Page 1

INSTALLATION INSTRUCTIONS

Communication Adaptor

Model No. CZ-CFUNC1U

For your safety

Read the following instructions carefully, and carry out secure installation and electrical work.

■

The precautions given in this manual consist of specifi c “Warnings” and “Cautions”. They provide important safety-related information. Be

■

sure to strictly observe all safety procedures. The labels and their meanings are as described below.

Warning

Caution

* After installation is completed, perform a test run to check for operating trouble. Explain operating procedures to the customer following the

central control device Operating Instructions and then request the customer to store this Instructions for the Electrical Installer together with

the central control device Operating Instructions.

Be sure to arrange installation by the dealer where the system was purchased or by a professional installer. Electric shock or fi re may result

●

if an inexperienced person performs any installation or wiring procedures incorrectly.

Be sure that this unit is securely installed in accordance with this Instructions for the Electrical Installer. Electric shock or fi re may result if

●

any installation or wiring procedures are incorrectly performed.

Only a qualifi ed electrician should attempt to connect this system, in accordance with the instructions in this manual. Insuffi cient electrical

●

circuit capacity or incorrect installation may cause electric shock and fi re.

Use the specifi ed cables for the electrical connections, and connect the cables securely. Run and fasten the cables securely so that

●

external forces or pressure placed on the cables will not be transmitted to the connection terminals. Overheating or fi re may result if

connections or attachments are not secure.

Depending on the installation conditions and location, an earth leakage breaker may be required. If an earth-leakage breaker is not

●

installed, there is a danger of electric shock or fi re.

This symbol refers to a hazard or unsafe procedure or practice that can result in severe personal injury or

death.

This symbol refers to a hazard or unsafe procedure or practice that can result in personal injury or product or

property damage.

Warning

Caution

Ground yourself to discharge static electricity before performing any wiring.

●

Note:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: To assure continued compliance, follow the attached installation instructions. Any changes or modifi cations not expressly

approved by the party responsible for compliance could void the user’s authority to operate this equipment.

