Page 1

Digital Camera/Lens Kit

DMC-L1KPP

DMC-L1KEB

DMC-L1KEG

DMC-L1KGC

DMC-L1KGK

DMC-L1KGN

DMC-L1KGT

ORDER NO. DSC0608017CE

B26

Vol. 1

Colour

(K)...........Black Type

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

CONTENTS

Page Page

1 INTRODUCTION 3

1.1. INTRODUCTION

1.2. HOW TO DEFINE THE MODEL SUFFIX (NTSC or PAL

model)

2 SAFETY PRECAUTIONS

2.1. GENERAL GUIDELINES

2.2. LEAKAGE CURRENT COLD CHECK

2.3. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

3 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

4 HOW TO RECYCLE THE LITHIUM ION BATTERY(U.S. ONLY)

5 CAUTION FOR AC CORD (EB/GC only)

5.1. INFORMATION FOR YOUR SAFETY

5.2. CAUTION FOR AC MAINS LEAD

6 OPERATING GUIDE

7 OPERATING INFORMATION

8 TROUBLESHOOTING

3

9 ERROR CODE MEMORY FUNCTION

3

10 CONFIRMATION OF FIRMWARE VERSION

11 MAINTENANCE

6

6

12 SERVICE NOTES

6

6

7

7

8

8

8

9

12.1. ABOUT THE LENS (Being Supplied as a KIT)

12.2. ABOUT THE BODY

13 DISASSEMBLY/ASSEMBLY

14 EXPLODED VIEWS

14.1. FRAME & CASING SECTION

14.2. LENS SECTION

14.3. PACKING PARTS & ACCESSORIES SECTION

15 REPLACEMENT PARTS LIST

15.1. MECHANICAL REPLACEMENT PARTS LIST

2

10

14

18

20

21

23

23

23

24

25

25

26

27

28

28

Page 3

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

1 INTRODUCTION

1.1. INTRODUCTION

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

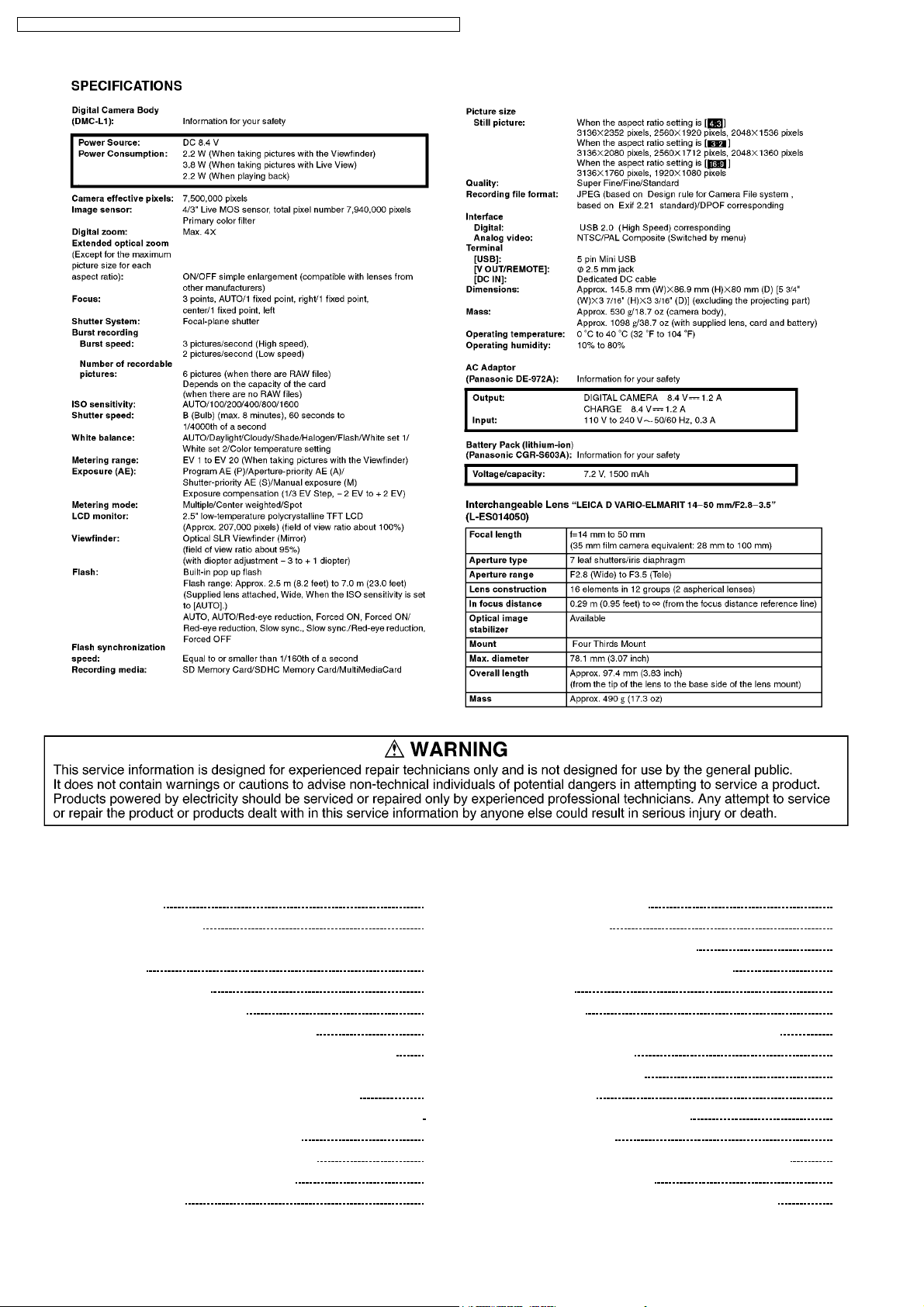

1.2. HOW TO DEFINE THE MODEL SUFFIX (NTSC or PAL model)

There are six kinds of DMC-L1K, regardless of the colours.

·a) DMC-L1KS

·b) DMC-L1KPP

·c) DMC-L1KEB/EG/GN

·d) DMC-L1KGC

·e) DMC-L1KGT

·f) DMC-L1KGK

(DMC-L1KS is exclusively Japan domestic model.)

What is the difference is that the “INITIAL SETTIN G” data which is stored in Flash ROM mounted on Main PCB.

1.2.1. Defining methods:

To define the model suffix to be serviced, refer to the nameplate which is putted on the bottom side of the Unit.

