Page 1

Operating and Installation Instructions

19

1/8

"

486 mm

11

13/16

"

300 mm

Mode d'emploi et notice d'installation

ENGLISHFRANÇAISESPAÑOL

Instrucciones de uso e instalación

Range Hood

Hotte de cuisine

Campana de cocina

Model No.

Modèle

Nº de modelo

FV-36RCQL1

FV-30RCQL1

READ AND SAVE THESE INSTRUCTIONS

Thank you for purchasing this Panasonic product.

Please read these instructions carefully before attempting to install, operate or service

the Panasonic product. Please carefully read the “GENERAL SAFETY INFORMATION”

Failure to comply with instructions could result in personal injury or property damage.

Please explain to users how to operate and maintain the product after installation, and

this booklet should be presented to users.

Please retain this booklet for future reference.

LIRE ET CONSERVER CE DOCUMENT

Nous vous remercions d'avoir acheté ce produit Panasonic. Veuillez lire attentivement

ces instructions avant d’essayer d’installer, d’utiliser ou de réparer ce produit Panasonic.

Veuillez également lire attentivement la section “CONSIGNES DE SÉCURITÉ” .

Le non-respect des instructions peut entraîner un risque de blessure corporelle et

de dommages matériels. Veuillez expliquer aux utilisateurs comment utiliser et eectuer

l’entretien de ce produit après l’installation et leur présenter ce document.

Conservez ce document pour référence ultérieure.

LEA Y CONSERVE ESTAS INSTRUCCIONES

Gracias por comprar este producto Panasonic. Lea atentamente estas instrucciones antes

de instalar, utilizar o mantener este producto Panasonic. Lea atentamente el capítulo

“INFORMACIÓN GENERAL SOBRE SEG URIDAD”. El incumplimiento de las instrucciones

podría causar daños personales o materiales. Explique a los usuarios cómo utilizar y

mantener el producto después de la instalación. Se recomienda ofrecer este manual a los

usuarios. Conserve este manual para consultas futuras.

Page 2

CONTENTS

GENERAL SAFETY INFORMATION .................................................................................................................................................................. 3

SUPPLIED ACCESSORIES ................................................................................................................................................................................... 7

OPERATION ............................................................................................................................................................................................................ 8

MAINTENANCE ..................................................................................................................................................................................................... 9

DIMENSIONS ....................................................................................................................................................................................................... 10

WIRING DIAGRAM ............................................................................................................................................................................................11

SPECIFICATIONS ................................................................................................................................................................................................. 11

INSTALLATION .....................................................................................................................................................................................................12

PRODUCT SERVICE ........................................................................................................................................................................................... 18

2

Page 3

GENERAL SAFETY INFORMATION

For Your Safety

To reduce the risk of injury, loss of life, electric shock, re, malfunction, and damage to

equipment or property, always observe the following safety precautions.

Explanation of symbol word panels

The following symbol word panels are used to classify and describe the level of hazard,

injury, and property damage caused when the denotation is disregarded and improper use

is performed.

Denotes a potential hazard that could

result in serious injury or death.

WARNING

Denotes a hazard that could result in

minor injury.

CAUTION

ENGLISH

The following symbols are used to classify and describe the type of instructions to be

observed.

This symbol is used to alert users to a specic operating procedure that

must be followed in order to operate the unit safely.

This symbol is used to alert users to a specic operating procedure that

must not be performed.

3

Page 4

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat.

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or lter.

d) Use proper pan size. Always use cookware appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE FOLLOWING:

a) SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray, then turn o the burner. BE CAREFUL TO

PREVENT BURNS. If the ames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN – You may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels – a violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a Class ABC extinguisher, and you already know how to operate it.

2) The re is small and contained in the area where it started.

3) The re department is being called.

4) You can ght the re with your back to an exit.

Based on “ Kitchen Firesafety Tips ” published by NFPA.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b) Before servicing or cleaning unit, switch power o at service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

GROUNDING INSTRUCTIONS

a) This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This appliance is equipped with a cord having a grounding

wire with a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded.

b) Improper grounding can result in a risk of electric shock.

c) Consult a qualied electrician if the grounding instructions are not completely understood, or if doubt exists as

to whether the appliance is properly grounded.

d) Do not use an extension cord. If the power supply cord is too short, have a qualied electrician install an outlet

near the appliance.

4

Page 5

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Installation work and electrical wiring must be done by qualied person(s) in accordance with all applicable

codes and standards, including re-rated construction.

b) Sucient air is needed for proper combustion and exhausting of gases through the ue (chimney) of fuel

burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety

standards such as those published by the National Fire Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d) Ducted fans must always be vented to the outdoors.

- Clean the lters and all laden surfaces on a regular basis.

- To provide protection against electric shock, connect to properly grounded outlets only.

- To reduce the risk of re, use only metal ductwork.

-

Stop using the unit when any abnormality / failure occurs and turn “OFF” the power switch or pull out the 3 pin plug.

Example of abnormality failure:

- Abnormal noise or heat.

- Abnormal emission of smell / smoke.

- Fire or oil ignition.

- Insert the Power Plug rmly, otherwise it may cause re or electric shock.

- The supply cord must be set properly not to be damaged. The manufacturer declines all liability if the safety

standards are not observed.

- The socket used to connect the installed equipment to the electrical power supply must be within reach:

otherwise, install a mains switch to disconnect the Range Hood when required.

- The wall plugs must have a secure grip.

- The enclosed screws and wall plugs are suitable for solid brickwork or solid concrete. Suitable fasteners must be

used for other structures (e.g. plasterboard, porous concrete, porous bricks).

- The maximum length of the ue fastening screws (supplied by the manufacturer) must be 0

Use of non-compliant screws with these instructions can lead to danger of an electrical nature.

- Keep in mind that installations with dierent types of fastening systems from those supplied, or which are not

compliant, can cause electrical and mechanical seal danger.

- Clean the Power Plug regularly with dry cloth, otherwise it may cause insucient insulation due to moisture, and

may cause re.

- There is a re risk if cleaning is not carried out in accordance with the instructions.

- Accessible parts may become hot when used with cooking appliances.

- Always supervise the cooking process during the use of deep-fryers:

Overheated oil can catch re.

- A statement to the eect that when the product is to no longer be used, it must not be left in place but remove,

to prevent it from possibly failing.

- Always check that all the electrical parts (lights, exhaust device), are o when the appliance is not being used.

- This appliance is not intended for use by young children or inrm persons unless they have been adequately

supervised by a responsible person to ensure that they can use the appliance safely. Young children should be

supervised to ensure they do not play with the appliance.

- To reduce the risk of re or electric shock, do not use this fan with any solid-state speed control device.

- Do not connect the appliance to ues (from boilers, replaces, etc.).

- Do not discard the packaging or any part of it, or leave it unattended.

It can constitute a suocation hazard for children, especially the plastic bags.

- Do not ambé under the Range Hood.

- Never cook on “open” ames under the Range Hood.

- Do not leave open, unattended ames under the Range Hood.

-

Do not switch “OFF” or “ON” the Range Hood when there may be a gas leak in your gas hob. Gas explosion may result in.

- Do not handle the Power Plug with wet hand, otherwise it may cause electric shock.

- Do not disassemble the unit for reconstruction.

33

/64"

(13mm).

ENGLISH

5

Page 6

CAUTION

- Use the neutral detergent only.

- For residential use only.

- The minimum distance between supporting surface for the cooking vessels on the hob and lowest part of the Range Hood

must be at least 25 9⁄16" (650 mm).

- To reduce risk of re and to properly exhaust air, be sure to duct air outside.

- Before the appliance is put into operation, all the protective lm must be removed.

- Check whether the Range Hood is installed securely and horizontally.

- Always operate the Range Hood when using gas cooker.

- Avoid parts from falling when detaching it for cleaning.

- Ensure that the wires inside the Range Hood are not disconnected or cut:

in the event of damage, contact your nearest Servicing Department.

- When disconnect the Power Plug, hold the plug itself. Do not pull the cord anyway.

The cord may be damaged, it may cause re or electric shock.

- Be sure to disconnect the Power Plug from the wall outlet or switch o the breaker when not using for a long time.

- Product must be installed on the wall, which is strong enough to hold the unit. Reinforce it if necessary.

- The Range Hood should be installed so that the metal part of the product and mounting screw do not contact with any metalic item

inside the wall, such as metal laths, wire laths and metal plate, it is possible to cause re harzards in case of electrical leak.

- During installation, always use personal protective equipment (e.g.: Safety shoes, gloves) and adopt prudent and proper conduct.

- Please wear gloves during the cleaning work.

- Make sure that the electric service supply voltage is AC 120 V, 60 Hz.

- Protect the supply wiring from sharp edges, oil, grease, hot surfaces, chemicals or other objects.

- Suitable for use in a household cooking zone.

- Before installing the Range Hood, check the integrity and function of each part.

Should anomalies be noted, do not proceed with installation and contact the Dealer.

- Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

- For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

- It is dangerous to modify or attempt to modify the characteristics of this system.

In the event of malfunctions or if repairs are required to the appliance, do not attempt to solve the problems directly. Repairs

performed by unqualied persons may cause damage. For all repair and other work on the appliance, contact the service centre.

- Insist on original spare parts.

- Do not insert pointed metal objects (cultery or utensils) into any aperture in the Range Hood.

- Do not use a steam cleaner for cleaning the appliance. The steam could reach the electronics, damaging them and causing

short-circuits.

- Do not use too much moisture or water around the push button control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

- Do not clean electrical parts, or parts related to the motor inside the Range Hood, with liquids or solvents.

- Never use petrol, benzene, thinner or any other similar chemicals to clean the product.

- Do not use abrasive products.

- Do not carry out any cleaning operations when parts of the Range Hood are still hot.

- Never use the product in a wet place. It may cause re or failure.

- During operation, never insert ngers or other objects into any aperture in the Range Hood. Failure or injury may result in.

- Do not put anything on the Range Hood. It may cause re, failure or injury.

- Do not kink the supply wiring.

- Never use the Range Hood without the metal lters:

in this case, grease and dirt will deposit in the equipment and compromise its operation.

6

Page 7

SUPPLIED ACCESSORIES

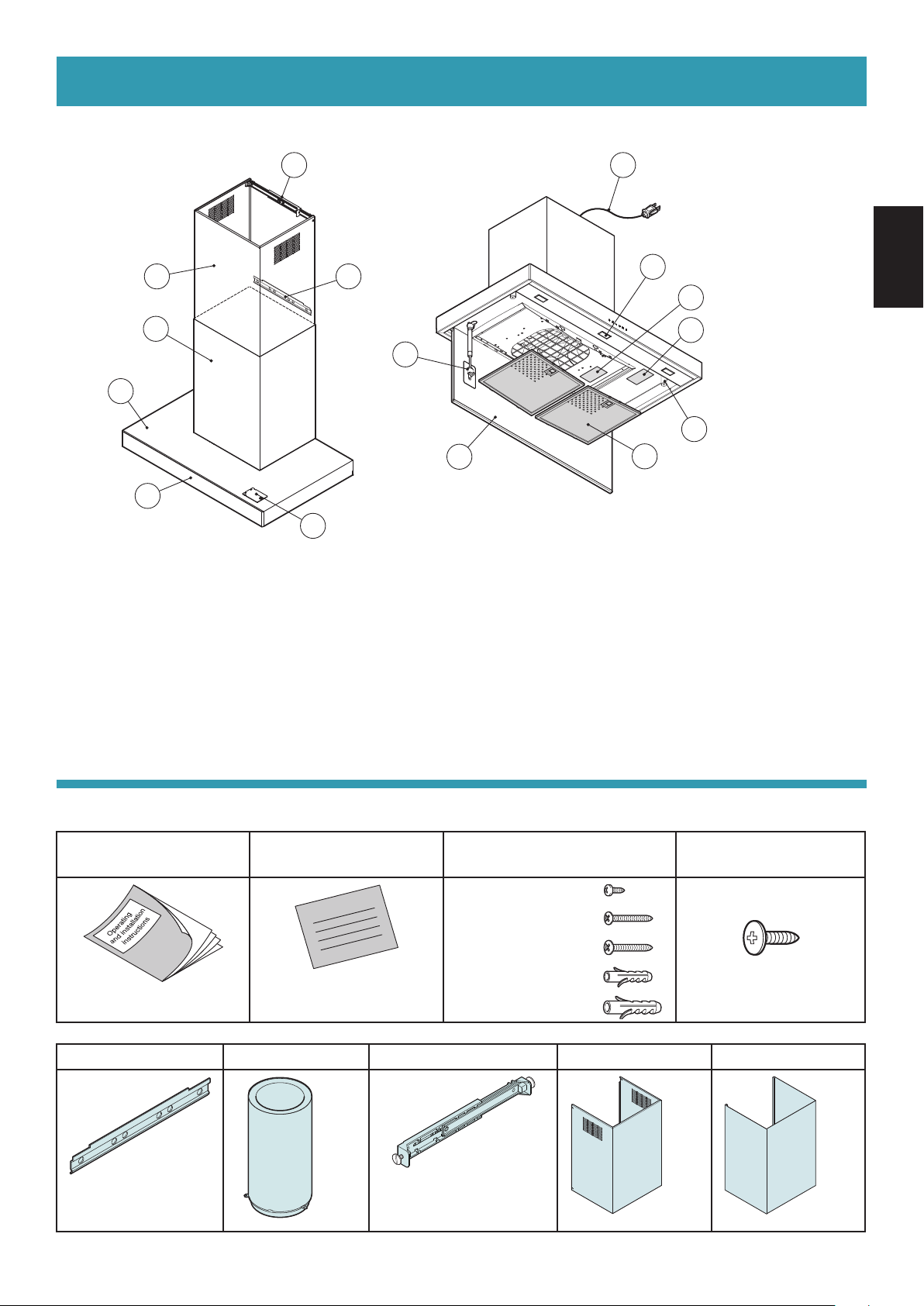

Part identication :

