Page 1

Cordles Impact Driver/Cordles Impact Wrench

Perceuse à impact sans fi l/Perceuse à impact sans fi l

Destornillador de impacto inalámbrico/Destornillador de impacto inalámbrico

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Model No: EY75A1/EY75A2

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Page 2

Index/Index/Indice

English: Page 5 Français: Page 20 Español: Página 38

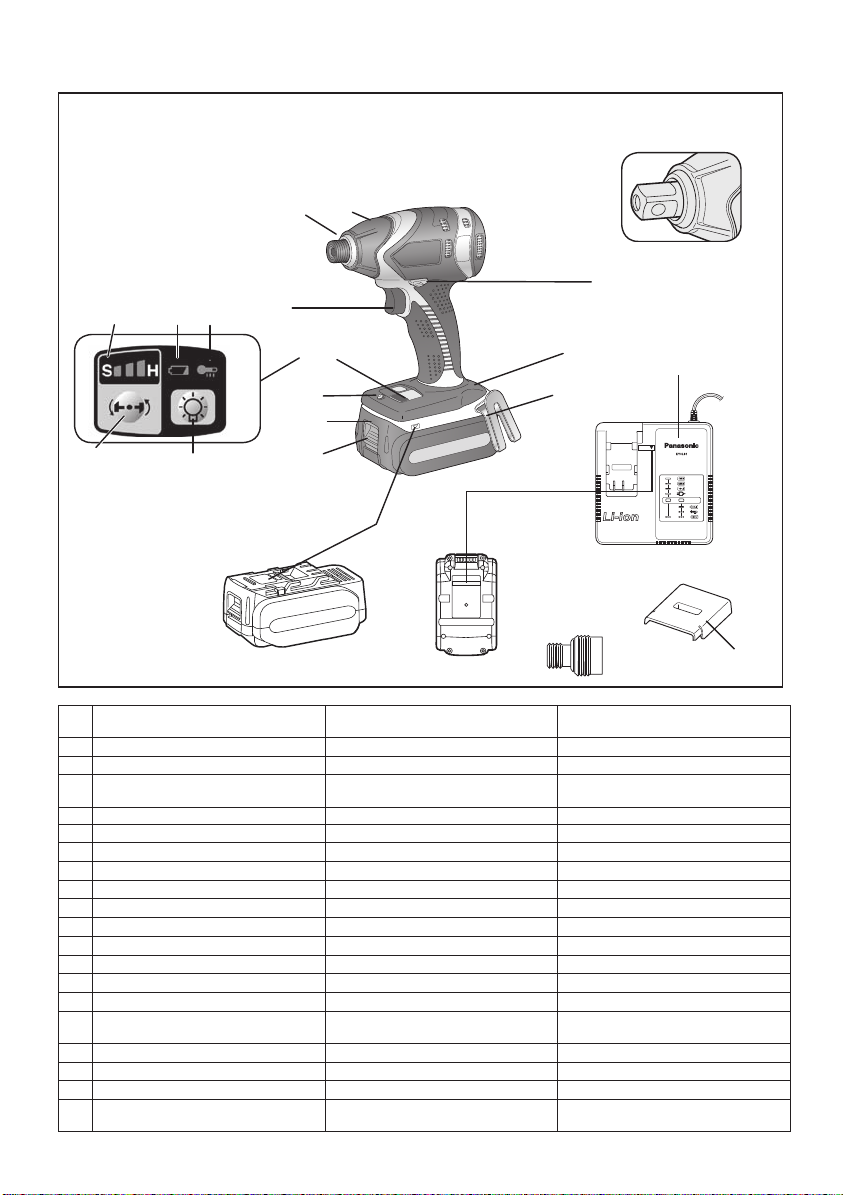

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

(A)′

DESCRIPCIÓN FUNCIONAL

(B)

(A)

(C)

(N)(M)

(O)

(P)

(J)

(I)

(D)

(Q)

(E)

(H)

(L)

(K)

(G)

10.8 V ─ 28.8 V

(F)

(S)

(A) 6.35 mm (1/4″) hex quick connect chuck

(A)′ Square drive (ball detent)

(B) Nose protector Protection du bec Protector del morro

(C) Forward/Reverse lever Levier d’inversion marche avant/

(D) Belt hook lock lever

(E) Belt hook Crochet de ceinture Gancho del cinturón

(F) Alignment marks Marques d’alignement Marcas de alineación

(G) Battery pack release button

(H) Battery pack Batterie autonome Batería

(I) LED light Lumière DEL Luz indicadora

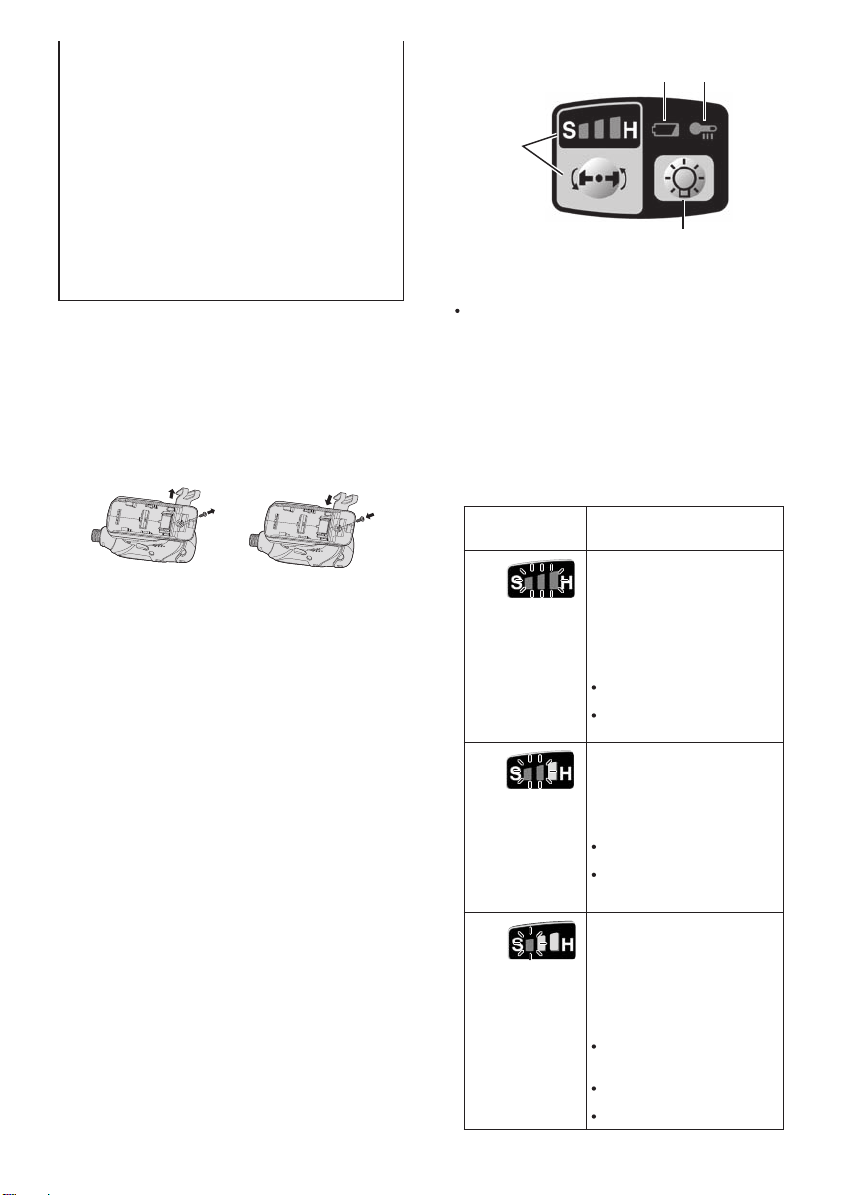

(J) Control panel Panneau de commande Panel de control

(K) LED light ON/OFF button Bouton Marche/Arrêt de la lumière DEL Botón ON/OFF de luz LED

(L) Impact power mode button

(M) Impact power mode display

(N) Battery low warning lamp

(O) Overheat warning lamp (motor/battery) Témoin d’avertissement de surchauffe

(P) Variable speed control trigger Gâchette de commande de vitesse

(Q) Battery charger Chargeur de batterie Cargador de batería

(R) Pack cover Couvercle de la batterie autonome Cubierta de batería

(S) 6.35 mm (1/4") hex quick change

chuck (EY9HX110E)

Mandrin de connexion rapide hexagonal

de 6,35 mm (1/4

Mandrin

marche arrière

Levier de verrouillage du crochet de ceinture

Bouton de libération de batterie autonome

Bouton du mode de puissance de percussion

Affi chage du mode de puissance de percussion

Témoin d’avertissement de batterie basse

(moteur/batterie)

Mandrin hexagonal de 6,35 mm (1/4")

de changement rapide (EY9HX110E)

″

)

Mandril hexagonal de conexión rápida de

6,35 mm (1/4″)

Portabroca

Palanca de avance/marcha atrás

Palanca de bloqueo del gancho de cinturón

Botón de liberación de batería

Botón de modo de potencia de impacto

Indicación de modo de potencia de impacto

Luz de aviso de baja carga de batería

Luz de advertencia de sobrecalenta-

miento (motor/batería)

Disparador del control de velocidad variable

Portabroca de 6,35 mm (1/4”) cambio

rápido hexaonal (EY9HX110E)

(R)

