Page 1

ORDER NO. PCZ1703034CE

Blu-ray Disc Player

Model No. DMP-UB300EB

DMP-UB300EG

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

Colour

(K)....................Black Type

© Panasonic Corporation 2017.

Unauthorized copying and distribution is a violation

of law.

Page 2

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1.) --------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. Caution for AC Cord (For EB)---------------------------5

2.3. Precaution of Laser Diode -------------------------------6

2.4. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------7

2.5. Static Electricity Protection Measures ----------------8

2.6. Ground for electrostatic breakdown

prevention----------------------------------------------------8

3 Service Navigation------------------------------------------------9

3.1. Service Infomation -----------------------------------------9

3.2. How to Update Firmware---------------------------------9

4 Specifications ---------------------------------------------------- 12

4.1. Others (Licenses) ---------------------------------------- 15

5 Location of Controls and Components------------------ 16

6 Operating Instructions ---------------------------------------- 18

6.1. Taking out the Disc from Drive Unit when the

Disc cannot be ejected by OPEN/CLOSE

button-------------------------------------------------------- 18

6.2. Micro Fuse Conducting Check------------------------ 19

7 Service Mode ----------------------------------------------------- 20

7.1. About the Multiple Pressing of the Unit’s

Remote Control------------------------------------------- 20

7.2. How to enter the Special Modes using the

Multiple Pressing Function of the Unit’s

Remote Control------------------------------------------- 20

7.3. About the Service Mode -------------------------------- 23

7.4. Service Mode List ---------------------------------------- 24

7.5. Self-Diagnostics Functions ---------------------------- 27

8 Service Fixture & Tools --------------------------------------- 29

9 Disassembly and Assembly Instructions --------------- 30

9.1. Unit----------------------------------------------------------- 30

9.2. Sticking position of Barrier Sheet -------------------- 35

10 Measurements and Adjustments -------------------------- 36

10.1. Service Positions ----------------------------------------- 36

10.2. Adjustment of Drive Unit ------------------------------- 38

