Page 1

10 Series CNC

PLUS LIBRARY

User Manual

Code: 45006682C

Rev. 09

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

e-mail: sales@osai.it

Web: www.osai.it

Copyright 20001-2002 by OSAI

All rights reserved

Edition: July 2001

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of the

product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment described

in this text.

Page 2

ABC

ABC

Page 3

Update

10 Series CNC PLUS Library - User Manual

SUMMARY OF CHANGES

General

This publication has been issued with the software release 6.1.

This issue completely replaces the previous ones (MOV.08)

PAGE TYPE OF UPDATE

INDEX updated

CHAPTERS 5, 6, 9, 10, 11 updated: the various functions with maximum process number to 20

CHAPTER 7

page 16 corrected: diagrams to which the $ANAIN function refers

CHAPTER 10

page 3 inserted: parameter 9 RCM in function $GBPROVAR

CHAPTER 11

page 7 inserted: Pilot Panel management in the multi-process environment

CHAPTER 12

pages 29, 32

pages 36, 38

page 41

page 63

page 65

pages 66, 67

APPENDIX D modified: field 7 in the axes table

APPENDIX G inserted: missing error messages

inserted: parameters 24 and 25 for reading Jerk information in function

$AX_GET7

inserted: parameters 21 to 25 in function $AX-PUT1.

inserted: note concerning the parameter “STANDSTILL_GAIN”

inserted: examples and details for the parameters for using function

$AXD_RDD

inserted: new results in the description of function $AXD_WRD

added: new considerations in the description of functions $AXD_RDS

and $AXD_WRS.

10 Series CNC PLUS Library - User Manual (09)

Page 4

asda

Page 5

Preface

10 Series CNC PLUS Library - User Manual

PREFACE

This manual contains the description of all block functions (FB) needed for the logic application

projects of the 10 Series CNC.

It contains the corresponding instruction list (IL) code for each FB and a description of the input and

output variables.

This manual deals specifically with functions and function blocks. For further information on PLUS, its

language and its applications in the 10 Series CNC environment consult the following manuals:

10 Series CNC PLUS APPLICATION MANUAL Code 45006677Z

10 Series CNC PLUS LANGUAGE & PLUSEDIT Code 45006672 P

You can find an FB or a function more easily if you look up the Function Reference List below in this

preface.

In this list the functions are ordered alphabetically and for each of them there is a short description

plus the page number.

In this manual the various function blocks have been subdivided into groups depending on the type of

operation they fulfil or the environment to which they belong. So if you do not know the exact name of

an FB, but know the environment to which it refers, you can easily find the FB in the manual by

consulting the index.

COMMON FEATURES OF FUNCTION BLOCKS:

All function blocks can be used in the Ladder Diagram / Function Block Diagram (LD/FBD) editors

and in the MACRO Instruction List (MACRO-IL) editor. The function blocks discussed in Chapters 1

and 3 are base function blocks i.e. built from standard elements of the instruction list (IL). All the

other function blocks are extensions which internally use a function call. These functions can also be

used in the IL editor. For each FB there is an example for the calls and the necessary parameters in

IL.

NOTE:

When using function calls in IL, there is no control to ensure that the number and type of parameters

are correct.

When using the MACRO-IL editor, the function block parameters are always checked.

10 Series CNC PLUS Library - User Manual (09) 1

Page 6

Preface

10 Series CNC PLUS Library - User Manual

enable input

Many of the function blocks shown in this manual have an “enable” input which enables/disables the

execution of the block.

• Enable is a Boolean variable which can be inverted if necessary.

• You can link all types of Boolean variables available in PLUS including the Boolean constants KB1

and KB0.

• The enable signal linked to the FB P1 (pulse) or the use of FBs for controlling the program flow

allows you to write faster and attain a more efficient machine code. In general it is better to try to

limit the number of always enabled FB (enable always = 1) by disabling them when their function

is not required, in order to increase the performance of the machine logic.

stat_wrd output (function status output word)

The function status output is available on all system function blocks. After the relevant function has

been completed, this word contain a value indicating that all went well or that there was some kind of

problem. When everything was ok, the status word will be zero. In case of problems the value of the

status word is different from zero. Please refer to the specific function block for the meaning of the

values returned in the status word.

Often you're not interested in knowing the status of the functions because your program has been

tested and always works well. You can then hook up only one single short variable, e.g. MW 999, to

the status output of many functions.

ax_id input (physical axis identifier)

The axis identifier is used for many system functions. It is a number identifying the internal resources

for one axis on an axes module. Each axes module supports 8 axes, 6 resources are reserved for

physical axes (which read encoders and/or write to D/A converters) and 2 for virtual axes. A machine

axis (e.g. "X") may be related to any of the available physical axis resources on any of the axes

modules.