3

Page 4

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

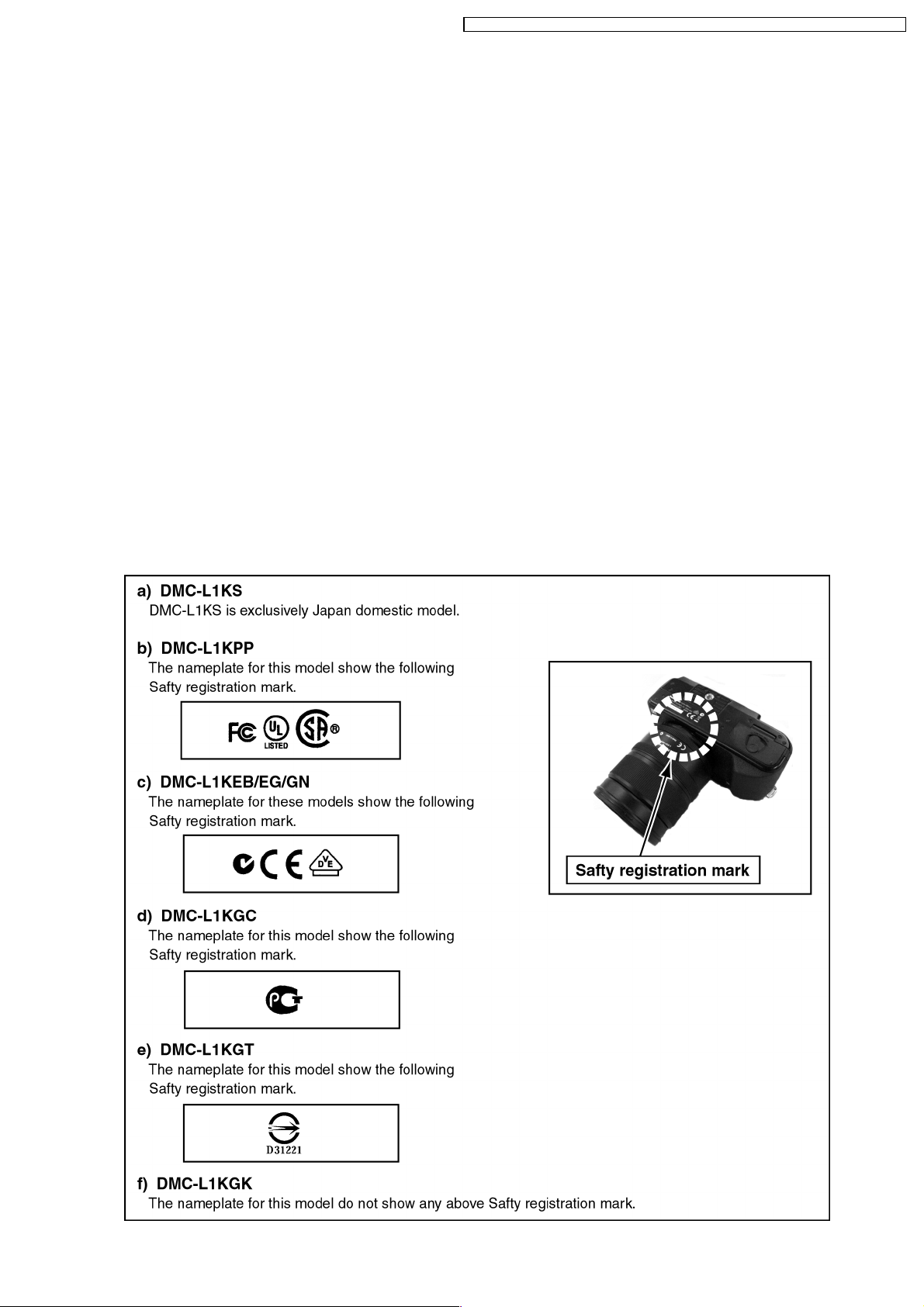

1.2.2. INITIAL SETTINGS:

When you replace the Main PCB be sure to perform the initial settings after achieving the Adjustment, by ordering the following

procedure in accordance with model suffix.

·Step 1. The temporary cancellation of factory setting:

Set the shutter speed dial to “ 8

While keep pressing AFL/AEL

·Step 2. The cancellation of factory setting:

Press the “ Playback

Press FUNC.2

” button to playback mode.

and “ UP of Cursor key” simultaneously, then turn the Power off.

·Step 3. Turn the Power on:

Set the shutter speed dial to “ A

·Step 4. Display the INITIAL SETTING:

1. Press the Playback

button, and then viewing information display.

2. While keep pressing MENU/SET

”.

, then turn the Power on.

”, and then turn the Power on.

and “ RIGHT of Cursor key” simultaneously, turn the Power off.

·Step 5. Set the INITIAL SETTING:

Select the area with pressing “ UP

/ DOWN of Cursor key”, and then press the “ RIGHT of Cursor key”.

The only set area is displayed, and then press the “ RIGHT of Cursor key” after confirmation.

(The unit is powered off automatically.)

4

Page 5

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

Confirm the display of “PLEASE SET THE CLOCK” in English when the unit is turned on again.

·Step 6. CONFIRMATION:

The display shows “PLEASE SET THE CLOCK” when turn the Power on again.

When the unit is connected to PC with USB cable, it is detected as removable media.

(When the “GT” or “GK” model suffix is selected, the display shows “PLEASE SET THE CLOCK” in Chinese.)

1) As for your reference Default setting condition is given in the following table.

·Default setting (After “INITIAL SETTINGS”)

MODEL VIDEO OUTPUT LANGUAGE DATE REMARKS

a) DMC-L1KS NTSC Japanese Year/Month/Date

b) DMC-L1KPP NTSC English Month/Date/Year

c) DMC-L1KEB/EG/GC/GN PAL English Date/Month/Year

d) DMC-L1KGK PAL Chinese (simplified) Year/Month/Date

e) DMC-L1KGT NTSC Chinese (traditional) Year/Month/Date

5

Page 6

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

2 SAFETY PRECAUTIONS

2.1. GENERAL GUIDELINES

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential

that these critical parts should be replaced with

manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufa cturer.

2. An Isolation Transformer should always be used during the

servicing of AC Adaptor whose chassis is not isolated from

the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents

resulting in personal injury from electrical shocks. It will also

protect AC Adaptor from being damaged by accidental

shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks

to prevent the customer from being exposed to shock

hazards.

