Page 1

SAFETY BEAM SENSOR

ST4

Instruction Manual

Page 2

BEFORE BEGINNING

The printed English and Japanese versions of this instruction manual are the original versions.

The English, French, German, Italian and Spanish versions published in the Internet are

copies of the original documentation and were produced by Panasonic Electric Works Europe

AG.

Liability and Copyright for the Hardware

This manual and everything described in it are copyrighted. You may not copy this manual, in

whole or part, without written consent of Panasonic Electric Works Europe AG (PEWEU).

PEWEU pursues a policy of continuous improvement of the design and performance of its

products. Therefore we reserve the right to change the manual/product without notice. In no

event will PEWEU be liable for direct, special, incidental, or consequential damage resulting

from any defect in the product or its documentation, even if advised of the possibility of such

damages.

We invite your comments on this manual. Please e-mail us at:

tech-doc@eu.pewg.panasonic.com.

Please direct support matters and technical questions to your local Panasonic representative.

LIMITED WARRANTY

If physical defects caused by distribution are found, PEWEU will replace/repair the product

free of charge. Exceptions include:

• When physical defects are due to different usage/treatment of the product other than

described in the manual.

• When physical defects are due to defective equipment other than the distributed

product.

• When physical defects are due to modifications/repairs by someone other than

PEWEU.

• When physical defects are due to natural disasters.

Page 3

Important Symbols

One or more of the following symbols may be used in this documentation:

DANGER!

1.

2.

3.

!

CAUTION

Indicates that you should proceed with caution. Failure to do so may result in

injury or significant damage to instruments or their contents, e.g. data.

NOTE

Contains important additional information.

EXAMPLE

Contains an illustrative example of the previous text section.

Procedure

The warning triangle indicates especially important safety

instructions. If they are not adhered to, the results could be fatal

or critical injury.

Indicates that a step-by-step procedure follows.

REFERENCE

Indicates where you can find additional information on the subject at hand.

Page 4

KEY POINTS

Summarizes key points in a concise manner.

SHORTCUTS

Provides helpful keyboard shortcuts.

EXPLANATION

Provides a brief explanation of a function, e.g. why or when you should use it.

next page

Indicates that the text will be continued on the next page.

Page 5

Panasonic ST4 Instruction Manual

Table of Contents

Table of Contents

1. Introduction ............................................................................1

1.1 Target Group ............................................................................................. 2

1.2 Safety Instructions..................................................................................... 3

1.3 Applicable Standards/Regulations............................................................. 6

2. Before Using this Device .......................................................7

2.1 Features..................................................................................................... 8

2.2 Part Description......................................................................................... 9

2.2.1 Elements of the Controller ST4-C11 ........................................................10

2.2.2 Elements of the Multifunctional Controller ST4-C12EX ...........................11

2.2.3 Elements of the Sensor ST4-A.................................................................14

2.3 Protection Area........................................................................................ 15

2.3.1 Sensing Range......................................................................................... 15

2.3.2 Safety Distance ........................................................................................ 16

2.3.2.1 Calculation Example for Europe .....................................................17

2.3.2.2 Calculation Example for the US ...................................................... 18

2.3.3 Influence of Reflective Surfaces............................................................... 20

2.3.4 Placement of Emitter and Receiver .........................................................21

2.3.5 Connecting Multiple Sensors Heads........................................................ 23

2.3.6 Address Allocations of the Sensor ST4-A.............................................. 25

2.4 Mounting and Removing.......................................................................... 29

2.4.1 Mounting and Removing the Controller ...................................................29

2.4.2 Mounting the Sensor ST4-A...................................................................30

2.4.3 Connecting Controller and Sensor ST4-A .............................................31

2.4.4 Series Connection of the Sensor ST4-A................................................32

v

Page 6

Table of Contents

Panasonic ST4 Instruction Manual

2.5 Wiring .......................................................................................................36

2.5.1 Power Supply Unit....................................................................................36

2.5.2 I/O Circuit Diagrams ................................................................................. 37

2.5.2.1 Circuit of Controller ST4-C11 .......................................................... 37

2.5.2.2 Circuit of Multifunctional Controller ST4-C12EX ............................. 38

2.5.2.3 Manual and automatic reset............................................................39

2.5.2.4 Emission Halt Input Terminals ........................................................40

2.5.3 Connecting to the Terminal Block ............................................................41

2.5.4 Terminal Arrangement Diagram...............................................................41

2.6 Adjustment and Operation........................................................................44

2.6.1 Beam-Axis Alignment...............................................................................44

2.6.2 Operation Test..........................................................................................46

2.6.3 Operation..................................................................................................47

3. Functions.............................................................................. 49

3.1 Self-Diagnosis Function ...........................................................................50

3.2 Reset Operation .......................................................................................51

3.2.1 Manual Reset ...........................................................................................51

3.2.2 Auto Reset................................................................................................52

3.3 Emission Halt Function.............................................................................53

3.4 Interference Prevention Function .............................................................54

3.4.1 Interference Prevention With One Controller ...........................................54

3.4.2 Interference Prevention Function When Using Two or More Controllers 54

3.5 Auxiliary Output ........................................................................................56

3.5.1 Auxiliary Output Operation of Controller ST4-C11...................................56

3.5.2 Auxiliary Output Operation of Controller ST4-C12EX .............................. 56

3.5.3 Emission Amount Adjustment Function ...................................................57

3.6 Muting Function (Only for ST4-C12EX)....................................................59

vi

3.6.1 What Is a Muting Sensor..........................................................................60

3.6.2 Installation of the Muting Sensor..............................................................60

Page 7

Panasonic ST4 Instruction Manual

Table of Contents

3.7 Override Function (Only ST4-C12EX) .....................................................63

3.8 Muting Pattern Selection Function (Only ST4-C12EX)............................ 67

3.8.1 Control Condition of Muting Pattern No. 1 ............................................... 68

3.8.2 Control Condition of Muting Pattern No. 2 ............................................... 69

3.8.3 Control Condition of Muting Pattern No. 3 ............................................... 70

3.9 Sensor Diagnosis Function (Only ST4-C12EX)....................................... 71

3.10 Muting Lamp Diagnosis Function (Only ST4-C12EX) ............................. 74

4. Maintenance..........................................................................75

4.1 Daily Inspection ....................................................................................... 76

4.2 Periodic Inspection Checklist (Every Six Months) ................................... 77

4.3 Inspection After Maintenance .................................................................. 78

5. Troubleshooting ...................................................................79

5.1 Troubleshooting of Controller ST4-C11 ................................................... 80

5.2 Troubleshooting of Controller ST4-C12EX .............................................. 83

5.3 Troubleshooting of the Sensor ST4-A ................................................... 86

6. Specifications .......................................................................87

6.1 Specifications, Controller ST4-C11.......................................................... 88

6.2 Specifications, Controller ST4-C12EX..................................................... 90

6.3 Specifications, Sensor ST4-A ................................................................ 92

6.4 Options .................................................................................................... 93

6.4.1 Extension Cable .......................................................................................93

6.4.2 Branch Cable............................................................................................93

6.4.3 Foot Angled Mounting Bracket................................................................. 93

vii

Page 8

Table of Contents

6.4.4 Back Angled Mounting Bracket ................................................................ 94

6.4.5 Foot Biangled Protective Mounting Bracket.............................................94

6.4.6 Slit Masks .................................................................................................94

Panasonic ST4 Instruction Manual

7. Dimensions........................................................................... 95

7.1 Controller ST4-C11 ..................................................................................96

7.2 Multifunctional Controller ST4-C12EX......................................................97

7.3 Single-beam Sensor ST4-A ...................................................................98

7.4 Branch Cable ST4-CCJ05-WY.................................................................99

7.5 Foot Angled Mounting Bracket MS-CX-1 ...............................................100

7.6 Back Angled Mounting Bracket MS-ST4-3.............................................101

7.7 Foot Biangled Protective Mounting Bracket MS-ST4-6..........................102

8. Glossary of Terms.............................................................. 103

9. Index.................................................................................... 105

viii

Page 9

Chapter 1

Introduction

Page 10

Introduction

Panasonic ST4 Instruction Manual

1.1 Target Group

Thank you for purchasing the PanasonicSafety Beam Sensor ST4 series (hereafter called 'this

device'). Please read this instruction manual carefully and thoroughly for the correct and

optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

This device is a safety beam sensor for protecting a person from dangerous parts of a machine

which can cause injury or accident.

This manual has been written for the personnel who:

• have undergone suitable training and have knowledge of safety beam sensors as well

as safety systems and standards.

• are responsible for this device

• design systems using this device

• install and connect this device

• manage and operate a plant using this device

Machine designer, installer, employer and operator

The machine designer, installer, employer and operator are solely responsible for ensuring that

all applicable legal requirements relating to the installation and the use in any application are

satisfied and all instructions for installation and maintenance contained in the instruction manual

are followed.

Whether this device functions as intended and systems including this device comply with safety

regulations depend on the appropriateness of the application, installation, maintenance and

operation. The machine designer, installer, employer and operator are solely responsible for

these items.

Engineer

The engineer must be a person who is appropriately trained, has widespread knowledge and

experience, and can solve various problems which may arise in his field of work, e.g. as a

machine designer or a person in charge of installation or operation, etc.

Operator

The operator should read this instruction manual thoroughly, understand its contents, and

perform operations following the procedures described in this manual for the correct operation

of this device.

In case this device does not perform properly, the operator should report this to the person in

charge and stop machine operation immediately. The machine must not be used until correct

performance of this device has been confirmed.

2

Page 11

Panasonic ST4 Instruction Manual

1.2 Safety Instructions

DANGER!

1.2 Safety Instructions

!

• Use this device as per its specifications. Do not modify the safety beam

sensor since its functions and capabilities may not be maintained and it may

malfunction.

• The safety beam sensor has been developed/produced for industrial use

only.

• Do not use the safety beam sensor under conditions or in environments not

described in this manual. Please consult us if there is no other choice but to

use this device in such an environment.

• Do not use the safety beam sensor in fields such as nuclear power control,

railroad, aircraft, automobiles, combustion facilities, medical systems,

aerospace development, e.g. in applications where failure could result in

large-scale damage to society or people.

• When the safety beam sensor is to be used for enforcing protection of a

person from any danger occurring around an operating machine, the user

must satisfy the regulations established by national or regional security

committees.

• No matter what kind of equipment you use the device with, follow the safety

regulations in regard to appropriate usage, mounting (installation), operation

and maintenance.

Please adhere to the following safety instructions when

you install and operate this device. Failure to do so can

result in fatal or critical injury during unprotected use of

hazardous machinery.

• Use the safety beam sensor by installing suitable protective equipment as a

countermeasure for failure, damage, or malfunction of this device.

• Before using this sensor, check whether the device performs properly and

has the functions and capabilities as stated in the design specifications.

• Dispose of the safety beam sensor as industrial waste.

Environment

• Do not use a mobile phone or a radio phone near this device.

• If the sensor is installed in a place where there are reflective surfaces, make

sure to install this device so that reflected light from the reflective surfaces

does not affect the receiver. Alternatively, take countermeasures such as

painting, masking, roughening, or changing the material of the reflective

surfaces, etc. Failure to do so may cause the sensor not to detect properly,

which may result in death or serious injury.

• Do not install the safety beam sensor in the following environments:

3

Page 12

Introduction

Installation

• Always keep the correctly calculated safety distance between the safety

• Install an extra protective structure around the machine so that the operator

• Install the beam sensor in a manner that some part of the operator's body

Panasonic ST4 Instruction Manual

- Areas exposed to intense interference light such as direct sunlight

- Areas with high humidity where condensation is likely to occur

- Areas exposed to corrosive or explosive gases

- Areas exposed to vibration or shock at levels higher than those specified

- Areas exposed to contact with water

- Areas exposed to excessive steam or dust

- Areas where the beam-receiving part of this device is directly exposed to

light from a high-frequency fluorescent lamp (inverter type) or

rapid-starter fluorescent lamp.

beam sensor and the dangerous parts of the machine.

must pass through the sensing area of the safety beam sensor to reach the

dangerous parts of the machine.

always remains in the sensing area until the operator has finished working

with the dangerous parts of the machine.

• Do not install the beam sensor at a location where it can be affected by wall

reflection.

• When installing multiple sets of the safety beam sensor, connect the sets

and, if necessary, install some barriers so that mutual interference does not

occur.

• Do not use any reflection type or recursive reflection type arrangement.

Equipment in which this device is installed

• When the safety beam sensor is used in the PSDI mode, an appropriate

control circuit must be configured between this device and the machinery.

For details, be sure to refer to the standards or regulations applicable in each

region or country.

• In Japan, do not use the safety beam sensor as safety equipment for a press

machine.

• Do not install the safety beam sensor with a machine whose operation

cannot be stopped immediately in the middle of an operation cycle by an

emergency stop.

• This sensor provides safety 2 seconds after the power has been switched

ON. Make sure that the control system takes the time delay into

consideration.

