Panasonic TH-42PH Service Manual

Panasonic Services Company

National Training

TH-42PHD5/TH-50PHD5

TH-42PHW5/TH50PHW5

GPH5D Chassis

Plasma Display Panel

Troubleshooting Guide

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does

not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair

the product or products dealt with in this service information by anyone else could result in serious injury or death.

Warning

2

Objective...............................................................................................................5

2002 Model Line Up..............................................................................................6

Specifications.....................................................................................................7

Features.............................................................................................................8

New Asymmetrical Cell Structure Panel .........................................................9

Model Differences...........................................................................................9

Disassembly .......................................................................................................11

Rear Cover Removal .......................................................................................11

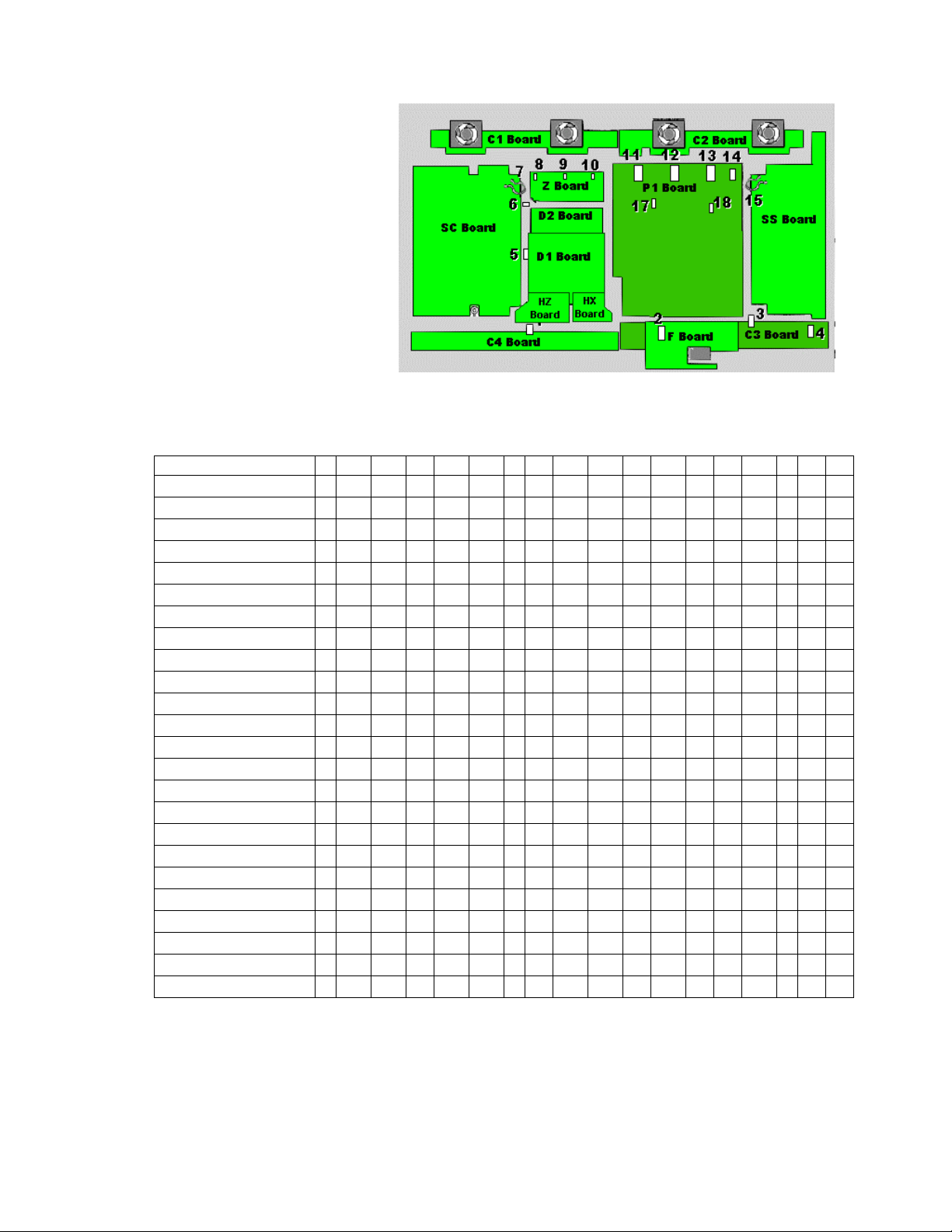

42” HD PCB Board Layout Diagram ...................................................................13

Printed Circuit Board Information Table ...........................................................13

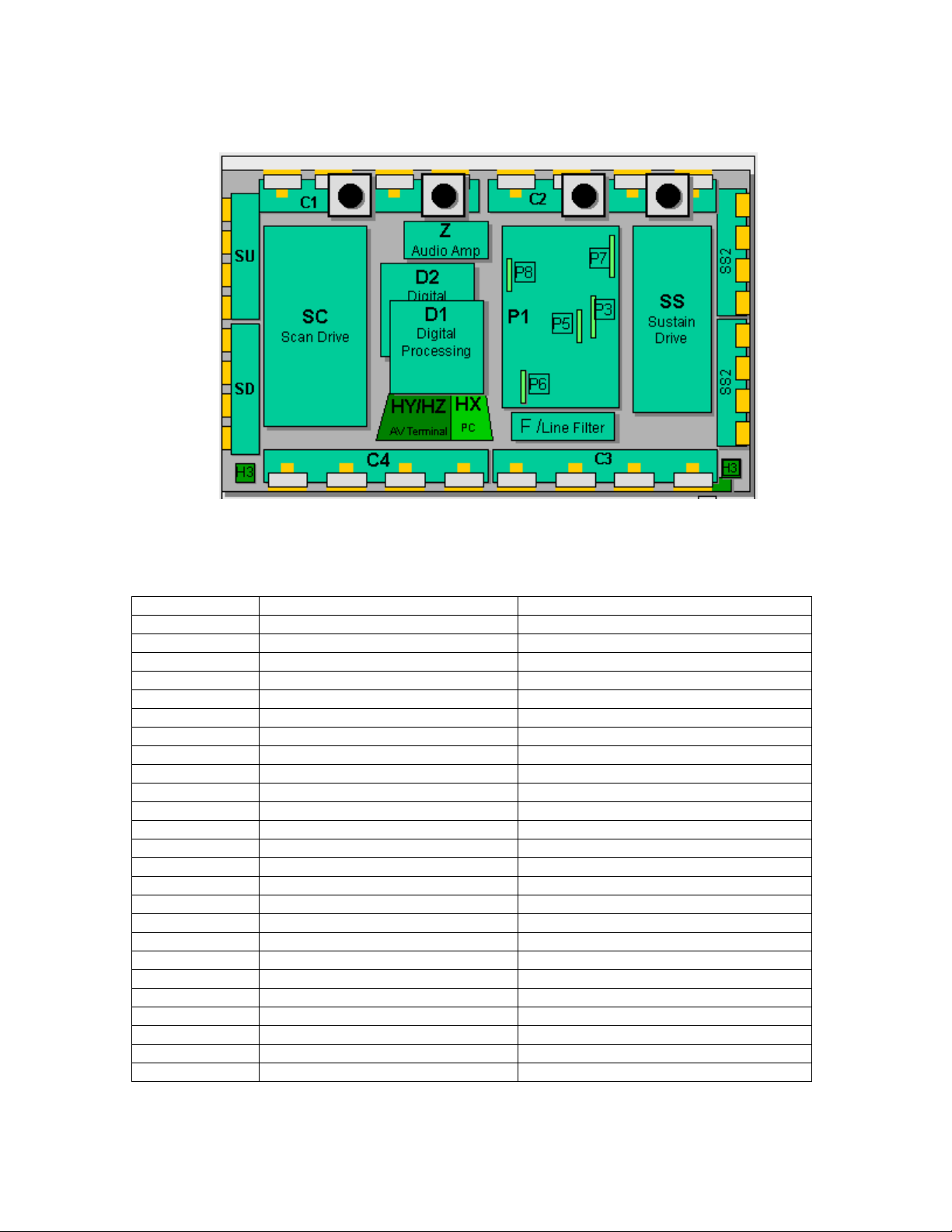

50” PCB Board Layout Diagram .........................................................................14

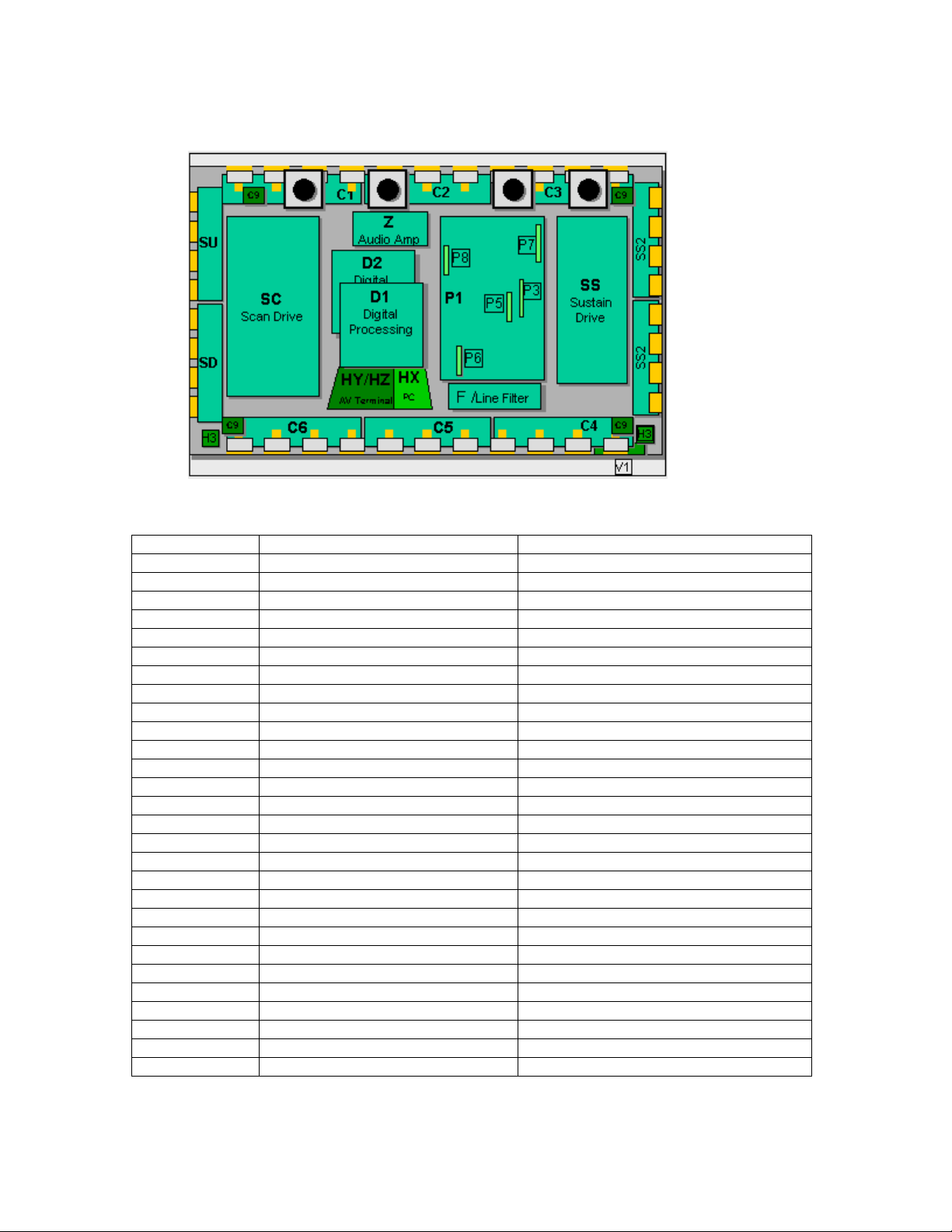

42” SD PCB Layout Diagram..............................................................................15

Video Signal Path Explanation............................................................................16

