Page 1

Operation and Maintenance Manual for the

®

SODRTEK

Radiant Pre-Heating System

P/N 5050-0540

ST 400

Page 2

TITLE PAGE

General Information .......................................................................................................3

Introduction...........................................................................................................3

Specifications .......................................................................................................3

Physical Parameters ............................................................................................3

Parts Identification................................................................................................4

Safety.............................................................................................................................5

Safety Guidelines.................................................................................................5

Preheating Basics..........................................................................................................5

System Power Up ..........................................................................................................6

Operation........................................................................................................................6

LED Operation......................................................................................................6

Variable Temperature Control..............................................................................7

Corrective Maintenance.................................................................................................7

General Maintenance...........................................................................................7

Heater Replacement ............................................................................................7

Power Source......................................................................................................12

Packing List...................................................................................................................12

Spare Parts...................................................................................................................12

Service ..........................................................................................................................12

“SODRTEK by PACE” LIMITED WARRANTY STATEMENT.......................................13

Contact Information.......................................................................................................14

©2004 PACE Inc., Annapolis Junction, Maryland Page 2 of 14

All Rights Reserved

Page 3

General Information

Introduction

Thank you for purchasing the PACE SODRTEK

®

model ST 400 Radiant Pre-Heating System. This

manual will provide you with the information necessary to properly set up, operate and maintain the

ST 400. Please read this manual thoroughly before using the unit.

The ST 400 unit is available in either the 115 VAC or 230 VAC version. The 115 VAC version system

bears the FCC Conformity Marking which assures the user that it conforms to all the requirements of

FCC Emission Control Standard, Title 47, Subpart B, Class A. The 230 VAC version system bears

the CE Conformity Marking which assures the user that it conforms to all the requirements of (EU)

directive EMC 89/336/EEC & 73/23/EEC.

Specifications

ST 400 - Operates on 97-127 VAC, 60 Hz (115 VAC version)

405 Watts maximum at 120 VAC, 60 Hz

ST 400E - Operates on 197-264 VAC, 50 Hz (230 VAC version)

405 Watts maximum at 230 VAC, 50 Hz

Heater Type: Radiant, 400 Watt (200 W x 2), closed loop, thermo-couple control

Temperature: 100 ºF (37.78 ºC) – 400 ºF (204.44 ºC) Range

Physical Parameters

Dimensions: 7” (17.78 cm) W x 4.1” (10.41 cm) H x 12.5” (31.75 cm) D

Unit Weight: 4.9 pounds (2.2 kg)