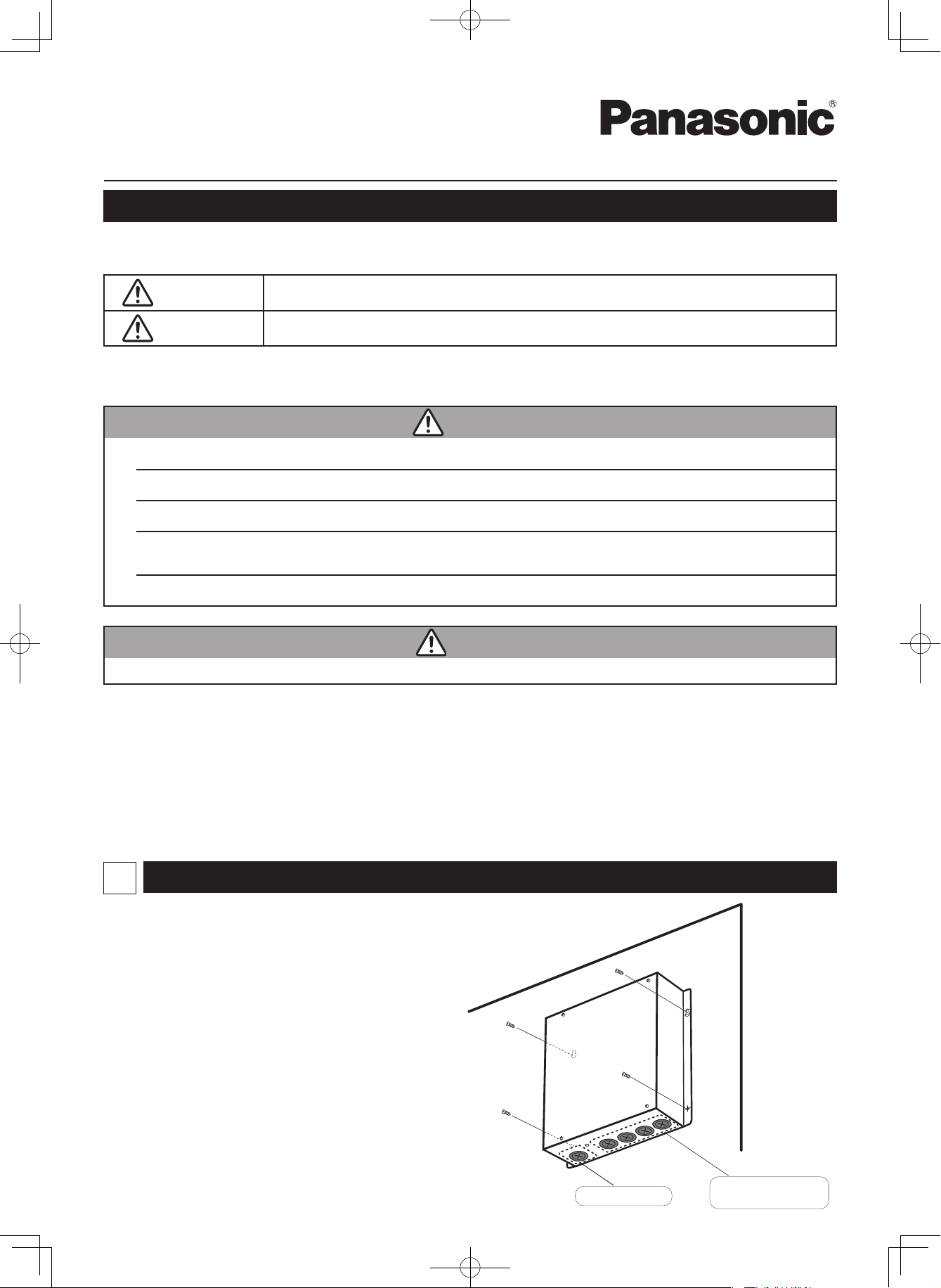

Installing

1

Note

Do not run the indoor/outdoor communication lines, input/

●

output lines, and power cables through the same conduit, or

twist those cables together, or place the cables near one

another. It can cause malfunction.

Install the main unit away from any sources of electrical

●

noise.

Avoid installing in any locations where the unit may come

●

into contact with water, or in any extremely humid locations.

Avoid installing in any location that is subject to excessive

●

vibration or physical impacts.

(1) After determining the attachment position, secure the

installation hardware as shown in the dimensions diagram. If

the included screws will not work for the installation, prepare

appropriate screws (such as metric ones) for use at the site.

(2) Attach the main unit and fasten the installation hardware as

illustrated.

(3) If the installation hardware is loose or appears like it will fall

out, remove the upper case on the unit and secure with

screws in the failsafe screw holes.

85464369525011

PanasonicCZ-CFUNC1UEng.indd1PanasonicCZ-CFUNC1UEng.indd1 2011/11/1112:03:532011/11/1112:03:53

