Page 1

CRS1

ORDER NO. MD0509368C0

A6

Mechanism Unit

CONTENTS

Page Page

1 Mechanism Overview 3

2 Mechanism Drive Unit

2.1. Tray Open/Close and Multi-Discs Change operations

2.2. Disc Selection operation

2.3. Play/Stop operation

3 Mechanism Operation Description

3.1. General Feature

3.2. Hardware composition

3.3. Mechanism Operation

3.4. Switches Chattering Check

3.5. Motor Movement Control

3.6. Plunger Timing Chart

3.7. Initialization of Mechanism Unit.

3.8. Mechanism "HOME" position

3.9. Mechanism "Play Driving" position

3.10. Trays Operation

3.11. Drive tray between STOCK and PLAY position

3.12. Selection of Tray by Moving UD base Up/down

3.13. Fail Safe

3.14. Manual Trigger Tray Close

3.15. Changer Error Code

4 Self diagnosis and special mode setting

12

12

12

15

16

17

18

25

26

29

30

31

32

4

4

5

7

9

9

9

9

4.1. Special Mode Table 32

4.2. Error code Table

5 Troubleshooting Explorer

5.1. Preparation of service jig

5.2. Checking of Changer Unit

5.3. Setting the trays in "STOCK" position

6 Flow Chart

6.1. Disassembly Flow Chart

6.2. Assembly Flow Chart

6.3. Disassembly Flow

7 Assembling and Disassemb ling Procedure.

7.1. Disassembling Procedures

7.2. Assembling Procedure

8 CRS1 (Changer Unit) Ageing / Reliability

8.1. Equipments

9 Notes of Schematic Diagram

10 Schematic Diagram

10.1. CD Loading Circuit

11 Printed Circuit Board

11.1. CD Loading P.C.B.

12 Exploded Views

12.1. CD Loading Mechanism

34

38

38

38

38

49

49

50

51

53

53

73

93

93

94

95

95

96

96

97

97

© 2005 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

CRS1

13 Replacement Parts List 100

13.1. CD Loading Mechanism Parts List

101

13.2. Electrical Parts List

102

2

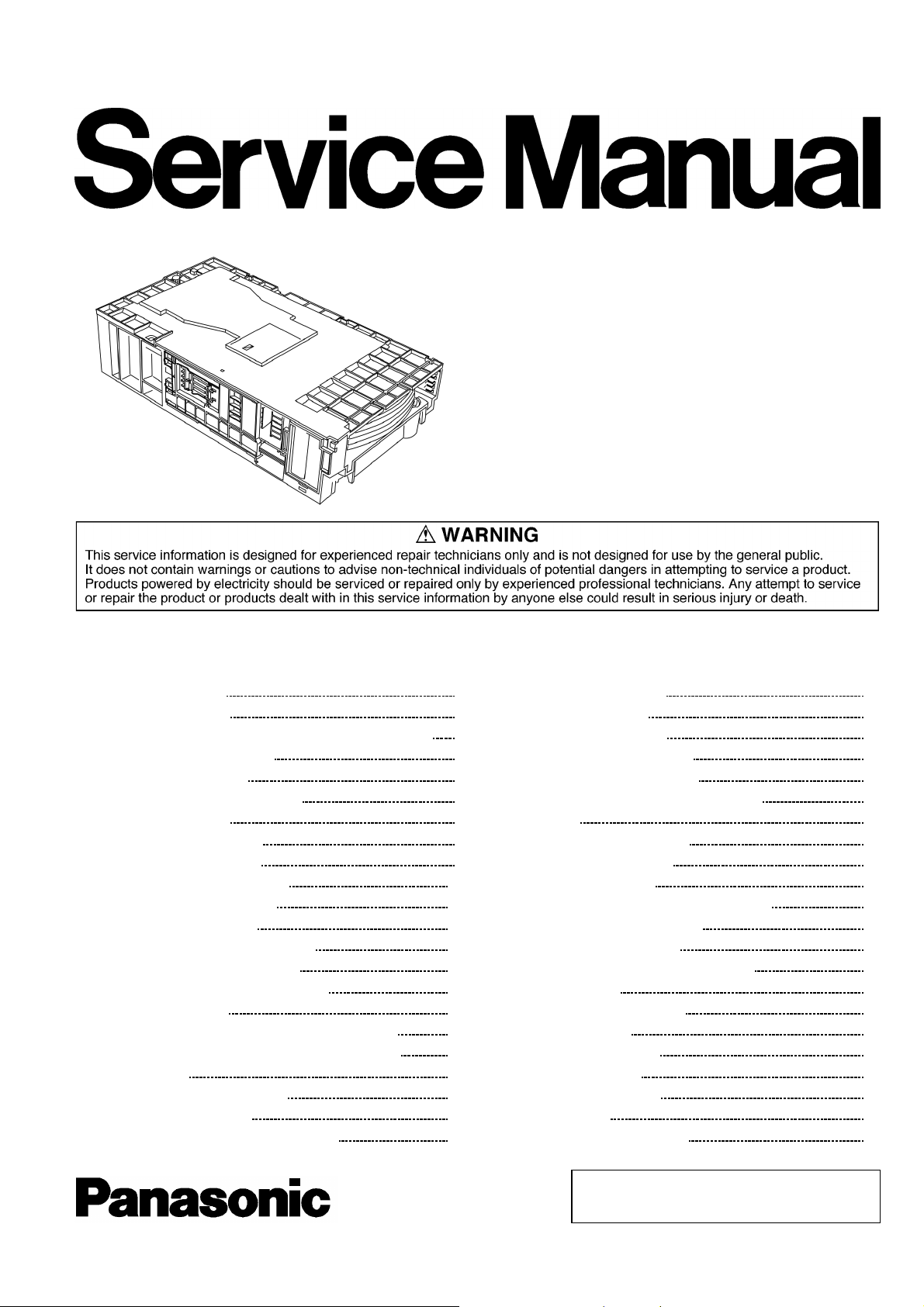

Page 3

1 Mechanism Overview

CRS1

3

Page 4

CRS1

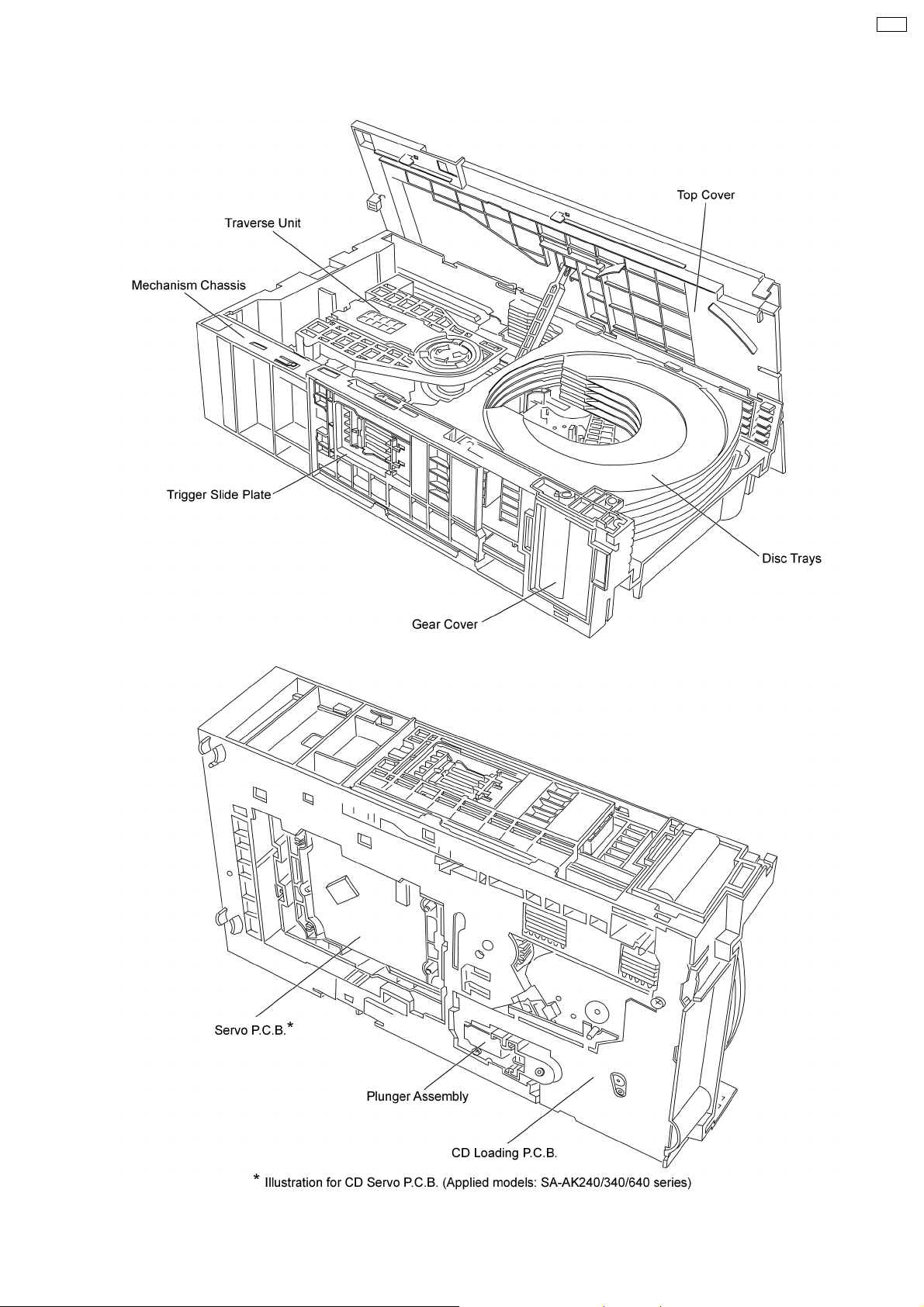

2 Mechanism Drive Unit

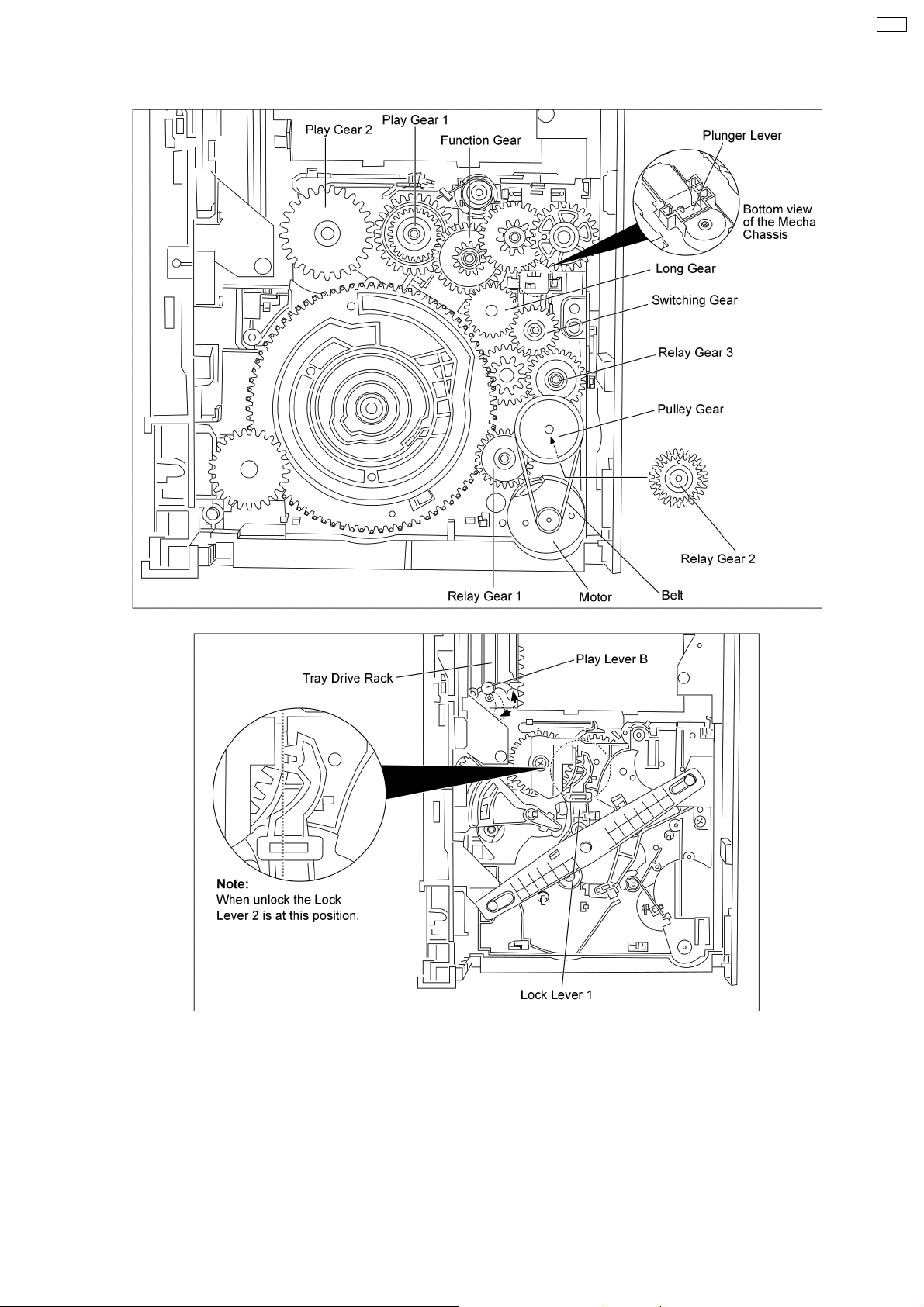

2.1. Tray Open/Close and Multi-Discs Change operations

2.1.1. Description of tray open/close and multi-discs change operations

1. The motor turns in the clockwise direction and the rotation is transmitted via the belt, the pulley gear also turns clockwise.

2. The relay gear 1 turns counterclockwise.

3. The relay gear 2 turns clockwise.

4. The relay gear 3 turns counterclockwise.

5. The switching gear at down position turns clockwise (up/down position functioned by the plunger lever).

6. The main drive gear turns counterclockwise.

4

Page 5

7. The cam gear turns clockwise, which is engaged with the trigger gear and slide plate, are driven, causes the tray lock lever

unlock.

8. The tray relay gear turns counterclockwise, which is engaged with the OC assy, is driven.

9. The movement of the OC assy releases the disc trays.

(The operation of the disc trays closed is the opposite of that for opening of disc trays.)

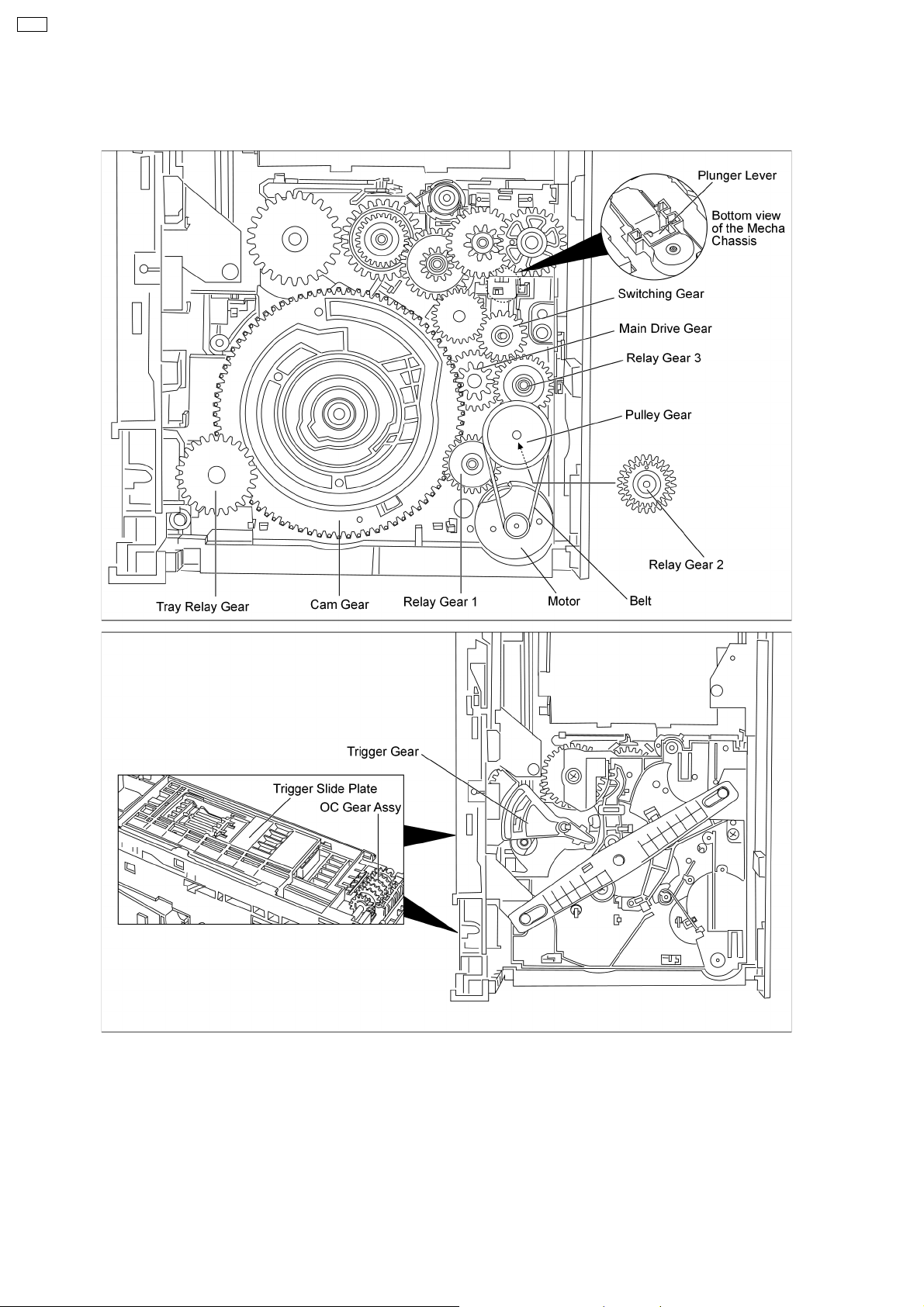

2.2. Disc Selection operation

CRS1

5

Page 6

CRS1

2.2.1. Description of disc selection operation

Note: Check that the cam gear is in “HOME” position.

1. The motor turns in the clockwise direction and the rotation is transmitted via the belt, the pulley gear also turns clockwise.

2. The relay gear 1 turns counterclockwise.

3. The relay gear 2 turns clockwise.

4. The relay gear 3 turns counterclockwise..

5. The switching gear move up turns clockwise (up/down position functioned by the plunger lever).

6. The long gear turns counterclockwise.

7. The function gear moved up turns clockwise.

8. The UD gear 1 turns counterclockwise.

9. The UD gear 2 turns clockwise engaged with the UD rack R drives the UD connection lever turns clockwise, UD rack L, is driven

to move the traverse deck assembly up.

(The operation of the traverse deck assembly down is the opposite of that for the traverse deck assembly up.)

6

Page 7

2.3. Play/Stop operation

CRS1

2.3.1. Description of play/stop operation

Note: Check that the Lock Lever 1 is unlock.

1. The motor turns in the clockwise direction and the rotation is transmitted via the belt, the pulley gear also turns clockwise.

