Page 1

ORDER NO. DSD1008038CE

Blu-ray Disc Player

Model No. DMP-BDT100EE

DMP-BDT100EG

Vol. 1

Colour

(K)...........Black Type

© Panasonic Corporation 2010 Unauthorized copying and distribution is a violation of law.

Page 2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1.)--------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. Caution for AC Cord (For the United Kingdo m

and Republic of Ireland)----------------------------------5

2.3. Precaution of Laser Diode -------------------------------6

2.4. Service Caution Based On Legal Restrictions------ 7

2.5. Static Electricity Protection Measures ----------------8

2.6. Ground for electrostatic breakdown

prevention----------------------------------------------------8

3 Service Navigation------------------------------------------------9

3.1. Service Infomation-----------------------------------------9

3.2. Caution for DivX------------------------------------------ 10

4 Specifications---------------------------------------------------- 11

4.1. Others (Licenses) ----------------------------------------13

5 Location of Controls and Components------------------14

6 Operating Instructions---------------------------------------- 15

6.1. Taking out the Disc from BD D rive Unit when

the Disc cannot be ejected by OPEN/CLOSE

button--------------------------------------------------------15

6.2. Micro Fuse Conducting Check------------------------16

7 Multiple Pressing Function ----------------------------------17

7.1. About the Multiple Pressing of the Unit’s

Remote Control-------------------------------------------17

7.2. How to enter the Special Modes using the

Multiple Pressing Function of the Unit’s

Remote Control-------------------------------------------17

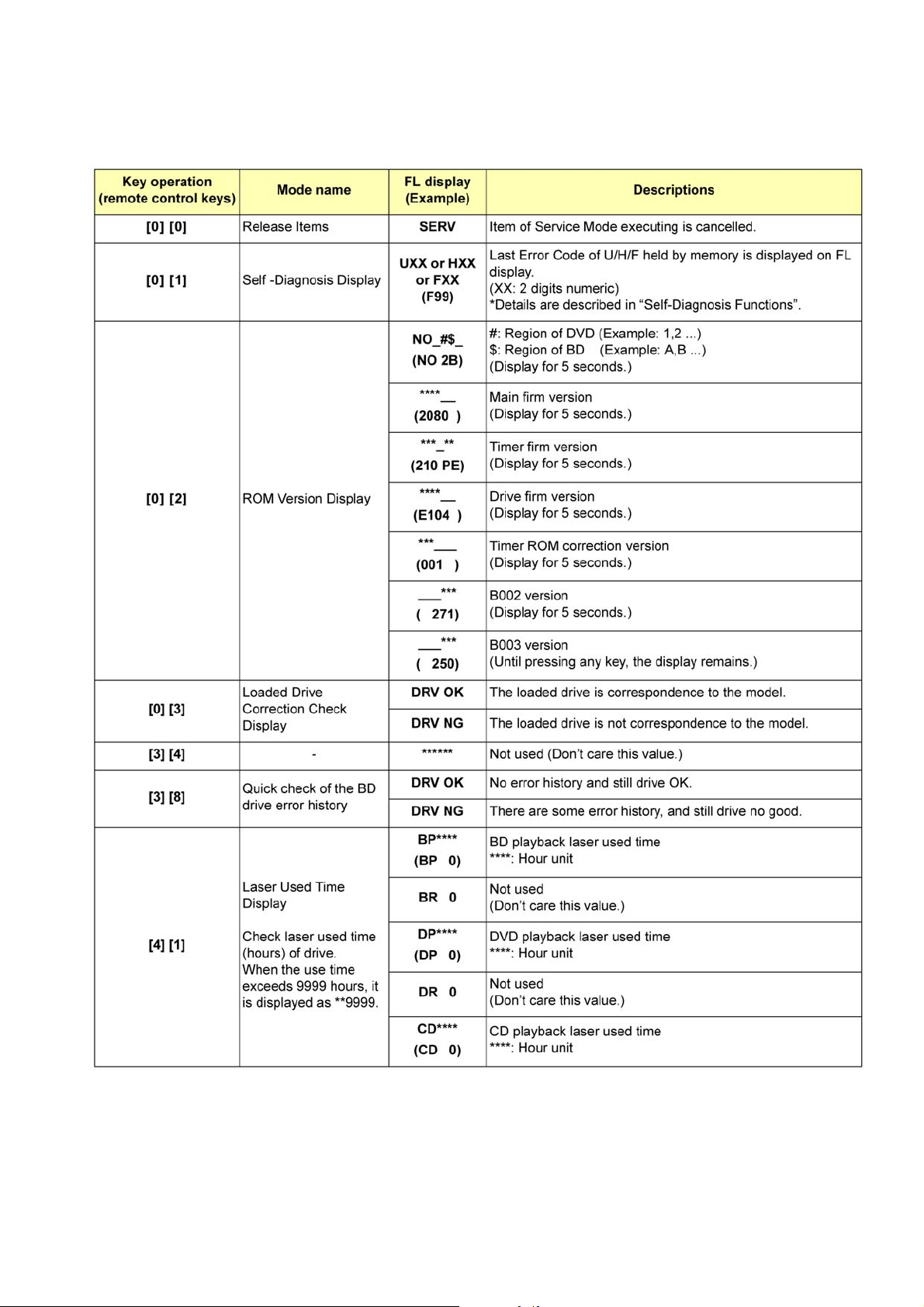

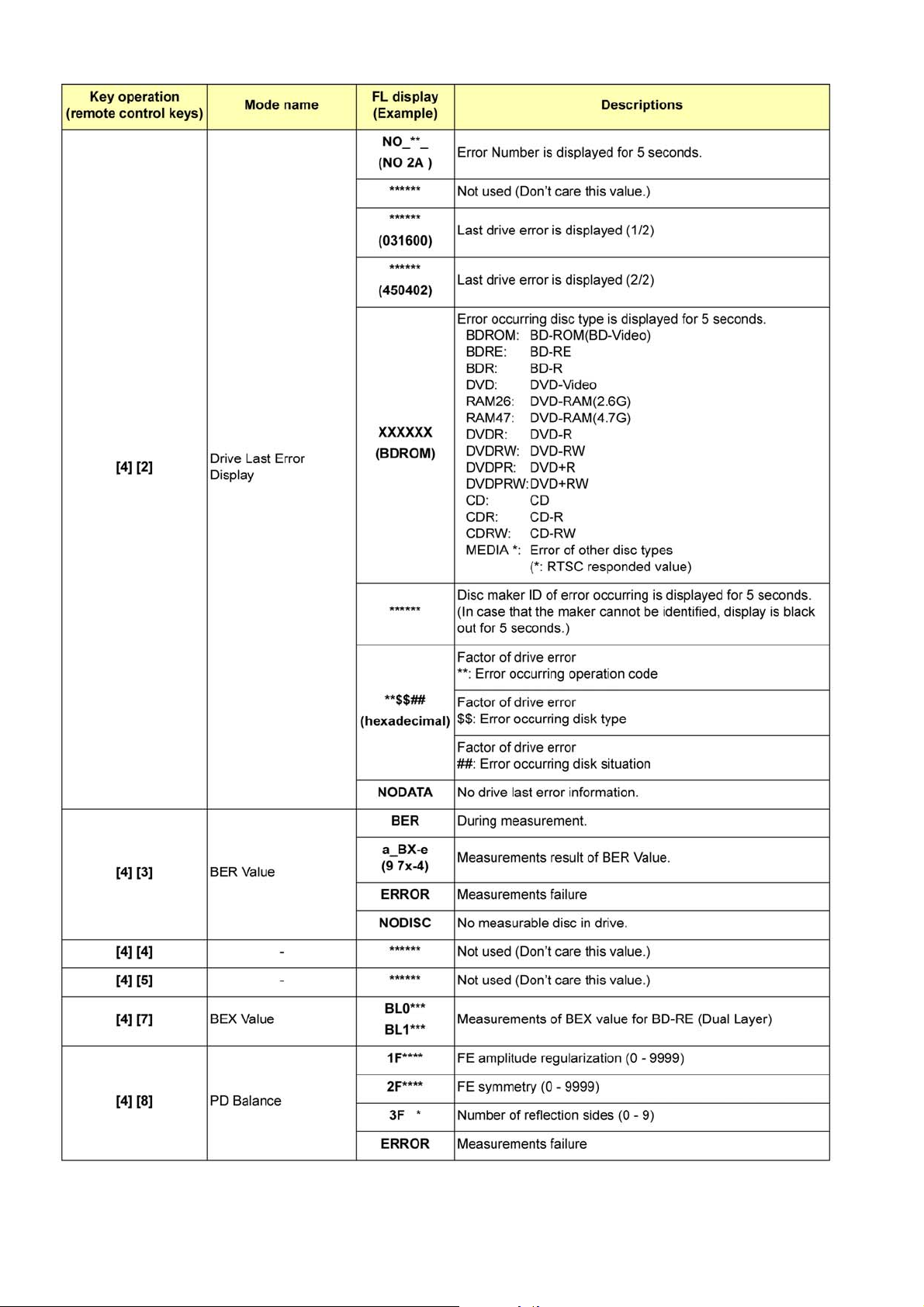

8 Service Mode-----------------------------------------------------20

8.1. About the Service Mode--------------------------------20

8.2. Service Mode List---------------------- -------- ---------- 21

8.3. Self-Diagnostics Functions ---------------------------- 24

9 Service Fixture & Tools---------------------------------------27

10 Disassembly and Assembly Instructions---------------28

10.1. Unit-----------------------------------------------------------28

10.2. BD Drive----------------------------------------------------31

11 Measurements and Adjustments --------------------------37

1 1 .1. Service Positions-----------------------------------------37

11.2. Adjustment of BD Drive Unit/Digital P.C.B.--------39

11.3. Caution for Replacing Parts ---------------------------40

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These p art s are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

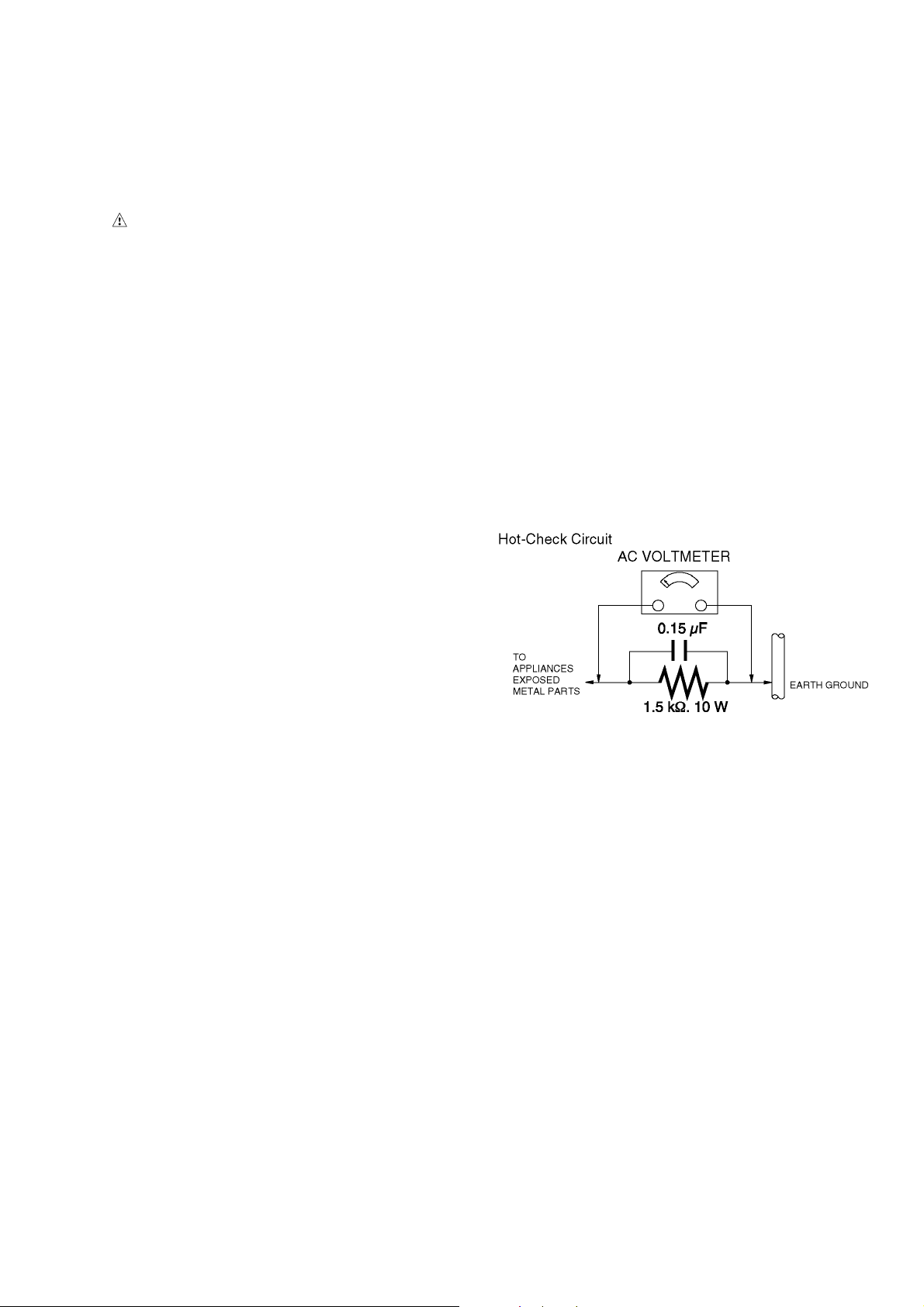

1.3. Leakage Current Hot Check

(See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

Page 4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface su ch as a luminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

4

Page 5

2.2. Caution for AC Cord

(For the United Kingdom and

Republic of Ireland)

