Panasonic RQ-SX77v Service Manual

AD0004074C1

A1

Stereo Radio Cassette Player

RQ-SX77V

AR10 Mechanism Series

Colour

(S)...............Silver Type

Area

(P)...............U.S.A.

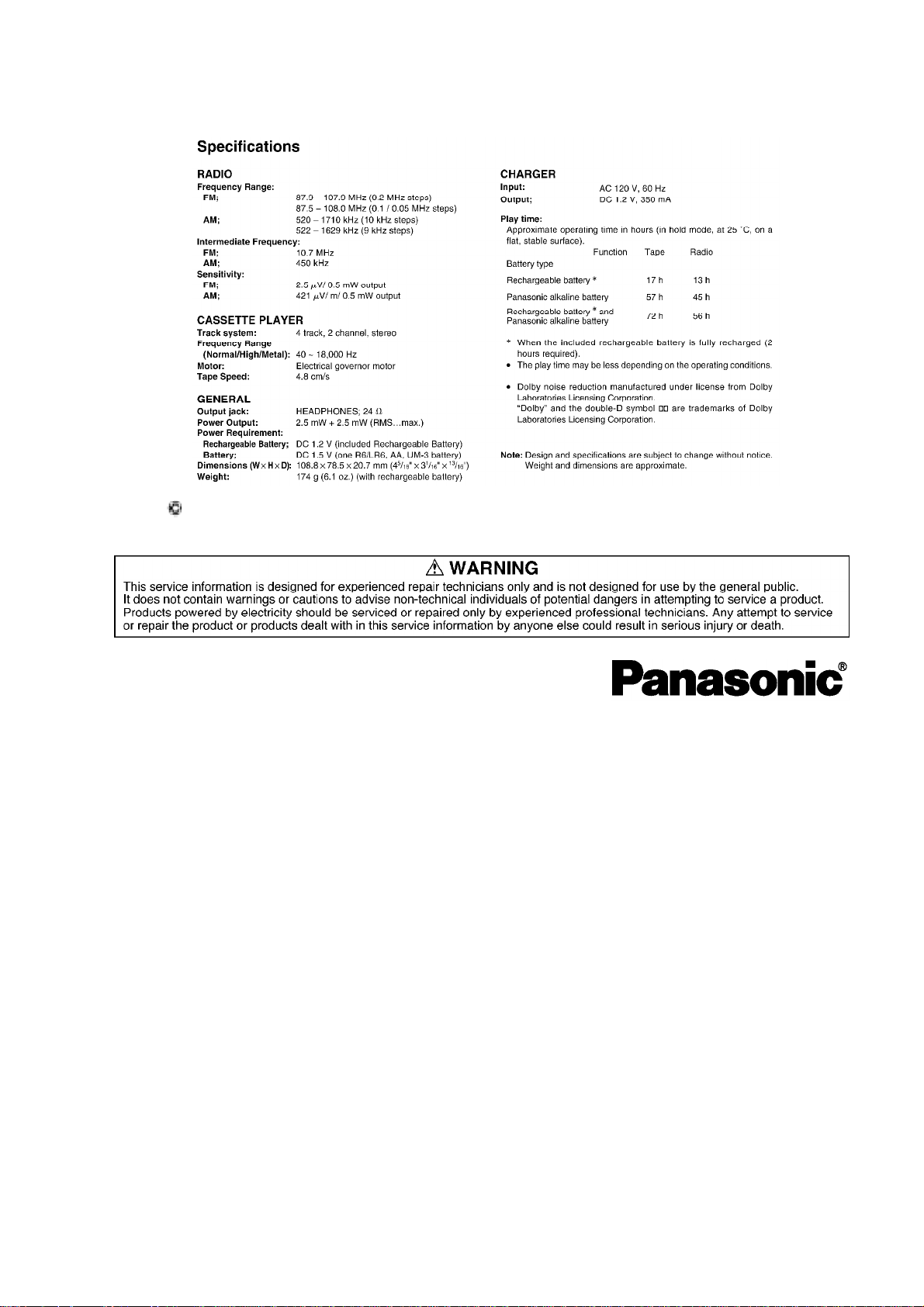

SPECIFICATIONS

<Note>

Please dispose of the service manual for Model No.

RQ-SX77V(P) TENTATIVE, Order No. AD0002039A1

and use this service manual.

2000 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

1. Accessories

- Battery charger

(RP-BC156BPY).........................1pc.

- Stereo headphones

(RFEV711P-KY)..........................1pc.

- Remote controller

(RFEV012P-KS)..........................1pc.

- Rechargeable battery (with case)

(RP-BP61PYS11).......................1pc.

- Dry cell battery case

(RFAT0002-H)............................1pc.

- Carring case

(RFC0056-K)..............................1pc.

