Page 1

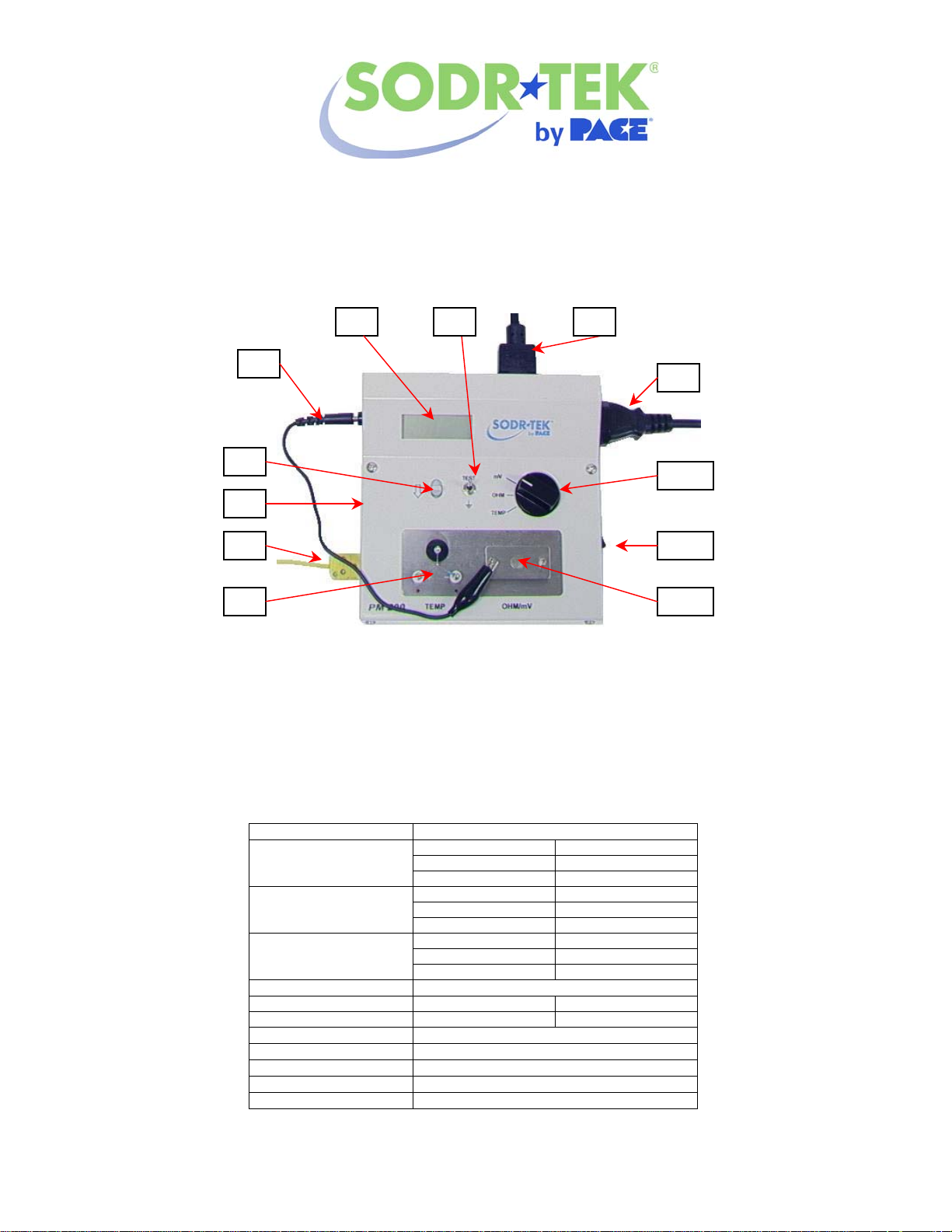

Parts Identification

1. Temperature Sensor.

2. External K-Type Thermocouple.

3. C / F Switch

4. Sensor Tension Control.

5. Grounding Cable with Clip.

6. LCD Display.

Specification

PACE PM 200 Process Monitor

PACE PART NUMBER 8007-0464-P1

Operation and Maintenance Instructions

MANUAL NUMBER 5050-0562

7. Test /Ground Switch.

8. Power Cord / Power Inlet.

9. Male to Female Power Cord / Power Outlet.

10. Function Control.

11. Power Switch.

12. Conduction Plate.

Item Temperature Tester

Measuring Range Temperature 0-600 °C / 32-1200 °F

Voltage 0-90mV (AC)

Resistance 0-90 Ω

Resolution Temperature 1 °C / 1 °F

Voltage 0.1mV

Resistance 0.1 Ω

Accuracy Temperature ± 3 °C ± 6 °F

Voltage ± (3%±2 digit)

Resistance ± (1%±2 digit)

Temperature Sensor K Type Thermocouple

Display Liquid Crystal Display 3.50Digits

Display of Over-range -1,1

Voltage Measurement Conform to MIL-STD-2000

Power Consumption 1W

Dimension 150mm (W) X 55mm (H) X 150mm (D)

Weight Approximately 910 grams (2 lb

Operational Environment 0-40 °C /32-104 °F 0-80RH%

©2005 PACE Incorporated, Annapolis Junction, MD All Rights Reserved. Printed in the USA

www.paceworldwide.com

Page 2

Maintenance

1. Periodically remove flux splatter from unit using an alcohol-moistened cloth.

2. Repeated measurement will cause sensor to wear out. A properly installed sensor is critical to

the accuracy of this device.

