Page 1

ORDER NO. MD0605164CE

DVD Recorder

DMR-ES35VEE

DMR-ES35VGC

DMR-ES35VGCS

DMR-ES35VGN

Vol. 1

Colour

(S).......................Silver Type

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

CONTENTS

Page Page

1 Safety Precautions 3

1.1. GENERAL GUIDELINES

1.2. Caution for AC Mains Lead (For GC only)

1.3. Before Repair and Adjustment

1.4. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Precaution of Laser Diode

4 Handling the Lead free Solder

4.1. General description about Lead Free Solder (PbF)

5 Service Navigation

5.1. Service Information

5.2. CAUTION FOR DivX

6 Specifications

7 Accessories

8 Operation Instructions Procedures

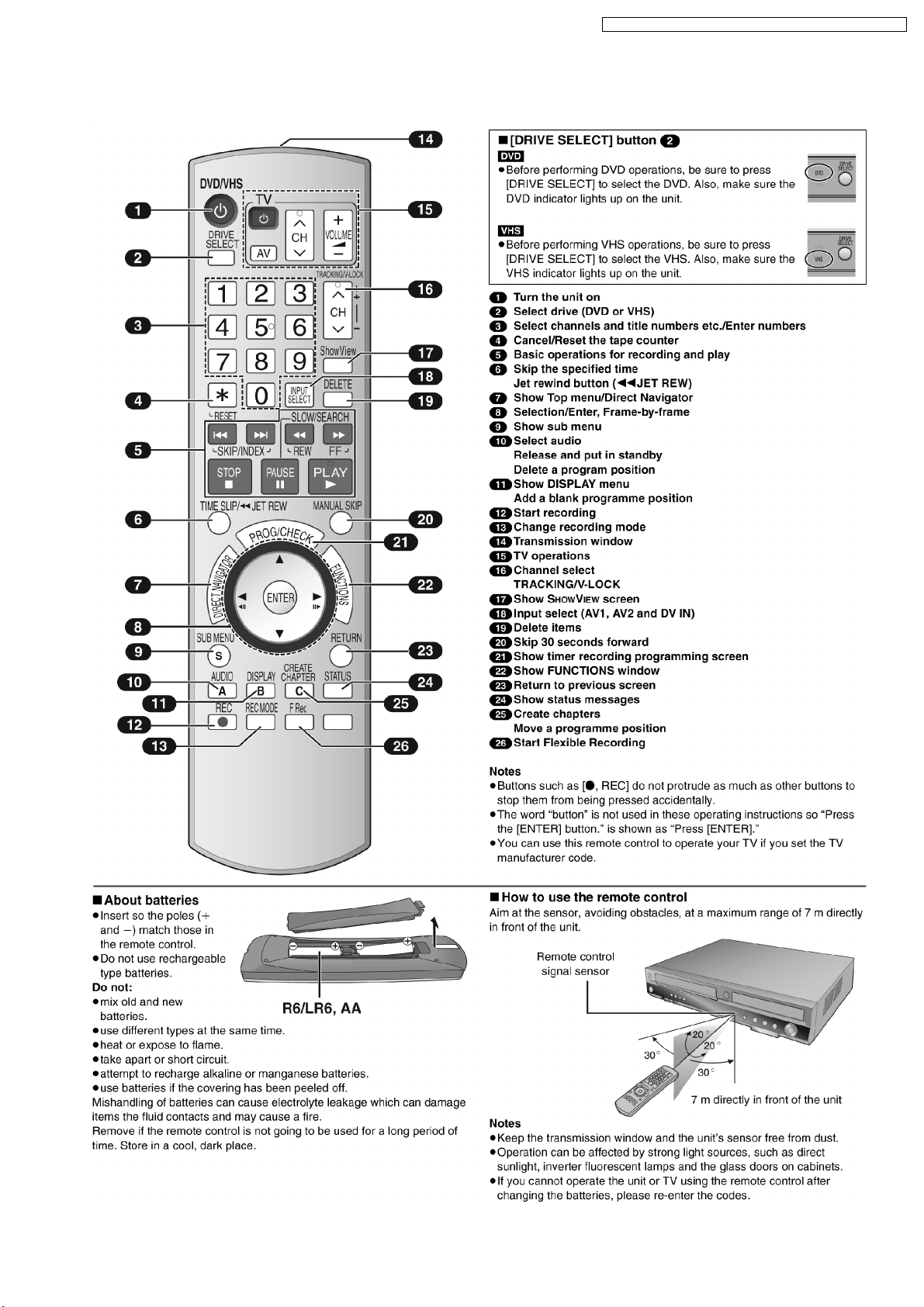

8.1. Remote Control Operation (For GN/GC/GCS)

8.2. Remote Control Operation (For EE)

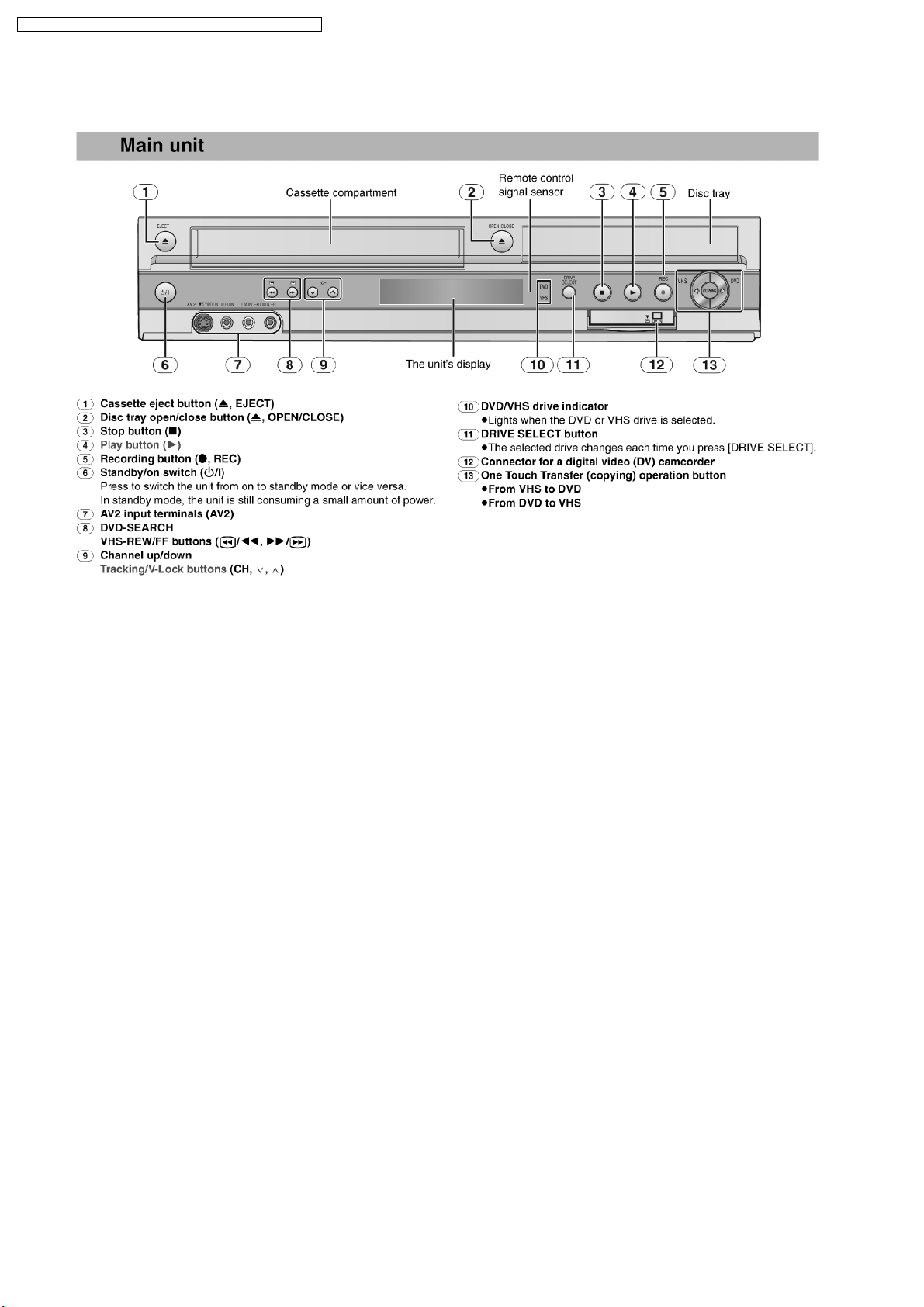

8.3. Main Unit Operation

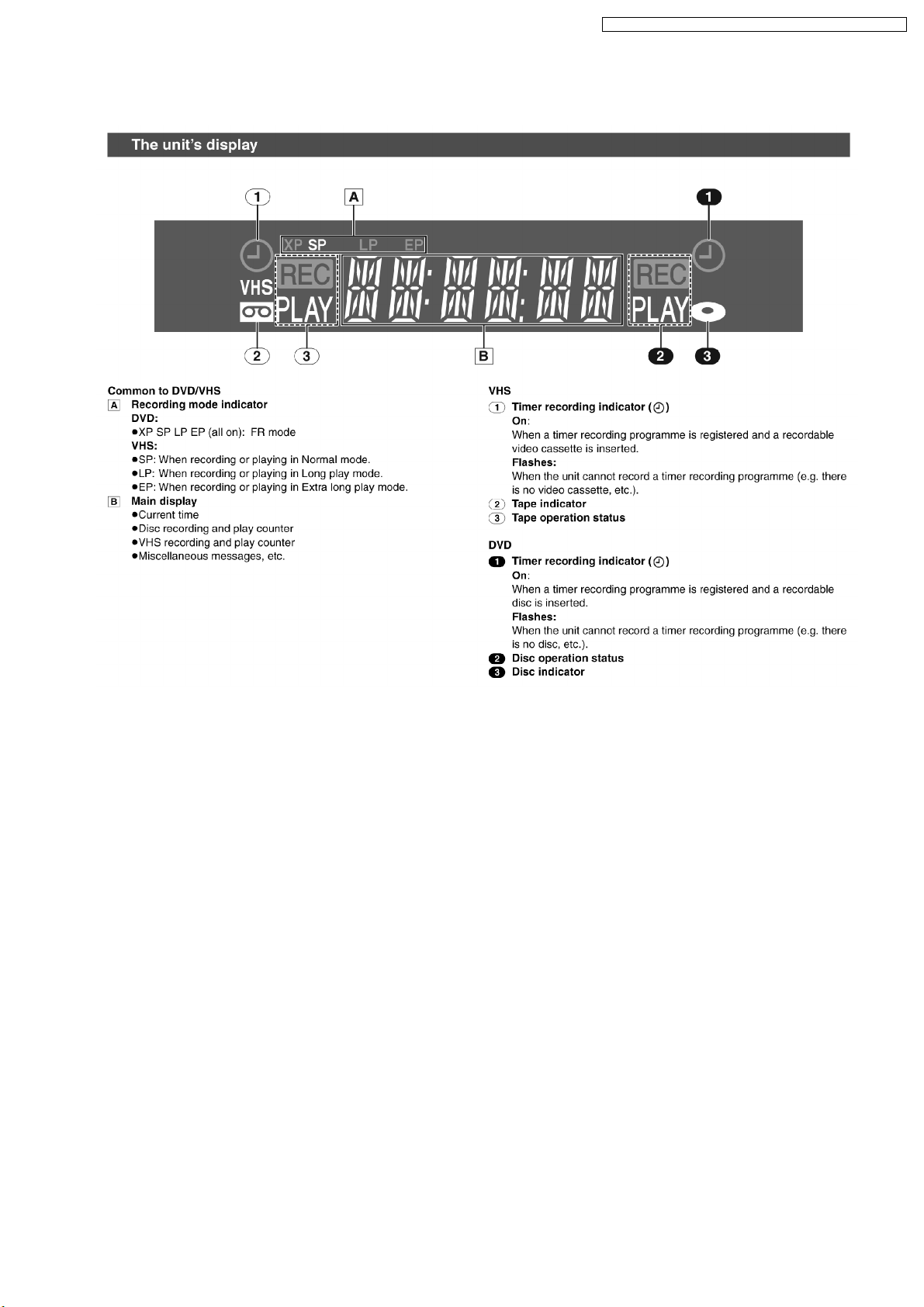

8.4. Main Unit Panel Display

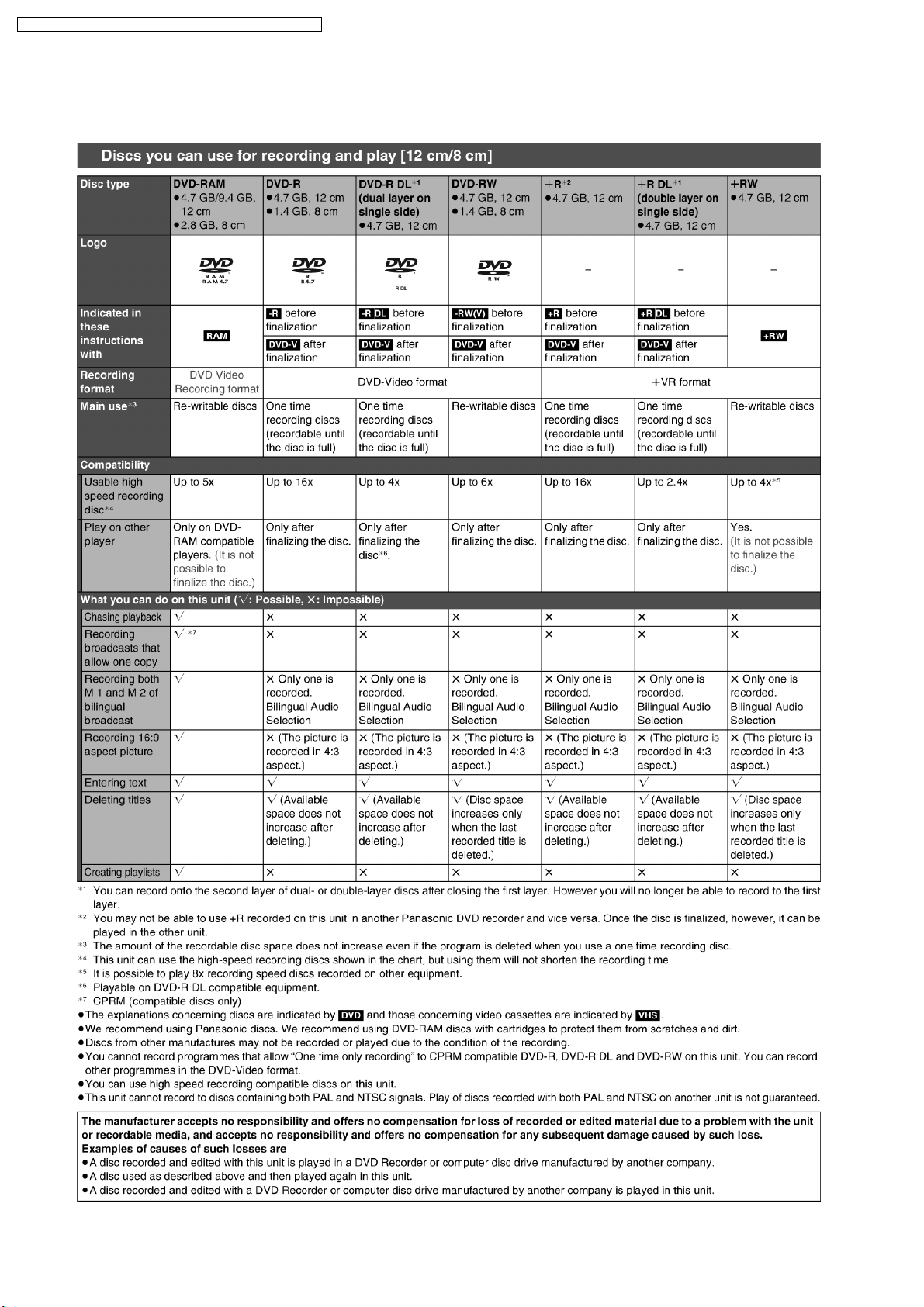

8.5. Disc Information

8.6. ABOUT DivX

8.7. Connection to other Devices

8.8. Connection to other Devices

9 Operation Instructions

9.1. (DVD) Taking out the Disc from RAM-Drive Unit when the

Disc cannot be ejected by OPEN/CLOSE button

9.2. (VHS) Removing Cassette Tape manually

10 Service Mode

10.1. (DVD) Self-Diagnosis and Special Mode Setting

10.2. (VHS) Self-Diagnosis and Special Mode Setting

11 Service Fixture & Tools

12 Assembling and Disassembling

12.1. Caution

12.2. Disassembly Flow Chart

12.3. Main Parts Location Diagram

12.4. Caution with inserting cassette tape when disassembling

the unit

12.5. Disassembly of Top Panel

12.6. Disassembly of Nicam Decoder P.C.B.

12.7. Disassembly of Front Panel

12.8. Disassembly of Front Jack P.C.B. & Panel P.C.B.

10

14

16

16

17

18

19

20

25

31

33

35

35

36

38

38

46

49

50

50

51

52

53

54

54

55

55

3

4

5

5

6

7

8

8

9

9

9

12.9. Disassembly of RAM / Digital P.C.B. Module

12.10. Disassembly of DV Jack P.C.B.

12.11. Disassembly of VTR Mechanism Unit

12.12. Disassembly of Rear Panel

12.13. Disassembly of Fan Motor

12.14. Disassembly of Digital I/F P.C.B.

12.15. Main P.C.B.

13 Measurements and Adjustments

13.1. Service Positions

13.2. Caution for Replacing Parts

13.3. Standard Inspection Specifications after Making Repairs

14 Miscellane ous

14.1. Abbreviations

15 Voltage Measurement and Waveform Chart

15.1. Voltage Measurement

15.2. Waveform Chart

16 Wiring Diagram

17 Block Diagram

17.1. Analog Audio Block Diagram

17.2. Analog Timer Block Diagram

17.3. Analog Video Block Diagram

17.4. Power Supply Block Diagram

17.5. System Control & ServoBlock Diagram

18 Notes of Schematic Diagram

19 Schematic Diagram

19.1. DIGITAL IF CIRCUIT

19.2. MAIN CIRCUIT

19.3. PANEL CIRCUIT

19.4. FRONT JACK CIRCUIT

19.5. NICAM DECODER CIRCUIT

19.6. DV JACK CIRCUIT

20 Printed Circuit Board

20.1. DIGITAL I/F P.C.B

20.2. MAIN P.C.B

20.3. PANEL P.C.B, FRONT JACK P.C.B, NICAM DECODER

P.C.B and DV JACK P.C.B

21 Exploded Views

21.1. Casing Parts & Mechanism Section1

21.2. Casing Parts & Mechanism Section 2

21.3. VHS Mechanism Section

21.4. Packing

22 Replacement Parts List

56

57

58

59

59

59

60

61

61

64

69

71

71

77

77

82

85

87

87

88

89

91

93

95

97

97

102

115

116

117

118

123

123

124

125

127

127

128

129

130

131

2

Page 3

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being expose d to shock hazards.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Figure. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transfo rmer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

