Page 1

Order No: PHAAM1111087C1

Indoor Unit Outdoor Unit

CS-E9NKUAW

CS-E12NKUAW

CU-E9NKUA

CU-E12NKUA

Please file and use this manual together with the service manual for Model No. CU-2E18NBU, Order No. PHAAM1111120A1.

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

WARNING

TABLE OF CONTENTS

1. Safety Precautions.............................................3

2. Specification .......................................................5

3. Features ..............................................................8

4. Location of Controls and Components ...........9

4.1 Indoor Unit....................................................9

4.2 Outdoor Unit.................................................9

4.3 Remote Control ............................................9

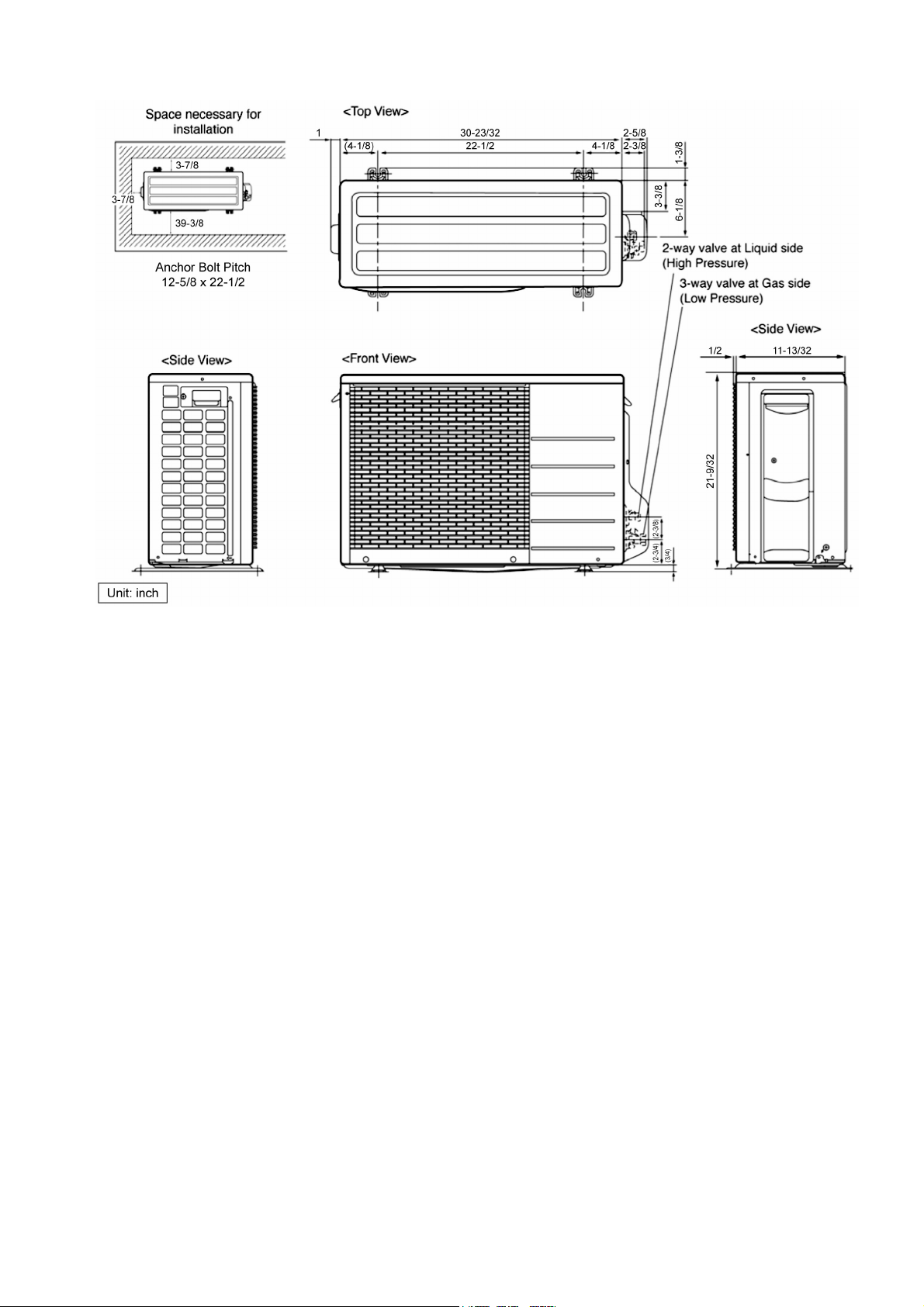

5. Dimensions.......................................................10

5.1 Indoor Unit..................................................10

5.2 Outdoor Unit...............................................11

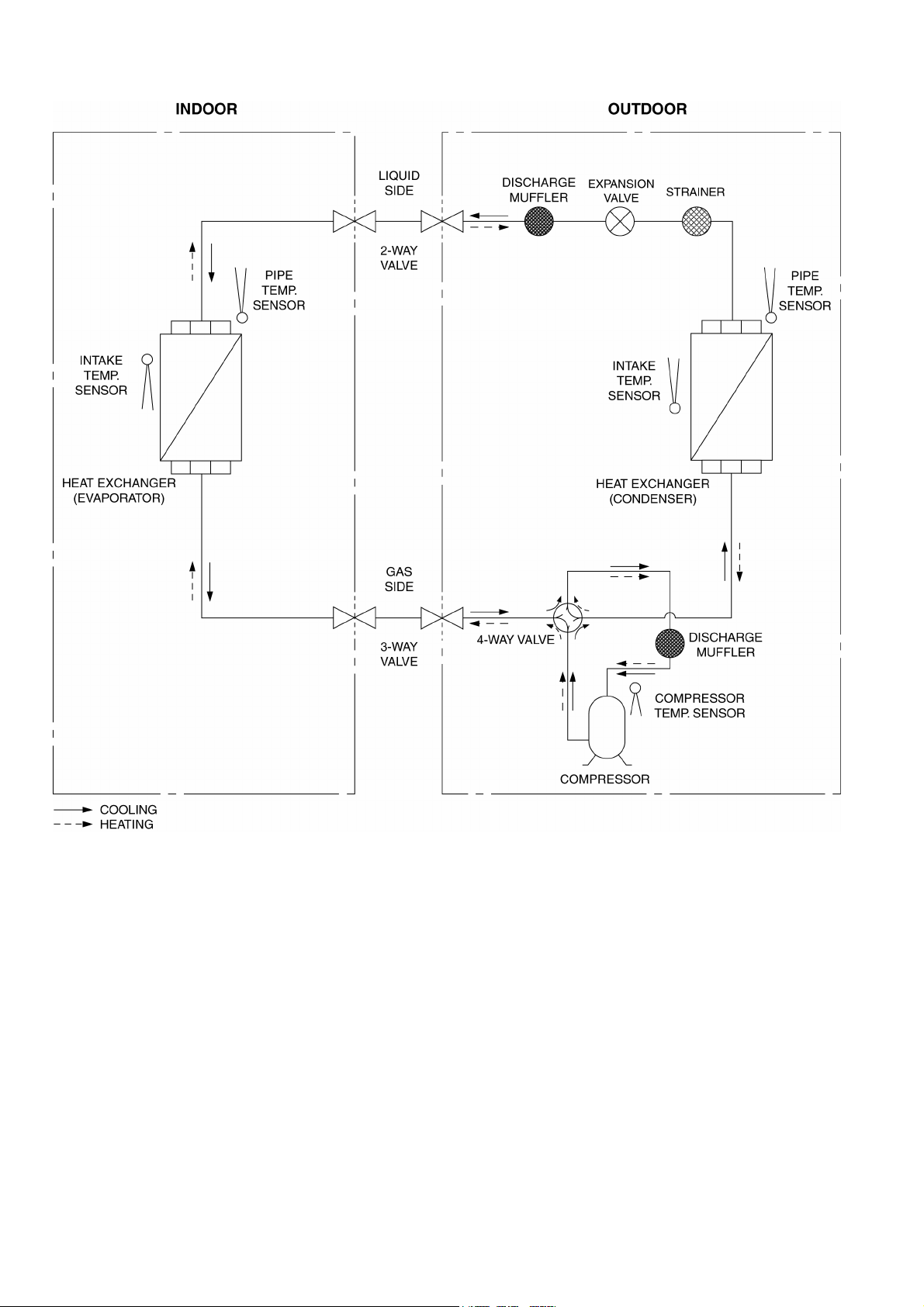

6. Refrigeration Cycle Diagram........................... 12

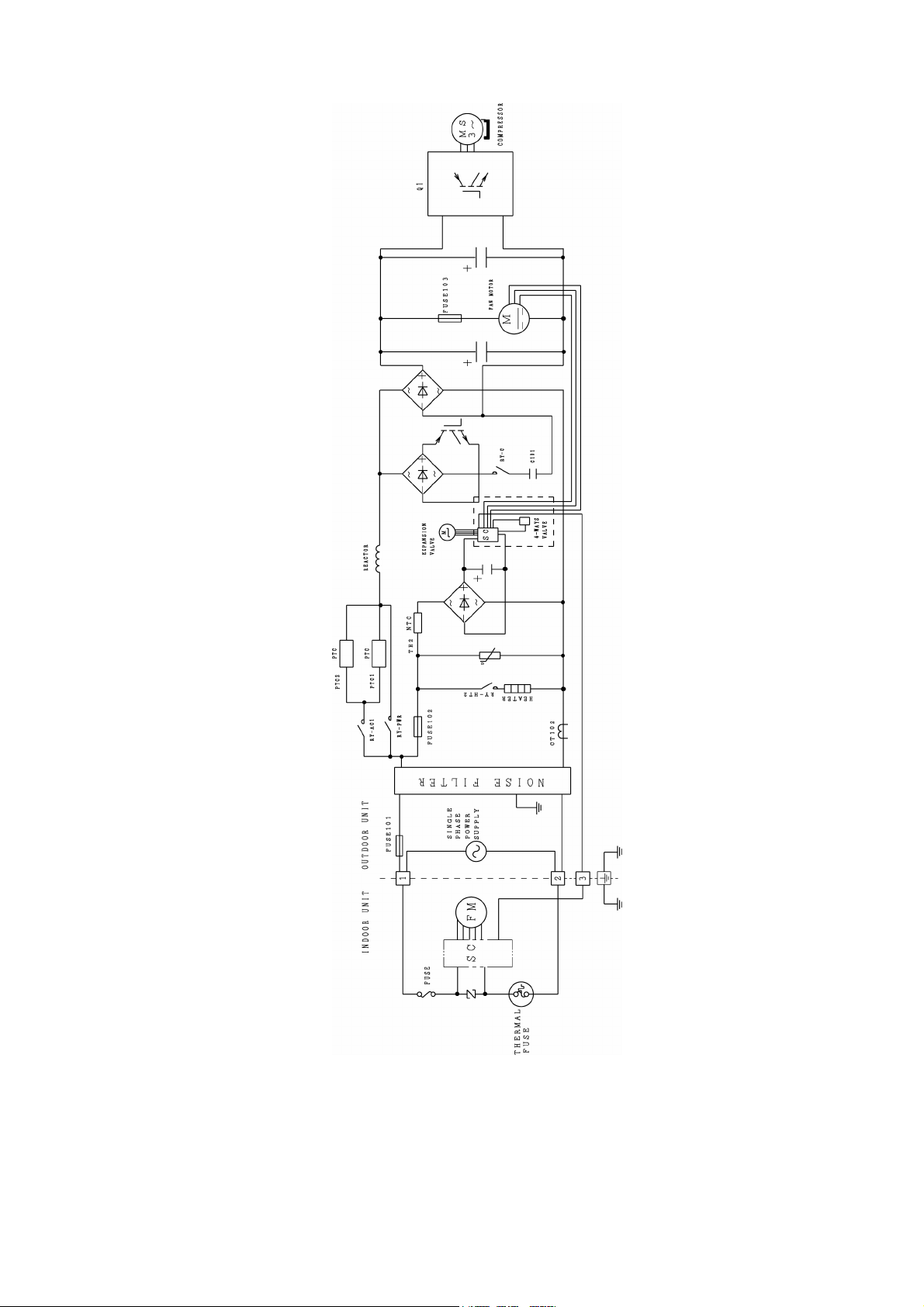

7. Block Diagram ..................................................13

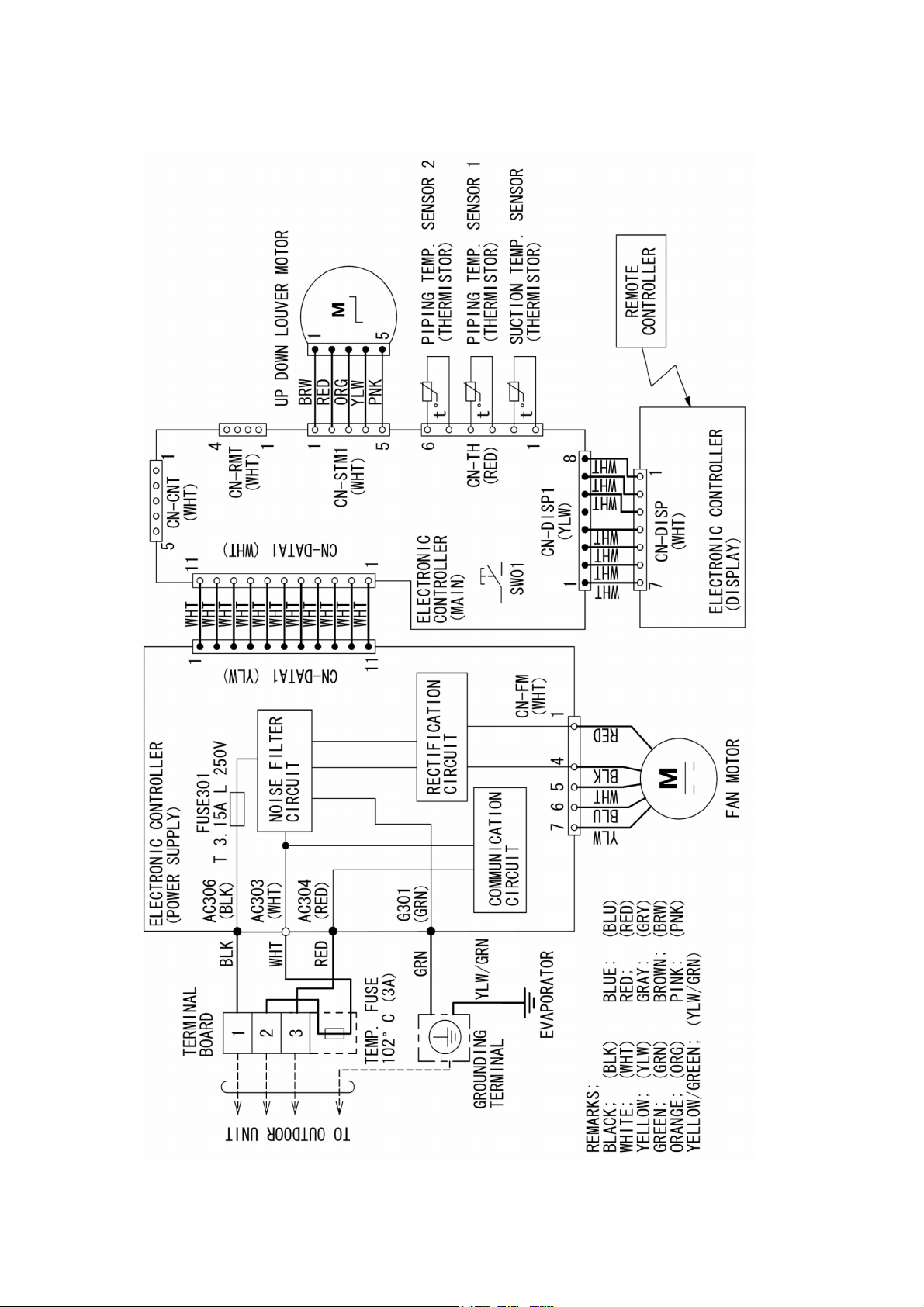

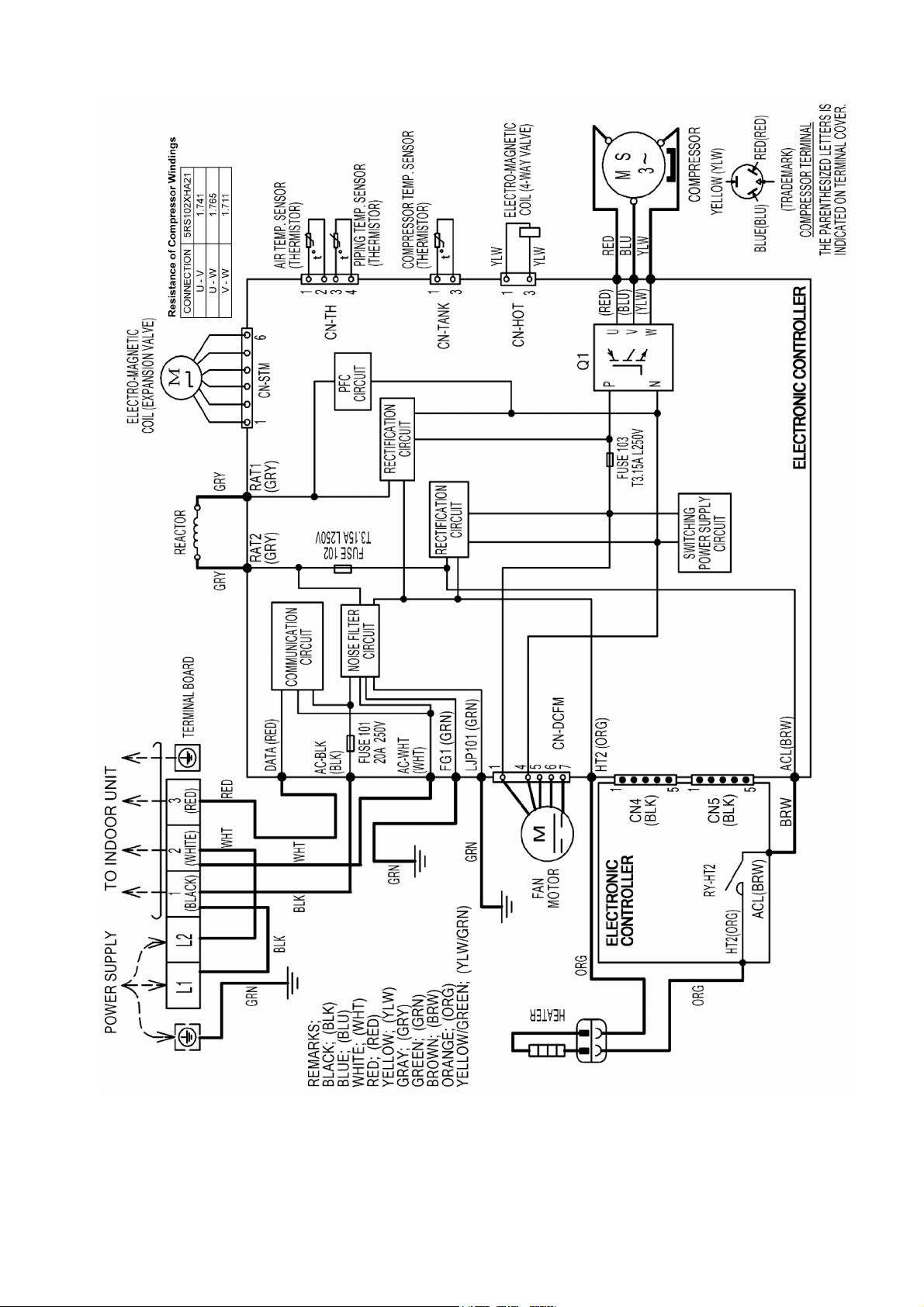

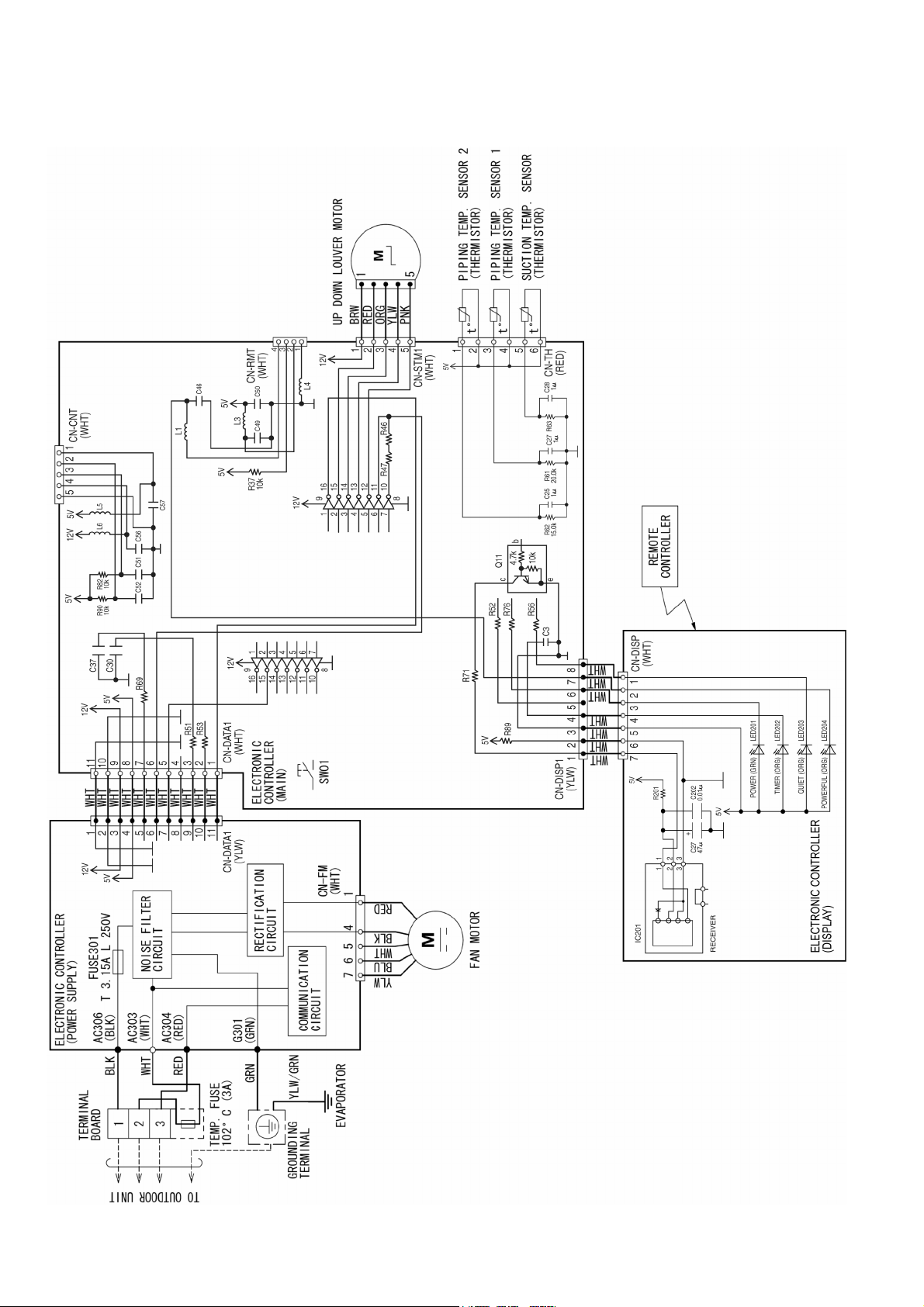

8. Wiring Connection Diagram............................14

8.1 Indoor Unit..................................................14

8.2 Outdoor Unit ...............................................15

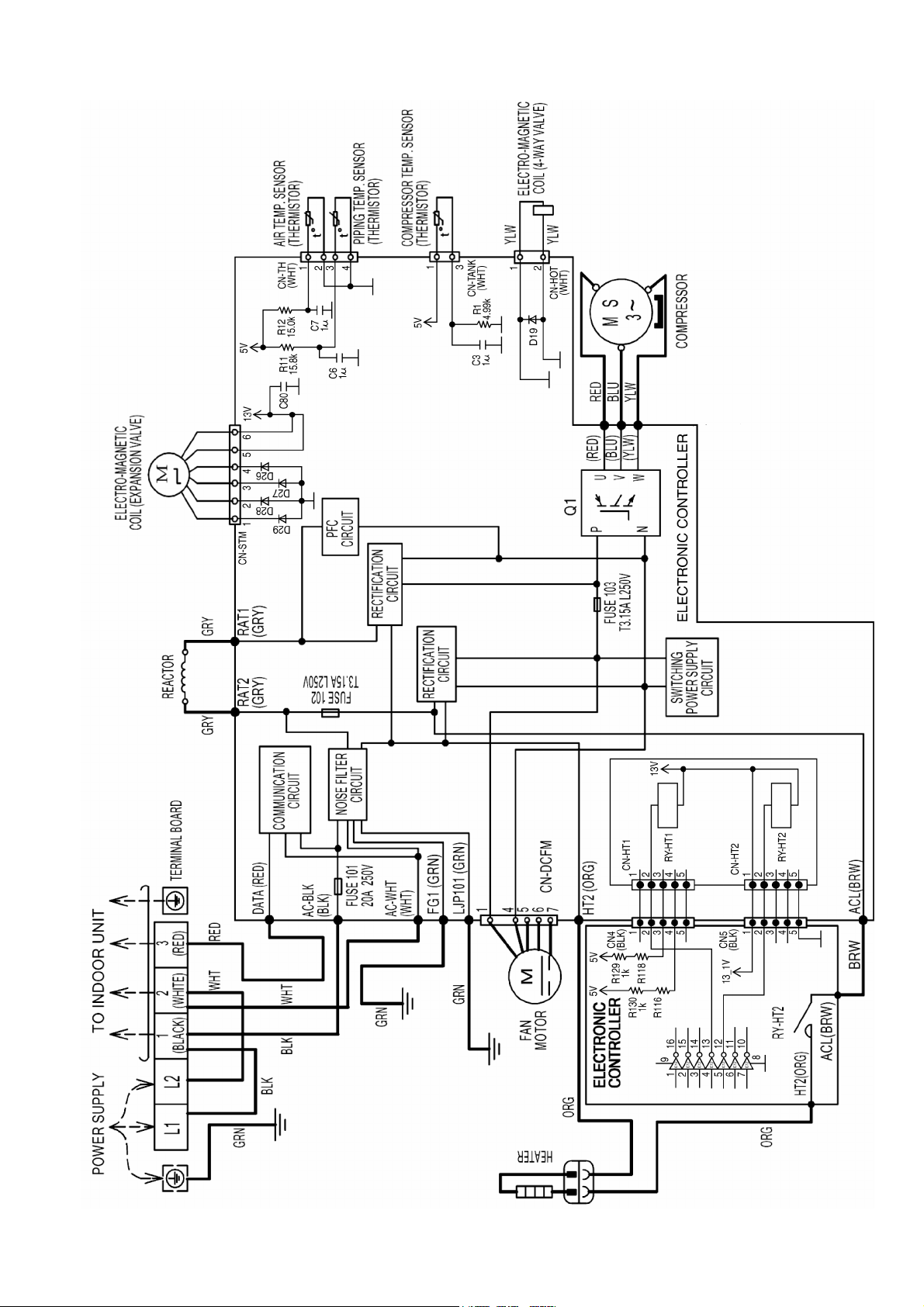

9. Electronic Circuit Diagram ..............................16

9.1 Indoor Unit..................................................16

9.2 Outdoor Unit ...............................................17

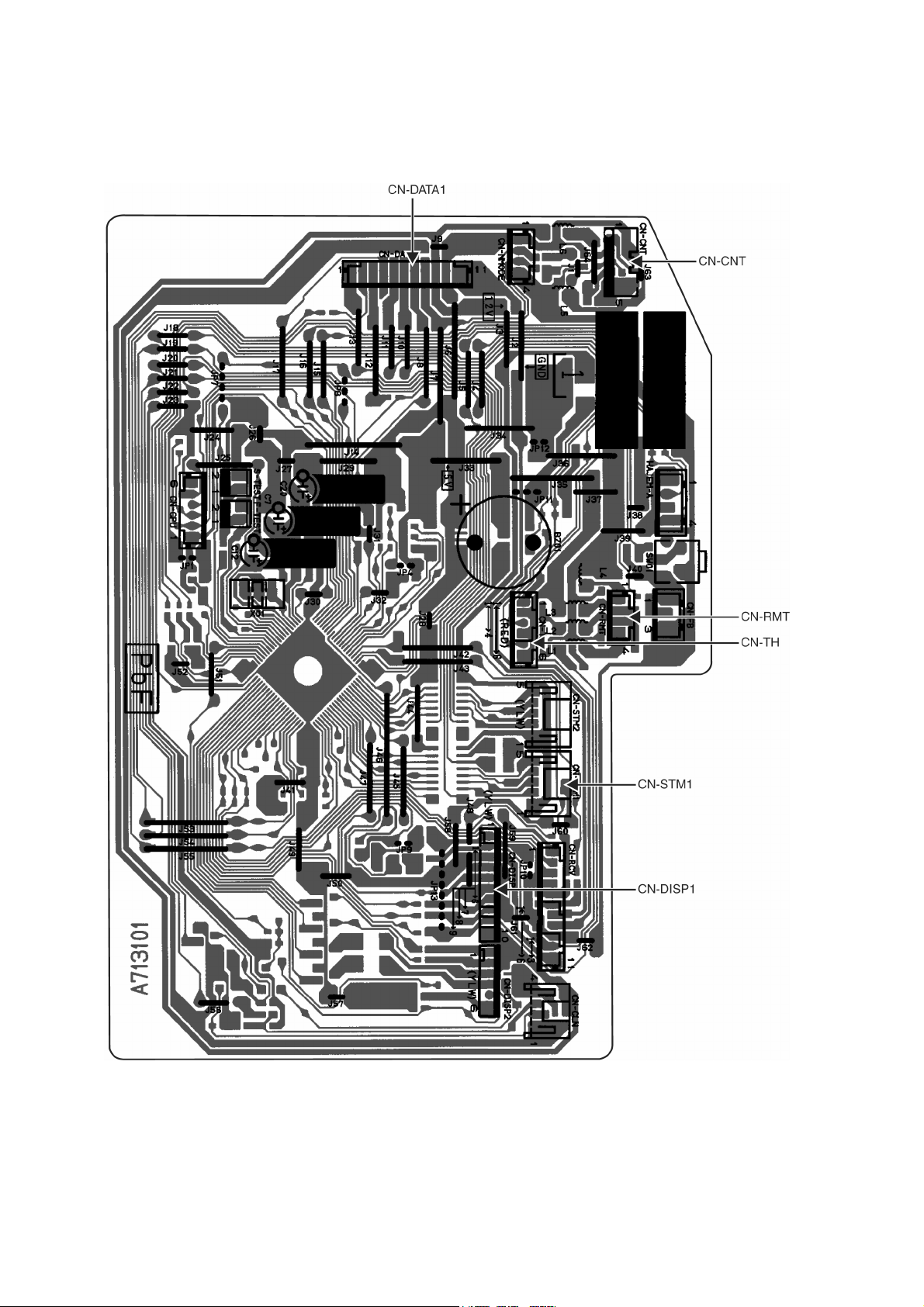

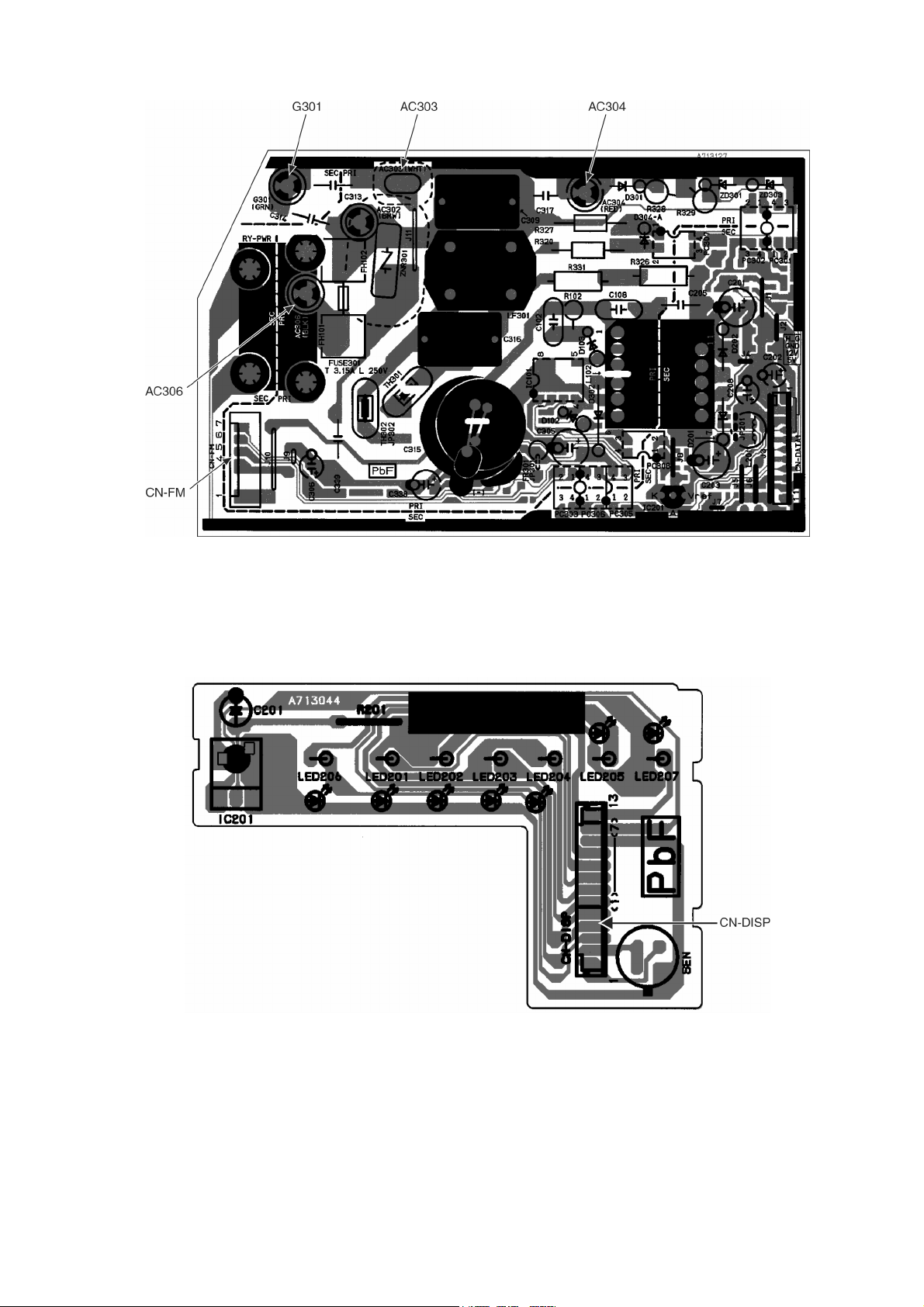

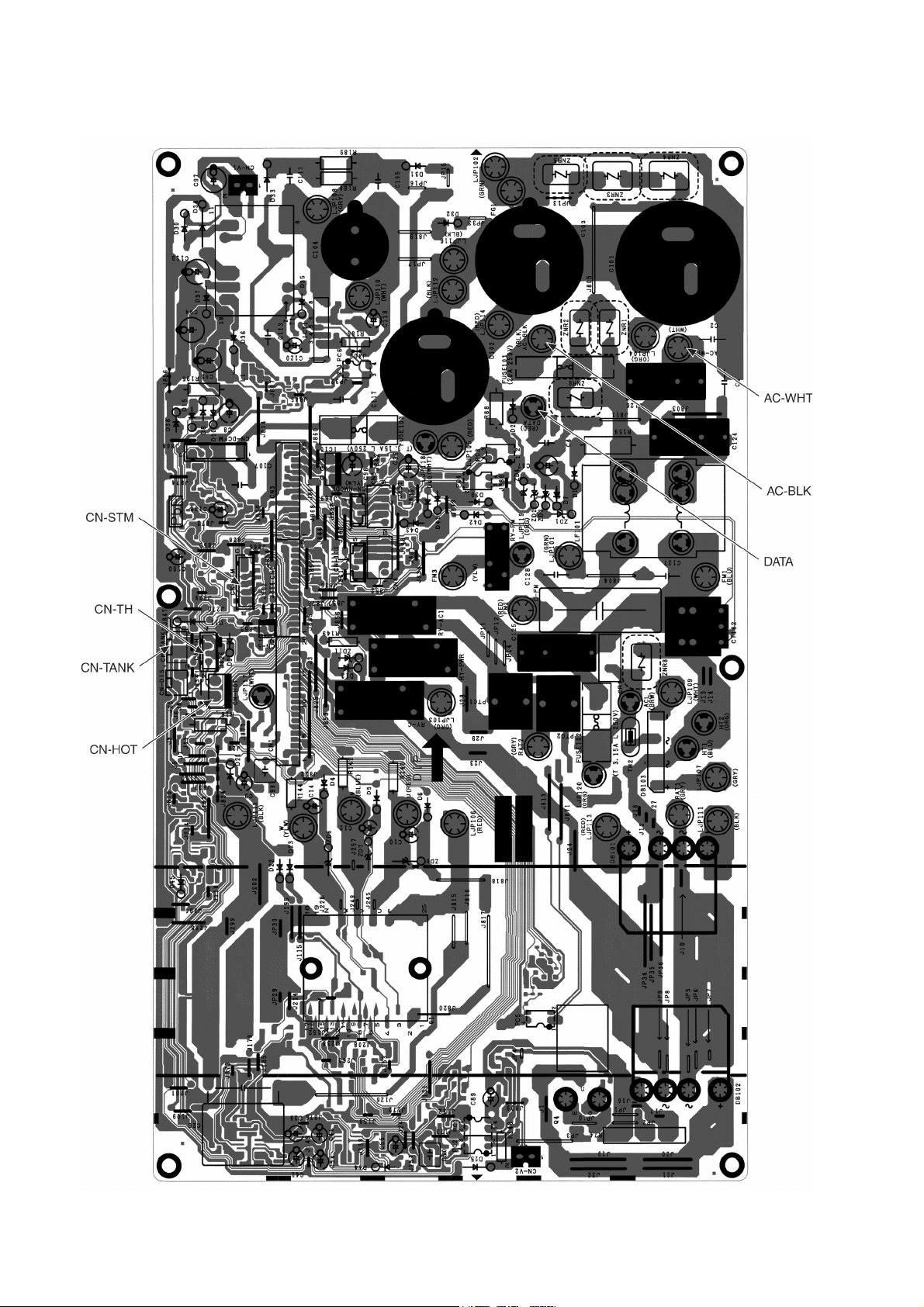

10. Printed Circuit Board .......................................18

10.1 Indoor Unit..................................................18

10.2 Outdoor Unit ...............................................20

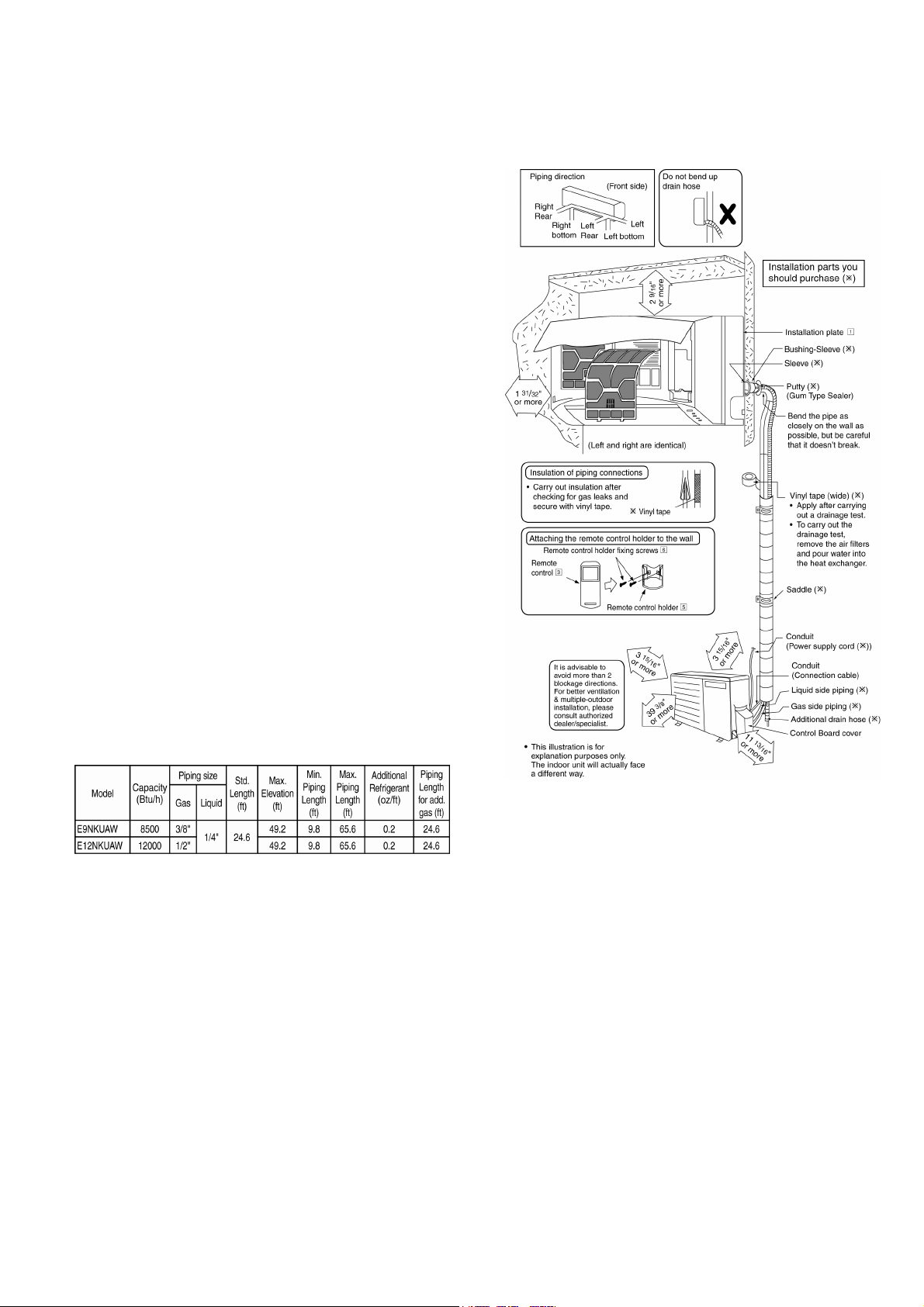

11. Installation Instruction.....................................21

11.1 Select the Best Location ............................21

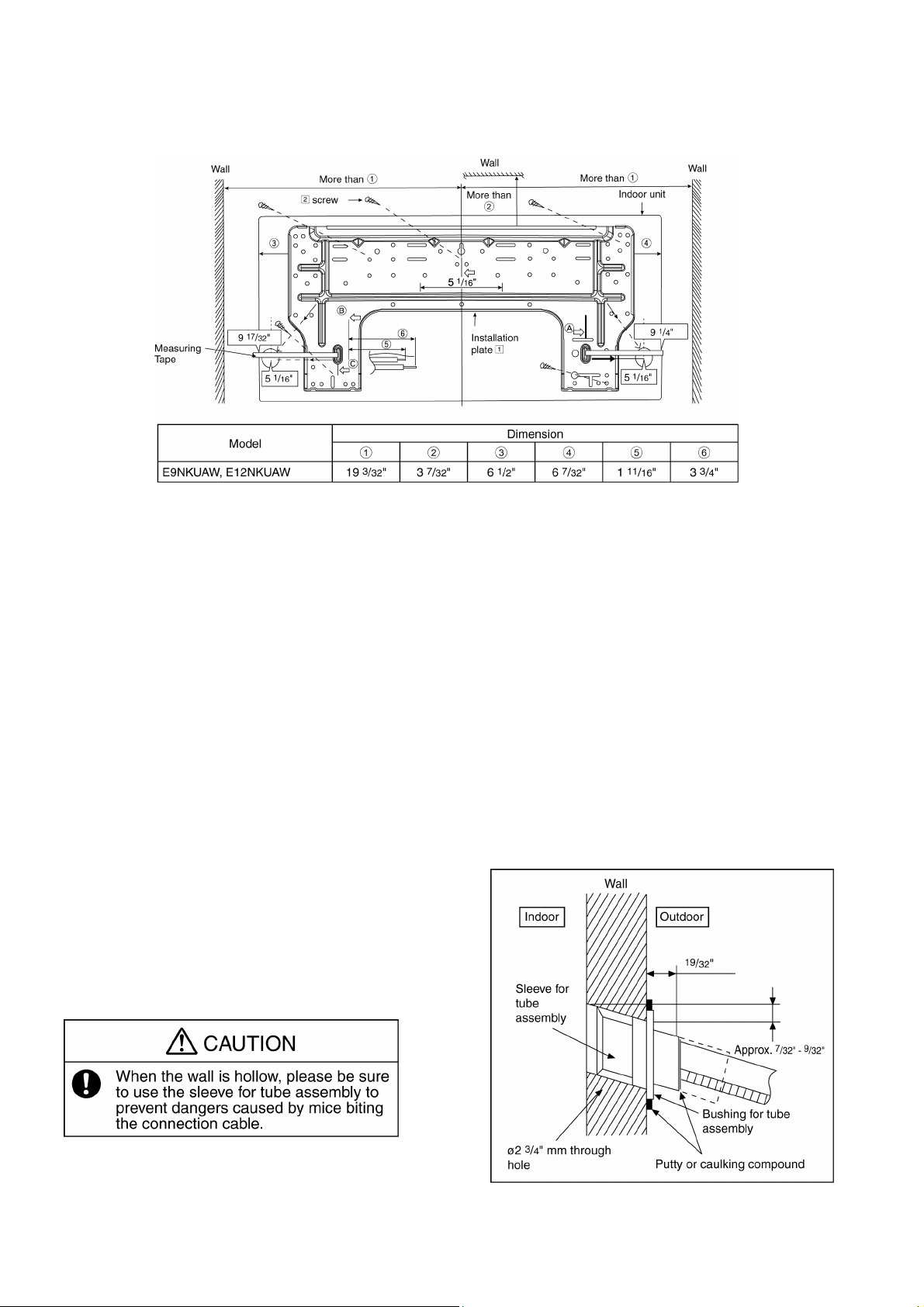

11.2 Indoor Unit..................................................22

11.3 Outdoor Unit ...............................................26

12. Operation Control.............................................29

12.1 Basic Function............................................29

12.2 Indoor Fan Motor Operation.......................30

© Panasonic HA Air-Conditioning (M) Sdn. Bhd. 2011.

Unauthorized copying and distribution is a violation of law.

Page 2

12.3

Outdoor Fan Motor Operation ....................31

12.4 Airflow Direction..........................................31

12.5 Quiet Operation (Cooling Mode/Cooling Area

of Dry Mode)...............................................32

12.6 Quiet Operation (Heating) ..........................32

12.7 Powerful Mode Operation...........................33

12.8 Timer Control..............................................33

