Order No: MAC0112083C2

Room Air Conditioner

CS-E9BKP CU-E9BKP5

CS-E12BKP CU-E12BKP5

CONTENTS

Page Page

1 Features 2

2 Functions

3 Product Specifications

4 Dimensions

5 Refrigeration Cycle Diagram

6 Block Diagram

7 Wiring Diagram

8 Operation Details

9 Operating Instructions

10 Installation And Servicing Air Conditioner Using R410A 41

3

11 Installation Instructions

6

12 Servicing Information

13 Technical Data

10

12

14 Exploded View

13

15 Replaceme nt Parts List

16 Exploded View

14

16

17 Replaceme nt Parts List

36

18 Electronic Circuit Diagram

© 2001 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D) All rights reserved. Unauthorized copying

and distribution is a violation of law.

52

61

70

73

74

75

76

77

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

1 Features

Product

•

Microcomputer-controlled compressor operating

−

frequency

Vertical and Horizontal Airflow Directions

−

Five modes of operation selection

−

Power Mode operation

−

Sleep Mode operation

−

Delay ON Timer and OFF Timer

−

Standby operation

−

Remote Controller with illuminable buttons

−

Power Monitor Display LED

−

Catechin Air Purifying Filter

−

Solar Refreshing Deodorizing Filter

−

Serviceability

•

Washable Front Panel

−

Breakdown Self Diagnosis function

−

Environmental Protection

•

Non-ozone depletion substances refrigerant (R410A)

−

Quality Improvement

•

Gas leakage detection

−

Deice operation

−

Auto restart control

−

2

2 Functions

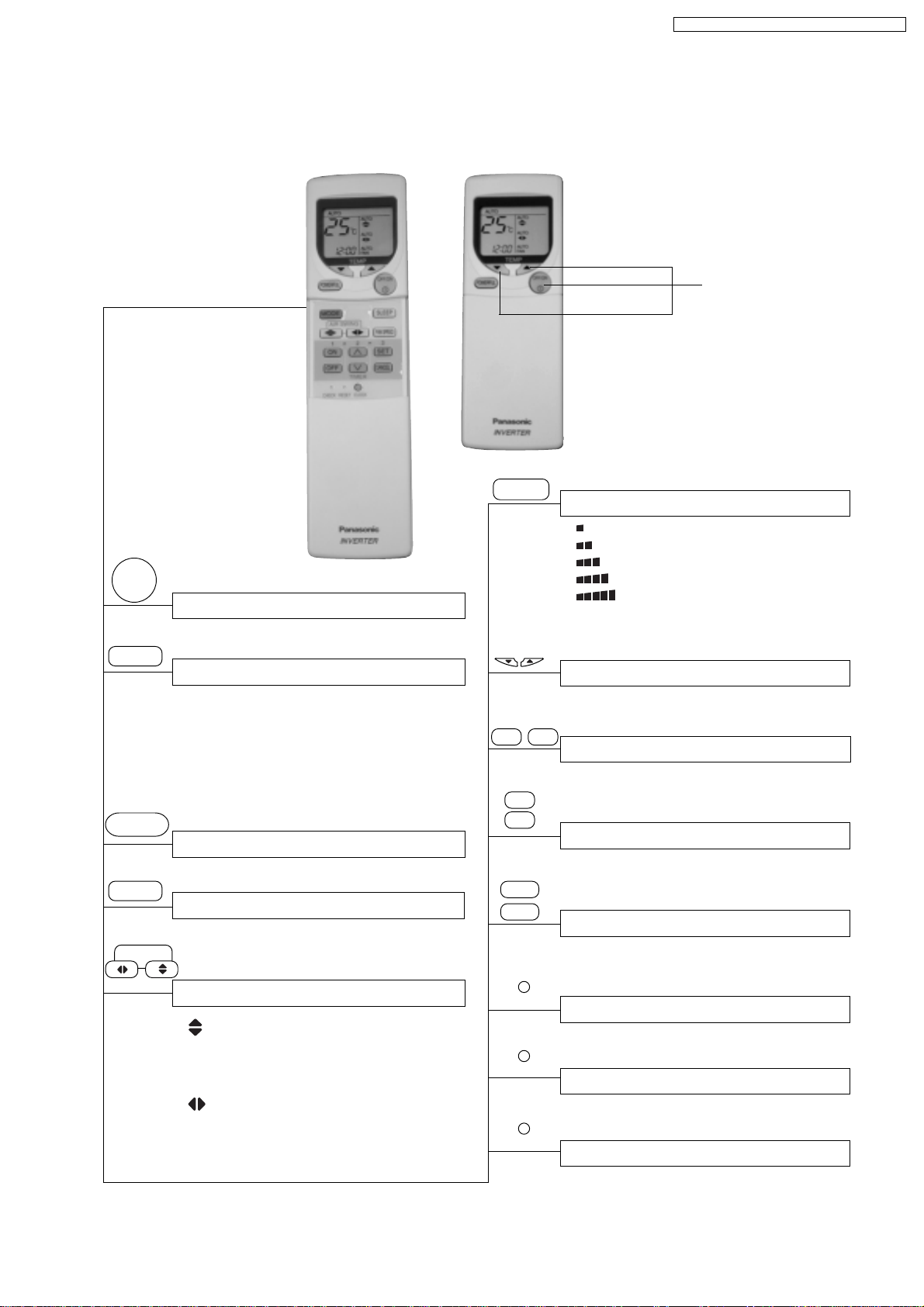

Remote Control

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Illuminable

buttons

OFF/ON

I

MODE

POWERFUL

SLEEP

Operation OFF / ON

Operation Mode Selection

•

•

•

•

•

a

HEAT

COOL

DRY

FAN

Automatic Operation

Heating Operation

Cooling Operation

Soft Dry Operation

Fan Operation

Powerful Mode Operation

Sleep Mode Operation OFF / ON

FAN SPEED

TEMP

TIMER

ON

OFF

∧

∨

SET

CANCEL

Indoor Fan Speed Selection

• Low

• Medium-

• Medium

•

•

•

AUTO

FAN

Medium+

High

Automatic Fan Speed

Room Temperature Setting

• Temperature Setting (16°C to 30°C)

Timer Operation Selection

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

Timer Operation Set / Cancel

AIR SWING

Airflow Direction Control

• Vertical Automatic Airflow

Direction Control and Manual

Airflow Direction Control (5

stages of adjustment).

•

Horizontal Automatic Airflow

Direction Control and Manual

Airflow Direction Control (5

stages of adjustment).

• ON Timer and OFF Timer setting and

cancellation.

CLOCK

Clock Setting

• Current time setting.

CHECK

Check Point

• Breakdown self diagnosis function.

RESET

3

Reset Point

• Clear memory data.

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

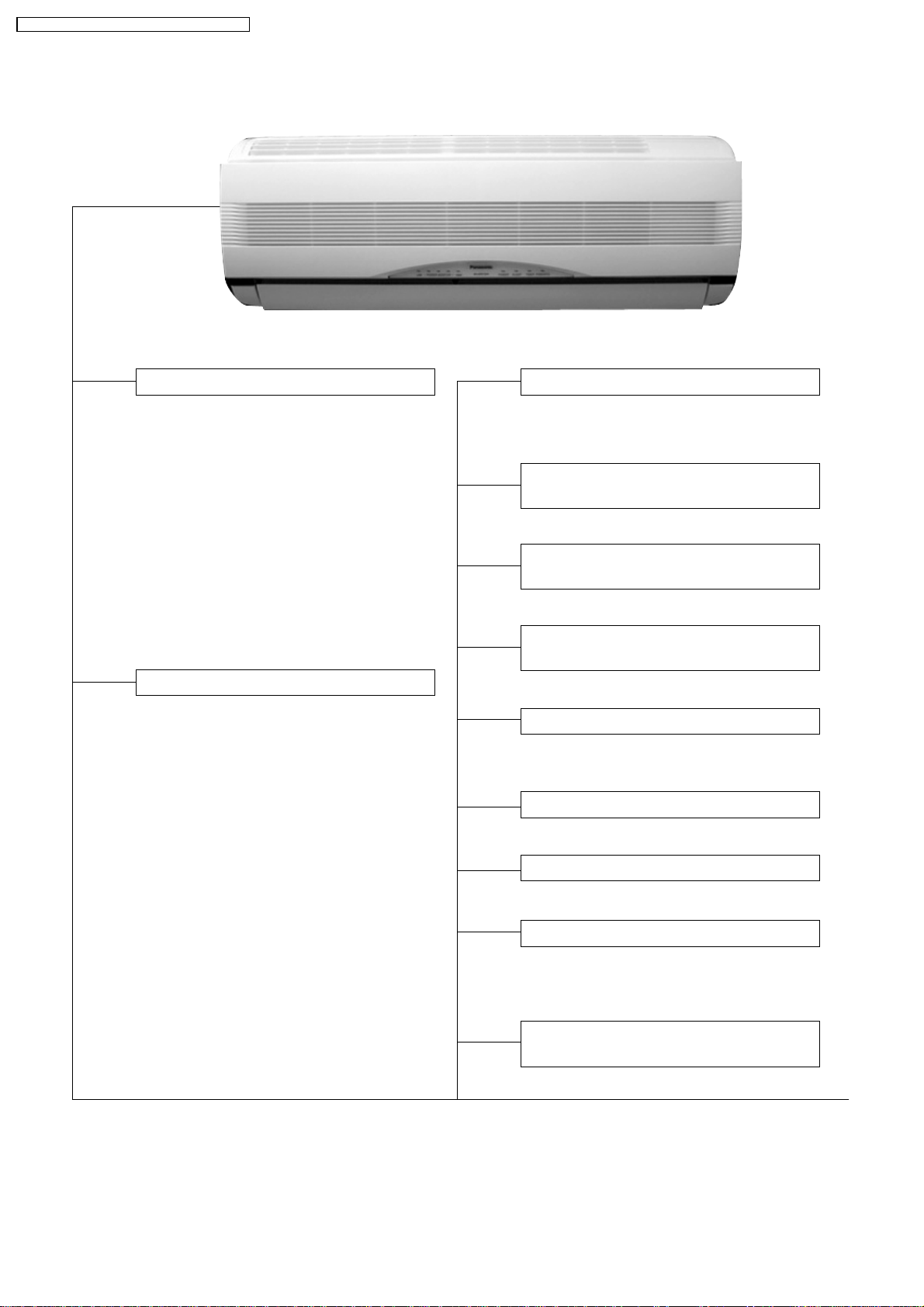

Indoor Unit

Automatic Operation Switch

• Press for < 5s to run Automatic Operation.

(Used when the remote control cannot be used.)

• Press continuously for 5s and < 8s to run

Forced Cooling Operation.

• Press continuously for 8s and < 11s to run

Forced Heating Operation.

• Press continuously for 11s and < 16s to

change different remote controlling

setting (A↔B Mode).

• Press continuously for 16s or < 21s to

switch OFF / ON Remote Control

Receiving Sound or H14 Abnormality

Detection Mode.

Operation Indication Lamps (LED)

•

POWER

MONITOR

•

POWER

TIMER

•

SLEEP

•

POWERFUL

•

(Orange) .....

(Green) ........ Lights up in

(Orange) .......Lights up in Timer

(Orange)........ Lights up in Sleep

(Orange)..Lights up when

Lights up during

compressor operation.

operation, blinks in

Automatic Operation

Mode judging and

Hot Start operation.

Setting.

Blinks in Self

Diagnosis Control.

Mode Operation.

Powerful Mode is

selected.

Five Operation Modes

• Automatic, Heating, Cooling, Soft Dry

and Fan Operation.

Automatic and 5 Manual Indoor

Fan Speeds

Automatic and 5 Manual Vertical

Airflow Directions

Automatic and 5 Manual Horizontal

Airflow Directions

Powerful Mode

• For quick cooling or heating.

Sleep Mode

Delay ON Timer and OFF Timer

Automatic Restart Control

• Operation is restarted after power failure

at previous setting mode.

Microcomputer-controlled Room

Temperature Control

4

Breakdown Self Diagnosis

Function

Low Pressure Control

(Gas Leakage Detection)

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

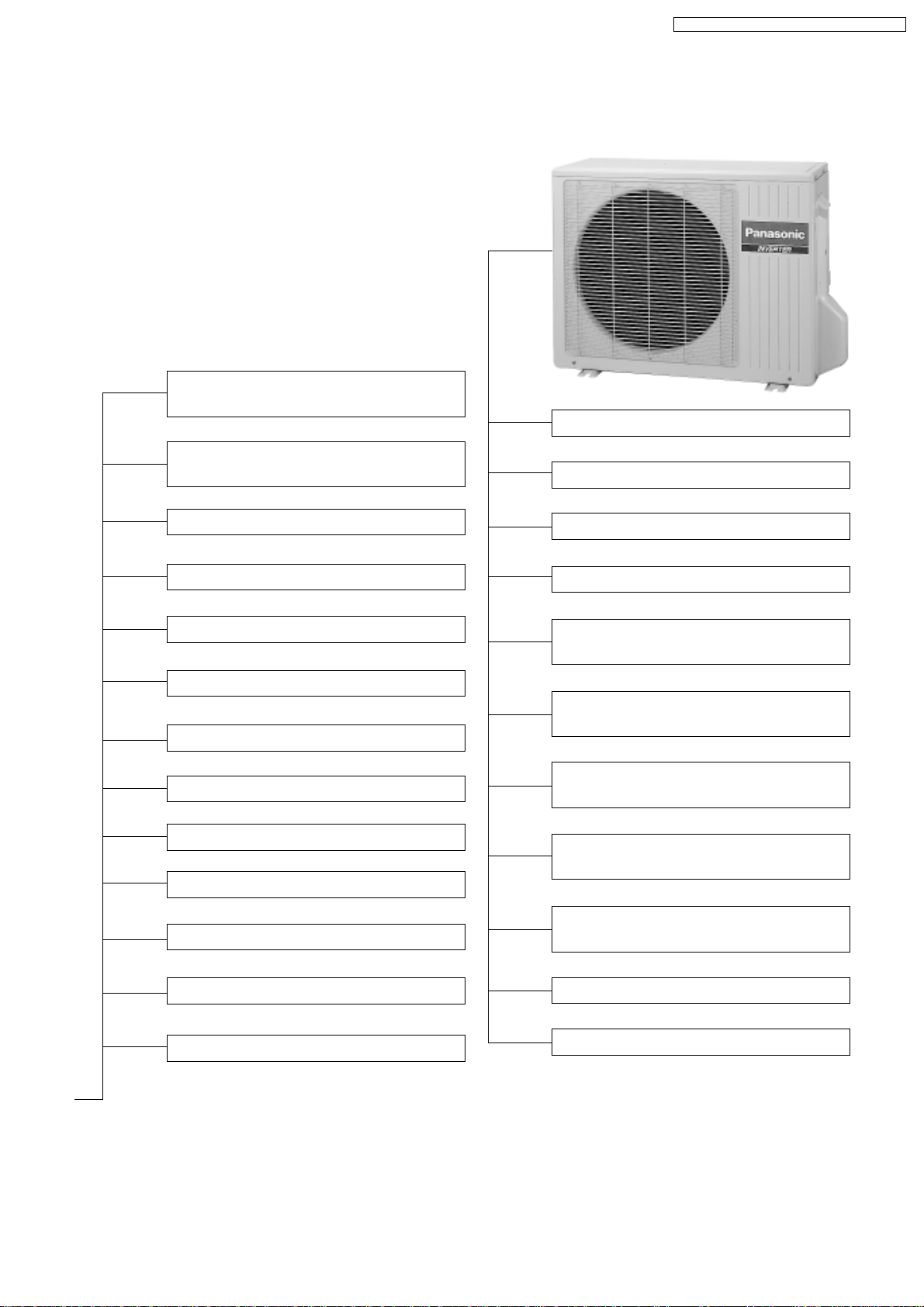

Outdoor Unit

Time Delay Safety Control

30 seconds Forced Operation

Indoor Power Relay Control

Automatic Restart Control

Deodorizing Control

Anti-Fog Discharge Control

Anti Freezing Control

Anti-Cold Draft Control

Hot Start

Intake Air Temperature Control

High Pressure Control

High Pressure Control

Total Running Current Control

Compressor Overheating

Prevention Control

IPM (Power Transistor)

Overheating Protection Control

Low Operation Frequency

Protection Control

Mininum Operation Frequency

Protection Control

Outdoor Air Temperature

Control

Standby Control

Deice Operation

Standby Control

Deice Operation

**

* Details can be refered to OPERATION

**

DETAILS in this manual.