1 13

122

3

4

5

14

1 - Bracket

2 - Extension

3 - Chimney

4 - Range Hood body

5 - Electronic push button control panel

6 - LED spotlight illumination x 2 (FV-30RCQL1)

x 3 (FV-36RCQL1)

6

(FV-30RCQL1)

11

(FV-36RCQL1)

11

8

9

7

10

7 - Perimeter suction panel

8 - Piston bar

9 - Magnet x 2

10 - Metal lter x 2

11 - Name plate

12 - Support bar

13 - Power cord

14 - Module support for add-on Module that provides additional

features (Module sold separately)

ENGLISH

Supplied accessories :

A - Operating and

installation instructions

1 pc

B - Warranty sheet C - Screw pack 1 D - Screw pack 2

Ø3.9 x 9.5 mm (10 pcs)

Warranty sheet

2 pcs

Ø4.5 x 40 mm (4 pcs)

Ø5 x 50 mm (2 pcs)

Ø6 wall plug (4 pcs)

Ø8 wall plug (2 pcs)

Ø4.2 x 12.5 mm (3 pcs)

E - Support bar F - Pipe G - Bracket H - Extension I - Chimney

1 pc

1 pc

Wall plugs are for solid brickwork or solid concrete.

1 pc

2 screws

Ø4 x 7 mm

1 pc

1 pc

7

Page 8

OPERATION

1

2

3

1

212

1

2

3

Key No.

1 2 3 4 5 6

Key 1 : [ Function ] Filter alarm / Timer

The BLUE lighting indicates that the metal lter alarm is active (after 30 hours); to deactivate this alarm and

reset the hour meter, press the button for 3 seconds.

The BLUE blinking indicates that the timer function is active. This function can be activated only if the motor

is already active with any speed when the key is pressed. This function activates the auto power o function

of the Range Hood after 15 minutes. The Range Hood can be turned o by the user and the function will be

disabled.

Key 2 : [ Function ] On (1st Speed) / O motor / 24 hours function

Press the key to select the 1st speed (the BLUE lighting).

When the 1st speed is on and the key is pressed, both the LED and MOTOR will turn o.

If the motor is active with any speed, to turn o the Range Hood, press key 2 twice.

When the LED is o, if the key is pressed for at least 3 sec, the 24 hours function activates.

During the 24 hours function (which lasts 24 hours), the LED blinks.

From the activation of this function, the Range Hood will remain active for 1 hour at 1st speed, then it will stop

for 3 hours and reactivate for another hour. These cycles are repeated until timeout. With activation of this

function, other speeds may not be selected. To deactivate this function, keep key 2 pressed for at least 3 seconds.

Key 3 : 2nd Speed

If the LED is o and another speed is active, press the key to select the 2nd speed (the BLUE lighting) and turn

the LED associated to the previously selected speed o.

If the LED is o and no speed is active, the key is disabled.

When the LED is on, key 3 is disabled.

To turn o the Range Hood, press key 2 twice.

Key 4 : 3rd Speed

If the LED is o and another speed is active, press the key to select the 3rd speed (the BLUE lighting) and turn

the LED associated to the previously selected speed o.

If the LED is o and no speed is active, the key is disabled.

When the LED is on, key 4 is disabled.

To turn o the Range Hood, press the key 2 twice.

Key 5 : 4th Speed (BLUE blinking)

If the LED is o and another speed is active, press the key to select the 4th speed (the BLUE blinking) and turn

the LED associated to the previously selected speed o.

If the LED is o and no speed is active, the key is disabled.

When the LED is on, key 5 is disabled.

The fourth speed lasts 7 minutes, then the Range Hood changes to the third speed.

To turn o the Range Hood, press key 2 twice.

Key 6 : Light

Light : Pressing key 6 will turn the light on and o. The BLUE lighting if the light is on.

8

Page 9

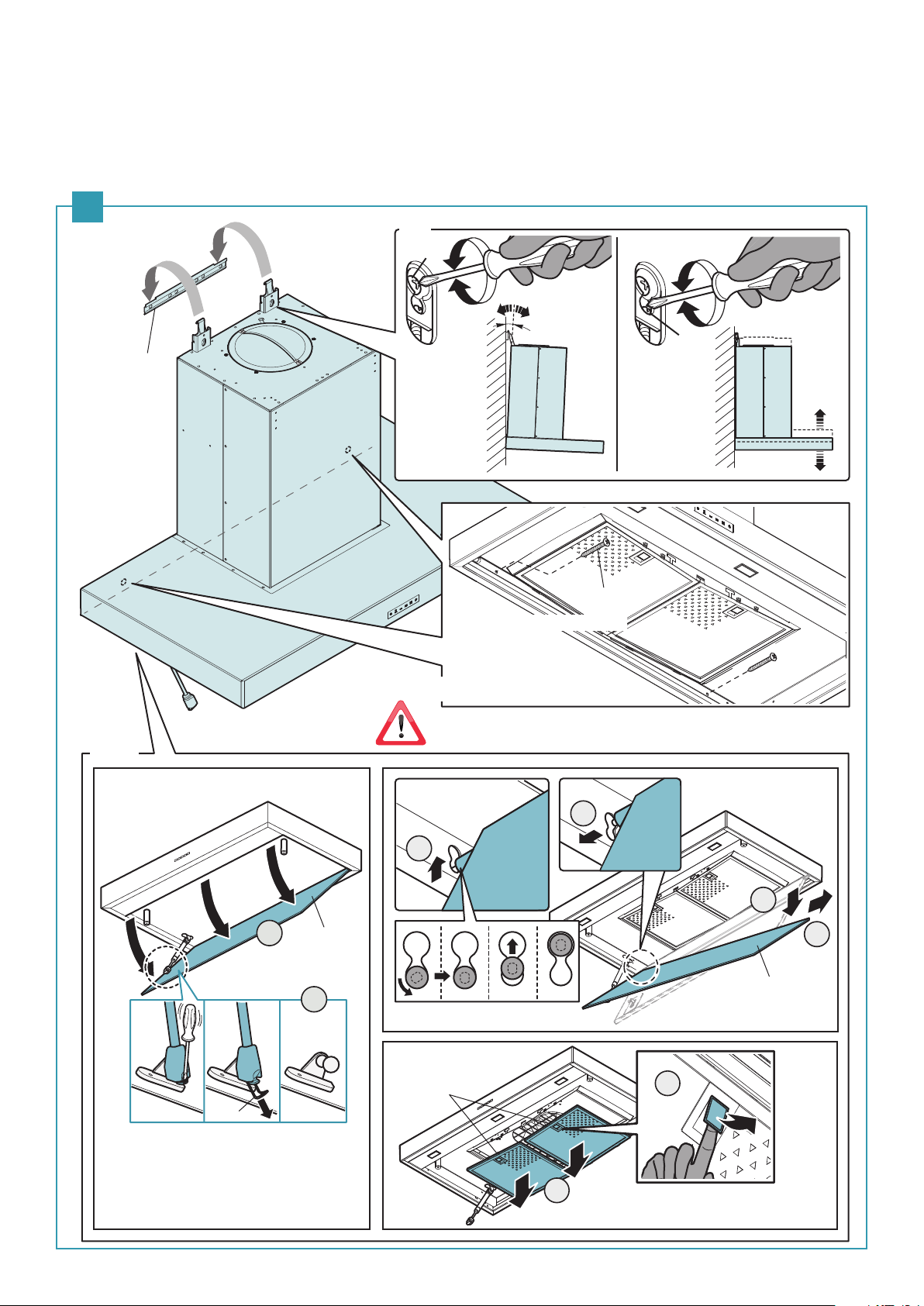

MAINTENANCE

WARNING

Before servicing or cleaning unit, switch power o at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

CAUTION

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal lters : frequent cleaning of the metal lters and their supports ensures that no

ammable grease is accumulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the Range Hood at least once every 15 days to prevent oily substances and

grease from sticking to them.

Alternatively and for all the other types of surfaces, it can be cleaned using a damp cloth, slightly moistened with mild,

liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use products that contain abrasive substances or cloths NOT specically designed for cleaning steel.

The glass panels can only be cleaned with specic, non-corrosive or non-abrasive detergents using a soft cloth.

The Manufacturer declines all responsibility for failure to comply with these instructions.

CAUTION

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside the Range Hood, with liquids or solvents.

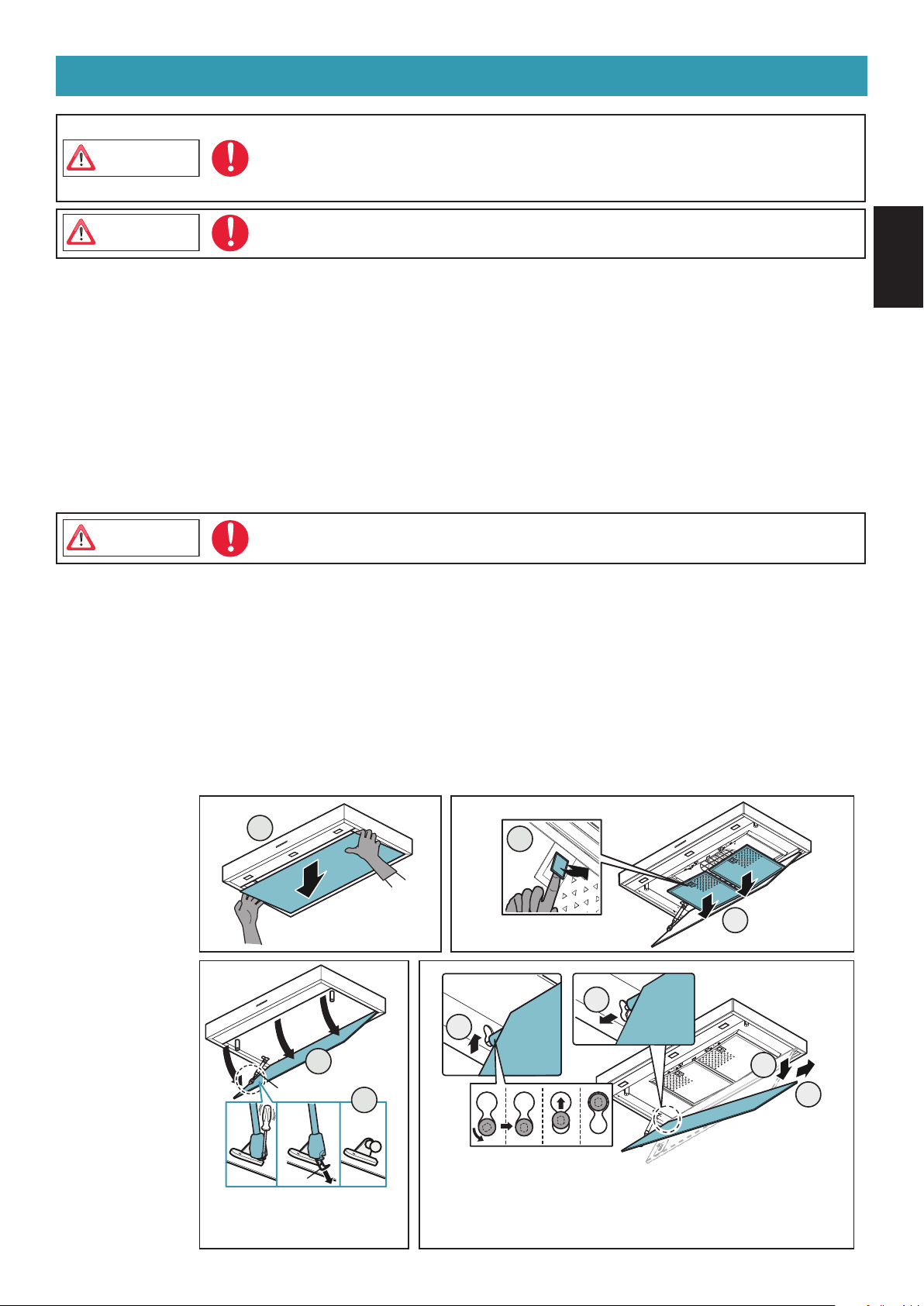

METAL FILTERS

It is advised to frequently wash the metal lters (at least once a month) leaving them to soak in boiling water and cleaning

solution for 1 hour, taking care not to bend them.

