Panasonic EY7546 User Manual

Cordles Impact Driver/Cordles Impact Wrench

Perceuse à impact sans l/Perceuse à impact sans l

Destornillador de impacto inalámbrico/Destornillador de impacto inalámbrico

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Model No: EY7546/EY7547

EY7550/EY7551

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index/Index/Indice

10.8 V ─ 28.8 V

English: Page 3 Français: Page 16 Español: Página 31

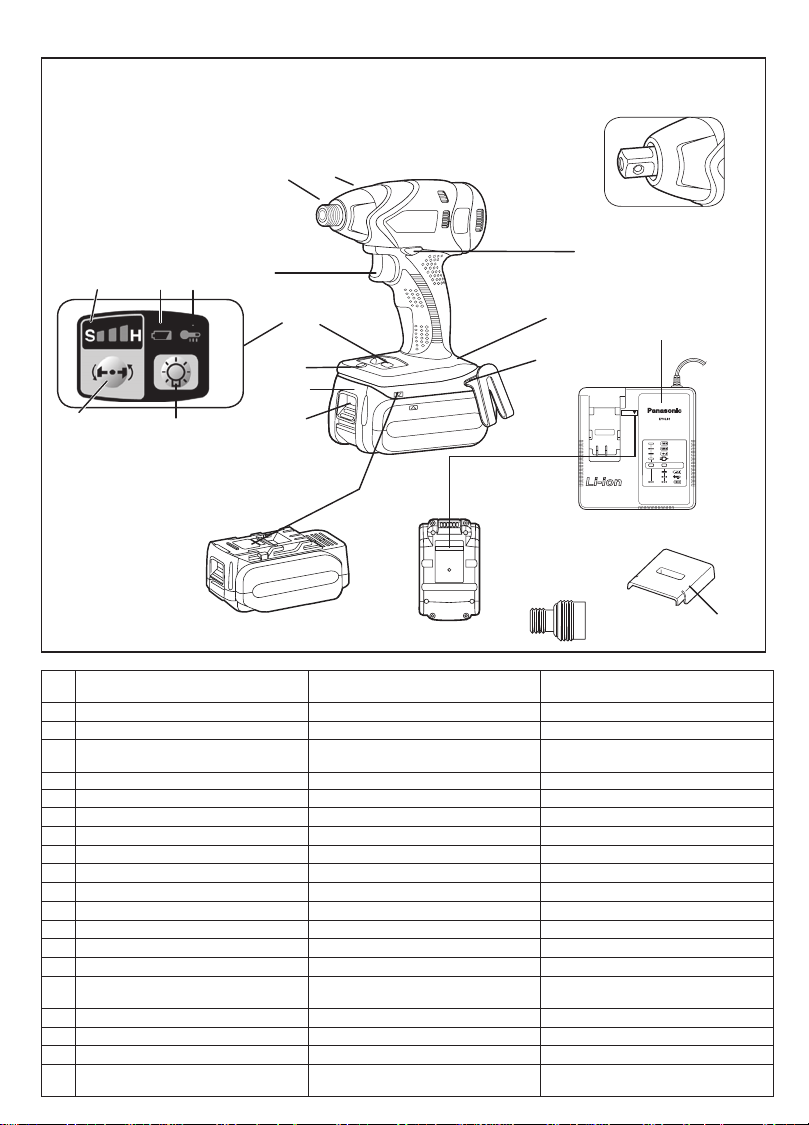

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

(A)′

DESCRIPCIÓN FUNCIONAL

(B)

(A)

(C)

(M)

(N)

(O)

(P)

(J)

(I)

(D)

(Q)

(E)

(H)

(L)

(A) 6.35 mm (1/4″) hex quick connect chuck

(A)′ Square drive (ball detent)

(B) Nose protector Protection du bec Protector del morro

(C) Forward/Reverse lever Levier d’inversion marche avant/

(D) Belt hook lock lever

(E) Belt hook Crochet de ceinture Gancho del cinturón

(F) Alignment marks Marques d’alignement Marcas de alineación

(G) Battery pack release button

(H) Battery pack Batterie autonome Batería

(I) LED light Lumière DEL Luz indicadora

(J) Control panel Panneau de commande Panel de control

(K) LED light ON/OFF button Bouton Marche/Arrêt de la lumière DEL Botón ON/OFF de luz LED

(L) Impact power mode button

(M) Impact power mode display

(N) Battery low warning lamp

(O) Overheat warning lamp (motor/battery) Témoin d’avertissement de surchauffe

(P) Variable speed control trigger Gâchette de commande de vitesse

(Q) Battery charger Chargeur de batterie Cargador de batería

(R) Pack cover Couvercle de la batterie autonome Cubierta de batería

(S) 6.35 mm (1/4") hex quick change

chuck (EY9HX110E)

(K)

(G)

(F)

Mandrin de connexion rapide hexagonal

de 6,35 mm (1/4

Mandrin

marche arrière

Levier de verrouillage du crochet de ceinture

Bouton de libération de batterie autonome

Bouton du mode de puissance de percussion

Afchage du mode de puissance de percussion

Témoin d’avertissement de batterie basse

(moteur/batterie)

Mandrin hexagonal de 6,35 mm (1/4")

de changement rapide (EY9HX110E)

″

)

(S)

Mandril hexagonal de conexión rápida de

6,35 mm (1/4″)

Portabroca

Palanca de avance/marcha atrás

Palanca de bloqueo del gancho de cinturón

Botón de liberación de batería

Botón de modo de potencia de impacto

Indicación de modo de potencia de impacto

Luz de aviso de baja carga de batería

Luz de advertencia de sobrecalenta-

miento (motor/batería)

Disparador del control de velocidad variable

Portabroca de 6,35 mm (1/4”) cambio

rápido hexaonal (EY9HX110E)

(R)

I. GENERAL

This tool, as a complete unit with a battery pack,

satisfies appropriate IP Degrees of Protection

based on the IEC regulations.

Definition of IP code

IP5X: Ingress of dust is not totally prevented,

but dust shall not penetrate in a quantity to

interfere with satisfactory operation of the tool

or to impair safety (In case that the talcum

powder under 75 μm intrudes inside the tool).