2. The relay gear 1 turns counterclockwise.

3. The relay gear 2 turns clockwise.

4. The relay gear 3 turns counterclockwise.

5. The switching gear move up turns clockwise (up/down position functioned by the plunger lever).

6. The long gear turns counterclockwise.

7

Page 8

CRS1

7. The function gear move down turns clockwise.

8. The play gear 1 turns counterclockwise.

9. The play gear 2 turns clockwise engaged with the tray drive rack and tray catch lever to push in the disc trays.

10. Play lever B engaged with the traverse deck assembly’s play lever A, causes slide plate move towards to the play position.

8

Page 9

3 Mechanism Operation Description

3.1. General Feature

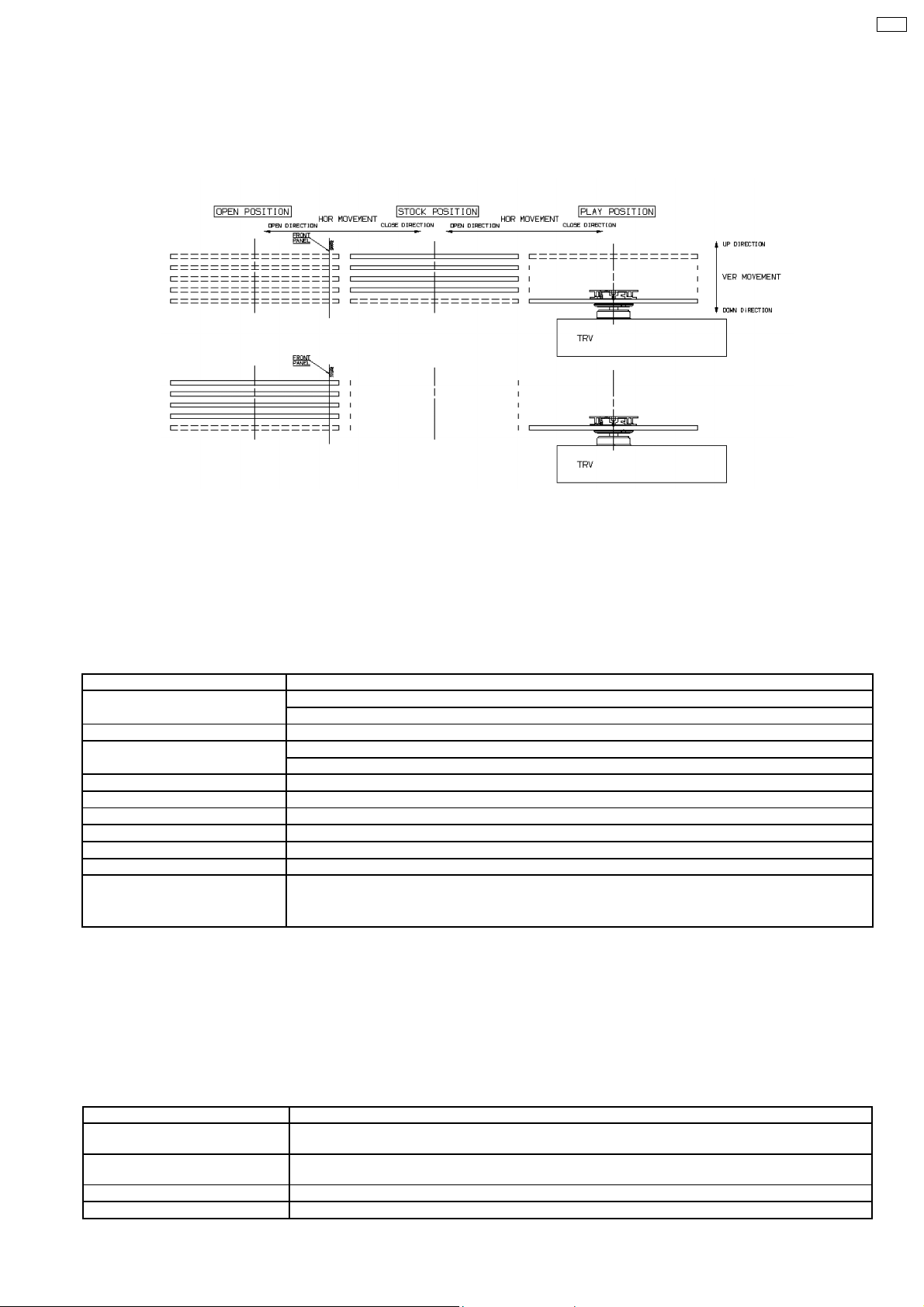

· This is a five disc changer mechanism for CD/DVD. The outline figure is shown below.

CRS1

· The mechanism has "CHANGE WHILE PLAY" function. It open other trays for disc exchanging while one tray is at PLAY

position performing recording or reproducing.

· The mechanism can quickly change all trays with "CHANGE ALL" function. All trays can be move to OPEN position with one

operation.

· There is no sensor to indicate presence of disc on any tray.

3.2. Hardware composition

· Below is the hardware components of the mechanism

Name Function

Open Switch (OPEN-SW) The switch is used to detect normal tray opening

The switch is used for detect tray being manually push/trigger when full open

Home Switch (HOME-SW) Is used to detect cam gear home position

Close Sensor (CLOSE-SENSOR) Used for normal single tray closing

Used to detect cam gear rotate to Play Driving position

Play Switch (PLAY-SW) Detect TRV clamping complete position

Stocking Switch (STOCK-SW) Detect tray completely transfer for play position to stocking positi

UD Sensor (UD-SENSOR) Detect TRV vertical movement position

Top Switch (TOP-SW) Detect a default position of TRV vertical movement position

Driver IC To drive Motor

Motor Main driving source for changer

Plunger Switching the driving source from motor to:

1. Tray open/close

2. Drive tray to play/stock position and TRV vertical movemen

3.3. Mechanism Operation

· This mechanism has the following state:

1. Driving of a tray to open/close

2. Up/down operation of a traverse performs a state changes of tray.

By using the plunger to lift/release of a switching gear, and the cam gear to lift/release the function gear the motor can be link

to several gear trains to perform various operations.

· The functions that can be perform in this mechanism are described as below:

Condition Explanation

Open current playing tray The state to change current playing disc. All tray will be open at once and current tray at PLAY position

Open All The state where all trays being driven to OPEN position. The disc can be taken in or out from tray to tray

Stock The state where the trays are stored in STOCK position

Play The state where one of the tray 5 trays is being driven to PLAY position and clamped by traverse unit

will be expose.

by close tray one by one from top to bottom.

9

Page 10

CRS1

Condition Explanation

Play & Open Tray-* The state where one of the tray is in playing position performing recording or reproducing, other trays can

Change The state when one of the opened tray being driven from OPEN position to STOCK position and other

Close All The state where all open trays will being driven from OPEN position to STOCK position, one by one from

Note: * represent tray number (from 1 ~ 5)

be used (OPEN position) for disc exchanging without stopping the recording or reproducing process.

opened trays remain still at OPEN position.

top to bottom

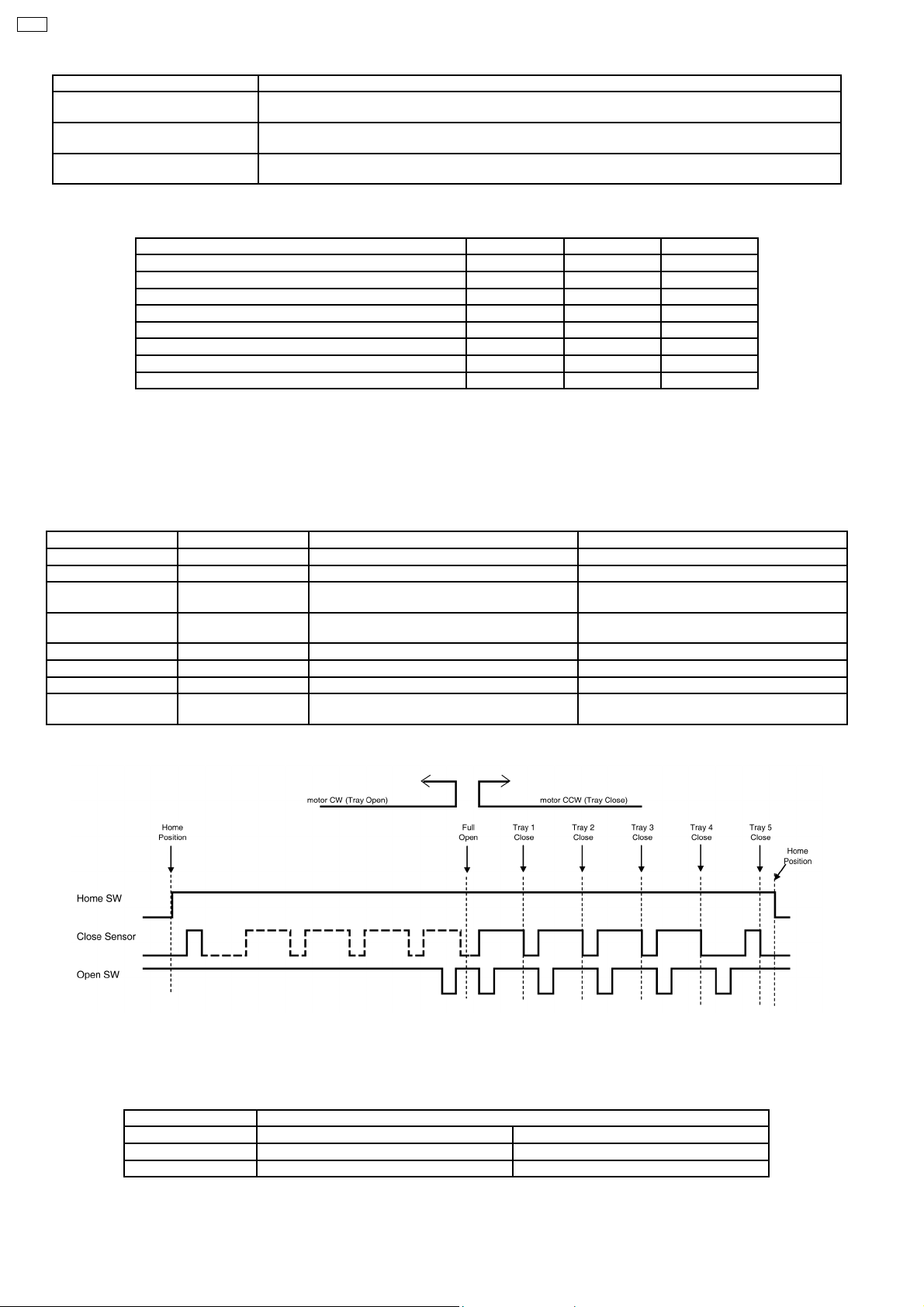

· Logics of motor control:

Action CW CCW Plunger

Tray Opening H L L

Tray Closing L H L

Cam move from Home Position to Play Driving Position H L L

Cam move from Play Driving Position to Home Position L H L

Drive tray to PLAY position H L H

Drive tray to STOCK position L H H

UD base moving upward H L H

UD base moving downward L H H

Notes :

CW/CCW : Motor direction control (CW : clockwise, CCW : Anti-clockwise)

Plunger : Solenoid Control (H : ON = Activation)

· Cam gear in the mechanism use for opening/closing of trays and lifting a function gear to link to gear train that drive UD base

moving up/down. When cam gear is being driven to play driving position, the function gear will be bring down to link the gear

train that drive tray to and from STOCK position and PLAY position. Below are the relation between mechanism function and

cam gear movement and position

Motor Direction Plunger Unit Cam gear movement/position Function

CW Release Home SW → rotate CW Trays Open

CCW Release Rotate CCW → Home SW Trays Close

CW Release Home SW → close sensor 1st L-H signal Cam gear move from Home Position to Play

CCW Release Close sensor 1st (H → L) signal → Home SW Cam gear move from Play Driving Position to

CW Up Cam Stop at Home Position UD base moving from bottom to top

CCW Up Cam Stop at Home Position UD base moving from top to bottom

CW Up Cam Stop at Play Driving Position Tray move from STOCK to PLAY position

CCW Up Cam Stop at Play Driving Position Tray move from PLAY position to STOCK

Driving Posi

Home Position

Position

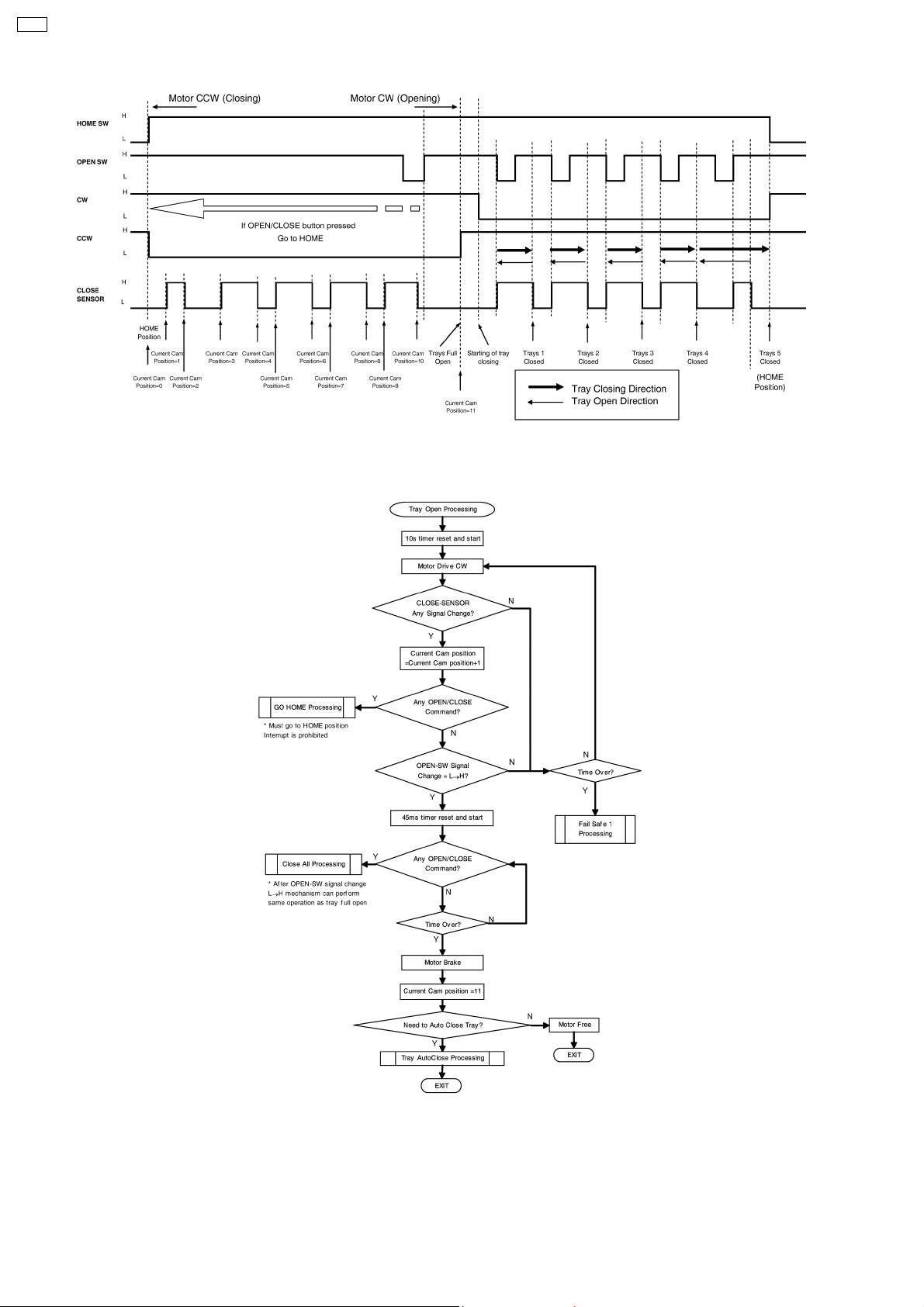

· Cam gear rotation direction, switch and state changes is show in figure below:

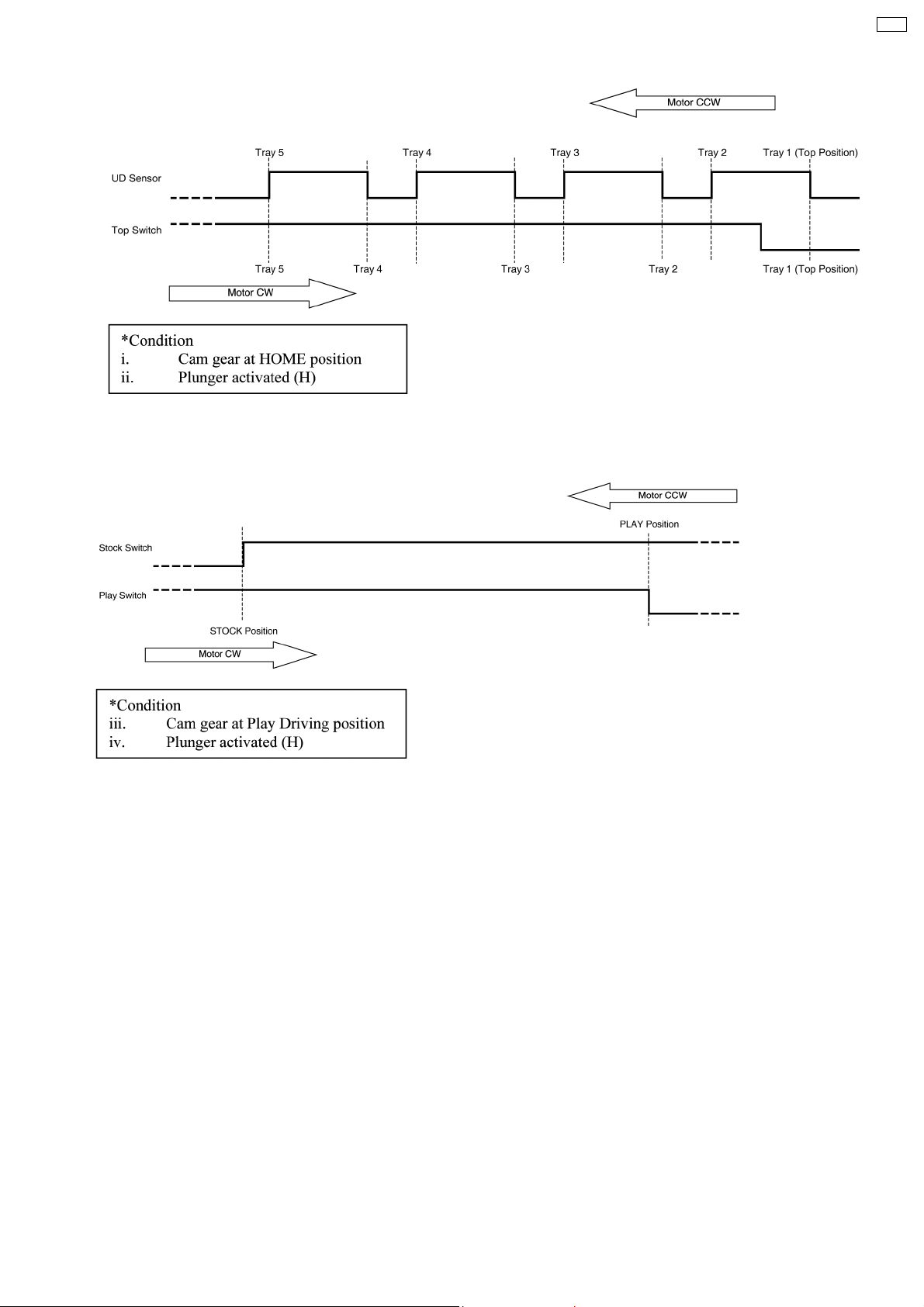

· The movement of UD base (vertical up/down) and driving of tray(s) between STOCK position and PLAY position is only enable

when plunger ON (lift up the switching gear to link driving source to the both gear train). Only one gear train can be driven at

one time, the selection of either gear train is depending on cam gear position. Below are figure showing the operation of motor

driving direction and its function carry out.