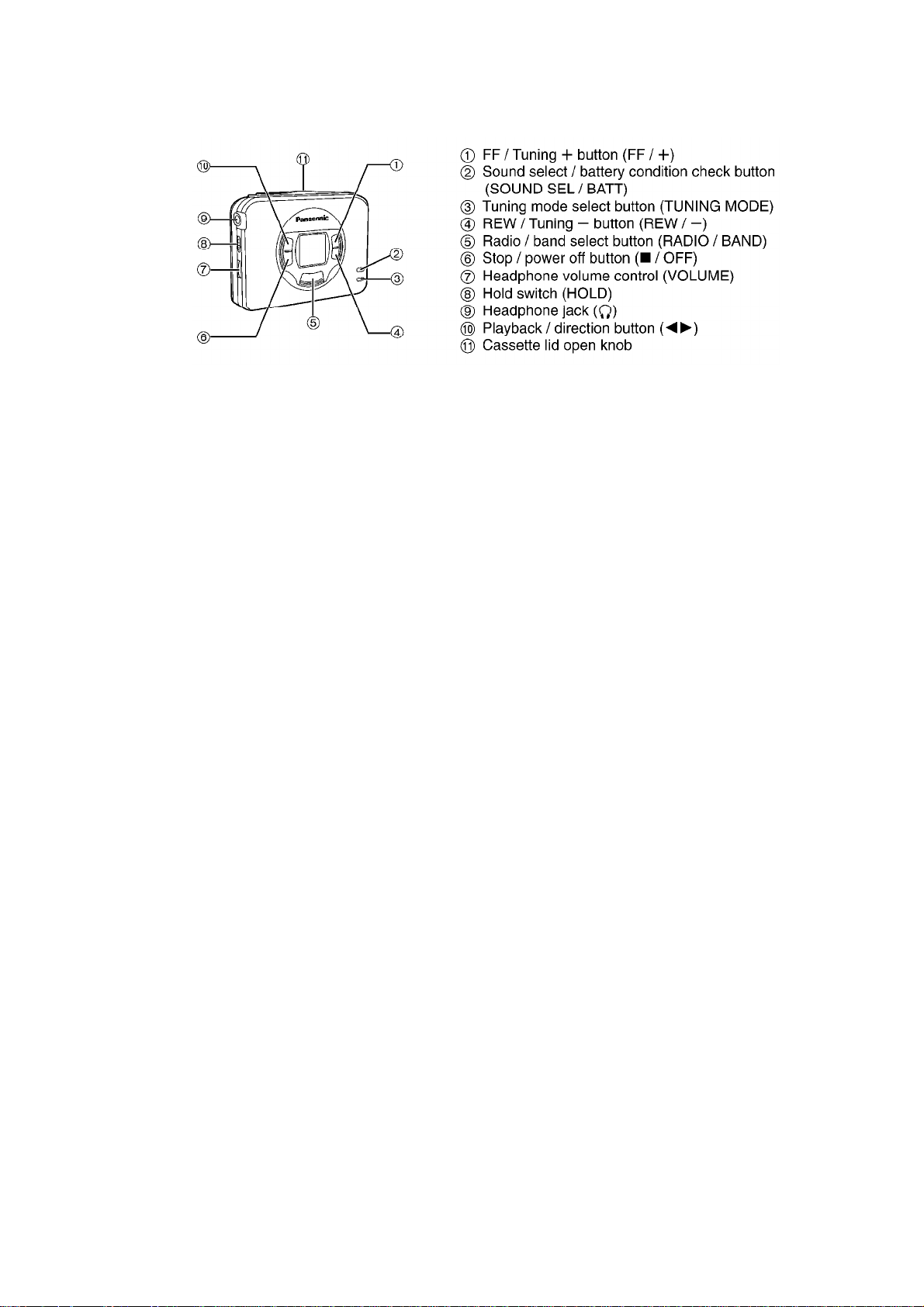

2. Location of Controls

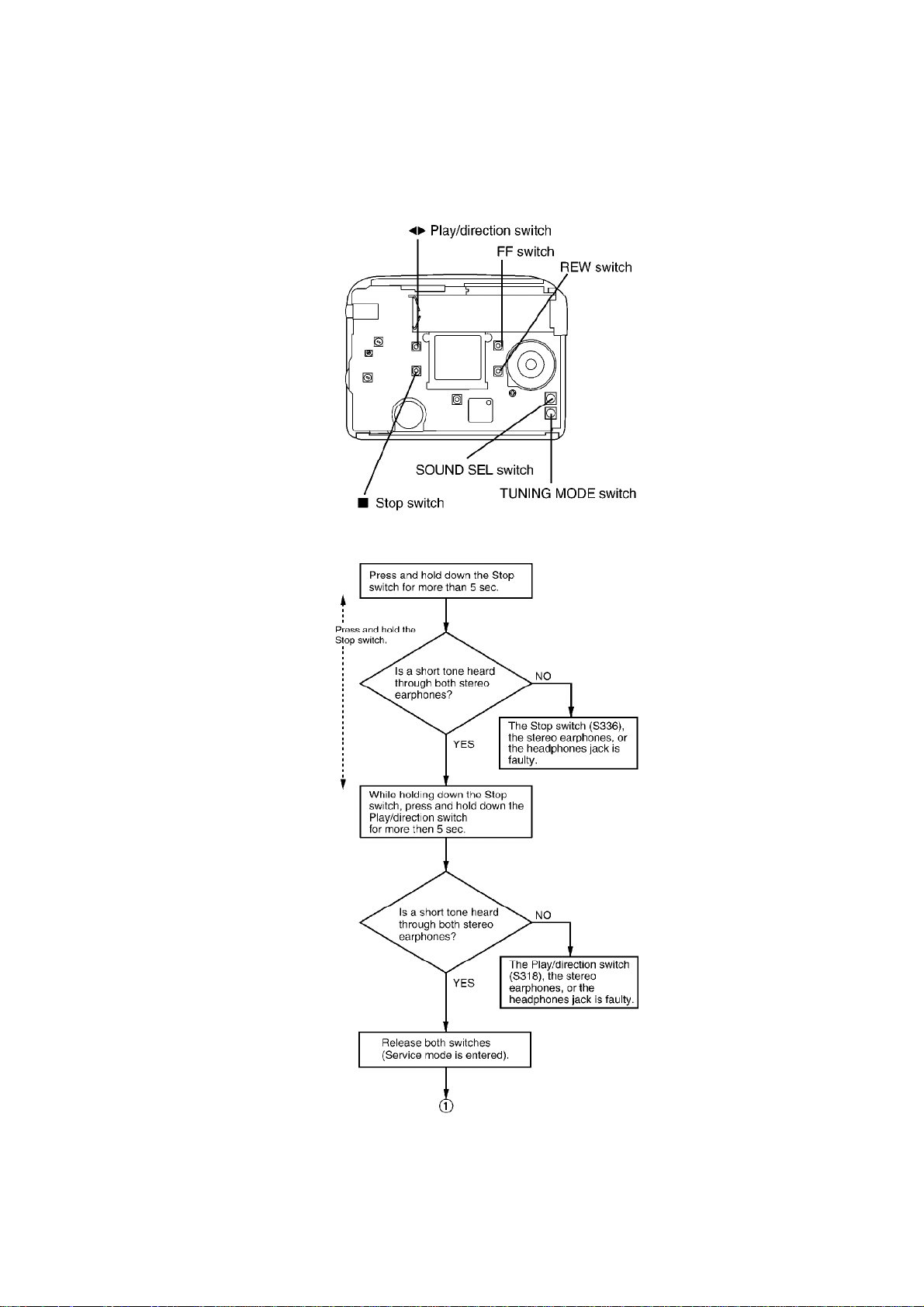

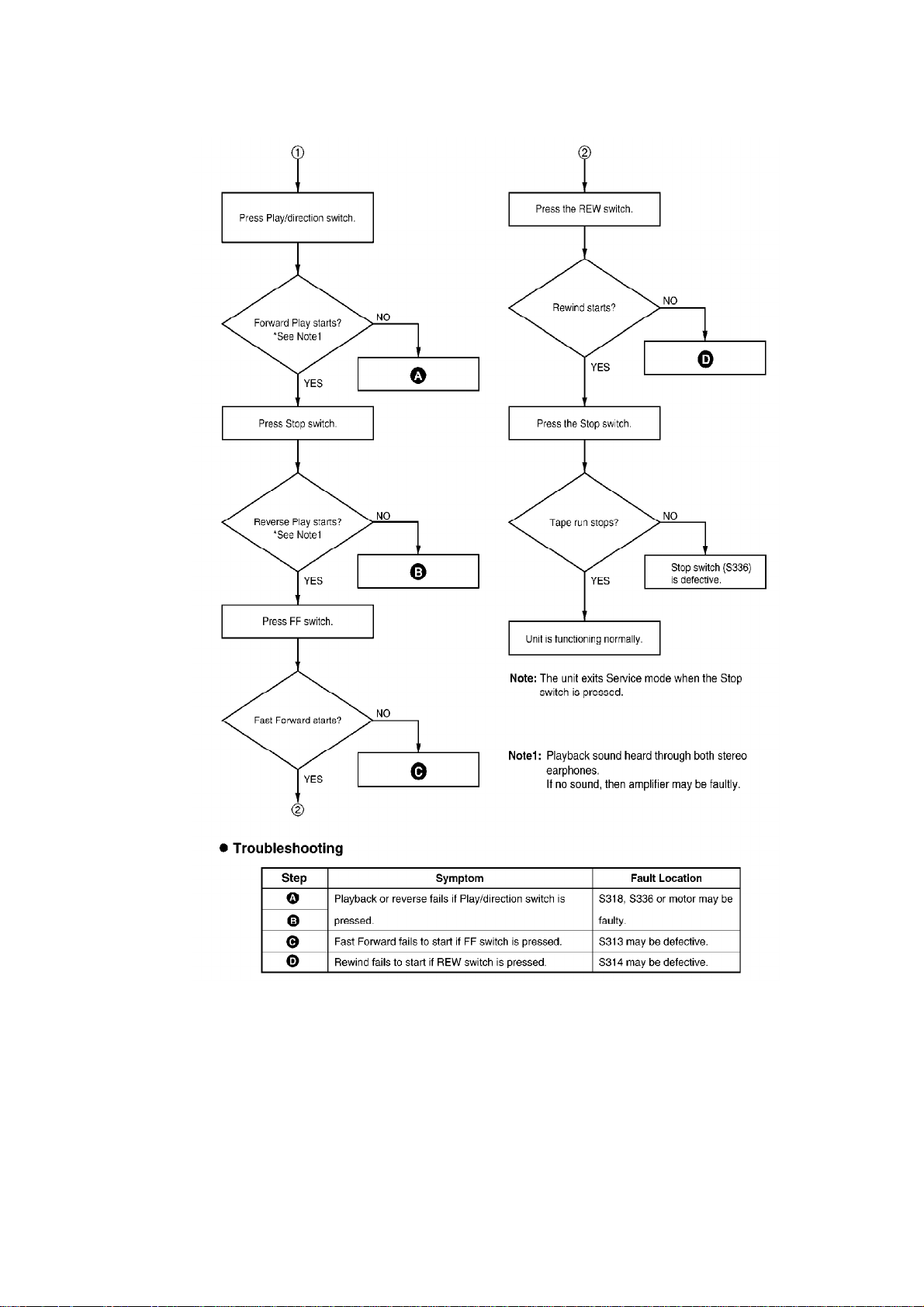

3. Service Mode

The RQ-SX77V has a Service mode designed to help identify faulty parts in the event of an error.

/ This mode is especially useful when servicing is carried out.

Items required

- Stereo earphones or stereo headphones

- Rechargeable battery or dry cell (R6/LR6, AA, UM-3) housed in case

Service mode functions

1. Unit and stereo earphones test

This checks for problems existing in the unit or stereo earphones.

2. Amplifier test

This test should be run if an “amplifier failure” occurred during

test 1. above.

3.1. Unit and stereo earphones test

Preparations:

1. Remove the unit case by following “Operation Checks and

Component Replacement Procedures”.

2. Plug the stereo earphones into the headphones jack.

3. Insert a fully-charged rechargeable battery or a dry cell (R6/LR6,

AA, UM-3) (housed in battery case).

