Panasonic TH-42PA60L Service manual

Plasma Television

TH-42PA60L

GP9DE Chassis

ORDER NO.ITD0604013AE

Please file and use this manual together with the service manual for Model No.TH-42PA60A,

Order No.ITD0603007.

Specifications

Power Source AC 110-220 V, 50 / 60 Hz

Power Consumption

Average use 294 W

Standby condition 0.3 W

Plasma Displ ay panel

Drive method AC type

Aspect Ratio 16:9

Contrast Ratio Max 10000:1

Visible screen size

(No. of pixels)

Sound

Speaker 12 cm × 6 cm × 2 pcs, 8 W

Audio Output 20 W (10 W + 10 W ), 10% THD

106 cmV

920 mm (W) × 518 mm (H) × 1,056 mm (diagonal)

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TH-42PA60L

Receiving Systems /

Band name

Receiving Channels

(Regular TV)

Aerial - Rear VHF / UHF

Operating Conditions Temperature : 0°C-40°C

Connection Terminals

AV1 Input AUDIO L-R RCA PIN Type × 2 0.5 V[rms]

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 W)

SVIDEO Mini Din 4-pin Y: 1.0 V[p-p] (75 W) C: 0.286 V[p-p] (75 W)

AV2 Input AUDIO L-R RCA PIN Type × 2 0.5 V[rms]

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 W)

COMPONENT Y 1.0 V[p-p] (including synchronization)

AV3 Input AUDIO L-R RCA PIN Type × 2 0.5 V[rms]

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 W)

COMPONENT Y 1.0 V[p-p] (including synchronization)

Others HDMI Input TYPE A Connector

Audio Input RCA PIN Type × 2 0.5 V[rms]

Monitor

Output

Dimensions ( W × H × D )

Weight

AUDIO L-R RCA PIN Type × 2 0.5 V[rms] (high impedance)

VIDEO RCA PIN Type × 1 1.0 V[p-p] (75 W)

VHF BAND UHF BAND CATV

2-13 (NTSC M USA) 14-69 (NTSC M USA) 1-125 (USA CATV)

Humidity : 20 % - 80 % RH (non-condensing)

PB/CB,PR/C

PB/CB,PR/C

1,068 mm × 701 mm × 97 mm (TV Set only)

1,068 mm × 764 mm × 320 mm (With Pedestal)

29.0 kg Net (TV Set only)

31.0 kg Net (With Pedestal)

R

R

±0.35 V[p-p]

±0.35 V[p-p]

Notes:

· Design and Specifications are subject to change without notice. Weight and Dimensions shown are approximate.

CONTENTS

Page Page

1 Difference PCB Structure sheet 4

2 Service Mode Function

2.1. How to enter SERVICE 1

2.2. How to enter SERVICE 2

2.3. Option Description

3 Adjustment

3.1. PAL panel white balance adjustment

3.2. HD white balance adjustment

3.3. Sub bright adjustment

3.4. ABL adjustment

10

11

12

5

5

5

7

9

9

3.5. Sub-Contrast adjustment

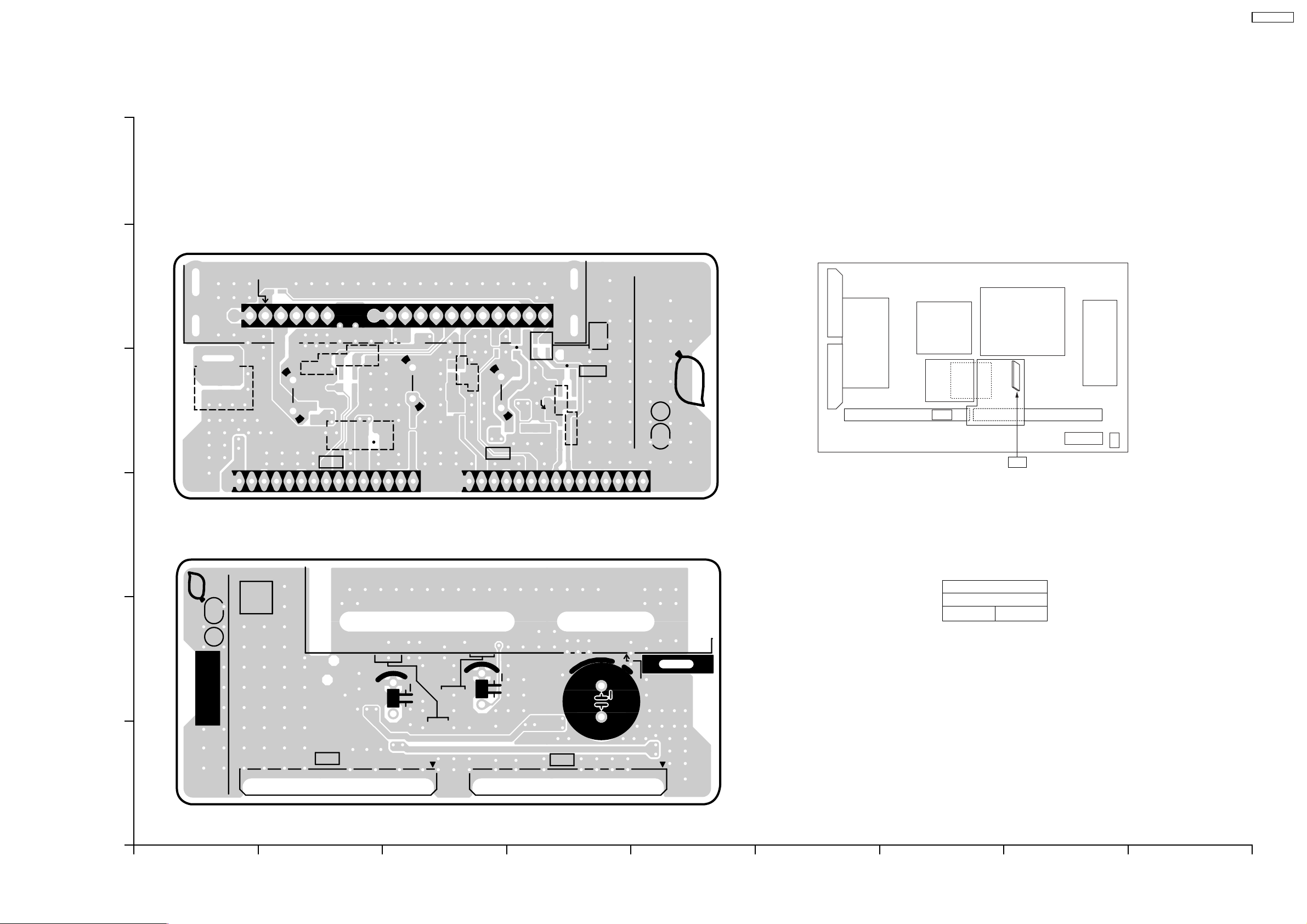

4 Conductor Views

4.1. TU-Board

4.2. DG-Board

5 Schematic and Block Diagram

5.1. Schematic Diagram Note

5.2. Main Block Diagram

5.3. TU-Board Block and Schematic Diagram

5.4. DG-Board (1 of 3) Block Diagram

5.5. DG-Board (2 of 3) Block Diagram

13

15

15

16

19

19

20

21

22

23

2

TH-42PA60L

5.6. DG-Board (3 of 3) Block Diagram 24

5.7. DG-Board (1 of 8) Schematic Diagram

5.8. DG-Board (2 of 8) Schematic Diagram

5.9. DG-Board (3 of 8) Schematic Diagram

5.10. DG-Board (4 of 8) Schematic Diagram

5.11. DG-Board (5 of 8) Schematic Diagram

5.12. DG-Board (6 of 8) Schematic Diagram

5.13. DG-Board (7 of 8) Schematic Diagram

5.14. DG-Board (8 of 8) Schematic Diagram

6 Parts Location & Mechanical Replacement Parts List

6.1. Parts Location 33

25

26

27

28

29

30

31

32

33

6.2. Packing Exploded Views (1)

6.3. Packing Exploded Views (2)

6.4. Packing Exploded Views (3)

6.5. Stand Exploded Views

6.6. Mechanical Replacement Parts List (PDP TV)

6.7. Mechanical Replacement Parts List (Stand)

7 Electrical Replacement Parts List

7.1. Replacement Parts List Notes

7.2. Electrical Replacement Parts List

34

35

36

37

38

39

40

40

41

3

TH-42PA60L

1 Difference PCB Structure sheet

n

nPrint List

nn

Board name Part No. Function Remarks

TH-42PA60A TH-42PA60L

C1 TNPA3799AB Data Draiver (Left)

C2 TNPA3800AB Data Draiver (Right)

S TZTNP01BMTB Format Converter, Plasma AI Processor

H TNPA3760AC AV Terminal, AV switch

HC TNPA3852 JIG Connection

K TNPA3603AH Remote receiver, LED, Keyscan

P TNPA3911AB Power Supply

PA TNPA3761AH DC-DC Converter, Power SOS

S TNPA3604AD Power Switch

SC TNPA3794AB Scan Drive

SD TNPA3875AB Scan Out (Lower)

