Page 1

SX-80SX-80

SX-80

SX-80SX-80

SX-80 Sodr-X-Tractor Handpiece

Operation & Maintenance InstructionsOperation & Maintenance Instructions

Operation & Maintenance Instructions

Operation & Maintenance InstructionsOperation & Maintenance Instructions

Page 2

SX-80SX-80

SX-80

SX-80SX-80

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of PACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

ARM-EVAC, FLO-D-SODR, MINI-WAVE, PACE, SENSATEMP, SNAP-VAC,

SODRTEK, SODR-X-TRACTOR, THERMOFLO, THERMOJET,

THERMOTWEEZ, TOOLNET, VISIFILTER

For any questions regarding this Operation & Maintenance Manual, contact your

local authorized PACE distributor or contact PACE directly at the appropriate address

listed below.

PACE USA 9893 Brewers Court

Laurel, Maryland 20723-1990

Tel.: (301)490-9860

(888)535-7223 (PACE)

Fax: (301)498-3252

PACE EUROPE Sherbourne House, Sherbourne Drive

Tilbrook, Milton Keynes,

MK7 8HX

United Kingdom

Tel.: (44)1908 277666 Fax: (44)1908 277777

or

www.paceworldwide.com

2000 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

2

Page 3

SX-80SX-80

SX-80

SX-80SX-80

SX-80

Sodr-X-Tractor Handpiece

Part Number 6010-0106

Manual Number 5050-0492

Rev. C

The following instructions detail the basic operational guidelines for using the

SX-80 Sodr-X-Tractor handpiece.

Introduction

The SX-80 Sodr-X-Tractor handpiece provides thermally enhanced through-hole

desoldering on extra heavy multilayer assemblies at safer, lower temperatures, even

during continuous use. It features a large, easy to replace solder trap. The SX-80

also provides safe removal of TQFP (Thin Quad FlatPack) and TSOP (Thin Small

Outline Package) surface mount components and continuous removal of old solder

from surface mount lands. Its slim-line, pencil grip design and finger actuated

vacuum switch facilitates ease of use and manipulation in tight places. The SX-80 is

a member of the PACE SensaTemp family of advanced handpieces.

CAUTION

Always return heated handpieces to the appropriate Tip & Tool Stand when not in

use. Failure to do so may cause burns to the operator, equipment or work surfaces

and may be a potential ignition source if combustible materials are nearby. Always

use this handpiece in a well ventilated area to avoid inhalation of fumes created by

solder flux.

NOTE

Always use your SX-80 Sodr-X-Tractor with a clean VisiFilter (See page 6) element.

Otherwise a deterioration in performance or damage to the unit may occur.

Select and enter your desired true operating temperature on your PACE power source.

To save tip life and reduce the possibility of damage, PACE recommends using the

lowest possible tip temperature that will provide rapid yet controllable melt of the

entire solder joint to be extracted. Begin with an operating temperature in the range

of 316°C (600°F) and adjust as necessary.