3

Page 4

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

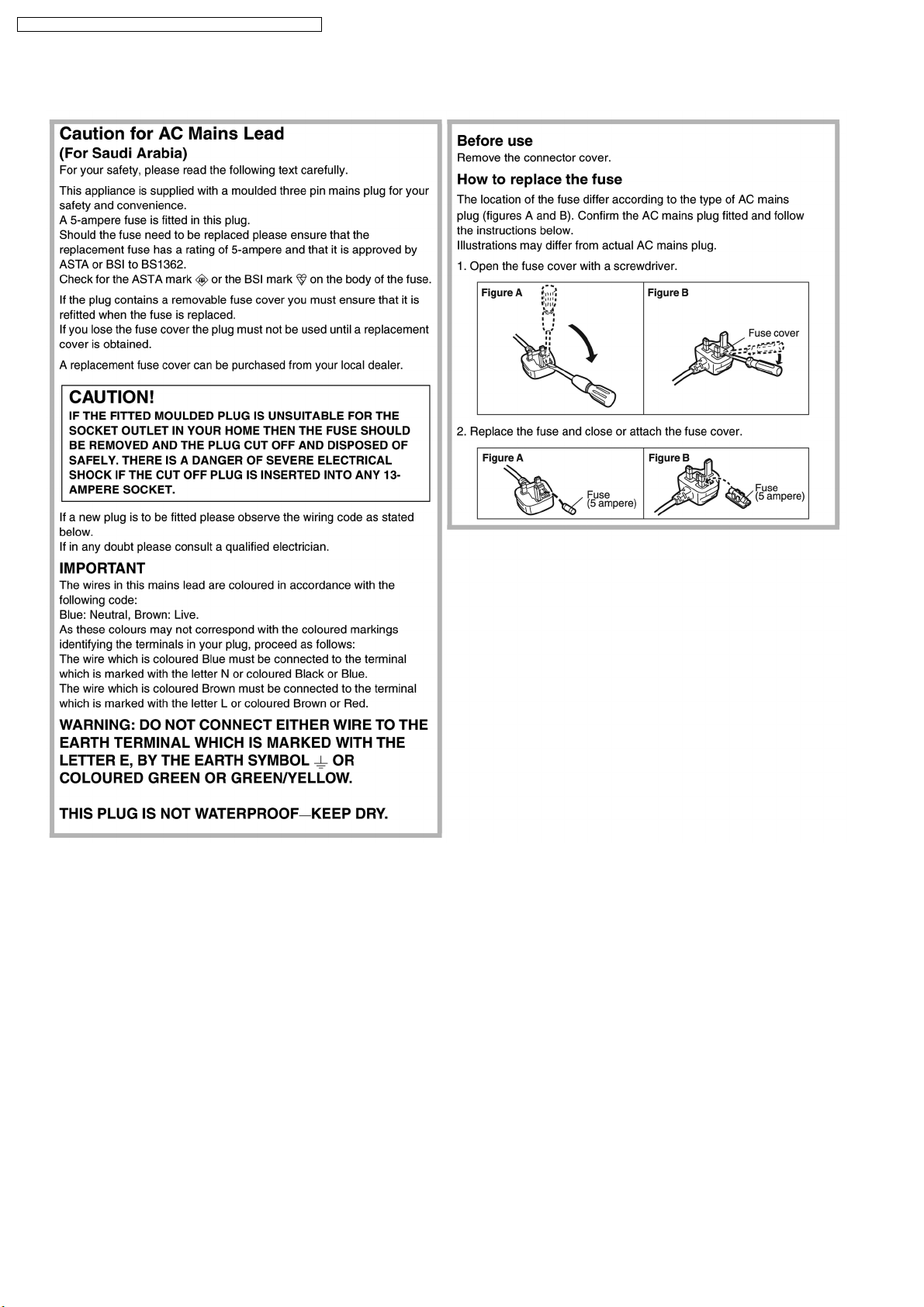

1.2. Caution for AC Mains Lead (For GC only)

4

Page 5

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

1.3. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C11101, C11104, C11105 and C11106 through a 10Ω, 1W resistor to

ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5

Page 6

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

6

Page 7

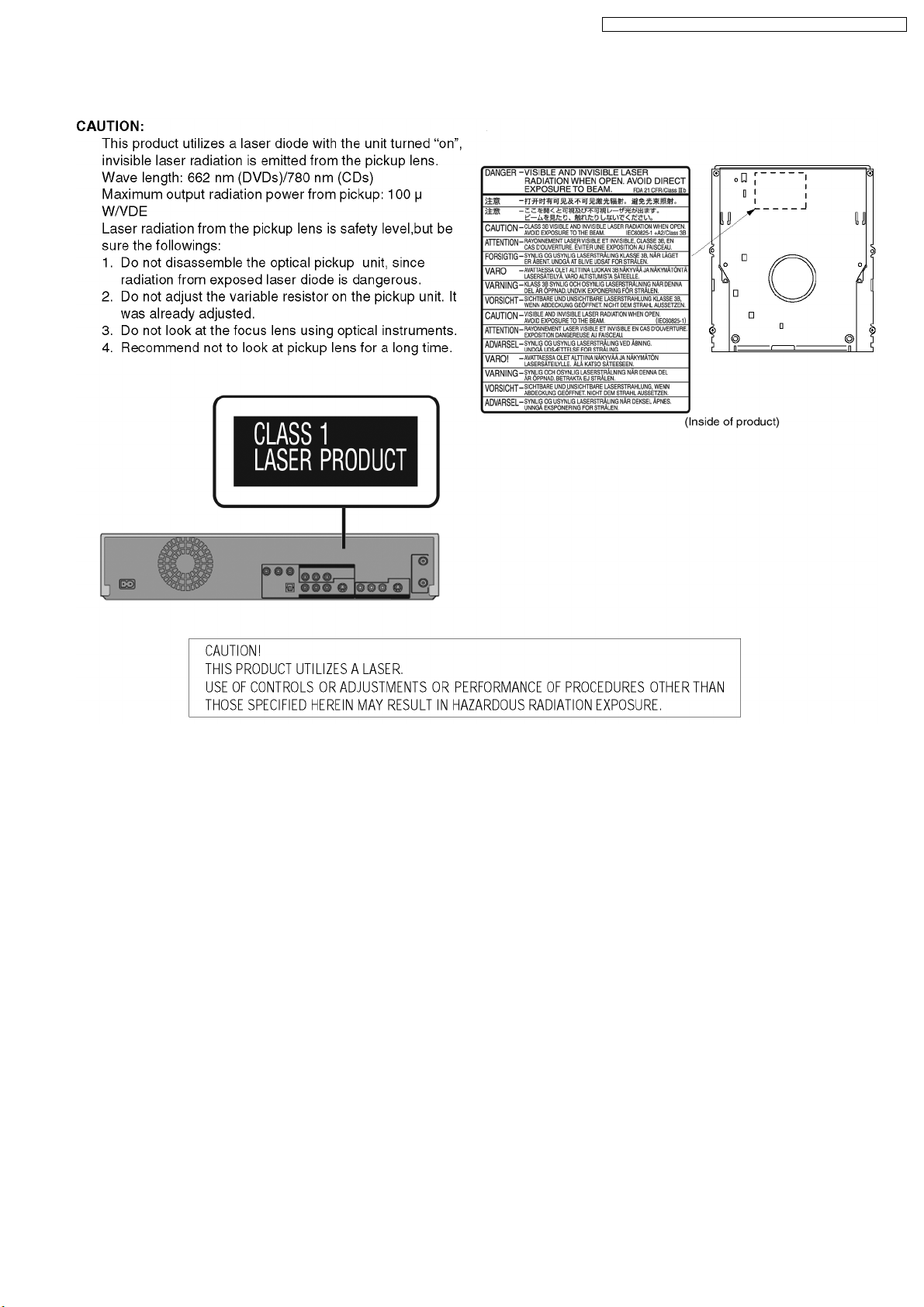

3 Precaution of Laser Diode

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

7

Page 8

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

4 Handling the Lead free Solder

4.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

Page 9

5 Service Navigation

5.1. Service Information

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

5.2. CAUTION FOR DivX

9

Page 10

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

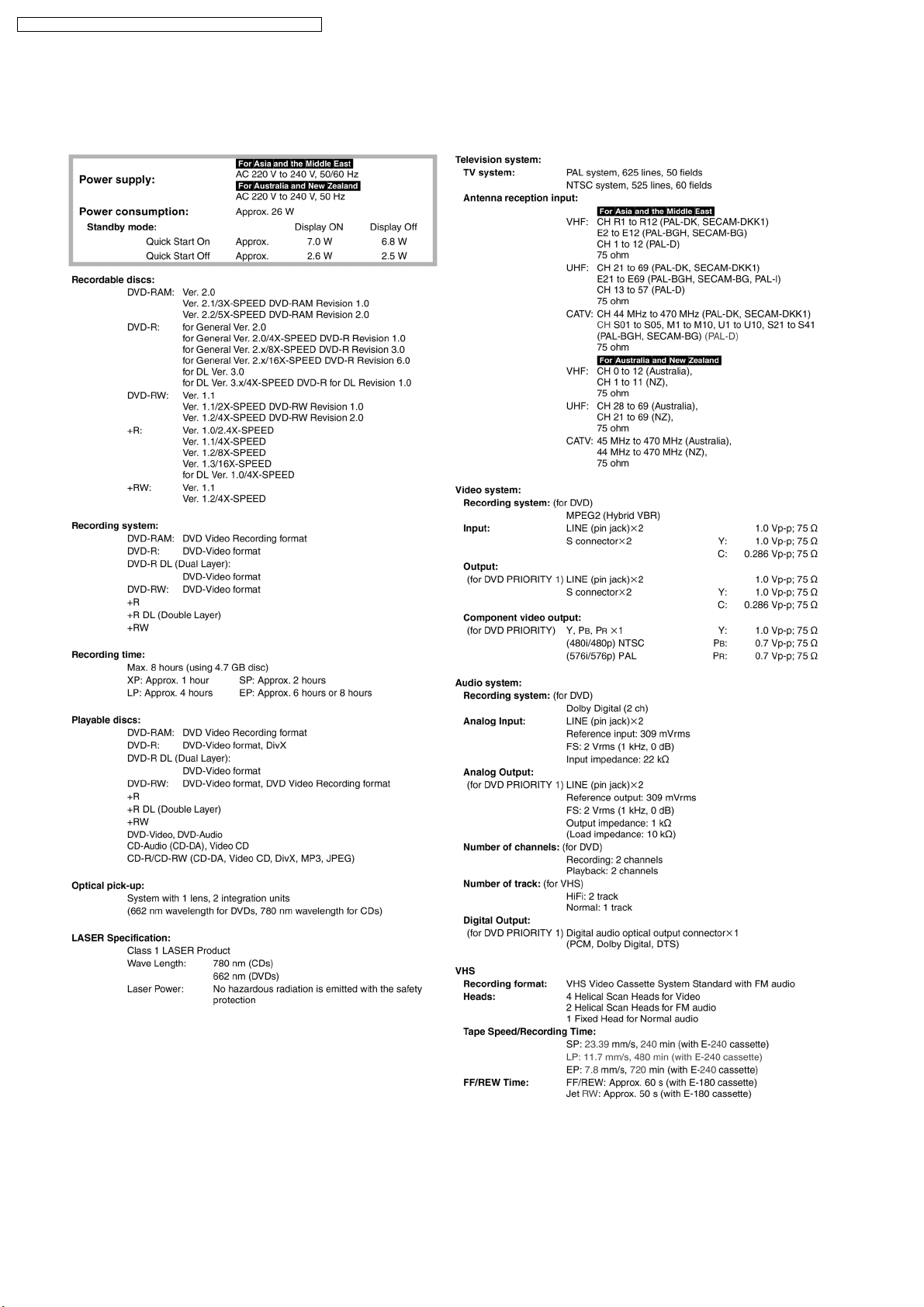

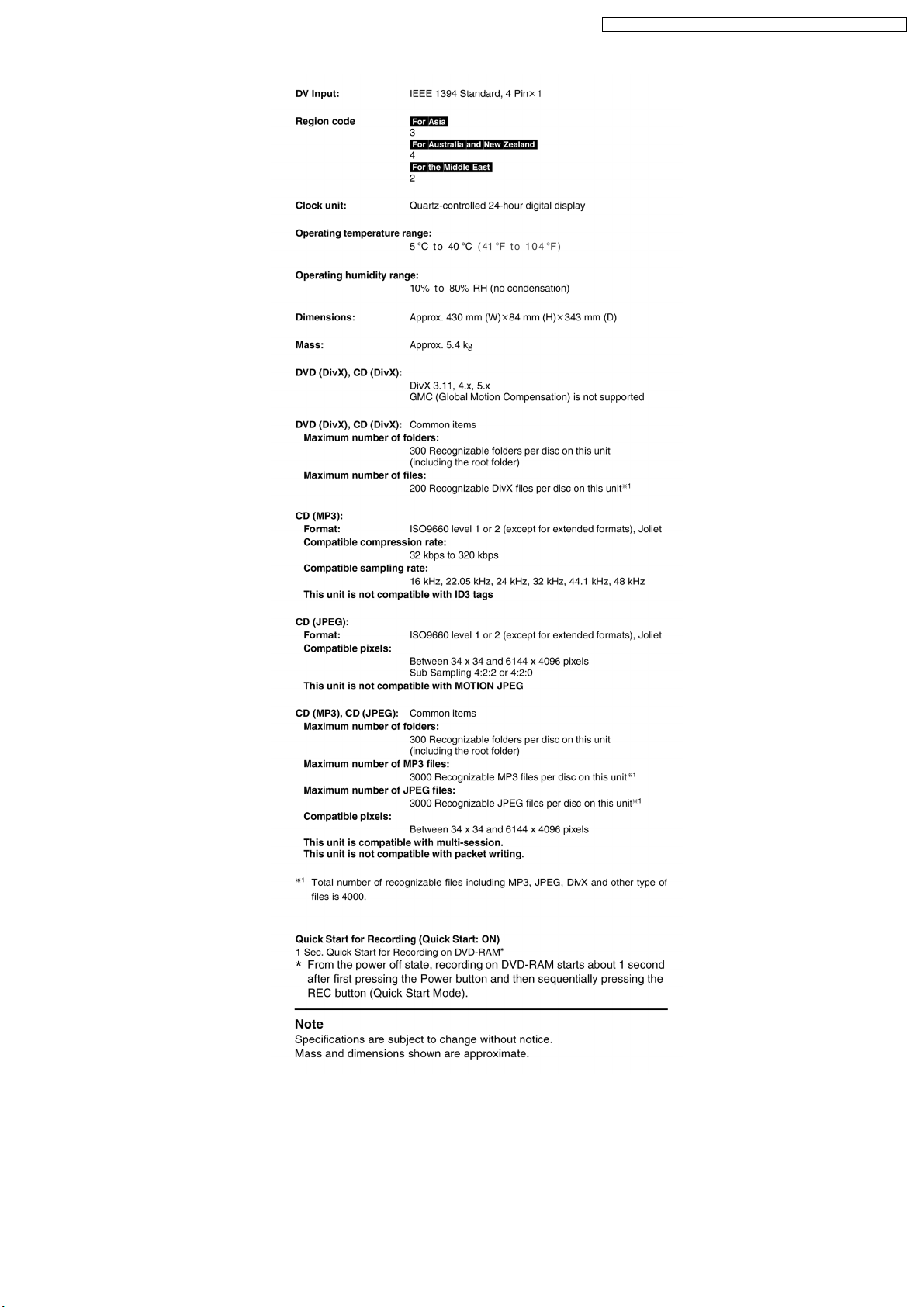

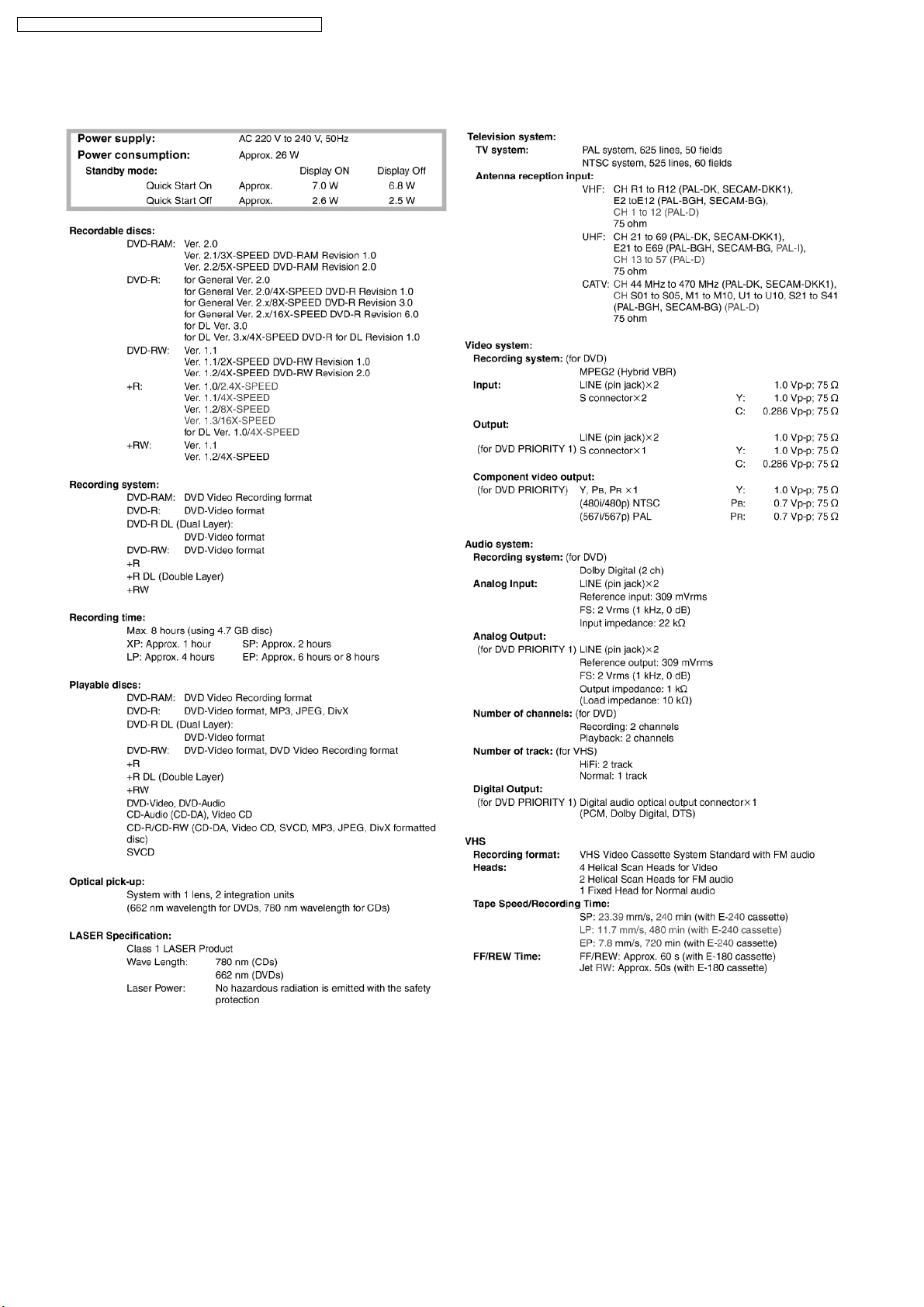

6 Specifications

(For GN/GC/GCS)