SS TNPA3795AB Sustain Drive

SU TNPA3874AB Scan Out (Upper)

DG TNPA3756CQ TNPA3756CY Digital Signal Processor Changed

TA TNPA3768AC ----- Tuner Deleted

TU ----- TNPA3851 Tuner Added

4

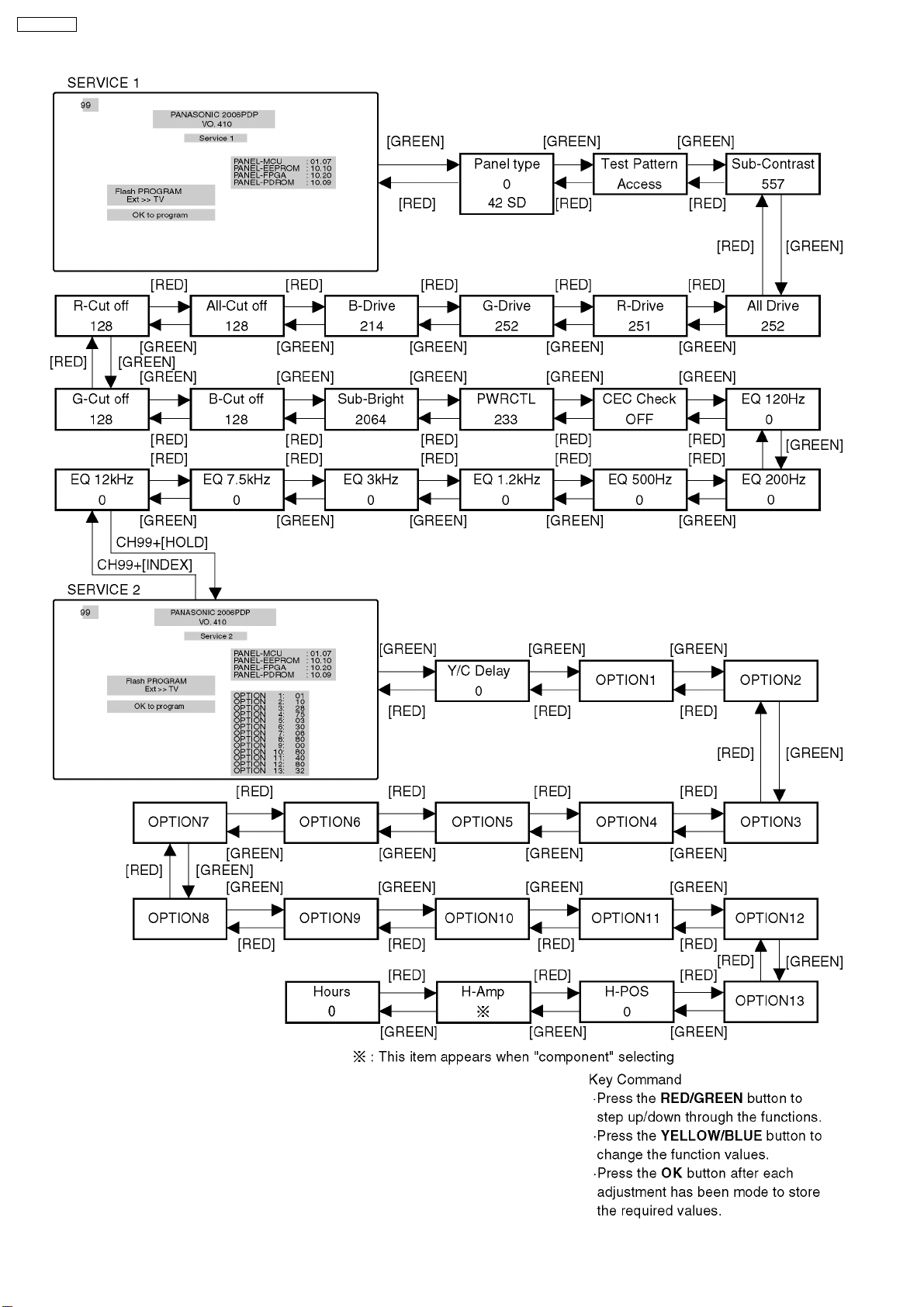

2 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Mode.

2.1. How to enter SERVICE 1

1. In sound menu, set BASS to MAXIMUM, and set TREBLE to MINIMUM.

2. Set the Volume to minimum, and set the off timer.

3. Simultaneously press Recall button on remote control and DOWN button [

2.2. How to enter SERVICE 2

1. Set the channel to CH99.

2. Select the EQ 12kHz.

3. Press Mute button on remote control and DOWN button [

Note:

To exit to Service mode, press EXIT or Power button on remote control.

]ontheTVset.

]ontheTVset.