Wiring

• Switch off the power before wiring the safety beam sensor.

4

Page 13

Panasonic ST4 Instruction Manual

• All electrical wiring should conform to the regional electrical regulations and

laws. The wiring should be done by skilled personnel with the required

electrical knowledge.

• Do not run the sensor cable together with high-voltage lines or power lines

or put them together in the same raceway.

• In case you need to extend the cable of the ST4-A□, you can use the

dedicated extension cable. The cable can be extended up to 50m (emitter and

receiver, respectively).

• Do not control the device at only one control output (OSSD 1, OSSD 2).

• To ensure that the output is not turned ON due to an earth fault of the control

output (OSSD 1, OSSD 2), ground the device on the 0V side (for PNP output)

or +24V side (for NPN output).

Maintenance

• When you need to replace parts, always use only genuine replacement parts

from the supplier. If you use substitute parts from another manufacturer, the

sensor may fail to detect properly, which may result in death or serious body

injury.

• The device must be inspected periodically by an engineer with the required

knowledge.

1.2 Safety Instructions

Others

• When you have adjusted or maintained the device, test the device following

the procedure specified in the maintenance chapter before you switch the

system back on.

• Clean this device with a clean cloth. Do not use thinner-based cleaners.

• Never modify this device. If you modify the device, the sensor may fail to

detect properly, which may result in death or serious injury.

• Do not use this device to detect objects flying over the sensing area.

• Do not use this device to detect transparent objects, translucent objects or

objects smaller than the specified minimum sensing size.

5

Page 14

Introduction

Panasonic ST4 Instruction Manual

1.3 Applicable Standards/Regulations

This device complies with the following standards and regulations.

• EU Machinery Directive 98/37/EC, EMC Directive 2004/108/EC

• EN 61496-1 (Type 4), EN 55011, EN 50178,

EN ISO 13849 (Category 4, PLe), EN 61508-1 to 7 (SIL3)

• IEC 61496-1/2 (Type 4), ISO 13849-1 (Category 4, PLe),

IEC 61508-1 to 7 (SIL3), IEC 62061 (SIL3)

• JIS B 9704-1/2 (Type 4), JIS B 9705-1 (ISO 13849-1) (Category 4), JIS C 0508-1 to 7

(SIL3)

• UL 61496-1/2 (Type 4), UL 1998, CSA C22.2 No.14, CSA C22.2 No.0.8

• OSHA 1910.212, OSHA 19 10.217(C), ANSI B11.1 to B11.19, ANSI/RIA 15.06,

ANSI/ISA S84.01 (SIL3)

NOTE

• Conformity to JIS, OSHA and ANSI for this device has been evaluated by us.

•

directive. The CE-mark indicates that this product conforms to the EMC

directive.

•

•

Canadian and U.S. requirements.

• If you want to use this device in a location other than already described (see

page

regulations applicable in your region or country.

: This device conforms to the EMC directive and the Machinery

: This device is certified by TÜV Süd.

: The C-CL US Listing Mark indicates compliance with both

3), confirm first that the intended use complies with the standards or

6

Page 15

Chapter 2

Before Using this Device

Page 16

Before Using this Device

Panasonic ST4 Instruction Manual

2.1 Features

This device is a safety beam sensor with the following features.

• The controller ST4-C11 or the multifunctional controller ST4-C12EX is used in

combination with the single-beam sensor ST4-A.

• The type ST4-AV comes with an emission amount adjuster to reduce the emission

amount.

• Up to six units of the ST4-A can be connected per controller. The controller has an

automatic interference prevention function.

• Wiring can be easily done by using the extension cable ST4-CCJ (optional) and the

branch cable ST4-CCJ05-WY (optional), since the cables are connector types

• The control output (OSSD 1/2) is a PNP/NPN output switching type. The output type

can be switched with the output polarity selection switch on the controller.

• Replacing the relay is not necessary since a semiconductor output is used.

• The muting function complying with ISO 12643 (safety requirements for graphic

technology equipment and systems) is available on the ST4-C12EX. For details, refer to

the Muting Function (see page

59).

.

8

Page 17

Panasonic ST4 Instruction Manual

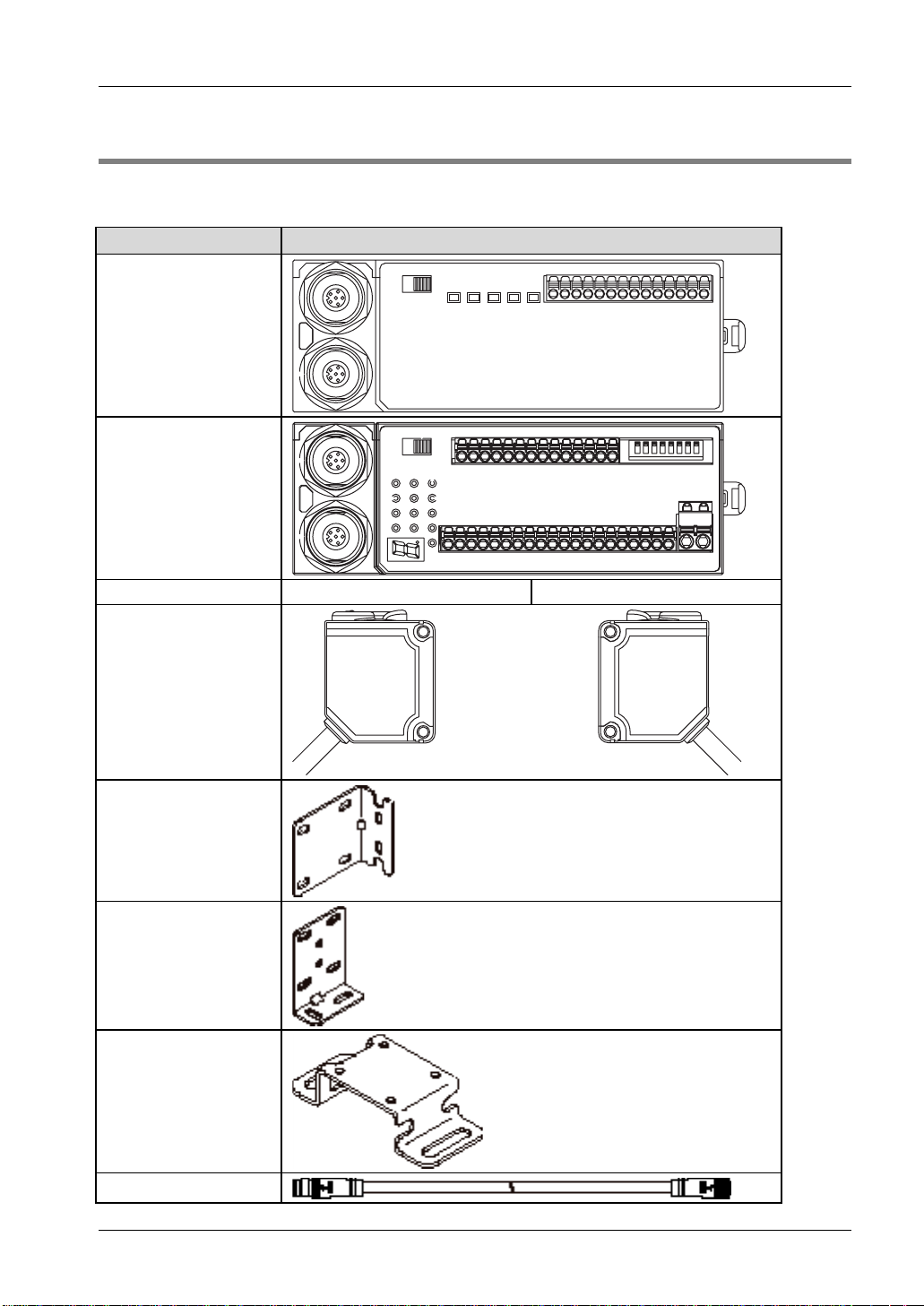

2.2 Part Description

2.2 Part Description

The ST4 system can be built up from the following parts. Which controller type you choose

depends on your requirements and applications.

Part name Part

Controller ST4-C11

Multifunctional Controller

ST4-C12EX

Emitter ST4-A and

Receiver ST4-A

Emitter Receiver

Back angled mounting

bracket (optional)

Foot angled mounting

bracket (optional)

Foot biangled protective

mounting bracket

(optional)

Extension cable ST4-CCJ

9

Page 18

Before Using this Device

Part name Part

(optional)

Branch cable

ST4-CCJ-WY (optional)

Slit mask (optional)