5

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

3 Product Specifications

Unit CS-E9BKP CU-E9BKP5

Cooling Capacity kW

kcal/h

Heating Capacity kW

kcal/h

Moisture Removal l/h

Pint/h

Power Source Phase

V

Cycle

Airflow Method OUTLET

INTAKE

2.6 (0.60 - 3.00)

2,240 (520 - 2,580)

3.6 (0.60 - 5.00)

3,100 (520 - 4,300)

1.6

(3.4)

Single

230

50

SIDE VIEW TOP VIEW

Air Volume Indoor Air (Lo) m3/min (cfm) Cooling; 6.5 (231) —

Heating; 7.1 (249)

Indoor Air (Me) m3/min (cfm) Cooling; 8.1 (286) —

Heating; 8.8 (312)

Indoor Air (Hi) m3/min (cfm) Cooling; 9.9 (350) —

Heating; 10.6 (374)

dB (A) Cooling; High 39, Low 26 Cooling; 46

Heating; High 40, Low 27 Heating; 47

Noise Level

Power level dB Cooling; High 50 Cooling; High 59

Heating; High 51 Heating; High 60

Electrical Data Input W Cooling; 700 (115 - 880)

Heating; 900 (110 - 1,400)

Running Current A Cooling; 3.3

Heating; 4.0

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

EER W/W (kcal/hw) Cooling; 3.71(3.20)

COP W/W (kcal/hw) Heating; 4.00 (3.44)

Starting Current A 4.00

inch

inch

inch

inch

Inner diameter mm 12 —

Length m 0.7 —

G ; Half Union 3/8”

L ; Half Union 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

G ; 3-way valve 3/8”

L ; 2-way valve 1/4”

G (gas side) ; 3/8”

L (liquid side) ; 1/4”

6

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Power Cord Length

Number of core-wire

3 core wires × 1.0 mm

2.1 m

2

—

—

Dimensions Height inch (mm) 10 - 31/32 (275) 21 - 9/32 (540)

Width inch (mm) 31 - 15/32 (799) 27 - 17/32 (780)

Depth inch (mm) 7 - 27/32 (210) 11 - 7/32 (289)

Net Weight lb (kg) 20 (9.0) 77 (35)

Compressor Type — Involute scroll

Motor Type — Brushless (4-pole)

Rated Output W — 700

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 20% P.P

Motor Type Transistor (4-poles) Induction (6-poles)

Input W — 61.3

Rate Output W 30 25

Fan Speed Lo (Cool/Heat) rpm 800 / 840 —

Me (Cool/Heat ) rpm 1,000 / 1,040 —

Hi (Cool/Heat ) rpm 1,200 / 1,270 770

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Corrugated Fin

Row / Stage (Plate fin configuration, forced draft)

2/15 1/20

FPI 21 19

Size (W × H × L) mm 610 × 315 × 25.4 732.1 × 508 × 22

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — RB68A (360)

Refrigerant (R-22) g (oz) — 840 (29.7)

Thermostat Electronic Control —

Protection Device Electronic Control Electronic Control

Length mm — C1, C2 ; 1,100, C3 ; 440

Capillary Tube Flow Rate l/min — C1, C2 ; 5.0, C3 ; 18.6

Inner Diameter mm — C1, C2 ; 1.2, C3 ; 1.7

Air Filter Material

Style

P.P.

Honeycomb

—

Fan Motor Capacitor µF, VAC — 1.8 µF, 400 VAC

•

Specifications are subject to change without notice for further improvement.

7

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Unit CS-E12BKP CU-E12BKP5

Cooling Capacity kW

kcal/h

Heating Capacity kW

kcal/h

Moisture Removal l/h

Pint/h

Power Source Phase

V

Cycle

Airflow Method OUTLET

INTAKE

3.45 (0.60 - 4.00)

2,970 (520 - 3,440)

4.80 (0.60 - 6.50)

4,130 (520 - 5,590)

2.0

(4.2)

Single

230

50

SIDE VIEW TOP VIEW

Air Volume Indoor Air (Lo) m3/min (cfm) Cooling; 7.3 (258) —

Heating; 9.2 (325)

Indoor Air (Me) m3/min (cfm) Cooling; 9.2 (323) —

Heating; 10.3 (360)

Indoor Air (Hi) m3/min (cfm) Cooling; 10.9 (384.4) —

Heating; 11.8 (416.5)

dB (A) Cooling; High 42, Low 29 Cooling; 48

Heating; High 42, Low 33 Heating; 50

Noise Level

Power level dB Cooling; High 53 Cooling; High 61

Heating; High 53 Heating; High 63

Electrical Data Input W Cooling; 950 (120 - 1,280)

Heating; 1,260 (115 - 1,890)

Running Current A Cooling; 4.4

Heating; 5.6

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Number of core-wire

EER W/W (kcal/hw) Cooling; 3.63 (3.13)

COP W/W (kcal/hw) Heating; 3.81 (3.28)

Starting Current A 5.60

inch

inch

inch

inch

G ; Half Union 1/2”

L ; Half Union 1/4”

G (gas side) ; 1/2”

L (liquid side) ; 1/4”

G ; 3-way valve 1/2”

L ; 2-way valve 1/4”

G (gas side) ; 1/2”

L (liquid side) ; 1/4”

Inner diameter mm 12 —

Length m 0.7 —

3 core wires × 1.5 mm

2.1 m

2

8

—

—

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Dimensions Height inch (mm) 10 - 31/32 (275) 21 - 9/32 (540)

Width inch (mm) 31 - 15/32 (799) 27 - 17/32 (980)

Depth inch (mm) 7 - 27/32 (210) 11 - 7/32 (289)

Net Weight lb (kg) 20 (9.0) 81.6 (37)

Compressor Type — Involute scroll

Motor Type — Brushless (4-pole)

Rated Output W — 700

Air Circulation Type Cross-flow Fan Propeller Fan

Material AS + Glass Fiber 20% P.P

Motor Type Transistor (4-poles) Induction (6-poles)

Input W — 65.9

Rate Output W 30 29

Fan Speed Lo (Cool/Heat) rpm 880 / 1,100 —

Me (Cool/Heat ) rpm 1,100 / 1,230 —

Hi (Cool/Heat ) rpm 1,310 / 1,410 830

Heat Exchanger Description Evaporator Condenser

Tube material Copper Copper

Fin material Aluminium Aluminium

Fin Type Slit Fin Corrugated Fin

Row / Stage (Plate fin configuration, forced draft)

2/15 2/24

FPI 21 17

Size (W × H × L) mm 610 × 315 × 25.4 703.8

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — RB68A (360)

Refrigerant (R410A) g (oz) — 1,020 (36.0)

Thermostat Electronic Control —

Protection Device Electronic Control Electronic Control

Length mm — C1, C2 ; 1,100, C3 ; 750

Capillary Tube Flow Rate l/min — C1, C2 ; 5.0, C3 ; 15.4

Inner Diameter mm — C1, C2 ; 1.2, C3 ; 1.7

Air Filter Material

Style

Fan Motor Capacitor µF, VAC — 2.0 µF, 400 VAC

P.P.

Honeycomb

× 504 × 36.4

735.0

—

•

Specifications are subject to change without notice for further improvement.