3

Page 4

SX-80SX-80

SX-80

SX-80SX-80

Handpiece Setup

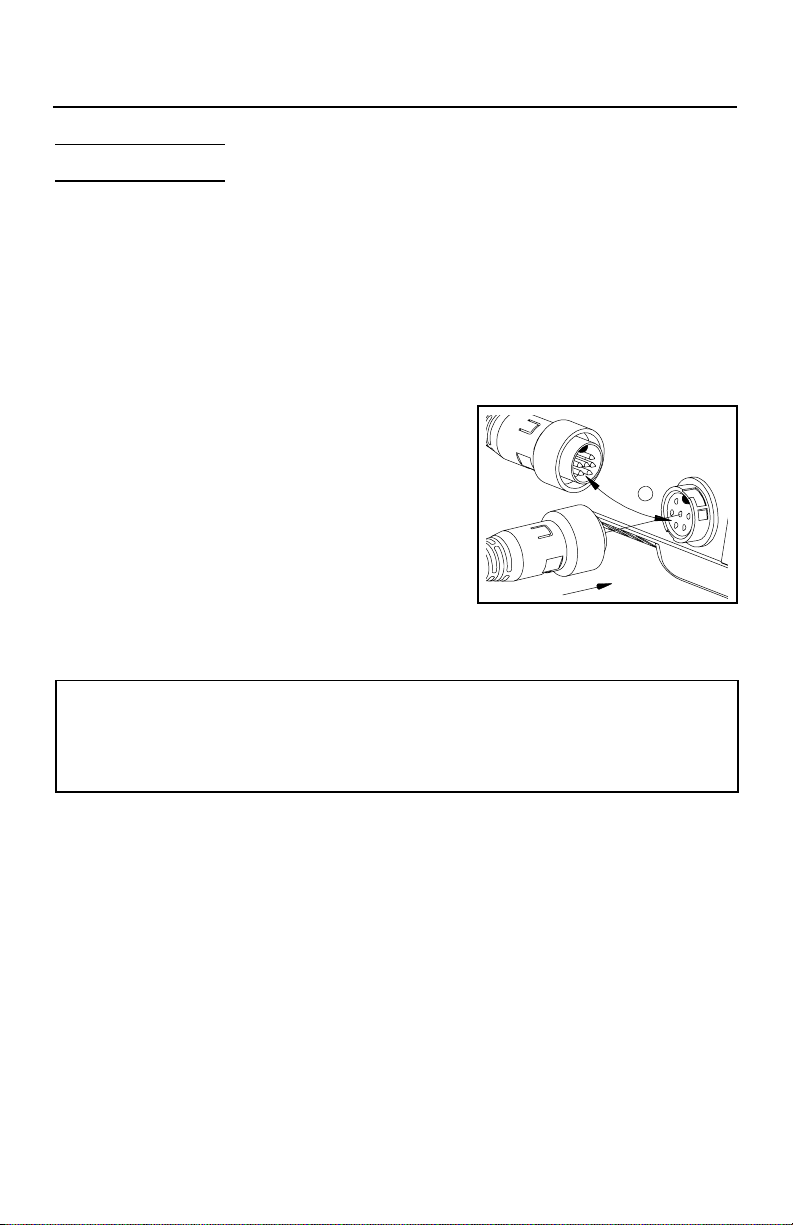

Handpiece Connection

Connect the handpiece connector plug into one of the Power Receptacles on your

PACE power source in the following manner.

1. Align guide on connector with slot on power

receptacle.

2. Insert connector into power receptacle.

3. Turn the connector housing clockwise to

lock in place.

Air Hose Connection

NOTE

Insure that only one air handpiece is connected to either the Vacuum Port or

Controllable PRESSURE Port at one time. Attachment to both ports

simultaneously will cause a deterioration of performance.

To set up your SX-80 air hose connection, perform the following steps:

1. Air Hose To Handpiece Connection

a) Attach one end of a 137cm (54 inch) length of air hose to the metal

tube in the back of the handpiece.

b) If you have a PACE system incorporating only one handpiece, attach

the air hose to the SX-80 power cable using the supplied Hose Clamps

(P/N 1321-0085-01). Space them evenly along the length of the power

cable starting at a point 6 inches from the ends of the handpiece.

c) If you have a PACE system incorporating 2 or more air handpieces

(e.g., SX-80, DTP-80, TJ-70, TP-65), you may wish to leave the air hose

assembly unattached to allow a quick change to any air handpiece

being used.

4

Page 5

SX-80SX-80

SX-80

SX-80SX-80

2. Prepare a VisiFilter (P/N 1309-0028) in the following manner:

a) Connect a 1 inch (2.5cm) length of clear

pvc air hose to the FLOW OUT side of

the VisiFilter; push and turn the hose

onto the VisiFilter nipple to seat.

b) Insert the ribbed end of a male quick

connect hose mount fitting (P/N 1259-

0087) into the free end of the 1 inch

(2.5cm) length of air hose connected to

the FLOW OUT side of the VisiFilter.

c) Connect the free end of the 137cm (54

inch) length of air hose to the FLOW

IN side of the VisiFilter.

d) Insert the end of the quick connect

hose mount fitting (on VisiFilter FLOW

OUT side) into the power source

Vacuum Port.

