Page 1

ST 115 Systems

Operation & Maintenance Manual

Page 2

TABLE OF CONTENTS

TITLE PAGE

General Information ............................................................................................... 2

Introduction .................................................................................................. 2

Specifications ............................................................................................... 2

Parts Identification ...................................................................................... 4

Safety ....................................................................................................................... 5

Safety Guidelines, English Language ....................................................... 5

Safety Guidelines, French Language......................................................... 6

Safety Guidelines, German Language ....................................................... 7

Safety Guidelines, Italian Language ......................................................... 8

Safety Guidelines, Portuguese Language .................................................. 9

Safety Guidelines, Spanish Language ..................................................... 10

Safety Guidelines, Swedish Language .................................................... 11

Set-Up .................................................................................................................... 12

Tip & Tool Stand ..................................................................................... 12

Handpiece Vacuum/Pressure ..................................................................... 13

Handpiece Connection .............................................................................. 14

System Power Up ...................................................................................... 14

Heater Burn In ........................................................................................... 14

Quick Start - Basic Operation ............................................................................ 16

Introduction ................................................................................................ 16

Quick Start Procedure ............................................................................... 16

Operation ............................................................................................................... 17

Definitions .................................................................................................. 17

Password ..................................................................................................... 18

Auto Tip Temperature Compensation ..................................................... 18

LED Display, Normal Operation .............................................................. 19

LED Display, Temperature Adjust Mode ................................................ 20

Temperature Setback ................................................................................. 21

Auto Off Safety System ............................................................................ 22

Quick Tour ................................................................................................. 23

Factory Settings ......................................................................................... 25

Set-Up Mode......................................................................................................... 26

Introduction ................................................................................................ 26

Entering Set-Up Mode .............................................................................. 26

Operation .................................................................................................... 27

Repair .................................................................................................................... 31

Repair Procedure ....................................................................................... 31

LED Display Accuracy.............................................................................. 32

LED Display Message Codes .................................................................. 32

Corrective Maintenance ............................................................................ 33

Disassembly/Assembly............................................................................... 35

i

Page 3

TABLE OF CONTENTS

TITLE PAGE

Assembly Detail ......................................................................................... 37

Wiring Diagram .......................................................................................... 3 8

Schematic ................................................................................................... 39

Packing List/Spare Parts ...................................................................................... 41

Packing List ............................................................................................... 41

Spare Parts .................................................................................................. 41

Limited Warranty Registration ............................................................................ 42

TABLE PAGE

Table 1 Factory Settings.................................................................................... 25

Table 2 LED Display Message Codes ............................................................. 32

Table 3 Power Source Corrective Maintenance .............................................. 33

Table 4 Heater Assembly Checkout Procedures.............................................. 34

Table 5 Packing List.......................................................................................... 41

Table 6 Spare Parts ............................................................................................ 41

ii

Page 4

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized P ACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of P ACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine P ACE products or

services:

Arm-Evac, Flo-D-Sodr , Mini-Wave, P ACE, SensaTemp, Snap-V ac, Sodrtek,

Sodr-X-T ractor, ThermoFlo, ThermoJet, ThermoT weez, Toolnet, Visifilter.

For any questions regarding this Operation & Maintenance Manual,

contact your local authorized P ACE distributor or contact PACE

directly at the appropriate address listed below.

P ACE USA 9893 Brewers Court

Laurel, Maryland 20723-1990

Tel.: (301) 490-9860

(888) 535-7223 (PACE)

Fax (301) 498-3252

PACE EUROPE Sherbourne House, Sherbourne Drive

Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel.: (44)1908 277666

Fax: (44)1908 277777

or

www .paceworldwide.com

© 2000 P ACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

iii

Page 5

MANUAL NUMBER 5050-0460

REV. D

SYSTEM QUICK START

The ST 115 system is very easy to operate and can be

quickly set up for use in standard desoldering/soldering

operations. To begin operation of your new system

quickly, perform the "Set-Up" and "Quick Start Basic Operation" procedures detailed on pages 12-16 of

this manual. A shaded title bar on each of these pages

highlight their location.

1

Page 6

General Information

Introduction

Thank you for purchasing the P ACE model ST 1 15 Digital Desoldering System. This

manual will provide you with the information necessary to properly set up, operate

and maintain the ST 115 system.

The ST 115 systems are available in either the 1 15 VAC, or 230 VAC version

which incorporates a highly responsive SensaTemp (closed loop) control system

providing up to 80 Watts of total power to a single output channel. The systems

package the power source with a selection of accessories and functional aids.

The Sodr-X-Tractor handpiece provides thermally enhanced thru-hole desoldering,

safe removal of TQFP (Thin Quad FlatPack) and TSOP (Thin Small Outline Package)

surface mount components and continuous removal of old solder from surface

mount lands.

Other P ACE SensaTemp handpieces may be used with the ST 1 15 system to perform a

wide variety of advanced surface mount & thru-hole component removal/replacement

operations.

Specifications

System power sources are available in either the 115 VAC or 230 V AC version.

The 115 VAC version system conforms to all the requirements of FCC Emission Control

Standard, Title 47, Subpart B, Class A. This system has been tested and found to

comply with the limits for a Class A digital device, pursuant to part 15 of FCC rules.

These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with this manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which

case the user will be required to correct the interference at his own expense.

The 230 volt system bears the Conformity Marking which assures the user that it

conforms to all the requirements of (EU) directive EMC 89/336/EEC & 73/23/EEC.

2

Page 7

General Information

System Power Source Power Requirements:

ST 115 .........Operates on 97-127 V AC, 50/60Hz

120 W atts maximum at 115 V AC, 60Hz

ST 1 15E ......Operates on 197-253 V AC 50/60Hz

120 W atts maximum at 230 V AC, 50Hz

T emperature Specifications:

Tip T emperature Range: 204°C to 482°C (400°F to 900°F) nominal.

T emperature Stability: ±1.1°C (±2°F) at idle from set tip temp.

NOTE

Actual minimum and maximum Operating Tip Temperatures may vary depending on

Handpiece, Tip selection and application.

Vacuum And Air

Measurements at front panel Vacuum and Contr ollable Pressure Ports.

V acuum Rise Time: ------- 200 ms average as measured by PACE

PPM 100 Process Monitor.

V acuum: ............................ 51 cm Hg. (20 in. Hg.) (nominal)

Pressure:.......................... 1.44 Bar (21 P .S.I.) (nominal at MAX setting)

Air Flow: ........................... 6 SLPM (0.22 SCFM) maximum

EOS/ESD Specifications:

The specifications shown below apply except on "Soft Ground Systems" which have

a 1 meg ohm current limiting resistance and a label placed on the power source front

panel referring to EN 100015-1.

Tip-T o-Gr ound

Resistance: ...................... Less than 2 ohms.

AC Leakage:.................... Less than 2 millivolts RMS from 50Hz to 10MHz.

T ransient Level: ............... Less than 500mV peak, out to 100MHz.