TH-42PA60L

5

TH-42PA60L

6

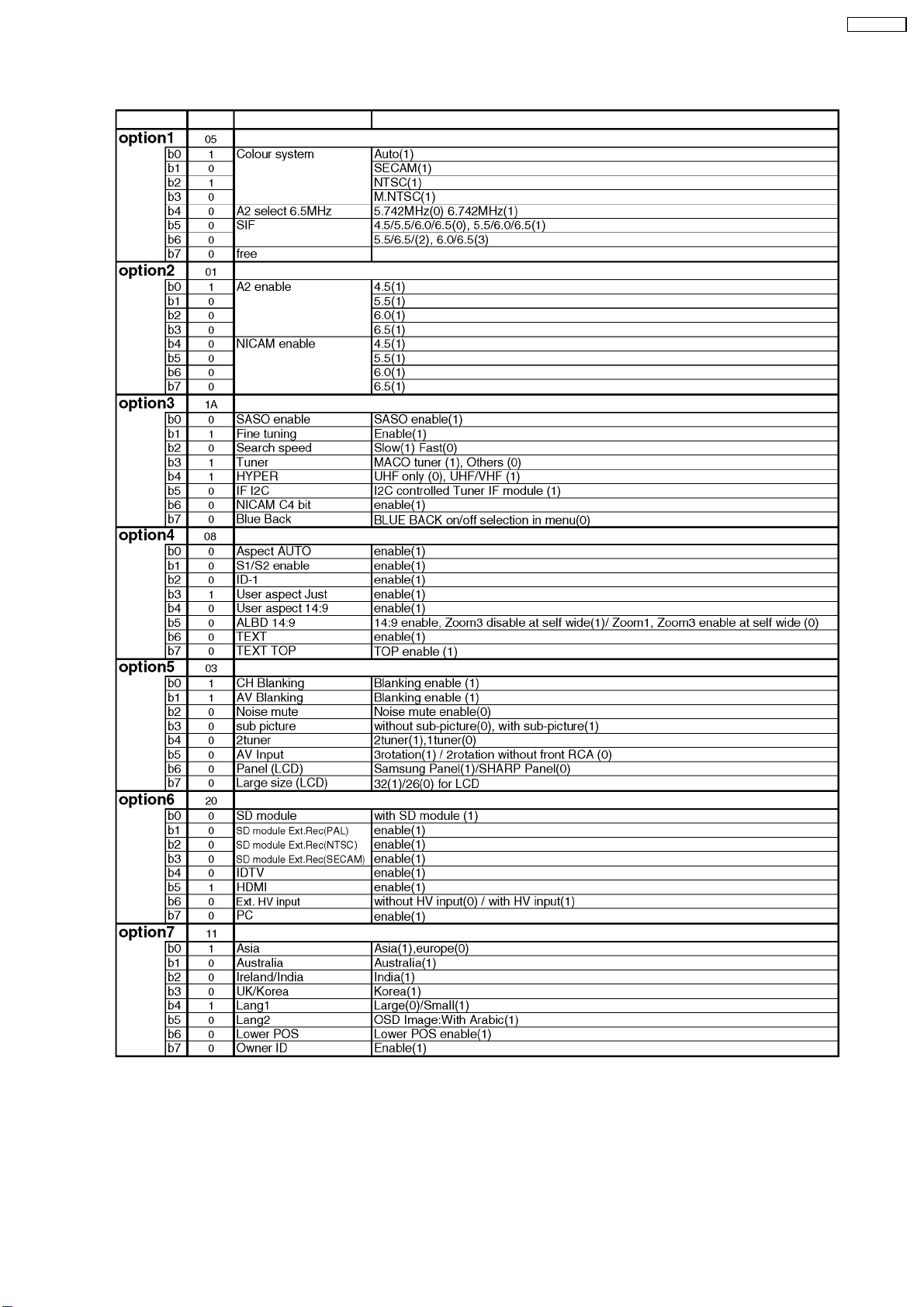

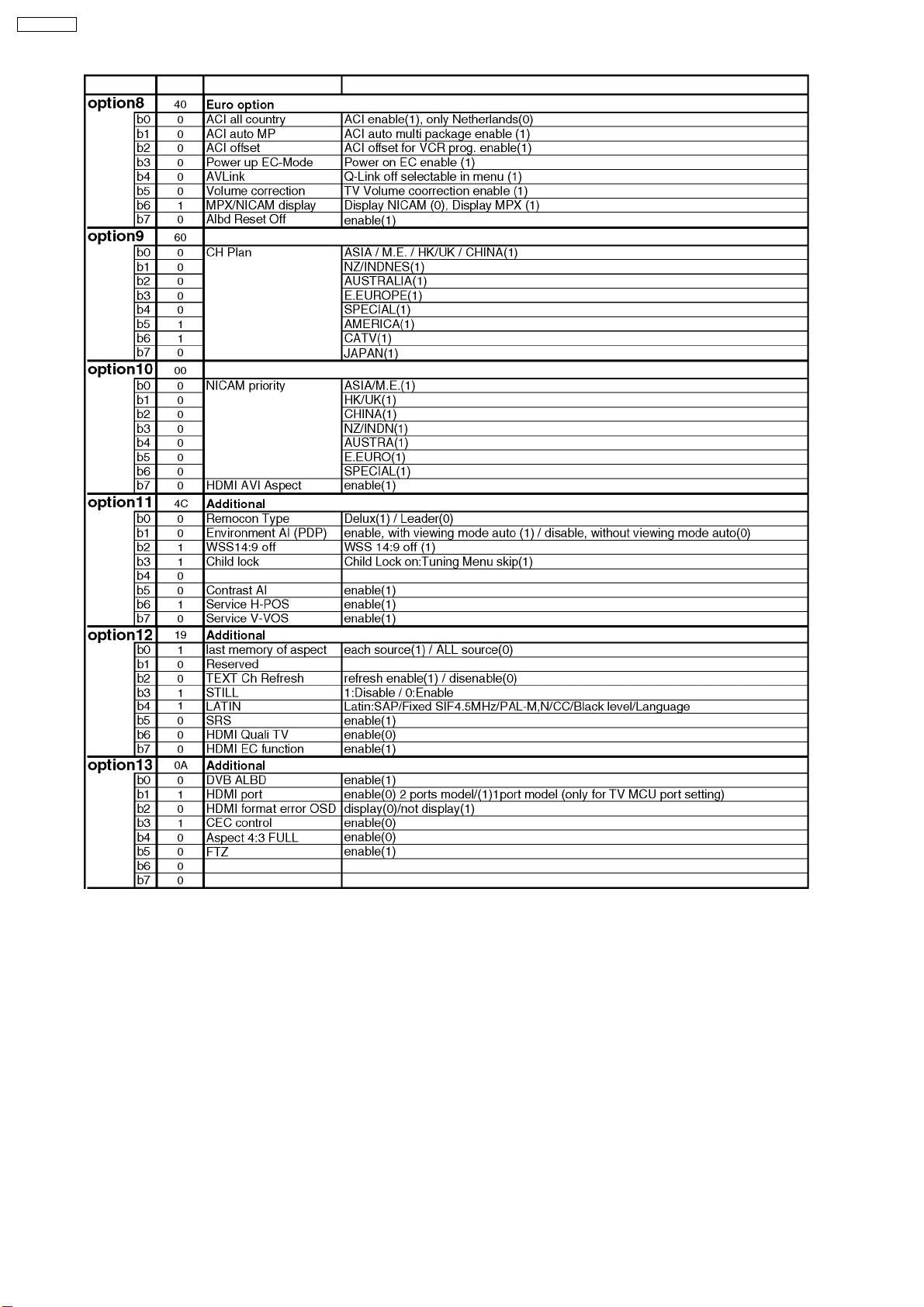

2.3. Option Description

TH-42PA60L

7

TH-42PA60L

8

3 Adjustment

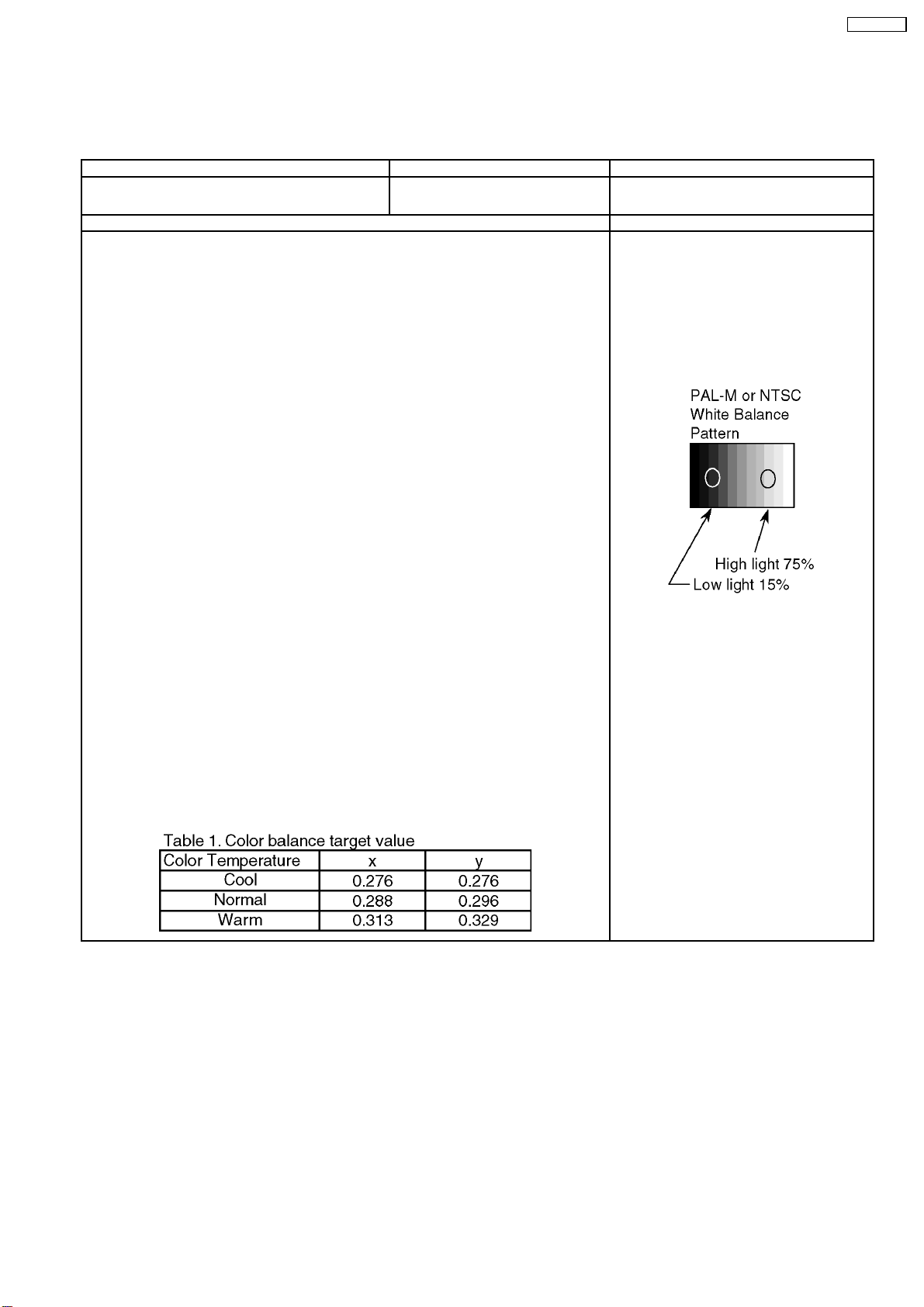

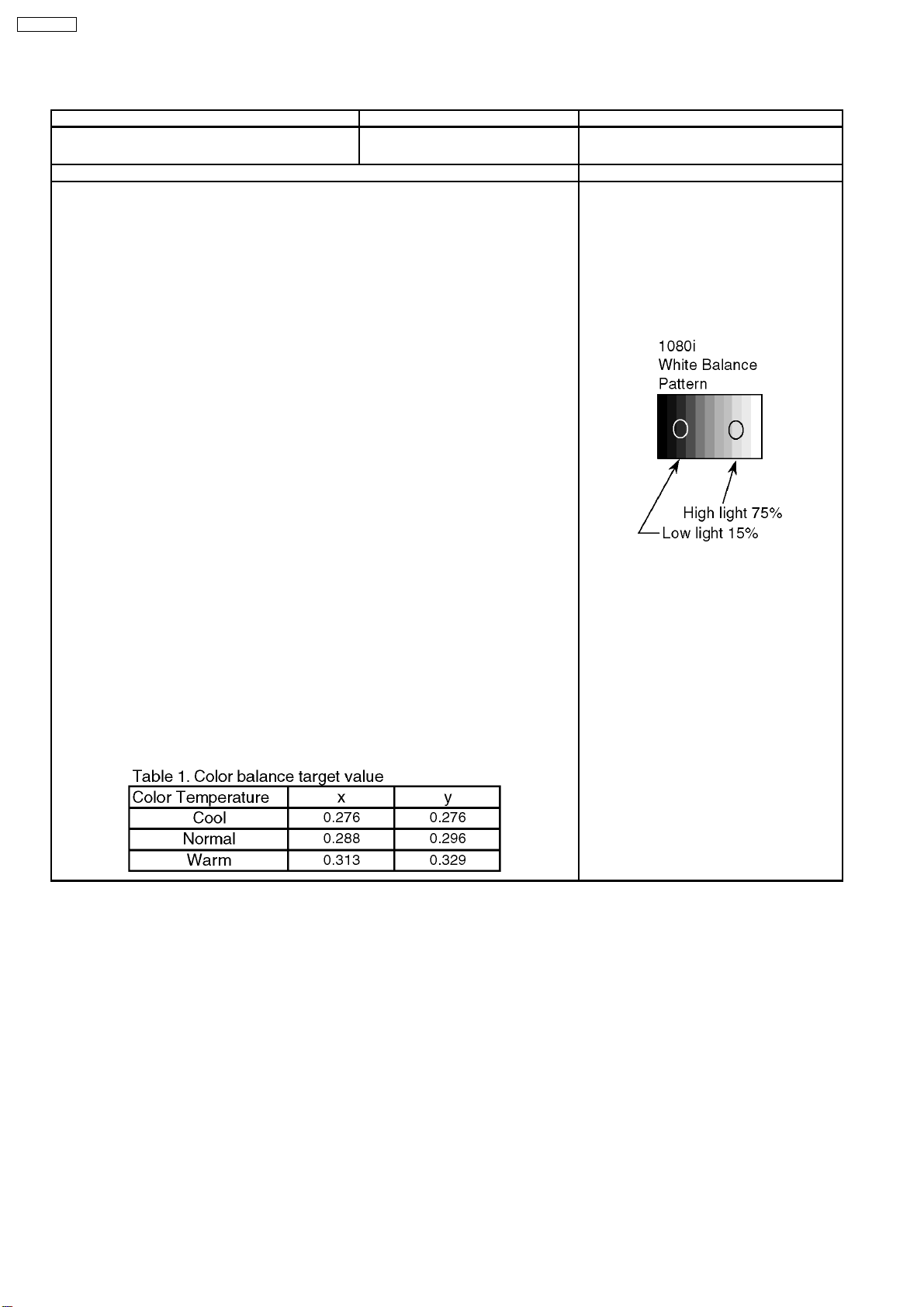

3.1. PAL panel white balance adjustment

Instrument Name Connection Remarks

· W/B pattern (PAL-M or NTSC signal)

· Color analyzer (Minolta CA-100 or equivalent)

Procedure Remarks

· Asing time is longer than 15min.

· Make sure the front panel to be used on the final set is fitted.

· Make sure a color signal is not being shown before adjustment.

· Put the color analyzer where there is little colour variation.

Complete the adjustment within 10 minutes after the turn on electricity.

Turn on the power supply again when it is not possible to complete it by aging etc.

1. Display the white balance pattern.

2. Check that the color balance is “cool”.

3. Enter the <Service1> mode.

4. Select “G-CUTOFF” item, using the color-key “Red” or “Green”, and set to “128”, using the

color-key “Yellow” or “Blue”.

Also, “B-CUTOFF” and “R-CUTOFF” set to “128”.

5. Set “G-DRIVE” at “224”.

6. Touch the signal receiver of color analyzer to the highlight window’s center, and adjust B

drive and R drive so x, y become the “Color balance Cool” in the below table.

7. Set “ALL-DRIVE” to “252”.

8. Set colorbalance to “Normal”.

9. Fix G cutoff , B cutoff and R cutoff at “128”.

10. Fix G drive at “224”.

11. Adjust B drive and R drive so the highlight window’s x, y become the “Color balance

“Normal” in the below table.

12. Set “ALL-DRIVE” to “252”.

13. Set color balance to “Warm”.

14. Set G cutoff, B cutoff and R cutoff to “128”.

15. Set G drive to “224”.

16. Adjust B drive and R drive so the highlight window’s x, y become the “Color balance Warm”

shown in the below table.

17. Set “ALL-DRIVE” to “252”.

RF input

Panel surface

User setting: Normal

Picture menu : Dynamic

ASPECT : 16:9

· Highlight section

Signal amplitude 75%

TH-42PA60L

9

TH-42PA60L

