Panasonic CSCU-PE9DKD, CSCU-PE12DKD Service Manual

Order No.

GMAC0506049C3

Air Conditioner

CS/CU-PE9DKD

CS/CU-PE12DKD

hr

LAY

AUTO

E

D

ON

hr

HEAT

LAY

E

D

OFF

COOL

ON

DRY

OFF

OFF

L

NCE

A

SET/C

LECT

E

S

T

E

RRES

O

RR

E

TER

INVER

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

CONTENTS

Page Page

WARNING

1 Features 2

2 Functions 3

3 Product Specifications 6

4 Dimensions 10

5 Refrigeration Cycle Diagram 12

6 Block Diagram 13

7 Wiring Diagram 14

8 Operation Details 15

Installation instructions

9

--------------------------------------------------------

------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

10 Installation and Serving Air Conditioner Using R410A

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

41

--------------------------------------------------

--------------------------------------------------

--------------------------------------------------

--------------------------------------

----------------------------------------

-----------------------------------------

-----------------------------------------

--------------------------------------

50

62

65

67

68

69

70

71

72

C

R

R

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

1 Features

High Efficiency

Air Quality Indicator

Auto Restart Control

Automatically restart after power failure

12-hour Timer Setting

Delay ON Timer and OFF Timer

Enviromental Friendly (For Refrigerant : R410A Model)

Zero ozone depleting potential and low global

warming potential by using R410A refrigerant.

Comfort Environment

Air filter with function to reduce dust and smoke

Removable and washable Front Panel

Breakdown Self Diagnosis function

2

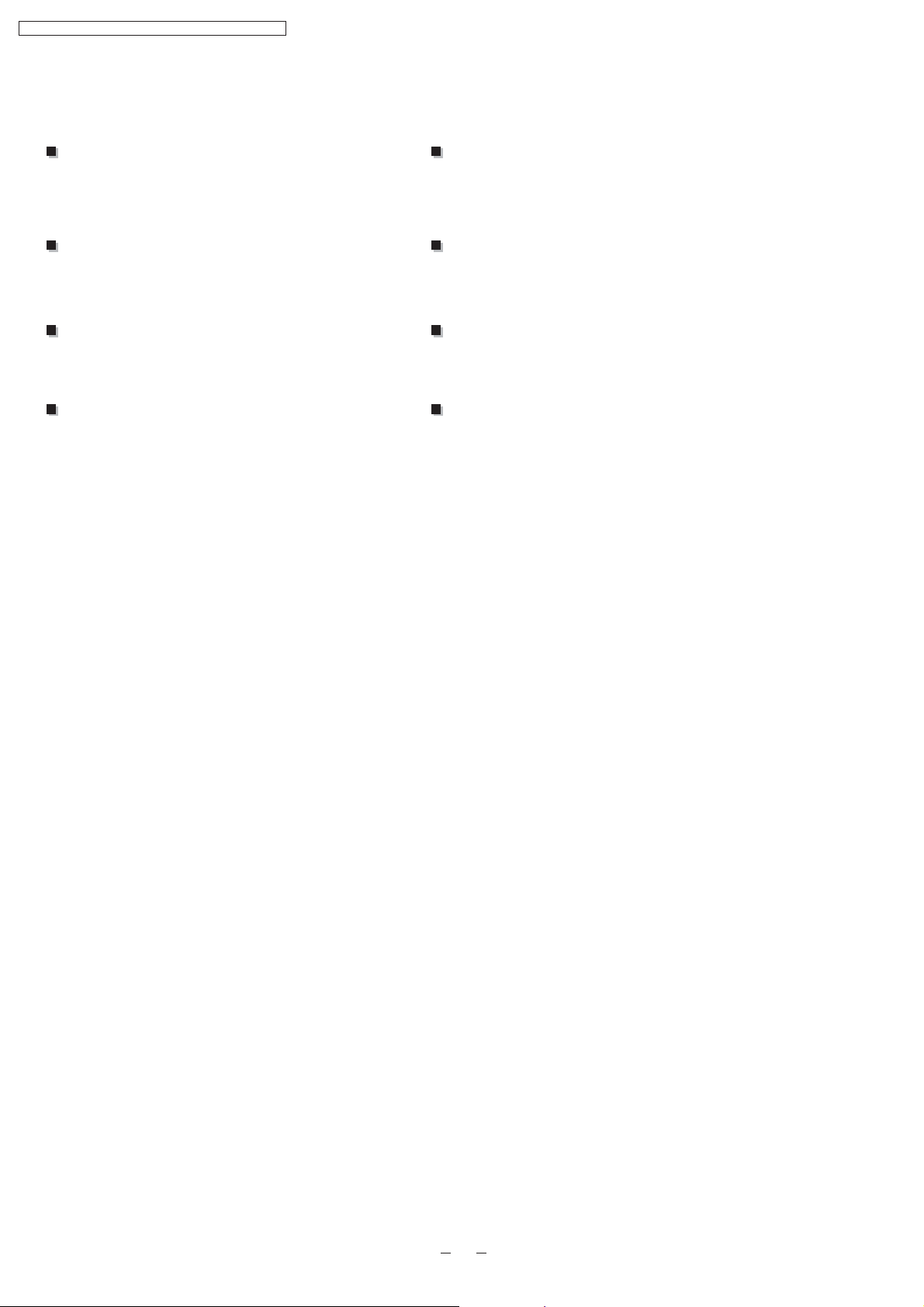

2 Functions

Remote Control

AUTO

HEAT

COOL

DRY

OFF

hr

DELAYhrDELAY

OFF ON

ON OFF

SELECT

ERRORRESET

INVERTER

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

SET/CANCEL

OFF/ON

MODE

FAN

SPEED

Operation START/STOP

Turn on/off the air conditionor

When stop the operation by pressing

OFF/ON button,the cursor key points

to OFF.

Operation Mode Selection

Automatic Operation

Heating Mode Operation

Cooling Mode Operation

Soft Dry Mode Operation

Mode

Indoor Fan Speed Selection

Low Speed

Med- Speed

AIR

SWING

Airflow Direction Control

Horizontal Airflow Direction Control

-Auto Control

-Manual Control

Vertical Airflow Direction Manual Control

TEMP

Room Temperature Setting

Temperature Setting(16 to 30 )

Auto Operation

TIMER

OFF/ON

Timer Operation Selection

Stop/Start Operation Control

(set the ON/OFF Timer hourly later)

TIMER

SET/

CANCEL

Set /Cancel Timer Operation

A,B

Med Speed

Med+ Speed

High Speed

Automatic Speed

Time Changing Button

Change the setting time.

Set timer/Cancel the set timer

By pressing SET button for 5seconds

continuously to switch to set the sensor

sensitivity.

CHECK

Check Point

Self diagnosis function

ERROE

RESET

ERROE Reset Point

To reset the indoor unit.

RESET

Reset Point

Clear memory data

3

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

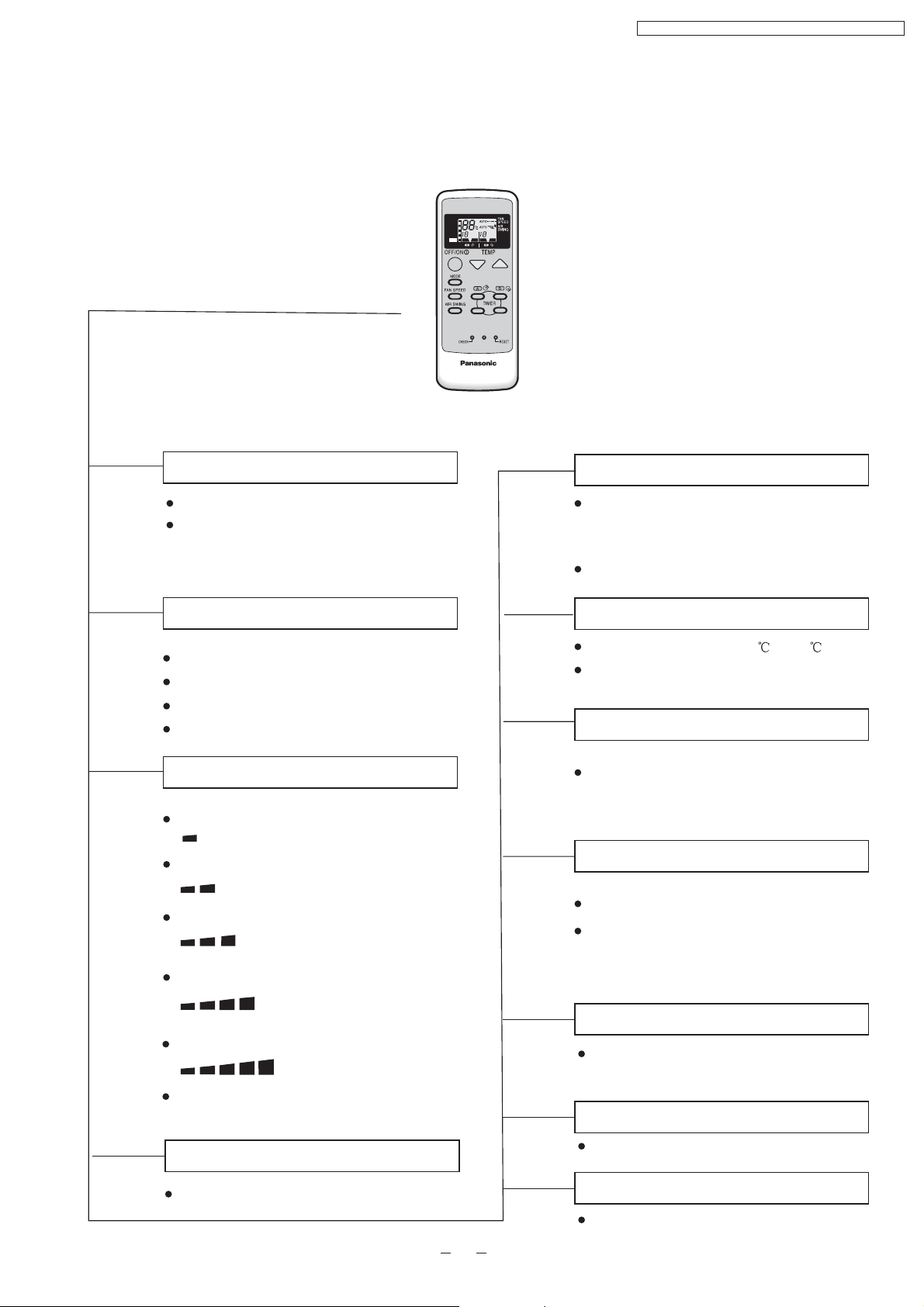

Indoor Unit

Auto Switch

Button

Power Switch ON/OFF

When the remote control cannot be used or

for repairing and testing ,please use this

button.

Anti-freezing Control for the Evaporator

Cooling or Soft Dry Operation

Force Cooling Operation

Keep pressing this button for 5 seconds to start

the force cooling operation.

Force Heating Operation

Keep pressing this button for 8 seconds to start

the force heating operation.

Different Remote Controlling Setting

Keep pressing this button for11 to change

different remote controlling setting(A B)

Mode.

Signal Receiving Sound

Keep pressing this button for 16 seconds to turn

off or turn on the signal receiving sound

H14 Abnormality Detection Mode.

or

Operation Indication Lamps

Power (green)

Timer(orange)

Air quality

Green

Orange

Red

Lights up in operation;

Blinks during Hot Start

operation and

determining Auto

Operation mode

Light up in Timer Setting.

Blinks in Self Diagnosis Control

Operation Mode

Cooling/Heating/Soft Dry /Auto Operation

Time Delay Safety Control

The unit will restart operation in 3-4

minutes after each pause.

Warm Booting Control

Indoor fan starts running when indoor

piping reaches 19 or above.temperature

Indoor Fan Speed Control

High,Med+, Med, Med-,Low

Auto Fan Speed

Airflow Direction Control

Automatic Airflow Direction Control

The louver automatically swings up and down

Five Manual Airflow Direction Control

Delayed On-timer Control

For cooling or soft dry mode, the unit

starts 15 minutes before the set time with

the remote control, but for heating mode

30 minutes before the set time.

Automatic Restart Control

Operation is restarted after power failure

at previous setting mode.

4

Outdoor Unit

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Panasonic

4-way Valve Control

If the unit is stopped during Heating

Operation, the 4-way valve will remain in

heating mode operation for 3 minutes.

Overload Protector

Inner protector

30 Seconds Forced Operation Control

Once the compressor is activated, it does not

stop within 30 seconds. It stops immediately with

remote control ON/OFF button.