3

Page 8

General Information

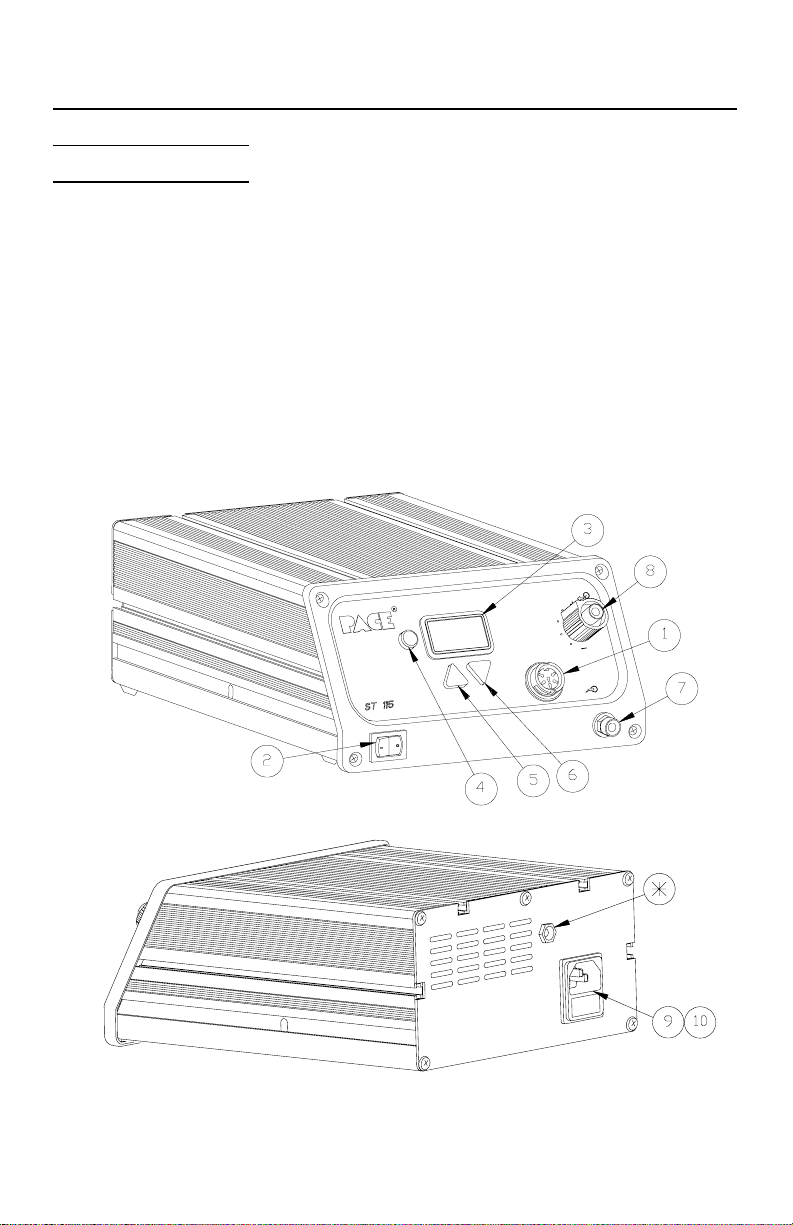

Parts Identification

1 - Power Receptacle

2 - Power Switch

3 - LED Display

4 - Program Key

5 - Scroll Up Key

6 - Scroll Down Key

7 - V acuum Port

8 - Controllable Pressure Port

9/10 - AC Power Receptacle/Fuse

Holder

* - Earth Ground Receptacle

(230 V AC sytems only)

4

Page 9

Safety

Safety Guidelines - English Language

The following are safety precautions which personnel must understand and follow

when using or servicing PACE products.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE

products should be performed by Qualified Service Personnel only.

Line voltage parts may be exposed when the equipment is disassembled.

Service personnel must avoid contact with these parts when

troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in accordance

with OSHA and other applicable safety standards.

3. SensaTemp handpiece heaters and installed tips are hot when the

handpiece is powered on. DO NOT touch either the heater or the tip.

Severe burns may result.

4. PACE Tip & Tool Stands and handpiece cubbies are designed

specifically for use with the associated handpiece and houses it in a

manner which protects the user from accidental burns. Always store the

handpiece in its holder. Be sure to place the handpiece in its holder after

use and allow to cool before storing.

5. Always use PACE systems in a well ventilated area. A fume extraction

system such as those available from PACE are highly recommended to

help protect personnel from solder flux fumes.

6. Exercise proper precautions when using chemicals (e.g., solder paste).

Refer to the Material Safety Data Sheet (MSDS) supplied with each

chemical and adhere to all safety precautions recommended by the

manufacturer.

5

Page 10

Sécurité

Directives de Sécurité, Française Langue

Les précautions suivantes, sont celles que le personnel doit comprendre et suivre

lorsqu'il utilise, effectue la maintenance ou se sert d'un produit PACE.

1. Danger potentiel de choc èlectrique - Les procédures de réparation sur

les produits PACE doivent être effectuées seulement par du personnel

qualifié. Des parties de l'équipement désassemblées peuvent être sous

tension. Le personnel de maintenance doit éviter tout contact avec ces

parties en réparant le produit.

2. Pour prévenir tout préjudice, le personnel adhère au guide de sécurité en

accord avec OSHA (équivalent à des normes françaises de sécurité) et

d'autres standards de sécurité applicable.

3. La mise sous tension des outils SensaTemp comporte des éléments

chauffants (buse). Ces derniers, gardent la chaleur même après la mise

hors tension pendant un certain temps. Ne pas toucher les parties

chaudes aux extrémités des outils. Des brûlures sévères peuvent en

résulter.

4. Les outils PACE et leurs pannes ainsi que le support sont dessinés de

manière spécifique afin de protéger l'utilisateur/opérateur de brûlures

accidentelles. Reposer toujours les outils après chaque utilisation dans

leurs étuis/supports afin de permettre leur refroidissement.

5. Utiliser toujours les stations Pace dans unlieu bien ventilé. Des

extracteurs de fumée Pace sont hautement recommandés pour protéger

votre personnel des vapeurs de soudure/flux.

6. Prenez les mesures nécessaires quand vous utilisez des produits (ex:

solder paste) chimiques. Reportez-vous au document (fiche technique/

sécurité) du fabricant fourni avec chaque produit. Respectez toutes les

procédures de sécurité recommandées par le constructeur.

6

Page 11

Sicherheit

Sicherheit Korrekturlinien, Deutsche Sprache

Die nachfolgenden Sicherheitsvorschriften sollten vom Bedien- un Servicepersonal

verstanden und befolgt werden.

1. Entladung spannungsfuehrender Teile - Reparaturen an PACE

Produkten sollten nur von qualifizierten Personal durchgefuehrt werden.

Spannungsfuehrende Teile koennen sich bei gezogenen Netzstecker

entladen. Servicepersonal muss den Kontakt dieser Teile vermeiden.

2. Um moegliche Gefahren fuer Personen auszuschliessen, muessen alle

Sicherheitsvorschriften in Uebereinstimmung mit OSHA und anderen

anwendbaren Sicherheitsstandards eingehalten werden.

3. Angeschlossene SensaTemp Heizelemente von Handwerkzeugen und

installierte Loetspitzen sind heiss wenn das System eingeschaltet ist oder

erst vor kurzer Zeit ausgeschaltet wurde. Heizelement und Loetspitze

nicht beruehren. Verbrennungsgefahr.

4. PACE Tip & Tool und andere Handwerkzeugablagen sind so konstruiert,

dass ein versehentliches Beruehren des dazugehoerendes

Handwerkzeuges vermieden wird. Bewahren Sie das Handwerkzeug nach

Gebrauch stets in der Ablage auf. Bevor das Handwerkzeug an einem

anderen Ort gelagert werden muss, lassen Sie es in der Werkzeugablage

vollstaendig abkuehlen.

5. Benutze PACE Systeme nur in gut beluefteten Raeumen. Ein

Loetrauchabsaugsystem, wie es z.B. von PACE erhaeltlich ist, hilft

Bedienpersonen von den Gefahren von Loetrauch zu schuetzen.