3.2. HD white balance adjustment

Instrument Name Connection Remarks

· 1080i W/B Pattern

· Color analyzer(Minolta CA-100 or equivalent)

Procedure Remarks

· Asing time is longer than 15min.

· Make sure the front panel to be used on the final set is fitted.

· Make sure a color signal is not being shown before adjustment.

· Put the color analyzer where there is little colour variation.

Complete the adjustment within 10 minutes after the turn on electricity.

Turn on the power supply again when it is not possible to complete it by aging etc.

1. Display the white balance pattern.

2. Check that the color balance is “cool”.

3. Enter the <Service1> mode.

4. Select “G-CUTOFF” item, using the color-key “Red” or “Green”, and set to “128”, using the

color-key “Yellow” or “Blue”.

Also, “B-CUTOFF” and “R-CUTOFF” set to “128”.

5. Set “G-DRIVE” at “224”.

6. Touch the signal receiver of color analyzer to the highlight window’s center, and adjust B

drive and R drive so x, y become the “Color balance Cool” in the below table.

7. Set “ALL-DRIVE” to “252”.

8. Set colorbalance to “Normal”.

9. Fix G cutoff , B cutoff and R cutoff at “128”.

10. Fix G drive at “224”.

11. Adjust B drive and R drive so the highlight window’s x, y become the “Color balance

“Normal” in the below table.

12. Set “ALL-DRIVE” to “252”.

13. Set color balance to “Warm”.

14. Set G cutoff, B cutoff and R cutoff to “128”.

15. Set G drive to “224”.

16. Adjust B drive and R drive so the highlight window’s x, y become the “Color balance Warm”

shown in the below table.

17. Set “ALL-DRIVE” to “252”.

· RF input

· Panel surface

User setting: Normal

Picture menu: Dynamic

ASPECT:16:9

· Highlight section

Signal amplitude 75%

* The Color balance COOL differs from

Japanese model values.

10

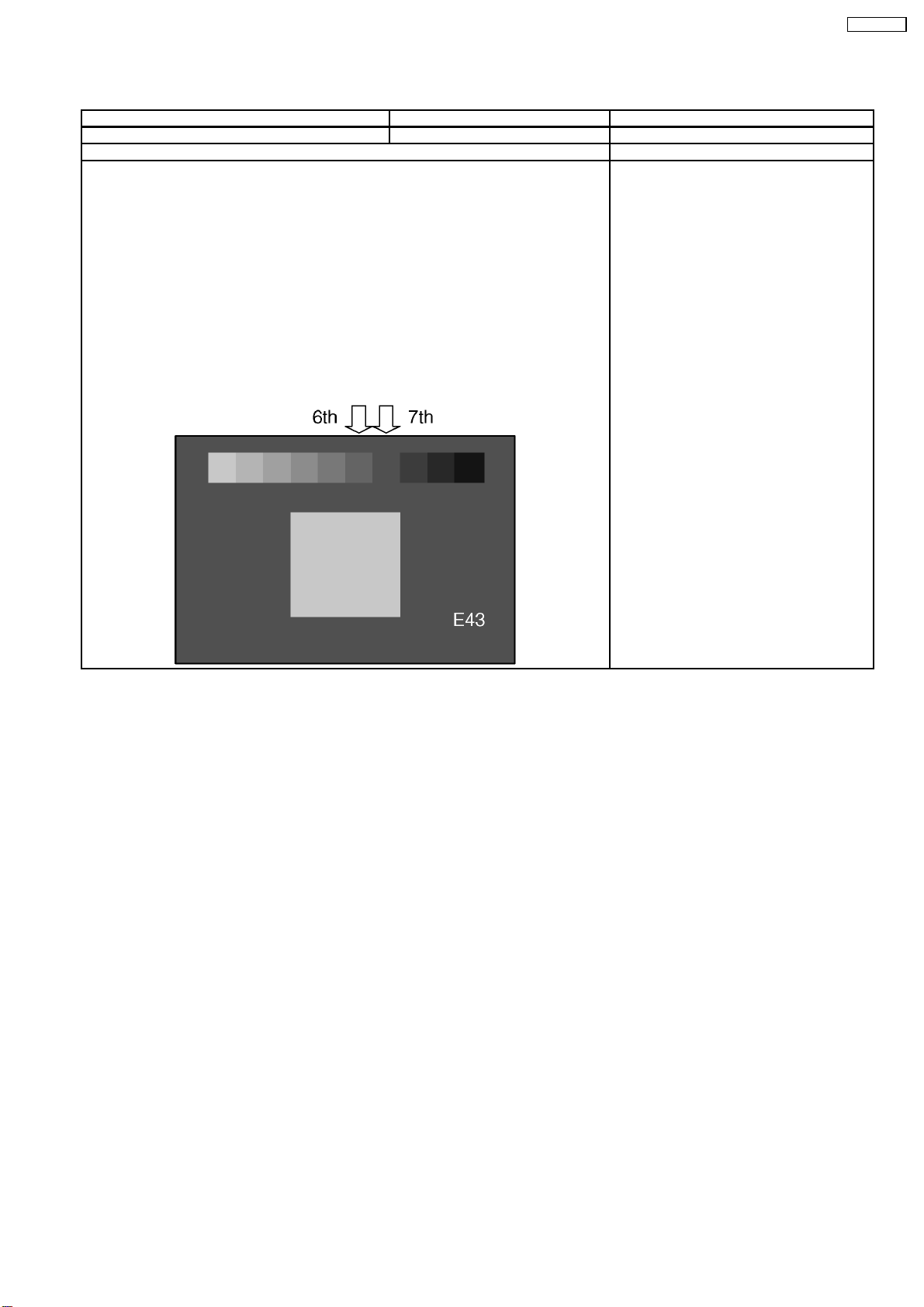

3.3. Sub bright adjustment

Instrument Name Connection Remarks

1. PAL-M or NTSC signal generator (or RF) Connect to the input terminal User setting: Normal

Procedure Remarks

· White balance adjustment is finished for each signal.