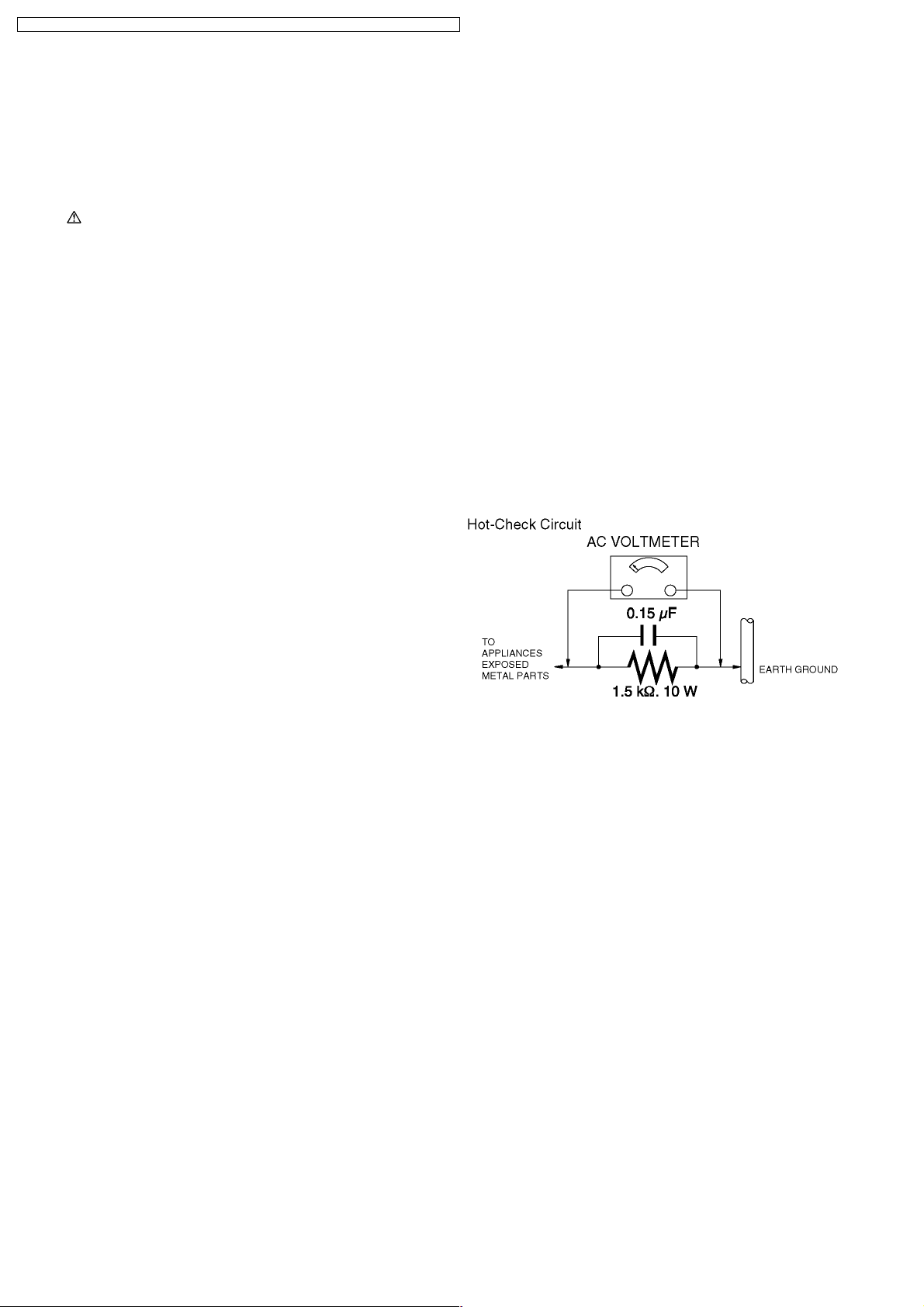

2.3. LEAKAGE CURRENT HOT

CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5 k:, 10 W resistor, in parallel with a 0.15 µF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 k:/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurement s.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must

not exceed 1/2 mA. In case a measurement is outside of

the limits specified, there is a possibility of a shock hazard,

and the equipment should be repaired and rechecked

before it is returned to the customer.

2.2. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between 1

M: and 5.2 M:. When the exposed metal does not have a

return path to the chassis, the reading must be infinity.

Figure. 1

6

Page 7

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

3 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electro static discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4 HOW TO RECYCLE THE LITHIUM ION BATTERY

(U.S. ONLY)

7

Page 8

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

5 CAUTION FOR AC CORD

(EB/GC only)