Panasonic ST4 Instruction Manual

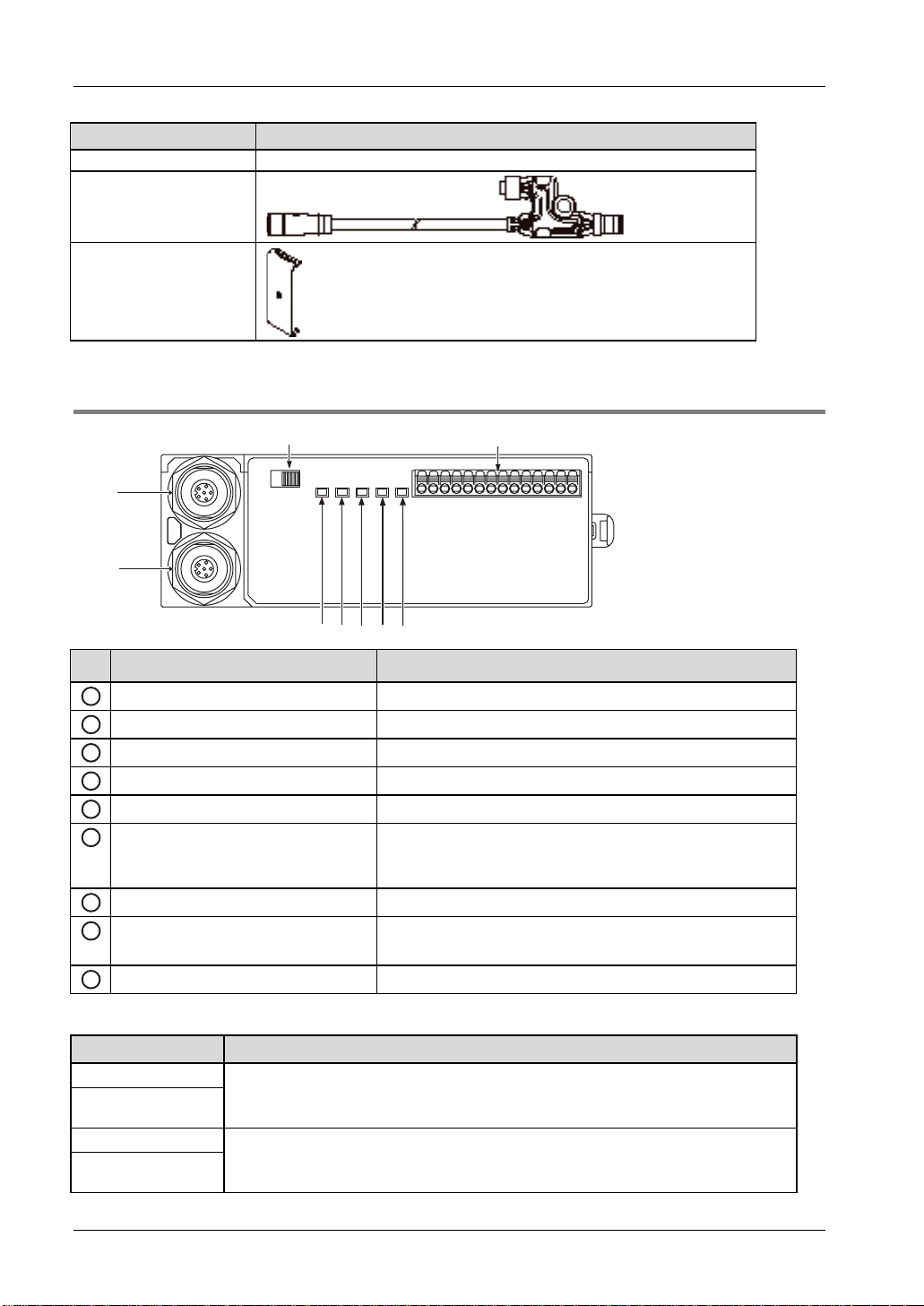

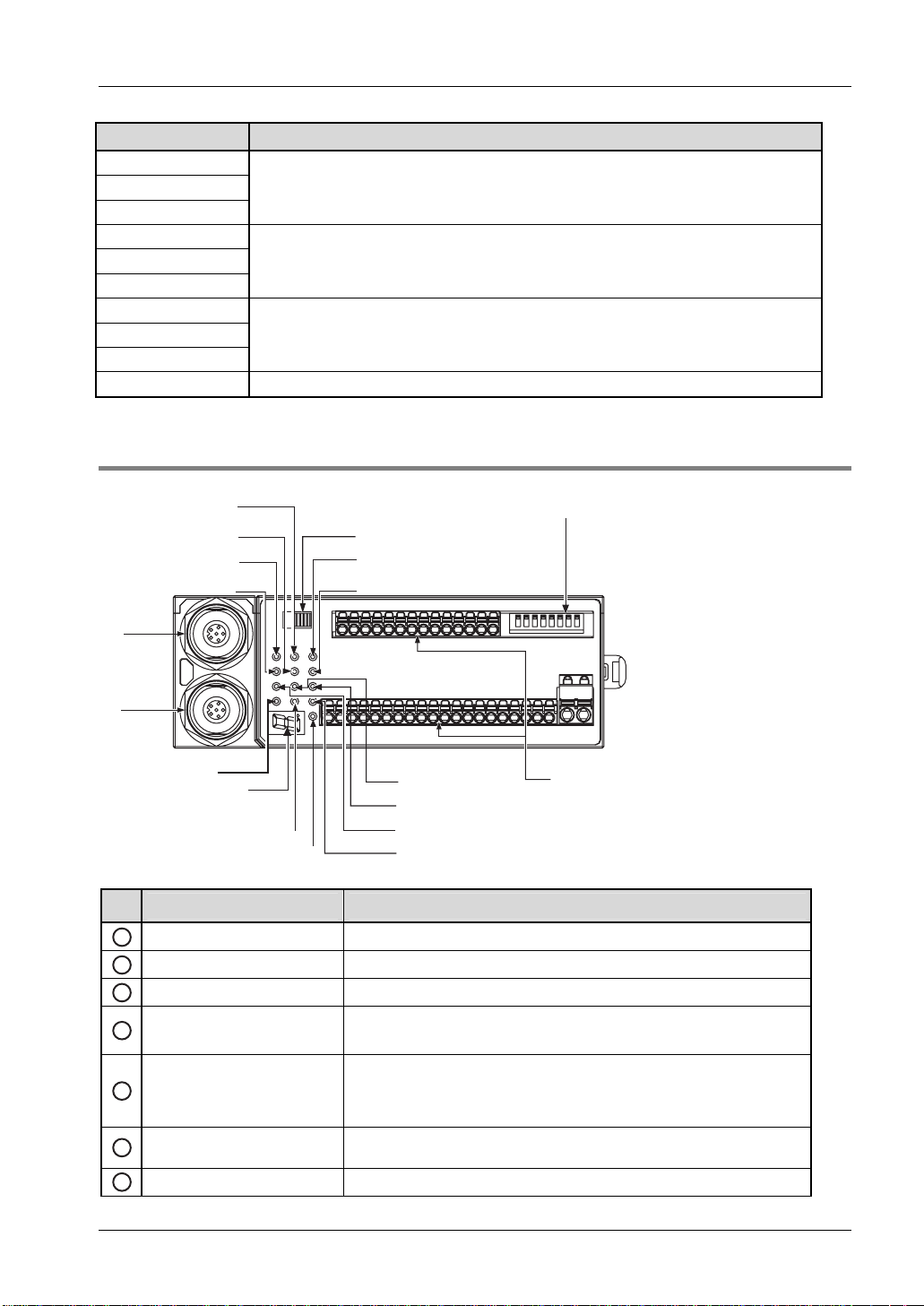

2.2.1 Elements of the Controller ST4-C11

3

2

1

456 7 8

Identifier Function

Emitter connector Connects the emitter of the ST4-A.

1

Receiver connector Connects the receiver of the ST4-A.

2

Output polarity selection switch Switches the control output to PNP output or NPN output.

3

Power indicator (Green) Lights up while power is ON.

4

Control output indicator (Green) Lights up while the control output (OSSD 1/2) is ON.

5

Interlock indicator (Yellow) Lights up while the interlock is ON.

6

Emission halt indicator (Orange) Lights up while the emission halt function is valid.

7

Fault indicator Lights up or blinks when an error occurs.

8

Terminal block See the following table.

9

Turns OFF when an error occurs or the control output (OSSD

1/2) is ON.

For details, refer to "Troubleshooting (see page

9

79)".

Terminal block

Terminal name Description

IL+

IL-

IU+

IU-

10

Interference prevention terminals (downstream)

For details, refer to "Interference Prevention Function see "

Function" on page

Interference prevention terminals (upstream)

For details, refer to Interference Prevention Function see "

Function" on page

54".

Interference Prevention

Interference Prevention

54.

Page 19

Panasonic ST4 Instruction Manual

Terminal name Description

X1

X2

X3

T1

T2

AUX

OSSD 1

OSSD 2

A1

A2 0V

Reset input terminals (When X1 and X2 are connected: manual reset, and when X1 and

X3 are connected: auto reset)

Emission halt input terminals

(Open: emission halt, Short-circuit: emission)

Control output (OSSD 1/2)

2.2.2 Elements of the Multifunctional Controller ST4-C12EX

2.2 Part Description

w

q

}

{

t

r

e

2

1

3

4

9

0

5

6

Identifier Function

1

Emitter connector Connects the emitter of the ST4-A.

Receiver connector Connects the receiver of the ST4-A.

2

3

Power indicator (Green) Lights up while power is ON.

4

Fault display (Red)

8

7

7-segment lights up when an error occurs.

For details, refer to Troubleshooting (see page

y

u

79).

5

Interlock indicator (Yellow)

Emission halt indicator

6

(Orange)

7

Control output indicator

Lights up while the interlock is ON.

Turns OFF when an error occurs or the control output (OSSD 1/2) is ON.

Lights up while the emission halt function is valid.

Lights up while the control output (OSSD 1/2) is ON.

11

Page 20

Before Using this Device

Identifier Function

(Green)

Auxiliary output 1 indicator

8

(Orange)

Auxiliary output 2 indicator

9

(Orange)

Auxiliary output 3 indicator

10

(Orange)

Muting input S-A indicator

11

(Orange)

Muting input S-B indicator

12

(Orange)

Muting input S-C indicator

13

(Orange)

Muting input S-D indicator

14

(Orange)

Muting input S-E indicator

15

(Orange)

Muting input S-F indicator

16

(Orange)

Output polarity selection

17

switch

Panasonic ST4 Instruction Manual

Turns OFF while the muting function is valid.

Lights up while the muting function is invalid.

Turns OFF while the override function is valid.

Lights up while the override function is invalid.

Lights up when the muting lamp is in normal operation.

Turns OFF when the muting lamp is in error.

Lights up when the sensor input connected to the muting input terminal

(S-A) is ON

.

Lights up when the sensor input connected to the muting input terminal

(S-B) is ON.

Lights up when the sensor input connected to the muting input terminal

(S-C) is ON.

Lights up when the sensor connected to the muting input terminal (S-D)

is input ON.

Lights up when the sensor input connected to the muting input terminal

(S-E) is ON.

Lights up when the sensor input connected to the muting input terminal

(S-F) is ON.

Switches the control output to PNP output or NPN output.

18

DIP switches

1ON 23456 87

See the table "DIP switches".

Terminal block See table "Terminal block".

19

DIP Switches

No. Description

1 to 4

5

6

7

8 Deactivates the muting lamp diagnosis function (see page 74).

Sets the ST4-A into the muting state.

Sets effective time for muting/override (see page

59).

Checks the states "beam received" and "beam interrupted" of the connected ST4-A, or a sensor

error (see "

Sensor Diagnosis Function (Only ST4-C12EX)" on page 71).

Unused

12

Page 21

Panasonic ST4 Instruction Manual

Terminal block

Terminal Name Description

S+ Muting input power supply (24V)

S-A Muting input S-A (for PNP type)

S-B Muting input S-B (for NPN type)

S- Muting input power supply (0V)

S+ Muting input power supply (24V)

S-C Muting input S-C (for PNP type)

S-D Muting input S-D (for NPN type)

S- Muting input power supply (0V)

S+ Muting input power supply (24V)

S-E Muting input S-E (for PNP type)

S-F Muting input S-F (for NPN type)

S- Muting input power supply (0V)

AUX1 Auxiliary output 1 (muting function)

AUX2 Auxiliary output 2 (override function)

AUX3 Auxiliary output 3 (lamp shutoff)

AUX4 Negative logic of the control output (OSSD 1/2)

OSSD 1

OSSD 2

L1

L2

A

A2

IL+

IL-

IU+

IU-

O1

O2

X1

X2

X3

T1

T2

Control output (OSSD 1/2)

Muting lamp connecting terminals

Interference prevention terminals (downstream)

For details, refer to Interference Prevention Function see "

Function" on page

Interference prevention terminals (upstream)

For details, refer to Interference Prevention Function see "

Function" on page

Override input terminals

Reset input terminals:

When X1 and X2 are connected: manual reset

When X1 and X3 are connected: auto-reset

Emission halt input terminals (open: emission halt, short-circuit: emission)

54.

54.