- Do not use corrosive, acid or alkaline detergents.

- Rinse them well and wait for them to be completely dry before reassembling them.

- Washing in a dishwasher is permitted, however, it may cause the metal lter material to darken : to reduce the possibility of

this problem from happening, use low-temperature washes (131 °F/ 55 °C max.).

To remove the perimeter suction panel and the metal lters as shown gure below.

Please wear gloves during the cleaning work.

Be careful when removing the perimeter suction panel in case oil has accumulated on it and

may fall out.

ENGLISH

How to remove of the

metal lters

How to remove of

the perimeter suction

panel

1

1

Piston bar

pin

Please slowly remove the pin

while supporting it with

ngers so that it will not fall.

2

2

3

4

3

5

6

Be sure to check that the pin is attached to the piston bar to

reassemble the perimeter suction panel. If not attached, the

perimeter suction panel cannot be supported at the specied

position.

9

Page 10

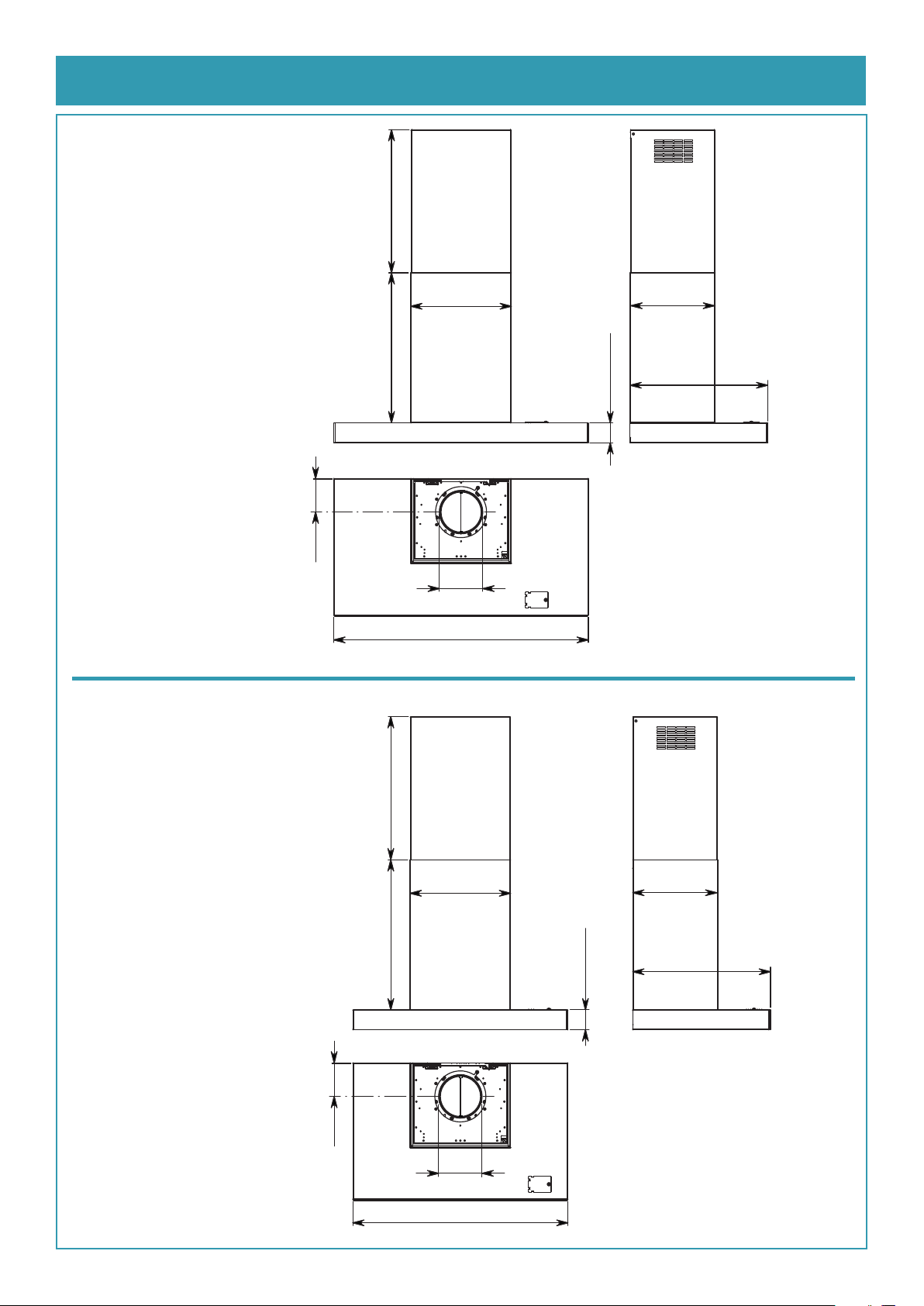

DIMENSIONS

FV-36RCQL1

max. 19 7/8"

max. 505 mm

FV-30RCQL1

4 5/8"

118 mm

529 mm

20 13/16"

14”

355 mm

Ø5 7/8"

Ø150mm

35 3/8"

900 mm

11 13/16"

300 mm

2 3/4" - 70 mm

19 1/8"

486 mm

4 5/8"

118 mm

max. 19 7/8"

max. 505 mm

529 mm

20 13/16"

Ø150 mm

14”

355 mm

Ø5 7/8"

29 7/8"

759 mm

11 13/16"

300 mm

19 1/8"

486 mm

2 3/4" - 70 mm

10

Page 11

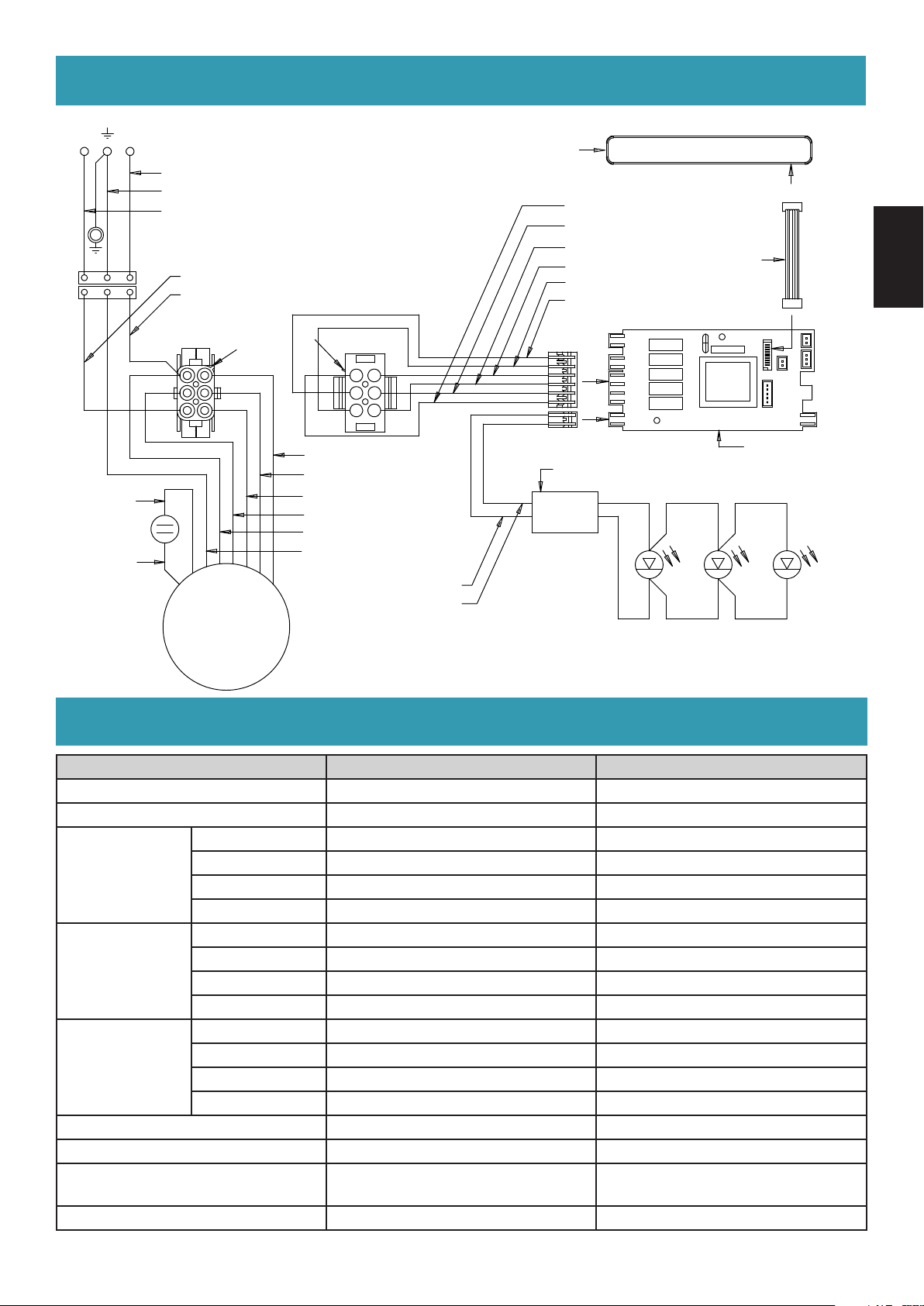

WIRING DIAGRAM

NL

WHITE

GREEN

BLACK

BROWN

BLUE

CONTROL PANEL

WHITE (2° SPEED)

ORANGE (4° SPEED)

GRAY (LINE)

RED (NEUTRAL)

BLACK (3° SPEED)

BLUE (1° SPEED)

5 V

FLAT CABLE

ENGLISH

PIN

REAR VIEW

1

2

3

WHITE (2° SPEED)

BLUE (1° SPEED)

GRAY (3° SPEED)

BLACK (4° SPEED)

RED

YELLOW - GREEN

4

5

6

MAIN BOARD

TRANSFORMER

12 V

BROWN

BLUE

LED LIGHT SPOT

BROWN

YELLOW

REAR VIEW

4

5

6

PIN

1

2

3

M

~

SPECIFICATIONS

Model No. FV-36RCQL1 FV-30RCQL1

Voltage AC 120V AC 120V

Frequency 60 Hz 60 Hz

4th Speed 328 331

Power (W)

Air Volume

at 0.1" WG

(CFM)

Noise (sones)

Lamp 1.2 W x 3 1.2 W x 2

Pipe Diameter Ø8" ( Ø203 mm ) Ø8" ( Ø203 mm )

Dimension (L x W x H)

Weight 75 lb. (34 kg) 71 lb. (32 kg)

3rd Speed 226 227

2nd Speed 180 182

1st Speed 137 147

4th Speed 440 440

3rd Speed 340 340

2nd Speed 240 240

1st Speed 130 130

4th Speed 4.0 4.5

3rd Speed 2.0 3.0

2nd Speed 0.9 1.0

1st Speed <0.3 <0.3

35 3/8" x 19 1/8" x 23 37/64"

( 900 mm x 486 mm x 600 mm )

29 7/8" x 19 1/8" x 23 37/64"

( 759 mm x 486 mm x 600 mm )

HVI Certied performance based on HVI Procedures 915, 916, and 920.

