Page 1

Model No. AW-SW350P

Before attempting to connect, operate or adjust this product, please

read these instructions completely.

Live Switcher

POWER

ON

OFF

GEN-LOCK PHASE

HSCSC FINE

WH1

SF0

YLW

INCOM

MWR

MGT RED BLE

LEVEL

WIPE PATTERN

WH2

SF1

CYN

INT

SETTING COLOR

A

1234

WH3

SF2

GRN

FRZ

INV

N

N / R

R

FRZ

5

FMEM

TRANSITION TIME

AUTO TAKE KEY AUTO

GAIN

SOURCE

IN5

FMEM

BLACK

COLOR

BAR

KEY

AUTO TAKE

Live Switcher AW-SW350

A

CLIP

KEY AUTO

MIX

WIPE

B

B

Page 2

32

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

REFER TO SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral triangle,

is intended to alert the user to the presence of uninsulated “dangerous

voltage” within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (service)

instructions in the literature accompanying the appliance.

WARNING:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD, DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD AND ANNOYING

INTERFERENCE, USE THE RECOMMENDED ACCESSORIES ONLY.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD, REFER

CHANGE OF SWITCH SETTING INSIDE THE UNIT TO QUALIFIED

SERVICE PERSONNEL.

Note:

The rating plate (serial number plate is on the bottom of the unit.

indicates safety information.

FCC Note:

This device complies with Part 15 of the FCC Rules. To assure continued

compliance follow the attached installation instructions and do not make any

unauthorized modifications.

This equipment has been tested and found to comply with the limits for a class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

indicates safety information.

The information marking of this product may be found on the bottom of the unit.

The serial number of this product may be found on the bottom of the unit.

You should note the serial number of this unit in the space provided and retain this book

as a permanent record of your purchase to aid identification in the event of theft.

Model No.

Serial No.

Page 3

54

CONTENTS

WARNING/CAUTION FOR SAFETY ..................................................................................... 5

PREFACE .............................................................................................................................. 6

FEATURES ........................................................................................................................... 6

PRECAUTIONS ..................................................................................................................... 7

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS ............................................ 8

■TOP (CONTROL PANEL) ........................................................................................ 8

■REAR PANEL ........................................................................................................ 15

IMAGE TRANSFER FUNCTION ......................................................................................... 20

■FUNCTIONS .......................................................................................................... 20

■SPECIFICATIONS ................................................................................................. 21

■INSTALLING THE DEVICE DRIVER ..................................................................... 22

■INSTALLING THE APPLICATION PROGRAM ..................................................... 25

■OPERATION METHOD ......................................................................................... 27

CONNECTIONS .................................................................................................................. 32

■CONNECTION WITHOUT EXTERNAL SYNCHRONIZATION ............................. 32

■CONNECTION FOR EXTERNAL SYNCHRONIZATION ...................................... 33

■CONNECTION TO PERSONAL COMPUTER ...................................................... 34

■EXAMPLE FOR THE CONNECTION

WITH PAN/TILT HEADS AND CONTROL PANEL ............. 36

RACK MOUNTING .............................................................................................................. 38

■RACK MOUNTING ................................................................................................ 38

INFORMATION RELATED TO SYSTEM UPGRADES ...................................................... 39

SPECIFICATIONS/STANDARD ACCESSORIES .............................................................. 40

■SPECIFICATIONS ................................................................................................. 40

■STANDARD ACCESSORIES ................................................................................ 41

WARNING/CAUTION FOR SAFETY

WARNING

• Refer all servicing to qualified personnel

To reduce the risk of electric shock, don't remove cover or back, unless you are a

qualified personnel. Refer all mountings, connections, servicing to qualified service

personnel.

• No water or moisture inside

Do not let water or moisture into the product, or expose it to moisture, to prevent a fire and

electric shock.

• If you see smoke or smell an odor from the product, if water or other foreign matter gets

inside, if it is damaged by dropping, or if you find anything wrong with it, immediately stop

using it.

• Do not disassemble or modify the product to prevent a fire and electric shock.

CAUTION

• Do not drop the product, do not expose it to strong shock, or do not step on it, to prevent

a fire and injuries.

• Do not install the product at a place full of moisture and dust, which may cause a fire and

electric shock.

• Do not mount the Live Switcher on a closed rack or bookshelf. (Otherwise, heat will build

up inside and may cause a fire.)

• Keep the ventilation port open to secure good flow of air.

Page 4

76

The AW-SW350 has five video inputs, wipe, mix and key synthesis functions despite its

compact dimensions. Since it has a built-in frame synchronizer, it accepts the input of

asynchronous signals. Moreover, it enables systems to be configured using the black burst

signals which it outputs, and it supports external synchronization (or genlock) to external sync

signals as well. Its image transfer function enables the images and text created using a

personal computer to be captured in the switcher through its USB port. The switcher can be

used in the field because it operates on an external power supply (12 V DC) while its tally

outputs and intercom inputs/outputs permit easy system configuration.

PREFACE

FEATURES

• Five Inputs Despite Compactness

The switcher has five composite video signal inputs. (Automatic termination. Loopthrough

output provided) It also has an S-terminal (4-pin), and can thus handle YC signals. Input 5

can be switched to the internal frame memory or vice versa by means of a switch. Internal

black or color signal (9 patterns) can be selected.

• Three Program Outputs, Preview Outputs Available

Effect outputs including two composite video outputs (BNC connectors) and one YC

signal output (S-terminal, 4-pin) are available, so it is easy to build a system with

monitors, VCRs, etc. The AW-SW350 also features the Preview output to confirm the next

operation. (Look Ahead Preview)

• Frame Synchronizer System and Genlock System Supported

The switcher contains a high-performance 10-bit frame synchronizer: this means that

asynchronous signals can be directly input to the input camera or other such device

without having to initiate genlock. Its inputs are equipped with a frame synchronizer

function so that its images are do not freeze even when the frames are switched.

Alternatively, the frame synchronizer can be turned off, genlock can be applied to a

camera or other such device, and the unit can be used as a wideband switcher with

minimal deterioration in image quality (resolution of 800 lines).

• Genlock

The switcher enables genlocking to the reference sync signal of an external device.

Furthermore, by using its BB output, the system can be upgraded using the

synchronization of the switcher as a reference.

• Image Transfer, Soft Keys and Linear Keys

Inside the switcher AW-SW350 has a 1-frame frame memory so that the images created

using a personal computer can be captured in this memory through the USB port. There

are nine different patterns for wipe, and one of three softness levels can be set. Text can

also be synthesized smoothly by performing linear key operations.

• External Power Supply

The switcher can be used both indoors and outdoors because it operates on an external

power supply of 12 V DC.

(However, it is not built rainproof or dripproof. Do not expose the switcher to rains or

moisture.)

• Tally and Intercom Provided

Five tally outputs and five intercom inputs and outputs are available so that the switcher

can be directly apply to conventional systems. (The switcher has its own intercom on the

panel.)

PRECAUTIONS

• Handle with Care.

Do not drop the switcher, or expose it to strong shock or vibration. This is important to

prevent trouble and accidents.

• Operating temperature range 32F to 104F

Avoid using it in a cold place below 32F or a hot place above 104F because low or high

temperature will adversely affect the parts inside.

• Switch power off before cables connection or disconnection.

Be sure to switch power off before connecting or disconnecting the cables.

• Use at a Place Not Humid, Not Dusty.

Avoid using the switcher at a humid, dusty place because the internal parts are subject to

damage by moisture and dust.

• Care

Switch power off and wipe the switcher with a dry cloth. If it is difficult to remove the dirt,

dip a cloth into a diluted solution of kitchen detergent, squeeze it hard, and wipe the

product carefully.

• Do not use benzine, paint thinner, or other volatile liquids.

