Panasonic FX-505-C2, FX-505P-C2 User guide

<PRO1>

INSTRUCTION MANUAL

Digital Fiber Sensor Amplier FX-505□-C2

MJE-FX505C2 No.0015-29V

Thank you very much for purchasing Panasonic products.

Please read this Instruction Manual carefully and thoroughly for the correct and

optimum use of this product.

Kindly keep this manual in a convenient place for quick reference.

WARNING

● Never use this product as a sensing device for personnel protection.

● In case of using sensing devices for personnel protection, use products which

meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel

protection applicable in each region or country.

1

INTENDED PRODUCTS FOR CE MARKING

● This product complies with the following standards / regulations.

<EU Directive>

EMC Directive 2004/108/EC

<Standards in US / Canada>

ANSI/UL 60947-5-2, CAN/CSA C22.2 No.14

<Regulations in Korea>

S1-G-1-2009, S2-W-5-2009

● Caution about UL recognition

In case requiring conformity of UL listing mark or C-UL listing mark, USe class

2 power supply unit.

2

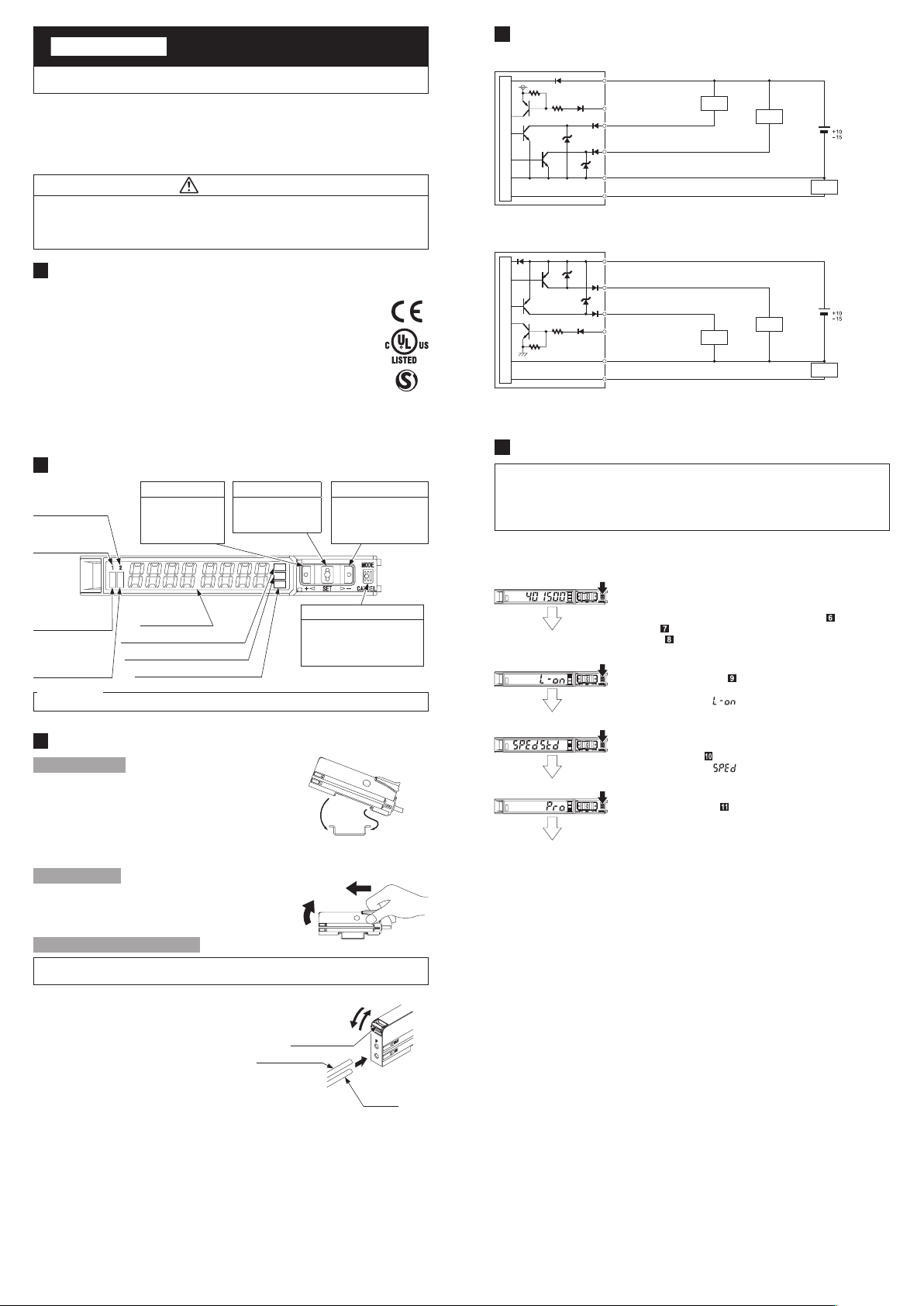

PART DESCRIPTION

Sensing output 2

selection indicator

(Yellow)

