Panasonic PT-AX200E, PT-AX200U Service Manual

PT-AX200U

PT-AX200E

ORDER NO. VED0709381C0

D10

LCD Projector

© 2007 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

PT-AX200U / PT- AX200E

2

PT-AX200U / PT- AX200E

3

PT-AX200U / PT- AX200E

CONTENTS

Page Page

1 Safety Precautions 5

1.1. General Guidelines

1.2. Leakage Current Check

1.3. UV Precaution and UHM Lamp Precautions

2 Ext Option

2.1. Procedure to enter EXT OPTION

2.2. EXT OPTION Menu and Functions

2.3. Canceling EXT OPTION

3 Self-Check Mode

3.1. Procedure to enter the self-check mode

3.2. Self Check Display and Contents

3.3. Canceling the self-check mode

4 Flicker Adjustment Mode

4.1. Procedure to enter the adjustment mode

4.2. Adjustment Display and Contents

4.3. Canceling the flicker adjustment mode

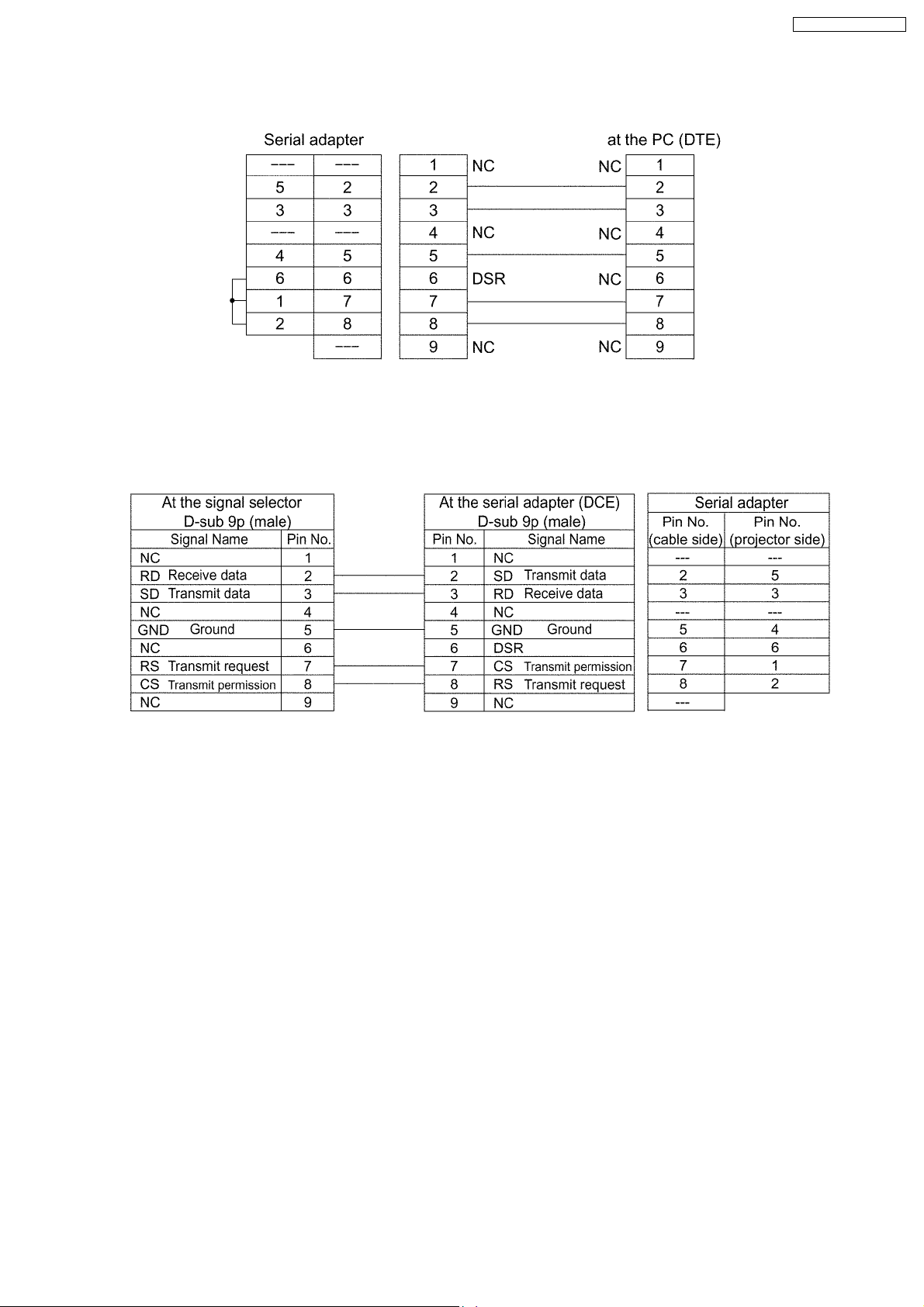

5 Using the SERIAL Connector

5.1. Connection

5.2. Pin Layout and Signal Names for SERIAL Connector

5.3. Communication Settings

5.4. Basic Format

5.5. Control / Query Commands

5.6. Communication Cable Specifications

5.7. Signal Selector Connecting Cable Specifications

6 Disassembly Instructions

6.1. Printed Circuit Board and Main Parts Location

6.2. Removal of Upper Case

6.3. Removal of A-P.C.Board

6.4. Removal of R-P.C.Board and S-P.C.Board

6.5. Removal of K-P.C.Board

6.6. Removal of B/Q-Module

6.7. Removal of P-Module

6.8. Removal of Lamp Unit

6.9. Removal of Analysis Block

6.10. Removal of LCD Block

6.11. Removal of Projection Lens

6.12. Replacement of LCD Panel (B)

6.13. LCD Panel Discrimination

6.14. LCD Panel Combination

6.15. Replacement of Projection Polarizer

10

10

10

10

11

11

13

13

14

14

15

15

15

15

16

16

16

17

17

18

18

19

19

19

5

5

5

6

6

6

6

7

7

8

9

9

9

9

9

6.16. Replacement of Incidence Polarizer

6.17. Replacement of PBS Array (Analysis Block)

6.18. Removal of Iris Unit

7 Measurement and Adjustments

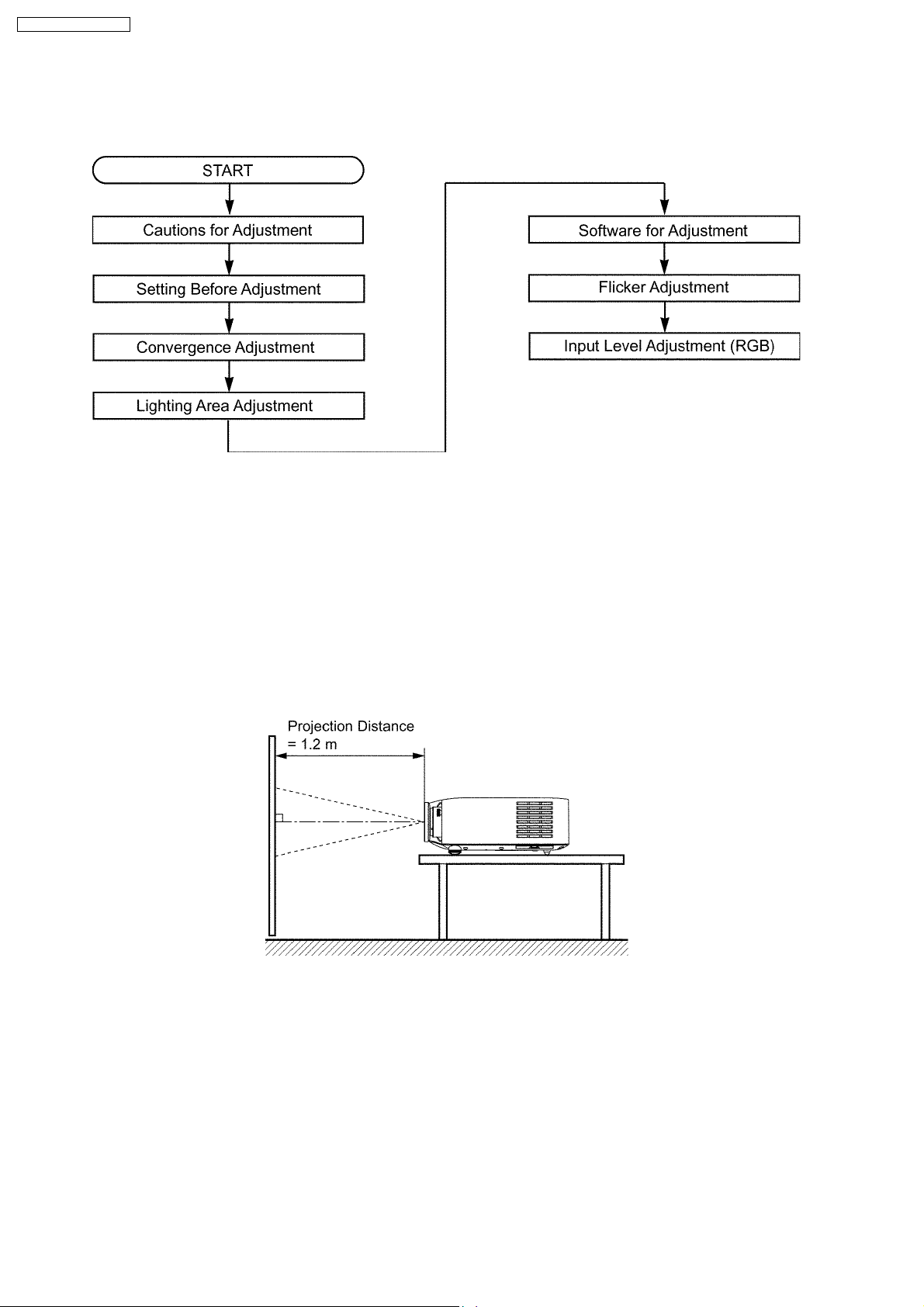

7.1. Adjustment Procedure Flowchart

7.2. Cautions for Adjustment

7.3. Setting Before Adjustment

7.4. Convergence Adjustment

7.5. Lighting Area Adjustment

7.6. Software for Adjustment

7.7. Flicker Adjustment

7.8. Input Level Adjustment (RGB)

8 Troubleshooting

9 Interconnection Block Diagram

9.1. Interconnection Block Diagram (1/2)

9.2. Interconnection Block Diagram (2/2)

10 Block Diagram

10.1. Power Supply

10.2. Signal Processing (1/2)

10.3. Signal Processing (2/2)

11 Schematic Diagram

11.1. A-P.C.Board (1/7)

11.2. A-P.C.Board (2/7)

11.3. A-P.C.Board (3/7)

11.4. A-P.C.Board (4/7)

11.5. A-P.C.Board (5/7)

11.6. A-P.C.Board (6/7)

11.7. A-P.C.Board (7/7)

11.8. K-P.C.Board

11.9. R-P.C.Board, S-P.C.Board, H-P.C.Board, M1-P.C.Board,

M2-P.C.Board

11.10. B-Module (1/2)

11.11. B-Module (2/2)

12 C irc uit Boards

12.1. A-P.C.Board

12.2. R-P.C.Board, S-P.C.Board

13 Te rm inal guide of ICs and transis tors

14 Ex ploded Views

15 Replacement Parts List

20

20

21

22

22

22

22

22

24

26

29

30

31

41

41

42

43

43

44

45

47

48

49

50

51

52

53

54

55

56

57

58

59

59

60

61

62

66

4

1 Safety Precautions

1.1. General Guidelines

· For continued safety, no modification of any circuit must be

attempted.