IPX6: Water projected in powerful jets against

the tool from any direction shall have no

harmful effects (In case that, with a nozzle

of 12.5 mm inner diameter, approximately

100 L/min of normal temperature water is

injected to the tool for 3 minutes from 3 meter

distance).

LIMITED WARRANTY

The rating of IP56 qualifies this tool for the

minimum impact of water or dust, but not for

the assurance of performance in such conditions. See Safety and Operating Instructions

for further details for proper operation.

SAFETY RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3) Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase

the risk of electric shock.

4) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1)

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury .

2) Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3) Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

4) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

5) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6) Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

2) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must

be repaired.

3) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7) Use the power tool, accessories

and tool bits etc. in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3) Use power tools only with specifically

designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

5) Under abusive conditions, liquid may

be ejected from battery; avoid contact.

If contact accidentally occurs, flush

with water. If liquid contacts eyes,

additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

II. SPECIFIC

SAFETY RULES

1) Wear ear protection. Exposure to noise

can cause hearing loss.

2)

Be aware that this tool is always in an

operating condition, since it does not have

to be plugged into an electrical outlet.

3)

Hold power tools by insulated grip-

ping sur faces when performing an

operation where the cutting tool may

contact hid den wiring.

Contact with a “live” wire will make ex-

posed metal parts of the tool “live” and

shock the operator.

4) If the bit becomes jammed, immediately

turn the trigger switch off to prevent an

overload which can damage the battery

pack or motor. Use reverse motion to

loosen jammed bits.

5) Do NOT operate the Forward/Reverse

lever when the trigger switch is on.

The battery will discharge rapidly and

damage to the unit may occur.

6) When storing or carrying the tool, set

the Forward/Reverse lever to the center

position (switch lock).

7) Do not strain the tool by holding the

speed control trigger halfway (speed

control mode) so that the motor stops.

The protection circuit will activate and

may prevent speed control operation. If

this happens, release the speed control

trigger and squeeze again for normal

operation.

8) Be careful not to get dust inside the

chuck.

9) Do not touch the rotating parts to avoid

injury.

10)

Do not use the tool continuously for a long

period of time. Stop using the tool from time

to time to avoid temperature rise and heat

overload of the motor.

11) Do not drop the tool.

Symbol Meaning

V Volts

Direct current

n

0

… min

Ah

-1

Electrical capacity of battery pack

No load speed

Revolutions or reciprocations

per minutes

To reduce the risk of injury user

must read and understand

instruction manual.

WARNING!

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Cr ysta lli ne s ili ca fr om br icks and

cement and other masonry products

• Arsenic and chromium from chemically-

treated lumber.

To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as dust masks that are specially

designed to filter out microscopic particles.

III.

FOR BA TTER Y CHARGER

& BATTER Y PACK

Important Safety Instructions

1) SAVE THESE INSTRUCTIONS -This

manual contains important safety and

operating instructions for battery charger.

2) Before using battery charger, read all

instructions and cautionary markings

on battery charger, battery pack, and

product using battery pack.

3) CAUTION -To reduce the risk of injury,

charge only Panasonic Battery Pack as

shown in last page.

Other types of batteries may burst

causing personal injury and damage.

4) Do not expose charger and battery pack

to rain or snow.

5) To reduce risk of damaging the electric

plug and cord, pull by plug rather than

cord when disconnecting charger.

6)

Make sure cord is located so that it

will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

7) An extension cord should not be used

unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric shock.

If extension cord must be used, make

sure that:

a. pins on plug of extension cord are

the same number, size and shape as

those of plug on charger.

b. extension cord is properly wired and

in good electrical condition.

c. wire size is large enough for ampere

rating of charger as specified below.

RECOMMENDED MINIMUM AWG SIZE OF

AC Input Rating. Amperes

Equal to or

greater than

0 2 18 18 18 16

EXTENSION CORDS FOR

BATTERY CHARGERS

But less

than

AWG Size of Cord

Length of Cord,

Feet

25 50 100 150

8) Do not operate charger with damaged

cord or plug-replace them immediately.

9) Do not operate charger if it has received

a sharp blow, been dropped, or otherwise damaged in any way; take it to a

qualified service personnel.

10

) Do not disassemble charger; take it

to a qualified service personnel when

service or repair is required. Incorrect

reassembly may result in a risk of

electric shock or fire.

11) To reduce the risk of electric shock,

unplug charger from outlet before

attempting any maintenance or cleaning.

12)

The charger and battery pack are

specifically designed to work together. Do

not attempt to charge any other cordless

tool or battery pack with this charger.

13) Do not attempt to charge the battery

pack with any other charger.

14) Do not attempt to disassemble the

battery pack housing.

15) Do not store the tool and battery pack

in locations where the temperature

may reach or exceed 50°C (122°F)

(such as a metal tool shed, or a car

in the summer), which can lead to

deterioration of the storage battery.

16) Do not charge battery pack when the

temperature is BELOW 0°C (32°F)

or ABOVE 40°C (104°F). This is very

important in order to maintain optimal

condition of the battery pack.

17) Do not incinerate the battery pack. It

can explode in a fire.

18) Avoid dangerous environment. Do not

use charger in damp or wet locations.

19) The charger is designed to operate on

standard household electrical power

only. Do not attempt to use it on any

other voltage!

20) Do not abuse cord. Never carry charger

by cord or yank it to disconnect from

outlet. Keep cord away from heat, oil

and sharp edges.

21) Charge the battery pack in a well

ventilated place, do not cover the

charger and battery pack with a cloth,

etc., while charging.

22) Use of an attachment not recommended

may result in a risk of fire, electric

shock, or personal injury.

23) Do not short the battery pack. A battery

short can cause a large current flow,

over heating and create the risk of fire

or personal injury.

24) NOTE: If the supply cord of this

appliance is damaged, it must only be

replaced by a repair shop authorized

by the manufacturer, because special

purpose tools are required.

25) TO REDUCE THE RISK OF ELECTRIC

SHOCK, THIS APPLIANCE HAS A

POLARIZED PLUG (ONE BLADE IS

WIDER THAN THE OTHER).

This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install the proper outlet. Do not change

the plug in any way.