12.9 Auto Restart Control...................................33

12.10 Indication Panel ..........................................34

13. Operation Control (For Multi Split

Connection).......................................................35

13.1 Cooling operation .......................................35

13.2 Soft Dry Operation......................................35

13.3 Heating Operation ......................................35

13.4 Automatic Operation...................................36

13.5 Indoor Fan Motor Operation .......................36

13.6 Powerful Mode Operation...........................36

13.7 Auto restart control .....................................36

13.8 Indication Panel ..........................................36

14. Protection Control ............................................37

14.1 Protection Control For All Operations.........37

14.2 Protection Control For Cooling & Soft Dry

Operation....................................................38

15. Servicing Mode .................................................41

15.1 Auto Off/On Button .....................................41

15.2 Remote Control Button...............................42

16. Troubleshooting Guide....................................43

16.1 Refrigeration Cycle System........................43

16.2 Breakdown Self Diagnosis Function...........45

16.3 Error Code Table........................................46

16.4 Self-diagnosis Method................................48

17. Disassembly and Assembly Instructions ......75

17.1 Indoor Electronic Controllers,

Cross Flow Fan and Indoor Fan Motor

Removal Procedures ..................................75

18. Technical Data ..................................................79

18.1 Operation Characteristics...........................79

19. Exploded View and Replacement Parts

List .....................................................................87

19.1 Indoor Unit ..................................................87

19.2 Outdoor Unit ...............................................89

2

Page 3

1. Safety Precautions

Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.

Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the

power plug and main circuit for the model installed.

The caution items stated here must be followed because these important contents are related to safety. The

meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction

will cause harm or damage, and the seriousness is classified by the following indications.

WARNING

CAUTION

The items to be followed are classified by the symbols:

Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for

future reference.

1. Do not modify the machine, part, material during repairing service.

This indication shows the possibility of causing death or serious injury

This indication shows the possibility of causing injury or damage to properties.

This symbol denotes item that is PROHIBITED from doing.

WARNING

2. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.

3. Do not wrench the fasten terminal. Pull it out or insert it straightly.

4. Engage authorized dealer or specialist for installation and servicing. If installation of servicing done by the user is defective, it will cause water