• When using a chemical duster, carefully read the caution notes on its use.

Note

Page 5

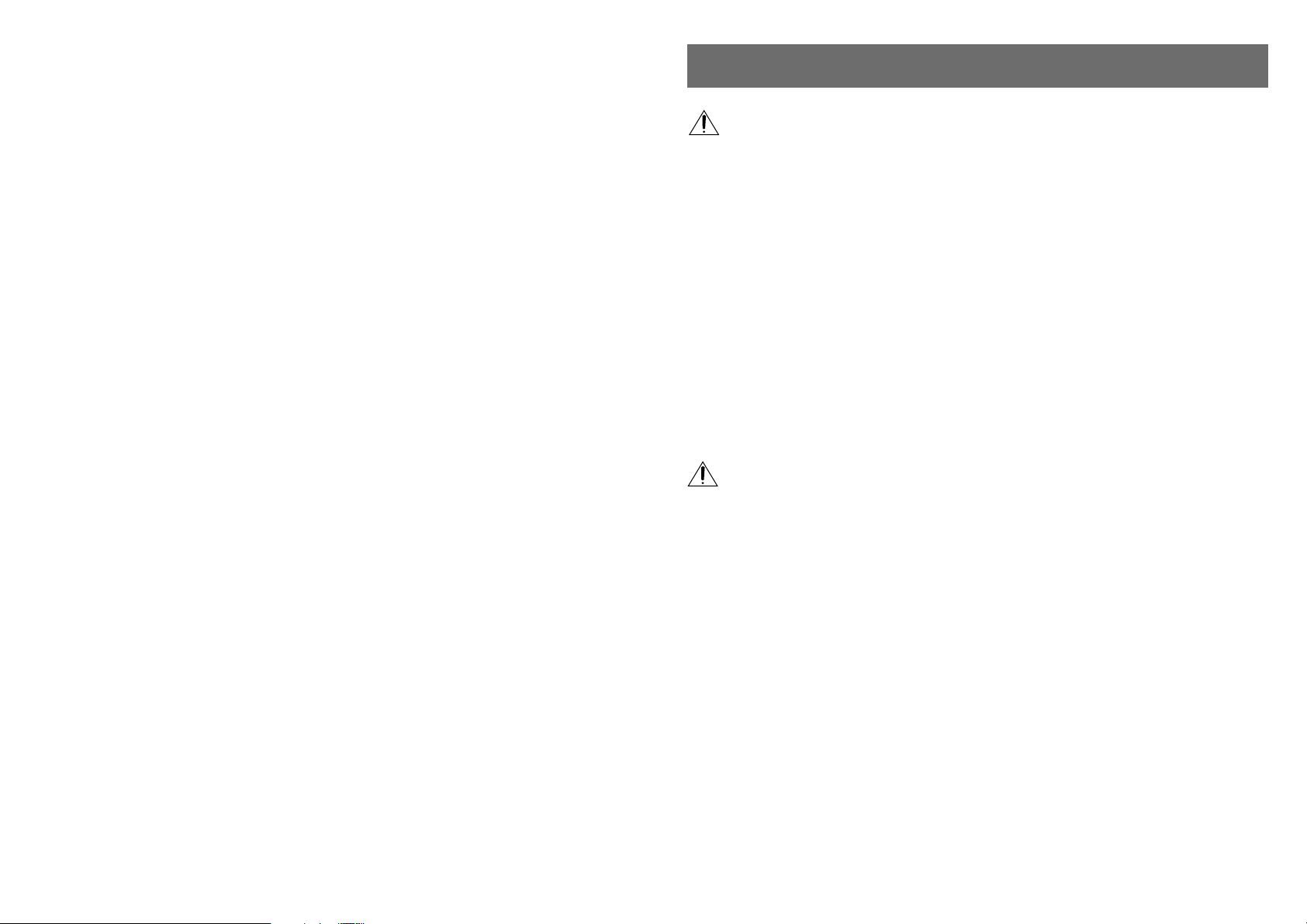

QPower Indicator [POWER]

Lights (green) when power is supplied to DC Power Input Terminal L and Power Switch W

set to the ON position, and goes out when Power Switch W is set to the OFF position.

WPower Switch [POWER ON/OFF]

Power is switched on and Power Indicator Q lights when this switch is set to the ON

position, provided that power is supplied to DC Power Input Terminal L. Power is switched

off and Power Indicator Q goes out when the switch is set to the OFF position.

98

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

■TOP (CONTROL PANEL)