3. When using air pressure, and/or utilizing multiple air handpieces, PACE

recommends the use of the following set up procedure which utilizes

additional quick connect hose mount fittings. An assortment of quick

connect air fittings are supplied with each additional air handpiece.

a) Disconnect the 137cm (54 inch) length of air hose from the FLOW IN

side of the VisiFilter assembly. Insert the ribbed end of a male quick

connect hose mount fitting (P/N 1259-0087) into the free end of this air

hose.

b) Connect the free end of a 1 inch (2.5cm) length of air hose with an

installed female quick connect hose mount fitting (P/N 1259-0086) to

the FLOW IN side of the VisiFilter Assembly.

c) The 137cm (54 inch) length of air hose can now be easily moved

between the VisiFilter Assembly and the Controllable Pressure Port.

The VisiFilter assembly remains connected to the Vacuum Port.

4. Additional fittings may also be added to the hose connection at the rear of

each air handpiece to ease changing of handpieces.

NOTE

When removing any air hose, turn and pull. Do not attempt to pull hose directly off.

Damage to or breakage of fitting or VisiFilter may occur. Use your SX-80 Sodr-XTractor with a clean VisiFilter element. Otherwise a deterioration in performance or

damage to the unit may occur.

5

Page 6

SX-80SX-80

SX-80

SX-80SX-80

Tip Selection

SX-80 Sodr-X-Tractor Tips come in three basic types:

1. Endura Desoldering Tips - These tips are tinnable and provide enhanced

thermal performance for thru-hole desoldering on high mass boards.

2. Endura Pik-Tips - Provides safe removal of TQFP (Thin Quad FlatPack)

and TSOP (Thin Small Outline Package) surface mount components.

3. Endura Flo-D-Sodr Tips - These tips provide rapid, continuous extraction

of old or excess solder from SMT lands.

Size selection of tips is important. For thru-hole desoldering, select a tip with an I.D.

just large enough to allow the lead to freely pass inside. The tip O.D. should not

exceed the diameter of the land to minimize risk of damage to the board substrate.

When removing TQFPs or TSOPs, the Pik-Tip should be sized so that the tip blades

make proper contact with all the lead/land connections simultaneously.

NOTE

The SX-80 Sodr-X-Tractor will only use the new Endura line of desoldering tips.

Tip Installation

For maximum productivity and proper fit, install tips into your SX-80 Sodr-X-Tractor

when the heater is hot and the Flux/Sodr trap and door are installed.

CAUTION

Hold the handpiece with the heater pointed at an

angle up to prevent injury to personnel.

1. Insert the Tip fully into heater bore using

supplied Tip Tool.

2. Gently tighten the Heater Set Screw.

3. Recheck the Heater Set Screw periodically to insure that it remains snug.

NOTE

Periodically, clean the heater bore with a properly sized wire brush (3/16" O.D.) to

insure optimum heat transfer and proper tip grounding.

6

Page 7

SX-80SX-80

SX-80

SX-80SX-80

Temperature Setting

To save tip life and reduce the possibility of damage to the PCB, PACE recommends

using the lowest possible tip temperature that will provide rapid yet controllable melt

of the entire solder joint. Begin with an operating temperature of 316°C (600°F) and

adjust as necessary. Tip temperatures in excess of 399°C (750°F) may cause damage.

For safest removal, some components on extra heavy assemblies may require

preheating or auxiliary heating.

Tip Cleaning

During heavy, continuous desoldering, on boards with flux residues or other

contamination, the tip may occasionally become clogged with such material. If

this should occur, clean the tip with the Tip Cleaning Kit (PACE part number

6993-0200) by inserting the wire tool into the tip end.

Special Applications

If you require assistance in the use of this handpiece or with a special application,

contact PACE Technical Support at:

Telephone: 1(888)535-7223 (toll-free)

Fax: (301)604 - 8782

7

Page 8

SX-80SX-80

SX-80

SX-80SX-80

Replacing the Disposable Flux/Sodr Trap

As the Sodr-X-Tractor is used, solder and flux build-up will begin to impede the

airflow and decrease system performance. The SX-80 utilizes a disposable chamber

which makes maintenance of the SX-80 a quick and simple process. Regular

replacement of the Sodr-Flux Trap will keep the Sodr-X-Tractor operating at peak

performance. To replace the Sodr-Flux Trap follow the procedures outlined below.