· Unplug the power cord from the power outlet before

disassembling this projector.

· Use correctly the supplied power cord and must ground it.

· It is advisable to use an isolation transformer in the AC

power line before the service.

· Be careful not to touch the rotation part (cooling fan, etc.) of

this projector when you service with the upper case

removed and the power supply turned ON.

· Observe the original lead dress during the service. If a short

circuit is found, replace all the parts overheated or

damaged by the short circuit.

· After the service, all the protective devices such as

insulation barriers, insulation papers, shields, and isolation

R-C combinations must be properly installed.

· After the service, check the leakage current to prevent the

customer from getting an electric shock.

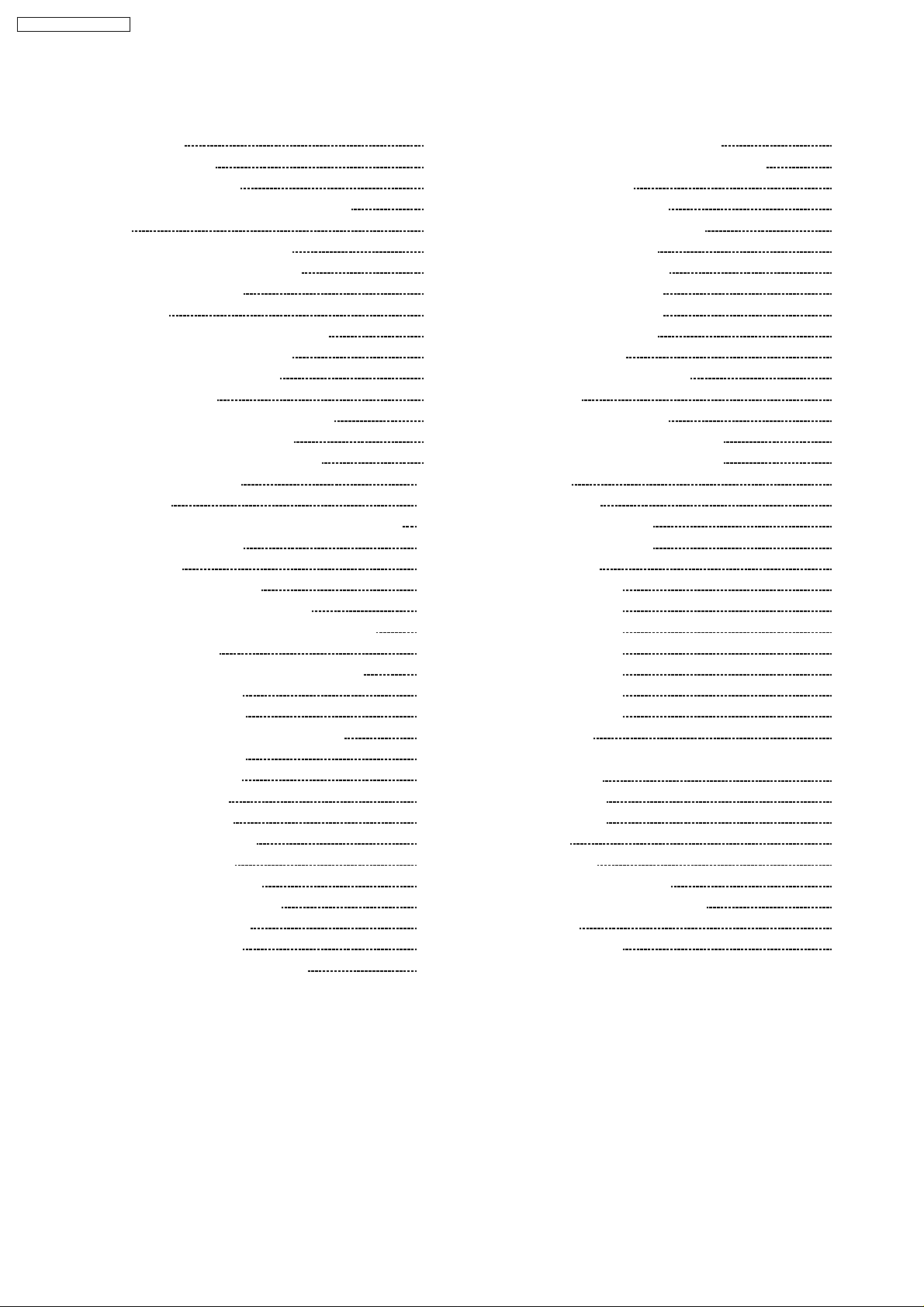

1.2. Leakage Current Check

1. Prepare the measuring circuit as shown in Fig.1.

Be sure to use a voltmeter having the performance

described in Table 1.

PT-AX200U / PT- AX200E

Fig. 2

2. Assemble the circuit as shown in Fig. 2. Plug the power

cord in a power outlet.

3. Connect M1 to T1 according to Fig. 2 and measure the

voltage.

4. Change the connection of M1 from T1 to T2 and measure

the voltage again.

5. The voltmeter must read 0.375 V or lower in both of steps

3 and 4. This means that the current must be 0.75 mA or

less.

6. If the reading is out of the above standard, the projector

must be repaired and rechecked before returning to the

customer because of a possibility of an electric shock.

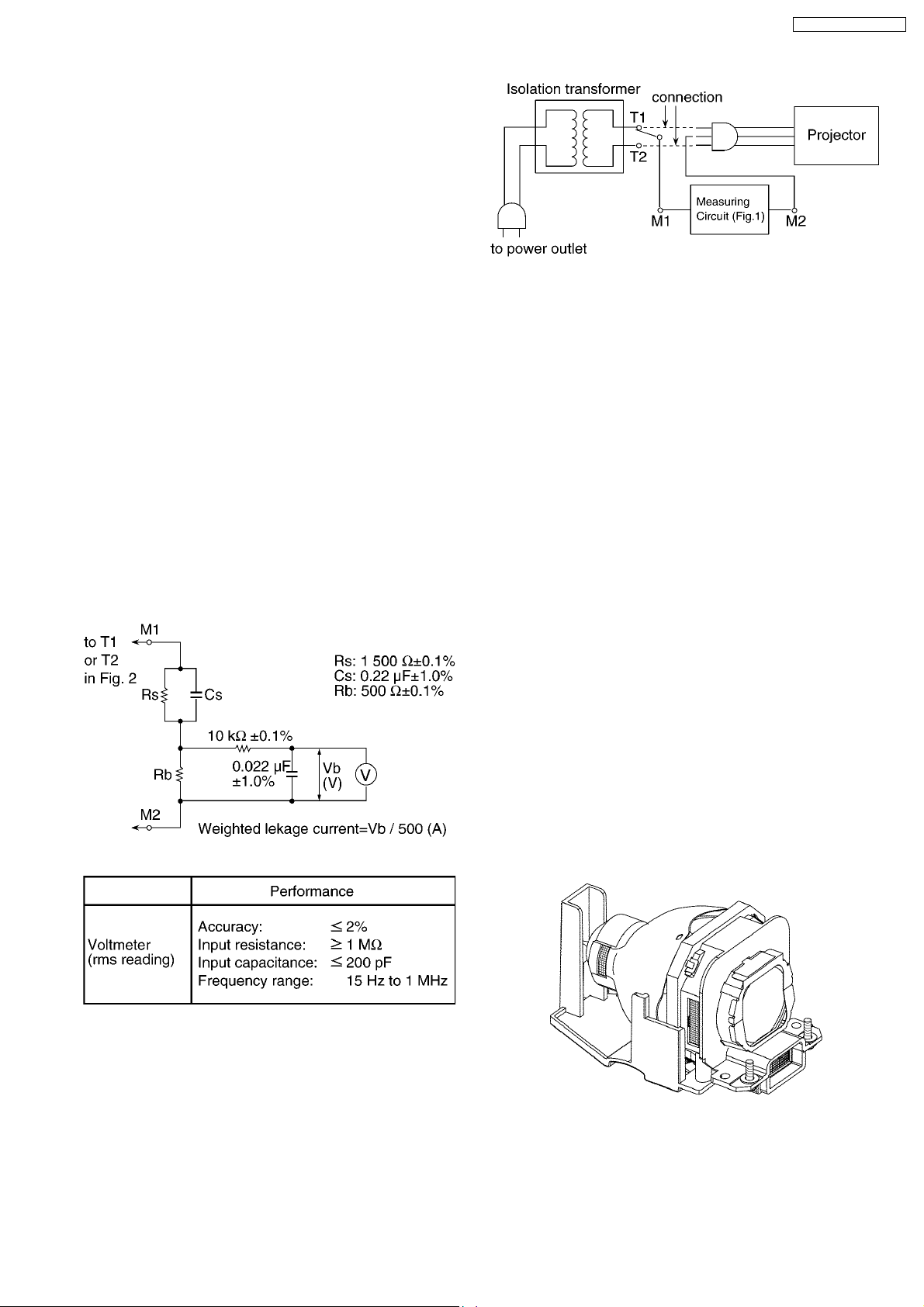

1.3. UV Precaution and UHM Lamp

Precautions

· Be sure to unplug the power cord from the power outlet

when replacing the lamp.

· Because the lamp reaches a very high temperature during

its operation, wait until it cools completely when replacing

the Lamp Unit.

· The lamp emits small amounts of UV-radiation, avoid directeye contact with the light.

· The lamp unit has high internal pressure. If improperly

handled, explosion might result.

· Because the high pressure lamp involves a risk of failure,

never touch the lamp wire lead during the service. (See Fig.

3)

Fig. 1

Table 1

Fig.3

5

PT-AX200U / PT- AX200E

2 Ext Option

This projector has EXT OPTION in addition to standard on-screen menus.

· There are SELF CHECK and FLICKER ADJUST for service, etc.

2.1. Procedure to enter EXT OPTION

1. When the projector is power ON, press "POWER" button on the main unit or remote control unit to display "POWER OFF"

confirmation screen.

2. Press the right-arrow "

3. On the main unit or remote control unit, press the buttons in order of up-arrow "

down-arrow "

(When the "ENTER" button is pressed, "EXT OPTION" menu is displayed.)

" and "ENTER".

