Page 1

A

A

A

ORDER NO.MD0403132C3

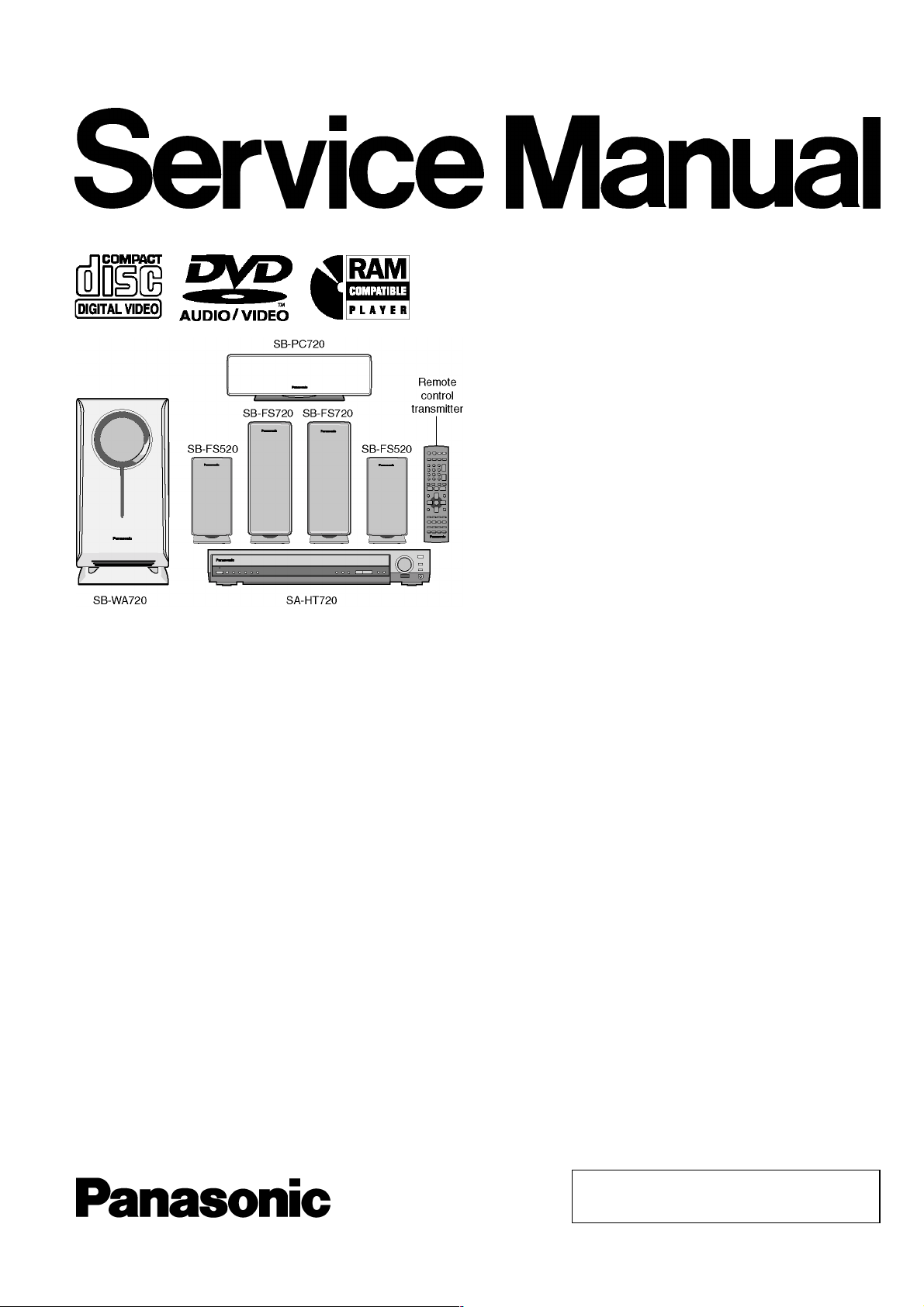

DVD Home Theater Sound System

SA-HT720GCP

Colour

(S).......................Silver Type

Specifications

lGeneral

Power Source:

Power consumption: 25 W

Dimensions (W×H×D): 430×68×432 mm

Mass: 4.1 kg

lAmplifiersection

RMS OutputPower: DolbyDigital Mode

lTotal RMS DolbyDigital

mode Power:

lPMPO outputpower: 6500 W

At1kHz and total harmonic of10%

lFront: 70 W/ Channel (4Ω)

lCenter: 260 W/ Channel (4Ω)

lSurround: 70 W/ Channel (4Ω)

At100Hz and total harmonic of10%

lActivesubwoofers: 260 W/ Channel (4Ω)

lFM tuner section

FrequencyRange: 87.5-108.0MHz

Sensitivity: 2.5µV (IHF)

S/N 26dB 2.2µV

C 110/127/220-230/240V,

50/60Hz

800 W

(50kHz in step)

ntennaTerminal: 75Ω (non balance)

lAM tuner section

FrequencyRange: 522-1629kHz (9kHz in step)

M SensitivityS/N 20dB at

999kHz:

Phone Jack:

Terminal: Stereo 3.5mmjack

lDisc section

Discs played [8 cm (3”) or 12 cm (5”)]:

(1) DVD-RAM (DVD-VR compatible, JPEG formatted discs)

(2) DVD-Audio

(3) DVD-Video

(4) DVD-R (DVD-Video compatible)

(5) CD-Audio (CD-DA)

(6) Video CD

(7) SVCD (Conforming to IEC62107)

(8) CD-R/CD-RW (CD-DA, Video-CD, SVCD, MP3, WMA, JPEG

formatted discs)

(9) MP3/WMA

lMaximum number of recognizable audio and picture contents

and groups:

560µV/m

4000 audio and picture

contents and 400 groups

© 2004 Panasonic AVC Networks Singapore Pte.

Ltd. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

V

Y

Y

SA-HT720GCP

lCompatible compression rate:

MP3: between 32 kbps and 320 kbps

WMA: between 48 kbps and 320 kbps

(10) JPEG

lExifVer 2.1 JPEG Baseline files

lPicture resolution: between 320x240 and 6144x4096

pixels (sub sampling is 4:2:2 or 4:2:0)

(11) HighMAT Level 2 (Audio and lmage)

Pick up:

Source oflightbeam: Semiconductor Laser

Wavelength:

lCD: 785nm

lDVD: 662nm

Audiooutput(DISC):

Number ofchannels: 5.1 ch (FL, FR, C, SL, SR,

SW)

Audioperformance:

Frequencyresponse:

DVD (linear audio): 4 Hz-22 kHz (48 kHz sampling)

4 Hz-44 kHz (96 kHz sampling)

DVD-Audio: 4 Hz-88 kHz (192 kHz

sampling)

CD-Audio: 4 Hz-20 kHz

S/N ratio:

CD-Audio: 95 dB

Dynamicrange:

DVD (linear audio): 95 dB

CD-Audio: 93 dB

Total harmonic distortion:

CD-Audio: 0.005 %

lVideo section

ideo system:

Signal system: NTSC

Composite videooutput:

Outputlevel: 1 Vp-p (75 Ω)

Terminal: Pinjack (1 system)

S-videooutput:

outputlevel: 1 Vp-p (75 Ω)

C outputlevel: NTSC; 0.286 Vp-p (75 Ω)

Terminal S terminal (1 system)

Component videooutput(480P/480I):

outputlevel: 1 Vp-p (75 Ω)

PBoutputlevel: 0.7 Vp-p (75 Ω)

PRoutputlevel: 0.7 Vp-p (75 Ω)

Terminal: Pinjack (Y: green, PB: blue,

P

: red) (1 system)

R

Power consumption in standbymode:

approx 0.7W

Note:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured bythe digital spectrum

analyzer.

Solder:

This model uses lead free solder (PbF).

CONTENTS

Page Page

1 Use of Active Subwoofer

1.1. Checking Player when Active Subwoofer is not used

2 Safety Precautions

2.1. GENERAL GUIDELINES

4

3 Prevention of Electro Static Discharge (ESD) to

4

5

5

Electrostatically Sensitive (ES) Devices

4 Before Repair and Adjustment (Using Active Subwoofer)

5 Protection Circuitry

6 Precaution of Laser Diode

2

5

6

6

7

Page 3

SA-HT720GCP

7 About Lead Free Solder (PbF) 7

8 General Description

8.1. Operating instructions

8.2. Disc information

9 Accessories

10 Handling Precautions for Optical Pickup Unit

10

11

10.1. Cautions to Be Taken in Handling the Optical Pickup Unit

11

10.2. Cautions to Be Taken When Replacing the Optical Pickup

10.3. Grounding for electrostatic breakdown prevention

11

11

11 Disassembly and Main Component Replacement Procedures

11.1. Disassembling the Top Cabinet

11.2. Disassembling the Front Panel

11.3. Disassembling the Tray Assembly

13

14

14

14

11.4. Removal of the Tray Base Guide (L) and Tray Base Guide

(R)

11.5. Removal of the Rotary Tray

11.6. Removal of the Open Lock Gear

11.7. Removal of the Close Lock Gear

11.8. Removal of the Tray Motor P.C.B. and Sensor P.C.B.

11.9. Removal of the CD Traverse Unit

11.10. Removal of the Pulley Gear

11.11. Removal of the Loading Motor P.C.B.

11.12. Removal of the Drive Gear (A) & (B)

11.13. Disassembling the Fixed Plate, Magnet and Clamper

11.14. Removal of the Cam Gear & Support Piece

11.15. Removal of the Slide Plate (L) & (R) and Change Lever

11.16. Assembly of Tray Base

16

16

16

16

17

17

17

18

18

18

19

19

20

12 DVD-Optic al Pick-up Self-Diagnosis and Replacement

Procedure

12.1. Optical Pickup Breakdown Diagnosis

12.2. Service Mode Table 1

12.3. DVD Self Diagnostic Function-Error Code

12.4. Last Error Code saved during NO PLAY

21

21

22

22

23

12.5. Service mode table 2

8

8

9

12.6. Sales demonstration lock function

12.7. Handling After Completing Repairs

13 Self-Diagn osis Function

13.1. Automatic Displayed Error Codes

13.2. Memorized Error Codes

14 Service Precaution s

14.1. Recovery after the DVD player is repaired

14.2. Firmware version-up of the DVD player

15 Adjustment Procedure

15.1. Service Tools and Equipment

15.2. Important points in adjustment

15.3. Storing and Handling Test Discs

15.4. Optical adjustment

16 Abbreviations

17 Voltage Chart

17.1. DVD Module P.C.B.

17.2. Main P.C.B.

17.3. FL P.C.B.

17.4. Loading Motor P.C.B.

17.5. Tray Motor P.C.B.

17.6. Sensor P.C.B.

18 Schematic Diagram Notes

19 Block Diagram

20 Schematic Diagram

21 Printed Circuit Board Diagram

22 Wiring Connection Diagram

23 Illustration of IC 痴, Transistors and Diodes

24 Terminal Function of ICs

24.1. IC2018 (C2CBJG000401): System control

25 Parts Location and Replacement Parts List

25.1. Loading Mechanism, Traverse Unit & Cabinet

25.2. Component Parts List

25.3. Packing Materials & Accessories Parts List

25.4. Packaging

24

26

26

27

27

27

28

28

28

29

29

29

29

30

31

33

33

35

36

36

36

37

38

39

45

53

57

59

60

60

61

62

66

75

75

3

Page 4

SA-HT720GCP

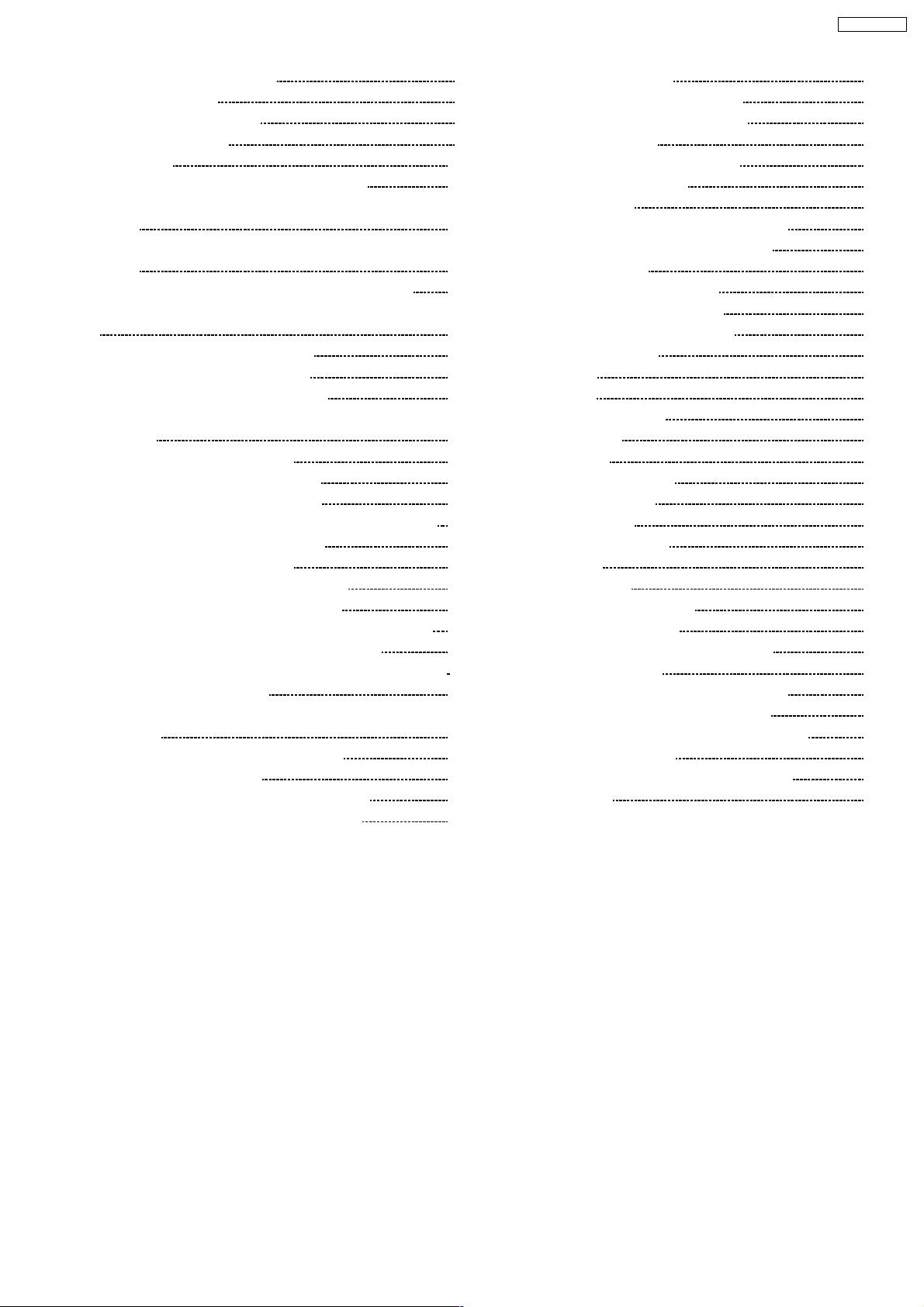

1 Use of Active Subwoofer

1.1. Checking Player when Active Subwoofer is not used

1. This unit uses the active subwoofer to supply the power of the component, and the active subwoofer should be connected to

the component to check operational conditions of the component.

