seller, Seller shall remedy such malfunctioning or

defective product at its own cost in one of the following ways to be selected by SELLER:

(i) repair such product, (ii) replace such product, (iii) supply of replacement parts.

However, this Warranty shall not cover the damages or defects that arise due to the reasons

any of the followings.

1. Specifications, standards or handling procedures specified by the Buyer.

2. Modifications to the structure, performance or specifications performed by a

party other than the Seller after the date of purchase or the date on which

the product is delivered.

3. Phenomena that could not have been foreseen with the technology that was

put into practical use at the time of purchase.

4. Exceeding the ranges, conditions, circumstances or environment described

in the Manuals or Specification sheet.

5. Damages that could be avoided if Seller’s product have the functions and

structures generally accepted in the industry, when incorporating the

product in to Buyer’s product.

6. Natural disasters or an Act of God.

7. Consumable goods such as batteries and relays, or optional accessories such

as cables.

viii

Precautions for use

・ SELLER SPECIFICALLY DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR USE OR

PURPOSE, AS WELL AS LIABILITY FOR INCIDENTAL, SPECIAL, INDIRECT,

CONSEQUENTIAL OR OTHER DAMAGES RELATING TO THE PRODUCT.

Product EOL (“end of life”)

・ Please understand that production of this product may be discontinued at any time for a

variety of possible circumstances. Note that repair services are not provided after a

product is discontinued.

ix

Contents

1 Features of the ANUJ 3000/3500................................1

2 Product components....................................................3

3 Parts names and functions...........................................4

4 Installation..................................................................6

4.1 Installation conditions..............................................6

4.2 General guidelines for irradiation distance and UV

intensity..................................................................7

5 Getting started.............................................................9

5.1 Hooking up the connection cable.............................9

5.2 Connecting the LED ................................................ 9

5.3 Connecting the external control signals.................. 11

5.4 Connecting the AC adapter ....................................12

5.5 Power on operation................................................12

6 Operation modes.......................................................13

6.1 Operation mode (default mode when power is turned

on)........................................................................13

1) Setting irradiation conditions..............................14

2) Timer irradiation.................................................14

3) Continuous irradiation........................................15

4) Irradiation using an external start signal.............15

5) Display of head management information..........16

6) Panel lock function.............................................16

6.2 UV measurement and Auto tuning mode................17

1) Measuring UV intensity. ................................... 17

2) Auto tuning .......................................................18

6.3 Default settings mode.............................................19

6.4 Timing chart...........................................................20

1) Batch irradiation.................................................20

2) Individual irradiation ......................................22

7 External control.........................................................24

7.1 External input/output control.....................................24

7.2 Serial communication control...................................26

RS-232C terminal specifications..........................26

Communication specifications..............................26

Commands and responses.....................................27

Command/response format...................................27

Block check code BCC (H) (L).............................27

Control commands................................................28

Support commands...............................................28

Error codes ...........................................................28

Data areas.............................................................29

7.3 Communications address map...................................30

Address for reading ..............................................30

Address for writing...............................................34

WRITE procedure.................................................38

7.4 Setup tool application for UJ35.................................39

Operation from a PC.............................................39

8 Warning indications ..................................................46

Temperature warning............................................46

Time warning........................................................46

Error codes ...........................................................47

9 Safety measures ........................................................48

9.1 Safety circuit..........................................................48

10 Specifications..........................................................49

10.1 Outline of specifications.......................................49

Controller specifications......................................49

Head specifications.............................................50

UV sensor specifications.....................................52

11 Dimensions..............................................................53

12 Option and spare parts list.......................................54

12.1 Options and spare parts.......................................54

12.2 How to replace the lens unit................................56

12.3 Fitting the mounting bracket ...............................56

13 Troubleshooting......................................................57

Manual revision history ..................................................58

x

1 Features of the ANUJ 3000/3500

UV

separately for

proce

sses 1 to 4.

1 to 4.

The ANUJ 3000/3500 is an UV curing device that quickly hardens UV resins (inks, adhesives, and coatings)

via irradiation with UV light from an LED light source. The focused application of UV radiation to UV resins

coated on minute surfaces (2 to 3 mm dia.) such as the lenses of CD, MD, and DVD players, and the LCD

panels of notebook PCs, enables precise adhesion.

■High-power irradiation: 10,000 mW/cm2 (with ANUJ6423 lens)

Higher radiation intensity and a wider range of applications. Shorter production cycles.