6. Wenn Chemikalien (z.B.: Lotpaste) verwendet werden, muessen alle die

in den Sicherheitsdatenblaettern des Herstellers ausgewiesenen

Sicherheitsvorschriften eingehalten werden.

7

Page 12

Sicurezza

Misure di Sicurezza, Italiana Lingua

Le seguenti instruzioni sono misure di sicurezza che il personale deve comprendere e

seguire quando utilizza o ripara I prodotti PACE.

1. EVENTUALI RISCHI DI SHOCK ELETTRICO- Si consiglia di far

eseguire le operazioni di riparazione dei prodotti PACE, da un servizio di

personale qualificato. Quando la stazione non é assemblata le parti

sottoposte alla tensione di linea potrebbero essere scoperte. Il personale

deve evitare il contatto con queste parti durante manutenzione del

prodotto.

2. Per evitare eventuali pericoli al personale, attenersi alle norme di sicurezza

previste dalla guida, in conformitá all’OSHA e agli altri Standard di

Sicurezza applicabili.

3. Le resistenze PACE Sensatemp e le punte installate sono calde quando la

stazione é accesa e per un periodo successivo allo spegnimento. Non

toccare la resistenza e la punta. Puó comportare gravi ustioni.

4. I supporti PACE sono specificamente costruiti insieme alla

corrispondente impugnatura e progettati per un uso che protegge gli

utenti da ustioni accidentali. Mettere sempre l’impugnatura nel propio

supporto dopo l’utilizzo e lasciarla raffredare prima di riporla.

5. Utilizzare sempre I stazioni PACE in una zona be aerata per proteggere il

personale dai fumi. É fortemente raccomandato un sistema di aspirazione

(dei fumi) come quello disposta dalla PACE.

6. Usare precauzioni quando si utilizzano sotanze chimiche (es. Pasta di

stagno). Fare riferimento al Material Safety Data Sheet (MSDS) fornita

con ogni sostanza chimica e seguire tutte le misure di sicurezza

raccomandate dal fabbricante.

8

Page 13

Segurança

Guidelines de Segurança, Portuguese Lingua

Segeum-se precauções de segurança que os operadores devem compreender e seguir

ao utilizar ou reparar produtos PACE.

1. Perigo de choque eléctrico - Os procedimentos de reparação em

produtos PACE, devem ser apenas efectuados por pessoal qualificado.

Linhas de alimentação podem ficar expostas ao desmontar o

equipamento. Pessoal de reparação deve evitar o contacto com essas

partes ao reparar o produto.

2. Para evitar danos pessoais, siga as normas de segurança OSHA ou outras

normas aplicáveis.

3. Resistencias de aquecimento dos ferros e as pontas instaladas estão

quentesquando o ferro está alimentado, e mesmo durante algum tempo

após ser desligado. NUNCA TOCAR nem na resistencia de

aquecimento nem na ponta. Pode resultar em queimaduras severas.

4. Os suportes para pontas e ferros da PACE, foram concebidos para uso

especifico, e para proteger o operador de queimaduras acidentais.

Coloque sempre os ferros nos respectivos suportes. Tenha a certeza de

colocar sempre o ferro no respectivo suporte após cada utilização e deixeo arrefecer antes de o guardar.

5. Utilize sempre os sistemas da PACE em locais bem ventilados. Um Sistema de

extracção de fumos, como os Sistemas disponiveis na PACE, são altamente

recomendados para a protecção dos utilizadores contra os fumos produzidos pela

solda e fluxo.

6. Tenha precauções apropriadas ao utilizar produtos quimicos (ex. pasta de soldar).

Lêr sempre atentamente os normas de segurança fornecidas com cada produto

químico e siga sempre todas as precauções de segurança recomendadas pelo

fabricante.

9

Page 14

Seguridad

Guias de Consulta de Seguridad, Espãnol Lenguaje

Lo siguiente es precauciones de seguridad que el personal debe entender y debe

seguir al usar o reparar productos de PACE.

1. RIESGO de SHOCK POTENCIAL - Los procedimientos de la

Reparación en productos de PACE sólo deben ser realizados por Personal de

Servicio Calificado. Pueden exponerse partes de voltaje de línea cuando el

equipo se desmonta. El personal de servicio debe evitar contacto con estas

partes al arreglar el producto.

2. Para prevenir lesión del personal, adhiera a las reglas de seguridad de

acuerdo con OSHA y otras normas de seguridad aplicables.

3. Las herramientas SensaTemp tienen sus calentadores y las puntas

instaladas calientes cuando la herramienta esta encendida y por un

periodo de tiempo después de apagar el equipo. No toque el calentador

o la punta. Las quemaduras severas pueden resultar.

4. El Soporte de punta y Herramienta PACE se diseñan específicamente

para el uso con las herramientas asociadas y las almacena de una manera

que protege al usuario de las quemaduras accidentales. Siempre guarde

la herramienta en su soporte. Esté seguro de poner la herramienta en su

soporte después del uso y permita que la herramienta enfríe antes de

guardar.

5. Siempre use sistemas de PACE en una área bien ventilada. Un sistema de

extraccíon de humo como esos disponibles de PACE se recomiendan para

ayudar a protejer al personal contra los humos de flujo de soldadura.

6. Ejercicie las precauciones apropiadas al usar químicos (ej., pasta de la soldadura).

Refiérase a la Hoja de Datos de Seguridad de Material (MSDS) proporcionadó

con cada químico y adhiere a todas las precauciones de seguridad recomendadas

por el fabricante.

10

Page 15

Säkerhetsföreskrifter

Säkerhetsföreskrifter , Svenska

Följande säkerhetsföreskrifter måste förstås och följas av personal som använder

eller utför service på PACE produkter.

1. RISK FÖR STRÖMSTÖT - Service / Reparation av PACE produkter

får endast utföras av aktoriserad service personal. Strömförande delar

kan kommas åt när produkten är isärplockad. Iaktag aksamhet när

felsökning görs för att undvika strömstötar.

2. För att undvika personskada rekommenderas att OSHA eller andra

liknande arbetssäkerhets standarder följs.

3. SensaTemp verktygselement och installerade spetsar är heta när

strömmen är påslagen och en tid efter att strömmen slagits av. RÖR EJ

element eller spets. Risk för brännskador!

4. PACE Spets och Verktygshållare är speciellt utformade för att passa

PACE respektive verktyg så att risken för brännskador kan undvikas. När

verktyget ej används bör det alltid förvaras i sin hållare.

5. Tillse att ventilationen är god där PACE System används. Ett

lödröksutsug system som t.ex. PACE tillhandahåller rekommenderas för

att skydda användaren för giftig lödrök.

6. Tillse att gällande säkerhetsföreskrifter följs vid användning av

kemikalier, t.ex. lodpasta.Se säkerhetsdatabladen som medföljer

kemikalierna och följ de rekommenderade säkerhetsföreskrifterna från

respektive tillverkare.

11

Page 16

Set-Up

Tip & Tool Stand

If you have purchased a system with a handpiece, set up the Tip & Tool Stand in the

following manner. Set up any other SensaTemp handpiece, use the instructions

enclosed with the handpiece and associated Tip & Tool Stand.

1. Attach the stand to either side of the power source, in the following manner.

a) Insert the 2 large hex head

Mounting Screws (head first) into

the lower "T" slot on the side of

the power source case as shown.

b) Place the T ip & Tool Stand in

position beside the power source.

Insert ends of the 2 Mounting

Screws into the 2 Tip & Tool

Stand mounting holes shown.

c) Install a Thumb Nut onto the end

of each Mounting Screw .

Tighten Thumb Nuts to secure

the stand in position.