10.3. Caution for Replacing Parts ---------------------------39

11 Block Diagra m --------------------------------------------------- 40

11.1. Overall Block Diagram ----------------------------------40

11.2. Power Supply Circuit Block Diagram---------------- 41

11.3. Digital P.C.B. Unit Regulator Circuit Block

Diagram----------------------------------------------------- 42

11.4. Timer Circuit Block Diagram--------------------------- 43

11.5. Digital Circuit Block Diagram -------------------------- 44

12 Wiring Connection Diagram --------------------------------- 45

12.1. Interconnection Diagram ------------------------------- 45

13 Schematic Diagram--------------------------------------------- 46

14 Printed Circuit Board ------------------------------------------ 46

15 Exploded View and Replacement Parts List -----------46

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

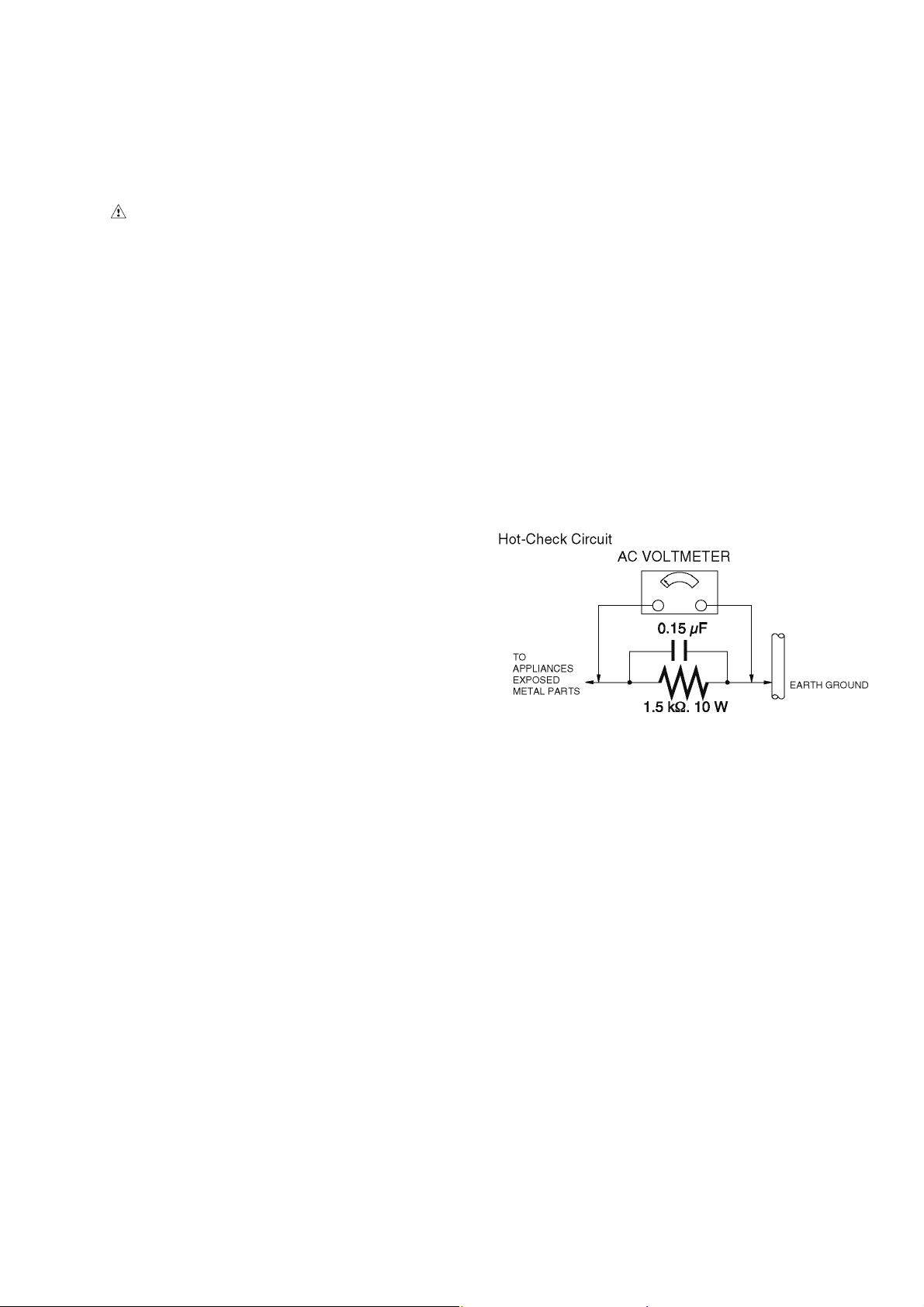

1.3. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

Page 4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

4

Page 5

2.2. Caution for AC Cord (For EB)

2.2.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

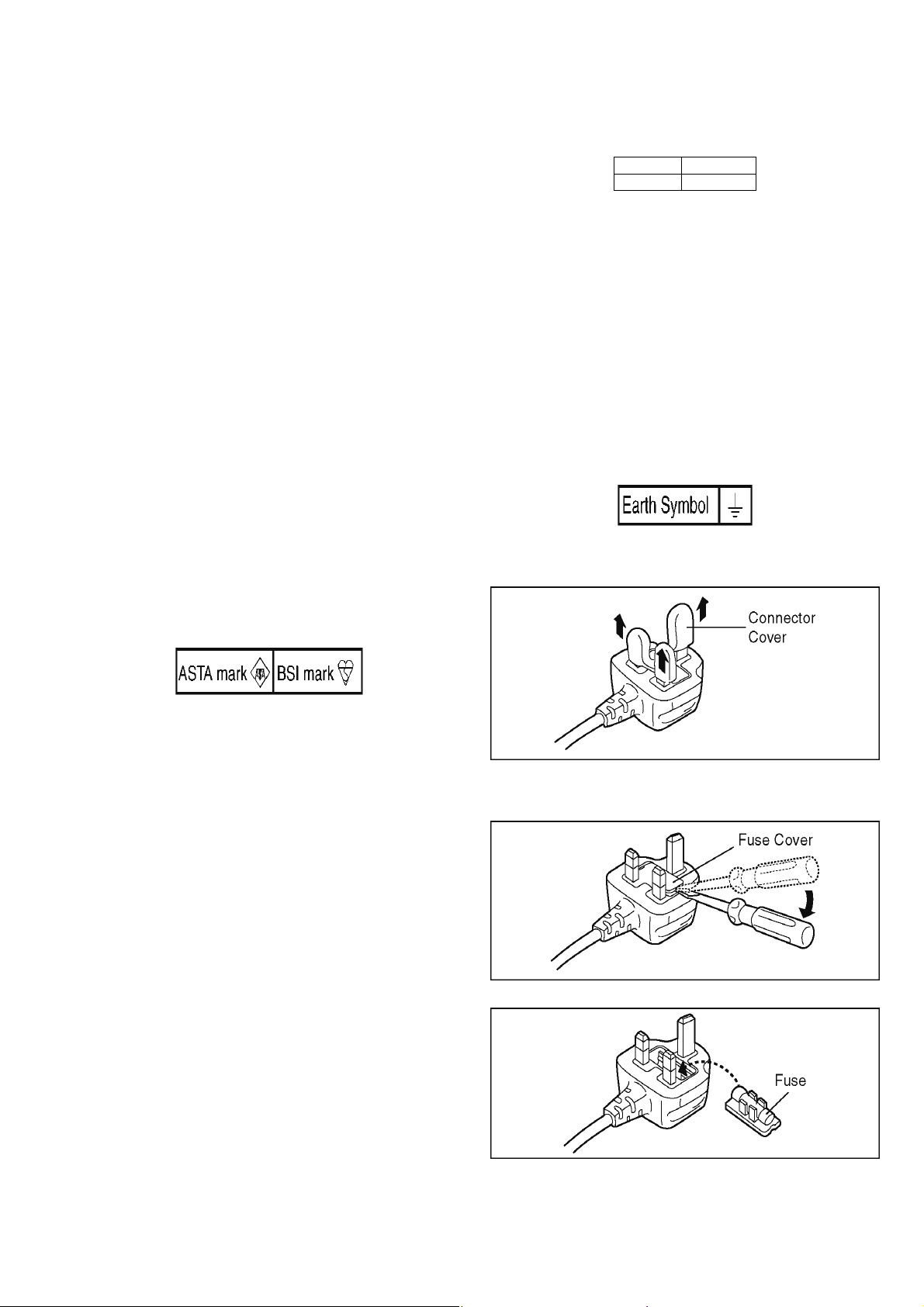

2.2.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

2.2.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with the letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.2.2.2. Before Use

Remove the Connector Cover as follows.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.2.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

5

Page 6

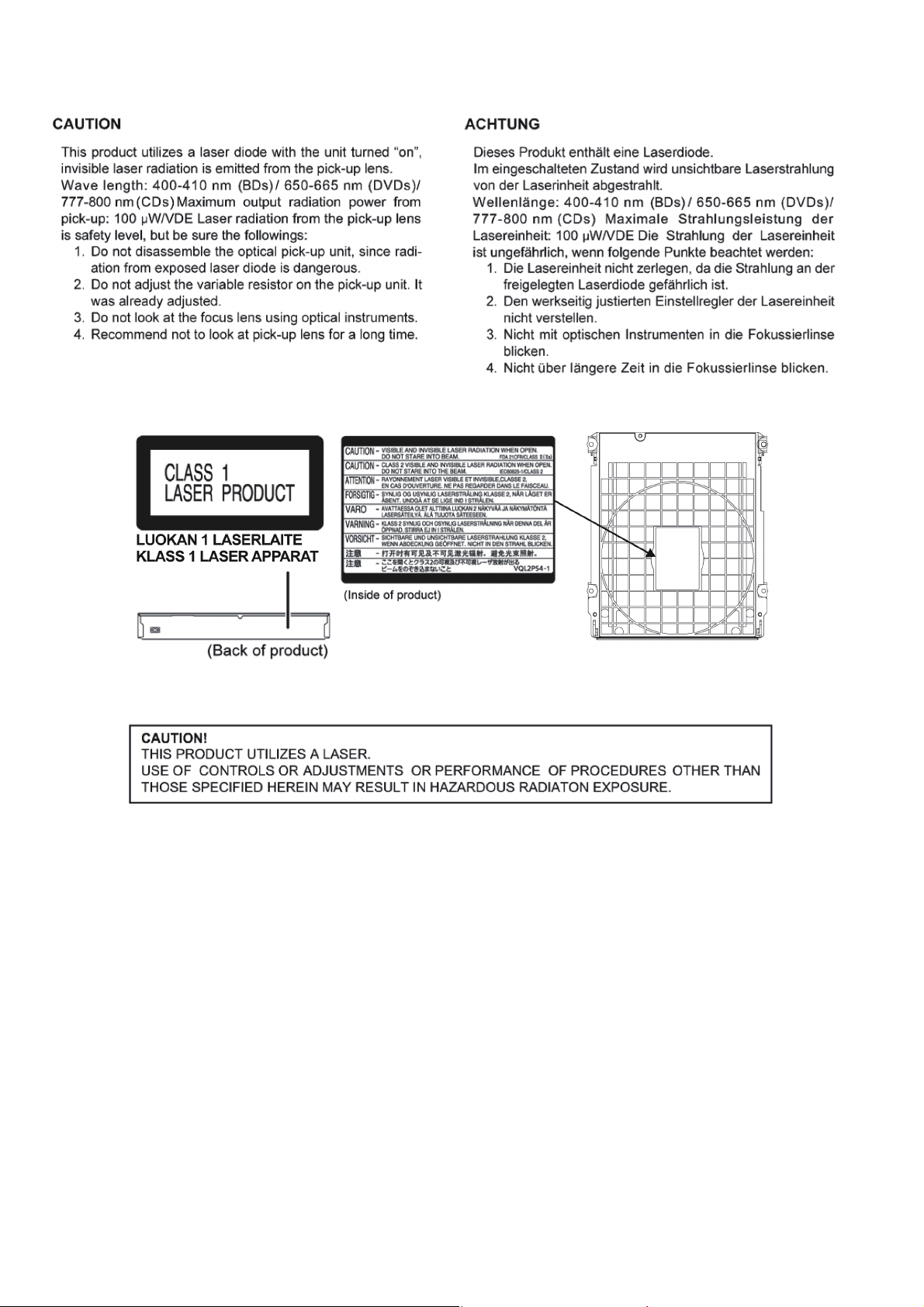

2.3. Precaution of Laser Diode

6

Page 7

2.4. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

SVKZ000001-----------(0.3mm 100g Reel)

SVKZ000002-----------(0.6mm 100g Reel)

SVKZ000003-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn) 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%. (Flux cored)

7

Page 8

2.5. Static Electricity Protection Measures

• The laser diode in the traverse unit (optical pick-up) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse unit (optical pick-up).

2.6. Ground for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.6.1. Work table grounding

• Put a conductive material (sheet) or steel sheet on the area where the traverse unit (optical pick-up) is placed, and ground the

sheet.

2.6.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity from your body.