Cam Gear

Motor Home Position (UD Driving Position) Play Driving Position

CW UD base move upwards direction 5→1 Stock → Play

CCW UD base move downwards direction 1→5 Play → Stock

· For driving UD base up/down the cam gear must be at the home position (UD driving position) and plunger need to be

activated, the switch and state change is as figure below:

10

Page 11

· To drive the tray(s) between STOCK/PLAY position, cam gear must be at the play driving position and plunger need to be

activated, the switch and state change is as figure below:

CRS1

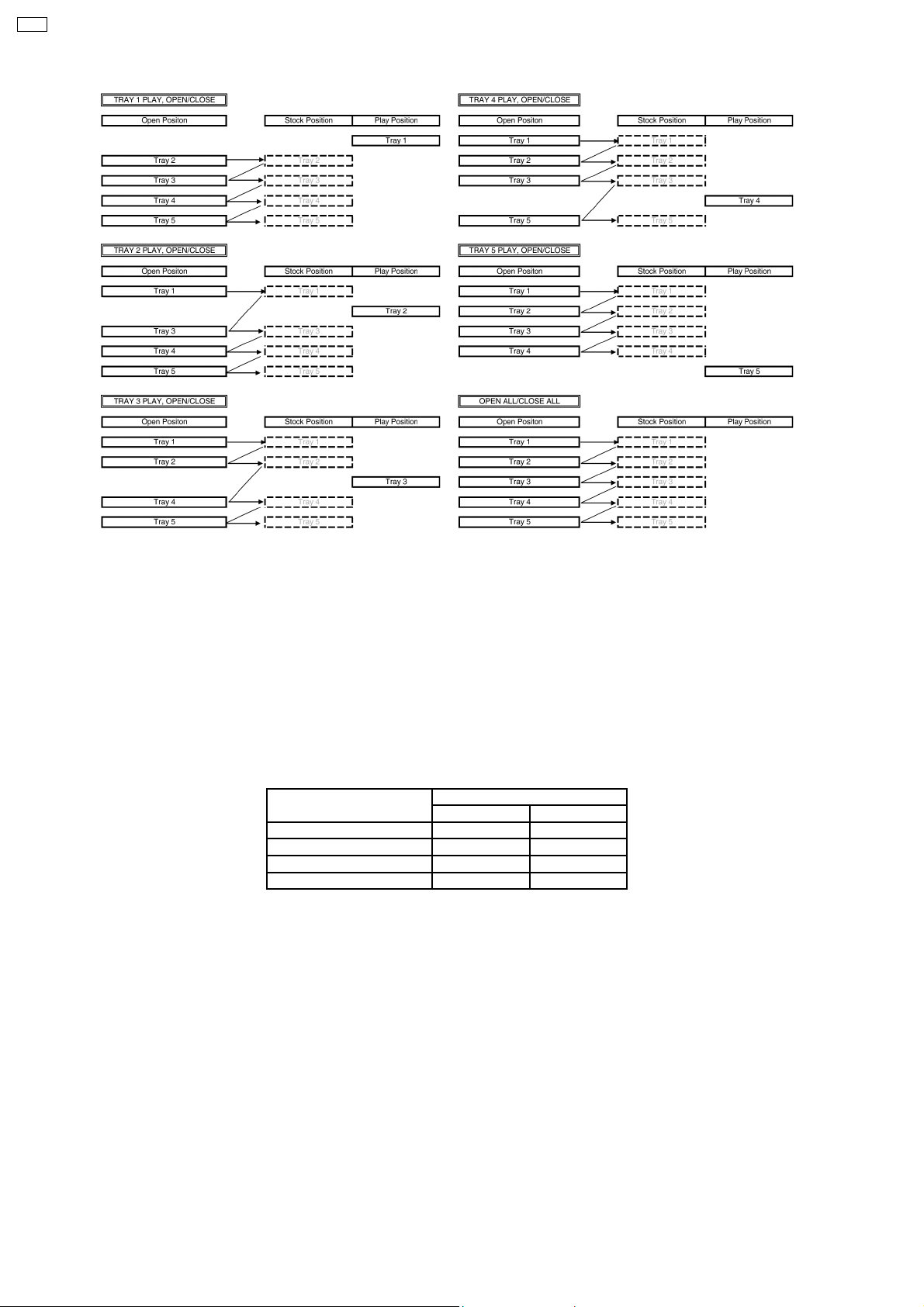

· The mechanism tray opening and closing is cycle process. It is able to open all trays in STOCK position while one of the tray

is in PLAY position. The closing can be done one by one or close all at once depend on the user instruction. Below show the

tray opening and closing flow.

11

Page 12

CRS1

3.4. Switches Chattering Check

· Each input shall perform chattering check processing.

OPEN-SW 2ms Periodic sampling. It logic-decides by continuation same 5 times.

PLAY-SW 2ms Periodic sampling. It logic-decides by continuation same 5 times.

STOCK-SW 2ms Periodic sampling. It logic-decides by continuation same 5 times.

TOP-SW 2ms Periodic sampling. It logic-decides by continuation same 5 times.

HOME-SW 2ms Periodic sampling. It logic-decides by continuation same 5 times.

UD-SENSOR 2ms Periodic sampling. It logic-decides by continuation same 5 times.

CLOSE-SENSOR 2ms Periodic sampling. It logic-decides by continuation same 5 times.

3.5. Motor Movement Control

Condition Motor

CW CCW

Free L L

Rotate CW H L

Rotate CCW L H

Short Brake H H

3.6. Plunger Timing Chart

· Plunger is use for pulling the lever that a switching gear is sit on the lever. When current supply to the plunger to pulling (kick)

switching gear, it will be lift up to engage to 1

be bring done by gravity force and mechanical coil spring on top of it. Plunger use for connect the driving source from motor

to 2 different gear train in the mechanism, the functions of the gear trains are as below:

1. Tray open/close

2. Drive tray to play/stock position and TRV vertical movement

st

gear train. When current supply to plunger is cut off (release), switching gear will

· The plunger movement is define as below:

Kick = H, Release= L

· Each time during plunger activation time (Kick/Release), the motor shall perform a short time CW and CCW rotation for release

the gear side force and ensure complete gear to gear engagement.

12

Page 13

· The basic concept of the motor rotation sequence (CW or CCW) is base on the initial and final motor rotating direction. The

direction should be opposite to the initial and final motor driving direction in order to:

1. To release the gear teeth side force

2. To release mechanism belt tension

3. To ensure switching gear disengage or engage into other gear´s teeth

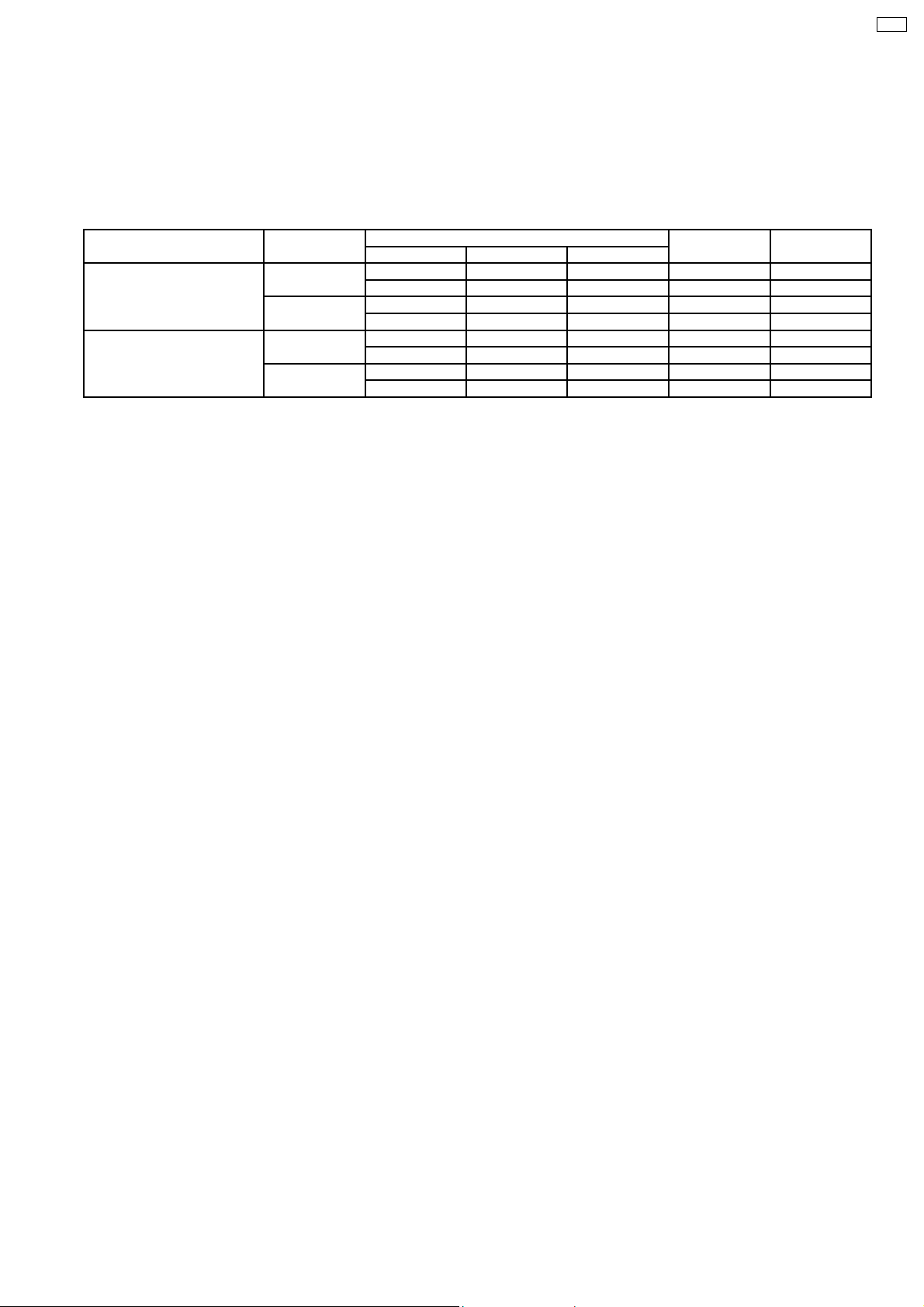

· Summary of the type of motor short rotation direction is as below:

Motor Direction Initial Short Rotate Direction Final Switching Mode

Plunger Kick CW CCW CW CCW CW A

CCW CW CCW - CW C

Plunger Release CW CCW CW CCW CW E

CCW CW CCW - CW G

st

1

nd

2

rd

3

CCW CW - CCW B

CW CCW CW CCW D

CCW CW - CCW F

CW CCW CW CCW H

· Below are the timing charts of plunger activation time.

CRS1

13

Page 14

CRS1

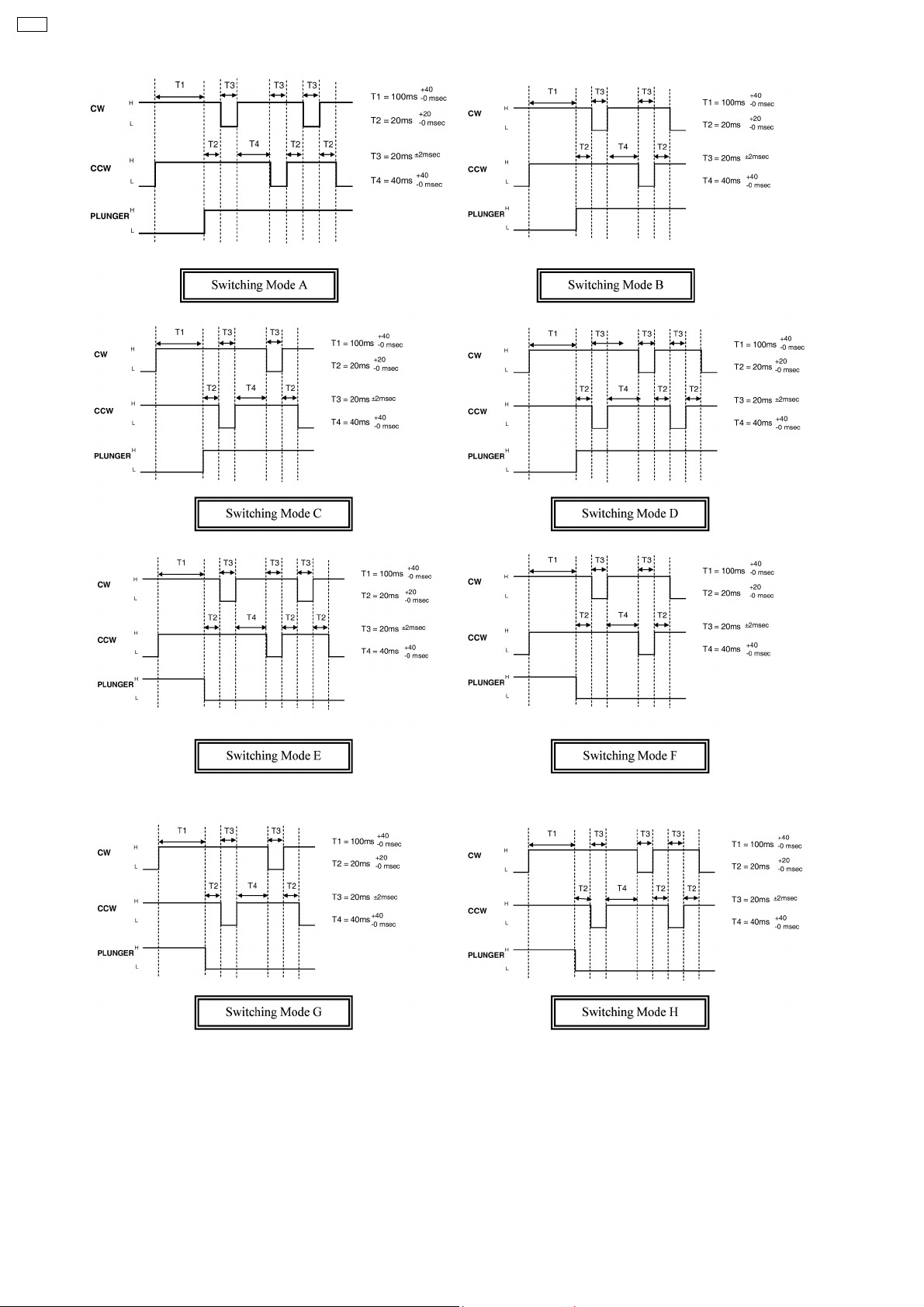

· As the plunger only activate at 2 position of cam gear. The plunger mode summary as below:

14

Page 15

CRS1

Switching

Position

Home

Position

Play

Driving

Position

Cam gear rotate CCW to HOME

Motor : CCW

Cam gear rotate CCW to HOME

Motor : CCW

UD base move from bottom to top

Motor : CW

UD base move from top to bottom

Motor : CCW

Cam gear rotate CW from HOME to Play

Driving Position. Motor : CW

Cam gear rotate CW from HOME to Play

Driving Position. Motor : CW

Drive tray from STOCK position to PLAY

position. Motor : CW

Drive tray from PLAY position to STOCK

position. Motor : CCW

Drive tray from PLAY position to STOCK

position. Motor : CCW

Initial Motor Direction Switching

Mode

C UD base move from bottom to top

D UD base move from top to bottom

E Cam gear rotate CW from HOME to

G Cam gear rotate CW from HOME to

A Drive tray from STOCK position to

B Drive tray from PLAY position to

F Cam gear rotate CCW from Play

H Cam gear rotate CCW from Play

G Cam gear rotate CW from until trays full

Initial Motor Direction Function

Motor : CW

Motor : CCW

Play Driving Position. Motor : CW

Play Driving Position. Motor : CW

PLAY position. Motor : CW

STOCK position. Motor : CCW

Driving Position to HOME. Motor : CCW

Driving Position to HOME. Motor : CCW

open. Motor : CW

Tray selection from bottom

to top

Tray selection from top to

bottom

After tray selection, cam

gear rotate to Play Driving

Position

After tray selection, cam

gear rotate to Play Driving

Position

Load tray to Play

Unload tray from Play to

Stock

After load tray to Play, cam

gear return to HOME

After unload tray from Play,

cam gear return to HOME

Open trays while one tray

Play

· Switching mode G is used during initialization to ensure that the switching gear is at the release (down) condition before the

initialization process begins.

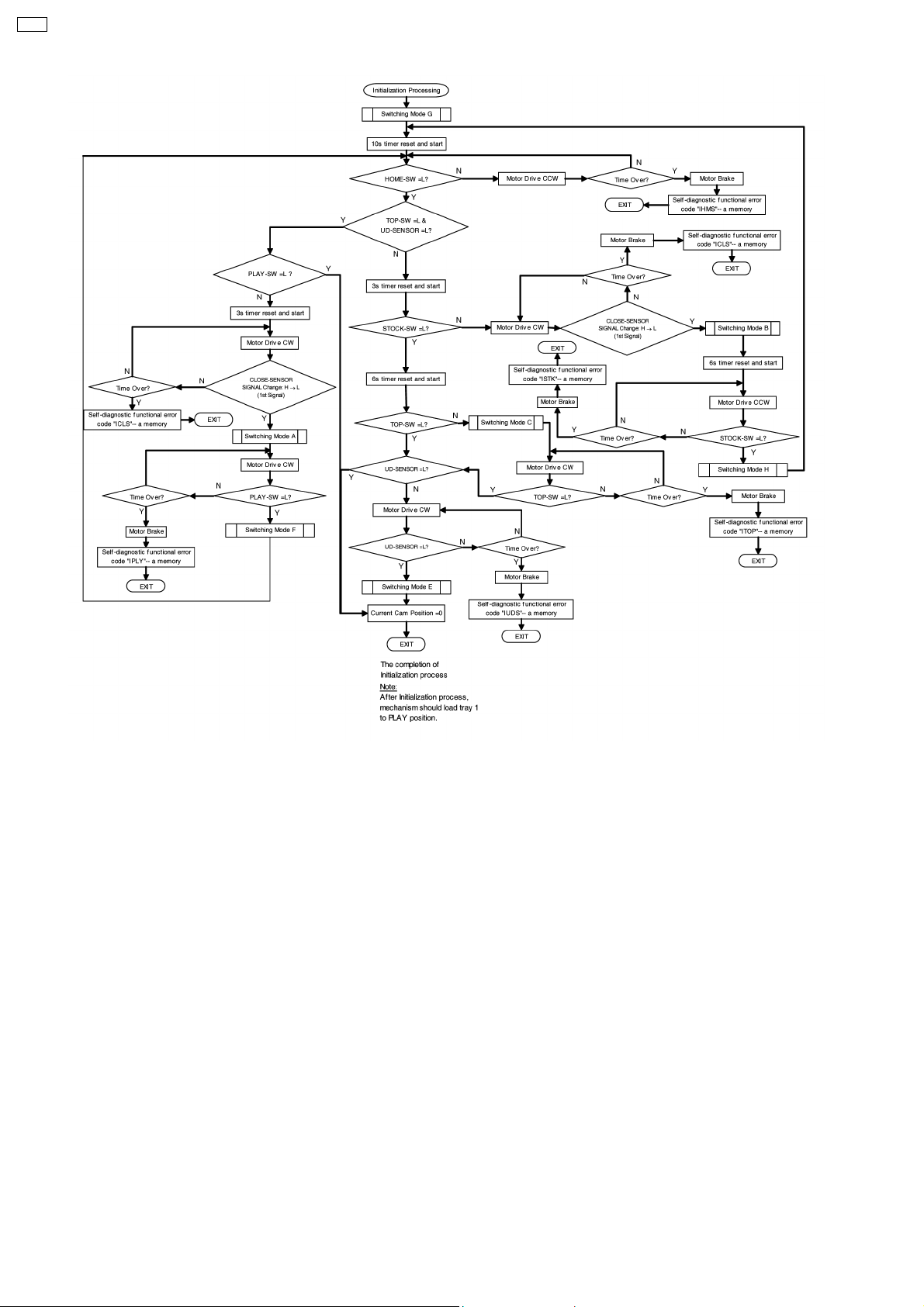

3.7. Initialization of Mechanism Unit.

· Mechanism Initialization -- This mechanism is designed to operate & set to a pre-defined position to prevent malfunction when

unavoidable circumstances happen. For examples: user mis-handling during transportaion or abnormal user operations.This is

comply to the product shippin g reliability standards.