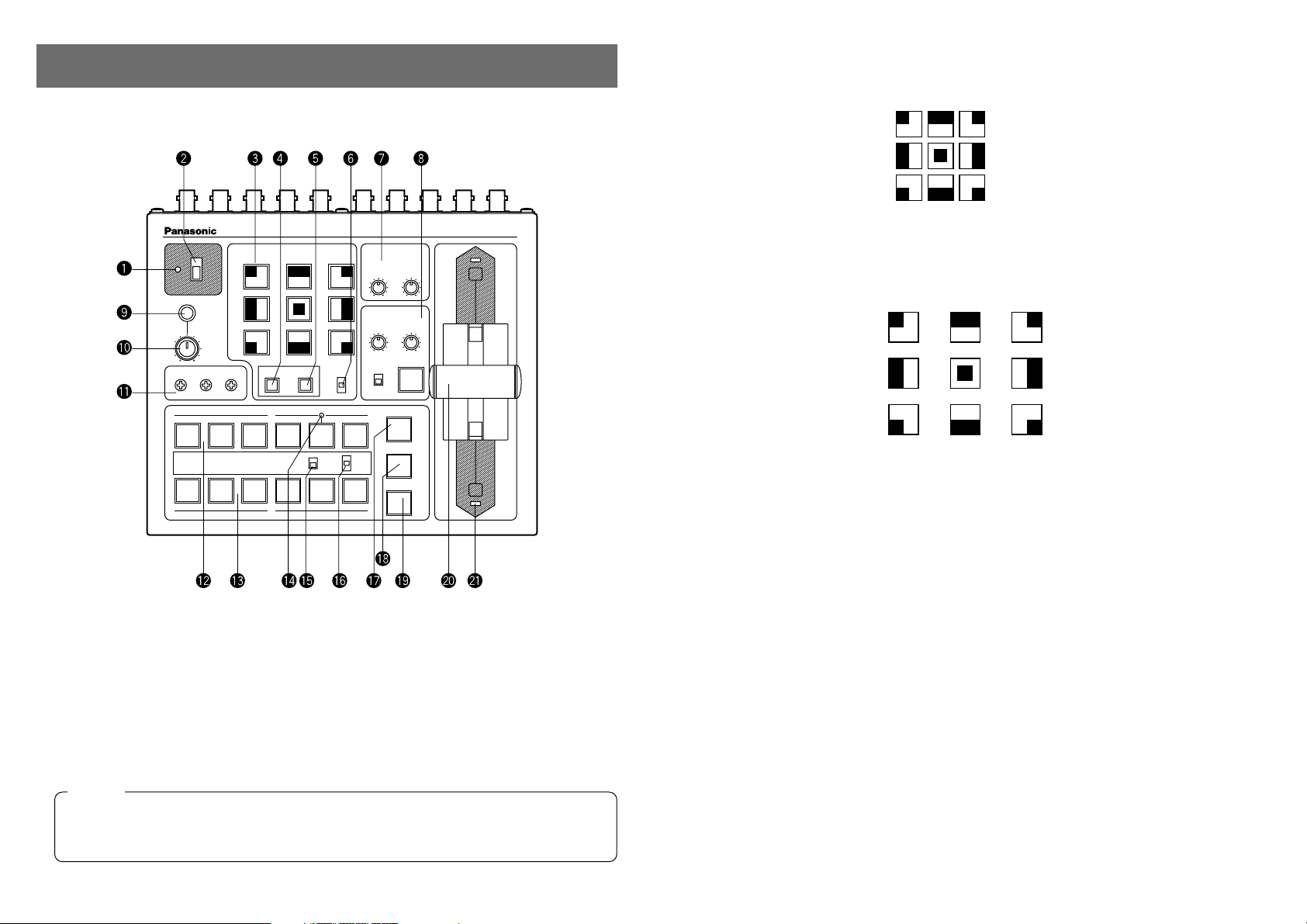

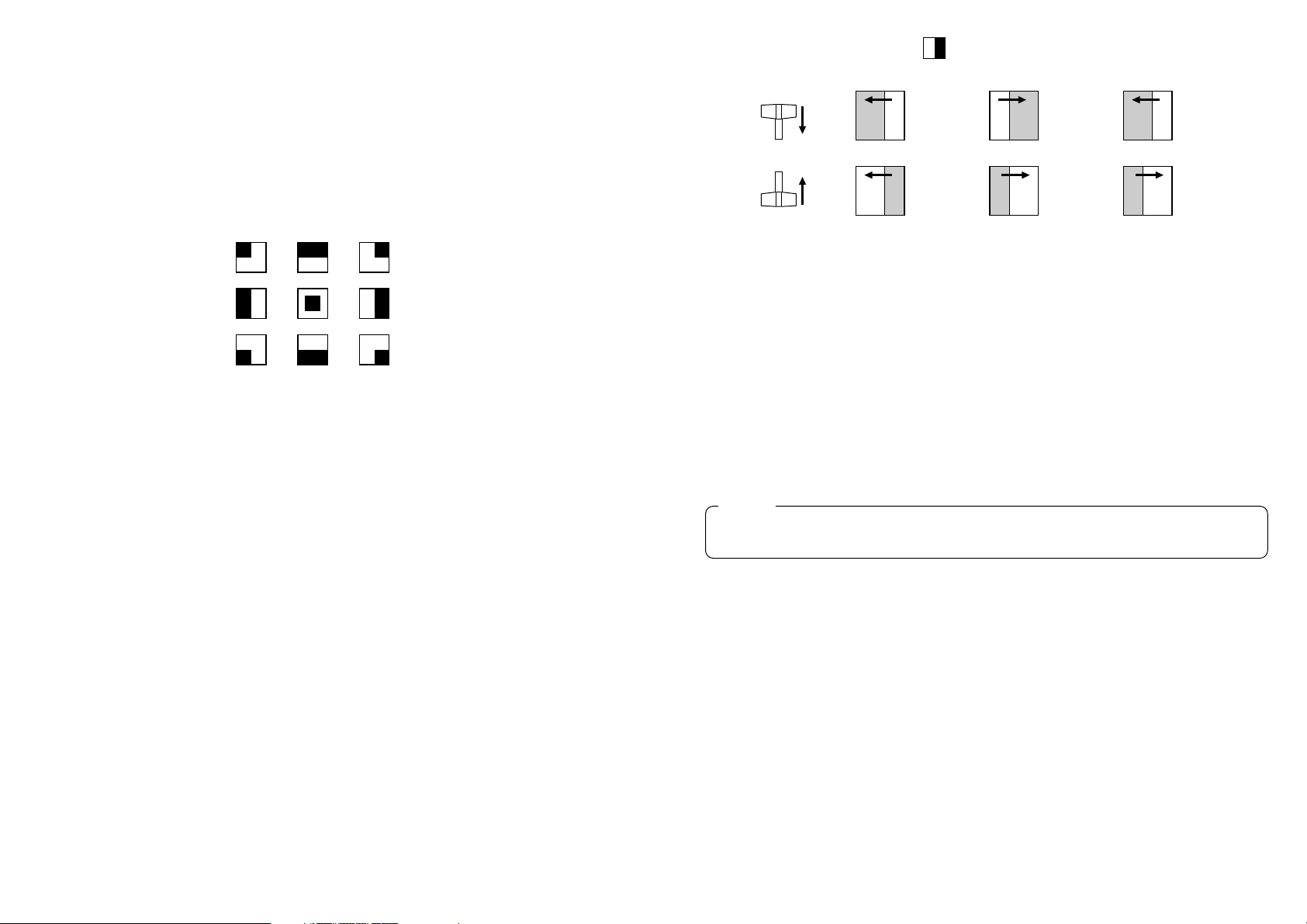

EWipe Pattern Selection Switches [WIPE PATTERN]

To select a wipe pattern after pressing Wipe Switch y. One of the nine patterns can be

selected. The selected switch lights.

RSetting Switch [SETTING]

This functions as the shift key for the wipe patterns. While it is held down, the Wipe Pattern

Selection Switches can select the functions described below. The functions are indicated

with blue characters.

SF0, SF1, SF2: These are used to set the three wipe softness levels.

The minimum softness level is set by SF0 (a hard key), and the maximum

softness level is set by SF2.

MWR: This makes it possible for the user to set the initial statuses of the panel

when the power is turned on.

First, set the statuses of the panel to be recorded. Once the setting has

been performed, keep pressing MWR while holding down the SETTING

switch until the nine switches go off. The recorded statuses will be

reproduced when the power is next turned on.

INT: This is used to restore the initial settings which were established at the

factory.

Keep pressing INT while holding down the SETTING switch until the nine

switches go off. The same statuses as the factory setting statuses will be

established when the power is next turned on.

FRZ: This is used to set the freezing of the Video Input 5 signal to ON or OFF.

When FRZ is pressed while holding down the SETTING switch, the Video

Input 5 signal is frozen. While the signal is frozen, the FRZ w LED lights.

This signal can be used as the source of the VIDEO IN 5 signal.

✽If the freeze function is used while the FS switch is in the OFF position,

only the Video Input 5 signal will be set to the FS ON status.

SF0

MWR

SF1

INT

SF2

FRZ

INV

POWER

INCOM

LEVEL

GEN-LOCK PHASE

WIPE PATTERN

TRANSITION TIME

KEY

SETTING COLOR

WH1

SF0

WH2

SF1

WH3

AUTO TAKE KEY AUTO

A

GAIN

SOURCE

IN5

FMEM

KEY AUTO

CLIP

SF2

YLW

MWR

CYN

INT

GRN

FRZ

MGT RED BLE

N

N / R

R

INV

H

SC

SC FINE

ON

OFF

A

123 4

5

FMEM

BLACK

MIX

FRZ

WIPE

AUTO TAKE

BAR

COLOR

B

B

Live Switcher AW-SW350

Even when the Power Switch is at the OFF position, some of the power supply circuits

are still operating. To turn off the power completely, set the external power adaptor to

OFF.

Cautio

n

Page 6

1110

INV: This is used to invert the polarity of the key signal.

Use the inversion mode when the input is black text on a white base.

When the INV function is used with VIDEO IN 5 selected for the key source

and with the FS switch in the OFF position, only the Video Input 5 signal will

be set to the FS ON status.

TColor Background Color Selector Switch [COLOR]

This functions as the shift key of the Wipe Pattern Selection Switches. While it is pressed,

the Wipe Pattern Selection Switches can select the color to be used for the color

background, as shown below. The functions are indicated with red characters.