-

2 -

Page 3

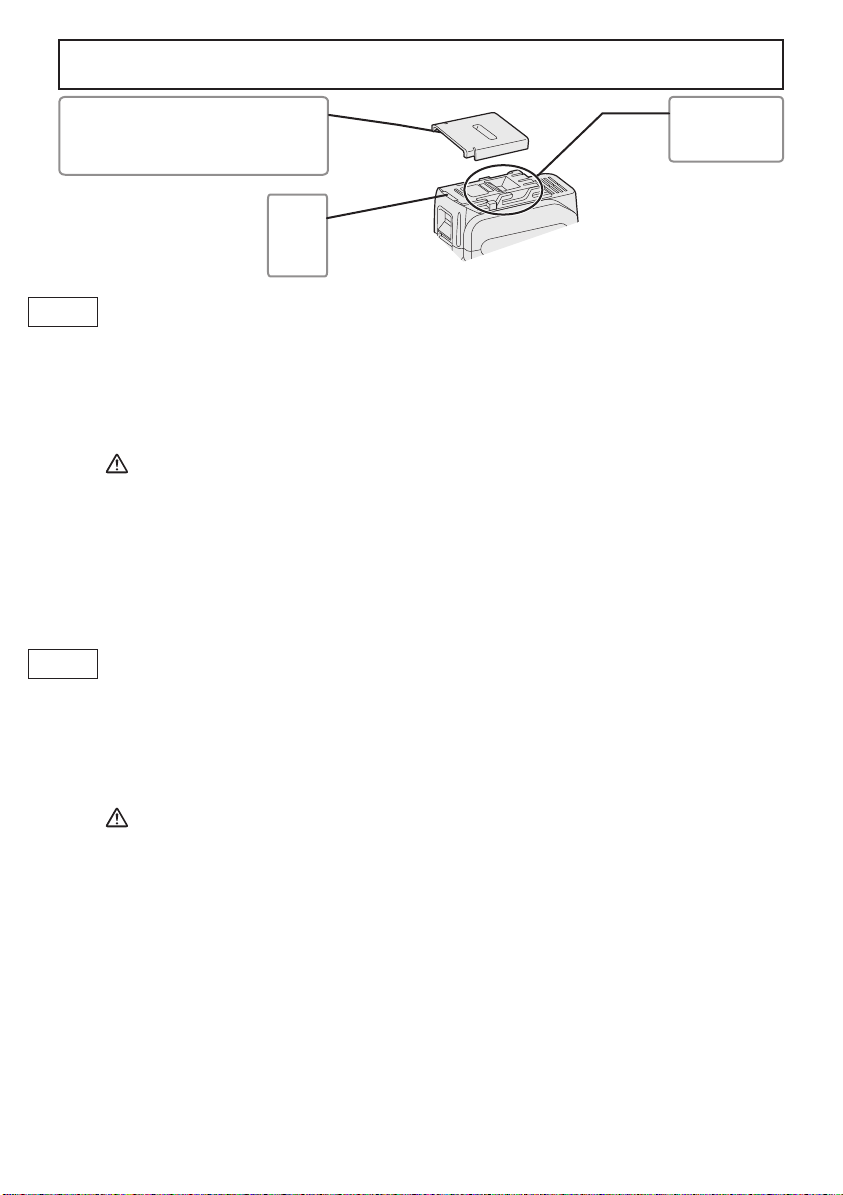

Recommendations for use / Recommandations concernant l’utilisation / Recomendaciones par el uso

Pack cover

Couvercle de la batterie autonome

Cubierta de batería

EN

Be sure to use the Pack cover

• When the battery pack is not being used, store the battery in a way that foreign substances such as dust and

water etc. do not contaminate the terminals. Be sure to attach the battery pack cover to protect the battery

terminals.

• When charging the battery pack, confirm that the terminals on the battery charger are free of foreign

substances such as dust and water etc. Clean the terminals before charging the battery pack if any foreign

substances are found on the terminals.

The life of the battery pack terminals may be affected by foreign substances such as dust and water etc.

during operation.

CAUTION: To protect the motor or battery, be sure to note the following when carrying out this operation.

• If the motor or battery becomes hot, the protection function will be activated and the motor or battery will stop

operating.

The overheat warning lamp on the control panel illuminates or flashes when this feature is active.

For safe use

• The battery pack is designed to be installed by proceeding two steps for safety. Make sure the battery pack is

installed properly to the main body before use.

• If the battery pack is not inserted firmly when the switch is switched on, the overheat warning lamp and the

battery low warning lamp will flash to indicate that safe operation is not possible, and the bit will not rotate

normally. Insert the battery pack into the body of the tool until the red label disappears.

FR

Veillez à utiliser le couvercle de la batterie autonome

• Lorsque le couvercle de la batterie autonome n’est pas utilisé, rangez la batterie de façon à ce qu’aucun corps

étranger comme de la poussière et de l’eau ne contamine les bornes. Veillez à fixer le couvercle de la batterie

autonome afin de protéger les bornes de la batterie.

• Lors de la charge de la batterie autonome, assurez-vous que les bornes du chargeur de batterie sont libres de

tout corps étranger comme de la poussière et de l’eau, etc. Nettoyez les bornes avant de charger la batterie

autonome si des corps étrangers se trouvent sur les bornes.

La durée de vie des bornes de la batterie autonome peut être affectée par des corps étrangers comme de la

poussière et de l’eau, etc. pendant le fonctionnement.

MISE EN GARDE: Pour protéger le moteur ou la batterie, veillez à bien noter les points suivants lorsque

• Si le moteur ou la batterie deviennent chauds, la fonction de protection sera activée et le moteur ou la batterie

cesseront de fonctionner. Le témoin d'avertissement de surchauffe s'allume ou clignote sur le panneau de

commande lorsque cette caractéristique est active.

Pour un usage sans risque

• La batterie est conçue pour être installée en procédant en deux étapes pour des raisons de sécurité. Assurezvous que la batterie est mise en place correctement avant d'utiliser l'outil.

• Lorsque la batterie autonome n'est pas fermement insérée, le té moin d'avertissement de surchauffe et le témoin

d’avertissement de batterie basse clignotent et la machine ne fait pas tourner la mèche comme habituellement

pour nous signaler que la machine ne fonctionne pas en toute sécurité même si un interrupteur a été enclenché.

Insérez la batterie autonome dans le corps de l'outil jusqu'à ce que l'indicateur rouge disparaisse.

Terminals

Bornes

Terminales

label

rouge

rojo

vous effectuez cette opération.

-

3 -

Page 4

ES

Asegúrese de utilizar la cubierta de la caja de batería

• Cuando no utilice la caja de batería, guarde la batería de tal forma que las materias extrañas tales como polvo

y agua, etc. ensucien los terminales. Asegúrese de colocar la cubierta de la caja de batería de tal forma de

proteger los terminales de la batería.

• Cuando cargue la caja de batería, confirme que los terminales en el cargador de batería estén libres de

materias extrañas tales como polvo y agua, etc. Limpie los terminales antes de cargar la caja de batería si hay

materias extrañas en los terminales.

La vida de los terminales de la caja de batería puede verse afectada por materias extrañas tales como polo y

agua, etc. durante su funcionamiento.

PRECAUCIÓN: Para proteger el motor o la batería, asegúrese de observar lo siguiente cuando efectúe

esta operación.

• Si el motor o la batería se calienta, se activará la función de protección y el motor o la batería dejará de

funcionar. La lámpara de advertencia de sobrecalentamiento en el panel de control se ilumina o destella

cuando esta característica está activada.

Para un uso más seguro

• La batería está diseñada para instalarse siguiendo dos pasos por motivos de seguridad.

Compruebe que la batería está instalada correctamente en el cuerpo principal antes de utilizar la herramienta.

• Si la batería no ha quedado bien introducida, la luz de advertencia de sobrecalentamiento y la luz de aviso de

baja carga de batería parpadearán, y la broca no girará del modo habitual para alertar al operario de que la

máquina no funcionará de manera segura si se acciona algún interruptor. Introduzca la batería en el cuerpo de

la herramienta hasta que el indicador rojo desaparezca.

-

4 -

Page 5

This tool, as a complete unit with a battery pack,

t

r

r

satisfies appropriate IP Degrees of Protection

based on the IEC regulations.

Definition of IP code

IP5X: Ingress of dust is not totally prevented,

but dust shall not penetrate in a quantity to

interfere with satisfactory operation of the tool

or to impair safety (In case that the talcum

powder under 75 μm intrudes inside the tool).

IPX6: Water projected in powerful jets agains

the tool from any direction shall have no

harmful effects (In case that, with a nozzle

of 12.5 mm inner diameter, approximately

100 L/min of normal temperature water is

injected to the tool for 3 minutes from 3 mete

distance).

LIMITED WARRANTY

The rating of IP56 qualifies this tool for the

minimum impact of water or dust, but not fo

the assurance of performance in such conditions. See Safety and Operating Instructions

for further details for proper operation.

I. GENERAL

SAFETY RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3) Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase

the risk of electric shock.

4) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

6)

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RC D) protected

supply.

Use of RCD reduces the risk of

electrical shock.

Personal Safety

1)

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury .

2) Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3) Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

-

5 -

Page 6

4) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

5) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6) Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

2) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must

be repaired.

3) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7) Use the power tool, accessories

and tool bits etc. in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3) Use power tools only with specifically

designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

5) Under abusive conditions, liquid may

be ejected from battery; avoid contact.

If contact accidentally occurs, flush

with water. If liquid contacts eyes,

additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

-

6 -

Page 7

II. SPECIFIC

SAFETY RULES

1) Wear ear protection. Exposure to noise

can cause hearing loss.

2)

Be aware that this tool is always in an

operating condition, since it does not have

to be plugged into an electrical outlet.

3)

Hold power tools by insulated grip-

ping sur faces when performing an

operation where the cutting tool may

contact hid den wiring.

Contact with a “live” wire will make ex-

posed metal parts of the tool “live” and

shock the operator.

4) If the bit becomes jammed, immediately

turn the trigger switch off to prevent an

overload which can damage the battery

pack or motor. Use reverse motion to

loosen jammed bits.

5) Do NOT operate the Forward/Reverse

lever when the trigger switch is on.

The battery will discharge rapidly and

damage to the unit may occur.

6) When storing or carrying the tool, set

the Forward/Reverse lever to the center

position (switch lock).

7) Do not strain the tool by holding the

speed control trigger halfway (speed

control mode) so that the motor stops.

The protection circuit will activate and

may prevent speed control operation. If

this happens, release the speed control

trigger and squeeze again for normal

operation.

8) Be careful not to get dust inside the

chuck.

9) Do not touch the rotating parts to avoid

injury.

10)

Do not use the tool continuously for a long

period of time. Stop using the tool from time

to time to avoid temperature rise and heat

overload of the motor.

11) Do not drop the tool.

Symbol Meaning

V Volts

Direct current

n

0

No load speed

… min

Ah

Electrical capacity of battery pack

To reduce the risk of injury user

per minutes

must read and understand

instruction manual.

Revolutions or reciprocations

-1

WARNING!

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement and other masonry products

• Arsenic and chromium from chemicallytreated lumber.