2. Place handpiece into Tip & Tool Stand.

12

Page 17

Set-Up

Handpiece V acuum/Pressure

T o set up your Sodr -X-Tractor air hose connection, perform the following steps:

1 . Air Hose To Handpiece Connection

a) Attach one end of a 137cm (54 inch) length of air hose to the metal

tube in the back of the handpiece.

b) If you have a PACE system incorporating only one handpiece, attach

the air hose to the power cable using the supplied Hose Clamps.

Space them evenly along the length of the power cable starting at a

point 6 inches from the ends of the handpiece.

c) If you have a PACE system incorporating 2 or more air handpieces,

you may wish to leave the air hose assembly unattached to allow a

quick change to any air handpiece being used.

2 . Prepare a VisiFilter in the following manner:

a) Connect a 1 inch (2.5cm) length of clear pvc air hose to

the FLOW OUT side of the V isiFilter; push and turn

the hose onto the V isiFilter nipple to seat.

b) Insert the ribbed end of a male quick connect hose

mount fitting (P/N 1259-0087) into the free end of

the 1 inch (2.5cm) length of air hose connected to

the FLOW OUT side of the V isiFilter.

c) Connect the free end of the 137cm (54 inch) length of

air hose to the FLOW IN side of the V isiFilter .

d) Insert the end of the quick connect hose mount

fitting (on V isiFilter FLOW OUT side) into the

power source Vacuum Port.

3 . When using air pressure, and/or utilizing multiple air

handpieces, PACE recommends the use of the following set up procedure

which utilizes additional quick connect hose mount fittings. An

assortment of quick connect air fittings are supplied with each additional

air handpiece.

a) Disconnect the 137cm (54 inch) length of air hose from the FLOW IN side of

the V isiFilter assembly . Insert the ribbed end of a male quick connect hose

mount fitting (P/N 1259-0087) into the free end of this air hose.

b) Connect the free end of a 1 inch (2.5cm) length of air hose with an

installed female quick connect hose mount fitting (P/N 1259-0086) to

the FLOW IN side of the V isiFilter Assembly .

c) The 137cm (54 inch) length of air hose can now be easily moved

between the V isiFilter Assembly and the Controllable Pressure Port.

The V isiFilter assembly remains connected to the Vacuum Port.

13

Page 18

Set-Up

4. Additional fittings may also be added to the hose connection at the rear of

each air handpiece to ease changing of handpieces.

NOTE

When removing any air hose, turn and pull. Do not attempt to pull hose directly off.

Damage to or breakage of fitting or V isiFilter may occur. Use your Sodr-X-T ractor with

a clean V isiFilter element. Otherwise a deterioration in performance or damage to the

unit may occur.

Handpiece Connection

Connect the handpiece connector plug into the

Power Receptacle in the following manner.

1. Align guide on connector with slot on

power receptacle.

2. Insert connector into power receptacle.

3. Turn the connector housing clockwise

to lock in place.

System Power Up

1 . Insert the female end of the power cord into the AC Power Receptacle at

the rear panel of the power source.

2 . Plug the prong end (male end) of the power cord into a 3 wire grounded

AC supply receptacle. The system is now ready for operation.

CAUTION

To insure operator safety, the AC supply receptacle must be checked for proper

grounding before initial operation.

3 . Read this manual and all other included manuals thoroughly before

operating the system.

Heater Burn In

T o ensure optimum performance and long life, new TJ-70 handpieces must under go a

burn in procedure. A Red tag is attached to each handpiece and with replacement

heater assemblies which describes the proper procedure. The ST 115 system

however, has a Burn In feature which, when activated will burn in the TJ-70 heater in

a similar manner as is described on the tag. Use this feature when setting up a new

ST 115 system or when replacing a TJ-70 handpiece heater assembly .

NOTE

Ensure that the system is placed in a well-ventilated area. Smoke will be emitted from

the heater assembly during the burn in cycle.

14

Page 19

Use the following instructions to perform the Heater Burn In procedure.

1 . Place the Power Switch in the “OFF” ("0") position.

2. Ensure that the handpiece is connected to the system power source.

Some handpieces heater assemblies are shipped with a plastic cap

installed on the end of the heater assembly. If this cap is present, remove

the cap and discard. The cap is used for shipping purposes only.

3 . Press and hold the Program and Scroll Up (s) keys together.

4 . Place the Power Switch in the “ON” ("I")

position.

5 . Release the Program and Scroll Up (s) keys. The

Display will read “brn”.

6 . Press the Scroll Up (s) Key to enter the Burn In

Mode. The handpiece heater will begin to heat

up with the temperature displayed (in °C or °F)

on the Display. The temperature of the heater

will stabilize at 315°C (or 600 °F) and remain at

that temperature for 10 minutes.

Set-Up

7 . At the conclusion of the 10 minute period, the

heater temperature will increase to 427°C (or

800°F) and remain at that temperature for 15

minutes.

8 . At the conclusion of the 15 minute time period, power is removed from the

heater. The Display will read “End”. Press and release the Scroll Up (s)

Key to exit Heater Burn In and return the to normal operation.

NOTE

The microprocessor circuitry within the unit monitors the system to ensure proper

results. If any abnormalities are encountered, the Burn In cycle will be interrupted and

an error message displayed. If this situation should occur, turn the system off and

perform the procedure again. If the cycle is interrupted a second time, refer to T able

4 and check for handpiece malfunction. If a second handpiece is available, perform

the procedure using that handpiece.

15

Page 20

Quick Start - Basic Operation

Introduction

The ST 115 system is very easy to operate. As received from the factory, the system

can be quickly set up for use in standard desoldering/soldering operations. Simply

perform the following Quick Start Procedure to begin system operation.

Quick Start Procedure

1. Ensure that the Set-Up procedure has been performed; including the

Heater Burn In procedure. Check for the following:

a) Handpiece connections (connector plug and air hose) to the power

source.

b) Proper tip installed in handpiece.

c) Power cord connection between house AC

supply receptacle and the power source.

d) House air supply connection to power supply.

2 . Turn the Power Switch “On” (“I”).

3. Press the Scroll Up (s) Ke y to enter the

T emperature Adjust Mode..

4. Press the Scroll Up (s) Ke y to increase the desired T ip Temperature. Press

the Scroll Down (t) Key to decrease the desired Tip Temperature.

5 . Press the Program Key. The system will now return to

normal operation.

6 . Observe the Digital Readout as the temperature stabilizes at the desired

Set Tip T emperature

7 . If you have a Sodr-X-Tractor or other PACE air handpiece connected to

your system, press and hold the Vacuum Switch to check for proper

operation. You will hear a noise as the motor pump starts up and

continues to run. Release the Vacuum Switch.

NOTE

Read the “Operation” and “Set-Up Mode” sections of this manual to utilize the full

capabilities of the system. This is especially important when using large soldering

tips or other SensaTemp handpieces.

16

Page 21

Operation

IMPORT ANT

P ACE recommends that you not read the “Set-Up Mode” section until after you feel

comfortable with system operation. Please read the following “Operation" section

thoroughly before changing the system settings.

Definitions

Please read and become familiar with the definitions of each of the following terms

which are used repeatedly in the following operational procedures.

AUTO OFF - Safety feature which turns power off (10-90 minutes, settable in 10

minute increments) after the system has entered T emperature Setback.

NORMAL OPERA TION - Normal operating mode of the system in which the

Operating Tip Temperature is displayed.

OPERA TING TIP TEMPERA TURE - The true tip temperature at which the handpiece

tip operates at any given time.

SET TIP TEMPERATURE - The operator selected idle tip temperature entered into

the system memory.