Sensing output 1

selection indicator

(Yellow)

Sensing output 1

operation indicator

(Orange)

Sensing output 2

operation indicator

(Orange)

<Reference>

Pressing down SET key + MODE key for 3 sec : Set key lock or Release key lock

3

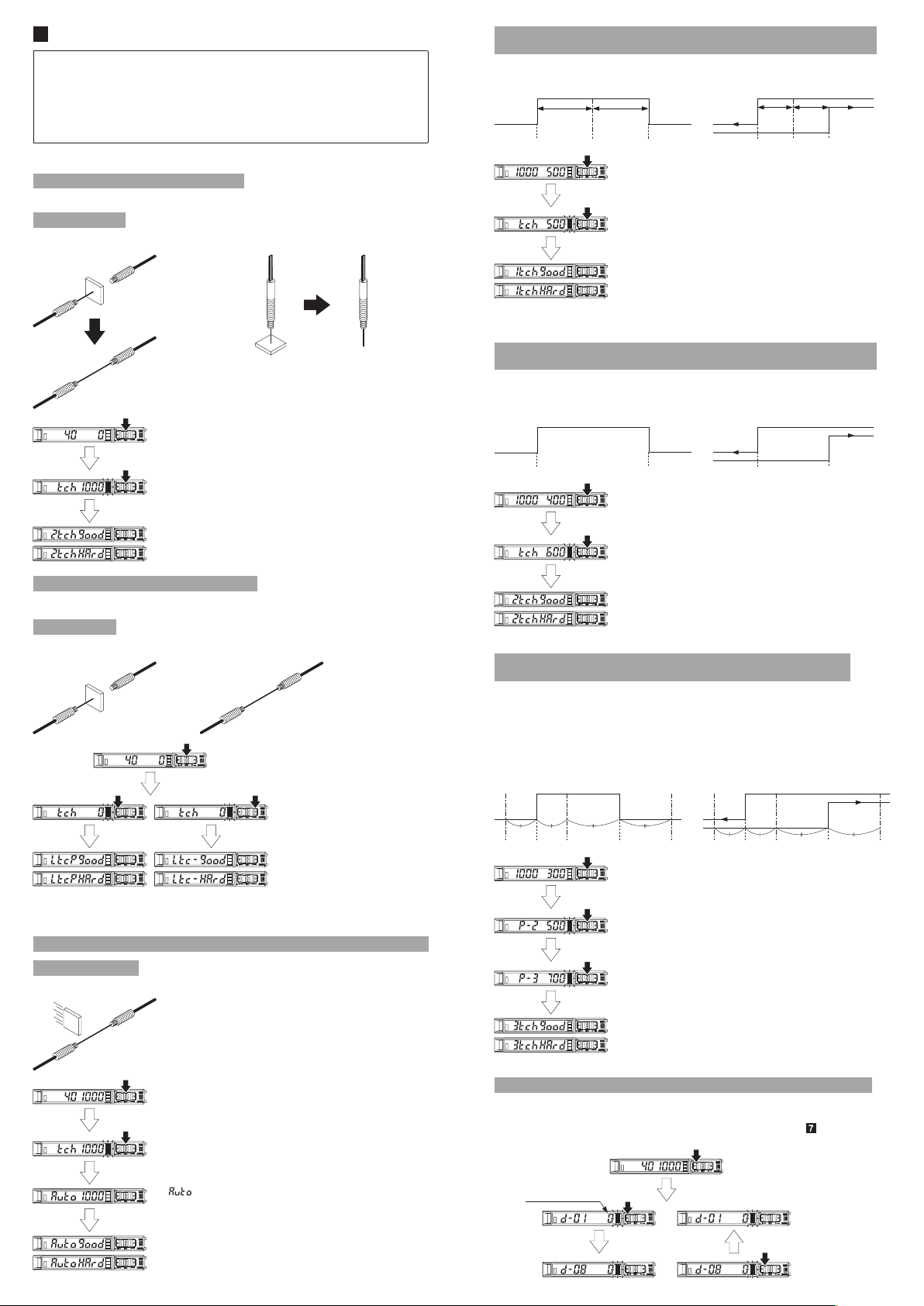

MOUNTING

How to connect

1. Fit the rear part of the mounting sec-

tion of the amplier on a DIN rail.