10

Page 11

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

11

Page 12

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

(For EE)

12

Page 13

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13

Page 14

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

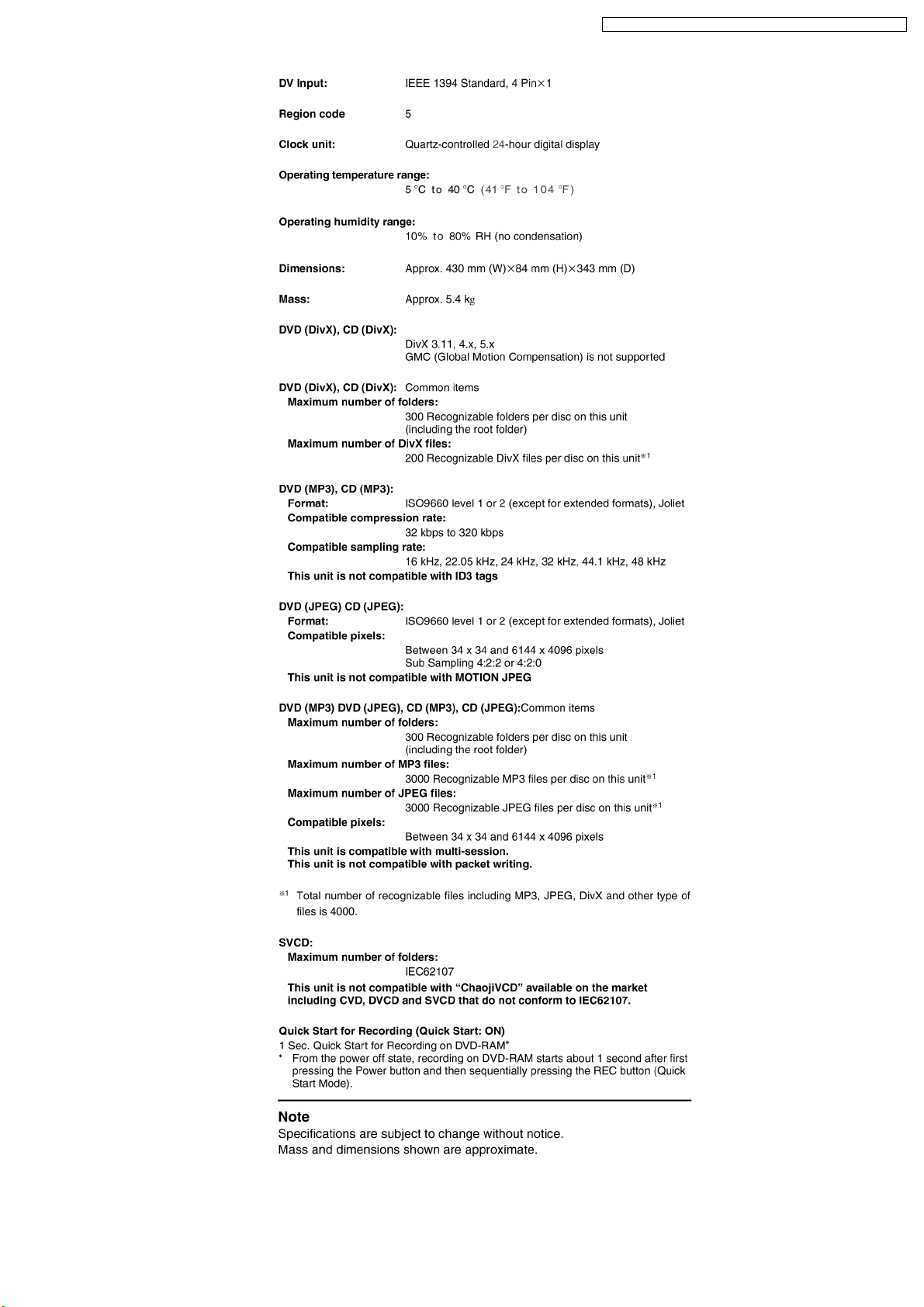

7 Accessories

Note : Refer to Replacement Parts List (Section 22) for the part number.

Remote control (For

GC/GCS)

Remote control (For

GN)

Remote control (For

EE)

AC Cord (For GN)

AC Cord (For

GC/GCS/EE)

AC Cord (For GC)