· Do adjustments in a dark room.

· Complete the adjustment within 10 minutes after the turn on electricity.

Turn on the power supply again when it is not possible to complete it by aging etc.

1. Display the 10 step gray-scale pattern for adjusting sub-bright from video input.

2. Use "Sub-Bright" in the <Sevice1> mode to adjust so the 6th section shows up and the

7th fades away.

Data

Sub-Bright data addresses

Sub-Bright (upper) A0-0116

Sub-Bright (lower) A0-0117

Picture menu: Dynamic

Color balance: Normal

ASPECT: 16:9

TH-42PA60L

11

TH-42PA60L

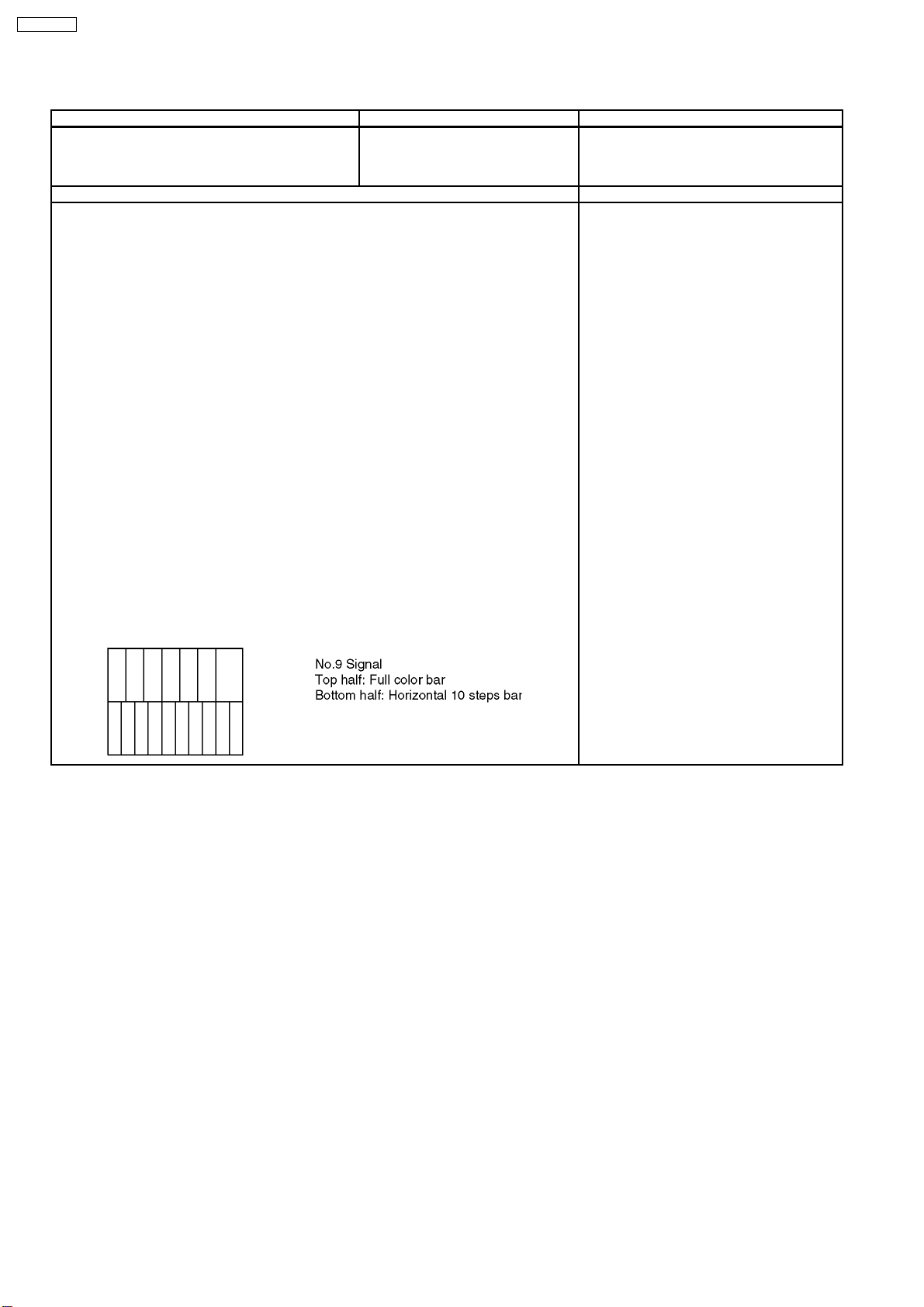

3.4. ABL adjustment

Instrument Name Connection Remarks

1. HD signal emitter (or Leader : 1080i/No.9 signal)

2. Wattmeter

Procedure Remarks

· Make sure the set is aged for 30 minutes or more before adjustment.

(Do not switch off during or after aging.)

· Voltage 230V 50Hz (variation within 1%)

· Volume at minimum and screen size at “16:9”

Component input, dynamic, standard

1. Connect the set´s AC power to the wattmeter.

2. Input the signal (top half: color bar, Bottom half :Horizontal 10steps bar).

3. Select the “PWRCTL” item in the <Service1> mode.

4. Adjust PWRCTL so the set´s power consumption is

289 (+5/-10)W

Remarks

1. The initial data are

Data address : A0-0102

Default data : 0×00

2. The power and data are in reverse relationship. Data is displayed by 2’C.

(Lower the data to raise the power.)

· Raising direction (): 0®255, 254, 253.....

· Lowering direction (¯):0®1, 2, 3.....

3. There is a possibility that the adjustment value can do two places, adjust it in that case, that

the value of PWRCTL is large.

COMPONENT input terminal

Connect the AC power of the set to the

wattmeter.