leakage, electrical shock or fire.

5. Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electric shock or fire.

6. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage, fire

or electrical shock.

7. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done,

the set will drop and cause injury.

8. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outlet

must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

9. This equipment is strongly recommended to be installed with Earth Leakage Circuit Breaker (ELCB) or Residual Current Device (RCD).

Otherwise, it may cause electrical shock and fire in case equipment breakdown or insulation breakdown.

10. Do not use joint cable for indoor/outdoor connection cable. Use the specified indoor/outdoor connection cable, refer to installation instruction

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connecting or fixing is not perfect, it will cause heat up or fire at the connection.

11. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will cause

heat-up or fire at the connection point of terminal, fire or electrical shock.

12. When install or relocate air conditioner, do not let any substance other than the specified refrigerant, eg. air etc. mix into refrigeration cycle

(piping). (Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.).

13. Do not install outdoor unit near handrail of veranda. When installing air-conditioner unit at veranda of high rise building, child may

climb up to outdoor unit and cross over the handrail and causing accident.

14. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and

telephone. Otherwise, it may cause electrical shock in case equipment breakdown or insulation breakdown.

15. Keep away from small children, the thin film may cling to nose and mouth and prevent breathing.

16. Do not use unspecified cord, modified cord, joint cord or extension cord for power supply cord. Do not share the single outlet with

other electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.

17. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare may

break and cause refrigerant gas leakage.

18. For R410A models, when connecting the piping, do not use any existing (R22) pipes and flares nuts. Using such same may cause

abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. In case of using existing (R22)

pipes during installation of R410A models, must carry out pump down properly to collect back the refrigerant and oil before installation

new unit.

Thickness of copper pipes used with R410A must be more than 1/64". Never use copper pipes thinner than 1/64".

It is desirable that the amount of residual oil is less than 0.0014 oz/32.8ft.

3

Page 4

19. During installation, install the refrigerant piping properly before run the compressor. (Operation of compressor without fixing refrigeration piping

and valves at opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc.).

20. During pump down operation, stop the compressor before remove the refrigeration piping. (Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury

etc.).

21. After completion of installation or service, confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

22. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire.