©2004 PACE Inc., Annapolis Junction, Maryland Page 3 of 14

All Rights Reserved

Page 4

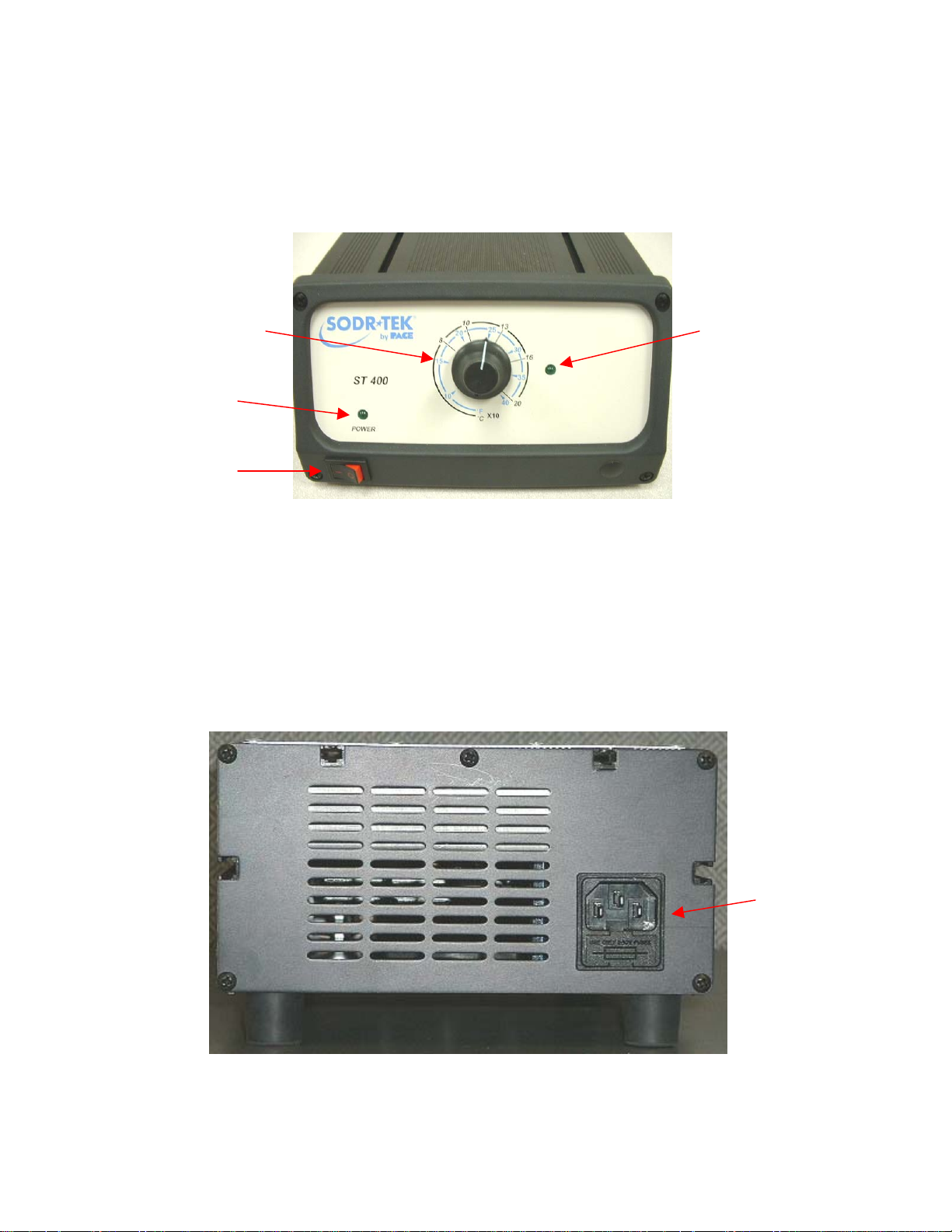

Parts Identification

Variable

Temperature

Control

Power LED

Power Switch

Temperature

Indicator LED

Figure 1

AC Power

Receptacle/Fuse

Holder

Figure 2

©2004 PACE Inc., Annapolis Junction, Maryland Page 4 of 14

All Rights Reserved

Page 5

Safety

Safety Guidelines

The following are safety precautions that personnel must understand and follow when using or

servicing this product.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE products should be

performed by Qualified Service Personnel only. Line voltage parts may be exposed

when the equipment is disassembled. Service personnel must avoid contact with these

parts when troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in accordance with OSHA and

other applicable safety standards.

3. Always use PACE systems in a well ventilated area. A fume extraction system such as

those available from PACE are highly recommended to help protect personnel from

solder flux fumes.

4. Exercise proper precautions when using chemicals (e.g., solder paste). Refer to the Material

Safety Data Sheet (MSDS) supplied with each chemical and adhere to all safety precautions

recommended by the manufacturer.

5. Do not contact the Heater or its peripheral parts during operation.

6. Once turned off, let the unit cool completely before contacting.

7. After use, verify that the amber indicator lamp is off.

8. When using Fluxes, use fume extraction equipment or use in a well-ventilated area to

minimize operator exposure to fumes.

Preheating Basics

Preheating of a printed circuit assembly is normally required in the repair process whenever any one or

more of the following situations exist.