WARNING:

• Do not use other than the Panasonic battery packs that are designed for use with

this rechargeable tool.

• Panasonic is not responsible for any damage or accident caused by the use of the

recycled battery pack and the counterfeit

battery pack.

• Do not dispose of the battery pack in a

fire, or expose it to excessive heat.

Do not drive the likes of nails into the battery

•

pack, subject it to shocks, dismantle it, or

attempt to modify it.

• Do not allow metal objects to touch the

battery pack terminals.

• Do not carry or store the battery pack

in the same container as nails or similar

metal objects.

• Do not charge the battery pack in a

high-temperature location, such as next

to a fire or in direct sunlight. Otherwise,

the battery may overheat, catch fire, or

explode.

• Never use other than the dedicated charger to charge the battery pack. Otherwise,

the battery may leak, overheat, or

explode.

• After removing the battery pack from the

tool or the charger, always reattach the

pack cover. Otherwise, the battery contacts could be shorted, leading to a risk of

fire.

• When the Battery Pack Has Deteriorated,

Replace It with a New One.

Continued use of a damaged battery pack

may result in heat generation, ignition or

battery rupture.

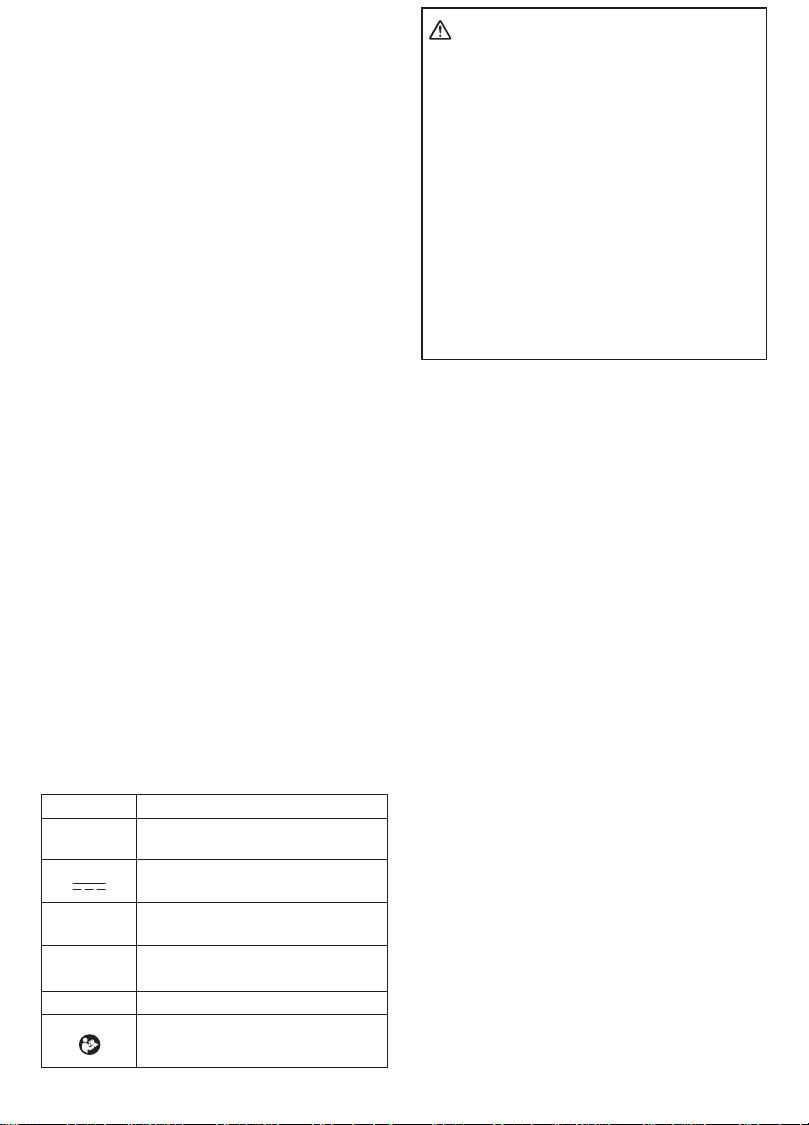

IV. ASSEMBLY

Attaching or Removing Bit

NOTE:

•

When attaching or removing a bit, disconnect battery pack from tool or place the

switch in the center position (switch lock).