9

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

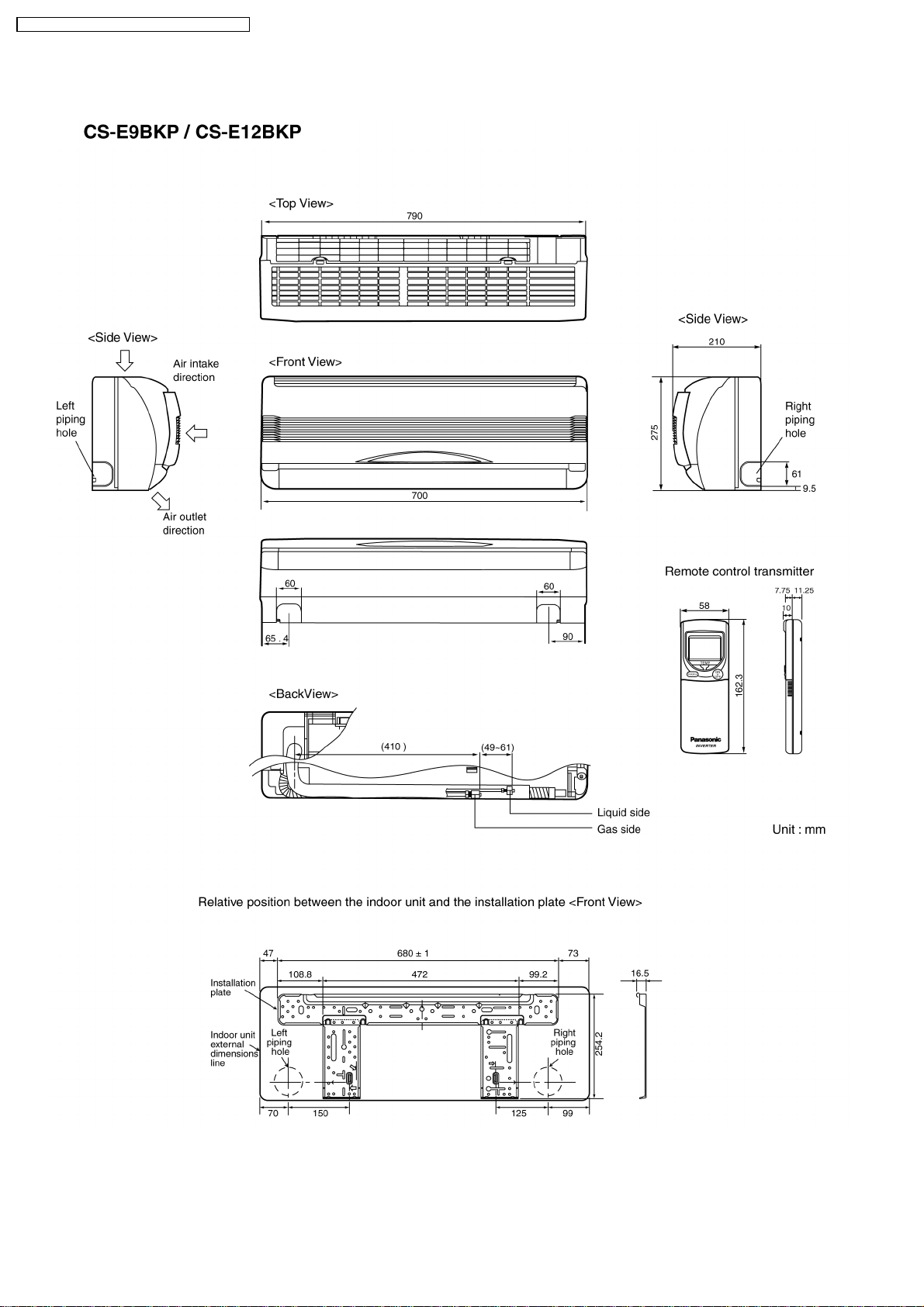

4 Dimensions

10

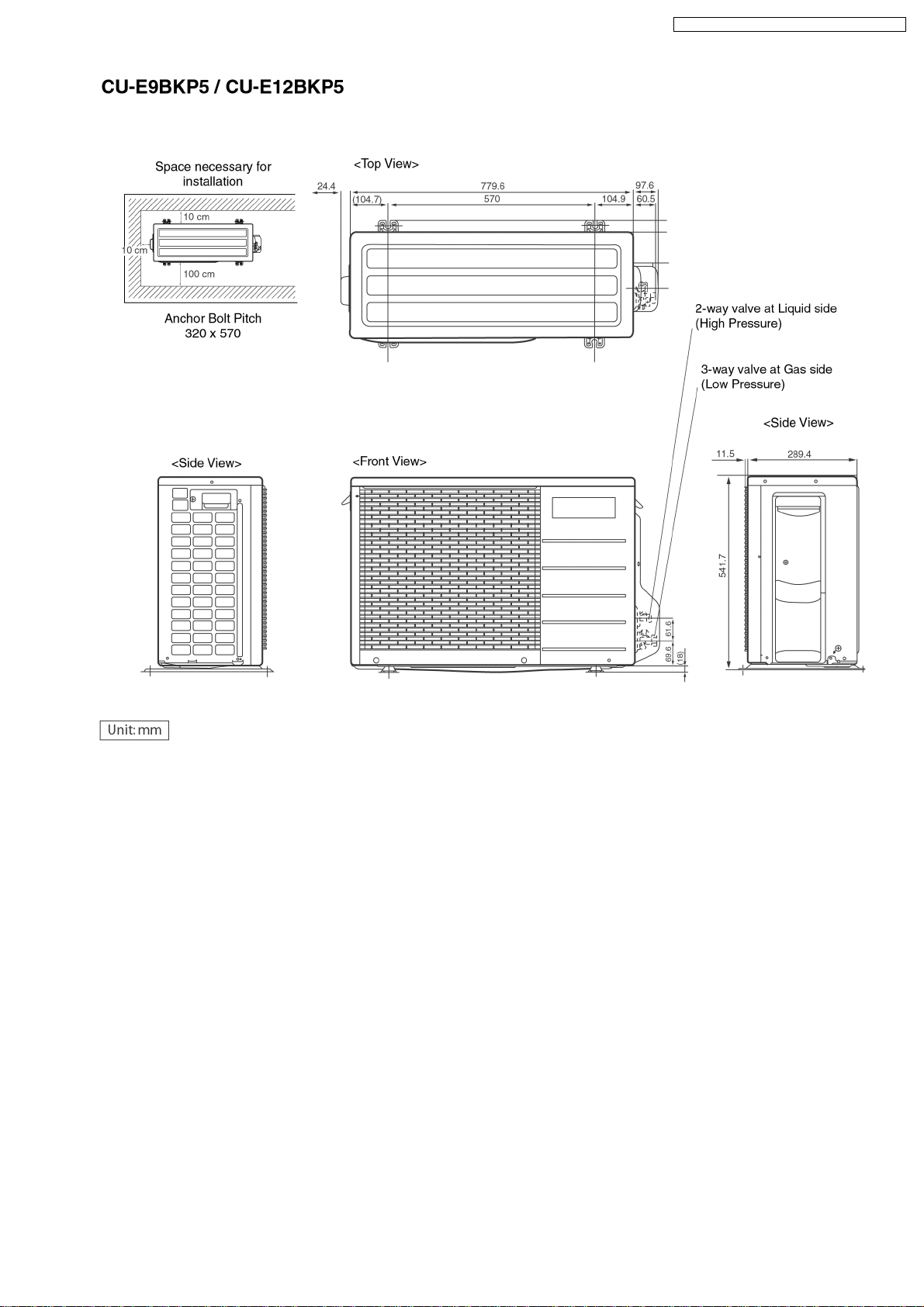

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

11

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

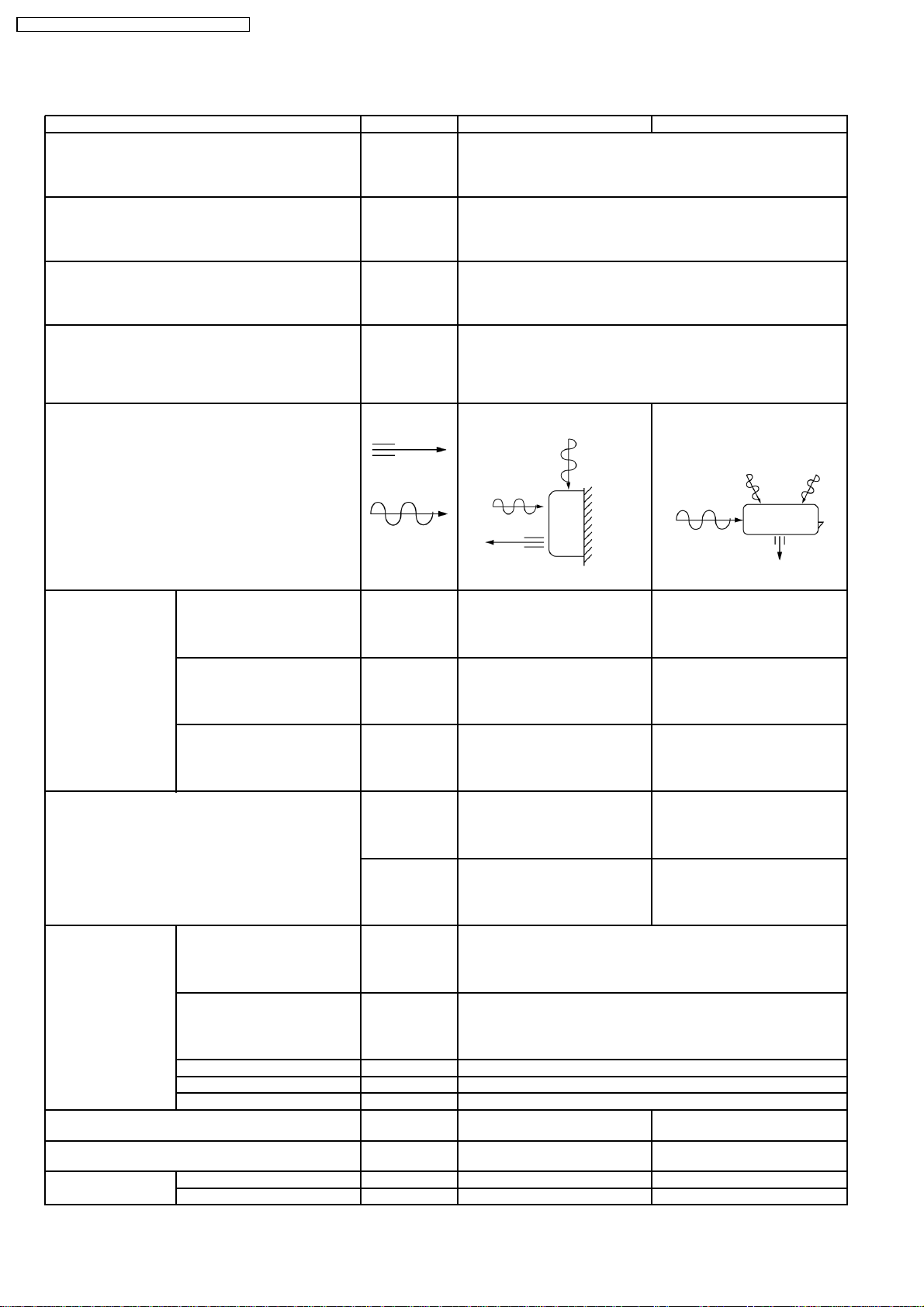

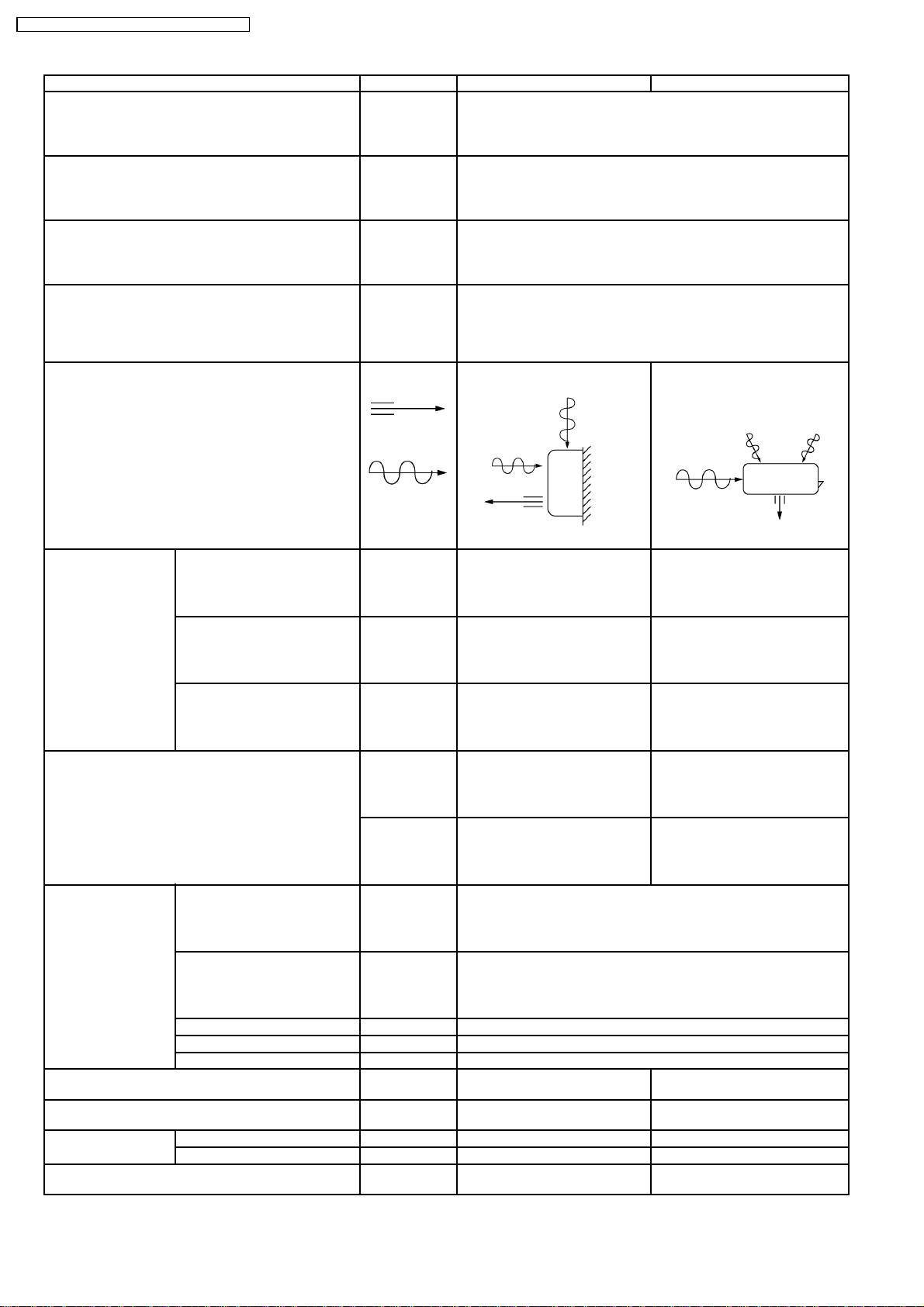

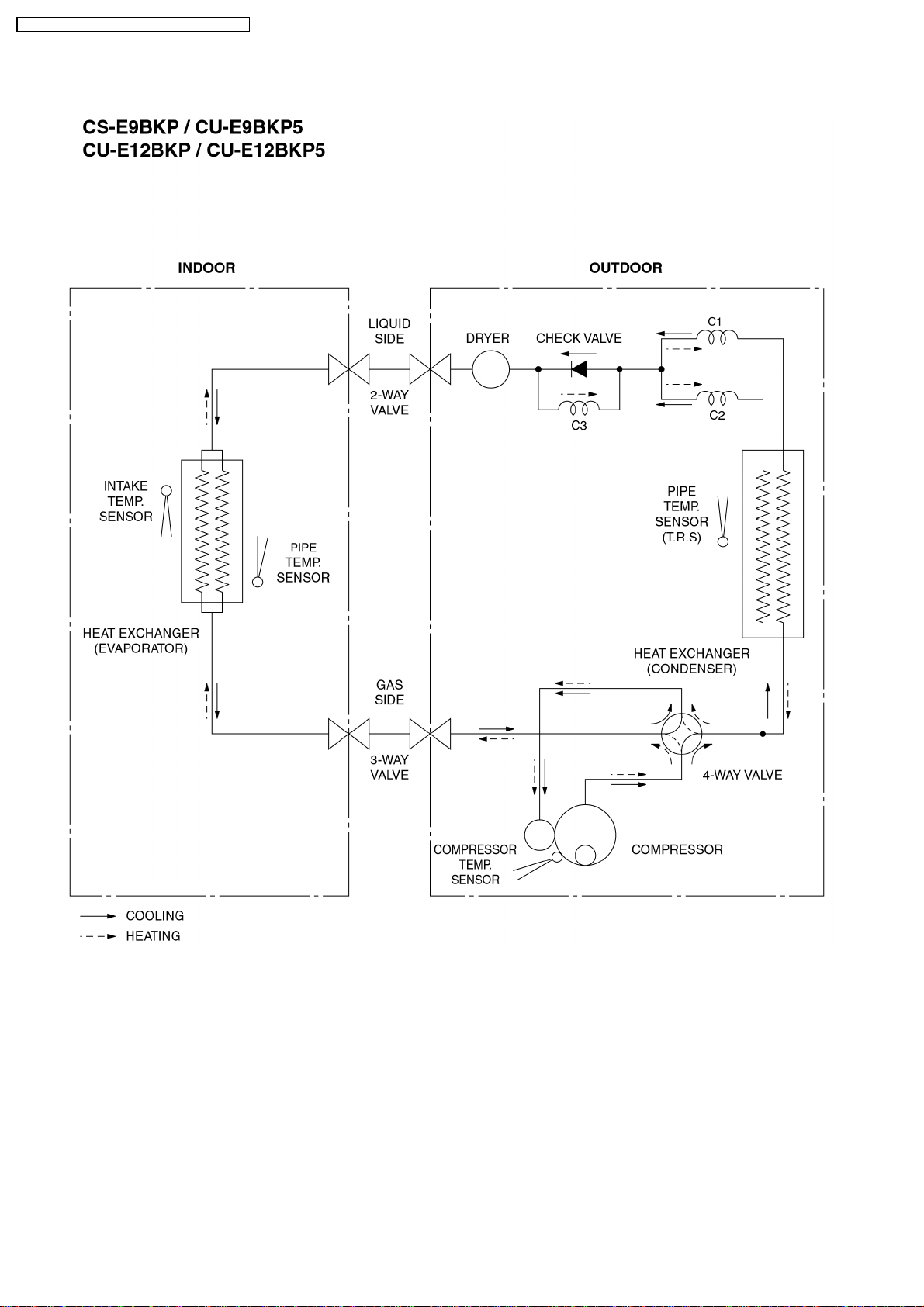

5 Refrigeration Cycle Diagram

12

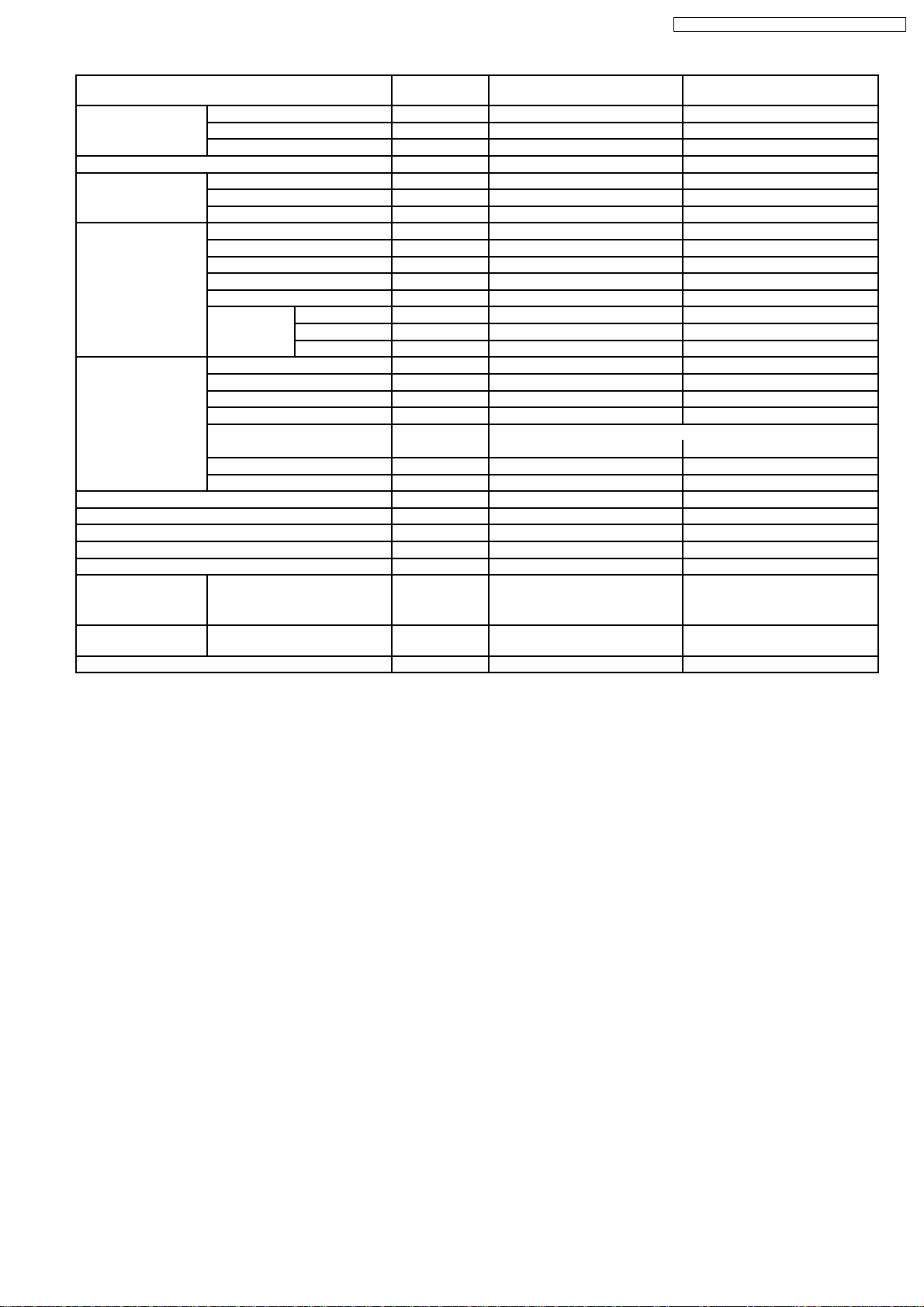

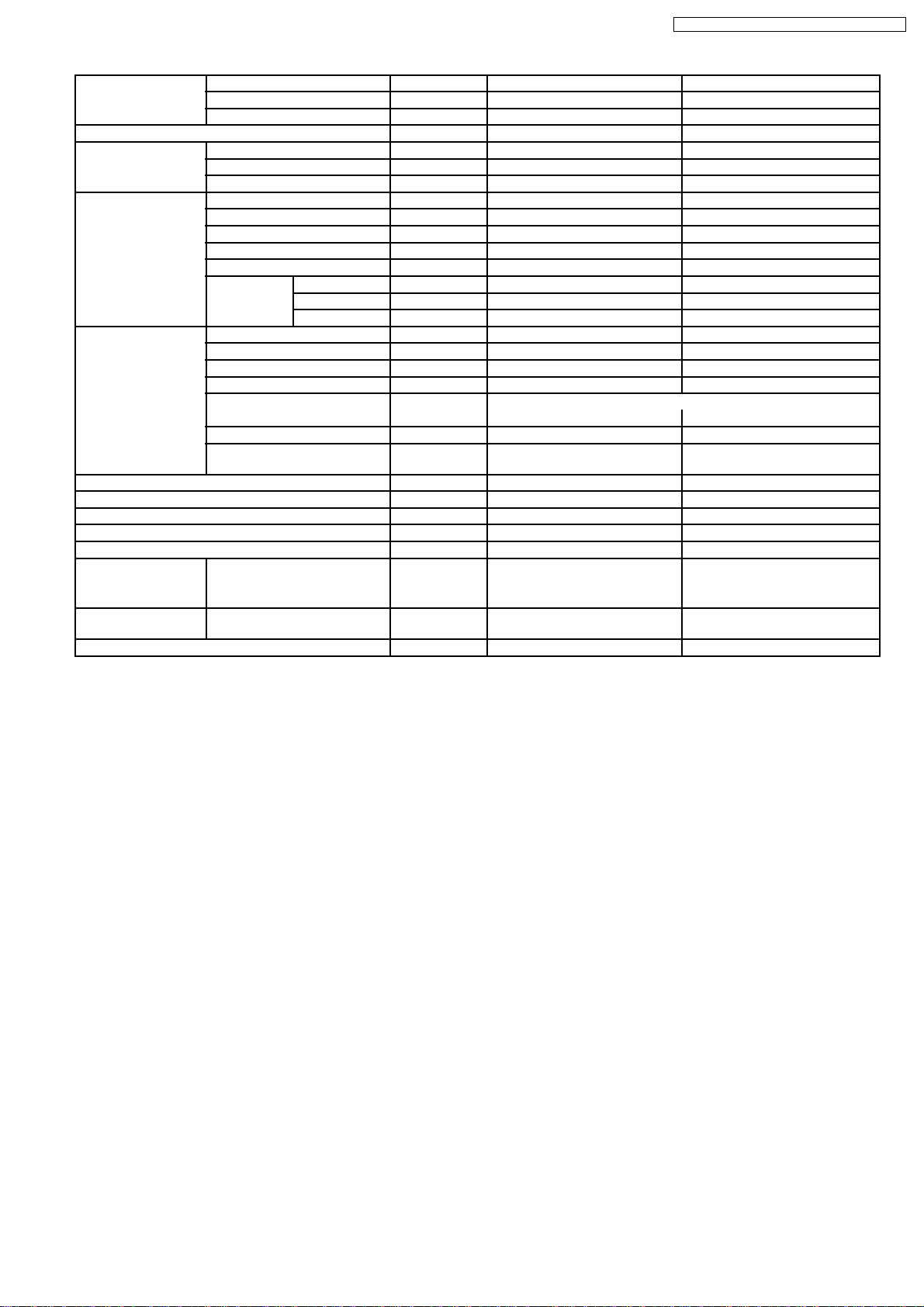

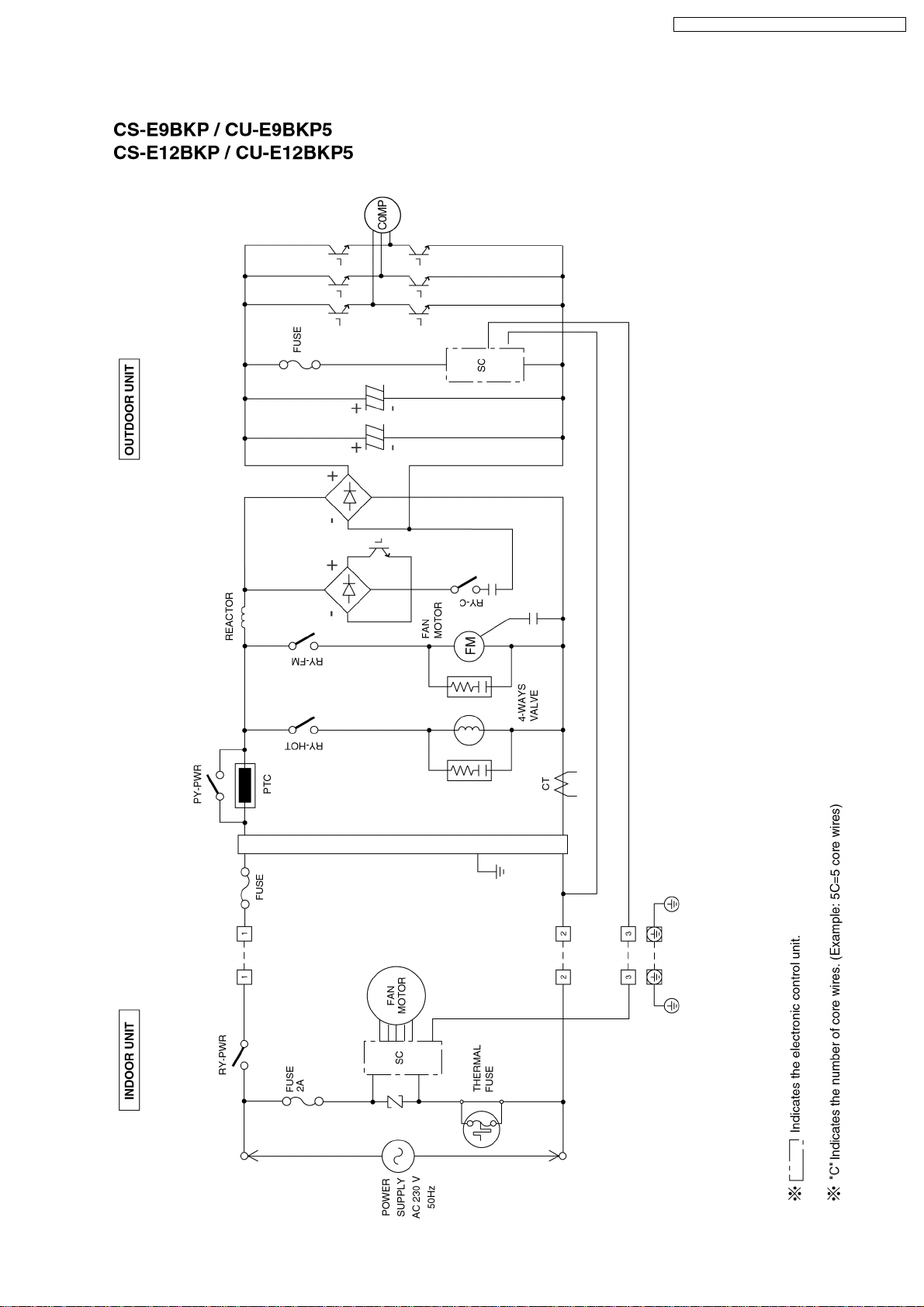

6 Block Diagram

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

13

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

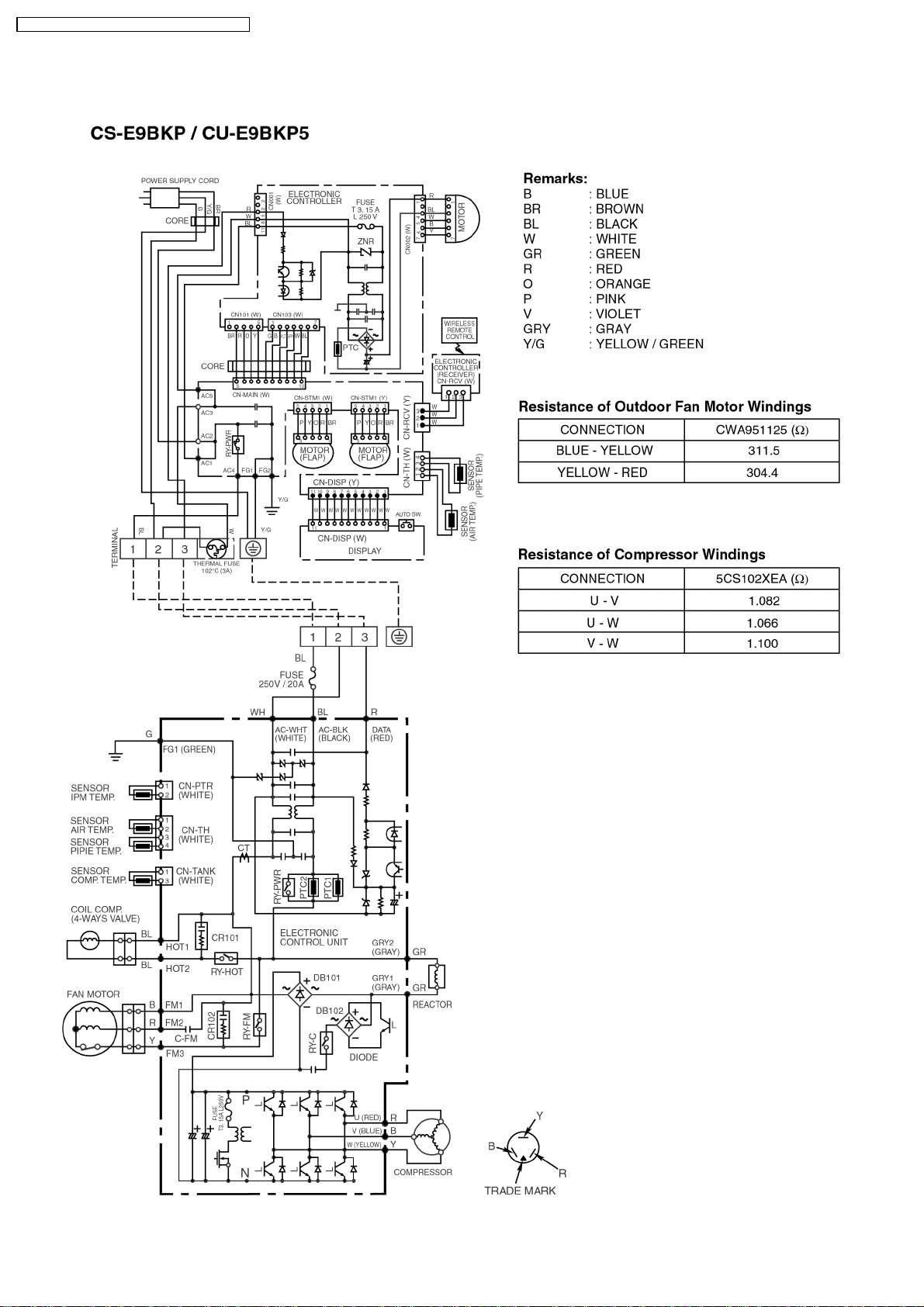

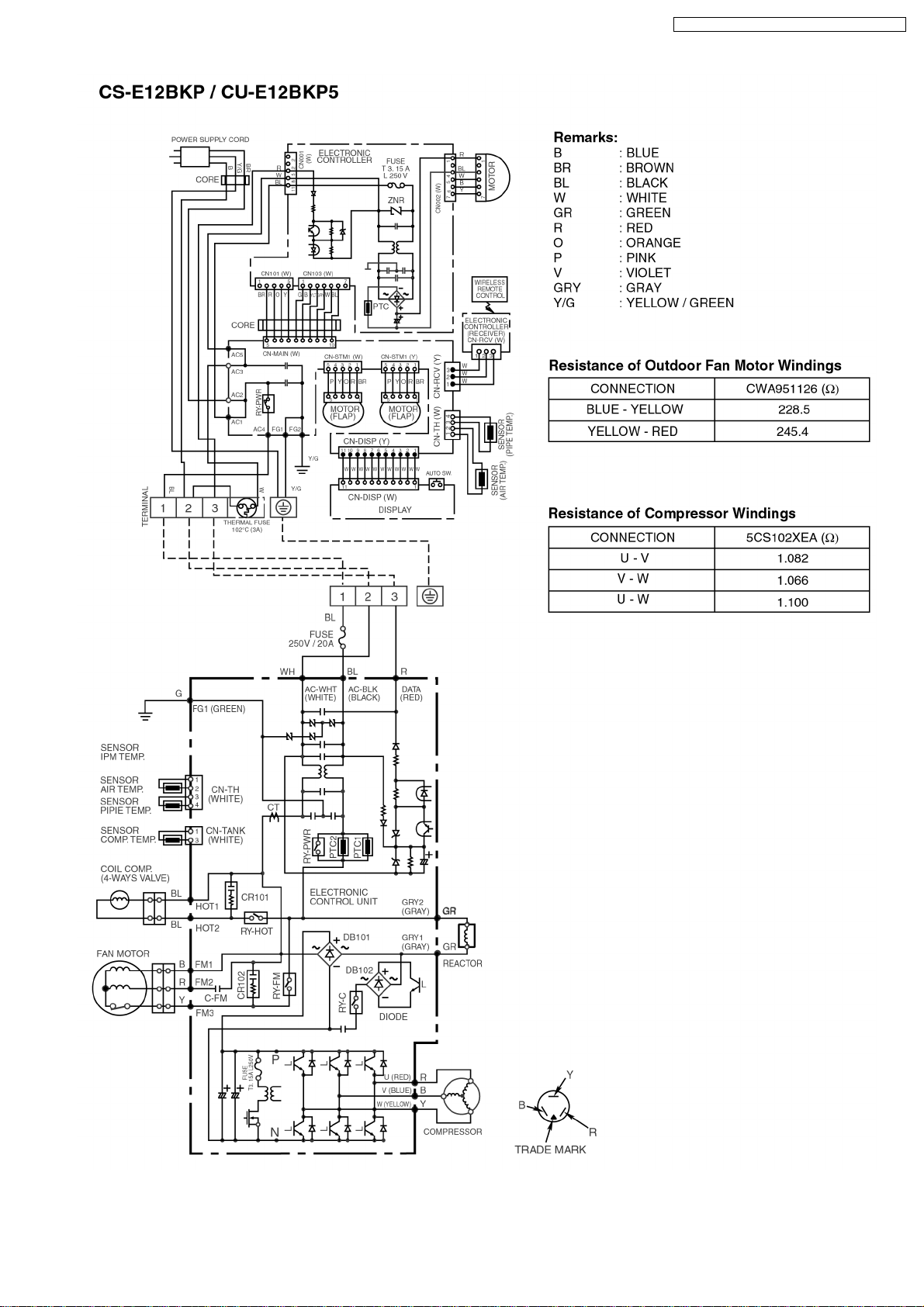

7 Wiring Diagram

14

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

15

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

8 Operation Details

8.1. BASIC FUNCTION

Inverter control, which equipped with a microcomputer in determining the most suitabl e operating mode as time passes,