23. Do not insert your fingers or other objects into the unit, high speed rotating fan may cause injury.

24. Must not use other parts except original parts describe in catalog and manual.

25. Using of refrigerant other than the specified type may cause product damage, burst and injury etc.

1. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the

unit, it may cause fire.

2. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage

the furniture.

3. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare

may break and cause refrigerant gas leakage.

4. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.

CAUTION

5. Select an installation location which is easy for maintenance.

6. Pb free solder has a higher melting point than standard solder; typically the melting point is 50°F – 70°F (30°C – 40°C) higher. Please use

a high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F / 600°C).

7. Power supply connection to the air conditioner. Connect the power supply cord of the air conditioner to the mains using one of the following

methods.

Power supply point shall be the place where there is ease for access for the power disconnection in case of emergency. In some countries,

permanent connection of this room air conditioner to the power supply is prohibited.

i. Power supply connection to the receptacle using a power plug.

Use an approved 15/16A (1.0 ~ 1.75HP) or 16A (2.0HP) or 20A (2.5HP) power plug with earth pin for the connection to the socket.

ii. Power supply connection to a circuit breaker for the permanent connection.

Use an approved 16A (1.0 ~ 2.0HP) or 20A (2.5HP) circuit breaker for the permanent connection. It must be a double pole switch with a

minimum 3.0 mm contact gap.

8. Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigerant parts. Take

care of the liquid refrigerant, it may cause frostbite.

9. Installation or servicing work: It may need two people to carry out the installation or servicing work.

10. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

11. Do not sit or step on the unit, you may fall down accidentally.

12. Do not touch the sharp aluminium fins or edges of metal parts.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury.

4

Page 5

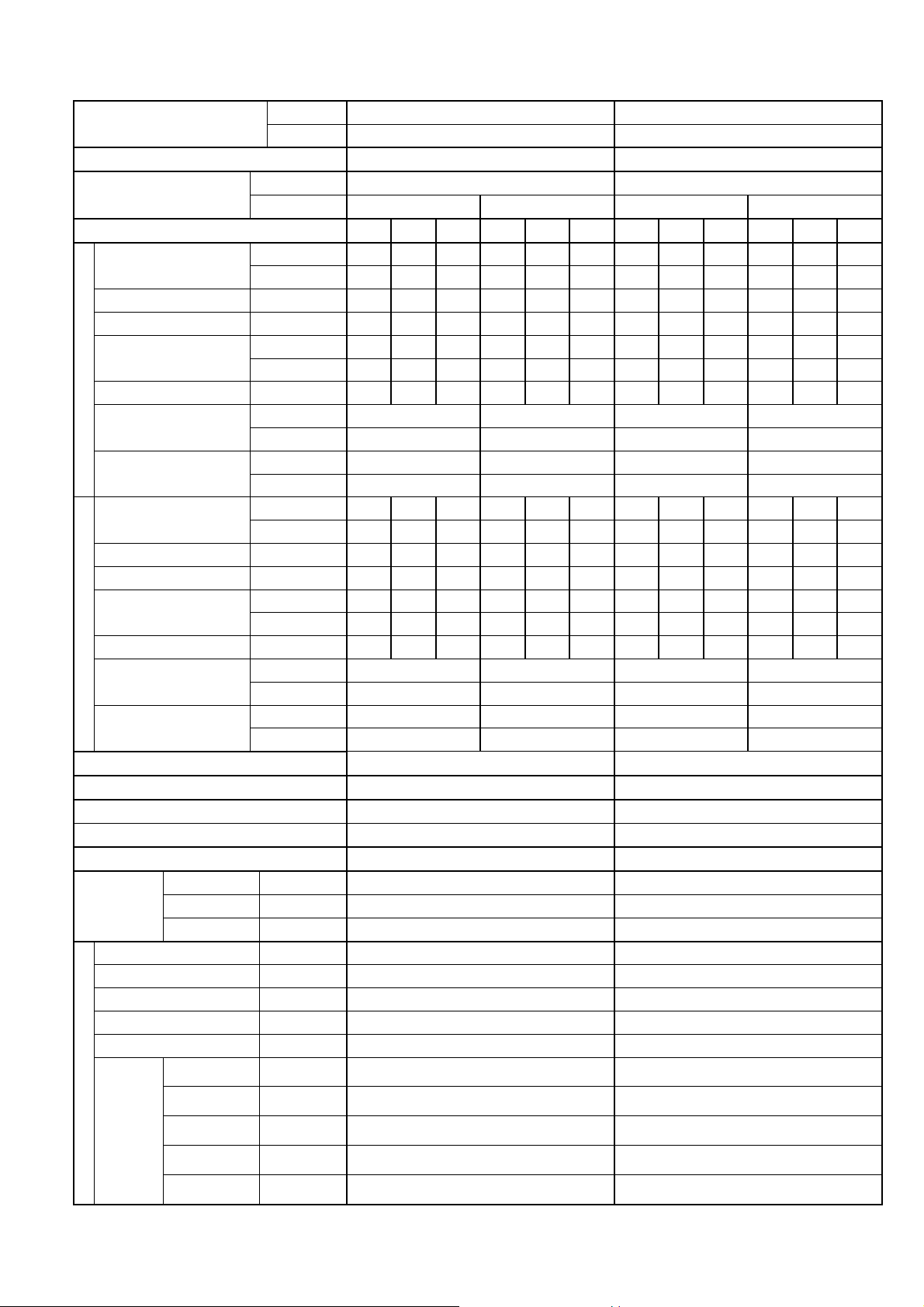

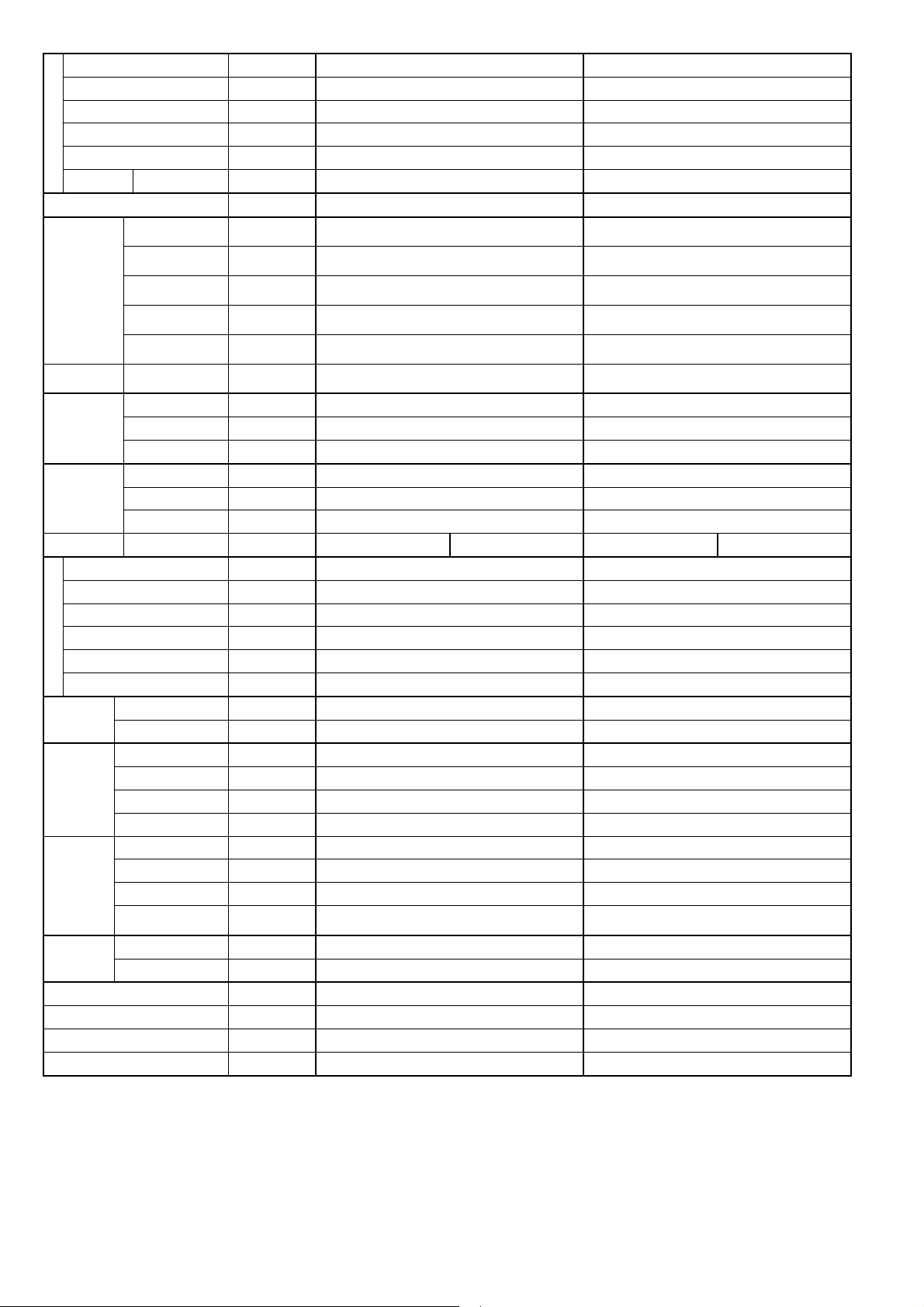

2. Specification

Model

Performance Test Condition ARI ARI

Power Supply

Min. Mid. Max. Min. Mid. Max. Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A - 3.5 - - 3.1 - - 5.2 - - 4.7 -

Input Power W 250 650 850 250 650 850 250 1.00k 1.15k 250 1.00k 1.15k

EER

Cooling

Power Factor % - 89 - - 91 - - 92 - - 93 -

Indoor Noise (H / L / QLo)

Outdoor Noise (H / L / QLo)

Capacity

Running Current A - 6.1 - - 5.4 - - 6.5 - - 5.8 -

Input Power W 200 1.15k 1.50k 200 1.15k 1.50k 200 1.30k 1.71k 200 1.30K 1.71k

COP

Heating

Power Factor % - 91 - - 93 - - 96 - - 97 -

Indoor Noise (H / L / QLo)

Outdoor Noise (H / L / QLo)

Max Current (A) / Max Input Power (W) 7.0 / 1.57k 7.8 / 1.71k

Starting Current (A) 6.1 6.5

Min Circuit Ampacity 15.0 15.0

Max. Current Protection 15.0 15.0

SEER / HSPF 21.00 / 10.50 20.00 / 10.00

Type Hermetic Motor Hermetic Motor

Compressor

Indoor Fan

Speed

Motor Type Brushless (4 poles) Brushless (4 poles)

Output Power W 700 700

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type Transistor (8 poles) Transistor (8 poles)

Input Power W 47.0 - 47.0 47.0 - 47.0

Output Power W 40 40

QLo rpm

Lo rpm

Me rpm

Hi rpm

SHi rpm

Indoor CS-E9NKUAW CS-E12NKUAW

Outdoor CU-E9NKUA CU-E12NKUA

Phase, Hz Single, 60 Single, 60

V 208 230 208 230

kW 1.20 2.49 3.00 1.20 2.49 3.00 1.20 3.51 3.90 1.20 3.51 3.90

BTU/h 4100 8500 10200 4100 8500 10200 4100 12000 13300 4100 12000 13300

W/W 4.80 3.83 3.53 4.80 3.83 3.53 4.80 3.51 3.39 4.80 3.51 3.39

Btu/hW 16.40 13.05 12.00 16.40 13.05 12.00 16.40 12.00 11.55 16.40 12.00 11.55

dB-A 40 / 25 / 20 40 / 25 / 20 43 / 28 / 20 43 / 28 / 20

Power Level dB 56 / - / - 56 / - / - 59 / - / - 59 / - / -

dB-A 47 / - / - 47 / - / - 48 / - / - 48 / - / -

Power Level dB 62 / - / - 62 / - / - 63 / - / - 63 / - / -

kW 1.20 3.27 4.14 1.20 3.27 4.14 1.20 4.05 4.77 1.20 4.05 4.77

BTU/h 4100 11200 14100 4100 11200 14100 4100 13800 16300 4100 13800 16300

W/W 6.00 2.84 2.76 6.00 2.84 2.76 6.00 3.12 2.79 6.00 3.12 2.79

Btu/hW 20.50 9.70 9.40 20.50 9.70 9.40 20.50 10.60 9.50 20.50 10.60 9.50

dB-A 42 / 29 / 26 42 / 29 / 26 44 / 35 / 32 44 / 35 / 32

Power Level dB 58 / - / - 58 / - / - 60 / - / - 60 / - / -

dB-A 46 / - / - 48 / - / - 49 / - / - 49 / - / -

Power Level dB 63 / - / - 63 / - / - 64 / - / - 64 / - / -

Cooling : 620

Heating : 750

Cooling : 720

Heating : 850

Cooling : 930

Heating : 1070

Cooling : 1150

Heating : 1300

Cooling : 1250

Heating : 1390

Cooling : 630

Heating : 970

Cooling : 790

Heating : 1070

Cooling : 1030

Heating : 1250

Cooling : 1270

Heating : 1430

Cooling : 1400

Heating : 1500

5

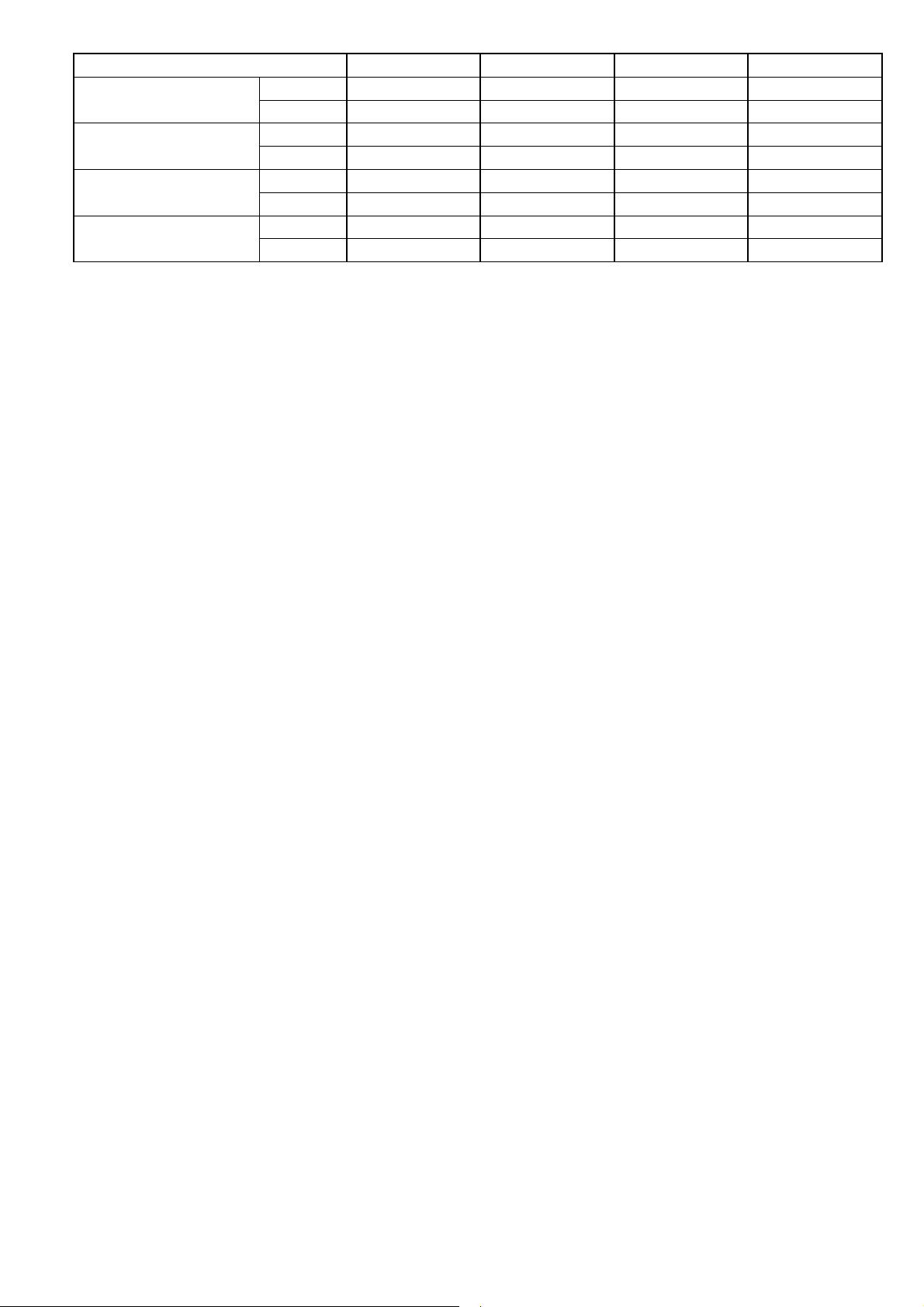

Page 6

Type Propeller Propeller

Material PP PP

Motor Type DC (8 poles) DC (8 poles)

Input Power W - -

Outdoor Fan

Output Power W 40 40

Speed Hi rpm C: 830 H: 780 C: 830 H: 780

Moisture Removal L/h (Pt/h) 0.6 (1.3) 1.2 (2.5)

Indoor Airflow

Outdoor

Airflow

QLo m3/min (ft3/min)

Lo m3/min (ft3/min)