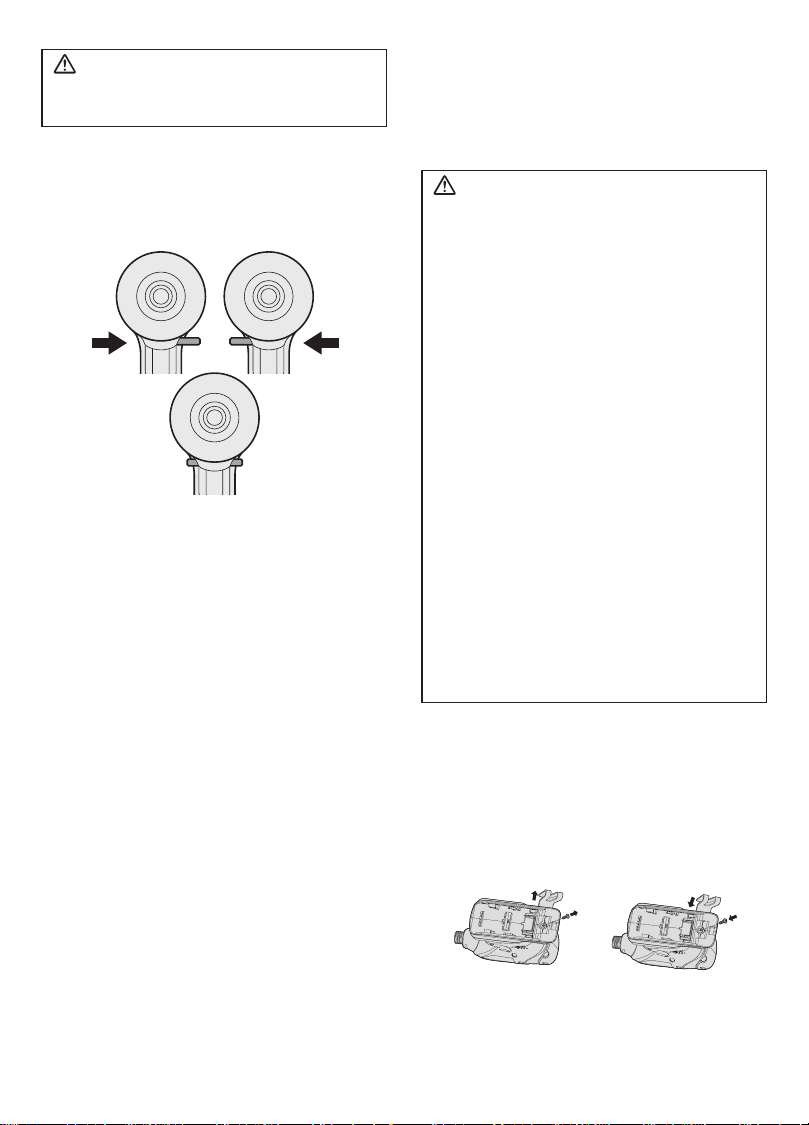

1. Hold the collar of quick connect chuck and

pull it out from the driver.

2. Insert the bit into the chuck. Release the

collar.

3. The collar will return to its original position

when it is released.

Pull the bit to make sure it does not come out.

4.

5. To remove the bit, pull out the collar in the

same way.

CAUTION:

• If the collar does not return to its origi-

nal position or the bit comes out when

pulled on, the bit has not been properly

attached. Make sure the bit is properly

attached before use.

Use 6.35 mm (1/4") hexagonal bits.

To ensure proper securement of the bit,

use only hexagonal bits with 9.5 mm (3/8")

detent.

6.35 mm (1/4")

9.5 mm (3/8")

Attaching or Removing

Sock et

1. Attaching Socket

Attach the socket by sliding the female

detent on the bottom of the socket to the

square drive on the body.

Make sure the

socket is firmly

connected to

the body.

2. Removing Socket

Pull out the socket.

NOTE:

Attaching or Removing Original Options

and Sockets

Keep the body above freezing point

(0°C 32°F) when attach or detach

original options and sockets to the

square drive on the body. The cushion

rubber in the square drive to push up

the ball may get hard under freezing

point. This requires extra force in

detaching and attaching sockets.

Attaching or Removing

Bat tery Pack

1. To connect the battery pack:

Line up the alignment marks and attach

the battery pack.

• Slide the battery pack until it locks into

position.

Alignment

marks

2. To remove the battery pack:

Pull the button from the front to release the

battery pack.

Button

V. OPERATION

Forward Reverse

Switch lock

WARNING!

• Do not inhale any smoke emitted from the

tool or battery pack as it may be harmful.

CAUTION:

•

To eliminate excessive temperature

increase of the tool surface, do not operate the tool continuously using two or

more battery packs. Tool needs cool off

time before switching to another pack.

[Main Body]

Switch and Forward/Reverse

Lever Operation

CAUTION:

To prevent damage, do not operate

Forward/Reverse lever until the bit

comes to a complete stop.

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

3. The speed increases with the amount of

depression of the trigger for efficient tightening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4. After use, set the lever to its center position (switch lock).

How to Use the Belt Hook

WARNING!

• Be sure to attach the belt hook securely to

the main unit with the screw firmly fastened.

When the belt hook is not firmly attached to

the main unit, the hook may disconnect and

the main unit may fall.

This may result in an accident or injury.

• Periodically check screw for tightness. If

found to be loose, tighten firmly.

Be sure to attach the belt hook firmly and

•

securely onto a waist belt or other belt. Pay

attention that the unit does not slip off the

This may result in an accident or injury.

belt.

• When the main unit is held by the belt

hook, avoid jumping or running with it.

Doing so may cause the hook to slip and

the main unit may fall.

This may result in an accident or injury.

• When the belt hook is not used, be sure

to return it to the storing position. The belt

hook may catch on something.

This may result in an accident or injury.

When the unit is hooked onto the waist belt

•

by the belt hook, do not attach driver bits to

the unit. A sharp edge object, such as a drill

bit, may cause injury or an accident.

To Change the Belt Hook

Location Side

The belt hook can be attached to either side

of the unit.

1. Removing the hook

(1) Remove the nut.

(2) Draw out the hook.

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

direction of rotation before use.

2.

Depress the trigger switch slightly to start the

tool slowly.

3. After use, set the lever to its center position (switch lock).

the

2. Attaching the hook to the other side

(1) Insert the hook in the other side.

(2) Tighten the nut fully so that it securely

fastened.

Control Panel

(4) (3)

(1)

(2)

(1) Impact Power Mode Select

Selecting the impact power among 3

modes (Soft, Medium, Hard).

Press the impact power mode button

to set it. The mode changes to hard,

medium, or soft each time the button is

pressed.

The driver is preset to “hard” impact mode

setting when shipped from the manufacturer.

Recommended work guideline table

Impact

Power mode

Display

H

0 – 2300 r.p.m./

0 – 2500 r.p.m.

and

0 – 3000 i.p.m./

0 – 3300 i.p.m./

0 – 3500 i.p.m.

M

0 – 1400 r.p.m.

and

0 – 2800 i.p.m.

S

0 – 1000 r.p.m.

and

0 – 2000 i.p.m.

* i.p.m. = Impact per minute.

Recommended Application

Jobs requiring a high level

of torque where there is

no possibility of the screw

breaking, its top shearing off,

or the bit coming loose. (This

setting provides maximum

torque.) Suitable applications

include:

Tightening M8 and larger

bolts

Tightening long screws

during interior finishing work

Jobs requiring limited torque

where there is a possibility of

the screw breaking or its top

shearing off. (This setting limits

torque.) Suitable applications

include:

Tightening bolts with

smaller diameters (M6)

Tightening metalwork

screws when installing

fixtures

Jobs requiring limited torque

where there is a possibility

of the screw breaking, its

top shearing off, or the bit

coming loose and damaging

a nished exterior surface.

(This setting limits torque.)