2.2.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

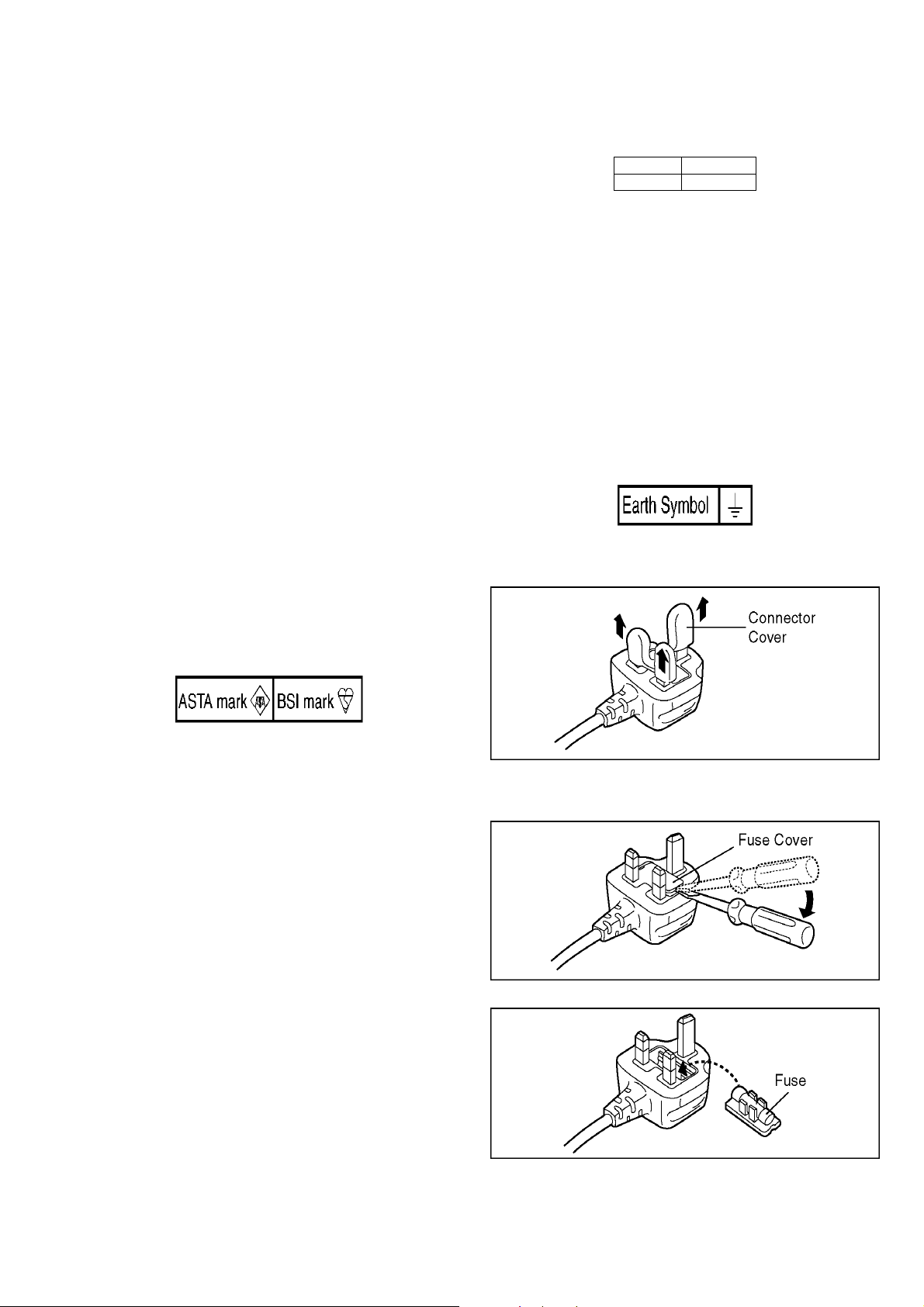

2.2.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

2.2.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this applianc e

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with the letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wi res be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.2.2.2. Before Use

Remove the Connector Cover as follows.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.2.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

5

Page 6

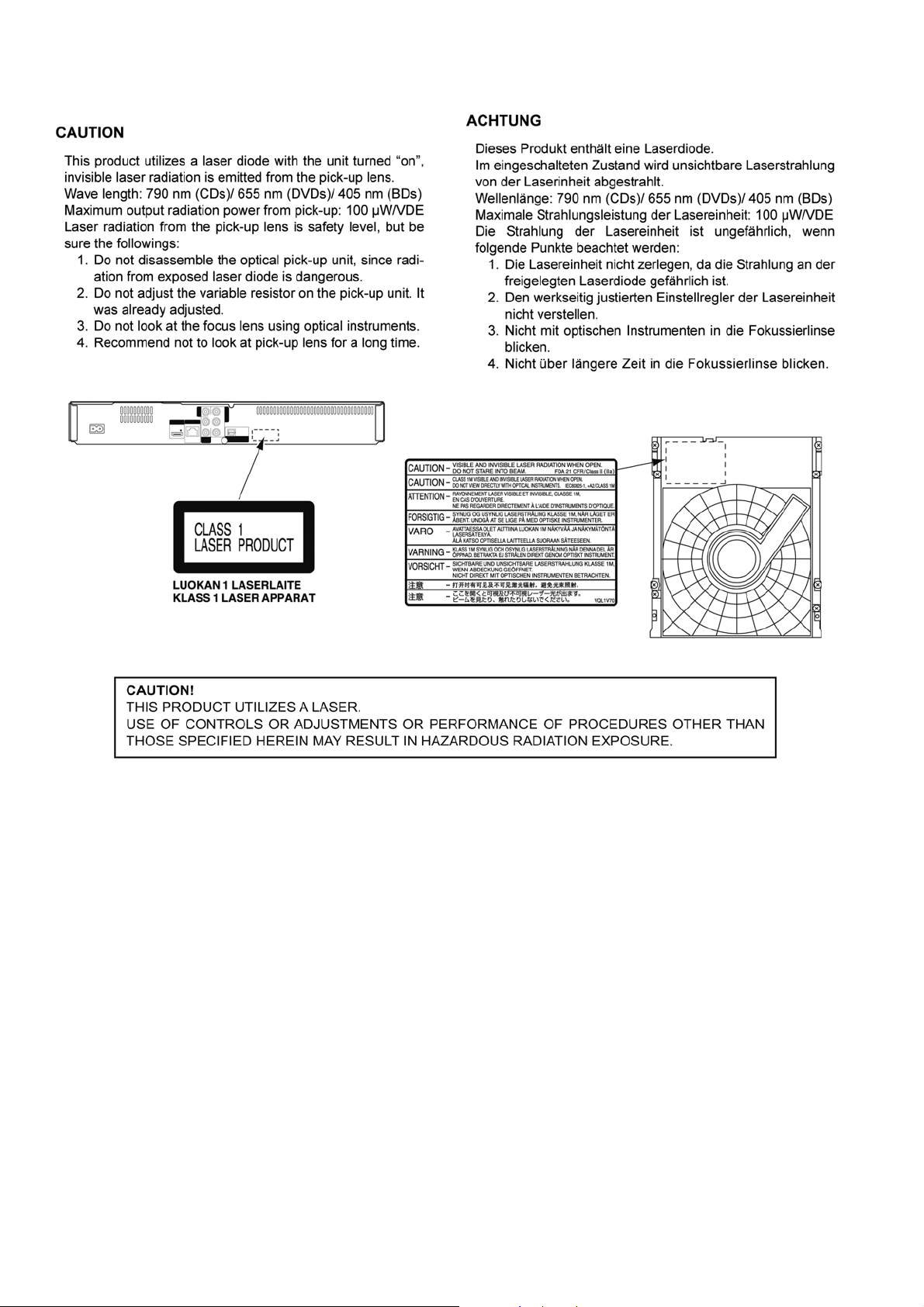

2.3. Precaution of Laser Diode

6

Page 7

2.4. Service Caution Based On Legal Restrictions

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

2.4.1. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting proce ss of a ll electrical components on the printed circuit board s used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

Page 8

2.5. Static Electricity Protection Measures

• The laser diode in the traverse unit (optical pick-up) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse unit (optical pick-up).

2.6. Ground for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.6.1. Work table grounding

• Put a conductive material (sheet) or steel sheet on the area where the traverse unit (optical pick- up) is placed, and ground t he

sheet.

2.6.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity from your body.

2.6.3. When exchange the BDP Drive

• Before remove the ESD prevention bag, make sure to use the anti-static wrist strap to discharge the static electricity when

replace the BDP Drive.

Note:

The ESD prevention bag is used to replace the original short-circuit point.

It can be removed while placing the BDP Drive.

8

Page 9

3 Service Navigation

3.1. Service Infomation

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information wil l be fol lowed by supp lement service ma nual to be filed with original servic e

manual.

1. This service manual does not contain the following information, because of the impossibility of servicing at component level.

• Schematic Diagram, Block Diagram and P.C.B. layout of Digital P.C.B., Drive P.C.B..

• Parts List for individual parts of Digital P.C.B..

• Exploded View and Parts List for individual parts of BD Drive.

2. The following category are recycle module part. Please send them to Central Repair Center.

• Digital P.C.B. (DMP-BDT100EE: RFKB76231DT)

• Digital P.C.B. (DMP-BDT100EG: RFKB76231BT)

• BD Drive: VXY2094

9

Page 10

3.2. Caution for DivX

Please will always pass the customer “Warning for Customers Who Use the DivX Video-on-Demand content.” with the product and

get it when you unavoidably exchange FLASH ROM or P.C.B. including FLASH ROM (Wh en the product is exchanged, it is the

same.).

You must use print attached to service part (FLASH ROM or P. C.B. including FLASH ROM) or must use copy of print below as

“Warning for Customers Who Use the DivX Video-on-Demand content.”

Information needed without fail for the customer for whom it is used continuing DivX Video-on-Demand Service to “Manual for the

customer” is recorded.

Appendix:

*Parts that memorize user’s information are only FLASH ROM.

*The registration of Registration Code is possible for half a year up to 6 recorders up to 10 recorders a year.

Registration Code is memorized in FLASH ROM (Digital P.C.B.).

If exchange above P.C.B. or FLASH ROM, new registration Code differ from previous Registration Code will be generated.

In this case if your customer uses DivX Video-on-Demand service, he/she will no longer be able to play any content that he/she purchased under that same registration code.

Therefore your customer will need to obtain and register the new registration code.

*Copy this page and cut on the dotted line and give the lower half to your customer.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Warning for Customers Who Use the DivX Video-on-Demand content.

1. The registration code has been changed for the repair of the product or the product exchange.

2. Obtain and register a new registration code, otherwise you will no longer be able to play DivX Video-on-Demand content.

3. Follow the procedure on the DivX Video-on-Demand web site to register at http://vod.divx.com/

*If you do not use the DivX Video-on-Demand content, please ignore this warning.

10

.

Page 11

4 Specifications

Power supply: AC 220 to 240 V, 50 Hz

Power consumption: Approx. 24 W

In standby mode: Approx. 0.2 W

In quick start standby mode: Approx. 7 W

Operating temperature range: +5°C to +35°C

Operating humidity range: 10 % to 80 % RH (no condensation)

Signal system: PAL/NTSC

Video output:

Output level: 1.0 Vp-p (75 Ω)

Output connector: Pin jack (1 system)

Component video output:

(1080i/720p/480p/480i:60 Hz)

(1080i/720p/576p/576i:50 Hz)

Y output level: 1.0 Vp-p (75 Ω)

output level: 0.7 Vp-p (75 Ω)

P

B

P

output level: 0.7 Vp-p (75 Ω)

R

Output connector: Pin jack (Y:green, P

(1 system)

Video performance:

Horizontal resolution: More than 500 lines

Video S/N ratio: More than 65 dB

Audio output:

Output level: 2 Vrms (1 kHz, 0 dB)

Output connector: Pin jack

Number of connectors: 2 channel (1 system)

Audio performance:

Frequency response:

DVD(linear audio): 4 Hz to 22 kHz (48 kHz sampling)

4 Hz to 44 kHz (96 kHz sampling)

CD-Audio: 4 Hz to 20 kHz

S/N ratio: 100 dB

Dynamic range: 100 dB

Total harmonic distortion: 0.003 %

Digital audio output:

Optical digital output: Optical terminal

HDMI AV output:

Output format: 480p(525p)/1080i(1125i)/

720p(750p)/1080p(1125p)

HDMI (V.1.4a with 3D, Content

Type)

This unit supports “HDAVI Control 5”

function.

Output connector: TypeA (19 pin): 1 system

SD card slot:

Connector: 1 system

USB slot:

USB2.0: 1 system

Ethernet:

10BASE-T/100BASE-TX: 1 system

Optical pick-up: System with 2 lenses

Wave length: 790 nm (CDs)/655 nm (DVDs)/

405 nm (BDs)

LASER Specification

Class 1 LASER Product:

Wave length: 790 nm (CDs)/655 nm (DVDs)/

405 nm (BDs)

Laser power: No hazardous radiat ion is emitted

with the safety protection

Region management

information:

For the United Kingdom, Continental Europe and Republic of

Ireland (“EG” Model)

DVD-Video: region number “2” or “ALL”

BD-Video: region code “B”

For CIS and India (“EE” Model)

:blue, PR:red)

B

DVD-Video: region number “5” or “ALL”

BD-Video: region code “C”

Media:

Playable disc:

BD-Video (Blu-ray 3D, BDLIVE, BONUS VIEW): BD-ROM Version 2.4

BD-RE: Version3(Single Layer / Dual Layer),

JPEG

BD-R: V ersion2(Single Layer / Dual Layer),

4*5

DivX*

DVD-RAM: DVD Video Recording format,

AVCHD format, JPEG

DVD-R/DVD-R DL:

DVD-Video format*

1

,

DVD Video Recording format*

1

, JPEG*2, MP3*2,

1

,

DVD-RW:

AVCHD format*

2*3*5

DivX*

DVD-Video format*

DVD Video Recording format*

1

, AVCHD format*

1

+R/+RW/+R DL:

AVCHD format*

1

Video*

DVD-Video: DVD-Video format

CD-Audio: CD-DA

CD-R/CD-RW:

CD-DA, JPEG*

2

, MP3*2, DivX*2*

*1 Finalizing is necessary.

*2 ISO9660 level 1 or 2 (except for extended formats), Joliet

This unit is compatible with multi-session.

This unit is not compatible with packet writing.

*3 UDF1.02 without ISO9660, UDF1.5 with ISO9660

*4 UDF2.5

*5 DivX Certified to play DivX video up to Plus HD 1080p,

including premium content.

GMC (Global Motion Compensation) is not supported.

Maximum number of folders recognizable: 300 folders.

