Panasonic SR-TML500, SR-TML510, SR-TMS520 Service Manual

Order No. PAPTH140402CE

Service Manual

Multi-Cooker

SR-TML500

SR-TML510

SR-TMS520

© Panasonic Appliances (Thailand) Co., Ltd. 2014.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

There are special components used in this equipment which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do

not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

The service information is designed for experienced repair technicians only and is not designed for use by the general

public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting

to service a product. Products powered by electricity should be serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt within this service information by anyone

else could result in serious injury or death.

WARNING

Destination

Russia / Ukraine / Kazakhstan

Product Colour

Black (BO)

Silver (HS)

Dark Silver (HL)

- 2 -

CONTENT

Page

3

4

5

6 - 7

8

9

9

10

11

11

12

13

13

14

15

16 - 17

1. Specification

2. Schematic Diagram

2.1 Wiring Diagram

2.2 Circuit Diagram

3. Troubleshooting Guide

3.1 Table 1

3.2 Table 2

4. Testing Procedure

4.1 Bubbling Test

4.2 Evaporation Test

4.3 Heat reserving Test

5. Disassembly

5.1 Hinge cover removal

5.2 Inner enclosure and upper frame removal

5.3 Control unit A

5.4 Cast heater and Thermostat Ass’y

5.5 Side heater