There can be up to 4 axes modules in the 10 Series CNC chassis, allowing for up to 32 axes

(theoretically). The axis identifier now, is a number in the range of 1 through 32. It must be assigned

during the axes configuration in AMP and will also serve to define the page number of the axes table

on which this axis will be managed.

Even when you move the physical connections (encoder, D/A) of an axis to another axes module, its

ax_id will remain unchanged and the axis data will remain available on the same page of the axes

table.

The function A_TO_ID converts an ASCII axis address to its physical axis identifier number.

tc_id input (transducer/converter physical identifier)

The identifiers of the tansducer inputs are numbers in the range of 100Hex up to 1nnHex. On the first

servo module you will find (top to bottom) the transducers 100Hex through 105Hex, on the second

106Hex through 10BHex, on the third module 10CHex through 111, and so on.

The D/A converters have a similar numbering system. On the first module you will find the converters

200Hex through 205Hex, on the second module 206Hex through 20BHex, and so on.

2 10 Series CNC PLUS Library - User Manual (09)

Page 7

Preface

10 Series CNC PLUS Library - User Manual

symbolic names

Symbolic names to be associated to the user subroutine (DSRB) and to the label (LBL) must be

different from those predefined in PLUS (FB names, predefined routines, etc.) and should never begin

with a $.

Furthermore, symbolic names should always begin with a letter and not with a number.

TYPES OF SYSTEM FUNCTION CALLS

There can be 3 different types of system function calls (system function blocks):

WAIT

A WAIT function call suspends the execution of the task that called it. This task will resume its

activity after the function has been completely executed.

The suspension of a task implies the suspension of all routines that make up this task. The WAIT

function is normally executed by an environment other than the I/O processor module (the system).

For this reason a WAIT function is a synchronous call: when the logic scan exits from a WAIT

function block, this block has been completely executed.

NOWAIT

A NOWAIT function call does not suspend the execution of the logic task that called it. Immediately

after the call has been issued, the logic task resumes execution. The function call will be executed

by an environment other than the I/O processor module (system).

For this reason a NOWAIT function is an asynchronous call: when the logic scan exits from a

NOWAIT function block, the function is still being executed by another environment.

The execution of many NOWAIT function calls from a logic task may cause a system overloading

since the simultaneous execution of many functions is required.

When 15 NOWAIT functions are in parallel execution, the function that has generated the last call is

in any case executed and it returns to the word status a warning code (1000 hexadecimal).

If you continue to call NOWAIT functions after the warning message, that is when 25 functions are in

parallel execution, an unrecoverable emergency is generated ("too many requests").

INTERNAL

An INTERNAL function is similar to a WAIT function call but its execution is much faster because it's

done by the same environment that calls the function (PLUS). An INTERNAL function call is in all

aspects like a subroutine available to the PLUS environment. For this reason an INTERNAL function

is a synchronous call: when the logic scan exits from an INTERNAL function block, this block has

been completely executed.

10 Series CNC PLUS Library - User Manual (09) 3

Page 8

Preface

10 Series CNC PLUS Library - User Manual

LIST OF THE BASE ELEMENTS OF THE LANGUAGE

$=N Boolean inverter..............................................................................................1-5

$<< Logically shift 16 bit word sc places left ............................................................1-9

$>> Logically shift 16 bit word sc places right ........................................................ 1-10

$ADD Add two or more floating point numbers ...........................................................1-16

$ADDW Add two or more 16 bit words .........................................................................1-11

$AND Boolean AND gate..........................................................................................1-5

$ANDW Bitwise logical AND on 16 bit words ..................................................................1-8

$BCD_BIN Convert an integer from BCD to binary .............................................................1-13

$BIN_BCD Convert an integer from binary to BCD............................................................. 1-13

$CAL Call user defined subroutine and pass parameters............................................1-20

$CTD Count Down....................................................................................................3-3

$CTR Counter Reset ................................................................................................3-3

$CTS Set Counter Accumulator = Preset Value ..........................................................3-3

$CTU Count Up........................................................................................................3-3

$DECW Decrement word............................................................................................ 1-11

$DIV Divide floating point numbers, floating point result............................................. 1-17

$DIVW Divide two shorts, short result ........................................................................ 1-12

$DLY Wait for time-out ........................................................................................... 1-25