1) While holding the Sodr-X-Tractor with the tip facing away from you and the

handpiece in an downward

position, remove the door

assembly from the handpiece.

This action is accomplished by

pulling the plunger lock

approximately ¼” and turning it

approximately ten (10) degrees to

the right or left. The door

assembly can now be removed by

simply gripping the door near the

ear shaped protrusions and lifting

straight up.

2) Replace the disposable chamber by holding the door assembly in the palm of

your hand with the filter assembly facing up. With your free hand use a fresh

solder chamber with the arrows facing away to push the spent chamber out of

the door assembly and into a waste receptacle. The fresh chamber is now in

position and ready for reassembly.

CAUTION

The handpiece will not function properly if the chamber is inserted incorrectly. The

directional arrows on the solder chamber must be pointed at the heater.

3) Complete the process by lowering the door into the handle assembly. Insure that

the door is properly situated with the ears seated in their respective detents.

Now return the plunger assembly to its locked position by simply twisting the

plunger lock mechanism so that it returns to the channels in the handle assembly.

4) Insure that the door assembly is securely in place by attempting to lift the door

from the handle assembly. It should now be held firmly in place.

5) Check all air hose fittings. Actuate the vacuum and insure that proper vacuum is

present at the tip.

6) Return the handpiece to the cubby or resume work as required.

8

Page 9

SX-80SX-80

SX-80

SX-80SX-80

Heater Replacement

NOTE

Confirm that the heater assembly of your handpiece is defective by referring to the

Corrective Maintenance section of the manual.

9

Page 10

SX-80SX-80

SX-80

SX-80SX-80

Corrective Maintenance

Your SX-80 requires no special maintenance other than being kept clean. The heater

bore and the heater assembly set screw which secures the tip must be kept free of

oxidation and debris in order to maintain the proper tip-to-ground resistance.

Refer to the Handpiece Connector Plug pin out illustration and the table below for

information on troubleshooting most handpiece problems. Disconnect the

handpiece from the Power Source and perform the "Heater Assembly Checkout

Procedures" with the handpiece (and heater) at room temperature. Use a meter to

check resistance across the Handpiece Connector Plug pins as outlined in the

"Checkout Procedure" column.

Handpiece Connector Plug

Symptom Checkout Procedure Cause Solution

No heat Check resistance - Pin 2 to Pin 5.

Handpiece

overheating

Fuse blows

when unit is

turned on

No Ground

on Tip

Resistance should be 8.2 to

9.5 ohms. If not - -

Check resistance - Pin 3 to Pin 6.

If circuit reads open - -

Check resistance - Pin 3 to Pin 6.

Resistance should be 110 ohms. If

circuit reads less than 105 ohms - -

Check resistance - Pin 2 to Pin 5.

Resistance should be 8.2 to

9.5 ohms. If not - -

Check resistance - Pin 4 to a NEW

Tip. Resistance should be less than

2 ohms. If not - -

Open Heater Replace Heater

Open Sensor Replace Heater

Shorted Sensor Replace Heater

Shorted Heater

Replace Heater

Assembly

Oxidation buildup

in Heater Bore

Defective Heater Replace Heater

Clean Heater Bore

using appropriate

wire brush

Heater Assembly Checkout Procedures

10

Page 11

Replacement Parts

SX-80SX-80

SX-80

SX-80SX-80

3

6

9

10

9

11

1

8

9

7

12

4

2

SX-80 Exploded Diagram

Ref # Description Part #

1 Flux/Sodr Trap 1309-0054-P100

1309-0054-P1000

2 Handle Assembly 6010-0115-P1

3 Door Assembly 1119-0141-P1

4 Heater Assembly 6010-0107-P1

5 Plunger Shaft 1261-0154-P1

6 Plunger Lock 1500-0063-P1

7 Front Seal 1213-0087-P1

8 Rear Seal 1213-0086-P1

5

9 “C” Clips 1348-0387-P1

10 Spring (Long Side) 1221-0136-P1

11 Spring (Short Side) 1221-0137-P1

12 Door Lock 1119-0142-P1

Heater Assembly Replacement Part Numbers

11

Loading...

Loading...