WH1: White 100% WH2: White 90% WH3: White 80%

YLW: Yellow CYN: Cyan GRN: Green

MGT: Magenta RED: Red BLE: Blue

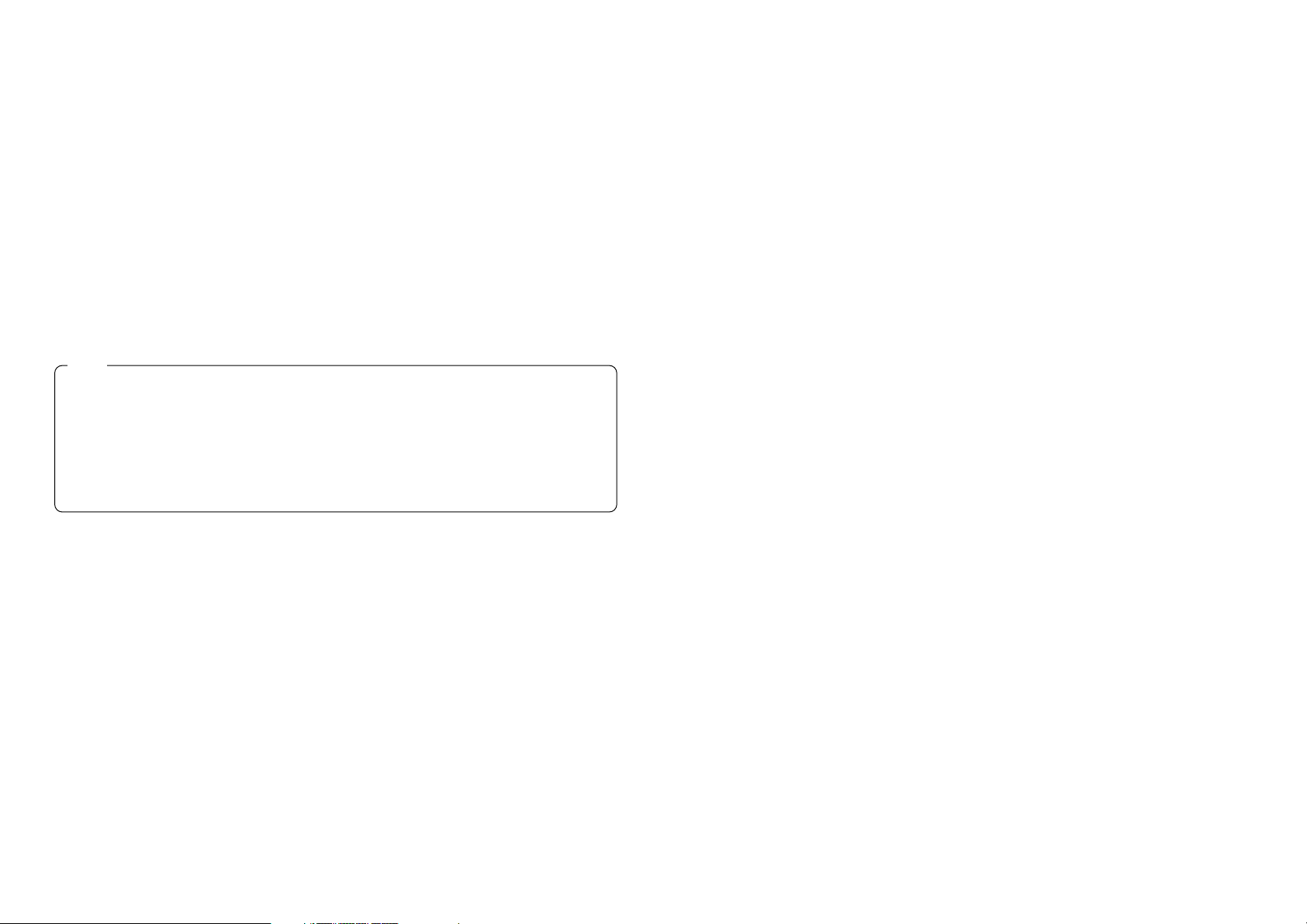

YWipe Direction Selection Switch [N/ N/R/ R]

To select one of the three directions in which to change the signals from A to B or vice

versa on the screen by moving Fader Lever i.

N (Normal):

When Fader Lever i is moved from A to B, the image is switched from the selected

A-bus signal to the selected B-bus signal in the direction of the black to white pattern

shown on Wipe Pattern Selection Switch. Similarly, when Fader Lever i is moved from

B to A, the image on the screen is switched from the selected B-bus signal to the

selected A-bus signal.

R (Reverse):

When Fader Lever i is moved from A to B, the image is switched from the selected

A-bus signal to the selected B-bus signal in the direction of the white to black pattern

shown on Wipe Pattern Selection Switch. Similarly, when Fader Lever i is moved from

B to A, the image on the screen is switched from the selected B-bus signal to the

selected A-bus signal.

N/R (Normal/Reverse):

When Fader Lever i is moved from A to B, the image is switched from the selected

A-bus signal to the selected B-bus signal in the direction of the black to white pattern

shown on Wipe Pattern Selection Switch. When Fader Lever i is moved from B to A,

the image on the screen is switched from the selected B-bus signal to the selected

A-bus signal.

WH1

YLW

WH2

CYN

RED

WH3

GRN

BLEMGT

[Example] Selected wipe pattern

UTransition Time Setting Controls [TRANSITION TIME]

These controls are used to set the transition time during auto fader operations.

AUTO TAKE: This is used to set the transition time of MIX or WIPE when the AUTO

TAKE u Switch has been pressed. Any transition time from 0 to about 10

seconds can be set.

KEY AUTO: This is used to set the transition time when the KEY AUTO I Switch has

been pressed. Any transition time from 0 to about 5 seconds can be set.

Turning either control knob counterclockwise reduces the transition time; conversely,

turning them clockwise increases the transition time. When either control knob is turned

counterclockwise as far as it will go, the transition time is set to 0 seconds, and the cut

operation results. Even when external takes are performed using external switches, the

settings of these controls remain in force. (When a switch has been connected to EXT

TAKE H)

IKey Synthesis Setting Controls [KEY]

These are used to perform the settings relating to key synthesis.

GAIN, CLIP: The AW-SW350 features a linear key system for key synthesis to ensure

smooth synthesis, and these two controls are used to set the synthesis

levels when text and other data are to be synthesized with the key signals.

The CLIP control is for setting the reference level at which the key signals

are to be created, and signals above this level are synthesized. If noise is

present in the background images, set the CLIP level on the high side.

The GAIN control is for raising or lowering the level of the key signals.

Adjust it in such a way that the text, etc. can be synthesized cleanly and

clearly.

[Example of adjustment]

Turn the CLIP control counterclockwise as far as it will go and, while

viewing the screen, adjust the GAIN control to achieve clean and clear

images. Next, adjust the CLIP and GAIN controls alternately to set to the

optimum state.

ABAB

B

A

B

A BA

BA

BA

A

B

Fader lever Normal (N) Reverse (R) Normal/Reverse (N/R)

Before proceeding with auto fader operations, set the transition times in advance using

these controls.

Caution

Page 7

1312

KEY AUTO: This switch is used to set the key synthesis to ON or OFF.

When it is pressed, it lights, and key synthesis is performed for the text, etc.

KEY AUTO U is used to set the transition time for the key synthesis. When

the switch is pressed again, it goes off, and the input signals used for the

key synthesis will be synthesized as they are with the base image but,

depending on the level of the input signals, it may not be possible to

achieve clean and clear images.

SOURCE: This selects whether to use the VIDEO IN 5 signal or image in the frame

memory as the source material for the key synthesis. In terms of the key

signals, use black base level signals, and provide a source with white

characters.

A source with color characters can also be synthesized with a black base

but, depending on the level of the character signals, it may not be possible

to achieve clean and clear images.

(By inverting the polarity of the key signals, images with a white base level

can also be synthesized. For details on key reversal, refer to SETTING R.)

OIntercom Jack [INCOM]

Connect an intercom headset to this terminal. Use the recommended headset (made by

Ashida Onkyo MT-12MFB-03).

PIntercom Volume [INCOM LEVEL]

To adjust the volume of the headset speaker connected to Intercom Jack O. Turning it

counterclockwise decreases the volume, and turning it clockwise increases it.