2.2. EXT OPTION Menu and Functions

" button to select "CANCEL" in the "POWER OFF" confirmation screen.

", down-arrow " ", up-arrow " ",

· FAN FULLMODE

Setting the cooling fan motor rotation speed

−

− Switching ON "FAN FULLMODE", the rotation level of the fan becomes high-speed rotation (fixed). Moreover, when "FAN

− −

FULLMODE" is ON, changing "ALTITUDE" in OPTION becomes impossible (setting FAN FULLMODE is given priority more

than ALTITUDE).

· AUTO SETUP

Setting AUTO SETUP mode

−

− NORMAL: To set the normal mode (the dot clock is adjusted strictly)

− −

−

− SPECIAL: To set the special mode (the dot clock is adjusted roughly)

− −

* Do not change the initial setting (NORMAL).

· SELF CHECK

To enter the self-check mode

· FLICKER ADJUST

To enter the flicker adjustment mode

· 525i SD

When non-standard signal of 525i/625i is inputted (AV amplifier, etc.), synchronization might be disordered according to

connected equipment. In this case, set 525i SD to ON.

· 525p OS

When 525p/625p signal is inputted, reflection noise (vertical striated beat) might be generated according to connected

equipment. In this case, set 525p OS to ON. However, the resolution decreases a little.

· HPLL

When non-standard signal of VIDEO/S-VIDEO is inputted (VTR, VHD, etc.), horizontal synchronization might be disordered

according to connected equipment. In this case, set HPLL to OFF.

2.3. Canceling EXT OPTION

Press "MENU" button on the main unit or remote control unit.

6

3 Self-Check Mode

This mode is used to narrow down the location of the failure.

3.1. Procedure to enter the self-check mode

Select "SELF CHECK" on "EXT OPTION" menu and press "ENTER" button on the main unit or remote control unit.

PT-AX200U / PT- AX200E

7

PT-AX200U / PT- AX200E

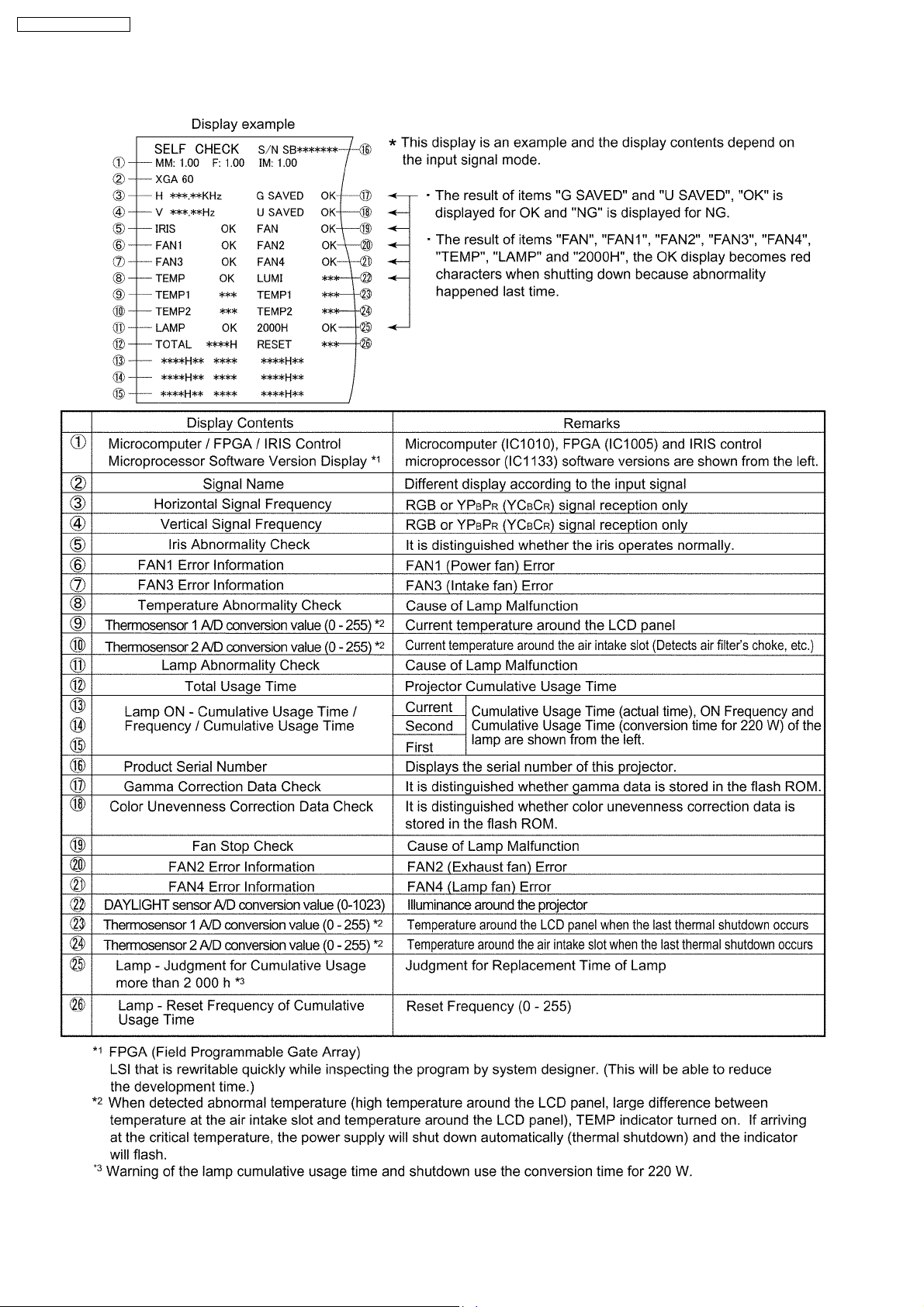

3.2. Self Check Display and Contents

8

PT-AX200U / PT- AX200E

3.3. Canceling the self-check mode

Press "MENU" button on the main unit or remote control unit.

4 Flicker Adjustment Mode

If replacing the optical parts (LCD Panel / LCD block) or A-P.C.Board of this projector, enter the flicker adjustment mode and

minimize the flicker.

4.1. Procedure to enter the adjustment mode

Select "FLICKER ADJUST" on "EXT OPTION" menu and press "ENTER" button on the main unit or remote control unit.

Note:

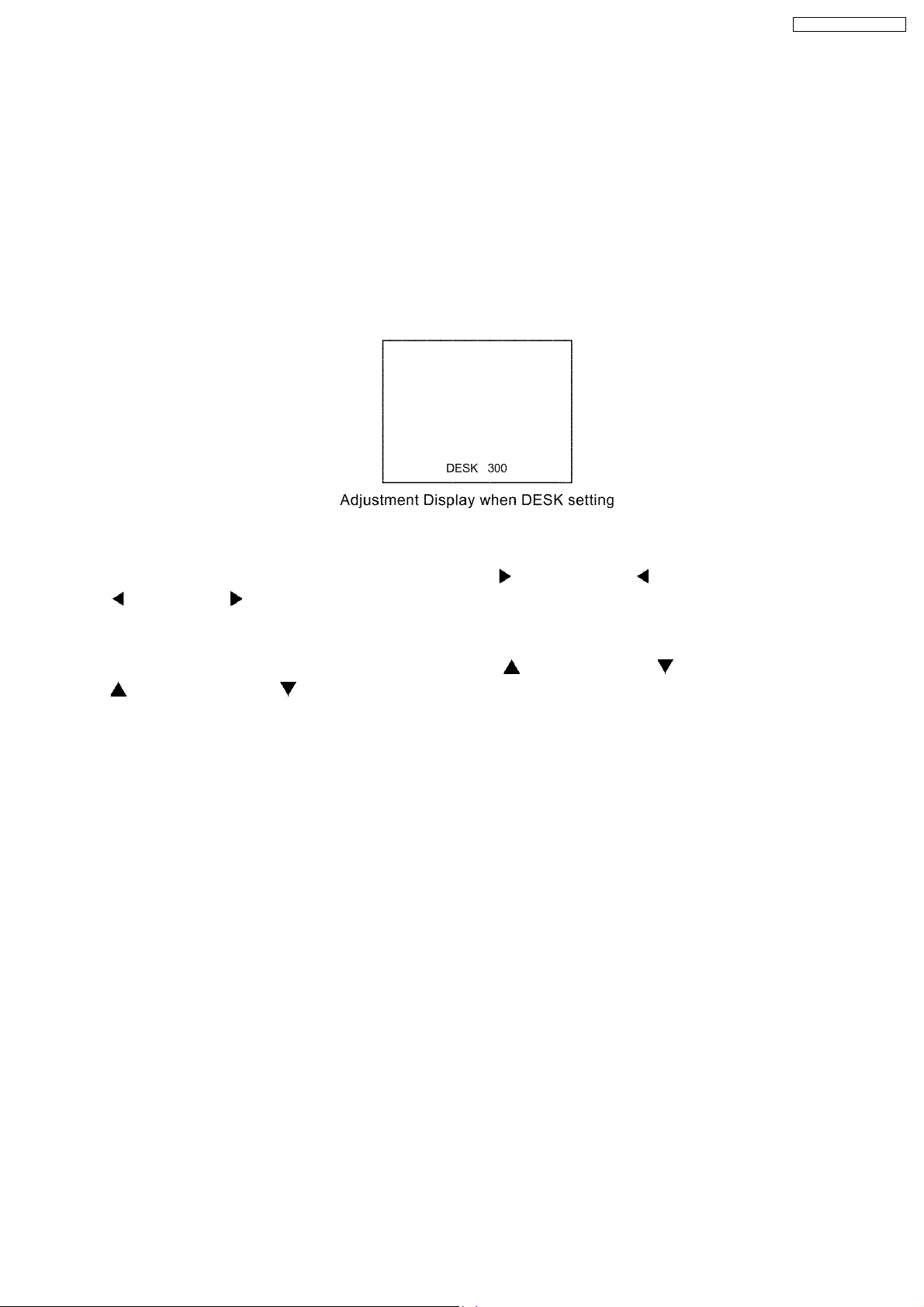

"DESK setting (red)" is displayed when entering the adjustment mode.

4.2. Adjustment Display and Contents

· Setting value is increased and decreased with the right-arrow " " and left-arrow " " buttons.

": Decrease, " ": Increase

"

−

− Adjust the setting value to minimize the flicker on the screen.

− −

−

− Execute the adjustment by 6 patterns below.

− −

· The pattern (adjustment display) is switched with the up-arrow "

"

": Forward direction, " ": Reverse direction

−

− There are 6 patterns of "DESK setting (red)", "DESK setting (blue)", "DESK setting (green)", "CEILING setting (red)",

− −

"CEILING setting (blue)" and "CEILING setting (green)".

−

− The setting value is saved into this projector when the pattern is switched.

− −

" and down-arrow " " buttons.

4.3. Canceling the flicker adjustment mode

Press "MENU" button on the main unit or remote control unit.