RF coaxial cable

14

Page 15

Audio/Video cable

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

15

Page 16

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

8 Operation Instructions Procedures

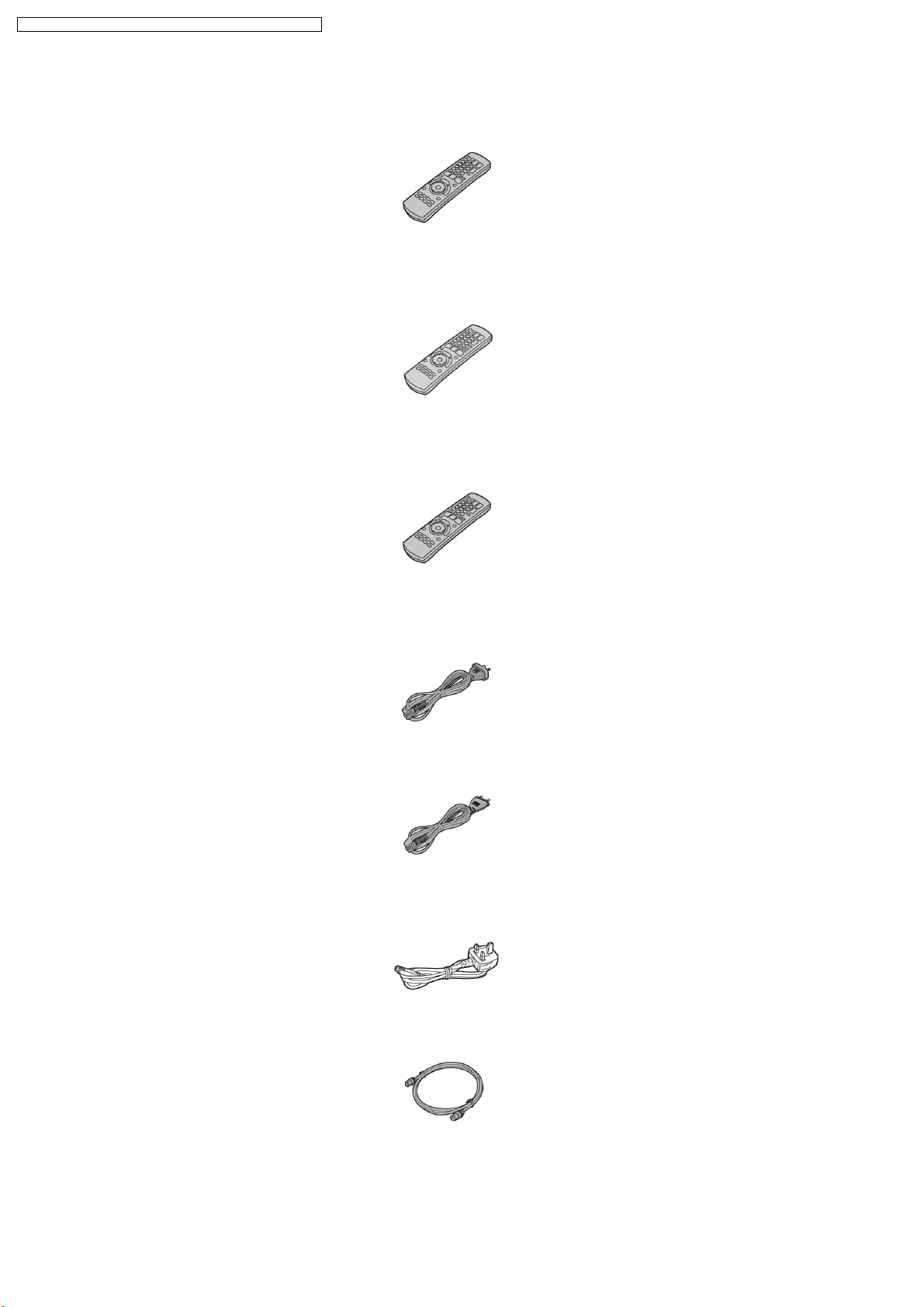

8.1. Remote Control Operation (For GN/GC/GCS)

16

Page 17

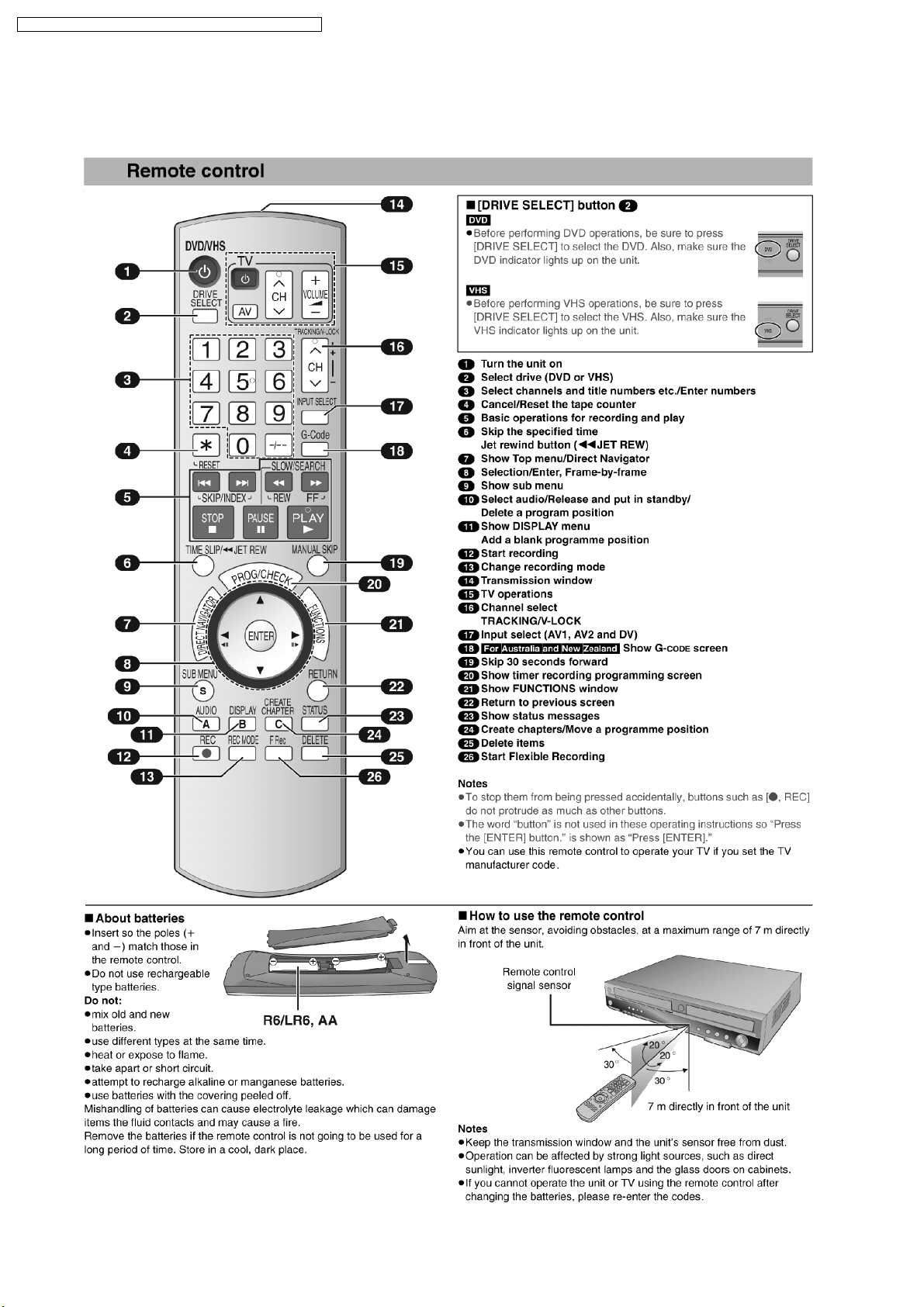

8.2. Remote Control Operation (For EE)

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

17

Page 18

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

8.3. Main Unit Operation

18

Page 19

8.4. Main Unit Panel Display

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

19

Page 20

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

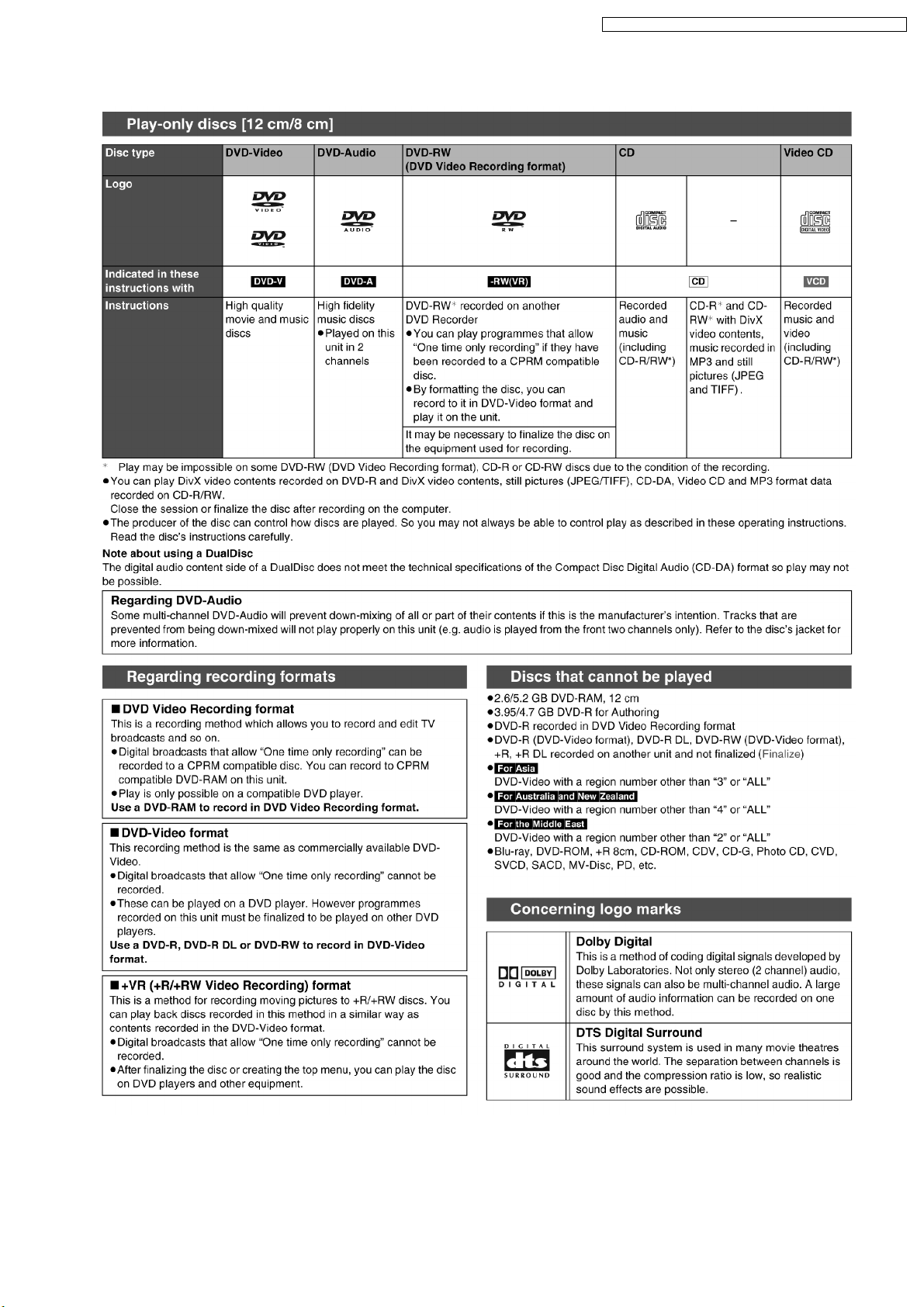

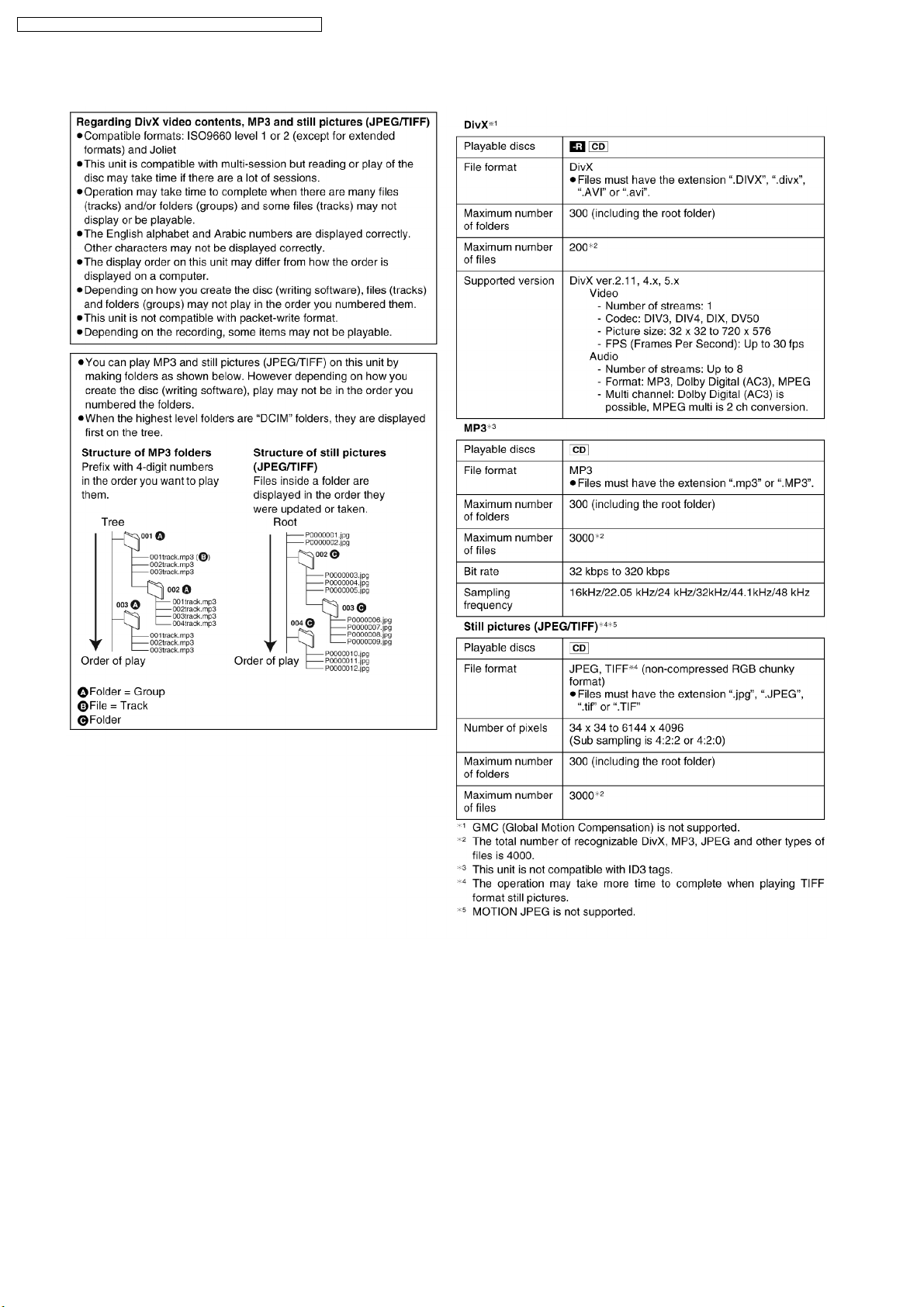

8.5. Disc Information

8.5.1. Discs for recording & play

20

Page 21

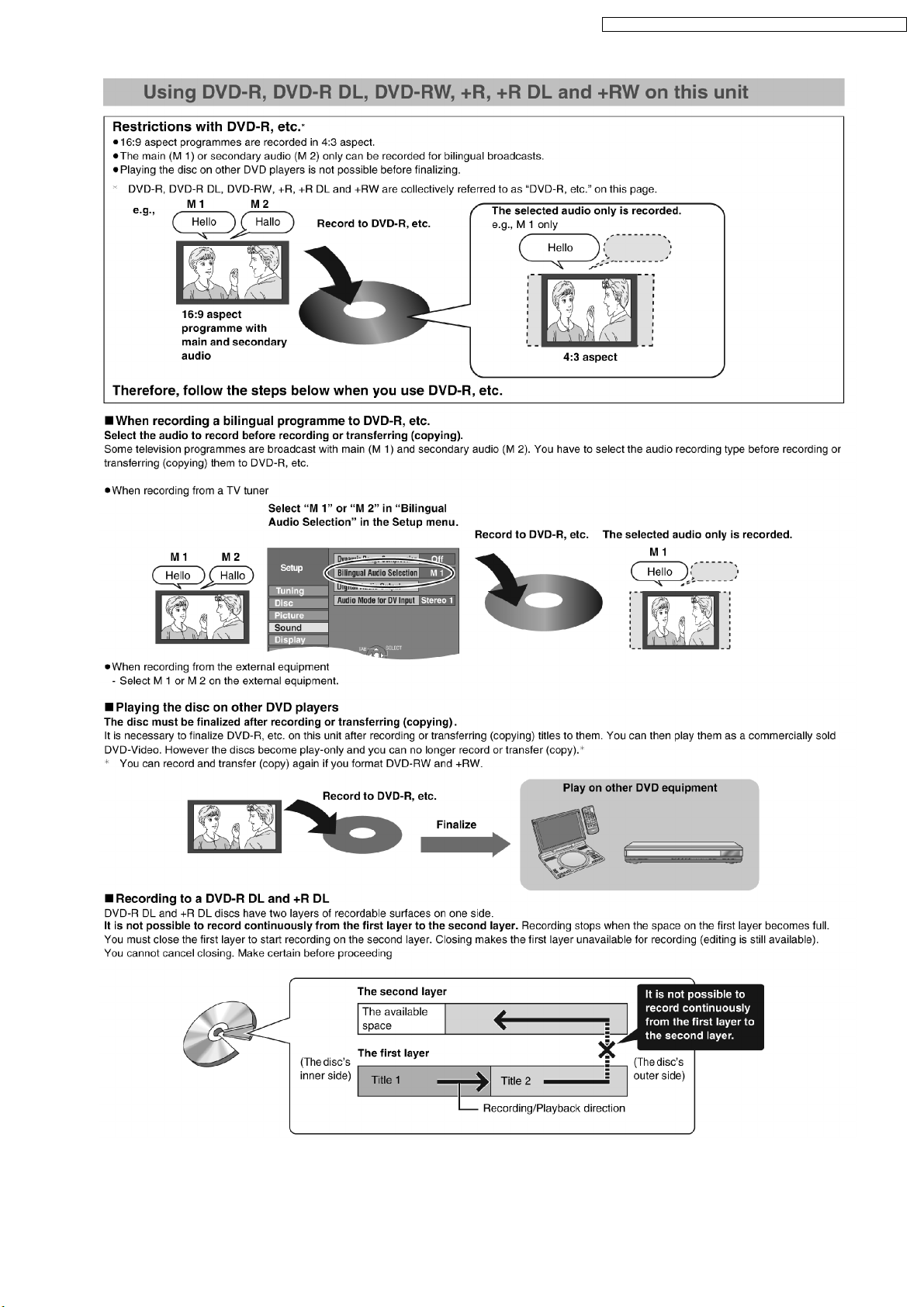

8.5.2. Discs for playing

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

21

Page 22

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

22

Page 23

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

23

Page 24

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

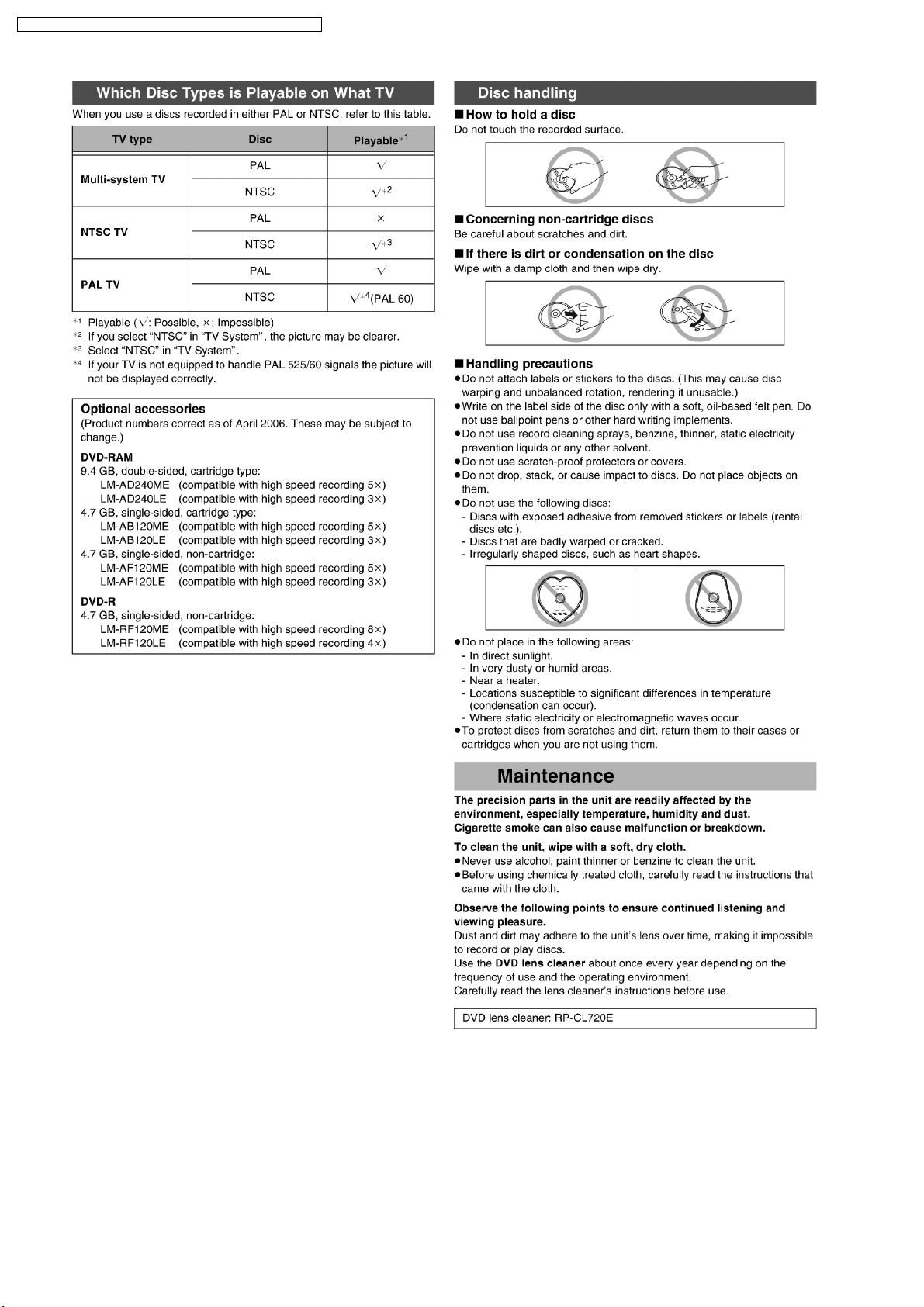

8.5.3. Data playable format (DivX, MP3, JPEG, TIFF)

24

Page 25

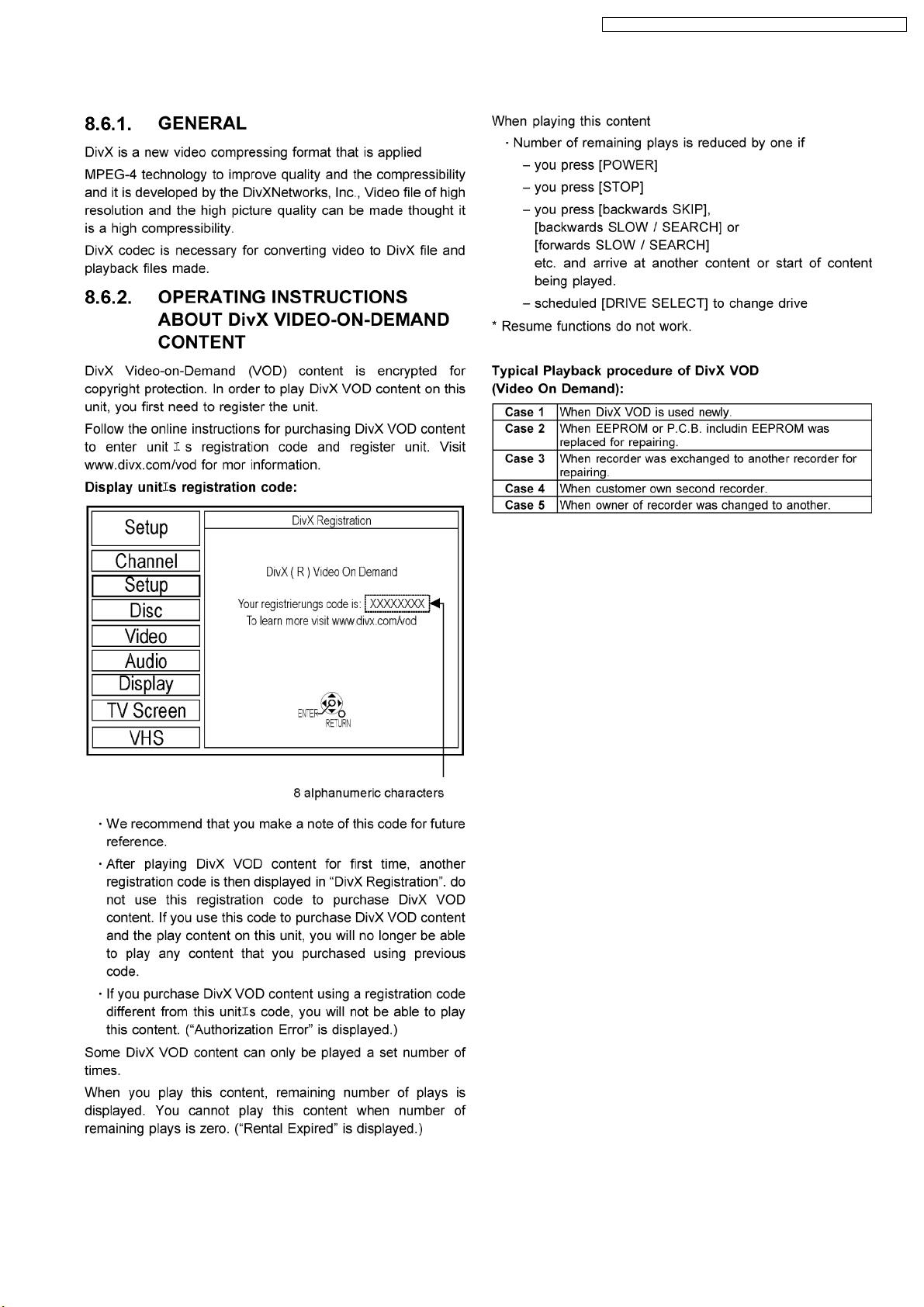

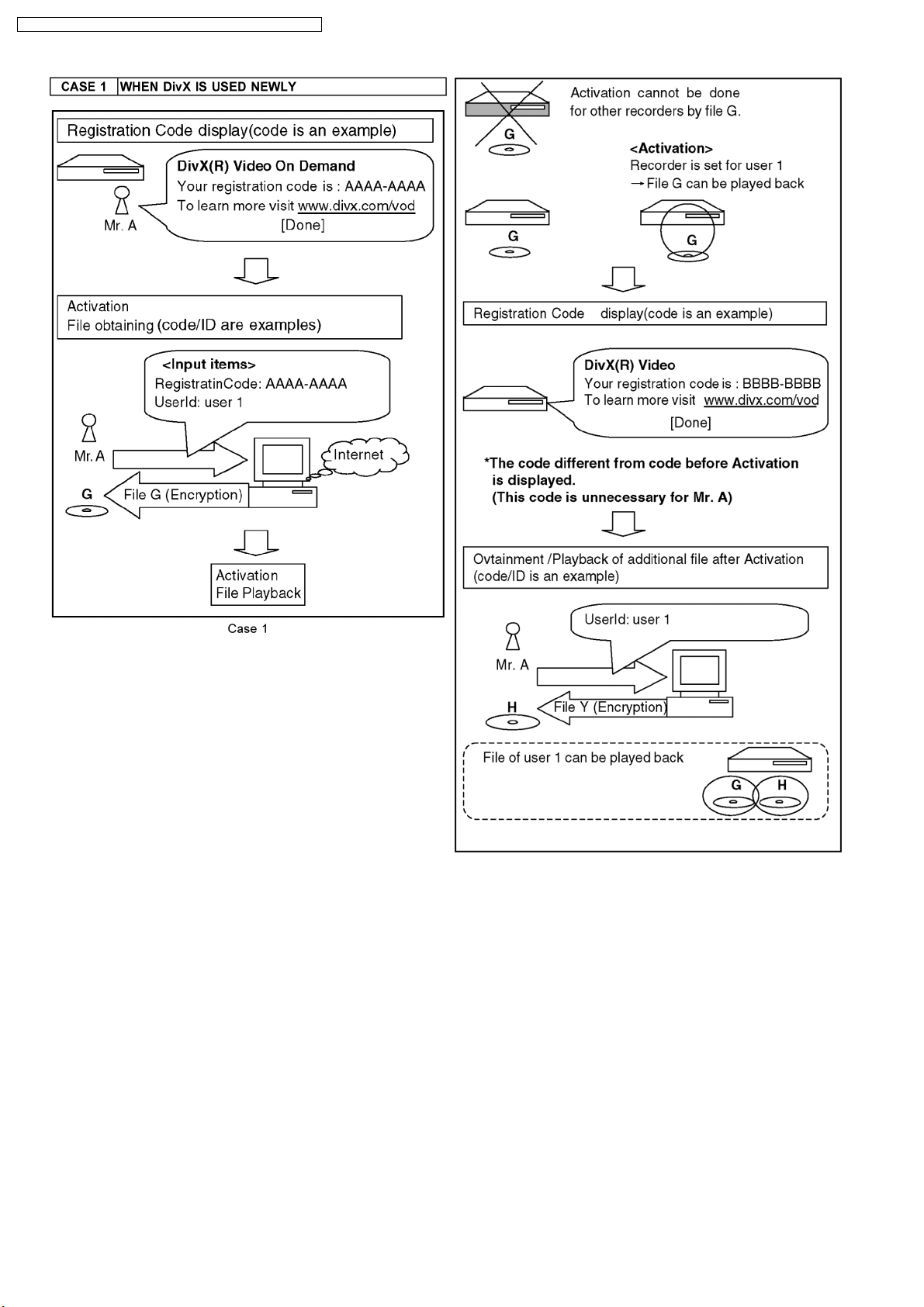

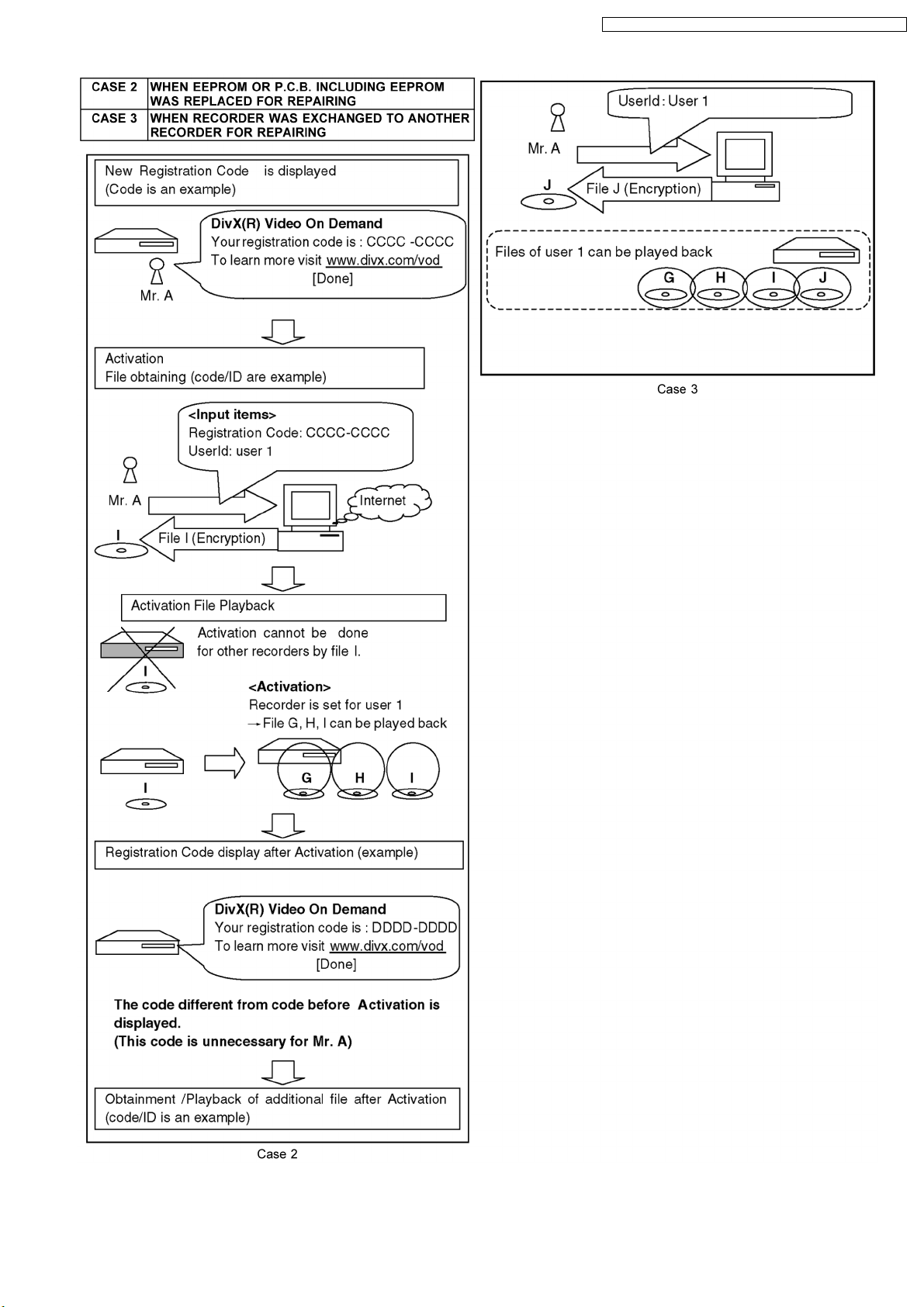

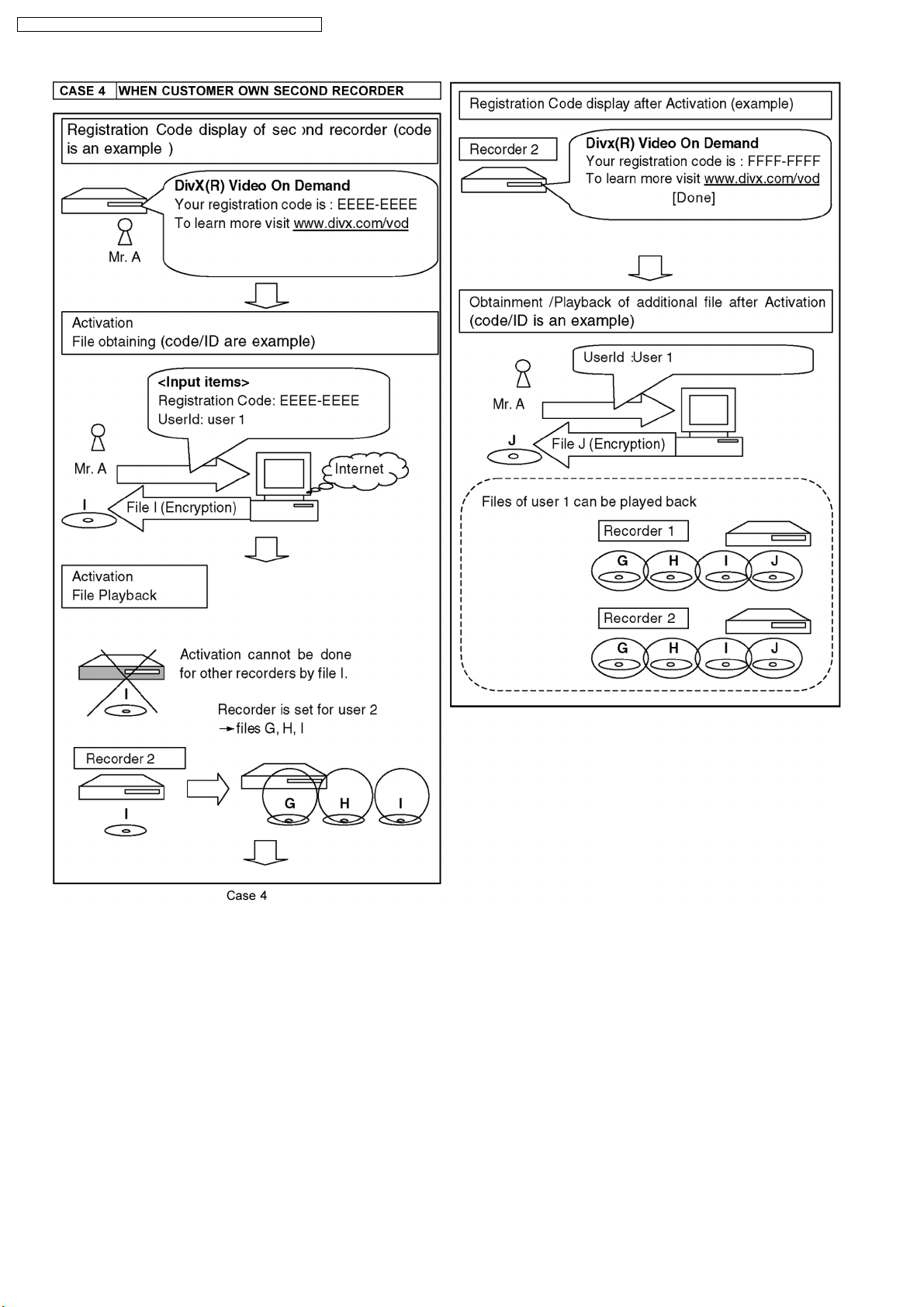

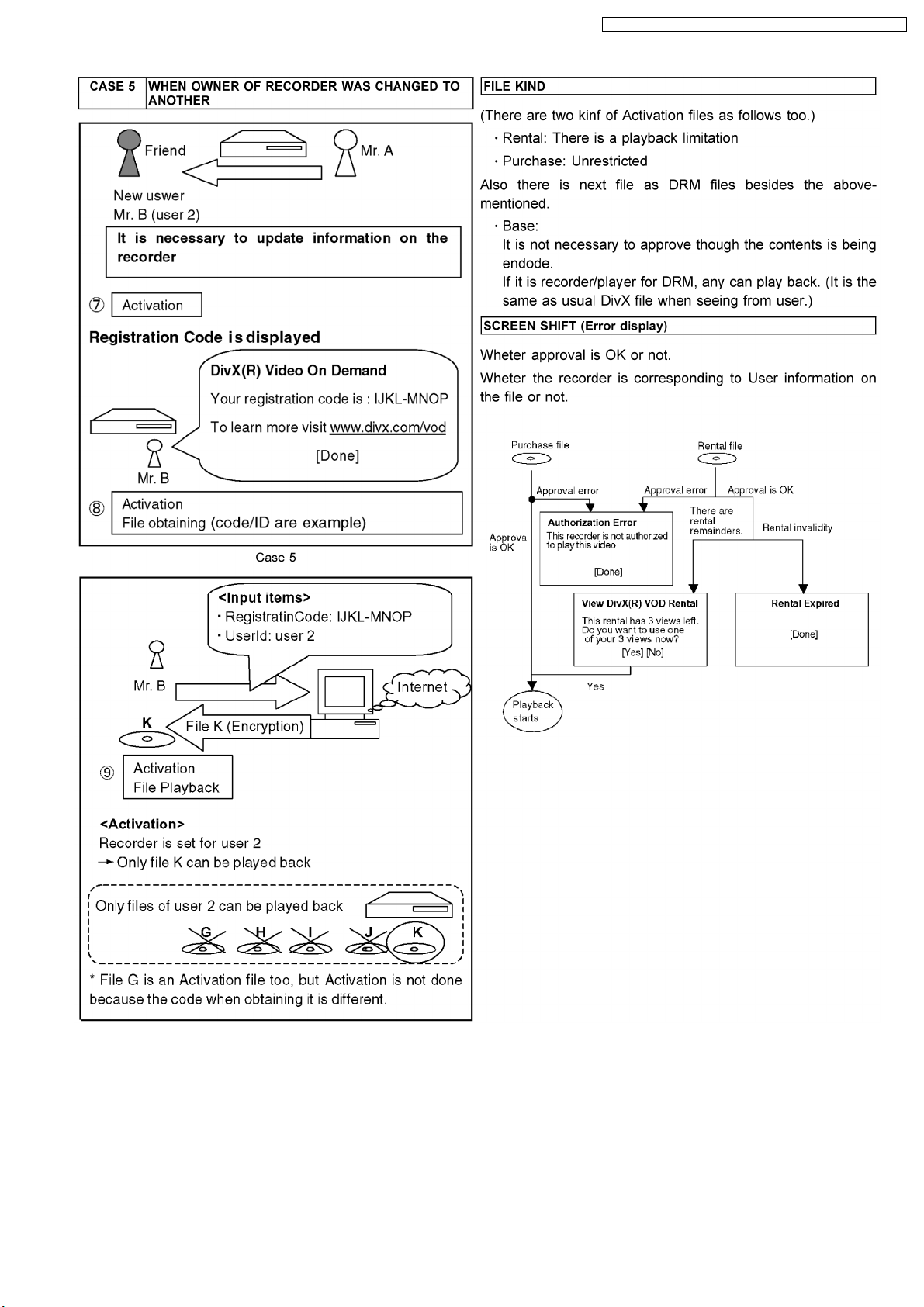

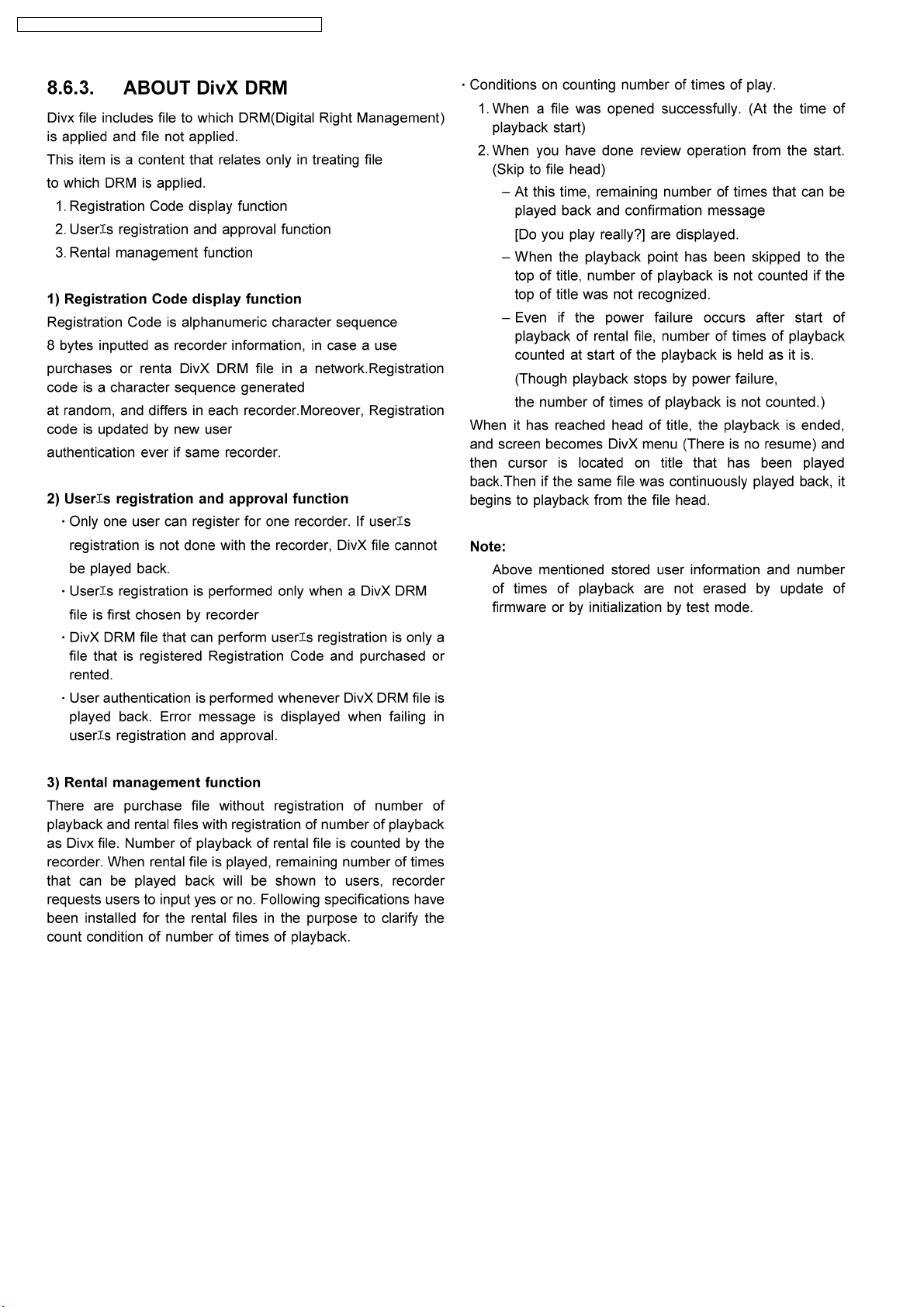

8.6. ABOUT DivX

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

25

Page 26

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

26

Page 27

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

27

Page 28

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

28

Page 29

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

29

Page 30

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

30

Page 31

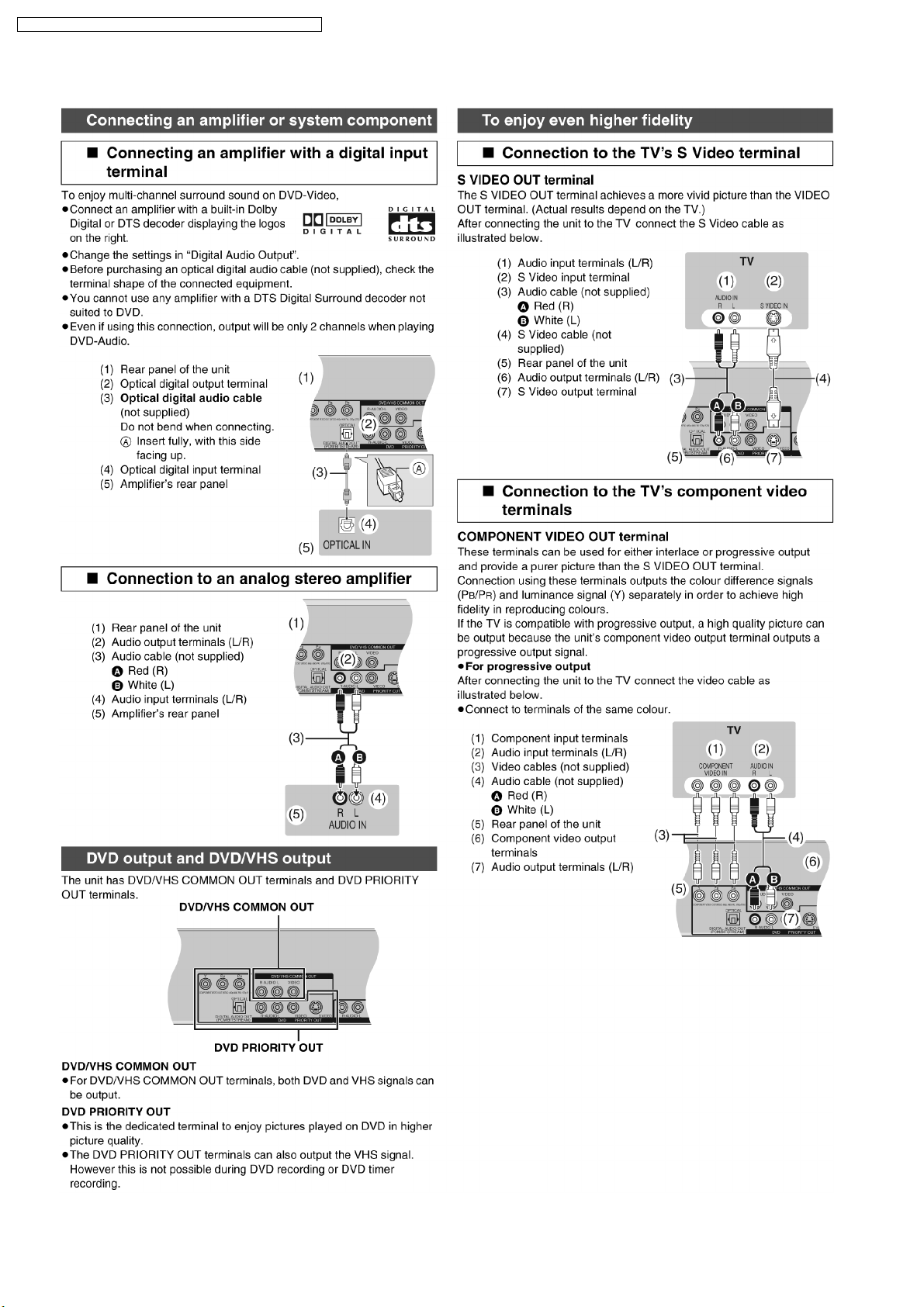

8.7. Connection to other Devices

8.7.1. Connection to TV (For GN/GC/GCS)

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

31

Page 32

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

8.7.2. Connection to amplifier / system component

32

Page 33

8.8. Connection to other Devices

8.8.1. Connection to TV (For EE)

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

33

Page 34

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