2. If the active subwoofer is not available due to repair of the unit, use the following equipment.

Jig product number: RFKZ0182 (110V, 127V, 220V, 230V-240V for overseas domestic use)

4

Page 5

SA-HT720GCP

2 Safety Precautions

2.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

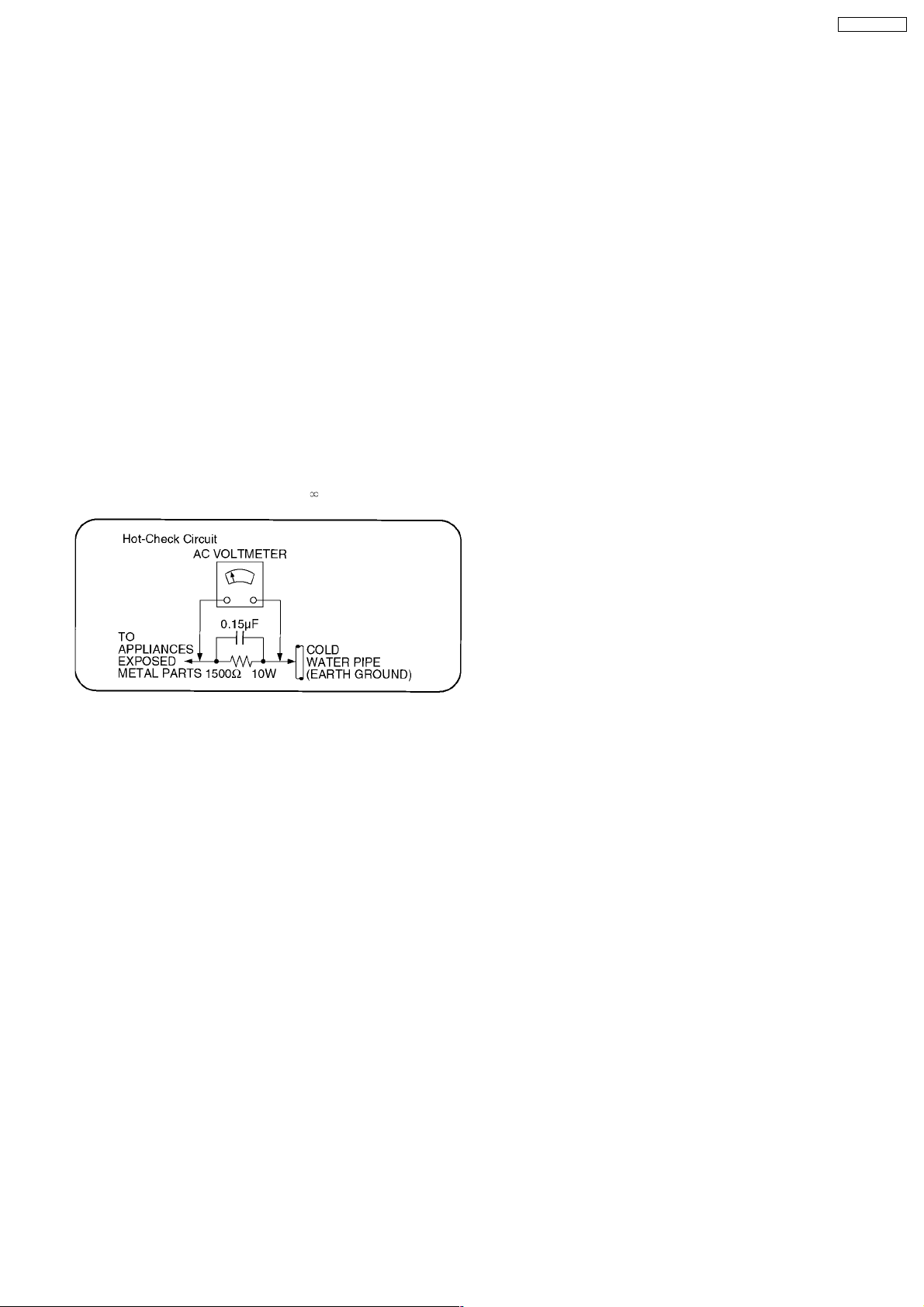

2.1.1. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to thechassis, the reading should be between

1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

2.1.2. LEAKAGE CURRENT HOT CHECK

(See Figure 1 .)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1 .

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in theAC outlet and repeat each ofthe

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outsideof the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

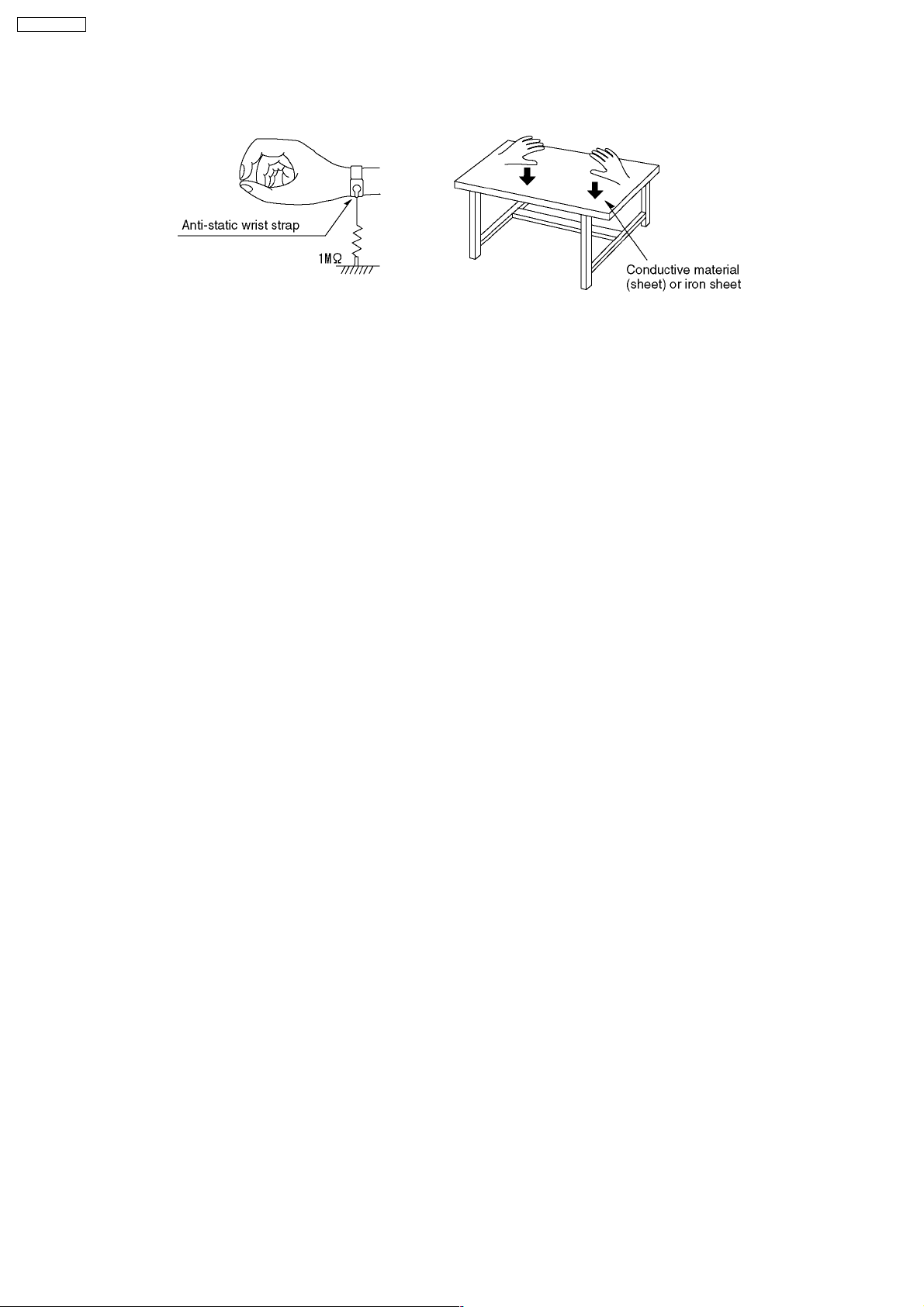

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistorsand

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available dischargingESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparableconductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

5

Page 6

SA-HT720GCP

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD)sufficient to damage an ES device).

4 Before Repair and Adjustment (Using Active Subwoofer)

Disconnect AC power, discharge Power Supply Capacitors C546~C549 through a 10 Ω, 10 W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 120 V, 60 Hz in NO SIGNAL mode should be ~ 1000 mA.

5 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

6

Page 7

6 Precaution of Laser Diode

CAUTION :

This product utilizes a laser. Invisible laser radiation is emitted from the optical pick up lens when the unit is turned on.

Wavelength : 662nm(DVD)/785nm(CD)

Maximum output radiation power from pick up : 100µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

SA-HT720GCP

7 About Lead Free Solder (PbF)

Distinction of PbF PCB: PCBs (manufactured) using lead free solder will have a Pbf stamp on the PCB.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of the soldering iron with temperature control,please set it to 700 ±

20°F (370 ± 10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

When soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

7

Page 8

SA-HT720GCP

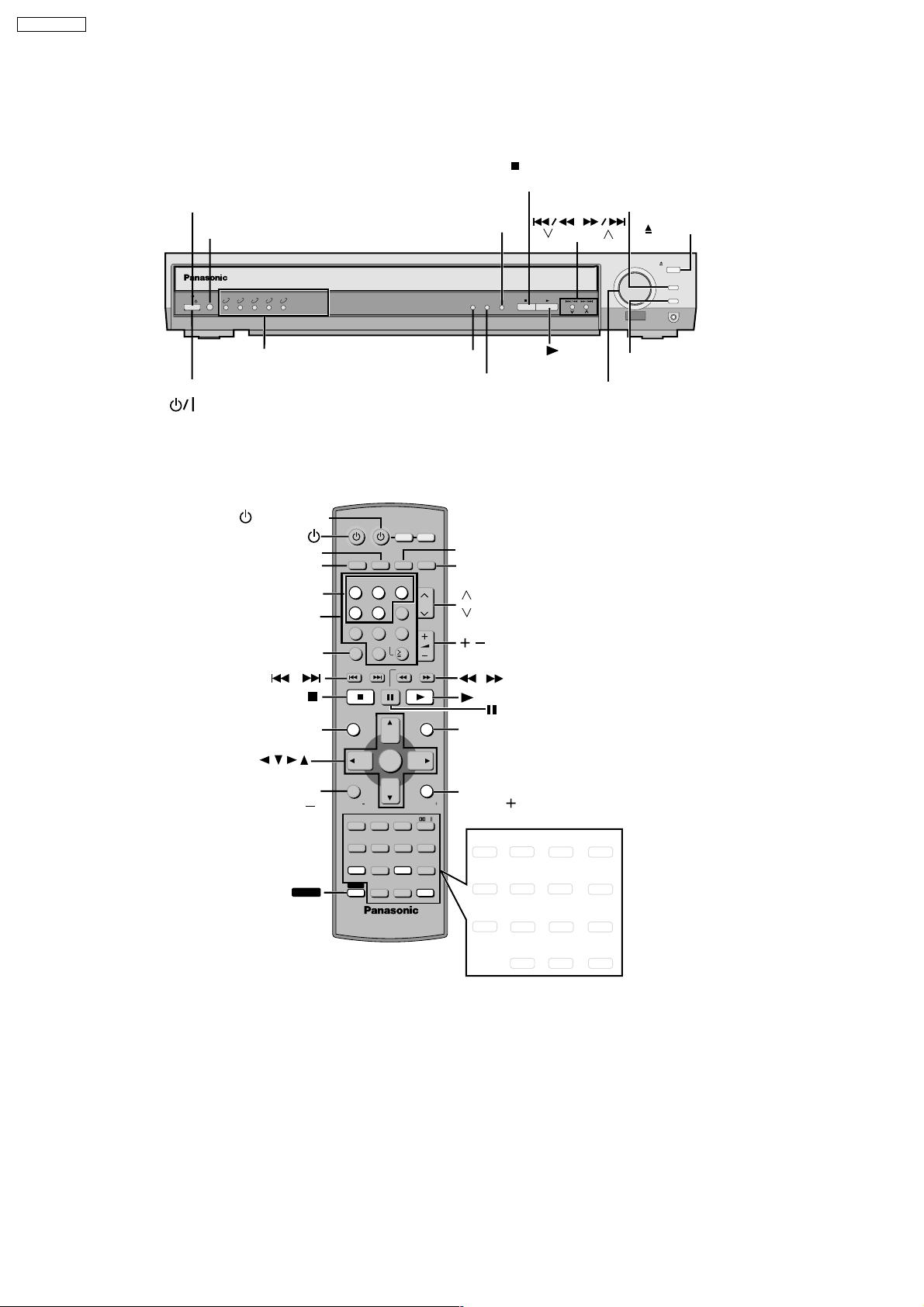

8 General Description

8.1. Operating instructions

STANDBY/ON INDICATOR

INPUT SELECTOR

STOP/

FM MODE

CD MODE/

TUNE MODE

DISC EXCHANGE

,

TUNING

OPEN/CLOSE

INPUT

1 2 3 4 5

SELECTOR

POWER

/I

5 DISC SELECTOR

5 DISC SELECTOR

INDICATIOR

STANDBY/ ON

()