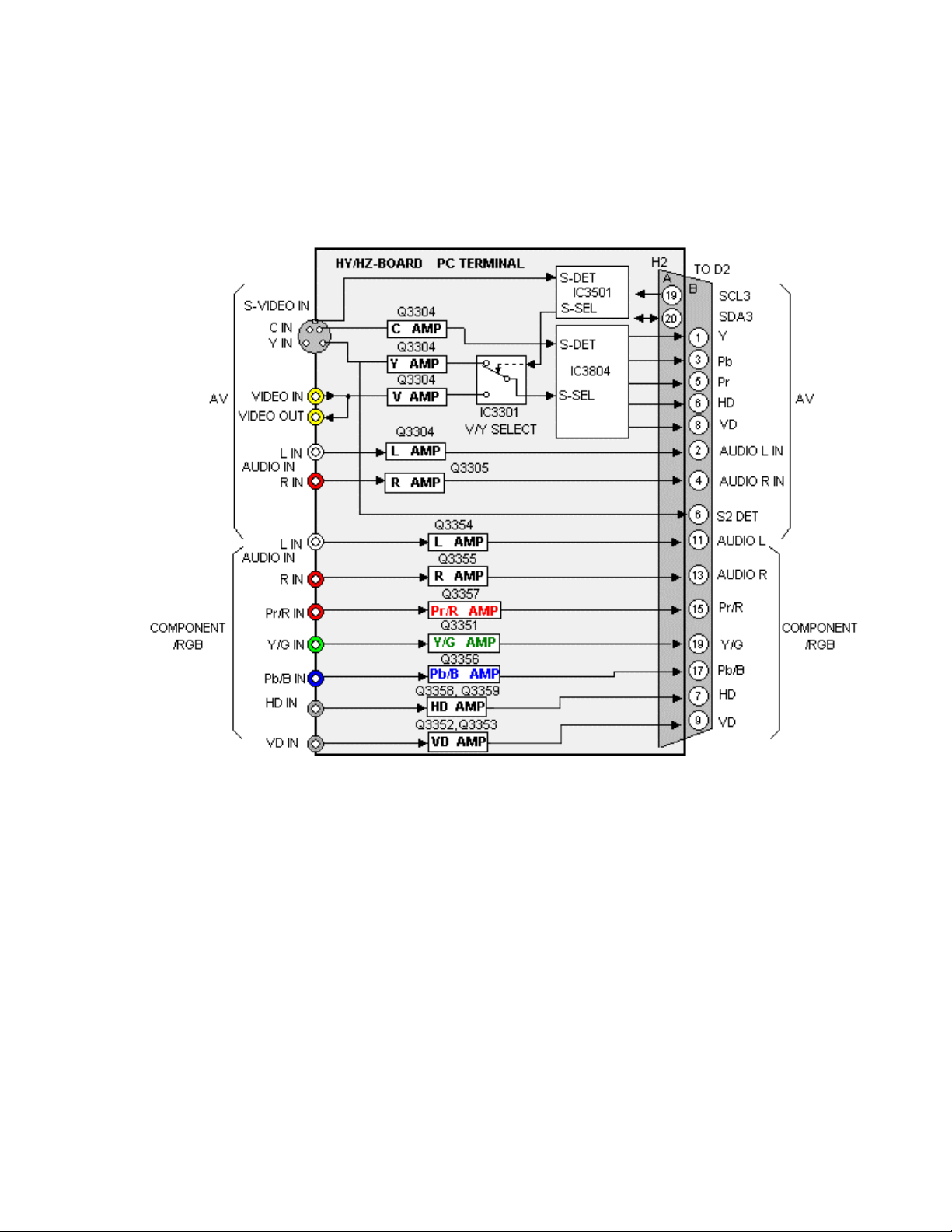

HY/HZ Board....................................................................................................16

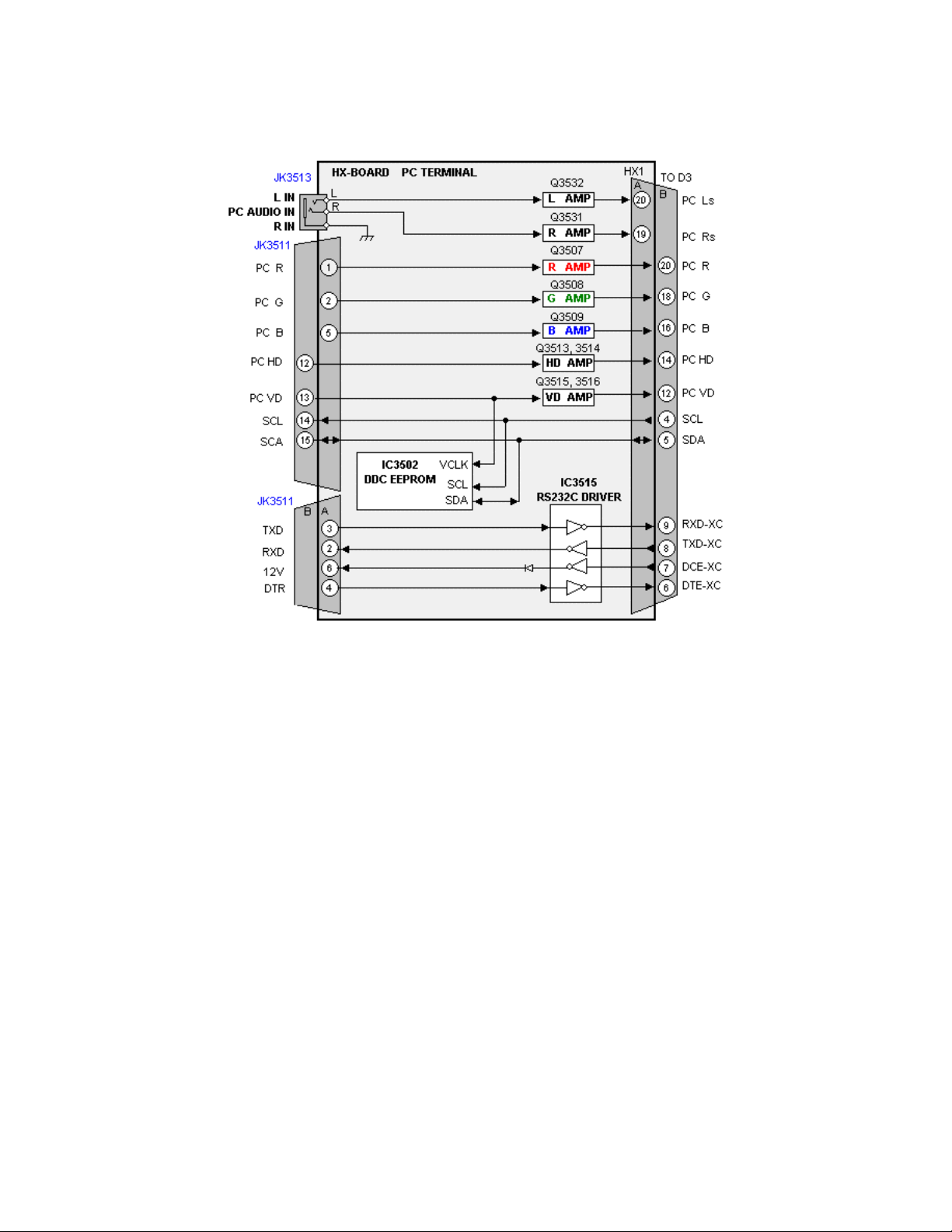

HX Board .........................................................................................................17

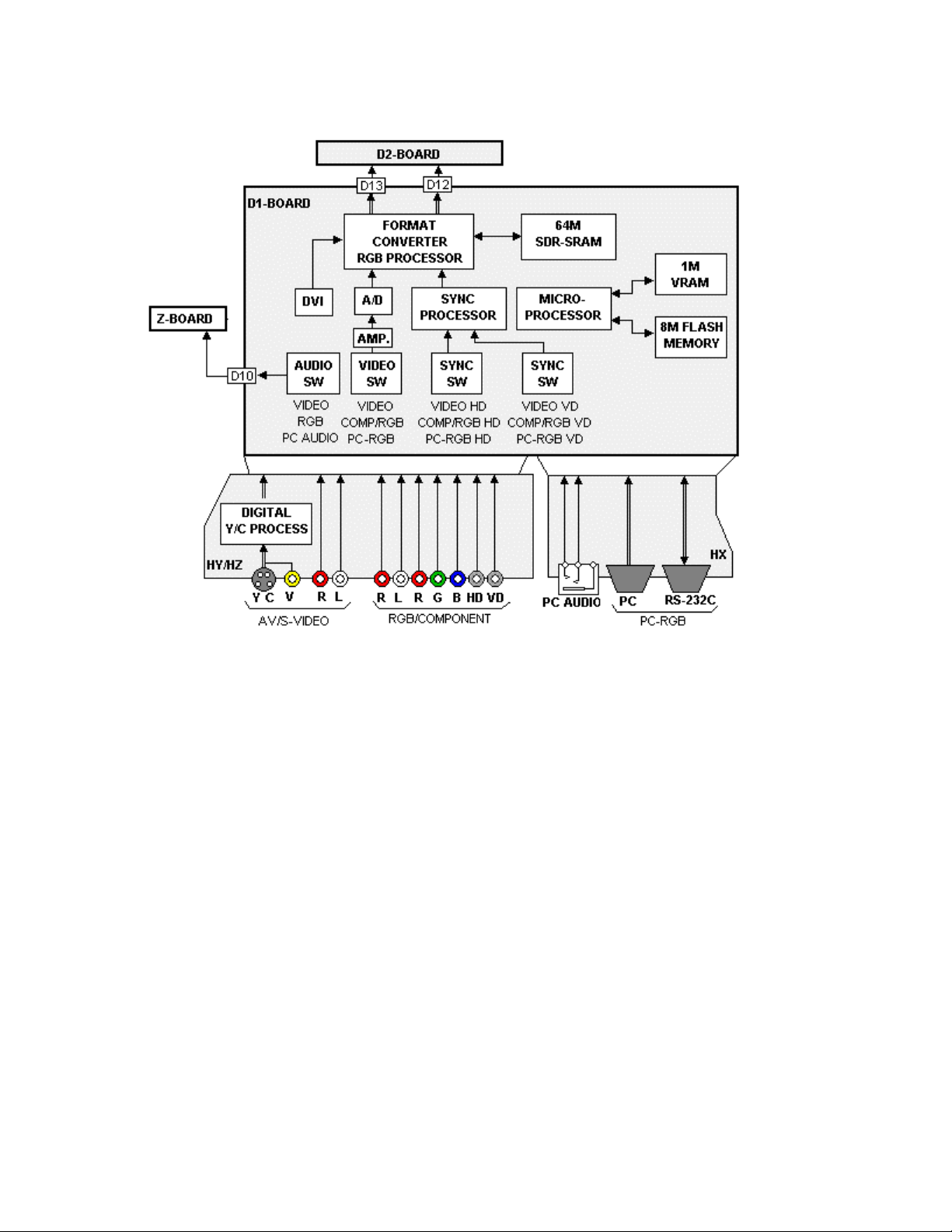

D1 Board..........................................................................................................18

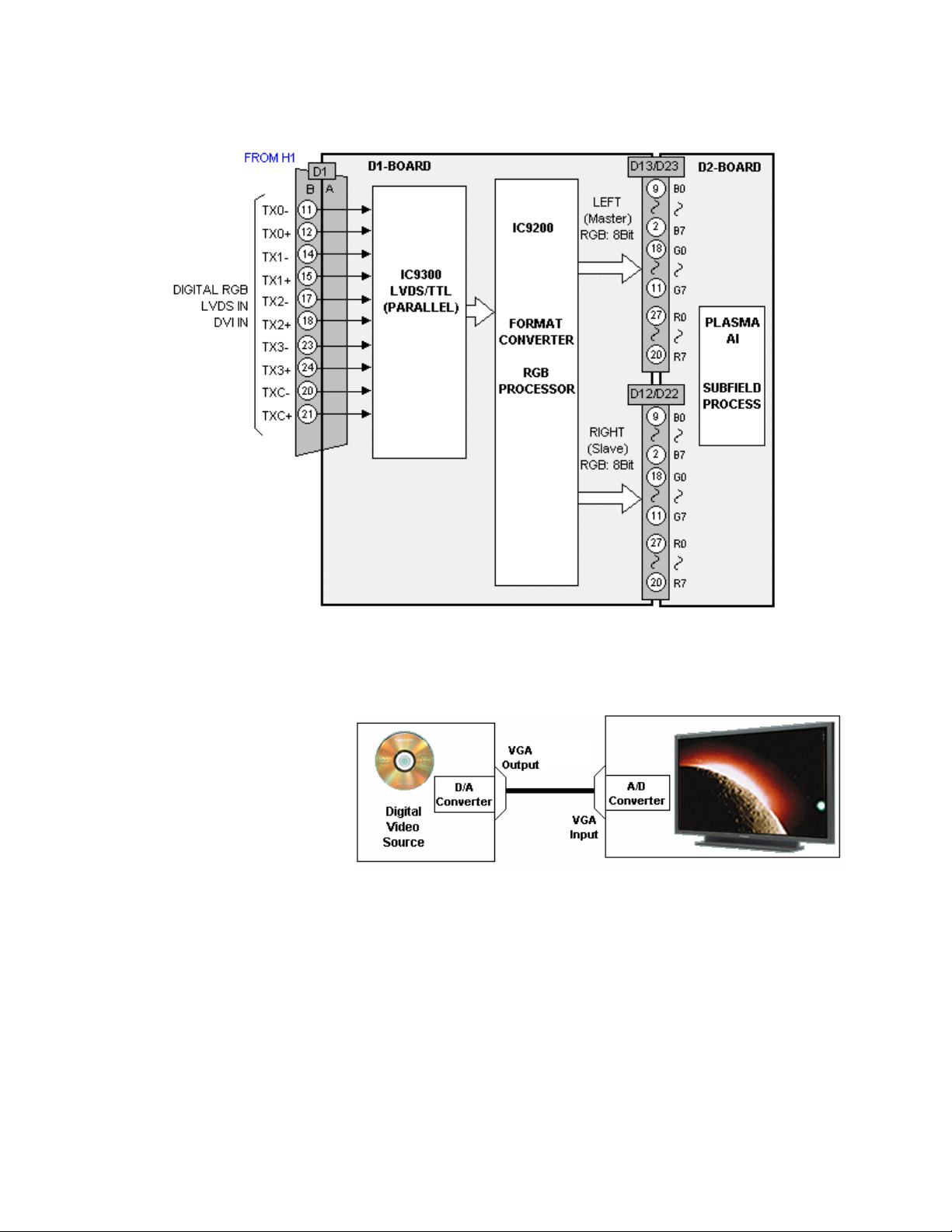

DVI Interface....................................................................................................19