1. Epoxy glass substrate with 4 or more layers.

2. Substrate with large ground planes.

3. Substrate of ceramic, polyimide or other high heat dissipative material.

4. Printed circuit assembly with large metal heat sinks.

Preheating of assemblies such as those listed above will accomplish the following objectives.

1. Minimize thermal shock by elevating the assembly temperature to a level closer to solder melt

temperature.

2. Minimize the heat cycle reflow time.

3. Overcome the heat dissipation characteristics of the assembly.

4. Minimize adjacent melts on densely populated assemblies.

©2004 PACE Inc., Annapolis Junction, Maryland Page 5 of 14

All Rights Reserved

Page 6

The assembly undergoing repair must be heated for a length of time sufficient to saturate at the preheat

temperature required. The PCB preheat temperature normally used is 100°C (212°F) for epoxy glass

substrates and 120°C (248°F) for ceramics and polyimides.

System Power Up

1. Insert the female end of the power cord into the AC Power Receptacle on the rear panel of

the power source.

2. Plug the prong end (male end) of the power cord into an appropriate 3 wire grounded AC

supply receptacle.

CAUTION: To insure operator and ESD/EOS safety, the AC power supply receptacle must be

checked for proper grounding before initial operation.

Operation

The PACE ST 400 unit is easy to operate and can be quickly set up for operation. The following steps

provide basic guidelines for rework using the PACE ST 400.

1. Turn on the Power Switch.

a. The Green Power LED will illuminate

b. If the LED does not illuminate, refer to the Corrective

Maintenance Section of this manual.

2. Position the ST 400 under your PACE board holding

fixture. The ST 400 can be placed under any ST 525 or

ST 550 system. Be sure to follow the board installation

steps, which are detailed in the ST 500 Series Manual.

Figure 3 illustrates a typical usage. Please note that the

ST 450 is pictured in Figure 3.

Figure 3

NOTE: For best results, keep the distance between the ST 400 and the board holding fixture to

no greater than 2 ¼ “ (5.72 cm).

3. Set Temperature knob to desired setting. It will take approximately 10 minutes for the radiant

heaters to reach their set temperature and stabilize. Use of a thermo-couple is recommended to

verify actual PCB temperatures.

LED Operation

The Green colored LED (Temperature Indicator LED) on the power source

front panel indicates System Status and Power Receptacle output status

Temperature Indicator LED

(LED OFF, ON or Flashing).

LED Full On - Continuous power is being delivered to the heaters. This

condition is evident when the system is first powered up (heaters cold) or

the Variable Temperature Control setting is increased.

LED Flashing - Indicates that the set heater temperature (as set on the

Variable Temperature Control) has been reached. Power to the heaters

is cycling Off and On to maintain set temperature.

Figure 4

©2004 PACE Inc., Annapolis Junction, Maryland Page 6 of 14

All Rights Reserved

Page 7

LED Off - No power is being delivered to the heaters. This condition is evident for a short period

of time when set temperature is reached and stabilizing or if the Variable Temperature Control

setting is decreased. If the LED never

illuminates, check for a faulty heater (see Corrective

Maintenance section).

Variable Temperature Control

Adjust the Variable Temperature Control Knob to the desired temperature

setting. Notice that the control panel has an outer graphic scale denoting

temperature in °C (Celsius) and an inner graphic scale denoting temperature in

°F (Fahrenheit). These numerical scales denote the set tip temperature times

10 (e.g., “10” on the outer scale is 10 x 10 or 100°C).

Corrective Maintenance

General Maintenance

NOTE: The ST 400 should be kept clean. If flux is spilled on the heaters, the ST 400 should be

allowed to cool to room temperature and the heater panels can be wiped off with an

appropriate flux cleaner. Always unplug the ST 400 before removing the cover to clean

the Heater Panels.

Heater Replacement

Should a heater need to be replaced, please order P/N 3018-0128-P1 for the domestic (115 volt)

system or P/N 3018-0129-P1 for the export (230 volt) system from your PACE Distributor. The

following steps provide the information as to how to replace the heating panels.