8.8.2. Connection to amplifier / system component

34

Page 35

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

9 Operation Instructions

9.1. (DVD) Taking out the Disc from RAM-Drive Unit when the Disc cannot

be ejected by OPEN/CLOSE button

9.1.1. (DVD) Forcible Disc Eject

9.1.1.1. (DVD) When the power can be turned off.

1. Turn off the power and press [STOP], [CH UP] keys on the front panel simultaneously for 5 seconds.

9.1.1.2. (DVD) When the power can not be turned off.

1. Press [POWER] key on the front panel for over 10 seconds to turn off the power forcibly, and press [STOP] [CH UP] keys on

the front panel simultaneousl y for 5 second s.

9.1.2. (DVD) When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Push in SLIDE CAM by Eject Pin(JZS0484) or minus screw driver (small) to eject tray slightly.

4. Push out Tray by Eject Pin (JZS0484) or minus screw driver (small).

35

Page 36

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

9.2. (VHS) Removing Cassette

Tape manually

When the cassette tape could not be uninstalled from an

electrical malfunction, there are 2 ways to remove a cassette

tape.

9.2.1. (VHS) Removal by compulsory

unloading.

If Service Mode can be activated when the power can not be

turned on, this operation is able.

1. Press [STOP] and [EJECT] button simultaneously for more

than 3 seconds and set the Service Mode to 7.

2. Press [STOP] button in order to unload the mechanism.

(Pay attention to tape slack)

Service Mode Display:

7 ** ** (STOP) → 7 0L ** (EJECT)

9.2.2. (VHS) Removal by manual

operation by rotating the Loading

Motor with the batteries.

1. Disconnect the AC plug, and remove the Top Panel and the

Front Panel by referring to the Disassembly Procedures.

2. Connect three batteries (1.5V spec.) to the Loading Motor

in series for supplying 4.5V to rotate the Loading Motor as

shown below.

3. Stop unload ing just before unloading will be completed as

shown below, and then the tape becomes slack as shown

below.

4. Rotate the S-Reel by a small minus screwdriver to remove

the slack tape as shown below.

5. Then unload again to remove the cassette tape as shown

below.

9.2.3. (VHS) Take out Cassette

Tapemanually after removing the

mechanism

1. Disconnect the AC plug, and remove the Top Case, Front

Panel and the Mechanism by referring to "12 Assembling

and Disassembling"

2. Remove the Screw and remove the Loading Motor as

shown below.