4. Insert cassette tape.

5. Release the hold mode.

Operation switches

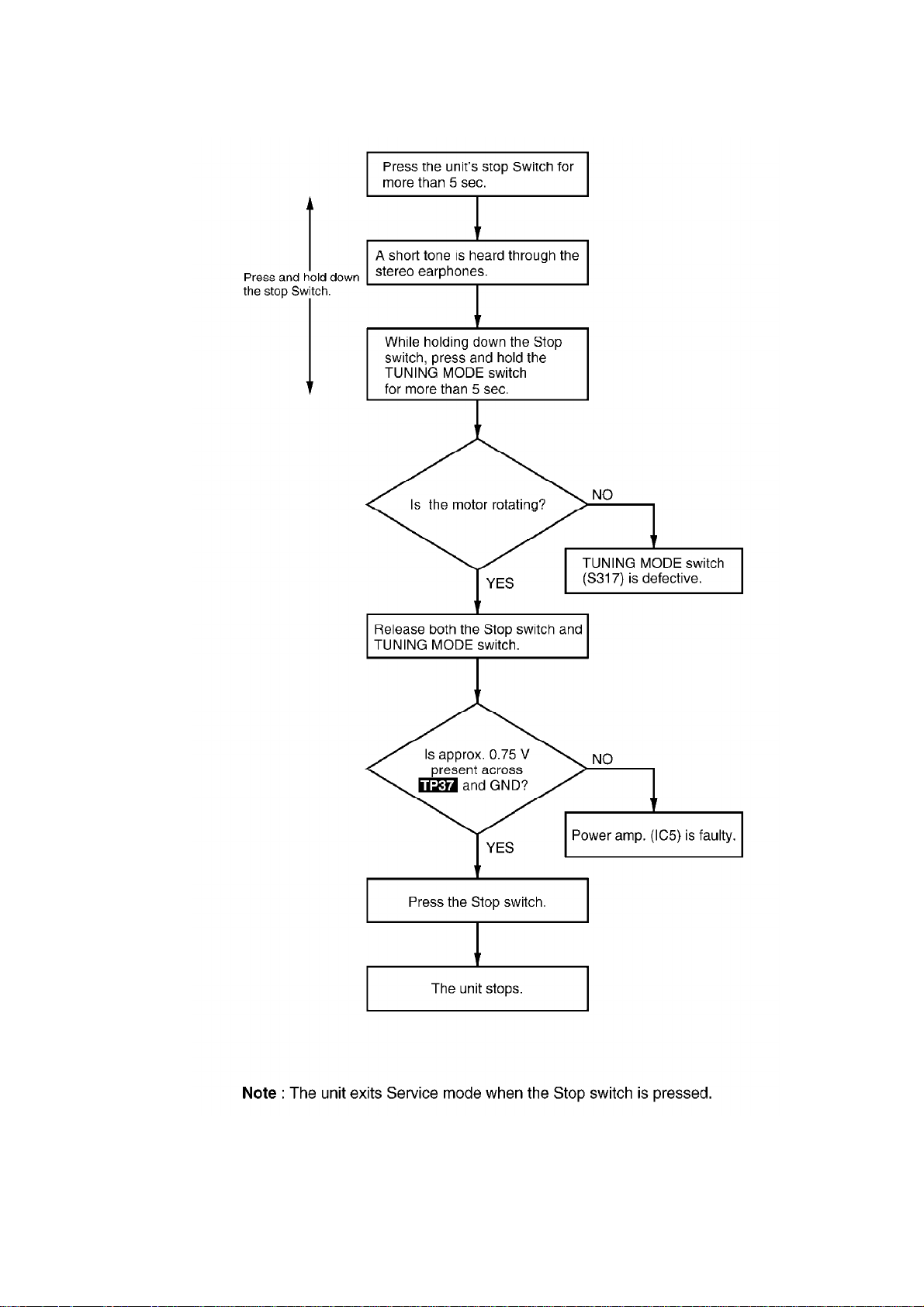

3.2. Amplifier test

This test is required if the amplifier is found to be malfunctioning thorough 3.1. Unit and stereo

earphone test.

Preparations:

See 3.1. Unit and stereo earphone test.