· Mechani sm is initialized when the mechanism controller is unable to detect the present condition/state of mechanism. For

example, when the microcomputer carries out a cold start. (In complete unit)

· Once the initialization process is completed, the mechanism unit is set to this condition:-

1. Tray 1 is at PLAY position (Top tray)

2. The traverse unit is at clamping condition (PLAY SW-L)

3. All the remaining trays are in STOCK Position (Trays 2 ~ 5 )

4. Plunger lever at release condition

5. Cam gear is at Home position ( HOME SW-L)

6. Motor is free (CW-L, CCW-L)

Note: This is same as shipment condition. (In complete unit)

· Below is the flow chart of the initialization process:-

15

Page 16

CRS1

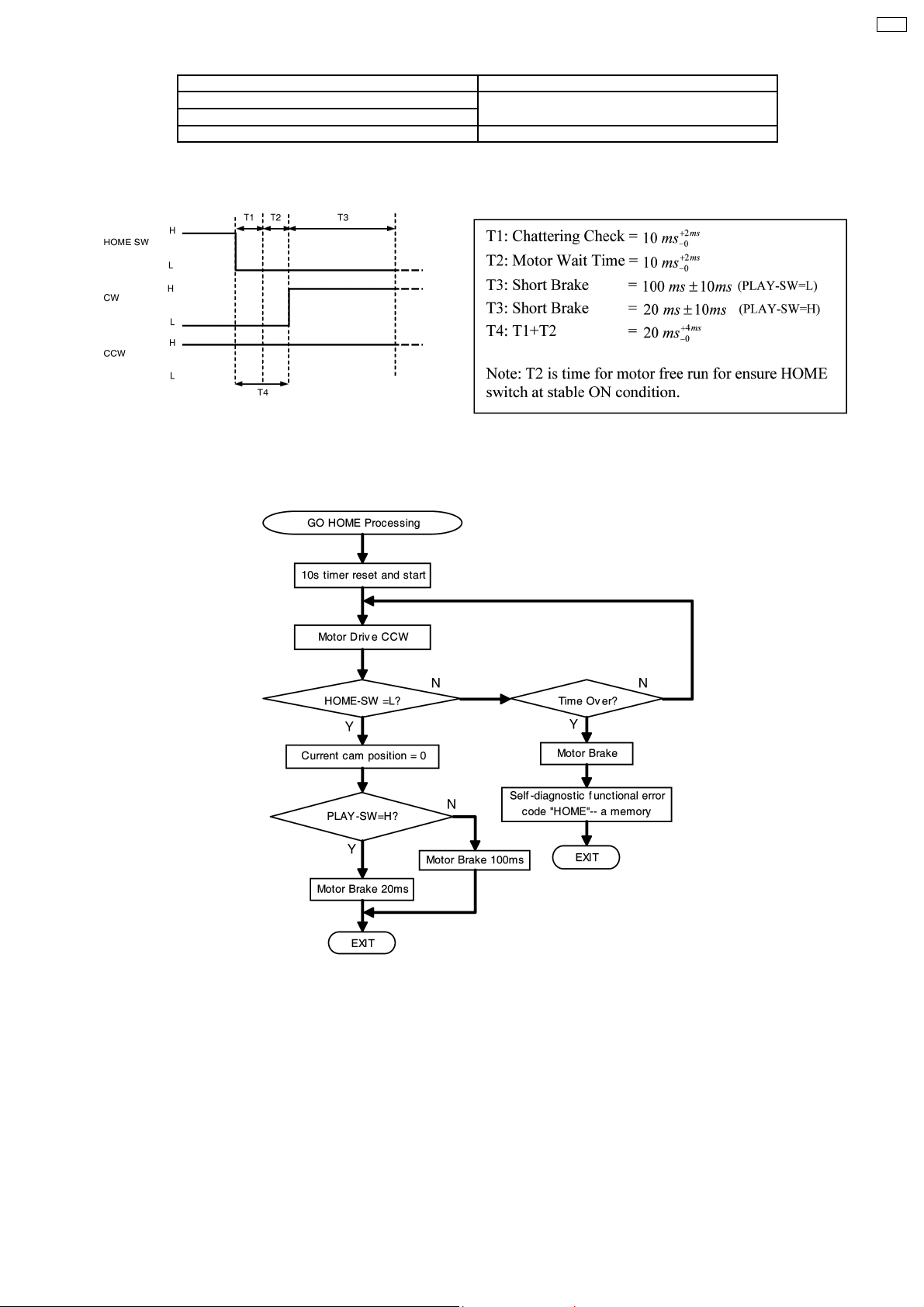

3.8. Mechanism "HOME" position

· Mechanism HOME position is a starting position for few functions, such as below:

1. Load tray from STOCK position to PLAY position

2. Unload tray from PLAY position to STOCK position

3. Open trays

4. Driving UD base up/down

· Besides this, it will always return to “HOME” position after performing below functions:

1. After tray completely clamped by Traverse unit

2. Closing All trays

3. Closing tray 5

4. After completely the UD base movement

· There are 2 type of mode to go to HOME position.

Mode 1 is to go to HOME position and motor brake and stay at HOME position, motor need longer brake time for reduce overrun

of mechanical parts.

For Mode 2, after mechanism go to HOME position, motor immediately rotate reverse direction to go do loading/unloading

processing, shorter brake time necessary to reduce the total mechanism operation time.

The table below is types of "GO HOME" mode and operation that use it.

16

Page 17

GO HOME MODE 1 GO HOME MODE 2

1. After loading tray to PLAY position 1. After closing all trays (no tray at PLAY position)

2. After unloading tray to STOCK position

3. After closing all trays (one tray at PLAY position)

· The timing chart for the mechanism to set to “HOME” position is illustrated as below.

CRS1

· Below is the flow chart for the mechanism to set to “HOME” position.

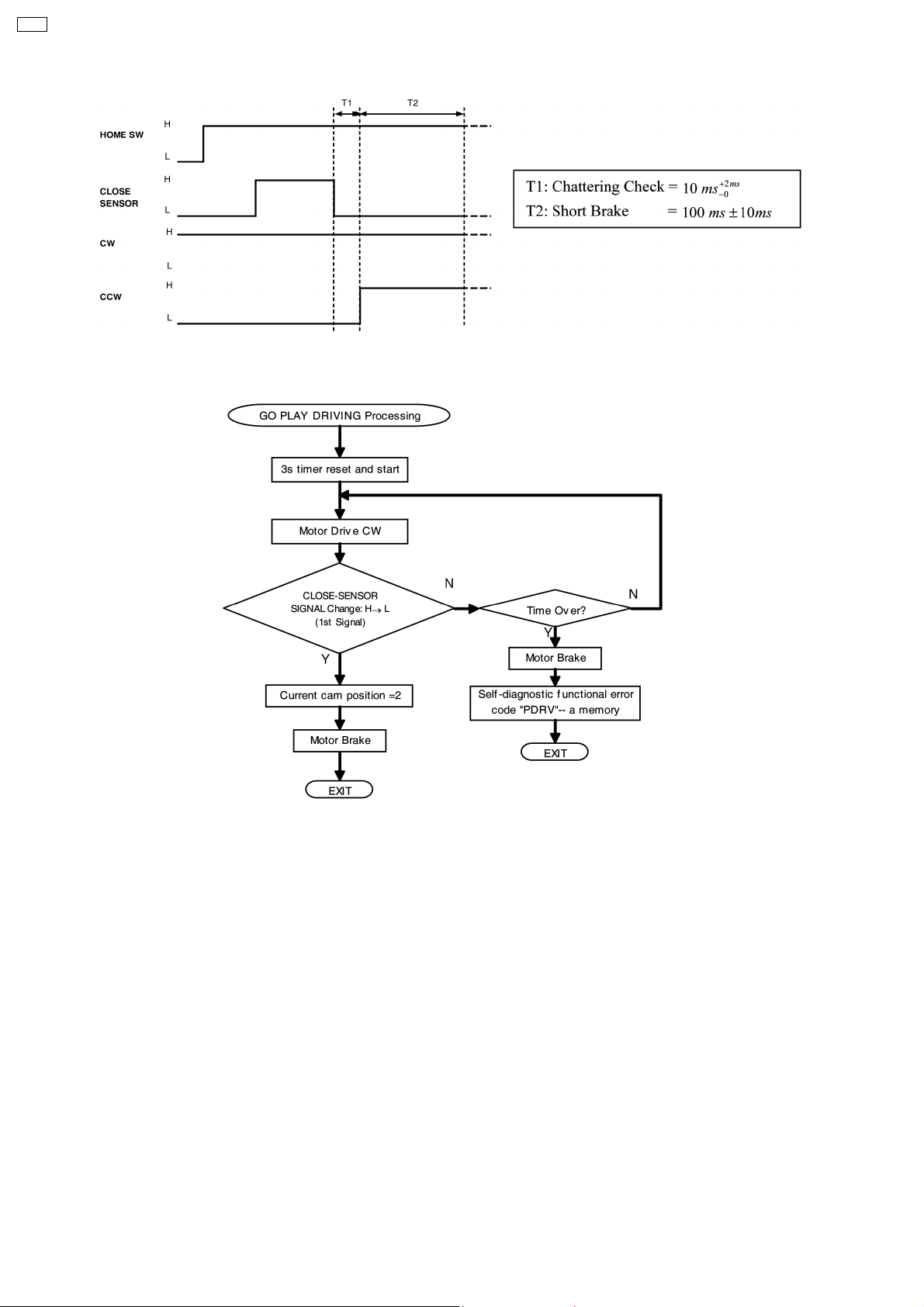

3.9. Mechanism "Play Driving" position

· Play driving position is a position driving source linkage to drive the tray(s) between STOCK position and PLAY position (load

and unload of tray). Cam gear will rotate to this position from HOME position, and after the completion of clamping process will

back to HOME position.

For Go to Play Driving position, cam gear move from HOME position, motor brake after detect 1

change from H→L

17

st

time CLOSE sensor signal

Page 18

CRS1

· Below is the flow chart for the mechanism to set PLAY DRIVING position.

3.10. Trays Operation

3.10.1. Tray ‘Open’ Operation

· Changer mechanisms are required to open trays to load a disc. This mechanism feature s an "All Open" or "Change all one by

one" function for quick & easy disc change. There are 3 kinds of "Tray Open" conditions.

1. All trays open

Occurs when OPEN/CLOSE button is pressed, playing tray will be driven to STOCK position and all trays will driven to

OPEN position. All trays will remain open until "DISC CHANGE" or "OPEN/CLOSE" is pressed. When "DISC CHANGE" is

pressed, the upper most tray will close while "OPEN/CLOSE" is close all trays.

2. Open selected tray while one tray at PLAY position

Occurs when specify tray is selected to be opened while one tray is at PLAY position. This operation never disturbs the

playing disc operation and allow user to change desire disc on specific tray.

3. Direct open playing tray

Occurs only when the user selects to open playing tray. Tray at PLAY position will stop recording/reproducing process and

being driven to STOCK position. This will follow by driven all trays to OPEN position and trays closing until the previous

playing tray expose for disc changing.Example: User press "DISC CHANGE" + "DISC 3". Mechanism opens all the trays,

then closes trays 1 & 2 respectively exposing the tray 3.

18

Page 19

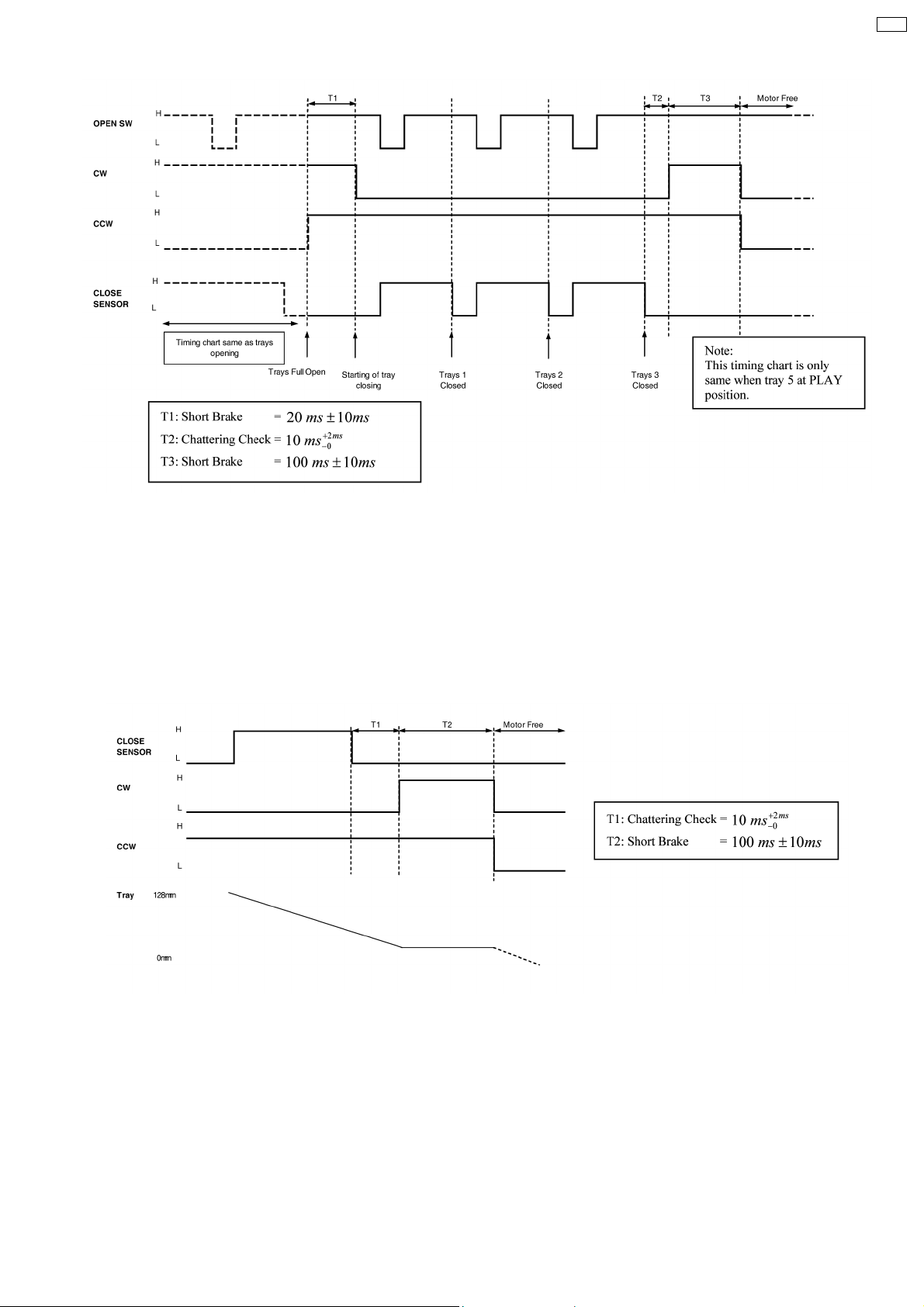

· The timing chart for both positions is the same, motor rotate CW direction, until OPEN SW changing signal H→ L → H, motor

need to continue run for 45ms.

· Motor free at the end of tray open, this is for enable the tray to be manually pushing by user.

· Below is the timing chart for tray opening.

CRS1

· For all type of trays openin g, either 4 trays (open remaining) or 5 trays (all open) will be set to OPEN position.

3.10.2. Tray Closing Operation

· The following action is tray closing. For this mechanism, there are 3 types of trays closing also.