Sync Process...................................................................................................21

RGB/PC Input Mode Sync ...............................................................................21

Composite/ Component Video Input mode Sync .............................................21

D1 Board.............................................................................................................22

D1 Main ICs Operation ....................................................................................22

D2 Board.............................................................................................................23

D2 Board details ..............................................................................................24

SC Board Explanation.........................................................................................25

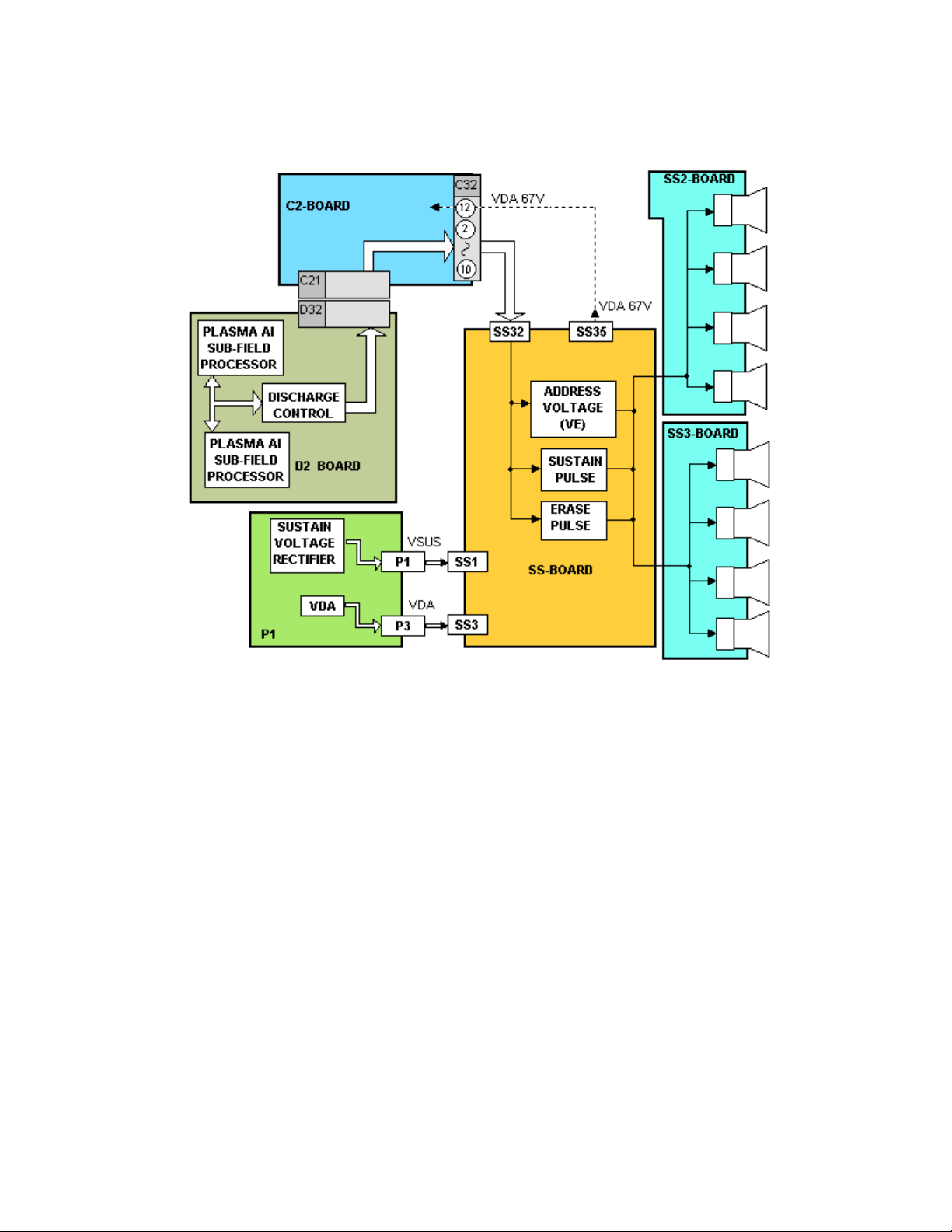

SS Board Explanation.........................................................................................28

Power Supplies...................................................................................................31

Standby Power Supply.....................................................................................31

Main Power Supply..........................................................................................32

Power Factor Control....................................................................................32

Low Voltage Power supply............................................................................33

Voltage Regulation........................................................................................33

High Voltage Power Supply .............................................................................34

Protection Circuits...............................................................................................36

Diagnostic Procedures........................................................................................38

Self Check Display Indication...........................................................................38

Power LED Flashing timing chart.....................................................................39

Diagnostic Flow Charts.......................................................................................40

No Power .........................................................................................................40

The Power LED is red and blinking on/off........................................................41

Power LED blinks twice ...................................................................................42

No Picture Flowchart 1.....................................................................................43

No picture Flowchart 2.....................................................................................44

Dark picture Flowchart.....................................................................................45

Local screen failure.............................................................................................46

3

Service Hints....................................................................................................46

After Image Prevention .......................................................................................53

Screen Saver Feature...................................................................................53

Side Bar Brightness adjustment....................................................................54

Option Setting .....................................................................................................55

Accessing the Option Menu.............................................................................55

Hidden Option Menu for GPH5D series...........................................................56

Sample Waveforms.............................................................................................58

HY/HZ board....................................................................................................58

HX board..........................................................................................................61

SC Board Input Signals....................................................................................63

SC Board Waveforms ......................................................................................64

SS-Board Input Signals....................................................................................66

SS Board Waveforms ......................................................................................67

PDP Defect Pixel Specification ...........................................................................68

Connector Tables................................................................................................69

F-BOARD CONNECTORS ..............................................................................69

P-BOARD CONNECTORS ..............................................................................69

HX- BOARD CONNECTORS...........................................................................73

HY / HZ- BOARD CONNECTORS...................................................................74

Adjustment Procedures.......................................................................................75

Panel label Information ....................................................................................75

+B Set-up.........................................................................................................76

Confirmation.....................................................................................................76

Driver Set-up....................................................................................................77

Initialization Pulse Adjust .................................................................................78

P.C.B. (Printed Circuit Board) exchange procedure.........................................79

Adjustment Volume Locations..........................................................................79

Test Point locations..........................................................................................80

Serviceman mode...............................................................................................81

CAT (computer aided test) Mode.....................................................................81

I2C Mode..........................................................................................................81

CD mode..........................................................................................................82

SD Mode..........................................................................................................83

2

C Menu Structure ..........................................................................................84

I

Alignment Procedures.........................................................................................85

NTSC Panel White Balance............................... Error! Bookmark not defined.

Pedestal Setting...............................................................................................85

NTSC (480i) White Balance Adjustment ..........................................................86

480p White Balance Adjustment......................................................................87

720p White Balance Adjustment......................................................................88

1080i White Balance Adjustment.....................................................................89

Sub Brightness Setting ....................................................................................90

Service Contact Information................................................................................91

4

Objective

The information provided in this document is designed to assist the technician in

determining the defective printed circuit board. The troubleshooting flow charts,

signal path charts and connector information should provide enough detail that

the technician can accurately determine which one of the printed circuit boards is

required to repair the product. Alignment and adjustment procedures are also

included in this document.

The Block diagrams and the schematic drawings reference the model TH42PHD5, but the technology is consistent with any GPH5D chassis.

5

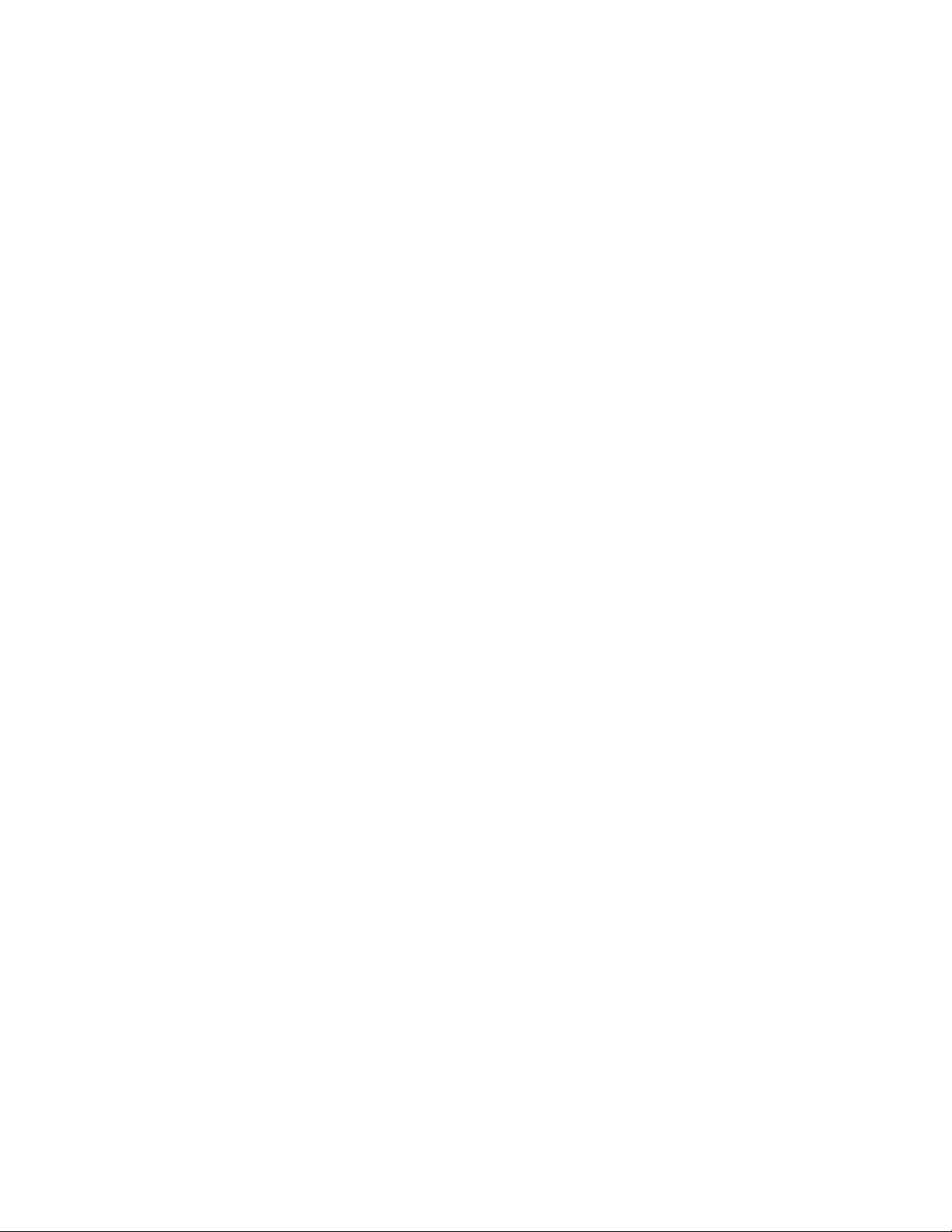

2002 Model Line Up

Digital Cinema Reality

Advanced 3-dimensional

1366 x 768 XGA Resolution

TH-50PHW5

50-inch (127 cm)

Wide Plasma Display

Plasma Contrast Automatic

Tracking System (C.A.T.S.)