5.1. INFORMATION FOR YOUR

SAFETY

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

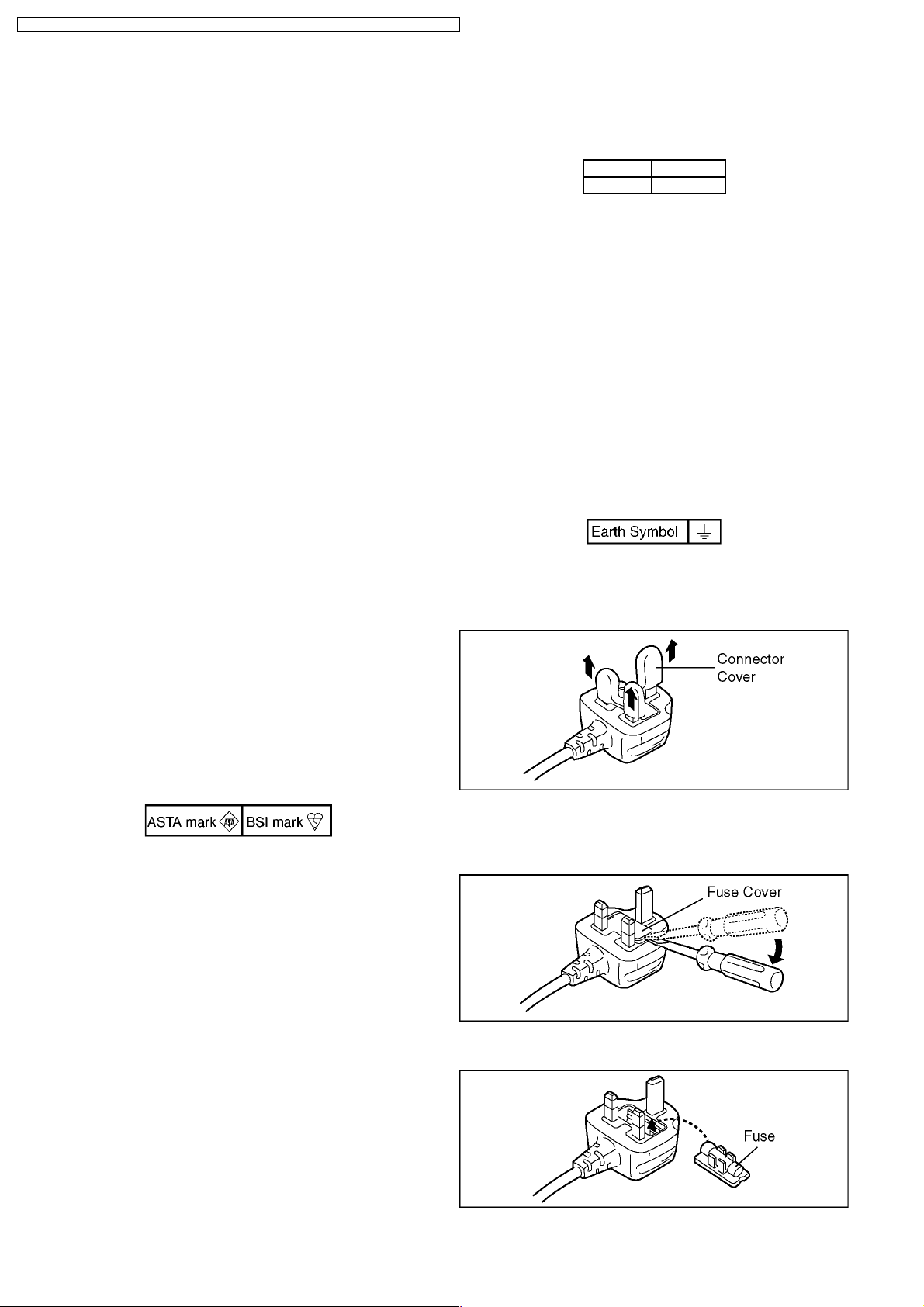

5.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the

terminal in the plug which is marked with the letter N or

coloured BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be

connected to the earth terminal of the three pin plug, marked

with the letter E or the Earth Symbol.

5.2. CAUTION FOR AC MAINS

LEAD

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASRA mark or the BSI mark on the body of the

fuse.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

5.2.2. Before use

Remove the Connector Cover as follows.

5.2.3. How to replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug

is inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2. Replace the fuse and attach the Fuse cover.

8

Page 9

6 OPERATING GUIDE

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

9

Page 10

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT11DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

7 OPERATING INFORMATION

10

Page 11

Page 12

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT13DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

12

Page 13

Page 14

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT15DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

8 TROUBLESHOOTING

14

Page 15

Page 16

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT17DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

16

Page 17

Page 18

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

9 ERROR CODE MEMORY FUNCTION

1. General description

This unit is equipped with history of error code memory function, and can be memorized 32 error codes in sequence from the

latest. When the error is occurred more than 32, oldest error is overwritten in sequence.

The error code is not memorized when the power supply is shut down forcibly (when the unit is powered on by the battery, the

battery is pulled out) because the error code is memorized to FLASH ROM when the unit is powered off.

2. How to display

The error code can be displayed by the following procedure:

Before perform the error code memory function , connect the AC adaptor or insert the battery, and insert the SD card.

·1. The temporary cancellation of factory setting:

Set the shutter speed dial to “ 8

While pressing AFL/AEL

·2. The display of error code:

Press FUNC.2

The display is changed as shown below when the above buttons is pressed simultaneously.

Normal display o Error code display o Operation history display o Normal display o .....

, MENU/SET and “ LEFT of Cursor key” simultaneously with the step 1 condition.

”.

, then turn the Power on.

Example of Error Code Display

·3. The change of display:

The error code can be memorized 32 error codes in sequence, however it is displayed 5 errors on the LCD.

Display can be changed by the following procedure:

"UP

or DOWN of Cursor key": It can be scroll up or down one.

" LEFT

·4. How to read the error code:

One error code is displayed for 8 bit, the contents of error codes is indicated the table as shown below.

or RIGHT of Cursor key": It can be display last 5 error or another 5 error.