(including the root folder)

Maximum number of files recognizable: 200 files.

MPEG-4 AVC (H.264) profile is up to High Profile, Level 4.

AAC-LC, MP3 and Dolby Digital audio can be decoded.

SD card:

SD Memory Card*

6

JPEG, AVCHD format, MPEG-2

formatted FAT12, FAT16,

FAT32, exFAT*

7

*6 support SDHC, SDXC card

TM

support miniSD

support microSD

(need a microSD

Cards (need a miniSDTM Adaptor.)

TM

/microSDHC/microSDXC Cards

TM

Adaptor.)

*7 SDXC only

USB device:

USB Standard: USB 2.0 High Speed

MP3, JPEG, DivX

Format: FAT12, FAT16, FAT32

Contents:

JPEG:

(SD card, CD-R/CD-RW, DVD-RAM, DVD-R/DVD-R DL, BD-RE,

USB device)

File format: JPEG

Pixels: 34 x 34 to 8192 x 8192

Sub Sampling: 4:2:2, 4:2:0

Motion JPEG not supported.

SD card: JPEG conforming DCF (Design rule

for Camera File system)

Thawing Time: approx. 2sec (7M pixels)

Maximum folders: CD-R/CD-RW: 99

SD card, DVD-RAM, BD-RE,

DVD-R/DVD-R DL, US B d ev ic e : 300

1

,

1

,

5

11

Page 12

Maximum files: CD-R/CD-RW: 999

SD card, DVD-RAM, DVD-R/

DVD-R DL, USB device: 3000

BD-RE: 9999

MP3:

(CD-R/CD-RW, DVD-R/DVD-R DL, USB device)

File format: MP3

Compression rate: 32 kbps to 320 kbps

Sampling rate: 44.1 kHz, 48 kHz

AVCHD (H.264):

(DVD-RAM, DVD-R/DVD-R DL, DVD-RW, +R/+RW/+R DL,

SD Card)

File format: AVCHD format V1.0

Dimensions: 430mm(W) x 199mm(D) x 59mm(H)

Mass: Approx. 2.1 kg

Solder: This model uses lead free solder

Note: Specifications are subject to change

(excluding the projecting parts)

430mm(W) x 207mm(D) x 59mm(H)

(including the projecting parts)

(PbF).

without notice.

12

Page 13

4.1. Others (Licenses)

13

Page 14

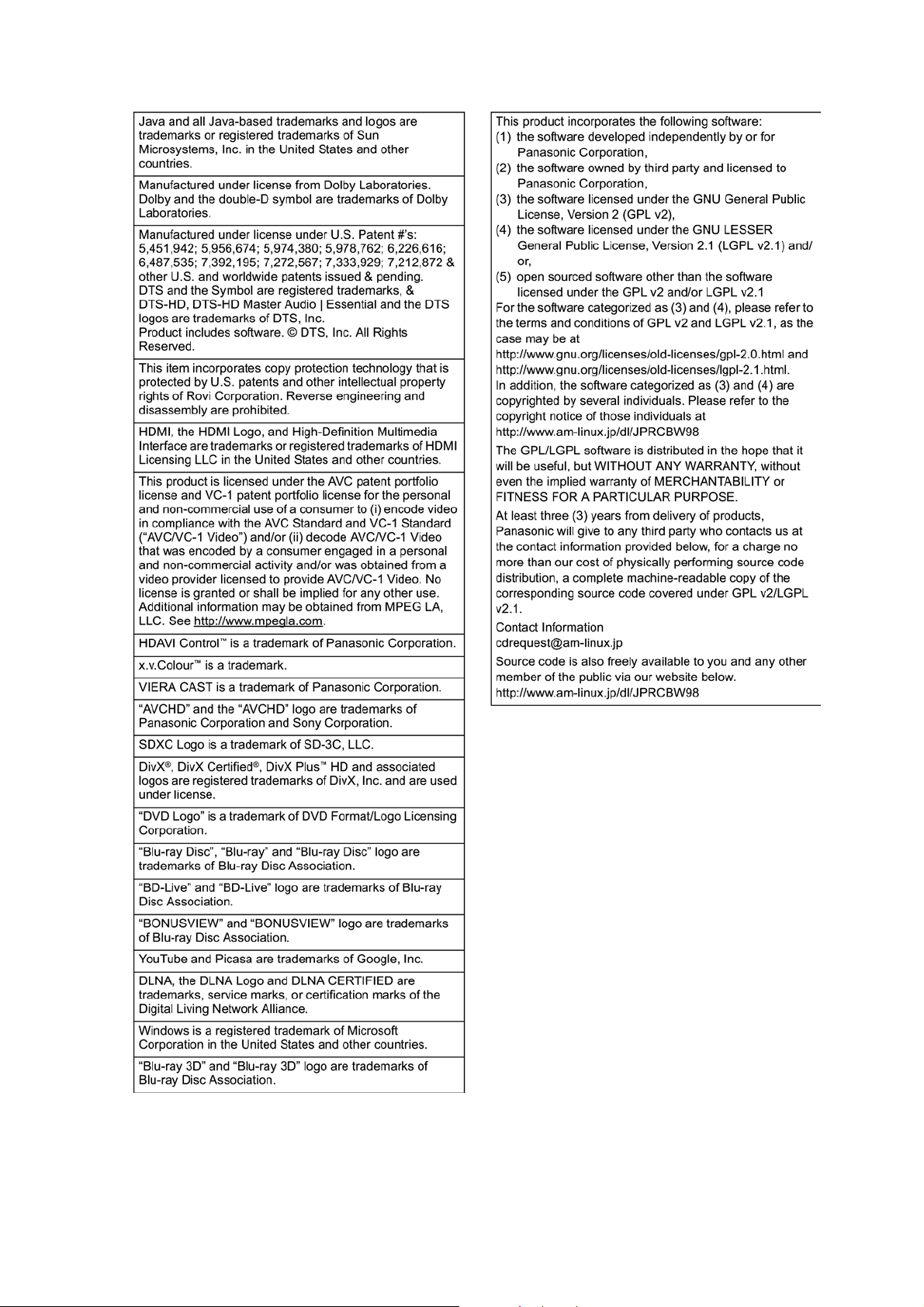

5 Location of Controls and Components

2

10

11

12

1

2

13

3

14

15

16

4

5

17

18

6

1 Turn the unit on and off

2 TV operation buttons

You can operate the TV through the unit’s remote control.

[ TV] : Turn the television on and off

[AV] : Switch the input select

[KLVOL] : Adjust the volume

[9:CH] : Channel select

3 Select title numbers, etc./Enter numbers or characters

[CANCEL] : Cancel

4 Show playback menu

5 Switch on/off Secondary Video (Picture-in-picture)

6 Basic playback control buttons

7 Show status messages

8 Show Pop-up menu

9 Show Top menu/DIRECT NAVIGATOR

10 Show OPTION menu

11 Coloured buttons (red, green, yellow

These buttons are used when;

Operating a BD-Video disc that includes Java

applications (BD-J).

Displaying “Title View” and “Album View” screens.

Operating contents of VIERA CAST.

12 Transmit the remote control signal

13 Open or close the disc tray

, blue)

TM

CAUTION

7

19

8

20

9

21

22

Do not place objects in front of the unit. The disc tray may

collide with objects when it is opened, and this may cause

malfunction.

14 Adjust the volume of an amplifier/receiver.

15 Select audio

16 Reproduce more natural audio

17 Select drive (BD/DVD/CD, SD card or USB device)

18 Displays the Home screen of the VIERA CAST

19 Exit the menu screen

20 Show FUNCTION menu

21 Selection/OK, Frame-by-frame

22 Return to previous screen

5

1

1 Standby/on switch ( /I)

Press to switch the unit from on to standby mode or vice

versa. In standby mode, the unit is still consuming a

small amount of power.

Disc tray

3 Display

Disc indicator SD card indicator

The indicator blinks when reading data from a disc, a

card or a USB device, or writing data to a card.

2

6

USB device

indicator

3

7

4 Remote control signal sensor

Distance: Within approx. 7 m

Angle: Approx. 20G up and down, 30G left and right

5 Open or close the disc tray

6 SD card slot

7USBport

8Stop

9 Start play

4

Pull to flip down

the front panel.

9

8

14

Page 15

6 Operating Instructions

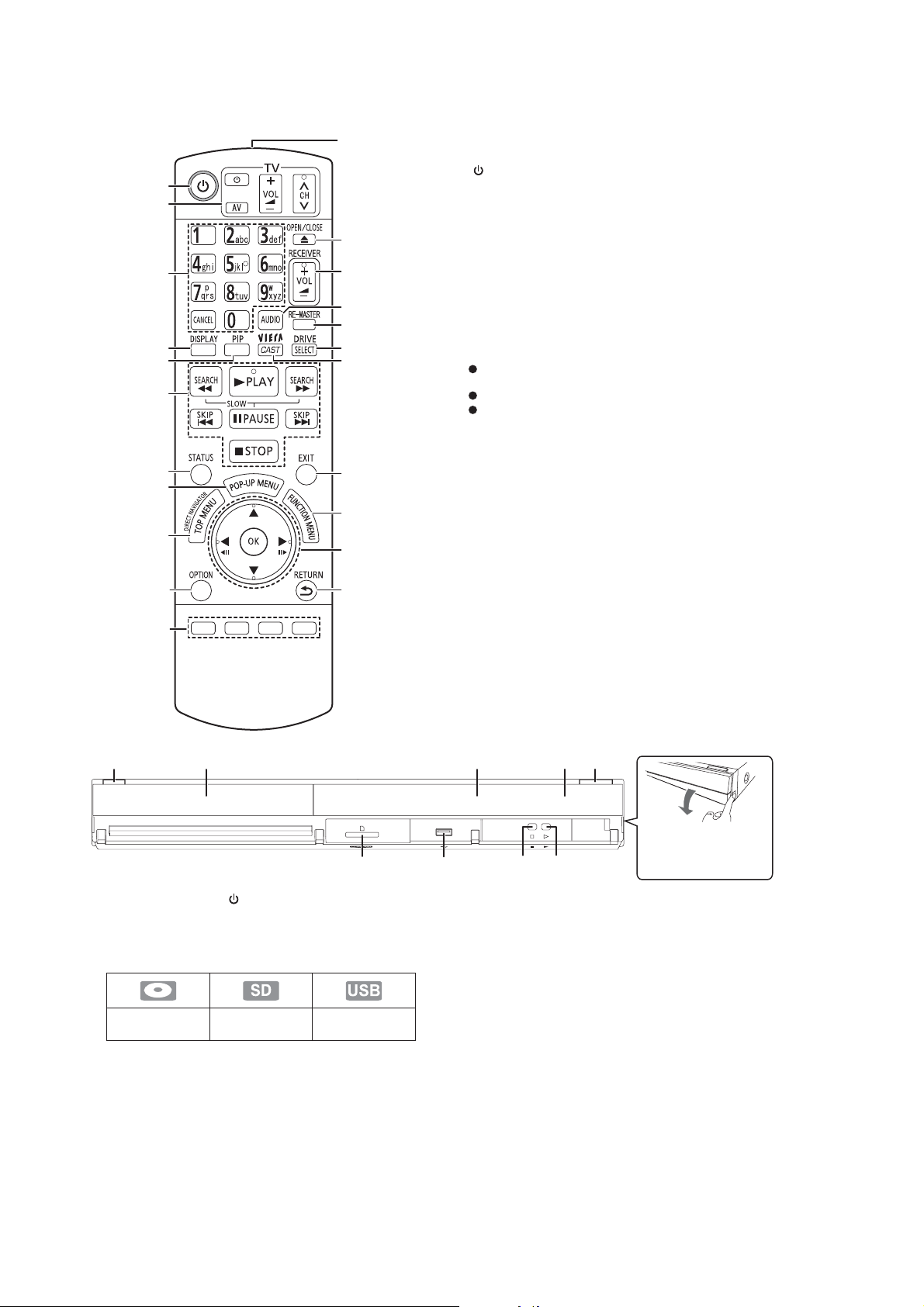

6.1. Taking out the Disc from BD Drive Unit when the Disc cannot be ejected

by OPEN/CLOSE button

6.1.1. When the power can be turned off.

6.1.1.1. When the power can be turned off.

1. Turn the unit off, then press and hold [OK], [Yellow] and [Blue] buttons on the remote control simultaneously for 5 seconds.

- “00 RET” is displayed on the unit’s FL display.

2. Repeatedly press the right cursor button on the remote Control or Power button on the u nit until “06 FTO” is displayed on the

unit's FL display.

3. Press [OK] button on the remote control or [OPEN/CLOSE] button on the unit.

6.1.1.2. When the power can not be turned off.

Press [POWER] button on the unit for over 4 seconds to turn off the power forcibly, and step 1 to 3 above.

6.1.2. When the Forcible Disc Eject can not be done.

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Put the unit so that bottom can be seen.

4. Insert paper clips, etc. into the hole on the bottom of BD Drive and slide th e paper clips, etc. in the direction of the arrow to

eject tray slightly.