2.6.3. When exchange the BDP Drive

• Before remove the ESD prevention bag, make sure to use the anti-static wrist strap to discharge the static electricity when

replace the BDP Drive.

Note:

The ESD prevention bag is used to replace the original short-circuit point.

It can be removed while placing the BDP Drive.

8

Page 9

3 Service Navigation

3.1. Service Infomation

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by service manual to be filed with original service manual.

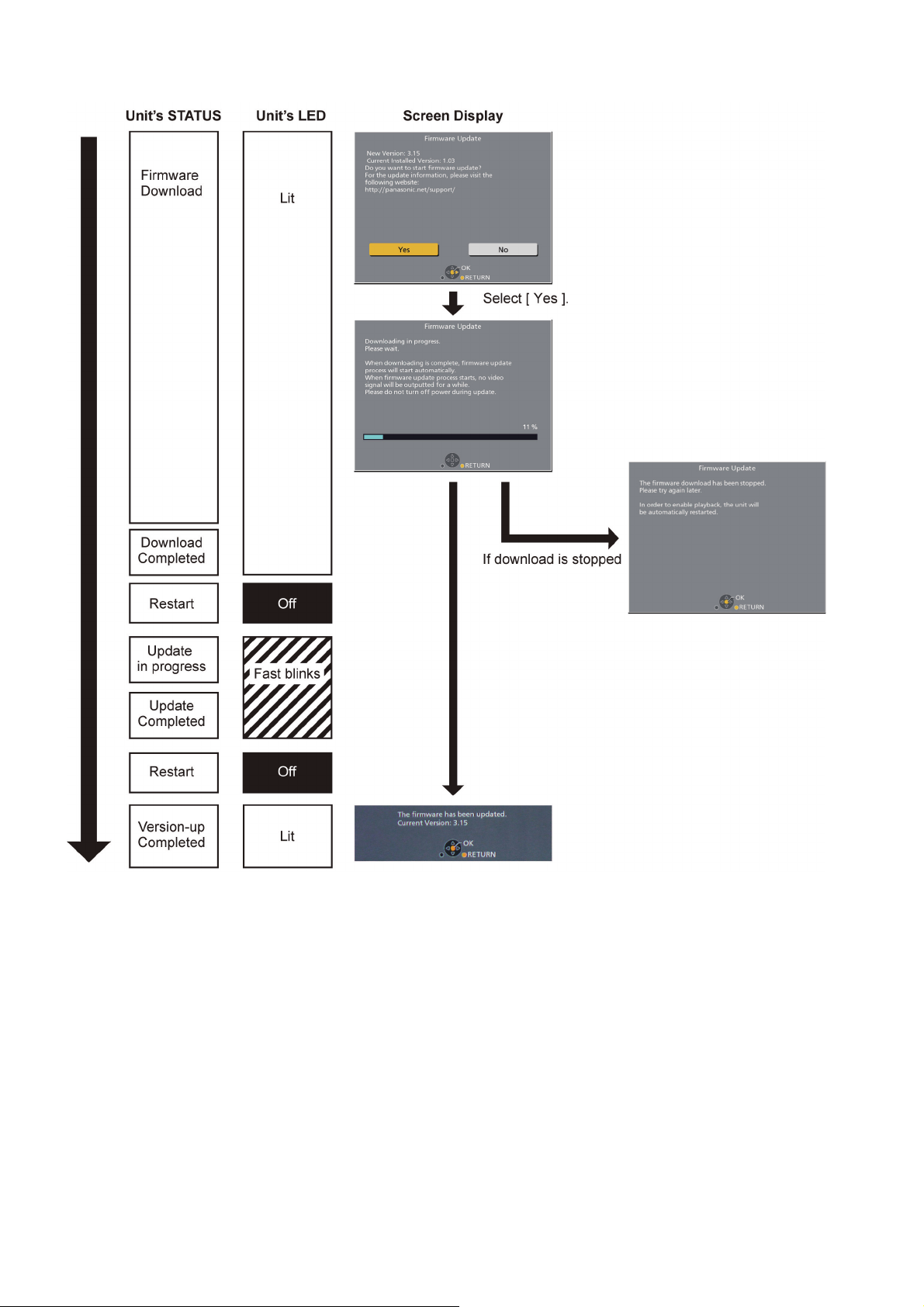

3.2. How to Update Firmware

The firmware of the unit may be renewed to improve the quality including operational performance and playability.

Make sure to refer the following procedure when performing version-up.

3.2.1. Confirmation of the Firmware Version

Perform following steps to checking the firmware version currently installed in the unit.

1. Turn the unit on and wait the Home screen is displayed.

2. Select [Setup] → [Player Settings] → [System] → [System Information] → [Firmware Version Information].

3. Firmware Version Information screen is displayed.

3.2.2. Updating Firmware

This unit has 2 updating method, one way to update via the internet, the other way to update using CD-R or USB device which is

stored pre-downloaded firmware update file.

3.2.2.1. Updating firmware via the internet

Occasionally, Panasonic may release updated

firmware for this unit that may add or improve the way a feature operates. These updates are available free of charge.

This unit is capable of checking the firmware automatically when connected to the Internet via a broadband connection.

When a new firmware version is available, the following message is displayed.

9

Page 10

[ Update procedure]

DO NOT DISCONNECT the unit from the AC

power or perform any operation while the update takes place.