2.2 Part Description

Interference Prevention

Interference Prevention

13

Page 22

Before Using this Device

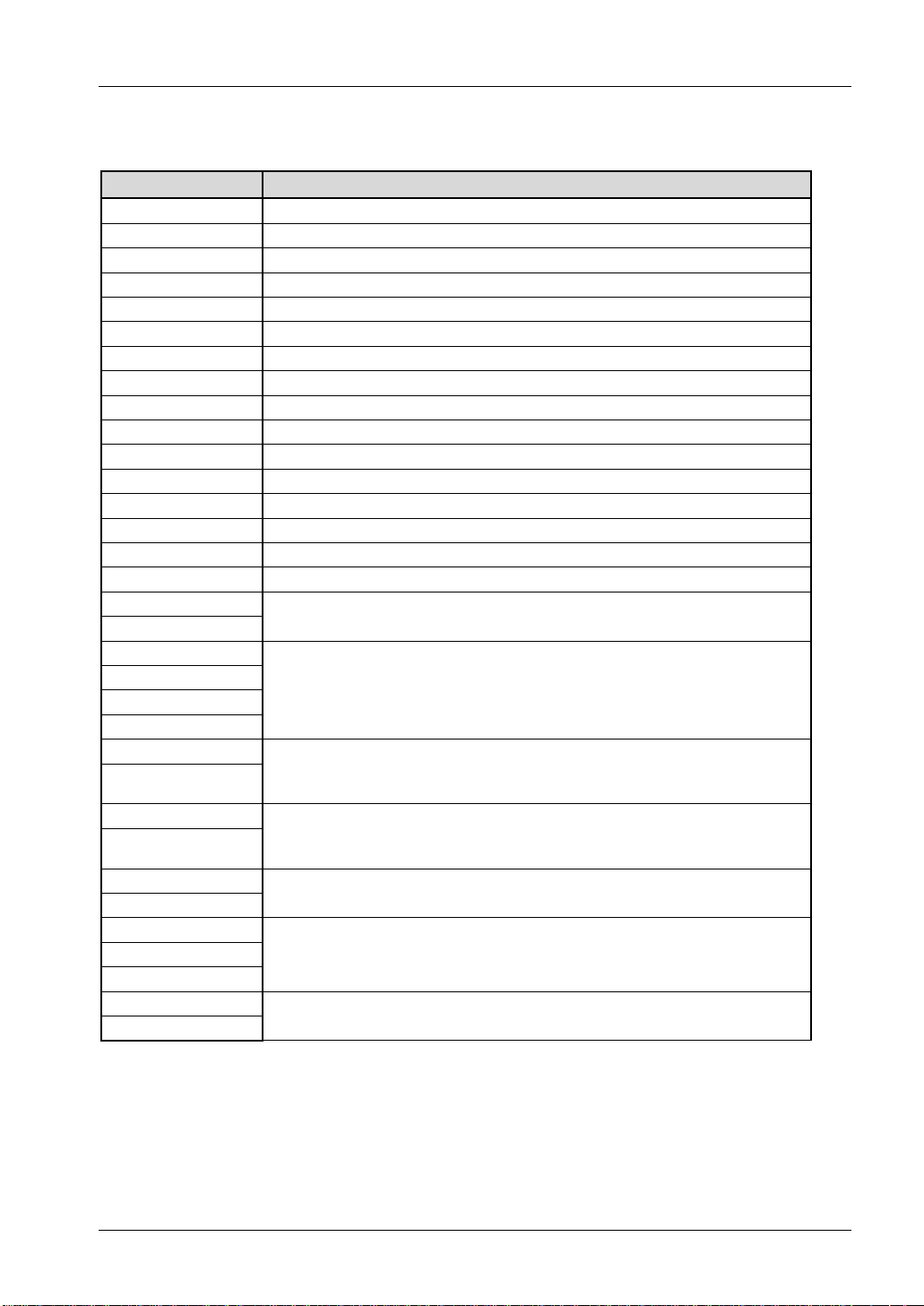

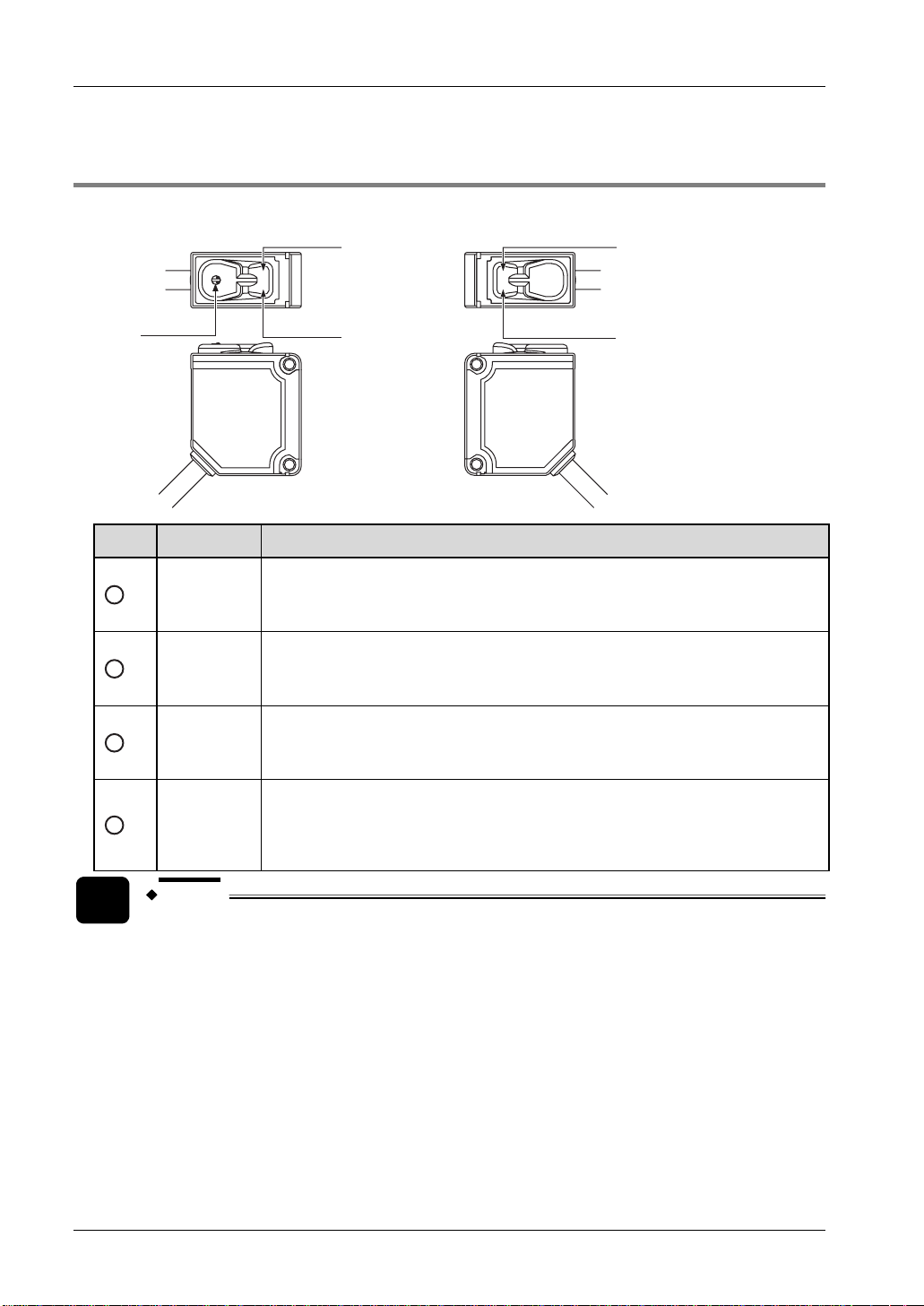

2.2.3 Elements of the Sensor ST4-A

Emitter Receiver

1

Panasonic ST4 Instruction Manual

2

3

1

2

3

4

Identifier Function

Beam

emission

indicator

(Green)

Beam

interruption

indicator

(Red)

Emission

amount

adjuster

(Note 1)

Stable

incident

beam

indicator

(Green)

2

4

Lights up during beam emission of the sensor.

Turns off during emission halt of the sensor.

Lights up during beam interruption of the sensor.

Lights up during lock out.

Turns off during beam reception of the sensor.

Adjusts the emission amount.

For details, refer to Operation Test (see page

Function (see page

Lights up when incident beam intensity is over 150%. (Note 2)

Turns off when incident beam intensity is 150% or less. (Note 2)

57).

46) or Emission Amount Adjustment

14

NOTE

1. Only available with the ST4-A□V type.

2. The incident beam intensity that turns the control output (OSSD 1/2) to ON is

regarded as 100%.

Page 23

Panasonic ST4 Instruction Manual

2.3 Protection Area

2.3.1 Sensing Range

DANGER!

2.3 Protection Area

!

that the operator must pass through the sensing area of the

single beam sensor to reach the dangerous parts of the machine.

Failure to do so can result in death or serious injury.

Do not use any reflection type or recursive reflection type

arrangement.

Installing multiple sets of this device produces a non-sensing

area or causes mutual interference, which may result in death or

Be sure to install a protective structure around the machine so

serious injury.

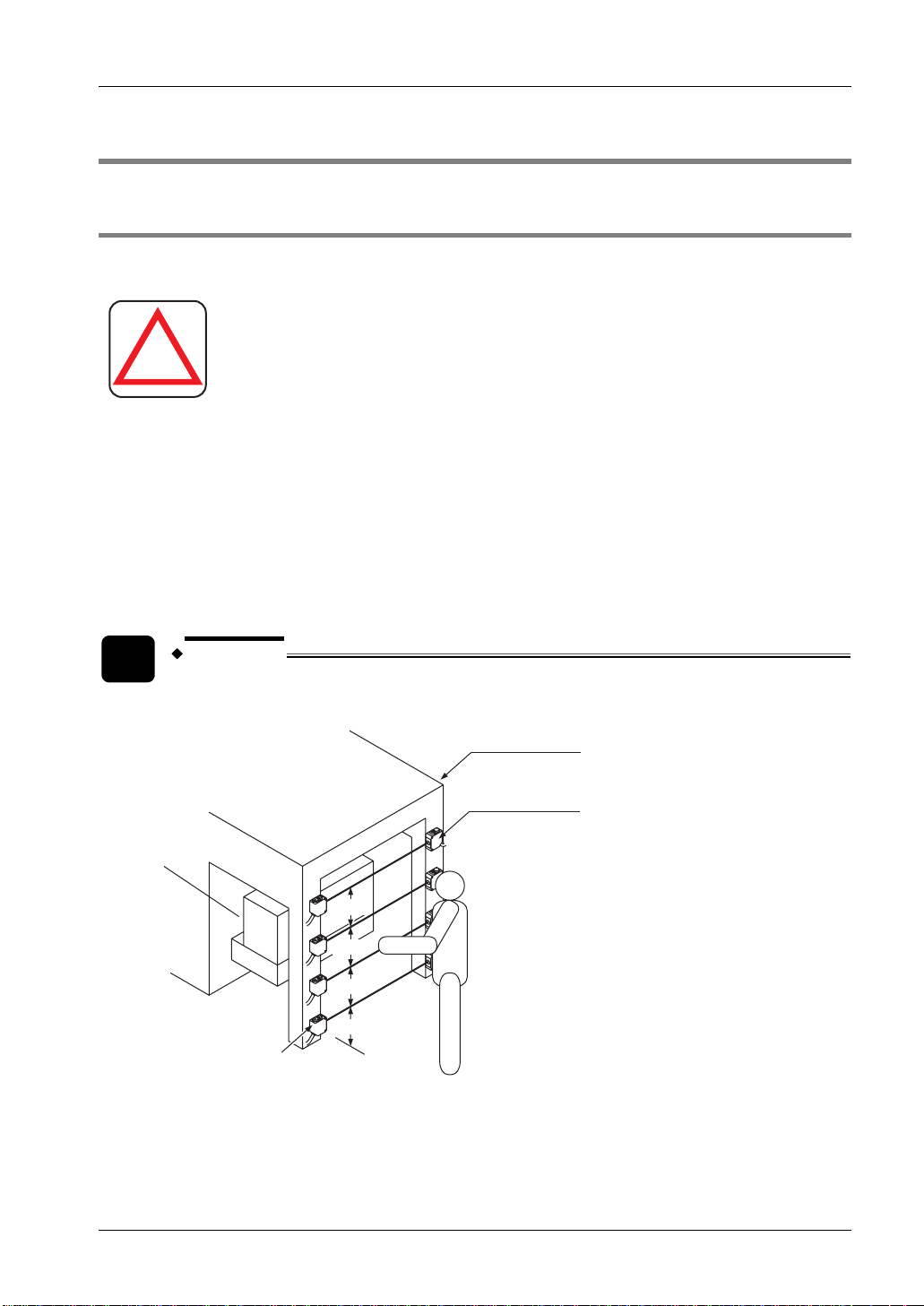

This example shows what a protective structure could be, where the dangerous part of a

machine should be situated and how the emitter and receiver can be arranged.

EXAMPLE

Installing four units of the ST4-A□

Protective structure

Receiver of the

Dangerous

part

ST4-A□

300mm

300mm

300mm

Emitter of the

ST4-A□

300mm

15

Page 24

Before Using this Device

Panasonic ST4 Instruction Manual

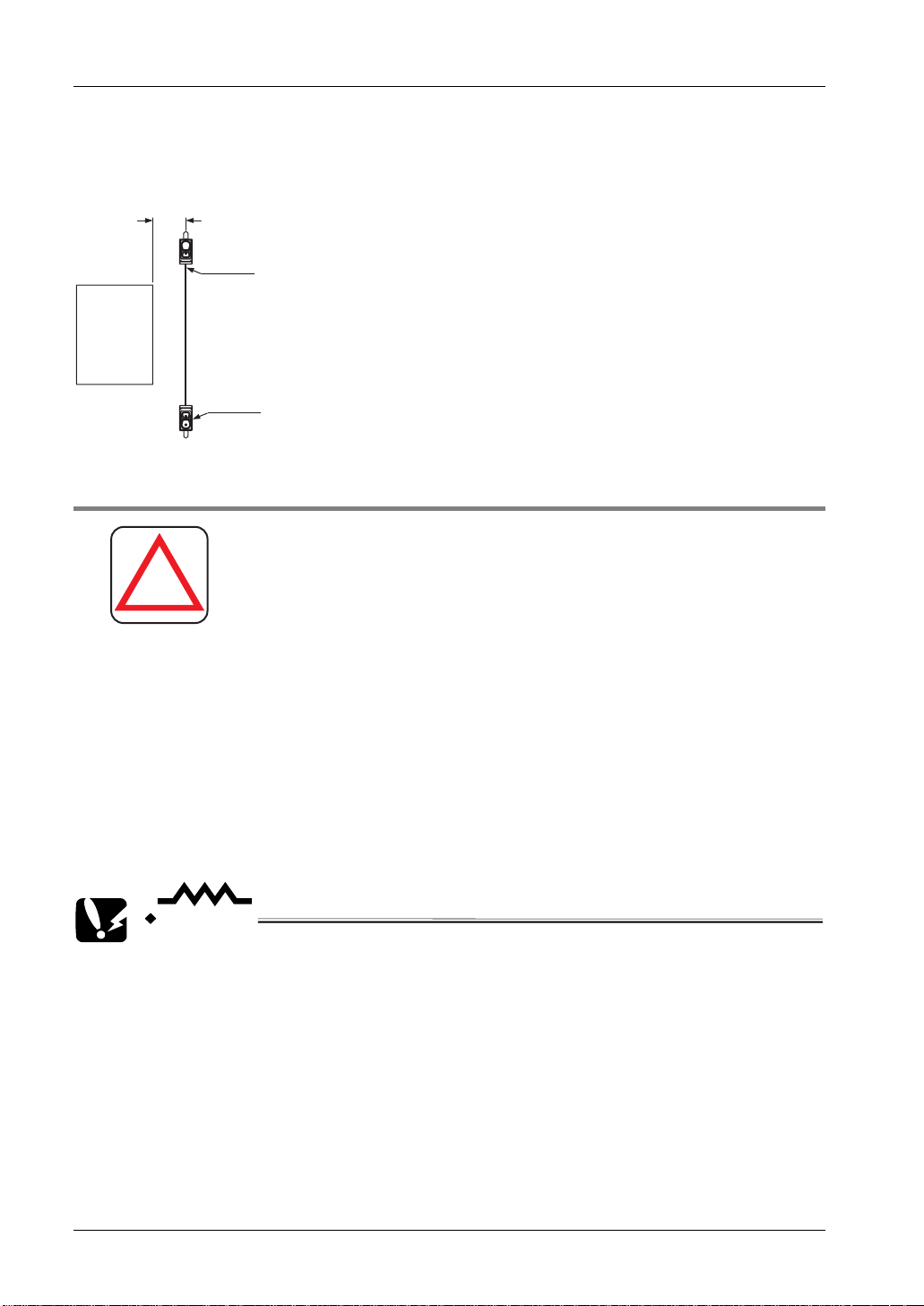

Top view

From the top view the safety distance between the sensing area and the dangerous part is

clearly visible.