3. Handle the temperature sensor carefully. The temperature sensor is extremely thin and may

break if handled incorrectly.

4. Before measuring, coat the soldering tip with fresh solder. This is necessary to ensure proper

contact between the tip and temperature sensor or tip and conduction plate.

5. When performing test, never let the soldering tip touch the stainless steel housing below the

measuring point. An error in measurement will occur.

6. Insure the power source is properly ground before operating this device.

7. If tests are preformed using the PACE TD-100 handpiece, make sure the Tip Heater Cartridge is

seated firmly in handle.

8. When operating the PS-90 or SX80 handpiece, make sure inside surfaces of the heater

assembly and setscrew are clean and free of oxidation. Insure the setscrew is tight before

continuing with test.

Sensor Installation

1. To install a new sensor (P/N 1285-0046-P1), adjust the

tension control slide to the down position.

2. Slip sensor loops onto the three posts making sure to

match positive and negative end to corresponding post.

Tension control

Note

Open sensor error will be displayed as “1”. Check

sensor post connections. If necessary, replace sensor.

Sensor posts

Measuring Tip Temperature

1. Connect power cord to PM200.

2. Connect your PACE soldering station power supply with handpiece

and tip to the PM200 using the supplied male to female power

cable.

3. Turn both the PM200 and soldering station power switch to the ON

position.

4. Select Celsius or Fahrenheit using the °F / °C Conversion Switch

on left side of unit.

5. Turn the dial control switch to “TEMP” position.

6. Clean and re-tin the handpiece tip with fresh solder.

7. Hold tip of handpiece to temperature sensor and heat the solder until display stabilizes. Add solder to tip

until sensor is immersed in solder.

8. Record displayed temperature value.

©2005 PACE Incorporated, Annapolis Junction, MD All Rights Reserved. Printed in the USA

www.paceworldwide.com

Page 3

A

Measuring the Difference In Potential Between Tip and Ground

1. Connect power cord to PM200.

2. Connect your PACE soldering station power supply with handpiece to the PM200 using the supplied male

to female power cable.

3. Turn both the PM200 and soldering station power switch to the ON position.

4. Set power supply temperature to the highest setting possible. (900 ºF for Sodr-Tek units / 850 ºF for THC

models).

5. Turn the dial control switch to “mV” position.

6. Using the ground clip cable, connect the ground terminal (GRD) on the left side of the PM200 to the

conduction plate. DO NOT touch handpiece tip to the conduction plate during this step.

Holding the test / ground switch while recording displayed values will produce the

same internal grounding condition as the ground clip cable.

7. Record the value displayed on the LCD display as V 1.

8. Disconnect the ground clip from the conduction plate.

9. Clean and re-tin the handpiece tip with fresh solder.

10. Using the soldering handpiece, place a small bead of soldering

the center of the conduction plate and heat the solder until it has

become completely melted.

11. When the LCD display has stabilized, record the value as V 2.

12. Subtract V 1 from V 2 to derive the difference in potential

between the tip and ground.

Example: V 1 (00.1) – V 2 (00.9) = 0.8mV

Measuring the Resistance Between Tip and Ground

1. With PM200, soldering station, and handpiece connected, power on both units.

2. Set tip temperature to the highest setting possible. (900ºF for Sodr-Tek units / 850 ºF for THC models).

3. Turn the dial control switch to “OHM” position.

4. Using the ground clip cable, connect the ground terminal (GRD) on the side of the PM200 to the

conduction plate.

5. Record the value displayed on the LCD display as R1.

6. Disconnect the ground clip from the conduction plate.

7. Clean and re-tin the handpiece tip with fresh solder.

8. Using the soldering handpiece, place a small bead of soldering the center of the conduction plate and

heat the solder until it has become completely melted.

9. When the LCD display has stabilized, record the value as R2.

10. Subtract R1 from R2 to derive the resistance from tip to ground.

Example: R1 (00.1) - R2 (00.4) = 0.3Ω

Note

PACE Incorporated

9030 Junction Drive

nnapolis Junction,

MD 20701

Tel: (301) 490-9860

Fax: (301) 498-3252

PACE Europe Limited

13 Tanners Drive

Blakelands

Milton Keynes

Tel: (44) 1908-277666

Fax: (44) 1908-277777

©2005 PACE Incorporated, Annapolis Junction, MD All Rights Reserved. Printed in the USA

www.paceworldwide.com

Loading...

Loading...