Removal

1. Remove the rear panel by removing the

5 screws.

Figure 6

2. Remove the front panel and bezel by

removing the 4 screws.

Figure 7

Figure 5

©2004 PACE Inc., Annapolis Junction, Maryland Page 7 of 14

All Rights Reserved

Page 8

3. Remove the screws on the sides of the

case (one screw on each side).

Figure 8

4. Carefully lift the top from the bottom

chassis.

Figure 9

5. Remove the two large heater wires.

They are located on the board as shown

in figure 10 and 11.

Figure 10

Figure 11

©2004 PACE Inc., Annapolis Junction, Maryland Page 8 of 14

All Rights Reserved

Page 9

6. Remove the heater sensor connector from the

J5 connection on the PC board.

Figure 12

7. Remove the 4 heater mounting plate

socket hex head screws. Carefully

remove the heater assembly from the

chassis.

NOTE: Be careful when removing the

heater assembly from the

chassis as the heater wires may

be caught on other wires or

caught on the chassis.

Requires a 9/64”

hex wrench

Figure 13

8. Carefully remove the heater retaining clip. Be sure

to support the heater during this process.

Figure 14

©2004 PACE Inc., Annapolis Junction, Maryland Page 9 of 14

All Rights Reserved

Page 10

9. Pull the heater and its wires from the

heater mounting plate.

Figure 15

Installation

10. Take the new heater and insert the heater wires through the heater mounting plate and

secure the heater as shown in figure 16 and 17 and install the heater retaining clip.

Figure 16

Figure 17

11. Tighten the 4 heater retaining socket hex

head screws.

Figure 18

©2004 PACE Inc., Annapolis Junction, Maryland Page 10 of 14

All Rights Reserved

Page 11

12. Reconnect and route the wires as shown in figures 19 through 22.

Figure 19 Figure 20

Figure 21 Figure 22

NOTE: The heater has been removed in the above pictures to allow proper viewing of wire

routing.

13. Reinstall the top half of the case.

Figure 23

14. Reinstall the rear panel.

Figure 24

©2004 PACE Inc., Annapolis Junction, Maryland Page 11 of 14

All Rights Reserved

Page 12

15. Reinstall the front panel.

NOTE: The front panel screws are longer than the

side and rear panel screws.

Figure 25

16. Reconnect power and test the system.

Power Source

Refer to the table below. Most malfunctions are simple and easy to correct.

Symptom Probable Cause Solution

No power to system

Blown Fuse Replace the fuse(s) with one of the same rated

value.

Line cord

Plug line cord into the appropriate AC outlet

unplugged

Heater Assembly does

not heat.

Blown Fuse Replace the fuse(s) with one of the same rated

value.

Open Heater Replace the heater. Refer to the Heater

Replacement section on page 7.

The indicated temperature is based on 1 ½” away from the top of the system .

Packing List

Item # Description Part Number ST 400

Only

ST 400 E

Only

1 System Power Supply 8007-0435 1 0

2 System Power Supply

8007-0436 0 1

(Export)

3 Power Cord, 115V 1332-0094 1 0

4 Power Cord, 230V 1332-0093 0 1

6 Operations Manual CD CD5050-0459 1 1

Spare Parts

Item # Description PACE Part Number

Fuse, 7 Amp, 125 V, Time Lag (ST 400) 1159-0274-P5 1

Fuse, 3.15 Amp, 250 V, Time Lag (ST 400E) 1159-0221-P5

Service

Please contact PACE or your local distributor for service and repair.

©2004 PACE Inc., Annapolis Junction, Maryland Page 12 of 14

All Rights Reserved

Page 13

“SODRTEK by PACE” LIMITED WARRANTY STATEMENT

Limited Warranty

Seller warrants to the first user that products manufactured by it and supplied hereunder are free of

defects in materials and workmanship for a period of one (1) year from the date of receipt by such user.