6. Parts Exploded View and Replacement Parts List

6.1 Parts Exploded View : Body

6.2 Parts Exploded View : Packing

6.3 Replacement Parts List

SR-TML500 / SR-TML510 / SR-TMS520

- 3 -

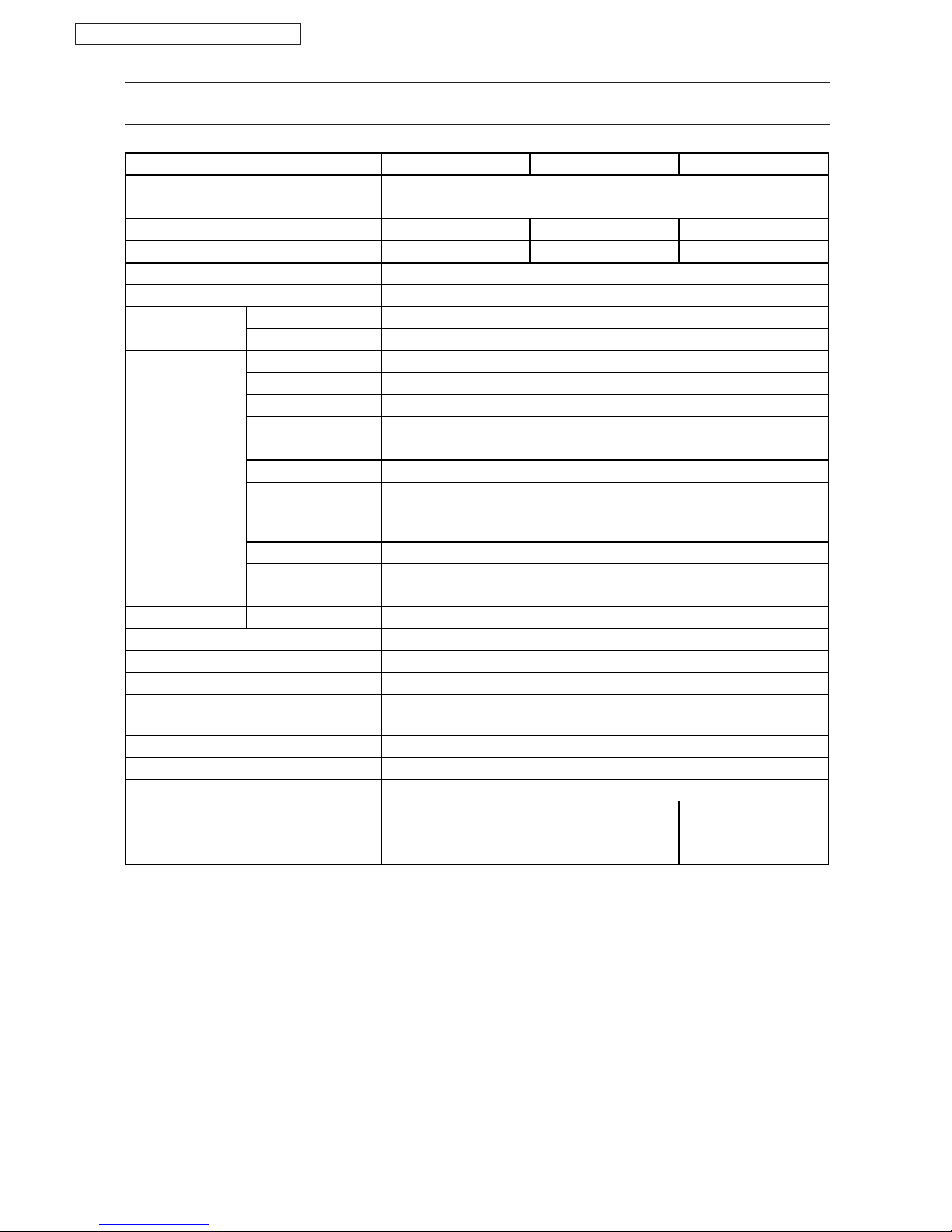

1. SPECIFICATION

MODEL

Countries

Power Supply

* For power cord replacement and product repairing, please contact the authorized service center of Panasonic.

* The design and specifications are subjected to change without prior notice.

SR-TML500 SR-TML510

Russia, Ukraine, Kazakhstan

220V / 50Hz / SH-3

Colour Name SilverDark Silver Black

HL BO

Measuring cup, Yogurt cup,

Steam basket assy,

Pan lid, Porridge scoop

Colour Code HS

Body Material Steel / Pre-coating

Pan Material Aluminium / Non stick coating

Power Consumption Cooking

Warming

Cooking Capacity Milk Porridge

Pilaf

Buckwheat

Yogurt

Baking

Fry

Stew / Soup / Compote

Holodetz / Stuffed /

Confiteur

670W

108W

1 ~ 2 cups

Warming Capacity

2 ~ 3 cups

2 ~ 8 cups

600 g.

900 g.

1.2 Kg.

4.0 L

Steam / Permeni

Plain Rice

4.0 L

Re-heat 1.0 L

Express 4.0 L

3 ~ 10 cups

Cooked rice warming Temperature 71°C ~ 79°C

Thermal fuse Specification 172°C 250V / 10A

Keep Warm (in Buckwheat function) 12 Hours

Weight (Approx.) 3.3 Kgs.

Power Cord (Approx.) 1.0 m.

Accessories Measuring cup, Steam basket assy

TheProduct Dimension

(Width x Depth x Height)

276 x 275 x 274 (mm)