12

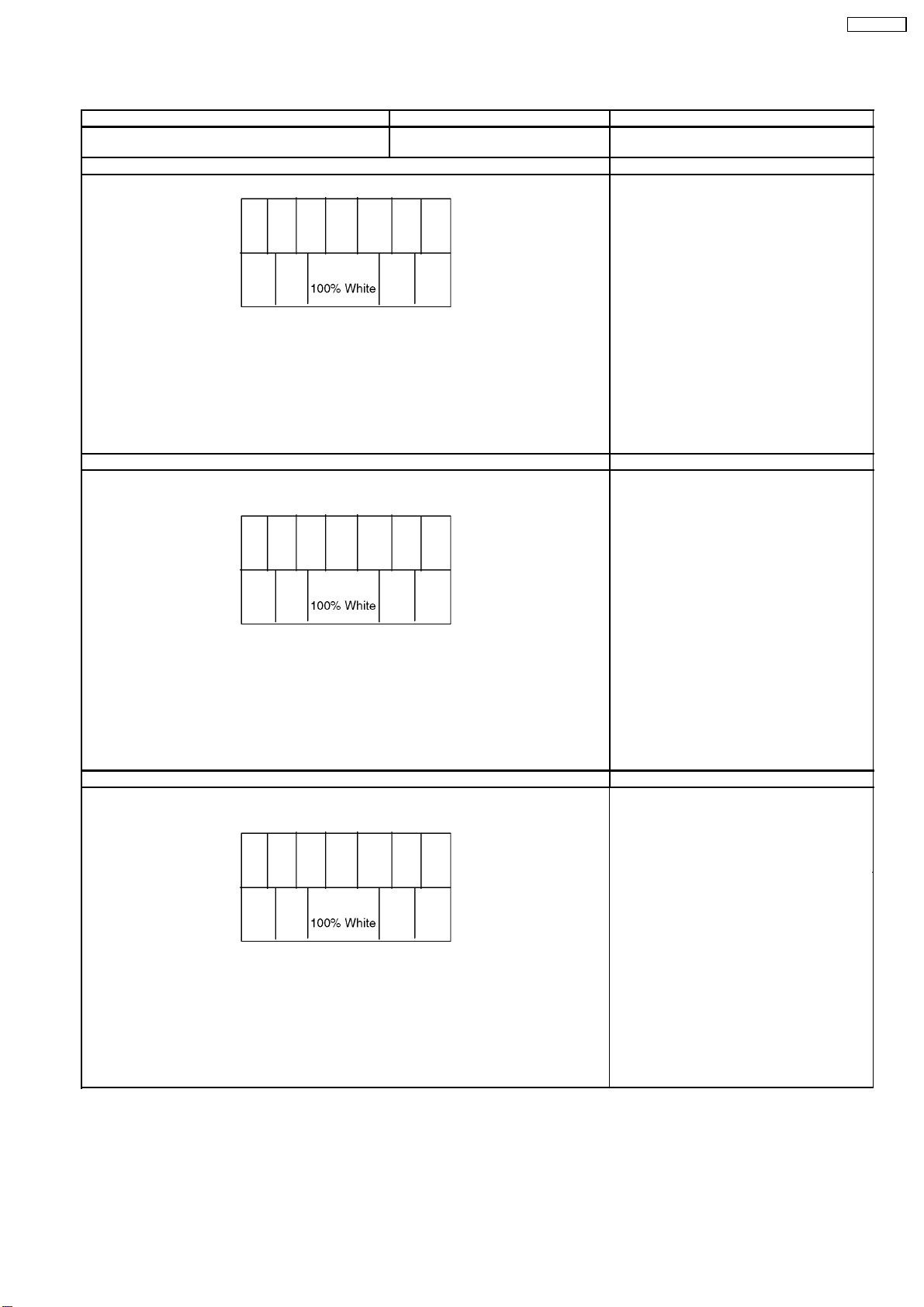

3.5. Sub-Contrast adjustment

Name of measuring instrument Connection Remarks

RF generator

Base Band generator

Adjustment of AV system Remarks

1. Receive AV1 (PAL-M or NTSC 100% Full White or Split Colour bar shown as below).

2. Goes into service mode, choose Sub-Contrast, and it checks that data value is 512.

(It checks that an initial value is a default)

3. The colour key yellow button of remote control is pushed.

4. The OSD character of sub-contrast becomes red.

(Inside under automatic adjustment)

5. The OSD character of sub-contrast returns to white.

6. End.

Adjustment of RF system Remarks

1. Receive a RF.

(PAL-M or NTSC 100% Full White or Split Colour bar shown as below).

TH-42PA60L

2. Goes into service mode, choose Sub-Contrast, and it checks that data value is 512.

(It checks that an initial value is a default)

3. The colour key yellow button of remote control is pushed.

4. The OSD character of sub-contrast becomes red.

(Inside under automatic adjustment)

5. The OSD character of sub-contrast returns to white.

6. End.

Adjustment of HD system Remarks

1. Recieve Component

(1080i/ 60Hz or 1080i/ 50Hz, 100% Full White or Split colour bar as shown below).

2. Goes into service mode, choose Sub-Contrast, and it checks that data value is 384.

(It checks that an initial value is a default)

3. The colour key yellow button of remote control is pushed.

4. The OSD character of sub-contrast becomes red.

(Inside under automatic adjustment)

5. The OSD character of sub-contrast returns to white.

6. End.

13

TH-42PA60L

14

4 Conductor Views

4.1. TU-Board

6

TU-BOARD (FOIL SIDE)

TNPA3851

AGCADJ

JS010

JS003

+B

C021

C007

C001

5

JS016

4

115

C019

L018

TU001

C017

TU5

R012

C023

C018

R013

BT

AGC

C013

C002

L017

IFOUT

R014

AGCCONT

SCL

SDA

C020

AFT

L021

L012

R016

SIFOUT

C003

L008

TU6

BTL

R011

C009

R005

L022

C016

VIDEOOUT

JS002

R008

Q002

R015

R009

R002

TNPA3851

SEE REVERSE FOR ORDER NO.

PbF

1

TU

115

TH-42PA60L

TU

3

TU-BOARD (COMPONENT SIDE)

TNPA3851

Parts Location

PbF

TU

TU-BOARD

TRANSISTOR

Q002 D-4

1

2

NO.

ORDER

1

TU001

VIDEOOUT

TU6

AGCCONT

C003

BT

AFT

SDA

SCLIFOUT

AGC

BTL

SIFOUT

115

C002

15

C001

TU5

+B

AGCADJ

1

TNPA3851

TH-42P A60L TU-BO ARD TNPA3851 TH-42P A60L TU-BO ARD TNPA3851

A

C E GIBDFH

15

TH-42PA60L

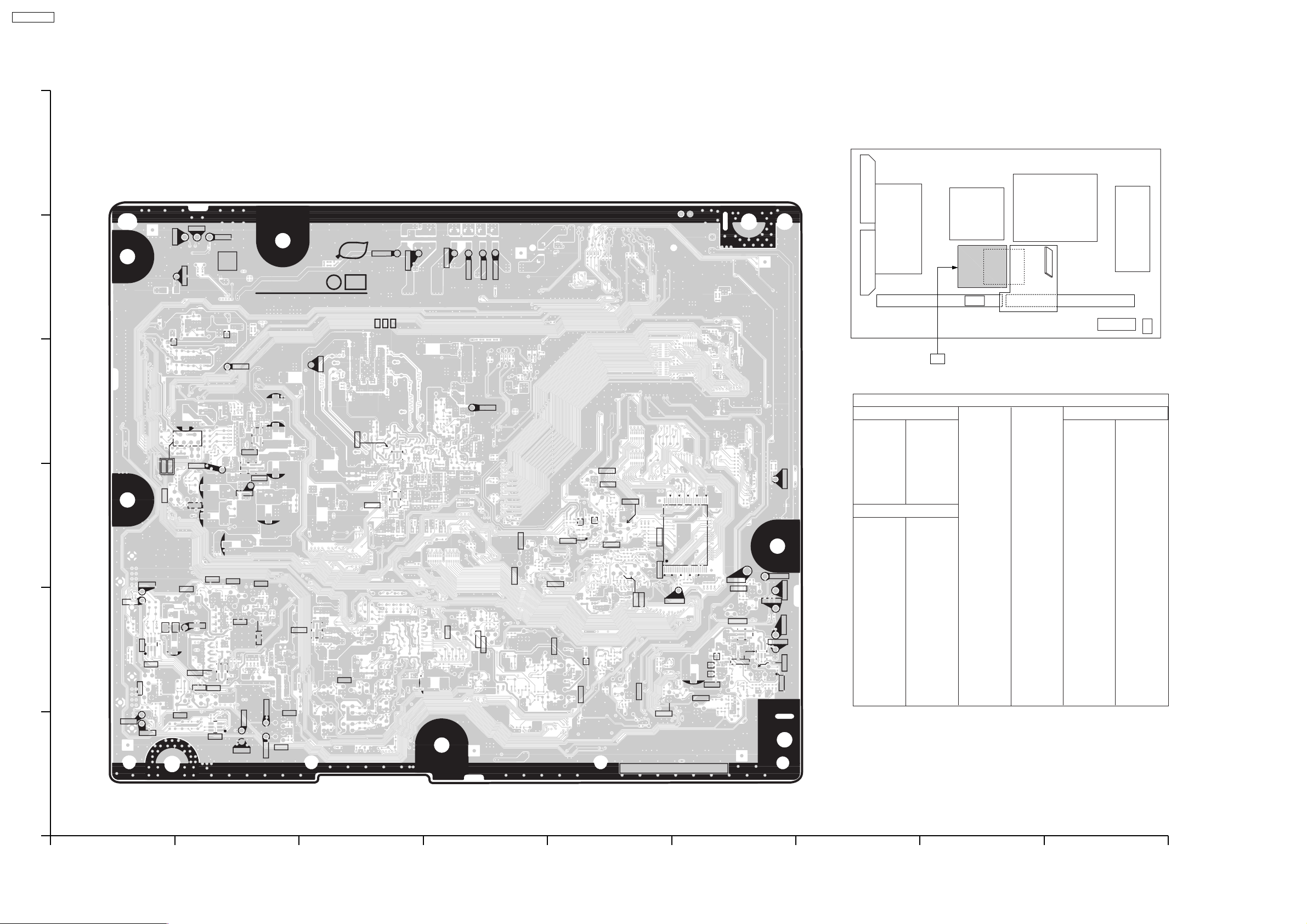

4.2. DG-Board

6

DG-BOARD (FOIL SIDE)

TNPA3756CY

TP038

TP039

TP040

TP1117

TP1113

PbF

TP1114

5

TNPA3756 DG

1

SEE REVERSE FOR SUFFIX

CR NO.4

IC017

TP041

+

IC029

1

+

+

1

Q045

IC030

1

TP028

4

1

TP029

IC018

IC016

1

Q053

Q078

Q055

TP030

Q079

3

Q075

Q073

Q076

Q074

Q067

TP031

TP033

Q071

Q068

TP066

2

Q066

Q065

TP034

TP032

Q077

IC024

Q082

Q083

Q070

1

TP035

TP064

TP065

TP036

Q084

Q069

TP1119

+

Q061

+

TP1118

Q1138

TP1116

TP037

Q1122

TP1115

Q1118

Q1117

Q1120

Q1134

Q1103

Q1135

Q1139

Q1101

Q1100

Q1102

Q918

Q1107

Q919

48

IC1101

Q1125

Q1106

1

TP1106

Q1112

Q1111

DG

Parts Location

DG-BOARD (FOIL SIDE)