{Genlock Phase Controls [GEN-LOCK PHASE]

Connect a signal generator or other such instrument to GLIN/BBOUT D, and use these

controls to adjust the phase when genlock is to be initiated. These controls need not be

adjusted when genlock is not going to be initiated.

H: This is used to adjust the horizontal sync phase.

SC: This is used to adjust the subcarrier phase coarsely.

SC FINE: This is used to adjust the subcarrier phase finely.

Adjusting the horizontal phase:

Monitor the waveforms of the genlock signal (black burst signal) and video

signal output using a dual-trace oscilloscope (or waveform monitor), and adjust

the H Control in such a way that the horizontal phase is aligned.

Adjusting the subcarrier phase:

Select the color bars of the switcher. Using the signal generator as a reference,

adjust the SC Control and SC FINE Control to align the color phase. A more

accurate adjustment can be achieved using a vectorscope.

}A-Bus Input Selection Switches

To select A-bus video signals. When a switch is pressed, it lights and indicates that the

corresponding signal is selected.

qB-Bus Input Selection Switches

These are used to select the B-bus video signals. When a switch is pressed, it lights to

indicate that the corresponding signal is selected.

Depending on the operation mode, the switches may light with full or half brightness.

Full brightness: When the selected input is being output to PGM OUT.

Half brightness: When the switch is selected but the selected input is not being output

to PGM OUT.

[Example] When the Fader Lever is at the A-bus side, the A-bus signals are output so that

the A-Bus Input Selection Switches will light with full birghtness, but the B-bus

signals are not output so that B-Bus Input Selection Switches will light with half

brightness.

wFreeze indicator [FRZ]

This LED lights to indicates that the VIDEO IN 5 signal is frozen. Bear in mind that since

the image remains frozen while it is lighted, the switcher output will not change even when

the input signal has changed.

eInput 5/FMEM Selector Switch [FMEM]

This is used to select the signal which has been input to VIDEO IN 5 or the internal frame

memory. When the switcher is used for the first time and the frame memory has been

selected, the factory setting screen is output. By transferring image data from a personal

computer to the frame memory, the images and text created by the user can be output. For

details, refer to the page on which image transfer is described.

rBLACK/COLOR/BAR Selector Switch [BLACK/COLOR/BAR]

This is used to select BLACK (black level signal), COLOR (color background) or BAR (color

bar). When COLOR is selected, one of nine colors can be selected. For details on how to

select the color, refer to the section on “T Color Background Color Selector Switch

[COLOR]”.

A 100% white signal is output at the factory setting.

Follow the procedure below to keep the key synthesis on the PVW screen at the OFF

setting at all times.

1. Press both the SETTING Button R and COLOR Button T at the same time.

2. With the two buttons in step 1 held down, press the KEY AUTO Button.

The KEY AUTO Button lamp now lights.

To turn the key synthesis on the PVW screen back to the ON setting, repeat the same

steps. The KEY AUTO Button lamp will then go off.

Note

Page 8

tMix Switch [MIX]

Press it to switch the signal selected with A-Bus Input Selection Switch } to the signal

selected with B-Bus Input Selection Switch q or vice versa by the mix effect. The switch

lights when MIX is selected.

yWipe Switch [WIPE]

Press it to switch the signal selected with A-Bus Input Selection Switch } to the signal

selected with B-Bus Input Selection Switch q or vice versa by the wipe effect. The switch

lights when WIPE is selected.

uAuto Take Switch [AUTO TAKE]

This switch is used for automatically wiping or mixing instead of performing these

operations manually using the Fader Lever i. This switch becomes operational when the

Fader Lever i is set all the way toward the A or B side, and when it is pressed once, the

wipe or mix operation is performed automatically. The transition time for switching the

signals can be adjusted using the AUTO TAKE U control. While the signals are being

switched, the AUTO TAKE switch lights, and it goes off when the signals are switched

completely. During an auto take operation, no manual operations will be performed even if

the Fader Lever i is moved.

iFader Lever [A/B]

This lever is used to switch the signal selected with A-Bus Input Selection Switch } to the

signal selected with B-Bus Input Selection Switch q or vice versa by the wipe or mix effect.

When the lever is moved from A to B, the video signal is also switched from A to B

accordingly. Similarly, when the lever is moved from B to A, the video signal is switched

from B to A.

oBus Tally Indicators [A], [B]

These indicate the output statuses of the A-bus and B-bus. The [A] or [B] LED lights to

indicate that A-bus or B-bus signals are being output.

[Examples] • [A] lights when the Fader Lever is at the A side since only the A-bus signals

are output.

• Both [A] and [B] light when the Fader Lever is between the A and B sides

since both A-bus and B-bus signals are output.

15

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

1234

5

VIDEO

IN

OUT

Y / C IN

■REAR PANEL

pVideo Signal Input Jacks 1 to 5 [VIDEO IN 1, 2, 3, 4, 5]

These jacks are to input composite video signals. (1 Vp-p, 75-ohm auto-terminated)

There are 5 input jacks corresponding to A-Bus Input Selection Switches } and B-Bus

Input Selection Switches q.

[Video Signal Loopthrough Output Jacks [VIDEO OUT 1, 2, 3, 4, 5]

These loopthrough output jacks are for the composite video signals input to Video Signal

Input Jacks p.

14

In using the Auto Take function, be sure to move Fader Lever i all the way to A or B.

Auto Take will not work unless the lever is fully moved to A or B.

Caution

Bus control based on the flip-flop system is enabled by changing the setting of the bus

selector switch [BUS A/B /F.F.]R which is one of the Setup Switches K. Under the flipflop system, the signals selected by the A-Bus Input Selection Switches } are always

selected as the program (PGM) video signals, and the signals selected by the B-Bus

Input Selection Switches q are always selected as the preview (PVW) video signals.

Furthermore, the PGM signals can be replaced with the PVW signals or vice versa by

means of bus switching using the AUTO TAKE Switch u and Fader Lever i.

Note

If a BNC coaxial cable is connected to Video Signal Loopthrough Output Jack [, the

75-ohm termination is automatically released. Do not connect a BNC coaxial cable to

any of these jacks in case of connecting YC signals to Y/C Signal Input Jack ]. Use

either composite signals or YC signals as video input signals.

Furthermore, when unstable video signals from a VHS format VCR, DVD player or other

device have been input, the frame synchronizer may malfunction.

Caution

Page 9

DGenlock Input/BB Output Connector [GLIN/BBOUT]

In compliance with the setting of the SETUP switch K, either the genlock input or BB

output is selected.

Genlock input: To apply genlock to the switcher, connect this signal to the signal generator

or other device.

BB output: At this position, the BB sync signal is output to apply genlock to a camera or

other input device by synchronizing it to the switcher. In this case, the same

signal as BBOUT F is output.

FBlack Burst Signal Output Connector [BBOUT]

Used to externally synchronize a input device connected to the Live Switcher. When

externally synchronizing two or more devices, distribute the black burst output to them

using a video distributor (VDA).

GY/C Video Output Connector [PGM Y/C OUT]

This connector delivers the Y/C signal video output which has the same function as the

video output signal A.

HAuto Take External Input Jack [EXT TAKE]

Use it for external auto take by applying a contact input. The operation is the same as when

using Auto Take Switch u and Key Auto Switch I.

✽Use an M3.5 stereo single head plug for connection with this unit.

Connect the switches as shown below.

]Y/C Signal Input Jacks [Y/C IN 1, 2, 3, 4, 5]

Connect YC signals to these jacks in using them as video input signals.

AVideo Output Connectors [PGM OUT 1, 2]

Two sets of composite signals (BNC) consisting of the switcher's main output together with

the wipe, mix, key or other effects added are output from these output jacks.