$DSBR Define user subroutine ...................................................................................1-20

$DTSK Define PLUS routine ......................................................................................1-21

$ELSE Alternative execution of a part of the program................................................... 1-26

$ENDIF End of alternative execution part of the program............................................... 1-26

$EQ Double equal comparison (I1 = I2)...................................................................1-31

$EQW Equal comparison of two words (I1 = I2).......................................................... 1-29

$ESBR Define End of user subroutine......................................................................... 1-20

$ETSK Define end of PLUS routine............................................................................ 1-21

$GE Double greater equal comparison (I1 >= I2)...................................................... 1-32

$GEW Greater equal word comparison (I1 >= I2)....................................................... 1-30

$GOTO Conditional jump to label................................................................................ 1-22

$GT Double greater than comparison (I1 > I2)......................................................... 1-32

$GTW Greater than comparison for words (I1 > I2) ..................................................... 1-30

$IF Conditional execution of a part of the program.................................................. 1-26

$IFWAIT Semaphore state inquiry................................................................................ 1-24

$INCW Increment word............................................................................................. 1-11

$LBL Define jump label .......................................................................................... 1-22

$LE Double less or equal comparison (I1 <= I2) ......................................................1-31

$LEW Less or equal comparison for words (I1 <= I2) ................................................1-29

$LT Double less than comparison (I1 < I2)............................................................. 1-31

$LTW Less than comparison for words (I1 < I2)......................................................... 1-29

$MOD Division remainder .........................................................................................1-13

$MUL Floating point multiplication............................................................................ 1-17

$MULW Multiply two shorts, short result...................................................................... 1-12

$NE Double not equal comparison (I1 <> I2)........................................................... 1-32

$NEG Negate word (2's complement).........................................................................1-9

$NEGD Invert sign of floating point number.................................................................. 1-15

$NEW Not equal comparison for words (I1 <> I2)........................................................ 1-30

$NOT Invert a 16 bit word (1's complement)................................................................1-9

$OR Boolean OR gate............................................................................................1-5

$ORW Bitwise logical OR 16 bit words ........................................................................1-8

$P1 Impulse on rising edge of inp I1 ...................................................................... 1-33

$P2 Divide by 2 element....................................................................................... 1-33

4 10 Series CNC PLUS Library - User Manual (09)

Page 9

Preface

10 Series CNC PLUS Library - User Manual

$P3 Impulses on rising and falling edges of input signal I1....................................... 1-34

$R/S RS flip flop with RESET priority ........................................................................1-6

$RES Reset a 16 bit word to 0................................................................................. 1-10

$RESD Reset a floating point variable (to 0) ................................................................ 1-15

$S/R RS flip flop with SET priority .............................................................................1-7

$SEND SEND a semaphore ...................................................................................... 1-23

$SET Set a 16 bit word to a value ............................................................................1-10

$SETD Set a floating point variable to a value.............................................................. 1-15

$STRADD Concatenation of strings ................................................................................ 1-14

$SUB Subtract floating point numbers ...................................................................... 1-16

$SUBW Subtract two or more 16 bit words .................................................................. 1-12

$TIM Timer enabled .................................................................................................3-7

$TMR Timer Reset/Preset .........................................................................................3-7

$WAIT Wait on semaphore .......................................................................................1-23

$XCH Swap low and high byte in a 16 bit word ............................................................1-9

$XOR Boolean XOR gate...........................................................................................1-6

$XORW Bitwise XOR operation on 16 bit words..............................................................1-8

10 Series CNC PLUS Library - User Manual (09) 5

Page 10

Preface

10 Series CNC PLUS Library - User Manual

FUNCTION REFERENCE LIST

$232_INIT: Initialize the RS 232 interface...........................................................................7-5

$232_RESE: Reset the RS 232 interface ............................................................................7-13

$232_RXD: Receive a data buffer via the RS-232 interface.................................................. 7-10

$232_RXS: Receive an ASCII string via the RS 232 interface.............................................. 7-12

$232_STAT: Get the RS-232 interface status ..................................................................... 7-14

$232_TERM: Set termination characters used in message handling........................................7-6

$232_TXD: Transmit data buffer via the RS 232 interface.....................................................7-8

$232_TXS: Transmit an ASCII string via the RS 232 interface...............................................7-9

$A_TO_ID: Requests conversion from process axis name to axis identifier.......................... 2-31

$AABORT: Abort a point-to-point-interpolator ......................................................................8-3

$ACLOSE: Close channel for point-to-point-interpolator .......................................................8-4