36

Page 37

3. Rotate the Main Cam Gear counter-clockwise until just

before the unloading will be completed as shown below. .

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

4. Rotate the Capstan Motor clockwise to remove the slack

tape as shown below.

5. Rotate the Main Cam Gear counter-clockwise again to

remove the cassette-tape as shown below.

6. Attach Loading Motor and tighten the screw.

7. Set the Position Switch to EJECT POSITION certainly and

attach the mechanism to chassis as shown below.

37

Page 38

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

10 Service Mode

10.1. (DVD) Self-Diagnosis and Special Mode Setting

10.1.1. (DVD) Self-Diagnosis Functions

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U**, H** and F** are stored in memory and held.

You can check latest error code by transmitting [0] [1] of Remote Controller in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

Error Code Diagnosis contents Description Monitor Display Automatic FL display

U30 Remote control code error Display appears when main unit and remote

U59 Abnormal inner temperature

detected

U61 The unit is carrying out its

recovery process.

controller codes are not matched.

Display appears when the drive temperature

exceeds 70°C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speed for the first 5 minutes. For the

remaining 25 minutes, fan motor is also

stopped.) The event is saved in memory as

well.

No display

“*” is remote controller code of the

main unit.

Display for 5 seconds.

No display

“U59 is displayed for 30 minutes.

No display

U88 The unit is carrying out its

U99 Hang-up Displayed when communication error has

H19 Inoperative fan motor When inoperative fan motor is detected after

F00 No error information Initial setting for error code in memory

F09 Serial Communication Error

F34 Initialization error when main

F58 Drive hardware error When drive unit error is detected, the event is

F60 DVD module has not been

recovery process.

between VHS Microprocessor

and Timer Microprocessor.

microprocessor is started up

for program recording

started.

occurred between Main microprocessor and

Timer microprocessor.

powered on, the power is turned off

automatically.

The event is saved in memory.

(Error code Initialization is possible with error

code initialization and main unit initialization.)

Please confirm Serial Communication

terminal of Microprocessor.

NOTE:

If F09 appears just after updating Firmware,

pull off and insert AC plug, then it will

disappear.

When initialization error is detected after

starting up main microprocessor for program

recording, the power is turned off

automatically.

The event is saved in memory.

saved in memory.

Defect of Digital P.C.B.

Mode: No change

No display

No display

Displayed is left until the

[POWER] key is pressed.

No display No display

No display No display

No display

No display No display

No display No display

No display

38

Page 39

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Error Code Diagnosis contents Description Monitor Display Automatic FL display

UNSUP-

PORT

NO READ Disc read error *A disc is flawed or dirty.

HARD

ERR

Unsupported disc error *An unsupported format disc was played,

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

Drive error The drive detected a hard error. “DVD drive error.” Display for 5 seconds.

“This disc is

incompatible.”

Display for 5 seconds.

“Cannot read.

Please check the

disc.”

SELF

CHECK

PLEASE

WAIT

UNFORMAT

IR ERR IR communication error [IR ERR] is display when communication

No REC Recording is impossible [No REC] is displayed when recording

Restoration operation Since the power cord fell out during a power

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears

automatically. If a display does not disappear,

there is the possibility that defective Digital

P.C.B. / RAM drive.

Unit is in termination process Unit is in termination process now.

“BYE” is displayed and power will be turned

off.

In case “Quick Start” of setup menu is ON, it

is displayed in restoration operation for AC

off.

Unformatted disc error You have inserted an unformatte d DVD-RAM

or DVD-RW that is unformatted or recorded

on other equipment.

between Timer microprocessor and IR

microprocessor fails.

isimpossible due to the defect, dirt or woundof

media.

No display

No display

No display

No display

10.1.2. (DVD) Special Modes Setting

Item FL display Key operation

Mode name Description Front Key

TEST Mode *All the main unit´s parameters (include tuner)

are initialized.

Rating password The audiovisual level setting password is

initialized to “Level 8”.

Service Mode Setting every kind of modes for servicing.

*Details are described in “10.1.3. (DVD)

Service Modes at a glance”.

Forced disc eject Removing a disc that cannot be ejected.

The tray will open and unit will shift to P-off

mode.

*When Timer REC is ON, execute " Forced

disc eject " after releasing Timer REC.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

The display before execution

leaves.

Press [VHS to DVD COPYING],

[REC] and [OPEN/CLOSE] keys

simultaneously for five seconds

when power is off.

Set DRIVE SELECT to [DVD].

While the tray is open, press [REC]

and [PLAY] simultaneously for 5

seconds.

When the power is off, press [VHS

to DVD COPYING], [OPEN/CLOSE]

and [STOP] keys simultaneously for

5 seconds.

When the power is off, press

[STOP] and [CH UP] keys

simultaneously for 5 seconds.

Forced power-off When the power button is not effective while

power is ON, turn off the power forcibly.

*When Timer REC is ON, execute “Forced

Power-off” after releasing Timer REC.

Display in P-off mode. Press [POWER] key over than 10

seconds.

39

Page 40

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Item FL display Key operation

Mode name Description Front Key

Child lock/unlock Set or release “Child Lock”. Press [ENTER] and [RETURN] by

remote controller simultaneously

until [X-HOLD] is displayed.

NTSC/PAL system select To switch PAL/NTSC altemately. The display before execution

Aging Perform sequence of modes as * Aging

Description shown below continually.

leaves.

Display following the then mode. When the power is ON, press [CH

Aging Contents (Example):

While the power is on (E-E mode),

press [STOP] and [OPEN/CLOSE]

simultaneously for 5 seconds.

DOWN], [VHS to DVD COPYING]

and [OPEN/CLOSE] simultaneously

for over 5 seconds and less than 10

seconds.

NOTE1:

If Unit has not turned into Aging

mode by operations shown above,

execute TEST MODE once and reexecute operation shown above.

(*All the main unit’s parameters

include tuner are initialized by TEST

mode.)

NOTE2:

If the unit has hung-up because of

pressing keys for over 10 seconds,

once turn off the power, and reexecute this command.

*When releasing Aging mode, press

[POWER] key.

Demonstration

lock/unlock

Progressive initialization The progressive setting is initialized to

ATP re-execution Re-execute ATP. Display at ATP executing. When the power is on (E-E mode),

Ejection of the disc is prohibited.

The lock setting is effective until unlocking the

tray and not released by “Main unit

initialization” of service mode.

Interlace.

*When lock the tray.

“LOCK” is displayed for 3 seconds.

*When unlock the tray.

“UNLOCK” is displayed for 3

seconds.

*When press OPEN/CLOSE key

while the tray being locked.

Display “LOCK” for 3 seconds.

The display before execution

leaves.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

Note:

When a disc is not in tray, this

setting is not effective.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

Press [OPEN/CLOSE] key while the

tray being locked.

When the power is on (E-E mode),

press [STOP] and [VHS to DVD

COPYING] simultaneously for 5

seconds.

press [CH UP] and [CH DOWN]

simultaneously for 5 seconds.

40

Page 41

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

10.1.3. (DVD) Service Modes at a glance

Service mode setting: While the power is off, press [STOP], [VHS to DVD COPYING] and [OPEN / CLOSE] simultaneously for

five second s (OPERATION SELECT should be set to DVD).

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

mode.

Error Code Display Last Error Code of U/H/F held by Timer is

displayed on FL.

*Details are described in “10.1.1. (DVD) Self-

Diagnosis Functions” .

ROM Version Display 1. Region code (displayed for 5 sec.)

2. Main firm version (displayed for 5 sec.)

3. Timer firm version (displayed for 5 sec.)

4. Drive firm version (displayed for 5 sec.)

5. ROM correction version

(displayed for 5 sec.)

6. VHS Microprocessor version

(displayed for 5 sec.)

7. VHS ROM correction version

(left displated)

White Picture Output White picture is output as component Output

from AV Decoder.

*White picture

(Saturation rate : 100%)

*It is enable to switch Interlace/P rogressive by

“I/P switch: [1] [4]”

Press [0] [1] in service mode

If any error history dose not exist,

[F00] is displayed.

Press [0] [2] in service mode

‘’’’ are version displays.

*Initial mode is “Interlace”. Press [1] [1] in service mode.

Switch Interlace/Progressive Press [1] [4] in White Picture Output

mode.

*I/P are switched alternately.

Magenta Picture Output Magenta picture is output with Component

RTSC Return in XP

(A & V)

Output from AV Decoder.

*Magenta picture

(Saturation rate: 100%)

*It is enable to switch Interlace/P rogressive by

“I/P switch: [1] [4]”

L1 input signal is encoded (XP), decoded

(XP) and output decoded signal to external

without DISC recording and DISC playback.

*Initial mode is “Interlace”. Press [1] [2] in service mode.

Switch Interlace/Progressive Press [1] [4] in Magenta Picture

Initial mode: EE2/ Interlace/ XP/

Audio 48kHz

Switch Interlace/Progressive Press [1] [4] in RTSC Return XP

Audio 44.1 kHz/ 48 kHz Switch Press [2] [4] in RTSC Return XP

Output mode.

*I/P are switched alternately.

Press [1] [3] in service mode.

mode.

*I/P are switched alternately.

mode.

*48 kHz / 44.1 kHz are switched

alternately.

41

Page 42

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Item FL display Key operation

Mode name Description (Remote controller key)

I/P Switch Switch Interlace and Progressive in EE mode.

*Initial setting is “Interlace”.

*This command is effective during executing

“White Picture Output”, “Magenta Picture

Output” and “RTSC Return in XP (A & V)”

modes.

Initial mode is Interlace

Switch Interlace/Progressive

Press [1] [4] in I/P Switch mode.

*I/P are switched alternately.

Audio Mute (XTMUTE) Check whether mute is applied normally by

the timer microprocessor.

Audio Mute (XDMUTE) Check whether mute is applied normally by

the Digital P.C.B..

Audio Pattern Output The audio pattern stored in the internal

memory is output

(Lch: 1kHz/-18dB)

(Rch: 400Hz/-18dB)

*Audio sound clock switching operation of

DAC can be confirmed by sub command [2]

[4].

Laser Used Time

Check laser used time (hours) of drive.

Indiction

Delete the Laser Used

Time

Laser used time stored in the memory of the

unit is deleted.

Press [2] [1] in service mode.

Press [2] [2] in service mode.

Initial mode (Audio 48kHz) Press [2] [3] in service mode.

Audio 44.1kHz/48kHz switching Press [2] [4] in Audio Pattern Output

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Press [4] [1] in service mode.

l(*****) is the used time display in

hour.

lLaser used time of DVD/ CD in

Playback/Recording mode is

counted.

Press [9] [5] in service mode.

42

Page 43

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Item FL display Key operation

Mode name Description (Remote controller key)

RAM Drive Last Error RAM Drive error code display.

*For details about the drive error code, refer

to the Service Manual for the specific RAM

Drive.

1. Error Number is displayed for 5

seconds.

Press [4] [2] in service mode.

When “INFO******” is being

displayed, past 19 error histories

can be displayed by pressing [0] [1]

- [1] [9]

2. Time when the error has occurred

is displayed for 5 seconds.

DD: Day

hh: Hour

mm: Minute

3. Last Drive Error (1/2) is displayed

for 5 seconds.

4. Last Drive Error (2/2) is displayed

for 5 seconds.

5. Error occurring Disc type is

displayed for 5 seconds.

Delete the Last Drive

Error

Delete the Last Drive Error information stored

on the DVD RAM-Drive.

Laser power confirmation Drive state is judged based on difference

between laser power value at shipping and

present laser power value.

Turn on all FL/LEDs All segments of FL and all LEDs are turned

on.

S1 signal output Forcibly superimpose the S1 signal (approx.

4.5V DC) on the EE chroma signal, and check

the output on the S terminal.

S2 signal output Forcibly superimpose the S2 signal (approx.

2V DC) on the EE chroma signal, and check

the output on the S terminal.

AV4(V)/AV1(RGB) I/O

Setting

Set input to AV4 (V) and set output to AV1

(RGB) for I/O checking

6. Disc Maker ID is displayed for 5

seconds.

In case that the maker cannot be

identified, display is black out.

7. Factor of Drive Error occurring is

left displayed

Press [9] [6] in service mode.

1. into RAM

Drive in service mode. (Other

media are assumed to be noncorrespondence.)

2. Press [4] [4].

If DVD-RAM disc in not inserted,

[NO DISC] is displayed.

If power value study was filed,

[ERROR] is displayed.

All segments are turned on. Press [5] [1] in service mode.

Press [5] [2] in service mode.

Press [5] [3] in service mode.

Press [8] [0] in service mode.

43

Page 44

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Item FL display Key operation

Mode name Description (Remote controller key)

AV2(Y/C)/AV1(V)

I/OSetting

Set input to AV2 (Y/C) and set output to AV1

(V) for I/O checking

Press [8] [0] in service mode.

Front connection

inspection

Press all front keys and check the connection

between Main P.C.B. and Front key Switches.

(1) Each time a key is pressed,

segment turned on increases one

by one.

(2) Total umber of keys that have

been pressed.

Production Date Display Display the date when the unit was produced.

YY: Year

MM: Month

DD: Day

Display the accumlated

Display the accumulated unit´s working time.

working time

(Indicating unit: Second)

Display the Error History Display the Error History stored on the unit. Display reason of error for 5

seconds.

01:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

02:

Defect of RAM Drive.

03:

Defect of Disc.

04:

Defect of Digital P.C.B. or

Communication Error.

05:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

Press [5] [4] in service mode.

Press [6] [1] in service mode.

Press [6] [4] in service mode.

Press [6] [5] in service mode.

Then press [0] [1] ~ [1] [9], the past

19 error histories are displayed.

Delete the Error History Delete Error History information stored on the

unit.

Tray OPEN/CLO SE Test The RAM drive tray is opened and closed

repeatedly.

Error code initialization Initialization of the last error code held by

timer (Write in F00)

Display the time when the error has

occurred for 5 seconds.

DD: Day

hh: Hour

mm: Minute

Accumulated working time till

occuring of the error is left

displayed.

(Indicating unit: Second)

“*” is number of open/close cycle

times.

Press [9] [7] in service mode.

Press [9] [1] in service mode

*When releasing this mode, press

the [POWER] button of Remote

Controller more than 10 seconds.

Press [9] [8] in service mode.

44

Page 45

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Item FL display Key operation

Mode name Description (Remote controller key)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

PB HIGH Signal Output 8 pin of AV 1 Jack (PB HIGH terminal) is High

Press [5] [2] in service mode.

(approx. 11V DC).

PB MIDDLE Signal

Output

8 pin of AV 1 Jack (PB HIGH terminal) is

Middle (approx. 5.5V DC)

Press [5] [3] in service mode.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel or Remote controller in

service mode.

AV2(V)/AV1(Y/C) I/O

Setting

AV2(RGB)/AV1(V)

I/OSetting

P50(H) Output Timer Microprocessor IC7504-76 output High

Set input to AV2 (V) and set output to AV1

(Y/C) for I/O checking

Set input to AV2 (RGB) and set output to AV1

(V) for I/O checking

When OK.

Press [8] [2] in service mode.

Press [8] [3] in service mode.

Press [8] [4] in service mode.

signal for AV1-pin 10 passing through inverter

(approx. 0V DC at AV1-pin 10).

When NG.

P50(L) Output Timer Microprocessor IC7504-76 output Low

When OK.

Press [8] [5] in service mode.

signal for AV1-pin 10 passing through inverter

(approx. 4.4V DC at AV1-pin 10).

When NG.

Tray OPEN/CLO SE Test The RAM drive tray is opened and closed

repeatedly.

Press [9] [1] in service mode*When

releasing this mode, press the

[POWER] button of Remote

“*” is number of open/close cycle

Controller more than 10 seconds.

times.

Error code initialization Initialization of the last error code held by

Press [9] [8] in service mode.

timer (Write in F00)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel or Remote controller in

service mode.

45

Page 46

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

10.2. (VHS) Self-Diagnosis and Special Mode Setting

10.2.1. (VHS) SPECIAL MODES SETTING

10.2.2. (VHS) SERVICE MODES

46

Page 47

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

10.2.3. (VHS) SELF-DIAGNOSIS FUNCTIONS

This model has a self-diagnosis. If the VHS section detects trouble during installation or during use, the power is

automaticallyturned off or become power-save mode and it is memorized into the EEPROM (IC37501) as error code of two-digit

number. It ismemorized error code can be display ed in "second" display portion (the last 2 digits of the FIP) by placing the unit is

Service ModeNumber 2 when turning on the Service Information Display as for example "01" or "02" etc. as below. If a second error

occurs, themost recent error will be memorized and can be displayed in Service Mode Number 2. It can be memorized until 3 selfdiagnosishistories in maximum.In order to erase the memorized error code, press STOP and EJECT buttons on the Front Panel

simultaneously over 5 secondsduring turning on Service Information Display mode.

10.2.3.1. MEMORY OF THE SELF-DIAGNOSIS HISTORY

*This is effective only in Service Mode 3, 4, 5.

10.2.3.1.1. ERROR NUMBERS AT A GLANCE

10.2.3.1.2. MEMORY FOR THE SELF-DIAGNOSIS HISTORY

3. The self-diagnosis result is memorized the state of the moment of detecting.

4. There are the histories from number 1 to number 3.

5. The latest error is memorized on history number 1, and then the old histories are shifted to the history number 2 and 3.The error

code memorized in the history number 2 and 3 is over-written by shift.

6. If the latest error is the same with the history number 1 (2nd-latest), it is not memorized.(The same error code is not memorized

47

Page 48

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

in succession)

10.2.3.1.3. CLEAR FOR THE SELF-DIAGNOSIS HISTORY

1. Press STOP and EJECT buttons simultaneously over 5 seconds during turning on Service Information Display mode.

10.2.3.1.4. INDICATION OF THE SELF-DIAGNOSIS HISTORY

The self-diagnosis histories can be indicated on the FIP with Service Mode number 3 to 5.

The procedure of service mode setting and indication format are the same as usual.

48

Page 49

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

11 Service Fixture & Tools

(For DVD)

Part Number Description Compatibility

RFKZ0168 Extension Cable (Digital I/F P.C.B. - FAN / 3 Pin) Same as E50 / ES30V Series

RFKZ0327 Extension Cable (Main P.C.B. - Digital I/F P.C.B. / 15 Pin / 40 mm)

RFKZ0240 Extension Cable (Main P.C.B. - Digital I/F P.C.B. / 19 Pin / 40 mm) Same as ES75V / ES30V Series

RFKZ0368 Extension Cable (Main P.C.B. - Digital I/F P.C.B. / 11 Pin / 40 mm) New

RFKZ0239 Extension Cable (Main P.C.B. - Panel P.C.B. / 12 Pin) Same as E75V / ES30V Series

RFKZ0239 Extension Cable (Main P.C.B. - Front Jack P.C.B. / 10 Pin) Same as E75V / ES30V Series

RFKZ0365 Extension Cable (Main P.C.B. - RAM / Digital P.C.B. Module / 64 Pin) Same as ES15 Series

JZS0484 Eject Pin Same as ES15 / E50 Series

RFKZ03D01K Lead Free Solder (0.3mm/10 0g Reel) Same as ES15 Series

RFKZ06D01K Lead Free Solder (0.6mm/10 0g Reel) Same as ES15 Series

RFKZ10D01 Lead Free Solder (1.0mm/10 0g Reel)) Same as ES15 Series

RFKZ0316 Solder Remover (Lead free 10W temperature Solder/180g) Same as ES15 Series

RFKZ0328 Flux Same as ES15 Series

RFKZ0329 Bottle of Flux Same as ES15 Series

(For VHS)

Part Number Description Compatibility

VFJ8125H3F NTSC VHS Alignment Tape Same as E75V / ES30V

VFK0329 Post Adjustment Screwdriver Same as E75V / ES30V

VFK0330 Fine Adjustment Gear Driver Same as E75V / ES30V

49

Page 50

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12 Assembling and Disassembling

12.1. Caution

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

4. Refer to the Parts No. on the page of “Replacement Parts List” (Section 22), if necessary.

Below is the list of disassembly sections

· Disasse mbly of Top Panel

· Disasse mbly of Nicam Decoder P.C.B.