SPreview Output Connector [PVW OUT]

When the switcher is used for live applications, this connector enables the next operation to

be previewed. (LOOK AHEAD PREVIEW)

• While the Fader Lever is at the A-bus side and A-bus signals are output, the B-bus signals

are output to the PVW OUT Connector, and the images can be previewed.

• When the PGM OUT Connectors are in the key OFF status, the PVW OUT Connector is

set to the key ON status and the key synthesis status can be previewed.

The table below shows the correlation between the program output and preview output

statuses.

1716

Do not connect a BNC coaxial cable to Video Signal Input Jack p in case of connecting

YC signals to Y/C Signal Input Jack ]. Use either composite signals or YC signals as

video input signals.

Caution

Bus selection Key ON/OFF

PGM OUT A-bus selected B-bus selected Key ON Key OFF

PVW OUT B-bus output A-bus output Key OFF Key ON

AUTO TAKE

KEY AUTO

Due to what is involved in the signal processing, the Y/C video output G has a phase

which is delayed by 1 line compared with the composite video output A.

Caution

423

1

Pin No. Signal

1Y GND

2 C GND

3Y

4C

Page 10

RBus Selector Switch [BUS A/B /F.F.]

This selects the bus switching system.

A/B: Set here when undertaking bus operations using the A/B bus system.

F.F.: Set here when undertaking bus operations using the flip-flop system.

LDC Power Input Terminal [DC 12V IN]

Apply 12-V DC power. (Use the AC adaptor AW-PS505.)

✽The AW-CA4T1 cable (sold separately) is required.

:Tally/Intercom Connectors [TALLY & INCOM 1, 2, 3, 4, 5]

Use these jacks to connect the Live Switcher to the tally/intercom connectors on a camera

control unit, for example, WV-RC700A or WV-RC550, for tally control and intercom

communication. Tally control is based on open collector output. These connectors are

compatible with either the 3-wire or 4-wire type of intercoms, selectable with Setup

Switch K.

aCord Clamp

Used to clamp the cable connected to the DC power input terminal to prevent its

disconnection. Once remove the screw, pass the cable, and retighten the screw till the

cable is securely clamped.

sGround Terminal [GND]

Connect this to the system frame ground.

JUSB port [USB]

Connect one end of the USB cable to this port and the other end to the personal computer

to transfer the image data created by the personal computer to this switcher. For details,

refer to the page on which image transfer is described.

KSetup switches

These are used to perform the following four settings.

QFrame Sync Switch [FS ON/FF]

This sets the frame synchronizer to ON or OFF.

ON: The asynchronous 5 input signal can be connected. A delay of up to one frame is

generated in the switcher output. Due to what is involved in the signal processing,

the signal band is narrower than at the OFF position.

OFF: The input signal source must be synchronized with the system. Use the switcher's

black burst signal output to apply genlock to the camera or other device. In this

case, perform the phase (horizontal phase, color phase) adjustments for the

genlock at the connected device. In this mode, analog processing is performed

internally, and there is virtually no deterioration in the image quality.

WGenlock input/Black burst output setting [GLIN/BBOUT]

This sets the input or output for the GLIN/BBOUT Connector D.

GLIN: Set here when genlocking the switcher with an external sync signal.

GLIN/BBOUT D now serves as an input connector, and an external sync signal

can be connected.

BBOUT: Set here when configuring a system based on the synchronization to the

switcher. GLIN/BBOUT D now serves as an output connector, and a black

burst signal is output. In this case, the output is the same as the BBOUT F

signal.

EIntercom Switch [INCOM 3/4]

The 3-wire or 4-wire type can be selected by setting the switch to the position appropriate

to your system.

(Set the switch to the 3-wire position if you are using the WV-RC700A or WV-RC550.)

1918

Pin No. Signal

1 MIC+

2 MIC–/COMMON

3 PHONE+

4 PHONE–/COMMON

5 TALLY

6GND

ON BBOUT

OFF GLIN

A/B

F. F.

FS GLIN

/BBOUT

INCOM BUS

3-wire

type

4-wire

type

If you are using other power supply, make sure that it outputs 12 V DC, 2.5 A or more.

The plug has GND on the inside and +12 V outside. (Be careful of the positive and

negative polarities.)

Caution

Positive (+)

Negative (–)

6

4

2

5

3

1

Page 11

2120

The AW-SW350 Live Switcher comes with a function for transferring images from the host

computer using the USB (Universal Serial Bus). The image data transferred from the host

computer can be used as the key input signals or main input signals of the AW-SW350.

When the image transfer function is to be used for the first time, the dedicated device driver

and application program must be installed in the host computer. They can be installed from

the CD-ROM that is supplied with the AW-SW350. For details on how to install them, refer to

“Installing the Device Driver” and “Installing the Application Program”.

■FUNCTIONS

The USB image transfer program used with the AW-SW350 contains the following

functions.

• Frame memory image transfer function (RAM)

• Flash memory image transfer function (ROM)

• Image cutout position designation function

• Image start position designation function

For more details on how to use these functions, refer to “Operation Method”.

■SPECIFICATIONS

In order for the host computer to run the USB image transfer program used with the

AW-SW350, it must satisfy the following system requirements.

Image files in two formats, the bitmap format (bmp) and JPEG format (jpg, jpeg), can be

used with the USB image transfer program for the AW-SW350. Also required separately

when using the image transfer function is the A-B type USB cable for connecting the host

computer with the AW-SW350.

IMAGE TRANSFER FUNCTION

Processor Pentium III, 1 GHz or up recommended

RAM 128 MB or more

Free hard drive memory 50 MB or more

Operating system Windows 98 Second Edition (SE), Windows Me,

Windows 2000, Windows XP

USB port USB Version 1.1 or up

CD-ROM drive Essential

More time is required to transfer the images if the performance of the personal

computer is low-level. The function will not work with versions of Windows that

are not recommended (Windows 3.1, Windows 95, Windows 98, Windows NT4.0

).

Pentium is a registered trademark of Intel Corporation.

Windows, Windows 98, Windows Me, Windows 2000 and Windows XP are

registered trademarks of Microsoft Corporation.

Caution

Page 12

2322

■INSTALLING THE DEVICE DRIVER

This section describes how to install the device driver used with the USB image transfer

program for the AW-SW350. In the example of the procedure given below, Windows XP is

used as the operating system.

Insert the CD-ROM supplied with the AW-SW350 in the CD-ROM drive of the host

computer. (In this example, E: is the drive used.)

Set the AW-SW350's Power Switch to ON, check that the Power Indicator has lighted,

and connect one end of the A-B type USB cable to the USB port on the rear panel of

the AW-SW350 and the other end to the USB port on the host computer. (Fig.1)

When the host computer recognizes the AW-SW350, as shown in Fig.2, the Found

New Hardware Wizard automatically starts up.

3

2

1

When the screen for specifying the driver loading directory appears as shown in Fig.3,

specify the \DRIVER folder of the drive where the CD-ROM supplied with the

AW-SW350 was inserted, and load the driver. (In this example, E: is the drive used.)

When the device driver has been loaded, a screen similar to the one shown in Fig.4

appears. This completes the installation of the device driver.

5

4

Fig.1 Connections

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

1234

5

VIDEO

IN

OUT

Y / C IN

AW-SW350

Windows PC

USB cable

Rear

Fig.2 Found New Hardware Wizard start screen

Fig.3 Driver specification screen

Fig.4 Driver loading completion screen

Page 13

2524

■INSTALLING THE APPLICATION PROGRAM

This section describes how to install the application program used with the USB image

transfer program for the AW-SW350. In the example of the procedure given below,

Windows XP is used as the operating system.

Insert the CD-ROM supplied with the AW-SW350 in the CD-ROM drive of the host

computer. (In this example, E: is the drive used.)