automatically adjust output power for maximum comfort always. In order to achieve the suitable operating mode, the

microcomputer maintains the set temperature by measuring the temperature of the environment and performing temperature

shifting. The compressor at outdoor unit is operating following the frequency instructed by the microcomputer at indoor unit that

judging the condition according to internal setting temperature and intake air temperature.

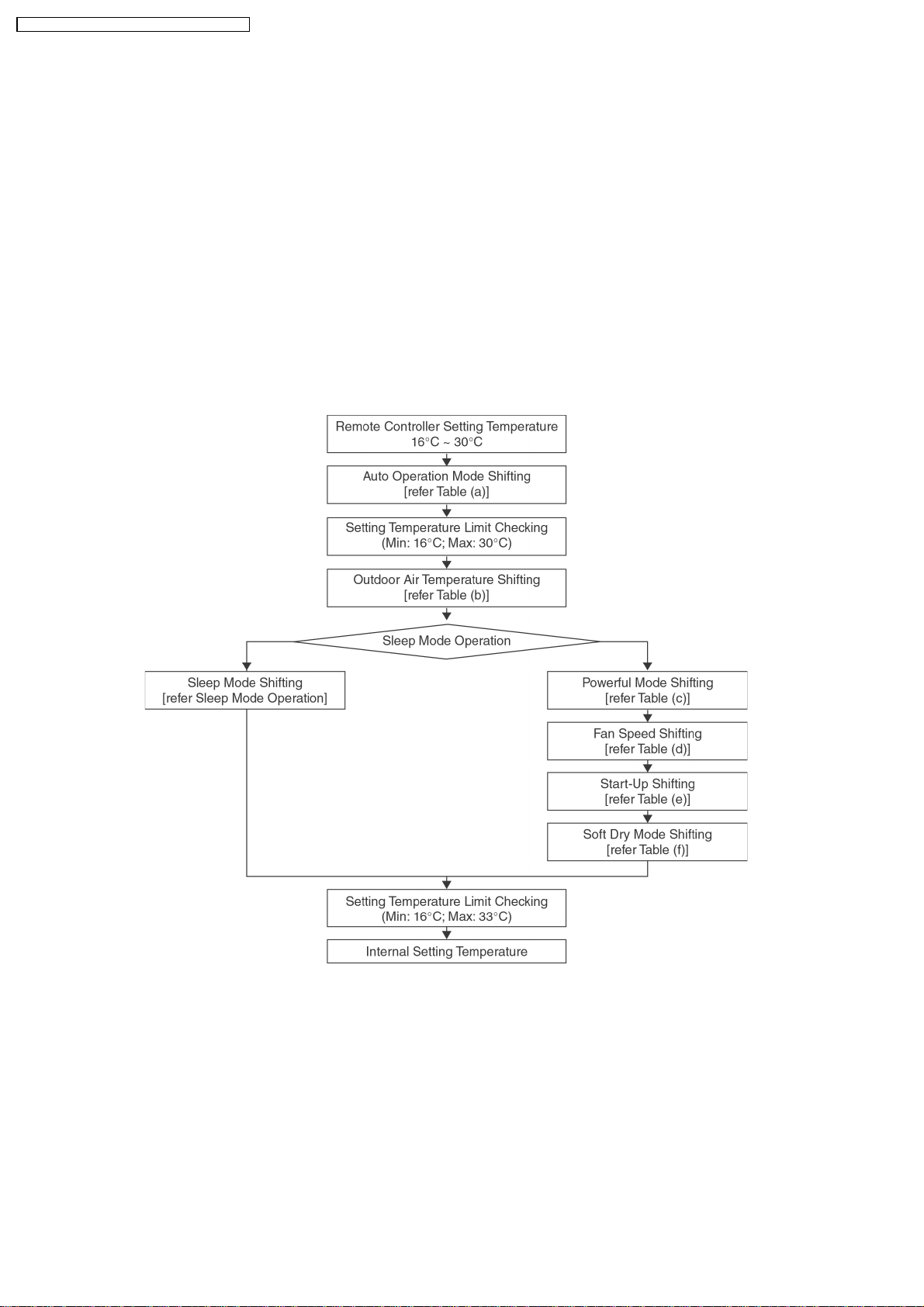

8.1.1. Internal Setting Temperature

Once the operation starts, remote controller setting temperature will be taken as base value for temperature shifting processes.

These shifting processes are depending on the air conditioner settings and the operation environment. The final shifted value

will be used as internal setting temperature and it is updated continuously whenever the electrical power is supplied to the unit.

16

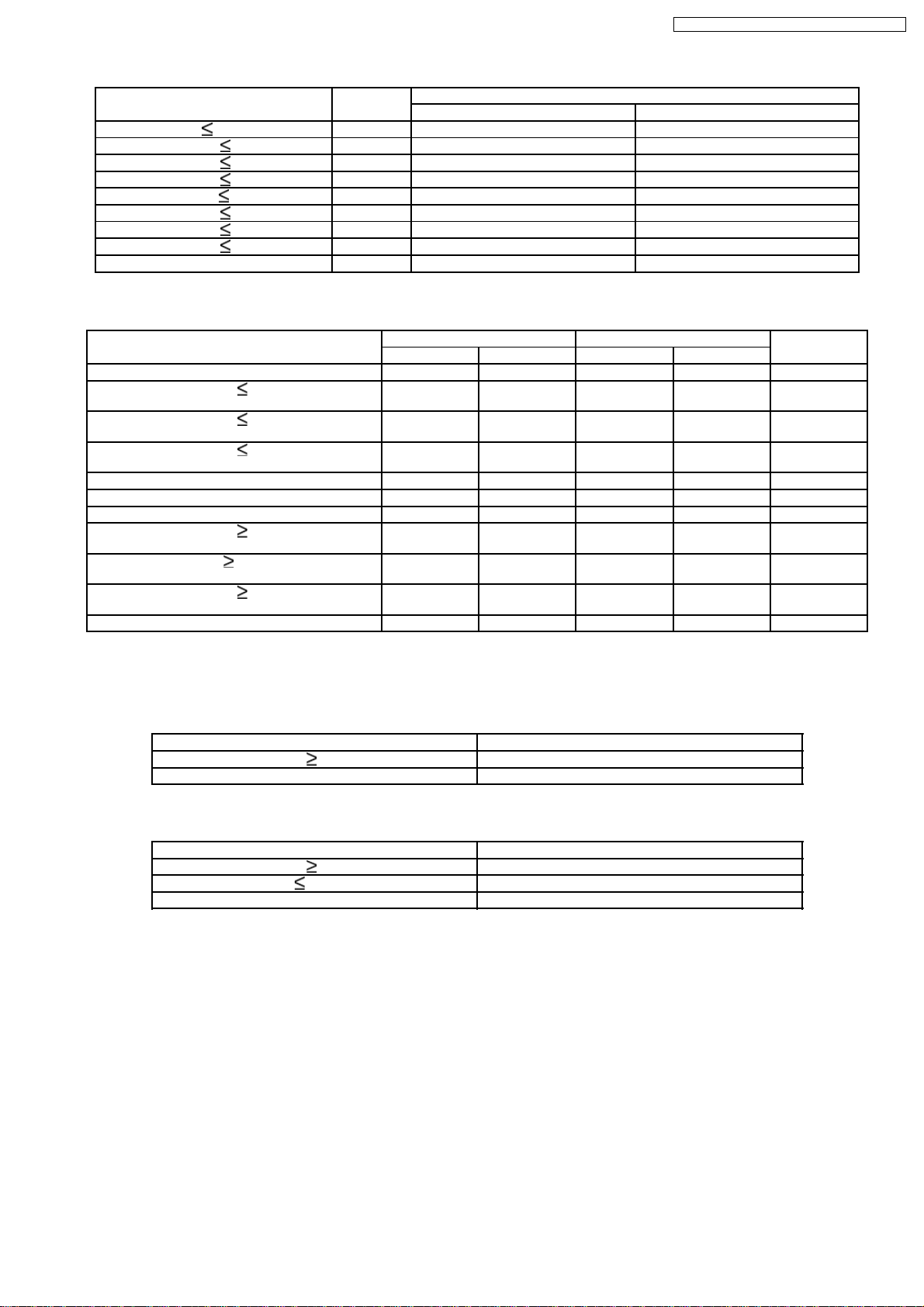

Table (a): Auto Operation Mode Setting