1

Power supply line

Communication lines

Input/output lines

Page 2

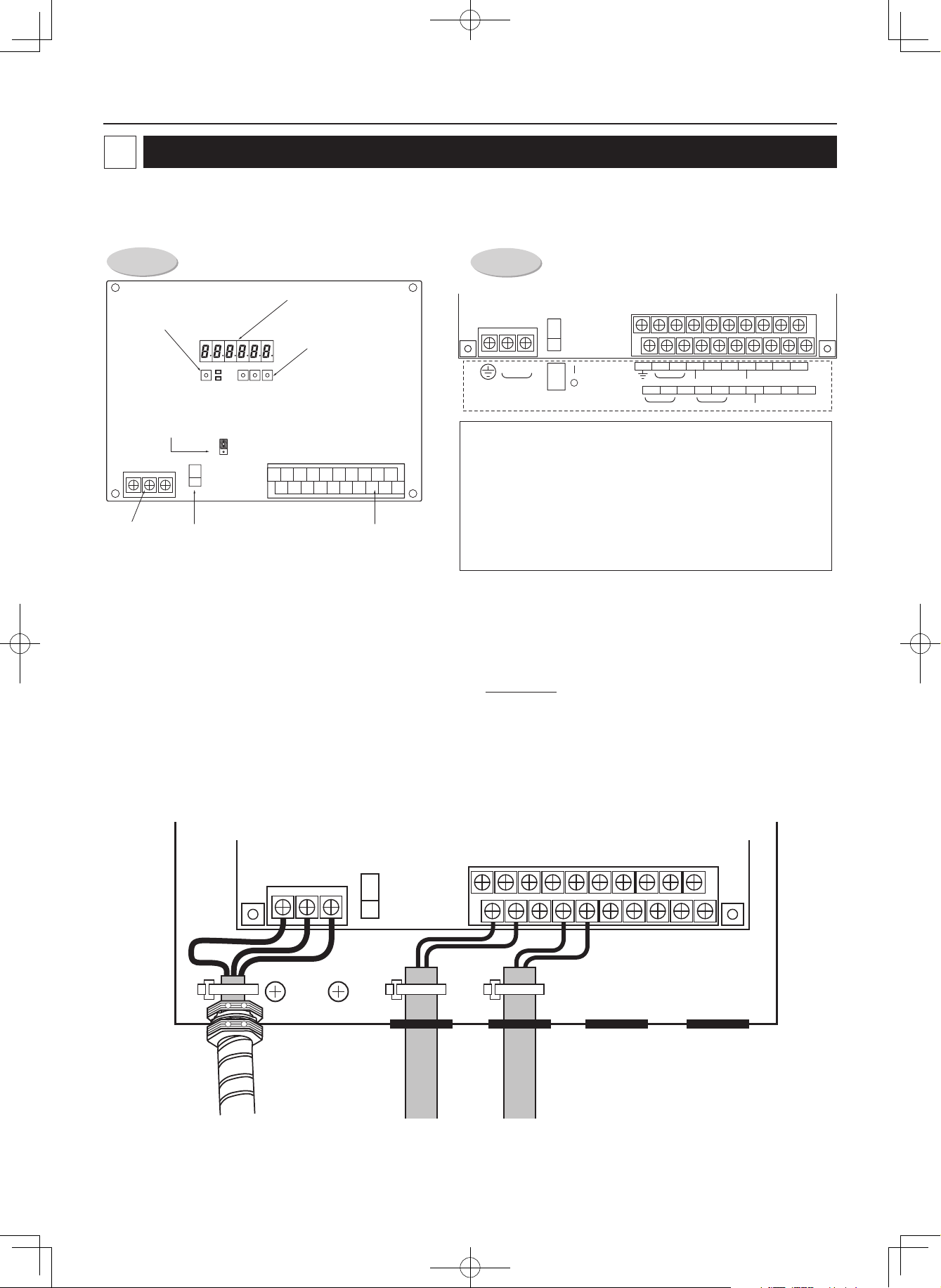

Wiring

2

Always shut off the power supply (breaker) before installing or uninstalling the Communication Adaptor.

Remove the two screws at the front of the unit and remove the upper case.

Arrangement of the terminal board and switches

Detailed board

illustration

Detailed terminal

assembly illustration

7-segment LED

Home key

Up, down and

set keys

S6 S9S8S7D1

HOME

Terminating resistance plug

for the Communication

Adaptor control wire

ADAPTER BOARD

S1

31

CN1

D2 UP

CN32

BA

DOWN

SET

N

L

100-240V

50/60Hz 1-PH

ON

OFF

POWER

ADAPT +/- : Communication Adaptor control wire (RS-485)

CN2

10

0

19

9

LINK 1/2: Inter-unit control wiring (HBS)

P1: Pulse meter inputs (gas fl ow meter and fuel fl ow meter) (*)

P2 and P3: Pulse meter input (power fl ow meter) (*)

DI1: All stop input (*)

DI2: All operation input (*)

10 11 12 13 14 15 16 17 18 19

+–

ADAPT(RS485)DO-COMMON DI-COMMON

0 1 2 3 4 5 6 7 8 9

(

LINK1

–U2

LINK1

DI3: Reserved

Power supply

terminal strip

Power switch

Signal terminal strip

(see details at right)

DO1: All alarm output (*)

DO2: All operation output (*)

(*) Input/output function when connecting to the Intelligent Controller

(1) Connecting the power supply

The unit can use AC power sources between 100 and 240 V.