Run the “Microsoft .Net Framework” setup file (E:\JPN\DOTNETFX.EXE).

The installer program shown in Fig.6 now starts. Proceed with the installation by

following the installer instructions.

Run the setup program (E:\JPN\SETUP.EXE).

4

3

2

1

In order to confirm that the device driver has been installed successfully, it is

recommended that you open the Device manager as shown in Fig.5, and check that

“AW-SW USB Device:AW-SW350” is displayed.

6

Fig.5 Device manager screen

Fig.6 Microsoft .Net Framework installer start screen

Page 14

2726

■OPERATION METHOD

This section describes how to operate the application program used with the USB image

transfer program for the AW-SW350.

Connect the host computer to the AW-SW350.

(Check that the AW-SW350's power is on.)

The main screen shown in Fig.9 appears when the application program used with the

USB image transfer program for the AW-SW350 is started up.

When the “Open File” button is clicked, the file selection dialog box shown in Fig.10

appears. Select the image file (BMP, JPG or JPEG) to be transferred, and click “OK”.

3

2

1

The installer program shown in Fig.7 now starts. Proceed with the installation by

following the installer instructions.

This completes the installation of the application program.

6

5

Fig.7 Application program installer start screen

Fig.8 Application program installation completion screen

Fig.9 Application program main screen

Fig.10 File selection dialog box

Page 15

2928

When the target image appears in the image display area, specify the start or cutout

position of the image. Which position is to be specified is determined by the number of

pixels in the image file.

• No. of pixels that can be displayed: 720 (H) x 487 (V)

• When the file is smaller than the number of pixels that can be displayed:

The spaces around the image are displayed in black. Move the image to the position

where it is to be displayed.

• When the file is larger than the number of pixels that can be displayed:

The frame outlining what can be displayed appears. Move the frame to the position

where the image to be displayed is framed.

<When the image is smaller than the number of pixels that can be displayed>

Drag the image displayed in the screen display area and drop it to change its

position. (Fig.11)

4

<When the image is larger than the number of pixels that can be displayed>

Drag the frame displayed in the screen display area and drop it to change the cutout

position. (Fig.12)

specify the

start position

of the image

AW-SW350

program output

Fig.11 Specifying the image start position

specify the

cutout position

of the image

AW-SW350

program output

Fig.12 Specifying the image cutout position

Page 16

3130

Click the “RAM” radio button or “RAM+ROM” radio button to select the type of memory

in which the data will be saved. (Fig.13) If “RAM” is selected, the image data is saved

only in the frame memory and so it cannot be used after the AW-SW350 power has

been turned off and back on again. If “RAM+ROM” is selected, the image data is saved

in the flash memory and so it can be used after the AW-SW350 power has been turned

off and back on again. However, the actual transfer takes longer than when “RAM” is

selected.

Click the “Write USB” button to start transferring the image data. After the completion

of the transfer, monitor the AW-SW350's PGM output and check that the image data

has been transferred. (Fig.14)

6

5

— When images could not be transferred —

If an error resulted or images could not be transferred because a cable was connected or

disconnected, turn off the switcher's power and exit the application program. Then turn the

switcher's power back on again and start up the application again.

Status after power has been turned off and back on again

Transfer time

RAM Transferred image data cannot be used Approx. 10 sec.

RAM+ROM Transferred image data can be used Approx. 60 sec.

✽The transfer times given in the above table are approximations only. The actual time

taken will depend on the performance of the host computer.

Fig.13 Memory selection

Click the

button

AW-SW350

program output

Fig.14 PGM check

Page 17

3332

■CONNECTION FOR EXTERNAL SYNCHRONIZATION

(Frame Synchronizer OFF)

●Adjust the horizontal and color phases of the cameras.

(Read the manual for the camera.)

■CONNECTION WITHOUT EXTERNAL SYNCHRONIZATION

(Frame Synchronizer ON)

CONNECTIONS

●For installation and connection, be sure to ask the store where you purchased the product.

●Before making any connection, switch off all the components of the system.

●Carefully read the manuals for the individual devices connected to the Live Switcher.

●Use coaxial cable to connect video and genlock signals.

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

12345

VIDEO

IN

OUT

Y / C IN

PVW OUT

AW-SW350

Convertible Camera AW —

E600

Convertible Camera AW —

E600

Convertible Camera AW —

E600

PGM OUT

VIDEO OUT

VIDEO OUT

Convertible Camera AW —

E600

VIDEO OUT

Camera

Color monitors

Camera or character

generator for key

synthesis

Signal

generator

✽

When a signal

generator is used to

generate the

reference signals

for the system

AC adaptor

AW-PS505

Q

FS switch [ON]

W

GLIN/BBOUT switch [GLIN]

VCR, etc.

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

12345

VIDEO

IN

OUT

Y / C IN

AW-SW350

Convertible Camera AW —

E600

Convertible Camera AW —

E600

Convertible Camera AW —

E600

1

2

3

1

2

3

OUTPUT BOUTPUT A

INPUT

THR SEP

75Ω HI-Z

B

A

PVW OUT PGM OUT

VIDEO OUT

G/L IN

VIDEO OUT

OUTPUT

INPUT

G/L IN

G/L IN

Convertible Camera AW —

E600

VIDEO OUT

Camera

Color monitors

Camera or character

generator for key

synthesis

Video distributor

WJ-300C

AC adaptor

AW-PS505

Q

FS switch [OFF]

W

GLIN/BBOUT switch [BBOUT]

VCR, etc.

When unstable video signals,

such as those from a VCR, are

being used for the input signals,

the internal frame synchronizer

may not operate correctly.

Caution

Page 18

3534

■CONNECTION TO PERSONAL COMPUTER

Windows PC

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

12345

VIDEO

IN

OUT

Y / C IN

AW-SW350

Convertible Camera AW —

E600

Convertible Camera AW —

E600

Convertible Camera AW —

E600

OUT

VIDEO OUT

VIDEO OUT

Convertible Camera AW —

E600

VIDEO OUT

These switches operate whether the FS

switch is in the ON or OFF position.

Color monitors

Connected with

USB cable

AC adaptor

AW-PS505

VCR, etc.

Camera or character

generator for key

synthesis

Camera

Page 19

3736

■EXAMPLE FOR THE CONNECTION WITH PAN/TILT HEADS

AND CONTROL PANEL

●The cameras can be locally controlled by using the pan/tilt head AW-PH300A,

multi-hybrid control panel AW-RP505, and multi-port hub AW-HB505.

TALLY

DC12V IN

AUX CONTROL IN

1234

5

PREVIEW INOUT G/L OUT

PREVIEW MONITOR OUT

CONTROL CONTROL OUT

PAN/TILT CAMERA

TD MULTI PORT HUB

G / L IN

VIDEO OUT 1-4

G/L IN

G/L OUT

CAMERA

CONTROL OUT

CAMERA

CONTROL IN

VIDEO OUT

PAM/TILT

CONTROL OUT

PAM/TILT

CONTROL IN

S-VIDEO OUT

VIDEO

IN

G/L

OUT

G/L

IN

CAMERA

CONTROL OUT

VIDEO OUT

PAM/TILT

CONTROL OUT

S-VIDEO OUT

VIDEO

IN

G/L

OUT

CAMERA

CONTROL OUT

VIDEO OUT

PAM/TILT

CONTROL OUT

S-VIDEO OUT

VIDEO

IN

G/L

OUT

CAMERA

CONTROL OUT

VIDEO OUT

PAM/TI LT

CONTROL OUT

S-VIDEO OUT

VIDEO

IN

G/L

OUT

CAMERA

CONTROL OUT

VIDEO OUT

PAM/TI LT

CONTROL OUT

S-VIDEO OUT

VIDEO

IN

G/L

OUT

4 3 2 15

DC12V IN

TO CAMERA PAM/TILT HEAD TO CONTROL PANEL

PREVIEW OUT

SEE MANUAL

Pan/tilt head

cameras 1 to 4

To pan/tilt head AW-PH300A,

Camera AW-E300/E600/E800A

Multi-port hub

AW-HB505

Multi-hybrid control panel

AW-RP505

AC adaptor

AW-PS301

AC adaptor

AW-PS505

Preview monitor

The FS switch may be in either the ON or OFF position.