SET-UP MODE - Mode of operation in which the operator can quickly and easily

adjust the system parameters (e.g., temperature limits, password, setback time).

TEMPERATURE ADJUST MODE - Mode of operation in which the operator can

quickly and easily adjust the Set Tip Temperature.

TEMPERATURE DISPLA Y IMPEDANCE (TDI) MODE - Stabilizes the tip

temperature shown on the LED Display by ignoring minor temperature fluctuations.

Displayed changes in temperature are delayed (impeded) for two seconds when a

load is applied to the tip. Two seconds after the load is removed, the displayed

temperature will begin rising to set temperature. Particularly useful in a production

environment for monitoring of set temperatures, since under most production

circumstances the temperature will not deviate.

TEMPERA TURE SETBACK - System feature which, when enabled, will

independently set back the Set Tip T emperature to 177°C (350°F) after a user selected

period of handpiece inactivity (10 to 90 minutes, settable in 10 minute increments).

This feature is enabled (or disabled) in the Set-Up Mode.

TIP OFFSET CONSTANT - Specific value for a given handpiece/tip combination

upon which the system automatically calculates the correct Tip Temperature Offset at

any entered Set Tip Temperature. This value is the temperature loss (Tip Temperature

Offset) at 371°C (700°F) and is set in the Set-Up Mode. A value of 0-115°C (0-240°F)

may be entered in the Set-Up Mode.

TIP TEMPERA TURE OFFSET - Difference in value between the temperature

measured by the temperature sensor (at the heater) and the true temperature of the tip

at a given Set Tip Temperature.

17

Page 22

Operation

NOTE

As with any system, Set and Operating Tip Temperatures are only exactly equal when

the handpiece is idling (unloaded at equilibrium). During use, (i.e., under load) the

Operating Tip Temperature will usually be lower .

Password

The Password feature of the ST 115 system, when activated, will prevent

unauthorized alteration of stored system temperature parameters and feature settings

(refer to T able I, “Factory Settings”). If a Password has been installed, the LED

Display will display an instruction to enter the Password (a 5 key sequence of the

keys on the system front panel) when a setting change is attempted.

Entry of the correct Password at this point will allow the operator to proceed with

the desired changes. Once the correct Password has been entered, the operator can

continue to make changes to Tip Temperature settings. To reactivate the Password

protection, simply turn the system Power Switch off and then back on. The system

is now in normal operation. Refer to the “Set-Up Mode” section of this manual for

instructions on entering, changing or removing a Password.

Auto Tip Temperature Compensation

Differences between the temperature settings and true tip temperatures are negligible

when using Thru-Hole, single point desoldering tips. With any heating system

however, T rue Tip Temperatures can dif fer greatly from temperature settings when

using larger SMT soldering tips. This dif ference is called T ip Temperature Offset.

The ST 115 Auto Tip Temperature Compensation feature lets you set and display

true tip temperatures regardless of size and type of tip or handpiece. PACE

recommends the use of the Tip & Temperature Selection System booklet (P ACE

P/N 5050-0251) as a guide to accurately set and maintain a true tip temperature for

any size and type of SMT tip. The booklet contains a listing of PACE tip information

including the Tip Offset Constant (for each tip) which must be stored in system

memory to ensure tip temperature accuracy. Refer to the “Set-Up Mode” section

of this manual for instructions on using this feature.

18

Page 23

Operation

The ST 115 system is very easy to adjust and operate. The following instructions

detail system features and operation of the system. Also included is a "Quick Tour"

of system operation. Information regarding changing of system options (e.g.,

Temperature Setback time, Auto Off) is contained in the "Set-Up Mode" portion of

this manual.

LED Display, Normal Operation

The LED Display provides a 3 digit display of

temperature information. The LED Display will show:

1. A display of "888" on power up to ensure that

all LEDs on the display are working.

2. A display of the the software version of the

installed microprocessor (e.g., "1-1") for 2 seconds on initial power up

after the "888" is displayed.

3. Actual tip temperature of the connected handpiece during normal operation.

4 The tip temperature displayed will flash when the system is in Temperature

Setback.

5. The displayed temperature will decrease and

stabilize at 177°C (350°F) when the system is in

Temperature Setback.

6. "OFF" when the Set Tip Temperature has been

set to Off (below minimum set tip temperature).

Refer to the "Set-Up Mode" portion of this

manual.

7. "OFF" plus the LED Display will be flashing

when the unit has entered Auto Off. Refer to

the "Set-Up Mode" portion of this manual.

8 Error messages ("OSE", "SSE" or "OCE") if a

system fault is detected. Refer to the

"Corrective Maintenance" portion of this

manual.

19

Page 24

Operation

LED Display, Temperature Adjust Mode

The LED Display will show the following when adjusting the desired Set Tip

Temperature.

1. The Set Tip Temperature.

2. "HiL" (High Temperature Limit) when

adjusting the set tip temperature and the

maximum allowable temperature is exceeded.

Refer to the "Set-Up Mode" portion of this

manual.

3. "OFF" (Low Temperature Limit) when

adjusting the set tip temperature and the

minimum allowable temperature is exceeded.

Refer to the "Set-Up Mode" portion of this

manual.

4. "EP0" will be displayed if a Set Tip

Temperature adjustment is attempted and a

Password has been stored in system memory.

As the 5 key Password is entered, the zero will

increase by one as each key entry is made.

Upon entry of the fifth password key, the

display will change to the Set Tip Temperature

if the entered Password matches the stored

Password.

5. "no" will be displayed if the entered password

does not match the stored Password.

20

Page 25

Operation

Temperature Setback

To preserve tip life and save energy, the ST 115 system can be programmed to

automatically set back its Tip Temperature to 177°C (350°F) after a selected period of

handpiece inactivity (adjustable 10-90 minutes in Set-Up Mode). As received from

the factory, this feature is enabled. Refer to the “Set-Up Mode” section of this

manual to disable or adjust the time-out period of this feature. The operator can also

force the system into Temperature Setback.

Activation

There are two ways in which the system will activate the Temperature Setback feature.

1. AUTOMATIC ACTIVATION - The system memory can be programmed

so that the system will automatically activate Temperature Setback after a

selected period (10-90 minutes) of handpiece inactivity. See the “Set-Up

Mode” section for details on programming this feature.

2. MANUAL ACTIVATION - The operator can manually force the system to

place the system in Temperature Setback by performing the following

procedure.

a) Press and hold the Scroll Down (▼) Key.

b) Press the Scroll Up (▲) Key.

c) Release both keys.

Operation

Temperature Setback is indicated by the following.

1. The LED display will be flashing.

2. The Operating Temperature will stabilize at 177°C (350°F).

21

Page 26

Operation

Exiting Temperature Setback

Listed below are 3 different ways to exit Temperature Setback.

1. Press and release either Scroll Key (▲ or ▼). This is the preferred

method.

2. Wipe the hot handpiece tip on a wet sponge to lower the tip temperature.

3. Method “1” is preferred but you can turn the Power Switch “OFF” ("0")

and then back “ON” ("I").

Set Tip Temperature and Tip Offset Constant values will be simultaneously restored.

Observe the LED Display as the Operating Tip Temperature stabilizes at the Set Tip

Temperature. For optimum performance, do not attempt to use the attached

handpiece until the Set Tip Temperature is achieved.

Auto Off Safety System

When enabled, the Auto Off safety system of the ST 115 system removes power 1090 minutes (enabled/disabled and adjustable in Set-Up Mode) after entering

Temperature Setback.