3-Dimensional Progressive

VGA Resolution (UXGA

TH-42PW5

42-inch (106 cm)

HD Plasma Display

HD Panel

Progressive Scan

(UXGA Compatible)

Scan

Compatible)

TH-42PHW5

42-inch (106cm)

TH-37PW5

37-inch (94cm)

6

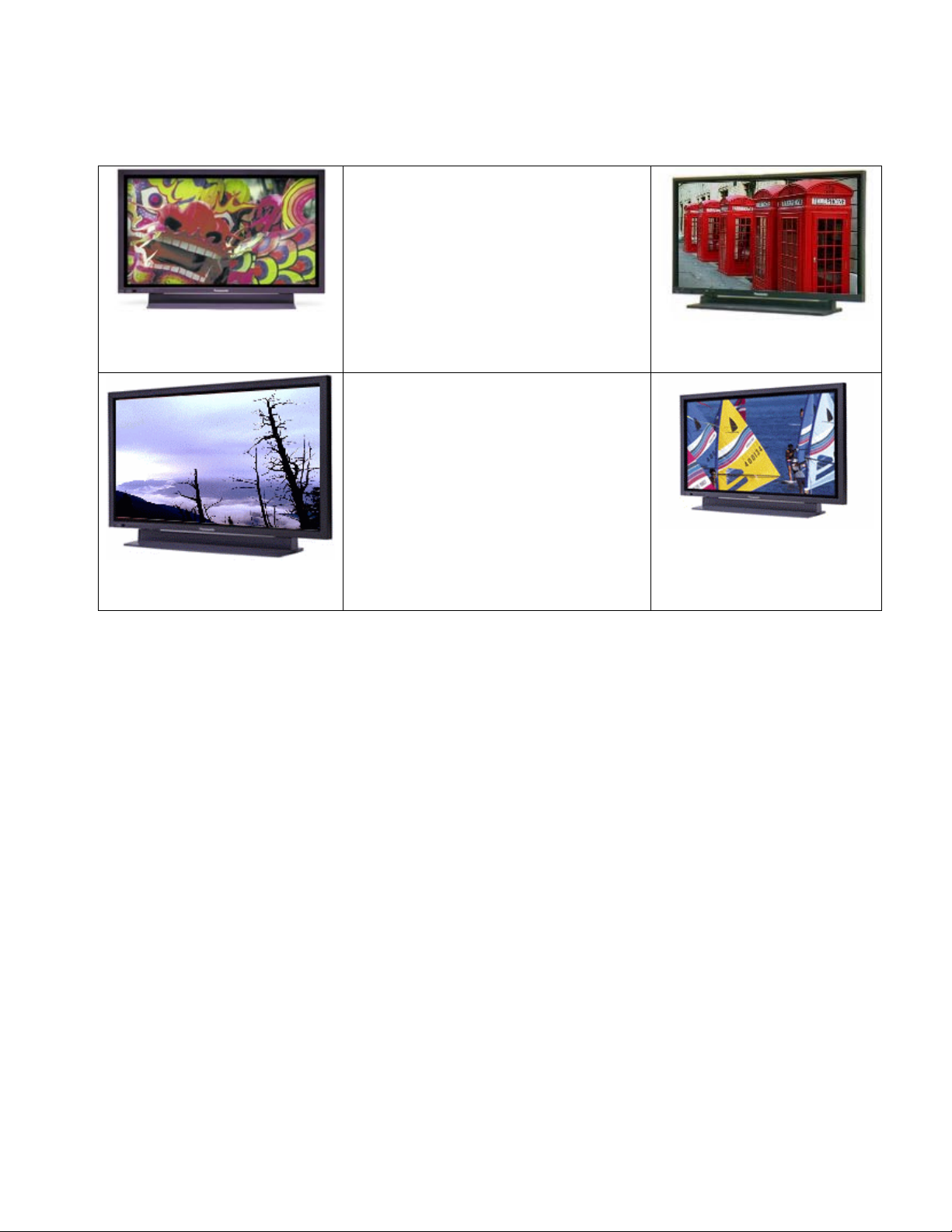

Specifications

Our New 50” & 42” HD Progressive Panels

The industry’s highest-resolution panels

Panasonic Company PI Company F/H

Scanning Method Progressive Progressive

50-

inch

1,366 x 768=

1.05 million pixels

1,280 x 768=

0.98 million pixels

Interlace

N/A

Pixel

pitch

42/43-

inch

Pixel

pitch

Relationship between Picture resolution and Scanning method: 768p > 720p >

680p = 1080i > 1024i

0.810 (H) x 0.810 (V)

= 0.656

(42” Screen size)

1,024 x 768=

0.79 million pixels

0.898 (H) x 0.674 (V)

= 0.605

0.858 (H) x 0.808 (V)

= 0.693

(43” Screen size)

1,024 x 768=

0.79 million pixels

0.930 (H) x 0.698 (V)

= 0.649

(42” Screen size)

1,024 x 512=

0.52 million pixels

0.90 (H) x 1.02 (V)=

0.918 / 2= 0.459

[1frame]

7

Features

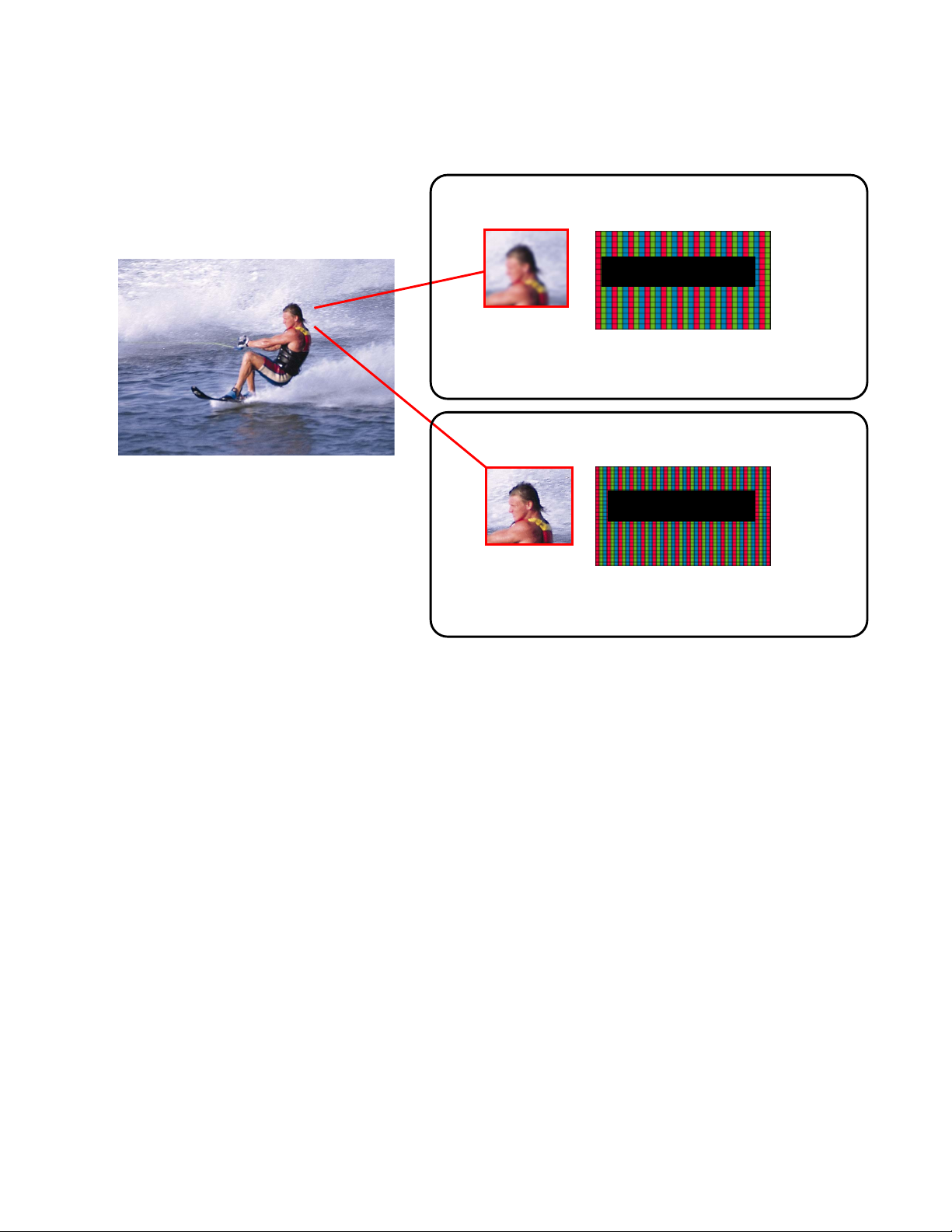

Pixel explanation

SD (Standard Definition) Panel

852 pixels

410,000 Pixels

Provides the optimum number of pixels for viewing

standard broadcasts and DVD.

480 pixels

HD (High-Definition) panel

1,024 pixels

768 pixels

790,000 pixels

Reproduces even the tiniest details of high-definition

sources and other high-quality images.

Figure 1

8

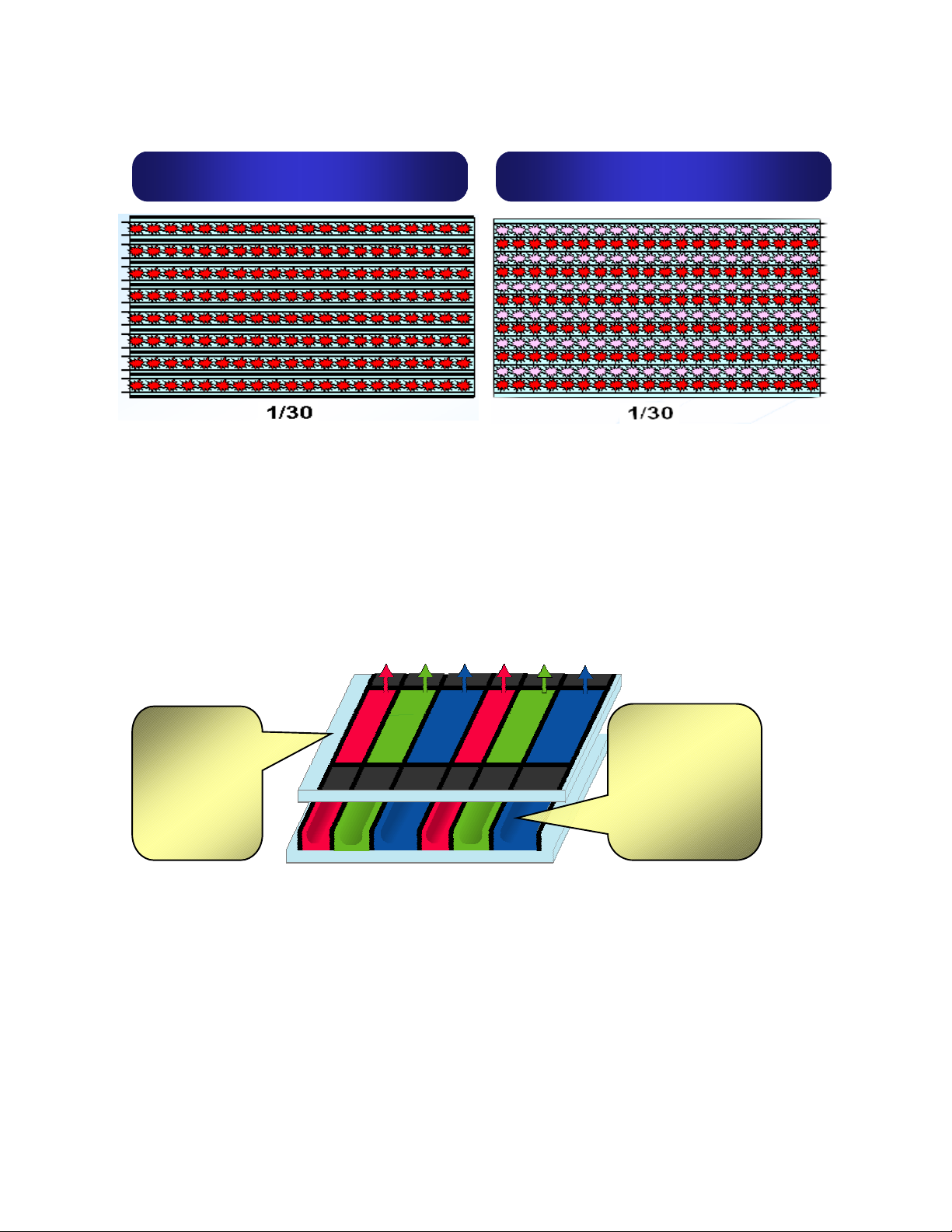

Scan Explanation

Panasonic progressive scan ALIS system Interlace scan

Figure 2

The 1-field (1/60 sec) display pixels on the Panasonic 42" and 37" SD models

and on the ALIS system models are VGA level. (Panasonic HD models are XGA

level, for higher resolution.)