Connect the power supply to terminals 2 (N) and 3 (L) on the power terminal strip CN1. (Connect the AC neutral end to N.)

Connect the ground line securely.

DO 1 DO 2

U1 U2

(

LINK2

)

)

–U2

LINK2 P-COMMON

DI 1 DI 2 DI 3

3P2P1P2U1U

(2) Connecting the communication line

For the Communication Adaptor control wires, use only two-conductor shielded wire with a cross-section between AWG#20 and AWG#14

●

(MVVS or CPEVS).

Be sure to ground only one end of the shielding.

●

The overall length of each line should be 3280 ft. or less.

●

Do not run the communication line through the same conduit as the power supply, use the same cable as the power supply, or run close to

●

the power supply line (maintain at least 11-13/16 in. separation).

Do not run the LINK1 and LINK2 signal lines through the same conduit, use the same cable for wiring, or run them close together.

●

Use different communication and power cables so they can be differentiated visually.

●

Conduit(Power cables) Inter-unit control wiring

2

PanasonicCZ-CFUNC1UEng.indd2PanasonicCZ-CFUNC1UEng.indd2 2011/11/1112:03:532011/11/1112:03:53

Page 3

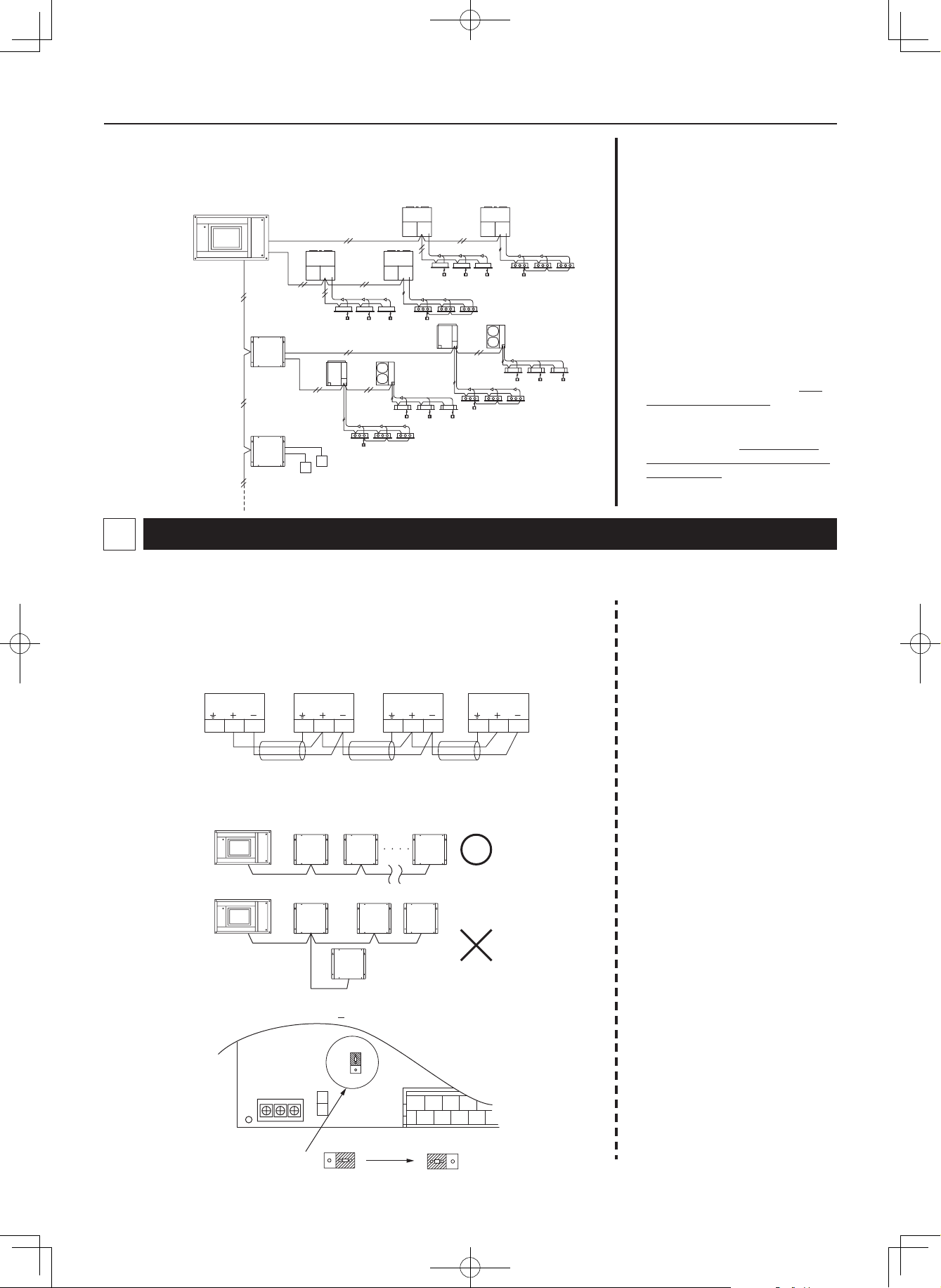

Basic wiring diagram

Wire up the Communication Adaptor control wire and Inter-unit control wiring as shown in the

fi gure below.

Intelligent controller

Inter-unit control wiring

(Example using an Intelligent Controller)

Outdoor unit

Wiring procedure

Inter-unit control wiring

●

Connect terminals 0 and 1 (LINK1)

on the Communication Adaptor signal

terminal strip CN2 to the inter-unit