Cooling/Soft Dry → Heating -2.0 -2.0

Heating → Cooling/Soft Dry +2.0 +2.0

Table (b): Outdoor Air Temperature Shifting

Mode: Outdoor Temperature, X (°C): Temperature Shift (K)

Cooling/Soft Dry X 30 0.0 0.0

Heating X 9 0.0 0.0

Table (c): Powerful Mode Shifting

Mode: Period, X (min): Temperature Shift (K)

Cooling X<20 -2.0 -2.0

Soft Dry X<20 -1.0 -1.0

Heating X<20 +3.5 +3.5

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Mode Shift: Temperature Shift (K)

E9BKP E12BKP

E9BKP E12BKP

X<30 +0.5 +0.5

5 X<9 +0.5 +1.0

1 X<5 +1.0 +1.5

X<1 +1.5 +2.0

E9BKP E12BKP

X 20 0.0 0.0

X 20 0.0 0.0

X 20 +3.5 +3.5

Table (d): Fan Speed Shifting

Mode: Fan Speed: Temperature Shift (K)

Cooling All +1.5 +1.5

Soft Dry All +1.0 +1.0

Heating Lo +1.0 +1.0

Table (e): Start-Up Shifting

Cooling/Soft Dry -1.0 -1.0

Heating +2.0 +2.0

Table (f): Soft Dry Mode Shifting

Soft Dry +1.0 +1.0

E9BKP E12BKP

Me-, Me, Me+, Hi, Auto +0.5 +0.5

Mode within 60 Minutes from Start-up: Temperature Shift (K)

E9BKP E12BKP

Mode: Temperature Shift (K)