Monitors, computers and other brand equipment supplied but not manufactured by PACE are covered

under their respective manufacturer’s warranty in lieu of this Warranty.

This warranty does not cover wear and tear under normal use, repair or replacement required as a result

of misuse, improper application, mishandling or improper storage. Consumable items such as tips,

heaters, filters, etc. which wear out under normal use are excluded. Failure to perform recommended

routine maintenance, alterations or repairs made other than in accordance with Seller’s directions, or

removal or alteration of identification markings in any way will void this warranty. This warranty is

available only to the first user, but the exclusions and limitations herein apply to all persons and entities.

SELLER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAKES NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Seller will, at its option, repair or replace any defective products at its facility or other location approved by

it at no charge to user, or provide parts without charge for installation by the user in the field at user’s

expense and risk. User will be responsible for all costs of shipping equipment to Seller or other location

for warranty service.

EXCEPT FOR THE REMEDY ABOVE DESCRIBED, UNLESS OTHERWISE REQUIRED BY

APPLICABLE LAW, SELLER WILL HAVE NO OTHER OBLIGATION WITH REGARD TO ANY BREACH

OF WARRANTY OR OTHER CLAIM WITH RESPECT TO THE PRODUCTS, OR LIABILITY FOR ANY

DIRECT, INDIRECT, CONSEQUENTIAL, OR INCIDENTAL LOSS OR DAMAGE CAUSED BY OR

OCCURRING IN CONNECTION WITH ANY OF THE PRODUCTS.

Warranty service may be obtained by contacting the appropriate PACE Company or local Authorized

PACE distributor as set forth below to determine if return of any item is required, or if repairs can be made

by the user in the field. Any warranty or other claim with respect to the products must be made with

sufficient evidence of purchase and date of receipt, otherwise user’s rights under this warranty shall be

deemed waived.

For PACE USA Customers:

PACE, INCORPORATED

9030 Junction Drive

Annapolis Junction, Maryland 20701

Tel. 301-317-3588

FAX. 301-498-3252

For PACE EUROPE Customers:

PACE EUROPE LIMITED

Sherbourne House, Sherbourne Drive,

Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel. (44) 1908 277666

WARRANTY SERVICE FAX: (44) 1908 277 777

All other Customers:

Local Authorized PACE Distributor

©2004 PACE Inc., Annapolis Junction, Maryland Page 13 of 14

All Rights Reserved

Page 14

PACE Incorporated retains the right to make changes to specifications contained herein at any time,

without notice. Contact your local authorized PACE Distributor or PACE Incorporated to obtain the latest

specifications.

The following are trademarks and/or service marks of PACE, Incorporated, MD, USA:

INSTACAL

POWERPORT

™

, FUMEFLO™, HEATWISE™, PACEWORLDWIDE™, PERMAGROUND™,

™

, POWERMODULE™, TEMPWISE™, TIP-BRITE™, AUTO-OFF™, and

TEKLINK™.

The following are registered trademarks and/or service marks of PACE Incorporated, Annapolis Junction

Maryland U.S.A.

ARM-EVAC

SODRTEK

VISIFILTER

®

, FLO-D-SODR®, MINIWAVE®, PACE®, SENSATEMP®, SNAP-VAC®,

®

, SODR-X-TRACTOR®, ST 400®, THERMOJET®, THERMOTWEEZ®,

®

, THERMO-DRIVE®, and TOOLNET®.

PACE products meet or exceed all applicable military and civilian EOS/ESD, temperature stability and

other specifications including MIL STD 2000, ANSI/JSTD 001, IPC7711, and IPC A-610.

www.paceworldwide.com

PACE USA PACE Europe

9030 Junction Drive Sherbourne House

Annapolis Junction, MD 20701 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 01908-277666

Fax: (301) 498-3252 (44) 01908-277777

©2004 PACE Inc., Annapolis Junction, Maryland Page 14 of 14

All Rights Reserved

Loading...

Loading...