control wiring terminals of the indoor

or outdoor unit. There is no polarity.

If connecting two inter-unit control

wiring systems, connect terminals 3

Communication

Adaptor control

wire

Indoor unit

Outdoor unit

Inter-unit control wiring

Outdoor unit

and 4 (LINK2) on CN2 in the same

manner.

Communication Adaptor control wire

●

Connect terminals 11 and 12 (ADAPT

+ and -) on the Communication

Adaptor signal line terminal strip

CN2 with the same terminals on the

other Communication Adaptor. The

Communication

Adaptor

W

G: Gas fl ow meter

G

Communication

Adaptor

Precautions for the Communication Adaptor control wire

3

W: Power fl ow meter

Indoor unit

terminals have polarity. Connect so

the positive and negative elements

are correct.

When connecting, be sure to use

crossover wiring, not a branching

confi guration.

(Some items are duplicated in other sections.)

(1) The overall length should be 3280 ft. or less.

(2) The communication wire has polarity. Connect so the positive and negative elements are

correct.

(3) Use only shielded wire. Be sure to ground only one end of the shielding.

Communication

Adaptor 1

ADAPT

(RS485)

10 11 12

(4) Be sure to use crossover wiring, not a branching confi guration.

* Connect the Intelligent Controller to the end of the crossover confi guration.

Intelligent

Controller

Intelligent

Controller

(5) Change the terminating resistance plug CN32 to the “B” side (with terminal resistance) on the

board for the Communication Adaptors (2 of them) at both ends of the confi guration.