Total Running Current Control

Deice Operation

5

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

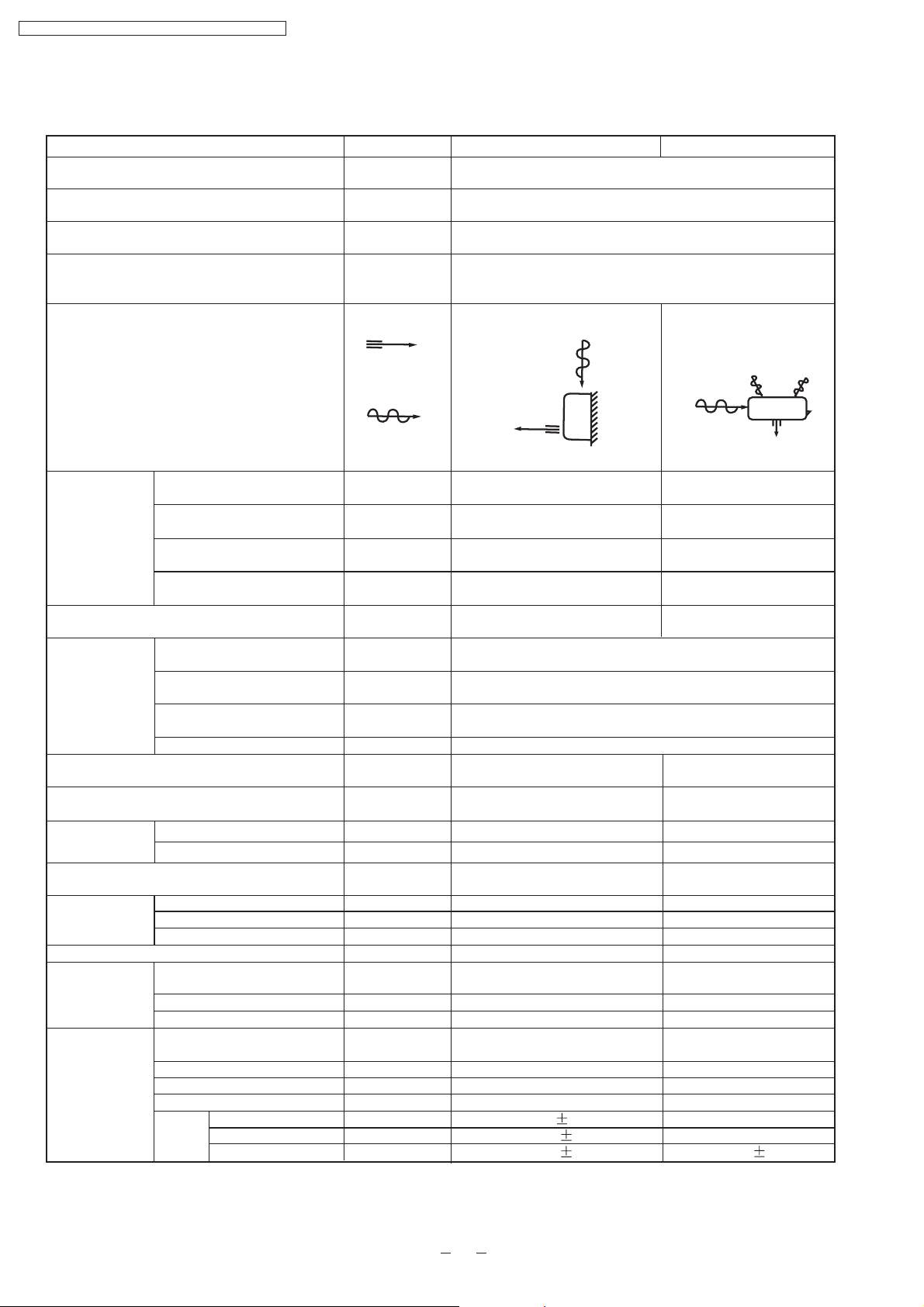

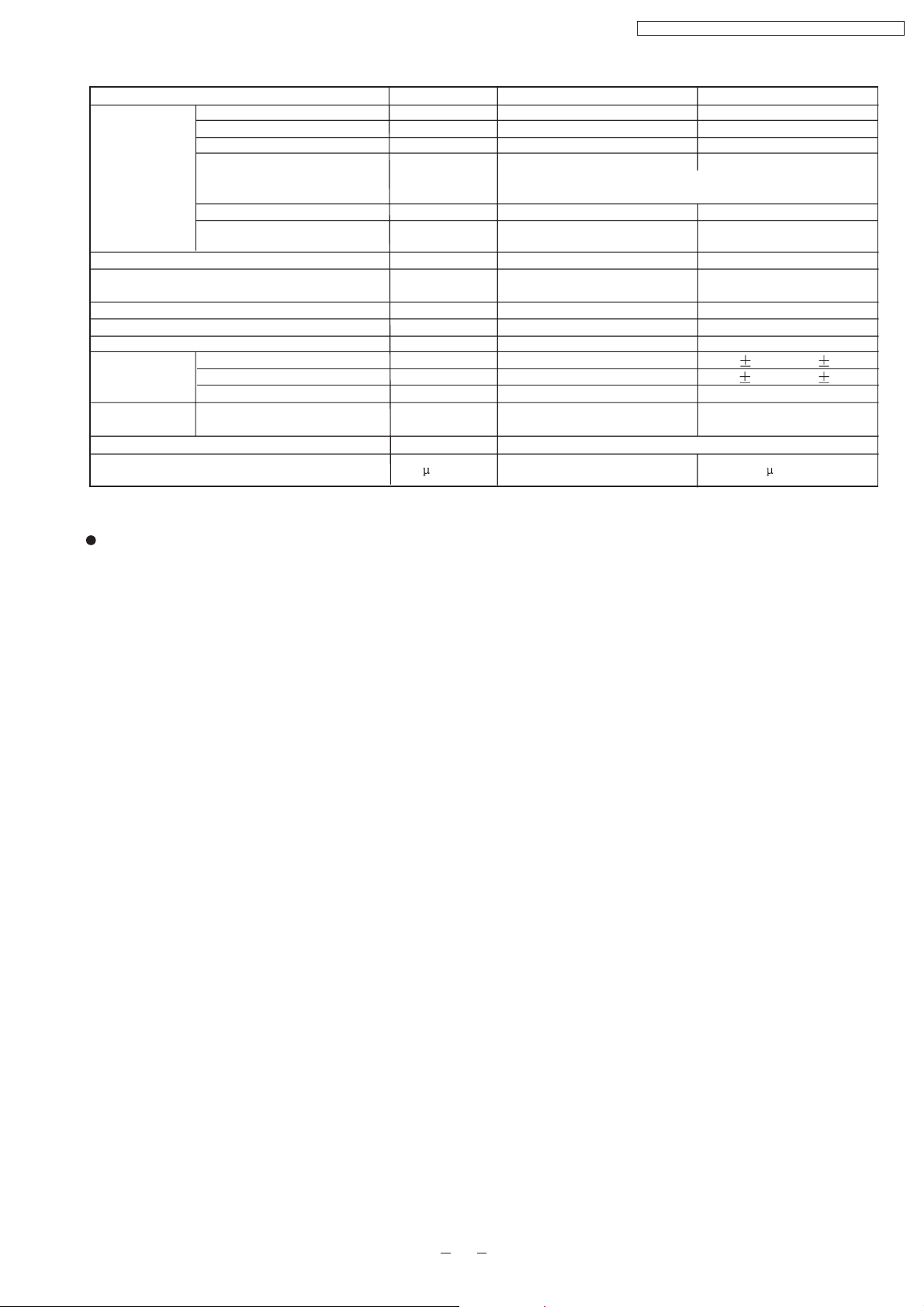

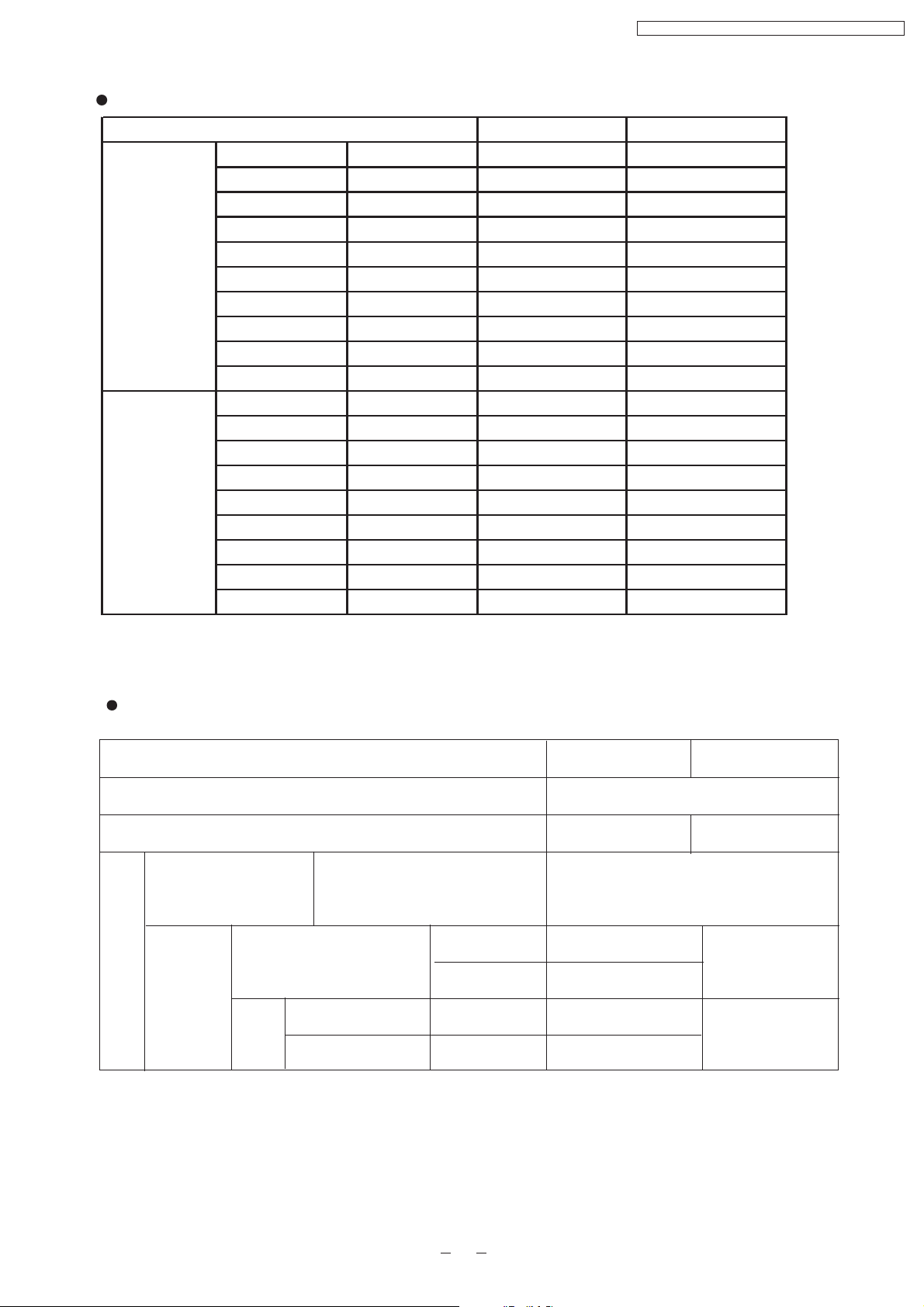

3 Product Specifications

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER/COP

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated output

Air Circulation

type

Motor type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

Inch

Inch

Inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PE9DKD CU-PE9DKD

2.50(0.90-3.00)

3.30(0.90-4.00)

-

Single

230

50

SIDE VIEW

TOP VIEW

6

7.7

9.8

-

Cooling:high42,Low27

Heating:high42,Low27

22.5

Cooling:high46

Heating:high47

Cooling:730(190-1000)

Heating:820(170-1110)

Cooling:3.4

Heating:3.7

Cooling:2.95(2.58-4.05)

Heating:3.46(3.10-4.53)

3.7

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

12

0.65

3 core-wire/1.5mm

1.9

280

799

183

2

540

780

289

8

-

-

-

-

-

Cross-flow fan

Induction(8poles)

Rotary(1 cylinder)

Rolling piston type

Induction(6 poles)

650

Propeller fan

Induction(6 poles)

-

30

840 60

1080 60

1370 60

670 60

-

-

-

-

-

-

-

30

-

15

-

-

6

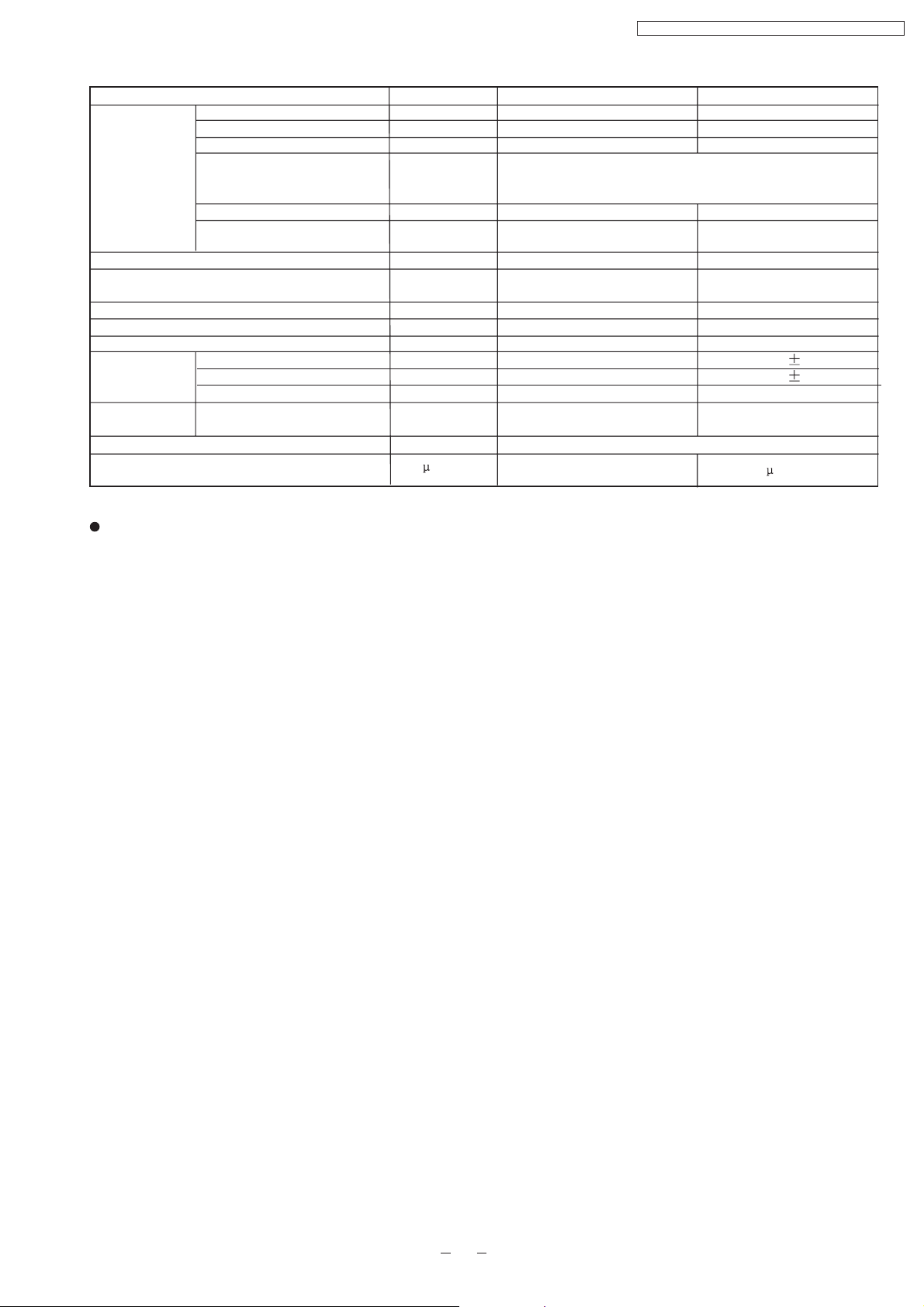

Heat

Exchanger

Description

Tube Material

Fin Type

Rows/Stage

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R410A)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Unit CS-PE9DKD CU-PE9DKD

Evaporator

Copper

Slot type

Condenser

Copper

Corrugation type

(Plate fin configuration,forced draft)

mm

(c.c)

g

mm

L/min

mm

2x15

20

610x252x25.4

-

-

-

Electronic Control

-

-

-

-

726x504x18.2

RB68A or Freol Alpha68M

1X24

18.5

Capillary Tube

840

sensor

Inner protector

600 10

8.15 0.2

1.3

Air Filter

P.P. Honeycomb

Refrigerant Circulation Control Device

Fan Motor Capacitor

F,V

Specifications are subject to change without notice for further improvement.