Note:

When "MENU" button is pressed, the setting value at that time is saved into this projector and the adjustment mode is canceled.

9

PT-AX200U / PT- AX200E

5 Using the SERIAL Connector

The serial connector which is on the back connector panel of the projector conforms to RS-232C standard. This projector can

be controlled by a PC which is connected as shown in "5.1. Connection".

For controlling this projector by a PC, requires communication software on the market, and inputs control commands according

to communication settings and basic format below.

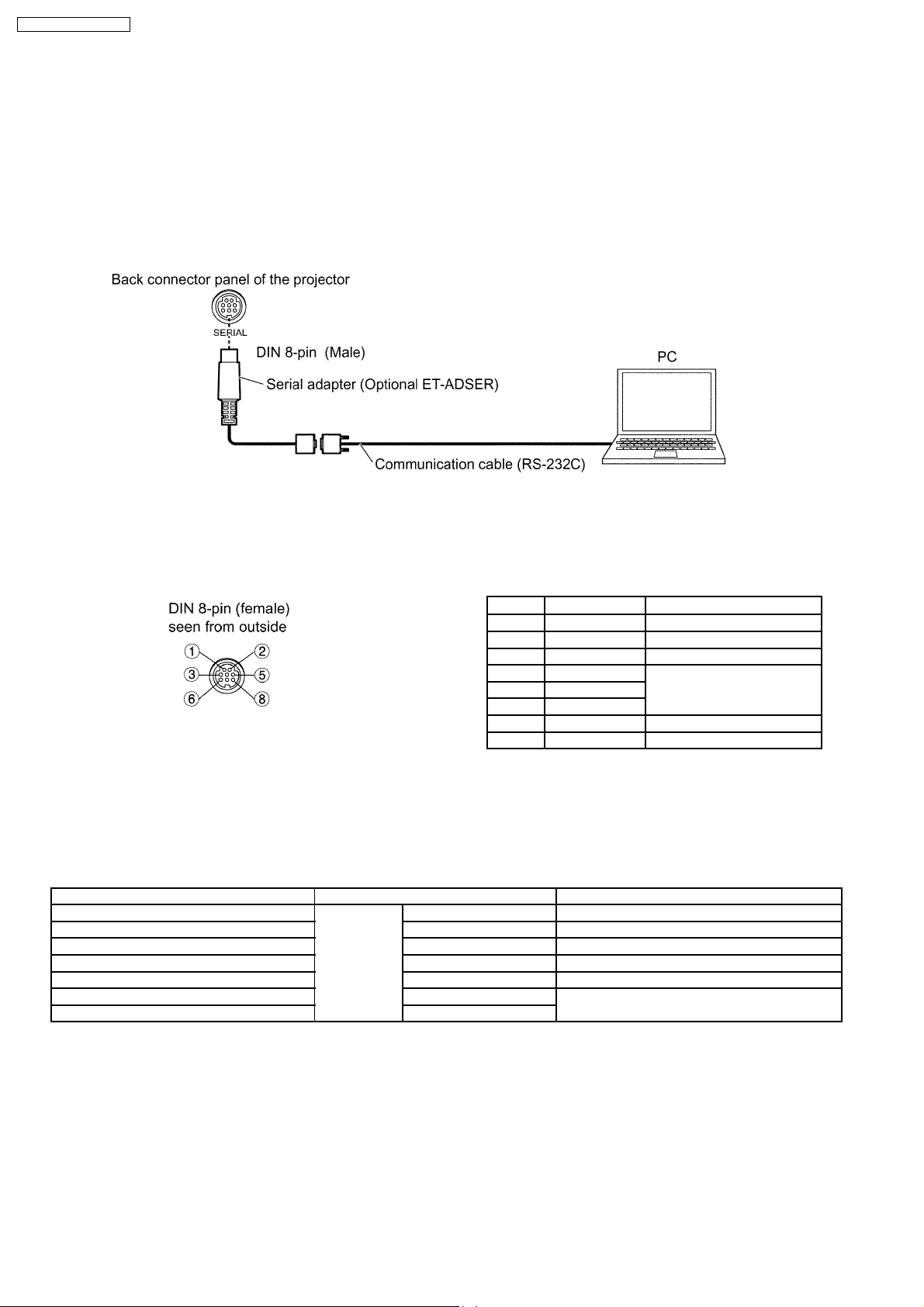

5.1. Connection

Note:

Use a proper communication cable which is suitable for the PC to connect the optional serial adapter, which is connected with

SERIAL connector of this projector, and the PC.

5.2. Pin Layout and Signal Names for SERIAL Connector

Pin No Signal Name Contents

3 RXD Receive data

4 GND Ground

5 TXD Transmit data

1 --2 --- Connected internally

6 --7 --- NC

8 --- NC

5.3. Communication Settings

Signal Level Contents Description

Sync. method Asynchronous Synchronizes every 1 character (8 bits)

Baud rate Conforms to 9 600 bps Data transfer speed

Parity RS-232C None Error detection method

Character length standard 8bits Number of bit composing 1 character

Stop bit 1bit Uses stop bit when asynchronous method

X parameter Not used

S parameter Not used

10

PT-AX200U / PT- AX200E

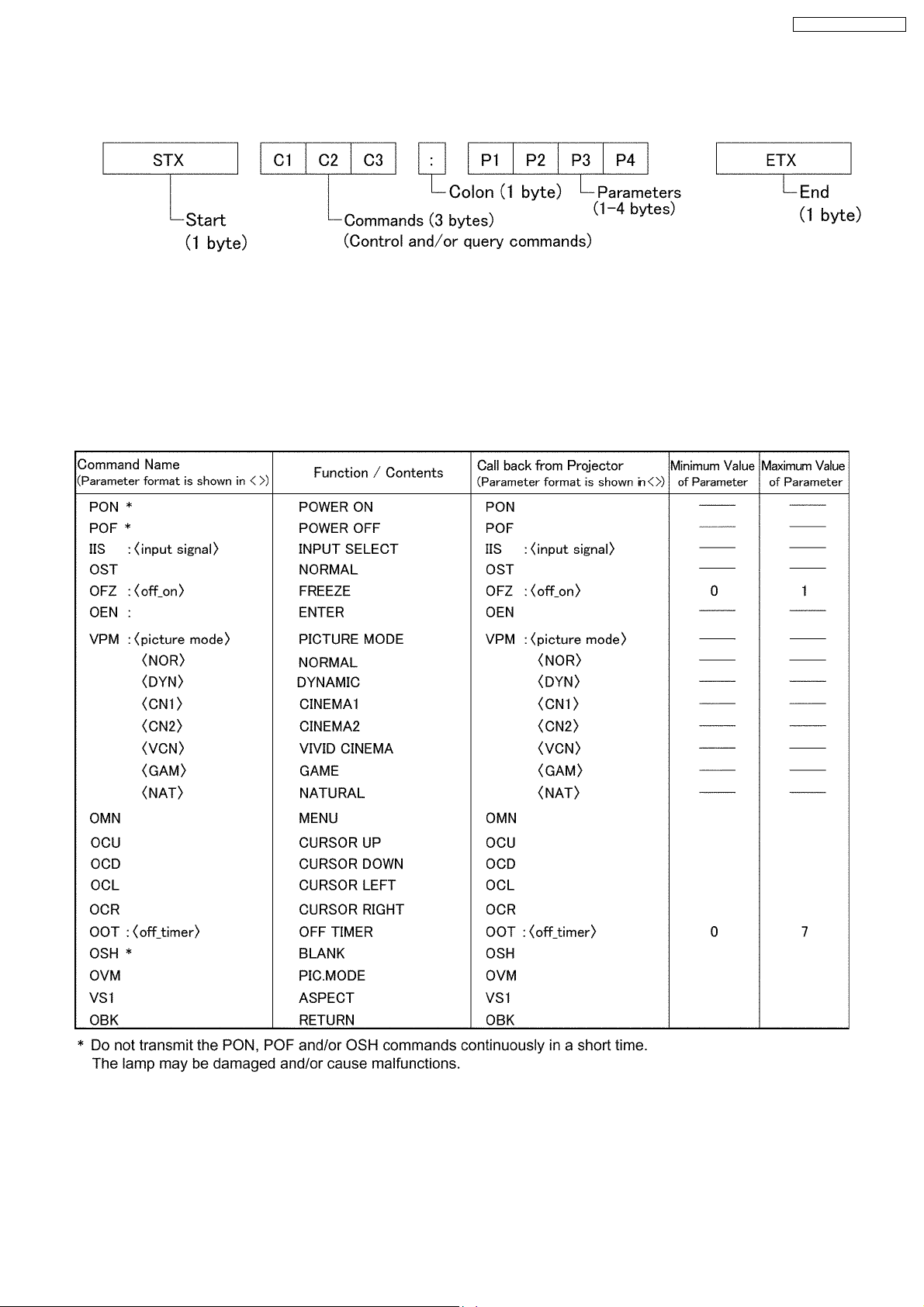

5.4. Basic Format

The data sent from the PC to the projector is transmitted in the format shown below.

Notes:

· If sending multiple commands, check that a call back has been received from the projector for 1 command before sending

the next command.

· When a command which does not require parameters is sent, the colon (:) is not required.

5.5. Control / Query Commands

Control Commands

11

PT-AX200U / PT- AX200E

Query Commands

Parameters

[Example]

When controls the audio volume to +30 by a PC

(Sends commands as the following:)

· When a command which does not require parameters is sent, the colon (:) is not required.

12

PT-AX200U / PT- AX200E

5.6. Communication Cable Specifications

5.7. Signal Selector Connecting Cable Specifications

When connecting to a signal selector (ex. TW-SWS62J), use a cable with specifications below.

Connecting method: Connects a video signal cable from the signal selector to "VIDEO IN", and an RGB signal cable to "PC IN".

Note:

Set VP control terminal switch of the signal selector to VP TYPE "B".

13

PT-AX200U / PT- AX200E

6 Disassembly Instructions

Warning:

· Be sure to unplug the power cord from the power outlet before disassembling this projector.

Caution:

· While turning over a printed circuit board, be sure to put a insulating material under it to prevent a short circuit.

· Printed circuit boards and wires must not be pulled forcibly, but be handled carefully.

· Connectors also must be handled carefully.

· When reassembling, replace used adhesive tape with new one (Do not re-use used tape).

· After repairing this projector, be sure to put back the wires and connectors to the original condition.

· Service or repair the product according to service information on the service manual, etc. so that a fire, injury or electric

shock caused by an improper repair may not occur.

1. Do not modify equipments, components and materials when attempting to service or repair.

2. Do not repair nor connect wires even in case of a part of the disconnection when the wiring unit is supplied as a

replacement parts, replace the wiring unit (complete).