Suitable applications include:

Tightening bolts smaller

than M6 that may shear

easily

Tightening screws into

molded plastic

Installing gypsum wallboard

Avoid repeatedly depressing the switch

when the bolts and screws are securely

fastened.

Not doing so may cause a delay in

rotation starting, or the Impact Power

mode display to flash and prevent rotation

from starting for circuit protection.

(2) LED light

Pressing the but ton

tog gles the LED light on

and off.

The light illuminates with

very low current, and

it does not adversely

affect the performance

of the

driver during use

or its battery capacity.

CAUTION:

• The built-in LED light is designed to illuminate the small work area temporarily.

•

Do not use it as a substitute for a regular

flashlight, since it does not have

enough brightness

This product has the built-in LED light.

This product is classified into “Class 1 LED

Product” to IEC (EN) 60825-1:2001.

Class 1 LED Product

Caution : DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance

of procedures other than those specied herein

may result in hazardous radiation exposure.

(3) Overheat warning lamp

Off (normal

operation)

The overheating protection feature halts

driver operation to protect the motor and

battery pack in the event of overheating.

The overheat warning lamp on the control

panel flashes when this feature is active.

• If the overheating protection feature activates, allow the driver to cool thoroughly

(at least 30 minutes). The driver is ready

for use when the overheat warning lamp

goes out.

• Avoid using the driver in a way that

causes the overheating protection feature to activate repeatedly.

.

Flashing: Overheat

Indicates operation has

been halted due to motor

or battery overheating.

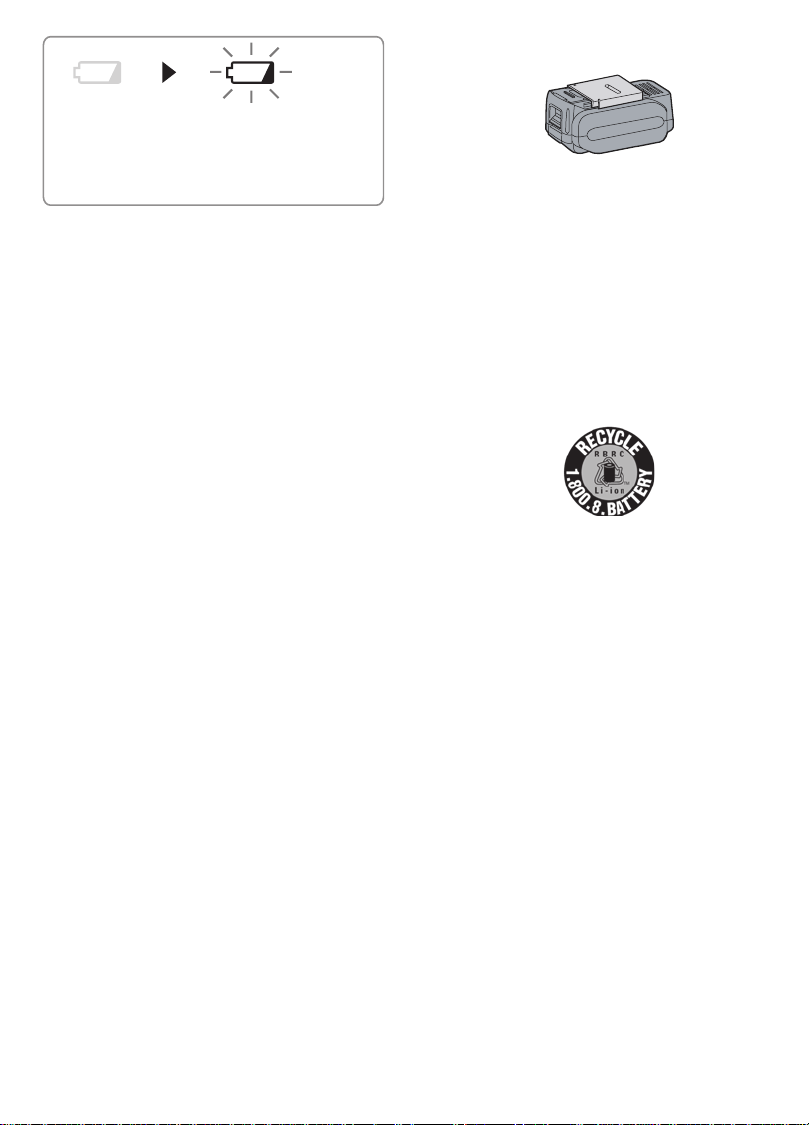

(4) Battery low warning lamp

pack cover immediately in order to prevent

dust or dirt from contaminating the battery

terminals and causing a short circuit.

Off (normal

operation)

Excessive (complete) discharging of

lithium ion batteries shortens their service

life dramatically. The driver includes a

battery protection feature designed to

prevent excessive discharging of the

battery pack.

• The battery protection feature activates

immediately before the battery loses its

charge, causing the battery low warning

lamp to flash.

• If you notice the battery low warning

lamp flashing, charge the battery pack

immediately.

Flashing (No charge)

Battery protection

feature active

Recommended Grip

Use the grip to hold and operate the driver

with one hand. If the job requires additional

force, you can push against the rear end of

the driver with your other hand.

[Battery Pack]

For Appropriate Use of Bat-

tery Pack

Li-ion Battery Pack

•

For optimum battery life, store the Li-ion battery pack following use without charging it.

• When charging the battery pack, confirm

that the terminals on the battery charger

are free of foreign substances such as

dust and water etc. Clean the terminals

before charging the battery pack if any

foreign substances are found on the terminals.

The life of the battery pack terminals may

be affected by foreign substances such as

dust and water etc. during operation.

• When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together

may cause sparks, burns or a fire.

• When operating the battery pack, make

sure the work place is well ventilated.

• When the battery pack is removed from the

main body of the tool, replace the battery

Battery Pack Life

The rechargeable batteries have a limited life. If the operation time becomes

extremely short after recharging, replace

the battery pack with a new one.

Battery Recycling

ATTENTION:

FOR Li-ion Battery Pack

A Li-ion battery that is recyclable powers the

product you have purchased. Please call 1-800-

8-BATTERY for information on how to recycle

this battery.

