Micro-Imagechecker

05/2005

AX30/AX40

Micro-Imagechecker AX30/AX40

05/2005

AX30/AX40

2

Micro-Imagechecker AX30/AX40

05/2005

The Systems at a Glance

Micro-Imagechecker

AX30 AX40

Colour

Colour

Differential

Easy to use colour image

processing system

Various ready-to-use inspection

tools for a wide range of visual

inspection applications

Supports 360° contour matching function

Compact and industrial stand-alone hardware

Fast and reliable

Time-saving setup thanks to an easy-to-use graphical interface

Two colour-CCD cameras connectable

Serial, parallel and Ethernet interfaces

VGA-monitor connection

Data storage of Compact Flash memory cards

Support dual language menu

Optional project management software AXTOOL

Grey Value

Everything the AX30 can do

plus several functions from tried and

tested A200

Colour processing and additional grey

value routines such as sub-pixel edge

detection, feature extraction and smart matching

Fast binary routines such as feature extraction

New differential pre-processing

Several useful add-ons such as setting help, data

monitoring and display functions

Binary

Contents:

The Sytems at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Hardware Highlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Software Highlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Inspection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Software AXTOOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

System Configuration and Dimensions . . . . . . . . . . . . . . . .14

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3

Micro-Imagechecker AX30/AX40

05/2005

Hardware Highlights

Compact and industrial

With their dimensions of just 130 x 59 mm, AX30/AX40 Imagecheckers help you

realise the growing demand of downsizing equipment.They permit space saving

DIN-rail installation in a switching cabinet or direct mounting at the inspection site.

All interface connectors are located on the front side, which makes it easy to install

and service the systems. Furthermore, they have an impressive record in industrial

safety, which results also from the fact that they do not employ any mechanical parts

such as fans or hard disks.

Precise and reliable

Being the successors to our successful A-Series Imagecheckers, AX30/AX40 systems

inherit proven image-processing technology built up over many years. These highprecision devices ensure advanced quality inspection of your products, since they

include colour data in the evaluation process. They are designed as stand-alone

devices with a proprietary operating system and a dedicated inspection firmware.

The systems are ready for operation immediately after power up and can provide

inspections 24 hours per day, 365 days a year.

Powerful dual camera inspection

AX Series Imagecheckers include a dedicated 32-bit RISC CPU that secures a highperformance inspection level. Besides the short response time, the systems enable

very powerful inspection algorithms, such as those used for the newly developed

contour matching. They detect objects reliably, even if they partially overlap or if

ambient light changes.

AX30/AX40 process the images of up to two colour CCD cameras in parallel and

output inspection results after a few milliseconds.

4

Micro-Imagechecker AX30/AX40

05/2005

A Sophisticated Hardware Concept

Indicator LEDs

■ Display of all essential signals

on the controller

Ethernet port

■ 100 Base-Tx

■ Several backup/restore functions

■ Optional: AXTOOL software

Two serial ports

■ Communicate with PCs

and/or PLCs

■ Direct connection to various PLCs

without programming efforts

1)

DIN rail installation

■ One touch at the rear, is all that is

required for DIN rail installation

Compact flash

memory card slot

■ Backup/restore of camera images,

screenshots and project data

■ Very reliable, rugged and cost

efficient storage media

Keypad interface

■ Easy video-game-like setting with

a four-button keypad

Parallel I/O

■ 14 digital outputs for judgement and

result data output plus additional

signals for error, ready, flash-light

trigger, etc.

■ 13 digital inputs for program change

teach-in, etc.

■ PhotoMOS technology

1)

Cannot be used simmultaneously

Two colour cameras

connectable

■ Single chip CCD technology

■ Fast progressive scan image

capturing

■ All camera parameters adjustable via

software

■ Miniature camera design

Original Product size

VGA-monitor interface

■ High-quality display (flicker-free)

■ Use of cost effective standard

monitors

5

Micro-Imagechecker AX30/AX40

05/2005

Software Highlights

Colour image processing opens a new world of possibilities.

Human eye-like sensitivity

The colour recognition/extraction

algorithms of AX30 and AX40 are based

on the LCH (luminosity, chroma and

hue) mode, which covers all colours a

human eye can recognise. This mode

allows for colour recognition more

similar to that of the human eye than

conventional RGB-mode colour

extraction.

Numerous advantages

Colours like green,

cyan or yellow can

hardly be

distinguished in

grey colour pictures.