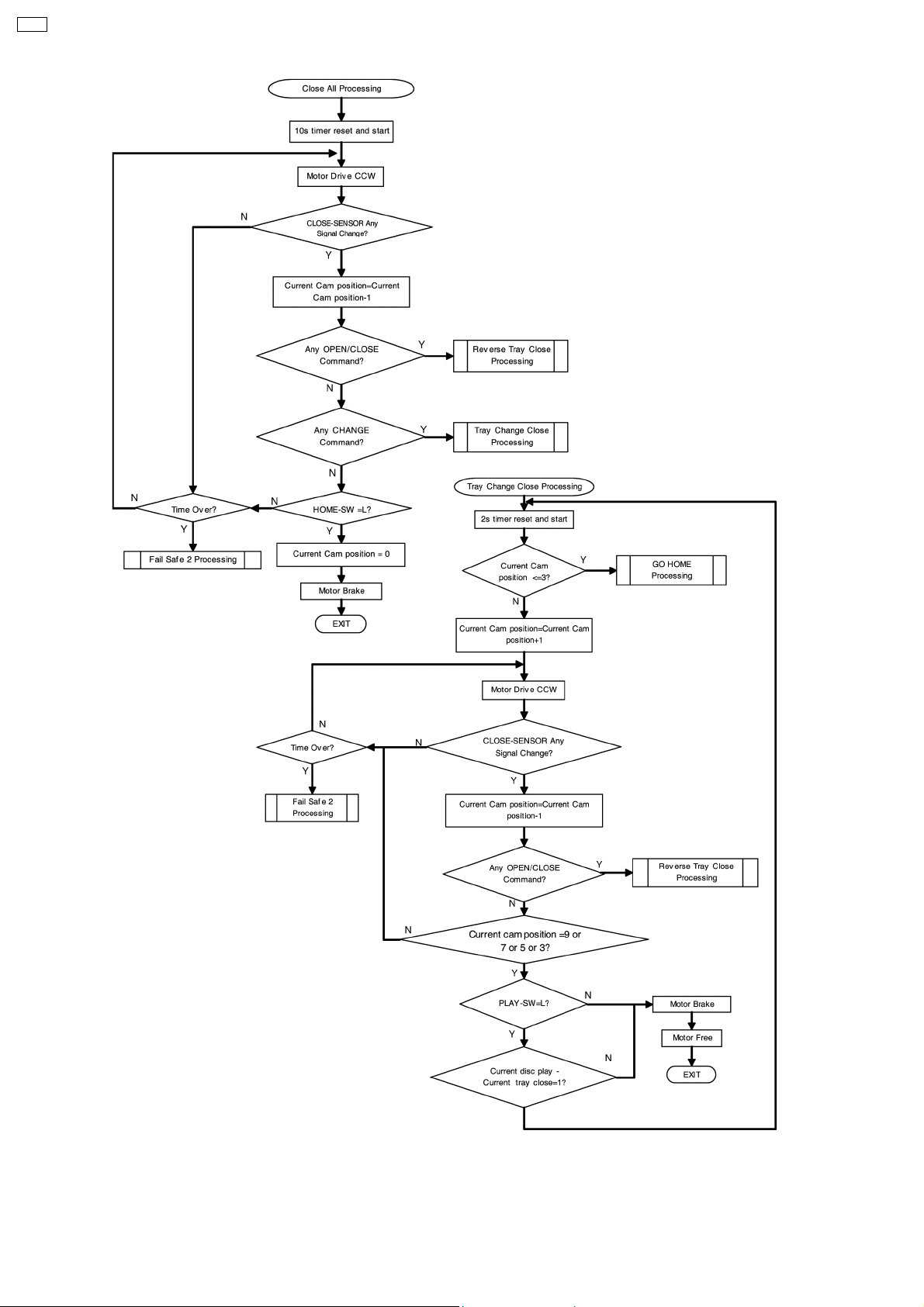

1. All trays close

When user press "OPEN/CLOSE" after trays open, all trays (at any condition) will being driven to STOCK position.

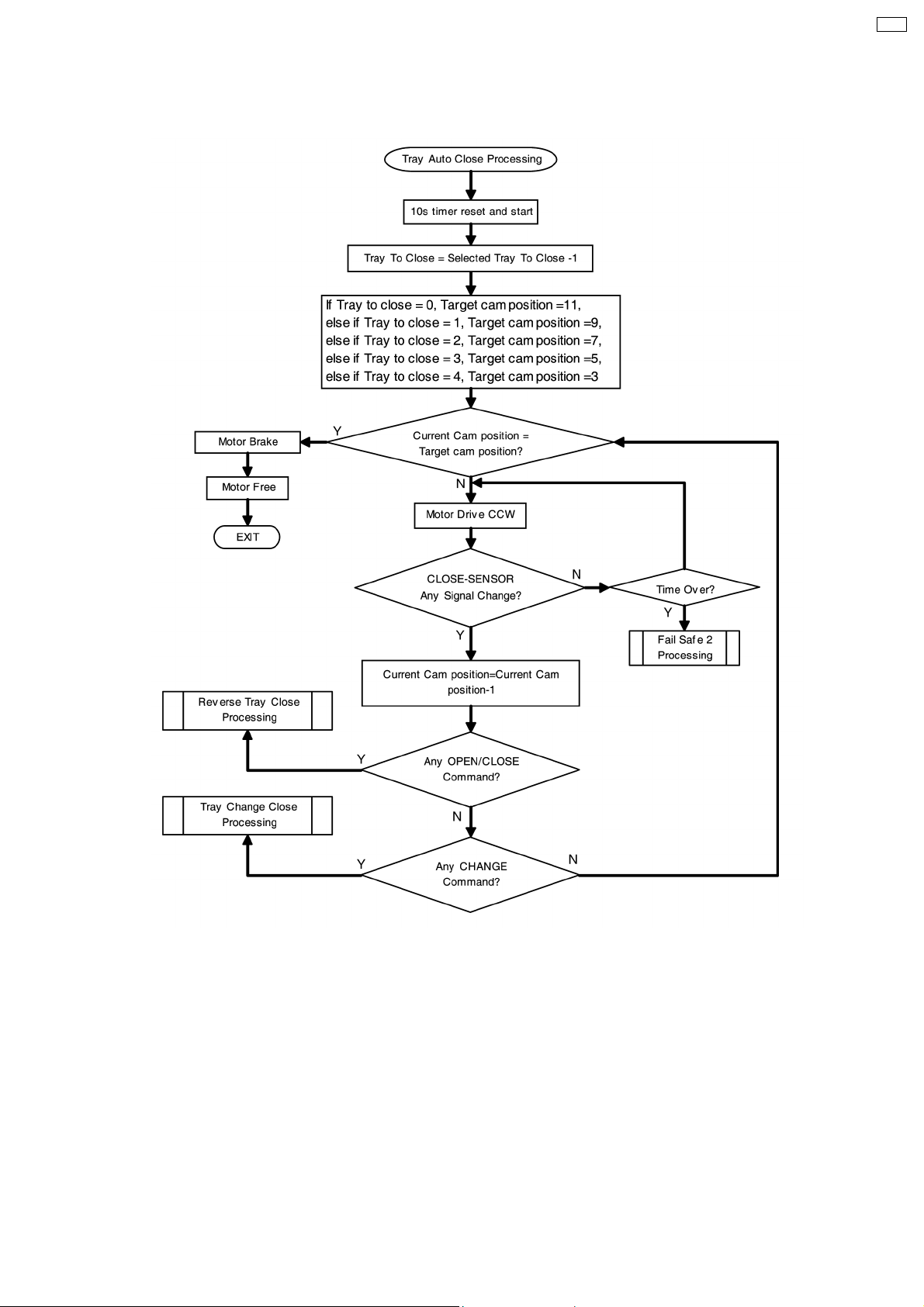

2. Auto Tray Close

This closing operation is an internal operation in the mechanism. This operation completes the open selected tray function.

Mechanism uses this operation to drive trays that cover top surface of desire tray to STOCK position and then expose the

selected tray for user to do disc exchanging.

3. Change

When user press "CHANGE", one tray will be driven to STOCK position. This operation is for changing disc one by one from

top to bottom. The operation each time will only drive the upper most tray to STOCK position, it can be only being interrupt

by "OPEN/CLOSE". If the "CHANGE" being pressed during one tray is closing, mechanism will close the second tray

immediately after 1

· All trays close can occurs anytime when there is tray at open condition. The all trays close processing is used when mechanism

carry out the function as:

1. Close Tray 5

2. Close Tray 4 while tray 5 is in PLAY position

3. User press OPEN/CLOSE to instruct all trays close.

st

tray. The number of tray will be closed equal to numbe r time of "CHANGE button " being pressed.

· Mechanism will close all the trays by rotating cam gear at CCW direction until detect HOME position

· Below is the timing chart for tray close (until detect HOME position).

19

Page 20

CRS1

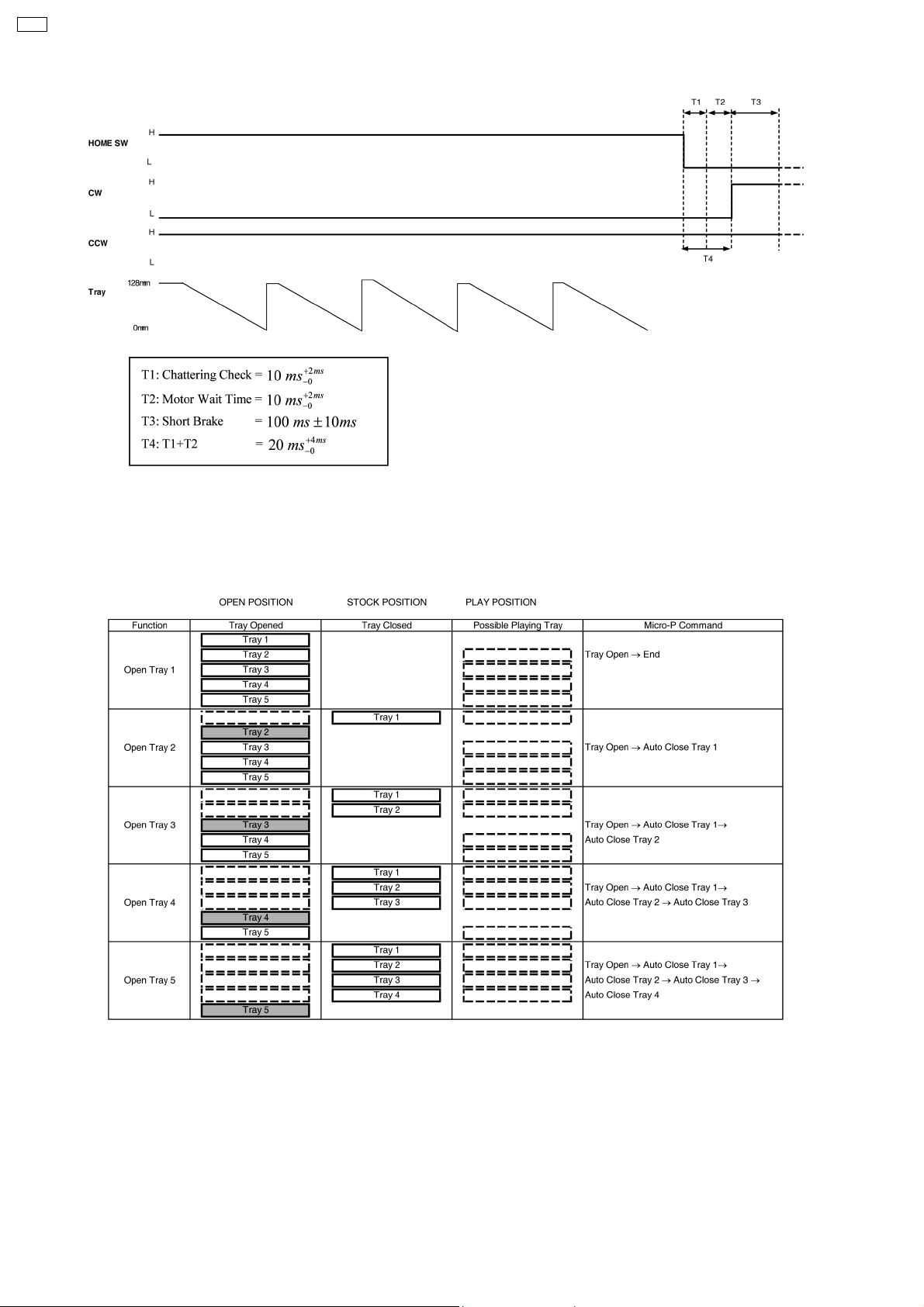

· Table below explain the function of open selected tray while one tray at PLAY position. This table indicated the possible tray

at playing trays. For opened tray, all trays will be open except the tray at PLAY position. Trays will close to expose the selected

tray for user to input or change the disc.

· Timing chart below, shown an example of user select to open tray 4 only.

20

Page 21

CRS1

· The "Change" operation is to close one tray each time when "CHANGE" is pressed. This is the basic operation of "auto tray

close". The "change" operation will stop after detect a signal change in CLOSE-SENSOR while "auto tray close" count the

number of CLOSE-SENSOR signal change and stop at before selected tray start to move to STOCK position.

If there is a case where user select a upper level tray of current tray in PLAY position to be closed, (e.g. current tray at PLAY

position is tray 4, user select tray 3 to be open), micro-p counting of CLOSE sensor signal must done until tray 4 position, before

motor brake. The reason is to eliminate long waiting time for the next tray closing.

· Below is the timing chart of tray closing (Change Operation):-

· Tray opening and closing is control by cam gear and CLOSE-SENSOR signal. OPEN-SW is only use for full open operation in

order to get more accurate tray stroke. Figure below show the cam gear rotation direction for tray opening and closing, and cam

important position.

21

Page 22

CRS1

· Below is the flow chart for tray open processing.

· The flow charts below shown the types of tray close processing, for tray auto close processing is use if user select a specify

tray to be close automatically after trays full open.

· Tray change close processing use if use select a function and want to change disc one by one from top tray to bottom tray.

22

Page 23

· Close all processing is use when user wants to close all trays at once, or want to close tray no.5 or close tray no.4 while tray

no. 5 is at PLAY position.

CRS1

23

Page 24

CRS1

· When there is a OPEN/CLOSE button pressed during tray open or tray close operation. Motor will rotate revere direction.

There are 2 type of cases, where 1

trays full open condition. For the 1

st

is before full open condition (open/close gear assembly still resting) and the 2ndis after

st

condition, motor will rotate the cam gear to move between HOME direction and tray open

24

Page 25

While for the 2ndcase, cam gear inside mechanism will move between specific positions by checking CLOSE-SENSOR signal

change.

· The flow chart for both open reverse (when tray opening motor reverse) and close reverse (when tray closing motor reverse)

is as below. The operation use when user press OPEN/CLOSE button during tray is opening or closing.

CRS1

3.11. Drive tray between STOCK and PLAY position

· Play position is defined as the position whereas the tray is aligned to be played over the CD/ DVD unit. Only a single tray can

be at this location & note that the traverse mechanism is at its clamped position. Play position can be either disc playing (actively

reading disc data) or its not playing (no data reading).

* Shipment or Initialize positions always finish with a tray at this location.

· Loading operation is process to move tray from STOCK position to PLAY position.

· Unloadin g operation is process to move tray from PLAY position to STOCK position.

· If there is a certain operation key pressed at the middle of movement. The reversal operation is necessary. The reversal

operation should carry out after the tray arriving the STOCK position or PLAY position.

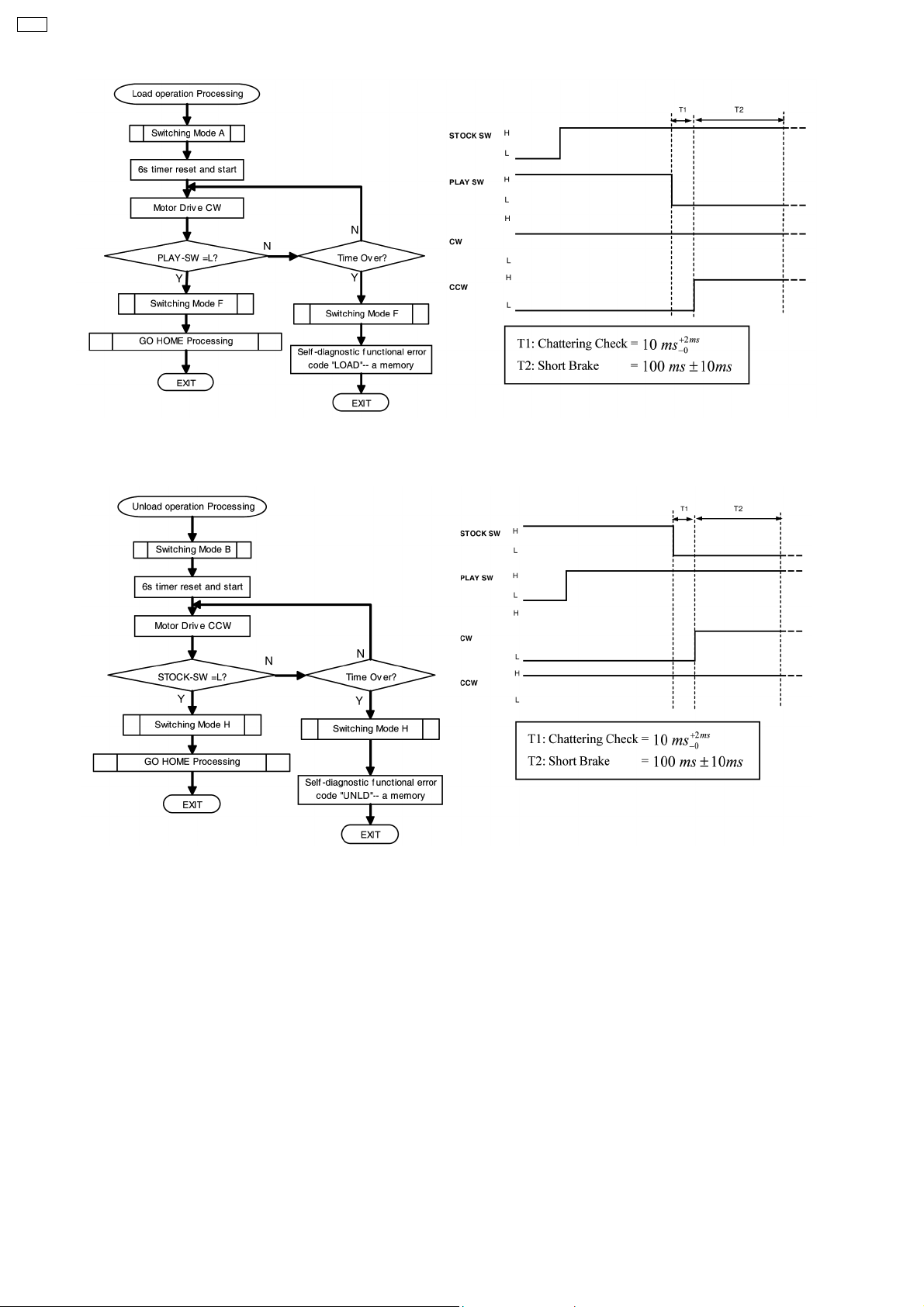

· The flow chart and timing chart for load a disc from STOCK position to PLAY position is as below:

25

Page 26

CRS1

· The flow chart and timing chart for unload a disc from PLAY position to STOCK position is as below:

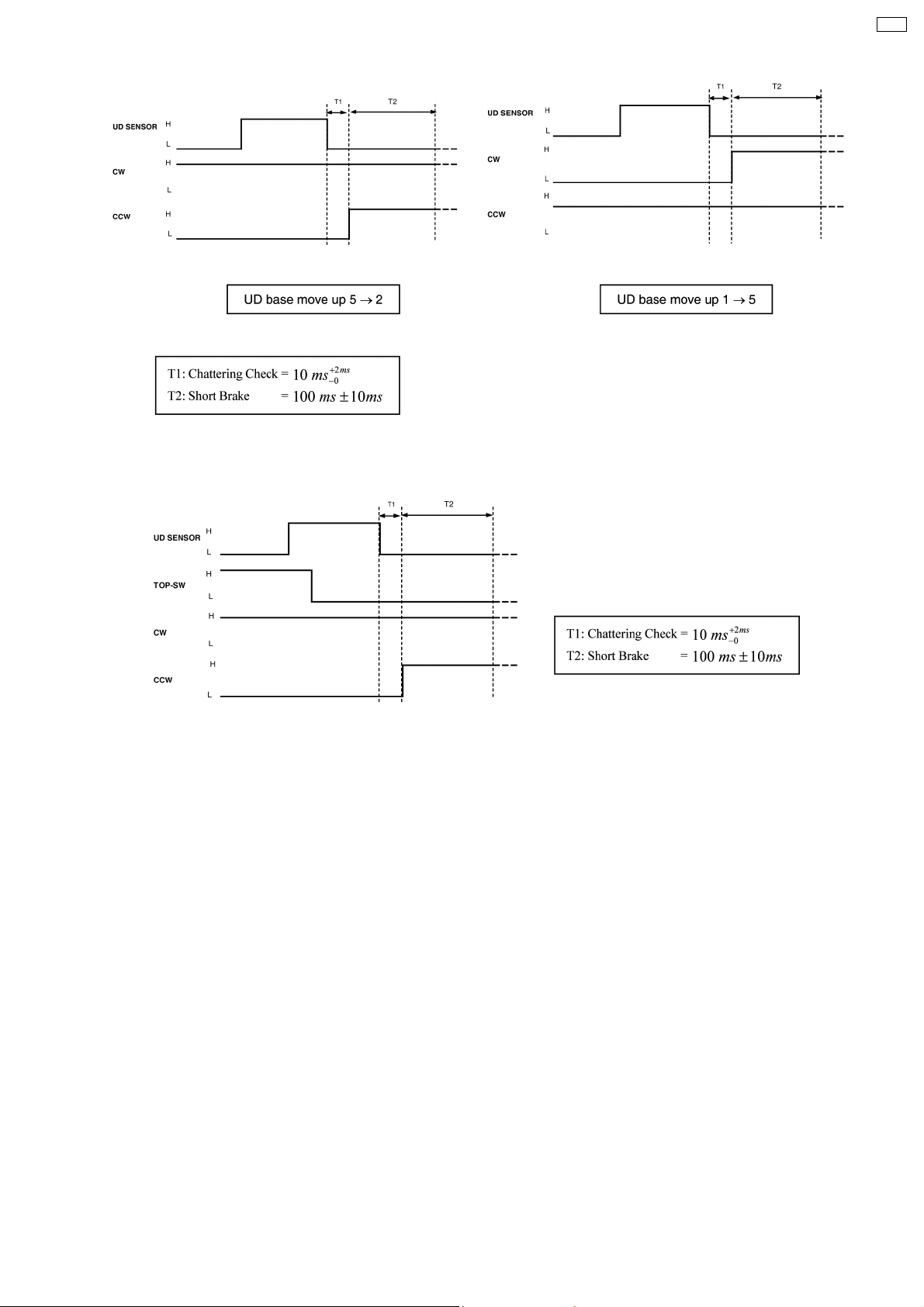

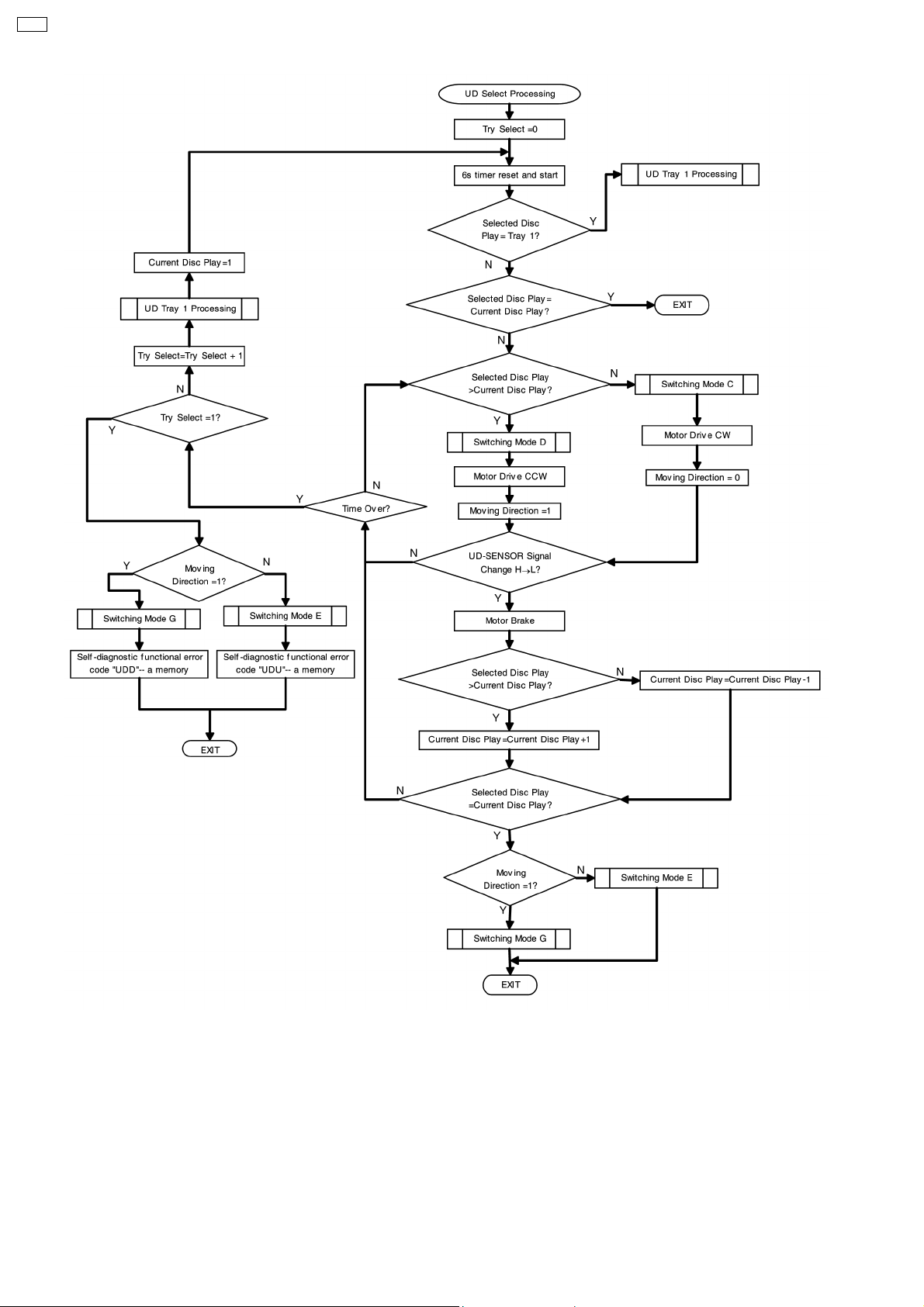

3.12. Selection of Tray by Moving UD base Up/down

· Tray alignment & selection is achieved by UD (up/down) movement, whereas the Mechanism vertically aligns itself to the

selected tray to be driven to PLAY position or STOCK position. The upper most tray is defined as tray 1 and bottom most tray

is defined as tray 5. Counting is achieved by resetting during initialization to the TOP-SW (tray 1) and counting the signal

change by UD-SENSOR.

· Below are the timing chart for UD base tray selection Up/down:

26

Page 27

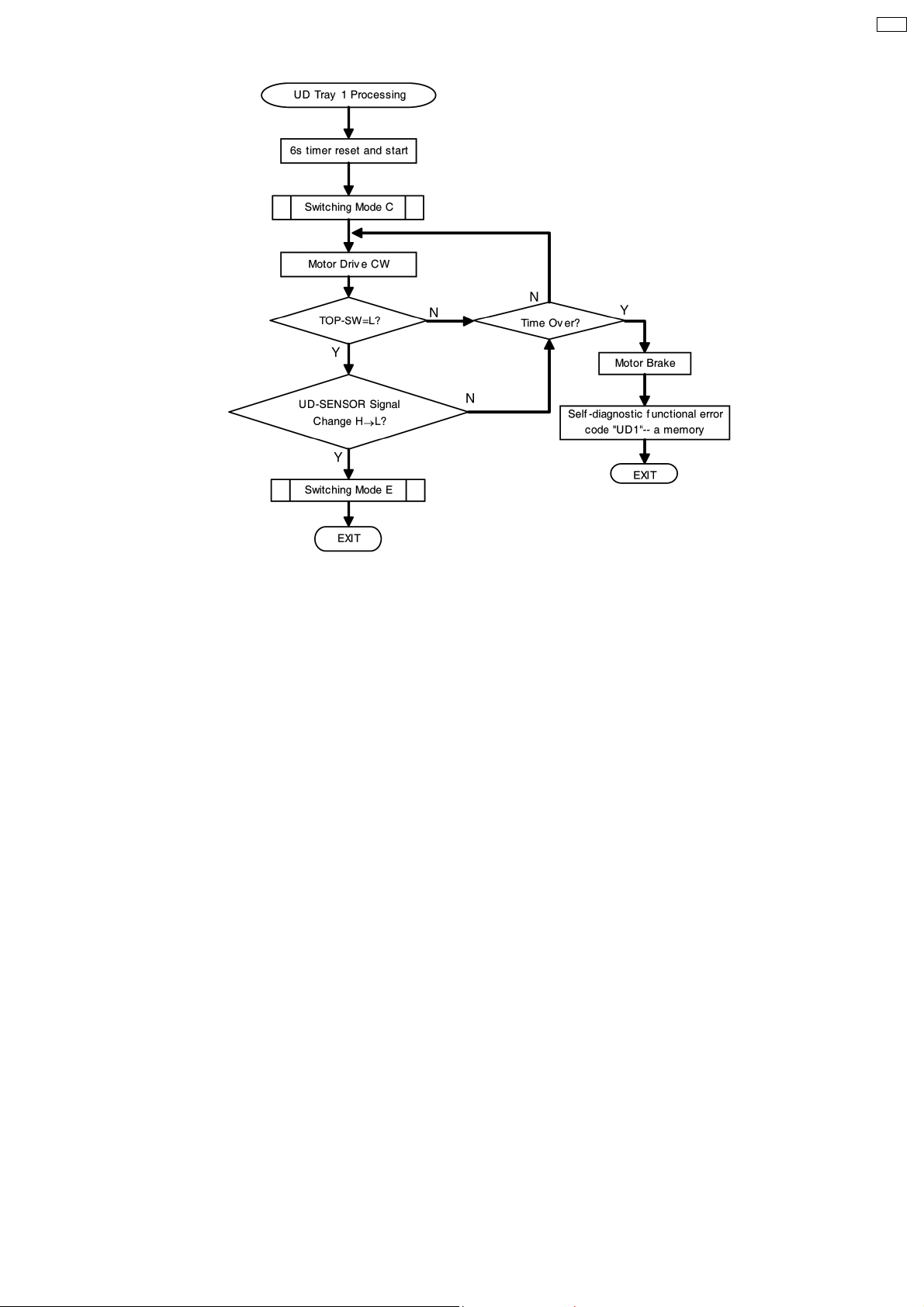

· Tray 1 is the reset position for UD base up/down processing. The position should be unique; a TOP-SW is use in this purpose.

CRS1

· Below is the flow chart for UD selection processing.

27

Page 28

CRS1

· For tray 1 selection, flow chart below will be used.

28

Page 29

CRS1

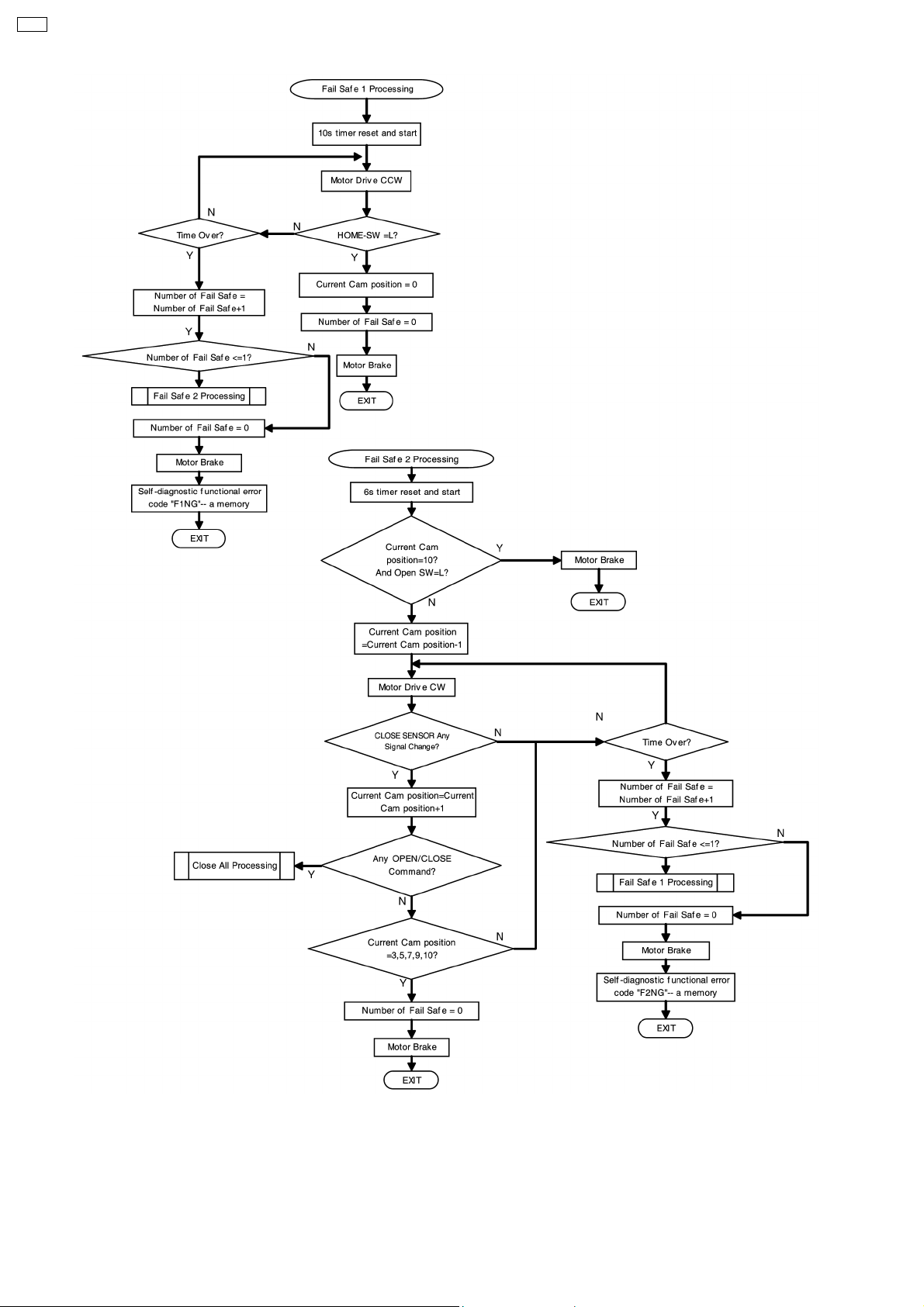

3.13. Fail Safe

· Fail safe function is for purpose of recovery of tray movement if the mechanism is not able to carry out tray open or close within

a specified time.

Fail safe 1: Tray can not open: Fail safe - move all trays to home position

Fail safe 2: Tray can not close: Fail safe - move to next close sensor transition position

Note : For Fail safe 2 :

1. If done on tray 1 - will fully go to Open position because OC gears are fully engaged

2. If done on either one of the remaining trays (2, 3, 4 & 5) - will only release the gear engagement and leave the tray at free

condition, tray can only open manually by user.

After fail safe, any subsequent button pressed on main set, the mechanism must follow "GO HOME" flowchart.

· Fail safe flow chart are shown as below:

29

Page 30

CRS1

3.14. Manual Trigger Tray Close

· W hen user push open tray at full open position, user may able to activate tray to be all close. This function will be disable if user

happen to press "OPEN/CLOSE" button and fail safe happen before.

30

Page 31

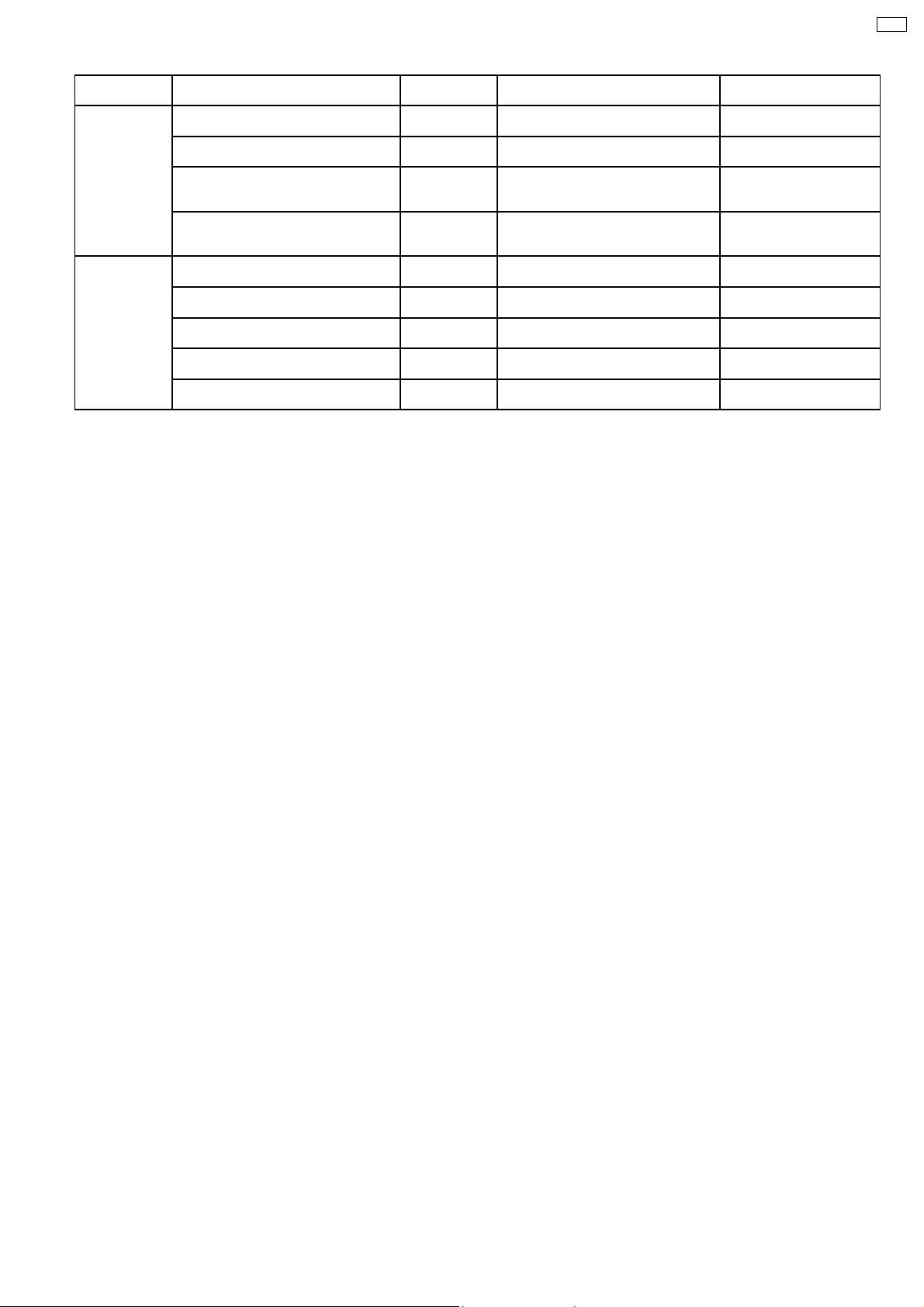

3.15. Changer Error Code

· The error code summary of CRS1 changer is as below:

Error Code Operation

IHMS Cam gear rotate to HOME position

ICLS Cam gear rotate to Play Driving position to drive playing tray to STOCK position

ISTK Move tray drive rack to STOCK position (drive tray to STOCK position)

IPLY Move tray drive rack to PLAY position (drive tray to PLAY position)

ITOP Move UD rack R to front direction (raise UD base to top position)

IUDS After TOP-SW detect, UD rack move to tray 1 position

HOME After load tray to PLAY position, cam gear move to HOMEAfter unload to STOCK position, cam gear

move to HOME

After all tray close, cam gear go to HOME position

LOAD Tray move from STOCK to PLAY position

UNLD Tray move from PLAY to STOCK position

PDRV Cam gear move from HOME to Play Driving position

UDU UD base move at up direction (from tray 5 to tray 2)

UDD UD base move at down direction (from tray 1 to tray 5)

UD1 UD base move to tray 1

F1NG Fail safe 1 NG (Fail safe 1 unsuccessful then try Fail Safe 2 also unsuccesful)

F2NG Fail safe 2 NG (Fail safe 2 unsuccessful then try Fail Safe 1 also unsuccesful)

CRS1

31

Page 32

CRS1

4 Self diagnosis and special mode setting

This unit is equipped with functions for checking and inspecting namely: Self-Diagnostic and Test Mode.