To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as dust masks that are specially

designed to filter out microscopic particles.

III.

FOR BATTERY CHARGER

& BATTERY PACK

Important Safety Instructions

1) SAVE THESE INSTRUCTIONS -This

manual contains important safety and

operating instructions for battery charger.

2) Before using battery charger, read all

instructions and cautionary markings

on battery charger, battery pack, and

product using battery pack.

3) CAUTION -To reduce the risk of injury,

charge only Panasonic Battery Pack as

shown in last page.

Other types of batteries may burst

causing personal injury and damage.

4) Do not expose charger and battery pack

to rain or snow.

5) To reduce risk of damaging the electric

plug and cord, pull by plug rather than

cord when disconnecting charger.

6)

Make sure cord is located so that it

will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

7) An extension cord should not be used

-

7 -

Page 8

unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric shock.

If extension cord must be used, make

sure that:

a. pins on plug of extension cord are

the same number, size and shape as

those of plug on charger.

b. extension cord is properly wired and

in good electrical condition.

c. wire size is large enough for ampere

rating of charger as specified below.

RECOMMENDED MINIMUM AWG SIZE OF

AC Input Rating. Amperes

Equal to or

greater than

0 2 18 18 18 16

EXTENSION CORDS FOR

BATTERY CHARGERS

But less

than

AWG Size of Cord

Length of Cord,

Feet

25 50 100 150

8) Do not operate charger with damaged

cord or plug-replace them immediately.

9) Do not operate charger if it has received

a sharp blow, been dropped, or otherwise damaged in any way; take it to a

qualified service personnel.

10

) Do not disassemble charger; take it

to a qualified service personnel when

service or repair is required. Incorrect

reassembly may result in a risk of

electric shock or fire.

11) To reduce the risk of electric shock,

unplug charger from outlet before

attempting any maintenance or cleaning.

12)

The charger and battery pack are

specifically designed to work together. Do

not attempt to charge any other cordless

tool or battery pack with this charger.

13) Do not attempt to charge the battery

pack with any other charger.

14) Do not attempt to disassemble the

battery pack housing.

15) Do not store the tool and battery pack

in locations where the temperature

may reach or exceed 50°C (122°F)

(such as a metal tool shed, or a car

in the summer), which can lead to

deterioration of the storage battery.

16) Do not charge battery pack when the

temperature is BELOW 0°C (32°F)

or ABOVE 40°C (104°F). This is very

important in order to maintain optimal

condition of the battery pack.

17) Do not incinerate the battery pack. It

can explode in a fire.

18) Avoid dangerous environment. Do not

use charger in damp or wet locations.

19) The charger is designed to operate on

standard household electrical power

only. Do not attempt to use it on any

other voltage!

20) Do not abuse cord. Never carry charger

by cord or yank it to disconnect from

outlet. Keep cord away from heat, oil

and sharp edges.

21) Charge the battery pack in a well

ventilated place, do not cover the

charger and battery pack with a cloth,

etc., while charging.

22) Use of an attachment not recommended

may result in a risk of fire, electric

shock, or personal injury.

23) Do not short the battery pack. A battery

short can cause a large current flow,

over heating and create the risk of fire

or personal injury.

24) NOTE: If the supply cord of this

appliance is damaged, it must only be

replaced by a repair shop authorized

by the manufacturer, because special

purpose tools are required.

25) TO REDUCE THE RISK OF ELECTRIC

SHOCK, THIS APPLIANCE HAS A

POLARIZED PLUG (ONE BLADE IS

WIDER THAN THE OTHER).

This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install the proper outlet. Do not change

the plug in any way.

-

8 -

Page 9

WARNING:

• Do not use other than the Panasonic battery packs that are designed for use with

this rechargeable tool.

• Panasonic is not responsible for any damage or accident caused by the use of the

recycled battery pack and the counterfeit

battery pack.

• Do not dispose of the battery pack in a

fire, or expose it to excessive heat.

Do not drive the likes of nails into the battery

•

pack, subject it to shocks, dismantle it, or

attempt to modify it.

• Do not allow metal objects to touch the

battery pack terminals.

• Do not carry or store the battery pack

in the same container as nails or similar

metal objects.

• Do not charge the battery pack in a

high-temperature location, such as next

to a fire or in direct sunlight. Otherwise,

the battery may overheat, catch fire, or

explode.

• Never use other than the dedicated charger to charge the battery pack. Otherwise,

the battery may leak, overheat, or

explode.

• After removing the battery pack from the

tool or the charger, always reattach the

pack cover. Otherwise, the battery contacts could be shorted, leading to a risk of

fire.

• When the Battery Pack Has Deteriorated,

Replace It with a New One.

Continued use of a damaged battery pack

may result in heat generation, ignition or

battery rupture.

IV. ASSEMBLY

Attaching or Removing Bit

NOTE:

•

When attaching or removing a bit, disconnect battery pack from tool or place the

switch in the center position (switch lock).

1. Hold the collar of quick connect chuck and

pull it out from the driver.

2. Insert the bit into the chuck. Release the

collar.

3. The collar will return to its original position

when it is released.

4.

Pull the bit to make sure it does not come out.

5. To remove the bit, pull out the collar in the

same way.

CAUTION:

• If the collar does not return to its origi-

nal position or the bit comes out when

pulled on, the bit has not been properly

attached. Make sure the bit is properly

attached before use.

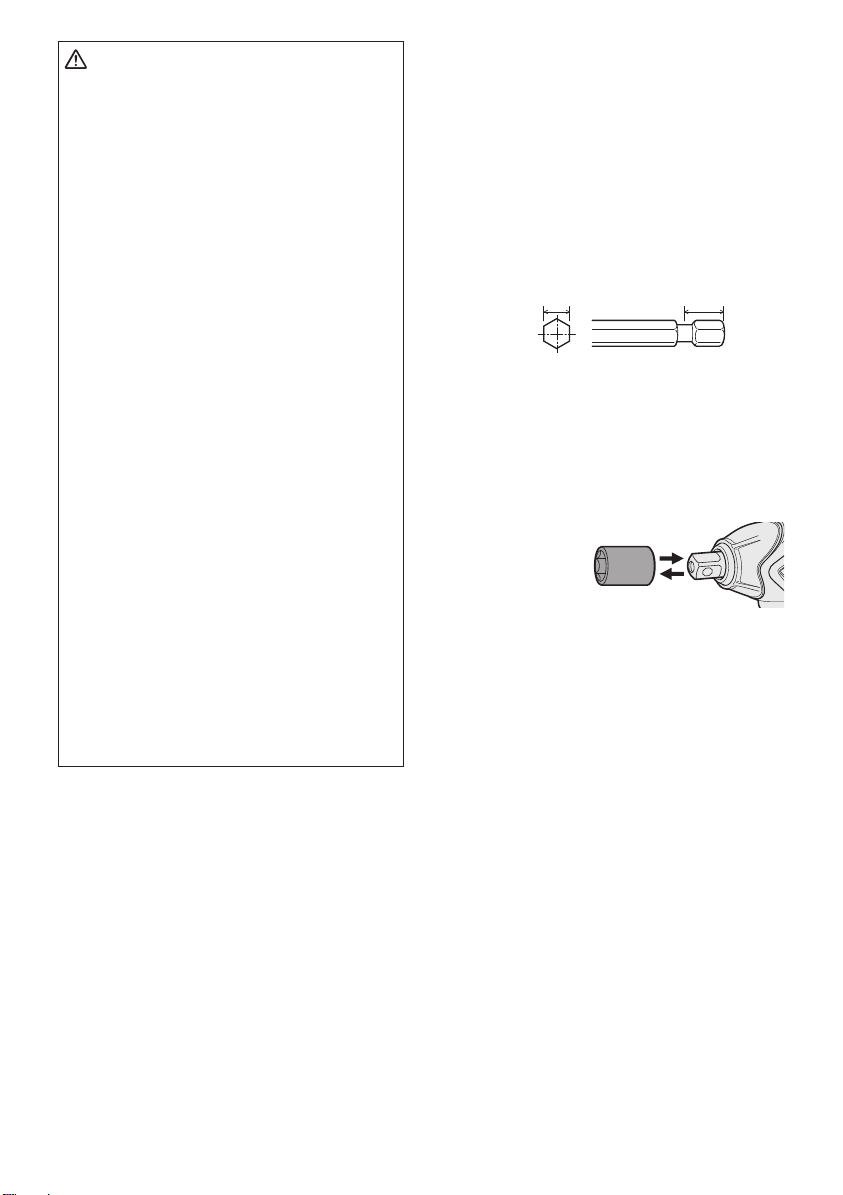

Use 6.35 mm (1/4") hexagonal bits.

To ensure proper securement of the bit,

use only hexagonal bits with 9.5 mm (3/8")

detent.