Only a colour system makes reliable

control possible.

Inspection examples

Independent evaluation of luminance, saturation and hue

Low influence by variation in luminance

Higher recognition certainty

Reliable detection of objects barly distinguishable

in grey colour pictures

Colour Detection, Presence Checking

Measures the area of the specified region or pre-defined

colours to detect foreign objects, perform presence checking,

sort or count objects.

6

Size Measurement

Grey-scale based inspection functions such as edge finders

allow the system to measure dimensions, angles, diameters,

radii, etc. with sub-pixel resolution.

Fast and easy setup

05/2005

Our newly designed user interface

allows you to set up your inspection

routine quickly. The clearly structured

screen with its pull-down menus,

semitransparent spreadsheets and

indicators makes it easy to configure the

AX30 or AX40 to each individual

application, even for non-experts.

Position detection

Several algorithms in the systems are made for precisely

detecting the position of an object.

x/y coordinates and the rotation angle are typically output.

Matching

Advanced matching functions such as contour-matching and

smart matching

details reliably and efficiently.

1)

can be used to identify or to validate object

1)

AX40 only

7

Micro-Imagechecker AX30/AX40

05/2005

Special Features

360° contour-matching

By calculating contour lines and judging,

stable positional detection is possible

even for hidden, overlapped objects that

have been difficult to detect up to now.

Thanks to this, better yields are

achieved.

AX40Previous

Versatile rotational and positional

adjustment

Highly accurate and reliable inspection

is realized by automatically adjusting

object orientation and stop-position

deviation. Since adjustment is done

using grey scale data, the AX40 shows

its strength when it comes to changes in

brightness. Complicated adjustments

are possible because of the priority

adjustment function.

Mask

The shape of the inspection area can be

set to match particular targets. Also,

mask area settings can be combined so

that efficient inspection can be carried

out just for a required part.

8

Colour tone diagram

Fine adjustment for color inspection is

possible. Even when colors resemble

each other, the target color alone can be

extracted to enable highly accurate

inspection.

Print screen

You can save setting displays or

displays that occur during operation as

bitmaps on a memory card. This is

convenient for creating documents or for

verifying previously shot images.

Micro-Imagechecker AX30/AX40

05/2005

Additional Features of the AX40

1 System – 4 inspection modes

AX40 commands four different inspection modes: colour, binary, grey-scale and differential image processing. Combined with a

large pool of ready-made and easy-to-configure inspection functions such as 360° contour-matching and smart matching, AX40

can handle nearly any inspection task.

Full colour

LCH mode for human-eye like colour

inspection

Suitable for various inspection tasks

such as sorting, counting, parts

recognition, etc.

Grey scale

256 grey tones for precise

measurement, positioning, etc.

Differential

Extracts edges/changes in the

image data

Ideal method e.g. for surface

inspection

Smart matching

Grey scale matching makes sub-pixel

positional detection possible

Furthermore, shape inspection, such as

for the detection of chipped objects, can

be carried out simultaneously with the

grey scale difference processing

function

Template

Detected

image

Difference result

Data monitor

Up to 50 inspection results are displayed

on the monitor in chart form for operator

verification. Also, threshold adjustment

(upper and lower limit values) can be

changed on the data monitor without

entering them in the setting menu.

Binary

A reduction of the image data to black

and white pixels allows fastest

inspection

Statistical support

Data can be tracked, e.g. as maximum

value, minimum value, average value,

and number of NG (no-good) results.

Maximum, minimum, average and other

OK judgment values can be verified,

which is useful as a guide for making

upper and lower limit settings.

Numerical calculation/judgement

output

The computation function, which has

been troublesome up to now, now can

be easily made, even by beginners.

Also, operation has become even easier

thanks to the ability to set both

numerical calculation and judgement

output on the same screen.

9

Micro-Imagechecker AX30/AX40

05/2005

User-friendly User Interface

Intuitive and clearly arranged

System uses

18-dot fonts.

Operating systems

equipped with pull-down

menus and dialogue

windows. System closer to

“look and feel” of Windows

applications for more

intuitive operation.

Easy-to-see overall

pass/fail result display.

Colour window achieves unrivaled ease of operation!

Select colours to detect right on the screen.

Image display area (512 x 480)

Reserved area for status

display (128 x 480).

Display results and more

without affecting the

camera image.