Temperature Detector Sensor thermistor

SR-TMS520

SR-TML500 / SR-TML510 / SR-TMS520

- 4 -

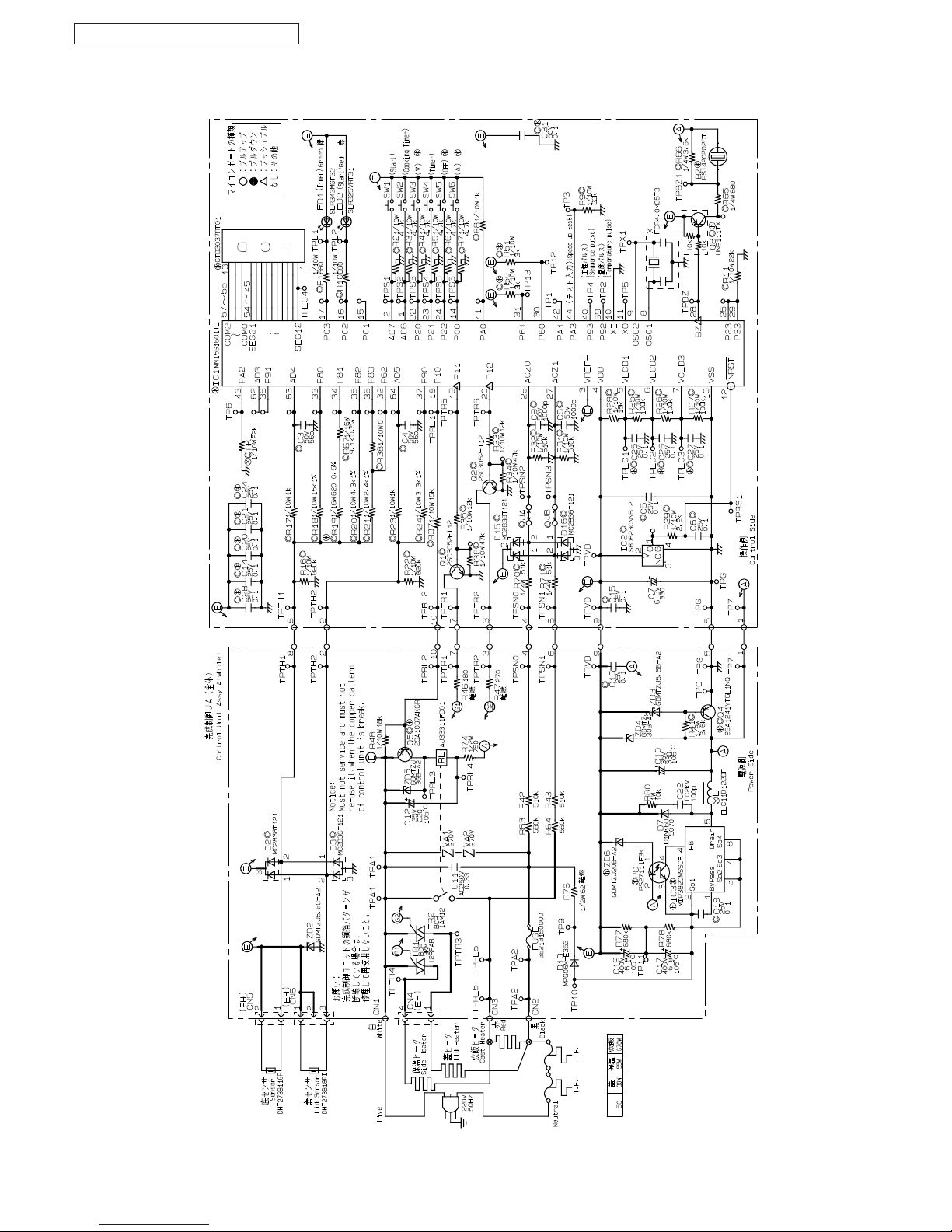

2. SCHEMATIC DIAGRAM

2.1 Wiring Diagram

Glass tape

size 40 X 85 mm

2

Inlet

Inlet

Shall be

closely covered with

tube to the bottom

Body earth lead wire (Green)

PCB lead wire A (White)

Thermal fuse lead wire B (Orange)

The glass tape affixes it from a

top and bottom direction, and

make it sealing up structure.

Impossible power do not be

added to a terminal joint.

5mm, or more

(Tape sealing area)

PCB lead wire B (Black)

Glass tape shall be

wraped around PCB

Thermistor lead wire (Red)

(Twisting 1 time)

Thermostat earth lead wire (Green)

Detail 2 : 1

Thermistor lead wire (Red)

Side heater lead wire A (Blue)

- Twisted vinyly tie 2 times.

- White, blue and black lead wire shall

not over lap PCB base boss.

- This blue wire shall be align in this portion.

Side heater lead wire D (White)

Side heater lead wire C (White)

Side heater lead wire B (Blue)

Terminal shall not be higher

than head of sems screw.

Side heater lead wire C (Black)

PCB lead wireC (Red)

Side heater lead wire D (Red)

Hinge earth lead wire (Green)

Tapping screw for body earth lead wire

Should be above Thermal fuse

lead wire A and then gose below

terminal of side heater lead wire D

Stamping earth

mark on PF.

5mm (around)

(Ø8)

- Twisted vinyly tie 2 times.

- All lead wire must not touch Cast heater terminal.

Thermal fuse

lead wire A (Black)

Thermostat earth lead wire (Green)

After twisted 2 times,

wind down this direction.

(Shall not touch Cast heater)

Vinyly tie

Lead wire

The clearance distance between terminal

& sems screw to other dead metal part

(Protecting frame, Cast heater pipe)

Should minimum 3.6 mm. (Any direction)

After inspection, screw head must be

mark with marker.

(Note) 1. Tightening torque of tapping screw for body earth lead wire and

sems screw for internal wiring : 60 ~ 120N - m

2. Each lead wire shall not contacting with sharp edges, moving parts,

high temperation portion.

3. All lead wire must not be hurt during assembly when apply 2N force.

Technical

Regulation

WARNING

Body earth lead wire

(Green)

Thermal fuse lead wire B (Orange)

PCB lead wire A (White)