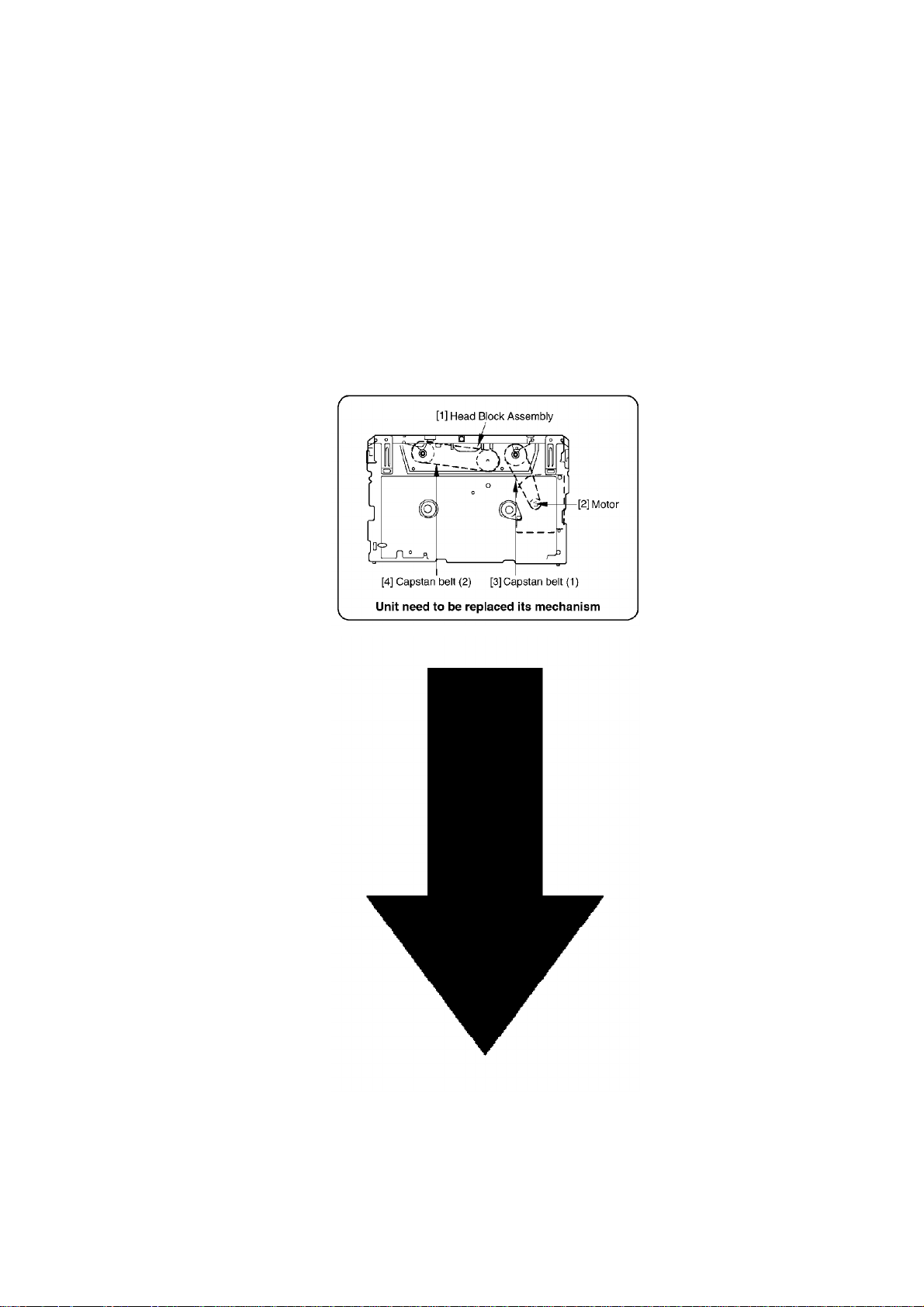

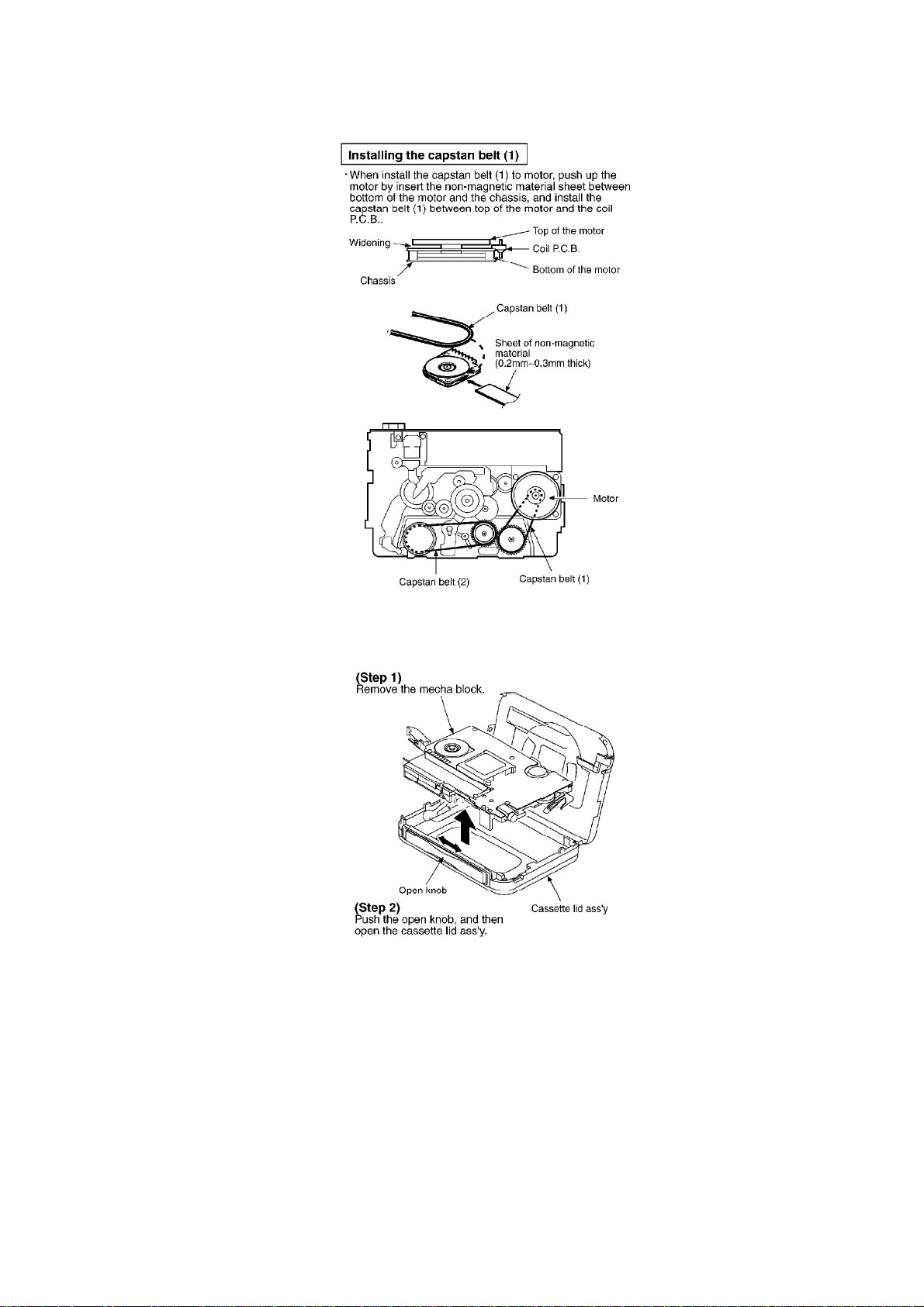

4. Mechanism Block Replacement Procedure

4.1. Replacing the tape transport assembly

The tape transport mechanism is supplied semi-assembled.

Configuration:

Tape transport mechanism excluding the head block assembly, capstan motor and capstan

belts (1) and (2).

When replacing the tape transport assembly, first remove the [1] head block assembly, [2]

motor, [3] capstan belt (1) and [4] capstan belt (2) from the assembly to be replaced, then install

these parts <[1] - [4]> onto the replacement assembly supplied. (For details of the dismantling

procedure, see Operation Checks and Component Replacement Procedures.)

Note:

After replacing, perform tape speed adjustment.