POWER

,

/AV SYSTEM

AUX

TV/VIDEO

DISC 1-5

Numbered

buttons

CANCEL

,

/

AV SYSTEM

TV/VIDEO

TUNER/BAND

AUX

DISC 1 DISC 2 DISC 3

123

DISC 4 DISC 5

456

7809

ENTER

CANCEL

SLOW/SEARCH

SKIP

VCR

TV

DVD/CD

CH

VOLUME

10

C.S.M

PROGRESSIVE

CD MODE

TUNE MODE

C.S.M

PROGRESSIVE

TUNER/BAND

DVD/CD

CH

CH

VOLUME

,

FM MODE MEMORY

TUNING

/

MEMORY

VOLUME

DOWN

VOLUME

OPEN/CLOSE

DISC EXCHANGE

DISC SKIP

UP

PHONES

DISC SKIP

TOP MENU

ENTER

DISPLAY/

TV VOL

SHIFT

TOP MENU

DIRECT

NAVIGATOR

DISPLAY

TV VOL

SUBWOOFER

LEVEL

SLEEP

C.S.M

FL DISPLAY

SHIFT

ENTER

SFC

POSITION

MEMORY

PAGE

GROUP

TEST

CH SELECT

C.FOCUS

SUPER SRND

ZOOM

AUDIO

CD MODE

QUICK REPLAY

MENU

PLAY

LIST

RETURN

TV VOL

MIX 2CH

PL

SETUP

MUTING

REPEAT

PLAY MODE

SUBTITLE

MENU

RETURN/

TV VOL

SUBWOOFER

LEVEL

SLEEP

C.S.M

FL DISPLAY

SFC

POSITION

MEMORY

PAGE

GROUP

TEST

CH SELECT

C.FOCUS

SUPER SRND

ZOOM

AUDIO

CD MODE

QUICK REPLAY

MIX 2CH

PL

SETUP

MUTING

REPEAT

PLAY MODE

SUBTITLE

8

Page 9

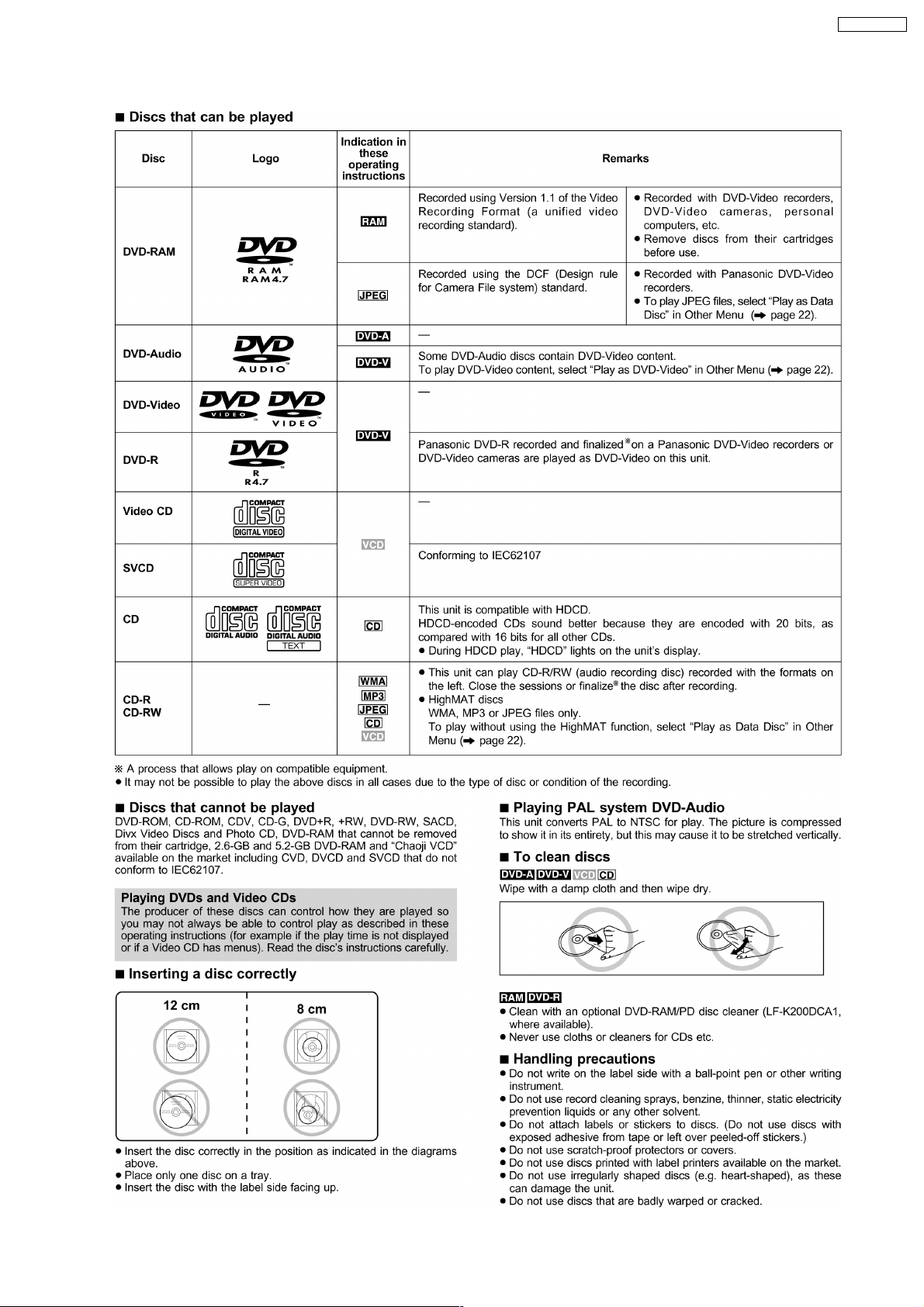

8.2. Disc information

SA-HT720GCP

9

Page 10

SA-HT720GCP

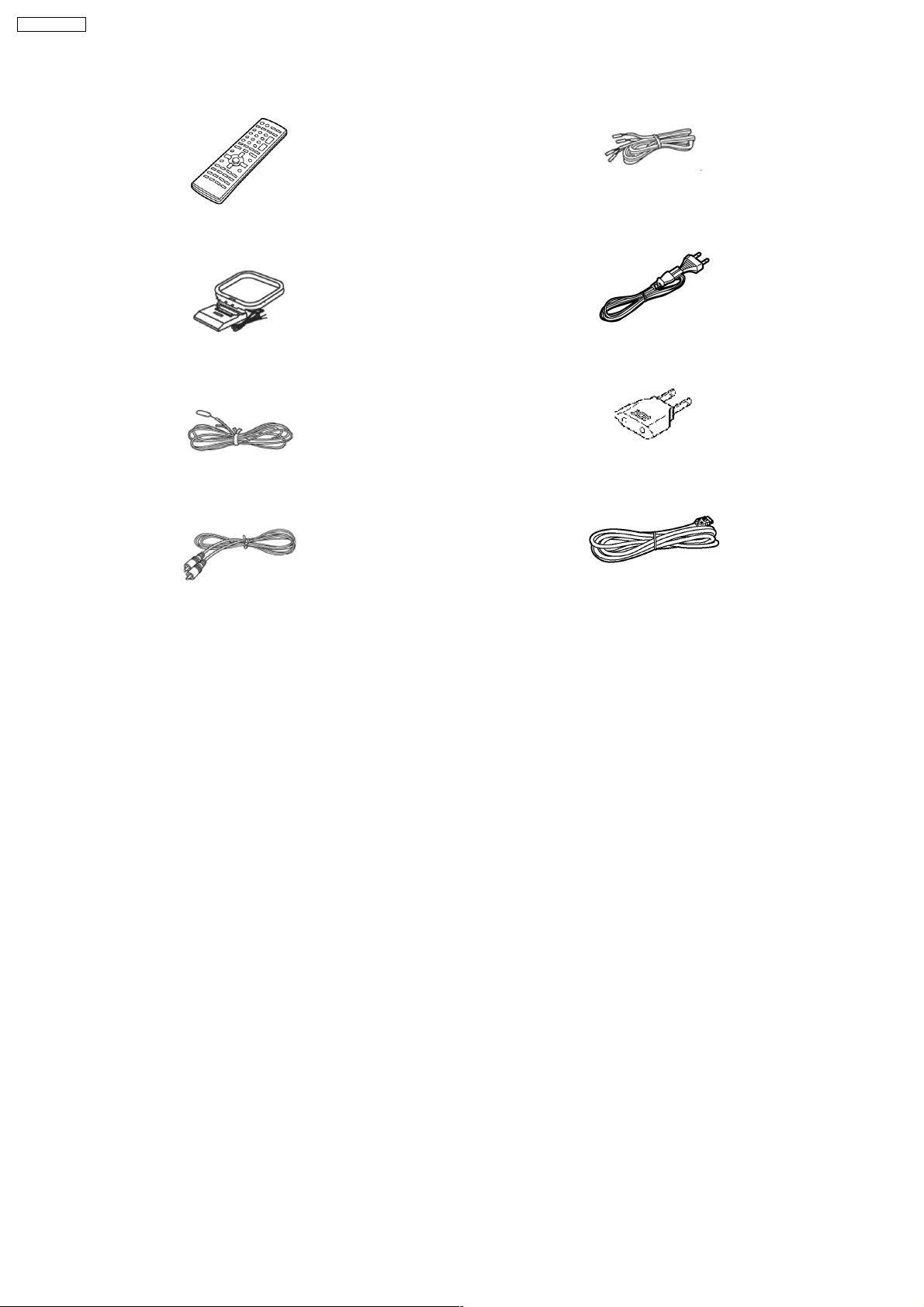

9 Accessories

5 Speaker cables (×5)

(4m×3, 10m×2)

Remote control

AC power supply cord

AM loop antenna

FM indoor antenna

Video Cable

AC Plug adaptor

System cable

10

Page 11

SA-HT720GCP

10 Handling Precautio ns for Optical Pickup Unit

The laser diode in the optical pickup unit may brake down due to static electricity of clothes or human body. Use due caution to

electrostatic breakdown when servicing and handling the laser diode.

10.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Use due caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed from

the PCB should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible

cable, cut off the antistatic FPC.

10.2. Cautions to Be Taken When Replacing the Optical Pickup

The flexible cable of the optical pickup unit which was supplied as a component is equipped with a short clip to prevent the laser

diode from being damaged due to electrostatic discharge. Remove the short clip before connecting the flexible cableand make sure

that the short land is open. (If the flexible cable is short-circuited, remove the solder.)

10.3. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

10.3.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

11

Page 12

SA-HT720GCP

10.3.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

12

Page 13

SA-HT720GCP

11 Disassembly and Main Component Replacem ent

Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the

main components.

2. For assembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

· Disassembly the Top Cabinet

· Disassembly the Front Panel

· Disassembly the Tray Assembly

· Removal of the Tray Base Guide (L) and Tray Base Guide (R)

· Removal of the Rotary Tray

· Removal of the Open Lock Gear

· Removal of the Close Lock Gear

· Removal of the Tray Motor P.C.B.and Sensor P.C.B.

· Removal of the CD Traverse Unit

· Removal of the Pulley Gear

· Removal of the Loading Motor P.C.B.

· Removal of the Drive Gear (A) & (B)

· Disassembly the Fixed Plate, Magnet and Clamper

· Removal of the Cam Gear & Support Piece

· Removal of the Slide Plate (L) & (R) and Changer Lever

· Assembly of Tray Base

13

Page 14

SA-HT720GCP

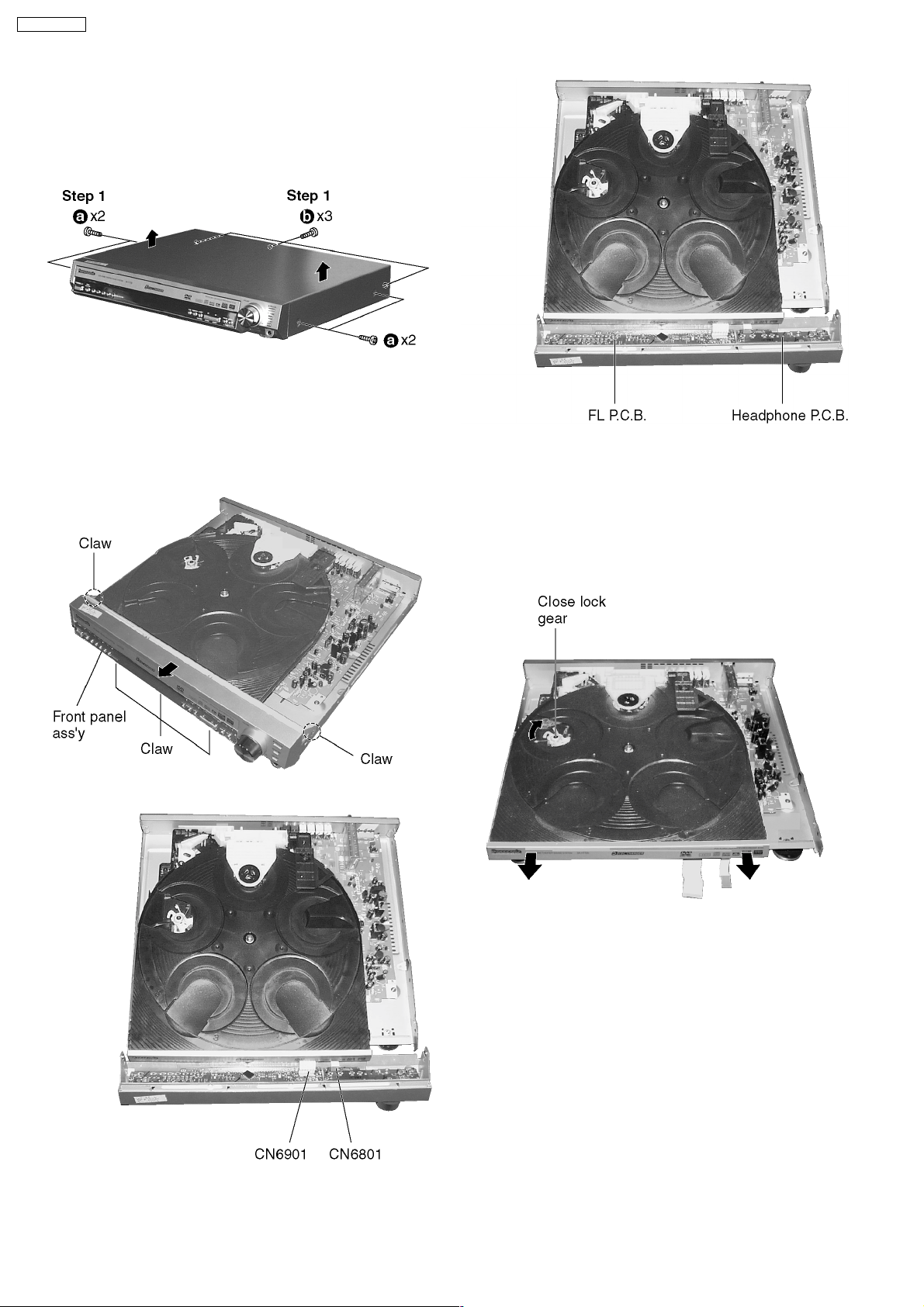

11.1. Disassembling the Top

Cabinet

Step 1 Remove 7 screws.

Step 2 Remove the top cabinet in the direction of arrow.

11.2. Disassembling the Front Panel

· Follow the (Step 1) - (Step 2) of Item 11.1.

Step 1 Pull the front panel ass’y in both direction of arrow to

unlock the claws of the chassis ass’y.

Step 2 Remove the front panel ass’y in the direction of arrow.

11.3. Disassembling the Tray

Assembly

Step 3 Pull out the FFC from connectors (CN6801 & CN6901).

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

Step 1 Keep the close lock gear pressed in clockwise, move

the tray assembly in the direction of the arrow.

Step 2 Hold close lock gear, push and release the 4 claws in

the direction of arrow, and then remove the tray assembly.

· Checking of Headphone P.C.B. and FL P.C.B.

14

Page 15

SA-HT720GCP

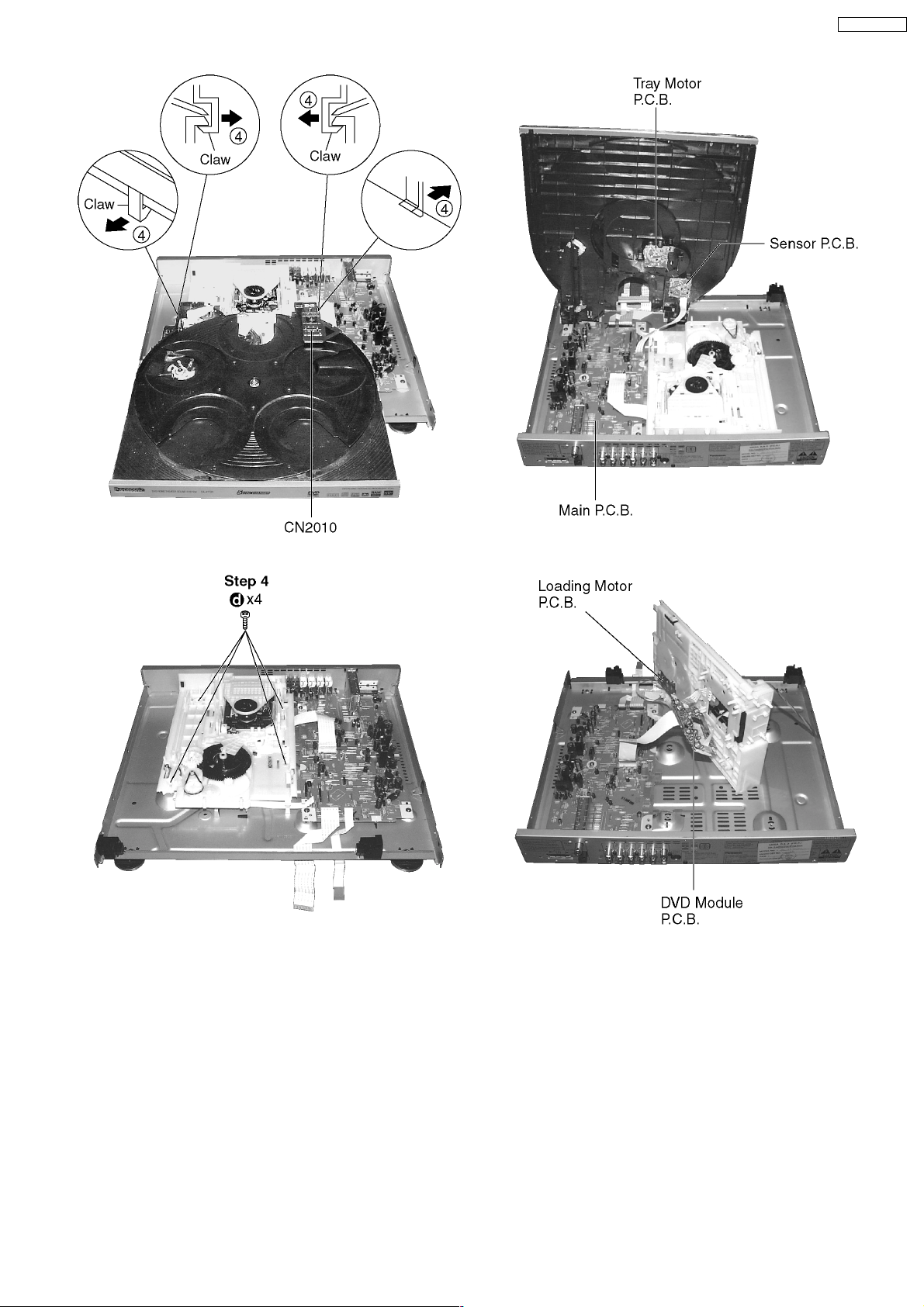

Step 3 Pull out FFC CN6002.

Step 4 Remove 4 screws.

· Checking of Main P.C.B., Tray Motor and Sensor P.C.B.

· Checking of Loading Motor P.C.B. and DVD Module P.C.B.

Step 5 Upset base assembly in vertical position.