$ACOS: Calculate the angle for a given cosine ...............................................................4-6

$ACTOFFS: Request activation of a tool offset .....................................................................9-5

$ACTRES: Request an active reset to be executed........................................................... 13-2

$ANAIN: Read one of the analog input channels of the I/O processor module ...................7-16

$AOPEN: Open channel for point-to-point-interpolator ........................................................8-5

$ARESET: Request to reset a point-to-point-interpolator......................................................8-6

$ASIN: Calculate the angle for a given sine value...........................................................4-5

$ATAN: Calculate the angle for a given tangent value ......................................................4-7

$ATOF: Convert an ASCII string to a floating point number..............................................2-4

$ATOI: Convert an ASCII string to an integer number (16 bit)..........................................2-2

$AUX_STAT: Read the status of a point-to-point axis and the spindle.................................... 8-18

$AX_CHAS: Change the servo mode of an axis.................................................................. 12-4

$AX_DISA: Disable the servo loop of an axis or disable its D/A converter. .............................6-3

$AX_ENAB: Enable the servo loop of an axis or enable its D/A converter................................6-2

$AX_GET1: Get axis (spindle) servo parameters..............................................................12-15

$AX_GET2: Get axis (spindle) servo parameters..............................................................12-17

$AX_GET3: Get axis (spindle) servo parameters..............................................................12-20

$AX_GET4: Get axis (spindle) servo parameters..............................................................12-22

$AX_GET5: Get axis (spindle) servo parameters..............................................................12-24

$AX_GET6: Get axis (spindle) servo parameters..............................................................12-26

$AX_GET7: Get axis (spindle) servo parameters..............................................................12-28

$AX_GET8: Get axis (spindle) servo parameters..............................................................12-33

$AX_GETS: Get axis status...........................................................................................12-46

$AX_PROB: Enable probing signal for one or more axis ...................................................... 12-5

$AX_PUT1: Set axis servo parameter.............................................................................12-35

$AX_PUT2: Set axis servo parameter.............................................................................12-42

$AX_PUT3: Set axis servo parameter.............................................................................12-44

$AX_RDPB: Read the probed positions of one or more axis................................................. 12-6

$AX_RESE: Aborts the actual operation of the addressed axis............................................ 12-8

$AX_RPOS: Resets the axis' position..............................................................................12-13

$AX_SELE: Activate axis monitor functions / gear range...................................................12-11

$AX_SETZ: It allows the activation of different functions for the specified axis .....................12-14

$AX_ZSH1: Write PLUS zero shift offset #1 ...................................................................... 12-9

$AX_ZSH2: Write PLUS zero shift offset #2 ....................................................................12-10

$AXD_PUT: It sets the enable/disable bits of a digital drive associated with a D.S.I.

axis...........................................................................................................12-68

$AXD_RDD: It reads a numerical parameter from a digital drive associated to a D.S.I.

axis...........................................................................................................12-63

$AXD_RDS: It reads a string parameter from a digital drive associated to a D.S.I. axis.........12-66

$AXD_WRD: It writes a numerical parameter to a digital drive associated to a D.S.I. axis......12-65

6 10 Series CNC PLUS Library - User Manual (09)

Page 11

Preface

10 Series CNC PLUS Library - User Manual

$AXD_WRS: It writes a string parameter to a digital drive as sociated to a D.S.I. axis............12-67

$AXMANFED: It sets the feedrate override for one or more axes in manual movement ...............5-41

$AXSELEC: Select one or more axes for manual operations ................................................5-16

$AXSELFED: It selects one or more axes allowing to change feedrate override ....................... 5-40

$AXTAN_D: It disables the tangent axis algorithm .............................................................6-14

$AXTAN_E: Tangent axis algorithm enabling ..................................................................... 6-12

$COMPOFF: Compute new axes offset .................................................................................9-7

$CON_LED: It manages the leds on the OPLink operator panel .........................................11-14

$COS: Calculates the cosine of an angle.....................................................................4-3

$CTOW: Convert a character to a word ...........................................................................2-9

$CYCLE: Request cycle start for a selected process ........................................................5-3

$CYSTART: Request cycle start for a selected process ........................................................5-2

$CYSTOP: Request cycle stop for the selected process .....................................................5-4

$DE_ETH: Enables or disables communication via Ethernet ...........................................13-10

$DIVF: Division of two short operands with a double result........................................... 2-29

$ENDRESE: Logic has finished reset actions ..................................................................... 5-19

$EXP: Calculates the power of “e” raised to the power of X..........................................4-11