5. Pull the unit upward, and push out Tray by paper clips, etc. or minus screw driver (small).

15

Page 16

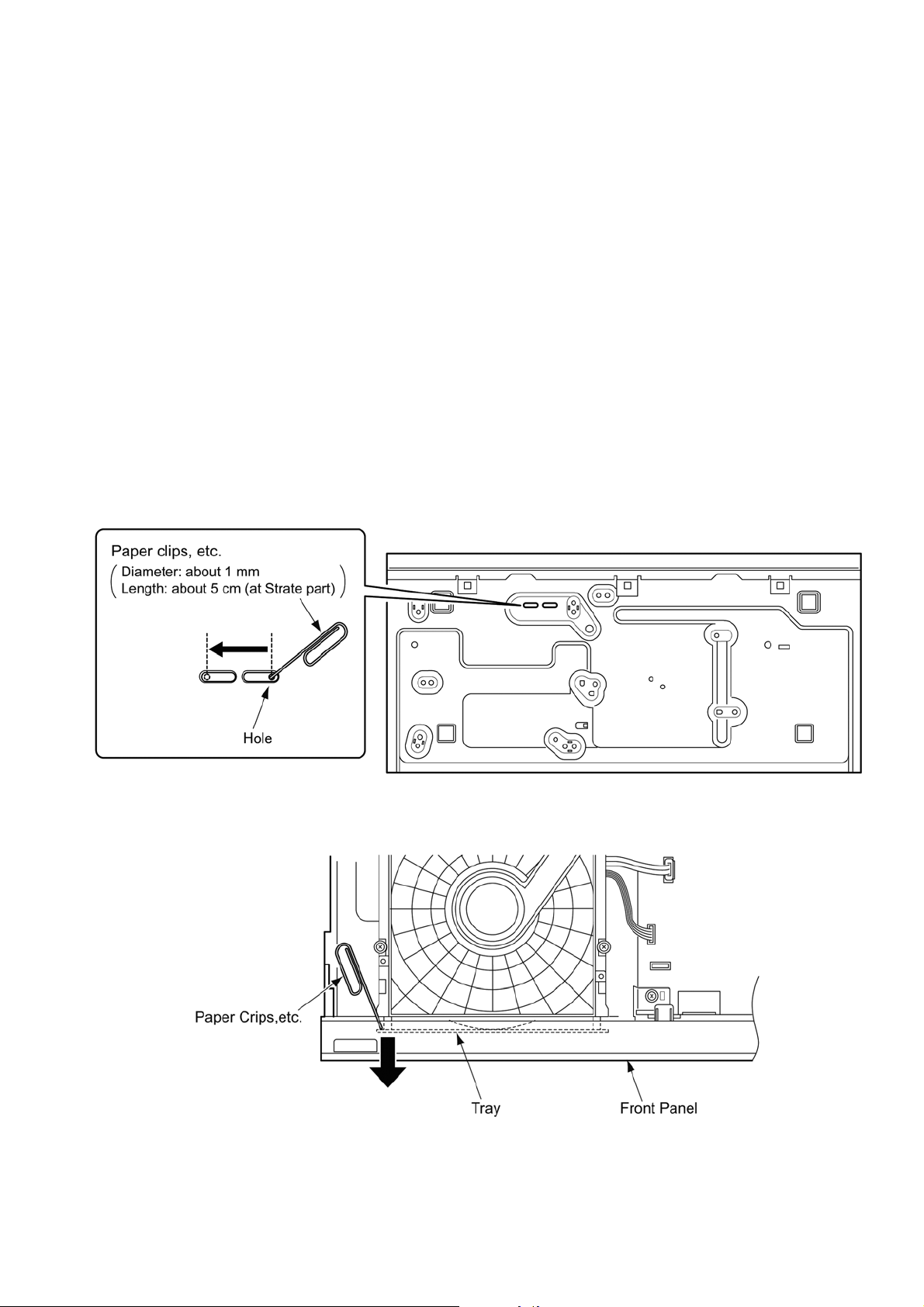

6.2. Micro Fuse Conducting Check

This unit uses the Micro Fuse.

Check the Micro Fuse conducting using the Tester at the check points below.

16

Page 17

7 Multiple Pressing Function

7.1. About the Multiple Pressing of the Unit’s Remote Control

The remote control which included this unit is possible pressing multiple buttons simultaneously (Multiple Pre ssing function), and

can operate for the customer's initial settings and the Service Mode, etc.

The Multiple Pressing function is not available for conventional models' remote control. Use the remote control included this unit.

7.2. How to enter the Special Modes using the Multiple Pressing Function of

the Unit’s Remote Control

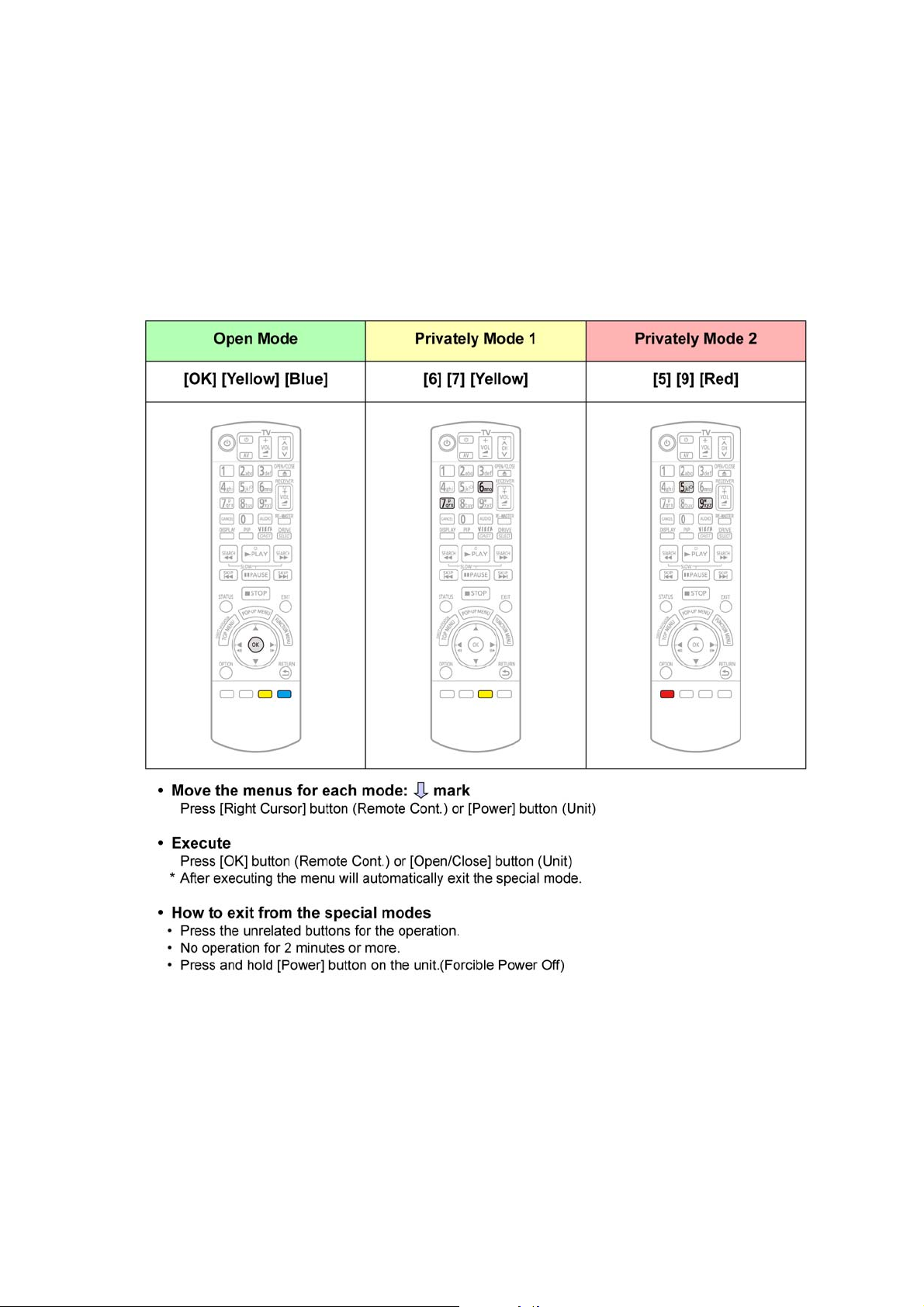

For pressing the multiple buttons of the remote control, this unit can be entering each of the following special modes.

After entering each mode, and then go to the menu you want to run.

17

Page 18

7.2.1. Open Mode (Remote Cont. Buttons: [OK] [Yellow] [Blue])

When pressing the 3 buttons, [OK], [Yellow] and [Blue] simultaneously for 5 seconds, “00 RET” is displayed on the FL display.

18

Page 19

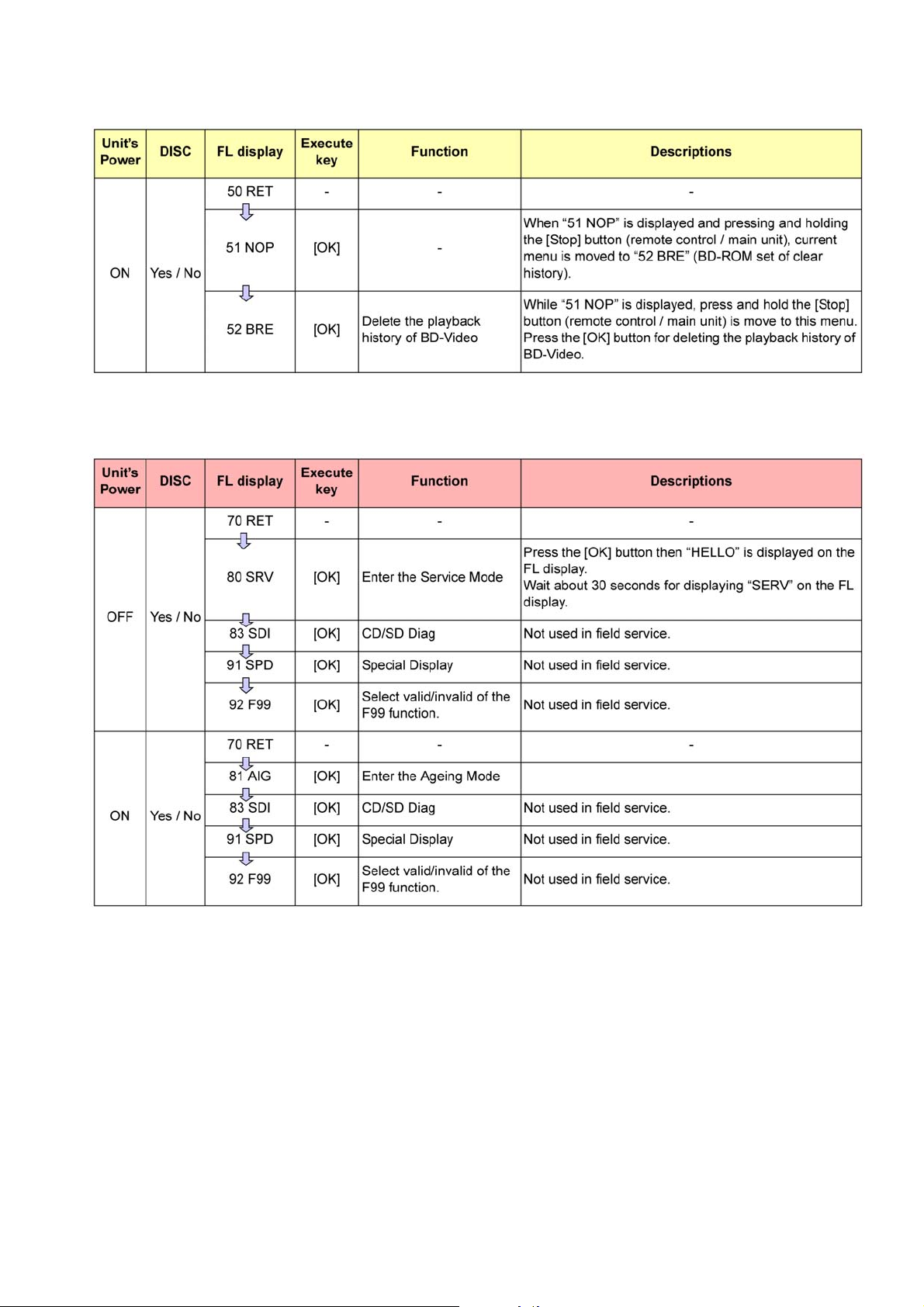

7.2.2. Privately Mode 1 (Remote Cont. Buttons: [6] [7] [Yellow])

When pressing the 3 buttons, [6], [7] and [Yellow] simultaneously for 5 seconds, “50 RET” is displayed on FL display.

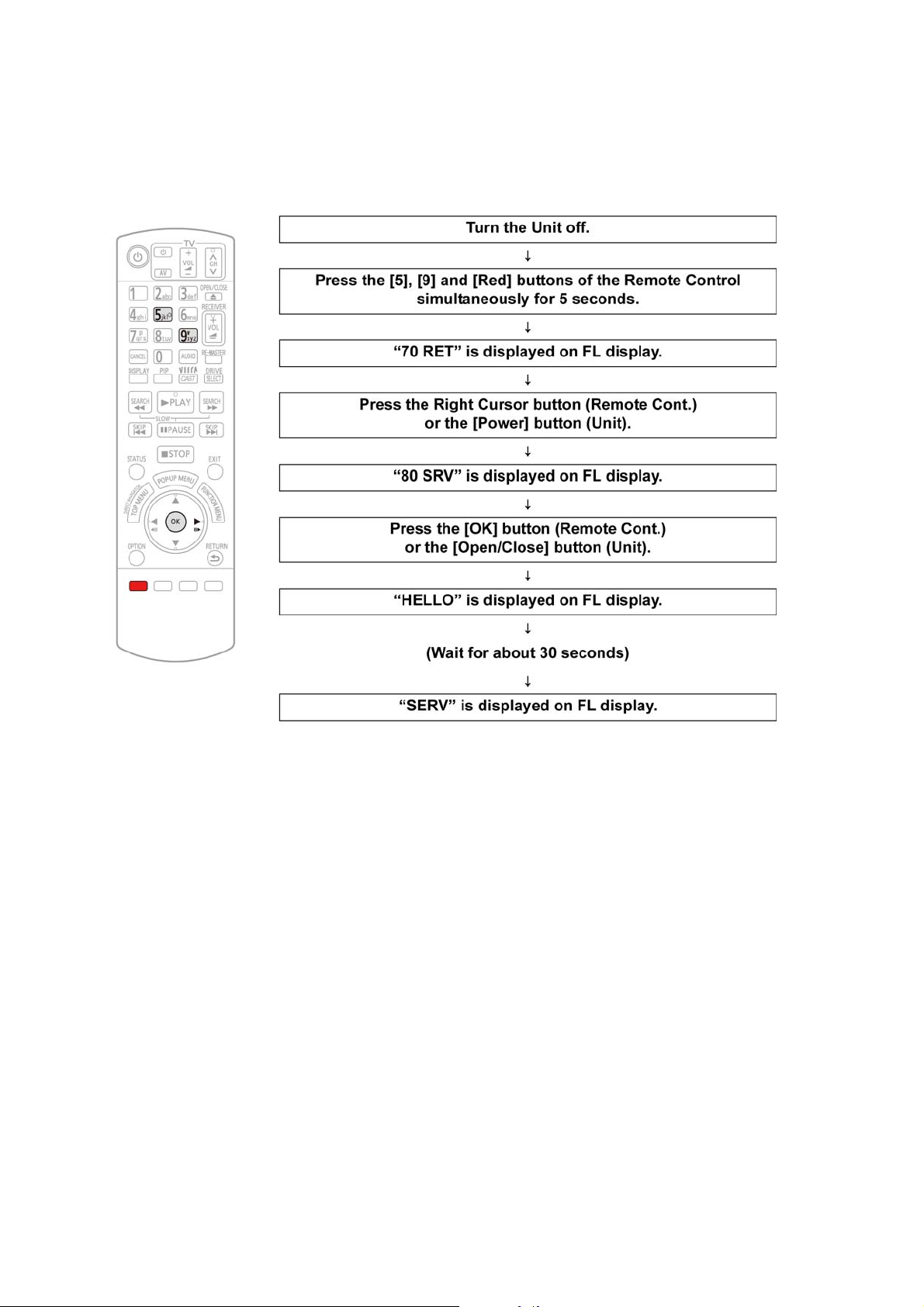

7.2.3. Privately Mode 2 (Remote Cont. Buttons: [5] [9] [Red])

When pressing the 3 buttons, [5], [9] and [Red] simultaneously for 5 seconds, “70 RET” is displayed on FL display.