Our newly designed user interface saves you time and allows you to set your visual inspection routine efficiently. The clearly

structured screen with its pull-down menus, semitransparent spreadsheets and indicators makes it easy even for non-experts to

adjust AX30/AX40 to each individual application. The big overall good/bad display as well as the status indicators give you

reliable output information any time during the setting and inspection procedure.

Since AX30/AX40 has a standard VGA interface, it can be connected to any normal computer monitor.

Other highlights:

Password protection

Multiple language configuration (German, English, French, etc.)

Setting help for focus and apperture (AX40)

Easy-to-see

semitransparent menu

screen. Configure various

settings while viewing

captured image.

10

Micro-Imagechecker AX30/AX40

05/2005

Inspection Functions

AX30/AX40 Imagecheckers can be used for a wide range of visual inspection applications such as 2D measurement,

presence/absence checking, object position detection, object identification, sorting, counting, print inspection, colour

discrimination and much more. Here are the inspection tools available in detail:

Detect the object position relative to a specified

Position

Detection

reference point, detect rotations or

displacements of objects. Output object

position or adjust other checkers accordingly.

Measure the area of pixels in order to check the

Area

Measurement

presence/absence of certain object features, to

detect foreign objects, etc.

Measure dimensions, distances and widths of

Size

Measurement

objects or of object features. Determine

diameters, radii, angles, etc.

Overview of inspection functions

Feature

PRE-PROCESSING

Colour extraction

Grey scale

Differential processing

PROCESSING

Position Detection

X/Y

Angle

Area Measurement

Colour extraction

Grey scale

Size Measurement

Colour (pixel)

Grey scale (sub-pixel)

Object/Feature Detection

Colour extraction

Colour (advanced)

Grey (advanced)

360° Contour-Matching

Colour extraction

Grey

Smart Matching

Grey scale

POST-PROCESSING

Advanced result calculation

AX30 Micro-Imagechecker

Object

Feature

Detection

360°

Contour-

Matching

Smart

Matching

Identify objects and their position based on

significant object features or differences.

Count, sort and categorise objects.

Detect contours in the current camera

image and output the correlation of the

found object with the given contour.

Detect an object based on stored reference

templates and extracts the differences

between the two images to find e.g. minute

imperfections in imprints or faulty print

images on discrete parts.