[Battery Charger]

Charging

CAUTION:

• If the temperature of the battery pack falls

approximately below −10°C (14°F), charg-

ing will automatically stop to prevent degradation of the battery.

• The ambient temperature range is between

0°C (32°F) and 40°C (104°F).

If the battery pack is used when the bat-

tery temperature is below 0°C (32°F),

the tool may fail to function properly.

•

When charging a cool battery pack (below

0°C (32°F)) in a warm place, leave the

battery pack at the place and wait for more

than one hour to warm up the battery to

the level of the ambient temperature.

•

Cool down the charger when charging more

than two battery packs consecutively.

• Do not insert your fingers into contact

hole, when holding charger or any other

occasions.

To prevent the risk of fire or damage to the

battery charger.

• Do not use power source from an engine

generator.

• Do not cover vent holes on the charger

and the battery pack.

• Unplug the charger when not in use.

NOTE:

Your battery pack is not fully charged at

the time of purchase. Be sure to charge

the battery before use.

Battery charger

1. Plug the charger into the AC outlet.

2.

Insert the battery pack firmly into the charger.

1 Line up the alignment marks and place the

battery onto the dock on the charger.

2 Slide forward in the direction of the arrow.

Alignment marks

3.

During charging, the charging lamp will be

lit.

When charging is completed, an internal

electronic switch will automatically be triggered to prevent overcharging.

• Charging will not start if the battery

pack is warm (for example, immediately

after heavy-duty operation).

The orange standby lamp will be flash-

ing until the battery cools down.

Charging will then begin automatically.

4. The charge lamp (green) will flash slowly

once the battery is approximately 80%

charged.

When charging is completed, the charging

5.

lamp in green color will turn off.

6. If the temperature of the batter pack is

0°C or less, charging takes longer to fully

charge the battery pack than the standard

charging time.

Even when the battery is fully charged, it

will have approximately 50% of the power

of a fully charged battery at normal operating temperature.

Consult an authorized dealer if the charging

7.

lamp (green) does not turn off.

8. If a fully charged battery pack is inserted

into the charger again, the charging lamp

lights up. After several minutes, the charging lamp in green color will turn off.

9. Remove the battery pack while the battery

pack release button is held up.

Battery pack

release button

LAMP INDICATIONS

Charging is completed. (Full charge.)

Battery is approximately 80% charged.

Now charging.

Charger is plugged into the AC outlet. Ready to charge.

(Green) (Orange)

Turn off Lit Flashing

Charging Status Lamp.

Left: green Right: orange will be displayed.

Battery pack is cool.

The battery pack is being charged slowly to reduce the load on the battery.

Battery pack is warm.

Charging will begin when temperature of battery pack drops. If the temperature of the

battery pack is -10° or less, the charging status lamp (orange) will also start flashing .

Charging will begin when the temperature of the battery pack goes up"

Charging is not possible. Clogged with dust or malfunction of the battery pack.

VI. MAINTENANCE

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M14

M16

M10

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M10

M8

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M14

M16

M10

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M10

M8

N s m

(kgf-cm)

• Use only a dry, soft cloth for wiping the unit.

Do not use a damp cloth, thinner , benzine,

or other volatile solvents for cleaning.

• In the event that the inside of the tool or

battery pack is exposed to water, drain

and allow to dry as soon as possible.

Carefully remove any dust or iron filings

that collect inside the tool. If you experience any problems operating the tool,

consult with a repair shop.

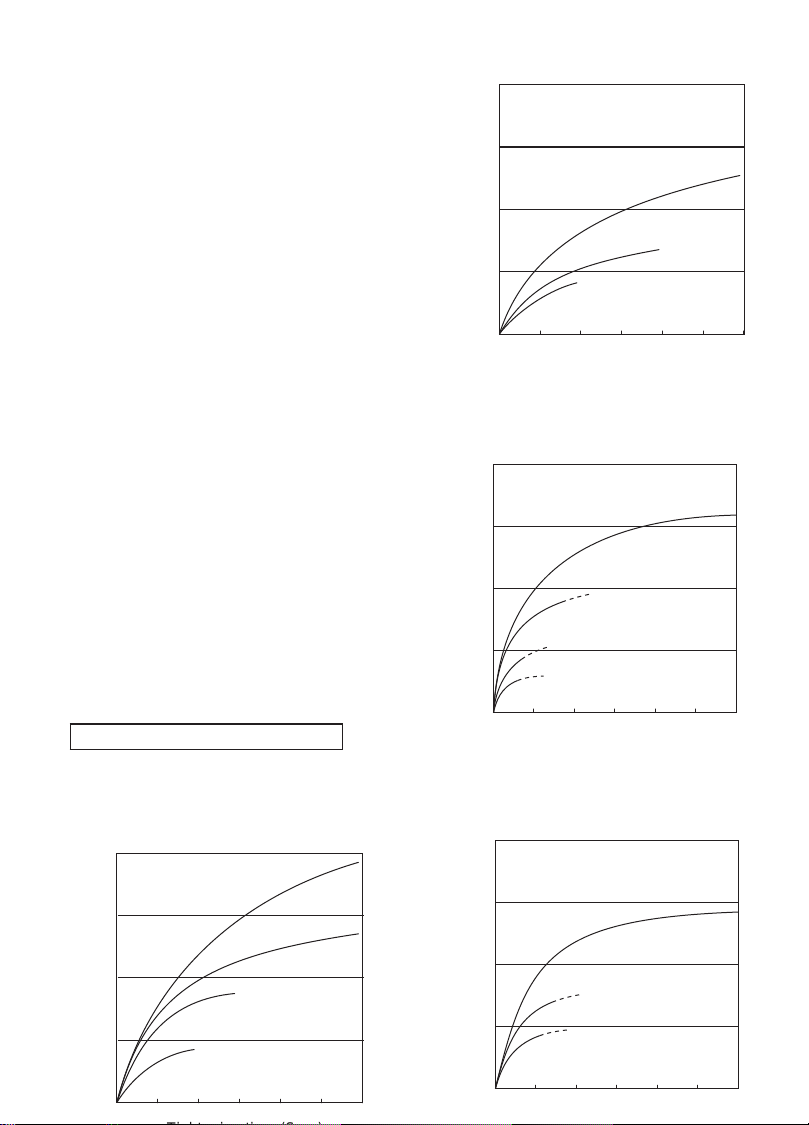

VII. TIGHTENING

TORQUE

The power required for tightening a bolt will

vary, according to bolt material and size, as

well as the material being bolted. Choose

the length of tightening time accordingly.