6.35 mm (1/4")

9.5 mm (3/8")

Attaching or Removing

Sock et

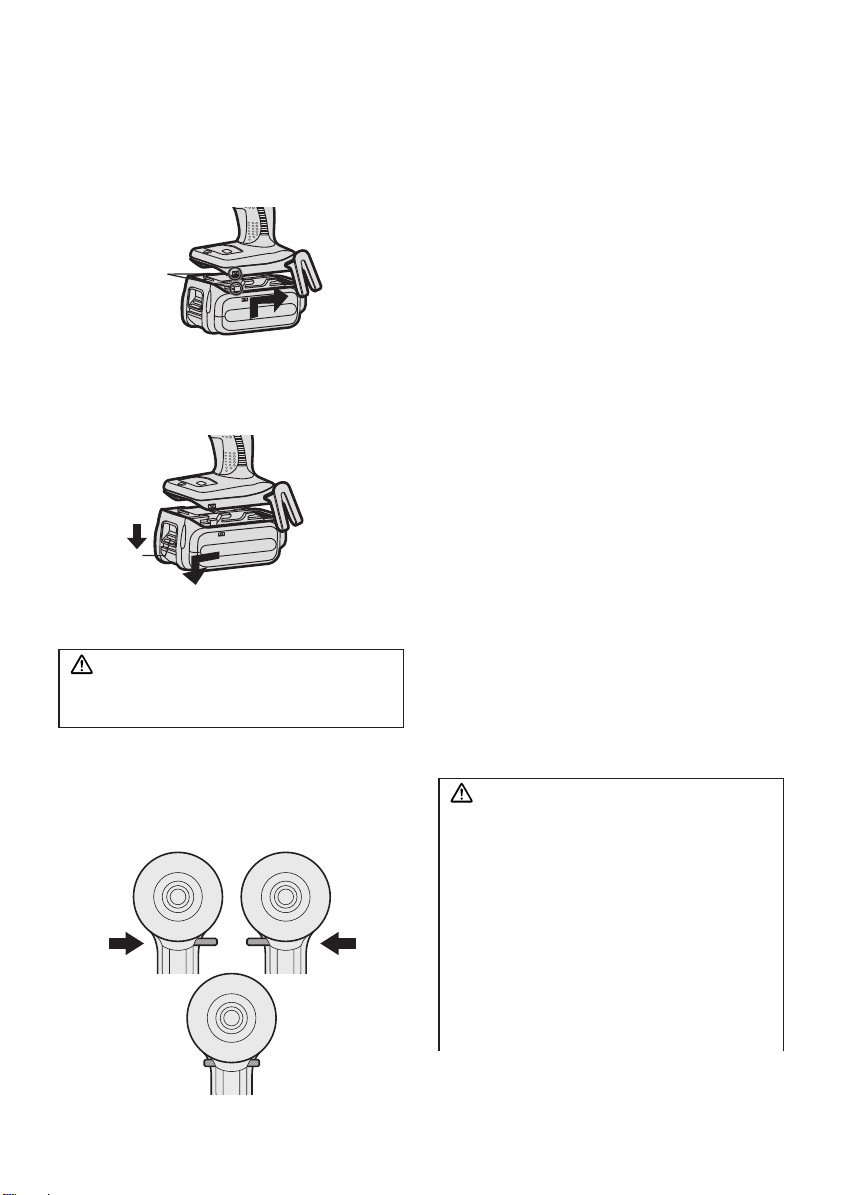

1. Attaching Socket

Attach the socket by sliding the female

detent on the bottom of the socket to the

square drive on the body.

Make sure the

socket is firmly

connected to

the body.

2. Removing Socket

Pull out the socket.

NOTE:

Attaching or Removing Original Options

and Sockets

Keep the body above freezing point

(0°C 32°F) when attach or detach

original options and sockets to the

square drive on the body. The cushion

rubber in the square drive to push up

the ball may get hard under freezing

point. This requires extra force in

detaching and attaching sockets.

-

9 -

Page 10

Attaching or Removing

Bat tery Pack

1. To connect the battery pack:

Line up the alignment marks and attach

the battery pack.

• Slide the battery pack until it locks into

position.

Alignment

marks

2. To remove the battery pack:

Pull the button from the front to release the

battery pack.

Button

V. OPERATION

WARNING!

• Do not inhale any smoke emitted from the

tool or battery pack as it may be harmful.

CAUTION:

To prevent damage, do not operate

Forward/Reverse lever until the bit

comes to a complete stop.

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

3. The speed increases with the amount of

depression of the trigger for efficient tightening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4. After use, set the lever to its center position (switch lock).

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

direction of rotation before use.

2.

Depress the trigger switch slightly to start the

tool slowly.

3. After use, set the lever to its center position (switch lock).

CAUTION:

•

To eliminate excessive temperature

increase of the tool surface, do not operate the tool continuously using two or

more battery packs. Tool needs cool off

time before switching to another pack.

the

[Main Body]

Switch and Forward/Reverse

Lever Operation

Forward Reverse

Switch lock

-

How to Use the Belt Hook

WARNING!

• Be sure to attach the belt hook securely to

the main unit with the screw firmly fastened.

When the belt hook is not firmly attached to

the main unit, the hook may disconnect and

the main unit may fall.

This may result in an accident or injury.

• Periodically check screw for tightness. If

found to be loose, tighten firmly.

Be sure to attach the belt hook firmly and

•

securely onto a waist belt or other belt. Pay

attention that the unit does not slip off the

This may result in an accident or injury.

belt.

10 -

Page 11

• When the main unit is held by the belt

hook, avoid jumping or running with it.

Doing so may cause the hook to slip and

the main unit may fall.

This may result in an accident or injury .

• When the belt hook is not used, be sure

to return it to the storing position. The belt

hook may catch on something.

This may result in an accident or injury.

When the unit is hooked onto the waist belt

•

by the belt hook, do not attach driver bits to

the unit. A sharp edge object, such as a drill

bit, may cause injury or an accident.

To Change the Belt Hook

Location Side

The belt hook can be attached to either side

of the unit.

1. Removing the hook

(1) Remove the nut.

(2) Draw out the hook.

2. Attaching the hook to the other side

(1) Insert the hook in the other side.

(2) Tighten the nut fully so that it securely

fastened.

V ariable Speed Control T rigger

To set the center of a hole, pull the trigger

slightly to start the bit rotation slowly.

The more the speed control trigger is

pulled, the higher the speed becomes.

CAUTION:

When operating the tool by pulling the

trigger, there may be a momentary lag

before rotation starts. This does not signal

a malfunction.

• This lag occurs as the tool’s circuitry

starts up when the trigger is pulled for

the first time after installing a new battery pack or after the tool has not been

used for at least 1 minute (or at least 5

minutes when the LED is on). Rotation

will start without any lag during second

and subsequent operations.

Control Panel

(4) (3)

(1)

(2)

(1) Impact Power Mode Select

Selecting the impact power among 3

modes (Soft, Medium, Hard).

Press the impact power mode button

to set it. The mode changes to hard,

medium, or soft each time the button is

pressed.

The driver is preset to “hard” impact mode

setting when shipped from the manufacturer.

Recommended work guideline table

Impact

Power mode

Display

H

0 – 2300 r.p.m./

0 – 2500 r.p.m.

and

0 – 3000 i.p.m./

0 – 3500 i.p.m.

M

0 – 1400 r.p.m.

and

0 – 2800 i.p.m.

S

0 – 1000 r.p.m.

and

0 – 2000 i.p.m.

Recommended Application

Jobs requiring a high level

of torque where there is

no possibility of the screw

breaking, its top shearing off,

or the bit coming loose. (This

setting provides maximum

torque.) Suitable applications

include:

Tightening M8 and larger

bolts

Tightening long screws

during interior finishing work

Jobs requiring limited torque

where there is a possibility of

the screw breaking or its top

shearing off. (This setting limits

torque.) Suitable applications

include:

Tightening bolts with

smaller diameters (M6)

Tightening metalwork

screws when installing

fixtures

Jobs requiring limited torque

where there is a possibility

of the screw breaking, its

top shearing off, or the bit

coming loose and damaging

a fi nished exterior surface.

(This setting limits torque.)

Suitable applications include:

Tightening bolts smaller

than M6 that may shear

easily

Tightening screws into

molded plastic

Installing gypsum wallboard

-

11 -

Page 12

* i.p.m. = Impact per minute.

Avoid repeatedly depressing the switch

when the bolts and screws are securely

fastened.

Not doing so may cause a delay in

rotation starting, or the Impact Power

mode display to flash and prevent rotation

from starting for circuit protection.

(2) LED light

Pressing the but ton toggles the LED light on and off.

The light illuminates with

very low current, and it does

not adversely affect the per-

of the

formance

driver during

use or its battery capacity.

CAUTION:

• The built-in LED light is designed to illuminate the small work area temporarily.

•

Do not use it as a substitute for a regular

flashlight, since it does not have

enough brightness

This product has the built-in LED light.

This product is classified into “Class 1 LED

Product” to IEC (EN) 60825-1:2001.

Class 1 LED Product

Caution : DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance

of procedures other than those specifi ed herein

may result in hazardous radiation exposure.

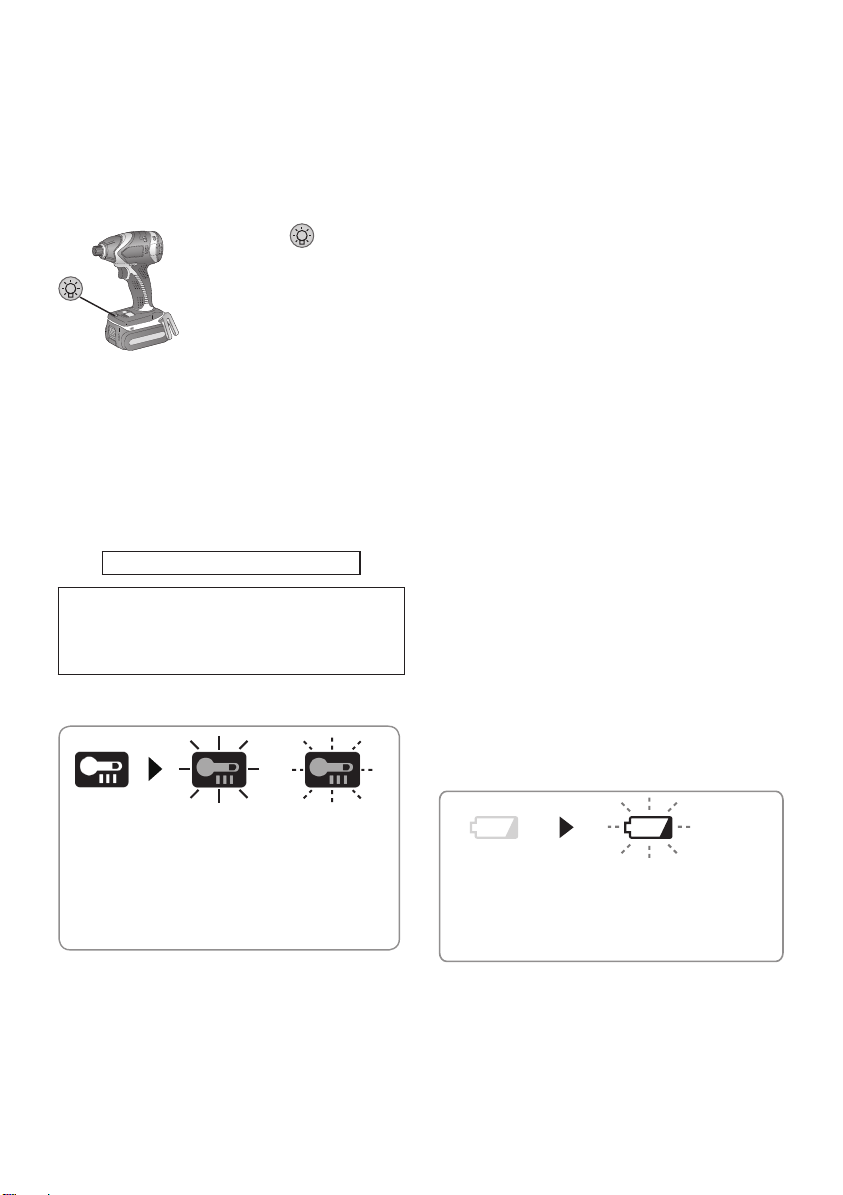

(3) Overheat warning lamp

.