19

Page 20

8 Service Mode

8.1. About the Service Mode

Informations necessary for service can be displayed.

8.1.1. How to enter the Service Mode

8.1.2. How to exit the Service Mode

Press and hold the [Power] button (remote control or unit).

>>> The Service Mode is terminated and automatically turns the unit off.

20

Page 21

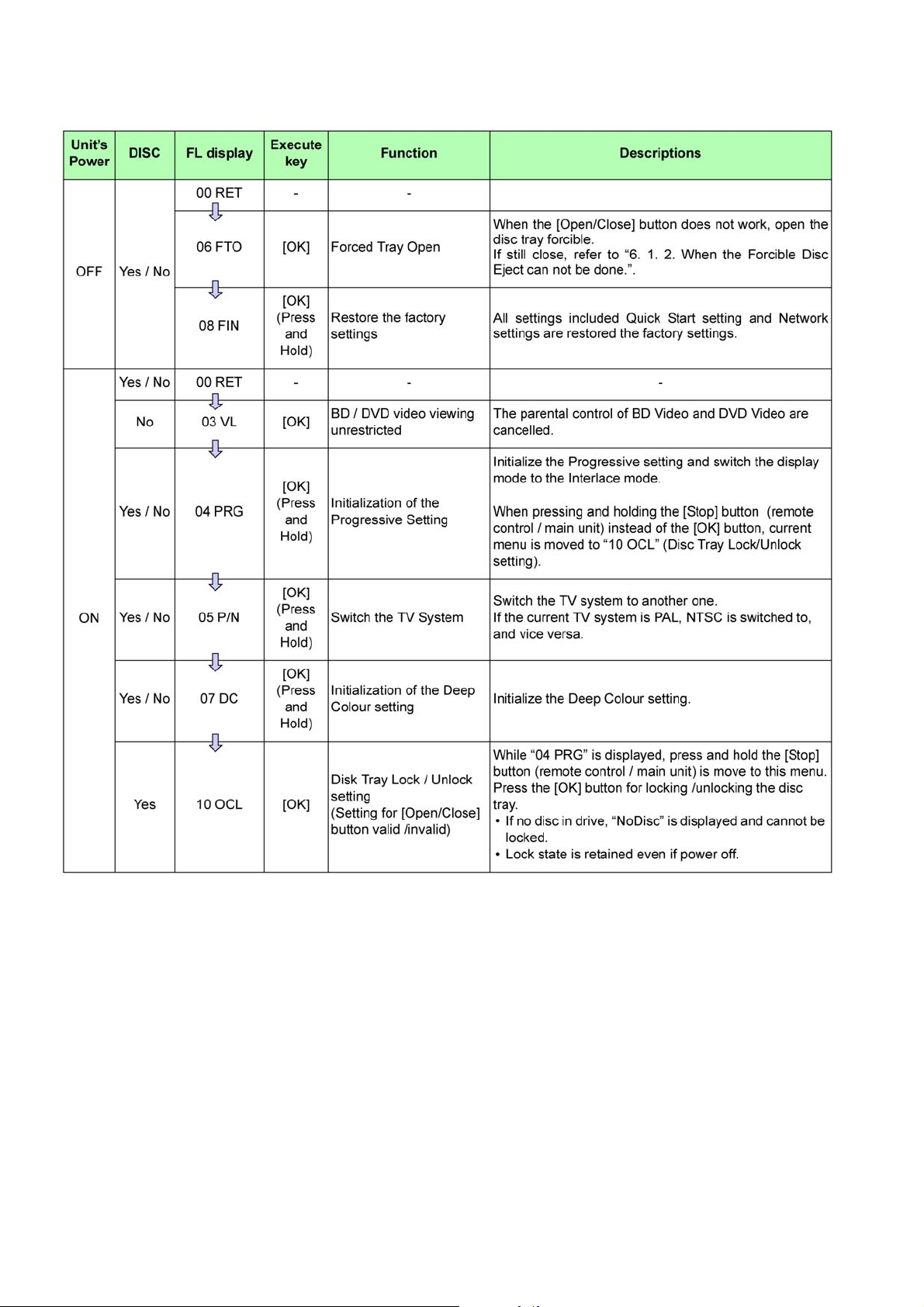

8.2. Service Mode List

The display of information to each command is as follows.

Note:

Do not use it excluding the designated command.

21

Page 22

222324

Page 23

Page 24

8.3. Self-Diagnostics Functions

8.3.1. Self-Diagnostics Functions

Self-Diagnosis Function provides information for errors to service personnel by Self-Diagnosis Display when any error has

occurred.

U** , H** and F** are stored in memory and held.

You can check last error code by transmitting [0] [1] of Remote Control in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

Page 25

252627

Page 26

Page 27

9 Service Fixture & Tools

*The above parts are supplied by AVC-CSC-SPC.

Page 28

10 Disassembly and Assembly Instructions

10.1. Unit

10.1.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

10.1.2. P.C.B. Positions

28

Page 29

10.1.3. T op Case

1. Remove the 2 screws (A) and 3 screws (B).

2. Slide Top Case rearward and open th e both ends at rear

side of the Top Case a littl e and lift the Top Case in the

direction of the arrows.

10.1.5. Power SW P.C.B. and FL P.C.B.

10.1.5.1. Power SW P.C.B. and FL P.C.B.

1. Remove the screw (A).

2. Remove the Power SW P.C.B..

3. Remove the 3 screws (B).

4. Remove the FL P.C.B..

10.1.5.2. How to assemble the Tray door

ass’y

1. Attach the Tray door spring to Tray door ass’y.

10.1.4. Front Panel

1. Unlock 6 tabs (A) - (F) turn.

Pull with the Front Panel in the direction of your side.

2. Attach Tray door ass’y in order from [1] to [2].

[1]: Insert the shaft to the hole.

[2]: Insert the shaft to the hole.

29

Page 30

3. Confirm the Tray door spring is attached as following.

10.1.6. BD Drive Unit

1. Remove the wire with connector (A) and (B).

2. Remove the FFC.

3. Remove the 4 screws (A) to remove BD Drive Unit.

10.1.8. Rear Panel

1. Remove the 4 screws (A) and 1 screw (B).

2. Unlock 2 locking tabs (A) to remove the Rear Panel.

10.1.9. Power P.C.B.

1. Remove the wire with connector (A).

2. Remove the 2 screws (A) to remove Power P.C.B..

10.1.7. Chassis Angle

1. Remove the 2 screws (A) and remove the Chassis Angle.

10.1.10. Digital P.C.B.

1. Remove the wire with connector (A) , (B) and (C).

2. Remove the FFC.

3. Remove the 2 screws (A) to remove Digital P.C.B..

30

Page 31

10.2. BD Drive

10.2.1. Upper Base Ass’y

1. Remove the 4 Screws (A), and push the Hook in.

10.2.2. Tray

1. Perform the step “10. 2. 1. Upper Base Ass’y”.

2. Insert the paper clips, etc. into the hole of the bottom side,

and slide it to the direction of arrow until it can be.

3. Pull the Tray to the direction of arrow until it can be.

2. Lift up the Upper Base Ass’y, and pull it out to the direction of arrow.

4. Insert the paper clips, etc. into the hole of the Tray at 45

degrees, and lean it to the direction of arrow with pushing

the dotted point of the tray forward.

31

Page 32

5. Insert the paper clips, etc. into the Tray as below figure,

lift up the lever using the Eject Pin while pushing the dotted point of the Tray.

10.2.3. Pulley Gear, Belt

1. Perform the step “10. 2. 2. Tray”.

2. Push the Post to the direction of arrow by using the slotted screwdriver.

10.2.4. Slide Cam

1. Perform the step “10. 2. 3. Pulley Gear, Belt”.

2. Disconnect the 3 FFCs.

3. Remove the 2 Screws (B) to remove the Radiator Plate.

4. Open the connector lock, and disconnect the FFC (A).

5. Remove the Drive P.C.B..

3. Remove the Pulley Gear and Belt.

Caution:

Though the Drive P.C.B. is not supplied as replacement parts, it must be removed for after disassembling.

6. Open the connector lock, and disconnect the FFC.

7. Remove the 2 Screws (C), and remove the Traverse

Base Ass'y with spreading the 2 hooks to the direction of

arrows.

32

Page 33

8. Remove the Slide Cam.

10.2.5. Mid Gear, Drive Gear and Loading

Motor

1. Perform the step “10. 2. 4. Slide Cam”.

2. Remove the Mid Gear and Drive Gear.

3. Remove the Screw (D).

4. Remove the Screw (E), and remove the Switch P.C.B.

with the Loading Motor.

Remove the 2 soldering points, and remove the Loading

Motor.

33

Page 34

10.2.6. Grease

34

Page 35

10.2.7. How to Clean the Lens of the Optical Pick-UP

After performing the step “10. 2. 1. Upper Base Ass'y”, clean the lens of the Optical Pick-UP.

35

Page 36

10.2.8. How to Clean up the Turntable

When “NoREAD” is displayed in FL display, clean up the Turntable according to the following steps.

1. Blow the dust from the Turntable in the blower.

(Do not strongly blow it.)

2. Put one drop of isopropyl or ethyl alcohol to clean cotton swab.

(Using a fresh cotton swab does not use chemicals or additives.)

3. Using the cotton swab, wipe out the dust on the Turntable.

(Be careful not touching the surface of Turntable directly.)

36

Page 37

11 Measurements and Adjustments

For description of the disassembling procedure, see the “10 Disassembly and Assembly Instructions”.

11.1. Service Positions

1 1 .1.1. Checking and repairing of Power P.C.B.

37

Page 38

11.1.2. Checking and Repairing of BD Drive Unit/Digital P.C.B.

38

Page 39

11.2. Adjustment of BD Drive Unit/Digital P.C.B.

1 1.2.1. Checking out symptoms and repair of BD Drive Unit/Digital P.C.B.

39

Page 40

11.3. Caution for Replacing Parts

After replacing the Digital P.C.B., [TEST] is displayed, so, once power off again to on.

1 1.3.1. Caution after replacing parts

After replacing the BD Drive Unit/Digital P.C.B., must be update Firmware.

1 1.3.2. Standard Inspect Specifications after Repairs

After making repairs, we recommend performing the following inspection, to check normal operation.

40

Page 41

Table of contents

Service Manual

DSD1008038CE

Diagrams and Replacement

Parts List

Vol. 1

(K)...........Black Type

Colour

Model No.

DMP-BDT100EE

DMP-BDT100EG

Blu-ray Disc Player

Name of Signal

OFTR

FEP

This signal is connected

to the FEP schematic diagram.

Circuit name being connected.

6.Use the parts number indicated on the Replacement Parts List .

7.Indication on Schematic diagrams:

5.The voltage being indicated here may be include observational-error (deviation) due to

internal-resistance and/or reactance of equipment. Therefore, handle the value

indicated on here as reference.

4.Although the voltage and waveform available on here is measured with standard frame,

it may be differ from actual measurement due to modification of circuit and so on.

3.The voltage being indicated on the schematic diagram is measured in

"Standard-Playback" mode when there is no specify mode is mentioned.

2.It is only the "Test Round" and no terminal (Pin) is available on the P.C.B.

when the TP (Test Point) indicated as " " mark.

1.Although reference number of the parts is indicated on the P.C.B. drawing and/or

schematic diagrams, it is NOT mounted on the P.C.B. when it is displayed with "$" mark.

FOR SAFETY. WHEN REPLACING ANY OF THESE COMPONENTS USE ONLY THE SAME TYPE.