If high picture quality is desired, set the FS switch to OFF and

adjust each camera for horizontal and color phases.

(Refer to the instruction manual for the camera.)

BBOUT

GLIN

/BBOUT

PVW

OUT

TALLY & INCOM

PGM OUT

2

54

DC 12V IN

SET UP

USB

EXT

TAKE

PGM

Y / C

OUT

1342

GND

321

1 1

75Ω

AUTO

2345

1234

5

VIDEO

IN

OUT

Y / C IN

AW-SW350

Convertible Camera AW —

E600

Convertible Camera AW —

E600

Convertible Camera AW —

E600

VIDEO IN 1-4

PVW OUT

PGM OUT

Convertible Camera AW —

E600

VIDEO OUT

G/L IN

VCR, etc.

AC adaptor

AW-PS505

Camera or character

generator for key

synthesis

Color monitors

Page 20

3938

RACK MOUNTING

■RACK MOUNTING

●Do not mount the Live Switcher on a closed rack or bookshelf.

(Otherwise, heat will build up inside and may cause a fire.)

●Keep the ventilation port open to secure good flow of air.

POW

ER

IN

C

O

M

L

E

V

E

L

G

E

N

-L

O

C

K

P

H

A

S

E

WIPE PATTERN

T

R

A

N

S

I

T

IO

N

T

I

M

E

K

EY

S

E

T

T

IN

G

COLOR

W

H

1

S

F

0

W

H

2

S

F

1

W

H

3

AUTO TAKE

KEY AUTO

A

G

A

I

N

S

O

U

R

C

E

I

N

5

F

M

E

M

K

E

Y

A

U

T

O

C

L

I

P

S

F

2

Y

L

W

M

W

R

C

Y

N

I

N

T

G

R

N

F

R

Z

M

G

T

R

E

DB

L

E

N

N

/

R

R

I

N

V

H

S

C

S

C

F

IN

E

ON

O

F

F

A

1

2

3

4

5

F

M

E

M

B

L

A

C

K

W

I

P

E

A

U

T

O

T

A

K

E

B

A

R

C

O

L

O

R

B

B

M

IX

F

R

Z

Rack mounting parts

Mounting

screw

Mounting

screw

Holes for

connecting plate

(Bottom)

Connecting

plate

INFORMATION RELATED TO SYSTEM UPGRADES

(1) Switcher phases

1) Video signal output phase (frame synchronizer is OFF)

2) Video signal input phase (frame synchronizer is ON)

3) Genlock adjustment range

(2) TALLY & INCOM connectors

Use a Mini DIN type 6-pin connector for tally and intercom connections.

(e.g.) TCP8060-01-520 manufactured by Hosiden Corporation

BB phase

Video signal input phase

Video signal output phase Approx. 50nS

Input phase range

max. of 1 frame

BB phase

Approx. 3µS

Approx.

1µS

BB phase

Page 21

4140

SPECIFICATIONS/STANDARD ACCESSORIES

■SPECIFICATIONS

Video Inputs

Composite video signal: VBS: 1.0 V[p-p]/75 Ω!5 (BNC connector, automatic

termination)

Y/C: Y: 1.0 V[p-p]/75 Ω

C: 0.286 V[p-p]/75 Ω!5 (S connector)

Video Outputs

Composite video output: VBS: 1.0 V[p-p]/75 Ω!2 (BNC connector)

Y/C: Y: 1.0 V[p-p]/75 Ω!1

C: 0.286 V[p-p]/75 Ω!1 (S connector)

Preview output: VBS: 1.0 V[p-p]/75 Ω!1 (BNC connector)

Black burst signal: BBS: Sync: 0.286 V[p-p], C: 0.286 V[p-p] burst level/

75 Ω!1 (BNC connector)

Signal loopthrough output: 1 each (BNC connector)

Functions and Performance

Frame synchronizer: 10 bit quantization, 13.5MHz sampling

Mounted to each channel of VIDEO IN 1 to 5.

Wipe patterns: 9 patterns

Wipe directions: 3 directions (normal, reverse, normal/reverse)

Mix: Cross fader

Auto take: Wipe, Mix (time adjustable)

Key synthesis: Self Key, Linear Key

Intercom: 1 to 5 (6-pin connector, 3/4 wire selectable),

Intercom jack (M6 jack)

Tally control: 1 to 5 (open collector output)

Color bar: Internal (SMPTE, Black/Color selectable)

White and black signals: Internal

Frequency response: FS ON: 6.0MHz +1 dB, –3dB

FS OFF: 10.0MHz +1 dB, –3dB

S/N: FS ON: More than 58 dB

FS OFF: More than 65 dB

DG/DP: FS ON: ±2°, ±2%

FS OFF: ±1.5°, ±1.5%

Operating temperature range: 32˚F to 104˚F (0˚C to 40˚C)

Humidity: 30% to 90%

Dimensions (W!H!D): 8-1/4”!3-7/16”!6-15/16” (210!86!176 mm)

Weight: Approx. 4.9 lb (2.2 kg)

Finish: AV ivory painting (Munsell 7.9Y6.8/0.8 or close to it)

Weight and dimensions indicated are approximate.

Specifications are subject to change without notice.

■STANDARD ACCESSORIES

Tally/intercom connector .............................................................................................. 5 pcs.

Rack mounting parts ..................................................................................................... 2 pcs.

Connecting plate ............................................................................................................ 1 pc.

Mounting screws ............................................................................................................ 1 set

Image transfer program setup CD .................................................................................. 1 pc.

indicates safety information.

Power supply: 12 V DC (+10.8 ~ 16.0V)

Power consumption: 16 W

Page 22

4342

Memo

Page 23

PANASONIC BROADCAST & TELEVISION SYSTEMS COMPANY

DIVISION OF MATSUSHITA ELECTRIC CORPORATION OF AMERICA

Executive Office:

3330 Cahuenga Blvd W., Los Angeles, CA 90068 (323) 436-3500

EASTERN ZONE:

One Panasonic Way 4E-7, Secaucus, NJ 07094 (201) 348-7621

Southeast Region:

1225 Northbrook Parkway, Ste 1-160, Suwanee, GA 30024 (770) 338-6835

Central Region:

1707 N Randall Road E1-C-1, Elgin, IL 60123 (847) 468-5200

WESTERN ZONE:

3330 Cahuenga Blvd W., Los Angeles, CA 90068 (323) 436-3500

Government Marketing Department:

52 West Gude Drive, Rockville, MD 20850 (301) 738-3840

Broadcast PARTS INFORMATION & ORDERING:

9:00 a.m.–5:00 p.m. (EST) (800) 334-4881/24 Hr. Fax (800) 334-4880

Emergency after hour parts orders (800) 334-4881

TECHNICAL SUPPORT:

Emergency 24 Hour Service (800) 222-0741

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3 (905) 624-5010

Panasonic de Mexico S.A. de C.V.

Av angel Urraza Num. 1209 Col. de Valle 03100 Mexico, D.F. (52) 1 951 2127

Panasonic Sales Company

Division of Matsushita Electric of Puerto Rico Inc.

San Gabriel Industrial Park, 65th Infantry Ave., Km. 9.5, Carolina, Puerto Rico 00630 (787) 750-4300

Printed in Japan

VQT0D92 F0303S0

P

D

Loading...

Loading...