11

Page 12

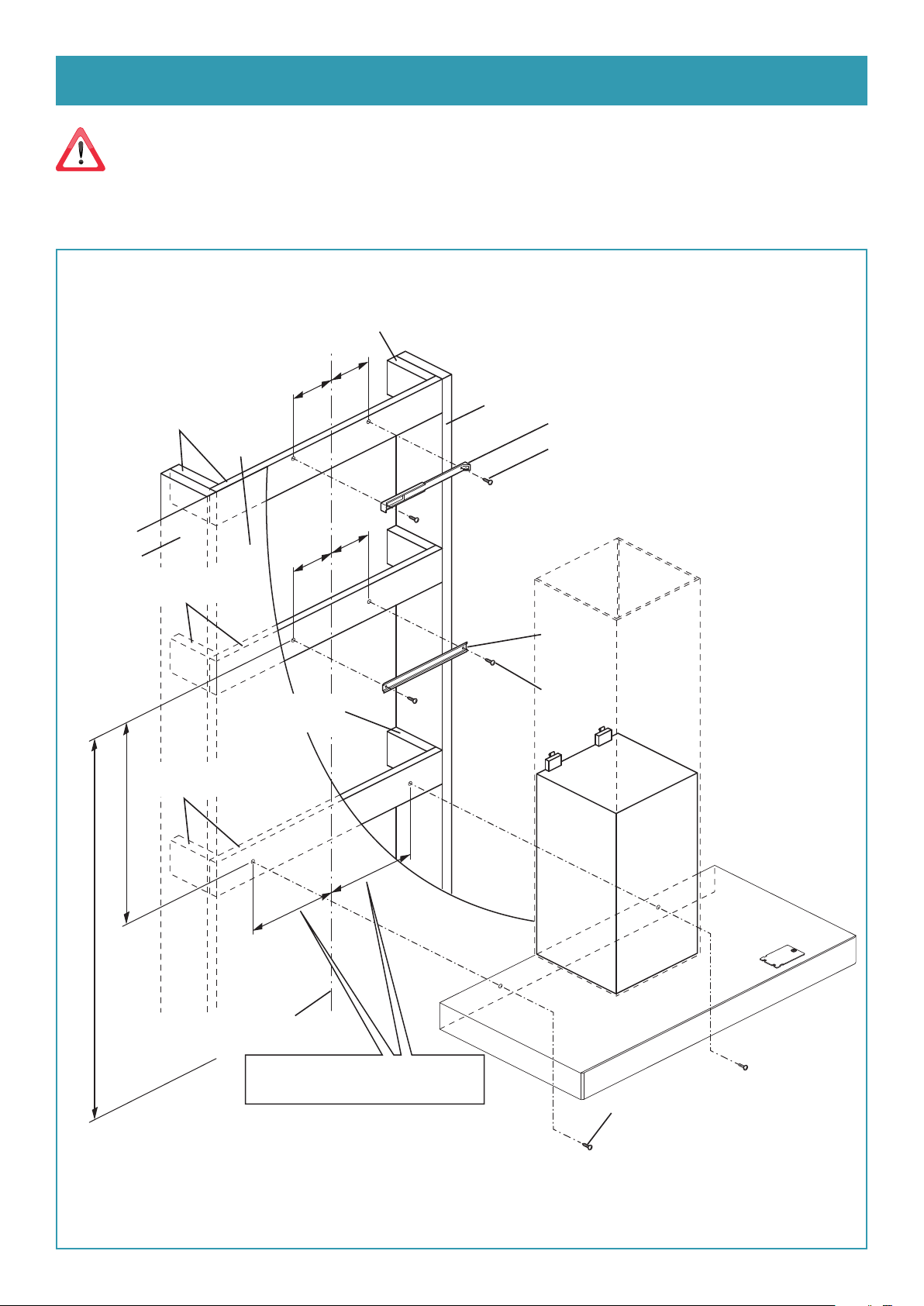

INSTALLATION

Before installing the Range Hood, carefully read chap. "GENERAL SAFETY INFORMATION".

Installation preparation

Additionally install reinforcement wooden frames between the studs behind the dry wall.

Measure the height B referring to Fig. A in next page.

Reinforcement wooden frame

3 15/16"

3 15/16"

Reinforcement wooden frame

Dry wall

154.5

mm

154.5

mm

Stud

Bracket

V6

2 - Ø4.5x40

B

Stud

Reinforcement

wooden frame

Reinforcement

wooden frame

548 mm

21 9/16"

4 1/64"

102

mm

Reinforcement

wooden frame

X

4 1/64"

102

mm

Support bar

V1

2 - Ø5x50

X

12

Top of

the cooking surface

Centerline

FV-30RCQL1 : 10 11/16" (272 mm)

X =

FV-36RCQL1 : 11 7/16" (290 mm)

V2

2 - Ø4.5x40

Page 13

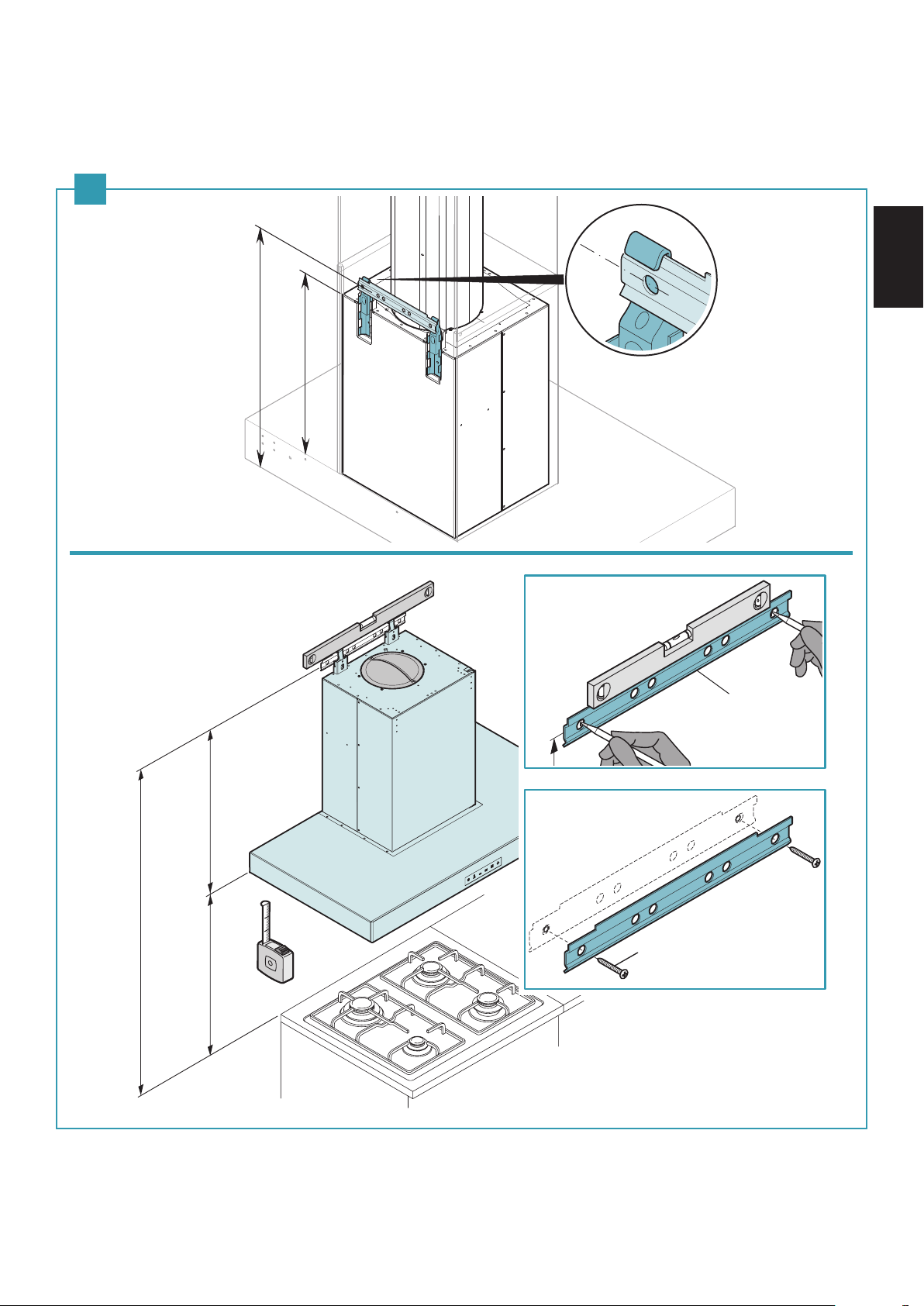

Phase 1 (Fig. A)

(1) Place the support bar (A) on the wall at a height B from the cooking surface resulting from the sum of the quotas :

C + 22 15/16" (582 mm).

(2) With a spirit level, verify the horizontal alignment;

(3) Mark 2 screw positions at the ends of support bar.

(4) Fasten the support bar (A) with the 2 relative screws (V1 Ø5x50).

A

582 mm

22 15/16”

460 mm

18 1/18”

ENGLISH

B

22 15/16”

( 582 mm )

C

Min. 25 9/16”

( Min. 650 mm )

(1)

(2)

(2)

(3)

A

(3)

(4)

V1

2 - Ø5x50

13

Page 14

D

Phase 2 (Fig. B)

(1) Hook the Range Hood on the support bar (A).

(2) Adjust the alignment of the Range Hood, using the xing screws. The upper screw (D) adjusts the distance from the wall, the

lower one (E) the vertical scrolling.

(3) Remove the perimeter suction panel (F) and the metal lters (G).

(4) To prevent the Range Hood from falling due to a pressure below, fasten it to the wall with 2 relative screw (V2 Ø4.5x40) using

the appropriate holes on the back of the Range Hood.

B

(1)

A

(2)

E

(3)

V2

2 - Ø4.5 x 40

(4)

Mandatory safety screws

4

3

5

1

F

2

6

F

14

Pin

Please slowly remove the pin while

supporting it with ngers so that it

will not fall.

G

7

8

Metal lter protective lm must be removed.

Page 15

J

K

K

L

H

(1)

(2)

(3)

Ø8”

(Ø203 mm)

28” (711 mm)

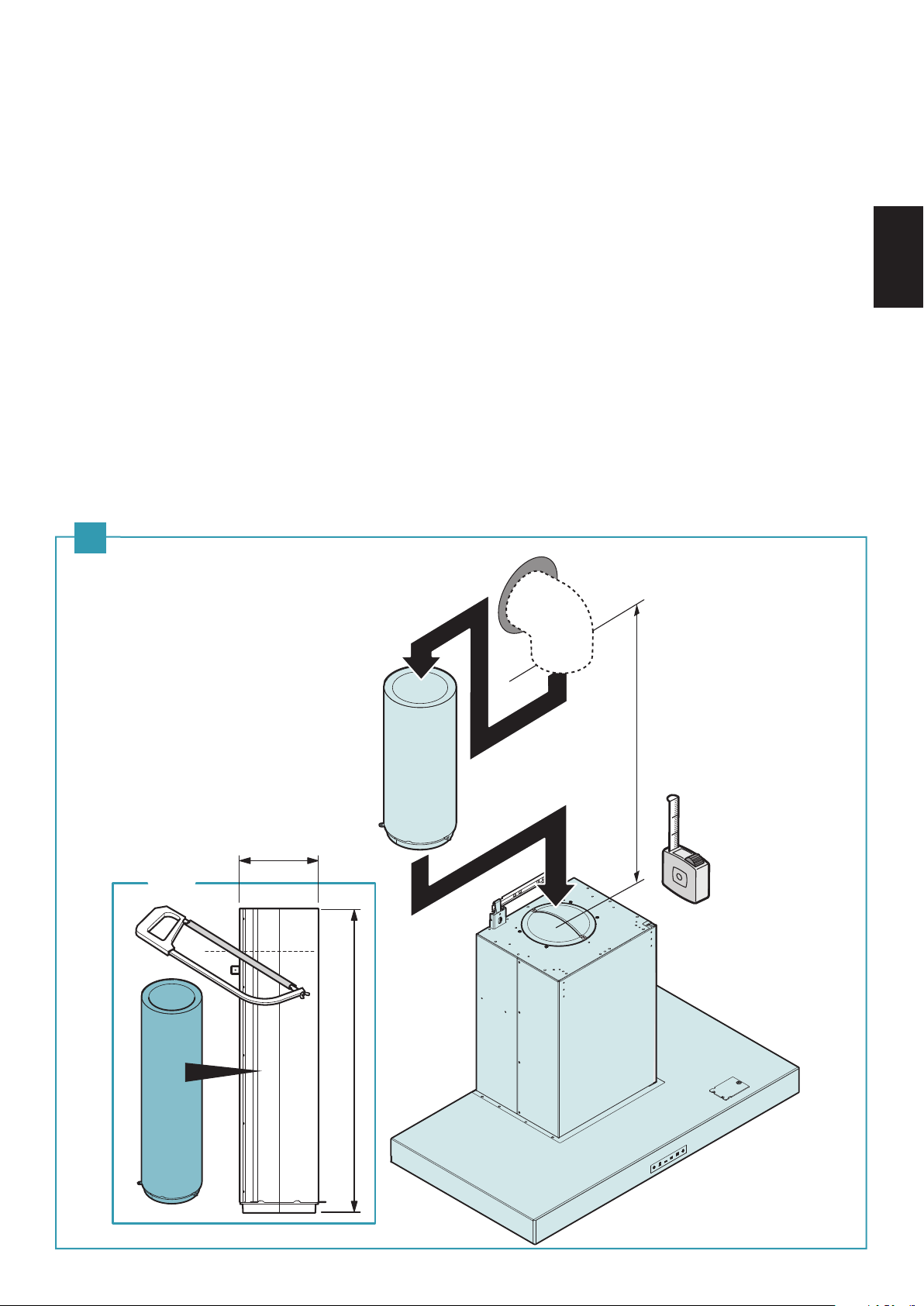

Phase 3 (Fig. C)

Connect the Range Hood to the external exhaust (H).