■Long LED life: 20,000 hours (LED life: Total irradiation time before UV intensity falls to 70% of

initial value)

At least six times longer LED life than a comparable lamp model, enabling reduced running costs.

■UV curing without temperature increases

Uses a single 365-nm LED UV light source that does not emit any infrared radiation, eliminating the risk of

heat damaging the workpiece.

■UV intensity stabilization

UV intensity is kept constant, even if the ambient or LED temperature changes.

■Easy-to-install LED head

At 12 mm dia. by 50 mm len., the LED is easy to mount on a jig. Mounting the LED head in place reduces

overheating and increases UV intensity.

■No cooling fan, enabling cleanroom use

There is no need to deal with exhaust.

■Programmable UV irradiation with four independently controlled heads

Each LED head can be controlled independently. The heads can also be controlled all together or in

combination. Up to eight different operation programs can be stored for each channel, including one program

for the constant intensity irradiation and seven programs composed of up to 10 steps each.

Program examples

Simple mode

1 Features of the ANUJ 3000/3500

intensity

Constant

intensity

Time

Up to 7 programs can be set.

Program 1

Program 7

Interval (closed)

[Lamp type]

Four units need to be installed

Fiber

Process 1 Process 2 Process 3 Process 4

One controller handles processes

Process 1 Process 2 Process 3 Process 4

1

Features of the ANUJ 3000/3500

The

■Universal design for easy operation

Easy operation has been achieved by the product’s universal design, including the large-sized color LED

display with a high level of visibility and the operation switches located at optimal locations.

After connecting the head, UV irradiation can be started simply by selecting a channel (CH), setting the UV

power (%) and irradiation time (TIME), and then pressing [EMISSION].

■Multiple safety features

Circuit breaks and short circuits of the LED head are automatically detected. If the LED overheats due to high

ambient temperature or other reason, it turns itself off. UV irradiation can be brought to an emergency by

opening INPUT terminal “INTERLOCK” (11) on the rear of the controller. Irradiation can also be stopped by

short-circuiting “STOP” (9) and “COM” (12).

■Detachable terminal blocks for external connection

The detachable terminal blocks facilitate connections with external equipment.

■Universal power supply

The supplied AC adapter is a universal type for 100 to 240 V ± 10%.

(The supplied AC adapter power cable is 100 V AC cable for use in Japan

2

2 Part names and functions

Controller

Optional parts (sold separately)

LED head

AC adapter

100 V (AC) power cable for use in Japan only

Instruction Manual

Standard lens

Connection cable x1

3

3 Part names and functions

Front of the controller

UV sensor (option)

Rear of the controller

AC adapter

DC output indicator LED

4

Part names and functions

●Front

(1) EMISSION switch

(9) Display unit

(8) Operation switch

(7) UV check switch

(only UJ35)

(6) UV sensor

connection port (only UJ35)

●

Rear

(13) CH1-CH4 LED head

connecting connector

(14) Protective seal

(12) AC adapter connector

Description Function Remark

(1) EMISSION switch

(2) READY indicator Indicates that UV irradiation is enabled (ready to start).

(3) CH1-CH4

operation switch

(4) CH1-CH4

selector/indicator

(5) Key operated

power switch

(6) UV sensor

connection port

(7) UV check button Views/calibrates values measured by the special UV sensor UJ35 only

(8) Operation unit switch

(9) Display unit

(10) Input/output terminal

block

(11) RS232C connector Connects a PC, PLC, or other external device with RS232C. UJ35 only

UV is irradiated and stopped by selected irradiating CH head. Red lamp is turned on

during UV irradiation.

Selects the LED head channels for irradiation.

Red = irradiation, green = standby, yellow = error

Commences/finishes operation of the controller.

Connects the special UV sensor. UJ35 only

Specifies irradiation conditions (intensity and time), replacement time settings, and

initial values, and switches the display.

Displays irradiation conditions (intensity and time), replacement time settings, head

temperature, and initial values.

Connects a PLC, foot switch, or other external device

(2) READY indicator

(3) CH1-CH4 operation switch

(4) CH1-CH4 selector/indicator

(5) Key operated power switch

(10) Input/Output terminal block

(11) RS232C connector

(only UJ35)

(12) AC adapter connector Connects the special AC adapter.

(13) CH1-CH4 head

connecting connector

(14) Protective seal Protects connectors.

Cconnects LED heads.