A.L.I.S. (Alternate Lighting of Surfaces) method is one of the new panel driving

systems of plasma display developed by Fujitsu Limited. ALIS method is a

system developed from the 3 electrode discharging system.

The ALIS method uses an interlaced driving scheme, which means the even and

odd lines are addressed alternately.

New front

protection

filter glass

improves

the natural

reds

New

phosphors

improve the

blue color

reproduction.

•

Figure 3

New Asymmetrical Cell Structure Panel

Figure 3 shows the unique asymmetrical cell structure that achieves both high

brightness and crisp whites. The asymmetrical arrangement of the red, blue and

green cells that control color reproduction results in a dramatically improved lightemitting balance of the three primary colors. This reproduces purer whites while

maintaining a high level of brightness.

Model Differences

9

SSiinnggllee SSccaann ((SSDD))

DDuuaall SSccaann ((HHDD))

Figure 4

•Simple and low cost circuit •High performance

•Higher brightness

10

Figure 5

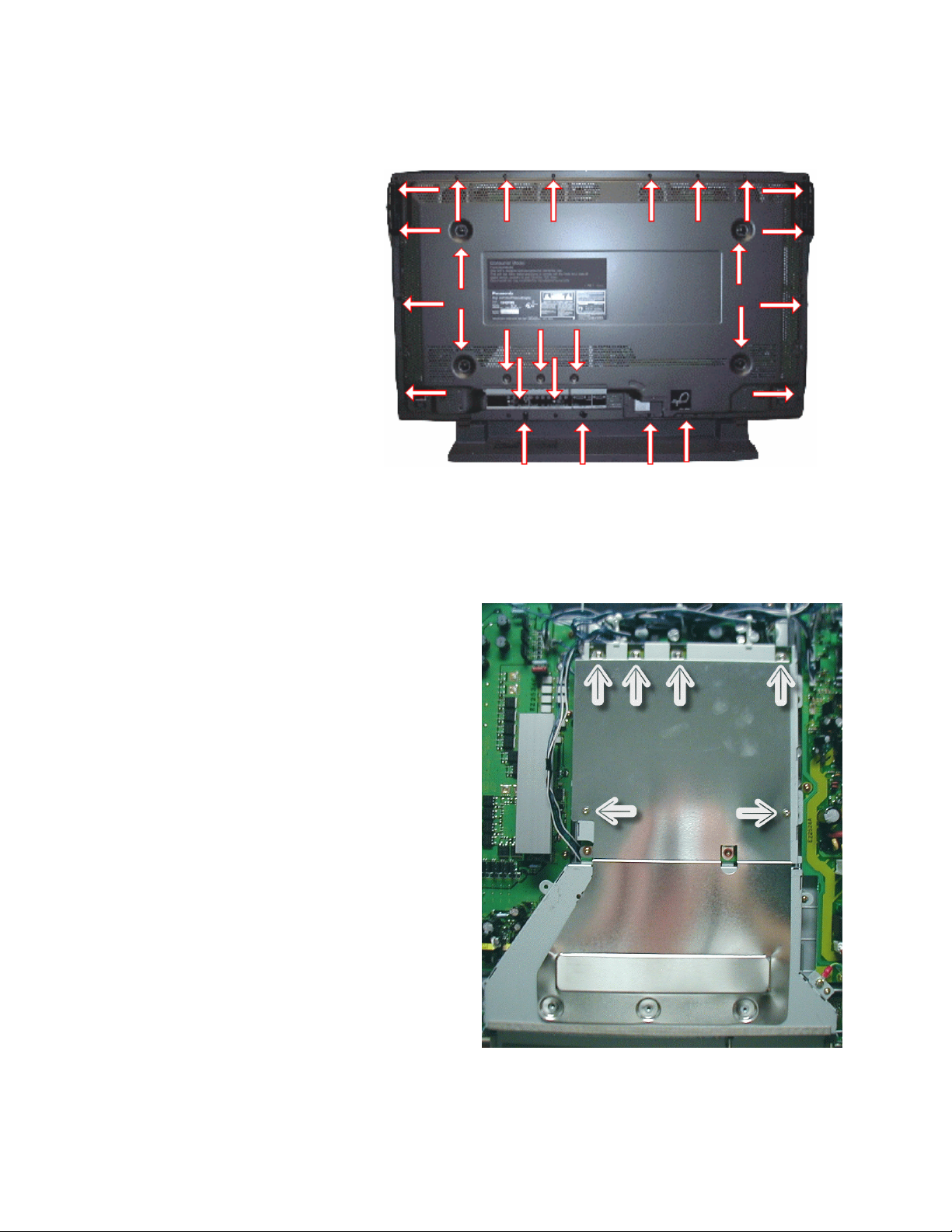

Disassembly

Rear Cover Removal

Remove the 27 screws,

shown in Figure 6, and

then pull away the rear

cover.

Removal of the shield

Remove the six screws, shown in

Figure 7, and then pull away the rear

shield cover.

Figure 6

11

Figure 8

Figure 7

Location of Lead Wiring

High frequency

electromagnetic signals can

create electrical interference

within the unit. Be sure to

route all wires through their

respective harnesses

reference.

The chart below is an

illustration representing the

connectors and the wire

harnesses associated

Clamper Locations

Figure 9

with them.

Harness Number

Connector Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Z6 P6

Z10 D10

Z17 D17

D12 D22

D16 D26

D25 P5

D27 P7

SC2 P2

SC4 P4

SC20 D20

SC21 D21

H37 Z3

H37 Z4

SS1 P1

SS3 P3

SS32 C32

SS42 C42

ESC POWER SS34

ESC V-BOARD C44

F9 P9

Fan 1 P10

Fan 2 P11

Fan 3 P12

Fan 4 P13

= Wind the cable through the clamper once

= Wind the cable through the clamper two times

= Wind the cable through the clamper three times

12

42” HD PCB Board Layout Diagram

Figure 10

Printed Circuit Board Information Table

Board Name Part Number Function

C1 TNPA2428 Data Drive (Upper Left)

C2 TNPA2429 Data Drive (Upper Right)

C3 TNPA2430 Data Drive (Lower Right)

C4 TNPA2431 Data Drive (Lower Left)

D1 TZTNP01LLSB Format Converter

D2 TNPA2427 Plasma AI Sub-Field Processor

F TNPA2444 Line filter

H3 TNPA2249 Speaker terminal

HX TZTNP01LLSU PC type Input terminal

HZ TXNHZ40JJS RCA type Input terminal

P TXN/P10LLS Power supply

P3 TNPA2439 Drive voltage oscillator

P5 TNPA2440 Primary oscillator

P6 TNPA2441 PFC oscillator

P7 TNPA2442 Drive voltage protection

P8 TNPA2443 Process voltage protection

S1 TNPA2283AC Power switch

SC TNPA2434 Scan out

SD TNPA2433 Scan connection (Lower)

SS TNPA2435 Sustain out

SS2 TNPA2436 Sustain connection (Upper)

SS3 TNPA2437 Sustain connection (Lower)

SU TNPA2432 Scan connection (Upper)

V1 TNPA2282AC Front SW. & Remote receiver

Z TNPA2445 Audio out

13

50” PCB Board Layout Diagram

Board Name Part Number Function

C1 TNPA2510 Data Drive (Upper Left)

C2 TNPA2511 Data Drive (Upper Center)

C3 TNPA2512 Data Drive (Upper Right)

C4 TNPA2513 Data Drive (Lower Right)

C5 TNPA2514AB Data Drive (Lower Center)

C6 TNPA2515 Data Drive (Lower Left)

C9 TNPA2608 Energy Recovery Circuit

D1 TZTNP01MHSB Format Converter

D2 TNPA2427AB Plasma AI Sub-Field Processor

F TXN/F10MHS Line filter

H3 TNPA2249 Speaker Terminal

HX TZTNP02KESE PC type Input terminal

HZ TXNHZ40JJS RCA type Input terminal

P1 TXNP110MHS Power supply

P3 TNPA2566 Drive voltage oscillator

P5 TNPA2567 Primary oscillator

P6 TNPA2568 PFC oscillator

P7 TNPA2569 Drive voltage protection

P8 TNPA2570 Process voltage protection

S1 TNPA2283AC Power switch

SC TNPA2434AB Scan out

SD TNPA2518 Scan connection (Lower)

SS TXNSS10MHS Sustain out

SS2 TNPA2519 Sustain connection (Upper)

SS3 TNPA2520 Sustain connection (Lower)

SU TNPA2517 Scan connection (Upper)