Operation

When the system has entered Temperature SetBack, an Auto Off timer within the

system circuitry will start running (if Auto Off is turned on in Set-Up Mode):

1. If any key is pressed during the selected time out period, the Auto Off

timer is reset. The system will return to normal operation.

2. At the end of the time out period, the system will enter Auto Off. Power is

removed, the LED Display will show “OFF ” and the display will be

flashing.

Exiting Auto Off

Auto Off can be exited; returning to normal operation by:

1. Pressing and releasing a Key (either of the 3 keys).

OR

2. By turning the Power Switch OFF (“0”) and then back ON (“I”).

22

Page 27

Operation

Quick Tour

1. Ensure that the Set-Up procedure has been performed; including the

Heater Burn In procedure. Check for the following:

a) Handpiece connection to the power source.

b) Proper tip installed in handpiece.

c) Power cord connection between house AC supply receptacle and the

power source.

2. Turn the Power Switch “On” (“I”).

3. Press the Scroll Up (▲) Key. The Set Temperature is now displayed. If no

other Key is pressed within 5 seconds, the system will revert to normal

operation. Allow time for the system to change back.

4. Press the Scroll Up (▲) Key. The Set Temperature is now displayed;

immediately perform step 5.

5. Adjust the Set Temperature in the following manner:

a) Press and release the Scroll Up (▲) Key to increase Tip Temperature in

increments. Press and release the Scroll Down (▼) Key to decrease

Tip Temperature. Observe the display as the Set Temperature

increases in increments of 1°.

NOTE

If a Password has been previously programmed into the system, "EP0" will appear on

the LED Display at this point. When this message appears, the operator must enter

the correct 5 key Password before adjusting the temperature. Refer to "Password"

in the "Operation" portion of this manual.

b) Adjust the temperature by pressing and holding Scroll Up (▲) Key.

Observe the display as the Set Temperature increases first in

increments of 1° and then in increments of 10°. Release the key.

c) Using the Scroll Keys, adjust the temperature to any standard

operating temperature used by your company.

NOTE

The Set Temperature can only be within the set temperature limits. If a limit (upper or

lower) is reached, the lower limit would display “OFF”; the upper limit would not allow

the Set Temperature to exceed that limit. Temperature limits can be adjusted in the SetUp Mode

23

Page 28

Operation

5. Press the Program Key. The system will now return to

normal operation.

6. Observe the Digital Readout as the temperature stabilizes at the desired

Set Tip Temperature

7. Manually force the system into Temperature Setback in the following

manner:

a) Press and hold the Scroll Down (▼) Key and the Scroll Up (▲) Key.

b) Release both keys.

8. The system is now in Temperature Setback. Observe the flashing of the

LED Display and the decreasing of the tip temperature. Allow time for the

temperature to stabilize at 177°C (350°F).

NOTE

If Auto Off has been enabled (turned on in Set-Up Mode), the system will enter Auto

Off (temperature Off and LED Display flashing "Off") after the preset time of handpiece

inactivity. Auto Off can be exited by pressing any key.

9. Manually force the system out of Temperature Setback in either of the

following manners:

a) Press and release a Key (either of the 3 keys). This is the preferred

method.

b) Wipe the hot handpiece tip on a wet sponge to lower the tip

temperature.

c) Turn the Power Switch Off ("0") and then back on ("I").

10. The system is now in normal operation. Observe the LED Display as the

tip temperature increases to the Set Temperature. Allow time for the

temperature to stabilize at the Set Temperature.

NOTE

Read the “Operation” and “Set-Up Mode” sections of this manual to utilize the full

capabilities of the system. This is especially important when using large soldering

tips or other SensaTemp handpieces.

11. If you have a Sodr-X-Tractor or other PACE air handpiece connected to

your system, press and hold the handpiece Vacuum Switch. You will hear

a noise as the motor pump starts up and continues to run. Release the

Vacuum Switch.

24

Page 29

Operation

FACTORY SETTINGS

The ST 115 system comes equipped with a number of features which may be

adjusted, enabled or disabled as desired by the user. Listed below are the features

and factory settings of each. To change and/or learn about any of these features,

refer to the applicable part of the “Set-Up Mode” portion of this manual.

FEATURE

Password None Entered

Default Temperature Scale (°C/°F)

"Hi L" (upper) Temperature Limit 482°C (900°F)

"LO" (lower) Temperature Limit 204°C (400°F)

Set Temperature "OFF"

Tip Offset Constant "0"

Temperature Setback Enabled

Setback Time 30 Minutes

Auto Off Enabled

Time To Auto Off 30 Minutes

FACTORY

SETTING

°F for 115V

Systems

°C for 230V

Systems

Table 1. Factory Settings

25

Page 30

Set-Up Mode

Introduction

The menu driven LED Display of the ST 115 system in the Set-Up Mode allows you

to easily customize your system. No calibration adjustments are necessary to

maintain the accuracy of the system.

In Set-Up Mode, you can:

1. Enter, remove or change a Password.

2. Set the Default Temperature scale to °F or °C as desired.

3. Change the Upper and Lower Temperature limits.

4. Enter a Temperature Offset Constant (Auto Tip Temperature

Compensation).

5. Enable or disable the Temperature Setback feature and adjust the timeout period (if enabled).

6. Enable or disable the Auto Off feature and adjust the time-out period (if

enabled).

7. Enable or disable the Average Temperature feature.

The following instructions should be performed to familiarize the operator with the

system.

Entering Set-Up Mode

1. Place Power Switch in the “OFF” (“0”) position.

2. Press and hold the Program Key.

3. Place Power Switch in the "ON" (“I”) position.

Release the Program Key.

26

Page 31

Set-Up Mode

Operation

Password

4. The LED Display will display the version of the microprocessor and

change to read “P--” or "EP0".

5. If the display reads "EP0", a Password has

been stored in system memory. Enter the 5 key

sequence Password. If the Password entered

is incorrect, "no" appears on the display and

the system then returns to normal operation. If

this occurs, repeat steps 1 through 5 and enter

the correct Password.

6. The LED Display reads "P- -". Choose one

of the following options:

a) Press the Program Key to

keep the currently stored Password

(including no Password).

b) Press and release the Scroll Up (▲) Key to enter a new Password.

c) Press and release the Scroll Down (▼) Key if you wish to remove a

stored password or do not wish to store a Password.

7. If the LED Display now reads "EP0", select and enter a 5 key password

sequence. Make a note of the entered Password. As the Password is

entered, the last digit of the display will count up with each key entry.

After the fifth key entry, proceed to step 8.

Temperature Scale

8. The LED Display now shows the stored

default Temperature Scale (°C or °F

temperature shown on LED Display). Choose

one of the following:

a) Press the Program Key t o keep

the stored default Temperature Scale.

b) Press and release the Scroll Up (▲) Key to

change the default Temperature Scale.

Press and release the Program Key.

27

Page 32

Set-Up Mode

Temperature Limits

9. The LED Display now shows the stored

default High ("Hi") Temperature Limit with the

display alternating to show "Hi" and the

stored limit. Choose one of the following:

a) Press and release the Program Key to keep the stored

High Temperature Limit.

b) Press and release the Scroll Up (▲) Key to increase the stored High

Temperature Limit (up to 482°C, 900°F). Press and release the Program

Key to proceed to the next step.

b) Press and release the Scroll Down (▼) Key to decrease the stored

High Temperature Limit. Press and release the Program Key to proceed

to the next step.