Me m3/min (ft3/min)

Hi m3/min (ft3/min)

3

SHi m

Hi m

/min (ft3/min)

3

/min (ft3/min)

Cooling : 5.42 (191)

Heating : 6.49 (229)

Cooling : 6.51 (230)

Heating : 7.53 (266)

Cooling : 8.80 (311)

Heating : 9.81

(346)

Cooling : 11.2 (395)

Heating : 12.2 (430)

Cooling : 12.29 (434)

Heating : 13.13 (464)

Cooling : 31.0 (1095)

Heating : 31.0 (1095)

Cooling : 5.30 (187)

Heating : 8.75 (309)

Cooling : 6.98 (246)

Heating : 9.78 (345)

Cooling : 9.49 (335)

Heating : 11.64 (411)

Cooling : 12.0 (425)

Heating : 13.5 (475)

Cooling : 13.36 (472)

Heating : 14.23 (502)

Cooling : 31.0 (1095)

Heating : 31.0 (1095)

Control Device Capillary Tube Capillary Tube

Refrigeration

Cycle

Refrigerant Oil cm3 FV50S (320) FV50S (320)

Refrigerant Type g (oz) R410A, 965 (34.1) R410A, 980 (34.6)

Height(I/D / O/D) mm (inch) 290 (11-7/16) / 540 (21-9/32) 290 (11-7/16) / 540 (21-9/32)

Dimension

Width (I/D / O/D) mm (inch) 870 (34-9/32) / 780 (30-23/32) 870 (34-9/32) / 780 (30-23/32)

Depth (I/D / O/D) mm (inch) 204 (8-1/16) / 289 (11-13/32) 204 (8-1/16) / 289 (11-13/32)

Weight Net (I/D / O/D) kg (lb) 9 (20) 37 (82) 9 (20) 37 (82)

Pipe Diameter (Liquid / Gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 12.70 (1/2)

Standard length m (ft) 7.5 (24.6) 7.5 (24.6)

Length range (min – max) m (ft) 3 (9.8) ~ 20 (65.6) 3 (9.8) ~ 20 (65.6)

I/D & O/D Height different m (ft) 15 (49.2) 15 (49.2)

Piping

Additional Gas Amount g/m (oz/ft) 20 (0.2) 20 (0.2)

Length for Additional Gas m (ft) 7.5 (24.6) 7.5 (24.6)

Drain Hose

Inner Diameter mm (inch) 16.7 (5/8) 16.7 (5/8)

Length mm (inch) 650 (25-5/8) 650 (25-5/8)

Fin Material Aluminium (Pre Coat) Aluminium (Pre Coat)

Indoor Heat

Exchanger

Fin Type Slit Fin Slit Fin

Row x Stage x FPI 2 x 15 x 21 2 x 15 x 21

Size (W x H x L) inch 1 x 12-3/8 x 24 1 x 12-3/8 x 24

Fin Material Aluminium (Blue coated) Aluminium (Blue coated)

Outdoor

Heat

Exchanger

Air Filter

Fin Type Corrugate Fin Corrugate Fin

Row x Stage x FPI 2 x 24 x 17 2 x 24 x 17

Size (W x H x L) inch

1-3/8 x 19-7/18 x 28-1/8

26-7/8

1-3/8 x 19-7/18 x 28-1/8

26-7/8

Material Polypropelene Polypropelene

Type One-touch One-touch

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

6

Page 7

DRY BULB WET BULB DRY BULB WET BULB

Indoor Operation Range

(Cooling)

Outdoor Operation Range

(Cooling)

Indoor Operation Range

(Heating)

Outdoor Operation Range

(Heating)

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Heating capacities are based on indoor temperature of 20°C Dry Bulb (68°F Dry Bulb) and outdoor air temperature of 7°C Dry Bulb (44.6°F

Dry Bulb), 6°C Wet Bulb (42.8°F Wet Bulb)

3. Specifications are subjected to change without prior notice for further improvement.

Maximum 89.6 73.4 89.6 73.4

Minimum 60.8 51.8 60.8 51.8

Maximum 109.4 78.8 109.4 78.8

Minimum 5.0 - 5.0 -

Maximum 86.0 - 86.0 -

Minimum 60.8 - 60.8 -

Maximum 75.2 64.4 75.2 64.4

Minimum 5.0 3.2 5.0 3.2

7

Page 8

3. Features

Inverter Technology

o Wider output power range

o Energy saving

o Quick Cooling

o More precise temperature control

Environment Protection

o Non-ozone depletion substances refrigerant (R410A)

Long Installation Piping

o CS/CU-E9/12NK, long piping up to 20 meters

Easy to use remote control

Quality Improvement

o Random auto restart after power failure for safety restart operation

o Gas leakage protection

o Prevent compressor reverse cycle

o Inner protector to protect Compressor

o Noise prevention during soft dry operation

Operation Improvement

o Quiet mode to reduce the indoor unit operating sound

o Powerful mode to reach the desired room temperature quickly

Serviceability Improvement

o Breakdown Self Diagnosis function

8

Page 9

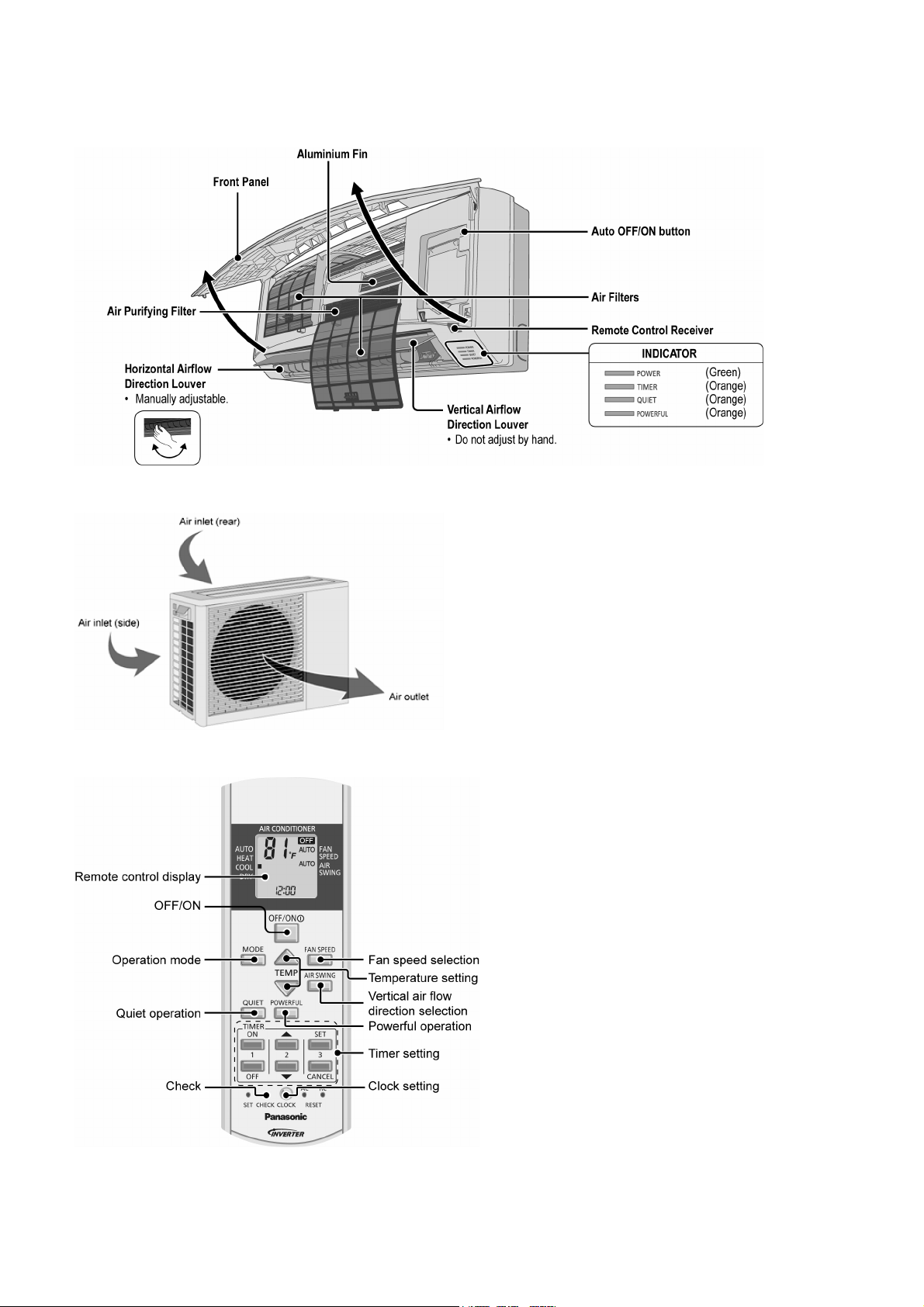

4. Location of Controls and Components

4.1 Indoor Unit

4.2 Outdoor Unit

4.3 Remote Control

9

Page 10

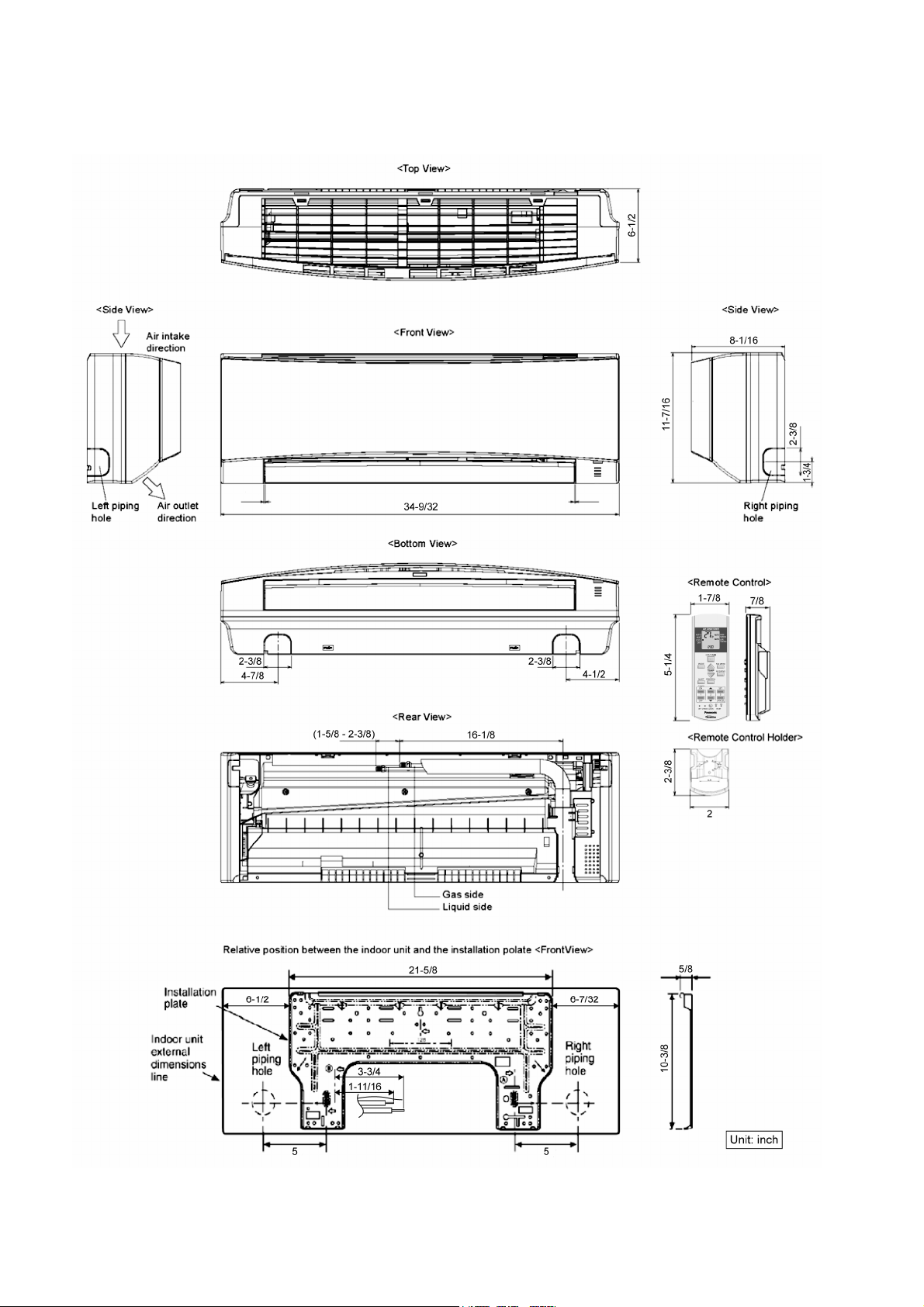

5. Dimensions

5.1 Indoor Unit

10

Page 11

5.2 Outdoor Unit

11

Page 12

6. Refrigeration Cycle Diagram

12

Page 13

7. Block Diagram

13

Page 14

8. Wiring Connection Diagram

8.1 Indoor Unit

14

Page 15

8.2 Outdoor Unit

15

Page 16

9. Electronic Circuit Diagram

9.1 Indoor Unit

16

Page 17

9.2 Outdoor Unit

17

Page 18

10. Printed Circuit Board

10.1 Indoor Unit

10.1.1 Main Printed Circuit Board

18

Page 19

10.1.2 Power Printed Circuit Board

10.1.3 Indicator Printed Circuit Board

19

Page 20

10.2 Outdoor Unit

10.2.1 Main Printed Circuit Board

20

Page 21

11. Installation Instruction

11.1 Select the Best Location

11.1.1 Indoor Unit

Do not install the unit in excessive oil fume area

such as kitchen, workshop and etc.

There should not be any heat source or steam

near the unit.

There should not be any obstacles blocking the air

circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into

consideration.

Do not install the unit near the door way.

Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

Recommended installation height for indoor unit

shall be at least 8.2 ft.

11.1.2 Outdoor Unit

If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from

the condenser is not obstructed.

There should not be any animal or plant which

could be affected by hot air discharged.

Keep the spaces indicated by arrows from wall,

ceiling, fence or other obstacles.

Do not place any obstacles which may cause a

short circuit of the discharged air.

If piping length is over the [piping length for

additional gas], additional refrigerant should be

added as shown in the table.

Recommended installation height for outdoor unit

should be above the seasonal snow level.

Example: For E9NKUAW

If the unit is installed at 32.8 ft distance, the quantity

of additional refrigerant should be 1.64 oz ....

(32.8 - 24.6) ft x 0.2 oz/ft = 1.64 oz.

11.1.3 Indoor/Outdoor Unit Installation

Diagram

21

Page 22

11.2 Indoor Unit

11.2.1 How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent if from the vibration.

The center of installation plate should be at more than c at right and left of the wall.

The distance from installation plate edge to ceiling should more than d.

From installation plate left edge to unit’s left side is e.

From installation plate right edge to unit’s right side is f.

B : For left side piping, piping connection for liquid should be about g from this line.

○

: For left side piping, piping connection for gas should be about h from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and using

a level gauge.

2 Drill the piping plate hole with ø2-3/4" hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended line is

the center of the hole. Another method is by putting measuring tape at position as shown in the diagram

above. The hole center is obtained by measuring the distance namely 5-1/6" for left and right hole

respectively.

o Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoor

side.