$FAST_RD: Reads data from a dedicated DP area .............................................................13-8

$FAST_WR: Writes data in the DP dedicated area.............................................................. 13-6

$FAX_GET: Reads in real time axis parameters ...............................................................12-61

$FAX_PUT: Real time updating of an axis' zero shift value................................................12-59

$FAX_RCON: Configures the driver for real time data communication from AXES to PLUS...... 12-57

$FAX_WCON: Configures the driver for real time data communication from PLUS to AXES......12-55

$FEED_GO: Request the interpolator to exit the feedhold status ............................................5-6

$FEEDBYOF: Restore the programmed feedrate after feedrate bypass.................................... 5-32

$FEEDBYON: Activate feedrate bypass................................................................................ 5-30

$FEEDHLD: Request the interpolator to enter the feedhold status ..........................................5-5

$FOUT: Set fast output.............................................................................................. 7-17

$FRORIDE: Set process feedrate override percentage value ................................................5-11

$FTOA: Convert a floating point number to an ASCII string..............................................2-5

$FTOI: Convert a floating point format to an integer format .............................................2-7

$GBPROVAR: Get Boolean process variable .........................................................................10-3

$GET_INTP: Reads in real time a number of interpolator data............................................... 5-35

$GET_POSD: Read the position and feed rate of a point-to-point axis interfaced with the

DAC drive via a RS-232 serial line ...................................................................8-21

$GETAXINT: Get real axis position .................................................................................... 12-3

$GETEPAR: Get part program E parameter ........................................................................10-5

$GETHFL: Reads part program H parameter flag (HF)....................................................... 10-9

$GETHPAR: Get part program H parameter ........................................................................10-7

$GETPNTR: Get block numbers of the active part program and nested

subroutines/macros.......................................................................................5-22

$GETPPNAM: Get the names of the active part programs ...................................................... 5-20

$GETSC: Get ASCII global part program variable (SC)...................................................10-11

$GETSN: Get numerical global part program variable (SN) .............................................10-13

$GETUSED: Reads double process user variables ............................................................10-15

$GJOG: Read jog value.............................................................................................. 5-14

$GSYSDATE: Get system date.............................................................................................7-2

$GSYSTIME: Get system time .............................................................................................7-3

$HISPROC: Select a process to control............................................................................ 11-2

$HOLDOFF: Exit from hold status .......................................................................................5-8

$HOLDON: Entry in hold status.........................................................................................5-7

$HPG_OFF: It-disables the hand pulse generator (HPG)...................................................... 6-11

$HPG_ON: It activates the hand pulse generator (HPG) .......................................................6-9

10 Series CNC PLUS Library - User Manual (09) 7

Page 12

Preface

10 Series CNC PLUS Library - User Manual

$HUM_ABI: It enables specified softkeys........................................................................11-10

$HUM_DIS: It disables specified softkeys .......................................................................11-12

$IBS_INP: Transfer of physical inputs from the INTERBUS modules to the

MW variables ................................................................................................7-35

$IBS_OUT: Transfer of the MW variables to the physical outputs of the

INTERBUS modules...................................................................................... 7-36

$I_STR: Copies a number of words to the ASCII array................................................... 2-27

$ID_TO_A: Conversion from physical axis identifier to ASCII axis name and its

process........................................................................................................ 2-32

$ILDGD: Indexed load of double from GD variables area................................................. 2-15

$ILDGW: Indexed load of word from GW word variables area........................................... 2-11

$ILDMD: Indexed load of a double from the MD variables memory area ............................2-14

$ILDMW: Indexed load of a word from the MW variables memory area.............................. 2-12

$ILDSW: Indexed load of the word from the SW word variables memory area.................... 2-13

$INDEX: Copy a range of M variables ........................................................................... 2-25

$INDEXA: Copy a range of ASCII variables ......................................................................2-24

$INTP_ABI: Enables the driver for real time reading of interpolator parameters...................... 5-33

$INTP_CMD: Send a command to the interpolator ............................................................... 5-42

$INTP_DIS: Disables the driver for real time reading of the interpolator parameters. ...............5-34

$INWORD: Read an n bit input word from the I/O ring ........................................................7-18

$ISTGD: Indexed storage of the input double to the GD variables memory area ...............2-19

$ISTGW: Indexed storage of the input word to the GW variables memory area .................2-16

$ISTMD: Indexed storage of the input double to the MD variables memory area ...............2-18

$ISTMW: Indexed storage of the input word to the MW variables memory area................. 2-17