SR-TML500 / SR-TML510 / SR-TMS520

- 5 -

SR-TML500 / SR-TML510 / SR-TMS520

2.2 Circuit Diagram

- 6 -

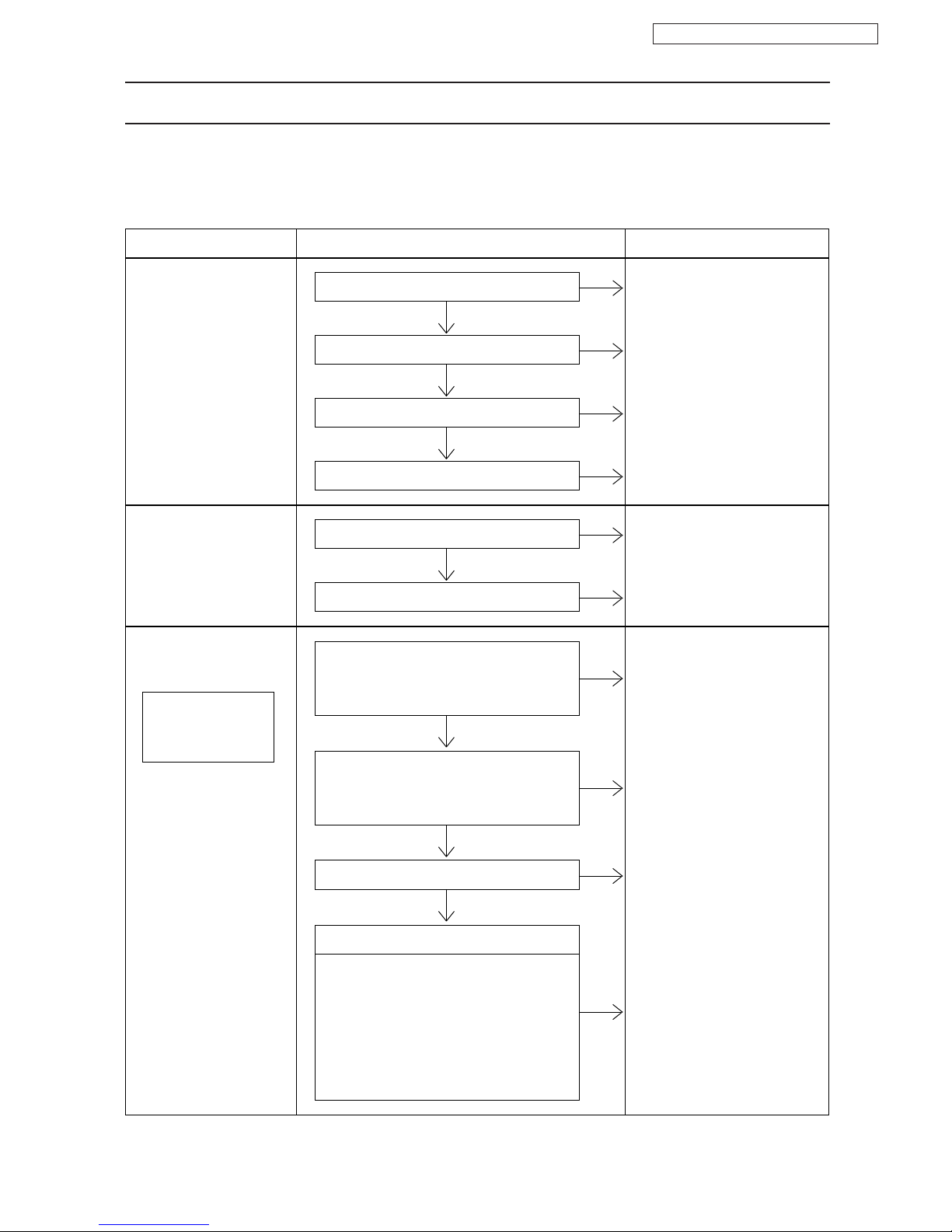

3. TROUBLESHOOTING GUIDE

3.1 Table 1

When receiving a rice boiler to be repaired, be sure to check that the main body is completely provide with the inner pan

and the inner lid, ask the condition (phenomenon) of the trouble in detail. Before troubleshooting single parts, be sure to

disconnect the power supply plug from the receptacle.

Condition

Rice boiling section

Plane rice.

• Rice is not boiling.

(The indicating lamp

does not come on)

• Rice is not boiling.

(The indicating lamp

is lit)

Troubleshooting Remedy

Is the power cord conductive?

• Replace the cord.

• Make sure insert therminal is

fasten.

• Replace the P.C.B. complete.

• Replace the P.C.B. complete.

• Replace the cast heater.

• Replace the center thermostat.

• Replace the inner pan or the

cast heater.

• Seeing at Table 2

• Explain the proper operation.

• Isolate the cause which melt

the thermal fuse, correct

the cause and

• Earlier cut off.

• Poor boiling up.

• Too hard

• Too soft

• Insufficient boiling

• Immediately after the switch is turned

off, open the cap.

• Rice is excessive or insufficient.

• Rice has not been scooped and mixed

well.

• Water is excessive or insufficient.

• The switch is turned off once during

boiling.

Is the pan bottom properly contacted with

the cast heater?

Yes

No

Is the thermal fuse conductive?

Yes

No

Is the therminal conductive?

Yes

Are the parts on the P.C.B. mistake?

Are the parts on the P.C.B. mistake?

Improper operation

No

Yes

No

Yes

Yes

Yes

No

Is the cast heater conductive?

Yes

No

Are the parts on the P.C.B. mistake?

(Check with the bubbling test).

Does the center thermostat operate

properly?

Yes

No

(Check with the operation test).

Yes

SR-TML500 / SR-TML510 / SR-TMS520

Loading...

Loading...