15

Page 16

SA-HT720GCP

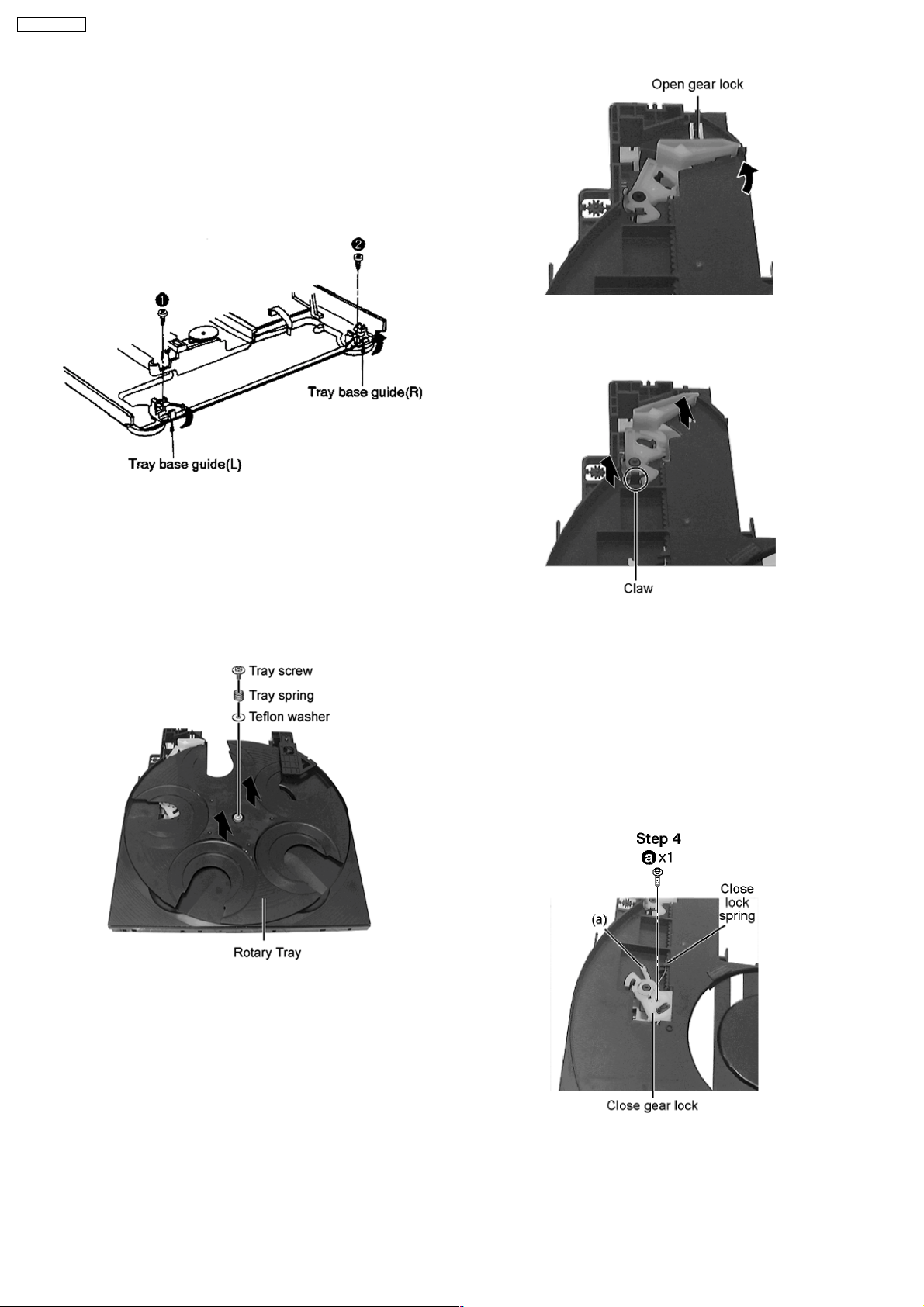

11.4. Removal of the Tray Base

Guide (L) and Tray Base Guide

(R)

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Rotate open lock gear in the direction of arrow. (Anticlockwise)

Step 1 Remove the 2 screws.

Step 2 Remove the tray base guide (L) and tray guide (R) in the

direction of arrow.

11.5. Removal of the Rotary Tray

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 2 Release claw of open lock gear, remove open lock gear

in the direction of arrow.

11.7. Removal of the Close Lock

Gear

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

· Follow the (Step 1) - (Step 2) of Item 11.5.

Step 1 Remove 1 screw.

Step 1 Remove tray screw, tray spring and teflon washer.

Step 2 Remove rotary tray.

11.6. Removal of the Open Lock

Gear

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

· Follow the (Step 1) - (Step 2) of Item 11.5.

Step 2 Hook close lock spring to claw (a).

16

Page 17

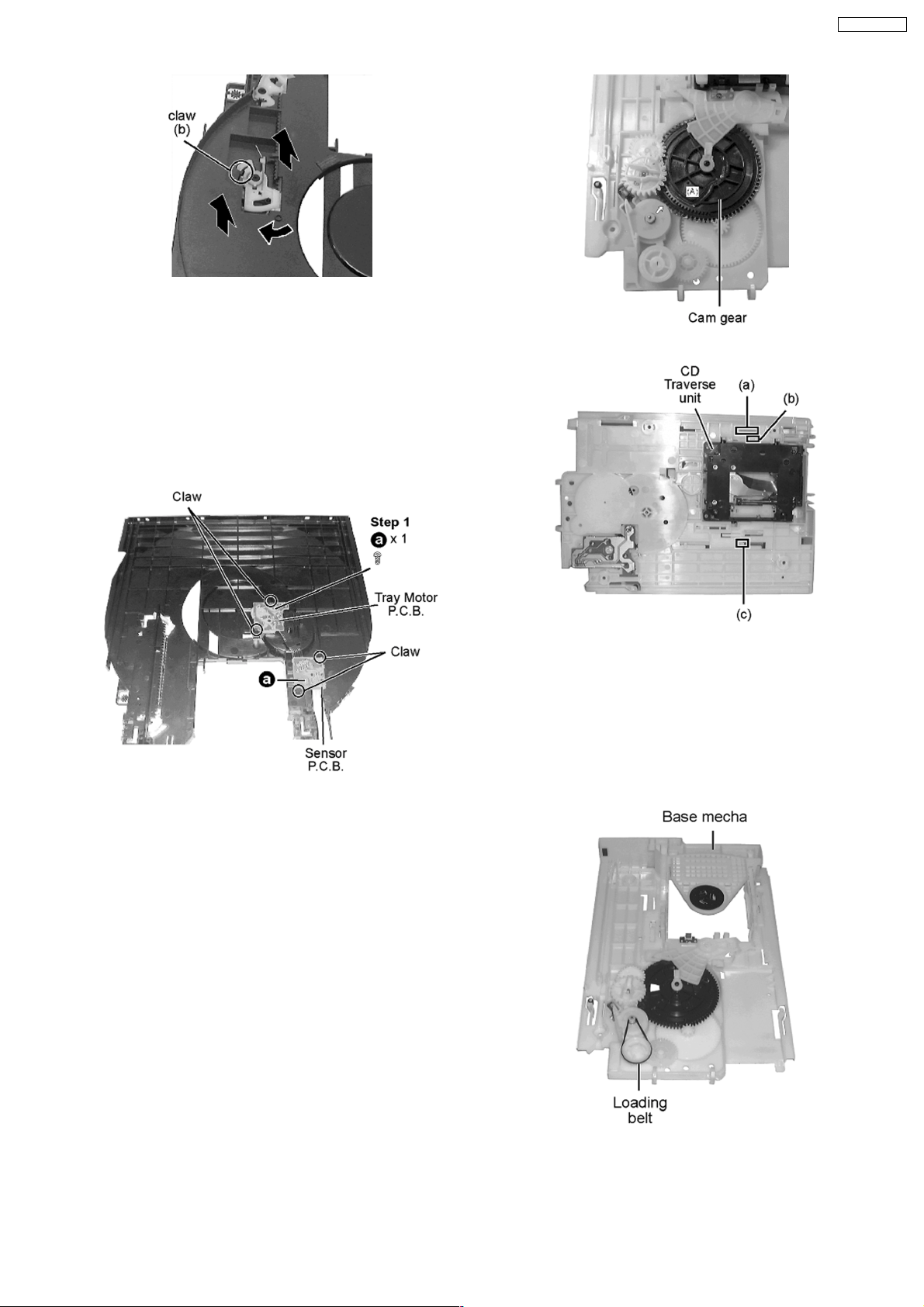

Step 3 Rotate close lock gear to direction of arrow, press claw

(b) and pull out close lock gear.

SA-HT720GCP

11.8. Removal of the Tray Motor

P.C.B. and Sensor P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Remove 2 screws.

Step 2 Release 4 claws at Tray Motor P.C.B. and Sensor

P.C.B.

Step 2 Flip the base mecha unit in vertical position.

Step 3 Press upward (a), push backward (b) and press to left

(c) to release CD traverse unit.

11.10. Removal of the Pulley Gear

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Remove of the loading belt.

11.9. Removal of the CD Traverse

Unit

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Rotate cam gear anti-clockwise. (Align at position (A) as

marking on gear with arrow)

Step 2 Flip the base mecha.

17

Page 18

SA-HT720GCP

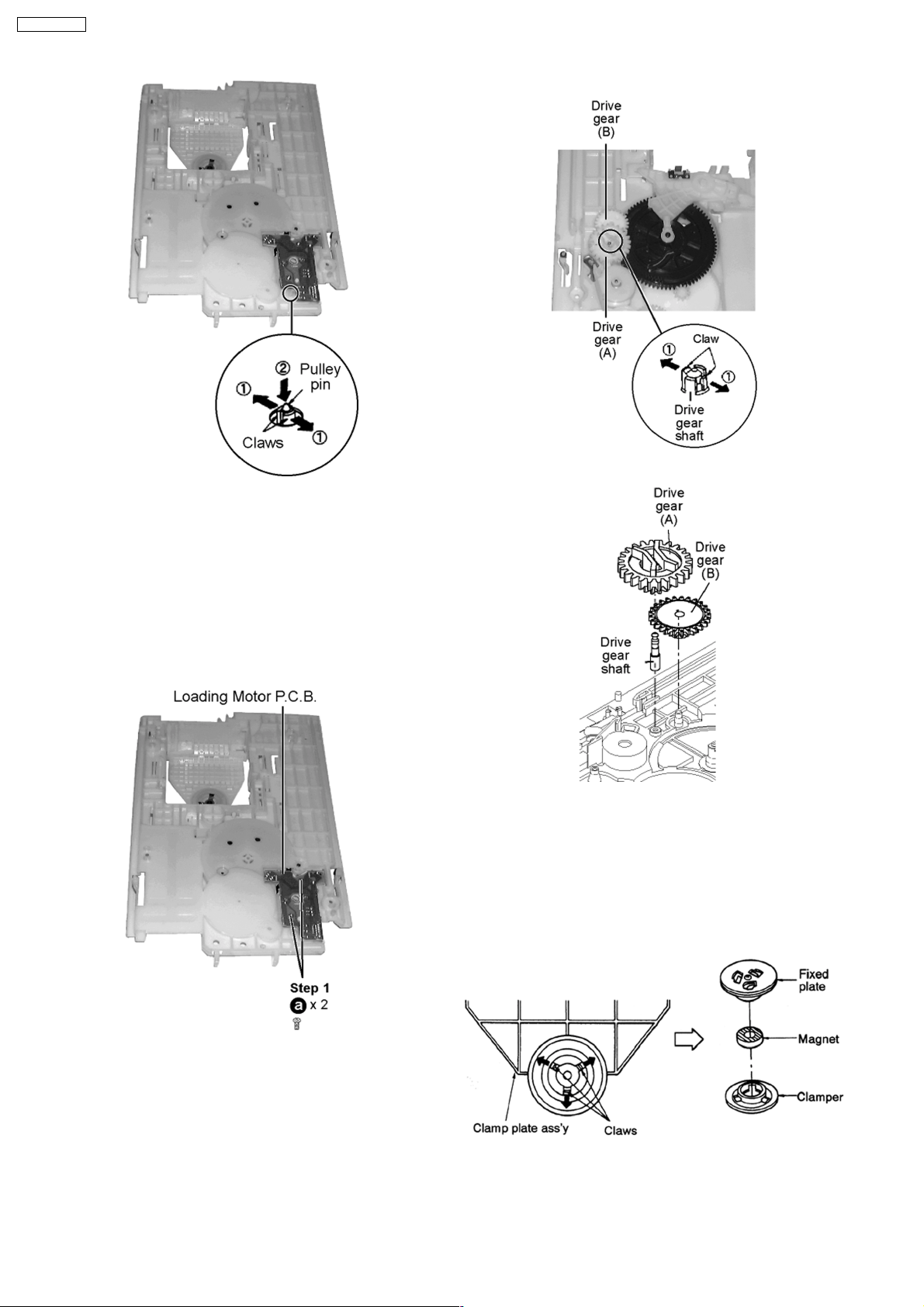

push drive gear shaft up.

Step 2 Remove Drive Gear (A) and Drive Gear (B).

Step 3 Release the 2 claws in the direction of arrow (1), and

then push the pulley pin in the direction of arrow (2).

11.11. Removal of the Loading Motor

P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Remove 2 screws.

11.13. Disassembling the Fixed Plate,

Magnet and Clamper

· Follow the (Step 1) - (Step 2) of Item 11.1

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Release 3 claws in the direction of arrow.

Step 2 Remove Loading Motor P.C.B.

11.12. Removal of the Drive Gear (A)

& (B)

· Follow the (Step 1) - (Step 2) of Item 11.1.

· Follow the (Step 1) - (Step 4) of Item 11.2.

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Release the claw in the direction of arrow (1), and then

18

Page 19

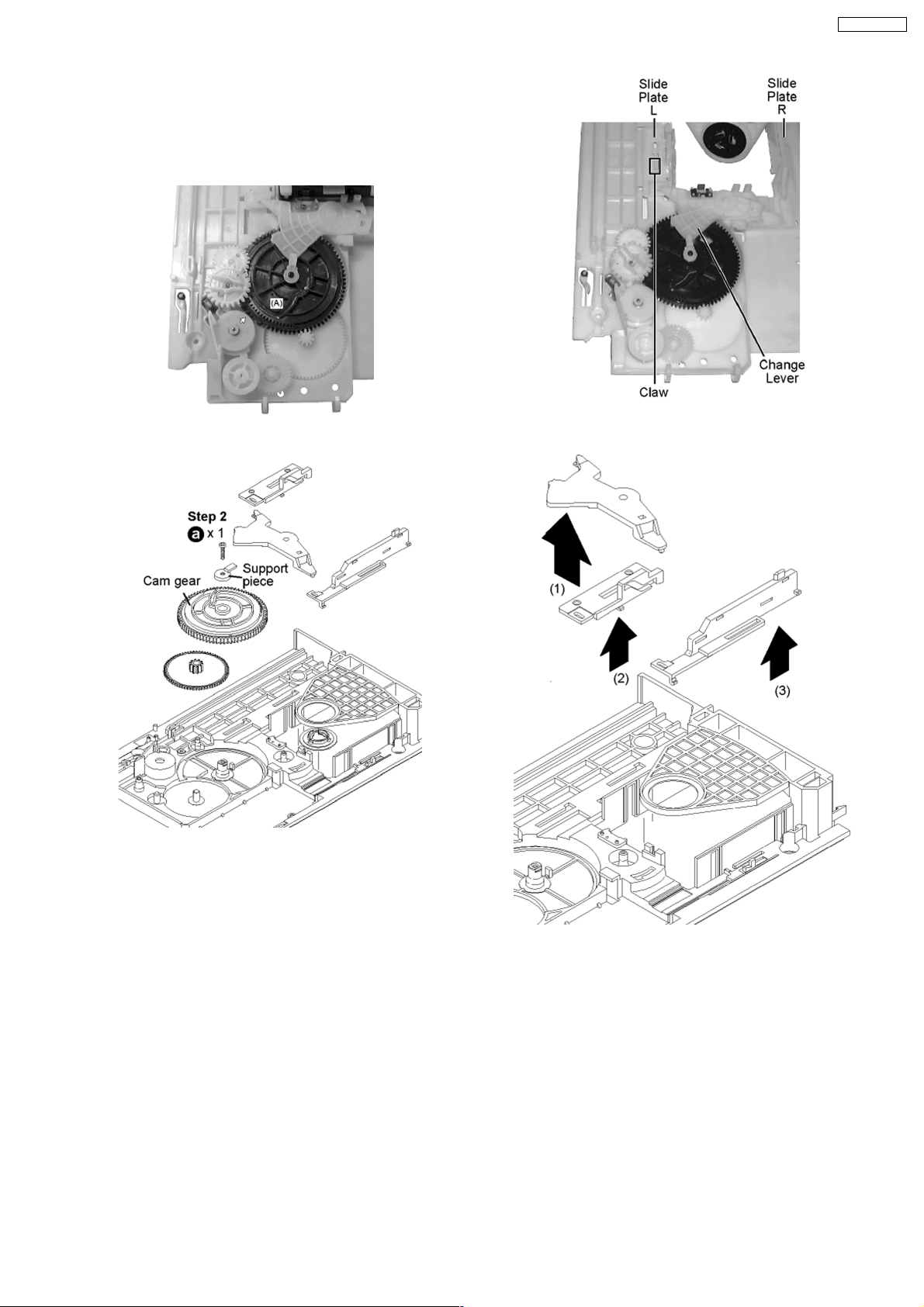

11.14. Removal of the Cam Gear &

Support Piece

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Rotate (A) in cam gear anti-clockwise.

Step 2 Remove 1 screw and support piece.

SA-HT720GCP

Step 2 Remove slide plate (L) & (R) and change lever as arrow

shown.

11.15. Removal of the Slide Plate (L)

& (R) and Change Lever

· Follow the (Step 1) - (Step 5) of Item 11.3.

Step 1 Press the claw and push the Slide Plate (L) up.