• If the overheating protection feature

activates, allow the tool to cool

thoroughly (at least 30 minutes). The

tool is ready for use when the overheat

warning lamp goes out.

• Avoid using the tool in a way that

causes the overheating protection

feature to activate repeatedly.

• If the tool is operated continuously

under high-load conditions or if it is

used in hot-temperature conditions

(such as during summer), the

overheating protection feature may

activate frequently.

• If the tool is used in cold-temperature

conditions (such as during winter) or if

it is frequently stopped during use, the

overheating protection feature may not

activate.

• The performance of the EY9L42

deteriorates significantly at and below

10°C due to work conditions and other

factors.

• The ambient temperature range is

between 0°C (32°F) and 40°C (104°F).

If the battery pack is used when the

battery temperature is below 0°C

(32°F), the tool may fail to function

properly.

• Use the charger at temperatures

between 0°C and 40°C, and charge the

battery at a temperature similar to that

of the battery itself. (There should be no

more than a 15°C difference between

the temperatures of the battery and the

charging location.)

(4) Battery low warning lamp

Off

(normal

operation)

Illuminated:

Overheat

(motor)

Indicates operation has

been halted due to motor

or battery overheating.

Flashing:

Overheat

(battery)

To protect the motor or battery, be sure to

note the following when carrying out this

operation.

• If the motor or battery becomes hot, the

protection function will be activated and

the motor or battery will stop operating.

The overheat warning lamp on the

control panel illuminates or flashes

when this feature is active.

-

12 -

Off (normal

operation)

Flashing (No charge)

Battery protection

feature active

Excessive (complete) discharging of

lithium ion batteries shortens their service

life dramatically. The driver includes a

battery protection feature designed to

prevent excessive discharging of the

battery pack.

• The battery protection feature activates

immediately before the battery loses its

Page 13

charge, causing the battery low warning

lamp to flash.

• If you notice the battery low warning

lamp flashing, charge the battery pack

immediately.

• If it is started with too little battery power

remaining, the tool may stop operating

without the battery low warning lamp

flashing first. This indicates that there is

too little battery power remaining to use

the tool, and the battery pack should be

charged before further use.

• If the tool is subject to a sudden load

during use that causes the motor to lock

up, the over current prevention sensor

may be triggered, and the impact power

select display may flash. The lamp will

stop flashing once you address the

cause of the motor’s locking up and

cycle the trigger.

Recommended Grip

Use the grip to hold and operate the driver

with one hand. If the job requires additional

force, you can push against the rear end of

the driver with your other hand.

[Battery Pack]

For Appropriate Use of Bat-

tery Pack

Li-ion Battery Pack

•

For optimum battery life, store the Li-ion battery pack following use without charging it.

• When charging the battery pack, confirm

that the terminals on the battery charger

are free of foreign substances such as

dust and water etc. Clean the terminals

before charging the battery pack if any

foreign substances are found on the terminals.

The life of the battery pack terminals may

be affected by foreign substances such as

dust and water etc. during operation.

• When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together

may cause sparks, burns or a fire.

• When operating the battery pack, make

sure the work place is well ventilated.

• When the battery pack is removed from

the main body of the tool, replace the battery pack cover immediately in order to

prevent dust or dirt from contaminating the

battery terminals and causing a short circuit.

Battery Pack Life

The rechargeable batteries have a limited life. If the operation time becomes

extremely short after recharging, replace

the battery pack with a new one.

Battery Recycling

ATTENTION:

FOR Li-ion Battery Pack

A Li-ion battery that is recyclable powers the

product you have purchased. Please call

1-800-8-BATTERY for information on how to

recycle this battery.

[Battery Charger]

Charging

Cautions

• If the temperature of the battery pack

falls approximately below −10°C (14°F),

charging will automatically stop to prevent

degradation of the battery.

• The ambient temperature range is

between 0°C (32°F) and 40°C (104°F).

If the battery pack is used when the battery

temperature is below 0°C (32°F), the tool

may fail to function properly.

• Use the charger at temperatures between

0°C and 40°C, and charge the battery at

a temperature similar to that of the battery

itself. (There should be no more than a

15°C difference between the temperatures

of the battery and the charging location.)

• When charging a cool battery pack (below

0°C (32°F)) in a warm place, leave the

battery pack at the place and wait for more

than one hour to warm up the battery to

the level of the ambient temperature.

-

13 -

Page 14

• Cool down the charger when charging

more than two battery packs consecutively.

• Do not insert your fingers into contact

hole, when holding charger or any other

occasions.

CAUTION:

To prevent the risk of fire or damage to

the battery charger.

• Do not use power source from an

engine generator.

• Do not cover vent holes on the

charger and the battery pack.

• Unplug the charger when not in use.

Li-ion Battery Pack

NOTE:

Your battery pack is not fully charged at

the time of purchase. Be sure to charge

the battery before use.

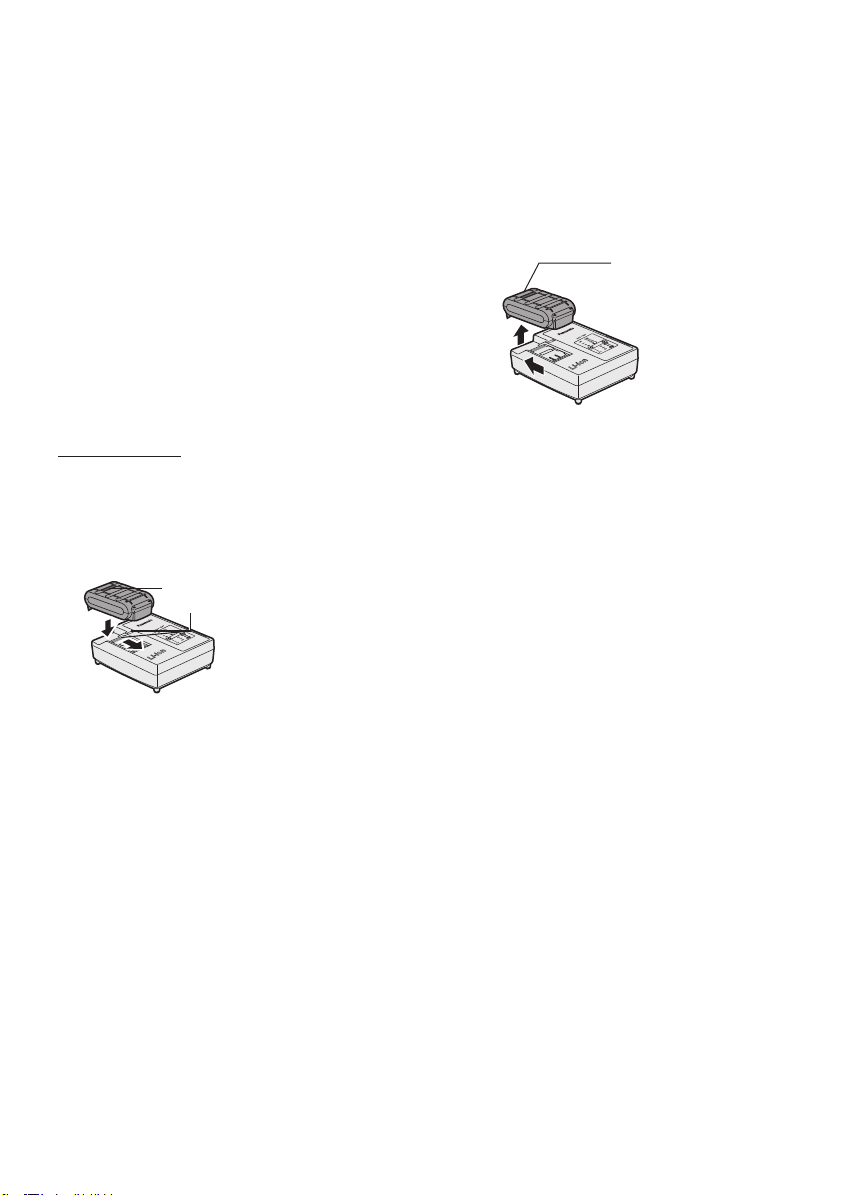

Battery charger

1. Plug the charger into the AC outlet.

2.

Insert the battery pack firmly into the charger.

1 Line up the alignment marks and place the

battery onto the dock on the charger.

2 Slide forward in the direction of the arrow.

Alignment marks

of a fully charged battery at normal operating temperature.

Consult an authorized dealer if the charging

7.

lamp (green) does not turn off.

8. If a fully charged battery pack is inserted

into the charger again, the charging lamp

lights up. After several minutes, the charging lamp in green color will turn off.

9. Remove the battery pack while the battery

pack release button is held up.

Battery pack

release button

3.

During charging, the charging lamp will be

illuminated.

When charging is completed, an internal

electronic switch will automatically be triggered to prevent overcharging.

• Charging will not start if the battery pack

is warm (for example, immediately after

heavy-duty operation).

The orange standby lamp will be flash-

ing until the battery cools down.

Charging will then begin automatically.

4. The charge lamp (green) will flash slowly

once the battery is approximately 80%

charged.

When charging is completed, the charging

5.

lamp in green color will turn off.

6. If the temperature of the batter pack is

0°C or less, charging takes longer to fully

charge the battery pack than the standard

charging time.

Even when the battery is fully charged, it

will have approximately 50% of the power

-

14 -

Page 15

LAMP INDICATIONS

Charging is completed. (Full charge.)

Battery is approximately 80% charged.

Now charging.

Charger is plugged into the AC outlet. Ready to charge.