Safety distance S (Ds)

Receiver of the

ST4-A□

Dangerous

part

Emitter of the

ST4-A□

2.3.2 Safety Distance

DANGER!

!

Calculate the safety distance correctly, and always

maintain a distance equal to or greater than the safety

distance, between the sensing area of this device and the

dangerous parts of the machine. If the safety distance is

miscalculated or if sufficient distance is not maintained,

the machine will not stop quickly before reaching to the

dangerous parts, which can result in death or serious

injury.

The safety distance is the minimum distance that must be maintained between the ST4-A and

the dangerous parts of the machine so that the machine can be stopped before a human body

or an object can reach the dangerous parts.

The safety distance is calculated based on the equation (see page

17) when a person moves

perpendicular to the sensing area of the area sensor.

CAUTION

• Before designing the system, refer to the relevant standards of the region

where the single beam sensor is to be used.

• The equation should only be used when the intrusion direction is

perpendicular to the sensing area. If the intrusion direction is not

perpendicular to the sensing area, be sure to refer to the relevant standard

(regional standard, specification of the machine, etc.) for details of the

calculation.

16

• The max. response time of the machine is from the point when the machine

receives the halt signal from this device to the point when the dangerous

part of the machine stops. The max. response time of the machine should be

timed with the machine actually used.

Page 25

Panasonic ST4 Instruction Manual

2.3 Protection Area

2.3.2.1 Calculation Example for Europe

The minimum safety distance S is calculated in accordance with EN 999 and ISO 13855 with

the following equation:

S:

K:

T:

C:

S = K x T + C

Safety distance (mm)

Minimum distance required between the sensing area surface and the dangerous

parts of the machine.

Intrusion velocity of operator's body or object (mm/s). The equation assumes an

intrusion direction perpendicular to the sensing area. The recommended value is

1600 mm/s.

+ T

Response time of total equipment (s). T = T

: Maximum halt time of the machine (s). To determine Tm, refer to the

T

m

m

ST4

machine documentation or take a measurement using a special device

called a "brake monitor".

T

: Response time of the safety beam sensor (s).

ST4

Additional distance (mm).

Depending on the height of the beam axis EN 999 recommends different additional

distances as shown in the following table.

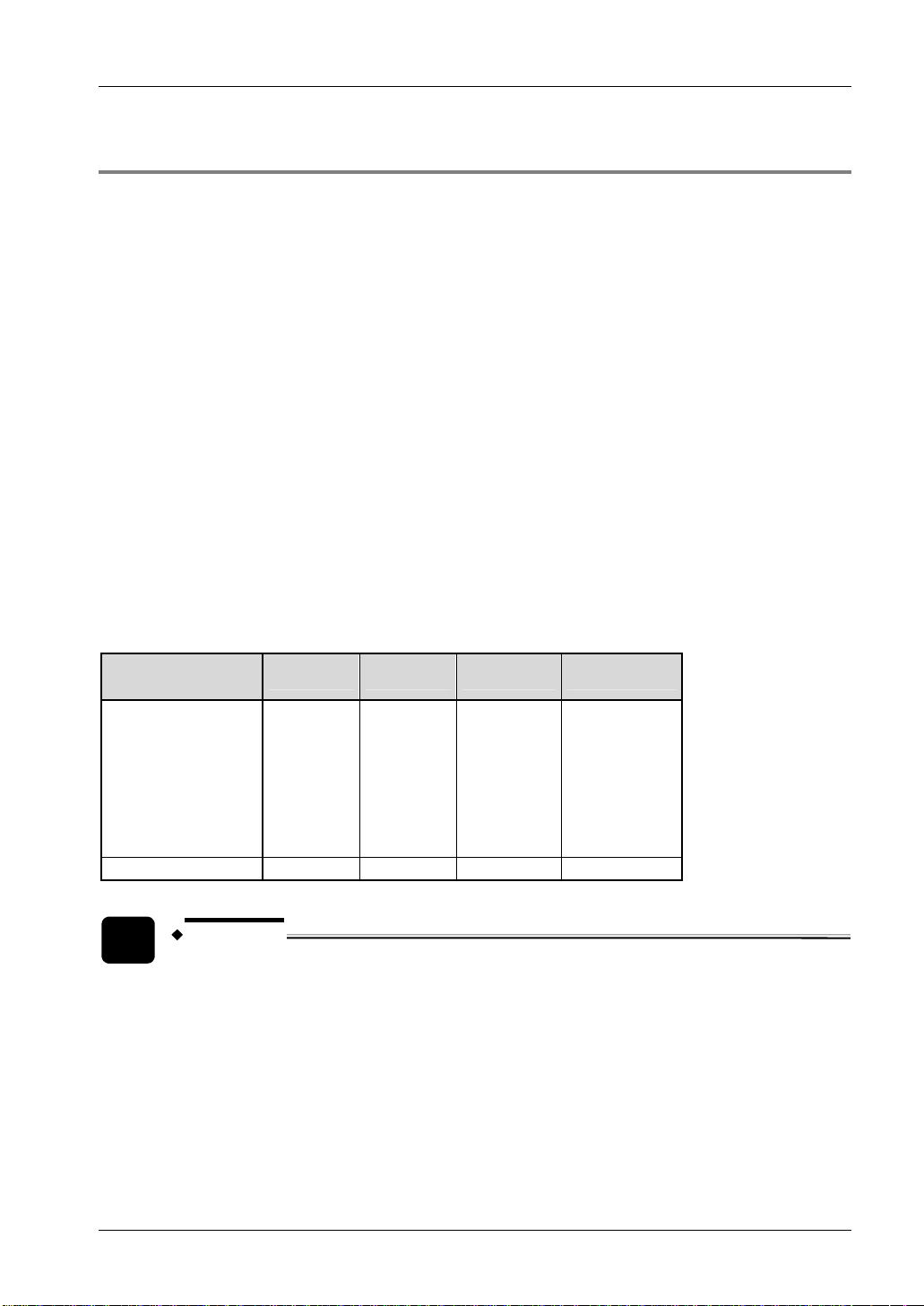

Number of beam

axes

Height of beam axis

(e.g. height from the

floor)

Additional distance 1200mm 850mm 850mm 850mm

EXAMPLE

1 2 3 4

750 mm 400mm 300mm 300mm

900mm 700mm 600mm

1100mm 900mm

1200mm

Calculation of the safety distance (S) with the following values and four units of the

ST4-A installed.

K: 1600mm/s

T

: 0.1s

m

T

: 0.025s

ST4

C: 850mm

17

Page 26

Before Using this Device

S = K x T + C

Panasonic ST4 Instruction Manual

= 1600 × (T

m

+ T

) + 850

ST4

= 1600 × (0.1s + 0.025s) + 850

= 1600 × 0.1s

+ 1600 × 0.025 + 850

= 160 + 40 + 850

= 1050

Hence, as per the calculations S is 1050mm.

2.3.2.2 Calculation Example for the US

The safety distance Ds is calculated in accordance with ANSI/RIA 15.06 with the equation:

Ds:

Ds = K × T + D

Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous

parts of the machine

K:

Intrusion velocity of operator's body or object. The recommended value in OSHA is

63inch/s ( 1600mm/s).

ANSI/RIA 15.06 does not define the intrusion velocity "K." When determining K,

consider possible factors including the physical ability of the operators.

T:

Response time of total equipment (s). T = Ts + Tc + T

T

is the worst stopping time of the machine/equipment

s

T

is the worst stopping time of the control system

c

pf

ST4

18

T

is the response time of the safeguarding device (25ms)

ST4

Dpf:

Additional distance calculated from the size of the minimum sensing object of the

sensor (mm).

REFERENCE

Since the calculation is based on 1 inch = 25.4mm, there is a slight difference

between the representation in mm and that in inches. Refer to the relevant

standard for the details.

Page 27

Panasonic ST4 Instruction Manual

2.3 Protection Area

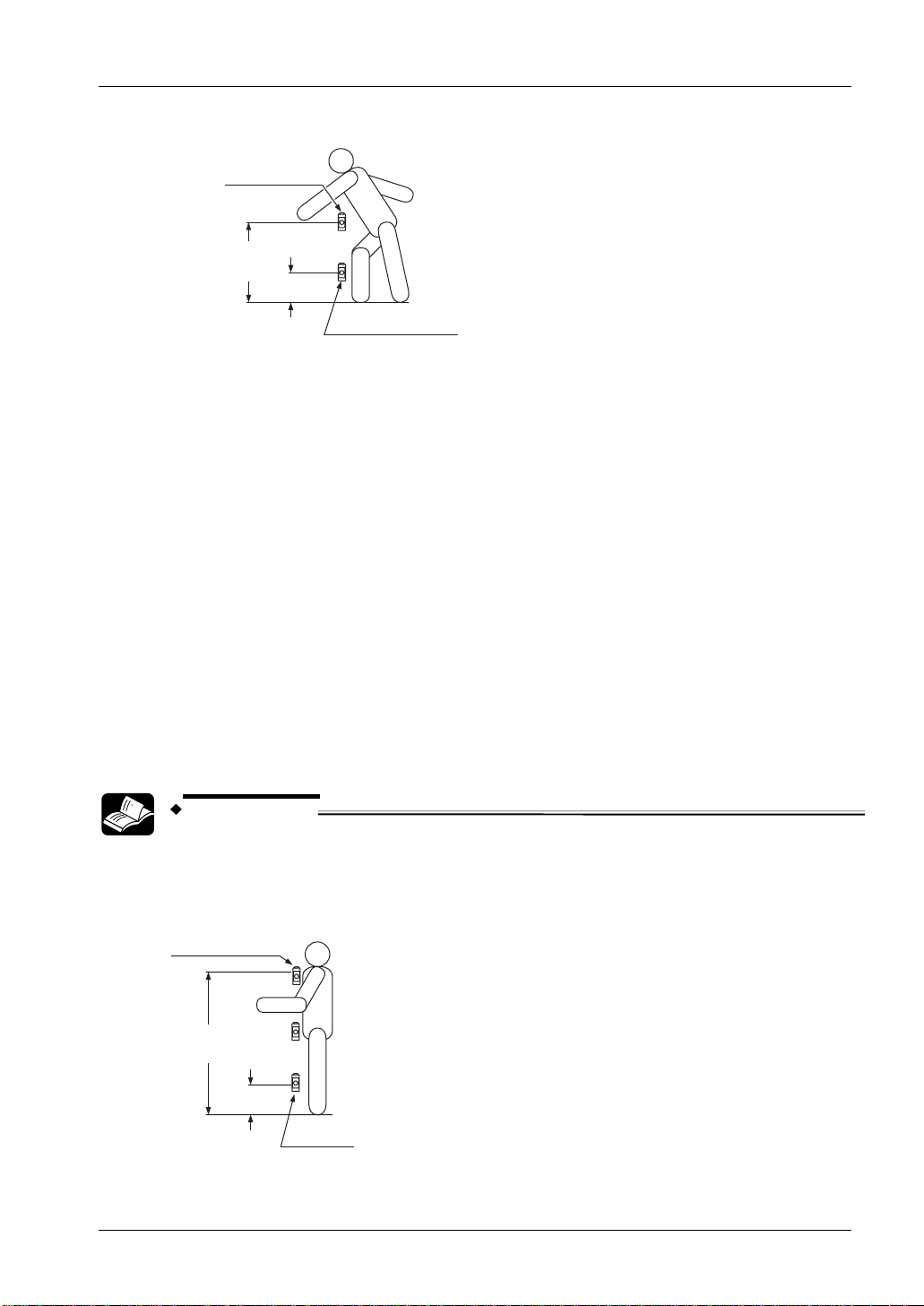

Example calculation of the safety distance for a "REACH OVER" application

Topmost beam axis

35.434 inch (≈ 900mm) or more

11.812 inch (≈ 300mm) or less

Undermost beam axis

The following default values of ANSI/RIA 15.06 are used for the example calculation:

Detectable minimum sensing

object

Undermost beam axis: 11.812inch ( 300mm) or less

Topmost beam axis 35.434inch ( 900mm) or more

T

D

pf

Ds

= K × T + Dpf

Min. 2.52inch ( 64mm) and max. 23.623inch ( 600mm)

0.5s

47.245inch ( 1200mm)

= 63 × T + 47.245

= 63 × 0.5 + 47.245

= 31.5 + 47.245

= 78.745inch

= 2000.123mm

2001mm

Hence Ds = 2001mm.

REFERENCE

Since the calculation is based on 1 inch = 25.4mm, there is a slight difference between the

representation in mm and that in inches. Refer to the relevant standard for the details.