10

Page 11

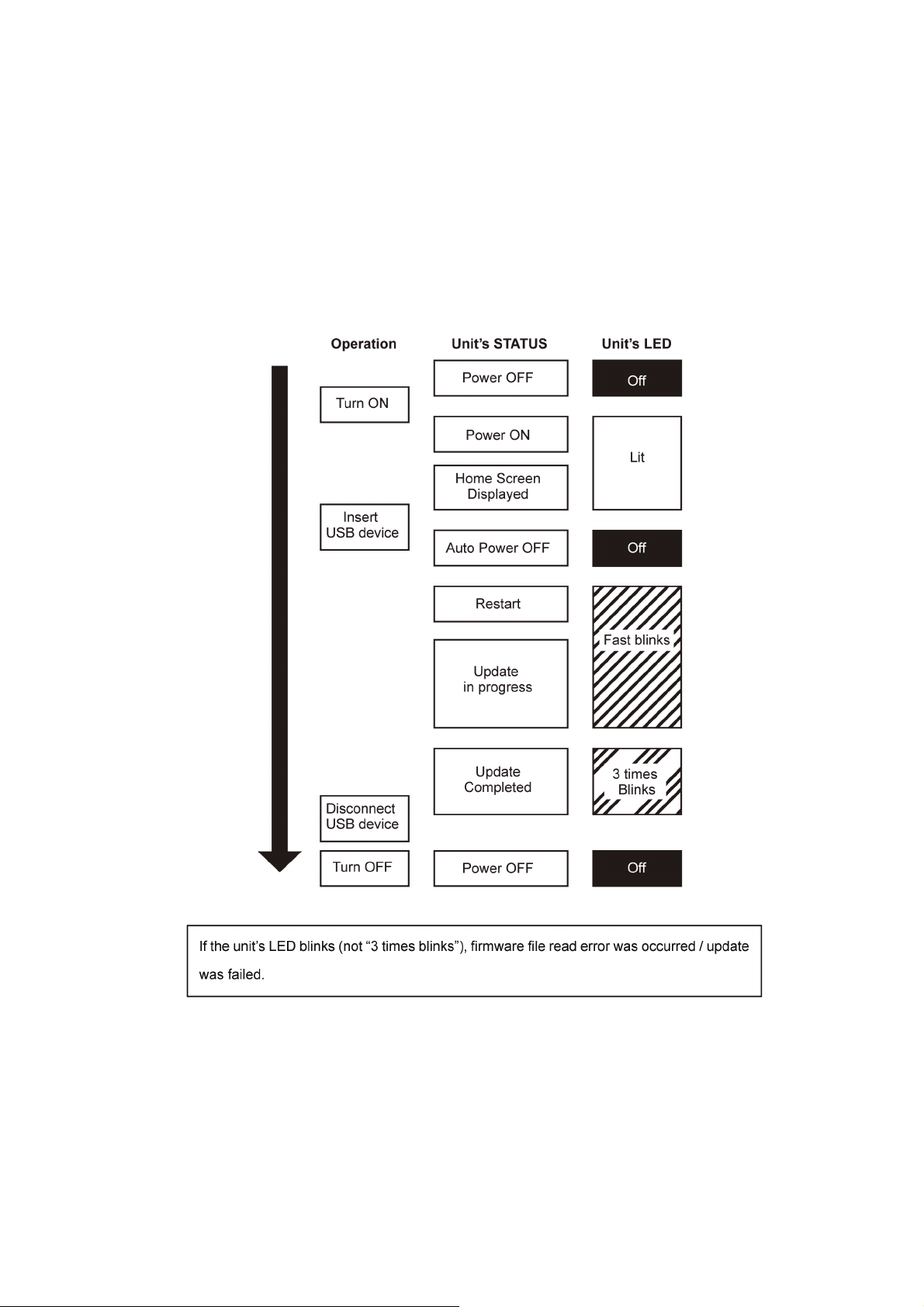

3.2.2.2. Updating firmware using the USB device

When updating firmware using USB device, perform following procedures.

(When using CD-R instead of USB device, perform same procedures)

1. Download the latest firmware file of the unit

The latest firmware required for version-up can be downloaded from TSN-Web site.

Click file name to download.

After download, click file to decompress.

2. Decompress the downloaded file

The decompressed file will be named as follows.

File Name: PANAEUSB.FRM

Copy the file to root folder of the USB device.

(If using CD-R instead of USB device, burn the file to a blank CD-R by writing software.)

3. Update the unit

Turn the unit on and home screen displayed, the firmware update is completed.

11

Page 12

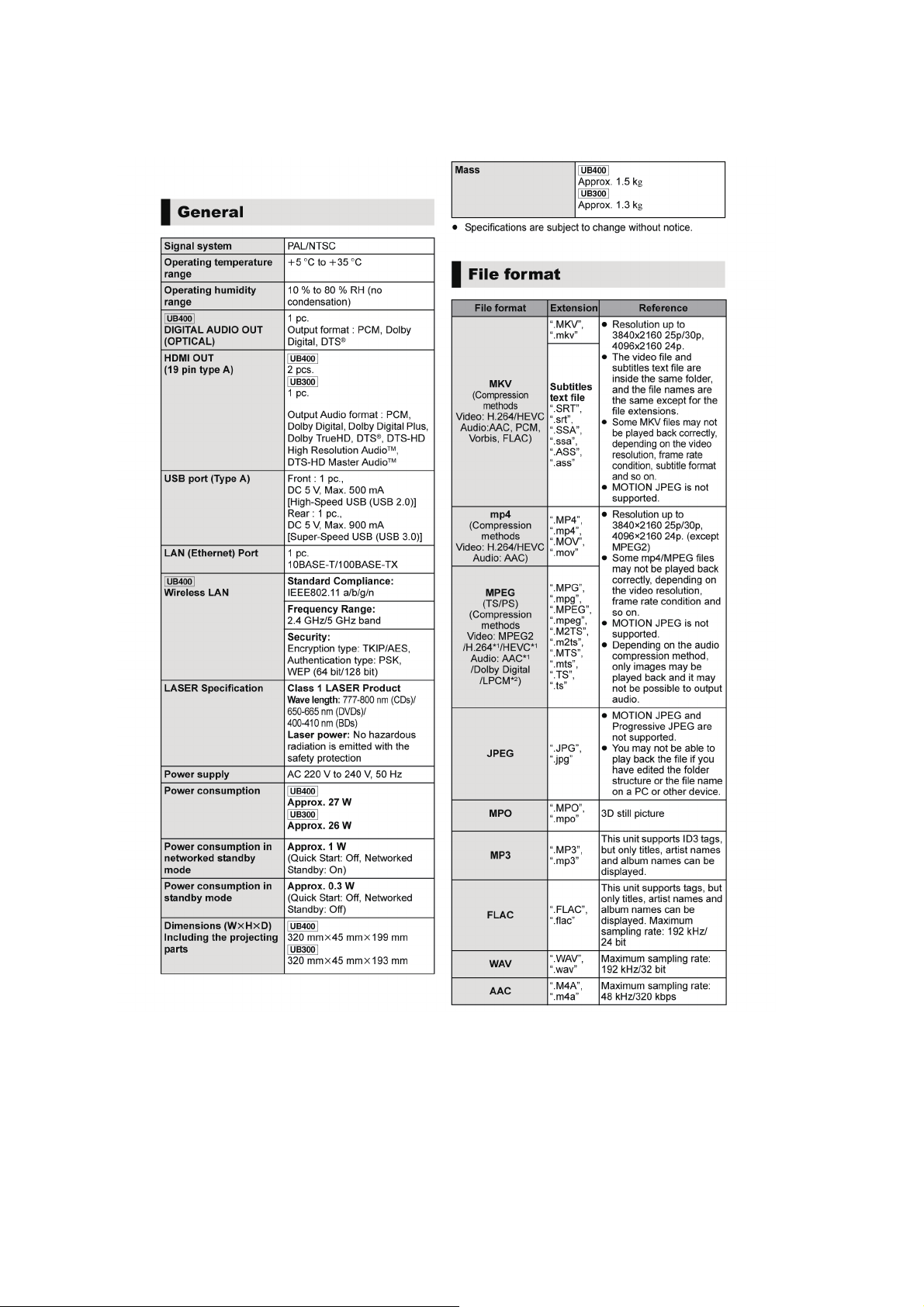

4 Specifications

The following specification is for DMP-UB400EB/UB300EB.

Some specifications may differ depending on model suffix.