Reference values are provided below.

(They may vary according to tightening conditions.)

Factors Affecting Tightening Torque

The tightening torque is affected by a wide

variety of factors including the followings.

After tightening, always check the torque

with a torque wrench.

1) Voltage

When the battery pack becomes near-

ly discharged, the voltage decreases and

the tightening torque drops.

EY7546

M8, M10 x 35 mm. M12 x 45 mm

High tensile bolt

Tightening torque

Tightening time (Sec.)

EY7547

M10 x 35 mm M12, M14, M16 x 45 mm

Standard bolt

Tightening torque

EY7546

Bolt Tightening Conditions

M10 x 35 mm M12, M14, M16 x 45 mm

Tightening torque

Standard bolt

Tightening time (Sec.)

EY7547

M8, M10 x 35 mm. M12 x 45 mm

High tensile bolt

Tightening torque

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M10

M8

N s m

(kgf-cm)

4.8

Explanation of the strength type

Bolt yield point

(

80% of tensile strength)

32 kgf/mm

2

(45000 psi)

Bolt tensile strength

40 kgf/mm

2

(56000 psi)

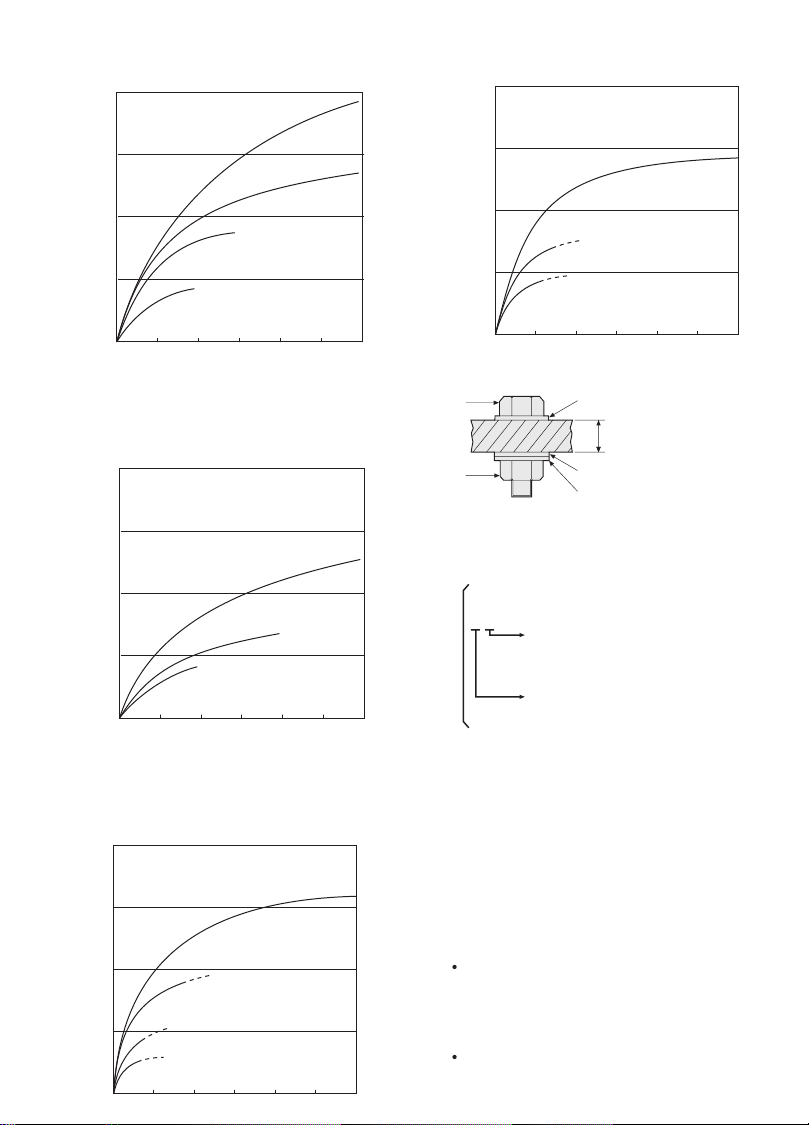

EY7550

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M14

M16

M10

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M10

M8

N s m

(kgf-cm)

196.0

(2000)

147.0

(1500)

98.0

(1000)

49.0

(500)

0.50.0 1.0 1.5 2.0 2.5 3.0

M12

M14

M16

M10

N s m

(kgf-cm)

M10 x 35 mm M12, M14, M16 x 45 mm

Standard bolt

EY7551

M8, M10 x 35 mm. M12 x 45 mm

High tensile bolt

Tightening torque

Tightening time (Sec.)

EY7550

M8, M10 x 35 mm. M12 x 45 mm

Tightening torque

Tightening time (Sec.)

EY7551

M10 x 35 mm M12, M14, M16 x 45 mm

Tightening torque

High tensile bolt

Standard bolt

Tightening torque

Tightening time (Sec.)

Bolt

Washer

Steel plate

thickness 10 mm (3/8")

Nut

Washer

Spring washer

Tightening conditions

• The following bolts are used.

Standard bolts: Strength type 4.8

High tensile type 12.9

2) Tightening time

Longer tightening time results in increased

tightening torque. Excessive tightening,

how ever, adds no value and reduces the

life of the tool.

3) Different bolt diameters

The size of the bolt diameter affects the

tight ening torque.

Generally, as the bolt diameter increases,

tightening torque rises.

4) Tightening conditions

Tightening torque will vary, even with the

same bolt, according to grade, length, and

torque coefficient (the fixed coefficient indicated by the manufacturer upon production).

Tightening torque will vary, even with

the same bolting material (e.g. steel),

accord ing to the surface finish.

Torque is greatly reduced when the bolt

and nut start turning together.