V1 TNPA2282AC Front SW. & Remote receiver

Z TNPA2445 Audio out

Figure 11

14

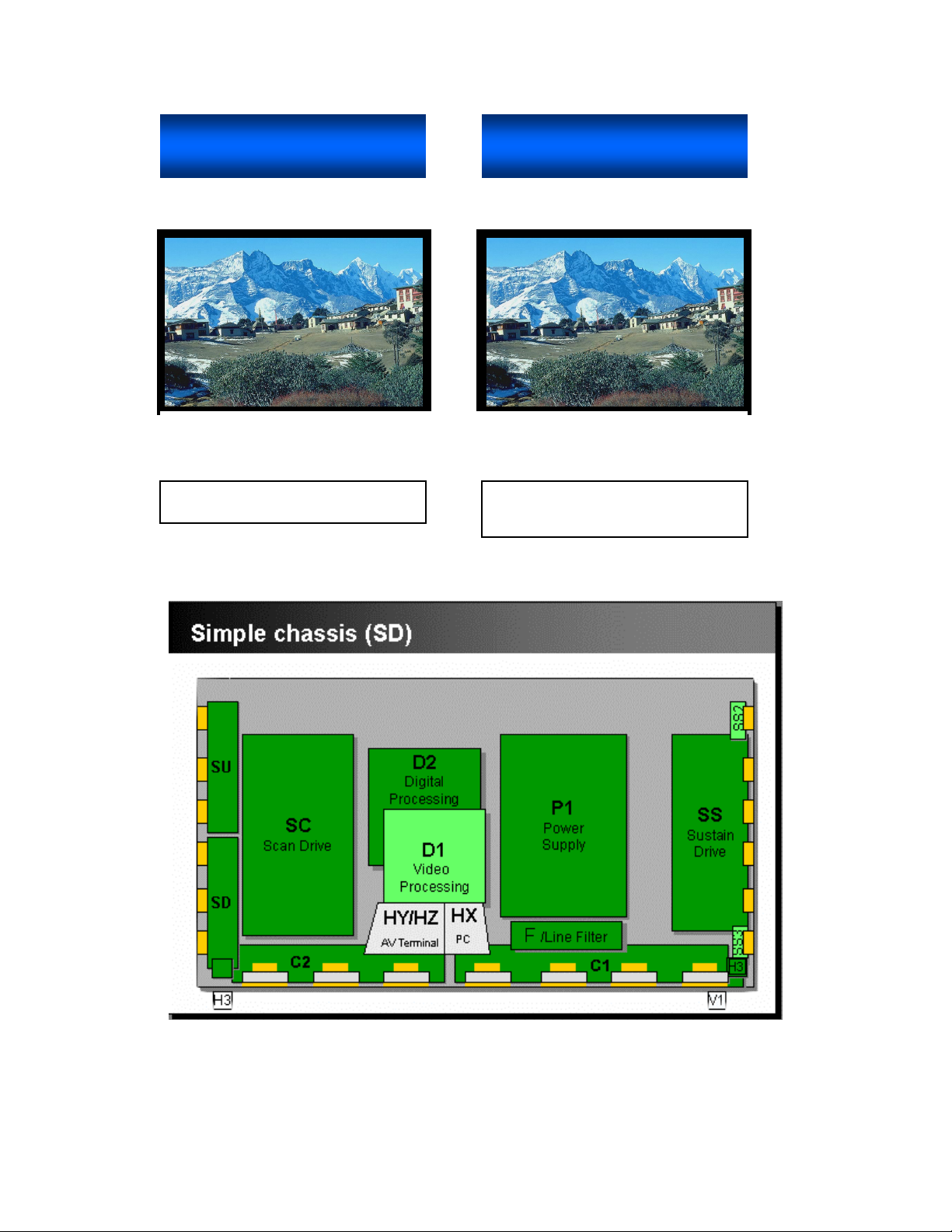

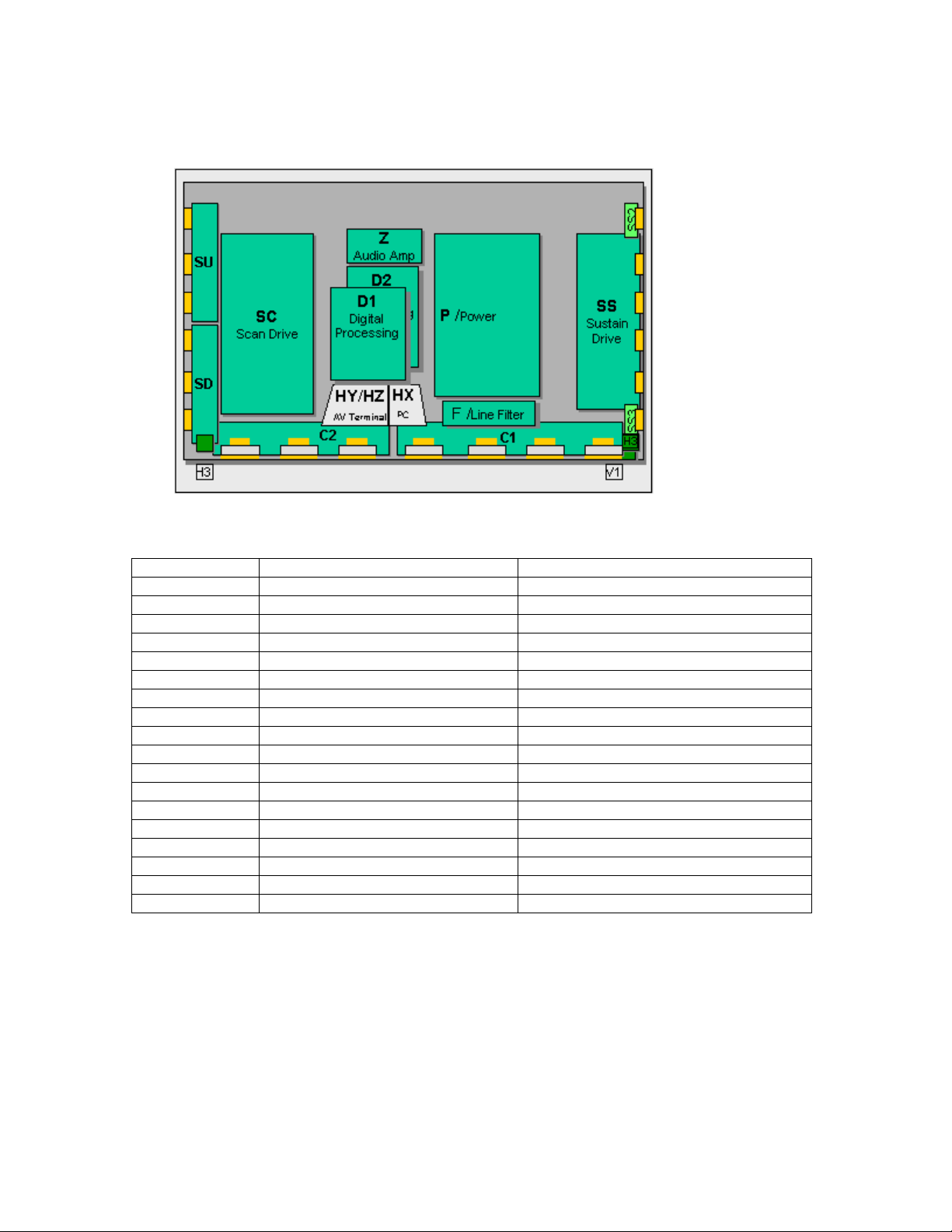

42” SD PCB Layout Diagram

Figure 12

Board Name Part Number Function

C1 TNPA2540 Data Drive (Lower Right)

C2 TNPA2541 Data Drive (Lower Left)

D1 TZTNP01MMSB Format Converter

D2 TNPA2589 Plasma AI Sub-Field Processor

F TXN/F10MMS Line filter

H3 TNPA2249 Speaker terminal

HX TZTNP020JAS PC type Input terminal

HZ TXNHZ40JJS RCA type Input terminal

P TNPA2598 Power supply

S1 TNPA2622 Power switch

SC TNPA2534 Scan out

SD TNPA2584 Scan Connection (Lower)

SS TNPA2535 Sustain Out

SS2 TNPA2536 Sustain Connection (Upper)

SS3 TNPA2537 Sustain Connection (Lower)

SU TNPA2583 Scan Connection (Upper)

V1 TNPA2621 Front SW. & Remote Receiver

Z TNPA2590 Audio out

15

Video Signal Path Explanation

HY/HZ Board

Figure 13

The "HY/ HZ" board is equipped with one Component input, one Composite input

and one S-Video input. The Composite and S-Video inputs are applied to a

switching circuit, which is controlled by the system control IC, located on the D1Board. The switch select command is sent via the SCL3 and SDA3 lines. After

signal selection the composite or S-Video signals are amplified, buffered, and

applied to a 3D comb filter inside IC3803. The 3D Comb filter converts the

Composite input signals to Y, Pb, and Pr component signals. The output of

IC3804 is applied to the D1 Board via pins 1, 3, and 5 of the connector H2/D2.

Individual amplifiers buffered the Component input signals that are then applied

to the D1-Board via pins 15, 17, and 19 of the connector H2/D2. Vertical and

Horizontal Sync signals are also amplified on this board before they are applied

to the D1 Board.

16

HX Board

Figure 14

PC RGB Signals are input to the HX Board. The RGB signals as well as the

vertical and horizontal sync signals are amplified by a series of transistor

amplifiers. The RS232C communications bus line is also connected on this

board. The RS-232C connection is provided so that operation changes can be

made via PC. An example of an application of this port would be remote turn on

of the unit for a kiosk or similar display.

The outputs of the HX board are applied to the D1 board via connector HX1/D3.

17

D1 Board

Figure 15

After the input signals are amplified by the HY/HZ and HX boards the desired

signal is selected. The microprocessor sends the command via the IIC bus to the

input select switch (IC3001). The video switch selects from one of the three

inputs. The component video signal output from the video switch is amplified and

converted to digital. An optional Digital Visual Interface (DVI) input bypasses the

A/D process as DVI information is already in the digital format.

Concurrently, the desired sync signals are selected and applied to the Sync

Processor. NTSC and Component sync signals are stripped from the Green

video component while the PC sync is applied directly. The Sync Processor

combines the On-Screen Display Sync signal with the input sync and converts

them to match the video format.

The corresponding audio signal is selected by an Audio switch and applied to the

Z board for further amplification

18

DVI Interface

Figure 16

An optional Digital Visual Interface (DVI) module connection is provided on this

generation Plasma Display Panels. The DVI interface allows direct digital transfer

from a display device to

the panel. A VGA or

component video signal

requires a conversion

from the digital to

analog and then

conversion back to

digital prior to input to

the Format converter see

Figure 17. The double

conversion can introduce

distortion to the signal.

Figure 17

19

Figure 18 shows an

example of the DVI

interface. It permits direct

connection of the digital

video signal to the Format

converter. This bypasses

the D/A and A/D process

providing the better

quality picture.

Installation of the DVI interface requires removal of the HY/HZ Board and

replacing it with an optional DVI interface board.

Figure 18

20

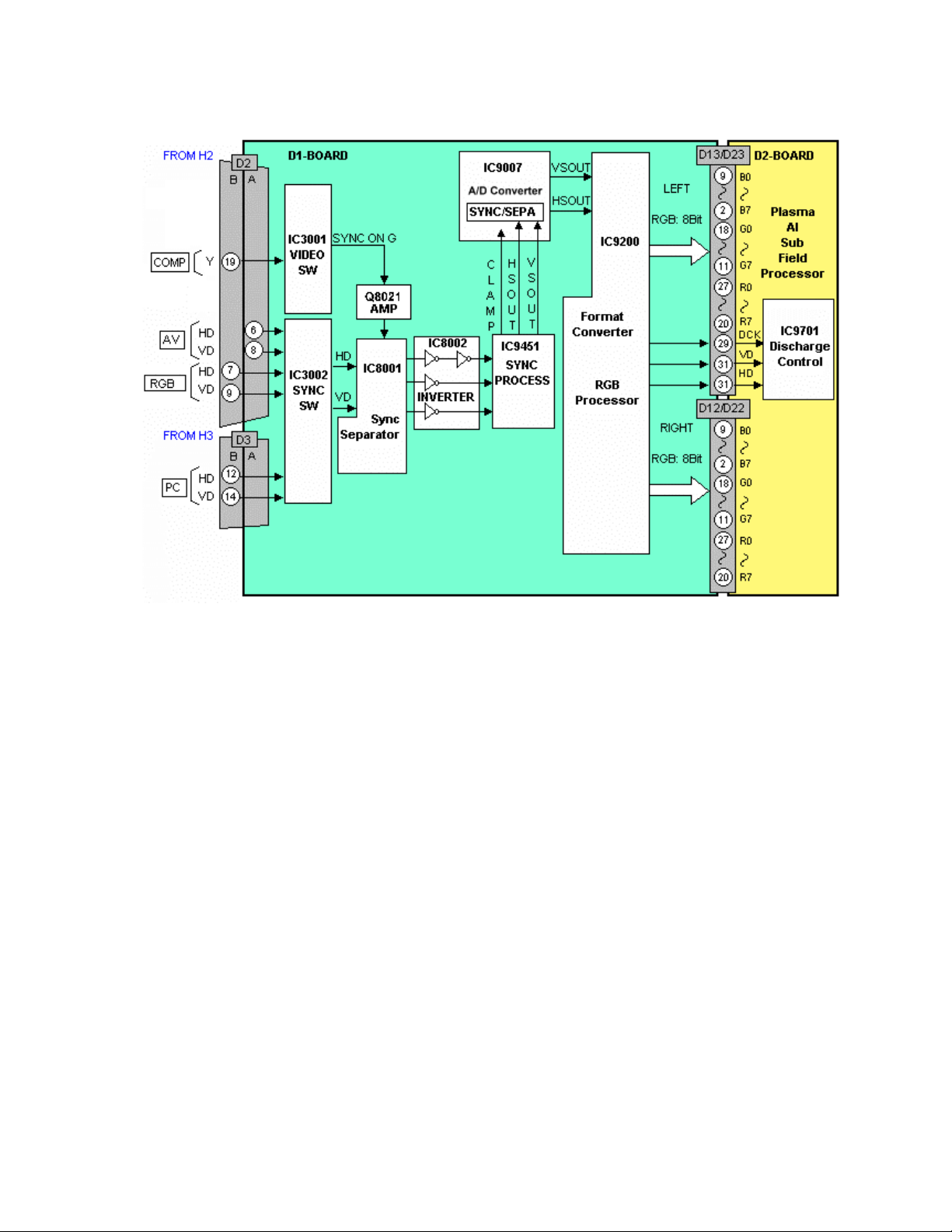

Sync Process

Figure 19

The vertical and horizontal sync signal paths are slightly different depending on

the Source signal.

AV/RGB/PC Input Mode Sync

The vertical and horizontal sync signals generated by the input device are

applied to connector D3 or D2 to a Sync switch (IC3002). IC3002 outputs the

vertical and horizontal sync signals. The signals are inverted by IC8002 and then

applied to a sync processor (IC9451). IC9451 mixes the image sync signal with

the OSD sync signal prior to output to the format converter (IC9200).

Component Video Input mode Sync

The Y video signal is applied to an input switch (IC3001). The Sync on green

signal is amplified by Q8001 and applied to a sync separator (IC8001). IC8001

outputs the Vertical and Horizontal sync signals. From that point on the sync path

is the same as the RGB/PC input mode.

The A/D converter (IC9007) shapes the analog sync signal to clean digital pulses

prior to input to the format converter.