E9BKP E12BKP

17

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

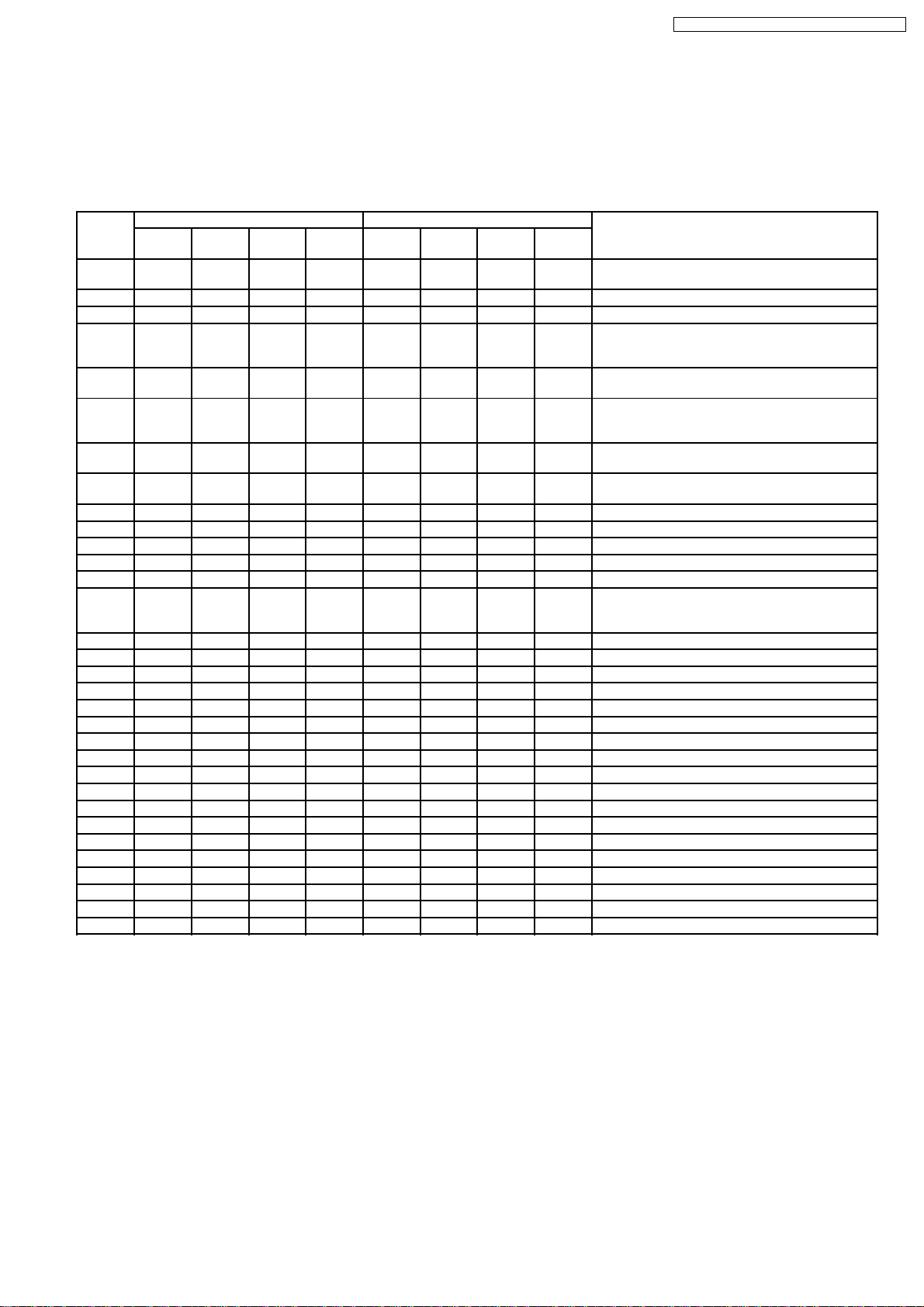

8.1.2. Frequency Instruction for Compressor Operation

Operation of compressor is based on instructed frequency, continuously from indoor unit´s microcomputer after performing

temperature sampling and judgment.

There are total 30 different frequency values, which listed as Table on Frequency Number, to be instructed based on the

temperature judgment

No. Frequency (Hz) Remarks

E9BKP E12BKP

1 12.0 12.0 Freq. MIN

2 15.0 15.0

3 18.0 18.0

4 21.0 21.0

5 23.0 23.0

6 25.0 25.0

7 26.0 28.0

8 30.0 32.0

9 33.0 36.0

10 35.0 40.0

11 36.0 44.0

12 38.0 48.0

13 39.0 52.0

14 40.0 57.0

15 47.0 62.0

16 49.0 67.0

17 56.0 68.5

18 58.0 72.0

19 63.0 76.0

20 66.0 80.0

21 70.0 85.0

22 73.0 88.0

23 77.0 91.0

24 80.0 94.0

25 83.0 98.0

26 86.0 102.0

27 87.0 104.0

28 88.0 106.0

29 89.0 108.0

30 90.0 110.0 Freq. MAX

Table on Frequency Number

For normal start of operation, including Thermo-OFF, Deice-Resuming, and remote controller ON-OFF starts, the compressor

starts to operate at frequency no. 8, values of 30Hz and 32Hz for E9BKP and E12BKP respectively, for 60 seconds.

The frequency to be judged and instructed, however, starts to judge once the air conditioner operated and the judgment will

continue every 30 seconds until it is stopped by all kinds of compressor off conditions. This judgment is based on the internal

temperature sampling that involving internal setting temperature and intake air temperature.

From the internal sampling, the temperature different (intake air temperature - internal setting temperature) will be used to judge

the Zone on which the frequency to be instructed for the initial operation of compressor (refer to Table on Initial Frequency Zone).

Temperature, X (K) Zone Freq. No. - E9BKP Freq. No. - E12BKP

(Intake Air - Internal Setting) Cooling Soft Dry Heating Cooling Soft Dry Heating

X -2.5 0 1 4 30 1 4 30

-2.5 < X -1.5 1 1 4 30 1 4 30

-1.5 < X -1.0 2 1 4 10 1 4 10

-1.0 < X -0.5 3 1 4 7 1 4 7

-0.5 < X +1.0 4 4 4 4 4 4 4

+0.5 < X +1.0 5 6 6 1 6 6 1

+1.0 < X +1.5 6 9 7 1 9 8 1

+1.5 < X +2.5 7 15 7 1 15 8 1

X > +2.5 8 15 7 1 15 8 1

Table on Initial Frequency Zone

After the initial operation, the instructed frequency will change or shift from initial frequency according to the judgment on

temperature different from sampling (refer to the Table on Shifting Frequency Zone).

18

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Temperature, X (K) Zone Frequency No. Shifting (shifting direction):

(Intake Air - Internal Setting) Cooling Mode / Soft Dry Mode Heating Mode

X -2.5 0 Shift to Freq. MIN (↑) Shift to Freq. MAX (↓)

-2.5 < X -1.5 1 Shift to Freq. MIN (↑) Shift to Freq. MAX (↓)

-1.5 < X -1.0 2 -2 Freq. No. (↑) +2 Freq. No. (↓)

-1.0 < X -0.5 3 -1 Freq. No. (↑) +1 Freq. No. (↓)

-0.5 < X +1.0 4 Same Freq. No. Same Freq. No.

+0.5 < X +1.0 5 +1 Freq. No. (↓) -1 Freq. No. (↑)

+1.0 < X +1.5 6 +2 Freq. No. (↓) -2 Freq. No. (↑)

+1.5 < X +2.5 7 Shift to Freq. MAX (↓) Shift to Freq. MIN (↑)

X > +2.5 8 Shift to Freq. MAX (↓) Shift to Freq. MIN (↑)

Table on Shifting Frequency Zone

Besides, the range of operation frequency will change according to the setting environment as listed below:

Condition: Freq. no. for E9BKP Freq. no. for E12BKP Remarks

MIN MAX MIN MAX

Cooling Mode 1 15 1 30 (a)

- if remote controller set 28°C & fan speed =

Hi

- if remote controller set 28°C & fan speed =

Me-, Me, Me+, Auto

- if remote controller set 28°C & fan speed =

Lo

- if Powerful Mode ON 7 15 7 30 (a), (c)

Soft Dry Mode 4 7 4 8

Heating Mode 1 16 1 30 (b)

- if remote controller set 18°C & fan speed =

Hi

- if remote control set 18°C & fan speed =

Me-, Me, Me+, Auto

- if remote controller set 18°C & fan speed =

Lo

- if Powerful Mode ON 10 16 10 30 (b), (d)

7 15 7 30 (a), (c)

5 15 6 30 (a), (c)

4 15 5 30 (a), (c)

10 16 10 30 (b), (d)

9 16 9 30 (b), (d)

8 16 8 30 (b), (d)

Remark:

(a) If frequency shifts up from MAX, the following frequency performed will be depending to outdoor temperature, as given in below table (for

30 seconds only) and then continues as normal rule.

Outdoor Temperature, X (°C) Frequency No.

X 30 13

X<30 7

(b) (If frequency shifts up from Freq. No. 17, the following frequency performed is as below (for 30 seconds only) and then continue as normal

rule.

Outdoor Temperature, X (°C) Frequency No.

X 10 10

X X<10 13

X<4 17

(c) When temperature different (intake - setting) < -1.0 K or Thermo-Off activated and only valid for 120 seconds; not applicable during Sleep

Mode, Soft Dry Mode, and Anti-freezing control.

(d) When temperature different (intake - setting) > +1.5 K or Thermo-Off activated and only valid for 130 seconds.

19

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

The frequency judgment will perform every 30 seconds. Nevertheless, the frequency is instructed to outdoor compressor after

every 90 seconds except when either one of the below conditions is met:

(a) The frequency judged changes from frequency number decreasing zones (Zone No. 0 or 1 or 2 or 3) to frequency number

increasing zones (Zone No. 5 or 6 or 7 or 8) and vice verse.

(b) The frequency judged falls on frequency shifting zone number 0 or 1 (shift to Frequency MIN).

(c) The frequency judged falls on frequency shifting zone number 4 (no shifting in frequency number).

(d) The frequency judged falls on frequency shifting zone number 7 or 8 (shift to Frequency MAX).

The instructed frequency is the value referred by the frequency number, which resulted from previous instructed frequency

number with the numbers of frequency numbers to be shifted, in Table on Frequency Number.

Time (s) 0 30 60 90 120 150 180 210 240 270 300 330

Zone (+/-) + + + + + +/- + - - +/- +

Freq. zone based on temp. diff. 8 7 7 6 6 6 4 5 3 1 4 5

Frequency shift Max Max +2 +2 +2 0 +1 -1 Min 0 +1

Freq. no. judged based on

previous

Freq. instruction (Y/N) & its

condition

Freq. control condition (g) (g) (h) (h) (i)

Instructed freq. 8 8 15 15 15 14 5 5 5

Operation freq. 8 8 15 15 15 15 15 15 14 5 5 5

15 30 30 17 17 17 15 16 14 5 4 6

Y (a) Y (a) Y (b) N N Y (c) Y (d) N Y (e) Y (f) Y (d) N

Note:

(a) Starting frequency.

(b) Frequency judged falls on Zone 7 or 8 (shift to Frequency MAX).

(c) 90 seconds frequency instruction limit.

(d) Frequency judged falls on Zone 4 (no shifting).

(e) Frequency no. changes from no. increasing zones to no. decreasing zones.

(f) Frequency judged falls on Zone 0 or 1 (shift to Frequency MIN).

(g) Normal initial operation starts (60 s).

(h) Maximum frequency for normal cooling operation

(i) Minimum frequency for normal cooling operation.

20

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

8.1.3. Indoor Fan Motor Operation

There are 31 fan speed numbers assigned for different fan speed operation at designed conditions, as shown in below table. The

fan speed can be set manually using remote control (5 speeds for cooling mode: Lo, Me-, Me, Me+, Hi; 5 speeds for heating: Lo,

Me-, Me, Me+, Shi) or let it automatically changes depending on the operation and its environment.

Fan

Speed

Voltage

No.

0 OFF OFF OFF OFF OFF OFF - Hot start control.

1

2 3.03 3.03

3 3.05 SLo 3.05 SLo - Soft Dry operation mode.

4 3.13 3.13 - Auto operation mode judgment (C/D).

5 3.15 3.23 - Auto operation mode judgment (H).

6 3.16 Lo 3.29 Lo - Sleep shift operation (C).

7 3.23 Lo 3.34 - ON timer pre-operation at Auto fan for E9BKP

8 3.24 3.40

9 3.31 Me- 3.44 Me10 3.36 3.53

11 3.39 Me- 3.60 Me - Powerful Mode at Lo fan for E123BKP (C).

12 3.44 3.63

13 3.47 Me 3.66 Lo - Powerful Mode at Lo fan for E9BKP (C).

14 3.55 Me 3.68 - Powerful Mode at Lo fan for E9BKP (H).

15 3.57 3.71

16 3.60 3.75 Me17 3.63 Me+ 3.77 Me+ - Powerful Mode at Me- fan (C).

18 3.66 3.83

19 3.68 3.85

20 3.71 3.86 Me - Powerful Mode at Lo fan for E12BKP (H).

21 3.73 Me+ 3.91 - Powerful Mode at Me- fan for E9BKP (H).

22 3.77 3.94

23 3.79 3.98 Me+ - Powerful Mode at Me- fan for E12BKP (H).

24 3.80 4.00

25 3.82 Hi 4.00 Hi - Powerful mode at Me, Me+ or Hi fan (C).

26 3.85 4.01

27 3.89 4.05

28 3.90 4.08

29 3.91 4.11

30 3.93 SHi 4.16 SHi - Powerful mode at Me, Me+ or Hi fan (H).

31 4.07 4.30

(V)

CS-E9BKP CS-E12BKP Remark

Cooling Dry Heating Voltage

Cooling Dry Heating

(v)

- Deice control.

- ON timer pre-operation (D).

- Sleep shift operation (D).

- ON timer preparation sampling (C/D).

- ON timer preparation sampling (H).

- Sleep shift operation at compressor off.

- ON timer pre-operation at Auto fan (C).

(H).

- ON timer pre-operation at Auto fan for E12BKP

(H).