· Disasse mbly of Front Panel

· Disasse mbly of Panel P.C.B. & Front Jack P.C.B.

· Disasse mbly of RAM/Digital P.C.B. module

· Disasse mbly of DV Jack P.C.B.

· Disasse mbly of VTR Mechanism Unit

· Disasse mbly of Rear Panel

· Disasse mbly of Fan Motor

· Disasse mbly of Digital I/F P.C.B.

· Disasse mbly of Main P.C.B.

50

Page 51

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.2. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

51

Page 52

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.3. Main Parts Location Diagram

52

Page 53

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.4. Caution with inserting cassette tape when disassembling the unit

Note1:

For description of the disassembling procedure, see the section 12.5.

Note2:

Video Cassette might not enter when a strong lighting is applied to VHS Mechanism when Video Cassette is inserted. Please

weaken the lighting or cover with the top panel etc.

53

Page 54

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.5. Disassembly of Top Panel

Step 1 : Remove 4 Screws (A) and 3 Screws (B).

Step 2 : Slide Top Panel rearward and open the both ends at

rear side of the Top Panel a little and lift the Top Panel in the

direction of the arrows.

12.6. Disassembly of Nicam

Decoder P.C.B.

· Follow the (step 1) - (step 2) of item 12.5.

Step 1 : Disconnect 2 connectors to remove Nicam Decoder

P.C.B. as arrow shown.

54

Page 55

12.7. Disassembly of Front Panel

· Follow the (step 1) - (step 2) of item 12.5.

Step 1 : Remove 1 screw (A).

Step 2 : Unlock tab (A) and tab (B) simultaneously.

Step 3 : Unlock tab (C) and tab (D) simultaneously.

Step 4 : Unlock 2 tabs (E) respectively, and pull out Front Panel

with connector slightly.

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

Note:

When attaching Front Panel, in order to hook Cassette

Door Opener Lever to Cassette Door, push up cassette

door in the direction of arrow and insert a front panel.

12.8. Disassembly of Front Jack

P.C.B. & Panel P.C.B.

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

Step 1 : Remove 6 screws (A) to remove Panel P.C.B.

Step 2 : Remove 3 screws (B) and unlock Locking Tab (A) to

remove Front Jack P.C.B.

55

Page 56

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.9. Disassembly of RAM / Digital

P.C.B. Module

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

Step 1 : Remove 3 Screws (A).

Note: Handle the RAM Drive with care. Please put on antistatic strap when handling the drive unit

Step 2 : With holding RAM drive as below illustration, remove

3 screws (B) and disconnect FFC.

And lift up Digital P.C.B. slightly so to disconnect connectors to

remove Digital P.C.B..

Step 3 : Place the Digital P.C.B. on RAM Drive and remove

RAM/Digital P.C.B. Module.

Note:

RAM/Digital P.C.B. Module as service part has no heat sink

unit.

Before returning to customer, heat sink unit should be

installed on Digital P.C.B..

56

Page 57

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.10. Disassembly of DV Jack

P.C.B.

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

· Follow the (step 1) - (step 2) of item 12.9.

Step 1 : Remove 7 Screws (A).

Step 2 : Remove DV Jack P.C.B. with Digital Angle.

57

Page 58

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.11. Disassembly of VTR

Mechanism Unit

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

Step 1 : Disconnect 3 Connectors (P1531, P2501 and P4002).

Step 2 : Remove 3 Black Screws (A), Screw (B) , Screw (C)

and Screw (D).

Step 3 : Lift up VTR Mechanism Unit perpendicularly so to

disconnect Connectors (P2571 and P3001).

Note:

Pay attention to stiff connections of P2571 and P3001,

when removing VTR Mechanism Unit.

12.11.1. Caution for attaching VTR

Mechanism Unit

Step 1 : Attach VTR Mechanism Unit so that Boss of Position

SW is put into long hole of Main Cam Gear, refer to Fig. (B).

58

Page 59

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.12. Disassembly of Rear Panel

· Follow the (step 1) - (step 2) of item 12.5.

Step 1 : Disconnect Fan Connector.

Step 2 : Remove 6 Screws (A) and 1 Screw (B).

Step 3 : Unlock 2 Locking Tabs (A) to remove panel Cabinet

with Fan Motor.

12.14. Disassembly of Digital I/F

P.C.B.

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

· Follow the (step 1) - (step 2) of item 12.9.

· Follow the (step 1) - (step 2) of item 12.10.

· Follow the (step 1) - (step 3) of item 12.12.

Step 1 : Disconnect 5 Connectors (A).

Step 2 : Remove the 2 Screws (A).

Step 3 : Remove Digital I/F P.C.B.

12.13. Disassembly of Fan Motor

· Follow the (step 1) - (step 2) of item 12.5.

Step 1 : Disconnect Fan Connector.

Step 2 : Remove 2 Screws (A) to Remove Fan Motor.

59

Page 60

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

12.15. Main P.C.B.

· Follow the (step 1) - (step 2) of item 12.5.

· Follow the (step 1) - (step 4) of item 12.7.

· Follow the (step 1) - (step 3) of item 12.11.

· Follow the (step 1) - (step 3) of item 12.12.

Step 1 : Disconnect 5 Conne ctors.

Step 2 : Remove 2 Screws (A) and remove Main P.C.B.

60

Page 61

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13 Measurements and Adjustments

13.1. Service Positions

Note:

For description of the disassembling procedure, see the section 12.

13.1.1. Checking and Repairing of RAM / Digital P.C.B. Module

61

Page 62

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13.1.2. Checking and Repairing of Panel, Front Jack and Digital I/F P.C.B.

62

Page 63

13.1.3. Checking and Repairing of Main P.C.B.

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

63

Page 64

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13.2. Caution for Replacing Parts

13.2.1. Notice for replacing parts of VHS Mechanism

13.2.1.1. Regarding change of parts of VHS mechanism

64

Page 65

13.2.2. Notice for Replacing Capstan Motor

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

65

Page 66

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13.2.3. Items that should be done after replacing parts

66

Page 67

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

67

Page 68

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

68

Page 69

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13.3. Standard Inspection Specifications after Making Repairs

After making repairs, we recommend performing the following inspection, to check normal operation.

No. Procedure Item to Check

1 Turn on the power, and confirm items pointed out. Items pointed out should reappear.

69

Page 70

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

No. Procedure Item to Check

2 Insert RAM disc. The Panasonic RAM disc should be recognized.

3 Enter the EE (TU IN / AV IN - AV OUT) mode. No abnormality should be seen in the picture, sound or operation.

4 Perform auto recording and playback for one minute using the RAM

disc.

No abnormality should be seen in the picture, sound or operation.

*Panasonic DVD-RAM disc should be used when recording and

playback.

5 If a problem is caused by a VCD, DVD-R, DVD-Video, Audio-CD, or

No abnormality should be seen in the picture, sound or operation.

MP3, playback the test disc.

6 Models with DV Input Jack: In case of that the trouble is caused by

DV terminal.

7 After checking and making repairs, upgrade the firmware to the

Models with DV Input Jack;

1) DV terminal: Check to be able to record from DVC.

Make sure that [UPDOK] appears in the FL display.

latest version.

8 Transfer [9][9] in the service mode setting, and initialize the service

settings (return various settings and error information to their

Make sure that [CLR] appears in the FL display.

After checking it, turn the power off.

default values. The laser time is not included in this initialization).

Use the following checklist to establish the judgement criteria for the picture and sound.

Item Contents Check Item Contents Check

Picture

Block noise

Crosscut noise Noise (static, background noise, etc.)

Dot noise The sound level is too low.

Picture disruption The sound level is too high.

Sound

Not bright enough The sound level changes.

Too bright

Flickering color

Color fading

Distorted sound

70

Page 71

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

14 Miscellaneous

14.1. Abbreviations

14.1.1. DVD

INITIAL/LOGO ABBREVIATIONS

A A0~UP

ACLK

AD0~UP

ADATA

ALE

AMUTE

AREQ

ARF

ASI

ASO

ASYNC

B BCK

BCKIN

BDO

BLKCK

BOTTOM

BYP

BYTCK

C CAV

CBDO

CD

CDSCK

CDSRDATA

CDRF

CDV

CHNDATA

CKSL

CLV

COFTR

CPA

CPCS

CPDT

CPUADR

CPUADT

CPUIRQ

CPRD

CPWR

CS

CSYNCIN

CSYNCOUT

D DACCK

DEEMP

DEMPH

DIG0~UP

DIN

DMSRCK

DMUTE

DO

DOUT0~UP

DRF

DRPOUT

DREQ

DRESP

DSC

DSLF

DVD

ADDRESS

AUDIO CLOCK

ADDRESS BUS

AUDIO PES PACKET DATA

ADDRESS LATCH ENABLE

AUDIO MUTE

AUDIO PES PACKET REQUEST

AUDIO RF

SERVO AMP INVERTED INPUT

SERVO AMP OUTPUT

AUDIO WORD DISTINCTION SYNC

BIT CLOCK (PCM)

BIT CLOCK INPUT

BLACK DROP OUT

SUB CODE BLOCK CLOCK

CAP. FOR BOTTOM HOLD

BYPATH

BYTE CLOCK

CONSTANT ANGULAR VELOCITY

CAP. BLACK DROP OUT

COMPACT DISC

CD SERIAL DATA CLOCK

CD SERIAL DATA

CD RF (EFM) SIGNAL

COMPACT DISC-VIDEO

CHANNEL DATA

SYSTEM CLOCK SELECT

CONSTANT LINEAR VELOCITY

CAP. OFF TRACK

CPU ADDRESS

CPU CHIP SELECT

CPU DATA

CPU ADDRESS LATCH

CPU ADDRESS DATA BUS

CPU INTERRUPT REQUEST

CPU READ ENABLE

CPU WRITE ENABLE

CHIP SELECT

COMPOSITE SYNC IN

COMPOSITE SYNC OUT

D/A CONVERTER CLOCK

DEEMPHASIS BIT ON/OFF

DEEMPHASIS SWITCHING

FL DIGIT OUTPUT

DATA INPUT

DM SERIAL DATA READ CLOCK

DIGITAL MUTE CONTROL

DROP OUT

DATA OUTPUT

DATA SLICE RF (BIAS)

DROP OUT SIGNAL

DATA REQUEST

DATA RESPONSE

DIGITAL SERVO CONTROLLER

DATA SLICE LOOP FILTER

DIGITAL VIDEO DISC

INITIAL/LOGO ABBREVIATIONS

E EC

ECR

ENCSEL

ETMCLK

ETSCLK

F FBAL

FCLK

FE

FFI

FEO

FG

FSC

FSCK

G GND COMMON GROUNDING (EARTH)

H HA0~UP

HD0~UP

HINT

HRXW

I IECOUT

IPFRAG

IREF

ISEL

L LDON

LPC

LRCK

M MA0~UP

MCK

MCKI

MCLK

MDATA

MDQ0~UP

MDQM

MLD

MPEG

O ODC

OFTR

OSCI

OSCO

OSD

P P1~UP

PCD

PCK

PDVD

PEAK

PLLCLK

PLLOK

PWMCTL

PWMDA

PWMOA, B

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE

ENCODER SELECT

EXTERNAL M CLOCK (81MHz/40.5MHz)

EXTERNAL S CLOCK (54MHz)

FOCUS BALANCE

FRAME CLOCK

FOCUS ERROR

FOCUS ERROR AMP INVERTED INPUT

FOCUS ERROR AMP OUTPUT

FREQUENCY GENERAT OR

FREQUENCY SUB CARRIER

FS (384 OVER SAMPLING) CLOCK

HOST ADDRESS

HOST DATA

HOST INTERRUP T

HOST READ/WRITE

IEC958 FORMAT DATA OUTPUT

INTERPOLATION FLAG

I (CURRENT) REFERENCE

INTERFACE MODE SELECT

LASER DIODE CONTROL

LASER POWER CONTROL

L CH/R CH DISTINCTION CLOCK

MEMORY ADDRESS

MEMORY CLOCK

MEMORY CLOCK INPUT

MEMORY SERIAL COMMAND CLOCK

MEMORY SERIAL COMMAND DATA

MEMORY DATA INPUT/OUTPUT

MEMORY DATA I/O MASK

MEMORY SERIAL COMMAND LOAD

MOVING PICTURE EXPERTS GROUP

OPTICAL DISC CONTROLLER

OFF TRACKING

OSCILLATOR INPUT

OSCILLATOR OUTPUT

ON SCREEN DISPLAY

PORT

CD TRACKING PHASE DIFFERENCE

PLL CLOCK

DVD TRACKING PHASE DIFFERENCE

CAP. FOR PEAK HOLD

CHANNEL PLL CLOCK

PLL LOCK

PWM OUTPUT CONTROL

PULSE WAVE MOTOR DRIVE A

PULSE WAVE MOTOR OUT A, B

71

Page 72

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

INITIAL/LOGO ABBREVIATIONS

R RE

RFENV

RFO

RS

RSEL

RST

RSV

S SBI0, 1

SBO0

SBT0, 1

SCK

SCKR

SCL

SCLK

SDA

SEG0~UP

SELCLK

SEN

SIN1, 2

SOUT1, 2

SPDI

SPDO

SPEN

SPRCLK

SPWCLK

SQCK

SQCX

SRDATA

SRMADR

SRMDT0~7

SS

STAT

STCLK

STD0~UP

STENABLE

STSEL

STVALID

SUBC

SBCK

SUBQ

SYSCLK

T TE

TIBAL

TID

TIN

TIP

TIS

TPSN

TPSO

TPSP

TRCRS

TRON

TRSON

READ ENABLE

RF ENVELOPE

RF PHASE DIFFERENCE OUTPUT

(CD-ROM) REGISTER SELECT

RF POLARITY SELECT

RESET

RESERVE

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SERIAL CLOCK

SERIAL DATA CLOCK

AUDIO SERIAL CLOCK RECEIVER

SERIAL CLOCK

SERIAL CLOCK

SERIAL DATA

FL SEGMENT OUTPUT

SELECT CLOCK

SERIAL PORT ENABLE

SERIAL DATA IN

SERIAL DATA OUT

SERIAL PORT DATA INPUT

SERIAL PORT DATA OUTPUT

SERIAL PORT R/W ENABLE

SERIAL PORT READ CLOCK

SERIAL PORT WRITE CLOCK

SUB CODE Q CLOCK

SUB CODE Q DATA READ CLOCK

SERIAL DATA

SRAM ADDRESS BUS

SRAM DATA BUS 0~7

START/STOP

STATUS

STREAM DATA CLOCK

STREAM DATA

STREAM DATA INPUT ENABLE

STREAM DATA POLARITY SELECT

STREAM DATA VALIDITY

SUB CODE SERIAL

SUB CODE CLOCK

SUB CODE Q DATA

SYSTEM CLOCK

TRACKING ERROR

BALANCE CONTROL

BALANCE OUTPUT 1

BALANCE INPUT

BALANCE INPUT

BALANCE OUTPUT 2

OP AMP INPUT

OP AMP OUTPUT

OP AMP INVERTED INPUT

TRACK CROSS SIGNAL

TRACKING ON

TRAVERSE SERVO ON

INITIAL/LOGO ABBREVIATIONS

V VBLANK

VCC

V BLANKING

COLLECTOR POWER SUPPLY

VOLTAGE

VCDCONT

VIDEO CD CONTROL (TRACKING

BALANCE)

VDD

VFB

VREF

VSS

W WAIT

WDCK

WEH

WSR

X X

XALE

XAREQ

XCDROM

XCS

XCSYNC

XDS

XHSYNCO

XHINT

XI

XINT

XMW

XO

XRE

XSRMCE

XSRMOE

XSRMWE

XVCS

XVDS

XVSYNCO

DRAIN POWER SUPPLY VOLTAGE

VIDEO FEED BACK

VOLTAGE REFERENCE

SOURCE POWER SUPPLY VOLTAGE

BUS CYCLE WAIT

WORD CLOCK

WRITE ENABLE HIGH

WORD SELECT RECEIVER

X´ TAL

X ADDRESS LATCH ENABLE

X AUDIO DATA REQUEST

X CD ROM CHIP SELECT

X CHIP SELECT

X COMPOSIT E SYNC

X DATA STROBE

X HORIZONTAL SYNC OUTPUT

XH INTERRUPT REQUEST

X´ TAL OSCILLATOR INPUT

X INTERRUPT

X MEMORY WRITE ENABLE

X´ TAL OSCILLATOR OUTPUT

X READ ENABLE

X SRAM CHIP ENABLE

X SRAM OUTPUT ENABLE

X SRAM WRITE ENABLE

X V-DEC CHIP SELECT

X V-DEC CONTROL BUS STROBE

X VERTICAL SYNC OUTPUT

72

Page 73

14.1.2. VHS

443NT [L]

A. COMP

A. COMPO

A. D.P [L]

A. D/L [L]

A. DEF [S]

A. DEF [S] [L]

A. DUB P [L]

A. DUB [H]

A. ERASE

A. H. SW

A. HEAD [R]

A. HEAD [W]

A. IN [L]

A. IN [R]

A. MUT [H]

A. MUTE [H]

A. OUT [L]

A. OUT [R]

A. RF OUT

A/VS/S. DATA

AC ONLINE

AC. O/EE. H

AFC S C

AFC [S]

AFC. DEF

ARFC OUT

ART. V

ART. V. MM

ART. V/H/N

AT. V/H/N

ATSW/TEST/NOR/SE

AUDIO IN [L]

AUDIO IN [R]

AUDIO OUT [L]

AUDIO OUT [R]

AUDIO SELECT [H]

AUDIO. L

AUDIO. R

AV CNT

AV CTL

AV CTL/S. CLK

AV. C.M.

AVCNT/METER. R

AVSW/METER. L

B MODE. H

B.G.P

BACKUP 5V

BAND. U.E.