3. For a fasten terminal (push-in type terminal), pull out or insert straightly without twisting it.

4. When the fuse has blown, do not turn on the power supply replacing only the fuse because the secondary disaster of

fumes, fire or other hazards is expected. Turn on the power supply after doing the confirmation and measures of

defective causes (structure and circuit, etc.).

5. After the service or the repair is completed, confirm the operation of the product is normal.

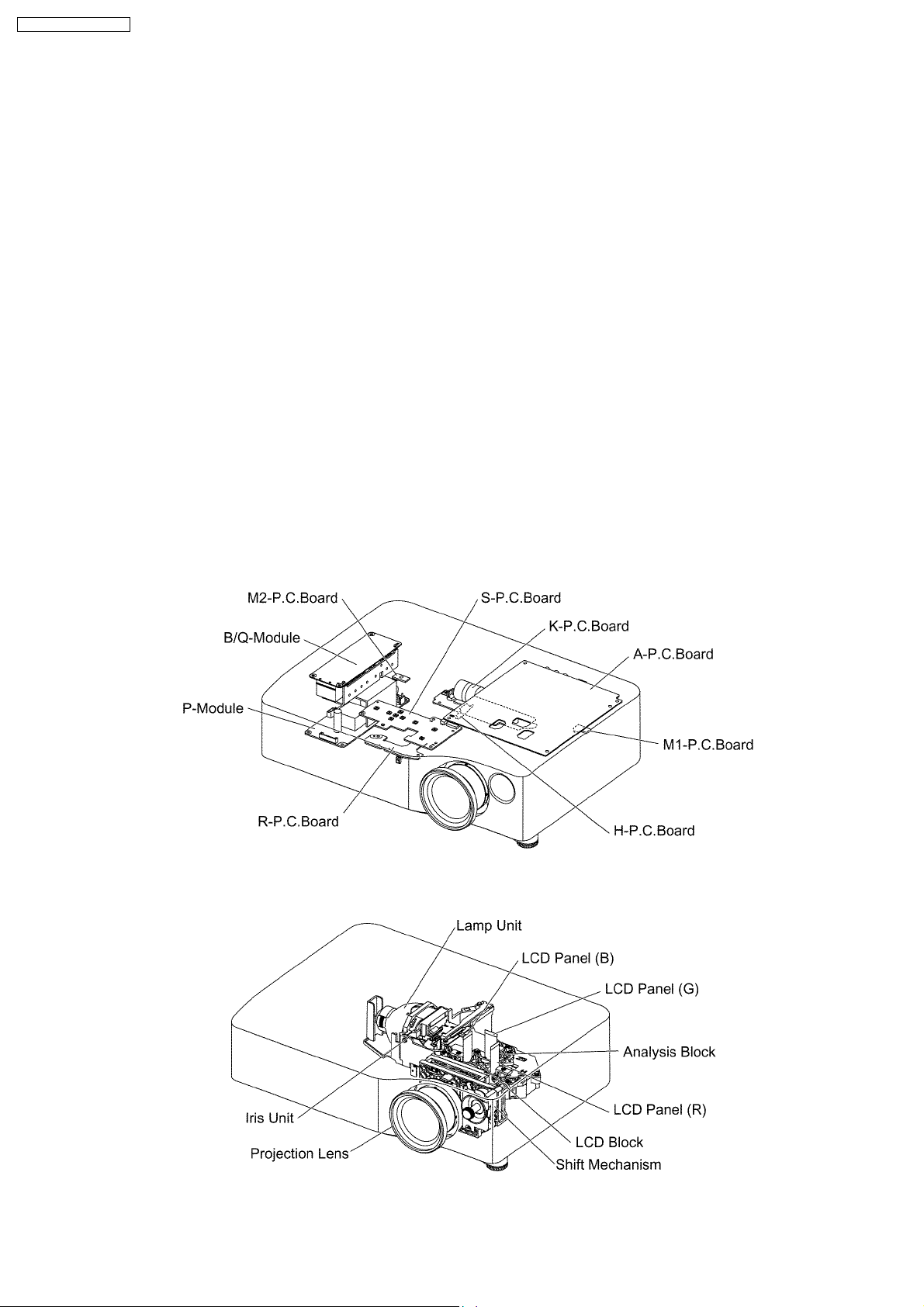

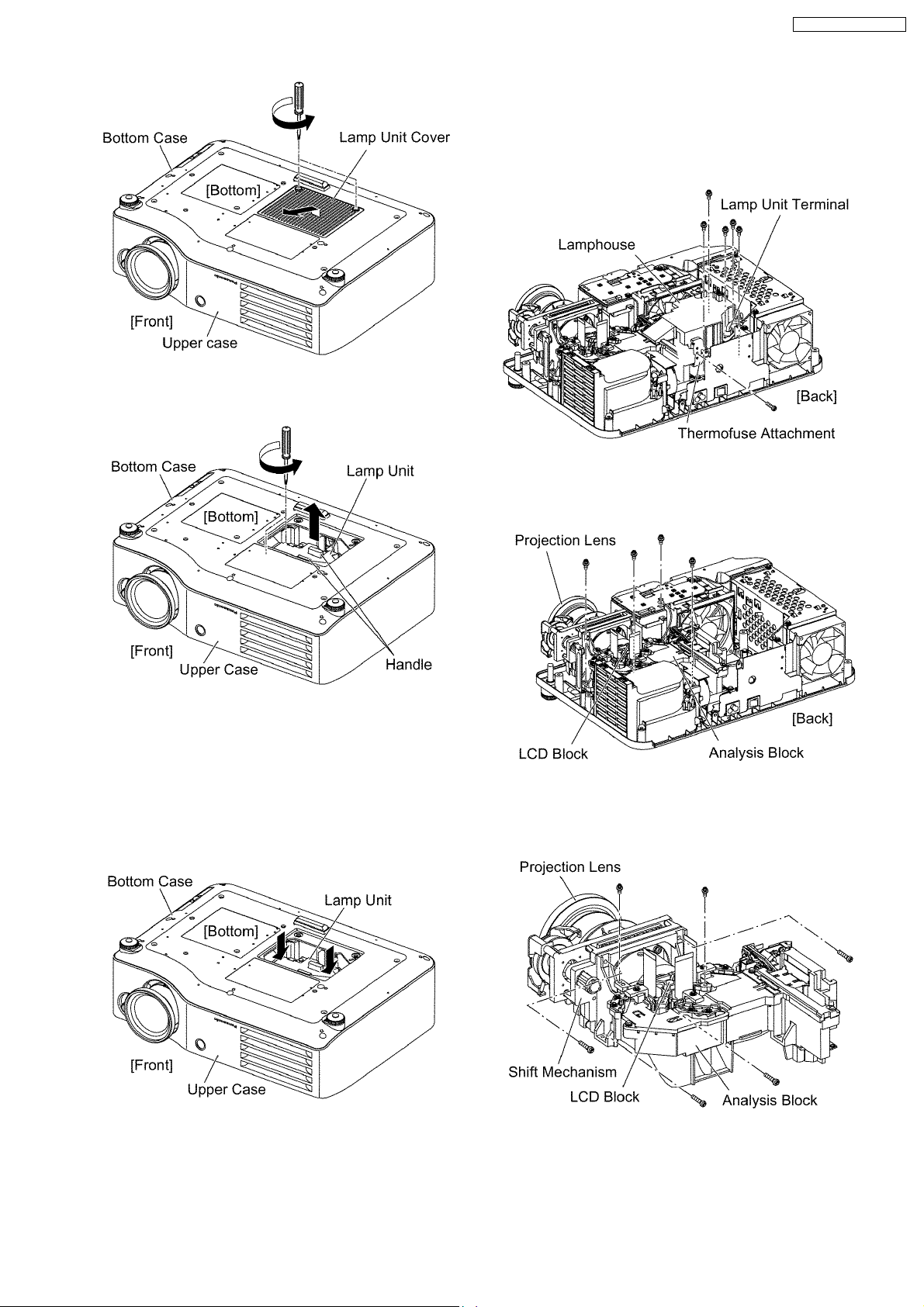

6.1. Printed Circuit Board and Main Parts Location

Electrical Parts

Optical Parts

14

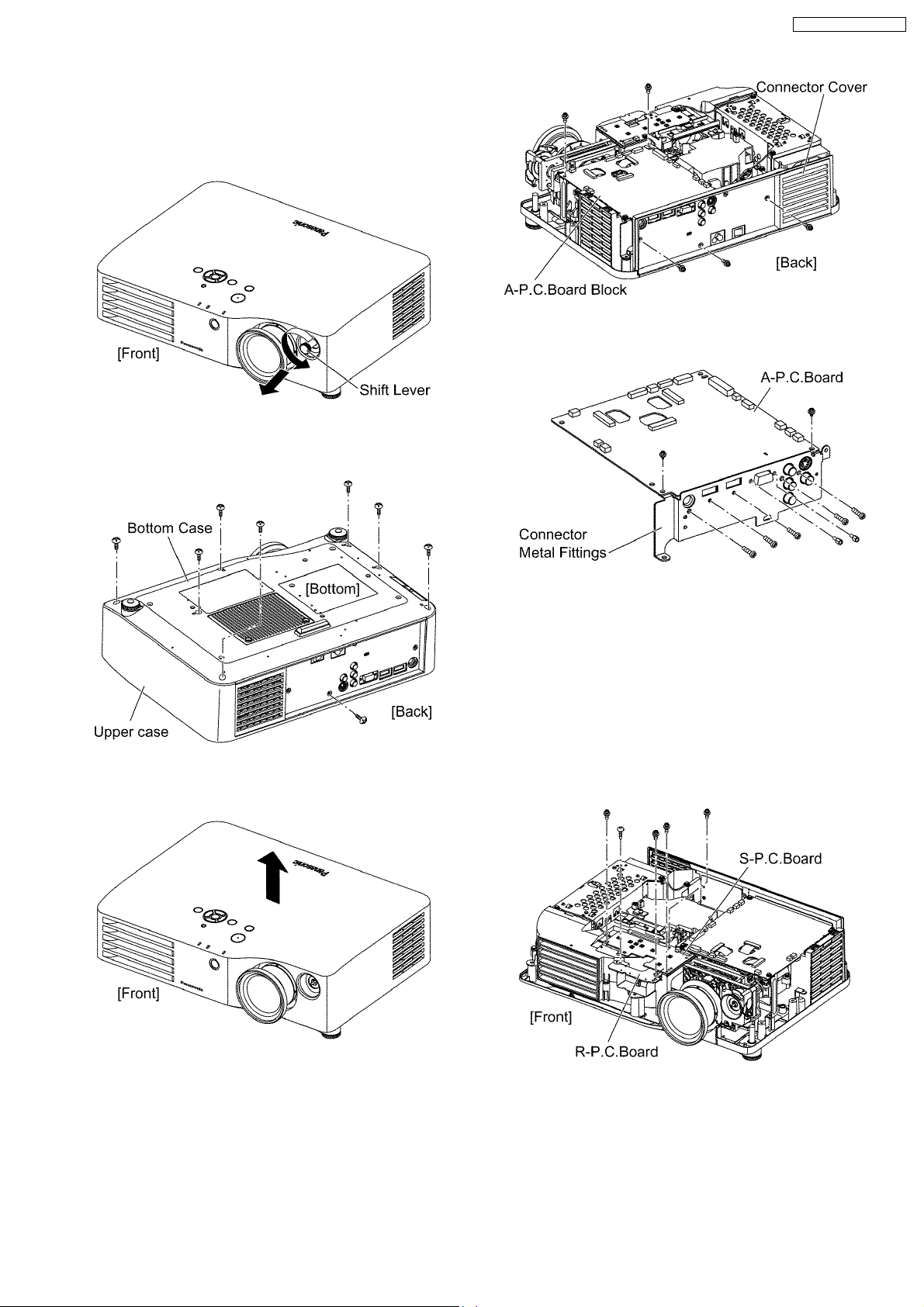

6.2. Removal of Upper Case

1. Turn counterclockwise the shift lever by about one and a

half rotations (540 ° ) from the position in which it is locked,

and pull it forward to remove.