19

Page 20

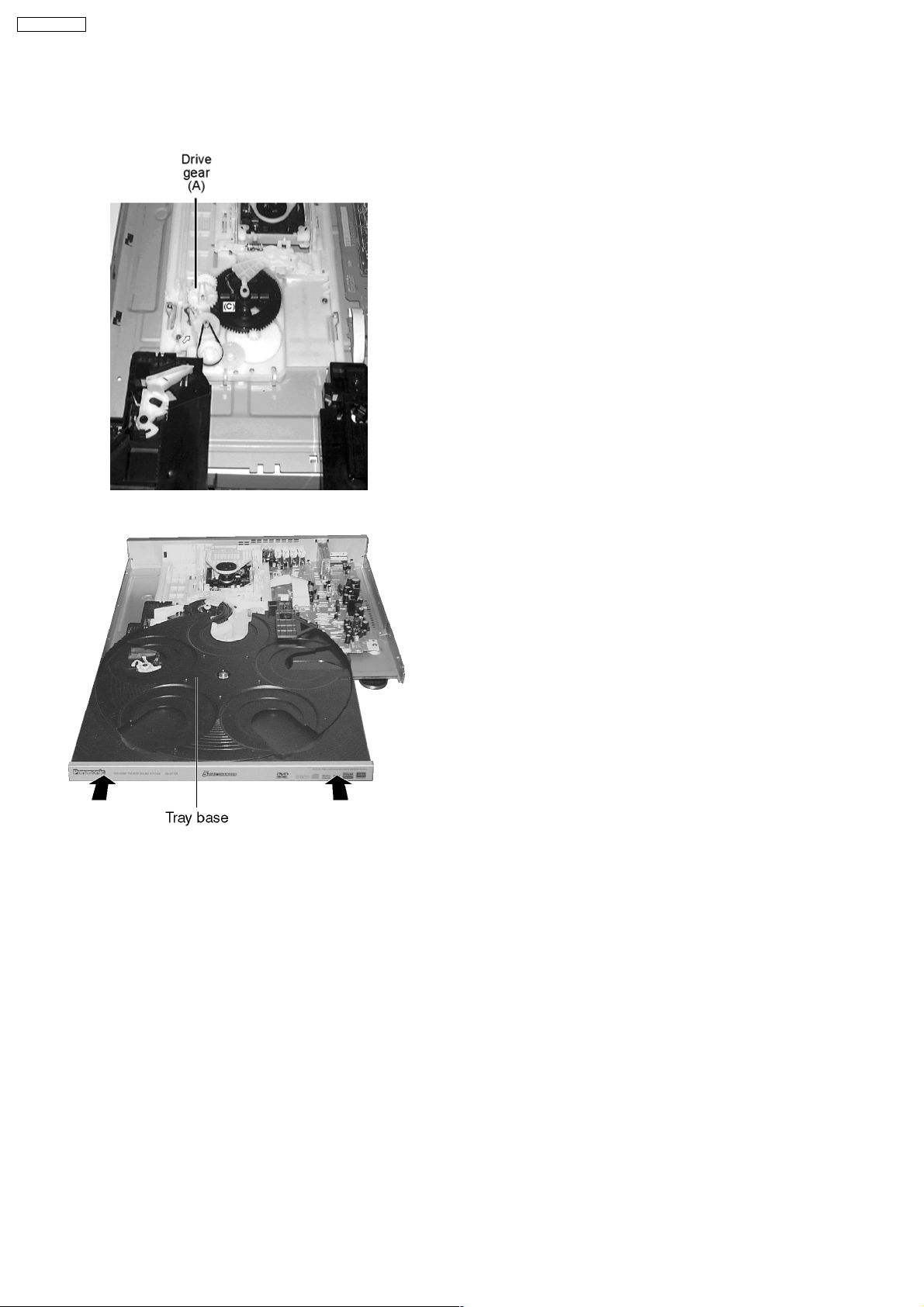

SA-HT720GCP

11.16. Assembly of Tray Base

Step 1 Rotate cam gear anti-clockwise. Align at position (C) as

marking on gear with arrow.

Step 2 Make sure drive gear (A) at vertical position.

Step 3 Push tray base to the direction of arrow shown.

20

Page 21

SA-HT720GCP

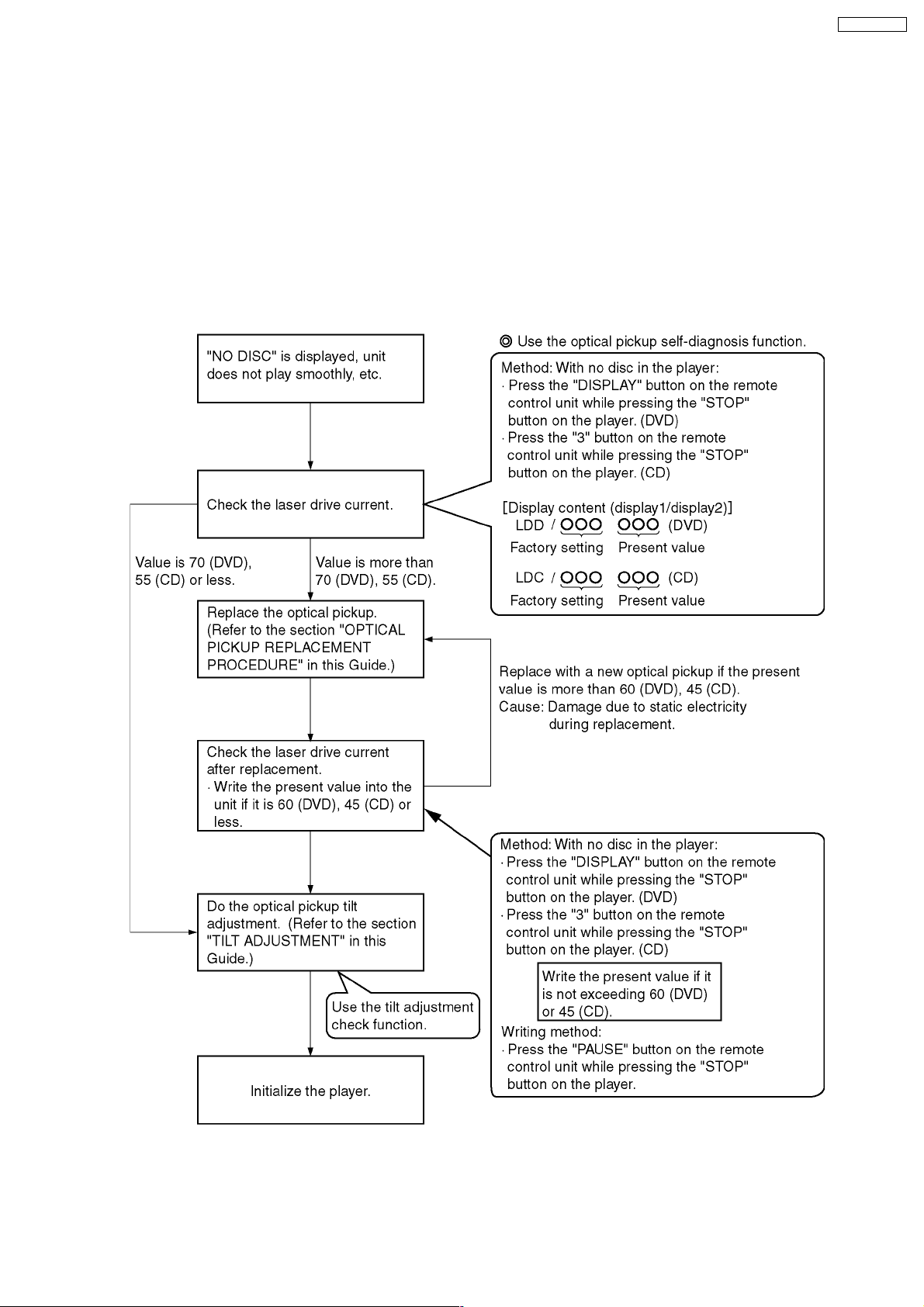

12 DVD-Optical Pick-up Self-Diagnosis and Replacement

Procedure

12.1. Optical Pickup Breakdown Diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing, use

the following procedure for effective Self-diagnosis and tilt adjustment.Be sure to use the self-diagnosis functionbefore replacing

the optical pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup when the value of the laser

drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up. (Otherwise,

the result will be incorrect.)

21

Page 22

SA-HT720GCP

12.2. Service Mode Table 1

The service modes can be activated by pressing various button combination on the player and remote control unit.

Player buttons Remote control unit buttons Application Note

STOP 0 Error code display (Refer to the item, “12.3.

5 Tilt adjustment Refer to the item “15.4.

6 Area number and broadcasting system check

7 Built-in program version check

DISPLAY DVD laser drive current check Refer to the item “12.1.

3 CD laser drive current check

PAUSE Writing of laser drive current value after replacement of optical

pickup (Do use this function only when optical pickup is

replaced.)

10 Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer and its peripherals

and printed circuit board.

DVD Self Diagnostic

Function-Error Code ”).

Optical adjustment”).

Optical Pickup

Breakdown Diagnosis ”.

12.3. DVD Self Diagnostic Function-Error Code

Error Code Error Content Additional error explanation

U, H error

U11 Focus error

H01 Tray loading error

H02 Spindle servo error (Spindle servo, DSC (IC8271) SP motor, CLV servo error)

H03 Traverse servo error (TRAVERSE MOTOR, IC8251)

H04 Tracking servo error

H05 Seek error

H06 Power error Cannot switch off the power because of the panel and system computer communication error

H07 Spindle motor drive error Spindle motor

DSC related

F500 DSC error DSC (IC8271) stops in the occurrence of servo error (startup, focus error, etc.)

F501 DSC not Ready DSC-system computer communication error (Communication failure caused by idling of DSC)

F502 DSC Time out error Similar disposal as F500

F503 DSC communication Failure Communication error (result error occurred although communication command was sent)

F504 Error adjusting DSC data slice offset

F505 DSC Attention error Similar disposal as F500

F506 Invalid media Disc is flipped over, TOC unreadable, incompatible disc media

ODC related

F600 Access failure to management

information caused by demodulation

error

F601 Indeterminate sector ID requested Operation stopped caused by the request to access abnormal ID data

F602 Access failure to LEAD-IN caused by

demodulation error

F603 Access failure to KEYDET caused by

demodulation error

F610 ODC abnormality No permission for command execution

F611 6626 QCODE don’t read Error Access failure to seek address in CD series

F612 No CRC OK for a specific time Access failure to ID data in DVD series

F620 Laser safeguard: high temperature

condition

F621 Laser safeguard: circuit failure

condition

F630 No reply to KEY DET enquiry (for internal use only)

F631 CPPM KEY DET is not available till

the FILE terminal

F632 CPPM KEY DET is not available Been revoked or falsified

Disc code

F103 Illegal highlight Position Big possibility of disc specification violation during highlight display

HIC Error

F4FF Force initialize failure (time out)

Micro computer error

F700 MBX overflow When replying message to disc manager

F701 Message command does not end Next message is sent before replying to disc manager

F702 Message command changes Message is changed before it is sent as a reply to disc manager

F880 Task number is not appropriate Message coming from a non-existing task

Operation stopped because navigation data is not accessible caused by the demodulation

defect

LEAD IN data unreadable

Access failure to CSS data of disc

(CPPM file system is unreadable caused by scratches)

22

Page 23

Error Code Error Content Additional error explanation

F890 Sending message when message is

being sent to AV task

F891 Message couldn’t be sent to AV task Begin sending message to AV task

F893 FROM falsification

F894 EEPROM abnormality

F895 Language area abnormality Firm version agreement check for factory preset setting failure prevention

F896 No existence model Firm version agreement check for factory preset setting failure prevention

F897 Initialize is not completed Initialize completion check for factory preset setting failure prevention

F898 Disagreement of hardware and

software

F8A0 Message command is not appropriate Begin sending message to AV task

Sending message to AV task

Unsuitable combination of AV DECORDER, SDRAM and FLASH ROM

(firmware)

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

12.4. Last Error Code saved during NO PLAY

Error code Error Content System computer Setting task System computer internal error code

F0BF 6) Cannot playback because

physical layer is not recognizable

F0C0 8) DVD: Cannot playback because it

is not DVD Video/Audio/VR

F0C1 9) DVD: Prohibited by the restricted

region code

F0C2 A) DVD: PAL restricted playback PCND_NOPLAY PAL 0x90 DiscManager 0xDOC2

F0C3 B) DVD: Parental lock setting

prohibits the playback of the entire

title

F0C4 C) VCD: Prohibited because it is in

PHOTO CD format

F0C5 VCD/CD: Prohibited because it is

CDROM without CD-DA

PCND_NOPLAY PHYSICAL

0x50

PCND_NOPLAY VIDEO 0x70 DiscManager 0xDOC0

PCND_NOPLAY RCD 0x80 DiscManager 0xDOC1

PCND_NOPLAY PTL 0xA0 DiscManager 0xDOC3

PCND_NOPLAY PHOTO CD

0xB0

PCND_NOPLAY CDROM 0xC0 DiscManager 0xDOC5

DriveManager 0xDOBF

DiscManager 0xDOC4

SA-HT720GCP

23

Page 24

SA-HT720GCP

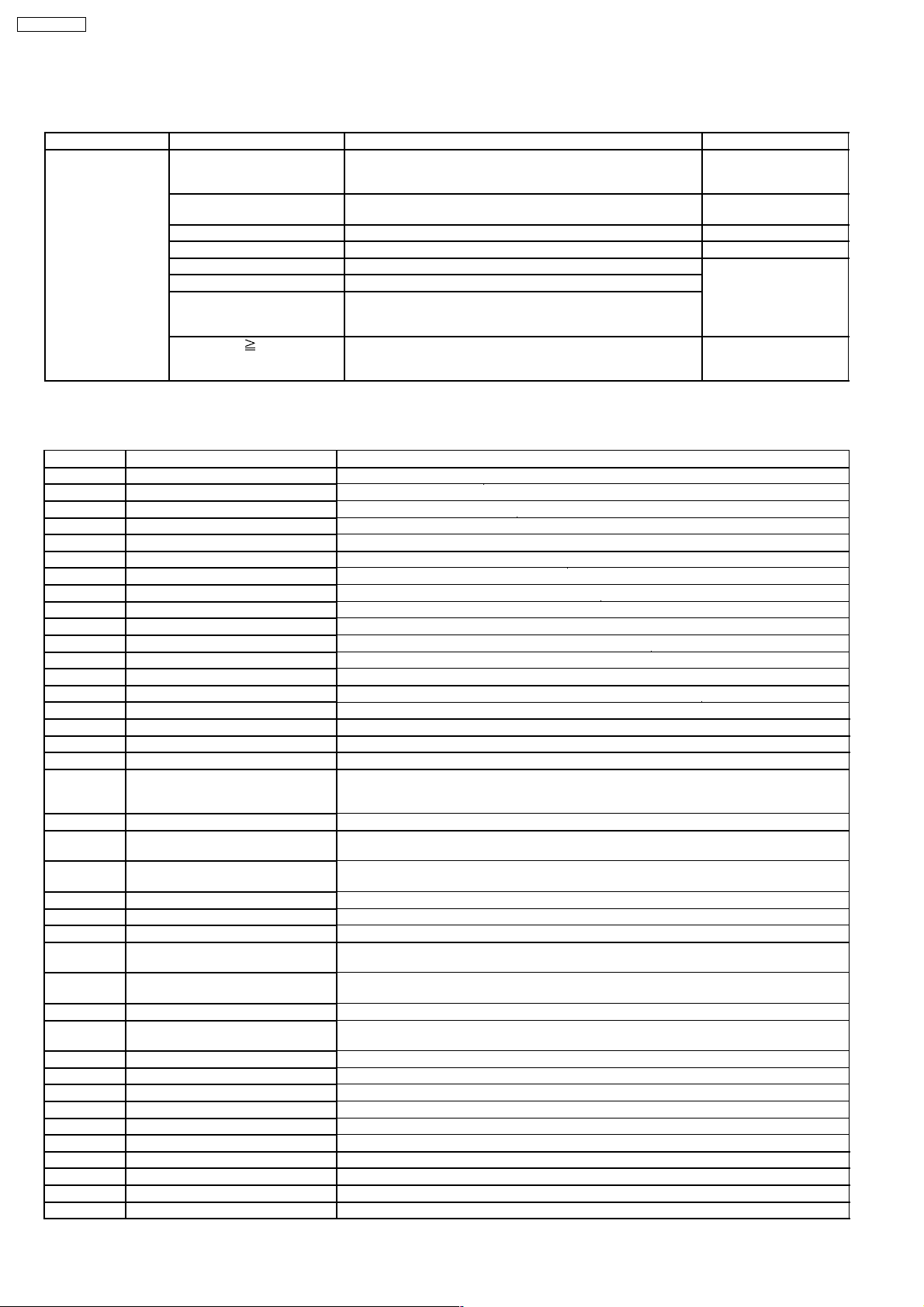

12.5. Service mode table 2

Pressing various button combinations on the player and remote control unit can activate the service modes.

24

Page 25

SA-HT720GCP

25

Page 26

SA-HT720GCP

12.6. Sales demonstration lock function

This function prevents discs from being lost when the unit is used for sales demonstrations by disabling the disc eject function.

"LOCKED" is displayed on the unit, and ordinary operation is disabled.

12.6.1. Setting

· Prohibiting removal of disc

1. Select the DVD/CD function.

2. Press and hold down the

seconds. (The message, “___LOCKED_” appears whenthe function is activated.)

Note:

OPEN/CLOSE

the lock function mode is entered.

· Prohibiting operation of selector and disk

1. Select the DVD/CD function.

2. Press and hold down the

seconds. (The message, “___LOCKED_” appears whenthe function is activated.)