Communication

Adaptor 2

ADAPT

(RS485)

10 11 12

Communication

Adaptor

Communication

Adaptor

S1

CN1

Communication

Adaptor 3

A

CN32

B

ADAPT

(RS485)

10 11 12

101112

Communication

Adaptor 4

0

123

ADAPT

(RS485)

10 11 12

13

(6) Do not hook more than 16 units up

to the Communication Adaptor. The

system you are using (such as an

Intelligent Controller) may have

further restrictions. Consult the

Installation Instructions for your

system.

* The Intelligent Controller has a

maximum restriction of seven

units.

(7) Make sure that high voltage AC

lines are not connected to the

Communication Adaptor control

wire or the inter-unit control wiring

terminals.

* If high voltage AC is accidentally

applied to the inter-unit control

wiring terminals, a fuse will blow to

protect the controller board.

If this happens, disconnect the AC

line, and connect the U2 terminal

wire of the inter-unit control wiring

to the spare terminal. (Do not

change the U1 terminal wire.)

Spare terminals are located right

next to U2.

Change terminal number 1 LINK1U2

to terminal number 2 (LINK1-

→

U2)

Change terminal number 4 LINK2U2

to terminal number 5 (LINK2-

→

U2)

Terminating resistance

plug for Communication

Adaptor control wire

BA BA

Terminating resistance

“off” (factory setting)

Terminating

resistance “on”

3

PanasonicCZ-CFUNC1UEng.indd3PanasonicCZ-CFUNC1UEng.indd3 2011/11/1112:03:532011/11/1112:03:53

Page 4

Setting the Communication Adaptor board

4

The switches on the board control the adaptor numbers, turn the inter-unit control wiring connection on and off, and control other settings.

3D8DD4D5D6D7

7-segment LED

9S6SS8S7D1

DOWN

SET

Set key

Down key

Up key

Home key

HOME

Monitor LED

D1: red

D2: green

D2 UP

(1) Switch operation overview

Turn on the Power switch(S1) on the board.

Item selection

1

Use the

Changing the settings

2

UP

and

Use the UP and

Hold down the

lost.)

keys to fi nd the desired item, then press the

DOWN

keys to change the setting, then press the

DOWN

key for at least two seconds to reset to the default setting (Any settings in progress will be

HOME

key to select.

SET

key to confi rm.

SET

(2) Adaptor number setting procedure

Hold down the

1

Press the

2

This automatically switches to the below display after 2 more seconds. (Operation is not necessary.)

Press the

3

key for at least two seconds so the initial display shows as follows:

HOME

(no.00)

After 2 seconds

(AdP.dt)

key fi ve times so the following display appears:

UP

(no.05)

(FirSt)

key so the below display appears. (Only the green monitor LED is on.)

SET

(1.Ano.00) (Factory setting)

Hold down the

4

key for at least 1 second so the “00” part blinks, indicating that the setting can be changed. (The green and red monitor

SET

LEDs are both on.)

Use the

For example, to set number 3, press the

Press the

5

and

UP

keys to set the adaptor number.

DOWN

UP

key three times. The following will display:

(1.Ano.03)

key for at least 1 second to confi rm. (Only the green monitor LED is on.)

SET

4

PanasonicCZ-CFUNC1UEng.indd4PanasonicCZ-CFUNC1UEng.indd4 2011/11/1112:03:542011/11/1112:03:54

Page 5

(3) Setting the inter-unit control wiring connection on/off

Repeat steps 1 to 3 in section (2) “Adaptor number setting procedure” above. The following will display:

1

Press the

2

Hold down the

3

key once so the following display appears:

UP

key for at least 1 second so the “0” part blinks, indicating that the setting can be changed. (The green and red monitor

SET

(1.Ano.03) (When the adaptor number is 3)

(2.Adyu.0) (Factory setting)

LEDs are both on.)

Use the

UP

and

keys to turn the iinter-unit control wiring connection on or off as shown in the table below.

DOWN

Setting value Inter-unit control wiring connection

0 LINK1: On, LINK2: On (factory setting)

1 LINK1: On, LINK2: Off

2 LINK1: Off, LINK2: On

3 LINK1: Off, LINK2: Off

For example, to connect the inter-unit control wiring only to LINK1, press the

Press the

4

key for at least 1 second to confi rm. (Only the green monitor LED is on.)