4.1. Special Mode Table

Item FL Display Key Operation

Mode Name Description Front Key

Self -Diagnostic

Mode

CD Test Mode To enter into checking the

CD Auto

Adjustment

To enter into self

diagnostic checking for

main unit.

reliability of changer unit.

To check the CD auto

adjustment result for

FLOCK, TLOCK and

CLVS.

1. Select [ ] for TAPE mode (Ensure no

tape is inserted).

2. Press and hold [

seconds follow by [

To exit, press

unit or remote control.

1. Select [ ] for CD mode.

2. Press and hold [

seconds follow by [

To exit, press

unit or remote control.

In CD Test Mode:

1. Press [0] button on the remote control.

To exit, press

unit or remote control.

]button for 3

].

button on main

] button for 3

].

button on main

button on main

CD Changer

Reliability Test

(CRS1)

Doctor Mode To enter into Doctor

Cold Start To activate cold start

Changer

Reliability Test

FL Display Test To check the FL

To determine the

reliability of CD Changer

Unit.

(For more information,

refer to section 4.1.1)

Mode for checking of

various items and

displaying EEPROM and

firmware version.

upon next AC power up.

To check the function

operation of changer unit.

(For more information,

refer to 4.1.1)

segments display (All

segments will light up and

LED will blink at 0.5

second interval)

1.

2.

1. All segments will light up for 1 second.

2. The Check Sum of EEPROM and firmware

version will be display.

* ROM correction

** Firmware version No:

In Self-Diagnostic Mode:

1. Select [

2. Press [

To exit, press

unit or remote control.

(The tray will return to PLAY position and then

power off)

In any mode:

1. Press [

by [4] and [7] on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

In doctor mode:

1. Press [4] button on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

In doctor mode:

1. Press [DISC] on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

In doctor mode:

1. Press [PROGRAM] button on remote

control.

] for CD mode.

] button.

button on main

] button on main unit follow

button on main unit

button on main unit

button on main unit

32

Page 33

Item FL Display Key Operation

Mode Name Description Front Key

Tape Eject Test To check on the tape

eject function (For deck

1/2)

In doctor mode:

1. Press [PROGRAM] button on remote

4.1.1. CD changer unit ageing test mode

Below is the process flow chart of ageing for the CD changer unit.

CRS1

control.

33

Page 34

CRS1

4.2. Error code Table

Self-Diagnosis Function (refer Section 4.1) provides information on any problems occuring for the unit and its respective

components by displaying the error codes. These error code such as U**, H** and F** are stored in memory and held unless it is

cleared.

34

Page 35

The error code is automatically display after entering into self-dia gnostic mode.

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

IHMS Cam gear

abnormality

Cam gear does not

rotate to “HOME”

position.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

CRS1

ICSL Cam gear/gear units

abnormal

Cam gear does not

rotate to “PLAY” driving

position and hence does

not drive playing tray to

“STOCK” position.

ISTK Drive rack/gear

assembly abnormal

The tray drive rack does

not move to “STOCK”

position. (Tray does not

move to “STOCK”

position)

IPLY Drive rack/gear

assembly abnormal

The tray drive rack does

not move to “PLAY”

position. (Tray does not

move to “PLAY” position)

ITOP UD assembly UD Rack does not move

to front direction. This

lead to UD base not

raise to top position.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

IUDS UD assembly After TOP SW is

detected, UD rack does

not move into tray 1

position.

HOME Cam gear/gear

assembly abnormal

Cam gear does not

move to “HOME”

position under following

conditions

1. After tray is load to

“PLAY” position.

2. After tray is unload

to “STOCK” position.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

35

Page 36

CRS1

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

LOAD Tray drive assembly

abnormal

Tray unit does not move

from “STOCK” to “PLAY”

position

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

PDRV Cam gear/gear

assembly abnormal

UDU UD base asssembly

abnormal

UDD UD base asssembly

abnormal

UD1 UD base asssembly

abnormal

F1NG Fail - safe mode. (For

open/close tray

unit(s))

Cam gear does not

move from “HOME” to

“PLAY” drive position.

UD Base assembly does

not move upwards from

tray 5 to tray 2

UD Base assembly does

not move downwards

from tray 1 to tray 5.

UD Base assembly does

not move to tray 1.

When the tray open

operation is performed, it

fails to open. It will

automatically close all

trays after the time-out

by the microprocessor.

During this time when it

fails, the error code will

appear.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

F2NG Fail - safe mode. (For

open/close tray

unit(s))

SRVC_TRV To unlock the

traverse unit for

service

RSET Cam gear jam/close

sensor faulty

When the tray close

operation is performed, it

fails to close. It will

automatically open all

trays after the time-out

by the microprocessor.

During this time when it

fails, the error code will

appear.

1. All trays set to

“STOCK” position

2. Mechanism set to

tray 5

3. Cam gear set to

“HOME” position

During tray re-open, the

cam gear will rotate in

the opposite direction to

reset the cam

gearposition. When it

fails, the error code will

appear.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

CRS1 Error Code display

1. The errors that occured in CRS1 Mechanism can be recalled and displayed, in the order of the occurence under self-diagnostic

(Refer to Section 4.1 for procedures to enter this mode.

· Only the first 5 errors will be memorized (in backup memory). The subsequence error shall be ignored and not memorize.

For system with EEPROM as memory backup,memory space in EEPROM is neccesary.

2. To display all error code memorized

36

Page 37

In CRS1 Self-Diagnostic mode, press [SINGLE CHANGE] to display subsequence error code.

It shall repeat after reaching error no. 5.

e.g.:

[1____IHMS]→ [SINGLE CHANGE]

[2____ITOP]→ [SINGLE CHANGE]

[3____HOME]→ [SINGLE CHANGE]

[4____LOAD]→ [SINGLE CHANGE]

[5_____UDD]→ [SINGLE CHANGE]

3. To clear the error code memory

In CRS1 Self-Diagnostic mode, long press [SINGLE CHANGE] key (2s or more)

CRS1

37

Page 38

CRS1

5 Troubleshooting Explorer

5.1. Preparation of service jig

· This unit has a gear which is used for checking items

(open/close of disc tray, up/down operation of traverse unit

by manually) when servicing. (For gear information, that is

described on the items for disassembly procedures.)

· For preparation of gear (for servicing), perform the

procedures as follows.

· In case of re-servicing the same set, the “gear for servicing”

may be took off becaus e it had been used. So, the “gear for

servicing” must be stored.

5.3.1. No CD in the tray

Step 1: Check any disc tray at the play position from the

mechanism side.

5.2. Checking of Changer Unit

Below is the procedures for checking the function of the

changer unit.

Step 1: Enter into doctor mode.

Step 2: Press [DISC] on remote control unit.

Step 3: Error code will appear if there is any function problems.

(Pls refer to section 4.2 on more information of error code).

5.3. Setting the trays in "STOCK"

position

· Below is procedures for setting the main unit into service

mode:-

1. Enter into self-diagnostic (Refer to section 4.1)

2. Press [SINGLE CHANGE] on main unit.

· If fail to set the main unit into service mode, do it manua lly

by the below procedures

Step 2: Press the 2 claws and then lift up the top cover as

arrows shown.

Caution: Do not exert strong force on the claws.

38

Page 39

CRS1

Step 3: Release the top cover from the tray rear stopper

as arrow shown and remove the top cover.

Step 4: Remove the open lever spring.

Step 5: Insert the service gear into the service hole and

rotate the gear anti-clockwise.

Step 6: Press and hold the plunger lever and rotate the

gear clockwise until it stop.

39

Page 40

CRS1

Step 7: Release the plunger lever, rotate the gear clockwise

continuously until it stop at “HOME” position.

Step 8: Install the open lever spring as shown.

Step 9: Install the top cover, fix the top cover hook to the

tray rear stopper as arrow shown.

Step 10: Fix the top cover as arrow shown, the 2 claws

should be latched.

40

Page 41

5.3.2. When CD in the tray

CRS1

Step 1: Check any disc tray at the play position from the

mechanism side.

Step 2: Press the 2 claws and then lift up the top cover as

arrows shown.

Caution: Do not exert strong force on the claws.

Step 3: Release the top cover from the tray rear stopper

as arrow shown and remove the top cover.

Step 4: Remove the open lever spring.

41

Page 42

CRS1

Step 7: Push forward and remove the gear cover as arrow

shown.

Step 5: Press the claw, push backwards and remove the

trigger slide plate as arrows shown.

Step 6: Prepare the service key for use.

Step 8: Remove the open switch lever.

42

Page 43

CRS1

Step 9: Remove the OC gear assy followed by the OC

gear spring as arrow shown.

Caution: Ensure the OC gear assy and OC gear spring

are handle properly and keep them in a safe place.

Step 10: Insert the service key into the hole.

Step 11: Turn the service key to release the tray lock lever.

43

Page 44

CRS1

Step 12: Push the disc trays towards the front as arrow

shown.

Step 13: Turn the service key back to its original position

and remove it.

Step 14: Remove the disc.

Step 15: Push the disc trays back to the unit as arrow

shown.

44

Page 45

CRS1

Step 16: Install the OC gear assy followed by the OC gear

spring.

Step 17: Install the open switch lever.

Step 18: Install the gear cover as arrow shown.

45

Page 46

CRS1

Step 21: Release the plunger lever, rotate the gear

clockwise continuously until it stop at “HOME” position.

Step 19: Insert the service gear into the service hole and

rotate the gear anti-clockwise.

Step 20: Press and hold the plunger lever and rotate the

gear clockwise until it stop.

Step 22: Install the trigger slide plate as arrows shown in

sequence.

46

Page 47

Step 23: Install the open lever spring as shown.

CRS1

Step 25: Fix the top cover as arrow shown, the 2 claws

should be latched.

Step 24: Install the top cover, fix the top cover hook to the

tray rear stopper as arrow shown.

47

Page 48

CRS1

48

Page 49

6 Flow Chart

6.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

7.1.1 UD Base Assembly

Step 1: Press the 2 claws downward and push the top

cover backwards and lift up the top cover to

remove it.

Step 2: Release the top cover from the tray rear stopper

and remove the top cover.

7.1.7 Traverse Unit

Step 1: Press and hold the plunger lever and

rotate the gear until it stop.

Step 2: Push the traverse slide plate to release

the traverse unit.

Step 3: Remove the traverse unit.

7.1.8 Limit Spring

Step 1: Remove the limit spring.

7.1.9 Play Lever Spring

Step 1: Remove the play lever spring.

Step 3: Remove the open lever spring from the gear cover.

Step 4: Push forwards and remove the gear cover.

Step 5: Remove the open switch lever.

Step 6: Remove the OC gear assy followed by the OC

gear assy.

Step 7: Press the claw, push backwards and remove the

trigger slide plate.

Step 8: Use a minus screwdriver slot into the gap and

push out the tray lock lever.

Step 9: Push the disc trays towards the front.

Step 10: Turn the UD connection lever clockwise.

Step 11: Push the claw and slide the UD rack L.

Step 12: Press and hold the claw at the pitch plate then push

the UD rack R.

Step 13: Remove the UD base assembly.

7.1.2 DiscTrays

UD connection lever

Step 1: Remove the UD connection lever.

Step 2: Push the claw and remove the lock lever 1.

Step 3: Push the tray drive rack to hit the stopper.

Step 4: Push the 5 disc trays until it stop.

Step 5: Lift up slightly and push the 5 disc trays further.

Step 6: Tilt and remove the 5 disc trays.

7.1.3 CD Loading Unit

Play lever B

Step 1: Push the UD rack L forwards.

Step 2: Position the tray drive rack in the center.

Step 3: Push the play lever B and lift up the rib slightly to

remove the play lever B.

Tray drive rack

Step 4: Release the claw and then slide and remove the tray

drive rack.

UD rack L

Step 5: Push the claw.

Step 6: Slide the UD rack L.

Step 7: Lift up the unit.

Step 8: Follow the groove to lift up and remove the UD rack L.

UD rack R

Step 9: Slide the UD rack R until it stop.

Step 10: Press the claw.

Step 11: Continue to slide the UD rack R until it stop.

Step 12: Lift up the UD rack R and slide backwards to stop

at the stopper.

Step 13: Remove the UD rack R.

Trigger gear

Step 14 Turn the trigger gear clockwise and remove it.

Pitch plate

Step 15: Release 3 screws.

Step 16: Remove 4 claws in order followed by detach the pitch

plate.

Lock lever 2

Step 17: Release the claw and pull out the lock lever 2.

Change spring

Step 18: Remove the change spring.

Pulley gear and belt

Step 19: Remove the belt and pull out the pulley gear.

Gears

Step 20: Remove relay gear 1, relay gear 3, UD gear 2, long

gear, play gear 2 and tray gear in order.

Step 21: Remove relay gear 2, switching gear, UD gear 1 in

order.

Cam gear

Step 22: Remove cam gear.

Function gear and main drive gear

Step 23: Remove main drive gear and function gear.

Play gear 1

Step 24: Remove play gear 1.

Function lever

Step 25: Remove the function lever from the ribs.

Step 26: Release the spring from the ribs to remove the play

switch lever.

CRS1

7.1.10 Pitch Plate Assembly

Step 1: Slide the UD rack L backwards, push

the claw.

Step 2: Slide the UD rack R until it stop.

Step 3: Press the claw.

Step 4: Push the claw, then turn the trigger

gear clockwise and remove it .

Step 5: Remove 3 screws.

Step 6: Release 4 claws in order followed by

detach the pitch plate.

7.1.4 CD Loading P.C.B.

Step 1: Turn over the unit and remove 4 screws

from the CD loading P.C.B.

Step 2: Unsolder the 4 points.

Step 3: Release the claw.

Step 4: Remove the CD Loading P.C.B.

Plunger assembly

Step 5: Remove the plunger assembly by using

a minus screw driver.

7.1.5 Plunger Lever

Step 1: Remove the switching gear.

Step 2: Install the pitch plate.

Step 3: Lift up the plunger lever in 90 degree.

Step 4: Remove the plunger lever in 90 degree

position.

7.1.6 Motor Unit

Step 1: Push the motor unit to remove it.

49

Page 50

CRS1

6.2. Assembly Flow Chart

The following chart is the procedure for assembling the casing and inside parts for internal inspection when carrying out the servicing.

7.2.1 CD Loading Unit

Plunger lever

Step 1: Turn over the unit and install the plunger lever in 90

degree position.

Step 2: Push in the plunger lever.

Step 3: Turn over the unit and install the motor unit properly.

Plunger assembly

Step 4: Install the plunger assembly.

CD loading P.C.B.

Step 5: Install the CD Loading P.C.B.

Step 6: The claws should be latched.

Step 7: Solder the 4 points.

Step 8: Fix it with 4 screws.

Play switch lever

Step 9: Install the play switch lever.

Step 10: Fix the spring below the rib.

Function lever

Step 11: Install the the function lever.

Play gear 1

Step 12: Install the play gear 1.

Function gear and main drive gear

Step 13: Install the main drive gear.

Step 14: Install the function gear.

Gears

Step 15: Install the relay gear 2, switching gear and UD gear 1

respectively.

Step 16: Install the cam gear.Make sure the big hole is fix at the

position (A) at 90 degree.

Step 17: Turn the cam gear anti-clockwise until the big hole

stop at position (B).

Step 18: Install the relay gear 1, relay gear 3, UD gear 2, long

gear and play gear 2 respectively.

Step 19: Install the tray relay gear.

Pulley gear and belt

Step 20: Install the pulley gear followed by the belt.

Change spring

Step 21: Install the change spring.

Pitch plate

Step 22: Install the lock lever 2 in sequence.

Step 23: Install the pitch plate.

Step 24: The 4 claws should be latched properly.

Step 25: Fix it with 3 screws.

Trigger gear

Step 26: Install the trigger gear in sequence.

Step 27: Use the screwdriver to turn the hole

on the UD gear 2 align with the pitch

plate hole.

UD rack R

Step 28: Insert the UD rack R.

Step 29: Push the UD rack R.

UD rack L

Step 30: Insert the UD rack L.

Step 31: Push the claw.

Step 32: Pull the UD rack L.

Tray drive rack

Step 33: Install the tray drive rack.

Play lever B

Step 34: Install the play lever B below the rib.

7.2.2 Disc Trays

Step 1: Tilt and fix the 5 disc trays.

Step 2: Push the 5 disc trays until it stop.

Step 3: Push the tray drive rack until it stop.

Lock lever 1

Step 4: Fix the lock lever 1 onto the pitch plate.

Step 5: Press and hold the claw at the pitch plate then push

the UD rack R.

Step 6: Push the claw and slide the UD rack L.

UD connection lever

Step 7: Install the UD connection lever.

7.2.3 UD Base Assembly

Step 1: Push the traverse slide plate.

Step 2: Install the UD base assembly.

Step 3: Turn UD connection lever anti-clockwise,

the UD base assembly will move downwards.

Step 4: Install the tray lock lever to the mechanism base

and push the tray lock lever with a hand to fix it.

Step 5: Push the disc trays back to the unit.

Trigger Slide Plate

Step 6: Install the trigger slide plate, push forwards and

push the trigger until locked by the claw.

Step 7: Install the OC gear spring followed by the OC gear

assy.

Step 8: Install the open switch lever.

Step 9: Install the gear cover.

Step 10: Install the open lever spring.

Step 11: Install the top cover, fix the top cover hook to

the tray rear stopper.

Step 12: Fixed the top cover, the 2 claws should be latched.

7.2.5 Traverse Unit

Step 1: Turn over the unit and install traverse unit.

Step 2: Push the traverse slide plate to lock the

traverse unit.

7.2.4 CD Loading P.C.B

Step 1: Install the plunger assembly.

Step 2: Install the CD Loading P.C.B.

Step 3: The claw should be latched.

Step 4: Fix it with 4 screws.

Step 5: Solder the 4 points.

