Page 1

Product

Instructions

Indoor Ceiling Housing

PID5CN

Manufactured by

Before attempting to connect or operate this product,

please read these instructions completely.

for

81-IN3089

10/16/06

Page 2

MODEL: Indoor Ceiling Housing

PID5

PRODUCT INSTRUCTIONS

6. With the support arms (3) rotated to the inside, slide the

housing into the pre-cut hole (Figure 3).

Before attempting to connect or operate this product, please

read these instructions completely.

• This product has been designed and engineered for the

unitized camera(s) WV-NS202 & CF-284, CW-484 for ease

of installation and service.

• This product is a discreet indoor recessed surveillance

enclosure designed to mount into a drop ceiling tile or sheet

rock ceiling.

• This unit completely encloses the unitized camera resulting

in discreet viewing.

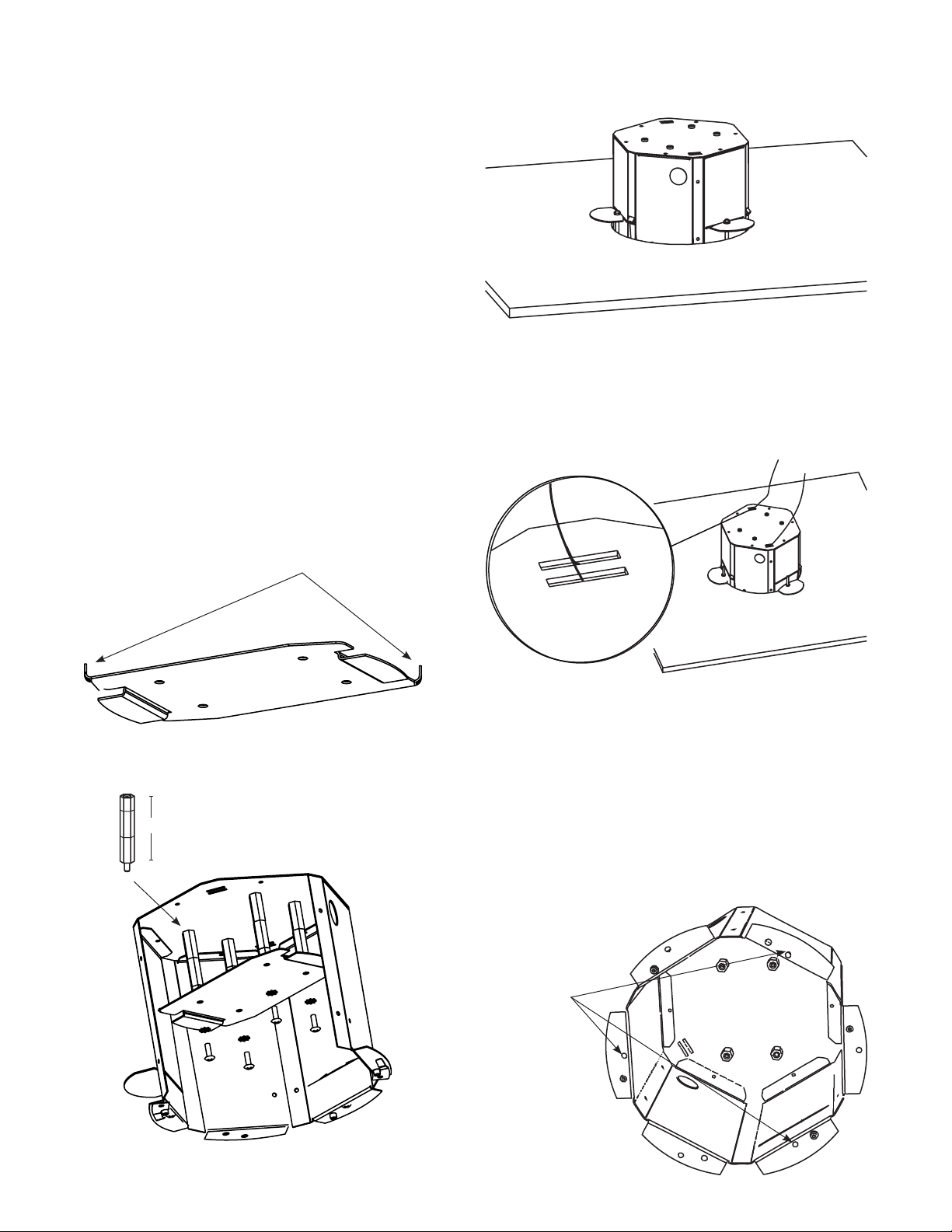

STANDARD INSTALLATION PROCEDURE WV-NS202

1. Carefully remove all equipment from the box.

2. Using the template provided, cut a 7.5” hole into the ceiling

in the desired spot. (See #8 below for special note)

3. Remove the desired conduit knockout from the side of the

PID5 housing.

4. Detach the camera mounting base from the camera and

mount it to the PID5 housing using 2½" of spacers as shown.

5. Before camera mounting plate can be installed in housing,

tabs must be bent as a shown below (Figure 1).