Capillary

F,1.2 450V

7

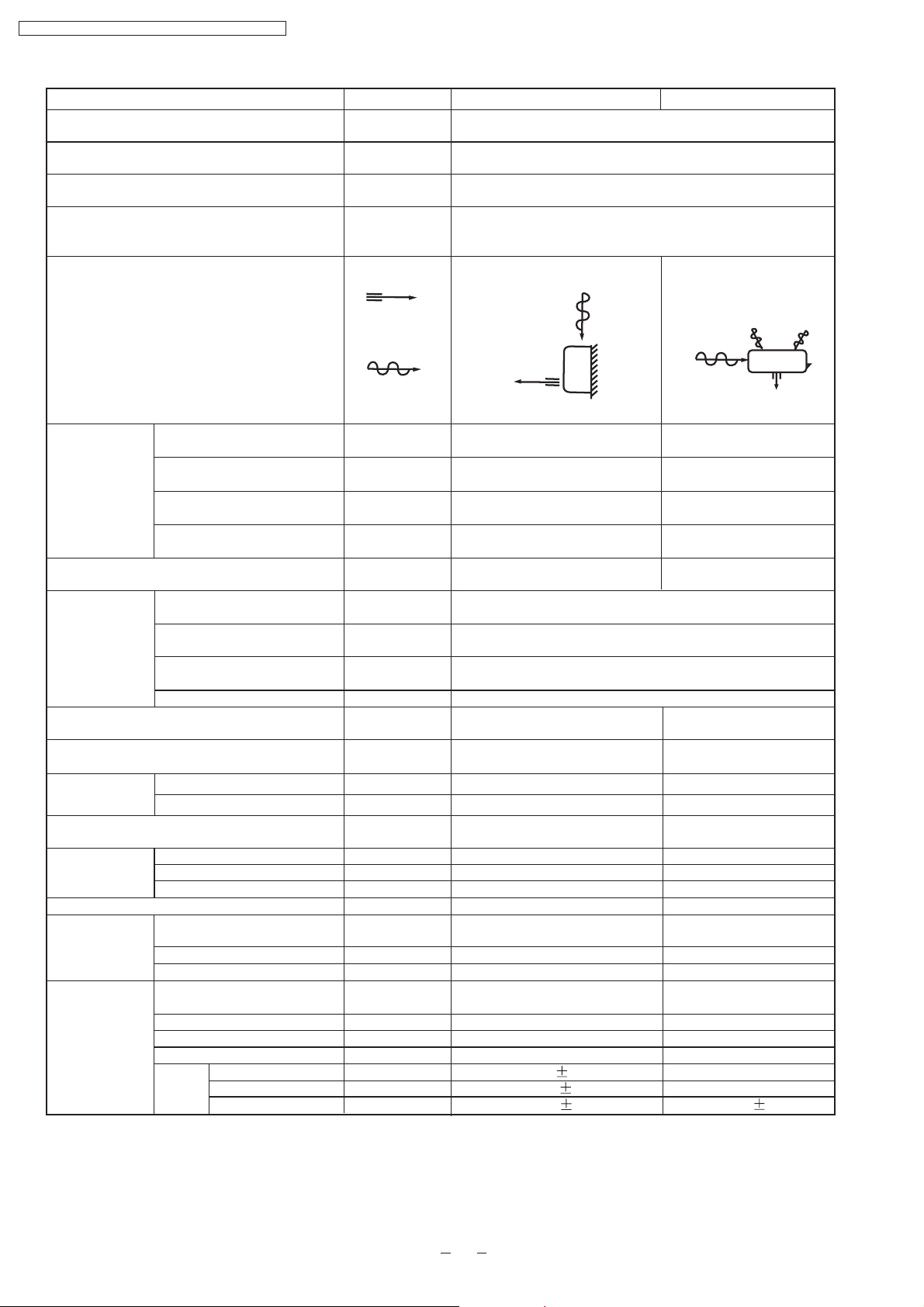

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER/COP

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated output

Air Circulation

type

Motor type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

Inch

Inch

Inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PE12DKD CU-PE12DKD

3.15(0.90-3.80)

4.10(0.90-5.00)

-

Single

230

50

SIDE VIEW

6.8

8.4

9.9

-

Cooling:high42,Low30

Heating:high42,Low33

TOP VIEW

-

-

-

27.4

Cooling:high48

Heating:high50

Cooling:900(190-1270)

Heating:1110(170-1410)

Cooling:4.2

Heating:4.9

Cooling:2.98(2.57-4.05)

Heating:3.18(3.07-4.53)

4.9

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

12

0.65

1.9

3 core-wire/1.5mm

280

799

183

8

-

-

-

-

-

-

Cross-flow fan

Induction(8poles)

-

30

950 60

1170 60

1380 60

2

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

-

-

-

540

780

289

34

Rotary(1 cylinder)

Rolling piston type

Induction(6 poles)

650

Propeller fan

Induction(6 poles)

-

25

-

-

770 60

8

Heat

Exchanger

Description

Tube Material

Fin Type

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Unit CS-PE12DKD CU-PE12DKD

Evaporator

Copper

Slot type

Condenser

Copper

Corrugation type

Rows/Stage

(Plate fin configuration,forced draft)

2x15

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R410A)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

mm

(c.c)

g

Electronic Control

mm

L/min

mm

P.P. Honeycomb

20

610x252x25.4

-

-

-

-

-

-

-

Refrigerant Circulation Control Device

Fan Motor Capacitor

F,V

Specifications are subject to change without notice for further improvement.

2X24

17

726

X504x18.2

696

Capillary Tube

RB68A or Freol Alpha68M

1020

-

Inner protector

300 10

11.3 0.2

1.3

565 20

12.3 0.2

1.5

Capillary

F,1.8 450V

9

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

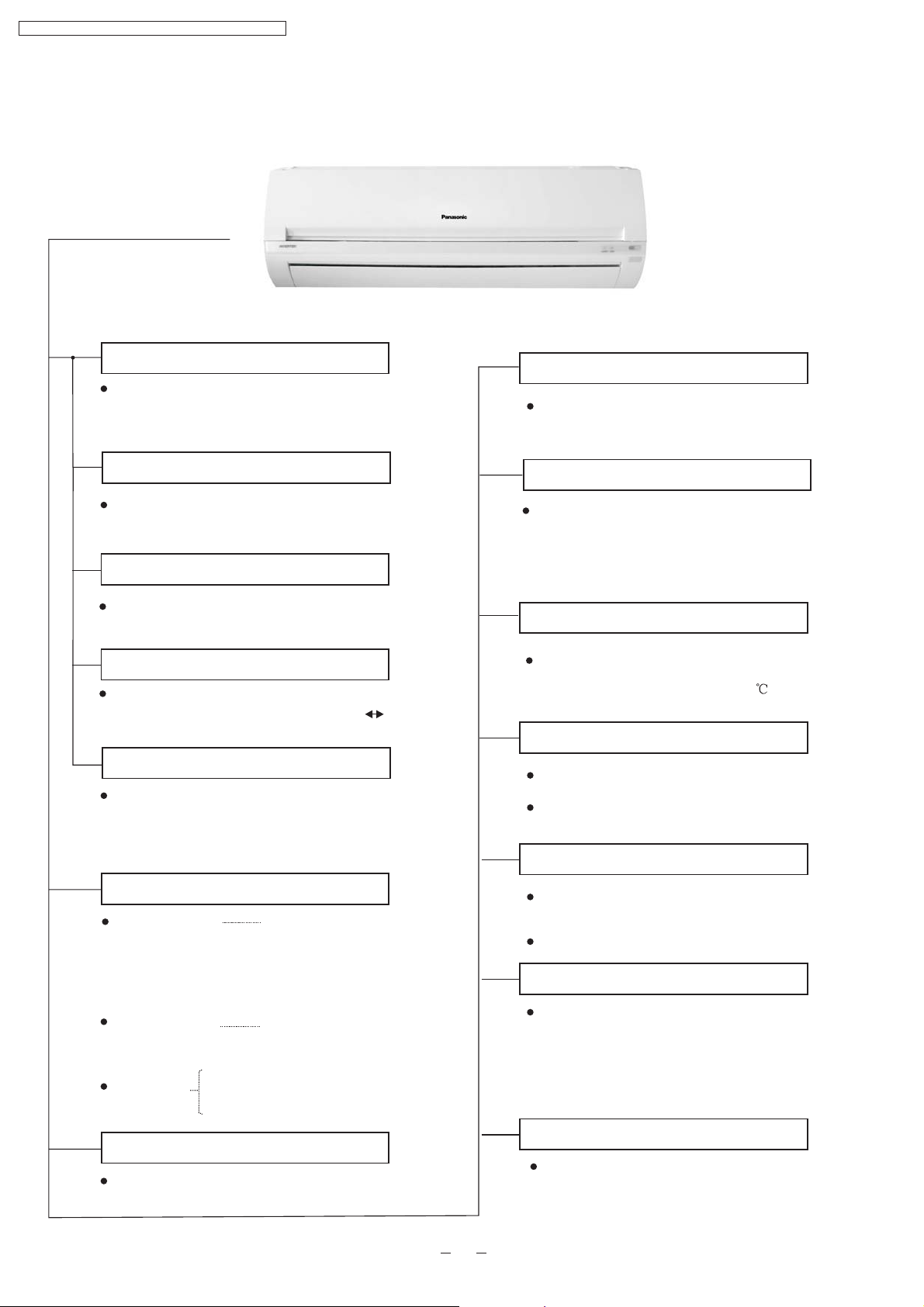

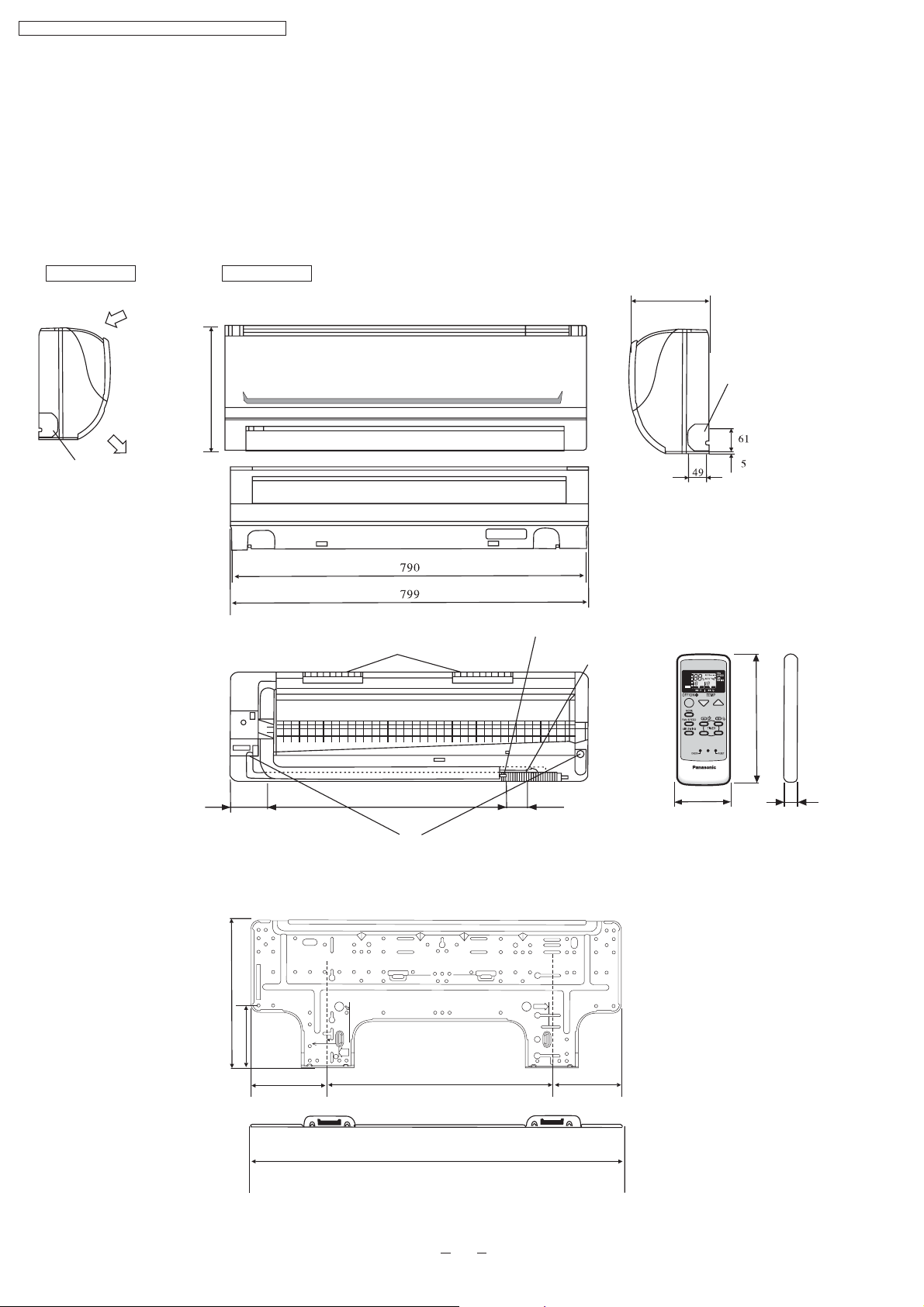

4 Dimensions

Indoor Unit

CS-PE9DKD

CS-PE12DKD

Unit:mm

Side view

Left Piping

Hole

Air intake

Air outlet

Front View

280

<Back View>

(100)