Example calculation of the safety distance for a "REACH THRU" application

Topmost beam axis

47.245 inch

(

≈ 1200mm) or more

11.812 inch

(≈ 300mm) or less

Undermost

beam axis

The following default values of ANSI/RIA 15.06 are used for the example calculation:

19

Page 28

Before Using this Device

Detectable minimum sensing object Min. 2.52inch ( 64mm) and max. 23.623inch ( 600mm)

Undermost beam axis 11.812inch ( 300mm) or less

Topmost beam axis 47.245inch ( 1200mm) or more

T

D

pf

Ds

= K × T + Dpf

0.5s

35.434inch ( 900mm)

Panasonic ST4 Instruction Manual

= 63 × T + 35.434

= 63 × 0.5 + 35.434

= 31.5 + 35.434

= 66.934inch

= 1700.1236mm

1701mm

Hence Ds = 1701mm.

REFERENCE

Since the calculation is based on 1 inch = 25.4mm, there is a slight difference between

the representation in mm and that in inches. Refer to the relevant standard for the

details.

2.3.3 Influence of Reflective Surfaces

DANGER!

!

If a reflective surface exists where this device is to be installed,

make sure to install this device so that reflected light from the

reflective surface does not enter the receiver. Alternatively, take

countermeasures such as painting, masking, roughening, or

changing the material of the reflective surface, etc. Failure to do so

may cause the device not to detect, resulting in serious injury or

death.

20

Page 29

Panasonic ST4 Instruction Manual

2.3 Protection Area

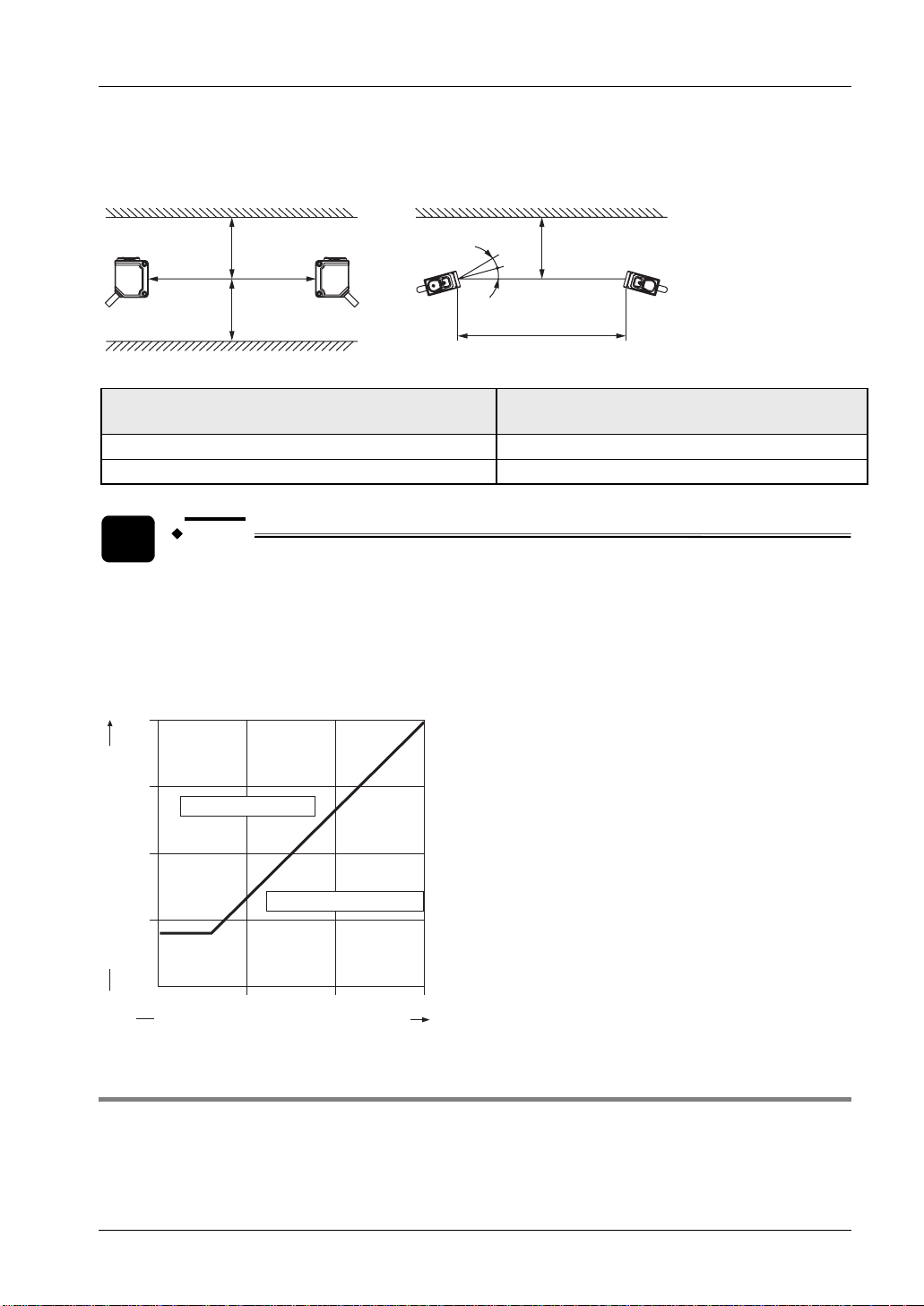

Install this device at a distance of at least A m (provided as follows) away from reflective

surfaces such as metal walls, floors, ceilings, work pieces, covers, panels or glass surfaces.

Side view Top view

Reflective ceiling

Reflective surface

Emitter

A A

Sensing range

A

Reflective floor

Distance between emitter and receiver (sensing

Receiver

L

Emitter

∂°

∂°

Sensing range L

Allowable installation distance A

range L)

0.1 to 3m 0.16m

3 to 15 m L/2 x tan 2 = L x 0.053m ( = 3°)

NOTE

The effective aperture angle for this device is ±2.5° (when L > 3m) as required by

IEC 61496-2/UL 61496-2. However, install this device away from reflective

surfaces, taking into consideration an effective aperture angle of ±3° to account

for beam misalignment during installation.

Allowable distance from sensor beam axis to reflective surface

0.8

0.6

Install in this area

0.4

Do not install in this area

0.2

Allowable installation distance A (m)

0 5 10 15

Distance between emitter and receiver L (m)

2.3.4 Placement of Emitter and Receiver

You can install a system in which multiple sets of controllers and their respective sensors face

each other. Use this configuration if there is a problem in wiring or additional equipment has to

be protected. If you arrange multiple sets, perform an operation test (see page

46).

21

Page 30

Before Using this Device

DANGER!

Panasonic ST4 Instruction Manual

!

understand them thoroughly before installation. Improper

placement could cause device malfunction, which can result in

serious injury or death.

If this device is used in multiple sets, avoid mutual interference.

If mutual interference occurs, it can result in serious injury or

death.

Refer to the examples of device placement as follows and

EXAMPLE

Arrangement of the emitter and receiver back to back:

ST4-A□ ST4-A□

EmitterReceiver

ST4-C11

ST4-C12EX

or

Emitter

Receiver

Arrangement of the emitter and receiver vertically on opposite sides:

22

ST4-A□

Emitter Receiver

Receiver

ST4-A□

Emitter

ST4-C11

or

ST4-C12EX

ST4-C11

or

ST4-C12EX

Page 31

Panasonic ST4 Instruction Manual

Arrangement of the emitter and receiver horizontally on opposite sides

2.3 Protection Area

Receiver

Emitter

ST4-A□

or

Emitter

ST4-A□

Receiver

ST4-C11

ST4-C12EX

Installation of a barrier

ST4-A□

NOTE

ReceiverEmitter

Barrier

ST4-C11

ST4-C12EX

Emitter

or

ST4-A□

Receiver

The preceding arrangements are just examples of device placement. If there are

any questions or problems, please contact our office.

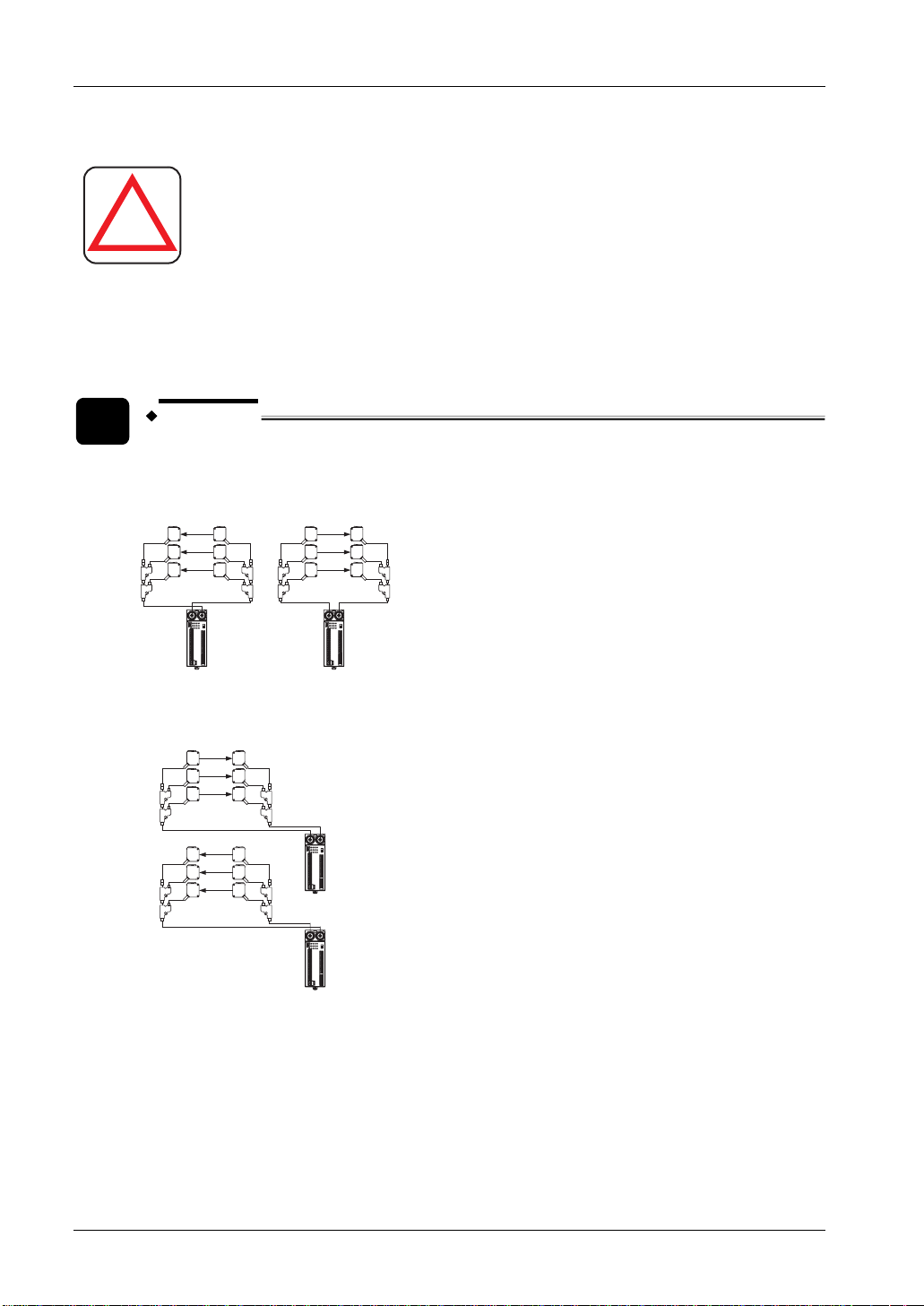

2.3.5 Connecting Multiple Sensors Heads

You can connect up to six units of the ST4-A per controller.

The cable length between all emitters and the controller, as well as between all receivers and

the controller, must not exceed 50m, respectively.

23

Page 32

Before Using this Device

DANGER!

Panasonic ST4 Instruction Manual

!

emitters and receivers, the device will not operate properly. This

may result in serious injury or death.

The cable length between all emitters and the controller, as well

as between all receivers and the controller, must not exceed

50m, respectively. If this length is exceeded it leads to improper

operation of the device, resulting in serious injury or death.

If you hook up the connectors incorrectly or mix connecting the

EXAMPLE

Six sensor units can be connected, whereas the following cables are used:

A1 + A2 + A3 + A4 + A5 + A6 + B1 + B2 + B3 + B4 + B5 + B6

Emitter of Receiver of

A6

A5

A4

B6

B5

B4

B3

ST4-A□

S6

S5

S4

S3

S6

S5

S4

S3

ST4-A□

B6

B5

B4

B3

A6

A5

A4

1.

2.

24

A3

A2

Branch cable

ST4-CCJ05-WY

(Optional)

B2

B1

A1

Extension cable

ST4-CCJ□

(Optional)

S2

S1

S2

S1

ST4-C11

ST4-C12EX

B2

B1

A1

or

A3

A2

3.

Procedure

1. Insert the male emitter connector of the ST4-A□ (color: gray) into the female

emitter connector of the controller (color: gray).

2. Insert the male receiver connector of the ST4-A□ (color: black) into the

female receiver connector of the controller (color: black).