Figure 1

Bend Down Tabs

Figure 3

7. With the bottom ange pressed up against the ceiling,

rotate the support arms to the outside, the arms will fall to

the back side of the ceiling (Figure 3). Tighten the (3) 8-32 x

1½” Phillips screws (Figure 5).

8. Support wires (not provided) must be connected to the top

of the housing through the two provided slots (Figure 4).

2½"

spacer

Figure 4

CAUTION: The wires must be able to support

up to 15 lbs (6.8 kg).

9. If the housing is going into a ceiling where the support arms

will not work, the housing can be secured to the ceiling by

running bolts (not provided) through the bottom ange into

the solid ceiling (Figure 5).

NOTE: If you use bolts instead of support wires the

hole will need to be the same size and shape

as the top of the housing. DO NOT USE THE

7.5” TEMPLATE. Use the top of the housing as a

template to cut

out the hole.

Use to attach

housing to

solid ceiling

Figure 5

Figure 2

- 2 -

Page 3

WV-NS202 CAMERA INSTALLATION

Use with Class 2 Power Supply only.

!

10. Run electrical cable into the housing through one of the

three conduit knockouts.

11. Complete all electrical and video connections.

12. Attach the WV-NS202 camera to the camera mounting

base and secure with the safety screw provided with the

camera (Figure 6).

Figure 6

WV-NF284 AND WV-CW484 CAMERA INSTALLATION

1. This enclosure can also be used to mount the WV-NF284 and

WV-CW484 cameras. Spacers are included inthe housing

packet to properly position the cameras within the housing.

See the Figure below for the correct spacing.

3.500

SPACERS

WV-NF284

4.000

SPACERS

WV-CW484

2. Once spacers are installed follow the same procedure as

mentioned above for installing the enclosure in the ceiling.

NOTE: The WV-NF284 and the WV-CW484 do not use

the installed dome. For these products it is necessary to

remove the dome and replace with insert provided in

housing packet.

Adding Insert

- 3 -

Page 4

13. Reattach the PID5 dome by pressing in and twisting the

two at spring clips into the housing (Figure 7).

Figure 7

- 4 -

Page 5

SPECIFICATIONS

3.287

1.811

O 7.650

6.650

7.310

3.287

1.811

O 7.650

6.650

7.310

1.200

8.373

.340

Metal Back Box 0000000000 18 and 20-gauge steel,

000000000000000000000000 w/black powdercoat nish

Support Arms 000000000000 18-gauge Galvanized steel

Decorative Trim Ring 000000 ABS Plastic

Electrical Input 00000000000 (3) .875" knockouts

Unit Weight 00000000000000 3.5 lbs. (1.6 kg)

.

.

.

.

1

EXPLODED VIEW

1. 00 PID9 Housing

2. 00 (3) Support Arms

3. 00 Trim Ring

4. 00 Packet Assembly

5. 00 Dome

2

RP-PID9-1000

RP-PID9-1010

RP-PID9-1020

RP-PID9-1025

RC5

.

.

.

DIMENSIONS

.

.

3

- 5 -

Page 6

1. Read Instructions - All the safety and operating instructions

should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating

instructions should be adhered to

4. Follow Instructions - All operating and user instructions should

be followed.

5. Electrical Connections - Only a qualified electrician should

make electrical connections

6. Attachments - Do not use attachments not recommended by the

product manufacturer as they may cause hazards

7. Cable Runs -All cable runs must be within permissible distance

8. Mounting - This unit must be properly and securely mounted to

a supporting structure capable of sustaining the weight of th e

unit. Accordingly:

a. The installation should be made by a qualified service person

and should conform to all local codes.

b. Care should be exercised to select suitable hardware to install

the unit, taking into account both the composition of the

mounting surface and the weight of the unit. Be sure to

periodically examine the unit and the supporting structure to

make sure that the integrity of the installation is intact. Failure

to comply with the foregoing could result in the unit separating

from the support structure and falling, with resultant damages

or injury to anyone or anything struck by the falling unit.

SAFETY PRECAUTIONSIMPORTANT SAFEGUARDS

CAUTION

RISK OF

!

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE .

!

UNPACKING

Unpack carefully. Electro nic componen ts can be

damaged if improperly handled or dropped. If an item

appears to have been damaged in shipment, replace it

properly in its carton and notify the shipper

ELECTRIC SHOCK!

The lightning flash with an arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of non-insulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons

The exclamation point within an equilateral

triangle is intended to alert the user to

pr esenc e of im porta nt oper ating and

maintenance (servicing) instructions in the

literature accompanying the appliance

Be sure to save :

1. The shipping carton and packaging material. They are the

safest material in which to make future shipments of the

equipment.

2. These Installation and Operating Instructions

SERVICE

For service on Panasonic/Videolarm equipment contact:

Panasonic Technical Center

54 West Gude Dr

Rockville MD 20850-1150

Phone: 301-762-5125

Fax: 301-251-0347

PANASONIC TECHNICAL SUPPORT

1-800-528-6747

9:00 AM - 5:00 PM EASTERN TIME

- 6 -

Loading...

Loading...