COMPONENTS IDENTIFIED WITH THE MARK HAVE THE SPECIAL CHARACTERISTICS

S1. About Indication of The Schematic Diagram

S1.1. Important Safety Notice

S1. About Indication of The Schematic Diagram ............................ S-1

S1.1. Important Safety Notice......................................................... S-1

S2. Voltage and Waveform Chart ................................................... S-2

S2.1. Power P.C.B. .........................................................................S-2

S3. Block Diagram .......................................................................... S-3

S3.1. Overall Block Diagram ..........................................................S-3

S3.2. Power Supply Block Diagram................................................ S-4

S3.3. Analog Video/Audio Block Diagram ...................................... S-5

S3.4. Timer Block Diagram ............................................................. S-6

S4. Schematic Diagram .................................................................. S-7

S4.1. Interconnection Diagram ....................................................... S-7

S4.2. FL Schematic Diagram .......................................................... S-8

S4.3. Power_SW Schematic Diagram ............................................ S-8

S4.4. Power Schematic Diagram.................................................. S-10

S6. Abbreviation ........................................................................... S-21

S7. Replacement Parts List .......................................................... S-25

S8. Exploded View .......................................................................S-31

S8.1. Frame and Casing Section.................................................. S-31

S8.2. Mechanism Section ............................................................. S-32

S8.3. Packing Parts and Accessories Section .............................. S-33

S5. Print Circuit Board .................................................................. S-14

S5.1. FL P.C.B. .............................................................................S-14

S5.2. Power_SW P.C.B. ............................................................... S-14

S5.3. Power P.C.B. .......................................................................S-16

S-1

Page 42

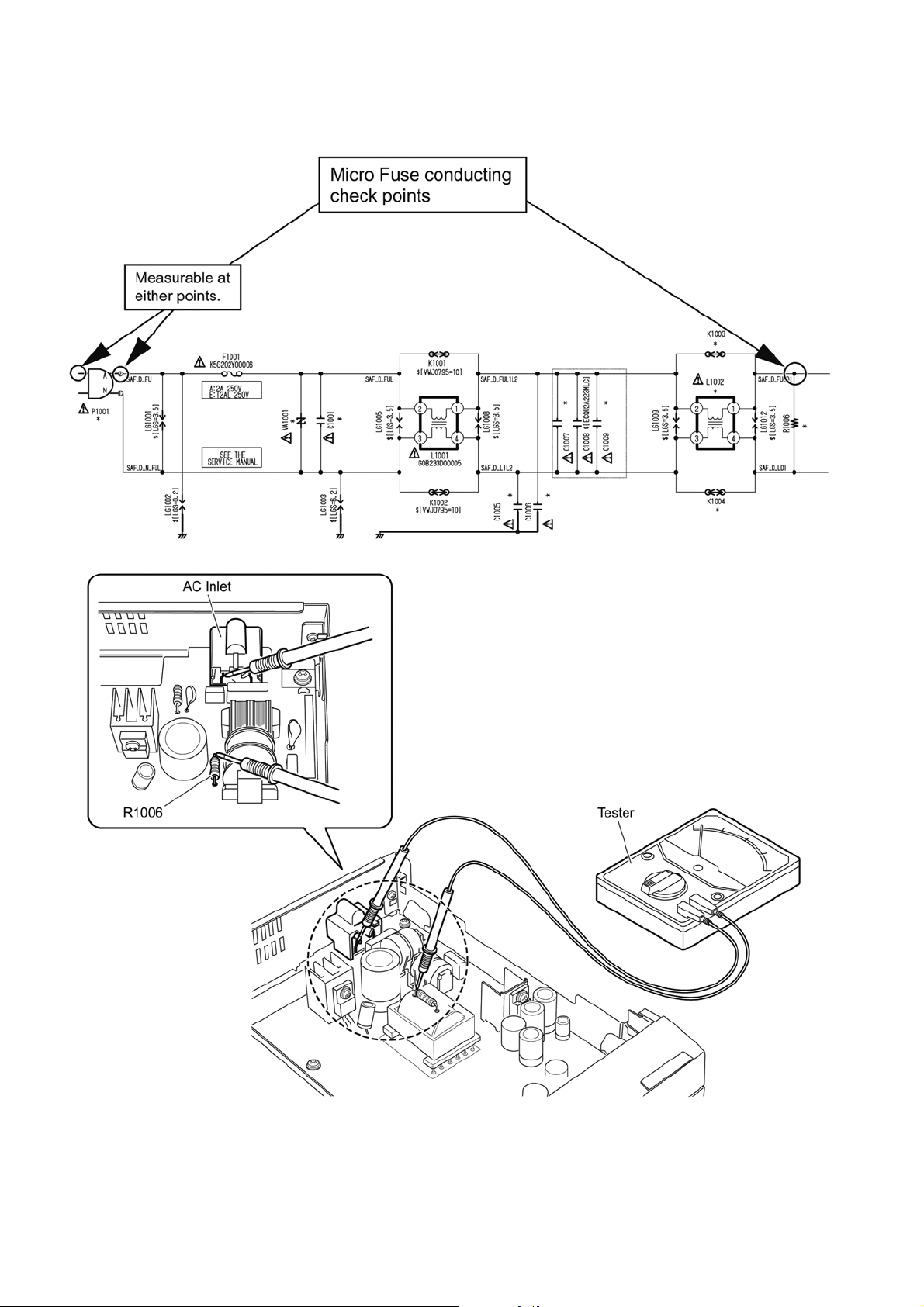

S2. Voltage and Waveform Chart

Note) Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance) with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

S2.1. Power P.C.B.

REF No.

IC1021 1 1.8 1.8

IC1021 2 1.6 1.5

IC1021 3 0.0 0.0

IC1021 4 16.5 16.5

IC1021 5 0.0 0.0

IC1021 6 - IC1021 7 321.0 319.0

IC1021 8 - IC1021 9 33.2 32.5

IC1102 1 0.0 0.0

IC1102 2 0.0 0.0

IC1102 3 8.3 8.4

IC1102 4 2.4 2.5

IC1130 1 4.4 4.5

IC1130 2 0.0 0.0

IC1130 3 0.0 0.0

IC1130 4 1.1 1.2

IC1130 5 1.2 1.3

IC1130 6 0.5 0.6

IC1130 7 5.3 5.5

IC1130 8 5.3 5.4

IC1130 9 1.1 1.2

IC1130 10 0.0 0.0

IC1130 11 0.0 0.0

IC1130 12 4.4 4.5

IC1130 13 5.7 5.9

IC1130 14 7.0 7.1

IC1130 15 9.9 10.6

IC1130 16 12.0 12.1

Q1022 1 9.4 9.5

Q1022 2 8.3 8.4

Q1022 3 0.0 0.0

Q1022 4 1.5 1.5

Q1023 1 1.1 1.2

Q1023 2 0.0 0.0

Q1023 3 0.0 0.0

Q1023 4 0.0 0.0

Q1131 1 5.8 5.8

Q1131 2 5.8 5.8

Q1131 3 10.0 10.6

Q1131 4 12.0 12.0

Q1131 5 5.8 5.8

Q1131 6 5.8 5.8

Q1170 1 11.3 11.3

Q1170 2 12.0 12.0

Q1170 3 11.9 11.9

Q1171 1 -0.2 -0.3

Q1171 2 0.0 0.0

Q1171 3 11.9 11.9

Q10101 1 0.1 0.0

Q10101 2 0.0 0.0

Q10101 3 5.8 5.8

QR1101 1 3.2 3.2

QR1101 2 0.0 0.0

QR1101 3 0.0 0.0

QR1131 1 3.2 3.2

QR1131 2 0.0 0.0

QR1131 3 0.0 0.0

QR1170 1 3.2 3.2

QR1170 2 0.0 0.0

QR1170 3 0.0 0.0

P1102 1 0.0 0.0

P1102 2 3.2 3.2

P1102 3 3.2 3.2

P1102 4 3.2 3.2

P1102 5 3.2 3.2

PIN No.

PB STOP

REF No.

PIN No.

P1102 6 2.1 2.2

P1102 7 3.2 3.2

P1102 8 3.2 3.2

P1102 9 3.2 3.2

P1102 10 3.2 3.2

P1102 11 - P1102 12 5.7 5.7

P1102 13 5.7 5.7

P1102 14 5.7 5.7

P1102 15 0.0 0.0

P1102 16 0.0 0.0

P1102 17 0.0 0.0

P1102 18 0.0 0.0

P1102 19 12.0 12.0

P1102 20 12.0 12.0

P1102 21 12.0 12.0

P1102 22 12.0 12.0

P1102 23 3.2 3.2

P1103 1 -18.5 -18.5

P1103 2 3.2 3.2

P1103 3 -15.6 -15.6

P1103 4 -21.0 -20.0

P1103 5 3.3 3.2

P1103 6 3.3 3.2

P1103 7 3.3 3.2

P1103 8 2.4 2.3

P1103 9 3.3 3.2

P1103 10 3.3 3.2

P1103 11 3.3 3.2

P1103 12 0.0 0.0

T1001 1 318.0 318.0

T1001 2 75.0 75.0

T1001 3 32.0 33.0

T1001 - - T1001 5 0.0 0.0

T1001 6 0.6 0.6

T1001 7 0.0 0.0

T1001 8 0.0 0.0

T1001 9 0.0 0.0

T1001 10 0.0 0.0

T1001 11 0.0 0.0

T1001 12 0.0 0.0

T1101 1 11.9 12.0

T1101 2 0.0 0.0

T1101 3 11.9 11.9

T1101 4 0.0 0.0

T1101 5 0.0 0.0

T1101 6 0.0 0.0

T1101 7 11.0 11.5

T1101 8 -18.5 -18.5

T1101 9 -18.5 -18.5

PB STOP

<IC1021>

<T1001>

S-2

Page 43

DMP-BDT100EE/EG OVERALL BLOCK DIAGRAM

TRAVERSE MECHANISM UNIT

OPTICAL

PICK-UP

UNIT

USB JACK

(FRONT)

X51006

IC57001

IC301

OPERATION/

TIMER

IC51001

AV DECODER/

SYSTEM CONTROLLER

L (MIX)

IC54002

R (MIX)

KEY

FL

V(COMPONENT)

PY

PB

CEC

PR

LASER DIODE

SERVO CONTROLLER/

OPTICAL DISC CONTROLLER

FOCUS COIL

TRACKING COIL

STEPPING

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

RESET

IC57005

AUDIO D/A

CONVERTER

IC55001

HDMI TX

DIGITAL

AUDIO OUT

(OPTICAL)

IC53001

VIDEO DRIVER

SD CARD

IC59020

IC51301

P59301

NAND FLASH

ROM/1GB

PHYSICAL LAYER

TRANSCEIVER

JK59001

ETHERNET

JACK

IC52201,IC52202

SDRAM/1GB

IC302

SERIAL FLASH

ROM/16Mbit

SDRAM/1GB

IC51004

PLL

IC52001,IC52002

REMOTE

SENSOR

HDMI

(JK55001)

JACK

AUDIO

X301

IC401

DISC

MOTOR

DRIVER

P51604

IC53002

IC101

LASER DIODE

DRIVER

S3. Block Diagram

S3.1. Overall Block Diagram

S-3

Page 44

DMP-BDT100EE/EG POWER SUPPLY CIRCUIT BLOCK DIAGRAM

F1001

P1001

(AC SOCKET)

A

N

VA1001,

L1001,1002

D1006,C1014

SURGE

SUPPRESSOR

AND

SURGE

ABSORBER

RECTIFIER

1

2

3

12

16

12

1

15

11

10

9

123

8

7

5

6

T1001

(POWER TRANSFORMER)

7

1

4

9

5

2

IC1021

(SWITCHING IC)

IC1130

(DC-DC CONVERTER)

IC1102

(SHUNT REGULATOR)

F/B

Z/C

3

GND

VCC

VIN

Q1022

(FEED BACK)

4

3

1

2

Q1131

(REGULATOR +5.9V)

4

3

1

5

6

2

Q1023

(FEED BACK)

4

3

1

2

Q10101

D1110

P1102

P58001

P1102

P58001

3

1

4

2

REF

CA

NC

QR1101

QR1131

D1027

D1026

D1029

D1031

D1032

VIN

V5

EN

EXT-Up

14

VB

13

LX

6

9

1

2

3

8

FB

OSC

7

RS+

8

RS-

P ch

MOS

FET

D

D

D

D

G

S

PW X SW12R2V

PW X SW5R9V

P1102

P58001

SP SAVE L

P1102

P58001

FL DCDC ON H

HOT COLD

T1101

(FL POWER

TRANSFORMER)

QR1170

Q1170

Q1171

9

5

12-14

23

19-22

10

To DIGITAL P.C.B.

P1103

3

P7001

P1103

1

P7001

F-

F+

VP

To FL P.C.B.

P1103

4

P7001

D1131 D1132

D1176

D1173

D1021

P1103

2

P7001

X SW3R3V

P1102

2

P58001

PW X SW3R3V

S3.2. Power Supply Block Diagram

S-4

Page 45

S3.3. Analog Video/Audio Block Diagram

IC57001

(TIMER)

IC53002

(OPTICAL FIBER

TRANSMITTER)

IC51001

(BP1 LSI)

DMP-BDT100EE/EG ANALOG VIDEO/AUDIO CIRCUIT BLOCK DIAGRAM

IC53001

(VIDEO DRIVER)

IC54002

(DAC)

1

SVDACO3

SYNC TIP

CLAMP

LPF

6.75MHz

LOGIC

MUTE

CTRL

LPF

13.5MHz

LPF

30MHz

3

SYNC TIP

CLAMP

VIN

PYIN

LPF

13.5MHz

8X

INTERPOLATOR

DE-EMPHASIS

CONTROL

CLOCK

DIVIDER MODULATOR

8X

INTERPOLATOR

LPF

30MHz

5

PBIN

LPF

13.5MHz

LPF

30MHz

7

8

6

7

8

2

PRIN

CTRL

15

14

13

12

11

10

4dB

2dB

2dB

2dB

2dB

4dB

4dB

4dB

VSAG

PYOUT

PYSAG

PBOUT

PROUT

VOUT

JK53001

(COMPONENT

AUDIO/VIDEO OUT)

VIDEO OUT

Y

PB

PR

AL

AR

SVDACO0

E 20

SVDACO1

B19

C15

Y OUT

(G Y OUT D)

PY OUT

(G PY OUT D)

PB OUT

(G PB OUT D)

SVDACO2

F19

PORT CA35

AF33

SBT2

G31

SBO2

H32

AO2DACCK

A22

AO2BCK

B22

AO2DMIX

B23

AO2LRCK

C20

AO2IEC

A21

PR OUT

(G PR OUT D)

CK53002

CK53001

CK53003

CK53004

CONTROL

INTERFACE

3

12

1

2

9

4

5

MODULATOR

AUDIO

DATA

INTERFACE

75

DRIVER

75

DRIVER

75

DRIVER

150k

BIAS

150k

BIAS

75

DRIVER

SCF

LPF

SCF

LPF

CSN

CCLK

CDTI

MCLK

BICK

SDTI

LRCK

AOUTL

AOUTR

SD L

4

CL57004

V OUT MUTE H

25

QR53001

VIN

VCC

DRIVER

IC

PW ADAC5V

1

10

PW ADAC5V

VDD

AVDD

2

16

PW ADAC5V

VCC1

VCC2

: VIDEO PB SIGNAL

: AUDIO PB SIGNAL

CK53006

CK53007

CK53008

S-5

Page 46

S3.4. Timer Block Diagram

IC57001

(TIMER)

DR PFAIL[L

]

SP SAVE L

SP SAVE L

G KEY3

G KEY1

G KEY2

G REMOCON

G FL TXD

G FL CLK

G FL CS

REMOCON

60

7

31

59

IC7001

(VFD DRIVER)

P110223P58001

P1103

8

P7001 P58001

6

P1102

P58001

12-14

P1102

P58001

19-22

P1102

PFAIL[L

]

VREF

VDD

6

IC57006

(REGULATOR)

4

1

5

VOUT

ON

VIN

PW X SW 5R9V

RESET

14

IC57005

(RESET)

12

OUTVDD

PW X SW12R2V

CL57014

CL57007

P1103

9

P7001 P58001

7

P1102

1

REMOCON

IR7001

REMOTE

SENSOR

27

FL TXD

18

FL CLK

20

FL CS[L

]

21

KEYIN2

2

P1103

10

P7001 P58001

8

P1102

KEYIN1 OP CL

1

P1103

11

P7001 P58001

9

P1102

KEYIN3 POWER

3

STOP

S7003

POWER

S7551

PLAY

S7002

OPEN/

CLOSE

S7001

REMOCON

KEY2

KEY1

PJ7004

1

PJ7551

KEY3

KEY POWER

POWER SW P.C.B.