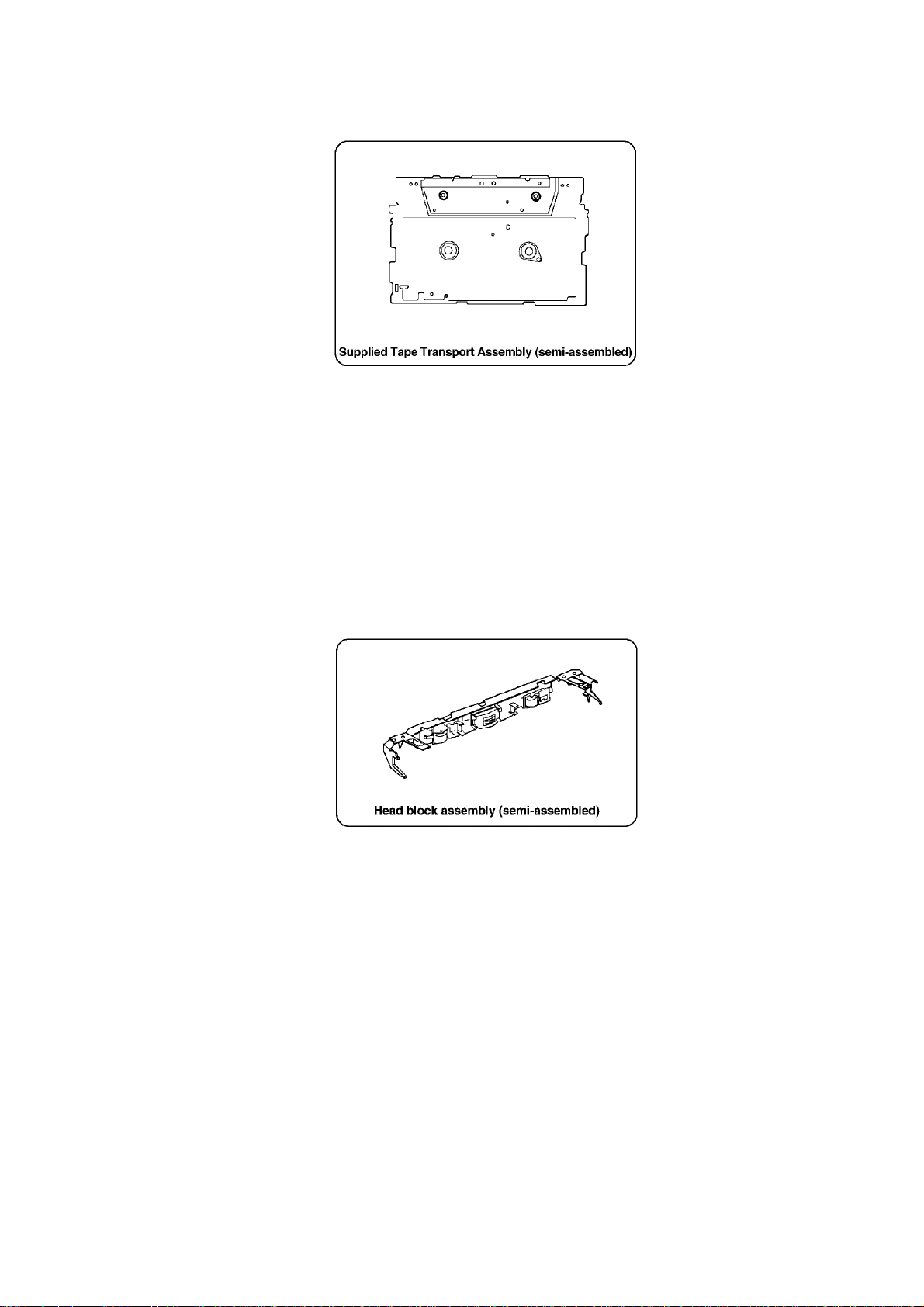

4.2. Replacing the head block assembly

The head block assembly is supplied semi-assembled.

Configuration:

Head block assembly with head arm spring and pinch roller arm

assembly (F) and (R).

The head arm spring and pinch roller arm assembly (F) and (R) will

also be supplied separately from the head block assembly.

Note:

The head block assembly requires no azimuth adjustment.

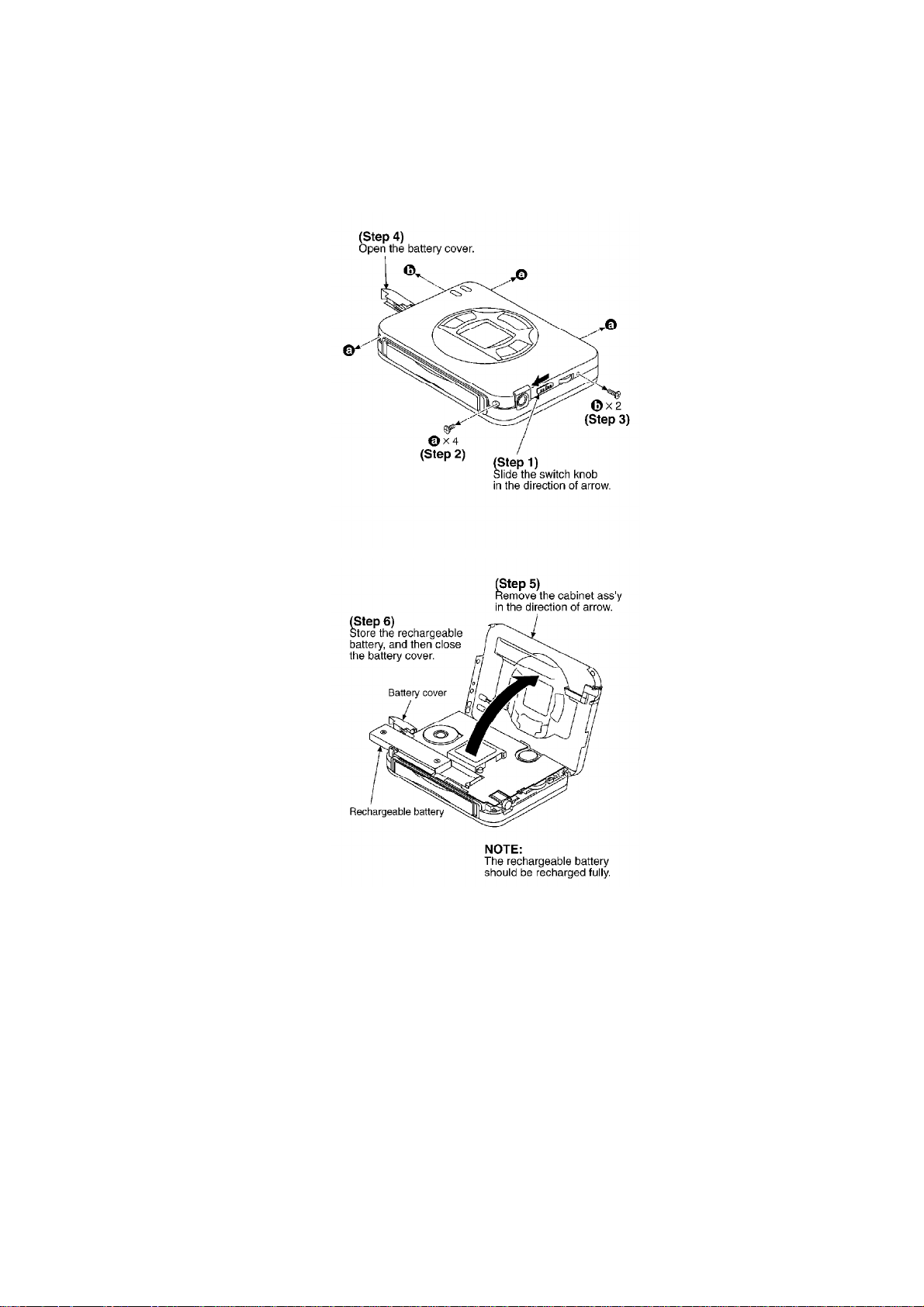

5. Operation Checks and Component Replacement

Procedures

- This section describes procedures for checking the operation of

the major printed circuit boards and replacing the main

components.