10. The LED Display now shows the stored

default Low ("Lo") Temperature Limit with the

display alternating to show "Lo" and the

stored limit. Choose one of the following:

a) Press and release the Program Key to keep the stored Low

Temperature Limit (204°C, 400°F min.).

b) Press and release the Scroll Up (▲) Key to increase the stored Low

Temperature Limit. Press and release the Program Key to proceed to

the next step.

c) Press and release the Scroll Down (▼) Key to decrease the stored Low

Temperature Limit. Press and release the Program Key to proceed to

the next step.

28

Page 33

Set-Up Mode

Offset Constant

11. The LED Display now shows the stored

Offset Constant with the display alternating

to show "OF" and the stored Offset Constant.

Choose one of the following:

a) Press and release the Program Key to keep the currently

stored Offset Constant.

b) Press and release the Scroll Up (▲) Key to increase the stored Offset

Constant. An Offset Constant of 0-133°C (0-240°F) can be stored.

Press and release the Program Key to proceed to the next step.

c) Press and release the Scroll Down (▼) Key to decrease the stored

Offset Constant. Press and release the Program Key to proceed to the

next step.

NOTE

If the attached handpiece is disconnected when the system is powered up, any stored

Offset Constant is reset to zero. The Offset Constant must be entered again in the SetUp Mode.

Temperature Setback

12. The LED Display now shows the stored

Temperature Setback time as "S-X" (x=0 thru

9). Time is shown as tens of minutes (e.g., "S3" equals 30 minutes). A display of "S- 0"

indicates that Setback is disabled. Choose

one of the following:

a) Press and release the Program Key to keep the currently

stored Temperature Setback time.

b) Press and release the Scroll Up (▲) Key to enable and/or increase the

stored Temperature Setback time. Press and release the Program Key

to proceed to the next step.

c) Press and release the Scroll Down (▼) Key to decrease or disable the

stored Temperature Setback time. Press and release the Program Key

to proceed to the next step.

29

Page 34

Set-Up Mode

Auto Off

13. The LED Display now shows the stored Auto

Off time as "AOx" (x=0 thru 9). Time is

shown as tens of minutes (e.g., "AO3" equals

30 minutes). A display of "AOO" indicates

that Auto Off is disabled. Choose one of the

following:

a) Press and release the Program Key to keep the currently

stored Auto Off time.

b) Press and release the Scroll Up (▲) Key to enable and/or increase the

Auto Off. Press and release the Program Key to proceed to the next step.

c) Press and release the Scroll Down (▼) Key to decrease or disable the

stored Auto Off time. Press and release the Program Key to proceed to

the next step.

Temperature Display Impedance

14. The LED Display now shows the Temperature

Display Impedance mode as Enabled or

Disabled ("AC0" = Disabled and "AC1" =

Enabled). Choose one of the following:

a) Press and release the Program Key to keep the currently

stored setting (Disabled or Enabled).

b) Press and release the Scroll Up (▲) Key to change the stored setting

(Disabled or Enabled). Press and release the Program Key to proceed

to the next step.

Exiting Set-Up Mode

15. The LED Display now reads "End". The SetUp Mode procedure is now complete. Choose

one of the following steps:

a) Press and release the Scroll Up (▲) Key to

exit Set-Up Mode and return to normal

operation.

b) Press and release the Scroll Down (▼) Key to return to the start of the

Set-Up Mode procedure. Go back to step 4.

30

Page 35

Repair

Repair Procedure

The "Repair" section of this manual provides the technician with the information

necessary to determine the source of a malfunction and take the necessary steps to

correct it. In order to perform the most expedient repair, the technician must follow

the process listed below step by step, in order. Failure to do so will make the

diagnosis and repair much more difficult.

1. Periodic Maintenance - Required on any PACE handpieces used. Refer to

the handpiece portion of this manual for specific instructions. No periodic

or special maintenance is required on the power source.

2. LED Display Message Codes - Many operation errors or system

malfunctions are detected by the system and displayed on the LED

Display. Check the LED Display for error messages and refer to

the LED Display Message Codes table (Table 2).

3. Corrective Maintenance - A guide for resolving minor malfunctions.

Locate the "Symptom" in the Corrective Maintenance Table which

best describes the malfunction. Check each point described under

"Solution" in order of listing.

4. Disassembly/Assembly - Contains simple instructions which enable

the technician to open/close the unit for servicing.

5. Repair Drawings - Exploded power source, wiring diagram and

schematic are included as aides in troubleshooting and repair.

6. PACE Service Department - If the cause for malfunction has not

been determined at this point, call the PACE Service Department

at tel.1-888- 535-PACE (toll free) or FAX 301-483-7030.

31

Page 36

Repair

LED Display Accuracy

No adjustments are necessary to maintain the accuracy of the system.

LED Display Message Codes

Following LED Display message codes which may appear if a mistake is made by the

operator (e.g., wrong Password entry) or if the system has malfunctioned.

LED Display Message Description

The incorrect Password has been entered. The displayed

message will time out after 6 seconds and revert to

normal operation. Enter the correct Password.

No handpiece is connected to the Power Receptacle.

Connect handpiece.

The LED Display is

flashing.

The handpiece heater assembly sensor is open. Refer

to Table 4 to check handpiece.

The handpiece heater assembly sensor is shorted.

The LED Display is

flashing.

The LED Display is

flashing.

Refer to Table 4 to check handpiece.

The handpiece heater assembly may be defective.

Refer to Table 4 to check handpiece.

Power source malfunction. Call the PACE Service

Department for assistance.

Tel. 1-888-535-7223 (toll-free), FAX 1-301-483-7030.

Table 2. LED Display Message Codes

32

Page 37

Repair

Corrective Maintenance

Power Source

Most malfunctions are simple and easy to correct. Refer to Table 3 below to clear

these malfunctions.

Symptom Probable Cause Solution

No power to system. Blown Fuse Check handpiece using

"Heater Assembly Checkout

Procedures", Table 4.

Replace fuse located in AC

Receptacle/Fuse Holder.

Insufficient vacuum or air

pressure.

Motor Pump runs.

No vacuum or air

pressure.

Motor Pump does not

run.

Handpiece air hose

has a kink or hole in

hose.

VisiFilter or handpiece

filter clogged.

Handpiece chamber

not seated properly in

handpiece.

Defective Motor Pump

Assembly.

Defective handpiece. Check handpiece using

Defective Motor Pump

Assembly.

Defective Main PCB

Check handpiece hose.

Replace air hose if

necessary

Replace VisiFilter or

handpiece filter.

Check handpiece. Reseat

chamber if necessary.

Check vacuum and air

pressure at Motor Pump

Assembly air hose

connections. Replace

Motor Pump Assembly if

necessary.

"Heater Assembly Checkout

Procedures", Table 4.

Check for 12 VDC at motor

terminals with handpiece

switch actuated. Replace

Motor Pump Assembly if

defective.

If there is no 12 VDC at

Table 3. Power Source Corrective Maintenance

33

Page 38

Repair

Handpieces

The following “Heater Assembly Checkout Procedures” (Table 4) is applicable to

all PACE SensaTemp handpieces used with the ST 115 system except for the TT65 and DTP-80handpieces. Refer to the applicable manuals for troubleshooting

procedures pertinent to that handpiece. Perform the procedures with the

handpiece heater at room temperature. If the heater is warm, resistance readings will

be different from those shown. Disconnect the handpiece from the power source.

Use a meter to check resistance across the handpiece connector plug pins as

outlined in the “Checkout Procedure” column.

Symptom Checkout Procedure Cause Solution

Handpiece

does not heat.

Handpiece

overheating.

Fuse blows

when unit is

turned on.

No Ground on

Tip.

Check resistance - Pin 2 to

Pin 5. Refer to "Heater

Specifications" column.