2. Turn the projector upside down.

3. Unscrew the 8 screws.

PT-AX200U / PT- AX200E

5. Unscrew the 9 screws and remove the connector metal

fittings.

4. Return the projector to the normal position.

5. Remove the upper case.

6.4. Removal of R-P.C.Board and

S-P.C.Board

1. Remove the upper case according to the section 6.2.

"Removal of Upper Case".

2. Unscrew the 5 screws and remove the R-P.C.Board and SP.C.Board.

Note:

· They are connected with the connector. Be careful

handling.

6.3. Removal of A-P.C.Board

1. Remove the upper case according to the section 6.2.

"Removal of Upper Case".

2. Unscrew the 3 screws and remove the connector cover.

3. Disconnect all connectors to/from the A-P.C.Board.

4. Unscrew the 2 screws and remove the A-P.C.Board block.

3. Disconnect the connector and separate them.

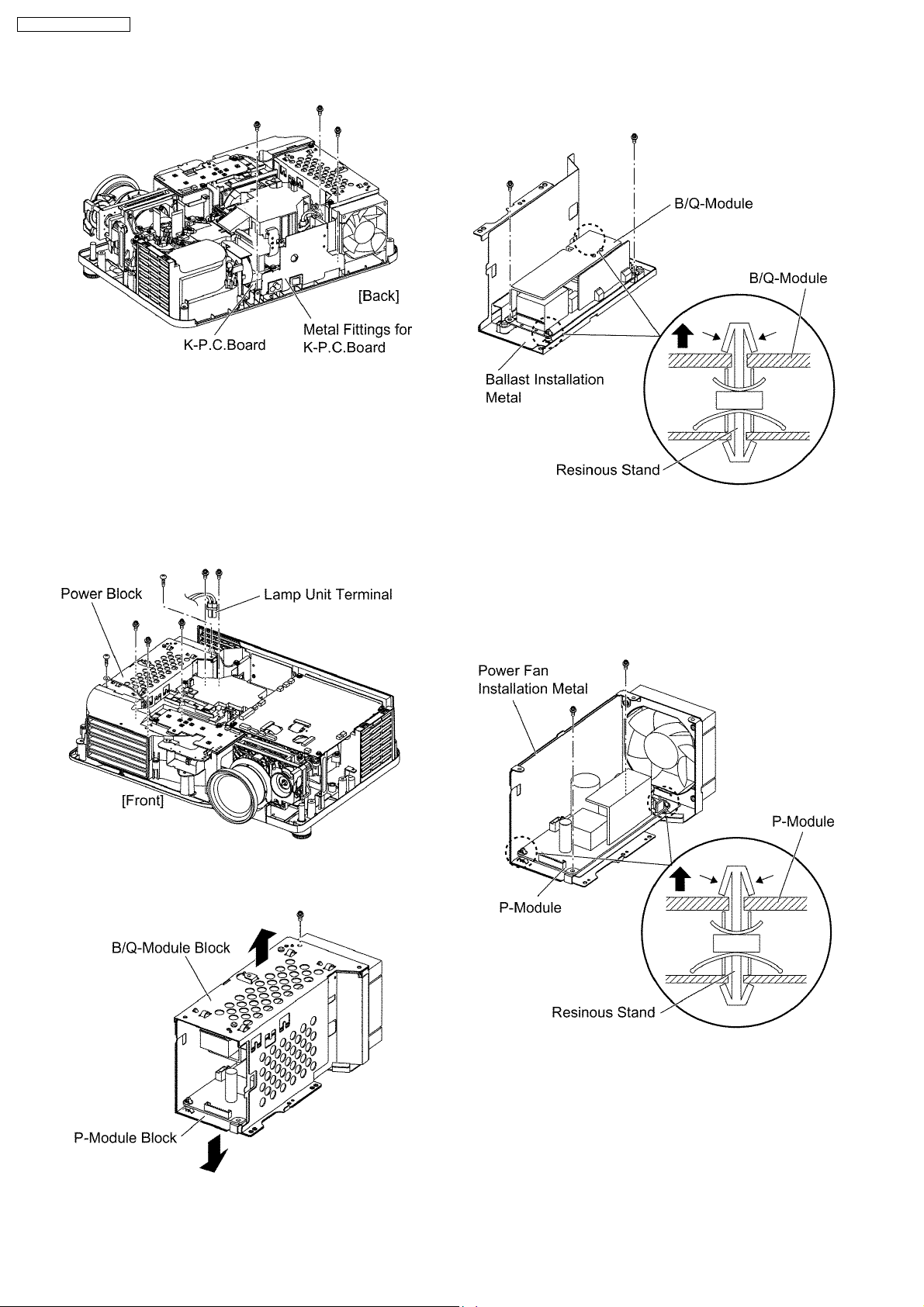

6.5. Removal of K-P.C.Board

1. Remove the A-P.C.Board block according to the steps 1

through 4 in the section 6.3. "Removal of A-P.C.Board".

2. Unscrew the 1 screw and release the grounding terminal.

15

PT-AX200U / PT-AX200E

3. Unscrew the 2 screws and remove the K-P.C.Board block.

6.6. Removal of B/Q-Module

1. Remove the upper case according to the section 6.2.

"Removal of Upper Case".

2. Unscrew the 2 screws and remove the lamp unit terminal.

3. Unscrew the 2 screws and release the 2 grounding

terminals.

4. Unscrew the 3 screws and remove the power block (B/QModule and P-Module).

7. While pressing to shut each hook of the 2 resinous stands,

remove the B/Q-Module.

6.7. Removal of P-Module

1. Remove the P-Module according to the steps 1 through 5 in

the section 6.6. "Removal of B/Q Module".

2. Unscrew the 2 screws.

3. While pressing to shut each hook of the 2 resinous stands,

remove the P-Module.

5. Unscrew the 1 screw and separate the B/Q-Module block

and P-Module block.

6. Unscrew the 2 screws.

6.8. Removal of Lamp Unit

1. Turn the projector upside down.

2. Loosen the 2 screws until they idle and remove the lamp

unit cover.

16

3. Loosen the 2 screws until they idle, remove the lamp unit

with the handle.

PT-AX200U / PT-AX200E

through 4 in the section 6.3. "Removal of A-P.C.Board".

3. Unscrew the 1 screw and remove the thermofuse

attachment.

4. Unscrew the 2 screws and remove the lamp unit terminal.

5. Unscrew the 3 screws and remove the lamphouse.

6. Unscrew the 1 screw and release the grounding terminal.

7. Unscrew the 3 screws and remove the block of Analysis

Block, LCD Block and Projection Lens Block.

Note:

· When installing the lamp unit (or a new one) in the

main unit, place it in a specified position and press

the connector side and the opposite side of the lamp

unit (arrow positions shown in the figure below), and

confirm the lamp unit is inserted securely.

Then, tighten the 2 screws fixing the lamp unit, and

attach the lamp unit cover.

6.9. Removal of Analysis Block

1. Remove the lamp unit according to the section 6.8.

"Removal of Lamp Unit".

2. Remove the A-P.C.Board block according to the steps 1

8. Unscrew the 2 screws and remove the LCD block.

9. Unscrew the 4 screws and remove the projection lens block

(with shift mechanism).

6.10. Removal of LCD Block

1. Remove the A-P.C.Board block according to the steps 1

through 4 in the section 6.3. "Removal of A-P.C.Board".

17

PT-AX200U / PT-AX200E

2. Unscrew the 2 screws and remove the LCD block.

Note:

· Be careful not to touch the surface of prism and LCD

panel.