FL P.C.B.

POWER P.C.B. DIGITAL P.C.B.

14

SG1

SG16

SG17

SG18

29

15

P15

P1

7

7G

6

P16

5

4

P17

P18

2

31

F-

1

F-

32

F+

F+

42

30

36

GR1

GR7

TIMER

DISPLAY

DP7001

P1103

3

P7001

P1103

1

P7001

P1103

6

P7001

P1103

5

P7001

P1103

7

P7001

P58001

4

P1102

P58001

3

P1102

P58001

5

P1102

F-

F+

VP

P1103

4

P7001

43

X SW3R3V

FL TXD

FL CLK

FL CS

PW X SW3R3V

P1103

2

P7001

P58001

2

P1102

VEE

VDD

13

VDD

6

DOUT

7

DIN

8

CLK

9

STB

FL DCDC

FL DCDC ON H

41

P110210P58001

2

DMP-BDT100EE/EG TIMER CIRCUIT BLOCK DIAGRAM

9

8

10MHz OUT

10MHz IN

X57001

(10MHz)

UARTP2M/TBUS TXD

UARTM2P/TBUS RXD

TBUS CLK

15

16

17

IC51001

(BP1 LSI)

AP24

AM24

AN24

SBPTM

AL23

XINTP

AM23

XINTM

AJ24

XMPREQ

SBMTP

SCLKM

CL57008 CL57010 CL57006 CL57011

CL57015 CL57013

TRY DILECT

40

CL57001

XINTM OUT

XINTP OUT

22

23

XINTM[TBUS

]

29

XMPREQ[TBUS

]

30

IC58006

(SWITCHING REGULATOR)

P STANDBY H

42

7

EN

IC58302

(REGULATOR)

DR P ON H

43

2

ON[H

]

TRY OP/CL

37

CL57003

CL57063

TRY PFAIL

50

Y31

XRST

SD BOOT

63

AK23

SDBOOT

XRES BP

51

To QR58001-B

IC58004

(DC-DC CONVERTER)

8

EN2

EN1

1

D58001

IC55002

(REGULATOR +5V)

HDMI P ON[H

]

55

1

5

4

ON

28

HDMI MONI(CEC IN)

26

HDMI CEC OUT

CL57028

CL57026

Q55001-55005

13

JK55001

(HDMI JACK)

CEC

18

+5V

VIN

VOUT

HD X SW5R9V

HDMI(CEC)

DRIVE

P53001 FP304

2 3

P53001 FP304

3 2

P53001 FP304

4 1

DRIVE P.C.B.

CL55001

CKS18

CKS13

13

1G

28

SG15

29

31

32

AJ23

XSRST

BP STATE

57

CL57057

S-6

Page 47

S4. Schematic Diagram

DMP-BDT100EE/EG INTERCONNECTION DIAGRAM

BD DRIVE UNITDRIVE P.C.B.

FP103

W 1

V 2

U 3

VH+ 4

U+ 5

U- 6

VH- 7

FP104

A- 1

B- 2

B+ 3

A+ 4

GND 5

XINRSW 6

FP102

CLOSE SW 1

GND 2

OPEN SW 3

LDM+ 4

LDM- 5

P1103

1 F2 X SW3R3V

3 F+

4 VP

5 FL CS

6 FL CLK

7 FL TXD

8 REMOCON

9 KEY2

10 KEY1

11 KEY3

12 GND

P1001

1 A

2 N

P1102

NC 1

PW X SW3R3V 2

FL CS 3

FL CLK 4

FL TXD 5

REMOCON 6

KEY2 7

KEY1 8

KEY3 9

FL DCDC ON H 10

NC 11

PW X SW5R9V 12

PW X SW5R9V 13

PW X SW5R9V 14

GND 15

GND 16

GND 17

GND 18

PW X SW12R2V 19

PW X SW12R2V 20

PW X SW12R2V 21

PW X SW12R2V 22

SP SAVE L 23

POWER SUPPLY P.C.B.

FL P.C.B.

POWER SW P.C.B.

P7001

1 F-

2 X SW3R3V

3 F+

4 VP

5 FL CS

6 FL CLK

7 FL TXD

8 REMOCON

9 KEY2

10 KEY1

11 KEY3

12 GND

PJ7004

KEY POWER 1

GND 2

PJ7551

KEY POWER 1

GND 2

P58001

1 NC

2 PW X SW3R3V

3 FL CS

4 FL CLK

5 FL TXD

6 REMOCON

7 KEY2

8 KEY1

9 KEY3

10 FL DCDC ON H

11 NC

12 PW X SW5R9V

13 PW X SW5R9V

14 PW X SW5R9V

15 GND

16 GND

17 GND

18 GND

19 PW X SW12R2V

20 PW X SW12R2V

21 PW X SW12R2V

22 PW X SW12R2V

23 SP SAVE L

DIGITAL P.C.B.

P53001

GND 1

BUSYLED 2

XEJECT 3

TRY PFAIL 4

P51602

GND 1

TX+ 2

TX- 3

GND 4

RX- 5

RX+ 6

GND 7

P58007

DR 5V 1

DRGND 2

DRGND 3

DR 12V 4

P301

1 GND SATA

2 DRX

3 NDRX

4 GND SATA

5 NDTX

6 DTX

7 GND SATA

P201

1 5V

2 MGND

3 GND

4 12V

FP304

4 GND

3 BUSYLED

2 XEJECT

1 TRY PFAIL

FP101

FCS2+ 1

FCS2- 2

TRK+ 3

FCS1+ 4

TRK- 5

FCS1- 6

A- 7

B- 8

A+ 9

B+ 10

GND PD 11

GND PD 12

GND PD 13

A(C/c/C) 14

B(B/b/B) 15

C(A/a/A) 16

D(D/d/D) 17

SA(F+J/e3+f3/E2) 18

SB(E+I/e2+f2/E1) 19

SC(H+L/e1+f1/F1) 20

SD(G+K/e4+f4/F2) 21

SW3 22

RF+ 23

RF- 24

SWB2 25

SWB1 26

VREF PD 27

VCC +5PD 28

GND PD 29

SW 30

GND 31

LDI BD 32

GND 33

LDI CD 34

GND 35

LDI DVD 36

GND 37

TEMP 38

VCC 39

VR DVD 40

VR CD 41

MD DVDCD 42

GND 43

MD BD 44

GND BDFPD 45

S4.1. Interconnection Diagram

S-7

Page 48

S4.2. FL Schematic Diagram / S4.3. Power_SW Schematic Diagram

Confidential

Until

2200

R7003

33

R7005

R7002

6200

R7009

82K

ZB7001 *

F1H1A105A028

C7002

10V

F1H1C104A071

C7006

16V

C7004

F1H1C104A071

16V

C7005

F1H1H104A783

50V

8 6 4 2 1579

32 31 28 2526

22 182021 19

24 232729

16 1314 11 10121517

A2BD00000200

DP7001

1

8

6

423

5

7

9

111210

P7001

K1KA12B00136

133

34

22

36 38 434140 42 44393735

20

6

18 1314

111210

17 1516

879

19

423

5

21

31

29

27

252324

26

28

30

32

C0HBB0000061

IC7001

EVQ11A05R

S7001

S7002

EVQ11A05R

S7003

EVQ11A05R

LB7003

$[J0JYC0000070]

321

G1 G2

IR7001

PNA4861M02VT

321

G1 G2

IR7002

$[B3RAD0000144]

1

2

PJ7004 REZ2025

PW-15V

PW-18V

PW-21V

PW_XN3R3V

STOPPLAY

KEY3

GND

GND

KEY2

KEY1

F-

F-

F-

or

or

or

or

or

(FL HOLDER)

KEY_POWER

P1

P2

5G

4G

P16

6G

7G

1GNC3G

2G

P18

P17

F+

F+

F+

P15

P13

P8

P7

P11

P12

P10

P9

P14

P4

P5P3P6

SG15 DOUT

LED4

[33]GR10

VEE

SG16 OSC

[23]SG10

[12]VSS

SG14 DIN

GR8

GR6

GR7

GR9

SG17

SG18

VDDVDD

VSS

GR3

GR5

GR4

GR1

GR2

LED3

LED2

[1]LED1

SG11

SG9

SG7

SG6

SG8

SG13

SG12 STB

CLK

SG1

K2

K1

SG4

SG5

SG2

SG3

REMOCON

FL_TXD

FL_CS

FL_CLK

VP

X_SW3R3V

2PIN FLAT CABLE 2.5mm PITCH

OPEN/CLOSE_SW

VariationCategory

ZB7001

DMP-BDT100P/GN DMP-BDT100EG

RMN0937-2 RMN0937-2J

Confidential

Until

S7551

EVQ11A05R

1

2

PJ7551

$[REZ2025]

POWER_SW

KEY_POWER

GND

DMP-BDT100EG/EE

Power_SW

Schematic Diagram

DMP-BDT100EG/EE

FL

Schematic Diagram

10987654321

G

F

E

D

C

B

A

S-8

Page 49

S-9

Page 50

C1031

*

*

C1006

*

C1005

C1009 *

C1007

*

C1001

*

*

C1019

C1008 $[ECQU2A223MLC]

*

R1006

*

R1011

*

R1012

R1013

*

VA1001

*

*

C1014

K1004

*

K1001

$[VWJ0795=10]

K1002

$[VWJ0795=10]

*

K1003

K1013

*

LG1008

$[LGS=3.5]

$[LGS=3.5]

LG1005

LG1003

$[LGS=6.2]

$[LGS=6.2]

LG1002

$[LGS=3.5]

LG1001

LG1012

$[LGS=3.5]

$[LGS=3.5]

LG1009

2 1

3 4

L1001

G0B233D00005

2 1

3 4

L1002

*

12

3 4

D1006

B0EDKT000009

K5G202Y00006

F1001

1

2

*

P1001

1

T1001

*

SAF_D_FULDI

SAF_D_DCV

SAF_D_DCV

SAF_D_DCV

SAF_D_LDISAF_D_L1L2

SAF_D_FUL1L2SAF_D_FUL

SAF_D_N_FUL

SAF_D_DCV_1

SAF_D_FU

(Y09140-1A)

XYN3+J8FJ

RADIATION

(S1WBA80-7062)

SEE THE

SERVICE MANUAL

A

N

VariationCategory1

C1001

C1005

C1006

C1007

C1009

C1014

C1018

C1019

C1021

C1023

C1024

C1026

C1031

D1012

D1021

D1029

D1110

IC1021

DMP-BDT100P DMP-BDT100EG/GN

C0DACZH00035 C0DACZH00017

B0JBSG000054 B0JBSL000002

B0BA01200046 B0BA01200046

$ B0HADV000001

$ B0HADV000001

$ F1B3D222A011

F1H1H222A013

│F1H1H222A219

F1H1H222A013

│F1H1H222A219

F1H1H101A004

│F1H1H1010005

F1H1H101A004

│F1H1H1010005

F1H1H471A792

│F1H1H471A004

F1H1H471A792

│F1H1H471A004

F1B3A122A009 F1B3D181A011

$ F1B2G681A015

F1B2G222A018 F1BAF1020020

F2B2E1010001 F2B2W4700003

$

F0CAF683A021

│ECQU2A683MLC

F0CAF223A021 $

F1BAF1020020 F1B2G471A014

F1BAF1020020 F1B2G471A014

F0CAF683A021

│ECQU2A683MLC

F0CAF683A021

│ECQU2A683MLC

VariationCategory

K1003

K1004

K1013

L1002

P1001

R1006

R1011

R1012

R1013

R1019

R1021

R1022

R1023

R1024

R1030

R1032

R1033

T1001

VA1001

ZA1021

ZA1023

DMP-BDT100P DMP-BDT100EG/GN

$ $

VSC5603-A VSC5603-A

ERZV05Z471CS

ERZV05Z471CS

│ERZV10D471C2

G4D2A0000313 G4D2A0000314

5600[G] 4700[G]

5100[G] 4700[G]

1500 3900

15K[G] 15K[G]

22K 10K

ERX2SZJR12E ERX2SJR33E

$(10K) $(10K)

$ $

$ ERG1SJ222E

$ ERG2SJ104P

$ ERG2SJ104P

$ D0BF685JA030

K2AB2B000007

│K2AB2B000011

K2AA2B000017

│K2AA2B000011

$ G0B233D00005

VWJ0795=5 $

VWJ0795=10 $

VWJ0795=10 $

HOT

COLD

CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE 2A 250V FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQUES

D' INCENDIE N' UTILISERQUE DES FUSIBLE DE MÉME TYPE 2A 250V.