(1) Measure the height J.

(2) Cut the pipe (K) to the required length.

(3) Carefully insert the pipe (K) in the motor tting (L).

Note :

- The exhaust conveyor that protrudes from the upper part of the Range Hood must be connected with the pipe that conducts

the fumes and vapours in an external output.

- The fumes and vapours are discharged outside through the exhaust pipe.

To this end, the Range Hood outlet tting must be connected via a pipe, to an external output.

- The diameter of the fume discharge duct must be no smaller than the Range Hood connection.

- The outlet pipe must have a diameter not less than that of the Range Hood tting.

- The outlet pipe must have :

• A slight slope downwards (drop) in the horizontal sections to prevent condensation from owing back into the motor.

• The duct must be installed not to bend it in the immediate vicinity of the discharge hole. Otherwise, the return valve will get

stuck with the duct, and will not work for the exhaust properly.

• Reduce curves to the bare minimum, and check that the length of the ducts is also the bare minimum.

• You are required to insulate the pipes if it passes through cold environments.

ENGLISH

C

15

Page 16

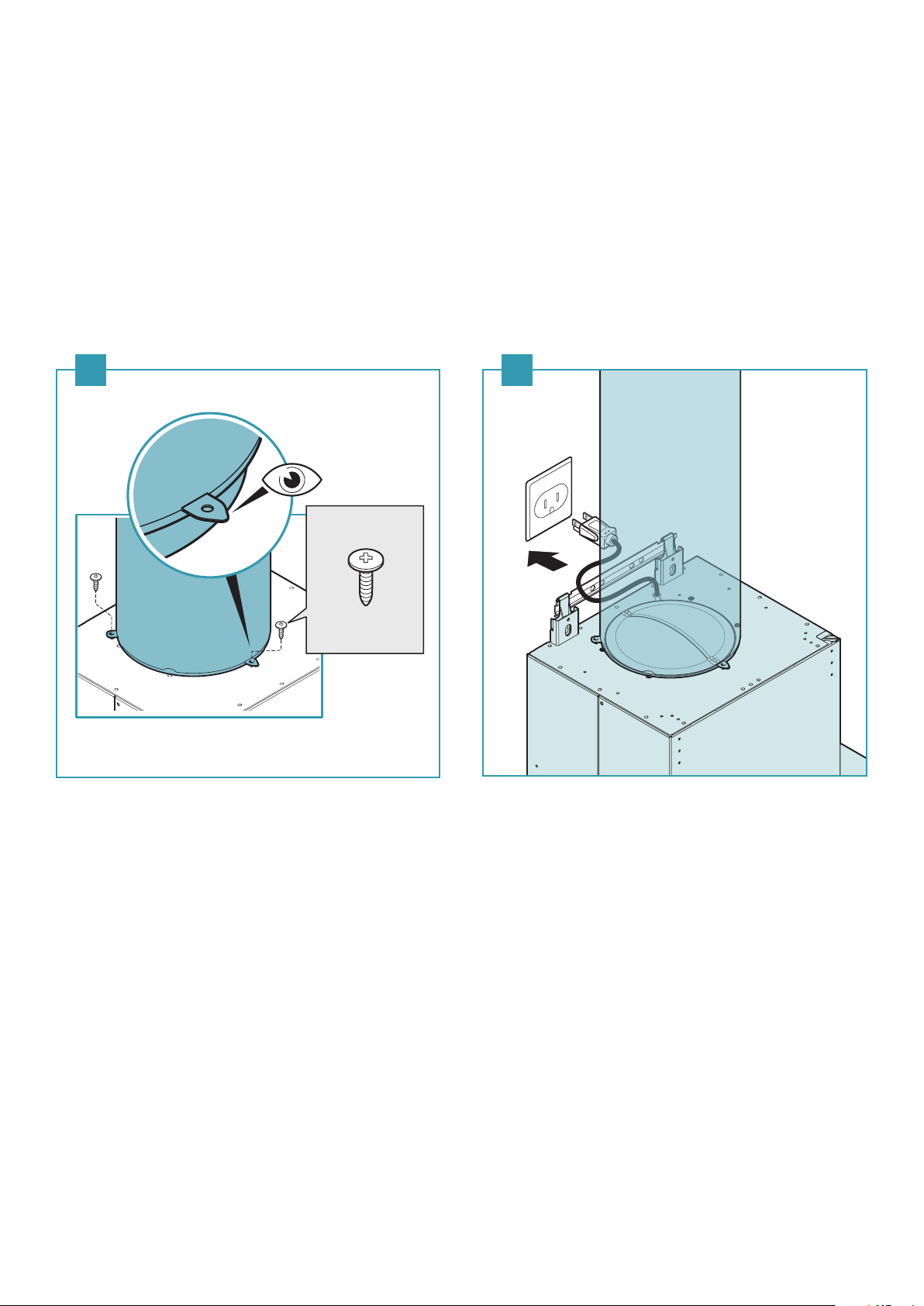

Phase 4 (Fig. D, E)

(1) Fasten the pipe (K) to the Range Hood body with the 3 screws (V3 Ø4.2x12.5).

(2) Set up the electric connection to power the Range Hood only after having disconnected the main power supply switch

and complied with current regulations.

Note :

- The electrical system to which the Range Hood is to be connected must be in accordance with local standards and supplied

with earthed connection in compliance with safety regulations in the country of use.

It must also comply with local standards regarding radio antistatic properties.

- Before connecting the Range Hood to the electrical mains power supply, check that : the power supply plug and cable do

not come into contact with temperatures exceeding 158 °F (70 °C);

- Check that the relief valve and the electrical system are able to support the load of the appliance (see the technical

specications displayed on the rated plate in the Range Hood).

D E

(2)

(1)

K

V3

3 - Ø4.2x12.5

16

Page 17

Phase 5 (Fig. F)

(1) Insert the extension (M) into the chimney (N).

(2) Fasten the chimney (N) to the Range Hood body using the screws (V4 Ø3.9x9.5).

(3) Slide the extension (M) until it reaches the desired height.

(4) Remove 2 screws (V5 Ø4x7) from the bracket (P).

Place the bracket (P) on the wall, verify the horizontal alignment with a spirit level and mark 2 screw positions at the ends.

(5) Fasten the bracket (P) with the 2 relative screws (V6 Ø4.5x40).

(6) Screw the extension (M) to the bracket (P) using the 2 screws (V5 Ø4x7).

- Power the Range Hood complying with the regulations in force.

F

V5

2 - Ø4x7

P

(4)

M

(1)

N

V4

(2)

8 - Ø3.9x9.5

ENGLISH

P

P

(5)

M

P

V6

2 - Ø4.5x40

(3)

(6)

V5

2 - Ø4x7

17

Page 18

PRODUCT SERVICE

Warning Concerning Removal of Covers. The unit should be serviced by qualied technicians only.

Your product is designed and manufactured to ensure a minimum of maintenance. Should your

unit require service or parts, call Panasonic Call Center at 1-866-292-7299 (USA) or

1-800-669-5165 (Canada).

WARNING!

The Manufacturer reserves the right to make changes to the equipment at any time and without

prior notice. Printing, translation and reproduction, even partial, of this manual are bound by the

Manufacturer's authorisation. Technical information, graphic rapresentations and specifications

in this manual are for information purposes and cannot be divulged.

Attach your purchase receipt here.

For your records :

The model number and serial number of this product can be found on the name plate in the

Range Hood. Please note them in the space provided and keep for future reference.

Model No. :

Serial No. :

Date of purchase :

Dealer's name :

Dealer's adress :

Telephone number :

Panasonic Corporation of North America

Two Riverfront Plaza, Newark, NJ 07102

www.panasonic.com

© Panasonic Corporation 2018

18

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3

www.panasonic.com

Printed in Italy

ZY02-C68

Fa1212k0

Page 19

TABLE DES MATIÈRES

CONSIGNES DE SÉCURITÉ ............................................................................................................................................................................... 20

ACCESSOIRES FOURNIS ...................................................................................................................................................................................24

FONCTIONNEMENT .......................................................................................................................................................................................... 25

MAINTENANCE ................................................................................................................................................................................................... 26

DIMENSIONS ....................................................................................................................................................................................................... 27

SCHÉMA DE CONNEXIONS ............................................................................................................................................................................28

SPÉCIFICATIONS ................................................................................................................................................................................................. 28

INSTALLATION .....................................................................................................................................................................................................29

SERVICE TECHNIQUE ....................................................................................................................................................................................... 35

FRANÇAIS

19

Page 20

CONSIGNES DE SÉCURITÉ

Pour votre sécurité

An de réduire les risques de blessure, de décès, de chocs électriques, d'incendie, de

dysfonctionnement et de dommages aux équipements ou aux biens, veuillez toujours

observer les consignes de sécurité suivantes.

Explication des panneaux de signalisation

Les panneaux de signalisation ci-dessous servent à classier et indiquer les niveaux de

risque, de blessure et de dommage aux biens résultant du non-respect de l'avertissement

et d'une utilisation inappropriée.

Indique un risque potentiel pouvant

MISE EN GARDE

ATTENTION

Les symboles suivants servent à classier et indiquer les types d'instruction à observer.

Ce symbole sert à alerter les utilisateurs de la présence d'une procédure

précise à suivre an d'utiliser l'appareil en toute sécurité.

Ce symbole sert à alerter les utilisateurs de la présence d'une procédure

d'utilisation précise à ne pas exécuter.

entraîner des blessures graves, voire

mortelles.

Indique un risque potentiel pouvant

entraîner des blessures légères.

20

Page 21

MISE EN GARDE

AFIN DE RÉDUIRE LE RISQUE D'INCENDIE DE GRAISSE SUR LA CUISINIÈRE :

a) Ne laissez jamais des unités de surface réglées sur des températures élevées sans surveillance. Les débordements

provoquent de la fumée et des résidus graisseux qui peuvent s'enammer. Faites chauer les huiles doucement,

à des températures faibles ou moyennes.

b) Mettez toujours la hotte en marche lorsque vous cuisinez à température élevée.

c) Nettoyez fréquemment les ventilateurs d'aération. La graisse ne doit pas s'accumuler sur le ventilateur ou le ltre.

d) Utilisez une poêle de taille appropriée. Utilisez toujours des ustensiles de cuisine appropriés à la taille de

l'élément de surface.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURE PHYSIQUE EN CAS D'INCENDIE DE GRAISSE SUR LA CUISINIÈRE,

RESPECTEZ LES CONSIGNES SUIVANTES :

a) ÉTOUFFEZ LES FLAMMES à l'aide d'un couvercle étanche, d'une plaque à biscuits ou d'un plateau de métal, puis

mettez le brûleur hors marche. SOYEZ ATTENTIF AFIN D'ÉVITER TOUTE BRÛLURE. Si les ammes ne s'éteignent

pas immédiatement, ÉVACUEZ ET APPELEZ LES POMPIERS.

b) NE SAISISSEZ JAMAIS UNE POÊLE ENFLAMMÉE – Vous pourriez vous brûler.

c) N'UTILISEZ PAS D'EAU, ni de serviettes ou torchons mouillés – cela entraînerait une violente explosion de vapeur.

d) Utilisez un extincteur UNIQUEMENT si :

1) Vous savez que vous disposez d'un extincteur de classe ABC et que vous savez déjà comment l'utiliser.

2) L'incendie est peu important et conné à la zone où il s'est déclaré.

3) Les pompiers ont été appelés.

4) Vous pouvez combattre l'incendie en ayant le dos à proximité d'une sortie.

Sur la base des conseils de sécurité en cas d'incendie dans une cuisine “ Kitchen Firesafety Tips ” publiés par la

NFPA.

FRANÇAIS

AFIN DE RÉDUIRE LE RISQUE D'INCENDIE, DE CHOCS ÉLECTRIQUES OU DE BLESSURES,

RESPECTEZ LES CONSIGNES SUIVANTES :

a) N'utilisez l'appareil qu'aux ns prévues et recommandées par son fabricant. Au besoin, communiquez avec ce

dernier.

b) Avant de nettoyer ou de faire la maintenance de l'appareil, coupez l'alimentation sur le panneau de service et

verrouillez le dispositif d'alimentation an de prévenir tout rétablissement accidentel. Si le verrouillage n'est pas

possible, posez un avis très visible sur le panneau de service.

CONSIGNES DE MISE À LA TERRE

a) Cet appareil doit être mis à la terre. En cas de court-circuit, le l de mise à la terre limite le risque de choc électrique

parce qu'il assure le retour du courant à la terre. L'appareil est livré avec un cordon muni d'un l de terre et d'une

che de mise à la terre, qui doit être branchée sur une prise mise à la terre correctement installée.

b) Une mise à la terre incorrecte peut entraîner des risques de choc électrique.

c) Consultez un électricien compétent en cas de doute sur ces consignes de mise à la terre ou en cas d'incertitude

concernant la mise à la terre correcte du circuit sur lequel l'appareil est branché.

d) N'utilisez pas de cordon de rallonge. Si le cordon d'alimentation est trop court, faites installer une prise par un

électricien compétent à proximité de l'appareil.