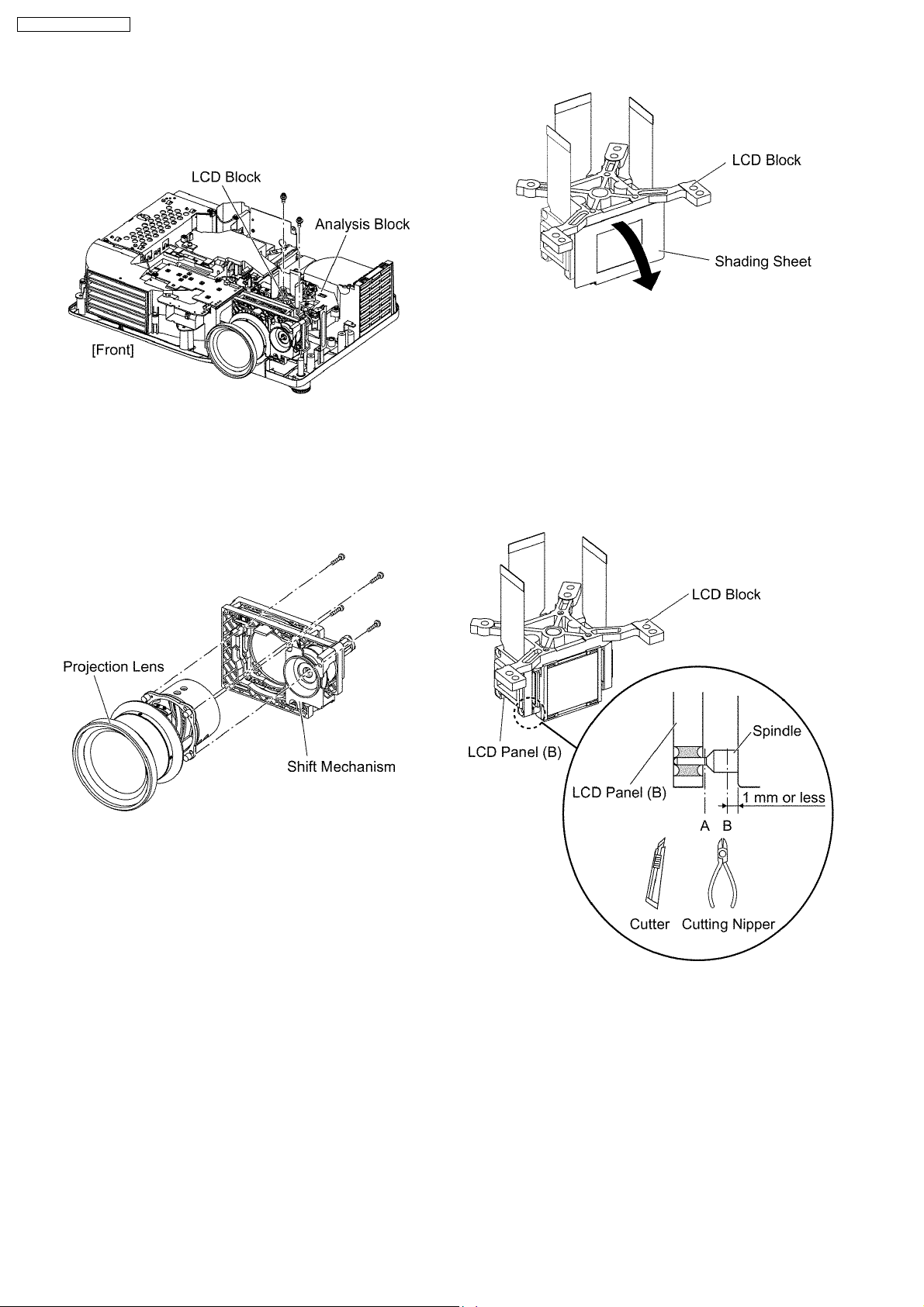

6.11. Removal of Projection Lens

1. Remove the projection lens block (with shift mechanism)

according to the section 6.9. "Removal of Analysis Block".

2. Unscrew the 4 screws and separate the projection lens and

the shift mechanism.

3. Cut the 4 LCD panel installation spindles at the position A

and remove the LCD panel (B).

4. Cut the 4 LCD panel installation spindles at the position B

and remove them.

Notes:

· Work carefully not to apply external force around the

spindle part by using a cutter, cutting nipper or the

like for cutting the spindle.

· Adjust the height after the spindle is cut to 1 mm or

less.

6.12. Replacement of LCD Panel (B)

1. Remove the LCD block according to the section 6.10.

"Removal of LCD Block".

2. Remove the shading sheet.

Note:

· The shading sheet is adhered with the adhesive

sheet. Do not touch the adhesive sheet of the

shading sheet because it is adhered on former

position after the LCD panel is replaced.

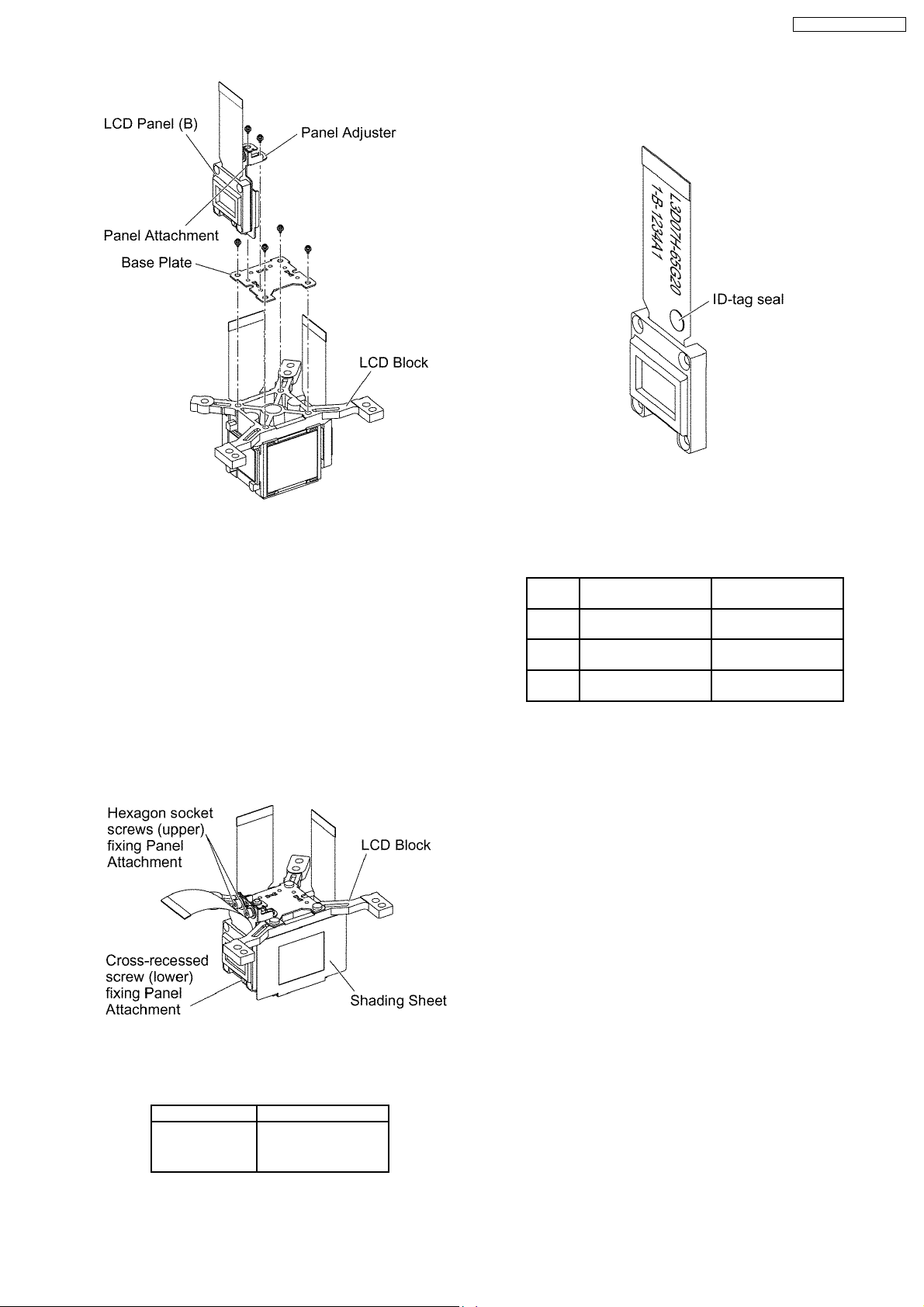

5. Attach the base plate with 4 screws.

6. Tighten the 2 screws temporarily just until new LCD panel

(with the panel attachment and panel adjuster) can be

shifted by your fingers.

Note:

· The panel adjustment fittings set (panel adjuster,

panel attachment and base plate) is an option for

service.

18

PT-AX200U / PT-AX200E

seal.

· Finally, identify the panel color by the part number printed

on the FPC.

7. Reassemble the projector in the reverse order of

disassembling, but leave the upper case and the screws

fixing the A-P.C.Board block as they are removed.

8. Adjust the convergence according to the section 7.4.

"Convergence Adjustment".

9. After the adjustment, while paying attention not to vary the

adjusting result, tighten the 2 screws (upper) fixing the

panel attachment temporarily with a hexagon head wrench.

Notes:

· Prepare a hexagon head wrench processed short.

10. Remove the LCD block again.

11. Tighten the 3 screws fixing the panel attachment.

12. Adhere the shading sheet as it was.

13. Reassemble the projector as it was.

6.13. LCD Panel Discrimination

ID-tag seal color LCD panel

Red LCD panel (R)

Blue LCD panel (B)

(No seal) LCD panel (G)

· Since the ID-tag seal is pasted to the FPC of LCD Panel,

(R), (G) or (B) can be easily identified by the color of the

6.14. LCD Panel Combination

· Part number is printed on the FPC of LCD Panel.

· When replacing LCD Panel, use a component which has

the same part number as the original.

LCD

panel

R L5BDAYY00020

G L5BDAYY00024

B L5BDAYY00022

Combination1 Combination2

(L3D07H-65G20)

(L3D07H-66G20)

(L3D07H-65G20)

L5BDAYY00023

(L3D07H-66G20)

L5BDAYY00021

(L3D07H-65G20)

L5BDAYY00025

(L3D07H-66G20)

6.15. Replacement of Projection

Polarizer

· The procedure is described as an example of projection

polarizer (B).

1. Remove the LCD block according to the section 6.10.

"Removal of LCD Block".

2. Remove the projection polarizer which requires replacing.

(The projection polarizer is secured with adhesive tape.)

Notes:

· Be careful not to damage peripheral components

(prism, LCD panel, etc.).

· Use tweezers.

3. Install new projection polarizer.

a. Put adhesive tape on the projection polarizer.

b. Stick the projection polarizer on the specified position.

Notes:

· Align the projection polarizer with the guides

(lower, side) of LCD block.

· Be careful not to touch the surface of projection

polarizer.

· Use tweezers.

c. Press the adhesive part and secure the projection

polarizer.

19

PT-AX200U / PT-AX200E

6.16. Replacement of Incidence

Polarizer

The procedure is described as an example of incidence

polarizer (G).

1. Remove the A-P.C.Board block according to the steps 1

through 4 in the section 6.3. "Removal of A-P.C.Board".

2. Mark positions of the incidence polarizer.

Note:

· Mark accurately as possible because the marks will

be used for resetting the incidence polarizer

position.

3. Unscrew the 1 screw and remove the incidence polarizer.

4. Attach a new incidence polarizer and align it with the mark.

5. Tighten the 1 screw with care not to move the incidence

polarizer position.