AX40 Micro-Imagechecker

11

Micro-Imagechecker AX30/AX40

05/2005

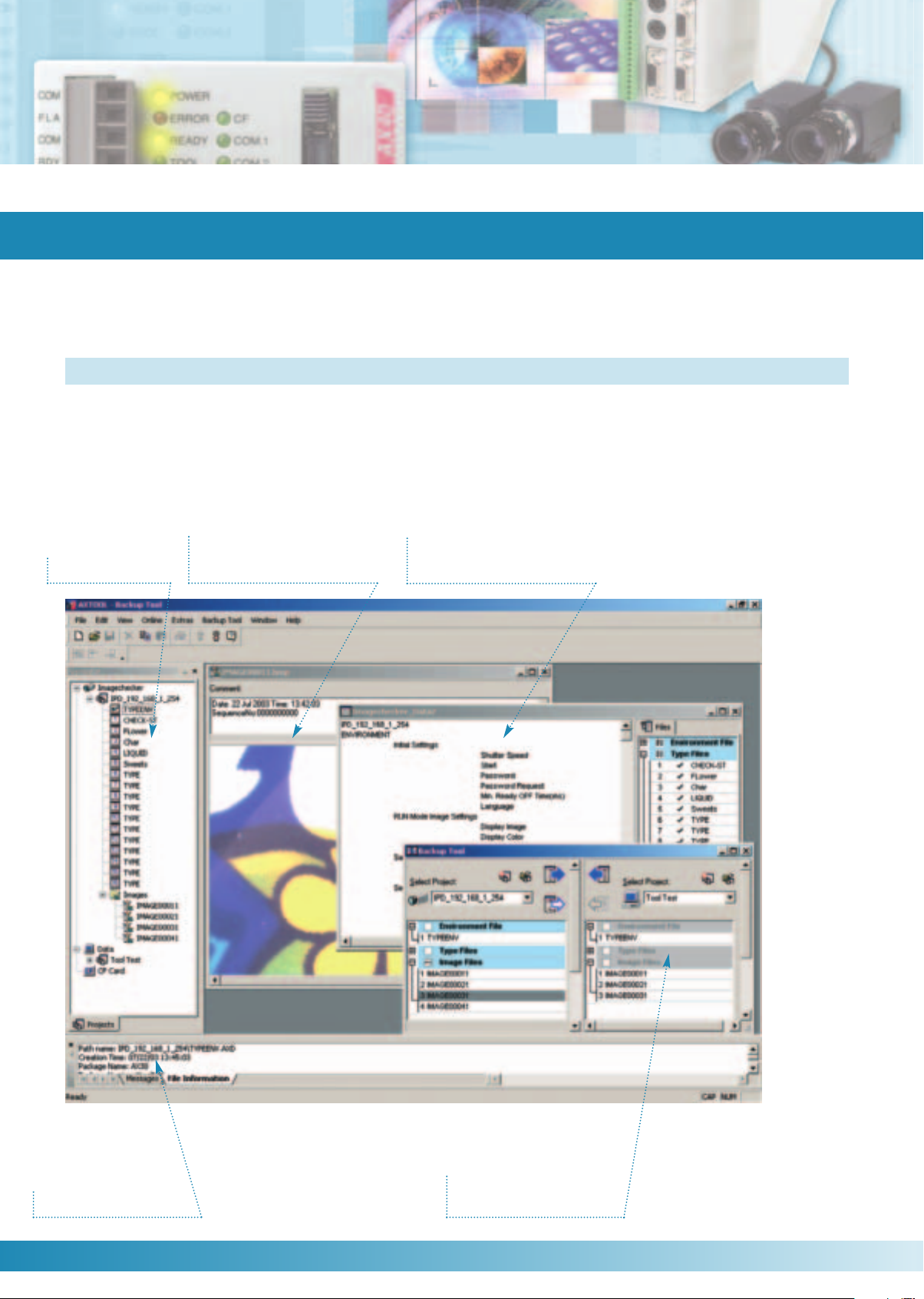

Software AXTOOL

AXTOOL

This new software tool makes it very convenient to administer and organise your AX30/AX40 projects comprehensively by drag & drop.

AXTOOL allows direct access to AX30/AX40 project data and images. It is easy to back up and to restore inspection program information

from/to your computer and to organise this data.

An integrated image viewer allows you to display and print out saved images. Last but not least the ‘Documenter’ gives you a detailed insight

into each inspection program and simplifies project documentation and archiving.

Navigator

Saved

image display

Set data

display screen

Message area

12

Communication

screen

Micro-Imagechecker AX30/AX40

05/2005

Technical Data

Main Unit

Micro-Imagechecker

PART NUMBER

English/German

French/English

CPU

RESOLUTION

PROCESSING

INTERFACES

Serial

Parallel

Ethernet

Storage device

NUMBER OF CAMERAS CONNECTABLE

VISUALISATION

SUPPLY VOLTAGE

CURRENT CONSUMPTION

OPERATING TEMP. RANGE

WEIGHT

AX30

ANMX304

ANMX305

32-bit RISC

512 (h) x 480 (v) pixel

2 x 8 colours

8-bit grey scale processing

8-bit differential processing

COM port: RS232C (max. speed 115,200 bps)

13-point input, 12-24VDC, bipolar (NPN/PNP), optically coupled

14-point output, 12-24VDC, bipolar (NPN/PNP), optically coupled

100Base-Tx, 10Base-T

Compact Flash Memory Card, type I, max. 512 MB

2

1 colour-VGA connection

24 VDC

< 0.9 A

0 to 50 °C (no frost or condensation)

Approx. 450 g

AX40

ANMX404

ANMX405

2 x 8 colours

Camera

Micro-Imagechecker

PART NUMBER

IMAGE SENSOR

LENS MOUNT

SHUTTER SPEED

OPERATING TEMPERATURE

VIBRATION RESISTANCE

SHOCK RESISTANCE

WEIGHT

All specification are subjected to change without further notice.