5

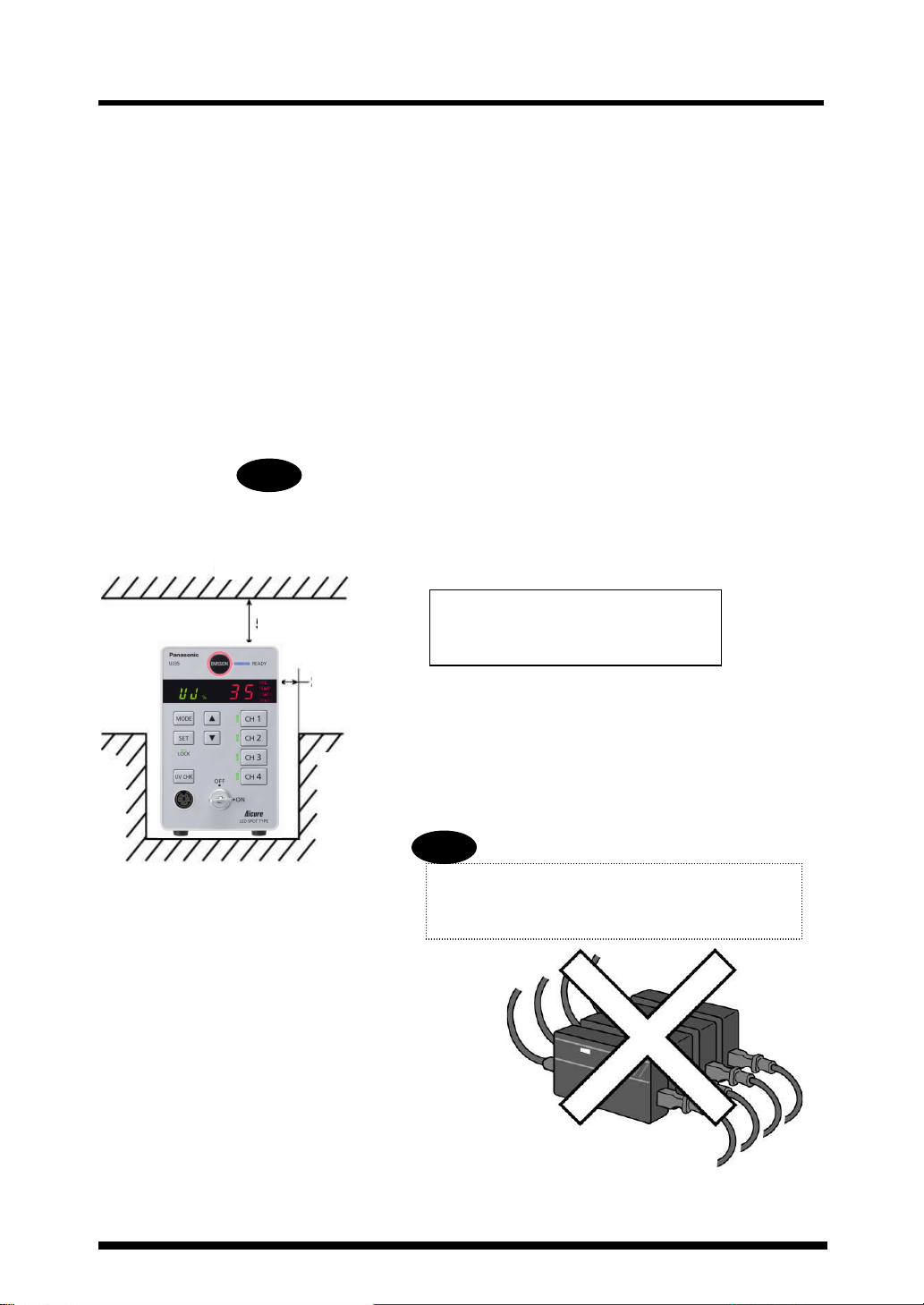

4 Installation

If using more than one controller, do not bundle

Ensure that there is enough space

Warning

WarningWarning

Warning

Warning

WarningWarning

Warning

Install and set up the product according to the following conditions.

4.1 Installation conditions

1) Ambient temp.: Controller: 0 to +35°C

Head: +5° to +35°C

2) Relative humidity: 30 to 85% (at 25°C, no condensation)

3) When setting up the controller, make sure that its rubber feet are

horizontally level.

4) To prevent damage due to overheating, make sure that the area around the

controller is free of any obstructions.