$ITOA: Convert an integer number to an ASCII string .....................................................2-3

$ITOF: Convert a short variable to a double variable ......................................................2-8

$LOCKTAB: Set table interlock status (inhibit third party access)........................................ 13-3

$LOG10: Calculate the base 10 logarithm ..................................................................... 4-10

$LOGE: Calculates the natural logarithm .......................................................................4-9

$MANFEED: Sets manual feedrate override percentage .........................................................5-9

$MDI_CMD: Enter part program blocks from PLUS in the MDI buffer .................................... 5-25

$MTB_OFF: Disconnect an Pilot panel from a process........................................................ 11-9

$MTB_ON: Assign an Pilot panel to a process ................................................................. 11-7

$MULF: Multiply two short operands with double result................................................. 2-28

$NAXOFF: Activate new axes offset ..................................................................................9-8

$OUTWORD: Write an n bit output word to the I/O ring......................................................... 7-19

$PALMOVE: Move a point-to-point-axis................................................................................8-7

$POW: Calculates the power of X raised to Y ..............................................................4-12

$PP_BSRC: It positions the pointer on the active Part Program by n blocks, onwards or

backwards....................................................................................................5-38

$PP_EXEC: Request part program execution up to a defined block ......................................5-24

$PP_SELE: Select a part program for execution ................................................................ 5-23

$PP_TSRC: It finds the string inside the active part program................................................ 5-37

$PPRESUME: Request process to resume part program execution after calculation stop

request ........................................................................................................ 5-27

$PREC_OFF: Disable part program block precalculation ....................................................... 5-28

$PREC_ON: Enable part program block precalculation........................................................ 5-29

$RCM_MOD: It defines how the auxiliary functions are sent to the Plus logic during the

search in memory......................................................................................... 5-39

$RD_ADA: Reads an ADARING device A/D channel......................................................... 7-24

$RD_ASCII: Read ASCII input parameters of a task (indexed store of ACCUS in ASCII

buffer) .......................................................................................................... 2-21

$RESRIF: Reset axes homed flag ....................................................................................6-6

8 10 Series CNC PLUS Library - User Manual (09)

Page 13

Preface

10 Series CNC PLUS Library - User Manual

$RIO_INP: Reads remote I/O inputs................................................................................ 7-33

$RIO_OUT: Write the remote I/O outputs ..........................................................................7-34

$RQESTOP: Request process E-STOP.............................................................................. 7-20

$RQRESET: Request process RESET............................................................................... 5-17

$RTIRES: Read RTI axes and spindle monitor table......................................................... 8-17

$SBPROVAR: Set Boolean process variable......................................................................... 10-4

$SCLOSE: Close RTI channel for spindle...........................................................................8-9

$SEL_SCR: It selects a screen ........................................................................................ 7-27

$SETCUSK: Set OEM softkey status; ON/OFF type........................................................... 11-3

$SETCUSL: Set OEM softkey status; Maintained, Data Entry and Normal ........................... 11-4

$SETEPAR: Set part program E parameter........................................................................ 10-6

$SETHFL: Sets part program HF flag ............................................................................10-10

$SETHINT: Set human interface protection bits................................................................. 11-5

$SETHPAR: Set part program H parameter........................................................................ 10-8

$SETMODE: Request mode of operation for a selected process ........................................... 5-13

$SETRANG: Select spindle gear range .............................................................................. 8-10

$SETRIF: Set axes homed flag .......................................................................................6-5

$SETSC: Set global ASCII part program "SC" variable ..................................................10-12

$SETSN: Set global numerical part program "SN" parameter .........................................10-14

$SETTEST: Set tes t mode / Reset test mode......................................................................6-8

$SG96RPM: Request G96 constant surface speed spindle control ....................................... 8-11

$SG97RPM: Set spindle speed in RPM ............................................................................. 8-13

$SIN: Calculate the sine of an angle ..........................................................................4-2

$SJOG: Write incremental jog value............................................................................ 5-15

$SOFTOTL: Enable /disable software overt ravel limits...........................................................6-4

$SOPEN: Open a channel for spindle management......................................................... 8-14

$SORIENT: Request spindle orientation ............................................................................8-15

$SPEPN: Request to energize the E-STOP relay(s)........................................................ 7-21

$SPORIDE: Forces process spindle speed override percentage value .................................. 5-12

$SQRT: Calculate the square root.................................................................................4-8

$SRESET: Request to reset a spindle............................................................................. 8-16

$STR_I: Copy ASCII characters from the ASCII buffer to the M variables......................... 2-26