(Green) (Orange)

Turn off Illuminated Flashing

Charging Status Lamp.

Left: green Right: orange will be displayed.

Battery pack is cool.

The battery pack is being charged slowly to reduce the load on the battery.

Battery pack is warm.

Charging will begin when temperature of battery pack drops. If the temperature of the

battery pack is -10° or less, the charging status lamp (orange) will also start flashing .

Charging will begin when the temperature of the battery pack goes up"

Charging is not possible. Clogged with dust or malfunction of the battery pack.

-

15 -

Page 16

VI. MAINTENANCE

• Use only a dry, soft cloth for wiping the unit.

Do not use a damp cloth, thinner, benzine,

or other volatile solvents for cleaning.

• In the event that the inside of the tool or

battery pack is exposed to water, drain

and allow to dry as soon as possible.

Carefully remove any dust or iron filings

that collect inside the tool. If you experience any problems operating the tool,

consult with a repair shop.

VII. TIGHTENING

EY75A1 14.4 V

N × m

(kgf-cm)

196.0

(2000)

147.0

(1500)

(1000)

Tightening torque

(500)

M8, M10 x 35 mm. M12 x 45 mm

98.0

49.0

High tensile bolt

M12

M10

M8

TORQUE

The power required for tightening a bolt will

vary, according to bolt material and size, as

well as the material being bolted. Choose

the length of tightening time accordingly.

Reference values are provided below.

(They may vary according to tightening conditions.)

Factors Affecting Tightening Torque

The tightening torque is affected by a wide

variety of factors including the followings.

After tightening, always check the torque

with a torque wrench.

1) Voltage

When the battery pack becomes near-

ly discharged, the voltage decreases and

the tightening torque drops.

Bolt Tightening Conditions

EY75A1 14.4 V

M10 x 35 mm M12, M14, M16 x 45 mm

N × m

(kgf-cm)

196.0

(2000)

147.0

(1500)

Standard bolt

M16

0.50.0 1.0 1.5 2.0 2.5 3.0

EY75A2 14.4 V

M10 x 35 mm M12, M14, M16 x 45 mm

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

Tightening torque

(500)

M12

M10

0.50.0 1.0 1.5 2.0 2.5 3.0

EY75A2 14.4 V

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

M8, M10 x 35 mm. M12 x 45 mm

Tightening time (Sec.)

Standard bolt

M16

M14

Tightening time (Sec.)

High tensile bolt

M12

98.0

(1000)

49.0

Tightening torque

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M14

M12

M10

Tightening time (Sec.)

-

16 -

98.0

(1000)

49.0

Tightening torque

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M10

M8

Tightening time (Sec.)

Page 17

EY75A1 18 V

M10 x 35 mm M12, M14, M16 x 45 mm

N × m

(kgf-cm)

196.0

(2000)

Standard bolt

EY75A2 18 V

N s m

(kgf-cm)

196.0

(2000)

M8, M10 x 35 mm. M12 x 45 mm

High tensile bolt

147.0

(1500)

98.0

(1000)

49.0

Tightening torque

(500)

EY75A1 18 V

N × m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

Tightening torque

(500)

EY75A2 18 V

M10 x 35 mm M12, M14, M16 x 45 mm

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

Tightening torque

(500)

M10

M16

M14

M12

M10

0.50.0 1.0 1.5 2.0 2.5 3.0

Tightening time (Sec.)

M8, M10 x 35 mm. M12 x 45 mm

High tensile bolt

M12

M10

M8

0.50.0 1.0 1.5 2.0 2.5 3.0

Tightening time (Sec.)

Standard bolt

M16

M14

M12

147.0

(1500)

98.0

(1000)

49.0

Tightening torque

(500)

M10

M8

0.50.0 1.0 1.5 2.0 2.5 3.0

Tightening time (Sec.)

Bolt

Washer

Steel plate

thickness 10 mm (3/8")

Nut

Washer

Spring washer

Tightening conditions

• The following bolts are used.

Standard bolts: Strength type 4.8

High tensile type 12.9

Explanation of the strength type

4.8

Bolt yield point

(

80% of tensile strength)

32 kgf/mm

Bolt tensile strength

40 kgf/mm

2

(45000 psi)

2

(56000 psi)

2) Tightening time

Longer tightening time results in increased

tightening torque. Excessive tightening,

how ever, adds no value and reduces the

life of the tool.

3) Different bolt diameters

The size of the bolt diameter affects the

tight ening torque.

Generally, as the bolt diameter increases,

tightening torque rises.

4) Tightening conditions

Tightening torque will vary, even with the

same bolt, according to grade, length, and

torque coefficient (the fixed coefficient indicated by the manufacturer upon production).

M12

0.50.0 1.0 1.5 2.0 2.5 3.0

Tightening time (Sec.)

-

17 -

Page 18

Tightening torque will vary, even with

the same bolting material (e.g. steel),

accord ing to the surface finish.

Torque is greatly reduced when the bolt

and nut start turning together.

5) Socket play

Torque is lowered as the six-sided configu-

ration of the socket of the wrong size is

used to tighten a bolt.

6) Switch (Variable speed control trigger)

Torque is lowered if the unit is used with

the switch not fully depressed.

7) Effect of Connecting Adaptor

The tightening torque will be lowered

through the use of a universal joint or a

connecting adaptor.

VIII. ACCESSORIES

Use only suitable size of bit.

Panasonic original Optional Quick change chuck (EY9HX110E).

Chuck Size: 6.35 mm (1/4”) hex

IX. APPENDIX

MAXIMUM RECOMMENDED CAPACITIES

Model

Screw driving

Bolt fastening

Wood screw

Self-drilling screw

EY75A1 EY75A2

3.5 mm - 9.5 mm

3.5 mm - 6 mm

Standard bolt: M6 - M16

High tensile bolt

X. SPECIFICATIONS

: M6 - M12

MAIN UNIT

Model

Motor voltage 14.4 V DC 18 V DC 14.4 V DC 18 V DC

soft mode 0 - 1000 min

No load speed

medium mode 0 - 1400 min

hard mode 0 - 2500 min

Maximum torque

150 N•m (1330 in - lbs)

soft mode 0 - 2000 min

Impact per minute

medium mode 0 - 2800 min

hard mode 0 - 3000 min

Overall length 143 mm (5 - 5/8”) 155 mm (6 - 1/8”)

Weight (with battery pack: EY9L44)

Weight (with battery pack: EY9L45)

1.55 kg (3.42 lbs)

1.55 kg (3.42 lbs)

Weight (with battery pack: EY9L50) Weight (with battery pack: EY9L51) -

EY75A1 EY75A2

-1

(rpm)

-1

(rpm)

200 N•m (1770 in - lbs)

-1

(rpm)

-1

(rpm)

1.55 kg (3.42 lbs)

1.55 kg (3.42 lbs)

-

-

-

18 -

-1

(rpm) 0 - 2300 min

155 N•m (1370 in - lbs)

-1

(rpm) 0 - 3500 min

-

-

1.65 kg (3.64 lbs)

1.65 kg (3.64 lbs)

-1

(rpm)

205 N•m (1815 in - lbs)

-1

(rpm)

-

-

1.65 kg (3.64 lbs)

1.65 kg (3.64 lbs)

Page 19

BATTERY PACK

Model EY9L41 EY9L42 EY9L44 EY9L45 EY9L50 EY9L51

Storage battery Li-ion Battery

Battery voltage

14.4 V DC

(3.6 V x 4 cells)

14.4 V DC

(3.6 V x 8 cells)

18 V DC

(3.6 V x 10 cells)

BATTERY CHARGER

Model EY0L81

Electrical rating See the rating plate on the bottom of the charger

Weight

EY9L41 EY9L42 EY9L44 EY9L45 EY9L50 EY9L51

Charging time

Model EY0L82

Electrical rating See the rating plate on the bottom of the charger

Weight

Charging time

Usable: 45 min Usable: 30 min Usable: 50 min Usable: 65 min Usable: 50 min Usable: 65 min

Full: 60 min Full: 35 min Full: 65 min Full: 80 min Full: 65 min Full: 80 min

EY9L41 EY9L42 EY9L44 EY9L45 EY9L50 EY9L51

Usable: 35 min Usable: 30 min Usable: 40 min Usable: 50 min Usable: 40 min Usable: 55 min

Full: 50 min Full: 35 min Full: 55 min Full: 60 min Full: 55 min Full: 70 min

NOTE: This chart may include models that are not available in your area.

Please refer to the latest general catalogue.

NOTE: For the dealer name and address, please see the included warranty card.

0.93 kg (2 lbs)

0.93 kg (2 lbs)

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: To assure continued compliance, install and use in accordance with provided instructions. Use only the battery pack specified in the instructions. Any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate this equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

This Class B digital apparatus complies with Canadian ICES-003.

19 -

-

Page 20

Cet outil, en tant qu'unité complète avec sa

batterie autonome, répond aux Degrés de

Protection IP appropriés selon les normes

IEC.

Définitions des codes IP

IP5X: L’entrée de poussière n’est

pas complètement empêchée mais

la poussière ne doit pas pénétrer au

point de perturber le fonctionnement

satisfaisant de l’outil ou d’en affecter

la sécurité (Au cas où de la poudre

de talc de moins de 75 μm s’introduirait à l’intérieur de l’outil).

IPX6: L’eau projetée en jets puissants contre l’outil de n’importe

quelle direction ne doit pas avoir d’

effets nuisibles (Au cas où approximativement 100 L/min d’eau à température normale est projetée sur l’

outil a 3 mètre de distance pendant 3

minutes avec une lance de 12,5 mm

de diamètre intérieur).

GARANTIE LIMITÉE

Le code IP56 rend possible un

impact minimum d’eau et de poussière sur cet outil mais il n’en garantit

pas les performances dans de telles

conditions. Veuillez lire la notice d’

utilisation et de sécurité pour plus de

détails quant à un fonctionnement

approprié.

I.

CONSIGNES DE SECURITE GENERALES

AVERTISSEMENT! Veuillez lire

toutes les instructions.

Si les instructions détaillées ci-dessous ne

sont pas observées, cela peut entraîner une

électrocution, un incendie et/ou des blessures

graves. Le terme “outil mécanique” utilisé dans

tous les avertissements ci-dessous se réfère

aux outils mécaniques opérés par cordons

d'alimentation et par batterie (sans fi l).