Installation Plate Hook

(420)

Gas Side

(50)

Liquid

Side

183

Right Piping

Hole

AUTO

HEAT

COOL

hr

DRY

DELAYhrDELAY

OFF ON

ON OFF

OFF

141

SET/CANCEL

SELECT

ERRORRESET

INVERTER

57

17.1

Drain Port

Installation plate (Front View)

254

95

(131)

B A

(382) (118)

(631)

10

Outdoor Unit

CU-PE9DKD

CU-PE12DKD

10cm

or more

10cm

or more

100cm

or more

<Top View>

105

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Unit : mm

48

780

570

57

18.6

289

INVERTER

11

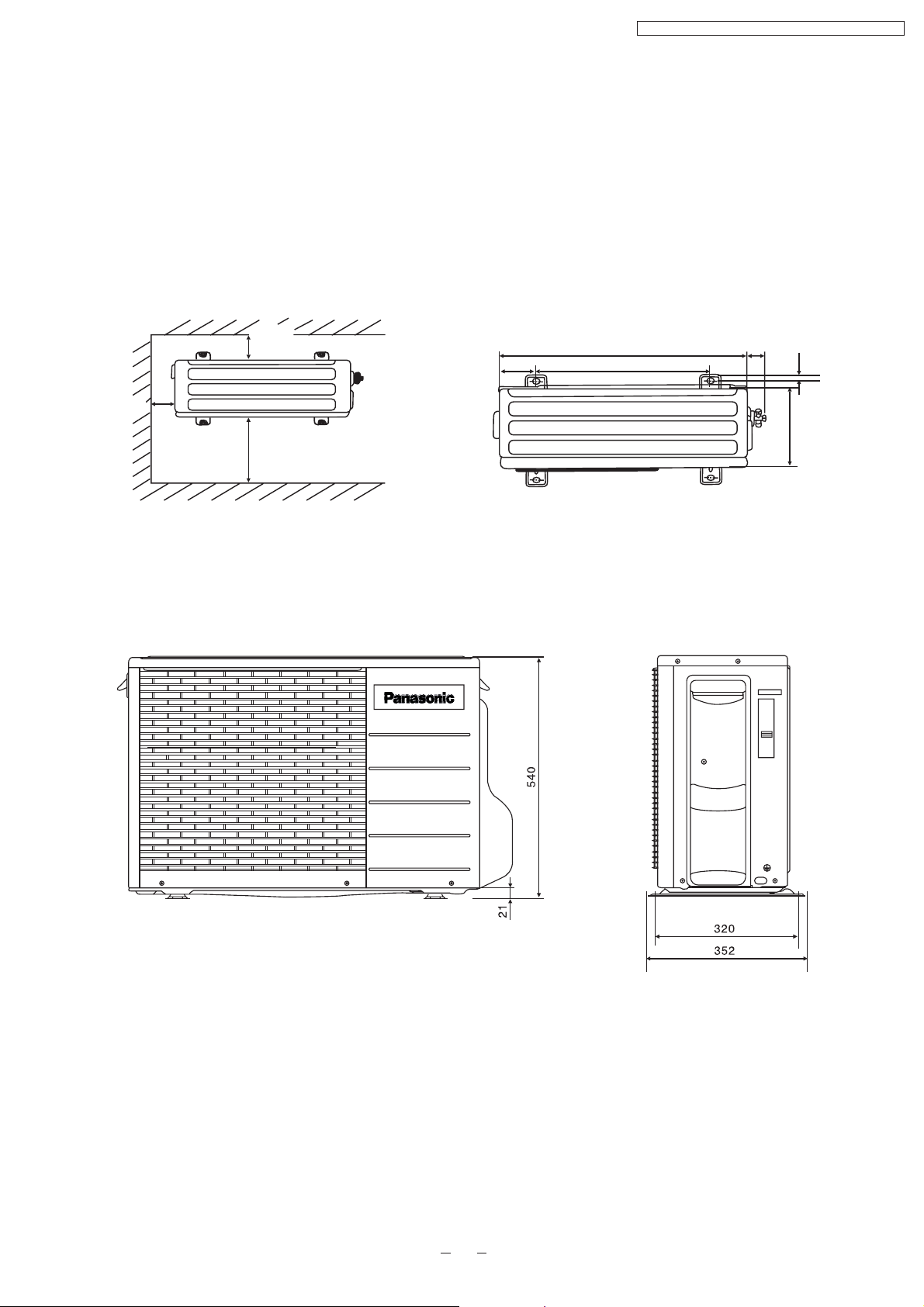

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

5 Refrigeration Cycle Diagram

CS/CU-PE9DKD

CS/CU-PE12DKD

INDOOR UNIT

INTAKEAIR

SENSOR

HEAT EXCHANGER

(EVAPORATOR)

PIPING

SENSOR

LIQUID

SIDE

2-WAY

VALV E

OUTDOOR UNIT

CAPILLARY TUBE C3

CAPILLARY TUBE C1

CAPILLARY TUBE C2

OUTDOOR AIR

SENSOR

HEAT EXCHANGER

(CONDENSOR)