- For reassembly after operation checks or replacement, reverse the

respective procedures. Special reassembly procedures are

described only when required.

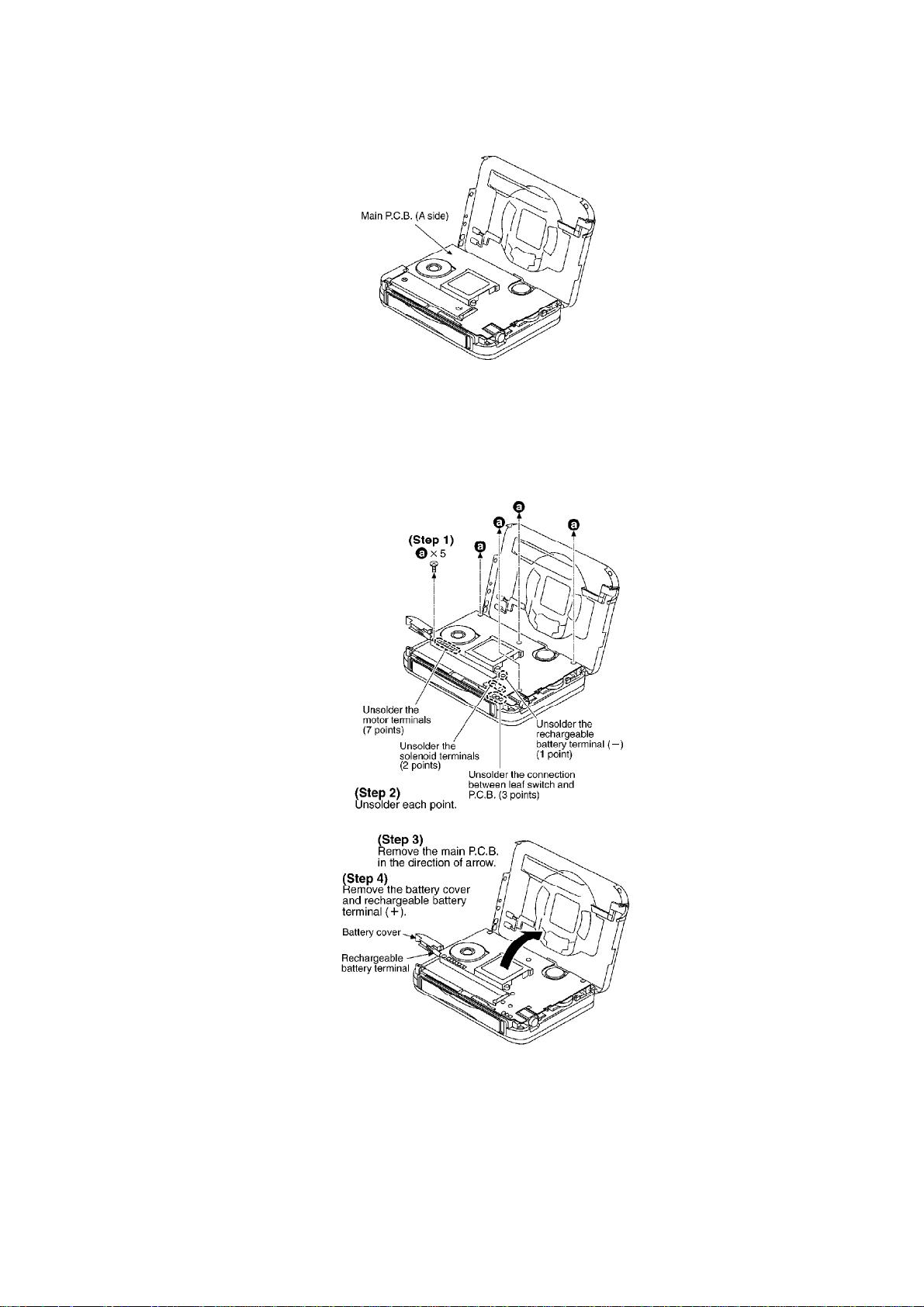

5.1. Checking for the main P.C.B.

5.1.1. Checking for the main P.C.B. / (A side)

- Check the main P.C.B. (A side) as shown below.