21

Page 22

MISE EN GARDE

AFIN DE RÉDUIRE LE RISQUE D'INCENDIE, DE CHOCS ÉLECTRIQUES OU DE BLESSURES,

RESPECTEZ LES CONSIGNES SUIVANTES :

a) Conez l'installation et les connexions électriques à une personne qualiée. L'installation doit être conforme aux

codes et normes applicables, y compris les normes en matière de parement pare-feu.

b) An de prévenir tout risque de contre-tirage, un ot d'air susant est requis pour assurer la combustion et

l'évacuation des gaz à travers la cheminée de tout appareil de combustion. Suivez les instructions du manufacturier

de l'équipement de chauage et observez les normes de sécurité en vigueur en matière de prévention des incendies

de même que celles des codes locaux.

c) Lors d'une découpe dans un mur ou un plafond ou lors de leur perçage, prenez garde de ne pas endommager le

câblage électrique et toute autre installation cachée.

d) Tout ventilateur canalisé doit donner directement sur l'extérieur.

- Nettoyez les ltres et toutes les surfaces sales de manière régulière.

- An d'assurer la protection contre les chocs électriques, branchez dans une prise correctement mise à la terre.

- An de réduire le risque d'incendie, utilisez uniquement un conduit en métal.

- En cas d'anomalie/de défaillance, arrêtez d'utiliser l'appareil et placez l'interrupteur d'alimentation sur “OFF” ou

retirez la che à 3 branches.

Exemple d'anomalie :

- Bruit ou chaleur anormale.

- Émission d'une odeur / de fumée anormale.

- Incendie ou inammation d'huile.

- Insérez la che d'alimentation solidement, sinon cela peut entraîner un incendie ou un choc électrique.

- Le cordon d'alimentation doit être correctement disposé pour ne pas être endommagé. Le fabricant décline toute

responsabilité en cas de non-respect des normes de sécurité.

- La prise utilisée pour le branchement électrique doit être facilement accessible avec l'appareil installé : si cela

n'était pas possible, prévoyez un interrupteur général pour déconnecter la hotte en cas de besoin.

- Les chevilles murales doivent avoir une bonne prise.

- Les vis et chevilles murales jointes sont adaptées aux briques ou au béton solide. Utilisez des éléments de xation

appropriés en cas d'autres structures (telles que des plaques de plâtre, du béton poreux ou des briques poreuses).

- La longueur maximum de la vis de xation de la cheminée (fournie par le fabricant) est de 13 mm (33/64 po).

L'utilisation de vis non conformes avec les présentes instructions peut comporter des risques de nature électrique.

- Tenez compte du fait que l'installation avec des systèmes de xation diérents de ceux fournis ou non conformes

peut comporter des risques de nature électrique et de tenue mécanique.

- Nettoyez régulièrement la prise électrique à l'aide d'un chion sec, car cela pourrait sinon entraîner une isolation

insusante due à l'humidité, et provoquer un incendie.

- Un risque d'incendie existe si le nettoyage n'est pas eectué conformément aux instructions.

- Les pièces accessibles peuvent devenir chaudes lorsqu'elles sont utilisées avec des appareils de cuisson.

- Contrôlez les friteuses pendant l'utilisation : l'huile surchauée pourrait s'enammer.

- Lorsque le produit n'est plus utilisé, il ne doit pas être laissé en place mais retiré an d'empêcher sa chute

probable.

- Vériez toujours que tous les composants électriques (éclairage, dispositifs d'aspiration) sont hors marche lorsque

vous n'utilisez pas l'appareil.

- Cet appareil n'est pas destiné à être utilisé par de jeunes enfants ou des personnes inrmes, à moins qu'ils ne

soient adéquatement supervisés par une personne responsable qui s'assure qu'ils utilisent l'appareil en toute

sécurité. Surveillez les jeunes enfants et faites en sorte qu'ils ne jouent pas avec l'appareil.

- An de réduire le risque d'incendie ou de chocs électriques, n'utilisez pas ce ventilateur avec un système de

commande électronique de la vitesse.

- Ne reliez pas l'appareil aux conduits d'évacuation des fumées dues à la combustion (chaudières, cheminées, etc.).

- Ne vous débarrassez pas de l'emballage ou d'une de ses parties, et ne le laissez pas sans surveillance. Il peut

représenter un danger de suocation pour les enfants, en particulier les sacs en plastique.

- Ne faites pas de ambées sous la hotte.

- Ne faites pas cuire avec une amme “nue” en dessous de la hotte.

- Ne laissez pas de ammes nues sous la hotte.

- Ne placez pas l'interrupteur de la hotte de cuisine sur “OFF” ou “ON” lorsqu'un risque de fuite de gaz se présente

dans votre plaque de cuisson au gaz. Cela peut provoquer une explosion de gaz.

- Ne manipulez pas la che d'alimentation avec les mains mouillées, sinon cela peut entraîner un choc électrique.

- Ne démontez pas l'appareil pour le reconstruire.

22

Page 23

ATTENTION

- Utilisez un détergent neutre uniquement.

- Pour emploi domestique seulement.

- La distance minimale entre la surface d'appui du récipient de cuisson sur la plaque et la partie la plus basse de la hotte doit être d'au

moins 650 mm (25 9⁄16 po).

- Pour réduire le risque d'incendie et pour évacuer correctement l'air, veuillez à évacuer l'air vers l'extérieur.

- Avant de mettre l'appareil en marche, toute pellicule de protection doit être retirée.

- Vériez que la hotte est installée solidement et horizontalement.

- Faites toujours fonctionner la hotte lors de l'utilisation d'une cuisinière au gaz.

- Empêchez les pièces de tomber lorsque vous les détachez pour nettoyer.

- Veiller à ce que les ls électriques à l'intérieur de la hotte ne soient pas débranchés ou coupés : dans le cas contraire, contacter le

centre de service le plus proche.

- Lorsque vous débranchez la che d'alimentation, tenez-la fermement. Ne tirez en aucun cas sur le cordon. Le cordon risque d'être

endommagé, ce qui peut provoquer un incendie ou un choc électrique.

- Assurez-vous de débrancher la che d'alimentation de la prise murale ou de désactiver le disjoncteur lorsque l'appareil n'est pas

utilisé pendant une longue période.

- Le produit doit être installé sur un mur assez solide pour supporter l'appareil. Renforcez-le si nécessaire.

- La hotte doit être installée de façon que les pièces métalliques du produit et les vis de montage ne soient pas en contact avec

un élément métallique à l'intérieur du mur, tel qu'un support métallique d'enduit, un chemin de câble et une plaque métallique, car

cela peut entraîner un risque d'incendie en cas de fuite électrique.

- Pendant l'installation, utilisez toujours des équipements de protection individuelle (ex. : des chaussures de sécurité, des gants) et

adoptez un comportement prudent et correct.

- Il est également recommandé de porter des gants lors du nettoyage.

- Assurez-vous que la tension nominale de l'alimentation secteur est 120 V c.a., 60 Hz.

- Protégez le cordon d'alimentation contre les arêtes vives, les lubriants, la graisse, les surfaces chaudes, les substances chimiques ou

tout objet susceptible de l'endommager.

- Convient à l'emploi dans une zone de cuisson domestique.

- Avant d'installer la hotte, vériez l'intégrité et la fonctionnalité de chaque partie : en cas de présence d'anomalies, ne procédez pas

à l'installation et contactez le revendeur.

FRANÇAIS

- N'évacuez pas l'air vicié dans des espaces situés entre des murs ou des plafonds ou dans des greniers, des vides sanitaires ou des

garages.

- Pour ventilation générale seulement. N'utilisez pas pour l'évacuation de vapeurs ou de matériaux dangereux ou explosifs.

- Il est dangereux de modier ou de tenter de modier les caractéristiques de ce système. En cas de dysfonctionnement ou si des

réparations de l'appareil sont nécessaires, n'essayez pas de résoudre les problèmes par vous-même. Les réparations eectuées par

des personnes non qualiées peuvent causer des dommages. Pour tous travaux de réparation et autres sur l'appareil, contactez le

centre de service.

- Exigez des pièces de rechange d'origine.

- N'insérez pas d'objets métalliques pointus (couverts ou ustensiles) dans une ouverture de la hotte de cuisine.

- N'utilisez pas de nettoyeur à vapeur pour le nettoyage de l'appareil. La vapeur peut atteindre les pièces électroniques et les

endommager, entraînant des courts-circuits.

- N'utilisez pas trop d'eau à proximité du panneau de commande à bouton-poussoir et des dispositifs d'éclairage pour éviter

que l'humidité atteigne des parties électroniques.

- Il est interdit de nettoyer les parties électriques ou celles relatives au moteur à l'intérieur de la hotte, avec des liquides ou des

solvants.

- N'utilisez jamais de pétrole, de benzène, de diluant ou autre produit chimique similaire pour le nettoyage du produit.

- N'utilisez pas de produits contenant des substances abrasives.

- N'eectuez pas d'opérations de nettoyage si des parties de la hotte sont encore chaudes.

- N'utilisez jamais le produit dans un endroit humide. Cela peut entraîner un incendie ou une défaillance.

- Lors du fonctionnement, n'insérez jamais les doigts ou d'autres objets dans une ouverture de la hotte. Cela peut provoquer une

défaillance ou des blessures.

- Ne posez rien sur la hotte de cuisine. Cela peut entraîner un incendie, une défaillance ou des blessures.

- Ne pliez pas le cordon d'alimentation.

- N'utilisez jamais la hotte sans les ltres métalliques; dans ce cas, la graisse et la saleté se déposeraient dans l'appareil et

compromettrait son fonctionnement.

23

Page 24

ACCESSOIRES FOURNIS

Identication des pièces :

1 13

122

3

4

5

14

1 - Support

2 - Prolongement

3 - Cheminée

4 - Boîtier de la hotte

5 - Panneau de commande à bouton-poussoir

6 - Lampe d'éclairage à DEL x 2 (FV-30RCQL1)

x 3 (FV-36RCQL1)

6

(FV-30RCQL1)

11

(FV-36RCQL1)

11

8

9

7

10

7 - Panneau périmétrique d'aspiration

8 - Barre de piston

9 - Aimant x 2

10 - Filtre métallique x 2

11 - Plaque signalétique

12 - Barre de support

13 - Cordon d'alimentation

14 - Support de module pour le module orant des caractéristiques

supplémentaires (vendu séparément)

Accessoires fournis :

A - Mode d'emploi et

B - Garantie C - Emballage de vis 1 D - Emballage de vis 2

notice d'installation

Ø3,9 x 9,5 mm (10 pièces)

1 pièce

Garantie

2 pièces

Ø4,5 x 40 mm (4 pièces)

Ø5 x 50 mm (2 pièces)

Ø6 Cheville (4 pièces)

Ø8 Cheville (2 pièces)

Ø4,2 x 12,5 mm (3 pièces)

E - Barre de support F - Tube G - Support H - Prolongement I - Cheminée

1 pièce

1 pièce

Les chevilles sont adaptées pour briques ou béton solide.

1 pièce

2 vis

Ø4 x 7 mm

1 pièce

1 pièce

24

Page 25

FONCTIONNEMENT

1

2

3

1

2

1

2

1

2

3

Numéro de touche

1 2 3 4 5 6

Touche 1 : [ Fonction ] Alarme de ltre / Minuterie

Le voyant BLEU xe indique que l'alarme de ltre à graisse est déclenchée (après 30 heures); pour désactiver

cette alarme et réinitialiser le compteur d'heures, appuyez sur la touche pendant 3 secondes.

Le voyant BLEU clignotant indique que la fonction de minuterie est activée. Cette fonction ne peut être

activée que si le moteur est déjà en marche, à n'importe quelle vitesse, lorsque vous appuyez sur la touche.

Cette fonction active la fonctionnalité d'arrêt automatique de la hotte au bout de 15 minutes. La hotte peut

être mise hors marche par l'utilisateur et la fonction sera désactivée.

Touche 2 : [ Fonction ] Mise en (1re vitesse) / Hors marche du moteur / Fonction 24 heures

Appuyez sur la touche pour sélectionner la première vitesse (voyant BLEU xe).

Lorsque la première vitesse est allumé, une pression sur la touche éteint aussi bien le voyant que le moteur.

Si le moteur est en marche, à n'importe quelle vitesse, pour mettre la hotte hors marche, appuyez deux fois sur

la touche 2.

Une pression sur la touche pendant au moins 3 secondes lorsque le voyant à DEL est éteint active la fonction

24 heures.

Durant la fonction 24 heures (qui dure au moins 24 heures), le voyant à DEL clignote.