PIPING

SENSOR

Cooling

Heating

GAS SIDE

3- WAY VA LVE

COMPRESSOR

SENSOR

12

4- WAY VA LVE

COMPRESSOR

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

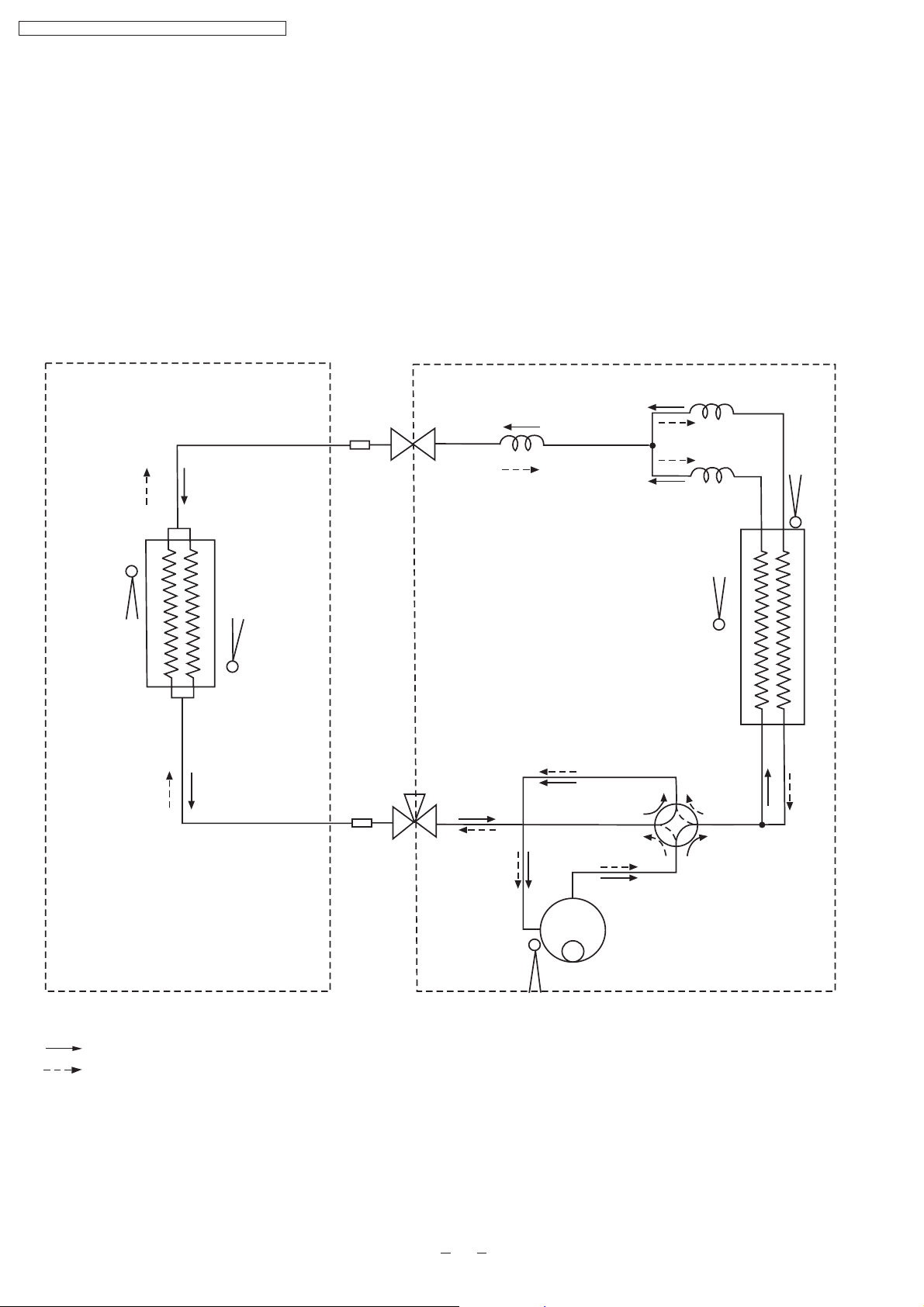

6 Block Diagram

FM

FM

4-WAY VALVE

REACTANCE

OUTDOOR UNIT

FM

INDOOR UNIT

CS-PE9DKD/CU-PE9DKD

CS-PE12DKD/CU-PE12DKD

V

230

50HZ

2

THERMAL

FUSE

3

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

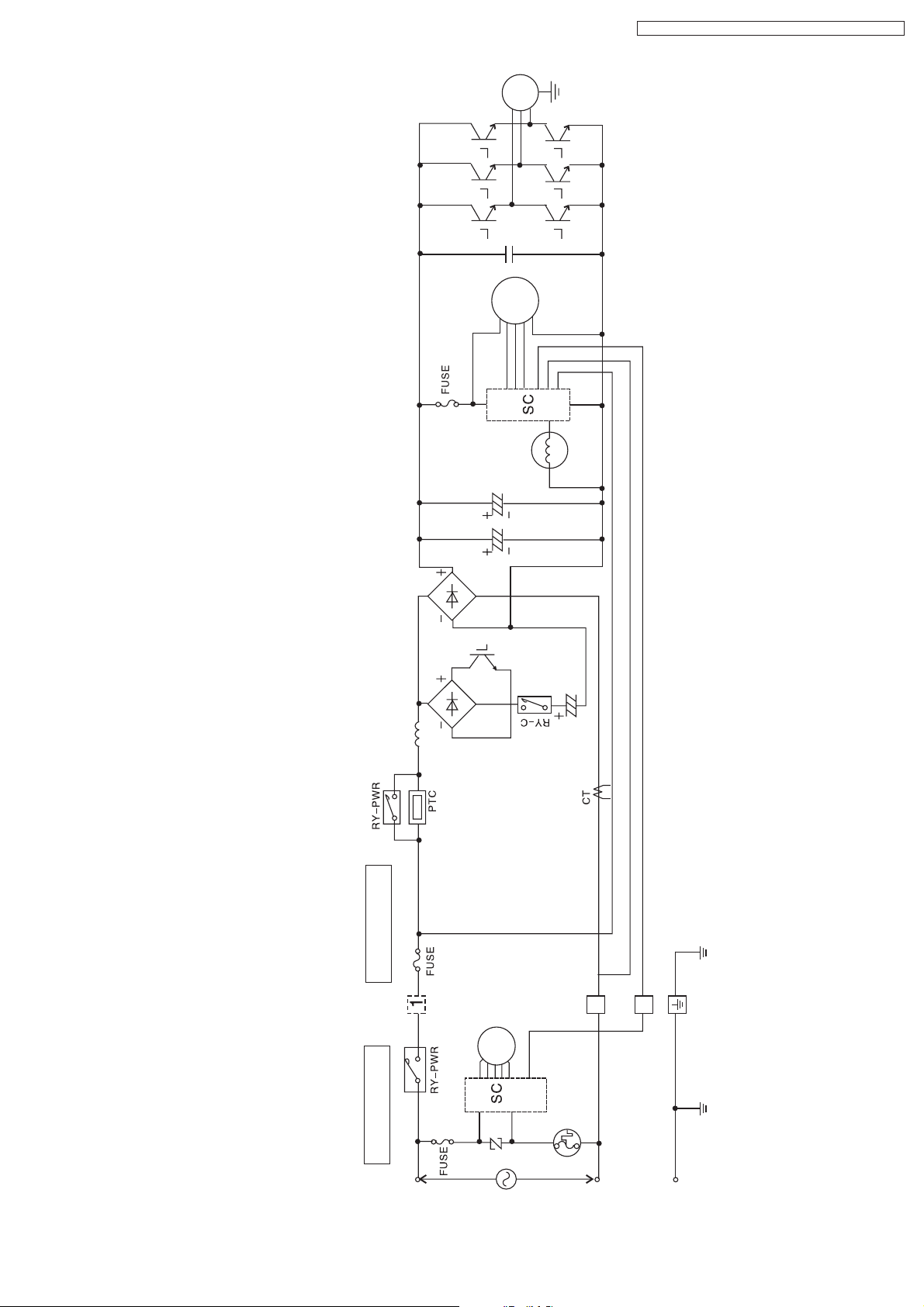

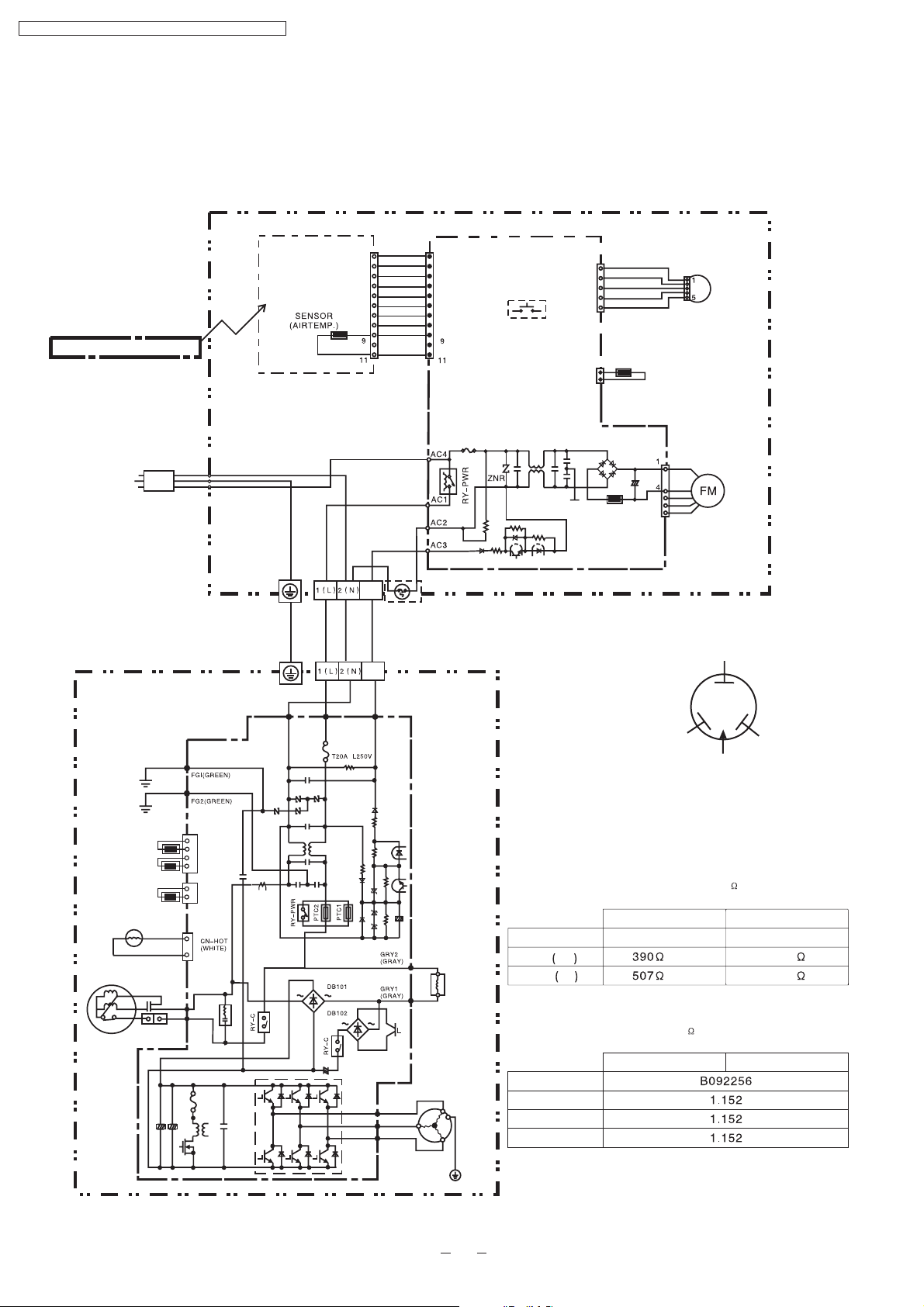

7 Wiring Diagram

CS-PE9DKD/CU-PE9DKD

CS-PE12DKD/CU-PE12DKD

WIRELESS REMOTE CONTROL

POWER SUPPLY CORD

B

AC230V,50Hz

BR

OUTDOOR UNIT

TERMINAL

TERMINAL

ELECTRONIC

CONTROLLER

(DISPLAY,RECEIVER)

CN-DISP

(W)

Y/G

BL

W

W

W

W

W

CN-DISP

W

W

W

W

W

W

(Y)

AUTO SW

ELECTRONIC

CN-STM

CN-TH

CONTROLLER

(W)

(Y)

BR

R

O

Y

P

SENSOR

(PIPING TEMP.)

MOTOR

(MAIN)

FUSE

T 2.5A L 250V

R

MOTOR

BL

BL

W

R

3

3

R

CN-FM

(W)

W

B

Y

INDOOR UNIT

YELLOW

SENSOR

(AIR TEMP)

SENSOR

(PIPING TEMP)

SENSOR

(COMP.TEMP)

COIL COMP

(4-WAYVAVLE)

Fan Motor

G

G

1

2

3

4

1

3

Y

Y

CAPACITOR Fm2

B

B

Y

Y

FUSE2

++

T3.14A L250V

CN-TH

(WHITE)

CN-TANK

(WHITE)

Fm1

AC-WHT

(WHITE)

AC-BLK

(BLACK)

FUSE

DATA

(RED)

BLUE

RED

TRADE MARK

COMPRESSOR TERMINAL

CT101

+

GRY

+

-

+

GRY

REACTOR

-

+

P

(BLUE)

(YELLOW)

N

(RED)

COMPRESSOR

R

B

Y

Y/G

OUTDOOR FAN MOTOR RESISTANCE( )

CU-PE9DKD CU-PE12DKD

CONNECTING

L6LAHAG00001

Y-B M

Y-R A

COMPRESSOR RESISTANCE( )

CU-PE9DKD CU-PE12DKD

CONNECTING

U-V

U-W

V-W

L6LAJAG00001

290

287

14

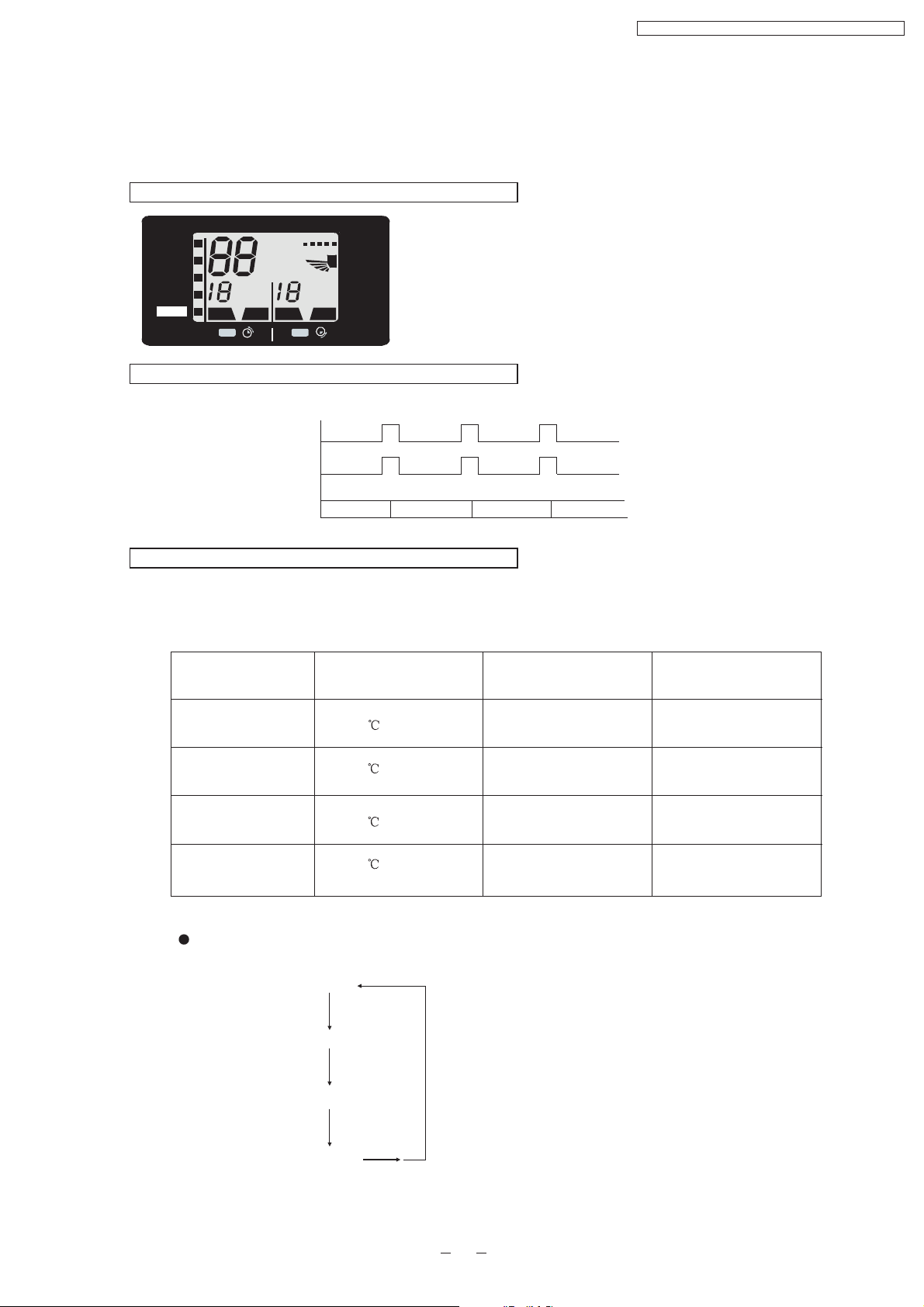

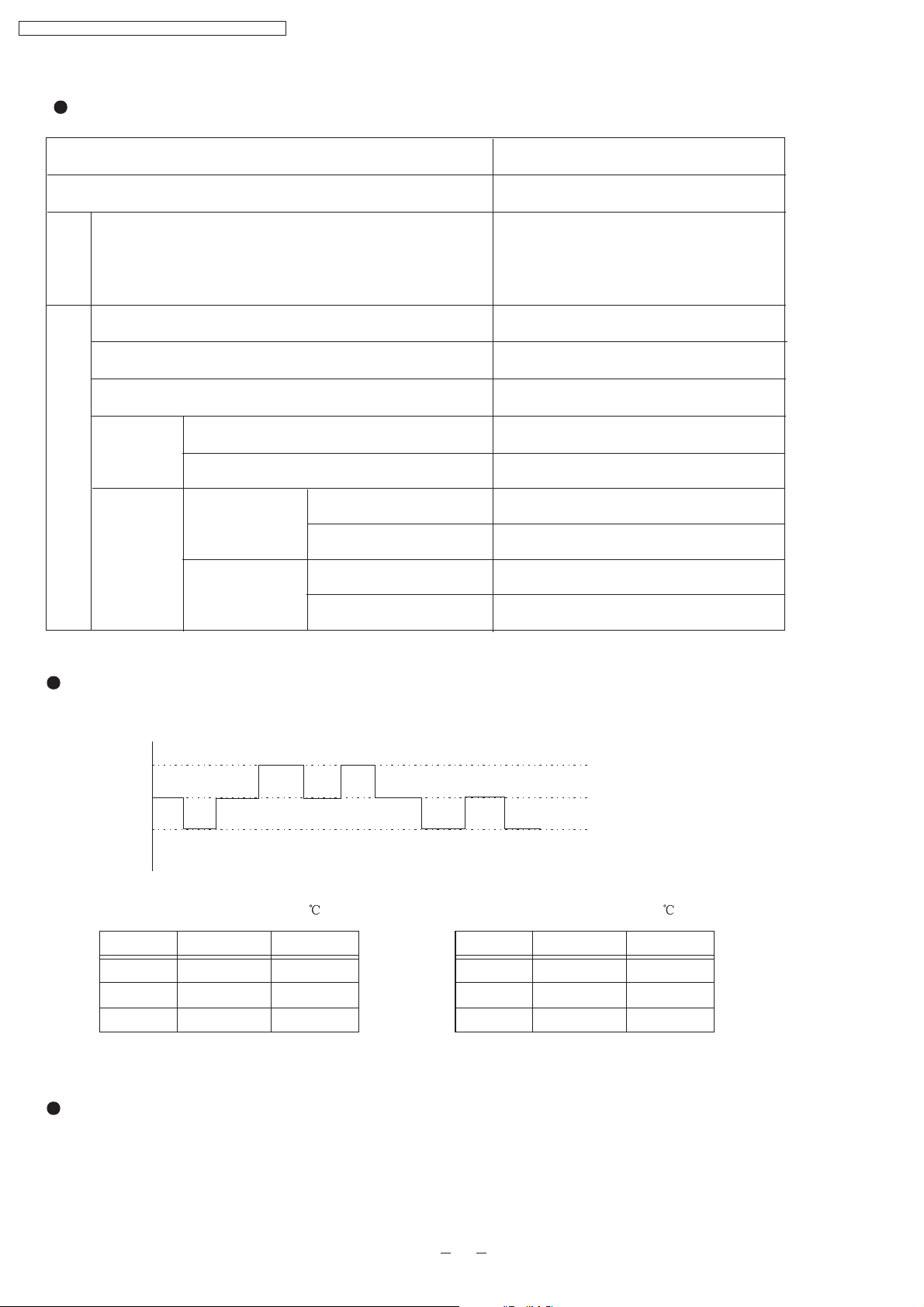

8 Operation Details

8.1 Operation and Display of Remote Controller

Original Setting

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

hr

DELAY

FAN

SPEED

AIR

SWING

AUTO

HEAT

COOL

DRY

OFF

AUTO

AUTO

hr

DELAY

OFF ONON OFF

AB

ON/OFF Button

ON/OFF Switch

Signal Transmitting

Indoor Indicator

Mode Selecting Button

1.Function and Display of the button:

AUTO, HEAT, COOL, DRY can be selected by pressing the button. Initial display of LCD is as follow

Green

MODE SET TEMP FAN SPEED AIR SWING

AUTO

HEAT

COOL

DRY

25

20

28

25

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

Keeping the button depressed continuously, the operation mode will change as

HEAT

COOL

DRY

AUTO

15

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

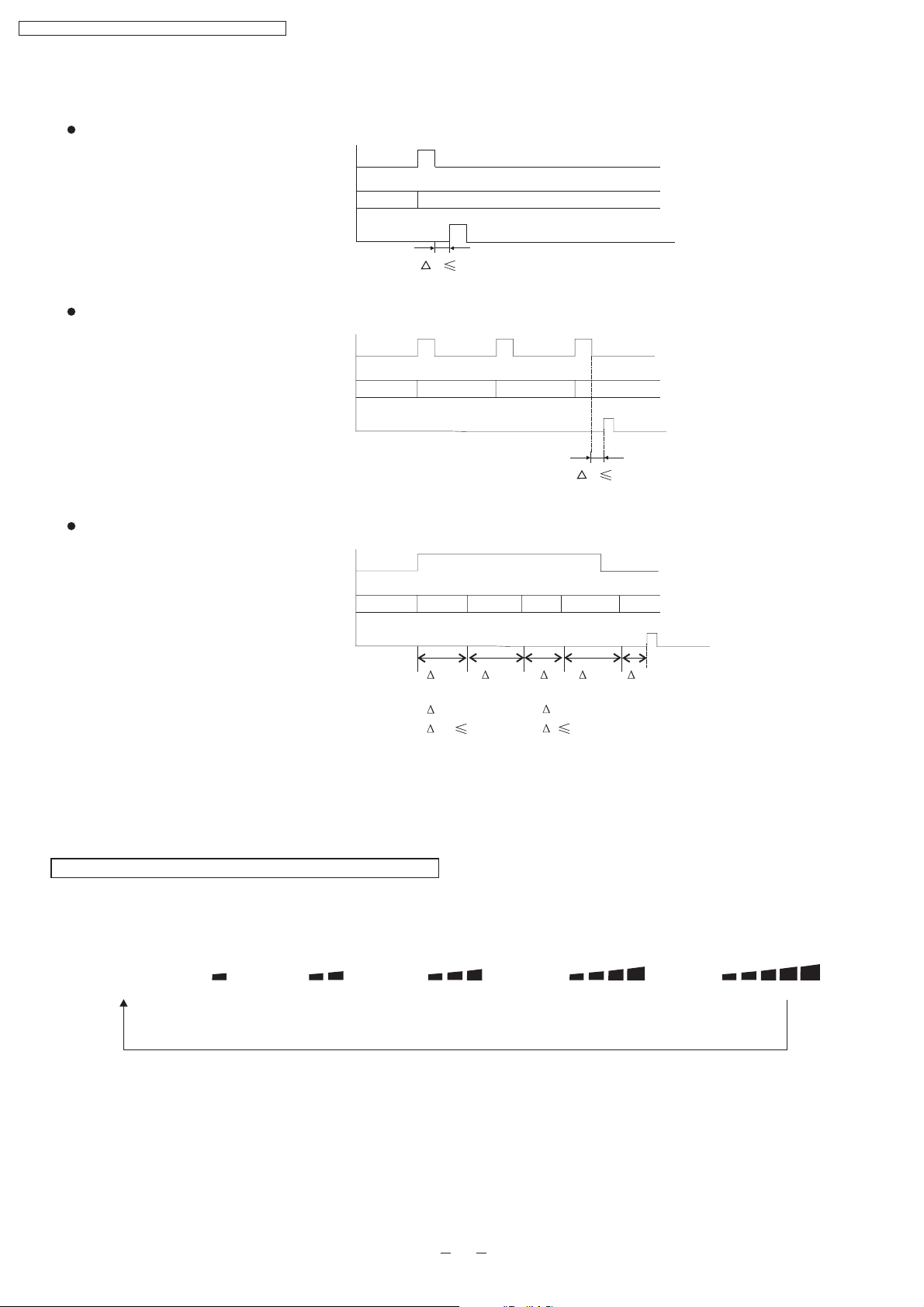

2.Shift time of the Mode selection button

Single press

Mode Selecting Button

LCD of Remote Control

Signal Transmitting

Keep depressed( less than 500ms)

Mode Selecting Button

LCD of Remote Control

Signal Transmitting

Keep depressed continuously

Mode Selecting Button

LCD of Remote Control

Signal Transmitting

AUTO

AUTO

AUTO

HEAT

t

HEAT

HEAT

500ms

COOL DRY

500ms

t

COOL DRY HEAT

AUTO

T1 T T T T2

T1=1s

T2 250ms

T=250ms

t 500ms

If the ON/OFF button is pressed after the operation mode is set, or change the operation mode during operation,

or the signal is received from the remote controller, the indoor indicator will flash or light up to start the operation.

Fan Speed Button

1.The display on the remote controller changes as follow by pressing the AIR SWING button.

AUTO

2.If the ON/OFF button is pressed after the fan speed mode is set, or change the fan speed mode during operation,

or the signal is received from the remote controller, the indoor indicator will flash or light up to start the operation.

3.The shift time of the fan speed button is the same to that of mode selecting button.

16

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Temp Adjusting Button

1.Press this button to change the set temperature

Increase the set temperature(Max.30 )

Decrease the set temperature(Min.16 )

2.If the ON/OFF button is pressed after temperature is set, or change the temperature during operation,

or the signal is received from the remote controller, the indoor indicator will flash or light up to start the operation.

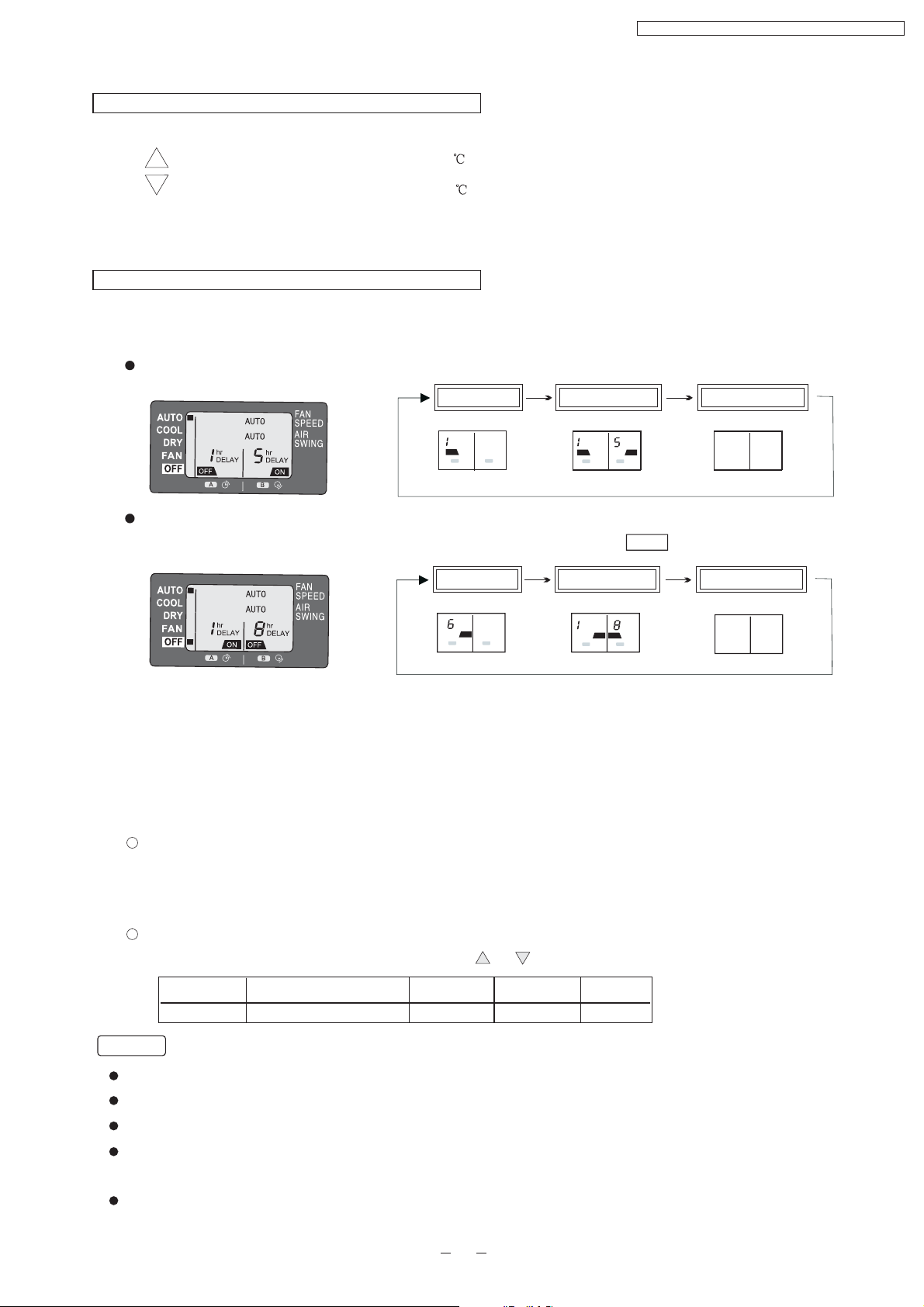

Timer Set Button

1.The Function of the Timer-Setting Button

1) SELECT Button

When the airconditioner is in operation

OFF Timer Setting Exit Timer SettingOFF-ON Timer Setting

hr

DELAY

OFF

AB

hr

hr

DELAY

DELAY

OFF ON

AB

When the airconditioner is turned off.

Make sure that the cursor key on the display of remote control points to OFF .

Eixt Timer SettingON-OFF Timer Setting

FAN

SPEED

AIR

SWING

ON Timer Setting

hr

DELAY

ON OFF

B

A

hr

hr

DELAY

DELAY

ON OFF

AB

2) Timer Selecting Button A and B

The set time can be changed with manner of 1,2,3,4,5,6,7,8,9,10,11,12,1,2,3,4... By pressing the buttons.

Pressing the button A can change the time for ON Timer and OFF Timer, off time for OFF-ON Timer, on time for

ON-OFF Timer; Pressing the button B can change the time for on time for OFF-ON Timer and off time for

ON-OFF Timer setting.

3) SET/CANCEL Button

Pressing the button to set or cancel the set timer during the timer setting or activate the previous timer setting.

1

After the timer setting is determined, “ON” or “OFF” will stop flashing. If the timer setting is cancelled, “ON” or

“OFF” will disappear on the remote control display.

The time on the remote control will change every hour.

2

By pressing this button for 5 seconds continuously, the number indicating the air quality sensor sensitivity will

appear in the remote control display. Then press or button to increase pr decrease the sensitivity.

Indicate

Sensitivity

Turn off the air quality Normal Standard hight

0123

Notes:

OFF Timer and OFF- ON Timer can only be set during the operation;

During the operation, if the ON Timer or ON-OFF Timer is set, the operation will be stopped.

Timer setting can operate only once.

If the OFF/ON button on the remote control or the AUTO Switch on the indoor unit is pressed, the timer setting

will be cancelled.

If Auto Restart Control occurs , timer setting will be cancelled.