21

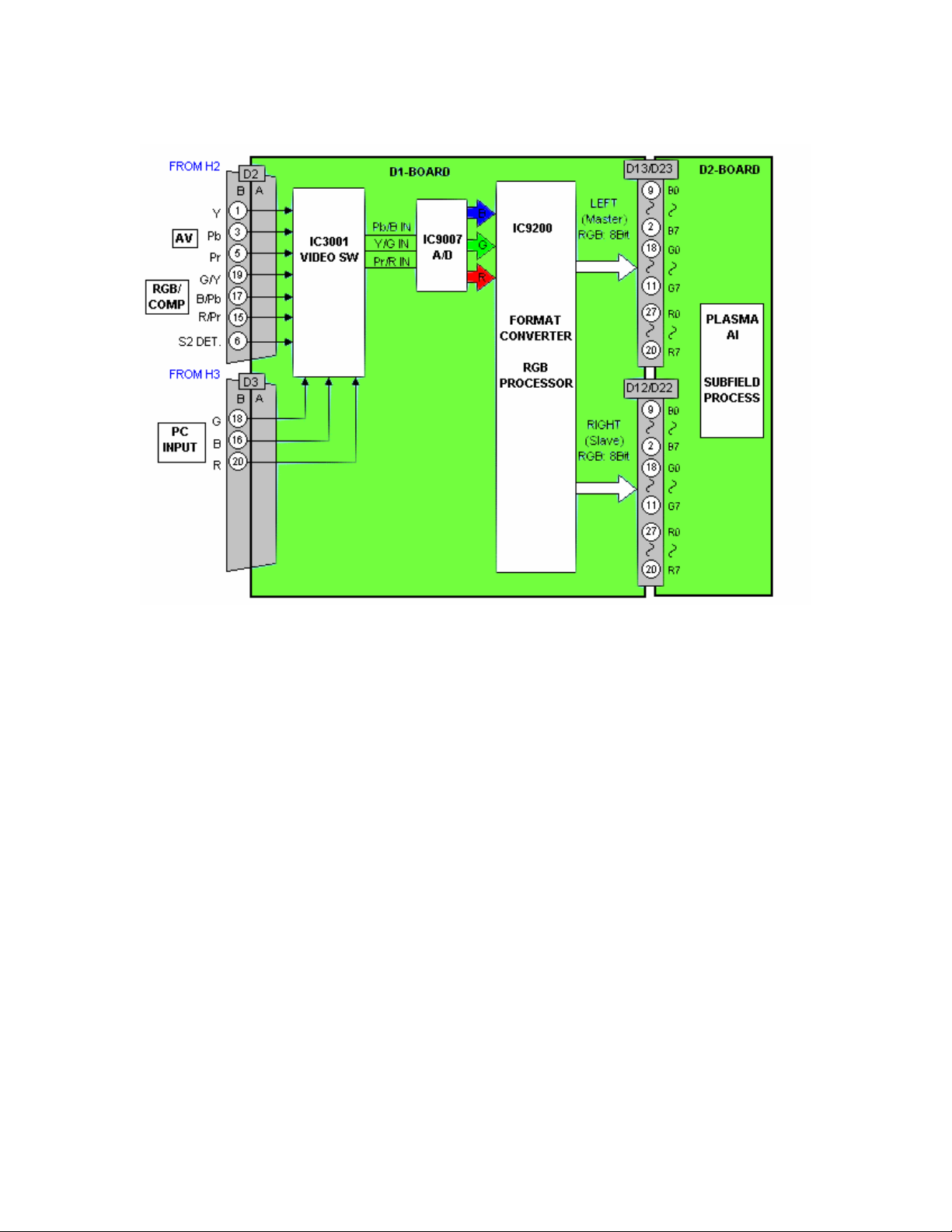

D1 Board

Figure 20

D1-board consists of the Analog and Digital signal process. It also contains the

Discharge control and Microprocessor control block. Supply voltages of 13.5V,

5V, Standby 5V, 3.3V, and 1.8 V operate the D1-board. The input RGB video

signals are at 0.7Vp-p. Video signals in the form of parallel data and the control

signals for the data drive circuit are output.

D1 Main ICs Operation

IC3001 Video Switch

The user selects the desired video input using the front panel button or the

remote control. The microprocessor reads this data and sends out a command

via the IIC bus line. The IIC data is read by IC3001 and the video input is chosen.

IC9007 A/D Converter

This integrated circuit converts the RGB analog signals to eight bit parallel data.

IC9200 Format Converter

The digital video data is converted to progressive scan and mixed with the OSD

data. Other adjustments such as white balance, contrast and color are also

corrected here. The two channels of data are output to the D2 board for the subfield drive circuit.

22

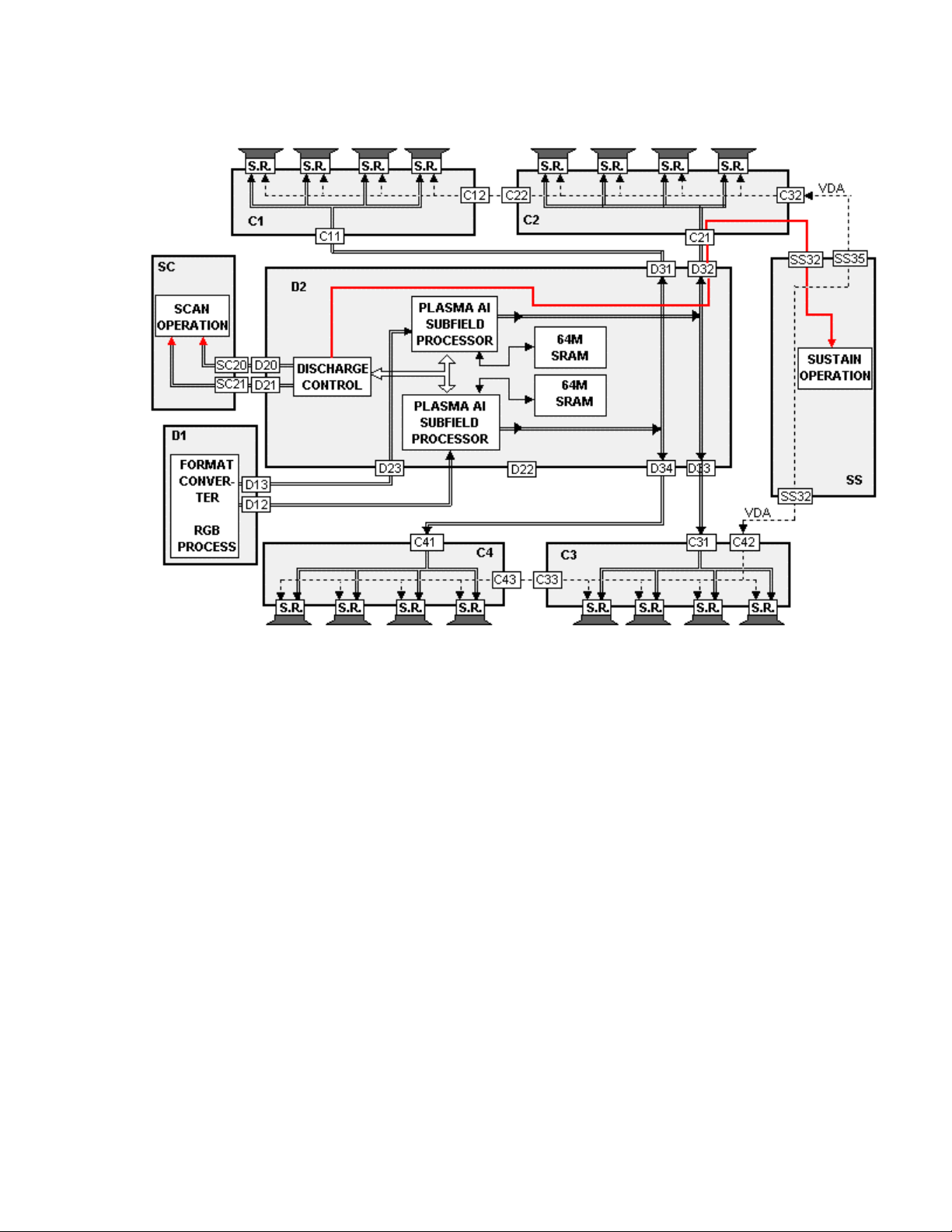

D2 Board

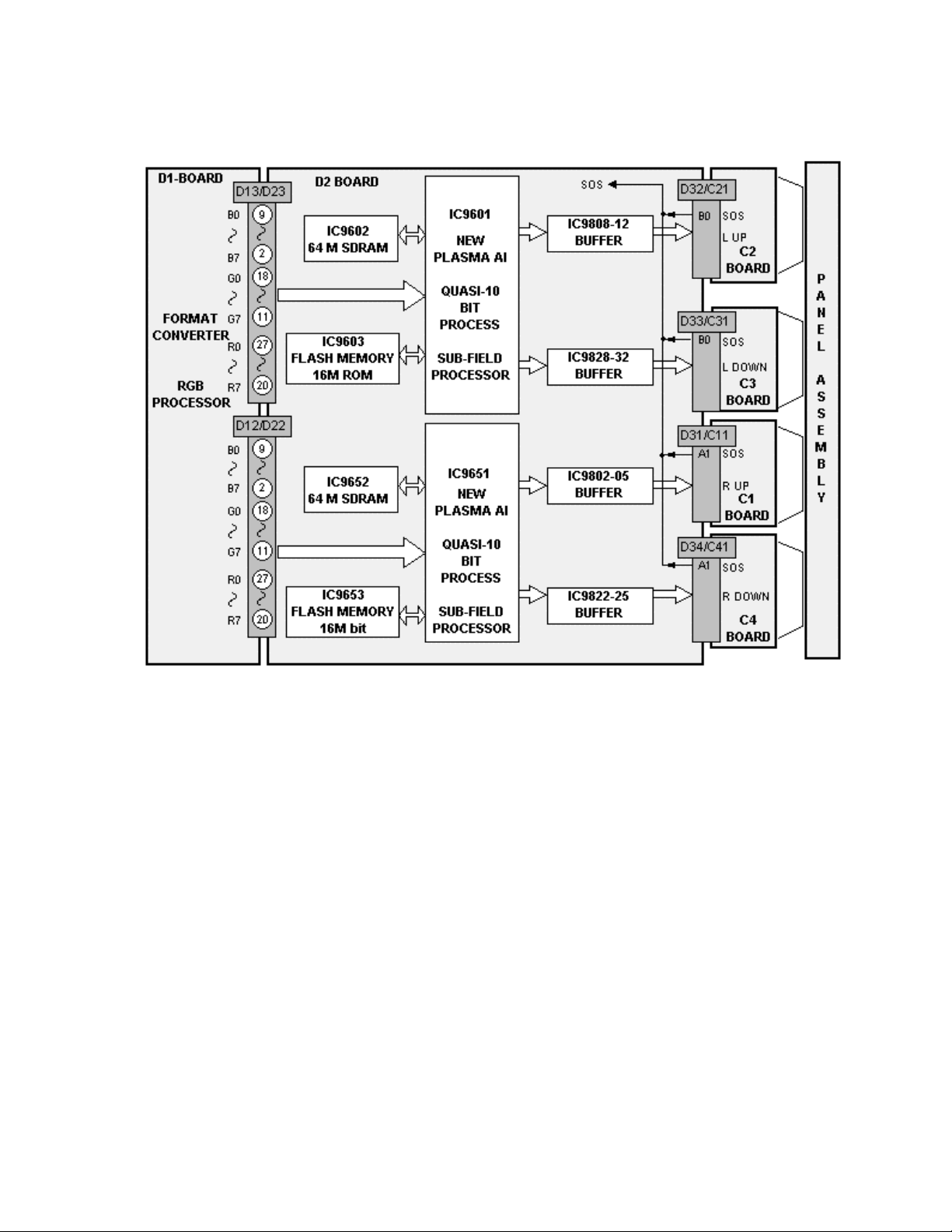

Figure 21

The D2 board provides the scan, sustain and data drive signals. The scan pulses

are output to the SC board. The sustain pulses are output to the SS board. The

data drive signals are output to the C1, C2, C3 and C4 boards. The C1 board

drives the Upper right portion of the panel; the C2 board drives the upper left

portion. The C3 and C4 boards drive the lower right and left portions of the panel

respectively.