2. Press down the rear part of the

mounting section of the unit on the

DIN rail and fit the front part of the

mounting section to the DIN rail.

UP key

• Teaching

• Threshold value

ne adjustment

• Select setting items

Digital display

(Green / Red)

MODE indicator: L / D (Yellow)

MODE indicator: CUST (Yellow)

MODE indicator: PRO (Yellow)

SET key

• Teaching

• Confirm setting

contents

MODE key

• Select Modes

• Cancel during setting

• Select sensing output 1/2

by pressing long

2. Press down

35mm width DIN rail

DOWN key

• Teaching

• Threshold value ne

adjustment

• Select setting items

1. Fit

4

I/O CIRCUIT DIAGRAMS

<FX-505-C2>

(Brown) +V

Load

Load

+

12 to 24V DC

%

-

Load (0 to 250Ω)

Main circuit

(Pink) External input

(Black) Sensing output 1

(White) Sensing output 2

(Blue) 0V

(Gray) Monitor current output (4 to 20mA)

<FX-505P-C2>

(Brown) +V

(Black) Sensing output 1

+

(White) Sensing output 2

Main circuit

Note: Make sure to insulate the ends of the unused lead wires.

5

OPERATION PROCEDURE

(Pink) External input

(Blue) 0V

(Gray) Monitor current output (4 to 20mA)

Load

Load

12 to 24V DC

%

-

Load (0 to 250Ω)

● The sensing output can be switched to sensing output 1 or sensing output 2

by holding down the mode key.

● The changed settings are not stored if turning the power OFF while setting.

Therefore, conrm the settings by pressing the SET key before turning the

power OFF.

● When turning ON the power, RUN mode is displayed and the digital display

shows the threshold value (green) and the incident light intensity (red).

<RUN mode>

<Sensing output operation mode>

<CUSTOM mode>

<PRO mode>

<RUN mode>

• Displays threshold value (green) and incident light intensity (red).

• Teaching, threshold value ne adjustment and key lock function

can be set.

• For setting method of each function, refer to “

MODE,” “

TION,” or “

• Select either Light-ON or Dark-ON.

• For the setting, refer to

MODE

• The default setting is “ ” (Light-ON).

• An item set in CUSTOM mode (Response time setting, Emission

power setting and Hysteresis setting) is displayed.

• For details, refer to “

• The default setting is “

• Advanced setting can be done.

• For the setting, refer to “

THRESHOLD VALUE FINE ADJUSTMENT FUNC-

KEY LOCK FUNCTION.”

.”

“ SENSING OUTPUT OPERATION

CUSTOM MODE.”

” (response time setting).

PRO MODE.”

TEACHING

How to remove

1.

Push the controller forward.

2. Lift up

1. Push forward

2. Lift up the front part of the amplier

to remove it.

How to connect the ber cable

Be sure to t the attachment to the bers rst before inserting the bers to the

amplier. For details, refer to the Instruction Manual enclosed with the bers.

1. Snap the fiber lock lever down till it

stops completely.

2. Insert the ber cables slowly into the

inlets until they stops. (Note)

3. Return the fiber lock lever to the

original position till it stops.

Note: With the coaxial reective type ber, such as , FD-G4 or FD-FM2, insert the single core ber cable into the

beam-emitting inlet “P” and the multi-core ber cable into the beam-receiving inlet.

If they are inserted in reverse, the sensing performance will deteriorate.

Fiber for emitter

1. Snap

Fiber lock lever

3. Return

2. Insert

Fiber for

receiver

6

<PRO1>

TEACHING MODE

● Be sure that detection may become unstable depending on the use environ-

ment in teaching if less margin is applied.

● When teaching in Window comparator mode or Hysteresis mode, a setting

has to be made in PRO mode beforehand.

In case 1-point teaching, make sure to set the shift amount. (initial value is

10% or 100)

For the setting, refer to “PRO MODE OPERATION MANUAL.”

● Teaching can be set in RUN mode.

Useful when sensing object can be set

● This is basic teaching method.