5) Socket play

Torque is lowered as the six-sided configu-

ration of the socket of the wrong size is

used to tighten a bolt.

6) Switch (Variable speed control trigger)

Torque is lowered if the unit is used with

the switch not fully depressed.

7) Effect of Connecting Adaptor

The tightening torque will be lowered

through the use of a universal joint or a

connecting adaptor.

VIII. ACCESSORIES

Use only suitable size of bit.

Panasonic original Optional Quick change chuck (EY9HX110E).

Chuck Size: 6.35 mm (1/4”) hex

IX. APPENDIX

MAXIMUM RECOMMENDED CAPACITIES

Model

Screw driving

Bolt fastening

Wood screw

Self-drilling screw

EY7546 EY7547 EY7550 EY7551

3.5 mm - 9.5 mm

3.5 mm - 6 mm

Standard bolt:M6-M16

High tensile bolt

: M6 - M12

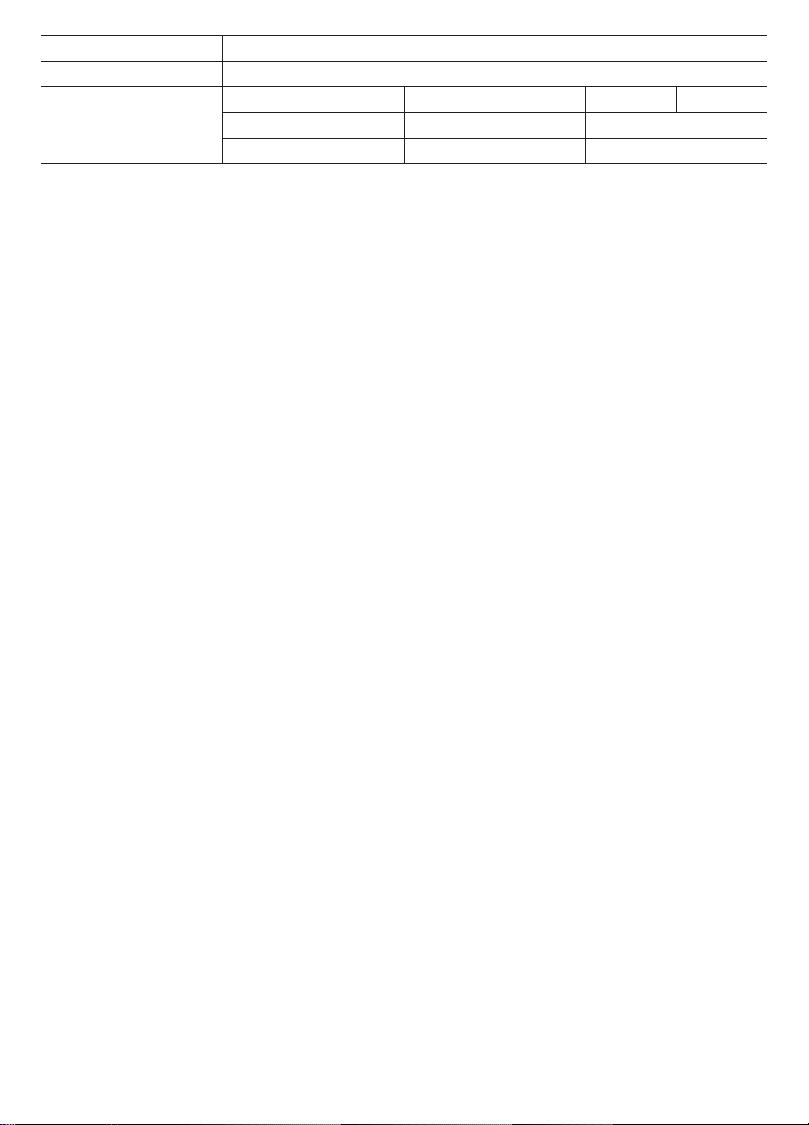

X. SPECIFICATIONS

MAIN UNIT

Model

Motor voltage 14.4 V 18 V

soft mode 0 - 1000 min

No load speed

Maximum torque

Impact per minute

Overall length

Weight (with battery pack EY9L44)

Weight (with battery pack EY9L50)

medium mode 0 - 1400 min

hard mode

soft mode 0 - 2000 min

medium mode 0 - 2800 min

hard mode

BATTERY PACK

Model EY9L41 EY9L42 EY9L44 EY9L50

Storage battery Li-ion

Battery voltage

14.4 V DC

(3.6 V x 4 cells)

EY7546 EY7547 EY7550 EY7551

-1

(rpm)

-1

(rpm)

0 - 2500 min-1 (rpm) 0 - 2300 min-1 (rpm) 0 - 2500 min-1 (rpm) 0 - 2300 min-1 (rpm)

150 N·m (1330 in.Ibs) 200 N·m (1770 in.Ibs) 155 N·m (1370 in.Ibs) 205 N·m (1815 in.Ibs)

0 - 3000 min-1 (rpm) 0 - 3500 min-1 (rpm) 0 - 3300 min-1 (rpm) 0 - 3500 min-1 (rpm)

143 mm (5-5/8˝) 155 mm (6-1/8˝) 143 mm (5-5/8˝) 155 mm (6-1/8˝)

1.5 kg (3.3Ibs)

— —

1.55 kg (3.4Ibs)

14.4 V DC

(3.6 V x 8 cells)

-1

(rpm)

-1

(rpm)

— —

1.6 kg (3.5Ibs)

(3.6 V x 10 cells)

1.65 kg (3.6Ibs)

18 V DC

BATTERY CHARGER

Model EY0L81

Electrical rating See the rating plate on the bottom of the charger.

EY9L41 EY9L42 EY9L44 EY9L50

Charging time

Usable: 45 min. Usable: 30 min. Usable: 50 min.

Full: 60 min. Full: 35 min. Full: 65 min.

NOTE: This chart may include models that are not available in your area.

Please refer to the latest general catalogue.

For the dealer name and address, please see the included warranty card.

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: To assure continued compliance, install and use in accordance with provided in-

structions. Use only the battery pack specified in the instructions. Any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate this equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

This Class B digital apparatus complies with Canadian ICES-003.

Loading...

Loading...