SET

(2.AdYu.1)

key once. The following display will result:

UP

(4) Other settings

With the display status showing as in number 3 in section (2) “Adaptor number setting procedure”, press the

setting items shown in the table below. Set as needed.

The setting procedure is the same as above.

(Press the

key for at least 1 second, press the UP and

SET

keys to change, then press the

DOWN

key at least one second to confi rm.)

SET

UP

and

DOWN

keys to select the

Note

When confi guring, do not set the same adaptor number more than once.

1

* Use numbers between 1 and 7 for connecting to an Intelligent Controller.

Turn the inter-unit control wiring connection on/off as appropriate.

2

(Set to “Off” for LINKs with no connection.)

For connecting the inter-unit control wiring to only one link, use the

3

“LINK1” side.

5

PanasonicCZ-CFUNC1UEng.indd5PanasonicCZ-CFUNC1UEng.indd5 2011/11/1112:03:542011/11/1112:03:54

Page 6

Table 1 Communication Adaptor setting items

Display Setting item ( grayed in areas indicate factory setting)

[1] Adaptor number setting

xx = 00 to 15: adaptor number

Sets the Communication Adaptor number.

(1.Ano.xx)

(2.AdYu.x)

(3.Cont.x)

(4.CAn1.x)

DOWN

UP

(5.CAn2.x)

Set 1 to 7 for the Intelligent Controller, making sure the same number is not used twice.

When actually communicating from a master system, the link system address LINK1 is 2n and

LINK2 is 2n + 1, where n is the Communication Adaptor number.

Thus, when the adaptor number is 2, the LINK1 address is 4 and the LINK2 address is 5.

[2] Inter-unit control wiring connection settings

x = 0: LINK1 on, LINK2 on

x = 1: LINK1 on, LINK2 off

x = 2: LINK1 off, LINK2 on

x = 3: LINK1 off, LINK2 off

Set so any LINK (inter-unit control wiring) connected to the air conditioner is “on”, and any LINK not

connected is “off”.

* For solo installation (pulse meter dedicated), use x = 3: LINK1 and 2 both set to off.

[3] Base unit settings

Always use 0 (the initial value).

[4] Settings for the number of Communication Adaptor units in one link, part 1

x = 0 to 7

x = 0: First Communication Adaptor in the LINK1 link

x = 1: Second Communication Adaptor in the LINK1 link

x = 7: Eighth Communication Adaptor in the LINK1 link

[5] Settings for the number of Communication Adaptor units in one link, part 2

x = 0 to 7

x = 0: First Communication Adaptor in the LINK2 link

x = 1: Second Communication Adaptor in the LINK2 link

(6.PUL.xx)

(7.LoCA.x)

(8.SCAn.x)

x = 7: Eighth Communication Adaptor in the LINK2 link

Set the Communication Adaptor unit number for each LINK system when connecting multiple

Communication Adaptors to one inter-unit control wiring.

[6] Minimum pulse input detection time setting

x = 03: 30 msec

x = 10: 100 msec

If connecting a pulse meter with a pulse width between 30 and 100 msec, set to 30 msec.

[7] Interface Adaptor connection settings

x = 0: LINK 1 on, LINK2 on

x = 1: LINK 1 off, LINK2 on

x = 2: LINK 1 on, LINK2 off

x = 3: LINK 1 off, LINK2 off

Set whether there is a Interface Adaptor (for turning off and on) for each LINK system.

If the setting is “off”, startup will be faster as no Interface Adaptor detection is run.

[8] Initial communication setting

Always use 0 (the initial value).