Note:

The following buttons are invalid and the player displays “___LOCKED_” while the lock function mode is entered.

Player , , , SELECTOR, , , VOLUME KNOB, DISC CHECK, DISC CHANGE, DISC1-DISC5

Remote

controller unit

SLEEP, REPEAT, 0~9, RETURN, TOP MENU, , , , , , , POSITION

MEMORY, TUNER/BAND, D.MIX, CH SELECT/ TEST, SET UP/ MUTING, DISPLAY, GROUP, TV, VCR/ AUX, QUICK

REPLAY, SUBTITLE, FL DISPLAY, CH & VOLUME

, DISC CHECK and DISC CHANGE buttons are invalid and the player displays “___LOCKED_” while

button on the player and the power button on the remote controller unit for at least three

button on the player and the power button on the remote controller unit for at least three

12.6.2. Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCK" is displayed on cancellation. Disconnecting the

power cable from power outlet does not cancel the lock.)

12.7. Handling After Completing Repairs

Use the following procedure after completing repairs.

12.7.1. Method

Confirm that the power is turned on:

1. Press the "OPEN/CLOSE" button to close the tray.

2. Press the "POWER" button to turn off the power.

3. Disconnect the power plug from the outlet.

12.7.2. Precautions

Do not disconnect the power plug from the outlet with the tray still open, then close the tray manually.

26

Page 27

SA-HT720GCP

13 Self-Diagnosis Function

13.1. Automatic Displayed Error

Codes

13.1.1. Automatic Display Function

For a power unit error, the code is automatically displayed.

F61: Automatically displayed on the LCD of

the player.

13.2. Memorized Error Codes

13.2.1. Activating Self-Diagnosis Function

and Displaying Method

1. Turn on the power.

2. Select DVD/CD function. With no DVD/CD inserted in the

player, press and hold down the

for at least two seconds, and press the F_SKIP

button for at least two seconds in order to display

“T___________”.

3. Press the

result of self diagnosis is displayed. (Ex.: T H15)(See table

below)

If several errors are detected, press the

display each.

button. If a memorized error is detected, the

13.1.2. Re-Display

· For F61 Display

−

− When the code, F61 is displayed, the power is

− −

automatically turned off.

−

− The code, F61 is displayed for three seconds, and then

− −

the current time appears.

−

− To retrieve the code, turn on the power button so that

− −

the code F61 appears, however, is switched to time

display after three seconds, and the power is

automatically turned off.

13.1.3. Description of Error Code

13.1.3.1. F61

· State, Condition

When the power is turned on, the unit is automatically

turned off. The power does not turn on.

· Cause, Troubleshooting

Power circuit system failure and/or direct current flown to

speaker terminal

Identify the cause and replace with new parts.

Error Code State, Condition Cause, Troubleshooting

H15 The disc tray cannot be opened: it closes spontaneously. Disc tray open/close detection switch (SW2601) failure.

H16 The disc tray cannot be closed: it opens spontaneously.

13.2.2. Re-Display

· Press the power button to turn off the power, and then turn

on the power.

· The details of self diagnosis are stored in the unit memory.

To retrieve them, follow the procedure described the above,

“Activating Self-Diagnosis Function and Displaying

Method”.

13.2.3. Deleting Details of Self Diagnosis

· After repair, press and hold down the button for at least

five seconds, “_ CLEAR __” appears for a second and then

“T________” appears. (Deletingthe details of self

diagnosis)

· After repairing errors, be sure to delete the details of self

diagnosis.

(Check and replace)

button simultaneously

button to

27

Page 28

SA-HT720GCP

14 Service Precautio ns

14.1. Recovery after the DVD player is repaired

· When FROM or module P.C.B. is replaced, carry out the recovery processing to optimize the drive.

Playback the recovery disk to process the recovery automatically.

· Recovery disc (Product number: RFKZD03R005)

· Performing recovery

1. Load the recovery disc (RFKZD03R005) on to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired.

When the recovery measures are taken, the customer setting will return to the factory setting as same as the procedure

described in item of "Initialization" in 12.5. is carried out. Write down the contents of the setting before recovery processing,and

reset the player.

14.2. Firmware version-up of the DVD player

· The firmware of the DVD player may be renewed to improve the quality including operability and playability to the substandard

discs.processing to optimize the drive.

The recovery disc has also firmware version-up.

· After version-up, recovery processing is executed automatically.

· Part number of the recovery disc for version-up will be noticed when it is supplied.

· Updating firmware

1. Load the recovery disc that is supplied to the player and run it.

2. Firmware version of the player is automatically checked. Appropriate message appears whenever necessary.

3. Using remote controller´s cursor key, select whether version updating is to be done or not. (Selection of Yes/No)

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc according to the message appearing on the screen.

b. Remove the disc according to the message appearing on the screen.

6. Turn off the power.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out.

In such a case, replace the FLASH ROM IC and carry out the version-up again.

28

Page 29

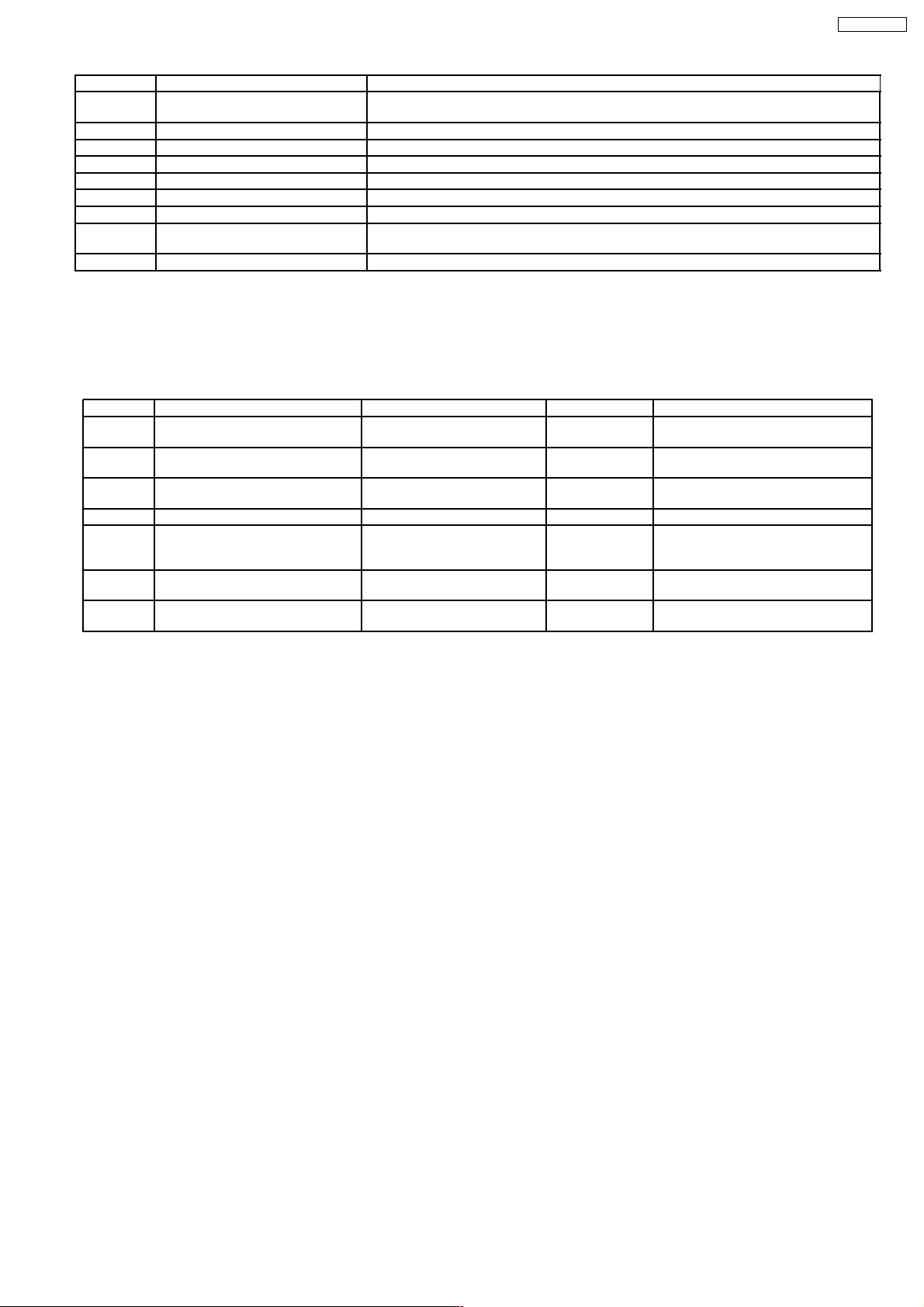

15 Adjustment Procedure

15.1. Service Tools and Equipment

Application Name Number

Tilt adjustment DVD test disc DVDT-S15 or DVDT-S01

SA-HT720GCP

TORX screw driver (T6) Available on sales route. (T6) or

Others Grease RFKXPG641

Confirmation CD test disc PVCD-K06 or any other commercially

VCD test disc PVCD-K06 or any other commercially

Recovery disc RFKZD03R005

RFKZ0185

available disc

available disc

15.2. Important points in adjustment

15.2.1. Important points in optical adjustment

· Before starting optical adjustment, be sure to take anti-static measures.

· Optical pickup tilt adjustment is needed after replacement of the following components.

1. Optical pickup unit

2. Spindle motor unit

3. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, make adjustment if there is a

noticeable degradation in picture quality. Optical adjustments cannot be made inside the optical pickup. Adjustment is generally

unnecessaryafter replacing the traverse unit.

15.2.2. Important points in electrical adjustment

· Follow the adjustment procedures described in this Manual.

15.3. Storing and Handling Test Discs

· Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store

discs in a cool place where they are not exposed to direct sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped when placed on a surface made of glass, etc. If this happens, use

a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

29

Page 30

SA-HT720GCP

15.4. Optical adjustment

15.4.1. Optical pickup tilt adjustment

Measurement point Adjustment point Mode Disc

Tangential adjustment screw

Tilt adjustment screw

Measuring equipment Adjustment value

None (Main unit display for servicing is used.) Adjust to the minimum jitter value.

15.4.1.1. Adjustment procedure

1. While pressing STOP button on the main unit, press "5" on

the remote control unit.

2. Confirm that "J_xxx/yyy_zz" (display1/display2) is shown on

the front display.

For your information:

"yyy" and "zz" shown to the right have nothing to do with

the jitter value. "yyy" is the error counter, while "zz" is

the focus drive value.

Note:

Jitter value appears on the front display.

3. Play test disc T30 (center periphery).

4. Adjust tangential adjustment screw so that the jitter value is

minimized.

5. Play test disc T30 (center periphery).

6. Adjust tilt adjustment screw 1 so that the jitter value is

minimized.

7. Play test disc T30 (center periphery).

8. Adjust tilt adjustment screw 2 so that the jitter value is

minimized.

9. Repeat adjusting tilt adjustment screws 1 and 2 alternately

until the jitter value is minimized.

15.4.1.2. Important points

1. Make tangential adjustment first, and then make tilt

adjustment.

2. Repeat adjusting two or three times to find the optimum

point.

3. Finish the procedure with tilt adjustment.

T01 (inner periphery) play

T30 (center periphery)

T43 (outer periphery) play

15.4.1.3. Check after adjustment

Play test disc or any other disc to make sure there is no picture

degradation in the inner, middle and outer peripheries, and no

audio skipping. After adjustment is finished, lock each

adjustment screw in position using screw lock.

15.4.1.4. Procedure for screw lock

1. After adjustment, remove top cover, tray, clamper base and

traverse unit in this sequence.

2. Lay the traverse unit upside down, and fix adjustment screw

with screw lock.

3. After fixing, reassemble traverse unit, clamper base, tray

and top cover.

DVDT-S15 or DVDT-S01

Jitter value depends on the model:

1. If the jitter value changes like B, the optimum point is easy to

find.

2. If the jitter value changes like A, set the optimum point near the

middle.

30

Page 31

16 Abbreviations

SA-HT720GCP

INITIAL/LOGO ABBREVIATIONS

A A0~UP

ACLK

AD0~UP

ADATA

ALE

AMUTE

AREQ

ARF

ASI

ASO

ASYNC

B BCK

BCKIN

BDO

BLKCK

BOTTOM

BYP

BYTCK

C CAV

CBDO

CD

CDSCK

CDSRDATA

CDRF

CDV

CHNDATA

CKSL

CLV

COFTR

CPA

CPCS

CPDT

CPUADR

CPUADT

CPUIRQ

CPRD

CPWR

CS

CSYNCIN

CSYNCOUT

D DACCK

DEEMP

DEMPH

DIG0~UP

DIN

DMSRCK

DMUTE

DO

DOUT0~UP

DRF

DRPOUT

DREQ

DRESP

DSC

DSLF

DVD

ADDRESS

AUDIO CLOCK

ADDRESS BUS

AUDIO PES PACKET DATA

ADDRESS LATCH ENABLE

AUDIO MUTE

AUDIO PES PACKET REQUEST

AUDIO RF

SERVO AMP INVERTED INPUT

SERVO AMPOUTPUT

AUDIO WORD DISTINCTION SYNC

BIT CLOCK (PCM)

BIT CLOCK INPUT

BLACK DROP OUT

SUB CODE BLOCK CLOCK

CAP. FOR BOTTOM HOLD

BYPATH

BYTE CLOCK

CONSTANT ANGULAR VELOCITY

CAP. BLACK DROP OUT

COMPACT DISC

CD SERIAL DATA CLOCK

CD SERIAL DATA

CD RF (EFM) SIGNAL

COMPACT DISC-VIDEO

CHANNEL DATA

SYSTEM CLOCKSELECT

CONSTANT LINEAR VELOCITY

CAP. OFF TRACK

CPU ADDRESS

CPU CHIP SELECT

CPU DATA

CPU ADDRESS LATCH

CPU ADDRESS DATA BUS

CPU INTERRUPT REQUEST

CPU READ ENABLE

CPU WRITE ENABLE

CHIPSELECT

COMPOSITE SYNC IN

COMPOSITE SYNC OUT

D/A CONVERTER CLOCK

DEEMPHASIS BIT ON/OFF

DEEMPHASIS SWITCHING

FL DIGIT OUTPUT

DATA INPUT

DM SERIAL DATA READ CLOCK

DIGITAL MUTE CONTROL

DROP OUT

DATAOUTPUT

DATA SLICE RF (BIAS)

DROP OUT SIGNAL

DATA REQUEST

DATA RESPONSE

DIGITAL SERVO CONTROLLER

DATA SLICE LOOP FILTER

DIGITAL VIDEO DISC

INITIAL/LOGO ABBREVIATIONS

E EC

ECR

ENCSEL

ETMCLK

ETSCLK

F FBAL

FCLK

FE

FFI

FEO

FG

FSC

FSCK

G GND COMMON GROUNDING (EARTH)

H HA0~UP

HD0~UP

HINT

HRXW

I IECOUT

IPFRAG

IREF

ISEL

L LDON

LPC

LRCK

M MA0~UP

MCK

MCKI

MCLK

MDATA

MDQ0~UP

MDQM

MLD

MPEG

O ODC

OFTR

OSCI

OSCO

OSD

P P1~UP

PCD

PCK

PDVD

PEAK

PLLCLK

PLLOK

PWMCTL

PWMDA

PWMOA, B

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE

ENCODER SELECT

EXTERNAL M CLOCK (81MHz/40.5MHz)

EXTERNAL S CLOCK (54MHz)