5) The dimensions of the controller are 80 mm (L) × 130 mm (H) × 145 mm

(D), but remember that the controller will have one or more LED heads

attached during use. The radius of the LED head connector cable should

be no less than 33 mm, otherwise the cable may become damaged.

Never place anything on top or below the controller, or obstruct the

ventilation openings in any way. Otherwise, overheating and burning may

occur.

Wall

Approx. 50 mm

Approx. 20 mm

Wall

above and on the sides of the

controller.

the supplied AC adapters together. Otherwise, the

AC adapters may overheat and fail.

6

Installation

WD=50

Irradiation area

4.2 General guidelines for irradiation distance and UV intensity

Fix the LED head to a jig at the appropriate distance from the workpiece, according to the size of the area to be

irradiated (irradiation diameter) and the required UV intensity.

General guidelines for work distance (WD) and UV intensity are offered below.

■ UV intensity data (typical characteristics)

[UV intensity level: 100% Room temperature: 25°C With a cooling device attached]

* See page 11 for the dimensions of the cooling device.

LED head: ANUJ6170

ANUJ 6423

ANUJ 6423 (φ3mm)

ANUJ 6423 ANUJ 6423

14,000

)

12,000

2

)

2

10,000

(mW/cm

8,000

6,000

4,000

UV強度(mW/cm

UV intensity

2,000

0

-5 -4 -3 - 2 -1 0 1 2 3 4 5

Irradiation area

ANU J64 24

ANU J64 24 (φ4mm)

ANU J64 24 AN UJ6 424

12,000

)

2

10,000

)

2

(mW/cm

8,000

6,000

4,000

UV intensity

UV強度(mW/cm

2,000

0

-5 -4 -3 -2 - 1 0 1 2 3 4 5

Irradiation area

ANUJ 6426

ANUJ 6426 (φ6mm)

ANUJ 6426 AN UJ6 42 6

6,000

)

2

5,000

)

2

4,000

(mW/cm

3,000

2,000

UV intensity

UV強度( mW/cm

1,000

0

-5 -4 -3 - 2 -1 0 1 2 3 4 5

Irradiation area

ANUJ 6428

ANUJ 6428 (φ8mm)

ANUJ 6428 ANUJ 6428

4,000

)

2

3,500

)

2

3,000

(mW/cm

2,500

2,000

1,500

1,000

UV強度(mW/cm

UV intensity

500

0

-5 -4 -3 -2 -1 0 1 2 3 4 5

Irradiation area

ANUJ 6420

ANUJ 6420 (φ10mm)

ANUJ 6420 A NUJ64 20

2,000

1,800

)

2

)

1,600

2

1,400

(mW/cm

1,200

1,000

800

600

UV強度(mW/cm

400

UV intensity

200

0

-7-6-5-4-3-2-10 1 2 3 4 5 6 7

Irradiation area

照射範囲(mm)

照射範囲(mm)

照射範囲(mm)

照射範囲(mm)

照射範囲(mm)

(mm)

(mm)

(mm)

(mm)

(mm)

WD=10

WD=12

WD=15

WD=20

WD=25

WD=30

WD=50

WD=10

WD=15

WD=20

WD=25

WD=30

WD=40

WD=50

WD=10

WD=15

WD=20

WD=25

WD=30

WD=40

WD=10

WD=15

WD=20

WD=25

WD=30

WD=50

WD=10

WD=12

WD=14

WD=16

WD=20

Irradiation distance vs

intensity and area

If an irradiation area of 6 mm diameter

is irradiated at an intensity of 500 mW/cm

or higher, draw lines on the graph at ±3 mm

and 500 mW/cm2. Find the irradiation

distance line that covers the area surrounded

by the drawn lines. In this example,

the ANUJ6428 head can maintain

an intensity of 500 mW/cm2 or higher

for a 6-mm diameter area

by setting the irradiation distance to 50 mm.