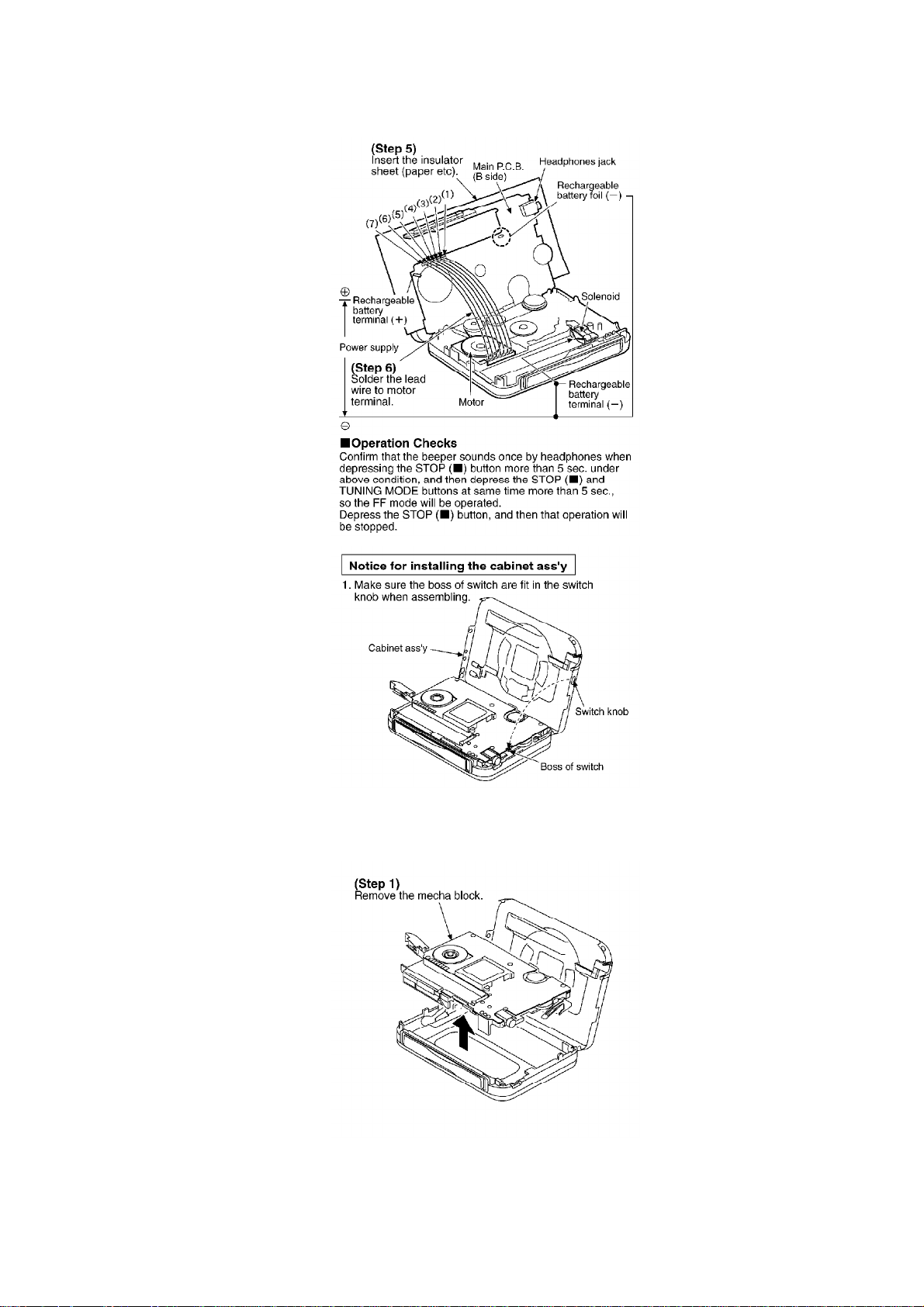

5.1.2. Checking for the main P.C.B. / (B side)

- Follow the (Step 1) - (Step 5) of item 5.1.1.

- Check the main P.C.B. (B side) as shown below.

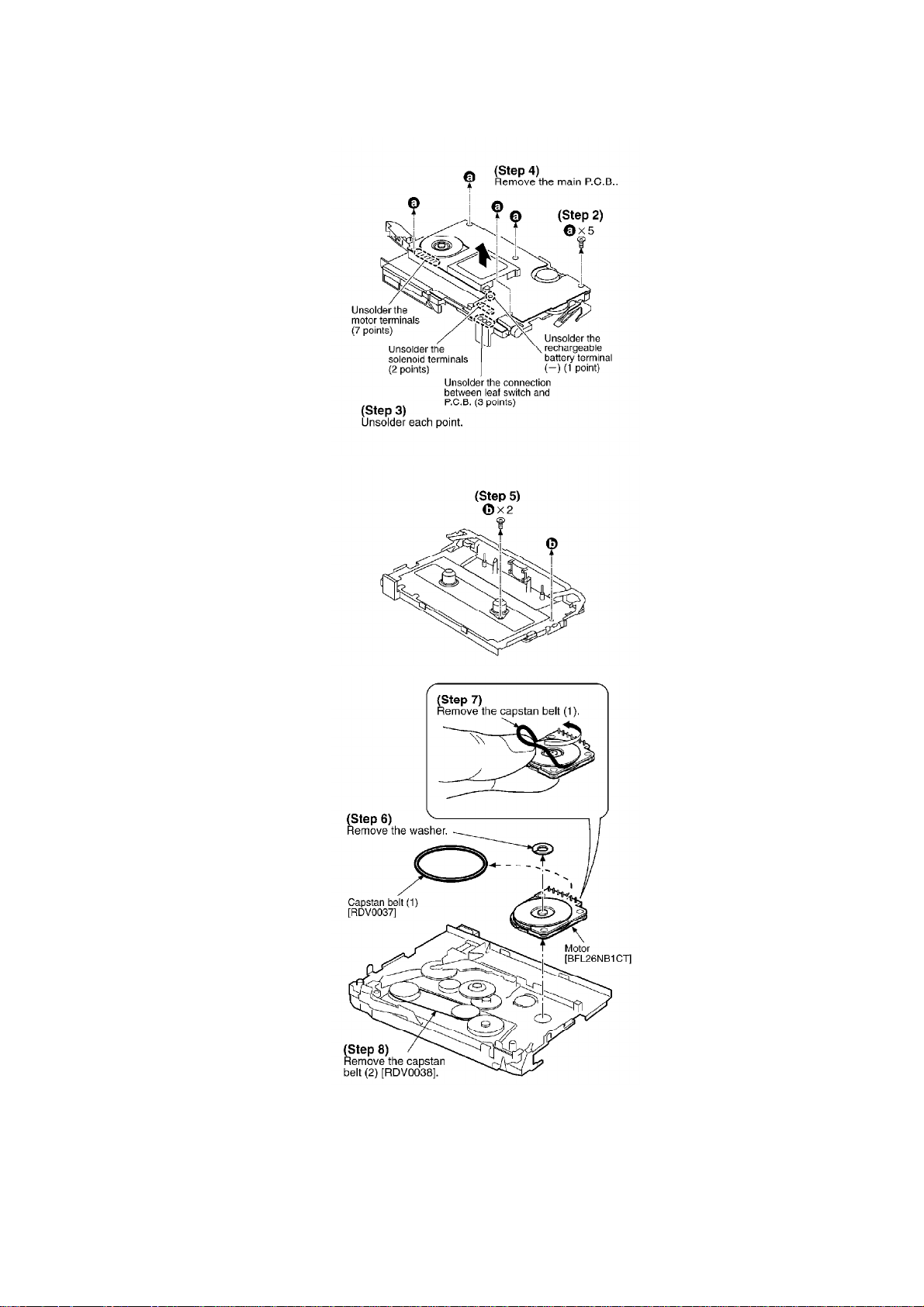

5.2. Replacement for the motor and capstan belt

- Follow the (Step 1) - (Step 5) of item 5.1.1.

5.3. Replacement for the cassette lid ass’y

- Follow the (Step 1) - (Step 5) of item 5.1.1.

Loading...

Loading...