-

20 -

CONSERVEZ CES INSTRUCTIONS

Sécurité de la zone de travail

1) Gardez la zone de travail propre et

bien aérée.

Les endroits encombrés et sombres invitent les accidents.

2) Ne faites pas fonctionner les outils

mécaniques dans des atmosphères

explosives, comme en présence de

liquides inflammables, de gaz ou de

poussière.

Les outils mécaniques génèrent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

3) Gardez les enfants et les spectateurs

éloignés lors du fonctionnement d’un

outil mécanique.

Les distractions peuvent en faire perdre le

contrôle.

Sécurité électrique

1) La fiche des outils mécaniques doit

correspondre aux prises secteur. Ne

modifiez la fiche sous aucun prétexte.

N’utilisez pas de fiche adaptatrice avec

les outils mécaniques mis à la terre.

Des fiches non modifiées et des prises

secteur correspondant réduisent les

risques d’électrocution.

2) Evitez tout contact physique avec les

surfaces mises à la terre telles que

tuyaux, radiateurs, micro-ondes et

réfrigérateurs.

Il y a un risque d’électrocution supplémentaire si votre corps est mis à la terre.

3) N’exposez pas les outils mécaniques à

la pluie ou à des conditions humides.

De l’eau pénétrant dans un outil mécanique augmente le risque d’électrocution.

4) Ne malmenez pas le cordon. N’utilisez

jamais le cordon pour transporter,

pour tirer ou pour débrancher l’outil

mécanique. Gardez le cordon éloigné

de la chaleur, de l’huile, d’objets aux

bords coupants ou de pièces en

mouvement.

Les cordons endommagés on emmêlés

augmentent le risque d'électrocution.

5)

Lors du fonctionnement des outils

méca niques à l

une rallonge adaptée à l

l

’

extérieur.

L’utilisation d’un cordon adapté à l’utilisation à l’extérieur réduit les risques d’électrocution.

’

extérieur, utilisez

’

utilisation à

Page 21

6)

Si le fonctionnement d’un outil mécanique

dans un endroit humide est inévitable, utilisez

une alimentation électrique pour dispositif

protégé contre le courant résiduel (RC D).

L’utilisation d’un RCD réduit les risques

d’électrocution.

Sécurité personnelle

1) Restez alerte, regardez ce que vous

faites et faites preuve de bon sens

lorsque vous utilisez un outil mécanique. N’utilisez pas un outil mécanique alors que vous êtes fatigué ou

sous les effets de drogue, d’alcool ou

de médicaments.

Un moment d’inattention pendant que

vous faites fonctionner l’outil mécanique

peut entraîner des blessures graves.

2) Utilisez des équipements de sécurité.

Portez toujours des protection pour

vos yeux.

Des équipements de sécurité comme

masque antipoussière, chaussures

de sécurité non glissantes, casque de

protection ou protections d’oreilles,

utilisés dans des conditions appropriées

réduisent les blessures corporelles.

3) Evitez tout démarrage accidentel.

Assurez-vous que l’interrupteur est

en position d'arrêt avant de brancher

l’outil.

Le transport d’outils mécaniques avec le

doigt sur l’interrupteur ou le branchement

d’outils mécaniques dont l’interrupteur

est sur la position de marche invite les

accidents.

4) Retirez toute clé d’ajustement ou

clé de serrage avant de mettre l’outil

mécanique en marche.

Une clé de serrage ou une clé d’ajustement laissée attachée à une pièce

tournante de l’outil mécanique peut

entraîner des blessures corporelles.

5) Ne vous mettez pas en déséquilibre.

Gardez une bonne prise au sol et votre

équilibre à tout moment.

Ceci permet un meilleur contrôle de l’outil

mécanique dans des situations inattendues.

6) Habillez-vous correctement. Ne portez

pas de vêtements lâches ou de bijoux.

Gardez vos cheveux, vêtements et

gants éloignés des pièces en mouvement.

Des vêtements lâches, des bijoux ou

des cheveux longs peuvent se faire

prendre dans les pièces en mouvement.

7) Si des dispositifs pour la connexion

d’ap pareils d’extraction et de ramassage de la poussière sont fournis,

assurez-vous qu’ils sont connectés et

correctement utilisés.

L’utilisation de ces dispositifs peut réduire

les risques concernés.

Utilisation et soins de l’outil

méca nique

1)

Ne forcez pas l’outil mécanique. Utilisez

l’outil mécanique correct pour votre

application.

L’outil mécanique correct exécute mieux

le travail dans de meilleurs conditions

de sécurité s’il est utilisé à l’allure pour

laquelle il a été conçu.

2) N’utilisez pas l’outil mécanique si

l’inter rupteur ne le met pas en marche

ou ne l’arrête pas.

Tout outil mécanique qui ne peut pas

être contrôlé par son interrupteur est

dangereux et doit être réparé.

3) Débranchez la fiche de la source d’ali-

mentation et/ou du bloc de batterie

avant d’effectuer tout ajustement, de

changer d’accessoire ou de ranger

l’outil mécanique.

De telles mesures de sécurité pré ventives

réduisent les risques de faire démarrer

l’outil mécanique accidentellement.

4)

Rangez les outils mécaniques inutilisés hors de la portée des enfants

et ne laissez personne qui n’est pas

familiarisé avec l’outil mécanique ou

ses instructions faire fonctionner l’outil

mécanique.

Les outils mécaniques sont dangereux

dans les mains des utilisateurs manquant

d’entraînement.

5) Entretenez bien les outils mécani ques.

Vérifiez l’alignement ou l’emboîtage

des pièces en mouvement, l’intégrité

des pièces et toute autre condition

pouvant affecter le fonctionnement de

l’outil mécanique. S’il est endommagé,

faites réparer l’outil mécanique avant

de l’utiliser.

De nombreux accidents sont provoqués

par des outils mécaniques mal entretenus.

6) Maintenez les outils de coupe affûtés

et propres.

Les outils de coupe bien entretenus

avec des lames bien affûtées ont moins

de chances de gripper et sont plus

faciles à contrôler.

-

21 -

Page 22

7) Utilisez l’outil mécanique, les acces-

soires, les mèches, etc., conformément à ces instructions et de la façon

pour laquelle l’outil particulier a été

conçu en tenant compte des conditions de travail et de la tâche à exécuter.

L’utilisation de l’outil mécanique à des

fins autres que celles pour lesquelles il

a été conçu peut présenter une situation à risque.

Utilisation et soins de la batterie

de l’outil

1) Assurez-vous que l’interrupteur est

dans la position d’arrêt avant d’insérer

le bloc de batterie.

L’insertion du bloc de batterie dans un

outil mécanique dont l’interrupteur est

sur la position de marche peut provoquer

des accidents.

2) N’effectuez la recharge qu’avec le

chargeur spécifié par le fabricant.

Un chargeur convenant à un bloc

de bat terie peut entraîner un risque

d’incendie lorsqu’un autre bloc de

batterie est utilisé.

3) N’utilisez les outils mécaniques

qu’avec les bloc de batterie spécialement conçus pour eux.

L’utilisation de tout autre bloc de batterie peut entraîner un risque de blessure et d’incendie.

4)

Lorsqu’un bloc de batterie n’est pas

utilisé, gardez-le éloigné d’objets métalliques comme agrafes, pièces de monnaie, clés, clous, vis ou tout autre petit

objet métallique pouvant établir une

connexion entre les deux bornes.

Si les bornes de la batterie sont mises

en court-circuit, cela peut entraîner des

brûlures ou un incendie.

5) Si elle est malmenée, du liquide peut

s’échapper de la batterie. Evitez tout

contact. Si un contact accidentel se

produit, rincez à l’eau. Si du liquide

entre en contact avec les yeux, consultez un médecin.

Le liquide éjecté de la batterie peut

entraîner des irritations ou des brûlures.

Réparation

1) Faites réparer votre outil mécanique

par du personnel de réparation qualifié en n’utilisant que des pièces de

rechange identiques.

Ceci assure le maintien de la sécurité

de l’outil mécanique.

-

II.

REGLES DE SECURITE

PARTICULIERES

1) Portez des lunettes lorsque vous uti-

lisez l’outil pendant de longues périodes.

L’exposition prolongée à du bruit de

haute densité peut entraîner la perte de

l’ouïe.

2) N’oubliez pas que cet appareil est toujours prêt à fonctionner, parce qu’il ne

doit pas être branché dans une prise

électrique.

3) Tenez l’outil par les surfaces de prise

isolées lorsque vous effectuez une

opération lors de laquelle l’outil de

coupe risque d’entrer en contact avec

des câblages cachés.

Le contact avec un fil sous tension fera

passer le courant dans les pièces métalliques exposées et électrocutera l’opérateur.

4) Si la mèche est coincée, mettez immé-

diate ment le commutateur de la gâchette

hors tension afin de prévenir une surcharge pouvant endommager la batterie

autonome ou le moteur. Dégagez la

mèche en inversant le sens de rotation.

5) NE manœuvrez PAS le levier d’inversion

marche avant - marche arrière lorsque le

commutateur principal est sur la position

de marche. La batterie se déchargerait

rapidement et la perceuse serait endommagée.

6) Lorsque vous rangez ou transportez

l’outil, mettez le levier d’inversion marche

avant - marche arrière sur la position centrale (verrouillage du commutateur).

7) Ne forcez pas l’outil en main tenant la

gâchette de contrôle de vitesse enfon cée

à moitié (mode de contrôle de la vitesse)

de sorte que le moteur s’arrête. Le

circuit de protection s’activera et pourra

empêcher le contrôle de la vitesse. Dans

ce cas, relâchez la gâchette de contrôle

de la vitesse, puis serrez-la à nouveau

pour le fonc tionnement normal.

8) Evitez la pénétration de poussière dans

le mandrin.

9) Ne touchez pas les pièces rotatives pour

éviter toute blessure.

10) N’utilisez pas l’outil continuellement pendant une longue période. Arrêtez d’utiliser

l’outil de temps en temps pour éviter une

augmentation de la température et de

surchauffer le moteur.

22 -

Page 23

11) Ne laissez pas tomber l’outil.