17

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

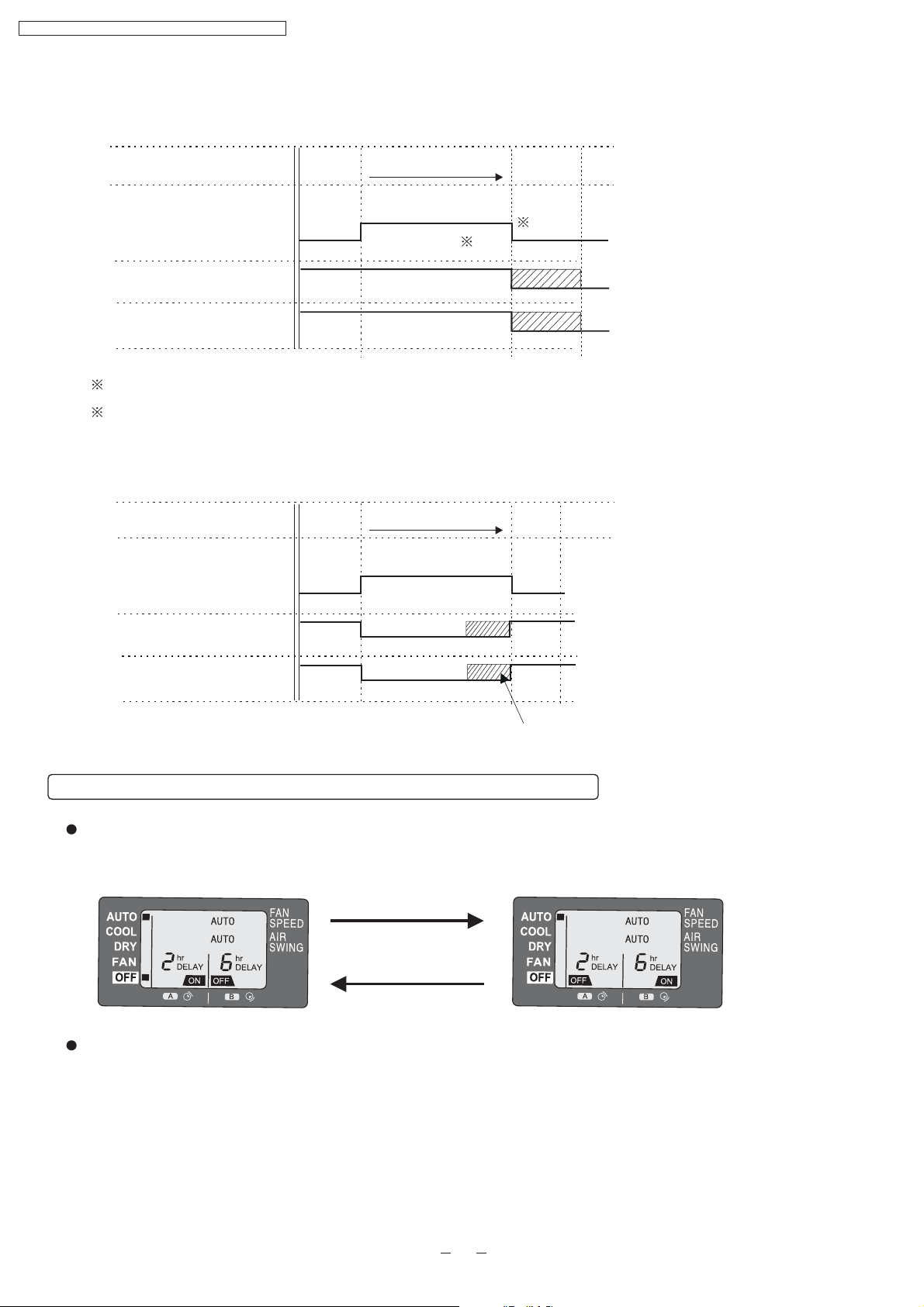

2.Timing Chart of Timer-Setting

1) OFF Timer

Initial Time

Changed Time

OFF Timer Setting

Remote Control LCD

Operation Indicator

1:During timer operation changing the set time.

2:During timer operation press the ON/OFF button to cancel the OFF-Timer and the timer indicator on

the indoor unit will go off.

2) ON Timer

ON Timer Setting

Remote Control LCD

Timer Indicator

Indoor Unit

Timer Indicator

3 hours later OFF

3 hours

2

Initial Time

5 hours later ON

5 hours

2 hours

1

Changed Time

Operation Indicator

Indoor Unit

OFF/ON Button

Preparation for operation

About Cursor Key Which Points To “OFF” On Remote Control

When the ON/OFF button on the remote control is pressed, the cursor key which points to “OFF” will appear or

disappear to indicate the ON/OFF status of the air conditioner.

FAN

SPEED

AIR

SWING

For some reason (Ex. The signal of the remote control does not reach the signal receiver of the indoor unit.), the

display of the remote control will not correspond with the actual ON/OFF status of the indoor unit:

The air conditioner is running but the cursor key which points to “OFF” appears. The air conditioner can be

1.

stopped with any button (Except for “ON/OFF”, “TIMER SET”, “TIMER ON”) pressed.

PRESS "OFF/ON" BUTTON

The air conditioner is on standby, but the cursor key which points to “OFF” disappears. The air conditioner can

2.

be started with any button(Except for “ON/OFF”, “TIMER SET”, “TIMER OFF”) pressed.

18

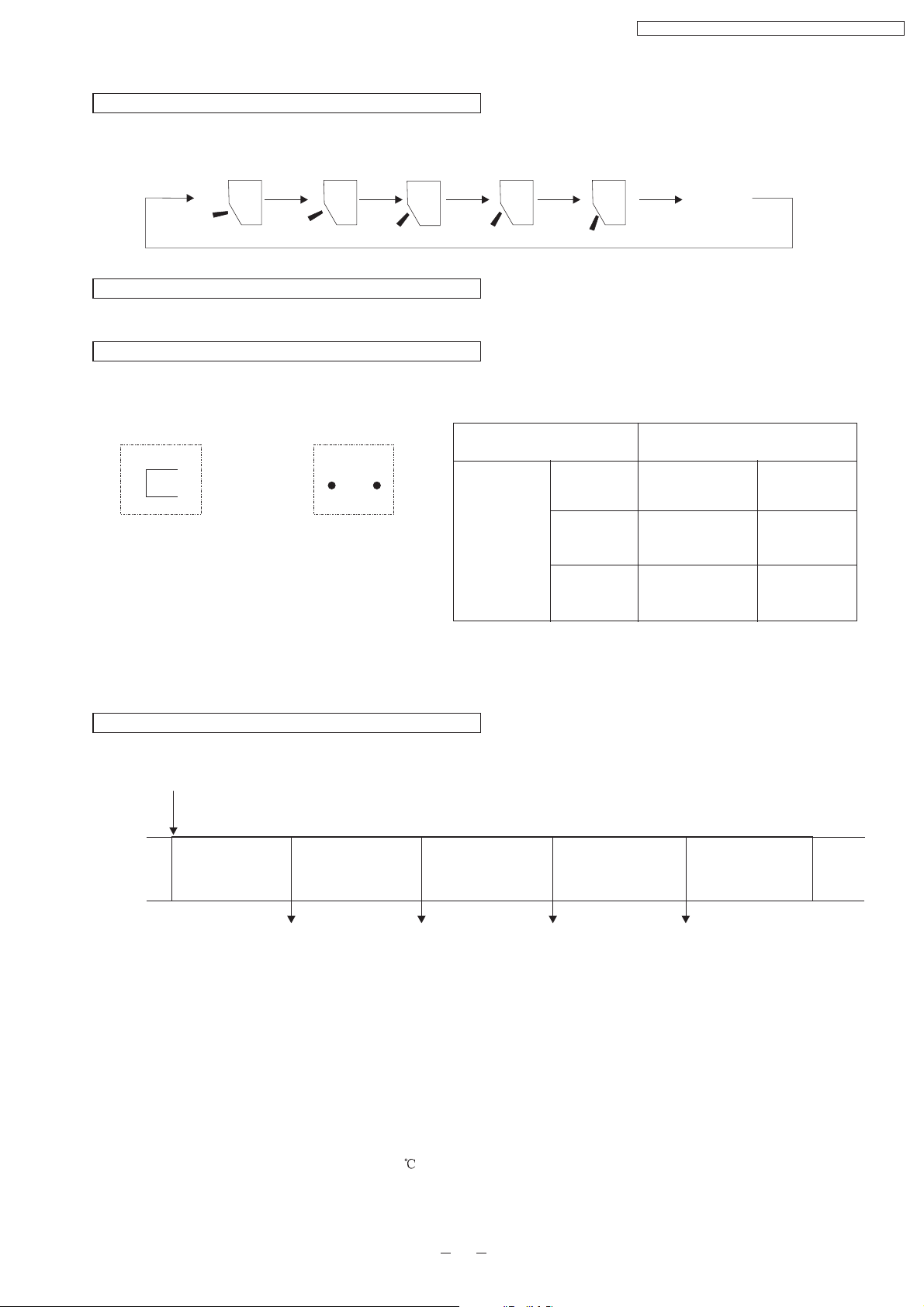

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Air Swing Button

The airflow direction will change as below by pressing the AIR SWING button.

Airflow Direction:

AUTO

Display of Diagnosis

Refer to Diagnosis section.

Change the Code of Remote Controller

Change the code of remote controller by joining or cutting jump wire on the remote controller and indoor PCB.

Four codes(A,B,C,D) can be selected.

J----B

JB

Inside the battery box of

remote controller.

On indoor PCB

Indoor PCB

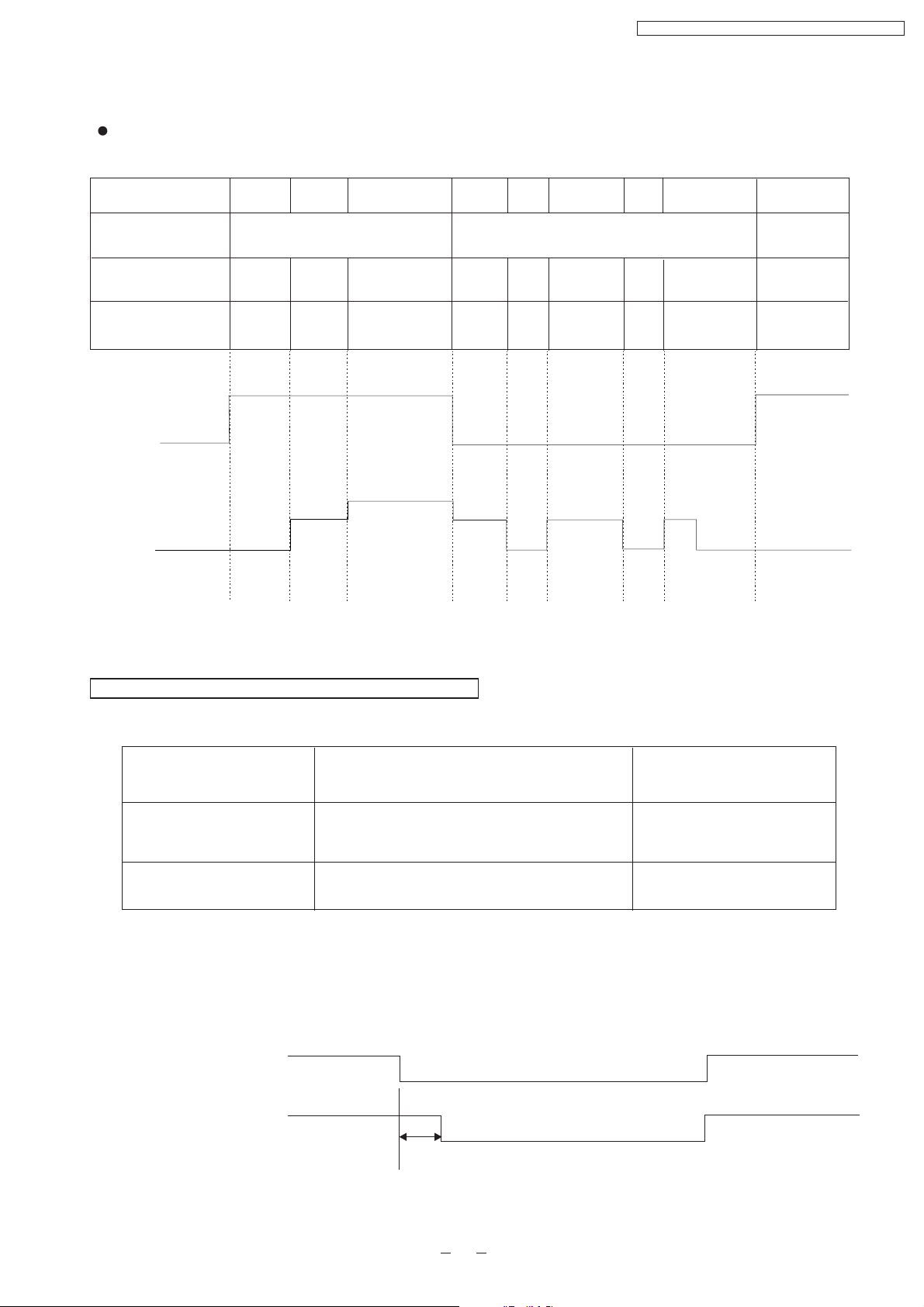

8.2 Operation and Display of Indoor Unit

AUTO Operation Switch

SW ON

5s 8s 11s 16s

Function

AUTO

Operation

Forced

COOL

Forced

HEAT

Short

Open

Various Setting

Mode

Short

AB

CD

Individual

Counter-action

Open

21s

Number of beep

1. When the switch is pressed between 0 to 5 seconds, Auto Mode operation starts to function.

2. When the switch is pressed between 5 to 8 seconds, the unit is forced to operate in Cooling Mode.

3. When the switch is pressed between 8 to 11 seconds, the unit is forced to operate in Heating Mode.

4. When the switch is pressed between 11 to 16 seconds and together with the signal from the remote controller,

the unit can be changed to different controlling setting .

5. When the switch is pressed between 16 to 21 seconds, either H14 error detection selection mode or remote

controller’s signal receiving sound can be cancelled or turned on.

6. If the intake air temperature is less than 16 and the Forced Cooling is activated, because the prior operation

mode is heating, the compressor will stop for 3 minutes to start the Forced Cooling operation.