À partir de l'activation de cette fonction, la hotte restera en marche pendant une heure à la 1re vitesse, puis se

mettra hors marche pendant trois heures et se réactivera pendant une heure. Ces cycles seront répétés jusqu'à

expiration du temps. Lorsque cette fonction est activée, il n'est pas possible de sélectionner d'autres vitesses.

Pour désactiver cette fonction, maintenez la touche 2 enfoncée pendant au moins 3 secondes.

FRANÇAIS

Touche 3 : 2e vitesse

Si le voyant est éteint et une autre vitesse est activée, appuyez sur la touche pour sélectionner la deuxième vitesse

(voyant BLEU xe) et éteindre le voyant associé à la vitesse précédente.

Si le voyant est éteint et si aucune vitesse n'est activée, la touche est désactivée.

Lorsque le voyant est allumé, la touche 3 est désactivée.

Pour mettre la hotte hors marche, appuyez deux fois sur la touche 2.

Touche 4 : 3e vitesse

Si le voyant est éteint et une autre vitesse est activée, appuyez sur la touche pour sélectionner la troisième vitesse

(voyant BLEU xe) et éteindre le voyant associé à la vitesse précédente.

Si le voyant est éteint et si aucune vitesse n'est activée, la touche est désactivée.

Lorsque le voyant est allumé, la touche 4 est désactivée.

Pour mettre la hotte hors marche, appuyez deux fois sur la touche 2.

Touche 5 : 4e vitesse (Voyant BLEU clignotant)

Si le voyant est éteint et une autre vitesse est activée, appuyez sur la touche pour sélectionner la quatrième

vitesse (voyant BLEU clignotant) et éteindre le voyant associé à la vitesse précédente.

Si le voyant est éteint et si aucune vitesse n'est activée, la touche est désactivée.

Lorsque le voyant est allumé, la touche 5 est désactivée.

La quatrième vitesse dure 7 minutes, puis la hotte de cuisine passe à la troisième vitesse.

Pour mettre la hotte hors marche, appuyez deux fois sur la touche 2.

Touche 6 : Éclairage

Éclairage : Appuyez sur la touche 6 pour allumer et éteindre la lampe. Le voyant BLEU xe si la lampe est allumée.

25

Page 26

MAINTENANCE

MISE EN GARDE

Avant de nettoyer ou de faire la maintenance de l'appareil, coupez l'alimentation sur le

panneau de service et verrouillez le dispositif d'alimentation an de prévenir tout

rétablissement accidentel. Si le verrouillage n'est pas possible, posez un avis très visible sur le

panneau de service.

ATTENTION

Un entretien constant garantit un bon fonctionnement et un bon rendement dans le temps.

Il faut accorder une attention particulière aux ltres métalliques : le nettoyage fréquent des ltres métalliques et de leurs

supports fait en sorte que les graisses inammables ne s'accumulent pas.

NETTOYAGE DES SURFACES EXTERNES

Il est conseillé de nettoyer les surfaces externes de la hotte au moins tous les 15 jours an d'éviter que les substances huileuses

ou grasses ne puissent les attaquer.

Sinon, pour tous les autres types de surface, le nettoyage doit être eectué en utilisant un chion humide légèrement

imprégné d'un détergent liquide neutre ou avec de l'alcool dénaturé.

Terminez le nettoyage en rinçant et en essuyant soigneusement avec des chions doux.

N'utilisez pas de produits contenant des substances abrasives, de chions rugueux ou de chions qui ne sont pas spécialement

conçus pour le nettoyage de l'acier.

Le nettoyage des panneaux en verre doit être eectué uniquement avec des détergents spéciques non corrosifs ni abrasifs

avec un chion doux.

Le fabricant décline toute responsabilité si ces instructions ne sont pas respectées.

ATTENTION

NETTOYAGE DES SURFACES INTERNES

Il est interdit d'utiliser des liquides ou des solvants pour nettoyer les parties électriques ou celles relatives au moteur à

l'intérieur de la hotte.

FILTRES MÉTALLIQUES

Il est conseillé de laver souvent les ltres métalliques (au moins tous les mois) en les laissant tremper pendant une heure

environ dans de l'eau bouillante avec un détergent à vaisselle, en évitant de les plier.

- N'utilisez pas de détergents corrosifs, acides ou alcalins.

- Rincez-les soigneusement et attendez qu'ils soient bien secs avant de les remonter.

-

Le lavage en lave-vaisselle est permis, mais il pourrait ternir le matériau des ltres métalliques : pour réduire cet inconvénient,

utiliser des lavages à basses températures (131 °F / 55 °C max.).

Retrait du panneau périmétrique d'aspiration et des ltres métalliques tel qu'illustré ci-dessous.

Comment retirer des ltres

métalliques

Il est également recommandé de porter des gants lors du nettoyage.

Soyez prudent lors du retrait du panneau périmétrique d'aspiration au cas où il y aurait de

l'huile qui pourrait tomber.

1

2

Comment retirer du

panneau périmétrique

d'aspiration

26

1

Barre de piston

2

Tige

Retirez délicatement la tige

en la tenant avec les doigts

pour ne pas l’échapper.

3

4

3

5

6

Assurez-vous que la tige est en place sur la barre de piston

lors du réassemblage du panneau périmétrique d’aspiration.

Si elle n’est pas xée, le soutien du panneau périmétrique

d’aspiration à l’endroit désigné ne sera pas possible.

Page 27

DIMENSIONS

FV-36RCQL1

max. 505 mm

max. 19 7/8 po

FV-30RCQL1

118 mm

4 5/8 po

po

529 mm

20 13/16

355 mm

14 po

Ø150mm

Ø5 7/8 po

900 mm

35 3/8 po

300 mm

11 13/16 po

486 mm

70 mm - 2 3/4 po

19 1/8 po

FRANÇAIS

po

118 mm

4 5/8

max. 505 mm

max. 19 7/8 po

529 mm

20 13/16 po

355 mm

14 po

Ø150mm

Ø5 7/8 po

759 mm

po

29 7/8

11 13/16

70 mm - 2 3/4 po

300 mm

po

486 mm

19 1/8 po

27

Page 28

SCHÉMA DE CONNEXIONS

NL

BLANC

VERT

NOIR

BRUN

BLEU

TIGE

PANNEAU DE COMMANDE

BLANC (2

ORANGE (4

GRIS (LIGNE)

ROUGE (NEUTRE)

NOIR (3

BLEU (1

e

VITESSE)

e

VITESSE)

e

VITESSE)

re

VITESSE)

5 V

CÂBLE PLAT

BRUN

JAUNE

VUE ARRIÈRE

4

5

6

M

TIGE

1

2

3

VUE ARRIÈRE

1

2

3

e

BLANC (2

BLEU (1

GRIS (3

NOIR (4

ROUGE

JAUNE - VERT

VITESSE)

re

VITESSE)

e

VITESSE)

e

VITESSE)

4

5

6

CARTE MÈRE

TRANSFORMATEUR

12 V

BRUN

BLEU

LAMPE À DEL

~

SPÉCIFICATIONS

Modèle FV-36RCQL1 FV-30RCQL1

Tension 120 V c.a. 120 V c.a.

Fréquence 60 Hz 60 Hz

Quatrième vitesse 328 331

Consommation

Électrique (W)

Débit d'air à 0,1 po

de colonne d'eau

(pi3/min)

Bruit (sone)

Lampe 1,2 W x 3 1,2 W x 2

Diamètre du conduit Ø203 mm ( Ø8 po ) Ø203 mm ( Ø8 po )

Dimensions (L x P x H)

Poids 34 kg ( 75 lb ) 32 kg ( 71 lb )

Spécications basées sur les normes HVI, conformément aux procédures 915, 916 et 920.

Troisième vitesse 226 227

Deuxième vitesse 180 182

Première vitesse 137 147

Quatrième vitesse 440 440

Troisième vitesse 340 340

Deuxième vitesse 240 240

Première vitesse 130 130

Quatrième vitesse 4,0 4,5

Troisième vitesse 2,0 3,0

Deuxième vitesse 0,9 1,0

Première vitesse <0,3 <0,3

900 mm x 486 mm x 600 mm

( 35 3/8 po x 19 1/8 po x 23 37/64 po )

759 mm x 486 mm x 600 mm

( 29 7/8 po x 19 1/8 po x 23 37/64 po )

28

Page 29

INSTALLATION

Avant d'eectuer l'installation de la hotte, lisez attentivement le chapitre. "CONSIGNES DE SÉCURITÉ".

Préparatifs d'installation

Installez également des ossatures de renfort en bois entre les montants derrière la cloison sèche.

Mesurez la hauteur B en vous référant à la Fig. A à la page suivante.

Ossature de renfort en bois

154,5

mm

po

mm

3 15/16

po

Montant

Support

V6

2 - Ø4,5x40

Ossature de renfort en bois

Cloison sèche

154,5

3 15/16

FRANÇAIS

Montant

548 mm

B

Ossature de

renfort en bois

Ossature de

renfort en bois

21 9/16 po

102

mm

4 1/64

po

Ossature de

renfort en bois

X

102

mm

4 1/64

po

Barre de

support

V1

2 - Ø5x50

X

Dessus de la surface

de cuisson

Ligne centrale

FV-30RCQL1 : 272 mm ( 10 11/16 po )

X =

FV-36RCQL1 : 290 mm ( 11 7/16 po )

V2

2 - Ø4,5x40

29

Page 30

Étape 1 (Fig. A)

(1)

Placez la barre de support (A) sur le mur à une hauteur B de la surface de cuisson résultant de la somme des valeurs :

C + 582 mm

(2) Avec un niveau à bulle, vériez l'alignement horizontal;

(3) Marquez les positions de 2 vis aux extrémités de la barre de support.

(4) Fixez la barre de support (A) avec les 2 vis (V1 Ø5x50).

(22 15/16 po).

A

582 mm

22 15/16 po

460 mm

18 1/18 po

B

582 mm

( 22 15/16 po )

C

Min. 650 mm

( Min. 25 9/16 po )

(1)

(2)

(2)

(3)

A

(3)

(4)

V1

2 - Ø5x50

30

Page 31

D

Étape 2 (Fig. B)

(1) Accrochez la hotte à la barre de support (A).

(2) Réglez l'alignement de la hotte à l'aide des vis de xation. La vis supérieure (D) permet de régler la distance de la paroi, celle

du bas (E) le décalement vertical.

(3) Retirez le panneau périmétrique d'aspiration (F) et les ltres métalliques (G).

(4)

Pour éviter que la hotte ne tombe suite à une pression du dessous, xez-la au mur avec les 2 vis (V2 Ø4,5x40) respectivement,

en utilisant les

trous prévus à l'arrière de la hotte.

B

(1)

A

(2)

E

FRANÇAIS

(3)

V2

2 - Ø4,5 x 40

(4)

Vis de sécurité obligatoires

4

3

5

1

F

2

6

F

Tige

Retirez délicatement la tige en la

tenant avec les doigts pour ne pas

l’échapper.

G

7

8

Pellicule de protection de ltre en

métal doit être retiré.

31

Page 32

Étape 3 (Fig. C)

Branchez la hotte à l'évacuation extérieure (H).

(1) Mesurez la hauteur J.

(2) Coupez le tube (K) selon la longueur requise.

(3) Insérez soigneusement le tube (K) dans le raccord du moteur (L).

Nota :

- La tuyauterie d'évacuation qui dépasse de la partie supérieure de la hotte doit être reliée au tuyau qui conduit les fumées et les

vapeurs vers la sortie externe.

- Dans cette version, les fumées et les vapeurs sont envoyées vers l'extérieur à travers un tuyau d'évacuation.

À cette n, le raccord de sortie de la hotte doit être raccordé par un tuyau à une sortie extérieure.

- Le diamètre du conduit d'évacuation des fumées ne doit pas être inférieur à la connexion de la hotte.

- Le tuyau de sortie des fumées doit avoir un diamètre supérieur à celui du raccord de la hotte.

- Le tuyau de sortie des fumées doit avoir :

・Une légère inclinaison vers le bas (chute) dans les troncons horizontaux pour éviter que, si de la condensation se forme,

celle-ci reue dans le moteur.

・Le conduit doit être installé de façon qu'il ne soit pas plié à proximité de l'orice d'évacuation. Dans le cas contraire, le

clapet anti-retour pourrait se bloquer et ne pas permettre aux gaz d'être aspirés correctement.

・Réduisez les courbes au strict minimum et vériez aussi que la longueur des conduits soit la plus courte possible.

・Il est nécessaire d'isoler la tuyauterie si elle passe par des endroits non chaués.

C

(2)

Ø203 mm

( Ø8 po )

K

(3)

H

J

(1)

L

32

K

711 mm ( 28 po )

Page 33

Étape 4 (Fig. D, E)

(1) Fixez le tube (K) au boîtier de la hotte avec les 3 vis (V3 Ø4,2x12,5).