12

Page 13

131415

Page 14

Page 15

4.1. Others (Licenses)

Page 16

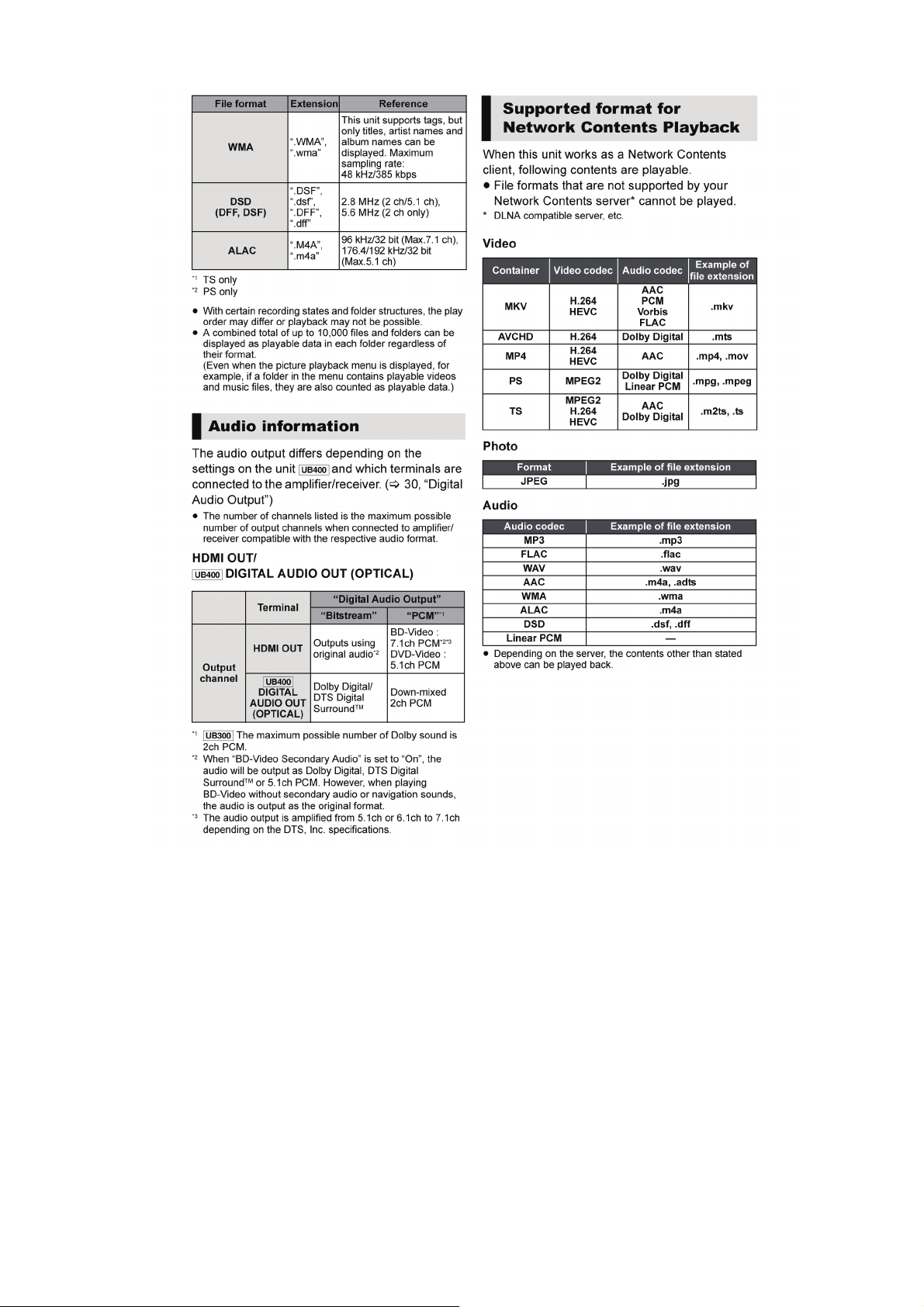

5 Location of Controls and Components

The following specification is for DMP-UB400EB/UB300EB.

Some descriptions may differ depending on model suffix.

The page number in this chapter does not show the page number of this service manual.

16

Page 17

17

Page 18

6 Operating Instructions

6.1. Taking out the Disc from Drive Unit when the Disc cannot be ejected by OPEN/CLOSE button

6.1.1. Forcible Disc Eject

6.1.1.1. When the power can be turned off.

1. Turn the unit off, then press and hold [OK], [Yellow] and [Blue] buttons on the remote control simultaneously for 5 seconds.

- “00 RET” is displayed on the screen.

2. Repeatedly press the [ ] button on the remote control or [POWER] button on the unit until “06 FTO” is displayed on the

screen.

3. Press [OK] button on the remote control or [OPEN/CLOSE] button on the unit.

6.1.1.2. When the power can not be turned off.

Press [POWER] button on the unit for over 4 seconds to turn off the power forcibly, and step 1 to 3 above.

6.1.2. When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Remove the Top Case Ass’y.

3. Put the unit so that bottom can be seen.

4. Insert paper clips, etc. into the hole on the bottom of Drive Unit and slide the paper clips, etc. in the direction of the arrow to

eject tray slightly.

5. Put the unit upward, and pull out Tray by finger.

18

Page 19

6.2. Micro Fuse Conducting Check

This unit uses the Micro Fuse.

Check the Micro Fuse conducting using the Tester at the check points below.

19

Page 20

7 Service Mode

7.1. About the Multiple Pressing of the Unit’s Remote Control

The remote control which included this unit is possible pressing multiple buttons simultaneously (Multiple Pressing function), and

can operate for the customer's initial settings and the Service Mode, etc.

The Multiple Pressing function is not available for conventional models' remote control. Use the remote control included this unit.

7.2. How to enter the Special Modes using the Multiple Pressing Function of the Unit’s Remote Control

For pressing the multiple buttons of the remote control, this unit can be entering each of the following special modes.

After entering each mode, and then go to the menu you want to run.

• Move the menus for each mode:

Press [ ] button (Remote Cont.) or [POWER] button (Unit)

• Execute

Press [OK] button (Remote Cont.) or [OPEN/CLOSE] button (Unit)

* After executing the menu will automatically exit the special mode.

• How to exit from the special modes

• Press the unrelated buttons for the operation.

• No operation for 2 minutes or more.

• Press and hold [POWER] button on the unit. (Forcible Power Off)

20

Page 21

7.2.1. Open Mode (Remote Cont. Buttons: [OK] [Yellow] [Blue])

When pressing the 3 buttons, [OK], [Yellow] and [Blue] simultaneously for 5 seconds, “00 RET” is displayed on the screen.

21

Page 22

7.2.2. Privately Mode 1 (Remote Cont. Buttons: [6] [7] [Yellow])

When pressing the 3 buttons, [6], [7] and [Yellow] simultaneously for 5 seconds, “50 RET” is displayed on the screen.

7.2.3. Privately Mode 2 (Remote Cont. Buttons: [5] [9] [Red])

When pressing the 3 buttons, [5], [9] and [Red] simultaneously for 5 seconds, “70 RET” is displayed on the screen.

22

Page 23

7.3. About the Service Mode

Informations necessary for service can be displayed.

7.3.1. How to enter the Service Mode

7.3.2. How to exit the Service Mode

Press and hold the [POWER] button (remote control or unit).

>>> The Service Mode is terminated and automatically turns the unit off.

23

Page 24

7.4. Service Mode List

The display of information to each command is as follows.

Note:

Do not use it excluding the designated command.

24

Page 25

252627

Page 26

Page 27

7.5. Self-Diagnostics Functions

7.5.1. Self-Diagnostics Functions

Self-Diagnosis Function provides information for errors to service personnel by Self-Diagnosis Display when any error has

occurred.

U** and F** are stored in memory and held.

You can check last error code by transmitting [0] [1] in Service Mode.

Automatic Display on the screen will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display

is ON.

Page 28

28

Page 29

8 Service Fixture & Tools

PartNo. Uses Pcs Compatibility

RFKZ0327 Extension Cable (Digital P.C.B. Unit - Main P.C.B. Unit / 15 Pin) 1 Same as DMP-BDT320 Series

SUKZ000007 Extension Cable (Digital P.C.B. Unit - Drive Unit / 18 Pin) 1 Same as DMP-UB900 Series

SVKZ000001 Lead Free Solder (0.3mm/100g Reel) Same as DMP-BDT320 Series

SVKZ000002 Lead Free Solder (0.6mm/100g Reel) Same as DMP-BDT320 Series

SVKZ000003 Lead Free Solder (1.0mm/100g Reel) Same as DMP-BDT320 Series

RFKZ0316 Solder Remover (Lead free Iow temperature Solder/50g) Same as DMP-BDT320 Series

RFKZ0328 Flux Same as DMP-BDT320 Series

*The above parts are supplied by HEBD.