6

PanasonicCZ-CFUNC1UEng.indd6PanasonicCZ-CFUNC1UEng.indd6 2011/11/1112:03:552011/11/1112:03:55

Page 7

Connecting to external equipment

5

(1) External all input (No-voltage a-contact

static)

Equipment

DI–COMMON

All stop input (∗)

All operation input (∗)

(Reserved)

DI 1

DI 2

DI 3

(2) External all output (No-voltage a-contact

static)

(Common output)

(∗) All alarm output

(∗) All operation output

Keep the signal input line lengths to 66 ft. or less. For distances greater than this, install a standalone Communication Adaptor or use a

●

relay.

For use in areas that may be susceptible to electrical noise, use a two-conductor shielded cable (with one line grounded), with a

●

crosssection at least AWG#20.

Do not apply external voltages to the input terminals.

●

About 10 mA of 5 V DC voltage is applied to the contact point for input terminal detection.

●

The output terminal allowable contact voltage and current are 30 V DC and 0.5 A.

●

DO–COMMON

DO 1

DO 2

Equipment

Digital input

(3) Pulse meter input (No-voltage a-contact

pulse)

P–COMMON

P1

P2

P3

Minimum pulse width: 100 msec

●

Minimum pulse interval: 1 sec

●

(∗) Input/output function when connecting to the Intelligent

Controller

Gas fl ow meter (∗)

(fuel fl ow meter)

Power fl ow meter 1 (∗)

Power fl ow meter 2 (∗)

Outer dimensions Specifi cations

6

10-5/64

5-ø7/8

11-27/64

10-5/8

7-3/32 1-1/21-1/23-7/64

(in.)

7

Rated voltage 100 - 240 V 1-PH

Rated frequency 50/60 Hz

Power consumption 5.6 W max

Operating temperature 14 to 122°F

Operating humidity 20 to 80% (no condensation)

7

PanasonicCZ-CFUNC1UEng.indd7PanasonicCZ-CFUNC1UEng.indd7 2011/11/1112:03:552011/11/1112:03:55

Page 8

Appendix A. Connecting to an Intelligent Controller

Before making the initial settings for the Communication Adaptor, check to ensure the below

operations are complete.

(1) Is the air conditioner test operation complete?

(2) Is the wiring for the air conditioner and the Communication Adaptor complete?

To set, follow steps 1 to 5 below in sequence.

This is a required setting.

●

Set the address for the Communication Adaptor control wire.

●

(1) Adaptor number setting

(2) Inter-unit control wiring

connection setting

For the Intelligent Controller internal board, the address is 0. Set a value between 1

and 7 for the external adaptor, ensuring no value is used twice.

Refer to the number (2) “Adaptor number setting procedure” in section

the Communication Adaptor board”.

* Refer to Table 1 [1].

This setting is required for two or more Communication Adaptors.

●

Two links can be connected to a Communication Adaptor.

●

For links without an air conditioner or other such connection, set the LINK to “off”.

The Intelligent Controller can be connected to only four links that are set to be active.

●

Refer to the number (3) “Setting the inter-unit control wiring connection on/off” in

4

section

* Refer to Table 1 [2].

“Setting the Communication Adaptor board”.

4

“Setting

(3) Number of Communication

Adaptor units in one link

setting

(4) Minimum pulse input

detection time setting

(5) Interface Adaptor

connection setting

This setting is required only for using an Intelligent Controller in conjunction

●

with a AMY Software.

When adding another Communication Adaptor to the inter-unit control wiring,

●

the adaptor address for the added unit needs to be changed.

* Refer to Table 1 [4] and [5].

This setting is not required if pulse input (P1, P2, P3) is not used.

●

Use a pulse meter whose minimum pulse width is normally at least 100 msec.

●

If and only if a pulse meter 30 msec or higher must be used, use this setting.

* Refer to Table 1 [6].

By not using a Interface Adaptor, the confi guration confi rmation time can be

●

shortened.

Not using this setting will not affect operation of the device.

●

* Refer to Table 1 [7].

Complete!

Printed in Japan

8

PanasonicCZ-CFUNC1UEng.indd8PanasonicCZ-CFUNC1UEng.indd8 2011/11/1112:03:552011/11/1112:03:55

Loading...

Loading...