11.2.2 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32"

from the wall.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

22

Page 23

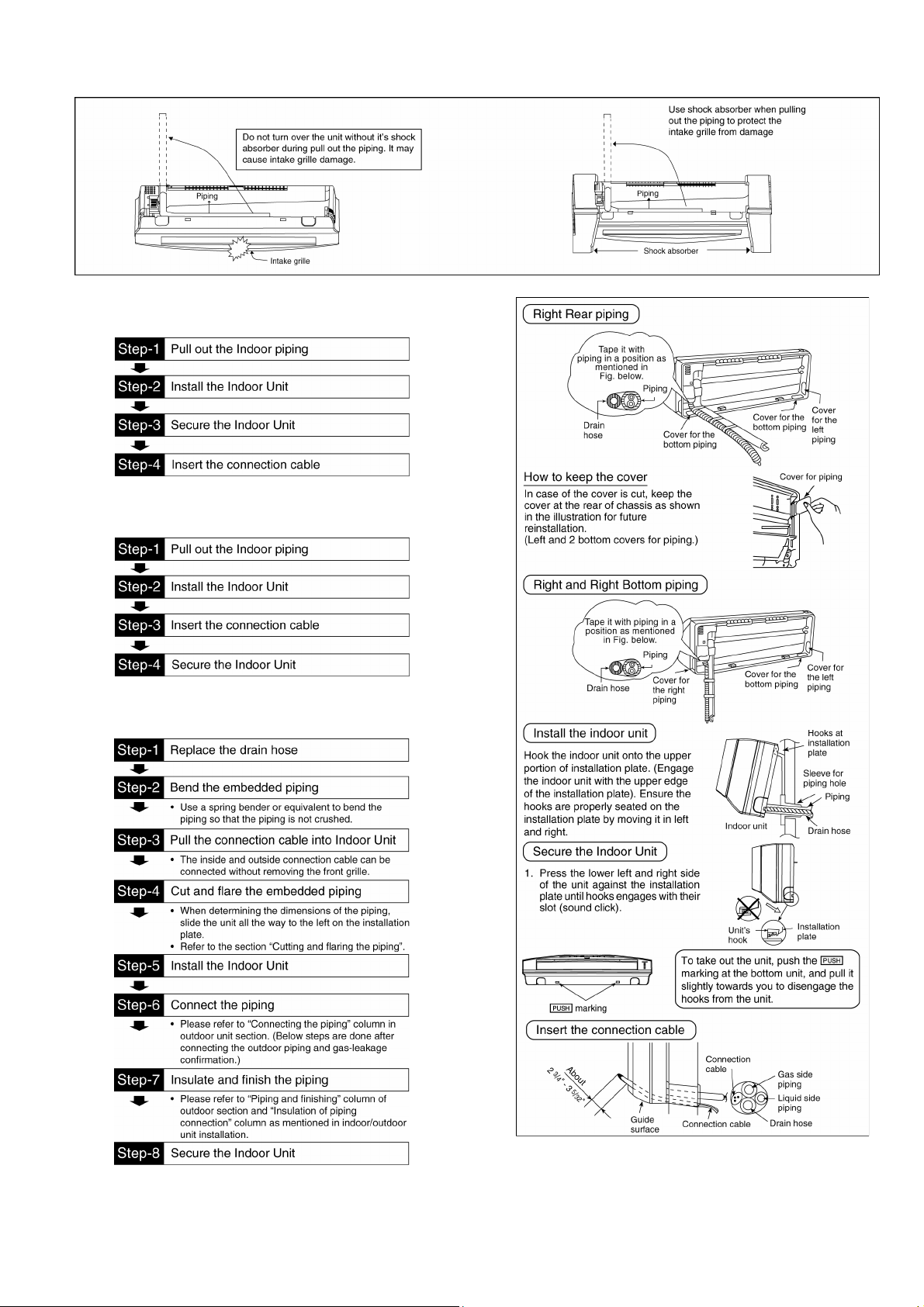

11.2.3 Indoor Unit Installation

11.2.3.1 For the right rear piping

11.2.3.2 For the right bottom piping

11.2.3.3 For the embedded piping

(This can be used for left rear piping and bottom

piping also.)

23

Page 24

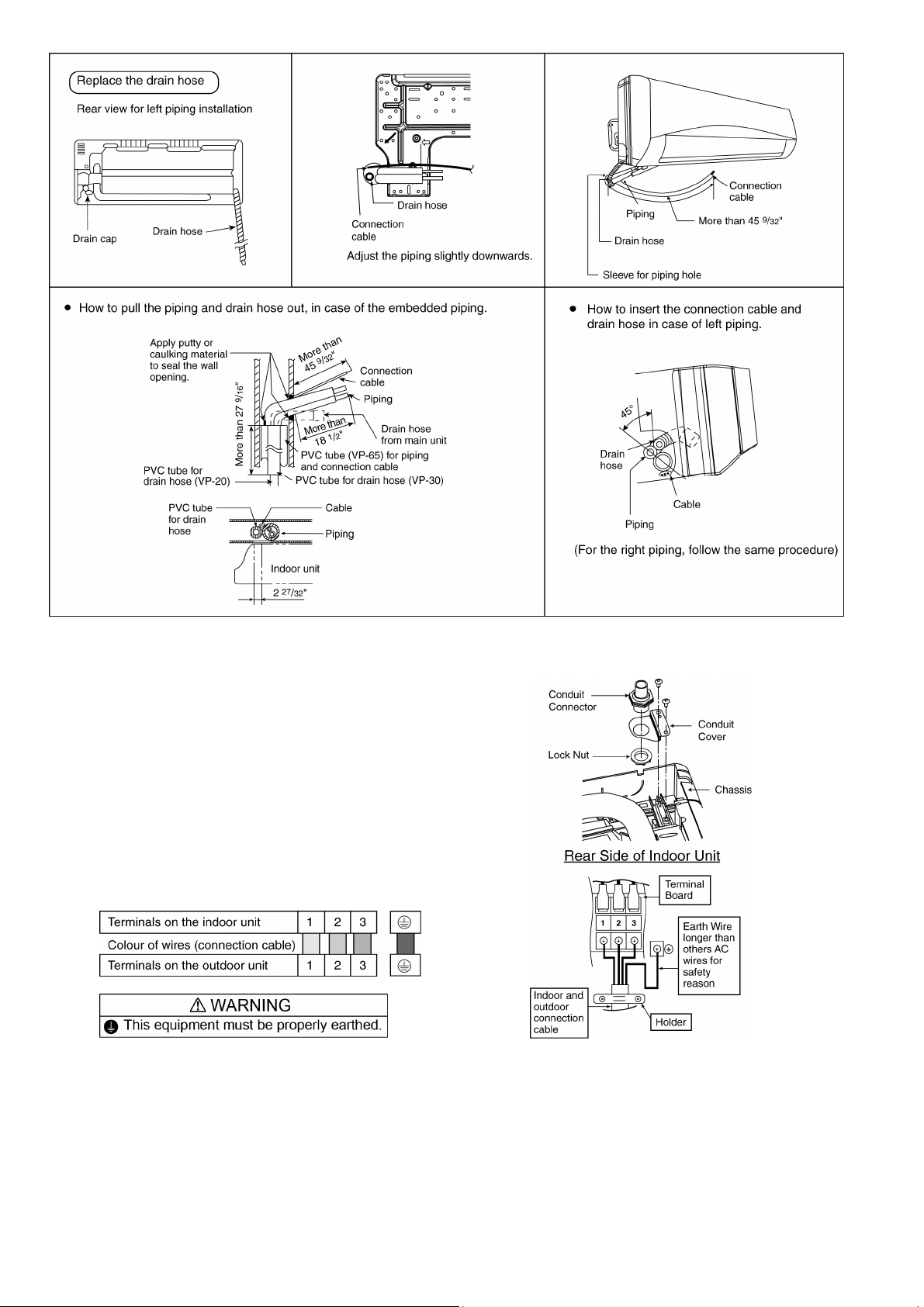

11.2.4 Connect the Cable to the Indoor Unit

1. The inside and outside connection cable can

be connected without removing the front grille.

2. Unscrew the conduit cover and fix the conduit

connector to conduit cover with lock nut, then

secure it against chassis.

3. Connection cable between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

o Ensure the colour of wires of outdoor unit

and terminal number are the same as the

indoor's repectively.

o Earth lead wire shall be Yellow/Green

(Y/G) in colour and shall be longer than

other lead wires as shown in the figure for

electrical safety in case of the slipping.

24

Page 25

11.2.5 Wiring Stripping and connecting requirement

11.2.5.1 Cutting and flaring the piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs are not removed, gas leakage may be caused. Turn the piping

end down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

25

Page 26

11.3 Outdoor Unit

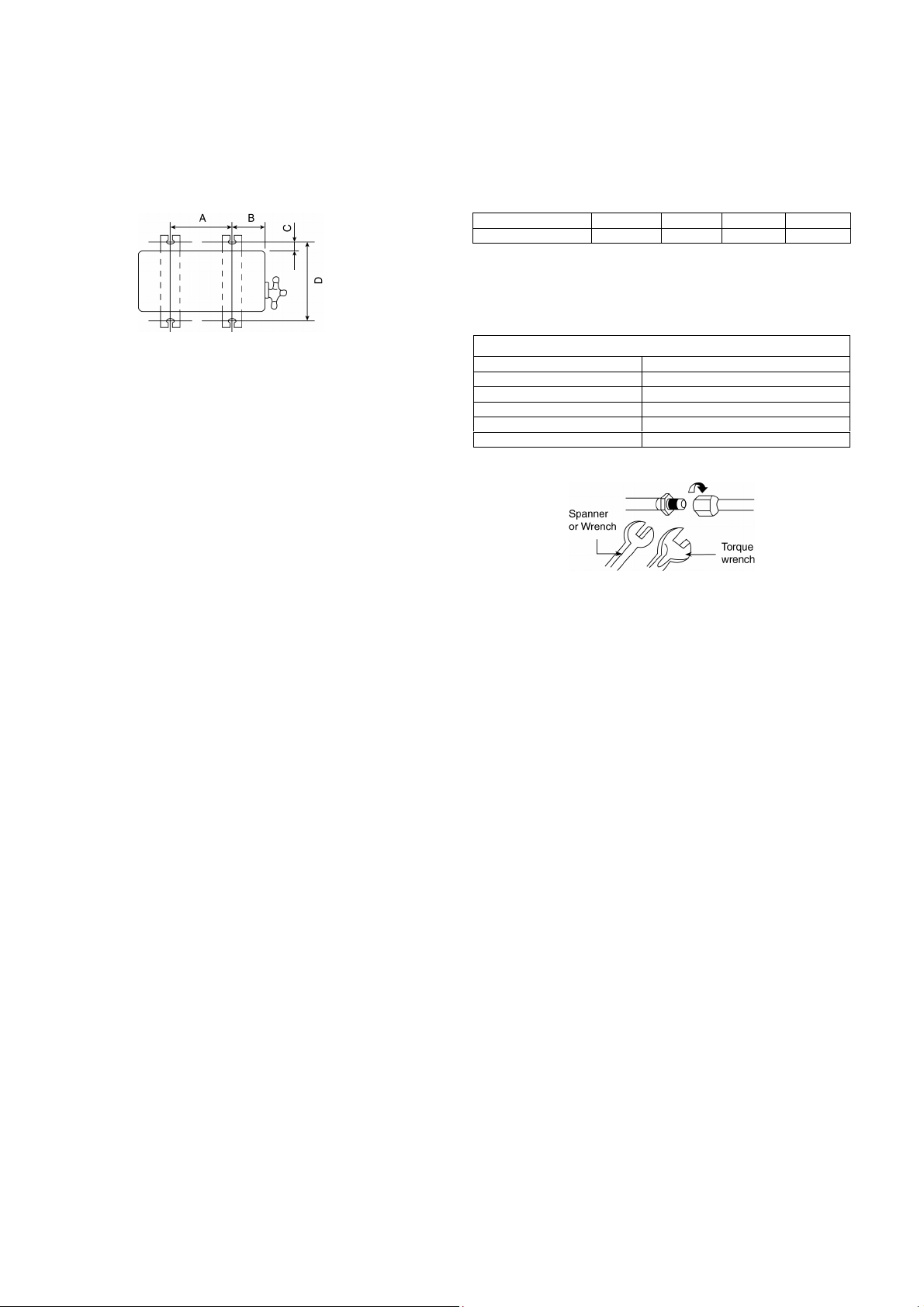

11.3.1 Install the Outdoor Unit

After selecting the best location, start installation according to indoor/outdoor unit installation diagram.

1 Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø13/32").

2 When installing at roof, please consider strong wind and earthquake.

Please fasten the installation stand firmly with bolt or nails.

Model A B C D

E9NKUA, E12NKUA 22-7/16" 4-1/8" 23/32" 12-19/32"

11.3.2 Connect the Piping

11.3.2.1 Connecting the piping to

indoor

Please make flare after inserting flare nut (locate at

joint portion, of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

11.3.2.2 Connecting the piping to

outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valves and then tighten with

torque wrench to the specified torque as stated in the

table.

Do not over tighten, over tightening may cause gas leakage.

Piping size Torque

1/4" 13.3 Ibf.ft

3/8” 31.0 Ibf.ft

1/2" 40.6 Ibf.ft

5/8” 47.9 Ibf.ft

3/4" 73.8 Ibf.ft

26

Page 27

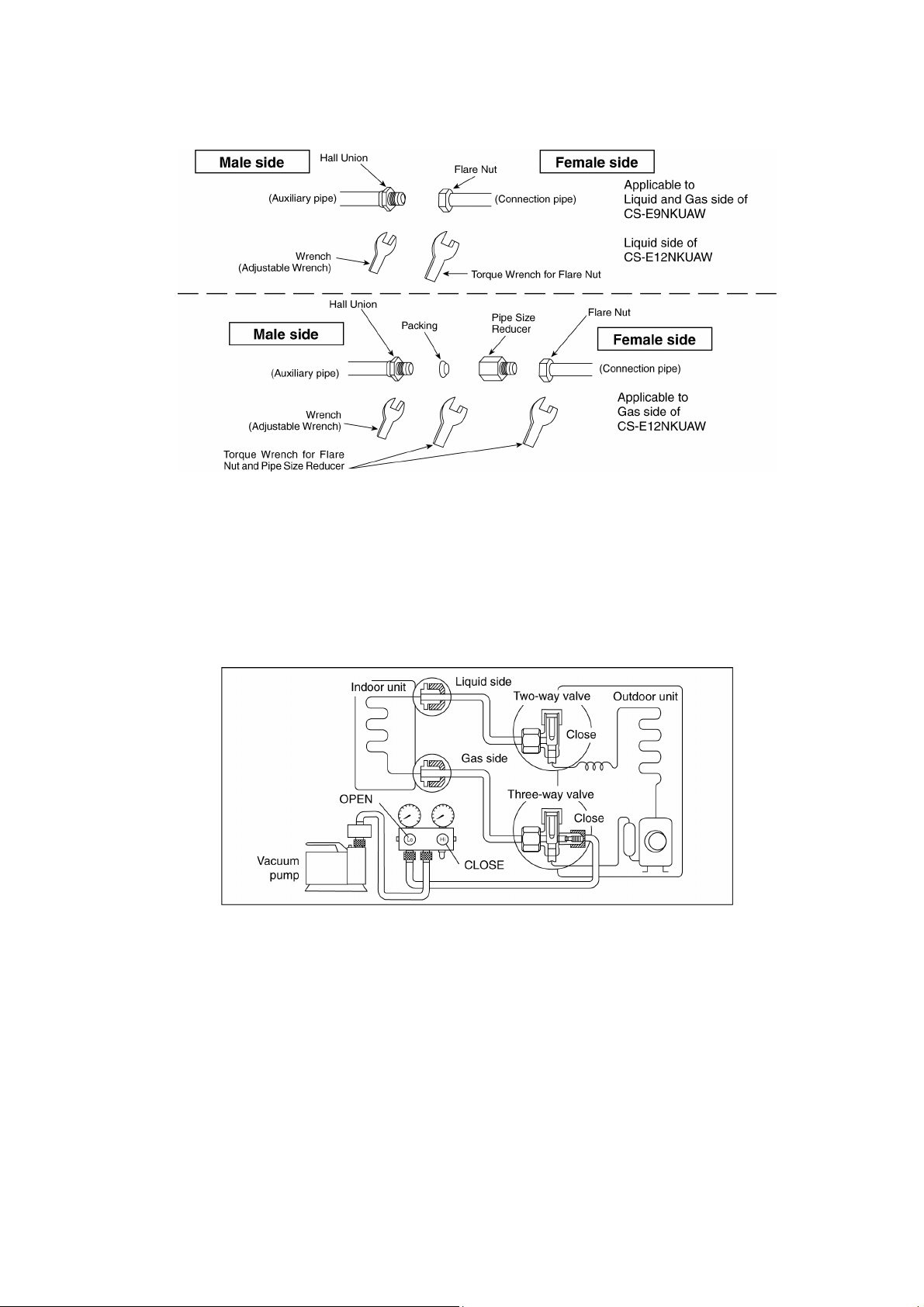

11.3.2.3 Connecting the piping to outdoor multi

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve) onto the copper pipe.

Align center of piping to valve and then tighten with torque wrench to the specified torque as stated in the table.

11.3.2.4 Gas Leak Checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 11.3.3.

11.3.3 Evacuation of the equipment

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedures.

1. Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

valve.

2. Connect the micron gauge between vacuum pump and service port of outdoor units.

3. Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge and to pull

down to a value of 500 microns.

4. To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn off

the vacuum pump.

5. Disconnect the vacuum pump house from the service port of the 3-way valve.

6. Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf.ft with a torque wrench.

7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Open”

using a hexagonal wrench (5/32").

27

Page 28

8. Mount valve caps onto the 2-way valve and the 3-way valve.

o Be sure to check for gas leakage.

11.3.3.1 Connect the Cable to the Outdoor Unit

1. Remove Top panel.

2. Remove Control Board Cover (Resin and Metal).

3. Remove Plugs.

4. Fix the conduit connectors to the knockout holes with

lock-nuts, then secure them against the side panel.

5. All wires pass through conduits.

6. Connection cable between indoor unit and outdoor

unit should be UL listed or CSA approved 4 conductor

wires minimum AWG16 in accordance with local

electric codes.

7. Wire connection to the power supply (208/230V 60Hz)

through circuit breaker.

o Connect the UL listed or CSA approved wires

minimum AWG14 to the terminal board, and

connect the other end of the wires to ELCB /

GFCI.

8. Connect the power supply cord and connection cable

between indoor unit and outdoor unit according to the diagram below.

9. Secure the wire onto the control board with the holder

(clamper).

10. After completing wiring connections, reattach the control

board cover (Metal and Resin) and the top panel to the

original position with the screws.

11. For wire stripping and connection requirement, refer to

instruction 11.2.4 of indoor unit.

Earth lead wire shall be Yellow/Green (Y/G) in colour and shall

be longer than other lead wires as shown in the figure for

electrical safety in case of the slipping.

11.3.3.2 Piping Insulation

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E-FOAM with thickness 1/4" or above.