$STR_LEN: Calculate string length................................................................................... 2-23

$STRCMP: Compare ASCII strings..................................................................................2-22

$STTRAVEL: Set coordinated axes hardware overtravel condition............................................6-7

$T_READ: Reads the timer status .................................................................................. 3-12

$T_START: Enables/disables PLUS timer......................................................................... 3-11

$TAN: Calculates the tangent of an angle ....................................................................4-4

$TBLGETD: Read double information from a system or user table........................................ 9-10

$TBLGETW: Read short information from a system or user table ............................................9-9

$TBLPUTD: Write double information to a system or to the user table.................................. 9-12

$TBLPUTW: Write short information to a system or to the user table ....................................9-11

$TBLSRCD: Request a table lookup (floating point entry).................................................... 9-13

$TBLSRCW: It requests a table search (short format field) ................................................... 9-15

$TC_CONF: It configures the transducer ERDC for read operations ....................................12-48

$TC_READ1: It reads the physical position of the transducer ..............................................12-50

$TC_WRIT: Set D/A Converter output .............................................................................12-52

$TCPACT: Enable/disable the Tool Center Point feature.................................................... 6-15

$TCPREAD: Reads the variables associated to the Tool Center Point................................... 6-18

$TCPWRT: Writes the variables associated to the Tool Center Point ...................................6-16

$TOOL_RD: Acquisition of the identifiers of the slave tools involved in multitool T

function programming.................................................................................... 9-17

$TOOLACT: Update axis table with new tool offset ...............................................................9-2

10 Series CNC PLUS Library - User Manual (09) 9

Page 14

Preface

10 Series CNC PLUS Library - User Manual

$UNLKTAB: Cancel table interlock status (enable third party access).................................. 13-5

$URLFEED: Forces rapid feedrate override percentage........................................................ 5-10

$WARN_HIS: Displays a message defined by the user and stores it in system history............ 7-26

$WARNING: Display user defined error message..................................................................7-4

$WR_ADA: Writes an ADARING device D/A channel .........................................................7-22

$WR_ASCII: Write ASCII task output parameters (indexed loading of ACCUS from

ASCII buffer)................................................................................................. 2-20

$WRI_SCR: User-defined (PLUS screen) ...........................................................................7-30

$WTOC: Convert a word to character............................................................................ 2-10

END OF PREFACE

10 10 Series CNC PLUS Library - User Manual (09)

Page 15

10 Series CNC PLUS Library - User Manual

INDEX

BASIC LANGUAGE FUNCTION BLOCKS

LINE ELEMENT ........................................................................................................1-3

BOOLEAN FUNCTION BLOCKS ...............................................................................1-5

FUNCTION BLOCKS FOR WORD OPERATIONS.......................................................1-8

FUNCTION BLOCKS FOR STRING OPERATIONS.....................................................1-14

FUNCTION BLOCKS FOR FLOATING POINT OPERATIONS ......................................1-15

PROGRAM FLOW CONTROL FUNCTION BLOCKS...................................................1-18

Subroutines ....................................................................................................1-18

PLUS PRE-DEFINED ROUTINES (TASKS).................................................................1-21

JUMPS....................................................................................................................1-22

TASK SYNCHRONIZATION BLOCKS ........................................................................1-23

CONDITIONAL EXECUTION OF BLOCKS .................................................................1-26

Application Note:.............................................................................................1-27

WORD COMPARISON FUNCTION BLOCKS ..............................................................1-29

FLOATING POINT COMPARISON FUNCTION BLOCKS ............................................1-31

COMPOSED FUNCTION BLOCKS ............................................................................1-33

Index

LANGUAGE EXTENSIONS

NUMBER AND FORMAT CONVERSIONS ..................................................................2-2

$ATOI: Convert an ASCII string to an integer number (16 bit)...............................2-2

$ITOA: Convert an integer number to an ASCII string ..........................................2-3

$ATOF: Convert an ASCII string to a floating point number ..................................2-4

$FTOA: Convert a floating point number to an ASCII string ..................................2-5

$FTOI: Convert a floating point format to an integer format ...................................2-7

$ITOF: Convert a short variable to a double variable............................................2-8

$CTOW: Convert a character to a word ..............................................................2-9

$WTOC: Convert a word to character.................................................................2-10

INDIRECT LOAD AND STORE ..................................................................................2-11

$ILDGW: Indexed load of word from GW word variables area ...............................2-11

$ILDMW: Indexed load of a word from the MW variables memory area..................2-12