29

Page 30

9 Disassembly and Assembly Instructions

9.1. Unit

9.1.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

9.1.2. P.C.B. Positions

30

Page 31

9.1.3. Top Case Ass’y

1. Remove the 3 screws (A).

2. Slide the Top Case Ass’y rearward (1) and open the both

ends at rear side of the Top Case Ass’y a little and lift the

Top Case Ass’y in the direction of arrow (2), then remove

the Top Case Ass’y.

2. Unlock 2 tabs turn.

Pull the Tray Ornament in the direction of arrow.

9.1.4. Front Panel Unit

1. Insert paper clips into the hole on the bottom of Dive Unit

through the hole of Chassis, and slide the lever in the

direction of arrow to eject tray slightly.

3. Disconnect the connector (P59303).

4. Unlock the 6 locking tabs turn, then remove the Front

Panel Unit in the direction of arrows.

31

Page 32

9.1.5. WLAN Module (UB310/UB314 only)

1. Remove the screw (A), then remove the WLAN Module.

9.1.6. DC Fan Motor

1. Remove the 2 screws (A).

2. Dosconnect the connector (P58804).

3. Remove the DC Fan Motor.

9.1.8. Drive Unit

1. Remove the FFC (connected to P58805).

2. Remove the 4 screws (A) to remove the Drive Unit.

9.1.8.1. Belt

1. Remove the 3 screws (A).

2. Unlock the 2 locking tabs.

9.1.7. Rear Panel

1. Remove the screw (A) and 2 screws (B).

2. (UB390 only) Remove the screw (C) .

3. Unlock 2 locking tabs to remove the Rear Panel in the

direction of arrow.

3. Lift up the Upper Base Ass’y in the direction of arrow (1),

and pull it out to the direction of arrow (2).

32

Page 33

4. Insert the Paper Clip into the hole of bottom side , and

slide it to the direction of arrow until it can be.

5. Pull ou the Tray to the direction of arrow.

9.1.9. Main P.C.B. Unit

1. Disconnect the connector (P58801).

2. Remove the screw (A) and 2 screws (B) to remove the

Main P.C.B. Unit.

6. Remove the Belt.

33

Page 34

9.1.10. Digital P.C.B. Unit

1. Disconnect the FFC ( connected to P58805).

2. Disconnect the connector (P58801).

3. Remove the 2 screws (A) to remove the Digital P.C.B.

Unit.

34

Page 35

9.2. Sticking position of Barrier Sheet

9.2.1. Barrier Sheet

• Stick Barrier Sheet on the Chassis.

35

Page 36

10 Measurements and Adjustments

For description of the disassembling procedure, see the “9 Disassembly and Assembly Instructions”.

10.1. Service Positions

10.1.1. Checking and repairing of Main P.C.B. Unit

36

Page 37

10.1.2. Checking and repairing of Drive Unit/Digital P.C.B. Unit

37

Page 38

10.2. Adjustment of Drive Unit

10.2.1. Repair Flowchart

10.2.2. Adjustment

This unit does not have the necessity for adjustment after replacing the Drive Unit.

38

Page 39

10.3. Caution for Replacing Parts

After replacing the Digital P.C.B. Unit, [TEST] is displayed, so, once power off again to on.

10.3.1. Caution after replacing parts

After replacing the Drive Unit/Digital P.C.B. Unit, must be update Firmware.

Please see the Chapter 3.2. How to Update Firmware.

10.3.2. Standard Inspect Specifications after Repairs

After making repairs, we recommend performing the following inspection, to check normal operation.

39

Page 40

11 Block Diagram

DDR3

4G-bit x1

DDR3

2G-bit x2

DDR3

2G-bit x 2

MAIN MICROCOMPUTER

(PXS2)

TIMER MICROCOMPUTER

DIGITAL P.C.B. UNIT

BD/DVD DRIVE

MAIN P.C.B. UNIT

Wi-Fi MODULE

SW REGULATOR

REAR PANEL

DIGITAL OUTPUT

AV OUTPUT

NETWORK/GENERAL-PURPOSE IF

HDMI

VIDEO/AUDIO

OUTPUT

OPTICAL

AUDIO

OUTPUT

EACH VOLTAGE

REGULATOR

NICAESUF

USB 2.0

USB TERMINAL

COOLING

FAN

HDMI

AUDIO

OUTPUT

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

OVERALL BLOCK DIAGRAM

LED

REMOTE

SENSOR

KEY

FRONT PANEL

NAND FLASH

ROM/4G-bit

ETHERNET

CONTROLLER

USB 3.0

USB

TERMINAL

ETHERNET

(LAN TERMINAL)

USB0

(3.0)

USB3

(2.0)

USB1

(3.0)

(UHD BD)

SATA

DMP-UB310EG

DMP-UB314EG

ONLY

DMP-UB390EB

ONLY

11.1. Overall Block Diagram

40

Page 41

11.2. Power Supply Circuit Block Diagram

F11101

10111L10111P

D11102

C11301

Q11301

MAIN

SW

DRIVER

T11301

D13201

D13202

C13201

C13202

C13203

PW_X_SW12R0V

10231L

AC_INLET

FUSE

LINE FILTER

RECTIFYING

CIRCUIT

8

3

6

IC11301

ON/OFF

CONTROL

1 5 4

2

MAIN SW

GATE CONTROL

STANDBY

CONTROL

Q12201

IC12202

PHOTO

COUPLER

SHUNT

REGULATOR

IC

OUTPUT VOLTAGE

FEED BACK

OVERCURRENT

DETECTION

Z/C DETECTION

GATE ON TRIGGER

12,13,14,15

P58801P6702

TO

DIGITAL P.C.B.

UNIT

REGULATOR

BLOCK SECTION

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

POWER SUPPLY CIRCUIT BLOCK DIAGRAM

C11105

41

Page 42

PW_X_SW12R0V

12,13,14,15

P58801P6702

FROM

MAIN P.C.B. UNIT

IC58401

DR_5V

(REG. 5V)

3

5

2

DR_12V

VIN

EN

SW

HDD_PFAIL_L

(RESET)

IC58402

VDD

2

OUT

1

DR_P_ON_H

IC59501-

41

DR_P_ON_H

IC59501-

41

IC59501-

38

TO BD DRIVE

Q58401

QR58401

IP58401

2 1

IC58202

(REG. 3.3V)

3

7

VCC

SW

EN

4

PG

IP58202

2 1

2

PXS2_PFAIL_1

IC59501-

16

IC58201

(REG. 1.8V)

3

7

VCC SW

VCC SW

VCC SW

EN

4

PG

IP58201

2 1

2

PXS2_PFAIL_1

IC59501-

16

IC58101

(REG. 1.5V)

3

7

EN

6

PG

IP58101

2 1

2

PXS2_PFAIL_1

IC59501-

16

AW_0R9V_PFAIL

IC59501-

5

IC58001

(REG. 0.9V)

5

4

OUT_H

EN

7

OUT_L

IP58001

2 1

9

LX

8

VIN

IC58002

(REG. 0.9V)

3

7

EN

IP58002

2 1

2

IP58803

2 1

IP58802

2 1

HDMI_P_ON_H

HDMI_P_ON_H

PW_HDMI1_5V

JK55301, IC55301

IC58602

(REG. 5V)

3

6

EN

VO

IC59501-

37

67

1VI

PW_HDMI2_5V

PW_AUSW5R1V

JK55302, IC55302

IC58604

(REG. 5V)

3

6

EN

VO

IC59501-

37

1VI

IC58501

(REG. 5.1V)

3

5

2

VIN

EN

SW

IP58502

2 1

IP59501

2 1

W LAN SW ON H

PW_5V_VBUS_1

PW_DRIVE_5V

PW_DR_11R9V

Wi-Fi MODULE

IC58704

(REG. 5V)