FOCUS BALANCE

FRAME CLOCK

FOCUS ERROR

FOCUS ERROR AMP INVERTED INPUT

FOCUS ERROR AMP OUTPUT

FREQUENCY GENERATOR

FREQUENCY SUB CARRIER

FS (384 OVER SAMPLING) CLOCK

HOST ADDRESS

HOST DATA

HOST INTERRUPT

HOST READ/WRITE

IEC958 FORMAT DATA OUTPUT

INTERPOLATION FLAG

I (CURRENT) REFERENCE

INTERFACE MODE SELECT

LASER DIODE CONTROL

LASER POWER CONTROL

L CH/R CH DISTINCTION CLOCK

MEMORY ADDRESS

MEMORY CLOCK

MEMORY CLOCK INPUT

MEMORY SERIAL COMMAND CLOCK

MEMORY SERIAL COMMAND DATA

MEMORY DATA INPUT/OUTPUT

MEMORY DATA I/O MASK

MEMORYSERIAL COMMAND LOAD

MOVING PICTURE EXPERTS GROUP

OPTICAL DISC CONTROLLER

OFF TRACKING

OSCILLATOR INPUT

OSCILLATOR OUTPUT

ON SCREEN DISPLAY

PORT

CD TRACKING PHASE DIFFERENCE

PLL CLOCK

DVD TRACKING PHASE DIFFERENCE

CAP. FOR PEAK HOLD

CHANNEL PLL CLOCK

PLL LOCK

PWM OUTPUT CONTROL

PULSE WAVE MOTOR DRIVEA

PULSE WAVE MOTOR OUT A, B

31

Page 32

SA-HT720GCP

INITIAL/LOGO ABBREVIATIONS

R RE

RFENV

RFO

RS

RSEL

RST

RSV

S SBI0, 1

SBO0

SBT0, 1

SCK

SCKR

SCL

SCLK

SDA

SEG0~UP

SELCLK

SEN

SIN1, 2

SOUT1, 2

SPDI

SPDO

SPEN

SPRCLK

SPWCLK

SQCK

SQCX

SRDATA

SRMADR

SRMDT0~7

SS

STAT

STCLK

STD0~UP

STENABLE

STSEL

STVALID

SUBC

SBCK

SUBQ

SYSCLK

T TE

TIBAL

TID

TIN

TIP

TIS

TPSN

TPSO

TPSP

TRCRS

TRON

TRSON

READ ENABLE

RF ENVELOPE

RF PHASE DIFFERENCE OUTPUT

(CD-ROM) REGISTER SELECT

RF POLARITY SELECT

RESET

RESERVE

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SERIAL CLOCK

SERIAL DATA CLOCK

AUDIO SERIAL CLOCK RECEIVER

SERIAL CLOCK

SERIAL CLOCK

SERIAL DATA

FL SEGMENT OUTPUT

SELECTCLOCK

SERIAL PORT ENABLE

SERIAL DATA IN

SERIAL DATA OUT

SERIAL PORT DATA INPUT

SERIAL PORT DATA OUTPUT

SERIAL PORT R/W ENABLE

SERIAL PORT READ CLOCK

SERIAL PORT WRITE CLOCK

SUB CODE Q CLOCK

SUBCODE Q DATA READ CLOCK

SERIAL DATA

SRAM ADDRESS BUS

SRAM DATA BUS 0~7

START/STOP

STATUS

STREAM DATA CLOCK

STREAM DATA

STREAM DATA INPUT ENABLE

STREAM DATA POLARITY SELECT

STREAM DATAVALIDITY

SUB CODE SERIAL

SUB CODE CLOCK

SUB CODE Q DATA

SYSTEM CLOCK

TRACKING ERROR

BALANCE CONTROL

BALANCE OUTPUT 1

BALANCE INPUT

BALANCE INPUT

BALANCE OUTPUT 2

OP AMP INPUT

OP AMP OUTPUT

OP AMP INVERTED INPUT

TRACK CROSSSIGNAL

TRACKING ON

TRAVERSE SERVO ON

INITIAL/LOGO ABBREVIATIONS

V VBLANK

VCC

V BLANKING

COLLECTOR POWER SUPPLY

VOLTAGE

VCDCONT

VIDEO CD CONTROL (TRACKING

BALANCE)

VDD

VFB

VREF

VSS

W WAIT

WDCK

WEH

WSR

X X

XALE

XAREQ

XCDROM

XCS

XCSYNC

XDS

XHSYNCO

XHINT

XI

XINT

XMW

XO

XRE

XSRMCE

XSRMOE

XSRMWE

XVCS

XVDS

XVSYNCO

DRAIN POWER SUPPLY VOLTAGE

VIDEO FEED BACK

VOLTAGE REFERENCE

SOURCE POWER SUPPLYVOLTAGE

BUS CYCLE WAIT

WORD CLOCK

WRITE ENABLE HIGH

WORD SELECT RECEIVER

X´ TAL

X ADDRESS LATCH ENABLE

X AUDIO DATA REQUEST

X CD ROM CHIP SELECT

X CHIP SELECT

X COMPOSITE SYNC

X DATA STROBE

X HORIZONTAL SYNC OUTPUT

XH INTERRUPTREQUEST

X´ TAL OSCILLATOR INPUT

X INTERRUPT

X MEMORY WRITE ENABLE

X´ TAL OSCILLATOR OUTPUT

X READ ENABLE

X SRAM CHIP ENABLE

X SRAM OUTPUT ENABLE

X SRAM WRITE ENABLE

X V-DEC CHIPSELECT

X V-DEC CONTROL BUS STROBE

X VERTICAL SYNC OUTPUT

32

Page 33

17 Voltage Chart

17.1. DVD Module P.C.B.

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 3.0 3.0 0 3.0 3.2 3.4 3.0 3.1 0 3.1 3.1 3.3 2.9 3.0 2.8 0 3.0 3.0 3.4 0

STANDBY 3.0 3.0 0 3.1 3.2 3.3 3.1 3.1 0 3.2 3.1 3.3 0 3.1 0 0 3.1 3.0 3.3 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 3.3 2.7 1.7 2.2 1.2 2.5 3.4 0 2.3 0.9 2.3 2.4 3.4 0 2.5 2.0 2.2 1.7 2.4

STANDBY 0 3.3 2.9 0 2.4 1.2 2.6 3.3 0 2.7 0.4 2.6 2.3 3.3 0 2.7 1.8 2.6 1.3 2.3

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 2.3 2.6 0.7 1.2 1.8 1.5 2.3 3.4 0 2.3 0.8 2.3 3.3 0 0 2.8 3.3 0.7 3.3 3.3

STANDBY 2.4 2.6 0.4 1.2 2.1 0.8 2.6 3.3 0 2.3 0.9 2.6 3.3 0 3.3 2.8 3.3 0.6 3.3 3.3

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 3.3 0 0 0 0.5 0 3.0 2.8 3.1 0 1.6 3.1 0 1.7 1.6 1.7 0.1 3.3 0

STANDBY 0 3.3 0 0 0 0.7 0 3.0 0 3.0 0 3.3 3.1 0 1.7 0 0 3.3 0 3.3

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY3.303.33.400001.2000000003.33.30

STANDBY 3.3 0 0 3.3 0 0 0 0 0 000000003.30.80

Ref No.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

CD PLAY 0 2.1 1.8 0.1 0 1.7 3.3 2.1 2.0 1.8 1.8 0.7 0.7 1.7 1.7 1.7 1.7 3.3 1.9 1.7

STANDBY 2.4 2.1 1.8 -0.1 0 1.7 3.3 2.1 2.1 1.8 1.8 0.7 0.7 1.7 1.6 1.6 1.6 3.3 1.9 1.7

Ref No.

MODE 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140

CD PLAY 1.4 0 0 0.1 0 1.0 2.2 1.7 2.6 2.6 2.7 2.6 2.6 2.5 2.5 2.4 2.4 2.4 1.7 1.7

STANDBY 1.4 0 0 0 0 0 0 1.7 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 2.2 1.7 1.6

Ref No.

MODE 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160

CD PLAY 3.4 1.2 1.8 2.2 0 1.7 1.7 1.7 0.4 3.3 0.5 0.4 1.0 1.0 2.3 0.4 0 0.8 3.4 0

STANDBY 3.3 1.2 1.9 2.1 0 1.7 1.7 1.7 0.4 3.3 0.5 0.4 1.0 1.0 2.2 0.4 0 0.8 3.3 0

Ref No.

MODE 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180

CD PLAY 3.4 0 1.6 0 1.5 1.5 3.4 0.2 1.7 1.6 1.3 1.2 0 0 0 1.3 1.7 3.4 0 3.3

STANDBY 3.3 0 1.6 0 1.5 1.5 3.3 0 1.7 1.6 0 1.2 0 0 0 0 1.7 3.3 0 3.3

Ref No.

MODE 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200

CD PLAY 0 3.3 0 0 0 0 0 0.1 0.1 3.4 0.1 1.0 1.6 0.7 1.4 3.4 - - - -

STANDBY 0 3.3 00000003.300.60.30.33.33.30.30.60.60.6

Ref No.

MODE 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220

CD PLAY 0.1 3.4 - - 0.1 - - - 3.4 - - - 0 2.8 2.8 3.4 2.0 0

STANDBY 0 3.3 0.6 0.6 0 0.6 0.6 3.3 3.3 0.6 0.6 0 0 2.9 3.3 3.3 2.2 0

Ref No.

MODE 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240

CD PLAY 0.2 0 1.6 0.2 3.4 1.7 0.1 1.6 0 0 3.4 1.6 0.1 2.4 0 1.2 0 0.1

STANDBY 0 0 1.6 0 3.3 1.6 0 1.5 0 0 3.3 1.6 0.1 2.9 0 1.2 0 0

Ref No.

MODE 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256

CD PLAY 1.6 0 1.6 3.2 3.3 3.4 0 3.3 2.9 0 2.8 2.8 0 3.0 3.4 2.9

STANDBY 1.6 0 1.6 3.2 3.3 3.3 0 3.3 2.9 0 2.9 2.9 0 3.1 3.3 3.0

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 3.4 3.0 3.4 3.0 3.1 0 3.0 3.1 3.4 3.0 2.9 0 2.8 3.4 2.8 3.3 3.3 3.2 3.2 2.4

STANDBY 3.3 3.1 3.3 3.1 3.1 0 3.1 3.2 3.3 3.0 3.0 0 2.9 3.3 2.9 3.3 3.3 3.2 3.2 2.6

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 1.6 0 0.1 0.2 0.2 2.0 3.3 0 1.5 1.6 1.7 1.6 0.1 0.1 0 0 3.4 1.6

STANDBY 1.7 0 0.1 0.2 0.2 2.2 3.3 0 1.6 1.6 1.6 1.5 0.1 0 0 0 3.3 1.6

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54

CD PLAY 0 3.0 3.3 3.0 3.0 0 3.0 3.1 3.3 2.9 2.8 0 2.9 0

STANDBY 0 3.1 3.3 3.0 3.1 0 3.1 3.2 3.3 2.9 2.9 0 0 0

Ref No.

MODE 1 2 3 4 5 6 7 8

CD PLAY 3.3 0 0 1.9 4.8 0 0 4.8

STANDBY 3.3 0 0 1.9 4.9 0 0 4.9

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 1.7 1.7 1.7 1.7 1.7 1.7 0 4.8 3.3 0 2.8 2.8 2.8 2.8 2.1 2.1 2.1 2.0 0 0

STANDBY 1.7 1.7 1.7 1.7 1.7 1.7 0 4.9 0 0 2.8 2.8 2.8 2.8 2.1 2.1 2.1 2.1 0 0

Ref No.

MODE 21 22 23 24 25 26 27 28

CD PLAY 4.8 9.1 1.7 1.7 1.7 1.7 3.3 3.1

STANDBY 4.9 9.2 1.7 1.7 1.7 1.7 0 3.1

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 0 7.6 0 7.6 0 0 7.6 0 2.8 2.8 2.8 2.8 2.8 2.8 0.9 0 0.7 0 2.4 0.1

STANDBY 0 0.3 0 0.3 0 0 0.3 0 4.9 4.9 4.9 4.9 4.9 4.9 4.9 0 0 0 4.9 4.8

Ref No.

MODE 21 22 23 24 25 26 27 28

CD PLAY 1.7 1.6 3.3 1.6 4.8 0 9.2 9.2

STANDBY 1.7 1.7 0 3.3 4.9 0 9.3 9.3

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 3.3 3.3 0 0 0 0 0 0 2.4 2.5 2.4 2.5 2.4 2.5 2.5 2.5 0 5.0 0 2.5

STANDBY 0 0 0 0 0 0 0 0 2.4 2.5 2.4 2.5 2.4 2.5 2.5 2.5 0 5.0 0 2.4

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8001

IC8051

IC8051

IC8051

IC8111

IC8251

IC8251

IC8271

IC8271

IC8451

1.2 1.5

1.2 1.6

3.4 3.2

3.3 3.2

2.8 0

2.9 0

SA-HT720GCP

33

Page 34

SA-HT720GCP

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 5.0 0 5.0 0 5.0 0 5.0 0 3.3 1.3 3.3 0.3 3.3 2.8 3.3 3.1 1.7

STANDBY 0 5.0 0 5.0 0 5.0 0 5.0 00000.33.32.83.33.11.7

Ref No.

MODE 41 42 43 44 45 46 47 48

CD PLAY 1.7 0 3.3 0 1.3 0 0 3.3

STANDBY 1.7 0 3.3 0 0 0 0 0

Ref No.

MODE 1 2 3

CD PLAY 0 3.1 3.4

STANDBY 0 3.1 3.3

Ref No.

MODE 1 2 3 4 5

CD PLAY 0.6 1.2 0 0 1.1

STANDBY 0.6 1.2 0 0 1.1

Ref No.

MODE 1 2 3 4 5 6 7 8

CD PLAY 0 0 0 0 3.3 3.3 0 3.3

STANDBY 0 0 0 0 3.3 3.3 0 3.3

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 1.4 2.3 2.6 2.5 2.2 2.4 2.2 2.2 1.7 0 3.4 3.1 0 3.4 0.6 0.9 0.7 2.3 2.5 2.4

STANDBY 0.8 2.6 2.7 2.6 2.2 2.3 2.4 2.4 2.1 0 3.3 3.1 0 3.3 0.6 0.5 0.4 0 2.7 2.3

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 1.7 0.8 2.0 1.7 2.7 2.2 0 2.3 0.9 0.7 1. 0 0.8 1. 5 0.9 1. 4 1.3 3.4 1.3 0.9 1.5

STANDBY 2.0 0.9 1.8 1.3 2.9 2.5 0 2.6 0.9 0.6 1.1 0.7 1.6 0.8 1.5 1.4 3.3 1.4 0.7 1.3

Ref No.

MODE 41 42 43 44 45 46 47 48

CD PLAY 1.4 1.4 1.8 1.6 1.9 0 3.4 2.2

STANDBY 1.3 1.6 1.8 1.6 1.9 0 3.3 2.7

Ref No.

MODE 1 2 3 4 5

CD PLAY 3.0 3.0 0 4.3 4.8

STANDBY 3.0 3.0 0 4.4 4.9

Ref No.

MODE 1 2 3 4 5

CD PLAY 2.8 2.8 0 4.0 4.8

STANDBY 2.9 2.9 0 4.2 4.9

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 4.9 4.9 4.2 0 4.9 0.1 4 . 9 0 4.9 0 0.1 0.7 0.4 3.7 1.0

STANDBY 5.0 4.9 4.3 0 4.9 0 4.9 0 4.9 0 0.1 0.7 0 4.9 0

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 4.3 2.2 3.7 0 0.1 0.6 0 3.1 0.1 0 2.8 0 3.4 3.3 0.1

STANDBY 4.9 0 4.9 0 0.1 0.6 0 3.1 0.1 0 0 3.3 3.3 -0.3 3.3

Q8550

Q8562

Q8551 Q8552 Q8560

Q8605

IC8451

IC8451

IC8601

IC8605

IC8611

IC8651

IC8651

IC8651

IC8691

IC8695

Q8561

Q8606 QR8420 QR8571

1.7 1.7

1.8 1.6

34

Page 35

17.2. Main P.C.B.

Ref No.

MODE 1 2 3

CD PLAY 6.1 0 5.0

STANDBY 6.1 0 5.0

Ref No.

MODE 1 2 3 4 5

CD PLAY 13.4 2.9 0 1.0 3.5

STANDBY 13.5 2.6 0 1.0 3.5

Ref No.

MODE 1 2 3 4 5

CD PLAY 13.5 6.0 0 1.0 3.5

STANDBY 13.7 6.0 0 1.0 3.5

Ref No.

MODE 1 2 3

CD PLAY 6.1 0 5.0

STANDBY 6.1 0 5.0

Ref No.

MODE 1 2 3 4 5

CD PLAY 2.4 5.0 1.3 1.0 0

STANDBY 2.4 5.0 1.3 1.0 0

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 4.8 2.2 4.8 0 0 1.7 2.4 0 1.9 0 0 1.7 0 2.2 4.8 2.2 0 2.2 2. 2 0

STANDBY 4.8 2.2 4.8 0 0 1.7 2.4 0 1.9 0 0 1.7 0 2.2 4.8 2.2 0 2.2 2.2 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34

CD PLAY 2.2 2.2 0 1.8 1.6 0 1.8 1.7 0 1.7 1.6 0 2.2 4.8

STANDBY 2.2 2.2 0 1.8 1.6 0 1.8 1.7 0 1.7 1.6 0 2.2 4.8

Ref No.

MODE 1 2 3 4 5 6 7 8 9

CD PLAY 0 0 0 0 8.7 9.2 4.6 0 4.6

STANDBY 0 0 0 0 8.7 9.2 4.6 0 4.6

Ref No.

MODE 1 2 3 4 5 6 7 8 9

CD PLAY 0 0 0 0 8.7 9.2 4.6 0 4.6

STANDBY 0 0 0 0 8.7 9.2 4.6 0 4.6

Ref No.

MODE 1 2 3 4 5 6 7 8

CD PLAY 0 0 0 -6.7 0 0 0 6.8

STANDBY 0 0 0 -6.7 0 0 0 6.9

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 0 0 0 0 0 0 000000000000

STANDBY 0 0 0 0 00000000000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 0 0 0 0 0 0 0 0000-6.02.40000

STANDBY 0 0 0 0 00000000-6.02.40000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 -6.0 6.1 0 0 0 0 0 0000000000

STANDBY 0 -6.0 6.1 0 0 0 0 00000000000

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 0 0 0 0 0 0 0 000000000000

STANDBY 0 0 0 0 0 0 0 0 000000000000

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14

CD PLAY 0 0 0 6.8 0 0 0 0 0 0 -6.7 0 0 0

STANDBY 0 0 0 6.8 0 0 0 0 0 0 -6.7 0 0 0

Ref No.