2-point teaching

<Thru-beam type>

1

2

1. Press the SET key in the sensing object present condition.

<Reective type>

1 2

1-point teaching

[Window comparator mode (except sensing output 2) / Hysteresis mode]

● This is method to set the shift amount to the desired value and to set the

threshold range by using the 1-point teaching.

<Window comparator mode>

Set to desired value

1_SL P-1 2_SL

Notes 1)

The shift amount of 10% is an initial value. The shift amount can be set in PRO mode. Furthermore, the shift

value can be set in incident light amount. For setting method, refer to “PRO MODE OPERATION MANUAL.”

2) If the value after setting exceeds the maximum (minimum), the maximum (minimum) sensitivity will be set.

Set to desired value

1. Pressing SET key down

2. Press the SET key down in the sensing object present condition.

3. The threshold value (1_SL) that is 10% lower from the incident

light intensity and the threshold value (2_SL) that is 10% higher

from the incident light intensity are set. (Note 1, 2)

Stable sensing is possible

Stable sensing is not possible

<Hysteresis mode>

Set to desired value

1_SL P-1 2_SL

Set to desired value

2-point teaching

[Window comparator mode (except sensing output 2) / Hysteresis mode]

● This is method to set the threshold range by conducting the 2-point teaching (P-1, P-2).

● When conducting teaching, use sensing objects (P-1 and P-2) whose incident

light intensities are different from each other.

<Window comparator mode>

<Hysteresis mode>

2. Press the SET key in the sensing object absent condition.

Stable sensing is possible

Stable sensing is not possible

Useful when sensing object cannot be set

● This is teaching method in case small object or object in back ground are existing

Limit-teaching

<Thru-beam type and refractive type are common>

or

1. Press the SET key in the sensing

object present condition or non

sensing object present condition.

2. The threshold level is shifted to

high value (low sensitivity) by

pressing down UP key.

The threshold level is shifted to low

value (high sensitivity) by pressing

down UP key.

Stable sensing is possible

Stable sensing is not possible

Note: The shift value of approx. 15% is an initial value. Display of the shift value can be change in percentage

[approx. 0 to 999% (unit 1 %)] or incident light intensity [0 to 9999 (unit 1)].

For setting the shift amount, refer to “PRO MODE OPERATION MANUAL.”

Useful when not want to stop production line and to keep the sensing object move

Full-auto teaching

<Thru-beam type and refractive type are common>

1_SL (P-1) 2_SL (P-2)

1. Pressing SET key down (1st time)

2. Press down the SET key in the sensing object present condition.

(2nd time)

Stable sensing is possible

Stable sensing is not possible

Note: If the value after setting exceeds the maximum (minimum), the maximum (minimum) sensitivity will be set.

1_SL (P-1) 2_SL (P-2)

3-point teaching

[Window comparator mode (except sensing output 2) / Hysteresis mode]

● This is the method to conduct the 3-point teaching (P-1, P-2, P-3) and to set the

threshold range by setting the threshold value (1_SL) of the mid-point between “A”

and “B” and the threshold value (2_SL) of the mid-point between “B” and “C”.

● When conducting teaching, use sensing objects (A, B and C) whose incident

light intensities are different.

● After teaching, P-1, P-2 and P-3 will be automatically relocated in ascending order:

i.e. the lowest value is placed in “A”, the second lowest in “B” and the highest in “C”.

<Window comparator mode>

A 2_SL1_SL B C

1. Press SET key down in the sensing object present condition (1st time)

2.

Press SET key down in the sensing object present condition (2nd time)

3.

Press SET key down in the sensing object present condition (3rd time)

<Hysteresis mode>

A 2_SL1_SL B C

1. Pressing SET key down

Pressing down long

Run the sensing object on the line and hold down the SET key.

2.

3. “ ” is displayed on the digital display (green) and when the

sensing object passed through, release the SET key.

Automatic

Stable sensing is possible

Stable sensing is not possible

Stable sensing is possible

Note: If the value after setting exceeds the maximum (minimum), the maximum (minimum) sensitivity will be set.

Stable sensing is not possible

Span adjustment in rising differential mode or trailing differential mode

● Press the SET key to conrm the setting item.

● The threshold can be set by using the threshold value ne adjustment function.

For the threshold value ne adjustment function, refer to “

THRESHOLD

VALUE FINE ADJUSTMENT FUNCTION”

Changed intensity

Short span

Long span

Loading...

Loading...