50

Page 51

6.3. Disassembly Flow

CRS1

1. Top Cover

10. UD Connection

Lever

19. Screw

28. Relay Gear 3

2. Open Lever Spring

11. Lock Lever 1

20. Pitch Plate

29. Relay Gear 1

3. Gear Cover

12. Tray

21. Change Spring

30. Cam Gear

4. Open Switch Lever

13. Play Lever B

22. Belt

31. UD Gear 1

5. OC Gear Spring

14. Tray Drive Rack

23. Pulley Gear

32. Switching Gear

6. OC Gear Assy

15. UD Rack L

24. Tray Relay Gear

33. Relay Gear 2

7. Trigger Slide Plate

16.UD Rack R

25. Play Gear 2

34. Function Gear

8. Tray Lock Lever

17. Trigger Gear

26. Long Gear

35. Main Drive Gear

9. UD Base Assy

18. Lock Lever 2

27 UD Gear 2

36. Play Gear 1

37. Play Switch Lever

38. Function Lever

39. Screw

40. CD Loading

PCB

41. Plunger Lever

51

42. Mech Base

43. Play Lever Spring

44. Limit Spring

Page 52

CRS1

52

Page 53

7 Assembling and Disassembling Procedure.

7.1. Disassembling Procedures

Caution:

Do ensure that the main unit is set to service mode before repair.

For information on setting to service mode for changer unit, pls refer to section 5.3.

Note:

Change unit (CRS1) reliability test must be carry out in complete unit or using the Service P.C.B (Refer section 8).

7.1.1. Disassembly of UD Base Assembly

CRS1

Step 1: Press the 2 claws downwards and push the top

cover backwards and lift up the top cover to remove it.

Caution: Do not exert strong force on the claws when

pressing the claws.

Step 3: Remove the open lever spring from the gear cover.

Caution: Ensure the open lever spring is handle

properly and keep it in a safe place.

Step 4: Push forwards and remove the gear cover as

arrow shown.

Step 2: Release the top cover from the tray rear stopper

as arrow shown and remove the top cover.

53

Page 54

CRS1

Step 7: Press the claw, push backwards and remove the

trigger slide plate as arrows shown.

Step 5: Remove the open switch lever.

Step 6: Remove the OC gear assy followed by the OC

gear spring as arrow shown.

Caution: Ensure the OC gear assy and OC gear spring

are handle properly and keep them in a safe place.

Step 8: Use a minus screwdriver slot into the gap and

push out the tray lock lever as arrows shown.

Caution: Do not exert force as it may cause damage to

the tray lock lever.

54

Page 55

Step 9: Push the disc trays towards the front as arrow

shown.

CRS1

Step 11: Push the claw and slide the UD rack L as arrows

shown.

Step 12: Press and hold the claw at the pitch plate then

push the UD rack R as arrows shown.

Step 10: Turn the UD connection lever clockwise.

55

Page 56

CRS1

Step 13: Remove the UD base assembly as arrow shown.

7.1.2. Disassembly of Disc Trays

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

Step 1: Remove the UD connection lever.

· Disasse mbly of UD connection lever

Step 2: Push the claw as arrow shown and remove the

lock lever 1.

Caution: Do not exert force as it may cause the claw to

be damage.

56

Page 57

CRS1

Step 3: Push the tray drive rack as arrow shown to hit the

stopper.

Step 4: Push the 5 disc trays as arrow shown until it stop

(bottom picture).

57

Page 58

CRS1

Step 5: Lift up slightly and push the 5 disc trays further as

arrows shown.

Step 6: Tilt and remove the 5 disc trays as arrows shown.

7.1.3. Disassembly of CD Loading Unit

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

· Follow the (Step 1) to (Step 6) of item 7.1.2. (Disassembly

of Disc Trays)

· Disasse mbly of play lever B

58

Page 59

CRS1

Step 1: Push the UD rack L forwar ds as arrow shown.

Step 2: Position the tray drive rack in the center.

Step 3: Push the play lever B and lift up the rib slightly to

remove the play lever B as arrows shown.

Caution: Make sure do not break the rib when

removing the play lever B. The rib break easily by

using the tools.

· Disasse mbly of tray drive rack

Step 4: Release the claw as arrow shown (top picture) then

slide and remove the tray drive rack as arrow shown

(bottom picture).

· Disasse mbly of UD rack L

59

Page 60

CRS1

Step 5: Push the claw as arrow shown.

Step 6: Slide the UD rack L as arrow shown.

Step 7: Lift up the unit as shown.

Step 8: Follow the groove to lift up and remove the UD

rack L as arrow shown.

· Disasse mbly of UD rack R

60

Page 61

CRS1

Step 9: Slide the UD rack R as arrow shown until it stop.

Step 10: Press the claw as arrow shown.

Step 11: Continue to slide the UD rack R as arrow shown

until it stop.

Step 12: Lift up the UD rack R and slide backwards to stop

at the stopper.

Step 13: Remove it as arrow shown.

· Disasse mbly of trigger gear

61

Page 62

CRS1

Step 14: Turn the trigger gear clockwise and remove it as

arrows shown.

Step 16: Release 4 claws as arrows shown in order

followed by detach the pitch plate.

· Disasse mbly of lock lever 2

· Disasse mbly of pitch plate

Step 15: Remove 3 screws

Step 17: Release the claw and pull out the lock lever 2 as

arrows shown. (The rib is fragile, do not exert force on it).

· Disasse mbly of change spring

62

Page 63

Step 18: Remove the change spring.

Caution: Handle the change spring carefully, do not

lose it. Put in a proper storage location.

CRS1

· Disasse mbly of pulley gear and belt

Step 19: Remove the belt and pull out the pulley gear.

· Disasse mbly of gears

63

Page 64

CRS1

Step 20: Remove the relay gear 1, relay gear 3, UD gear 2,

long gear, play gear 2 and tray relay gear in order.

Step 21: Remove relay gear 2, switching gear, UD gear 1

in order.

· Disasse mbly of cam gear

Step 22: Remove cam gear.

· Disasse mbly of function gear and main drive gear

64

Page 65

CRS1

Step 23: Remove main drive gear and function gear.

· Disasse mbly of play gear 1

Step 24: Remove play gear 1.

· Disasse mbly of function lever

65

Page 66

CRS1

7.1.4. Disassembly of CD Loading P.C.B.

Step 25: Remove the function lever from the ribs as arrow

shown.

Step 26: Release the spring from the rib as arrow shown

to remove the play switch lever.

Note: For changing of the mecha chassis, please

follow Step 1 to Step 5 of item 7.1.4 (Disassembly

of CD Loading P.C.B.), Step 3 to Step 4 of item 7.1.5

(Disassembly of Plunger Lever) and Step 2 of item

7.1.6 (Disassembly of Motor Unit)

Step 1: Turn over the unit and remove 4 screws from the

CD Loading P.C.B.

Step 2: Unsolder the 4 points.

Step 3: Release 1 claw as arrow shown.

66

Page 67

CRS1

Step 4: Remove the CD Loading P.C.B. as arrows shown.

· Disasse mbly of plunger assembly

Step 5: Remove the plunger assembly by using a minus

screwdriver.

7.1.5. Disassembly of Plunger Lever

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

· Follow the (Step 1) to (Step 6) of item 7.1.2. (Disassembly

of Disc Trays)

· Follow the (Step 1) to (Step 18) of item 7.1.3. (Disassembly

of CD Loading Unit)

· Follow the (Step 1) to (Step 5) of item 7.1.4. (Disassembly

of CD Loading P.C.B.)

67

Page 68

CRS1

Step 1: Remove the switching gear.

Step 2: Install the pitch plate.

Note: Ensure the pitch plate seats properly onto it.

Step 3: Lift up the plunger lever in 90°

68

Page 69

Step 2: Push the motor unit as arrow show to remove it.

CRS1

Step 4: Remove the plunger lever in 90° position.

7.1.6. Disassembly of Motor Unit

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

· Follow the (Step 1) to (Step 6) of item 7.1.2. (Disassembly

of Disc Trays)

· Follow the (Step 1) to (Step 16) of item 7.1.3. (Disassembly

of CD Loading Unit)

· Follow the (Step 1) to (Step 4) of item 7.1.4. (Disassembly

of CD Loading P.C.B.)

7.1.7. Disassembly of Traverse Unit

Important notes: Ensure all the trays are in the “STOCK”

position before proceeding to the disassemble of traverse

unit. For procedures to set the trays in “STOCK” position,

please refer to (5. Troubleshooting Explorer)

Step 1: Remove the belt.

Step 1: Press and hold the plunger lever and rotate the

gear as arrows shown until it stop.

69

Page 70

CRS1

Step 1: Remove the limit spring as arrow shown.

Step 2: Push the traverse slide plate as arrow shown to

release the traverse unit.

Caution: Do not exert strong force on the traverse

slide plate.

7.1.9. Disassembly of Play Lever Spring

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

· Follow the (Step 1) to (Step 6) of item 7.1.2. (Disassembly

of Disc Trays)

· Follow the (Step 1) to (Step 26) of item 7.1.3. (Disassembly

of CD Loading Unit)

Step 1: Remove the play lever spring as arrow shown.

Step 3: Remove the traverse unit as arrow shown.

7.1.8. Disassembly of Limit Spring

· Follow the (Step 1) to (Step 9) of item 7.1.1. (Disassembly

of UD Base Assembly)

7.1.10. Disassembly of Pitch Plate

Assembly

· Follow the (Step 1) to (Step 13) of item 7.1.1. (Disassembly

of UD Base Assembly)

· Follow the (Step 1) to (Step 6) of item 7.1.2. (Disassembly

of Disc Trays)

· Follow the (Step 1) to (Step 3) of item 7.1.3. (Disassembly

of CD Loading Unit)

70

Page 71

CRS1

Step 1: Slide the UD rack L backwards, push the claw as

arrow shown.

Step 2: Slide the UD rack R as arrow shown until it stop.

Step 3: Press the claw as arrow shown.

Step 4: Push the claw as arrow shown, then turn the

trigger gear clockwise and remove it as arrows shown.

71

Page 72

CRS1

Step 5: Remove 3 screws.

Step 6: Release 4 claws as arrows shown in order

followed by detach the pitch plate.

72

Page 73

7.2. Assembling Procedure

CRS1

7.2.1. Assembly of CD Loading Unit

· Assembly of Plunger Lever

· Assembly of Motor Unit

Step 1: Turn over the unit and install the plunger lever in

90° position.

Step 3: Turn over the unit and install the motor unit

properly.

· Assembly of Plunger Assembly

Step 2: Push in the plunger lever as arrow shown.

73

Page 74

CRS1

Step 4: Install the plunger assembly as arrow shown, the

catch should be latched.

· Assembly of CD Loading P.C.B.

Step 5: Install the CD Loadin g P.C.B. as arrows shown.

74

Page 75

Step 6: The claw should be latched.

CRS1

Step 7: Fix it with 4 screws.

Step 8: Solder the 4 points.

Step 9: Install the play switch lever.

· Assembly of play swtich lever

Step 10: Fix the spring below the rib as arrow shown.

· Assembly of function lever

75

Page 76

CRS1

Step 11: Install the function lever.

Note: Ensure the function lever seats properly onto

the ribs. A click sound will be heard when

installing.

· Assembly of play gear 1

Step 12: Install the play gear 1.

· Assembly of function gear and main drive gear

76

Page 77

CRS1

Step 13: Install the main drive gear.

Step 14: Install the function gear.

· Assembly of gears

Step 15: Install the relay gear 2, switching gear and UD

gear 1 respectively.

77

Page 78

CRS1

Step 16: Install the cam gear. Make sure the big hole is fix

at the position (A) at 90°

Step 17: Turn the cam gear anti-clockwise until the big

hole stop at position (B).

Step 18: Install the relay gear 1, relay gear 3, UD gear 2,

long gear and play gear 2 respectively.

Step 19: Install the tray relay gear.

· Assembly of pulley gear and belt

78

Page 79

Step 21: Install the change spring.

Caution: Handle the change spring carefully, do not

lose it. Ensure the change spring seats properly on

the groove of long gear.

CRS1

Step 20: Install the pulley gear followed by the belt.

Note: Do not apply the grease to the belt.

· Assembly of change spring

· Assembly of pitch plate

Step 22: Install the lock lever 2 as arrows whown in

sequence.

79

Page 80

CRS1

Step 25: Fix it with 3 screws

Step 23: Install the pitch plate.

· Assembly of trigger gear

Step 24: The 4 claws should be latched properly.

Step 26: Install the trigger gear in sequen ce.

Note: Ensure the trigger seats properly onto the

groove (cam gear).

80

Page 81

· Assembly of UD rack R

Step 27: Use the screwdriver to turn the hole on the UD

gear 2 align with the pitch plate hole.

CRS1

Step 28: Insert the UD rack R as arrow shown.

Step 29: Push the UD rack R as arrow shown.

· Assembly of UD rack L

Step 30: Insert the UD rack L as arrow shown.

Step 31: Push the claw as arrow shown.

81

Page 82

CRS1

Step 33: Install the tray drive rack as arrow shown.

Step 32: Pull the UD rack L as arrow shown.

· Assembly of tray drive rack

· Assembly of play lever B

Step 34: Install the play lever B below the rib.

82

Page 83

7.2.2. Assembly of Disc Trays

CRS1

Step 1: Tilt and fix the 5 disc trays as arrows shown.

Step 3: Push the tray drive rack as arrow shown until it

stop.

· Assembly of lock lever 1

Step 2: Push the 5 disc trays as arrow shown until it stop.

83

Page 84

CRS1

Step 5: Press and hold the claw at the pitch plate then

push the UD rack R as arrows shown.

Step 6: Push the claw and slide the UD rack L as arrows

shown.

Step 4: Fix the lock lever 1 onto the pitch plate as arrow

shown in sequence.

· Assembly of UD connection lever

84

Page 85

7.2.3. Assembly of UD Base Assembly

CRS1

Step 1: Push the traverse slide plate as arrow shown.

Step 7: Install the UD connection lever.

· Follow the (Step 1) to (Step 12) of item 7.2.3. (Assembly of

UD Base Assembly)

85

Page 86

CRS1

Step 3: Turn the UD connection lever anti-clockwise, the

UD base assembly will move downwards.

Note: When the UD connection lever is turn and the

UD base assembly did not move downwards, check for

step 1 to step 3 again.

Step 2: Install the UD base assembly.

Note: Ensure the UD base assembly seats properly into

the grooves and engage with the play lever B and tray

drive rack.

86

Page 87

CRS1

Step 4: Install the tray lock lever to the mechanism base

and push the tray lock lever with a hand to fix it.

Step 5: Push the disc trays back to the unit as arrow

shown.

· Assembly of Trigger Slide Plate

87

Page 88

CRS1

Step 6: Install the trigger slide plate, push forwards and

push the trigger gear as arrows shown until locked by the

claw.

Step 7: Install the OC gear spring followed by the OC gear

assy.

Caution: OC gear free to rotate after assembly

88

Page 89

Step 10: Install the open lever spring.

CRS1

Step 8: Install the open switch lever.

Step 9: Install the gear cover as arrow shown.

Step 11: Install the top cover, fix the top cover hook to the

tray rear stopper as arrow shown.

89

Page 90

CRS1

Step 12: Fix the top cover as arrow shown, the 2 claws

should be latched.

The mechanism unit will be ready to be checked using

service jig or be mounted to the main unit for checking.

7.2.4. Assembly of CD Loading P.C.B.

Step 1: Install the plunger assembly as arrow shown, the

catch should be latched.

90

Page 91

Step 3: The claw should be latched.

CRS1

Step 2: Install the CD Loadin g P.C.B. as arrows shown.

Step 4: Fix it with 4 screws.

Step 5: Solder the 4 points.

91

Page 92

CRS1

7.2.5. Assembly of Traverse Unit

Step 1: Turn over the unit and install the traverse unit.

Step 2: Push the traverse slide plate as arrow shown to

lock the traverse unit.

92

Page 93

8 CRS1 (Changer Unit) Ageing / Reliability

Purpose: It is necessary to test the mechanism unit by using the Service Jig P.C.B., make sure it works in order before

install it to the main unit.

8.1. Equipments

CRS1

93

Page 94

CRS1

9 Notes of Schematic Diagram

(All schematic diagrams may be modified at any time with

the development of new technology)

Note :

SW1 Open switch

SW2 Stock switch

SW3 Home switch

SW4 Top switch

SW5 Play switch

· The voltage value and waveforms are the reference voltage

of this unit measured by DC electro nic voltmeter (high

impedance) and oscilloscope on the basis of chassis.

Accordingly, there may arise some error in voltage values

and waveform s depending upon the internal impedance of

the tester or the measuring unit.

· Importance safety notice :

Components identified by

characteristics important for safety. Furthermore, special

parts which have purposes of fire-retardant (resistors), highquality sound (capacitors), low-noise (resistors), etc. are

used. When replacing any of components, be sure to use

only manuf acture r´s specified parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during

repair.

· Cover the parts boxes made of plastics with aluminium foil.

· Put a conductive mat on the work table.

· Ground the soldering iron.

· Do not touch the pins of IC, LSI or VLSI with fingers directly.

mark have special

94

Page 95

10 Schematic Diagram

10.1. CD Loading Circuit

SCHEMATIC DIAGRAM - 1

CRS1

CD LOADING CIRCUIT

C0GAG0000007

LOADING MOTOR DRIVE

VREF

OUT2

RNF

23456

1

M1

M

SW4

TOP

124

3

PH1

SG233

UD SENSOR

R1

1K

4

3

IC1

OUT1VMVCC

41

32

SW5

PLAY

1

2

: +B SIGNAL LINE

IN1

GND

IN2

789

SW2

STOCK

SW1

OPEN

124

3

C1

16V100

SW3

HOME

PH2

SG233

CAM SENSOR

R2

390

41

32

CN1

CCW

1

CW

2

PGND

3

VCC_8V

4

HOME_SW

5

ST_SW

6

OPEN_SW

CAM_SENSOR

PLAY_SW

UD_SENSOR

BOTTOM_SW

DGND

SPEED

TO

7

MAIN

8

CIRCUIT

5V

9

10

11

12

13

14

95

Page 96

CRS1

11 Printed Circuit Board

11.1. CD Loading P.C.B.

ABCDEFG

1

A

CD LOADING P.C.B (REPX0439A)

SOLENOID

2

3

SW5

(PLAY)

412

3

4

5

6

7

8

12

34

PH1

(UD SENSOR)

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN1

9

8

7

6

5

4

3

2

1

IC1

SW4

(TOP)

2143

W7

W2

W1

W3

W5

W4

R2

W6

W8

R1

M1

M

C1

SERVICE JIG

PH2

(CAM SENSOR)

SW3

(HOME)

21

43

SW2

(STOCK)

0458A

PbF

0458A

SW1

(OPEN)

12

34

9

96

Page 97

12 Exploded Views

12.1. CD Loading Mechanism

CRS1

97

Page 98

CRS1

98

Page 99

CRS1

99

Page 100

CRS1

13 Replacement Parts List

Notes:

· Important safety notice:

Components identified by

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise

(resistors), etc. are used.

When replacing any of these components, be sure to use only manufacturers’s specified parts shown in the parts list.

· Capacitor values are in microfarad (µF) unless specified otherwise, P=Pico -farads(pF); Farads.

· Resistance values are in ohms, unless specified otherwise, 1K=1,000(ohms).

· The marking (RTL) indicates that the Retention Time is limited for this item. After the discon tinuatio n of this assembly in

production, the item will continue to be available for a specific period of time. The retention period of availability is dependant

on the type of assembly, and in accordance with the laws governing part and product retention. After the end of this period, the

assembly will no longer be available.

· [M] Indicates in the Remarks columns indicates parts that are supplie d by PAVCSG.

mark have special characteristics important for safety.

100

Loading...

Loading...