MODE 1 2 3 4 5 6 7 8

CD PLAY 0 0 0 -6.7 0 0 0 6.9

STANDBY 0 0 0 -6.7 0 0 0 6.9

Ref No.

MODE 1 2 3 4 5 6 7 8

CD PLAY 0 0 0 -6.7 0 0 0 6.8

STANDBY 0 0 0 -6.7 0 0 0 6.9

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY 4.5 4.7 4.7 0 0.2 0 4.7 0 0 0 0 4.6 2.3 0 2.2 4.7 4.7 4.6 2.6 4.7

STANDBY 4.5 4.7 4.7 0 0.2 0 4.7 0 0 4.7 0 4.6 2.3 0 2.2 4.7 4.7 4.7 2.6 4.7

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0.1 0.5 0.3 0 0 4.6 0 0.1 4.7 4.7 0.5 0 0 0 3.6 3.9 4.3 4.6

STANDBY 0.1 0.2 0.1 0 0 4.6 0 0 4.8 4.8 0.2 0 0 4.6 3.5 4.0 4.3 4.7

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 0 0 0 0 0 0 0 0 0 0 4.6 0 4.7 000000.5

STANDBY 0 4.6 0 4.7 0 0 0 0 0 0 0 4.6 0 4.7 000000.2

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 4.7 0 0 0 4.6 0 4.6 0 4.4 0 4.7 0 0 0 4.7 0 0

STANDBY 0 4.7 0 0 0 4.6 0 4.6 0 4.4 0 4.7 0 0 0 4.8 0 0

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y 0 0 0 0 0 4.6 4.7 2.1 3.3 0.7 2.8 0 0.4 0 0 0 4.7 4.8 4.7 0.2

STANDBY -0.1 0 0 0 0 4.7 4.7 2.0 3.3 0.9 2.8 0 0.4 0 0 0 4.8 4.8 4.7 0.2

IC2000

IC2001

IC2002

IC2004

IC2005

IC2006

IC2006

IC2007

IC2008

IC2010

IC2011

IC2011

IC2011

IC2011

IC2012

IC2013

IC2015

IC2018

IC2018

IC2018

IC2018

IC2018

SA-HT720GCP

00

00

00

00

00

00

0 4.6

4.6 4.6

00

00

35

Page 36

SA-HT720GCP

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14

CD PLAY 0 0 0 6.8 0 0 0 0 0 0 -6.7 0 0 0

STANDBY 0 0 0 6.8 0 0 0 0 0 0 -6.7 0 0 0

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

CD PLAY 0 0 0 0 0 0 -6.7 0 4.7 4.7 4.7 0 0 0 0 5.1

STANDBY 0 0 0 0 0 0 -6.7 0 4.6 4.6 4.6 0 0 0 0 5.1

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 0 4.6 0 0 0 4.5 0 0 4.5 0 0 4.6 13.5 -3.0 13.5

STANDBY 0 4.6 0 0 0 4.5 0 0 4.5 0 0 4.5 13.8 -3.0 13.7

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 13.5 9.2 12.9 8.5 12.9 9.1 13.6 12.9 13.5 -29.2 -34.8 -29.9 0 -7.3 -0.6

STANDBY 13.6 9.2 12.9 8.5 12.9 9.1 13.6 12.9 13.6 -29.3 -35.0 -29.9 0 -7.3 -0.6

Ref No.

MODE 1 2 3 E C B E C B E C B E C B

CD PLAY -6.7 -12.0 -7.3 13.4 9.2 12.2 8.6 12.8 9.1 13.6 12.8 13.4 9.2 5.6 5.0

STANDBY -6.7 -12.3 -7.3 13.8 9.2 13.1 8.6 13.1 9.1 13.9 13.1 13.8 9.2 5.6 5.0

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 7.4 13.2 6.9 10.1 13.1 9.5 0 4.7 -3.0 0 -4.5 0 1.8 1.7 0

STANDBY 6.9 13.4 7.4 10.1 13.2 9.5 0 4.7 -3.0 0 -4.5 0 1.7 1.7 0

Ref No.

MODE E C B E C B 123456

CD PLAY 0 0 2.8 0 0 3.5 0 -4.5 0 0 -4.5 0

STANDBY 0 5.0 0 0 0 3.5 0 -4.5 0 0 -4.5 -0.5

Ref No.

MODE 1 2 3 4 5 6 123456 ECB

CD PLAY 0 0.6 0 0 0.6 0 0 -4.5 0 0 -4.5 0 1.7 1.7 0

STANDBY 0 0.6 0 0 0.6 0 0 -4.5 0 0 -4.5 0 1.7 1.7 0

Ref No.

MODE 1 2 3 4 5 6 E C B 1 23456

CD PLAY 0 0.6 0 0 0.6 0 0 -4.5 0 0 -4.5 0 0 -4.5 0

STANDBY 0 0.6 0 0 0.6 0 1.7 1.7 0 0 0.6 0 0 0.6 0

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 0 -4.5 0 0 0 0.7 2.0 2.0 0 2.9 2.0 2.2 0 -4.5 0

STANDBY 0 -4.5 0 0 0 0.7 2.0 2.0 0 2.9 2.0 2.2 2.1 2.1 0

Ref No.

MODE 1 2 3 4 5 6

CD PLAY 0 -4.5 0 0 0.6 0

STANDBY 0 0.7 0 0 0.6 0

Q2000

Q2012

Q2017 Q2018 Q2019 Q2020

Q2022

Q2101 Q2102

Q2104 Q2105 Q2200

Q2201 Q2300 Q2301 Q2500

Q2601

Q2001 Q2002 Q2004

Q2013

Q2023 Q2025 Q2026

IC2021

IC2022

Q2011

Q2014 Q2015 Q2016

Q2021

Q2027

Q2100Q2028 Q2029

Q2103

Q2600

17.3. FL P.C.B.

Ref No.

MODE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

CD PLAY -0.1 -0.1 -15.4 -21.5 -21.4 -21.4 -14.4 -21.4 -12.1 -16.8 -12.1 -21.5 0 0 -23.8 -21.5 -23.8 - 21.4 -19.1 -23.8

STANDBY 0 0 -14.5 -21.5 -23.8 -19.2 -16.8 -9.8 -14.5 -14.5 -14.5 -12.2 0 0 -23.8 -21.5 -21.5 -14.5 -21.5 -23.8

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY -26.5 -26.4 -26.4 -26.5 0 0 -26.4 -26.4 -26.4 -26.5 -26.5 -26.5 -26.5 -26.5 -26.4 -26.4 0 0 -29.1 0

STANDBY -26.5 -26.5 -26.5 -26.5 0 0 -26.5 -26.5 -26.5 -26.5 -26.5 -26.5 -26.5 -26.6 -26.5 -26.5 0 0 -29.2 0

Ref No.

MODE 41 42 43 44 45 46 47 48

CD PLAY 4.6 2.1 3.3 0.6 0 2.0 1.9 4.3

STANDBY 4.6 1.9 3.2 0.9 0 2.0 1.9 4.3

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 0 0.1 4.6 0 7.8 0 0 7.8 0 0 7.8 0 0 7.9 0

STANDBY 0 0.1 4.6 0 7.8 0 0 7.8 0 0 7.8 0 0 7.9 0

Q6900 Q6901 Q6902 Q6903 Q6904

IC6901

IC6901

IC6901

17.4. Loading Motor P.C.B.

Ref No.

MODE 1 2 3 4

CD PLAY 1.2 4.6 0 0

STANDBY 1.2 4.6 0 0

Q9001

17.5. Tray Motor P.C.B.

Ref No.

MODE 1 2 3 4 1 2 3 4

CD PLAY 1.2 0 4.8 0 2.5 1.2 0.1 0

STANDBY 1.2 0 4.8 0 2.5 1.2 0.1 0

Q9101 Q9102

36

Page 37

17.6. Sensor P.C.B.

SA-HT720GCP

Ref No.

MODE 1 2 3 4

CD PLAY 3.7 2.5 0 0.2

STANDBY 3.7 2.5 0 0.2

Q9103

37

Page 38

SA-HT720GCP

18 Schematic Diagram Notes

· This schematic diagram may be modified at any time

with the development of new technology.

Notes:

S6801: Play and memory switch (

Memory).

S6802: R. skip, search and tuning switch

(

S6803: F. skip, search and tuning switch

(

S6804: Stop and FM mode switch (

MODE).

S6805: Tray open / close switch (

Close).

S6806: Disc exchange switch (DISC

EXCHANGE).

S6807: Disc skip switch (DISC SKIP).

S6900: Standby / on switch (

S6901: Source select switch (INPUT

SELECTOR).

S6902-S6906: Disc switch (DISC1-DISC5).

S6907: Digital switch (DIGITAL).

S6908: Custom sound memory (C.S.M) switch.

S6909: Progressive out switch

(PROGRESSIVE).

S6910: CD / Tune mode switch [CD MODE /

TUNE MODE].

S9001: Loading switch.

VR6800: Volume control.

· Indicated voltage values are the standard values for the unit

measured by the DC electronic circuit tester (highimpedance) with the chassis taken as standard. Therefore,

there may exist some errors in the voltage values,

depending on theinternal impedance of the DC circuit

tester.

· Important safety notice:

Components identified by

characteristics important for safety.

Furthermore, special parts which have purposes of fireretardant (resistors), high-quality sound (capacitors), lownoise (resistors), etc. are used.

When replacing any of components, be sure to use only

manufacturer´s specified parts shown in the parts list.

· The supply part number is described alone in the

replacement parts list.

· Voltage and signal line

: +B Signal line

: CD-DA signal line

: Main signal line

: DVD (Video) signal line

: DVD (Audio) signal line

: FM/AM signal line

: -B Signal line

/ / TUNING ).

/ / TUNING ).

).

mark have special

Caution!

IC and LSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during

repair.

Cover the parts boxes made of plastics with aluminum foil.

Ground the soldering iron.

Put a conductive mat on the work table.

Do not touch the legs of IC or LSI with the fingers directly.

FM

Open /

38

Page 39

19 Block Diagram

SA-HT720GCP

OPTICAL PICK UP UNIT

PHOTO DETECTOR

B1 B2

A2

A1

A3

A4

B4

B3

SPINDLE MOTOR UNIT

HALL1

HALL2

HEAD

AMP

LASER DIODE

LASER DIODE

QR8571

POWER

SUPPLY

IC8271

C0GBF0000004

SPINDLE MOTOR DRIVE

2

A3

4

A2

7

A1

9

H1+

10

H1-

11

H2+

12

H2-

HALL AMP

+

-

+

-

+

-

+

-

+B

(D3.3V)

DRIVER

GAIN

CONTROL

(A5V)

CURRENT

SENSE AMP

TL

IC8001

MN2DS0003APH

DV2.1 LSI

138

VIN1

137

VIN2

136

VIN3

135

VIN4

131

VIN8

132

VIN7

133

VIN6

134

VIN5

129

VIN10

130

VIN9

Q8551,8552

LD DRIVE

Q8561,8562

LD DRIVE

Q8550,8560

+B

D

POWER

SUPPLY

TSD

PS 23

TL

+

EC 22

-

ECR

21

-+

R

Q

VCCCKQ

MUTE3

SP DRV

124

LPC01

123

LPC1

126

LPC02

125

LPC2

110

RFINN

111

RFINP

73

NRST

78

DRV3

79

DRV4

76

DRV1

128

VHALF

PWM1

PWM0

DRV0

DRV8

TRV DRV

147

F0 DRV

148

TRS DRV

75

MUTE12

83

60

SDA

P8

59

SCL

P9

IC8251

C0GBG0000044

TRACKING COIL/FOCUS COIL/TRAVERSE MOTOR DRIVE

1

2

3

23

24

27

9

IC8611

C3EBGZ000001

EE PROM

5

SDA

6

SCL

BIAS1

VIN1

VIN2

VIN3

LDIN

MUTE3

MUTE12

BIAS2

CH3

MUTE

CH1,2

MUTE

+

+

(Not supplied)

VOL4+

+

LEVEL

SHIFT

LEVEL

SHIFT

VOL4-

+

VOL3+

17

+

VOL3-

18

+

TRAVERSE

MOTOR

OPTICAL PICK UP UNIT

VOL1+

14

+

VOL1-

VOL2+

VOL2-

13

12

11

LEVEL

SHIFT

+

LEVEL

SHIFT

+

+

+

+

ACT T+

ACT T-

ACT F+

ACT F-

ACTUATOR

TRACKING

COIL

FOCUS

COIL

HALL3

TRAVERSE SW

13

H3+

14

H3-

+

-

+

-

FG 24

72

FG1

SW

81

DRV6

SA-HT720GCP BLOCK DIAGRAM

39

Page 40

SA-HT720GCP

IC8051

C3ABPG000068

64M SDRAM

IC8651

RFKFMH81T160

16M FLASH ROM

29

DQ0

31

33

35

40

42

44

30

32

34

36

39

41

43

45

DATA

DQ15

MEMORY

ADDRESS

12bit

MEMORY

DATA

16bit

IC8001

MN2DS0003APH

DV2

23

A0

24

A1

25

A2

26

A3

29

A4

30

A5

31

A6

32

A7

33

A8

34

A9

22

A10

35

A11

2

DQ0

4

DQ1

5

DQ2

7

DQ3

8

DQ4

10

DQ5

11

DQ6

13

DQ7

42

DQ8

44

DQ9

45

DQ10

47

DQ11

48

DQ12

50

DQ13

51

DQ14

53

DQ15

19

CS

18

NRAS

17

CAS

16

WE

38

CLK

25

A0

18

A7

8

A8

1

A15

48

A16

17

A17

16

A18

19

A19

20

A20

XOEXWEXCE

281126

227

MA0

224

MA1

221

MA2

217

MA3

220

MA4

223

226

228

233

238

230

237

17

14

11

256

252

254

10

13

15

18

240

244

245

248

243

23

39

37

51

24

40

36

50

25

41

33

47

27

42

32

46

30

43

31

45

21

52

22

38

212

210

207

204

200

198

195

193

192

194

197

199

203

206

208

211

MEMORY

MA5

ADDRESS

MA6

12bit

MA7

MA8

MA9

MA10

MA11

MDQ0

MDQ1

MDQ2

8

MDQ3

5

MDQ4

2

MDQ5

MDQ6

MEMORY

MDQ7

DATA

MDQ8

MDQ9

MDQ10

MDQ11

MDQ12

MDQ13

MDQ14

MDQ15

NCSM

NRAS

NCAS

NWE

MCK

EXADT0

EXADT7

EXADT8

EXADT15

EXADR16

EXADR17

EXADR18

EXADR19

EXADR20

NEXOE

NEXWE

NEXCE

MDQ16

MDQ31

16bit

ADDRESS

ADDRESS

DATA

1

4

7

SRCK

LRCK

AD OUT0

AD OUT1

AD OUT2

AD OUT3

NRST

P15

P12

P11

P10

DACCK

P13

DAC4 OUT

DAC5 OUT

DAC1 OUT

DAC2 OUT

DAC3 OUT

P3

P1

P2

170

169

176

175

174

171

IC8601

C0EBE0000384

VOLTAGE

DETECTING

RESET

73

53

56

57

58

163

A MUTE

55

Y

156

C

158

Y/PY/G

149

CB/PB/B

151

CR/PR/R

152

OP CPU CLK

68

OP CPU CMD

702

OP CPU STAT

69

2

IC8605

C0EBA0000031,

Q8605,8606

RESET

IC8451

C0FBBK000036

AUDIO DAC

40

BCK IN

LRC IN

41

45

D IN1

46

D IN2

47

D IN3

D IN4

31

RSTB

37

ML

36

MC

35

MDI

34

MDO

33

SCLKI

38

SERIAL

INPUT

I/F

4X/8X

OVERSAMPLING

DIGITAL FILTER

WITH

FUNCTION

CONTROLLER

FUNCTION

CONTROL

I/F

SYSTEM

CLOCK

SYSTEM

CLOCK

MANAGER

IC8691

C0JBCA000066

AND GATE

1

2

IC8695

C0JBCA000066

AND GATE

1

2

IC8111

C0CBCBD00018

POWER SUPPLY

(D3.3V) (D5V)

+B +B

V OUT V IN

GND

3

4

4

CONT

ZERO DETECT

8

5

ENHANCED

MULTI-LEVEL

DELTA-SIGMA

MODULATOR

DAC

DAC

DAC

DAC

DAC

DAC

DAC

DAC

OUTPUT AMP AND

LOW-PASS FILTER

OUTPUT AMP AND

LOW-PASS FILTER