Symbole Signifi cation

V

n

0

… min

Ah

Tours ou mouvements alternatifs

-1

Capacité électrique de la batterie

Afi n de réduire le risque de

blessure, il est nécessaire que

l’utilisateur lise et comprenne le

Volts

Courant continu

Vitesse sans charge

par minute

autonome

mode d’emploi.

A VERTISSEMENT!

La poussière résultant de ponçage, sciage,

meulage, perçage à haute pression et de

toute autre activité de construction, contient

des produits chimiques réputés être cause

de cancer, de malformations congénitales ou

autres problèmes reproductifs. Ces produits

chimiques sont, par exemple :

• Le plomb contenu dans les peintures à

base de plomb

• La silice cristalline, contenue dans les

briques, le ciment et autres produits de

maçonnerie; et

• L’arsenic et le chrome provenant du

bois traité chimiquement.

Pour réduire l’exposition à ces produits

chimiques, il faut travailler dans un lieu bien

aéré et porter un équipement de sécurité

approprié tel que certains masques antipoussière conçus spécialement pour filtrer

les particules microscopiques.

III.

CHARGEUR DE BATTERIE ET BATTERIE

AUTO NOME

Instructions de sécurité

impor tantes

1) CONSERVEZ CES INSTRUCTIONS –

La présente notice contient des instructions de sécurité et d’utilisation importantes pour le chargeur de batterie.

-

2) Avant d’utiliser le chargeur de batterie, lisez toutes les instructions et les

marques d’avertissement figurant sur

le chargeur de batterie, la batterie autonome et le produit utilisant la batterie

autonome.

3)

MISE EN GARDE

que de blessures, chargez la batterie

autonome Panasonic seulement comme

indiqué à la dernière page.

Les autres types de batteries risquent

d’exploser et de causer des blessures

corporelles et des dommages matériels.

4) N’exposez pas le chargeur à la pluie ou

à la neige.

5) Pour réduire les risques de domma ges

à la fiche et au cordon secteur, débranchez le chargeur en tirant la fiche et non

le cordon.

6) Veillez à acheminer le cordon de façon

que personne ne risque de le piétiner,

de trébucher dessus, d’endommager ou

d’étirer le cordon.

7) N’utilisez une rallonge qu'en cas de nécessité absolue.

Si vous utilisez une rallonge inadéquate,

vous risquez de causer un incendie ou

une électrocution. Si vous devez absolument utiliser une rallonge, veillez à respecter les points suivants:

a. Le nombre, la taille et la forme des bro-

ches de la fiche de la rallonge doivent

être identiques à ceux de la fiche du

chargeur de batterie.

b. La rallonge doit avoir des conducteurs

en bon état et être elle-même en bon

état d'utilisation.

c. La taille des conducteurs doit être suf-

fisante pour les normes d'intensité en

ampères du chargeur, comme indiqué

ci-dessous.

TAILLE AWG MINIMUM RECOMMANDÉE DES

RALLONGES POUR CHARGEURS

Norme d’entrée CAAmpères T aille A WG du

Egal ou

supérieur à

0 2 18 18 18 16

8) N’utilisez pas un chargeur dont la fiche

ou le cordon est endommagé – remplacez-les immédiatement.

9) N’utilisez pas le chargeur s’il a reçu un

choc violent, s'il a subi une chute ou s’il

a été endommagé de quelque manière

que ce soit; confiez-le à un technicien

qualifié.

23 -

– Pour réduire le ris-

DE BATTERIES

Mais

inférieur à

Longueur du

cordon, pieds

25 50 100 150

cordon

Page 24

10) Ne démontez pas le chargeur; si des

travaux d’entretien ou de réparation sont

nécessaires, confiez-le à un technicien

qualifié. Si vous le remontez incorrectement, vous risquez de causer une électrocution ou un incendie.

11) Pour réduire le risque d’électrocution,

dé branchez le chargeur de la prise de

courant avant d’entreprendre des travaux d’entretien ou de nettoyage.

12) Le chargeur et la batterie autonome ont

été conçus spécifiquement pour fonctionner ensemble.

Ne tentez pas de charger un autre outil à

batterie ou une autre batterie autonome

avec ce chargeur.

13) Ne tentez pas de charger la batterie

autonome avec un autre chargeur.

14) Ne tentez pas de démonter le logement

de la batterie autonome.

15) Ne rangez pas l’outil ou la batterie autonome à des endroits où la température

est susceptible d'atteindre ou de dépasser 50°C (122°F) (par exemple dans une

remise d’outils électriques, ou dans une

voiture en été), car ceci risquerait d'abîmer la batterie stockée.

16) Ne chargez pas la batterie autonome

lorsque la température est INFÉRIEURE

À 0°C (32°F) ou SUPÉRIEURE à 40°C

(104°F). Ceci est très important pour

conserver le bon état de fonctionnement

de la batterie autonome.

17) N’incinérez pas la batterie autonome.

Elle risquerait d'exploser dans les flammes.

18) Evitez toute utilisation dans un environnement dangereux. N’utilisez pas le

chargeur à un endroit humide ou mouillé.

19) Le chargeur a été conçu pour fonctionner uniquement sur des prises secteur

domestiques standard. Ne l’utilisez pas

sous des tensions différentes!

20) Ne manipulez pas brutalement le cordon

secteur. Ne transportez jamais le chargeur en le tenant par le cordon, ou ne le

tirez pas brutalement pour le débrancher

de la prise. Gardez le cordon à l’abri de

la chaleur, de l’huile et de bords coupants.

21) Chargez la batterie autonome à un endroit bien ventilé; ne couvrez pas le chargeur et la batterie autonome avec un

chiffon, etc., pendant la charge.

22) Si vous utilisez un accessoire non recommandé, un incendie, une électrocution,

des blessures risqueraient de s’ensuivre.

23) Ne court-circuitez pas la batterie autonome. Un court-circuit de la batterie

risquerait de faire passer un courant de

forte intensité, et une surchauffe, un incendie ou des blessures risqueraient de

s'ensuivre.

24) REMARQUE: Si le cordon secteur de

cet appareil est endommagé, il doit être

remplacé exclusivement dans un atelier

agréé par le fabricant, car ces travaux

exigent l’utilisation d’outils spéciaux.

25) POUR RÉDUIRE LES RISQUES

D’ÉLECTROCUTION, CET APPAREIL

EST ÉQUIPÉ D’UNE FICHE POLARISÉE (UNE LAME EST PLUS LARGE

QUE L’AUTRE).

Cette fiche ne pourra être insérée que

d'une seule façon dans une prise polarisée. Si la fiche ne peut pas être

insérée à fond dans la prise, insérez la

fiche sens dessus dessous. Si vous ne

parvenez toujours pas à insérer la fiche,

adressez-vous à un électricien qualifié

pour installer une prise de courant adéquate.

Ne modifiez la fiche en aucune façon.

AVERTISSEMENT:

• N’utilisez que la batterie autonome

Panasonic conçue pour l’utilisation avec

cet outil rechargeable.

• Panasonic décline toute responsabilité

en cas de dommage ou d’accident causé

par l’utilisation d’une batterie autonome

recyclée et d’une batterie autonome de

contrefaçon.

• Ne mettez pas la batterie autonome au

rebut dans un feu ou ne l’exposez pas à

une chaleur excessive.

• N’enfoncez pas de clous ou autres dans

la batterie autonome, ne la soumettez

pas à des chocs, ne la démontez pas ou

n’essayez pas de la modifier.

• Ne laissez pas d’objets métalliques entrer

en contact avec les bornes de la batterie

autonome.

• Ne transportez pas ou ne rangez pas

la batterie autonome dans un récipient

contenant des clous ou tout autre objet

métallique.

• Ne chargez pas la batterie autonome

dans un endroit où la température est élevée comme à proximité d’un feu ou à la

lumière directe du soleil. Sinon la batterie

peut surchauffer, prendre feu ou exploser.

• N’utilisez que le chargeur dédié pour

charger la batterie autonome. Sinon, la

batterie peut fuir, surchauffer ou exploser.

-

24 -

Page 25

•

Après avoir retiré la batterie autonome de

l’outil ou du chargeur, remettez toujours

le couverclede la batterie autonome en

place. Sinon, les contacts de la batterie

peuvent se mettre en court-circuit, entraînant le risque d’un incendie.

•

Si la batterie autonome s’est détériorée,

la remplacer par une batterie neuve.

L’utilisation prolongée d’une batterie autonome endommagée peut provoquer des

dégagements de chaleur, un départ de feu

ou l’explosion de la batterie.

IV. MONTAGE

Fixation ou retrait d’une

mèche

REMARQUE:

•

Lors de l’installation ou de l’enlèvement d’une mèche, débranchez la batterie autonome de l’outil ou placez le

commutateur sur la position centrale

(verrouillage du commutateur).

1. Maintenez le collier du mandrin de

connexion rapide et retirez-le de la

perceuse.

2. Insérez la mèche dans le mandrin.

Relâchez le collier.

3. Le collier reviendra dans sa position d’origine lorsqu’il sera relâché.

4. Tirez sur la mèche pour vérifier qu’elle ne

ressort pas.

5. Pour retirer la mèche, tirez le collier

vers l’extérieur de la même manière.

MISE EN GARDE:

• Si le collier ne revient pas dans sa

position d’origine ou si la mèche ressort lorsque vous tirez dessus, cela

signifie que la mèche n’a pas été

fixée correctement. Assurez-vous

que la mèche est bien fixée avant

toute utilisation.

Utilisez des mèches hexagonales de

6,35 mm (1/4").

Pour assurer une fixation correcte des

mèches, n’utilisez que des mèches

hexagonales avec une détente de 9,5

mm (3/8").

6,35 mm (1/4")

9,5 mm (3/8")

Fixation ou retrait de la

douille

1. Fixation de la douille

Fixez la douille en faisant coulisser la

détente femelle du fond de la douille

sur l’entraînement carré du corps.

Assurez-vous que

que la douille est

bien raccordée au

corps.

2. Pour retirer la douille

irez la douille vers l’extérieur.

T

REMARQUE:

Fixation et retrait des options et

douilles originales

Maintenez le corps au-dessus du

point de congélation (0ºC, 32ºF)

lors de la fixation ou du retrait des

options et des douilles originales à/

de l’entraînement carré du corps.