10 to 55 Hz; 1 sweep/min, vibration width 1.2 mm, 30 min each in x, y, z directions

Approx. 70 g (excluding camera cable, lens and camera mounting brackets)

AX30

ANMX8310

1/3” CCD, 659 x 494 square pixels

C mount

1/30, 1/100, 1/250, 1/500, 1/1000, 1/2000, 1/4000, 1/10000 s

Guaranteed performance range: 0 to 40 °C

Allowed operating temperature range: 0 to 50 °C

(no frosting, no condensation)

700 m/s3, 3 times each x, y, z directions

AX40

13

Micro-Imagechecker AX30/AX40

m

● Main unit (Controller)

AX30/AX40

(9.5) (.374) (Pullout dimensions)

(10)

(.394)

100

3.937

59

2.323

FCT2

FCT1

D6

D7

D3

D8

IN4

D4

D2

IN7

IN3

D5

COM

FLA

COM

RDY

ERR

REN

STR

OVF

D1

IN5

IN6

IN8

IN2

COM

STA

COM

ACK

TYP

IN1

-

+

COM.2

COM.1

CF

POWER

ERROR

READY

TOOL

KEYPAD

COM.1

COM.2

CAMERA1

CAMERA2

MONITOR

ø4.6

ø.181

5

.197

130

5.118

(5.5)

(.217)

05/2005

System Configuration and Dimensions

Standard internal Ethernet

interface.

High-speed interface with

AXTOOL makes backing up

images and product type data

a snap.

Easy configuration with

a handy keypad.

Supports max. 512MB

CompactFlash™ card*.

Save all that configuration data,

image data and display-screen

data.

* CompactFlash™ is a registered trademark of Sun Disk Inc., US.

Dimensions

(Unit: mm inch)

14

RS232C port makes

communicating with PLCs and

other external devices a snap.

Program-less connection via

our PLC protocol as well as

PLCs of other companies.

Supports dedicated 6.5-inch

colour LCD VGA monitor.

● Dedicated colour camera:

31

1.220

29

1.142

2-M3 .118

(Depth: 4 mm .157 inch)

54.5

2.146

8

(46.5)

.315

(1.831)

24.5±0.6

19

.965±.024

.748

13

.512

No mounting

bracket

Supports flashlight.

Large range of lights

and objectives available.

Connects up to two colour

cameras.

10

.394

4-M3 .118

(Depth 2.5 mm

.098 inch)

26±0.6

1.024±.024

(19)

(.748)

(31.3)

(1.232)

24.5±0.6

.965±.024

31

1.220

(3.25)

(.128)

With mounting

bracket

1/4-20UNC

(Depth 9 m

.354 inch)

31

1.220

2.5

.098

Micro-Imagechecker AX30/AX40

05/2005

Accessories

Photoelectric sensors

is the brand name for our sensor products. Whatever type of sensor is required, our wide

product range offers you the right solution.

Lenses and optics

High quality lenses for industrial machine vision applications.

Programmable Logic Controllers

Our Programmable Logic Controllers represent "Control advantages" that pay for themselves right

from the start.

Human Machine Interfaces

Our compact size, bright and easy-to-read Human Machine Interfaces can be used to visualise

inspection results. Touch panels can even replace the standard keypad if you so desire.

Power Supplies

Our DIN-rail power supplies offer all features required for industrial use in an incredibly compact

design.

ACD Components

Components such as Timers/Counters and Limit Switches round off our wide Factory Automation

product range.

15

Global Network

05/2005

Global Network Services Global Network Services

North America

Panasonic

Electric Works

Corporation of

Europe

Panasonic

Electric Works

Europe AG

Asia Pacific

Panasonic

Electric Works

Asia Pacific Pte. Ltd.

China

Panasonic

Electric Works

(China) Co., Ltd.

Japan

Matsushita

Electric Works, Ltd.

Global Headquarters

America

Panasonic Electric Works

Please contact our Global Sales Companies in:

Europe

Headquarters Panasonic Electric Works Europe AG Rudolf-Diesel-Ring 2, 83607 Holzkirchen, Tel. (08024) 648-0, Fax (08024) 648-111, www.panasonic-electric-works.com

Austria Panasonic Electric Works Austria GmbH Josef Madersperger Str. 2, 2362 Biedermannsdorf, Tel. (0 2236) 2 6846, Fax (0 2236) 4 6133, www.panasonic-electric-works.at

Benelux Panasonic Electric Works

Czech Republic Panasonic Electric Works Czech s.r.o. Prumyslová 1, 34815 Planá, Tel. (0374) 799990, Fax (0374) 799999, www.panasonic-electric-works.cz

France Panasonic Electric Works

Germany Panasonic Electric Works Deutschland GmbH Rudolf-Diesel-Ring 2, 83607 Holzkirchen, Tel. (08024) 648-0, Fax (08024) 648-555, www.panasonic-electric-works.de