18

Page 19

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

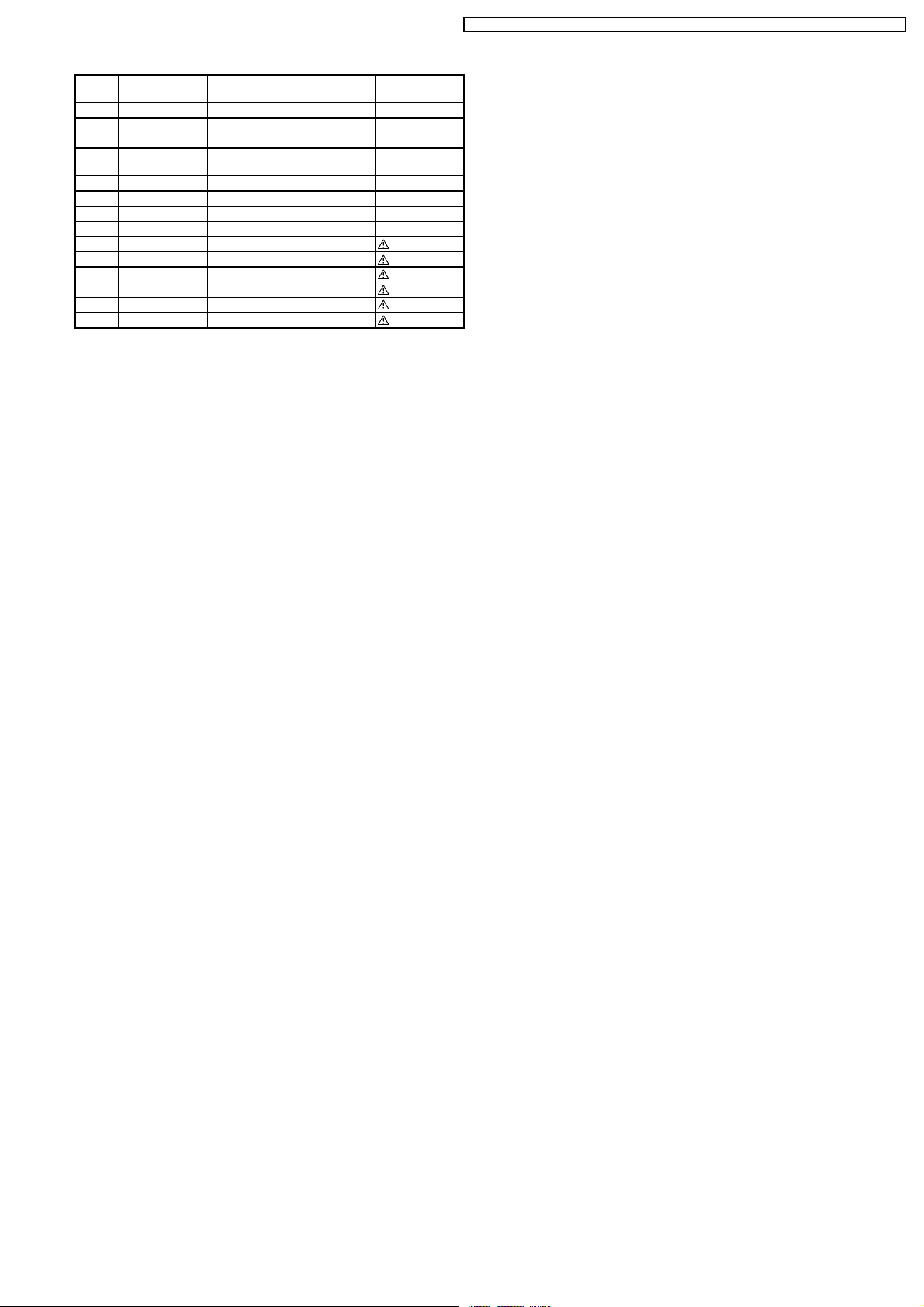

Attribute Main item Sub item Error code Contents

High 4 bits Low 4 bits

LENS Lens

communication

HARD VENUS A/D Flash 2800 0000 Flash capacitor charge is not completed in time (20 seconds)

FLASH ROM

(EEPROM

Area)

SYSTEM RTC 2C00 0001 Clock IC initialize failure error

SOFT CPU Reset 3000 0001

Card Card 3100 0001 Card logic error

CPU,

ASIC hard

Operation Power on 3B00 0000 FLASH ROM processing camera initialization’s operating

Zoom Zoom 3C00 0000 The camera side doesn´t do completion of processing after the fixed

Communication 1800 0x01 Serial transmission error

0x02 Serial receive error

0x03 Before transmits L2B is not LoH error

0x04 After transmits L2B is not Ho L error

0x05 Before recieves L2B is not Lo H error

0x06 After recieves L2B is not HoL error

0x07 D data before recieves L2B is not LoH error

0x08 B command before execute L2B is not LoH error

0x09 B command while executing L2B is not HoL error

0x0A A command check sum error

0x0B B command check sum error

0x0C C command check sum error

0x0D D command check sum error

0x0E C command data check sum error

0x0F Reply data number error (except type C)

0x10 Reply data number error (type C)

FLASH ROM

(EEPROM

Area)

Stop 3800 0001 Camera task finish process time out

2B00 0001 EEPROM breakdown (reading : power ON)

0002 EEPROM (writing : power OFF and adjustment)

0007

0002 Card physical error

0004 Write error

3900 0005 Internal format error

0002 Camera task invalid code error

0003 AF time out error

3500 0000 The dummy processing is executed by the command from the sequence

3501 0000 The sequence side doesn´t respond though the record preprocessing is

3502 0000 The sequence shifted to the record without completing the record

User setting and storage area of menu information are cannot be

normally read

NMI reset (30000001-30000007 are caused by factors)

|

EEP superscription error factor address is stored in 108-109

time though the zoom stop is done from the sequence

to the camera processing (Illegal command issue)

necessary on the camera side

preprocessing on the camera side

·5. How to returned to Normal Display:

Turn the power off and on, to exit from Error code display mode.