21

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

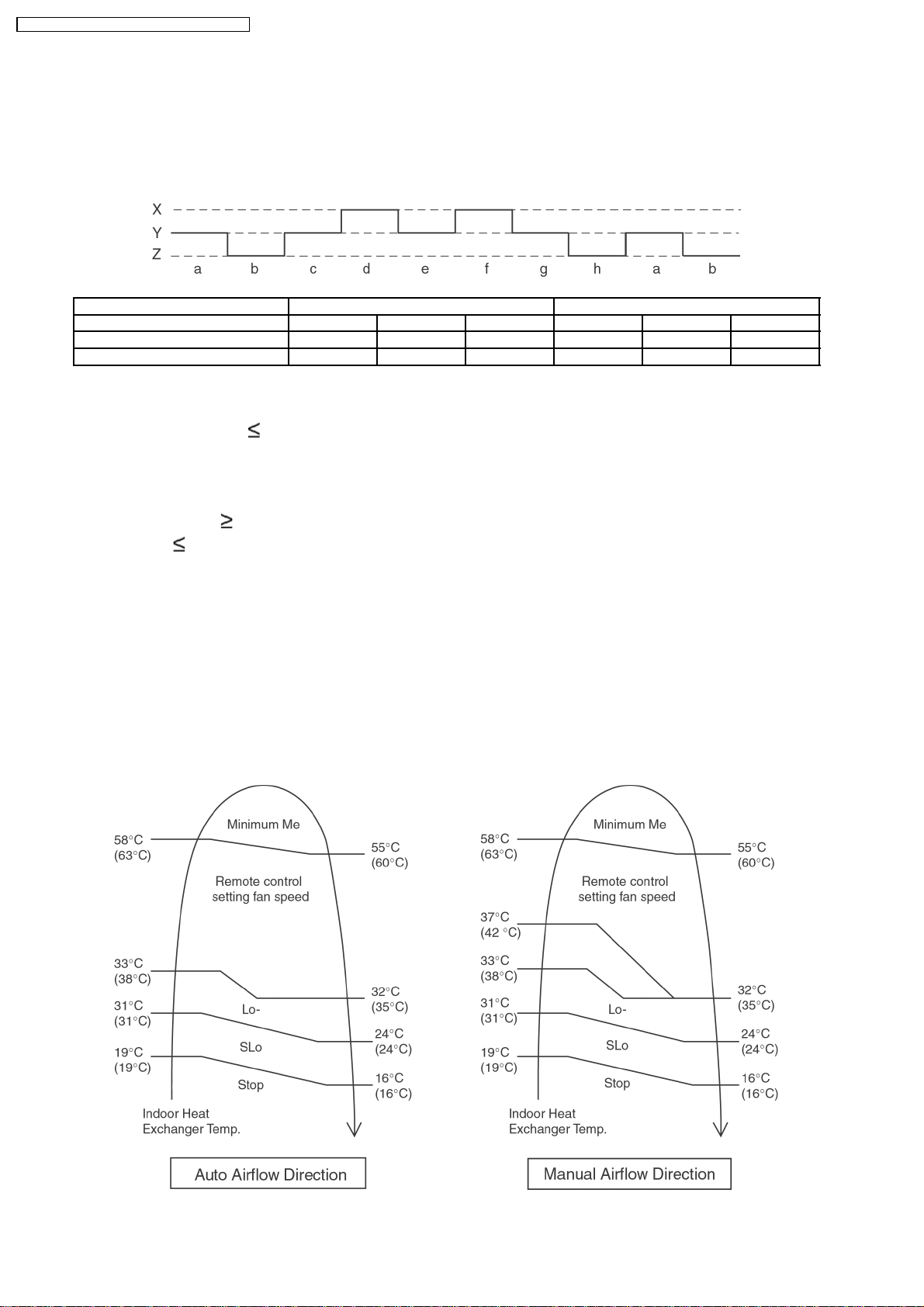

8.1.4. Cooling Mode Automatic Indoor Fan Speed

The automatic fan speed for cooling operation is as shown in below patterns (a→b→c

h) with each pattern 10 seconds.

→→

The fan speed for each level (X or Y or Z) is as below table.

Model No. E9BKP E12BKP

Level X Y Z X Y Z

Normal Operation Fan Speed No. 11 9 7 10 9 7

Powerful Mode Fan Speed No. 13 11 9 12 10 9

(a) During cooling operation, if all the following conditions occur, indoor fan speed will be shifted to Shi internally.

(i) Indoor intake air temperature

24°C.

(ii) Instructed frequency = 39 Hz (E9BKP) or 52 Hz (E12BKP).

(iii) Remote controller setting temperature = 16°C.

(iv) Remote controller setting fan speed = Hi.

(v) Outdoor air temperature

(vi) Operation starts

30 minutes.

30°C.

8.1.5. Heating Mode Indoor Fan Motor Operation (Anti Cold draft Control)

Indoor fan speed varies in accordance to indoor heat exchanger temperature, based on type of air volume and direction, as shown

below.

1. Manual Fan Speed

22

2. Auto Fan Speed

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

Note:

a. UP:

If move from Lo-, the fan speed will be shifted to Maximum.

•

If move from Maximum, the fan speed no change.

•

Other than that, the fan speed will be increased one Fan Speed No.

•

b. DOWN:

The fan speed will be decreased one Fan Speed No.

•

c. Fix:

No change in fan speed.

•

d. Maximum:

Fan speed will be increased to maximum auto fan speed.

•

e. Temperature in ( ) is for Powerful Mode operation.

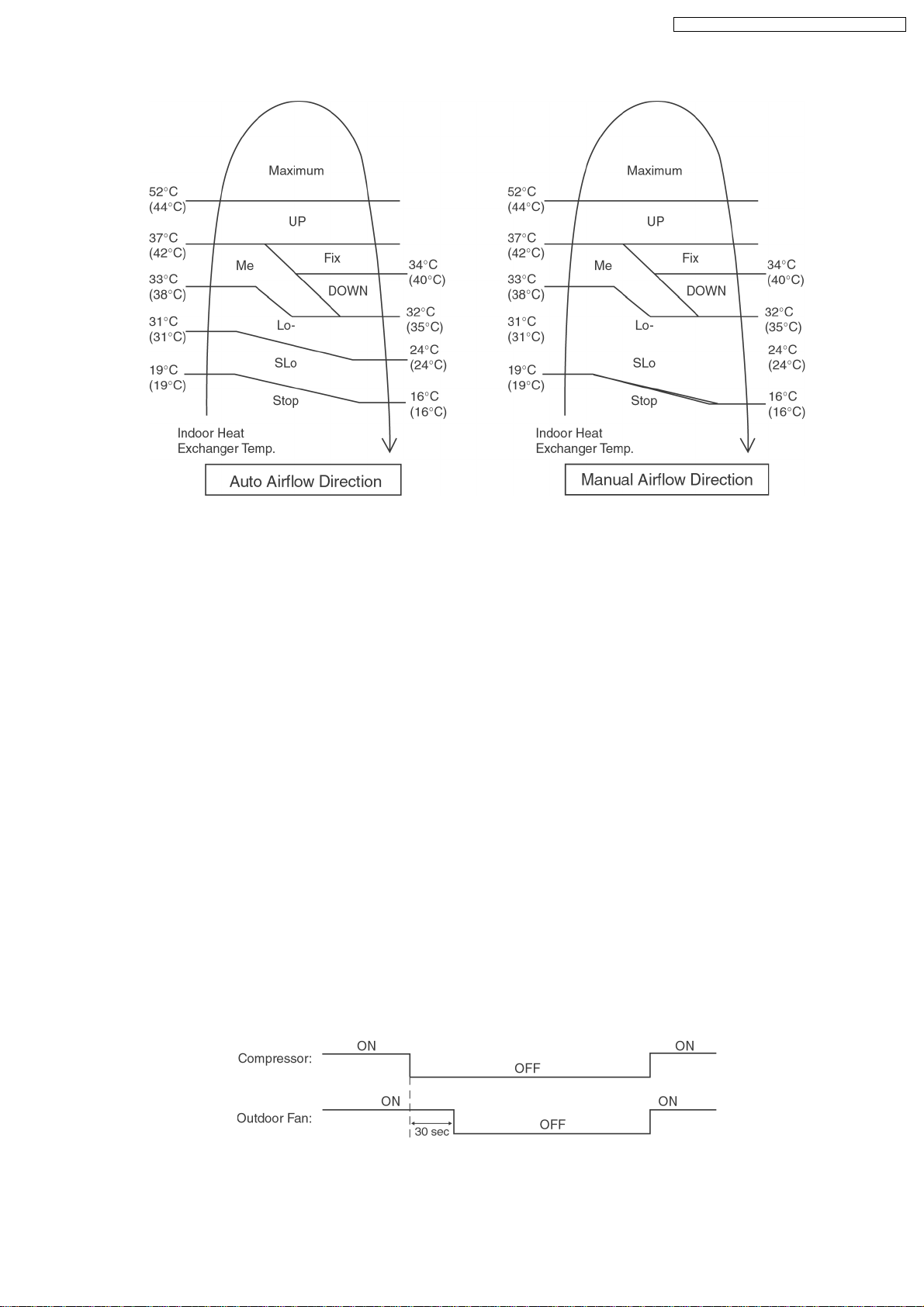

8.1.6. Outdoor Fan Motor Operation

Outdoor fan motor is operated with one fan speed only. It starts when compressor starts operation and it stops 30 seconds after

compressor stops operation.

23

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

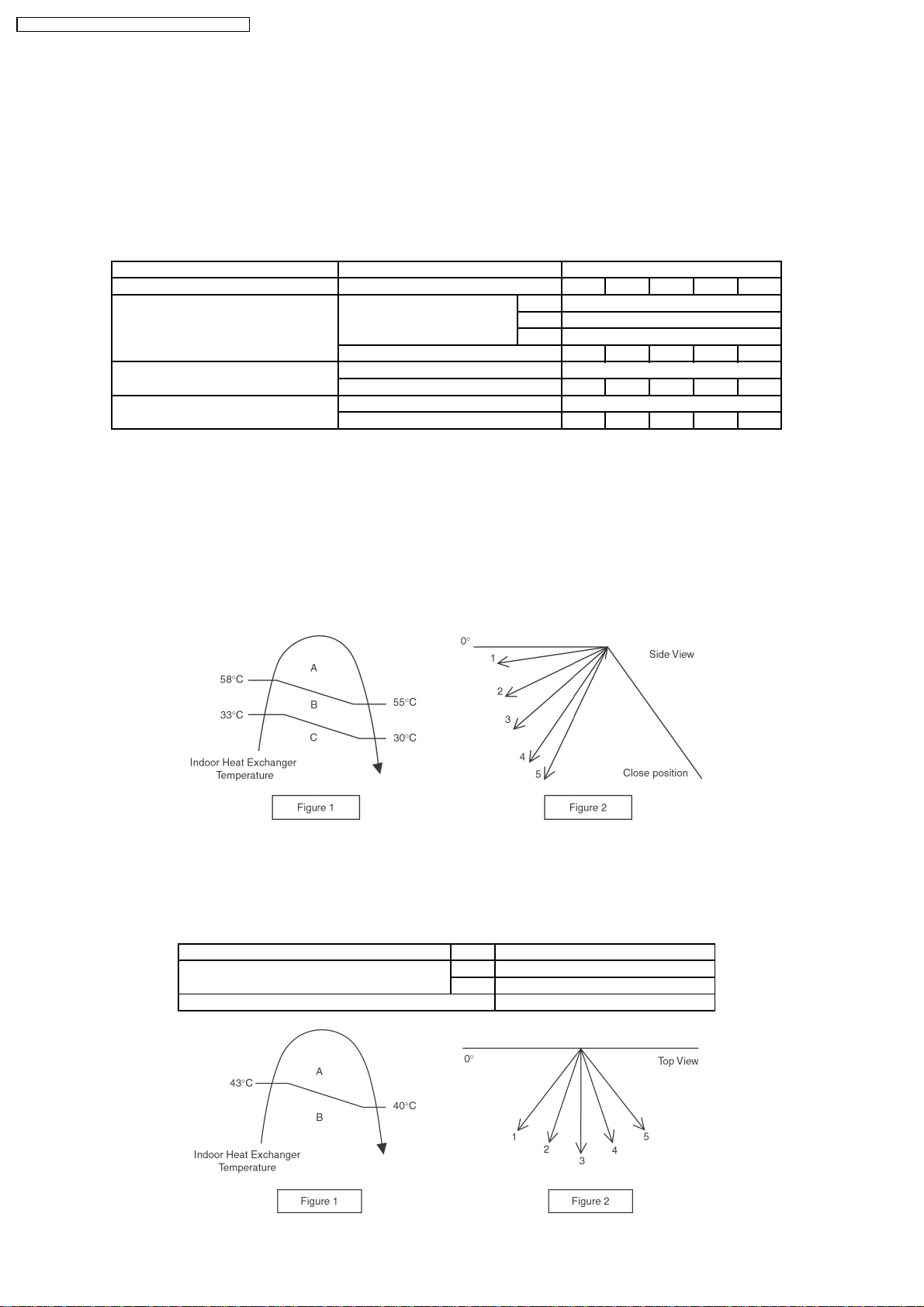

8.1.7. Airflow Direction

1. There are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by vertical vanes).

2. Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat exchanger temperature

and intake air temperature) and manual (angles of direction can be adjusted using remote controller).

Vertical Airflow

Operation Mode Airflow Direction Vane Angle (°)

1 2 3 4 5

Heating Auto, with Heat Exchanger A 17

Temperature B 58

C 7

Manual 7 17 33 49 67

Cooling, Soft Dry and Fan Auto 7~37

Manual 7 17 25 33 41

Mode Judgment in Auto Auto 7

Manual 7 17 25 33 41

1. Automatic vertical airflow direction can be set using remote controller; the vane swings up and down within the angles as

stated above. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as

Figure 1 below. When the air conditioner is stopped using remote controller, the vane will shift to close position.

2. Manual vertical airflow direction can be set using remote controller; the angles of the vane are as stated above and the

positions of the vane are as Figure 2 below. When the air conditioner is stopped using remote controller, the vane will shift

to close position.

Horizontal Airflow

1. Automatic horizontal airflow direction can be set using remote controller; the vane swings left and right within the angles as

stated below. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as

Figure 1 below.

Operation Mode Vane Angle (°)

Heating, with heat exchanger temperature A 55 ~ 125

B 90

Cooling, Soft Dry and Fan 55 ~ 125

24

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

2. Manual horizontal airflow direction can be set using remote controller; the angles of the vane are as stated below and the

positions of the vane are as Figure 2 above.