23

D2 Board details

Figure 22

The Plasma AI (Adaptive brightness Intensifier) circuits analyze the video

program level for the distribution of dark and bright components. The upper and

lower eight bit video signals are memorized into two Plasma AI processors

IC9651 and IC9601. The Plasma AI circuits converts the 8 bit signal data to 10

bit signal data. The Flash memories contain the algorithms for the AI circuit. Two

AI processors are used to speed up the scanning process and control the

number of sustain periods. This increases the brightness and improves the

contrast ratio.

24

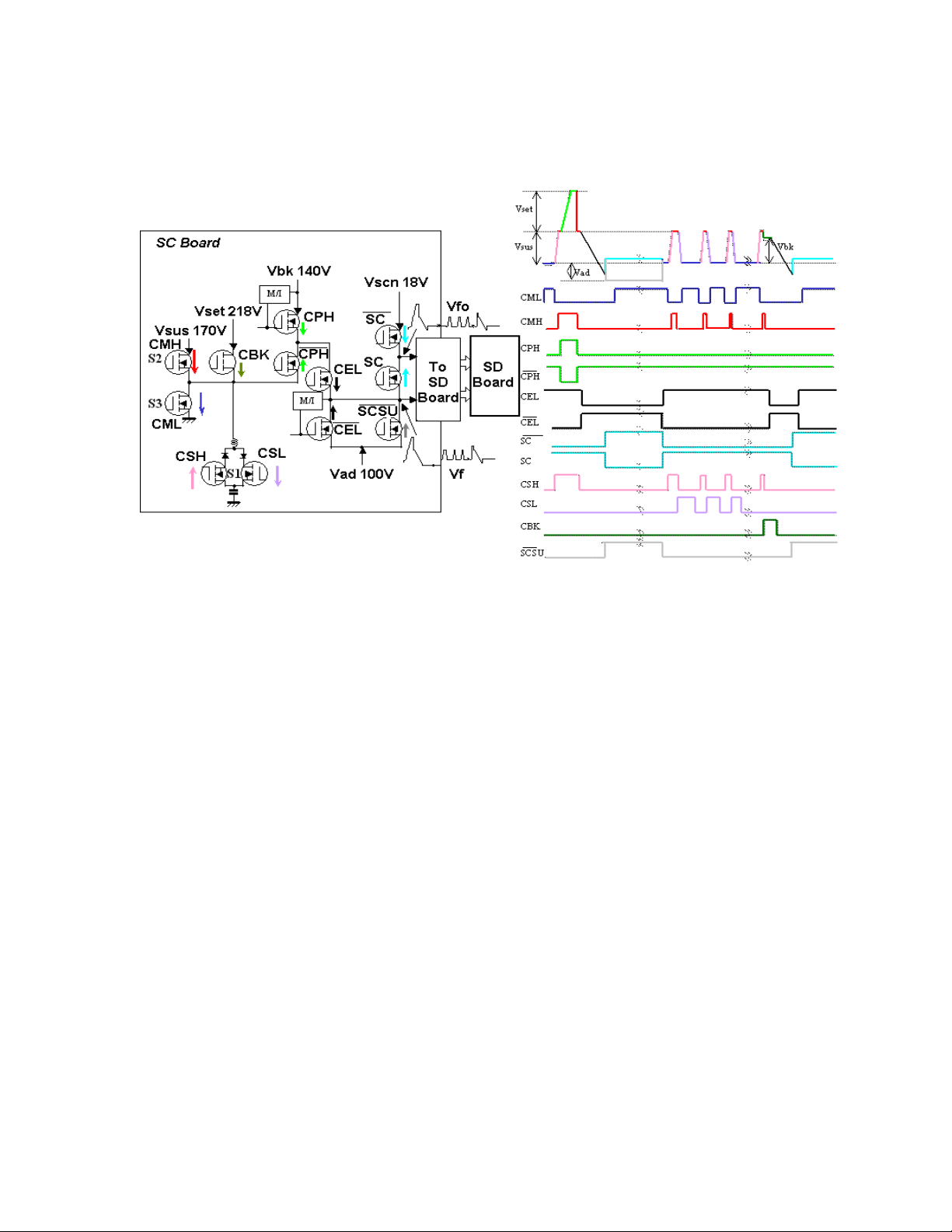

SC Board Explanation

Figure 23

25

Figure 24

The SC Board consists of buffers and drivers used to generate the scan signals

to the panel. The buffers provide isolation between the D2 board and the drivers.

Connector SC20 provides the drive voltages (140V, 100V and 18V). Connector

SC21 provides trigger signals to switch the FET transistors. The D2 board

switches the FETs on and off to create the distinctive scan signal. Each trigger

signal switches a drive FET creating a portion of the waveform. For example,

applying the CPH signal to the 140V FET creates the peak portion of the

waveform, see figure 23.

26

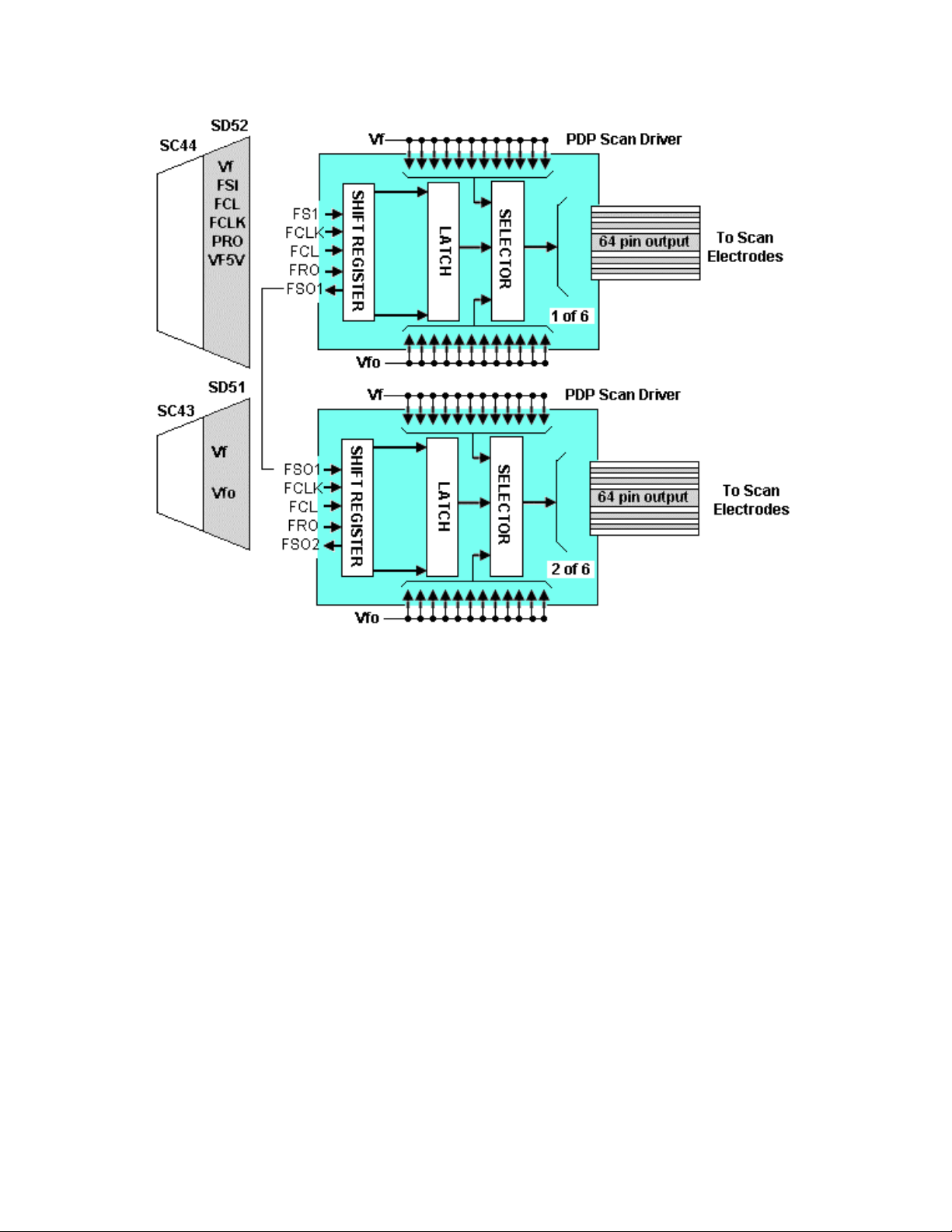

Figure 25

After the scan waveform is developed on the SC Board, it is applied to the SU

and SD boards for de-multiplexing. The signal is input to a series of shift registers

inside the PDP scan driver IC. Figure 25 shows an example of the demultiplexing circuit. There are six driver ICs on the SU board and six on the SD

board.

27

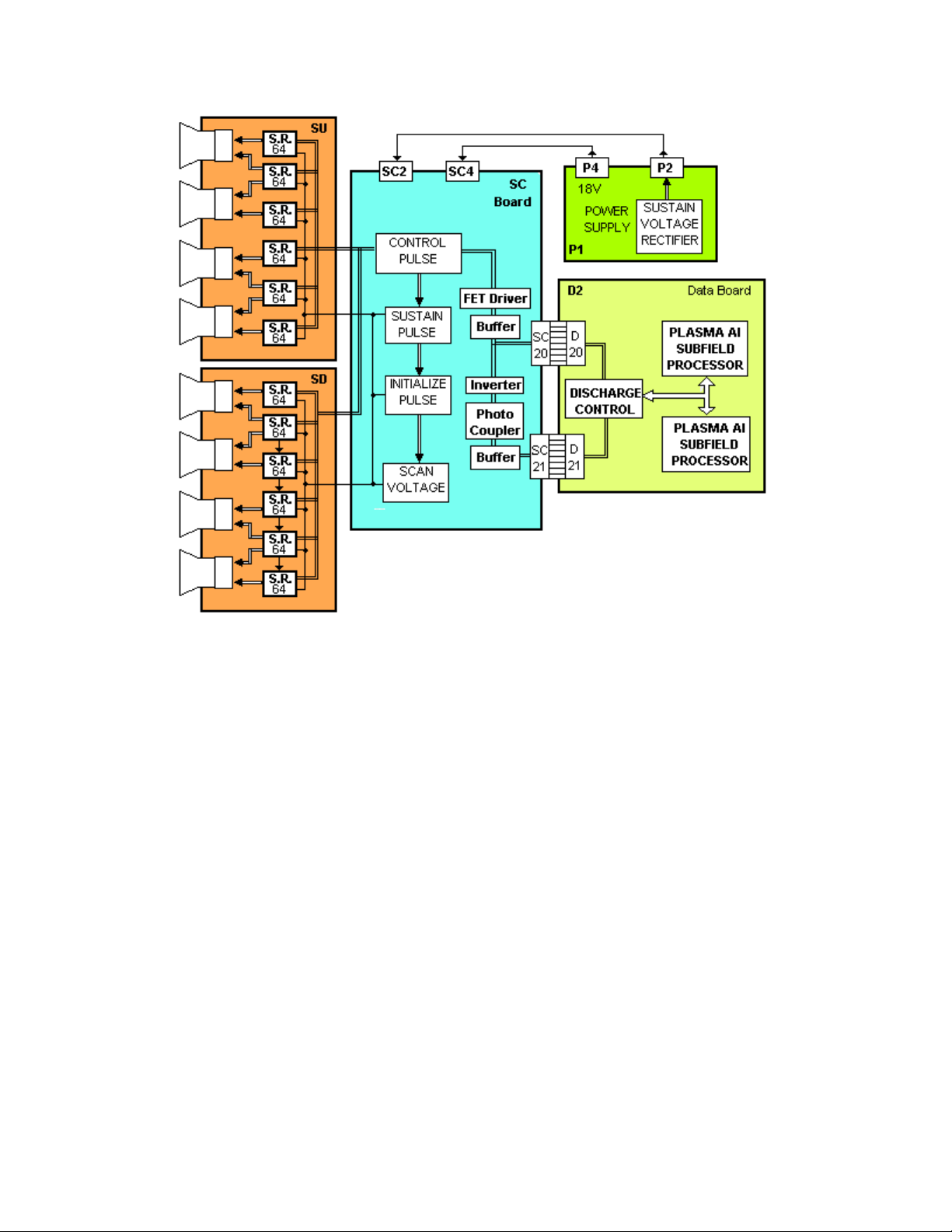

SS Board Explanation

Figure 26

After the video signal is processed on the D2 board, the sustain and erase pulses

are output to the SS board. The erase pulse is output at the beginning of each

scan period. The pulse is applied to the SS2 and SS3 boards to remove the

previous charge for the upper and lower sections of the display panel.

The sustain pulses are also developed on the D2 board and are applied after the

scan periods.

28

Loading...

Loading...