(2)

Eectuez le branchement électrique pour l'alimentation de la hotte uniquement après avoir désactivé l'interrupteur général

et en respectant les réglementations en vigueur.

Nota :

- Le circuit électrique, auquel est reliée la hotte, doit être aux normes et muni d'un raccordement à la terre, conformément aux

normes de sécurité du pays d'utilisation; en outre, il doit être conforme aux normes locales sur l'antiparasite radio.

- Avant de raccorder la hotte au réseau électrique, vériez que la che et le cordon d'alimentation ne sont pas exposés à

des températures supérieures à 158 °F (70 °C);

- Vériez que la soupape de sûreté et le circuit électrique sont en mesure de supporter la charge de l'appareil (consultez les

spécications techniques achées sur la plaque signalétique de la hotte).

D E

(2)

(1)

FRANÇAIS

K

V3

3 - Ø4,2x12,5

33

Page 34

Étape 5 (Fig. F)

(1) Insérez le prolongement (M) dans la cheminée (N).

(2) Fixez la cheminée (N) au boîtier de la hotte au moyen des vis (V4 Ø3,9x9,5).

(3) Faites glisser le prolongement (M) jusqu'à ce qu'il atteigne la hauteur souhaitée.

(4) Retirez les 2 vis (V5 Ø4x7) du support (P).

Placez le support (P) sur le mur, vériez l'alignement horizontal avec un niveau à bulle et marquez les 2 points de forage aux

extrémités.

(5) Fixez le support (P) à l'aide de 2 vis (V6 Ø4,5x40).

(6) Vissez le prolongement (M) sur le support (P) à l'aide des 2 vis (V5 Ø4x7).

- Alimentez la hotte conformément à la réglementation en vigueur.

F

M

(1)

V5

2 - Ø4x7

P

P

(4)

P

N

V4

(2)

8 - Ø3,9x9,5

(5)

M

P

V6

2 - Ø4,5x40

(3)

(6)

34

V5

2 - Ø4x7

Page 35

SERVICE TECHNIQUE

Mise en garde à propos du retrait des couvercles. Conez toute réparation à un technicien qualié.

Votre appareil a été conçu et fabriqué pour n'exiger qu'un minimum de maintenance. Toutefois, dans le

cas où une révision ou des pièces deviendraient nécessaires, appelez le Centre d'appels Panasonic au

1-866-292-7299 (États-Unis) ou 1-800-669-5165 (Canada).

MISE EN GARDE

Le fabriquant se réserve le droit d'apporter des modications aux appareils à tout moment et sans préavis.

L'impression, la traduction et la reproduction, même partielle, du présent document doivent être autorisées

par le fabricant. Les informations techniques, les représentations graphiques et les spécications présentes

dans ce document sont indicatives et non divulguables.

Fixez le reçu d'achat ici.

FRANÇAIS

Pour vos dossiers :

Le numéro de modèle et le numéro de série de cet appareil sont situés sur la plaque signalétique

de la hotte de cuisine. Veuillez les inscrire dans l'espace prévu à cette n et les conserver pour

référence ultérieure.

Nº de modèle :

Nº de série :

Date d'achat :

Nom du détaillant :

Adresse :

Téléphone :

Panasonic Corporation of North America

Two Riverfront Plaza, Newark, NJ 07102

www.panasonic.com

© Panasonic Corporation 2018

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3

www.panasonic.com

Imprimé en Italie

ZY02-C68

Fa1212k0

35

Page 36

ÍNDICE

INFORMACIÓN GENERAL SOBRE SEGURIDAD ........................................................................................................................................37

ACCESORIOS SUMINISTRADOS ....................................................................................................................................................................41

OPERACIÓN .........................................................................................................................................................................................................42

MANTENIMIENTO ..............................................................................................................................................................................................43

DIMENSIONES ..................................................................................................................................................................................................... 44

DIAGRAMA ELÉCTRICO ................................................................................................................................................................................... 45

ESPECIFICACIONES ...........................................................................................................................................................................................45

INSTALACIÓN ...................................................................................................................................................................................................... 46

SERVICIO TÉCNICO ........................................................................................................................................................................................... 52

36

Page 37

INFORMACIÓN GENERAL SOBRE SEGURIDAD

Por su seguridad

Para reducir el riesgo de lesión, muerte, choque eléctrico, incendio, avería y daños materia

o en el equipo, siempre cumpla con las siguientes medidas de seguridad.

Explicación de los letreros con símbolos

Los letreros con símbolos se utilizan para clasicar y describir el nivel de peligro, lesión y

daños materiales causados cuando se hace caso omiso de la indicación y se realiza un uso

incorrecto.

les

ESPAÑOL

Indica peligro de lesión grave o muerte.

ADVERTENCIA

Indica peligro de lesión menor.

PRECAUCIÓN

Los siguientes símbolos se utilizan para clasicar y describir el tipo de instrucciones

que deben cumplirse.

Este símbolo se emplea para alertar a los usuarios un procedimiento de

operación especíco obligatorio para utilizar el equipo de forma segura.

Este símbolo se emplea para alertar a los usuarios la prohibición de un

determinado procedimiento de operación.

37

Page 38

ADVERTENCIA

PARA REDUCIR EL RIESGO DE FUEGO GENERADO POR GRASA EN LA SUPERFICIE SUPERIOR DE UNA ESTUFA:

a) Nunca deje los quemadores superiores desatendidos cuando estén en posiciones altas de calor. Los derrames

generados por líquidos que hierven de más generan humo así como derrames grasosos que pueden incendiarse.

Caliente los aceites lentamente en posiciones bajas o medias de calor.

b) Siempre encienda la campana al cocinar con calor alto.

c) Limpie frecuentemente los ventiladores. No se debe dejar acumular grasa en el ventilador o el ltro.

d) Use el tamaño apropiado de sartén. Siempre use los trastes apropiados para el tamaño del quemador superior.

PARA REDUCIR EL RIESGO DE LESIONES A PERSONAS EN EL CASO DE LA GENERACIÓN DE FUEGO POR GRASA

EN LA SUPERFICIE SUPERIOR DE LA ESTUFA, ACATE LO SIGUIENTE:

a) AHOGUE LAS FLAMAS con una tapa que cierre ajustadamente, una charola para galletas o una charola metálica;

luego, apague el quemador. TENGA CUIDADO DE PREVENIR QUEMADURAS. Si las amas no se pagan

inmediatamente, EVACÚE Y LLAME AL DEPARTAMENTO DE BOMBEROS.

b) NUNCA TOME UNA SARTÉN QUE FLAMEA; puede quemarse.

c) NO USE AGUA, lo que incluye trapos de cocina húmedos o toallas húmedas; de lo contrario, se producirá una

explosión violenta de vapor.

d) Use un extinguidor SOLAMENTE si:

1) Usted sabe que tiene un extinguidor de clase ABC, y usted ya sabe cómo usarlo.

2) El fuego es pequeño y está contenido en el área en donde se inició.

3) Ya se ha llamado al departamento de bomberos.

4) Usted puede luchar contra el fuego teniendo una salida a sus espaldas.

Basado en “Consejos de seguridad contra el fuego en la cocina” (Kitchen Firesafety Tips), publicado por la NFPA.

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE ELÉCTRICO O LESIONES,

CUMPLA CON LO SIGUIENTE:

a) Utilice este equipo sólo en la forma prevista por el fabricante. Si tiene preguntas, comuníquese con el fabricante.

b) Antes de mantener o limpiar el equipo, desconecte la energía del panel de servicio y bloquee los medios de

desconexión de servicio para evitar que la energía se active de manera accidental.Cuando no sea posible

bloquear los medios de desconexión del servicio, coloque rmemente sobre el panel de servicio un dispositivo

de advertencia bien visible, como una etiqueta.

INSTRUCCIONES PARA LA CONEXIÓN A TIERRA

a) Este aparato debe conectarse a tierra. En caso de ocurrir un cortocircuito, la conexión a tierra reduce el riesgo

de producirse un choque eléctrico por medio de un cable de escape para la corriente eléctrica. Este aparato está

equipado con un cable que tiene un alambre de conexión a tierra con una clavija de conexión a tierra. La clavija

debe estar conectada a un tomacorriente que esté debidamente instalado y puesto a tierra.

b) Una mala conexión a tierra puede producir un riesgo de choque eléctrico.

c) Consulte con un electricista calicado si no comprende totalmente las instrucciones para la conexión a tierra, o si

existe alguna duda con respecto a la correcta conexión a tierra del aparato.

d) No use un cable de extensión. Si el cable de alimentación es demasiado corto, llame a un electricista calicado

para que instale un tomacorriente cerca del aparato.

38

Page 39

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, CHOQUE ELÉCTRICO O LESIONES,

CUMPLA CON LO SIGUIENTE

a) El trabajo de instalación y conexión eléctrica debe ser realizado por un electricista calicado conforme a las

normas y los códigos aplicables, incluidas las regulaciones relacionadas con la construcción ignífuga.

b) Se necesita suciente aire para que se lleve a cabo una combustión y una extracción adecuadas de los gases a

través del tubo de humos (chimenea) del equipo quemador de combustible, con el n de evitar el contratiro.

Siga las pautas y las normas de seguridad del fabricante del equipo de calentamiento, como las publicadas por

Asociación Nacional de Protección contra Incendios (NFPA, por sus siglas en inglés) y la Sociedad Estadounidense

de Ingenieros de Calefacción, Refrigeración y Aire Acondicionado (ASHRAE, por sus siglas en inglés) y las autoridades

normativas locales.

c) Cuando corte o perfore en una pared o un techo, no dañe los cables eléctricos ni otros servicios ocultos.

d) Los extractores con ductos siempre deben tener descarga hacia el exterior.

- Limpie periódicamente los ltros y todas las supercies cargadas de grasa.

-

Como protección contra el choque eléctrico, conecte el aparato solo a tomacorrientes debidamente conectados a tierra.

- Para reducir el riesgo de fuego, use ducto metálico solamente.

- Deje de usar el equipo cuando se produzca alguna anomalía o falla y coloque el interruptor de encendido en “OFF”

o desconecte la clavija de 3 polos.

Ejemplo de falla de anomalía:

- Ruido o calor anormales.

- Emisión anormal de olor o humo.

- Fuego o incendio de aceite.

- Inserte la clavija de alimentación rmemente; de lo contrario, podría producir fuego o choque eléctrico.

- El cable de alimentación debe quedar tendido correctamente para evitar que se dañe. El fabricante deslinda toda

responsabilidad en caso de falta de cumplimiento de las normas de seguridad.

- El tomacorriente utilizado para conectar el equipo instalado a la alimentación eléctrica debe ser de fácil alcance;

de lo contrario, instale un interruptor de alimentación para desconectar la campana puricadora cuando sea necesario.

- Los taquetes deben tener un agarre seguro.

- Los tornillos y los taquetes suministrados son adecuados para ladrillos sólidos o concreto sólido. Deben utilizarse

sujetadores adecuados para otras construcciones (por ejemplos, cartón-yeso, concreto poroso, ladrillos porosos).

- La longitud máxima de los tornillos de sujeción de la chimenea (suministrados por el fabricante) debe ser

pulg. (13 mm). El uso de tornillos que no cumplen con estas instrucciones puede generar un peligro de naturaleza

eléctrica.

- Tenga presente que las instalaciones con otros tipos de sistemas de sujeción distintos de los suministrados, o que

no cumplen con las instrucciones, pueden ocasionar un riesgo eléctrico y de sello mecánico.

- Limpie la clavija de alimentación periódicamente con un paño seco; de lo contrario, la humedad puede ocasionar

un aislamiento insuciente, lo cual puede producir fuego.

- Existe riesgo de fuego si la limpieza no se lleva a cabo de acuerdo con las instrucciones.

- Las piezas accesibles pueden calentarse si cuando se utilizan con artefactos de cocción.

- Siempre supervise el proceso de cocción durante el uso de freidoras: el aceite sobrecalentado puede incendiarse.

- Se indica que cuando el producto ya no se utilice, no debe quedar instalado, sino que debe quitarse para evitar su

posible caída.

- Siempre compruebe que todas las piezas eléctricas (luces, dispositivo de extracción) estén apagadas cuando el

aparato no está en uso.

- Este aparato no se destina para utilizarse por niños ni personas enfermas o de edad, a menos que dichas personas

sean supervisadas por una persona responsable para garantizar que puedan utilizar el artefacto de forma segura.

Se debe supervisar a los niños para garantizar que no empleen el artefacto como juguete.

- Para reducir el riesgo de fuego o choque eléctrico, no utilice este extractor con ningún dispositivo de control de

velocidad de estado sólido.

- No conecte el aparato a chimeneas (de calderas, hogares, etc.).

- No deseche el empaque ni ninguna de sus partes, ni lo deje desatendido. Puede producir riesgo de asxia para los

niños, especialmente las bolsas de plástico.