12

34

19

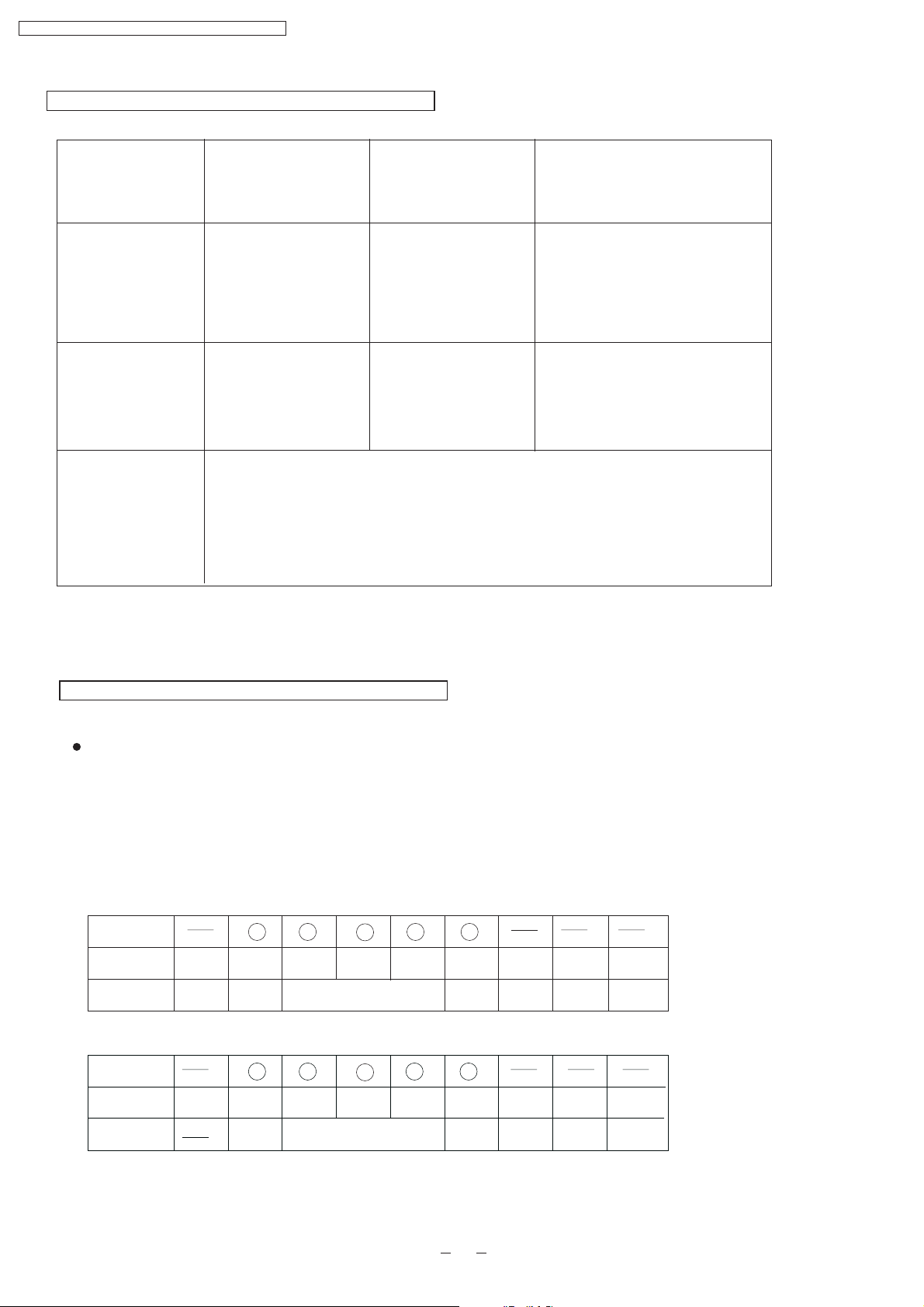

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Indoor Unit Indicator

ON OFF FLASH

Operation

(Green)

Timer

(Orange)

Air Quality

(Green

Orange

Red )

Timer set Timer not set

The air quality can be detected automatically by the air quality sensor and shown

by the color of the air quality indicator as bellow..

Color of indocator :Green Air qualuty: Normal

8.3 Common Features

Indoor Fan Motor Control

Run Stop

Orange Poor

Red Bad

Hot start, deice control,

mode judging and ONTimer Operation detecting.

Malfunction happens.

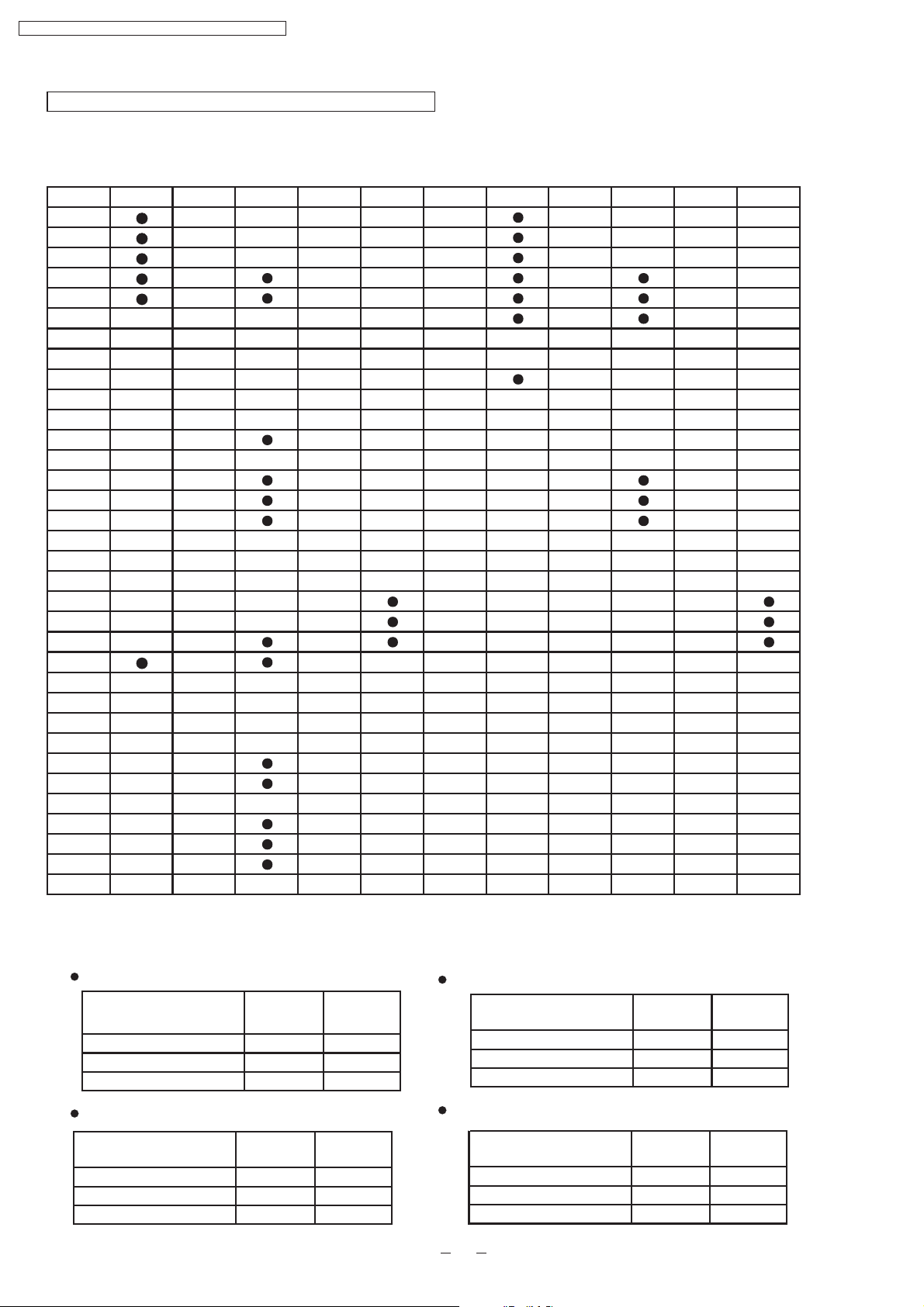

1. Basic Fan Speed

Fan speed is determined by the setting of the remote control. And W5~W6 can be calculated

according the equations below:

Those operation modes W4:Low , W8 : Hi , W10 have been regulated in the EEPROM data.

Me- : W5=W4+W10

Me : W6=W5+W10

Me+ : W7=W6+W10

Cool.Dry

REMOTE

CONTROL

FAN SPEED

ROTATING

SPEED

Heat

REMOTE

CONTROL

FAN SPEED

ROTATING

SPEED

SHI HI Me Me- Lo- Slo Sslo

W9C W8C Calculated W4C

SHI

HI Me Me- Lo Lo- Slo Sslo

W8W W4W W3W

Me+

Me+

Calculated

Lo

W3C

W2C

W2W

W1W

W1C

20

Basic fan speed of indoor unit

SHI W 9C 1420 1430

HI W 8C 1360 1370

Me+ W 7C 1190 1270

Me W 6C 1070 1160

COOL

Me- W 5C 950 1050

Lo W 4C 830 940

Lo- W 3C 770 880

Slo W 2C 740 840

SSLo W 1C 660 720

Interval W 10C 120 110

SHi W 8W 1420 1440

Me+ W 7W 1270 1340

Me W 6W 1150 1360

Me- W 5W 1030 1180

HEAT

Lo W 4W 910 1100

Lo- W 3W 670 800

Slo W 2W 580 580

SSLo W 1W 400 400

Interval W 10C 120 80

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

PE9DKE PE12DKE

2. Indoor Fan Control

Cool/Dry Operation

Protection Operation

Forced Cool

Minimum Control

Other than above

Other than above

Mode judging for Auto

Operation ON-Timer

Operation detecting

Mode judging during

ON-Timer detecting

Other

than

above

Auto Fan

Manual Fan

Auto Fan

Manual Fan

Other than

above

Other than

above

Cool Operation Dry Operation

Me

Hi

Lo-

Lo

Setting of Remote

Slo

Normal Auto Fan

Slo

Fan Speed Set

21

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Heat Operation

Protection Operation

Forced Heat

Minimum

Control

Mode judging in Auto Operation

Preparing Operation of Timer-ON operation

Hot Start

Deice Control

Low Temperature Control

Maximum

Control

Other

Other than above

than

above

Relay OFF(Comp OFF)

Indoor Piping Temp Control(Auto Fan)

Detection of

Timer-ON

Operation

Other than

above

Auto Fan Speed

Manual Fan Speed

Auto Fan Speed

Manual Fan Speed

Me

Shi

Lo-

Stop

Stop

SSHi

SLo- or SSLo

Refer to the following contents

Lo

Setting On Remote Control

Auto

Setting On Remote Control

Auto Fan Speed for Cooling Operation

Following eight patterns repeat over and over for auto fan speed. Each pattern persists ten

second.

No.C

No.B

No.A

a

Temp. Of outdoor unit under 35 Temp. Of outdoor unit above 35

No.A

No.B

No.C

c

b

PE9DKD PE12DKD

970

990

950

defg ha b

1070

1090

1050

No.A

No.B

No.C

PE9DKD PE12DKD

1130

1150

1110

1220

1240

1200

UNIT: rpm

Auto Fan Speed for Heating Operation

Refer to Piping Temperature Control.

22

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

3. Deodorizing Control

This type of control is applicable on Cooling Mode and Soft Dry Mode operating only.

During cooling or soft dry operation with automatic fan speed, the unit will operate as state below for deodorizing purpose.

Deodorising Status

Compressor status

Period(sec)

Indoor fan speed

1

23 45

ON

40 50 20 90

SloOFF

…

Note*

OFFSlo

ON

COMP

FM

OFF

OFF

Note*:Fan speed is automatic for cooling mode and Slo for soft dry mode.

4

OFF

20 90

OFFSlo

5

4.5.4....

40

OFF

1

ON

ON

Outdoor Fan Motor Control

1. Specification of outdoor fan motor

Model Fan Motor Speed(rpm)

CU-PE9DKD

CU-PE12DKD

2. Operation of the fan motor

The outdoor fan runs during the operation of the compressor or within 30 seconds after the compressor stops.

Compressor

Outdoor Fan

Induction Motor(6 Poles 1 speed)

Induction Motor(6 Poles 1 speed)

ON

ON

30 seconds

670

770

ON

OFF

ON

OFF

23

CS-PE9DKD / CU-PE9DKD / CS-PE12DKD / CU-PE12DKD

Frequency for Compressor Operation

1. Basic Frequency

If the frequency for the compressor calculated is prohibited, 1 Hz larger than this calculated

one will be selected.

Cool Dry Heat

12

13

14

15

16

17 51 12 85 17

18 12 52 9 86 18 9 52 86

19 53 87 19 53 87

20 54 88 20

21 55 89 21 55 89

22 56 9 90 22 56 12 90

23 57

24 58 92 24 58 92

25 59

26 60

27 61

28 62 96 28 62 96

29 63 97 29 63 97

30 64 98 30 64 98

31 65 99

32 66 9 100 32 66 12 100

33 67 101 33 67 12 101

34 68 102 34 68 12 102

35 12 69 103 35 69 9 103

36 9 70 104 36 70 104

37 71 105 37 71 9 105

38 12 72 106 38 72 9 106

39 12 73

40 74

41 9 75 109 41 75 109

42 76

43 77

44 12 78

45 12 79 113 45 79 113

46 80 12 46 80

47 81 13 47 81

48 82 14 48 82 12

49 83 15 49 83 12

50 84 16 50 84 12

51 85

54 88

91 23 57 91

93 25 59 93

94 26 60 94

95 27 61 95

31 65 99

107 39 73 107

108 40 74 108

110 42 76 110

111 43 77 111

112 44 78 12 112

2. Starting Control

Within 300 seconds after the start-up of the compressor, the frequency for the compressor

will change as below.

Start-up after the micron reset

Time From Start-up of

Compressor

60

60-120s

120-300

Min.Hz Max.Hz

40 40

40 40

\ 110

Start-up after thermal off ( Set Temp Reached)

Time From Start-up of

Compressor

60

60-120s

120-300

Min.Hz Max.Hz

38 38

38 38

\ 119

Start-up after thermal off ( Set Temp Reached, heating mode)

Time From Start-up of

Compressor

60

60-120s

120-300

Start-up under other conditions

Time From Start-up of

Compressor

60

60-120s

120-300

24

Min.Hz

40 40

40 40

\ 119

Min.Hz

40 40

40 40

\ 110

Max.Hz

Max.Hz

Loading...

Loading...