2A 250V

2A 250V

DMP-BDT100EG/EE

Power

Schematic Diagram

1/4

N

M

L

K

J

I

H

G

S4.4. Power Schematic Diagram

S-10

S-10

Page 51

B0JAMD000026

D1176

D1174

$[B0AADM000003]

D1173

B0AADM000003

D1132 B0JCMD000014

D1131 B0JCMD000014

*

C1019

F1H1H221A004

50V220PC1135

50V

F1H1H120A004

C1134 50V12P

50V

C1175

F1H1H392A013

50V

$[F1K1C106A062]C1138

16V10

$[F1K1C106A062]C1139 16V10

F1K1C106A062

16V10uC1131

16V

C1133

50V0.015

F1H1H153A013

50V

16V0.1

C1132

F1H1C104A071

16V

F1H1C104A071

16V0.1C1137

16V

F1H1C104A071

16V0.1

C1136

16V

16V0.1

C1141

F1H1C104A071

16V

*

R1006

27K[D]

R1136

R1173

5600

ERDS2TJ470T

R1174

R1178

$(3300)

27K[D]

R1138

4700

R1172

R1171

4700

R1141

220K

470K[D]

R1139

470K[D]

R1137

R1177 $(47K)

R1175 $(47K)

470

R1176

R1145

D1BDR027A135

R1135

27K[D]

R1133

10K[D]220K[D]

R1134

R1132

2700

R1131

33K

82K

R1142

470K

R1143

5600

R1144

G1 G2

VSC6221

ZA1112

F2A1C221B111

C1174

16V

F2A1C8210008C1140 16V820[JG]

16V

C1176

F2A1C221B111

16V

C1173

F2A1H100B040

50V

C1172

F2A1V470A831

35V

$[F2A1H100B040]

C1171

D1171

B0BA02100019

B0BA03600021

D1172

B0BA01800019

D1175

D1110

*

B1BACG000058

Q1171

LG1012

$[LGS=3.5]

J0JHC0000048

LB1131

QR1170

B1GBCFJJ0040

B1GBCFNN0041

QR1131

13

4

15 1614

1236 578

12119 10

C0DBAYY00624

IC1130

L1105

G0A100ZA0045

5

2

6

13

4

Q1131

B1CHRD000024

2

9

1

6

7

8

4

3

5

T1101

G4D1A0000129

1

9

7

5

3

2

4

6

8

22

23

12

13

11

20

19

21

16

15

17

14

18

10

P1102

K1KY23AA0606

CKAA4

CKAA3

CKAA5

CKAA2

CKAA1

CKAB12

CKAB4

CKAB3

CKAB6

CKAB5

CKAB1

CKAB2

CKAB10

CKAB9

CKAB11

CKAB7

CKAB8

CKAA22

CKAA14

CKAA18

CKAA23

CKAA9

CKAA10

CKAA7

CKAA6

CKAA8

CKAA11

B1ADGF000010

Q1170

1

8

6

4

2

3

5

7

9

11

12

10

K1KB12B00040

P1103

1

T1001

*

SAF_D_FULDI

SAF_D_DCV

SAF_D_LDISAF_D_L1L2

PW_12R2V

PW_5R9VPW_A

PW_5R9VPW_C

PW_12R2VPW_B

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

(Y09140-1A)

XYN3+J8FJ

RADIATION

ZA1111

D1110

OSC

D

D

D

D

(CPH6350)

S

Vref/SS

GND

GND

GND

GND

GND

GND

GND

GND

G

AL1473

SEL/SYNC

EN VIN

EXT-Up

VB

RS+

RS-

CC

EXT-Lo

V5

LX

FB

FL_CLK

FL_CLK

PW_X_SW5R9V

PW_X_SW5R9V

PW_X_SW5R9V

PW_X_SW3R3V

FL_DCDC_ON_H

REMOCON

REMOCON

PW_X_SW12R2V

PW_X_SW12R2V

PW_X_SW12R2V

PW_X_SW12R2V

SP_SAVE_L

FL_TXD

FL_TXD

FL_CS

FL_CS

KEY1

KEY1

KEY3

KEY3

KEY2

KEY2

X_SW3R3V

V+

V-

NC

F+

F-

VP

VP

HOT

COLD

DMP-BDT100EG/EE

Power

Schematic Diagram

2/4

S-11

S-11

Page 52

D1021

*

D1012

*

B0ACCK000005

D1031

B0ACCK000005

D1026

D1032

B0ACCK000005

D1027

B0HAGM000006

*

C1021

C1024

*

C1023

*

C1026

*

C1031

*

*

C1006

*

C1005

C1009 *

C1007

C1018

*

*

C1019

$[F1A3D331A005]

C1022

C1008 $[ECQU2A223MLC]

$(0.1)

C1112

R1022

*

R1026

ERDS2TJ221T

$(4700)

R1105

4700

R1104

R1031

$

R1041

100K

R1042

100K

10[22]R1029

R1028 10[22]

*

R1011

*

R1012

R1013

*

R1021

*

R1023

*

R1024

*

R1030

*

R1032*R1033

*

R1019

G1 G2

*

ZA1023

G1 G2

*

ZA1021

51 3

2 4 7

9

IC1021

*

*

C1014

C1025

F2A1V6800002

35V68[JG]

35V

D1029

*

B0BA01600007

D1025

B0BC03200002

D1023

K1004

*

K1002

$[VWJ0795=10]

K1013

*

XYN3+J8FJZA1022

XYN3+J8FJZA1111

B1ABDF000033

Q10101

2 13

ZA1002

$[K9ZZ00001279]

2 13

ZA1001

K9ZZ00001279

$[LGS=3.5]

$[LGS=3.5]

LG1003

$[LGS=6.2]

$[LGS=6.2]

LG1002

$[LGS=3.5]

$[LGS=3.5]

$[LGS=3.5]

3 4

L1001

G0B233D00005

3 4

J0JKB0000003

LB1021

12

3 4

D1006

B0EDKT000009

4

3 2

1

B3PBA0000454

Q1022

4

3 2

1

B3PBA0000454

Q1023

1

10 11 12

56

7 98

23

T1001

*

SAF_D_VDS_1

SAF_D_VDS_1

SAF_D_DCV

SAF_D_DCV

SAF_D_DCV

SAF_D_LDISAF_D_L1L2

SAF_D_N_FUL

SAF_D_VDS

SAF_D_DCV_1

PW_12R2VPW_E

VEP71187A

VEP71186A

or

(Y09140-1A)

NP1

NP2

XYN3+J8FJ

RADIATION

IC1021 RADITION

(S1WBA80-7062)

ZA1022 XYN3+J8FJ

SEE THE

SERVICE MANUAL

(MR4020)

NS12-2

NS12-3

NS12-1

NC

DMP-BDT100EG/EE

Power

Schematic Diagram

I

H

G

F

E

D

C

B

A

3/4

S-12

Page 53

D1027

D1132 B0JCMD000014

D1131 B0JCMD000014

C1018

*

*

C1019

$(0.1)

C1112

F1H1C104A071

C1114

16V

C1124

F1H1C104A071

16V

F1H1H221A004

50V220PC1135

50V

$[F1K1C106A062]C1138

16V10

$[F1K1C106A062]C1139 16V10

F1K1C106A062

16V10uC1131

16V

C1133

50V0.015

F1H1H153A013

50V

16V0.1

C1132

F1H1C104A071

16V

F1H1C104A071

16V0.1C1137

16V

F1H1C104A071

16V0.1

C1136

16V

16V0.1

C1141

F1H1C104A071

16V

$(4700)

R1105

R1118

330[D]

R1116

2200

2200

R1112

4700

R1104

R1113

10K

R1111

1000

18K[D]

R1119

4700[D]

R1115

R1042

100K

27K[D]

R1136

27K[D]

R1138

R1141

220K

470K[D]

R1139

470K[D]

R1137

R1145

D1BDR027A135

R1135

27K[D]

R1133

10K[D]220K[D]

R1134

R1132

2700

R1131

33K

82K

R1142

470K

R1143

5600

R1144

G1 G2

VSC6221

ZA1112

C1125

F2A1C102A236

16V

F2A1C8210008C1140 16V820[JG]

16V

16V1000uF[JG]

F2A1C1020095

C1121

16V

16V1000uF[JG]

C1118

F2A1C1020095

16V

D1029

*

1 2 3

D1110

*

$[LGS=3.5]

J0JHC0000048

LB1131

4

3 2

1

B3PBA0000454

Q1022

4

3 2

1

B3PBA0000454

Q1023

4123

C0DBZMC00006

IC1102

QR1101

B1GBCFLL0042

B1GBCFNN0041

QR1131

13

4

15 1614

12119 10

G0A100ZA0045

L1103

G0A100ZA0045

4

1

9

7

5

3

2

4

6

8

12

13

11

10

P1102

K1KY23AA0606

CKAA4

CKAA3

CKAA5

CKAA2

CKAA1

CKAA9

CKAA10

CKAA7

CKAA6

CKAA8

CKAA11

Confidential

Until

1

10 11 12

56

7 98

23

T1001

*

SAF_D_DCV

SAF_D_LDISAF_D_L1L2

SAF_D_VDS

PW_12R2V

PW_12R2VPW_D

SP_SAVE_L

PW_12R2VPW_E

PW_5R9VPW_A

PW_5R9VPW_C

C

N.C REF

[MM1431CURE]

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

(Y09140-1A)

NP1

NP2

XYN3+J8FJ

RADIATION

ZA1111

D1110

OSC

(CPH6350)

S

Vref/SS

GND

GND

GND

G

SEL/SYNC

EN VIN

EXT-Up

VB

RS+

RS-

CC

EXT-Lo

V5

LX

FB

FL_CLK

PW_X_SW5R9V

PW_X_SW5R9V

PW_X_SW3R3V

FL_DCDC_ON_H

REMOCON

FL_TXD

FL_CS

KEY1

KEY3

KEY2

NC

2010/06/30

[PR]

NS12-2

NS12-3

NS12-1

NC

DMP-BDT100EG/EE

Power

Schematic Diagram

4/4

212019181716151413121110987654321

S-13

Page 54

IBT6

W753

W752

W751

R7009

R7005

R7003

LB7003

C7005

C7004

C7002

C7006

R7002

1

1

1

12

22

23

33

3

4

44

IC7001

MK2

MK1

W707

W702

W705

W703

W704

W706

W701

32

1

IR7002

1

43132 229

DP7001

S7001

S7002S7003

1

3

IR7001

12

PJ7004

1

2

12

11

P7001

DMP-BDT100EG/EE

Power_SW P.C.B.

DMP-BDT100EG/EE

FL P.C.B.

10987654321

G

F

E

D

C

B

A

(Foil Side)

(Component Side)

12

PJ7551

S7551

S5. Print Circuit Board

S5.1. FL P.C.B. / S5.2. Power_SW P.C.B.

S-14

Page 55

S-15

Page 56

W12

W15

W3

ZA1023

K1013

ZA1021

ZA1112

R1011

R1012

D1021

D1012

C1031

R1013

VA1001

6 5 2 13

T1001

D1025

R1026

R1022

LB1021

9

75432

1

IC1021

D1027

C1025

C1022

C1021

D1029

C1014

R1006

2

1

4 3

L1002

2

1

4 3

L1001

K1004

K1003

K1002

K1001

F1001

C1019

C1018

C1009C1008C1007

C1006

C1005

C1001

P1001

3

1

ZA1001

3

1

ZA1002

(Component Side)

1/4

N

M

L

K

J

I

H

G

DMP-BDT100EG/EE

Power P.C.B.

S5.3. Power P.C.B.

S-16

S-16

Page 57

3.53.5

3.53.5

6.26.2

3.5

R1019

4

3 2

1

Q1023

4

3 2

1

Q1022

C1112

C1124

1

R1104

R1105

R1111

R1112

R1113

R1116

QR1101

D1023

R1042

R1041

R1033

R1032

R1031

R1030

R1029

R1028

R1024

R1023

R1021

Q10101

D1032

D1031

D1026

C1026

C1024

C1023

LG1012

LG1009

LG1008

LG1005

LG1003

LG1002

LG1001

+

-

D1006

2/4

DMP-BDT100EG/EE

Power P.C.B.

(Foil Side)

S-17

S-17

Page 58

W14

W7

W10

W4

W9

W12

W15

W2

W5

W6

W1

W8

W11

W13

K1013

ZA1112

R1013

121110987

6 5 2 13

T1001

C1176

R1174

Q1171

D1172

9

8

7

6

5 4

3

2

1

T1101

D1176

D1174

D1173

D1171

C1171

C1174

D1175

C1173

C1172

C1125

L1105

C1118

D1110

C1121

L1103

C1140

D1025

R1026

LB1021

D1027

C1025

C1014

4 3

K1004

C1019

C1018

C1005

22

23

1

2

P1102

1

2

11

12

P1103

I

H

G

F

E

D

C

B

A

3/4

(Component Side)

(Component Side)

DMP-BDT100EG/EE

Power P.C.B.

S-18

Page 59

CKAB1

CKAA11

CKAA9

CKAA7

CKAA5

CKAA3

CKAA1

CKAA8

CKAA6

CKAA4

CKAA2

CKAB2

CKAB4

CKAB3

CKAB12

CKAB10

CKAB9

CKAB8

CKAB6

CKAB5

CKAB7

CKAB11

CKAA10

CKAA18

CKAA23

CKAA22

C1175

R1173

Q1170

R1171

QR1170

R1172

R1177

R1176

R1175

R1178

4

3 2

1

Q1023

4

3 2

1

Q1022

CKAA14

R1135

R1134

R1133

R1138

R1139

R1137

C1132

R1131

C1133

R1132

C1138

R1142

R1141

QR1131

R1143

C1135

C1136

C1139

R1115

R1119 R1118

1 8

916

IC1130

C1137

C1141

R1144

LB1131

D1132

D1131

C1131

4

61

3

Q1131

C1134

R1136

R1145

C1112

C1114

C1124

3 2

4

1

IC1102

R1104

R1105

R1111

R1112

R1113

R1116

QR1101

D1023

R1042

R1041

R1029

R1028

R1024

D1026

C1023

LG1012

LG1009

+

-

DMP-BDT100EG/EE

Power P.C.B.

(Foil Side)

4/4

212019181716151413121110987654321

(Foil Side)

S-19

Page 60

S-20

Page 61

S6. Abbreviation

INITIAL/LOGO

A A0~UP ADDRESS

ACLK AUDIO CLOCK

AD0~UP ADDRESS BUS

ADATA AUDIO PES PACKET DATA

ALE ADDRESS LATCH ENABLE

AMUTE AUDIO MUTE

AREQ AUDIO PES PACKET REQUEST

ARF AUDIO RF

ASI SERVO AMP INVERTED INPUT

ASO SERVO AMP OUTPUT