Ireland Panasonic Electric Works UK Ltd. Irish Branch Office, Waverley, Old Naas Road, Bluebell, Dublin 12, Tel. (01) 4600969, Fax (01) 4601131, www.panasonic-electric-works.co.uk

Italy Panasonic Electric Works Italia s.r.l. Via del Commercio 3-5 (Z.I. Ferlina), 37012 Bussolengo (VR), Tel. (045) 6752711, Fax (045) 6700444, www.panasonic-electric-works.it

Nordic Countries Panasonic Electric Works Nordic AB Sjöängsvägen 10, 19272 Sollentuna, Sweden, Tel. (08) 59476680, Fax (08) 59476690, www.panasonic-electric-works.se

Portugal Panasonic Electric Works España S.A. Portuguese Branch Office, Avda Adelino Amaro da Costa 728 R/C J, 2750-277 Cascais, Tel. (21) 4812520, Fax (21) 4812529

Spain Panasonic Electric Works España S.A. Barajas Park, San Severo 20, 28042 Madrid, Tel. (91) 3293875, Fax (91) 3292976, www.panasonic-electric-works.es

Switzerland Panasonic Electric Works Schweiz AG Grundstrasse 8, 6343 Rotkreuz, Tel. (041) 7997050, Fax (041) 7997055, www.panasonic-electric-works.ch

United Kingdom Panasonic Electric Works UK Ltd. Sunrise Parkway, Linford Wood, Milton Keynes, MK14 6LF, Tel. (01908) 231555, Fax (01908) 231599, www.panasonic-electric-works.co.uk

PEW Electronic Materials Europe GmbH Industriehafenstraße 9, 4470 Enns, Tel. (07223) 883, Fax (0 72 23) 8 83 33, www.panasonic-electronic-materials.com

Sales Western Europe B.V.

Sales Western Europe B.V. French Branch Office, B.P. 44, 91371 Verrières le Buisson CEDEX, Tél. 01 60135757, Fax 01 60135758, www.panasonic-electric-works.fr

PEW Electronic Materials France S.A.R.L. 26 Allée du Clos des Charmes, 77090 Collegien, Tél. 01 64622919, Fax 01 64622809, www.panasonic-electronic-materials.com

PEW Building Materials Europe s.r.l. Viale Elvezia 18, 20154 Milano (MI), Tel. (02) 33604525, Fax (02) 33605053, www.panasonic-building-materials.com

PEW Lighting Europe s.r.l. Via del Commercio 3-5 (Z.I. Ferlina), 37012 Bussolengo (VR), Tel. (045) 6703882, Fax (045) 6717420

PEW Fire & Security Technology Europe AB Citadellsvägen 23, 21118 Malmö, Tel. (040) 6977000, Fax (040) 6977099, www.panasonic-fire-security.com

De Rijn 4, (Postbus 211), 5684 PJ Best, (5680 AE Best), Netherlands, Tel. (0499) 372727, Fax (0499) 372185, www.

panasonic-electric-works

.nl

North & South America

USA PEW Corporation of America 629 Central Avenue, New Providence, N.J. 07974, Tel. 1-908-464-3550, Fax 1-908-464-8513

Asia Pacific / China / Japan

China Panasonic Electric Works

Hong Kong Panasonic Electric Works Rm1601, 16/F, Tower 2, The Gateway, 25 Canton Road, Tsimshatsui, Kowloon, Hong Kong, Tel. (0852) 2956-3118, Fax (0852) 2956-0398

Japan Matsushita Electric Works, Ltd. 1048 Kadoma, Kadoma-shi, Osaka 571-8686, Japan, Tel. (06) 6908-1050, Fax (06) 6908-5781, www.mew.co.jp/e-acg/

Singapore

Head Office USA

(China) Co., Ltd.

(Hong Kong) Co., Ltd.

Panasonic Electric Works Asia Pacific Pte. Ltd.

2013, Beijing Fortune, Building No. 5, Dong San Huan Bei Lu, Chaoyang District, Beijing, Tel. (010) 6590-8646, Fax (010) 6590-8647

101 Thompson Road, #25-03/05, United Square, Singapore 307591, Tel. (06255) 5473, Fax (06253) 5689

Copyright © 2005 • Printed in Germany

3158 eu en 04/05

Loading...

Loading...