BANDVL. D

BI/MI [L]

4.43 NTSC

L

AUDIO COMPONENT SIGNAL

AUDIO COMPONENT SIGNAL

AUDIO DUBBING PAUSE

L

AUDIO DUBBING PAUSE L

AUDIO DEFEAT

AUDIO DEFEAT

AUDIO DUBBING PAUSE

L

AUDIO DUBBING H

AUDIO ERASE

AUDIO HEAD SWITCHING PULSE

AUDIO HEAD (REC)

AUDIO HEAD (PLAY)

AUDIO INPUT (L)

AUDIO INPUT (R)

AUDIO MUTE

H

AUDIO MUTE H

AUDIO OUTPUT (L)

AUDIO OUTPUT (R)

AUDIO RF SIGNAL OUTPUT

AV SW/SERIAL DATA

AC ONLINE

AC ONLINE/EE

H

AFC S CURVE

AFC S CURVE

AFC DEFEAT

AUDIO RF SIGNAL OUTPUT

ARTIFICIAL VERTICAL SYNC SIGNAL

ARTIFICIAL VERTICAL SYNC

SIGNAL MONO MULTI

ARTIFICIAL VERTICAL SYNC

SIGNAL

H/NORMAL

ARTIFICIAL VERTICAL SYNC SIGNAL

TEST/NORMAL/SERVICE

AUDIO INPUT (L)

AUDIO INPUT (R)

AUDIO OUTPUT (L)

AUDIO OUTPUT (R)

AUDIO SELECT

H

AUDIO (L)

AUDIO (R)

AV CONTROL

AV CONTROL

AV CONTROL/SERIAL CLOCK

AV CONTROL MODE

AV CONTROL/LEVEL METER (R)

AV SW/LEVEL METER (L)

B MODE

H

BURST GATE PULSE

BACK UP 5V

BAND U

BAND VL

BILINGUAL/MIX

L

BIL

BIL [L]

BIL. [H]

BIL/M1 [L]

BS CLOCK

BS DATA

BS LCH IN

BS MIX [H]

BS MON [H]

BS MONI [H]

BS RCH IN

BS VIDEO

BS VIDEO/BS1

BS [H]

BS. LEVEL

BS. M [H]

BS/VTR [H]

BUS CLK

BUS LSN

BUS TLK

BUZZER

CAP EC

CAP M GND

CAP. ET

CAP. FG1

CAP. FG2

CAS. SW

CCN

CCP

CHM

CHP

CINEM [L]

CINEMA [L]

CINEMA/MIX

CKL

CKS

CL

CLK

CLK (C.G)

CLOCK. IN

CLP

COL/B/W/NOR

COLOR [H]

CONV

CS

CTL GND

CTL HEAD [

+

]

CTL HEAD [

−

]

CTL [

+

]

CTL [

−

]

CUE BIAS

CURRENT LIM

CYL ET

BILINGUAL

BILINGUAL

L

BILINGUAL H

BILINGUAL L

BS CLOCK

BS DATA

BS L CHANNEL INPUT

BS MIX

H

BS MONITOR H

BS MONITOR H

BS R CHANNEL INPUT

BS VIDEO SIGNAL

BS VIDEO SIGNAL

BS

H

BS LEVEL

BS MONITOR

H

BS/VTR H

BUS CLOCK

BUS LISTEN

BUS TALK

BUZZER

CAPSTAN TORQUE CONTROL

CAPSTAN MOTOR GND

CAPSTAN TORQUE CONTROL

CAPSTAN FG1 PULSE

CAPSTAN FG2 PULSE

CASSETTE SW

PLAYBACK CONTROL SIGNAL (−)

PLAYBACK CONTROL SIGNAL (

+

)

CONTROL SIGNAL (+)

CONTROL SIGNAL (

−

)

CINEMA

L

CINEMA L

CINEMA/MIX

RATCH LOCK

SHIFT LOCK

CLOCK

CLOCK

CLOCK

CLOCK INPUT

CLAMP

COLOUR/BLACK & WHITE/NORMAL

COLOUR H

CONVERTOR

CHIP SELECT

CONTROL GND

CONTROL HEAD (

+

)

CONTROL HEAD (

−

)

CONTROL HEAD (

+

)

CONTROL HEAD (

−

)

CUE BIAS

CURRENT LIMMITER

CYLINDER TORQUE CONTROL

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

73

Page 74

CYL GND

D.F.M. REC [H]

D. FM REC [L]

D. GND

D. REC [H]

D4/S. LED

D4/STILLED

DAC [CLK]

DAC/FSCS

DAREC [H]

DATA

DECODER [L]

DECODER [R]

DEW

DEW SNS

DFMRE [H]

E. REC 5V

EC

ECR

EDT TRIG [L]

EDIT [H]

EE [H]

EE [H]/INS [M]

EE. VV. TR

EJECT. PO

EJECT/VDET

ENV. SEL

ENVE. OUT

ENVE. SEL

ENV SELECT

EP [H]

EP/LP [H]

EP/LP/SP

EP/SS [H]

EPROMCS

EX. REC 5V

FF/REW [L]

FG1 IN

FG2 IN

FILTER ADJUSTMENT

FLY ERASE [H]

FLY ON [H]

FLY. E [H]

FM MUT [H]

FM MUTE [H]

FM OUT [L]

FM OUT [R]

FM PACK OUT [L]

FM PACK OUT [R]

FM/BS SEL [L]

FM/BS SEL [R]

FS. CLK

FUL. E [H]

FULL. E [H]

CYLINDER GND

DELAIED FM RECORDING

H

DELAIED FM RECORDING L

DIGITAL GND

DELAYED RECORDING

H

D4/STILL LED

D4/STILL LED

TUNER DAC (CLOCK)

TUNER DAC/FS CHIP SELECT

DELAYED AUDIO RECORDING

H

DATA

DECODER (L)

DECODER (R)

DEW

DEW SENSOR

DELAYED FM AUDIO RECORDING

H

EXCEPT RECORDING 5V

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE VOLTAGE

EDIT TRIGGER

L

EDIT H

EE H

EE H/INSERT M

EE/VV/TRICK PLAY

EJECT POSITION

EJECT/REVERSE SLOW LOCK

ENVELOPE SELECT

ENVELOPE OUTPUT

ENVELOPE SELECT

ENVELOPE SELECT

LP

H

LP H

LP/SP

LP/SLOW/STILL/STOP

H

EPROM CHIP SELECT

EXCEPT RECORDING 5V

FIRST FORWARD/REWIND

L

FG1 PULSE INPUT

FG2 PULSE INPUT

FILTER ADJUSTMENT

FLYING ERASE HEAD ON

H

FLYING ERASE HEAD ON H

FLYING ERASE HEAD ON H

FM AUDIO MUTE H

FM AUDIO MUTE H

FM OUTPUT (L)

FM OUTPUT (R)

FM PACK OUTPUT (L)

FM PACK OUTPUT (R)

FM/BS SELECT (L)

FM/BS SELECT (R)

FS CLOCK

FULL ERASE HEAD ON

H

FULL ERASE HEAD ON H

FULL. E. 12V

GND [A]

GND [TU]

GND/N. SW. 12V

H. SYNC

H. AMP. SW

H. P <R>

H. P <L>

H. P GND

H. P OUT [L]

H. P OUT [R]

H. SW

HEAD PHONE [L]

HEAD PHONE [R]

HEAD SW

HEATER [

+

]

HEATER [

−

]

HSS

HTR [

+

]

HTR [

−

]

I RFE

ICL

IF

IN SELA1

IN SELA2

IN SELA3

INS L/R [L]

INS. [H]

INSEL A1

INSEL A2

INSERT

INSERT [H]

IO CS

JOG1

JOG S3 LED/FOWRD

JOG/F. LED

JSB [H]

JST. CLCK

JST. CLK

JST. CLOCK

L. OUT

L. CH [H]

L. CH [L]

LED (MAIN)

LED (STEREO)

LED (SUB)

LED CKL

LED CKS

LED DATA

LINE IN 1 [L]

LINE IN 1 [R]

LINE IN 2 [L]

LINE IN 2 [R]

LINE IN V

LINE IN [L]

FULL ERASE 12V

GND (ANALOG)

GND (TUNER)

GND/NON SW 12V

HORIZONTAL SYNC

HEAD AMP SW PULSE

HEAD PHONE (R)

HEAD PHONE (L)

HEAD PHONE GND

HEAD PHONE OUTPUT (L)

HEAD PHONE OUTPUT (R)

HEAD SW PULSE

HEAD PHONE (L)

HEAD PHONE (R)

HEAD SW

HEATER (

+

)

HEATER (

−

)

HORIZONTAL SYNC SIGNAL

HEATER (

+

)

HEATER (

−

)

REFERENCE CURRENT

CONTROL AGC CIRCUIT

INTERMEDIATE FREQUENCY

INPUT SELECT A1 POSITION

INPUT SELECT A2 POSITION

INPUT SELECT A3 POSITION

INSERT Lch/Rch

L

INSERT H

INPUT SELECT A1 POSITION

INPUT SELECT A2 POSITION

INSERT

INSERT

H

INPUT/OUTPUT CHIP SELECT

JOG1

JOG LED/FORWARD LED

JOG LED/FORWARD LED

JSB

H

JUST CLOCK

JUST CLOCK

JUST CLOCK

Lch OUTPUT

Lch

H

Lch L

LED (MAIN)

LED (STEREO)

LED (SUB)

LED SERIAL CLOCK

LED SERIAL CLOCK

LED SERIAL DATA

LINE INPUT 1 (L)

LINE INPUT 1 (R)

LINE INPUT 2 (L)

LINE INPUT 2 (R)

LINE INPUT VIDEO

LINE INPUT (L)

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

74

Page 75

LINE IN [R]

LINE OUT [L]

LINE OUT [R]

LP [H]

LPTRI [L]

Lch/A. DUB

M GND

M REG

MAIN OUT

MAIN [L]

MAIN/MONO

MAX IN

MES [H]

MESE [H]

MESE [L]

METER 5V

METER [L]

METER [R]

METER. L/AVS

METER. R/AVC

MI/BI [L]

MIC GND

MIC IN

MIC IN [L]

MIC IN [R]

MIC [H]

MIX [H]

MIX [H]/CINEMA [L]

MIX/CINE

MIX/CINEMA [L]

MN. H/M. L

MN. H/MAI. L

MN2/MES. L

MODE SEL

MODE SW

MODE. S. IN

MODE. S. OUT

MONO [H]

MONO [H]/MAIN [L]

MONO2 [L]

MONO2/MESE [FM(L)]

MOTOR GND

MUTE

N. A. REC [L]

N. SW 12V

N. SW. 5. DET

NICAM

NICAM [L]

NOL [H]

NOR/SOFT [H]

NORMAL [H]

NR BIAS

NTSC [L]

OCH

OUT

LINE INPUT (R)

LINE OUTPUT (L)

LINE OUTPUT (R)

LP

H

LP TRICK PLAY L

Lch/AUDIO DUBBING

MOTOR GND

MOTOR REGULATOR

MAIN OUTPUT

MAIN

L

MAIN/MONAURAL

MAXIMAM INPUT

MESECAM

H

MESECAM H

MESECAM L

LEVEL METER 5V

LEVEL METER (L)

LEVEL METER (R)

LEVEL METER (L)

LEVEL METER (R)

MIX

H/BILIGUAL

MIC GND

MIC INPUT

MIC INPUT (L)

MIC INPUT (R)

MIC

H

MIX H

MIX H/CINEMA SOUND L

MIX H/CINEMA SOUND L

MIX H/CINEMA SOUND L

MONAURAL H/MAIN L

MONAURAL H/MAIN L

MONAURAL 2/MESECAM L

AUDIO MODE SELECT

AUDIO MODE SW

AUDIO MODE SELECT INPUT

AUDIO MODE SELECT OUTPUT

MONAURAL

H

MONAURAL H/MAIN L

MONAURAL 2

MONAURAL 2/MESECAM (FM

L)

MOTOR GND

MUTE

NORMAL AUDIO RECORDING

NON SW 12V

NON SW 5V DETECT

NICAM

NICAM

L

PAL H/4.43 NTSC M/3.58 NTSC

L

NORMAL/SOFT TAPE PLAY H

NORMAL H

NR BIAS

NTSC

L

CONTROL AGC CIRCUIT

OUTPUT

P-OFF [H]

P-OFF [L]

P. FAIL

P. OFF [H]

P. OFF [L]

PAL [H]

PAL [L]/NTSC [H]

PB ADJ OUT

PB OUT

PB. H

PFG

PHOTSN +B

PICT. CNT

PLAY LED/RVS LED

PLAY. PO

PLAY/R. LED

PLY/DEW

POWER OFF [L]

PREROLL [H]

PWRFAIL

R. CH [H]

R. CH [L]

R. ST

R/S/F

RCH [H]

REC 12V

REC CHROMA

REC H

REC IN

REC OUT [L]

REC START

REC VR [C]

REC VR [L]

REC VR [R]

REC Y

REC [H]

REC. C

REC. Y

REC/EE CTL

REEL-T

REEL-S

REGULATOR FILTER

RESET

REV M F/R

REV M V1

REV M V2

REV MOTOR F/R

REV MOTOR V1

REV MOTOR V2

REV MOTOR [

+

]

REV MOTOR [

−

]

REV. M. GND

RF. CHROMA

POWER OFF

H

POWER OFF L

POWER FAILURE DETECT

POWER OFF

H

POWER OFF L

PAL H

PAL L/NTSC H

PLAYBACK ADJUST OUTPUT

PLAYBACK OUTPUT

PLAYBACK

H

PG/FG

PHOTO SENSOR +B

PICTURE CONTROL

PLAY LED/REVERSE LED

PLAY POSITION

PLAY LED/REVERSE LED

PLAY/DEW

H

POWER OFF L

PREROLL H

POWER FAILURE DETECT

Rch

H

Rch L

RESET

REVERSE H/STOP M/FORWARD

L

Rch H

RECORDING 12V

RECORDING CHROMINANCE SIGNAL

RECORDING H

RECORDING INPUT

RECORDING OUTPUT

L

RECORDING START

RECORDING VOLUME (COMMON)

RECORDING VOLUME (L)

RECORDING VOLUME (R)

RECORDING LUMINANCE SIGNAL

RECORDING H

RECORDING CHROMINANCE SIGNAL

RECORDING LUMINANCE SIGNAL

RECORDING/EE CONTROL

REEL PULSE (TAKE-UP)

REEL PULSE (SUPPLY)

REGULATOR FILTER

RESET

REVIEW MOTOR

FORWARD/REVERSE

REVIEW MOTOR V1

REVIEW MOTOR V2

REVIEW MOTOR

FORWARD/REVERSE

REVIEW MOTOR V1

REVIEW MOTOR V2

REVIEW MOTOR (

+

)

REVIEW MOTOR (

+

)

REVIEW MOTOR GND

RF CHROMINANCE SIGNAL

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

75

Page 76

RF OUT

RF Y

RF. Y. IN

RF. Y. OUT

ROTAR. SW

ROTARY

RST

RST [L]

Rch/INST

S IN

S OUT

S-PHOTO

S-RL. PLS

S. CLK

S. CLK/AV

S. DATA

S. DATA/A

S. PHOTO

S. TAB [L]

S/P/N

SC IN

SC OUT

SCK SELECT

SEL OUT [L]

SEL OUT [R]

SHUTTLE 1

SIF

SLMUT [H]

SLNID [

+

]

SLNID [

−

]

SLW TR. MM

SLW TR. REF

SNS. GND

SOFT [H]

SOFT [H]/NORMAL

SOLENOID ON [L]

SP [H]

SP/L/SLP

SSS [L]

STEREO LED

STEREO [H]

STEREO [L]

STOP. PO

STOP/5V

STOP1/TAPE SEL

STOP1/PAL:ST

STOP2. PO

STOP2/S-TAB

STREO [H]

SUB BIAS

SUB. SW

SVHS CAS [L]

SW. 5. DET

SYNC [L]

RF OUTPUT

RF LUMINANCE SIGNAL

RF LUMINANCE SIGNAL INPUT

RF LUMINANCE SIGNAL OUTPUT

ROTARY SW

ROTARY SW

RESET

RESET

L

Rch/INSERT

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SUPPLY PHOTO TRANSISTOR

SUPPLY REEL PULSE

SERIAL CLOCK

SERIAL CLOCK/AV

SERIAL DATA

SERIAL DATA

SUPPLY PHOTO TRANSISTOR

SAFETY TAB SW ON

L

SECAM/PAL/NTSC

SERIAL CLOCK INPUT

SERIAL CLOCK OUTPUT

SERIAL CLOCK SELECT

SELECT OUTPUT (L)

SELECT OUTPUT (R)

SHUTTLE 1

SOUND INTERMEDIATE FREQUENCY

INPUT SELECT MUTE H

SOLENOID (

+

)

SOLENOID (

−

)

SLOW TRACKING MONO MULTI

SLOW TRACKING REFERENCE

VOLTAGE

SENSOR GND

SOFT TAPE PLAY

H

SOFT TAPE PLAY H/NORMAL H

SOLENOID ON L

SP H

SP/LP

SLOW/STILL/STOP

STEREO LED

STEREO

H

STEREO L

STOP POSITION

STOP POSITION/5V

STOP1 POSITION/TAPE SELECT

STOP1 POSITION/PAL

STOP 2 POSITION

STOP 2 POSITION/SAFETY TAB SW

STEREO H

SUB BIAS

SUB SW

S-VHS CASSETTE

L

SW 5V DETECT

SYNC

L

SYSCON 5V

SYSTEM

T-PHOTO

T-RL. PLS

T. BUSCLK

T. BUSLSN

T. BUSTLK

T. END [L]

T. PHOTO

TAPE END [L]

TAPE END [L]/CAM

TEST

TPZ

TRIC [L]

TRICK [L]

TRK. ENV

TU. AUDIO

TU. GND

TU. V. IN

TU. VIDEO

TUN NOR IN

TUN R

TUN. AUDIO IN

TUNER 12V

TUNER L

TUNER V IN

TUNER [L]

TUNER [N]

TUNER [R]

TUNER. 12

TUOFF [H]

TV. AUDIO

TV/VTR

TXTON [L]

U. REG45V

UNREG

UNREG19V

V. REF

V. EE [H]

V. EE [L]

VCO REF

VD. IN

VD. OUT

VIDEO EE [L]

VIDEO IN

VIDEO OUT

VM

VM DOWN [L]

VSS

VTR [H]

VTR. 12V

X IN

X OUT

SYSTEM CONTROL 5V

SYSTEM SW

TAKE-UP PHOTO TRANSISTOR

TAKE-UP REEL PULSE

TIMER BUS CLOCK

TIMER BUS LISTEN

TIMER BUS TALK

TAPE END

L

TAKE-UP PHOTO TRANSISTOR

TAPE END

L

TAPE END L/CAMERA PAUSE

TEST MODE

TRAPEZOIDAL WAVE CIRCUIT

TRIC PLAY

L

TRIC PLAY L

AUTO TRACKING ENVELOPE DETECT

TUNER AUDIO

TUNER GND

TUNER VIDEO SIGNAL INPUT

TUNER VIDEO

TUNER NORMAL INPUT

TUNER AUDIO (R)

TUNER AUDIO INPUT

TUNER 12V

TUNER AUDIO (L)