NOTE:

The error code can not be initialized by the unit only.

19

Page 20

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

10 CONFIRMATION OF FIRMWARE VERSION

The Firmware version can be confirmed by ordering the following steps:.

·Step 1. The temporary cancellation of factory setting:

Insert the SD memory card which has a few photo data.

Set the shutter speed dial to “ 8

While keep pressing AFL/AEL

·Step 2. Confirm the version:

Press the “ Playback

Press FUNC.2

(The version information is displayed on the LCD with light blue colour letters.) (Fig. B)

CAUTION:

The version information does not display if the LCD has switched to LCD with indication already.

In this case, press DISPLAY

” button to playback mode, and then press [DISPLAY] to switch to LCD with indication. (Fig. A)

and “ DOWN of Cursor key” simultaneously. (No need to keep pressing.)

”.

, then turn the power on.

to switch to LCD with indication.

<Point>

·The firmware version and EEPROM version can be confirmed with the information (1).

·The information (2), (3) and (4) are just reference.

20

Page 21

11 MAINTENANCE

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

21

Page 22

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

22

Page 23

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

12 SERVICE NOTES

12.1. ABOUT THE LENS (Being Supplied as a KIT)

To minimize the possibilities of getting the dust/dirt on the lens surface, keep putting the lens cap other than necessary case.

The parts other than listed in replacement parts list are not allowed to disassemble/assemble.

It is not allowed to disassemble the Lens outside of the proper Clean facilities.

Once it is disassembled, proper adjustment/inspection facilities are required which are rather expensive.

12.2. ABOUT THE BODY

To squeeze the possibilities of getting the dust/dirt inside of the Mount space, keep putting the lens cap other than necessary case.

The parts other than listed in replacement parts list are not allowed to disassemble/assemble.

Since there is a open space especially in Finder unit, it gets dust/dirt easily.

Therefore, it is not allowed to replace the outer casing parts (such as Front, Rear, Top case and so on ) which are not listed in the

Replacement Parts list at the outside of the proper Clean facilities.

Besides, once it is disassembled, proper adjustment/inspection facilities are required which are rather expensive.

23

Page 24

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

13 DISASSEMBLY/ASSEMBLY

Refer to the following table and the illustration for disassembly

and assembly.

Part name Ref. No. Unscrew

Grip piece front (L) 14 B3, B15

Grip piece front (R) unit 40 B12, B13, B14

SD door unit 101 B22, B23

Shading frame 403 B401, B402, B403

24

Page 25

14 EXPLODED VIEWS

14.1. FRAME & CASING SECTION

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

25

Page 26

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

14.2. LENS SECTION

26

Page 27

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

14.3. PACKING PARTS & ACCESSORIES SECTION

27

Page 28

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

15 REPLACEMENT PARTS LIST

15.1. MECHANICAL REPLACEMENT

PARTS LIST

15.1.1. FRAME & CASING SECTION

PARTS LIST

Ref.

No.

14 VGQ8856 GRIP PIECE FRONT(L)

33 VMC2008 SHOE SPRING

40 VYF3095 GRIP PIECE FRONT (R) UNIT

101 VYF3093 SD DOOR UNIT

102-2 VYQ3887 EYE CUP

B1 VHD1680 SCREW

B2 VHD1680 SCREW

B3 VHD1684 SCREW

B4 VHD1684 SCREW

B5 VHD1892 SCREW

B6 VHD1892 SCREW

B7 VHD1892 SCREW

B8 VHD1892 SCREW

B9 VHD1892 SCREW

B10 VHD1892 SCREW

B11 VHD1892 SCREW

B12 VHD1892 SCREW

B13 VHD1892 SCREW

B14 VHD1892 SCREW

B15 XQN16+BJ5FJK SCREW

B16 XQN16+BJ5FJK SCREW

B17 XQN16+BJ5FJK SCREW

B18 VHD1689 SCREW

B19 VHD1690 SCREW

B20 VHD1690 SCREW

B21 VHD1690 SCREW

B22 XQN16+B2FN SCREW

B23 XQN16+B2FN SCREW

15.1.2. LENS SECTION PARTS LIST

Ref.

No.

403 VDW1327 SHADING FRAME

406 VMG1735 ZOOM RUBBER RING

B401 XQN14+B3FNK SCREW

B402 XQN14+B3FNK SCREW

B403 XQN14+B3FNK SCREW

Part No. Part Name & Description Remarks

Part No. Part Name & Description Remarks

15.1.3. PACKING PARTS & ACCESSORIES

SECTION PARTS LIST

Ref.