28

Page 29

12. Operation Control

12.1 Basic Function

Inverter control, which equipped with a microcomputer in determining the most suitable operation mode as time

passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operation

mode, the microcomputer maintains the set temperature by measuring the temperature of the environment and

performing temperature shifting. The compressor at outdoor unit is operating following the frequency instructed by

the microcomputer at indoor unit that judging the condition according to internal setting temperature and intake air

temperature.

12.1.1 Internal Setting Temperature

Once the operation starts, remote control setting temperature will be taken as base value for temperature shifting

processes. These shifting processes are depending on the air conditioner settings and the operation environment.

The final shifted value will be used as internal setting temperature and it is updated continuously whenever the

electrical power is supplied to the unit.

12.1.2 Cooling Operation

12.1.2.1 Thermostat control

Compressor is OFF when intake Air Temperature - Internal Setting Temperature < 29.3°F.

Compressor is ON after waiting for 3 minutes, if the Intake Temperature - Internal Setting Temperature >

Compressor OFF point.

12.1.3 Soft Dry Operation

12.1.3.1 Thermostat control

Compressor is OFF when Intake Temperature - Internal Setting Temperature < 28.4°F.

Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature >

Compressor OFF point.

12.1.4 Heating Operation

12.1.4.1 Thermostat control

Compressor is OFF when Intake Temperature - Internal Setting Temperature > 35.6°F.

Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature <

Compressor OFF point

29

Page 30

12.1.4.2 Automatic Operation

This mode can be set using remote control and the operation is decided by remote control setting temperature,

remote control operation mode, indoor intake air temperature and outdoor air temperature.

During operation mode judgment, indoor fan motor (with speed of Lo-) and outdoor fan motor are running for 30

seconds to detect the indoor intake and outdoor air temperature. The operation mode is decided based on below

chart.

Every 30 minutes, the indoor and outdoor temperature is judged. Based on remote control setting temperature,

the value of T1 will increase up to 50°F, T2 will decrease by 37.4°F and T3 will decrease up to 46.4°F.

The Auto Operation Mode shifting will take place whenever operation mode changed from Cool/Soft Dry to

Heating or vice versa.

12.2 Indoor Fan Motor Operation

12.2.1 Basic Rotation Speed (rpm)

Manual Fan Speed

[Cooling, Dry]

o Fan motor’s number of rotation is determined according to remote control setting.

Remote control ○ ○ ○ ○ ○

Tab Hi Me+ Me Me- Lo

[Heating]

o Fan motor’s number of rotation is determined according to remote control setting.

Remote control ○ ○ ○ ○ ○

Tab Shi Me+ Me Me- Lo

Auto Fan Speed

[Cooling, Dry]

o According to room temperature and setting temperature, indoor fan speed is determined automatically.

o The indoor fan will operate according to pattern below.

o During operation, indoor fan motor may stop due to odor prevention.

30

Page 31

[Heating]

o According to indoor pipe temperature, automatic heating fan speed is determined as follows.

Feedback control

o Immediately after the fan motor started, feedback control is performed once every second.

o During fan motor on, if fan motor feedback ≥ 2550 rpm or < 50 rpm continue for 10 seconds, then fan motor

error counter increase, fan motor is then stop and restart. If the fan motor counter becomes 7 times, then

H19 - fan motor error is detected. Operation stops and cannot on back.

12.3 Outdoor Fan Motor Operation

Outdoor fan motor is operated with fan speed number of rotation. It starts when compressor starts operation and it

stops 30 seconds after compressor stops operation.

ON ON

Compressor OFF

ON Fan Speed ON

Outdoor Fan 30 sec OFF

12.4 Airflow Direction

There are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by

vertical vanes).

Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat

exchanger temperature and intake air temperature) and manual (angles of direction can be adjusted using

remote control).

12.4.1 Vertical Airflow

Automatic vertical airflow direction can be set using remote control; the vane swings up and down within the

angles as stated above. For heating mode operation, the angle of the vane depands on the indoor heat

exchanger temperature as Figure 1 below. When the air conditioner is stopped using remote control, the vane

will shift to close position.

Manual vertical airflow direction can be set using remote control; the angles of the vane are as stated above and

the positions of the vane are as Figure 2 below. When the air conditioner is stopped using remote control, the

vane will shift to close position.

31

Page 32

12.4.2 Horizontal Airflow

The horizontal airflow direction louvers can be adjusted manually by hand.

12.5 Quiet Operation (Cooling Mode/Cooling Area of Dry Mode)

Purpose

o To provide quiet cooling operation compare to normal operation.

Control condition

o Quiet operation start condition

When “Quiet” button at remote control is pressed.

Quiet LED illuminates.

o Quiet operation stop condition

When one of the following conditions is satisfied, quiet operation stops:

Powerful button is pressed.

Stop by OFF/ON button.

OFF Timer activates.

Quiet button is pressed again.

When quiet operation is stopped, operation is shifted to normal operation with previous setting.

When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

When operation mode is changed, quiet operation is shifted to quiet operation of the new mode.

During quiet operation, if ON timer activates, quiet operation maintains.

After off, when on back, quiet operation is not memorised.

Control contents

o Auto fan speed is change from normal setting to quiet setting of respective fan speed. This is to reduce

sound of Hi, Me, Lo for 3dB.

o Manual fan speed for quiet operation is -1 step from setting fan speed.

12.6 Quiet Operation (Heating)

Purpose

o To provide quiet heating operation compare to normal operation.

Control condition

o Quiet operation start condition

When “Quiet” button at remote control is pressed.

Quiet LED illuminates.

o Quiet operation stop condition

When one of the following conditions is satisfied, quiet operation stops:

Powerful button is pressed.

Stop by OFF/ON button.

Timer “off” activates.

Quiet button is pressed again.

When quiet operation is stopped, operation is shifted to normal operation with previous setting.

When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

When operation mode is changed, quiet operation is shifted to quiet operation of the new mode.

During quiet operation, if timer “on” activates, quiet operation maintains.

After off, when on back, quiet operation is not memorised.

32

Page 33

Control contents

o Fan speed auto

Indoor FM RPM depends on pipe temperature sensor of indoor heat exchanger. Auto fan speed is

changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of Hi, Me,

Lo for 3dB.

o Fan speed manual

Manual fan speed for quiet operation is -1 step from setting fan speed.

12.7 Powerful Mode Operation

When the powerful mode is selected, the internal setting temperature will shift lower up to 35.6°F (for

Cooling/Soft Dry) or higher up to 38.3°F (for Heating) than remote control setting temperature for 20 minutes to

achieve the setting temperature quickly.

12.8 Timer Control

12.8.1 ON Timer Control

ON Timer can be set using remote control, where the unit with timer set will start operation earlier than the setting

time. This is to provide a comfortable environment when reaching the set ON time.

60 minutes before the set ON time, indoor (at fan speed of Lo-) and outdoor fan motor start operation for 30

seconds to determine the indoor intake air temperature and outdoor air temperature in order to judge the

operation starting time.

From the above judgment, the decided operation will start operation earlier than the set time as shown below.

12.8.2 OFF Timer Control

OFF Timer can be set using remote control, the unit with timer set will stop at set time.

12.9 Auto Restart Control

When the power supply is cut off during the operation of air conditioner, the compressor will re-operate within

three to four minutes (there are 10 patterns between 2 minutes 58 seconds and 3 minutes 52 seconds to be

selected randomly) after power supply resumes.

This type of control is not applicable during ON/OFF Timer setting.

33

Page 34

12.10 Indication Panel

Note:

If POWER LED is blinking, the possible operation of the unit are Hot Start, during Deice operation, operation

mode judgment, or ON timer sampling.

If Timer LED is blinking, there is an abnormality operation occurs.

34

Page 35

13. Operation Control (For Multi Split Connection)

During multi split connection, indoor unit’s operation controls are same with single split connection unless specified in

this chapter.

13.1 Cooling operation

13.1.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature — Internal setting

temperature < 28.4°F.

Capability resume supply to indoor unit after waiting for 3 minutes, if the Intake Air temperature — Internal setting

temperature > Capability supply OFF point.

13.2 Soft Dry Operation

13.2.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature — Internal setting

temperature < 26.6°F.

Capability resume to indoor unit after waiting for 3 minutes, if the Intake Air temperature — Internal setting

temperature > Capability supply OFF point.

13.3 Heating Operation

13.3.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature — Internal setting

temperature > 33.8°F.

During this condition, the indoor fan is stopped if compressor is ON.

Capability resume supply to indoor unit after waiting for 3 minutes, if the Intake Air Temperature — Internal

setting temperature < Capability supply OFF point.

13.3.2 Temperature Sampling Control

Temperature sampling is controlled by outdoor unit where room temperature for all power supply ON indoor unit

could be obtained.

When capability supply to the indoor unit is OFF and the compressor is ON during heating operation, the indoor

fan motor is stopped. During this condition, 15 seconds after sampling signal from outdoor unit is received, the

indoor fan start operation at low fan speed.

However, within first 4 minutes of capability stopped supply to the indoor unit, even sampling signal is received,

the sampling control is cancelled.

35

Page 36

13.4 Automatic Operation

This mode can be set using remote control and the operation is decided by remote control setting temperature,

remote control operation mode, indoor intake and outdoor air temperature.

During operation mode judgment, indoor fan motor (with speed of -Lo) and outdoor fan motor are running for

30 seconds to detect the indoor intake and outdoor air temperature. The operation mode is decided based on

below chart.

Every 180 minutes, the indoor and outdoor temperature is judge. Based on remote control setting temperature,

the value of T1 will increase up to 50°F, T2 will decrease by 37.4°F and T3 will decrease up to 46.4°F.

13.5 Indoor Fan Motor Operation

13.5.1 Residual Heat Removal Control

To prevent high pressure at indoor unit, when heating mode thermostat-off condition or power supply OFF,

indoor fan continue to operate at controlled fan speed for maximum 30 seconds then stop.

13.6 Powerful Mode Operation

When the power mode is selected, the internal setting temperature will shift lower up to 39.2F for Cooling/Soft

Dry or higher up to 42.8°F for heating than remote control setting temperature, the powerful operation continue

until user cancel the Powerful operation by pressing powerful button again.

13.7 Auto restart control

When the power supply is cut off during the operation of air conditioner, the compressor will re-operate between

three to four minutes (10 patterns to be selected randomly) after power resume.

During multi split connection, Indoor unit will resume previous mode, include unit standby mode.

13.8 Indication Panel

Note:

If POWER LED is blinking (0.5 second ON, 0.5 second OFF), the possible operation of the unit are during Indoor

Residual Heat Removal, Hot Start, during Deice operation, operation mode judgment, or ON timer sampling.

If POWER LED is blinking (2.5 seconds ON, 0.5 second OFF), the unit is in standby mode.

If TIMER LED is blinking, there is an abnormality operation occurs.

36

Page 37

14. Protection Control

14.1 Protection Control For All Operations

14.1.1 Restart Control (Time Delay Safety Control)

The compressor will not turn on within 3 minutes from the moment operation stops, although the unit is turned on

again by pressing OFF/ON button at remote control within this period.

This control is not applicable if the power supply is cut off and on again.

This phenomenon is to balance the pressure inside the refrigerant cycle.

14.1.2 30 Seconds Forced Operation

Once the air conditioner is turned on, the compressor will not stop within 30 seconds in a normal operation

although the intake air temperature has reached the thermo-off temperature. However, force stop by pressing the

OFF/ON button at the remote control is permitted or the Auto OFF/ON button at indoor unit.

The reason for the compressor to force operation for minimum 30 seconds is to allow the refrigerant oil run in a

full cycle and return back to the outdoor unit.

14.1.3 Total Running Current Control

When the outdoor unit total running current (AC) exceeds X value, the frequency instructed for compressor

operation will be decreased.

If the running current does not exceed X value for 5 seconds, the frequency instructed will be increased.

However, if total outdoor unit running current exceeds Y value, compressor will be stopped immediately for 3

minutes.

Model E9NKUA E12NKUA

Operation Mode X (A) Y (A) X (A) Y (A)

Cooling / Soft Dry (A) 3.89 15.00 6.55 15.00

Cooling / Soft Dry (B) 3.28 15.00 6.10 15.00

Heating 5.50 15.00 7.05 15.00

1. The first 30 minutes of cooling operation, (A) will be applied.

14.1.4 IPM (Power Transistor) Prevention Control

Overheating Prevention Control

o When the IPM temperature rises to 212°F, compressor operation will stop immediately.

o Compressor operation restarts after 3 minutes the temperature decreases to 203°F.

o If this condition repeats continuously 4 times within 20 minutes, timer LED will be blinking (“F96” is indicated).

DC Peak Current Control

o When electric current to IPM exceeds set value of 18.5A, the compressor will stop operate. Then, operation

will restart after 3 minutes.

o If the set value exceeds again more than 30 seconds after the compressor starts, the operation will restart

after 2 minutes.

o If the set value exceeds again within 30 seconds after the compressor starts, the operation will restart after 1

minute. If this condition repeats continuously for 7 times, all indoor and outdoor relays will be cut off, timer

LED will be blinking (“F99” is indicated).

37

Page 38

14.1.5 Compressor Overheating Prevention Control

Instructed frequency for compressor operation will be regulated by compressor discharge temperature. The

changes of frequency are as below.

If compressor discharge temperature exceeds 224.6°F, compressor will be stopped, occurs 4 times per 20

minutes, timer LED will be blinking. (“F97” is indicated.)

14.1.6 Low Pressure Prevention Control (Gas Leakage Detection)

Control start conditions

o For 5 minutes, the compressor continuously operates and outdoor total current is between 0.64A and 0.85A.

o During Cooling and Soft Dry operations:

Indoor suction temperature - indoor piping temperature is below 39.2.°F.

o During Heating operations:

Indoor piping temperature - indoor suction is under 41°F.

Control contents

o Compressor stops (and restart after 3 minutes).

o If the conditions above happen 2 times within 20 minutes, the unit will:

Stop operation

Timer LED blinks and “F91” indicated.

14.1.7 Low Frequency Protection Control 1

When the compressor operates at frequency lower than 24Hz continued for 240 minutes, the operation frequency

will be changed to 25Hz for 2 minutes.

14.1.8 Low Frequency Protection Control 2

When all below conditions comply, minimum limit of compressor will be set.

Temperature, T, for: Cooling / Soft Dry Heating

Indoor intake air (°F) T < 57.2 or T ≥ 86 -

Outdoor air (°F) T < 55.4 or T ≥ 100.4 T < 57.2 or T ≥ 82.4

Indoor heat exchanger (°F) T < 86 T ≥ 32

14.2 Protection Control For Cooling & Soft Dry Operation

14.2.1 Outdoor Air Temperature Control

The maximum current value is regulated when the outdoor air temperature rise above 57.2°F in order to avoid

compressor overloading.

38

Page 39

14.2.2 Cooling Overload Control

Pipe temperature limitation / restriction.

o Detects the outdoor pipe temperature and carry out restriction / limitation below (Limit the compressor

operation frequency)

o The compressor stops if outdoor pipe temperature exceeds 141.8°F.

o If the compressor stops 4 times in 20 minutes, Timer LED blinks (“F95” indicated: Outdoor high pressure rise

protection)

14.2.3 Freeze Prevention Control 1

When indoor heat exchanger temperature is lower than 32°F continuously for 6 minutes, compressor will stops

operation.

Compressor will resume its operation 3 minutes after the indoor heat exchanger is higher than 41°F.

At the same time, indoor fan speed will be higher than during its normal operation.

If the indoor heat exchanger temperature is higher than 55.4°F for 5 minutes, the fan speed will return to its

normal operation.

14.2.4 Freeze Prevention Control 2

Control start conditions

o During Cooling operation and soft dry operation

During thermo OFF condition, indoor intake temperature is less than 50°F or

Compressor stops for freeze prevention control

o Either one of the conditions above occurs 5 times in 60 minutes.

Control contents

o Operation stops

o Timer LED blinks and “H99” indicated

14.2.5 Dew Prevention Control 1

To prevent dew formation at indoor unit discharge area.

This control will be activated if:

o Outdoor air temperature and Indoor pipe temperature judgment by microcontroller is fulfilled.

o When Cooling or Dry mode is operated more than 20 minutes or more.

This control stopped if:

o Compressor stopped.

o Remote control setting changed (fan speed / temperature).

o Outdoor air temperature and indoor intake temperature changed.

Fan speed, angle of louver (vertical airflow angle) will be adjusted accordingly in this control.

1. Fan speed will be increased slowly when control is activated until predetermine value.

Compressor frequency will be regulated accordingly.

14.2.6 Protection Control For Heating Operation

14.2.6.1 Intake Air Temperature Control

Compressor will operate at limited freq., if indoor intake air temperature is 95°C or above.

39

Page 40

14.2.6.2 Outdoor Air Temperature Control

The maximum current value is regulated when the outdoor air temperature rise above 57.2°F in order to avoid

compressor overloading.

The compressor will be stopped to avoid compressor overloading.

14.2.6.3 Overload Protection Control

The compressor operating frequency is regulated in accordance to indoor heat exchanger temperature as shown

below.

If the heat exchanger temperature exceeds 60°C, compressor will stop.

14.2.6.4 Low Temperature Compressor Oil Return Control

In heating operation, if the outdoor temperature falls below 14°F when compressor starts, the compressor

frequency will be regulated up to 600 seconds.