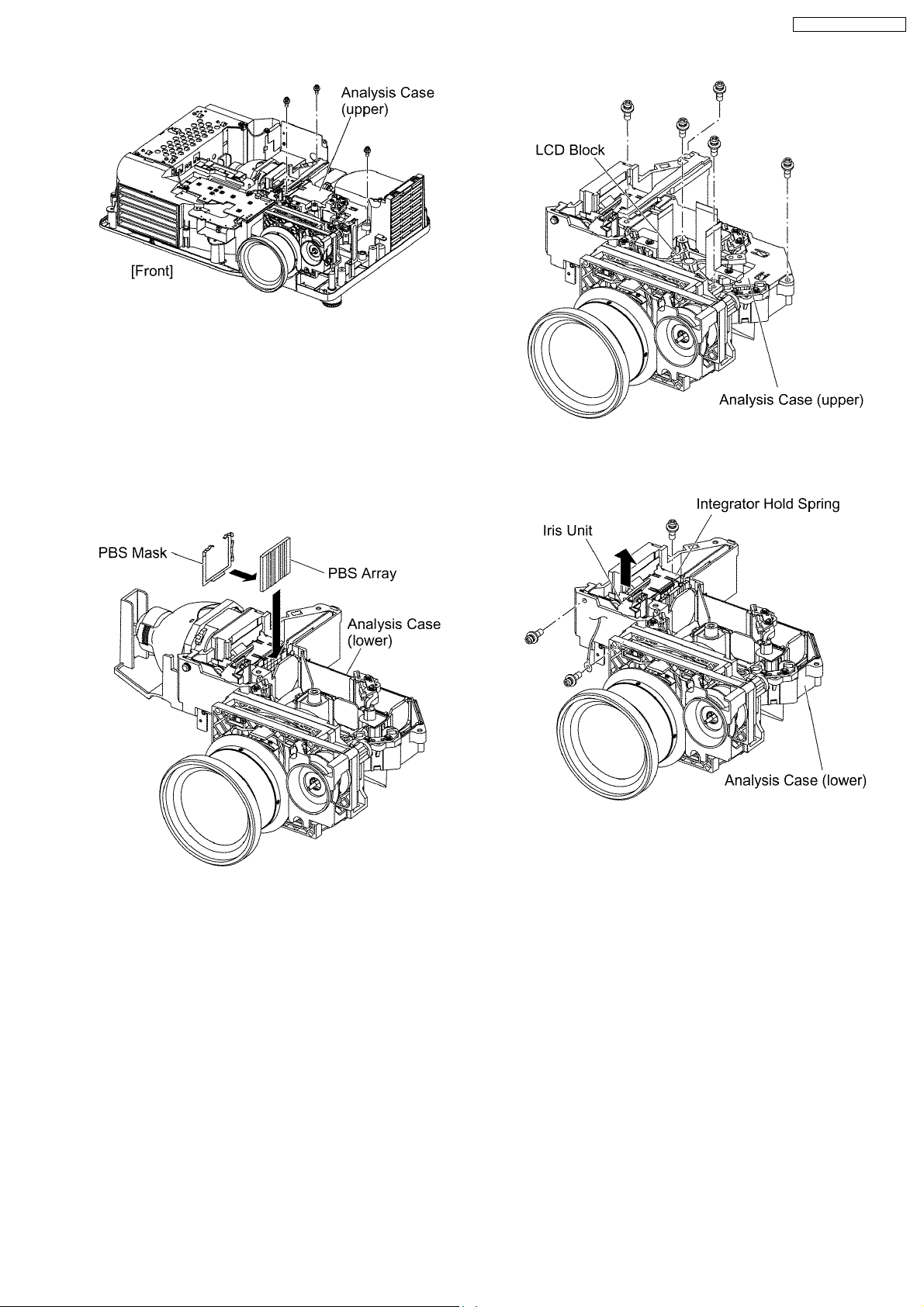

6.17. Replacement of PBS Array

(Analysis Block)

1. Remove the A-P.C.Board and lamphouse according to the

steps 2 through 5 in the section 6.9. "Removal of Analysis

Block ".

2. Unscrew the 2 screws and remove the LCD block.

Note:

· Be careful not to touch the surface of prism and LCD

panel.

3. Unscrew the 3 screws and remove the analysis case

(upper).

Note:

The incidence polarizer (R, G and B) are installed in the

analysis case (upper). Be careful not to shift the

installation position nor be damaged.

20

4. Remove the PBS array (with PBS mask).

5. Remove the PBS mask from the PBS array.

6. Install the PBS mask onto a new PBS array.

7. Install the new PBS array (with PBS mask) in the analysis

case (lower).

Note:

· Be careful not to mistake the direction

(inside/outside, upper/lower).

· Be careful not to touch the surface of PBS array.

PT-AX200U / PT-AX200E

4. Unscrew the 1 screw and remove the integrator hold spring.

5. Unscrew the 2 screws and remove the iris unit .

6.18. Removal of Iris Unit

1. Remove the block of Analysis Block, LCD Block and

Projection Lens Block according to the steps 1 through 7 in

the section 6.9. "Removal of Analysis Block".

2. Unscrew the 2 screws and remove the LCD block.

Note:

· Be careful not to touch the surface of prism and LCD

panel.

3. Unscrew the 3 screws and remove the analysis case

(upper).

Note:

· The incidence polarizer (R, G and B) are installed in

the analysis case (upper). Be careful not to shift the

installation position nor be damaged.

21

PT-AX200U / PT-AX200E

7 Measurement and Adjustments

7.1. Adjustment Procedure Flowchart

7.2. Cautions for Adjustment

· Never turn off the MAIN POWER switch until every fan completely stops.

· To maintain and ensure safety, always use the designated components for replacement parts.

· If removing any clamps, lead wires or connectors, always place them back in their proper locations.

· Be careful not to damage the lead wires or components when using a soldering iron or similar tool.

7.3. Setting Before Adjustment

· Set up the projector to obtain the projection distance below.

· Turn the zoom ring of the projector to obtain the largest size of the picture.

7.4. Convergence Adjustment

Execute this adjustment when replacing the LCD panel (B) .

7.4.1. Tools to be used

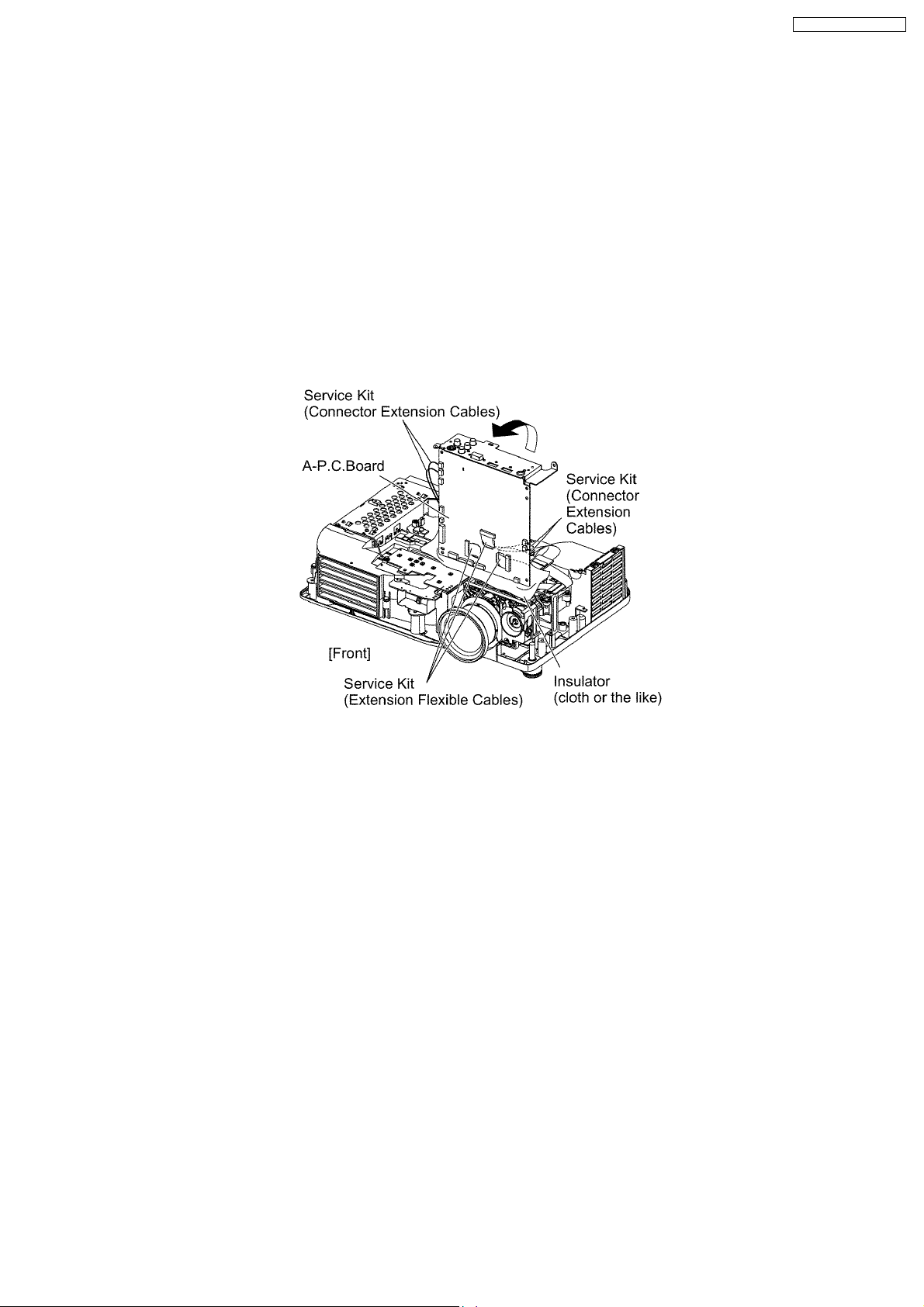

Service Kit : This kit is composed of 3 extension flexible cables and 4 connector extension cables.

Note:

· Consult your dealer or Authorized Service Center for the service kit.

7.4.2. Preparation

1. Loosen 2 screws fixing the panel adjuster and 3 screws fixing the panel attachment, then tighten the 5 screws temporarily just

until the LCD panel can be shifted by your fingers.

22

PT-AX200U / PT-AX200E

Note:

· See figures in the section 6.12. "Replacement of LCD Panel (B)" for 2 screws fixing the panel adjuster and 3 screws

fixing the panel attachment.

2. Reassemble the projector in the reverse order of disassembling, but leave the upper case and the screws fixing the AP.C.Board block as they are removed.

3. Connect the service kit (extension cables).

· Each flexible cable of LCD Panels ( R/G/B ) - Connectors (A1/A2/A3) on A-P.C.Board

· Thermosensor (Intake air) connector - Connector (A7) on A-P.C.Board

· Intake fan connector - Connector (A15) on A-P.C.Board

· Power fan connector - Connector (A16) on A-P.C.Board

· Lamp fan connector - Connector (A18) on A-P.C.Board

4. Covering with an insulator (cloth or the like) to prevent a short circuit, set the A-P.C.Board block on the main unit.

Note:

· Handle with care not to apply external force to connecting parts which connect the main unit and A-P.C.Board.

7.4.3. Adjustment Procedure

Prepare 2 pieces of thick black paper (23 mm × 100 mm) that can be shaded.

· Cover and shade LCD panels with the paper except the panel that attempts to be adjusted.

1. Display the green crosshatch pattern and adjust the lens focus.

2. Display green and blue crosshatch patterns.

3. Adjust focus by shifting the panel adjuster for LCD panel (B) back and forth, then tighten the 2 screws.

4. Adjust the LCD panel (B) position so that the vertical center of blue crosshatch pattern is overlapped with the vertical center of

green crosshatch pattern.

5. Adjust the LCD panel (B) position so that the horizontal center of blue crosshatch pattern is overlapped with the horizontal

center of green crosshatch pattern.

6. Correct the tilt of the blue crosshatch pattern by adjusting the LCD panel (B) position.

7. Display green, red and blue crosshatch patterns and confirm the convergence. If it is necessary, fine adjust the convergence

so that the blue crosshatch pattern is overlapped with green one.

23

Loading...

Loading...