If resistance is high - -

Check resistance - Pin 3 to

Pin 6. If circuit reads open -

Check resistance - Pin 3 to

Pin 6. Resistance should be

110 ohms. If resistance is

less than 105 ohms - -

Check resistance - Pin 2 to

Pin 5. Refer to "Heater

Specifications" column. If

resistance is low - -

Check resistance - Pin 4 to

a NEW Tip. Resistance

should be less than 2 ohms.

If not - -

Heater Specifications

PS-80 = 8-10 ohms

SX-80 = 8-10 ohms

SX-70 = 8-10 ohms

Open Heater Replace Heater

Open Sensor Replace Heater

Shorted

Sensor

Shorted

Heater

Oxidation in

Heater Bore.

Defective

Heater

Assembly.

Assembly.

Replace Heater

Assembly.

Replace Heater

Assembly & Fuse.

Clean Heater Bore

using appropriate

wire brush.

Replace Heater

Assembly.

Connector

Plug Pinouts

TP-65 = 9-11 ohms

TJ-70 = 6-8 ohms

Table 4. Heater Assembly Checkout Procedures

34

Page 39

Repair

Disassembly/Assembly

To remove the ST 115 power source cover, perform the following procedure step by

step, in sequence using the accompanying illustrations as a guide.

CAUTION

POTENTIAL SHOCK HAZARD - Disassembly of the ST 115 system power source

(PPS 115) exposes line voltage parts. Replacement of the Pump Assembly must be

performed by qualified service personnel only. Service personnel must insure that the

AC power cord is disconnected prior to disassembly. Contact the PACE Technical

Support for assistance at tel. 1-888-535-PACE (7223), FAX 1-301-483-7030.

1. Place the unit on a suitable work surface with the front of the power

source facing forward.

2. Disconnect the AC power cable from the unit (if present).

NOTE

Use all ESD control precautions when servicing the ST 115 system. The power source

contains a PCB assembly utilizing static sensitive components.

NOTE

At this point, you may wish to remove any accessories attached to the power

source to ease removal of the 2 Cover Mounting Screws (step 6).

3. Remove the 4 Front Panel

mounting screws located at

each corner of the Front Panel

Bezel.

4. Pull the Front Panel and Bezel

forward.

35

Page 40

Repair

5. Reposition the unit with the

rear of the power source

facing forward.

6. Remove the 3 upper Rear

Panel mounting screws.

7. A Cover Mounting Screw is located on each side of the power source

(positioned bottom center). Remove the 2 Cover Mounting Screws.

8. Lift the Cover from the power source. Set Cover aside.

9. The power source components are now exposed for servicing. When

replacing the Main PCB Assembly or the Motor Pump Asembly, separate

instructions are supplied with the part.

10. To assemble the power source, perform steps 1 through 8 in reverse order,

installing parts (e.g., screws) instead of removing.

36

Page 41

Repair

Assembly Detail

• Rear Panel

‚ Motor Pump Assembly

ƒ Front Panel

„ PCB Assembly

… Transformer

37

Page 42

Wiring Diagram

Repair

38

Page 43

Repair

Schematic

39

Page 44

Repair

40

Page 45

Packing List/Spare Parts

Packing List

Quantity Supplied

This is a packing list of the items shipped with the system and is current at

the time of publication of this manual.

Item # Description Part # ST 115 ST 115E ST 115 ST 115E

1 ST 115 System Power Source - - - - - 1 1 1 1

2 SX-80 Handpiece, (48 Watts) 6010–0106 1 1 1 1

3 Power Supply Cord, 115 VAC 1332-0094 1 0 1 0

4 Power Supply Cord, 230 VAC 1332-0093 0 1 0 1

5 Tip & Tool Stand Kit 6019-0060-P1 1 1 0 0

6 SX-80 Accessory Kit - - - - - 1 1 1 1

7 Portability Kit 6018-0109-P1 0 0 1 1

8 Air Fitting Adaptor 1259-0081 0 1 0 1

9 Operation & Maintenance Manual 5050-0460 1 1 1 1

10 Tip Tool 1100-0206 1 1 1 1

ST 115-SX80

Systems

Table 5. Packing List

Spare Parts

Item # Description Part Number

Fuse,(F1), 1.25 Amp Time Lag, 115 Volt Systems 1159-0251

1

Power Cord 115 Volt Systems 1332-0094

2

3 Power Switch 1157-0081

4 Bumpon (rubber foot) 1274-0021

5 PCB Assembly 6020-0124-P1

6 Motor Pump Assembly 1336-0037-P1

Accessories & Spare Parts (partial list, complete listing in catalogue)

7 Tip & Temperature Selection System Booklet 5050-0251

8 SX-80 Sodr-X-Tractor Handpiece 6010-0106-P1

9 SX-80 Heater Assembly 6010-0107-P1

10 PS-80 Handpiece 6025-0014-P1

11 DTP-80 Dual ThermoPik Handpiece 7029-0001-P1

12 TT-65 ThermoTweez Handpiece 7025-0001-P1

13 TP-65 ThermoPik Handpiece 7024-0001-P1

14 TJ-70 ThermoJet Handpiece 7023-0002-P1

Table 6. Spare Parts

0.63 Amp Time Lag, 230 Volt Systems 1159-0252

230 Volt Systems 1332-0095

ST 115P-SX80

Systems

41

Page 46

LIMITED WARRANTY

(1) year from the date of receipt by the first user.

storage. Failure to perform recommended routine maintenance, alterations or repairs made other than in

accordance with PACE’s directions, or removal or alteration of identification plates in any way will void this

etc., except that heaters are normally warranted for a period of six (6) months from the date of receipt by the

approved by it at no charge to the user, or provide parts without charge for installation by the user in the field

at user’s expense and risk. User will be responsible for all costs of shipping equipment to PACE or other

(or local authorized PACE Distributor outside the U.S.) within a reasonable time of the expiration date of this

PACE warrants that this equipment will be free of defects in materials and workmanship for a period of one

This warranty does not cover repair or replacement required as a result of misuse, mishandling or improper

warranty. This warranty is available only to the first user, but the exclusions and limitations therein apply to all

persons and entities.

This warranty does not apply to consumable items, such as tips, filter elements, hoses, collection chambers

first user.

PACE MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, AND MAKES NO

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

PACE will, at its option, repair or replace any defective equipment or parts at its facility or other location

warranty location for warranty service.

EXCEPT FOR THE REMEDY ABOVE DESCRIBED, UNLESS OTHERWISE REQUIRED BY

APPLICABLE LAW, PACE WILL HAVE NO OTHER OBLIGATION WITH REGARD TO ANY

BREACH OF WARRANTY OR OTHER CLAIM WITH RESPECT TO THE EQUIPMENT, OR

LIABILITY FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, OR INCIDENTAL LOSS OR

DAMAGE CAUSED BY OR OCCURRING IN CONNECTION WITH ANY OF THE EQUIPMENT.

To obtain warranty service, contact the appropriate PACE company listed below

PACE Inc. 9893 Brewers Court, Laurel, Maryland 20723-1990

Tel. (888) 535-7223 (toll-free) Warranty Service FAX 301 483 7030

PACE Europe Ltd. Sherbourne House Sherbourne Drive Tilbrook Milton Keynes

United Kingdom MK7 8HX

Tel. (44) 01908 277 666 Warranty Service FAX (44) 01908 277 777

Do NOT return defective equipment or parts to PACE without obtaining prior authorization.

Any warranty or other claim with respect to the equipment must be made in writing and delivered to PACE

warranty. Sufficient evidence of purchase and date of receipt must also be included, otherwise user’s rights

under this warranty shall be deemed waived.

42

Loading...

Loading...