IC

IC1101 E-3

IC1104 F-2

IC1110 F-2

IC4016 B-3

TP1120

25

IC4017 B-2

IC4018 B-4

IC4024 B-2

IC4029 C-4

IC4030 C-3

TRANSISTOR

Q1100 E-3

Q1101 E-3

Q1102 E-3

Q1103 E-3

Q1106 E-1

24

TP1101

Q1137

IC1110

IC1104

TP1102

TP1104

TP1103

1

TP1105

TP1107

Q1140

1

Q1141

Q1107 E-2

Q1111 F-2

Q1112 F-2

Q1117 D-3

Q1118 D-3

Q1120 E-3

Q1122 D-2

Q1125 E-3

Q1134 E-2

Q1135 E-2

Q1137 F-2

Q1138 D-2

Q1139 E-3

Q1140 F-2

Q1141 F-2

Q4045 C-2

Q4053 A-3

Q4055 A-3

Q4061 D-2

Q4065 A-2

Q4066 A-2

Q4067 B-2

Q4068 B-2

Q4069 B-1

Q4070 B-1

Q4071 A-2

Q4073 B-3

Q4074 B-2

Q4075 B-3

Q4076 B-3

Q4077 B-1

Q4078 A-3

Q4079 B-3

Q4082 B-2

Q4083 B-2

Q4084 B-1

Q4918 E-2

Q4919 E-2

TP

TP1101 F-3

TP1102 F-3

TP1103 F-2

TP1104 F-2

TP1105 F-2

TP1106 F-2

TP1107 F-2

TP1113 C-5

TP1114 B-5

TP1115 D-5

TP1116 D-5

TP1117 C-5

TP1118 D-5

TP1119 D-5

TP1120 F-3

TP4028 B-4

TP4029 B-3

TP4030 B-3

TP4031 A-2

TP4032 A-4

TP4033 A-3

TP4034 A-1

TP4035 B-1

TP4036 B-1

TP4037 D-4

TP4038 B-5

TP4039 B-5

TP4040 B-5

TP4041 C-4

TP4064 B-1

TP4065 B-1

TP4066 B-2

1

TH-42PA60L

DG-BOARD TNPA3756CY

ABCDEFGHI

TH-42PA60L

DG-BOARD TNPA3756CY

16

TH-42PA60L

6

DG-BOARD (COMPONENT SIDE)

TNPA3756CY

55

17

56

DG35

1

1

1

1

21

32

1

DG3

40

1

58

TP1109

PbF

Q1114

Q1108

Q1116

1

IC1105

1

64

IC036

49

48

27

28

54

55

IC1103

108

109

Q1109

Q1110

7

8

1

14

DG15

Q1104

1

IC1100

54

1

216

163

162

NP

Q1105

814

NP

IC1106

7

1

40

Q1143

DG7

16

17

33

Q1113

5

DG5

4

TP1108

3

4

IC1102

IC1111

2

1

Q1115

1

DG22

DG20

40

110

THERMAL PAD

IC032

1

8

TNPA3756

5

Q1130

4

IC034

IC037

IC020

1

8

25

Q062

Q063

1

IC040

A

100

26

Q064

1

IC014

Q051

1

4

IC039

58

Q1121

Q1132

Q1133

Q1142

19

20

18

16

9

14

1

7

IC1107

Q1131

1

2

1

SUFFIX

DADBDCDDDEDFDGDHDJDKDLDMDNDPDQDRDSDTDUDVDW

1

1

76

Q054

Q052

DG2

CACBCCCDCECFCG

75

50

CRNO.4

A

51

CHCJCKCLCMCNCP

Q060

Q046

Q044

Q043

Q040

Q042

Q041

151

DG

1

IC038

IC027

CQCRCSCTCUCVCWCXCY

8

1

100

1

25

26

4

1

THERMAL PAD

IC013

58

108

109

144

1

1

DX

5

IC035

THERMAL PAD

4

+

1

8

1

IC033

76

75

51

50

NP

IC028

8

1

4

5

16

9

8

1

IC025

73

36

8

14

DG10

7

45

Q059

Q058

Q057

Q056

IC019

NP

72

THERMAL PAD

IC026

IC022

37

5

IC023

Q081

Q080

80

Q050

DG

DG1

1

DG8

19 1

8

5

4

1

DG9

1

19

Parts Location

IC

IC1100 C-4

IC1102 A-2

IC1103 B-3

IC1105 B-2

IC1106 C-2

IC1107 D-2

IC1111 A-2

IC4013 E-3

IC4014 D-1

IC4019 F-4

IC4020 D-3

IC4022 F-2

IC4023 F-1

IC4025 F-3

IC4026 F-2

IC4027 E-1

IC4028 F-3

IC4032 D-5

IC4033 F-5

IC4034 D-4

IC4035 E-4

IC4036 B-4

IC4037 D-4

IC4038 E-4

IC4039 C-4

IC4040 D-2

DG-BOARD (COMPONENT SIDE)