No.

500 VYC0949 HOOD UNIT

500-1 VPF1263 HOOD BAG

501 VFC4185 LENS REAR CAP

502 VPF1262 LENS BAG (POLYETHYLENE)

503 VYF3089 LENS FRONT CAP

505 VPF1166 CAMERA BAG

507 DE-972AF AC ADAPTOR PP

507 DE-972CE AC ADAPTOR GC,GK

507 DE-972BF AC ADAPTOR GN,EB,EG

507 DE-972FE AC ADAPTOR GT

509 K2GJ2DZ00028 DC CABLE

510 VFC4189 STRAP

510-1 VGQ8990 EYEPIECE CAP

511 VFC4206 LENS STORAGE BAG

512 VFF0330-S CD-ROM (BUNDLE SOFT) PP

512 VFF0331-S CD-ROM (BUNDLE SOFT) GC,GN,GK,GT,

513-1 VPF1100 BAG, POLYETHYLENE PP

513-1 VPF1166 BAG,POLYETHYLENE GC,GN,GK,GT,

513-2 VQT0W41 O/I PC CONN.

513-2 VQT0W47 O/I PC CONN.

513-2 VQT0Z48 O/I PC CONN.

513-2 VQT0W46 O/I PC CONN.

513-2 VQT0W49 O/I PC CONN.

513-2 VQT0W48 O/I PC CONN.

513-2 VQT0W43 O/I PC CONN.

513-2 VQT0W44 O/I PC CONN.

513-3 VQT0W82 INSTRUCTION BOOK

513-3 VQT0W83 INSTRUCTION BOOK

513-3 VQT0W89 INSTRUCTION BOOK

513-3 VQT0W90 INSTRUCTION BOOK

513-3 VQT0W95 INSTRUCTION BOOK

513-3 VQT0W94 INSTRUCTION BOOK

513-3 VQT0W93 INSTRUCTION BOOK

513-3 VQT0W88 INSTRUCTION BOOK

513-3 VQT0W84 INSTRUCTION BOOK (GERMAN) EG

513-3 VQT0W85 INSTRUCTION BOOK (FRENCH) EG

513-4 VQT0Z34 O/I SOFTWARE

513-4 VQT0Z37 O/I SOFTWARE

513-4 VQT0Z36 O/I SOFTWARE (ENGLISH) GN,EB

513-4 VQT0Z39 O/I SOFTWARE

513-4 VQT0Z38 O/I SOFTWARE

513-4 VQT0Z35 O/I SOFTWARE

Part No. Part Name & Description Remarks

EB,EG

EB

(ENGLISH(SPANISH)/

CANADIAN FRENCH)

(ENGLISH/ARABIC/

CHINESE(TRADITIONAL))

(RUSSIAN)

(ENGLISH)

(CHINESE(SIMPLIFIED))

(CHINESE(TRADITIONAL))

(GERMAN/FRENCH/

ITALIAN/DUTCH)

(SPANISH/SWEDISH/DANISH/

PORTUGUESE)

(ENGLISH(SPANISH))

(CANADIAN FRENCH)

(ENGLISH)

(CHINESE(TRADITIONAL))

(ENGLISH)

(CHINESE(SIMPLIFIED))

(CHINESE(TRADITIONAL))

(ENGLISH)

(ENGLISH/CANADIAN FRENCH)

(ENGLISH/RUSSIAN/ARABIC/

CHINESE(TRADITIONAL))

(CHINESE(SIMPLIFIED))

(CHINESE(TRADITIONAL))

(GERMAN/FRENCH/ITALIAN/

DUTCH/PORTUGUESE/SPANISH/

SWEDISH/DANISH)

PP

GC

GC

GN,EB

GK

GT

EG

EG

PP

PP

GC

GC

GN

GK

GT

EB

PP

GC

GK

GT

EG

28

Page 29

DMC-L1KPP / DMC- L1KEB / DMC- L1KEG / DMC-L1KGC / DMC-L1KGK / DMC-L1KG N / DMC-L1KGT

Ref.

No.

514 K1HA05CD0004 USB CABLE

515 K2KJ2CB00001 AV CABLE

520 VPK3145 PACKING CASE PP

520 VPK3146 PACKING CASE GC,GN,GK,GT,

521 VPN6424 CUSHON A

522 VPN6425 CUSHON B

523 VPN6447 PAD

526 VKF4091 BODY CAP

530 K2CA2CA00019 AC CABLE PP

531 K2CQ2CA00006 AC CORD W/PLUG GC,EG

532 K2CT3CA00004 AC CORD W/PLUG GC,EB

533 K2CJ2DA00008 AC CORD W/PLUG GN

534 K2CA2CA00020 AC CORD W/PLUG GK

534 K2CA2CA00027 AC CORD W/PLUG GT

Part No. Part Name & Description Remarks

EB,EG

29

Loading...

Loading...