Page 33

Panasonic ST4 Instruction Manual

3. Make sure to use the optional exclusive cable (ST4-CCJ□, ST4-CCJ05-WY)

for wiring, and match the connector colors (gray: emitter, black: receiver).

4. After installing the ST4-A□, check that the ST4-A□ detects a part of human

body before it reaches to the dangerous part of the machine, by watching the

beam interruption indicator (red).

2.3 Protection Area

5. Check that the ST4-A□ is installed in the proper position.

2.3.6 Address Allocations of the Sensor ST4-A□

When connecting multiple units of the ST4-A, addresses are automatically allocated to the

newly connected units of the ST4-A, beginning with the unit closest to the controller.

The corresponding emitter and receiver have the same address (see following example).

The automatic interference prevention function is based on the address of the sensors.

CAUTION

Ensure that the emitter and the receiver operate only in combination with the

same address.

EXAMPLE

25

Page 34

Before Using this Device

Connection example 1: No branching between the ST4-A and the ST4-CCJ05-WY

when six units are connected

Panasonic ST4 Instruction Manual

Branch cable

ST4-CCJ05-WY

(Optional)

Emitter of

6

5

4

3

2

1

Extension cable

ST4-CCJ□

(Optional)

ST4-A□

Address 6

Address 5

Address 4

Address 3

Address 2

Address 1

Receiver of

Address 6

Address 5

Address 4

Address 3

Address 2

Address 1

ST4-C11

ST4-C12EX

ST4-A□

6

5

4

3

2

1

or

NOTE

Addresses are automatically allocated in the order of the arrows shown in the

preceding figure.

26

Page 35

Panasonic ST4 Instruction Manual

EXAMPLE

Connection example 2: Branching between the ST4-A and ST4-CCJ05-WY when six

units are connected

2.3 Protection Area

Branch cable

ST4-CCJ05-WY

(Optional)

6

5

3

2

1

Extension cable

ST4-CCJ□

(Optional)

Emitter of

4

ST4-A□

Address 6

Address 5

Address 4

Address 3

Address 2

Address 1

Address 6

Address 5

Address 4

Address 3

Address 2

Address 1

ST4-C11

ST4-C12EX

Receiver of

4

or

ST4-A□

6

5

3

2

1

NOTE

• Addresses are automatically allocated in the order of the arrows shown in

the preceding figure.

• Addresses of the ST4-A□ are allocated in the order of the numbers that are

marked on the main body of ST4-CCJ05-WY (optional).

27

Page 36

Before Using this Device

• Connect the ST4-A□s to the connector numbers 2 and 3 of the branch cable

ST4-CCJ05-WY (optional). If the ST4-A□s are not connected to the

connectors 2 and 3, the device will not operate properly. For an unconnected

condition, the fault indicator (yellow) of ST4-C11 blinks once. For

ST4-C12EX, "

Panasonic ST4 Instruction Manual

" is indicated on the fault display (red).

2

1

3

28

Page 37

Panasonic ST4 Instruction Manual

2.4 Mounting and Removing

2.4.1 Mounting and Removing the Controller

The controller can be mounted on a 35mm width DIN rail.

2.4 Mounting and Removing

1.

2.

3.

Procedure

1. Push the DIN rail stopper.

2. Fit the tab on the opposite side of the DIN rail stopper onto the DIN rail.

3. Press the device into place.

2

Remove the controller.

1.

2.

3.

Procedure

1. Insert a flathead screwdriver into the groove of the DIN rail stopper and pull

out the stopper.

2. Push the controller in the opposite direction.

DIN rail stopper

1

3

35mm width DIN rail

3. Lift and remove the controller.

1

3

2

1

CAUTION

Removing the controller without unlocking the DIN rail stopper may cause the

tabs to break.

29

Page 38

Before Using this Device

Panasonic ST4 Instruction Manual

2.4.2 Mounting the Sensor ST4-A□

Select the sensor mounting bracket based on the installation environment. The mounting

bracket is not included with this device. Please purchase the optional sensor mounting bracket

that fits with the mounting environment.

DANGER!

!

After installing the ST4-A□, check that the ST4-A□ detects a part

of human body before it reaches to the dangerous part of the

machine, by watching the beam interruption indicator (red).

Also check that ST4-A□ is installed in a proper position.

CAUTION

• Do not apply an improper load such as forcibly bending the cable of the

single-beam sensor, because the wire could break.

• The minimum bending radius of the cable is R5mm. When mounting,

consider the cable bending radius.

The following procedure shows the mounting of the single-beam sensor with the mounting

bracket MS-CX1.

NOTE

• Mount the emitter and the receiver at the same level and parallel to each

other. The effective aperture angle of this device is ±2.5° or less for a sensing

distance of 3m or more.

• In preparation for mounting, prepare mounting holes on the mounting

surface (see "

Dimensions" on page 95).

1.

2.

30

3.

Procedure

1. Mount the sensor with the M3 screws with washers (length 12mm) attached

to the sensor mounting bracket (optional).

Page 39

Panasonic ST4 Instruction Manual

The tightening torque should be 0.5N·m or less.

2. Mount the sensor on the mounting surface with M3 screws with washers.

2.4 Mounting and Removing

2.4.3 Connecting Controller and Sensor ST4-A□

DANGER!

!

The emitter of the ST4-A (connector color: gray) has to be connected with the emitter

connector of the controller (connector color: gray). The receiver of the ST4-A (connector color:

black) has to be connected with the receiver connector of the controller (connector color: black).

CAUTION

• Make sure to turn OFF the power before connecting disconnecting the

cables.

• Securely tighten by hand the fixing ring on the emitter or receiver of the

ST4-A□.

If you hook up the connectors incorrectly or mix connecting the

emitters and receivers, the device will not operate properly. This

may result in serious injury or death.

• If the fixing ring on the emitter/receiver of the ST4-A□ is tightened with pliers,

the connector may be damaged.

• If the tightening torque is insufficient, the fixing ring on the emitter or

receiver of the ST4-A□ may loosen due to vibrations, etc.

31

Page 40

Before Using this Device

Connecting the single-beam sensor with the controller:

Panasonic ST4 Instruction Manual

1.

2.

3.

Procedure

1. Insert the male connector of the ST4-A□ in connector of the controller.

2. Turn the fixing ring to tighten.

Fixing ring

Disconnecting

1.

2.

3.

Procedure

1. Loosen the fixing ring.

2. Pull out the connector by holding the fixing ring.

Emitter connector of the controller

Receiver connector of the controller

Connector of

ST4-A□

Fixing ring

CAUTION

• Before removing the connectors, make sure that the fixing rings are fully

loosened.

• If the connectors are forcibly pulled out with the fixing rings tightened, the

connectors may be damaged.

2.4.4 Series Connection of the Sensor ST4-A□

You can connect up to six units of the ST4-A per controller in series.

When connecting several sensors, the extension cable ST4-CCJ (optional) and the branch

cable ST4-CCJ05-WY (optional) are needed. Please purchase them separately.

32

Page 41

Panasonic ST4 Instruction Manual

DANGER!

2.4 Mounting and Removing

!

The emitter of the ST4-A (connector color: gray) has to be connected with the emitter

connector of the controller (connector color: gray). The receiver of the ST4-A (connector color:

black) has to be connected with the receiver connector of the controller (connector color: black).

• Addresses of the ST4-A□ are allocated in the order of the numbers that are

• Connect the ST4-A□s to the connector numbers 2 and 3 of the branch cable

If you hook up the connectors incorrectly or mix connecting the

emitters and receivers, the device will not operate properly. This

may result in serious injury or death.

The cable length between all emitters and the controller, as well

as between all receivers and the controller, must not exceed

50m, respectively. If this length is exceeded it leads to improper

operation of the device, resulting in serious injury or death.

After installing the ST4-A□, check that the ST4-A□ detects a part

of human body before it reaches to the dangerous part of the

machine, by watching the beam interruption indicator (red). Also

check that ST4-A□ is installed in a proper position.

NOTE

marked on the main body of ST4-CCJ05-WY (optional).

ST4-CCJ05-WY (optional). If the ST4-A□s are not connected to the

connectors 2 and 3, the device will not operate properly. For an unconnected

condition, the fault indicator (yellow) of ST4-C11 blinks once. For

ST4-C12EX, "

" is indicated on the fault display (red).

2

1

3

To connect the sensor in series, you need at least two sets of receiver and emitter of the

ST4-A, two extension cables ST4-CCJ□s and two branch cables ST4-CCJ05-WY.

1.

2.

3.

Procedure

33

Page 42

Before Using this Device

1. Insert the male connectors of the extension cables ST4-CCJ□s into the

connector of the controller, and turn the fixing ring to fix.

2. Insert connector no. 1 of the branch cables ST4-CCJ05-WY into the female

connectors of both extension cables ST4-CCJ□, and tighten the fixing ring.

Emitter connector of

the controller

Receiver connector

of the controller

Male connector of

ST4-CCJ□

Fixing ring

Panasonic ST4 Instruction Manual

Female

connector of

ST4-CCJ□

Fixing ring

Connector 1 of

ST4-CCJ05-WY

3. Insert the connector of the ST4-A□ into connector no. 2 of the branch cable

ST4-CCJ05-WY, and tighten the fixing ring.

ST4-A

K

Connector 2 of

Connector of

Fixing ring

ST4-CCJ05-WY

Fixing ring

4. Insert the connector of the second set of the ST4-A□ into connector no. 3 of

the branch cable ST4-CCJ05-WY, and tighten the fixing ring. If you want to

connect further sensors, insert connector no.1 of the third and fourth branch

cable ST4-CCJ05-WY to the connector no. 3 of first and second branch cable,

and tighten the fixing rings. After that, repeat the procedures 3 and 4.

Connector 3 of

Fixing ring

ST4-CCJ05-WY

Connector of

ST4-A□

34

Fixing ring

5. Use a M5 small pan head screw (please arrange separately) to mount

ST4-CCJ05-WY.

Page 43

Panasonic ST4 Instruction Manual

The tightening torque should be 0.7N·m or less.

M5 small pan

head screw

To remove the sensor:

2.4 Mounting and Removing

1.

2.

3.

Procedure

1. Loosen the fixing ring.

2. Pull out the connector by holding the fixing ring.

Fixing ring

Connector

CAUTION

• Before removing the connector, make sure that the fixing ring is fully

loosened. If the connector is forcibly pulled out with the fixing ring tightened,

the connector may be damaged.

35

Page 44

Before Using this Device

Panasonic ST4 Instruction Manual

2.5 Wiring

Read the following warnings carefully before wiring.

DANGER!

!

Switch off the power before wiring the device.

All electrical wiring should conform to the regional electrical

regulations and laws. The wiring should be done by engineer(s)

having the required electrical knowledge.

Do not run the sensor cable together with high-voltage lines or

power lines or put them together in the same raceway.

Take countermeasures regarding the system to ensure that

dangerous performance caused by the earth failure cannot

occur. Failure to do so could cause jeopardize the system stop,

resulting in serious bodily injury or death.

In order that the output is not turned ON due to earth fault of

control output (OSSD 1/2) terminal, be sure to ground to the 0V

side for PNP output or the 24V side for NPN output.

2.5.1 Power Supply Unit

The wiring of the power supply unit should be performed by a specialist who has the required

electrical knowledge.

NOTE

Use a safety relay unit or an equivalent control safety circuit for FSD.

DANGER!

!

The DC power supply unit must satisfy the following conditions.

• The power supply unit must be authorized for use in the region where this device is to be

used.

• The power supply unit must conform to the EMC Directive and Low-Voltage Directive

36

Wire correctly and use a power supply unit which conforms to

the laws and standards of the region where this device is to be

used. If the power supply unit does not conform to regional

requirements or the wiring is improper, may malfunction or be

damaged, which can result in serious injury or death.

Page 45

Panasonic ST4 Instruction Manual

2.5 Wiring

(where CE certification is required). The power supply unit must conform to CLASS 2

(where UL/cUL certification is required).

• If the power supply conforms to the Low-Voltage Directive and has an output of 100VA

or less, it is suitable.

• The frame ground (F.G.) terminal must be connected to ground when using a

commercially available switching regulator.

• The power supply unit must have an output holding time of 20ms or more.

• If there is a possibility of surge, take countermeasures such as connecting a surge

absorber to the origin of the surge.

2.5.2 I/O Circuit Diagrams

The following diagrams show the circuits of the controller and the wiring for different functions

and parts of the system.

2.5.2.1 Circuit of Controller ST4-C11

Controller ST4-C11

PNP output

24V

A1

3

Ui

2

A2

0V

1

= Main circuit

2

= Emitter side

3

= Receiver side

4

= Output polarity switch

5

= Emission halt input

PNP

NPN

4

1

X1 X2

Reset

KA

X3

T1

5

T2

AUX

IU+ IU- IL+ IL-

OSSD1

OSSD2

KAKBKB

0V

37

Page 46

Before Using this Device

NPN output

24V

A1

3

PNP

4

X1

X2

Reset

KA

KB

X3

Panasonic ST4 Instruction Manual

IU+ IU- IL+ IL-

AUX

NPN

Ui

1

2

A2

0V

T1

T2

5

1

= Main circuit

2

= Emitter side

3

= Receiver side

4

= Output polarity switch

5

= Emission halt input

2.5.2.2 Circuit of Multifunctional Controller ST4-C12EX

NOTE

KA and KB are the external devices (forcibly guided relay or magnetic

contactor).