TRANSISTOR

Q1104 B-2

Q1105 C-2

Q1108 B-2

Q1109 B-2

Q1110 B-2

Q1113 A-2

Q1114 B-2

Q1115 A-2

Q1116 B-2

Q1121 C-2

Q1130 D-2

Q1131 D-2

Q1132 C-2

Q1133 C-2

Q1142 C-1

Q1143 C-1

Q4040 E-2

Q4041 E-1

Q4042 E-2

Q4043 E-2

Q4044 E-2

Q4046 E-2

Q4050 F-5

Q4051 D-1

Q4052 D-2

Q4054 D-2

Q4056 F-4

Q4057 F-4

Q4058 F-4

Q4059 F-5

Q4060 E-2

Q4062 D-2

Q4063 D-2

Q4064 D-2

Q4080 F-4

Q4081 F-4

TP

TP1108 A-4

TP1109 A-5

1

TH-42PA60L

DG-BOARD TNPA3756CY

ABCDEFGHI

TH-42PA60L

DG-BOARD TNPA3756CY

17

TH-42PA60L

18

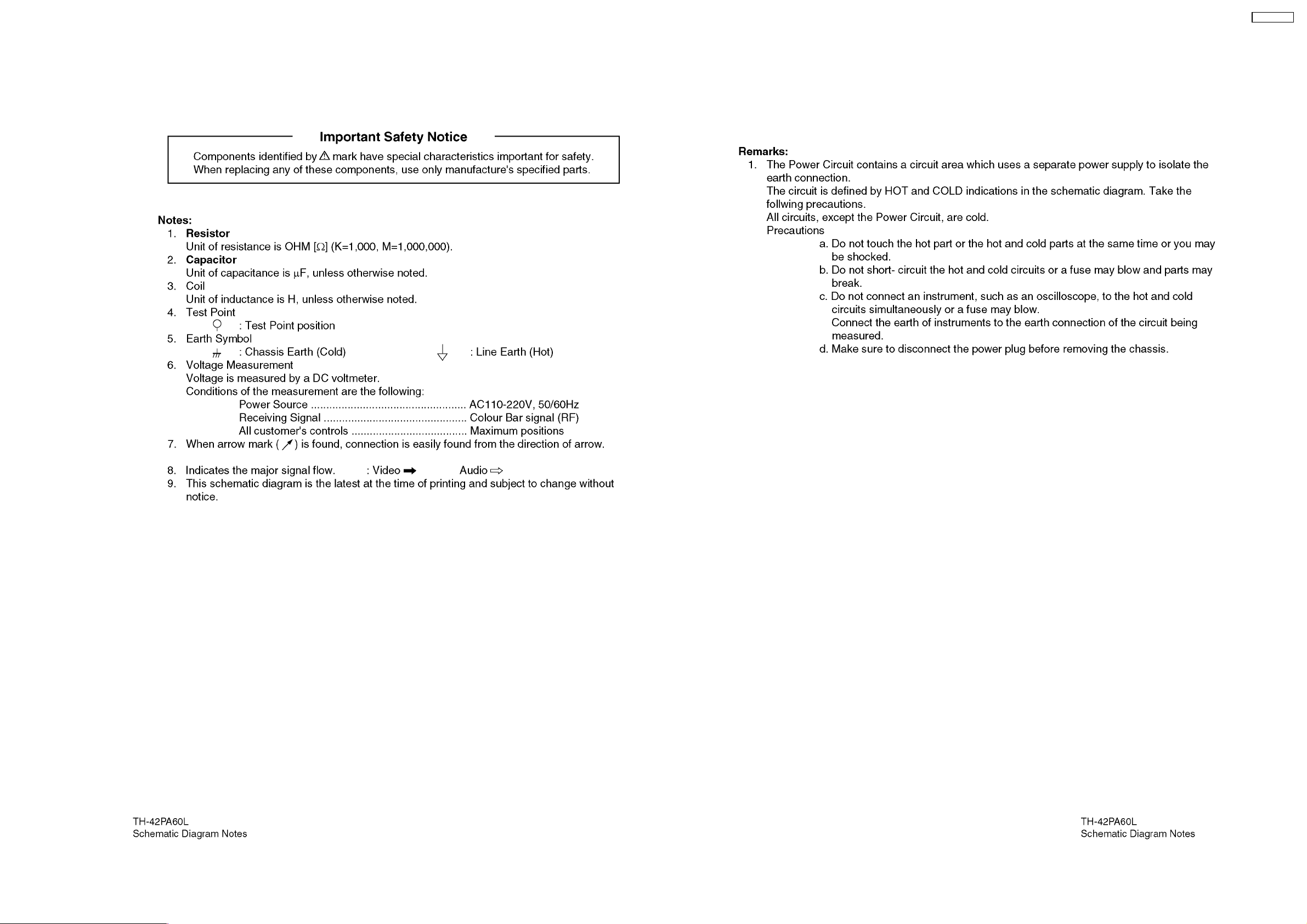

5 Schematic and Block Diagram

5.1. Schematic Diagram Note

TH-42PA60L

19

TH-42PA60L

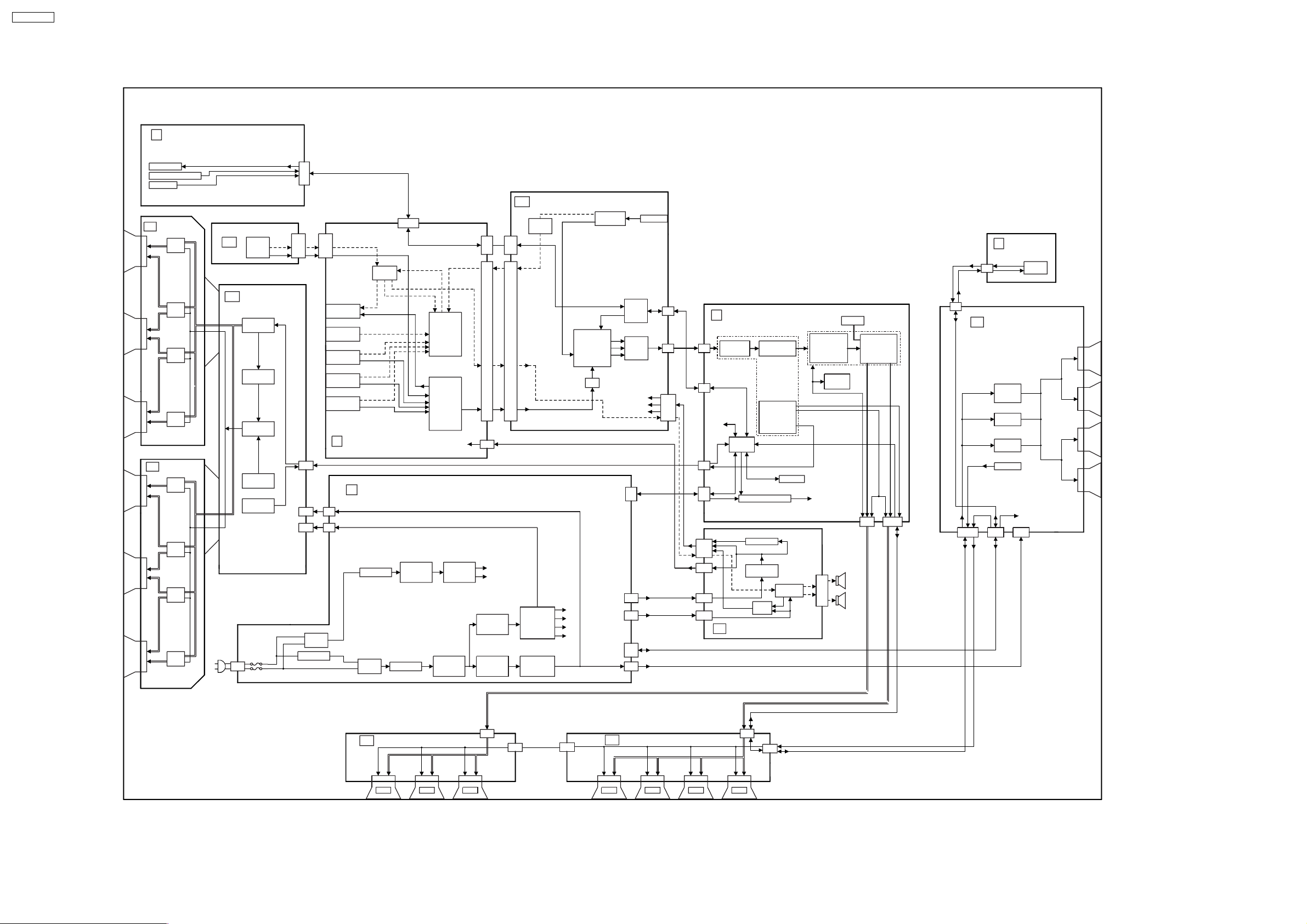

5.2. Main Block Diagram

K

KEY SCAN,

REMOTE RECEIVER,

LED

POWER LED

REMOTE RECEIVER

KEYSCAN

SCAN OUT

SU

S.R

48

TU

TUNER

TUNER

K1

DG

DIGITAL SIGNAL PROCESSOR

HDMI I/F

YG/UB

H53

SIF

TA6

V

SIF

H6

TV-V

MSP

L/R

H2

AUDIO

DAC

DG2

HDMI

L/R

RECEIVER

HDMI IN

S

POWER

SWITCH

STB_PS

STB12V

POWER

SWITCH

S1

SD

S.R

64

S.R

64

S.R

64

SCAN OUT

S.R

48

S.R

64

S.R

64

S.R

64

AC CORD

SC

SCAN DRIVE

GENERATOR

P9

CONTROL

PULSE

SUSTAIN

PULSE

SCAN

PULSE

VOLTAGE

SOS6

SOS7

SC20

SC23

SC2

LINE

FILTER

RELAY

MONITOR

OUT

AUDIO

IN

AV1

AV2

AV3

AV TERMINAL,

H

AV SWITCH,MSP

P

VSUS

P2

+15V

P23

L/R

L/R

L/R

V,Y, C

L/R

V

L/R

V,Y, PB ,P R

POWER SUPPLY

RECTIFIER

STANDBY

VOLTAGE

CONTROL

RECTIFIER

LINE

FILTER

TV_L/R

AUDIO

INPUT

SELECT

VIDEO

INPUT

SELECT

DC POWER

PROTECTION(SOS)

RECTIFIER

POWER

FACTOR

CONTROL

STANDBY

VOLTAGE

MAIN

MAIN

OSD

R

VDA

15V

12V

5V

RGB

PROCESSOR

(GC5)

A/D

F_STBY-14V

VSUS

STBY5V

PS_SOS

STB_PS

STB12V

+15V

+15V

+15V

G

B

+5V

Vda

LVDS

TRANSMITTER

SOUND SOS

DC POWER

PA SOS

P25

P10

P5

P12

P11

DG1

H1

MAIN_L/R

Y,PB/C,PR,CVBS

OUT

H40

STB12V

STB5V

PROCESS

VOLTAGE

CONTROL

SUSTAIN

VOLTAGE

CONTROL

PROCESS

VOLTAGE

RECTIFIER

SUSTAIN

VOLTAGE

RECTIFIER

MCU

DG3

DG5

DG20

D

FORMAT CONVERTER,

PLASMA AI PROCESSOR

LVD S

D5

RECEIVER

D3

IIC

SOS6/

SOS7

MICOM

D20

D25

PA2 0

PA4 0

PA1 0

PA5

PA

IIC

P_ON/OFF

DC/DC CONVERTER

POWER SOS

DC/DC

CONVERTER

SOUND

SOS

DC-DC CONVERTER

PICTURE

OUTPUT

FPGA

CONTROL

DISCHARGE

CONTROL

SOS8

SCAN CONTROL

EEPROM

SPEAKER

AMP

FORMAT

CONVERTER

RGB

PROCESSOR

FLASH

MEMORY

SUSTAIN CONTROL

DATA DRIVE

P3.3V

P2.5V

P1.2V

L

PA2

R

SPEAKER

L

SPEAKER

R

SDRAM

PLASMA AI

SUB-FIELD

PROCESSOR

VIDEO

DATA

D31

D32

S34

SUSTAIN DRIVE

SS

ADDRESS

VOLTAGE

(VE)

SUSTAIN

PULSE

ERASE

PULSE

SS_SOS8

STB_PS/

STB12V

SS12

VSUS

SS11

+15V

VDA

SS23

TH-42PA60L

Main Block Diagram

C1

DATA DRIVER(LEFT)

S.R.

S.R.

S.R.

C21

VDA

C23

C11

S.R.

Vda-70V

C12

C22

DATA DRIVER(RIGHT)

C2

S.R.S.R.

S.R.

TH-42PA60L

Main Block Diagram

20

Loading...

Loading...