3

6

EN

VO

IC59501-

1VI

PXS2_USB3VBUS

PXS2_PW_5V_VBUS_3

P58801

IC58901

(REG. 5V)

3

6

EN

VO

4

FLG

IC51001-

B36

PXS2_USB3OD

IC51001-

A37

1VI

PXS2_USB0VBUS

PXS2_PW_5V_VBUS_0

JK59001

IC58702

(REG. 5V)

3

6

EN

VO

4

FLG

IC51001-

N34

PXS2_USB0OD

IC51001-

K37

1VI

4

P59303

3,4,5

P58805

TO BD DRIVE

9,10,11

P58805

JK54003

IC59505

PW_PXS2_AW1R8V

(REG. 1.8V)

IC58304

ON

1

VIN

3

VOUT

4

IC51001,IC59506

PW_X_SW3R8V

IC59510

PW_X_SW3R3V

IC59501

PW_PXS2_M0R9V

IC51001

PW_PXS2_C0R9V

IC51001

PW_PXS2_D1R5V

PW_X_SW12R0V

IC59504

PW_X_SW12R0V

IC51001,IC52000,IC52001

IC52202,IC52203,IC52403

PW_PXS2_D1R8V

IC51001,IC51301,IC55301, IC55302

PW_PXS2_D3R3V

IC51001,IC59501

IC59501-

35

PW_EH_1R8V

(REG. 1.8V)

IC58305

ON

1

VIN

3

VOUT

4

IC59001

PXS2_ON_H

IC59501-

26

PXS2_ON_H

PXS2_AW_ON_H

IC59501-

26

EH_ON_H

IC59501-

65

PXS2_ON_H

IC59501-

26

Q58007

G

D

S

Q58008

G

D

S

OUT SIDE

Q58003,

Q58006

D3.3V OUT

Q58001,

Q58004

DELAY

Q58002,

Q58005

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

DIGITAL P.C.B. UNIT REGULATOR CIRCUIT BLOCK DIAGRAM

(REG. 3.3V)

IC59503

ON

1

VIN

4

VOUT

3

(REG. 3.8V)

IC59507

ON

1

VIN

4

VOUT

3

PW_PXS2_AW0R9V

(REG. 0.9V)

IC58303

ON

1

VIN

4

VOUT

3

IC51001

PW_PXS2_A2R3V

(REG. 2.3V)

IC58302

ON

1

VIN

4

VOUT

3

IC51001

PW_EH_3R3V

(REG. 3.3V)

IC58306

ON

1

VIN

4

VOUT

3

IC59001

DMP-UB310EG

DMP-UB314EG

ONLY

DMP-UB390EB

ONLY

DMP-UB390EB

ONLY

11.3. Digital P.C.B. Unit Regulator Circuit Block Diagram

42

Page 43

PW_X_SW3R3V

(RESET)

IC59505

OUT VDD PW_X_SW12R0V

PW_DR_11R9V

P FAIL[L]

32.768KHz OUT

32.768KHz IN

32.768KHz

X59502

IC59501

(TIMER)

REMOCON

DIGITAL P.C.B. UNIT

MAIN P.C.B. UNIT

G_REMOCON

REMOCON

KEY2(EJECT)

KEY1(POWER)

POWER LEDLED_POWER

KEY_PWR

KEY_OP_CL

P7201P58801

7

P67201P58801

6

P7201P58801

9

VDD(3.3)

17

12

31

13

11

2132

(RESET)

IC58402

OUT VDD

HDD_PFAIL[L]

2138

OUT VDD

21

IC59502

(RESET)

RESET

KEYIN3(POWER)

KEYIN1(OP/CL)

IR7401

SENSOR

REMOTE CTL.

1

PW_XSW_3R3V

PW_XSW_3R3V

2

IC51001

TIMER I/F

(PXS2)

TRY_DIRECT

46

P58805

1

1

WOW INT

56

P59303

5

TRY_OP_CL

47

P58805

2

TO/FROM

BD DRIVE

FROM

Wi-Fi MODULE

FANLOCK

FAN_LOCK

FAN_PWR

36

HDMI_P_ON[H]

HDMI_P_ON_H

37

DR_P_ON_H

41

DR_P_ON_H

PXS2_AW_ON_H

35

76

26

PXS2_ON_H

PXS2_AW_ON_H

FAN_DA

PXS2_ON_H

REGULATOR

BLOCK SECTION

TO/FROM

DIGITAL P.C.B.

PX2_PFAIL_L

0.9V_PFAIL_AW(AD)

PX2_PFAIL_1

16

28

7

SOC_INTTIM

SOC_INTSOC

SOC_SOCREQ

UART_TXD

UART_RXD

XRES_PXS2

PXS2_XRST

PXS2_O_STATE

G_PXS2_TXD3_B

G_PXS2_RXD3_B

G_TM_TIMREQ_B

G_TM_SOCREQ_B

G_TM_INTSOC_B

G_TM_INTTIM_B

48

57

58

BUFFER

QR51301,

QR51302

XRST

AI2D2

XIRQ20

AI2D3

XIRQ19

PORT225

PORT224

AV25

66

SD USB BOOT

PXS2_LPST

BUFFER

QR51309,

QR51306

LPST

AN21

52

PXS2 LPCTL

PXS2_LPCTL

BUFFER

QR51312,

QR51311

LPCTL

AM21

25

NC(OPEN)

SEL_DEV_WOL

BUFFER

QR59003,

QR59004

PORT284

AM25

27

NC(OPEN)

PXS2_WL_ON_H

BUFFER

QR59005,

QR59006

PORT285

AT25

PXS2_STATE

34

59

WOL INT

71

50

AI2D1

AD3

AE5

AD36

AD4

SOC_TIMREQ

AE37

AH33

AJ32

(RESET)

IC59506

OUTVDD

PW_PXS2_AW1R8V

1

2

(ETHER CONTROLLER)

IC59001

LED

30

PW_PXS2_AW0R9V

5

0.9V_PFAIL_M(AD)

3

PW_PXS2_M0R9V

M

FAN MOTOR

PW_X_SW12R0V

(FAN MOTOR DRIVE)

A OUT

1

8

A-IN

2

P58804

P58804

1

3

A+IN

V+

3

42

FAN_P_ON_H

IC59504

Q59508

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

TIMER CIRCUIT BLOCK DIAGRAM

POWER

S7201

P7201P58801

5

OPEN/CLOSE

S7202

D7501

POWER

LED

49

51

55

69

LED_POWER

LED_PWM/256Hz

QR59503

QR59504

QR59007

0.9V_PFAIL_C(AD)

2

IP59501

2 1

PW_EH_3R3V

PW_EH_1R8V

DMP-UB310EG

DMP-UB314EG

ONLY

11.4. Timer Circuit Block Diagram

43

Page 44

11.5. Digital Circuit Block Diagram

AO2IEC

VIDEO PB SIGNAL

AUDIO PB SIGNAL

D11

MM1CK

C11

D27

AE3

E27

MM1XCK

MM1XCK

MM1CK

MM1XCK

MM1CK

/CK

IC52202

(2GBIT DDR3 SDRAM FOR PEAKS-PRO_CH1)

K7

J7

K7

J7

MM1DQ0-15, MM1A0-13

CK

/CKK7

J7 CK

IC52203

(2GBIT DDR3 SDRAM FOR PEAKS-PRO_CH1)

/CK

CK

MM1DQ16-31, M1A0-13

MM1DQ0-15, MM1A0-13

MM1DQ16-31, MM1A0-13

IC52403

(4GBIT DDR3 SDRAM FOR PEAKS-PRO_CH2)