OSSD1

KA

OSSD2

KB

24V

Multifunctional Controller ST4-C12EX

PNP output

Output polarity

selection switch

PNP

PNP

NPN

NPN

S-AS+ S-B S- S-CS+ S-D S- S-ES+

(PNP output type)

Muting input

X1 X2 X3

Main circuit

Muting sensor

Muting sensor

(NPN output type)

Receiver side

Emitter side

38

24V

A1

A2

0V

Reset

KA

KB

S-F S- T2T1 O1 O2 L2L1

OUT

+V

PLC etc.

AUX2AUX1 AUX3 AUX4

0V

Emission

halt input

Override input Muting lamp

IU-IU+ IL+ IL-

OSSD1 OSSD2

KA KB

0V

Page 47

Panasonic ST4 Instruction Manual

NPN output

2.5 Wiring

Receiver side

Emitter side

24V

A1 X1 X2 X3

A2

0V

NOTE

Output polarity

selection switch

PNP

NPN

S-AS+ S-B S- S-CS+ S-D S- S-ES+

Main circuit

Muting sensor

(PNP output type)

Muting input

Muting sensor

(NPN output type)

Reset

KA

KB

S-F S- T2T1 O1 O2 L2L1

OUT

+V

PLC, etc.

AUX2AUX1 AUX3 AUX4

0V

Emission

halt input

Override input Muting lamp

IU-IU+ IL+ IL-

OSSD1 OSSD2

KA KB

24V

• KA and KB are the external devices (forcibly guided relay or magnetic

contactor).

• When using the normally open (NO) contact switch as a

S-AS+S-B S-

muting sensor, wire as shown right.

2.5.2.3 Manual and automatic reset

By wiring the reset input terminals (X1, X2, and X3) as shown, you can select a manual or an

automatic reset, with or without back check.

Manual reset

When the back check circuit is

needed:

Reset

KA

KB

X2 X3

X1

Automatic reset

When the back check circuit is

needed:

KA

X1 X2 X3

KB

When the back check circuit is not

needed:

Reset

X1

X2

X3

When the back check circuit is not

needed:

X1 X2 X3

39

Page 48

Before Using this Device

Panasonic ST4 Instruction Manual

2.5.2.4 Emission Halt Input Terminals

The internal circuits of the emission halt input terminals (T1 and T2) as well as the override input

terminals (O1 and O2) are switched by the output polarity selection switch.

Controller ST4-C11

PNP output NPN output

3kΩ

1

1

3kΩ

T1

1

= Main circuit

T2

T1

T2

Controller ST4-C12EX

PNP output NPN output

1

T1

T2 O1 O2

1

= Main circuit

3kΩ3kΩ

1

T1

T2 O1 O2

3kΩ3kΩ

Output waveform (control output OSSD 1/2 ON)

Since the controller performs a self-diagnosis of the output circuit when the sensor is in light

receiving status (ON), the output transistor periodically turns OFF (see following figure). If the

preceding OFF signal is received by the controller the output circuit is judged as normal. If the

OFF signal is not received, the controller judges either the output circuit or wiring as faulty, and

the control output (OSSD 1/2) switches OFF.

CAUTION

Since the OFF signal of this device might cause malfunction, ensure that the

input response time of the machine corresponds to the requirements of this

device.

ON

OSSD 1

OFF

ON

OSSD 2

OFF

30 - 50μs

The values in the preceding picture are approximate values.

50 - 100μs

11m s

30 - 50μs

30 - 50μs

120μs

50 - 100μs120μs

30 - 50μs

40

Page 49

Panasonic ST4 Instruction Manual

2.5 Wiring

2.5.3 Connecting to the Terminal Block

For the connection with the terminal block of the controller, insert a solid wire or twisted wire

(lead wire) with a ferrule into the hole till it stops. The wire is locked when properly inserted.

Flathead

screwdriver

Lead wire

Ferrule (sleeve) terminal

Release button

When connecting a twisted wire (lead wire) without a ferrule, insert the wire to the innermost of

the terminal hole while pressing the release button.

If you want to release the solid wire or the twisted wire (lead wire), pull the wire while pressing

the release button.

CAUTION

However, do not pull the wire with excessive force, as this can cause a cable

break.

The following wires are recommended:

2

• Terminal block connector: 0.2 to 1.5mm

• Power supply side connector (A1, A2) (ST4-C12EX only): 0.2 to 2.5mm

(AWG 24 to 16)

2

(AWG 24 to

12)

2.5.4 Terminal Arrangement Diagram

The following tables list the terminals of the controllers ST4-C11 and ST4-C12EX.

Controller ST4-C11

Terminal name Description

IL+

IL-

IU+

IU-

X1

X2

X3

Interference prevention terminals (downstream)

For details, see "

54.

page

Interference prevention terminals (upstream)

For details, see "

54.

page

Reset input terminals:

• When X1 and X2 are connected: manual reset

Interference Prevention Function" on

Interference Prevention Function" on

• When X1 and X3 are connected: auto-reset

41

Page 50

Before Using this Device

Panasonic ST4 Instruction Manual

Terminal name Description

Multifunctional Controller ST4-C12EX

T1

T2

AUX

OSSD 1

OSSD 2

A1

A2

Emission halt input terminals

(Open: emission halt, Short-circuit: emission)

Negative logic of the control output (OSSD 1/2)

Control output (OSSD 1/2)

24V DC

0V

Terminal

name

S+

S-A

S-B

S-

S+

S-C

S-D

S-

Muting

Pattern

Setting

Switch

S+

S-E

S-F

SAUX1

AUX2

AUX3

AUX4

OSSD 1

OSSD 2

L1

L2

A1

A2

Muting input power supply 24V

Muting input S-A for PNP output type sensor

Muting input S-B for NPN output type sensor

Muting input power supply 0V

Muting input power supply 24V

Muting input S-C (for PNP type)

Muting input S-D (for NPN type)

Muting input power supply 0V

Muting input power supply 24V

Muting input S-E for PNP type

Muting input S-F for NPN type

Muting input power supply 0V

Auxiliary output 1 (muting function)

Auxiliary output 2 (override function)

Auxiliary output 3 (lamp shutoff)

Negative logic of the control output (OSSD 1/2)

Control output (OSSD 1/2)

Muting lamp connecting terminal

24V DC

0V

Description

42

Terminal

name

IL+

IL-

IU+

IU-

Description

Interference prevention terminals (downstream)

For details, see "

54.

page

Interference prevention terminals (upstream)

For details, see "

54.

page

Interference Prevention Function" on

Interference Prevention Function" on

Page 51

Panasonic ST4 Instruction Manual

2.5 Wiring

Terminal

Description

name

O1

O2

X1

X2

X3

T1

T2

Override input terminals

Reset input terminals:

• When X1 and X2 are connected: manual reset

• When X1 and X3 are connected: auto-reset

Emission halt input terminals:

• Open: emission halt

• Short-circuit: emission

43

Page 52

Before Using this Device

2.6 Adjustment and Operation

2.6.1 Beam-Axis Alignment

Panasonic ST4 Instruction Manual

1.

2.

3.

Procedure

1. Turn ON the power supply unit of this device.

2. Check that the fault indicator (yellow) of the ST4-C11 or the fault display (red)

of the ST4-C12EX is OFF.

If the following error occurs, see "

possible countermeasures to the maintenance staff in charge.

- ST4-C11: The fault indicator (yellow) lights up or blinks

- ST4-C12EX: An error is indicated on the fault display (red).

3. Move the emitter of the ST4-A□ vertically and horizontally in order to

determine the range of light received with the help of the beam interruption

indicator (red). Then fix the emitter in the center of this range.

The tightening torque should be 0.5N·m or less.

Loosen the M3 screws slightly between the ST4-A and the sensor mounting

bracket (optional) to adjust the angle vertically.

Also, loosen the M3 screws slightly between the sensor mounting bracket and the

mounting surface to adjust the angle horizontally.

Troubleshooting" on page 79 and report it and

44

1

2

1

3

1

= M3 screws with washers

2

= Vertical adjustment

3

= Horizontal adjustment

For detailed information of the various sensor mounting brackets, refer to

Dimensions (see "

4. As you did for the emitter, perform the angular adjustment for the receiver of

the ST4-A□.

5. Check that the beam interruption indicators (red) on the emitter and the

receiver of the ST4-A□ are turned OFF. Also check that the stable incident

beam indicator (green) of the receiver lights up.

Dimensions" on page 95) to adjust the angle.

Page 53

Panasonic ST4 Instruction Manual

When adjusting the angle between the emitter and the receiver of the ST4-A,

remember where the beam interruption indicators (red) of the emitter and the

receiver turn OFF (both vertically and horizontally), and adjust the beam-axis to the

position roughly in the center of the range. This makes detection more stable.

Vertical angle adjustment

2.6 Adjustment and Operation

1

3

3

1

= Emitter

2

= Receiver

3

= Range where interruption indicators (red) turn off

2

Horizontal angle adjustment

1

3

3

1

= Emitter

2

= Receiver

3

= Range where interruption indicators (red) turn off

2

45

Page 54

Before Using this Device

2.6.2 Operation Test

DANGER!

Panasonic ST4 Instruction Manual

!

To test the installation:

1.

2.

3.

Procedure

1. Turn ON the power supply unit of this sensor.

2. Check that the fault indicator (yellow) of the ST4-C11 or the fault display (red)

The emission amount adjuster of the ST4-A□V is used to

reduce the beam emission of the ST4-A□V to prevent

influencing other sensors.

Do not use the emission amount adjuster of the ST4-A□V to

prevent the reflection off surfaces. If it is used for such

purposes and the emission amount adjuster is set at MAX.,

the reflection off surfaces increases. This may disable the

sensor from detecting objects, which could result in serious

injury or death.

To cope with reflective surfaces, see "

Surfaces" on page

of the ST4-C12EX are OFF.

If the following error occurs, see (see "

and possible countermeasures to the maintenance staff in charge.

- ST4-C11: The fault indicator (yellow) lights up or blinks

Influence of Reflective

20 .

Troubleshooting" on page 79) and report it

46

- ST4-C12EX: An error is indicated on the fault display (red).

3. When using the ST4-A□V, turn the emission amount adjuster on the emitter

of the ST4-A□V to the position at MAX. side.

1

1

= Emission amount adjuster

4. Check that the ST4-A□ is in the light beam received condition.

5. Check that the beam interruption indicators (red) on the emitter and receiver

of the ST4-A□ light up by interrupting the light beam between the emitter and

the receiver of the ST4-A□ by hand. Also, check that the control output

indicator (green) on the controller is off.

Page 55

Panasonic ST4 Instruction Manual

2.6 Adjustment and Operation

In case that even if the light beam between the emitter and the receiver of the

ST4-A is interrupted and the beam interruption indicator (red) on the

emitter/receiver on the ST4-A does not light up, or the control output indicator

(green) on the controller does not turn off, see (see "

Troubleshooting" on page 79)

and report the symptoms to the maintenance staff in charge.

NOTE

If the indicators show reception of the light beam even though the beam is

interrupted by hand, check whether there is a reflective object or extraneous

light source near the sensor.

2.6.3 Operation

This device starts operation two seconds after the power is on. Configure the control system

accordingly!

Power supply

Emission

condition

Reset input

Beam received

condition

Control output

(OSSD 1 / 2)

Timing chart for operation with manual reset

Stromversorgung

Emissionsstatus

Empfangsstatus

Schaltausgang

(OSSD 1 / 2)

Timing chart for operation with automatic reset

ON

OFF

Emission

Emission

halt

120ms or more

Open

0V/+V

Beam

received

Beam

interrupted

ON

OFF

EIN

AUS

Emission

Lichtunterbrechung

Strahl

empfangen

Strahl

unterbrochen

EIN

AUS

2s or less

max. 2s

120ms or more

T

ON

T

EIN

T

OFF

T

140ms or less, T

ON:

T

AUS

min. 100ms

T

EIN

: max. 90ms, T

T

ON

25ms or less

OFF:

T

EIN

: max. 25ms

AUS

47

Page 56

Page 57

Chapter 3

Functions

Page 58

Functions

Panasonic ST4 Instruction Manual

3.1 Self-Diagnosis Function

The controllers ST4-C11 and ST4-C12EX are equipped with a self-diagnosis function.

Self-diagnosis is carried out periodically during operation.

In case an abnormality is detected during self-diagnosis, the sensor is immediately put in the

lockout state and the control output (OSSD 1, OSSD 2) turns off. Find and remove the cause of

abnormality (see page

79).

50

Page 59

Panasonic ST4 Instruction Manual

3.2 Reset Operation

3.2 Reset Operation