14.2.6.5 Cold Draught Prevention Control

When indoor pipe temperature is low, cold draught operation starts where indoor fan speed will be reduced or

stop.

Horizontal vane angle may be adjusted in Auto vane setting.

14.2.6.6 Deice Operation

When outdoor pipe temperature and outdoor air temperature is low, deice operation start where indoor fan motor

and outdoor fan motor stop and operation LED blinks. Horizontal vane is closed during auto vane setting.

40

Page 41

15. Servicing Mode

15.1 Auto Off/On Button

1 AUTO OPERATION MODE

The Auto operation will be activated immediately once the Auto OFF/ON button is pressed. This operation

can be used to operate air conditioner with limited function if remote control is misplaced or malfunction.

2 TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE)

The Test Run operation will be activated if the Auto OFF/ON button is pressed continuously for more than 5

seconds. A “beep” sound will heard at the fifth seconds, in order to identify the starting of Test Run operation

(Forced cooling operation). Within 5 minutes after Forced cooling operation start, the Auto OFF/ON button is

pressed for more than 5 seconds. A 2 “beep” sounds will heard at the fifth seconds, in order to identify the

starting of Forced heating operation.

The Auto OFF/ON button may be used together with remote control to set / change the advance setting of air

conditioner operation.

3 REMOTE CONTROL NUMBER SWITCH MODE

The Remote Control Number Switch Mode will be activated if the Auto OFF/ON button is pressed

continuously for more than 11 seconds (3 “beep” sounds will occur at 11th seconds to identify the Remote

Control Number Switch Mode is in standby condition) and press “AC RESET” button and then press any

button at remote control to transmit and store the desired transmission code to the EEPROM.

There are 4 types of remote control transmission code could be selected and stored in EEPROM of indoor

unit. The indoor unit will only operate when received signal with same transmission code from remote control.

This could prevent signal interference when there are 2 or more indoor units installed nearby together.

To change remote control transmission code, short or open jumpers at the remote control printed circuit

board.

Jumper A (J1) Jumper B (D2) Remote Control No.

Short Open A (Default)

Open Open B

Short Short C

Open Short D

During Remote Control Number Switch Mode, press any button at remote control to transmit and store

the transmission code to the EEPROM.

4 REMOTE CONTROL RECEIVING SOUND OFF/ON MODE

The Remote Control Receiving Sound OFF/ON Mode will be activated if the Auto OFF/ON button is pressed

continuously for more than 16 seconds (4 “beep” sounds will occur at 16

Control Receiving Sound OFF/ON Mode is in standby condition) and press “AC Reset” button at remote

control.

Remote Control Printed Circuit Board

th

seconds to identify the Remote

41

Page 42

Press Auto OFF/ON button to toggle remote control receiving sound.

- Short “beep”: Turn OFF remote control receiving sound.

- Long “beep”: Turn ON remote control receiving sound.

After Auto OFF/ON button is pressed, the 20 seconds counter for Remote Control Receiving Sound OFF/ON

Mode is restarted.

15.2 Remote Control Button

15.2.1 SET Button

To check remote control transmission code and store the transmission code to EEPROM

o Press “Set” button continuously for 10 seconds by using pointer

o Press “Timer Set” button unit a “beep” sound is heard as confirmation of transmission code change.

15.2.2 RESET (RC)

To clear and restore the remote control setting to factory default.

o Press once to clear the memory

15.2.3 RESET (AC)

To restore the unit’s setting to factory default.

o Press once to restore the unit’s setting

15.2.4 TIMER ▲

To change indoor unit indicator’s LED intensity:

o Press continuously for 5 seconds.

15.2.5 TIMER ▼

To change remote control display from Degree Celsius (°C) to Degree Fahrenheit (°F)

o Press continuously for 10 seconds.

15.2.6 CLOCK Button

To change the remote control time format:

o Press for more than 5 seconds

42

Page 43

16. Troubleshooting Guide

16.1 Refrigeration Cycle System

In order to diagnose malfunctions, make sure that there are no

electrical problems before inspecting the refrigeration cycle.

Such problems include insufficient insulation, problem with the

power source, malfunction of a compressor and a fan.

The normal outlet air temperature and pressure of the

refrigeration cycle depends on various conditions, the standard

values for them are shown in the table on the right.

Normal Pressure and Outlet Air Temperature (Standard)

Cooling Mode

Heating Mode

Condition: Indoor fan speed = High

Gas Pressure

PSI

2

G)

(kg/cm

130.53 ~ 174.04

(9 ~ 12)

333.58 ~ 420.60

(23 ~ 29)

Outdoor temperature 95°F at cooling mode

and 44.6°F at heating mode.

Compressor operate at rated frequency

Outlet air

Temperature

(°F)

53.6 ~ 60.8

96.8 ~ 113

43

Page 44

16.1.1 Relationship between the condition of the air conditioner and pressure and

electric current

Carry out the measurements of pressure, electric current, and temperature fifteen minutes after an operation is

started.

44

Page 45

16.2 Breakdown Self Diagnosis Function

16.2.1 Self Diagnosis Function (Three Digits Alphanumeric Code)

Once error occurred during operation, the unit will stop its operation, and Timer LED blinks.

Although Timer LED goes off when power supply is turned off, if the unit is operated under a breakdown

condition, the LED will ON again.

In operation after breakdown repair, the Timer LED will not blink. The last error code (abnormality) will be stored

in IC memory.

16.2.2 To Make a Diagnosis

1 Timer LED starts to blink and the unit automatically stops the operation.

2 Press the CHECK button on the remote control continuously for

5 seconds.

3 “- -“ will be displayed on the remote control display.

Note: Display only for “- -“ (No signal transmission, no receiving sound

and no Power LED blinking)

4 Press the TIMER ▲ or ▼ button on the remote control. The code “H00”

(no abnormality) will be displayed and signal will be transmit to the main

unit.

5 Each press of the button (▲ or ▼) will increase error code number and

transmit error code signal to the main unit.

6 When the latest abnormality code on the main unit and code transmitted

from the remote control are matched, Power LED will light up for 30

seconds and a “beep” sound (continuously for

4 seconds) will be heard. If no codes are matched, Power LED will light up for 0.5 seconds and no sound will

be heard.

7 The breakdown diagnosis mode will be canceled unless pressing the CHECK button continuously for

5 seconds or operating the unit for 30 seconds.

8 The LED will be off if the unit is turned off or the RESET button on the main unit is pressed.

16.2.3 To Display Memorized Error Code (Protective Operation)

1 Turn power on.

2 Press the CHECK button on the remote control

3 “- -“ will be displayed on the remote control display.

Note: Display only for “- -“ (No signal transmission, no receiving sound and no Power LED blinking)

4 Press the TIMER ▲ or ▼ button on the remote control. The code “H00” (no abnormality) will be displayed

and signal will be transmit to the main unit.

5 Each press of the button (▲ or ▼) will increase error code number and transmit error code signal to the main

unit.

6 When the latest abnormality code on the main unit and code transmitted from the remote control are matched,

Power LED will light up for 30 seconds and a “beep” sound (continuously for 4 seconds) will be heard. If no

codes are matched, Power LED will light up for 0.5 seconds and no sound will be heard.

7 The breakdown diagnosis mode will be canceled unless pressing the CHECK button continuously for 5

seconds or operating the unit for 30 seconds.

8 The same diagnosis can be repeated by turning power on again.

16.2.4 To Clear Memorized Error Code after Repair (Protective Operation)

1 Turn power on (in standby condition).

2 Press the AUTO button for 5 seconds (a “beep” sound is heard) on the main unit to operate the unit at

Forced Cooling Operation Mode.

3 Press the CHECK button on the remote control for about 1 second with a pointed object to transmit signal to

main unit. A “beep” sound is heard, and the Error Code is cleared.

16.2.5 Temporary Operation (Depending On Breakdown Status)

1 Press the Auto OFF/ON button on the main unit (a “beep” sound is heard) to operate the unit. (Remote

control is enable again).

2 The unit can be temporarily be used until repaired.

Error Code Operation Temporary items

H23 Cooling

H27, H28 Cooling, Heating

Emergency Operation

with limited power

45

Page 46

16.3 Error Code Table

46

Page 47

Note:

“○” – Frequency measured and fan speed fixed

The memory data of error code is erased when the power supply is cut off, or press the Auto Switch until “beep”

sound heard following by pressing the CHECK button at remote control.

Although operation forced to stop when abnormality detected, emergency operation is possible for certain errors

(refer to Error Code Table) by using remote control or Auto OFF/ON button at indoor unit. However, the remote

control signal receiving sound is changed from one “beep” to four “beep” sounds.

47

Page 48

16.4 Self-diagnosis Method

16.4.1 H11 (Indoor/Outdoor Abnormal Communication)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the data received from outdoor unit in indoor unit signal

transmission is checked whether it is normal.

Malfunction Caused

Faulty indoor unit PCB.

Faulty outdoor unit PCB.

Indoor unit-outdoor unit signal transmission error due to wrong wiring.

Indoor unit-outdoor unit signal transmission error due to breaking of wire in the connection wires between the

indoor and outdoor units.

Indoor unit-outdoor unit signal transmission error due to disturbed power supply waveform.

Troubleshooting

48

Page 49

16.4.2 H12 (Indoor/Outdoor Capacity Rank Mismatched)

Malfunction Decision Conditions

During startup, error code appears when different types of indoor and outdoor units are interconnected.

Malfunction Caused

Wrong models interconnected.

Wrong indoor unit or outdoor unit PCBs mounted.

Indoor unit or outdoor unit PCBs defective.

Indoor-outdoor unit signal transmission error due to wrong wiring.

Indoor-outdoor unit signal transmission error due to breaking of wire 3 in the connection wires between the indoor

and outdoor units.

Troubleshooting

49

Page 50

16.4.3 H14 (Indoor Intake Air Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the indoor intake air

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

50

Page 51

16.4.4 H15 (Compressor Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor compressor

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

51

Page 52

16.4.5 H16 (Outdoor Current Transformer Open Circuit)

Malfunction Decision Conditions

A current transformer (CT) is detected by checking the compressor running frequency (≥ rated frequency) and

CT detected input current (less than 0.65A) for continuously 20 seconds.

Malfunction Caused

CT defective

Outdoor PCB defective

Compressor defective (low compression)

Troubleshooting

52

Page 53

16.4.6 H19 (Indoor Fan Motor – DC Motor Mechanism Locked)

Malfunction Decision Conditions

The rotation speed detected by the Hall IC during fan motor operation is used to determine abnormal fan motor

(feedback of rotation > 2550rpm or < 50rpm)

Malfunction Caused

Operation stops due to short circuit inside the fan motor winding.

Operation stops due to breaking of wire inside the fan motor.

Operation stops due to breaking of fan motor lead wires.

Operation stops due to Hall IC malfunction.

Operation error due to faulty indoor unit PCB.

Troubleshooting

53

Page 54

16.4.7 H23 (Indoor Pipe Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the indoor heat exchanger

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

54

Page 55

16.4.8 H27 (Outdoor Air Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor air temperature

sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

55

Page 56

16.4.9 H28 (Outdoor Pipe Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature

sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

56

Page 57

16.4.10 H30 (Compressor Discharge Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor discharge pipe

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

57

Page 58

16.4.11 H32 (Outdoor Heat Exchanger Temperature Sensor 2 Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor heat exchanger

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

58

Page 59

16.4.12 H33 (Unspecified Voltage between Indoor and Outdoor)

Malfunction Decision Conditions

The supply power is detected for its requirement by the indoor/outdoor transmission.

Malfunction Caused

Wrong models interconnected.

Wrong indoor unit and outdoor unit PCBs used.

Indoor unit or outdoor unit PCB defective.

Troubleshooting

59

Page 60

16.4.13 H36 (Outdoor Gas Pipe Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor gas pipe

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

60

Page 61

16.4.14 H37 (Outdoor Liquid Pipe Temperature Sensor Abnormality)

Malfunction Decision Conditions

During startup and operation of cooling and heating, the temperatures detected by the outdoor liquid pipe

temperature sensor are used to determine sensor errors.

Malfunction Caused

Faulty connector connection.

Faulty sensor.

Faulty PCB.

Troubleshooting

61

Page 62

16.4.15 H97 (Outdoor Fan Motor – DC Motor Mechanism Locked)

Malfunction Decision Conditions

The rotation speed detected by the Hall IC during fan motor operation is used to determine abnormal fan motor.

Malfunction Caused

Operation stops due to short circuit inside the fan motor winding.

Operation stops due to breaking of wire inside the fan motor.

Operation stops due to breaking of fan motor lead wires.

Operation stops due to Hall IC malfunction.

Operation error due to faulty outdoor unit PCB.

Troubleshooting

62

Page 63

16.4.16 H98 (Indoor High Pressure Protection)

Error Code will not display (no Timer LED blinking) but store in EEPROM

Malfunction Decision Conditions

During heating operation, the temperature detected by the indoor pipe temperature sensor is above 140°F.

Malfunction Caused

Clogged air filter of the indoor unit

Dust accumulation on the indoor unit heat exchanger

Air short circuit

Detection error due to faulty indoor pipe temperature sensor

Detection error due to faulty indoor unit PCB

Troubleshooting

63

Page 64

16.4.17 H99 (Indoor Freeze Prevention Protection: Cooling or Soft Dry)

Malfunction Decision Conditions

Freeze prevention control takes place (when indoor pipe temperature is lower than 35.6°F)

Malfunction Caused

Clogged air filter of the indoor unit

Dust accumulation on the indoor unit heat exchanger

Air short circuit

Detection error due to faulty indoor pipe temperature sensor

Detection error due to faulty indoor unit PCB

Troubleshooting

64

Page 65

16.4.18 F11 (Indoor Pipe Temperature Sensor Abnormality)

Malfunction Decision Conditions

When cooling operation, when indoor pipe temperature or indoor heat exchanger temperature sensor is above

113°F.

Malfunction Caused

Faulty connector connection.

Faulty indoor pipe temperature sensor.

Faulty indoor main PCB.

Troubleshooting

65

Page 66

16.4.19 F17 (Indoor Standby Units Freezing Abnormality)

Malfunction Decision Conditions

When the different between indoor intake air temperature and indoor pipe temperature is above 50°F or indoor

pipe temperature is below 30.2°F

Remark:

When the indoor standby unit is freezing, the outdoor unit transfers F17 error code to the corresponding indoor

unit and H39 to other indoor unit(s).

Malfunction Caused

Wrong wiring connection

Faulty sensor

Faulty expansion valve

Troubleshooting

66

Page 67

16.4.20 F90 (Power Factor Correction Protection)

Malfunction Decision Conditions

During startup and operation of cooling and heating, when Power Factor Correction (PFC) protection circuitry at

the outdoor unit main PCB senses abnormal high DC voltage level.

Malfunction Caused

DC voltage peak due to power supply surge.

DC voltage peak due to compressor windings not uniform.

Faulty outdoor PCB.

Troubleshooting

67

Page 68

16.4.21 F91 (Refrigeration Cycle Abnormality)

Malfunction Decision Conditions

During cooling, compressor frequency = Fcmax.

During cooling and heating operation, running current: 0.65A < I < 1.65A.

During cooling, indoor intake - indoor pipe < 39.2°F.

Malfunction Caused

Refrigerant shortage (refrigerant leakage)

Poor compression performance of compressor.

2/3 way valve closed.

Detection error due to faulty indoor intake air or indoor pipe temperature sensors.

Troubleshooting

68

Page 69

16.4.22 F93 (Compressor Rotation Failure)

Malfunction Decision Conditions

A compressor rotation failure is detected by checking the compressor running condition through the position

detection circuit.

Malfunction Caused

Compressor terminal disconnect

Outdoor PCB malfunction

Troubleshooting

69

Page 70

16.4.23 F95 (Cooling High Pressure Abnormality)

Malfunction Decision Conditions

During operation of cooling, when outdoor unit heat exchanger high temperature data (141.8°F) is detected by the

outdoor pipe temperature sensor.

Malfunction Caused

Outdoor pipe temperature rise due to short circuit of hot discharge air flow.

Outdoor pipe temperature rise due to defective of outdoor fan motor.

Outdoor pipe temperature rise due to defective outdoor pipe temperature sensor.

Outdoor pipe temperature rise due to defective outdoor unit PCB.

Troubleshooting

70

Page 71

16.4.24 F96 (IPM Overheating)

Malfunction Decision Conditions

During operating of cooling and heating, when IPM temperature data (212°F) is detected by the IPM temperature

sensor.

Malfunction Caused

IPM overheats due to short circuit of hot discharge air flow.

IPM overheats due to defective of outdoor fan motor.

IPM overheats due to defective of internal circuitry of IPM.

IPM overheats due to defective IPM temperature sensor.

Troubleshooting

71

Page 72

16.4.25 F97 (Compressor Overheating)

Malfunction Decision Conditions

During operation of cooling and heating, when compressor tank temperature data (233.6°F) is detected by the

compressor tank temperature sensor.

Malfunction Caused

Refrigerant shortage (refrigerant leakage).

2/3 way valve closed.

Detection error due to faulty compressor tank temperature sensor.

Troubleshooting

72

Page 73

16.4.26 F98 (Input Over Current Detection)

Malfunction Decision Conditions

During cooling and heating operation, when an input over-current (16.8A) is detected by checking the input current