MM1CK

MM1XCK

DDR3_CH1_IF

N4

MM0CK

N3

MM0XCK

MM0XCK

MM0CK

MM0XCK

MM0CK

/CK

IC52000

(2GBIT DDR3 SDRAM FOR PEAKS-PRO_CH0)

K7

J7

K7

J7

MM0DQ0-15, MM0A0-13

CK

IC52001

(2GBIT DDR3 SDRAM FOR PEAKS-PRO_CH0)

/CK

CK

MM0DQ16-31, MM0A0-13

MM0DQ0-15, MM0A0-15

MM0DQ16-31, MM0A0-13

MM0CK

MM0XCK

DDR3_CH0_IF

MM2CK

MM2XCK

MM2XCK

MM2CK

MM2DQ0-15, MM2A0-13MM2DQ0-15, MM2A0-13

MM2CK

MM2XCK

DDR3_CH2_IF

7

6

5

4

24

IC51301

NAND FLASH

ROM/4GB

BUS_NFD0-7_B

HOST

IF

(LAN/USB 3.0 PORT)

JK59001

P7406

(USB 2.0/FRONT)

2

3

IC59001

(ETHER CONTROLLER)

TXP

TXN

RXP

RXN

TDP

TDN

4

5

2

3

RDP

RDN

DN

DP

USB3DN

USB3DP

AR9

TXD0

32

19

16

AU2

RST#

AV3

REFCLK

AU4

RXD0

21

AT1

INTRP

RGMII_TXD0

25

AT9

TXD1

RGMII_TXD1

PHYRSTL

RGMII_RXCLK

18

AT6

CRSDV

RGMII_RXCTL

23

AR8

TXEN

RGMII_TXEN

RGMII_RXD0

15

AV5

RXD1

RGMII_RXD1

20

AT5

RXER

RGMII_RXER

MDIO_INTL

11

AU1

MDIO

MDIO

12

AR1

MDC

MDC

A35

A36

IC51001_PXS2

(HD DEC/ ENC/ CPU/ GFX PROSESSOR/DDR3-IF/RTSC/AV CORE/GRAPHICS)

P58805

BD/DVD

DRIVE

17

16

14

13

FI_EDI

SATA_RXP

SATA_RXN

SATA_TXN

SATA_TXP

SATARXP

SATARXM

SATATXM

SATATXP

C33

D33

C31

D31

L56002

L56001

T59301

L59303

IC55301

(LEVEL SHIFT)

SCL1

SDA1

SCL2

SDA2

6

5

3

4

IC59510

(CEC 1chip)

CONT

TIMER

CEC

4

2

3

XI

9

XO

8

19

18

16

15

13

12

SOC_INTTIM

SOC_INTSOC

SOC_SOCREQ

UART_TXD

UART_RXD

48

34

50

58

59

HDMI_MONI

(CEC IN)

HDMI_CEC_OUT

HDMI_CONT

HDMI_MONI

DIRECT

OPEN/CLOSE

BUFFER

Q55305,

Q55306

TRY_DIRECT

TRY_OP/CL

IC59501

(TIMER)

BD/DVD

DRIVE

AI2D2

XIRQ20

AI2D3

XIRQ19

PORT225

PORT224

1

P58805

2

46

47

33

39

AT24

AN22

AM22

AT20

AR20

AT21

AR21

AP21

AR22

AP23

AR23

PXS2_STATE

7

AI2D1

AD3

AE5

AD36

AD4

SOC_TIMREQ

57

AE37

AH33

AJ32

Wi-Fi

MODULE

P59303

USB1DN

USB1DP

C37

D36

2

3

L55301

L55302

JK55301

1

3

4

6

7

9

10

12

D2+

D2D1+

D1D0+

D0CLK+

CLK-

16

15

HDMISDA

HDMISCL

HOTPLG

HDMI JACK

(MAIN)

13 CEC

19

T0HPD

HTDDCSCL0

HTDDCSDA0

T0D3N

T0D3P

T0D2N

T0D2P

T0D1N

T0D1P

T0D0N

T0D0P

JK54003

OPTICAL

(DIGITAL AUDIO OUT)

1

DIGITAL P.C.B. UNIT

X51203

(25MHz)

AXO

AXI

X59001

(25MHz)

IC55302

(LEVEL SHIFT)

SCL1

SDA1

SCL2

SDA2

6

5

3

4

BUFFER

Q55301,

Q55302

AP24

AN23

AP22

AT15

AR15

AT16

AR16

AP17

AR16

AP18

AR18

L55303

L55304

JK55302

1

3

4

6

7

9

10

12

D2+

D2D1+

D1D0+

D0CLK+

CLK-

16

15

HDMISDA

HDMISCL

HOTPLG

HDMI JACK

(SUB)

19

T1HPD

HTDDCSCL1

HTDDCSDA1

T1D3N

T1D3P

T1D2N

T1D2P

T1D1N

T1D1P

T1D0N

T1D0P

L35

M35

L35

K35

L34

M34

USB0TXP

USB0TXN

USB0RXP

USB0RXN

USB0DP

USB0DN

AV24

AU24

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

DIGITAL CIRCUIT BLOCK DIAGRAM

DMP-UB310EG

DMP-UB314EG

ONLY

DMP-UB390EB

ONLY

DMP-UB390EB

ONLY

44

Page 45

12 Wiring Connection Diagram

DRIVE UNIT

MAIN P.C.B. UNIT DIGITAL P.C.B. UNIT

DMP-UB300EG/EB

DMP-UB310EG

DMP-UB314EG

DMP-UB390EB

INTERCONNECTION DIAGRAM

DMP-UB310EG

DMP-UB314EG

ONLY

WIFI MODULE

FAN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

USB3_DM

USB3_DP

PW_5V_VBUS3

GND

KEY2(EJECT)

REMOCON

POWER_LED

PW_X_SW3R3V

KEY1(POWER)

GND

GND

PW_XSW12R0V

PW_XSW12R0V

PW_XSW12R0V

PW_XSW12R0V

1

2

3

4

5

GND

USB1 DP

USB1 DN

PW_5V_VBUS_1

WLAN_WOL

FAN PWR

FAN GND

FAN LOCK

1

2

3

USB3_DM

USB3_DP

PW_5V_VBUS3

GND

KEY2(EJECT)

REMOCON

POWER_LED

PW_X_SW3R3V

KEY1(POWER)

GND

GND

PW_X_SW12R0V

PW_X_SW12R0V

PW_X_SW12R0V

PW_X_SW12R0V

LNLIVE

NEUTRAL

P58801P6702

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

DIRECT

OPEN/CLOSE

DR_5V

DR_5V

DR_5V

DRGND

DRGND

DRGND

DR_12V

DR_12V

DR_12V

GND

SATA BDTXP

SATA BDTXN

GND

SATA BDRXN

SATA BDRXP

GND

P11101

P58805

P58804

P59303

12.1. Interconnection Diagram

45

Page 46

13 Schematic Diagram

Please click the radio button for "Diagrams II / Parts List" on the menu bar in XML Service Manual.

If you want to print, please click the icon button for "Print" on the icon bar and select the item.

14 Printed Circuit Board

Please click the radio button for "Diagrams II / Parts List" on the menu bar in XML Service Manual.

If you want to print, please click the icon button for "Print" on the icon bar and select the item.

15 Exploded View and Replacement Parts List

Please click the radio button for "Diagrams II / Parts List" on the menu bar in XML Service Manual.

If you want to print, please click the icon button for "Print" on the icon bar and select the item.

46

Loading...

Loading...