ANUJ 6428

ANUJ 6428 (φ8mm)

ANUJ 6428 ANUJ 6428

4,000

3,500

)

2

)

2

2

3,000

2,500

(mW/cm

2,000

1,500

1,000

UV強度(mW/cm

500

0

-5 -4 -3 -2 - 1 0 1 2 3 4 5

照射範囲(mm)

(mm)

WD=10

WD=15

WD=20

WD=25

WD=30

WD=40

WD=50

7

Installation

U V

強 度

( m W

/

c m

)

U V

強 度

( mW

/

c m

)

U V

強 度

( m W

/

c m

)

U V

強 度

( mW

/

c m

)

U V

強 度

( mW

/

c m

)

U V

強 度

( m W

/

c m

)

U V

強 度

( m W

/

c m

)

U V

強 度

( m W

/

c m

)

U V

強 度

( m W

/

c m

)

Cylindrical lens data (typical characteristics)

■ Rod lens data (typical characteristics) ■

Length direction

長手方向

ANUJ6450S

2,000

WD=10

1,800

WD=15

1,600

2

WD=20

1,400

1,200

1,000

800

600

400

200

0

-10 -8 -6 -4 -2 0 2 4 6 8 10

照射範 囲(m m)

ANUJ6475S

2,000

1,800

WD=10

1,600

WD=15

2

WD=20

1,400

1,200

1,000

800

600

400

200

0

-10 - 8 -6 -4 -2 0 2 4 6 8 10

照射範囲(mm)

12,000

WD3

10,000

WD5

2

WD7

8,000

WD10

WD15

6,000

WD20

WD25

4,000

WD30

2,000

0

-5 -4 -3 -2 -1 0 1 2 3 4 5

照射範囲(mm)

8,000

7,000

WD3

WD5

2

6,000

WD7

5,000

WD10

WD15

4,000

WD20

WD25

3,000

2,000

1,000

0

-5 -4 -3 -2 -1 0 1 2 3 4 5

照射範囲(mm)

Width direction

幅方向

2,000

1,800

WD=10

WD=12

1,600

2

WD=15

1,400

1,200

1,000

800

600

400

200

0

-4 -3 -2 -1 0 1 2 3 4

照射範囲(mm)

2,000

1,800

WD=10

1,600

WD=12

2

1,400

WD=15

1,200

1,000

800

600

400

200

0

-4 -3 -2 -1 0 1 2 3 4

照射範囲(mm)

Side-view lens

Side-view lens data (typical characteristics)

6,000

WD5

5,000

WD10

2

WD15

4,000

WD20

WD25

3,000

WD30

WD40

2,000

1,000

0

-5 -4 -3 -2 -1 0 1 2 3 4 5

照射範囲(mm)

4,000

WD5

3,500

WD10

WD15

2

3,000

WD20

WD25

2,500

WD30

WD40

2,000

1,500

1,000

500

0

-5 -4 -3 -2 -1 0 1 2 3 4 5

照射範囲(mm)

1,000

800

2

600

400

200

0

-5 -4 -3 -2 - 1 0 1 2 3 4 5

WD5

WD10

WD15

WD20

WD25

WD30

WD40

照射範囲(mm)

8

Warning

WarningWarning

Warning

Connector

Lens prote

ctor cap

Connector

Connector

After connecting the necessary cords, lastly plug in the power cord.

This section describes the steps up to turning on the power.

5.1 Hooking up the connection cable

Plug the connection cable (for the LED head) into its connection port.

Connection cable

Plug the female side of the connection cable into the main unit. Plugging in

the wrong side (the male connector) could bend the connector pins or cause

other issues.

5.2 Connecting the LED

Connecting the head

LED head

5 Getting started

Connection cable

Main unit side

LED side

9

Getting started

Warning

WarningWarning

Warning

Warning

WarningWarning

Warning

Rear panel

<Procedure>

1. Plug in the connection cable.

2. Connect the LED head to the connection cable.

3. Remove the protective cap from the LED head.

<Reference> Heat dissipation device (aluminium)

(A metal fixture attached to the head)

Set the LED jig in place.

2-M4 (5mm D)

M6 (5mm D)

The rise in LED temperature depends on the duration

of irradiation time and the interval between irradiations.

If the temperature increases beyond a certain point an

alarm will be generated. In the event of such

overheating, increase the size of the heat dissipation

fixture, or add fins to it.

If the LED head is not fixed to a jig, the LED head can become very hot during irradiation. For this reason, do

not touch the head directly with your hands during irradiation.

10

5.3 Connecting the external control signals

The external control connectors on the back of the controller (two blocks of

12 pins) are removable.

External control connectors (12 pin × 2)

MINI COMBICON Plug 12P (Phoenix Contact MC 1.5/12-ST-3.5)

(Osada OS-85-12P)

Getting started

Compatible wire (stranded)

Size

AWG#24 to 16 0.2 to 1.25 mm2

Tightening torque: 0.22 Nm to 0.25 Nm

Conductor section area

Cover stripping length

6 to 7 mm

11

Loading...

Loading...