Pattern 1 2 3 4 5

Airflow Direction

Patterns at Remote

Controller

Vane Angle (°) 90 55 70 110 125

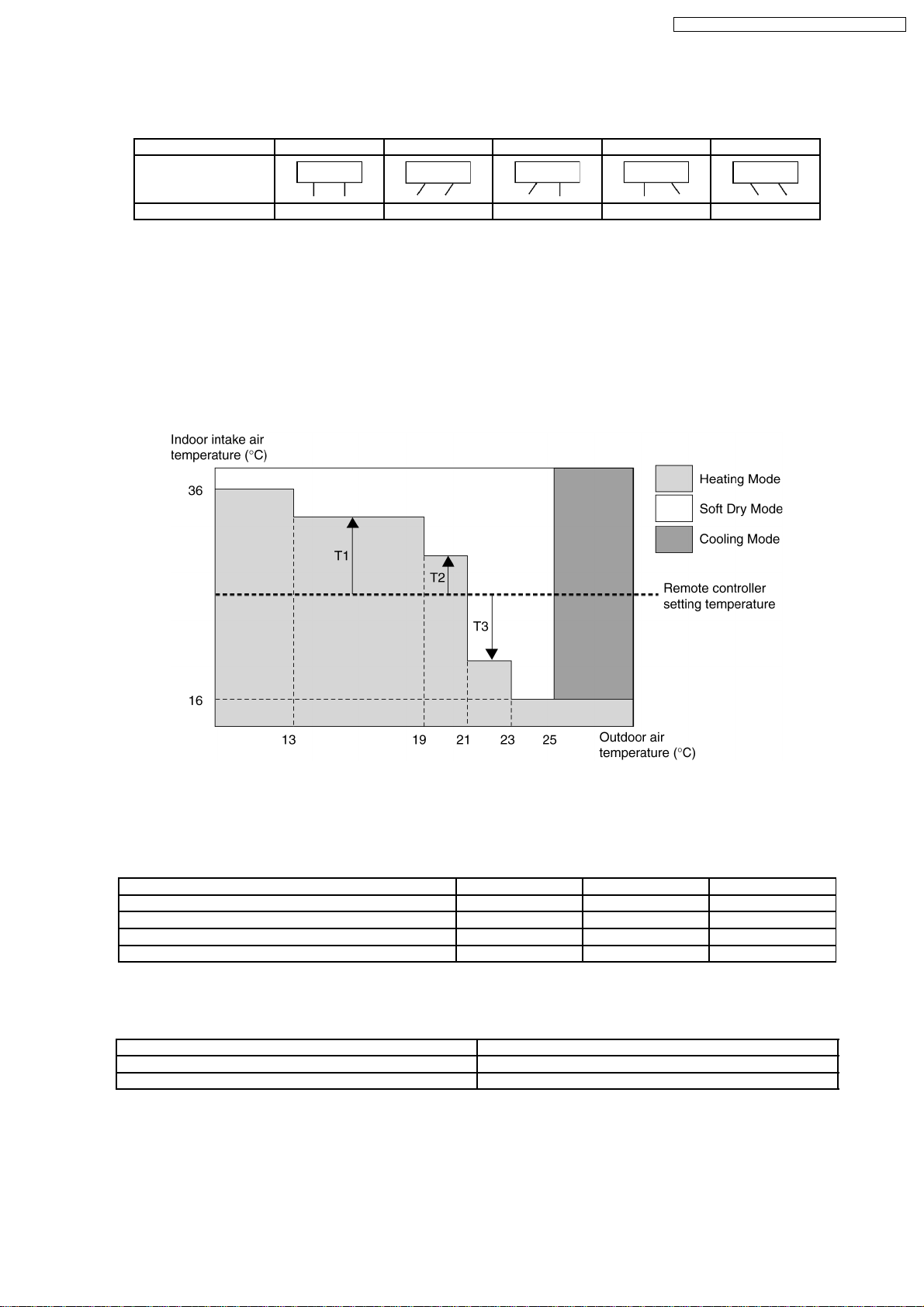

8.1.8. Automatic Mode Operation

This mode can be set using remote controller and the operation is decided by remote controller setting temperature, indoor intake

air temperature and outdoor air temperature.

During operation mode judgment, indoor fan motor (with speed of Lo-) and outdoor fan motor are running for 20 seconds to detect

the indoor intake and outdoor air temperature. The operation mode is decided based on below chart.

Values of T1, T2, and T3 depend on remote controller setting temperature, as shown in below table. After the adjustment of T1,

T2 and T3 values, the operation mode for that particular environment and remote controller setting is judged and performed, based

on the above operation mode chart, every 30 minutes. Heating mode operation will be performed, however, if deice operation is

detected.

Remote Controller Setting Temperature (°C) T1 T2 T3

16 ~ 18 +10 +8 -5

19 ~ 22 +8 +7 -7

23 ~ 26 +7 +6 -7

27 ~ 30 +6 +5 -8

There is a temperature shifting on T1, T2, and T3 if the operation mode judged is changed from Cooling/Soft Dry to Heating or vice

verse.

Operation Mode change from Temperature shifts (K)

Cooling/Soft Dry→Heating -2

Heating→Cooling/Soft Dry +2

Example of operation mode chart adjustment:

From the above table, if remote controller setting temperature = 25,

T1 = 25 + 7 = 32; T2 = 25 + 6 = 31; T3 = 25 - 7 = 18

25

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

The operation mode chart for this example is as shown in below figure and the operation mode to be performed will depend on

indoor intake air temperature and outdoor air temperature at the time when the judgment is made.

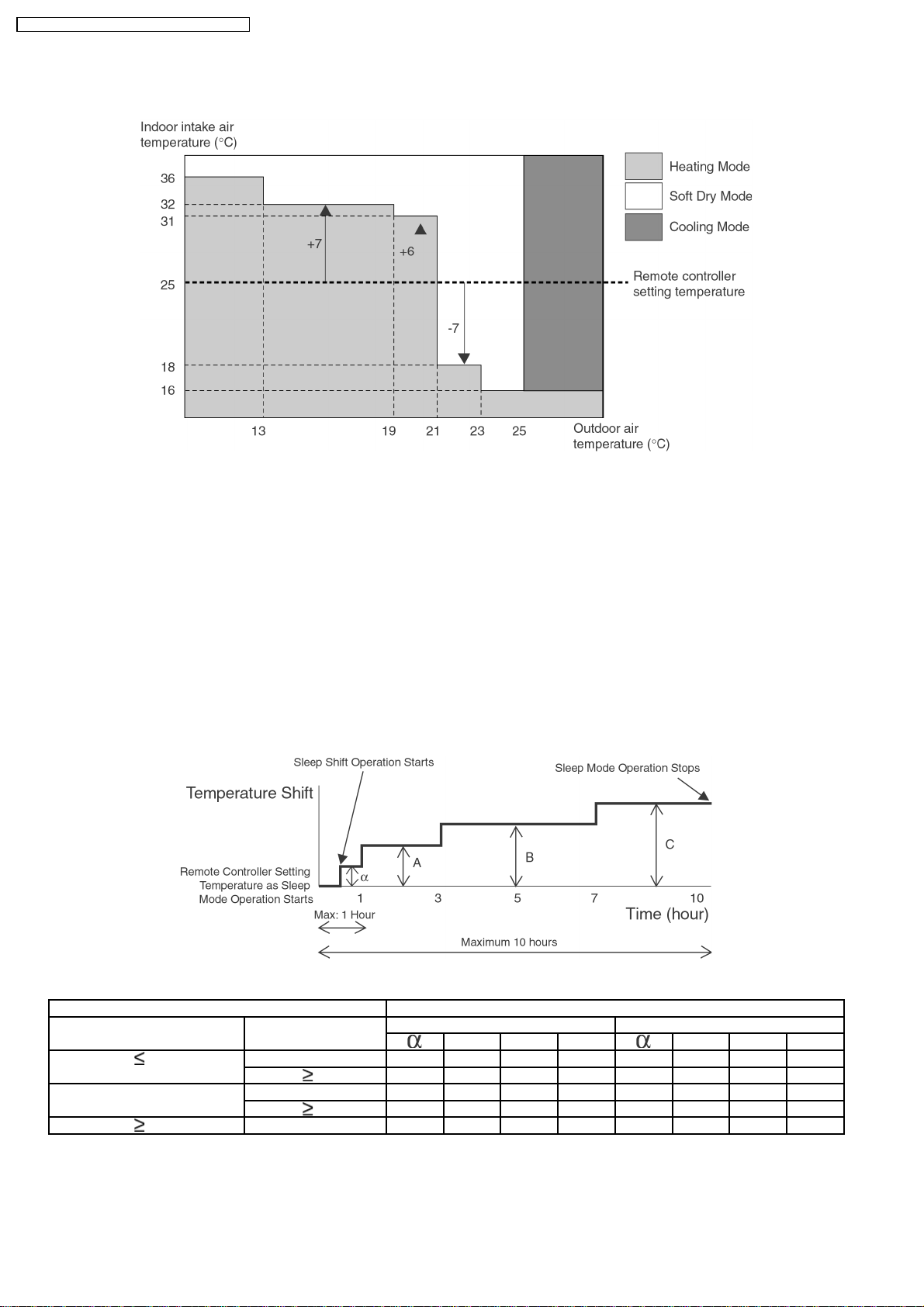

8.1.9. Sleep Mode Operation

1. Sleep Mode operation starts by pressing the button at remote controller and the operation last for a maximum of 10 hours. The

Sleep Shift operation starts when the intake air temperature = internal setting temperature or one hour after Sleep Mode

operation starts

2. For Cooling Mode or Soft Dry Mode operations, during Sleep Shift operation, indoor fan motor will operate at Lo speed and SLo

speed respectively. The internal setting temperature is shifted as stated in below figure and table.

Condition Shifting Temperature (°C)

Remote Controller Setting

Temperature (°C)

26 <25 +2 +3.0 +4.0 +5.0 +1.5 +2.0 +3.0 +4.0

27 <25 +2 +3.0 +4.0 +4.0 +1.5 +2.0 +3.0 +3.0

28 — +2 +3.0 +3.0 +3.0 +1.5 +2.0 +2.0 +2.0

Outdoor Air

Temperature (°C)

25 +2 +3.0 +3.5 +4.0 +1.5 +2.0 +2.5 +3.0

25 +2 +3.0 +3.5 +4.0 +1.5 +2.0 +2.5 +3.0

Cooling Mode Soft Dry Mode

A B C A B C

26

CS-E9BKP CU-E9BKP5 / CS-E12BKP CU-E12BKP5

3. For Heating Mode operation, during Sleep Shift operation, indoor fan motor will operate at Lo- speed. The internal setting

temperature is shifted as stated in below figure and table.

Remote Controller Setting Fan Speed Shifting Temperature (°C)

A B C

Lo -1.0 -1.0 -5.0 -4.0

Me-, Me, Me+, Hi, Auto -0.5 -0.5 -4.5 -3.5

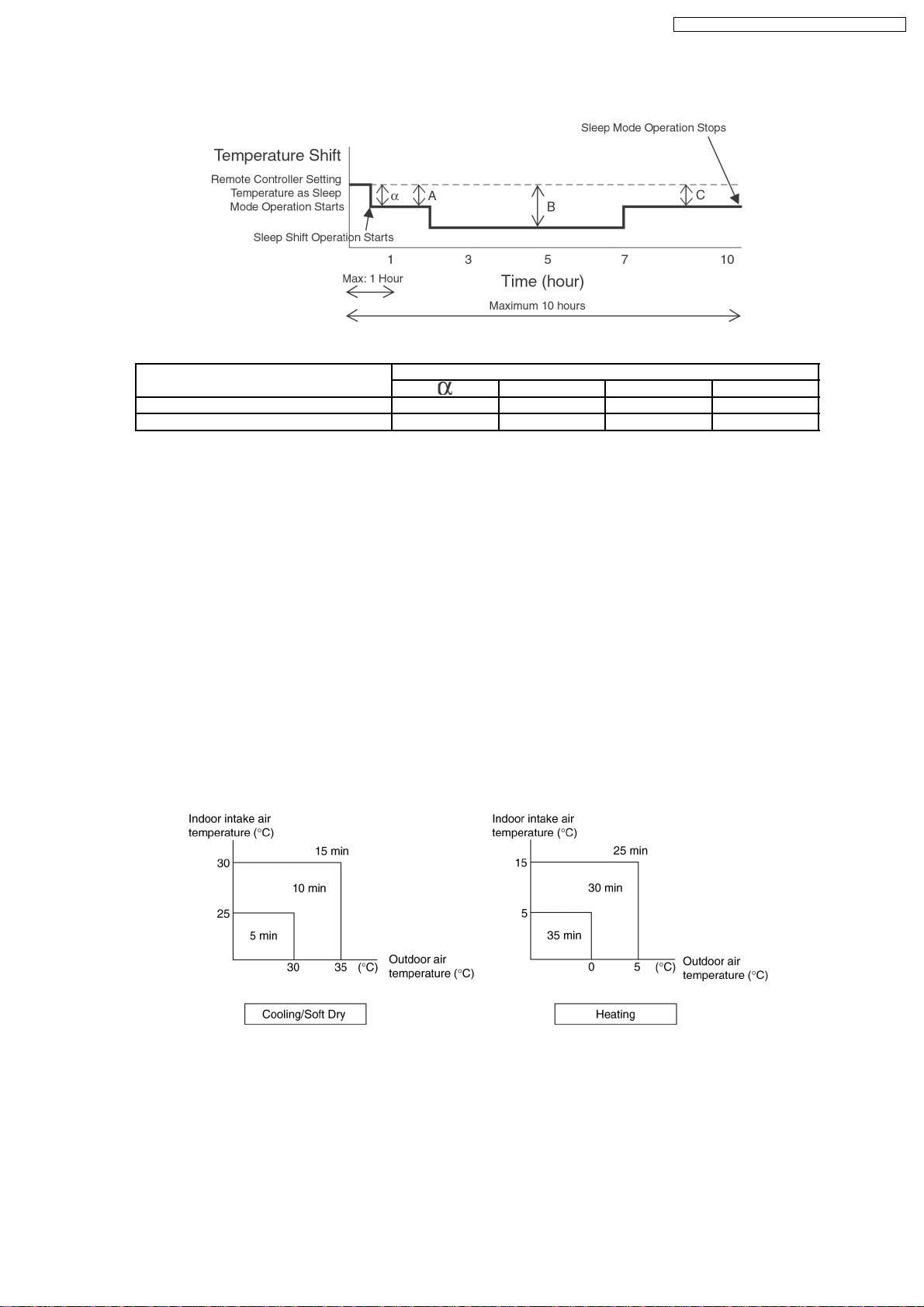

8.2. Protection Control Features

8.2.1. Delay ON Timer Control

This control is applicable to all kinds of operation mode.

Delay ON timer can be set using remote controller, the unit with timer set will start operate earlier than the setting time. This is to

provide a comfortable environment when reaching the set ON time.

Seventy minutes before the set time, indoor (at fan speed of Lo-) and outdoor fan motor start operate for 20 seconds to determine

the indoor intake air temperature and outdoor air temperature in order to judge the operation mode.

From the above judgment, the decided operation will start operate earlier than the set time as shown below.

8.2.2. OFF Timer Control

This control is applicable to all kinds of operation mode.

OFF timer can be set using remote controller, the unit with timer set will stop operate at set time.

27

Loading...

Loading...