$ILDSW: Indexed load of the word from the SW word variables memory

area ...............................................................................................................2-13

$ILDMD: Indexed load of a double from the MD variables memory area .................2-14

$ILDGD: Indexed load of double from GD variables area ......................................2-15

10 Series CNC PLUS Library - User Manual (09) i

Page 16

Index

10 Series CNC PLUS Library - User Manual

$ISTGW: Indexed storage of the input word to the GW variables

memory area..................................................................................................2-16

$ISTMW: Indexed storage of the input word to the MW variables

memory area..................................................................................................2-17

$ISTMD: Indexed storage of the input double to the MD variables

memory area..................................................................................................2-18

$ISTGD: Indexed storage of the input double to the GD variables

memory area..................................................................................................2-19

$WR_ASCII: Write ASCII task output parameters (indexed loading of

ACCUS from ASCII buffer)...............................................................................2-20

$RD_ASCII: Read ASCII input parameters of a task (indexed store of

ACCUS in ASCII buffer) ..................................................................................2-21

STRING / CHARACTER HANDLING ..........................................................................2-22

$STRCMP: Compare ASCII strings ...................................................................2-22

$STR_LEN: Calculate string length...................................................................2-23

$INDEXA: Copy a range of ASCII variables.........................................................2-24

$INDEX: Copy a range of M variables .................................................................2-25

$STR_I: Copy ASCII characters from the ASCII buffer to the M variables...............2-26

$I_STR: Copies a number of words to the ASCII array.........................................2-27

ARITHMETICAL FUNCTIONS ...................................................................................2-28

$MULF: Multiply two short operands with double result.......................................2-28

$DIVF: Division of two short operands with a double result...................................2-29

SPECIAL CONVERSIONS ........................................................................................2-31

$A_TO_ID: Requests conversion from process axis name to axis

identifier..........................................................................................................2-31

$ID_TO_A: Conversion from physical axis identifier to ASCII axis

name and its process. .....................................................................................2-32

COUNTERS AND TIMERS

COUNTERS .............................................................................................................3-2

TIMERS...................................................................................................................3-5

TIMERS AND FB PROGRAMMING............................................................................3-7

$T_START: Enables/disables PLUS timer..........................................................3-11

$T_READ: Reads the timer status ....................................................................3-12

MATH LIBRARY FUNCTIONS

$SIN: Calculate the sine of an angle ..................................................................4-2

$COS: Calculates the cosine of an angle ...........................................................4-3

$TAN: Calculates the tangent of an angle ..........................................................4-4

$ASIN: Calculate the angle for a given sine value ................................................4-5

$ACOS: Calculate the angle for a given cosine ...................................................4-6

$ATAN: Calculate the angle for a given tangent value..........................................4-7

$SQRT: Calculate the square root.....................................................................4-8

$LOGE: Calculates the natural logarithm...........................................................4-9

$LOG10: Calculate the base 10 logarithm ..........................................................4-10

$EXP: Calculates the power of “e” raised to the power of X..................................4-11

$POW: Calculates the power of X raised to Y.....................................................4-12

NC RELATED FUNCTIONS

ii 10 Series CNC PLUS Library - User Manual (09)

Page 17

Index

10 Series CNC PLUS Library - User Manual

$CYSTART: Request cycle start for a selected process ......................................5-2

$CYCLE: Request cycle start for a selected process ..........................................5-3

$CYSTOP: Request cycle stop for the selected process .....................................5-4

$FEEDHLD: Request the interpolator to enter the feedhold status........................5-5

$FEED_GO: Request the interpolator to exit the feedhold status .........................5-6

$HOLDON: Entry in hold status ........................................................................5-7

$HOLDOFF: Exit from hold status .....................................................................5-8

$MANFEED: Sets manual feedrate override percentage......................................5-9

$URLFEED: Forces rapid feedrate override percentage .......................................5-10

$FRORIDE: Set process feedrate override percentage value ................................5-11

$SPORIDE: Forces process spindle speed override percentage value...................5-12

$SETMODE: Request mode of operation for a selected process..........................5-13

$GJOG: Read jog value ....................................................................................5-14

$SJOG: Write incremental jog value..................................................................5-15

$AXSELEC: Select one or more axes for manual operations ................................5-16

$RQRESET: Request process RESET ..............................................................5-17

$ENDRESE: Logic has finished reset actions ....................................................5-19

$GETPPNAM: Get the names of the active part programs ...................................5-20

$GETPNTR: Get block numbers of the active part program and

nested subroutines/macros ..............................................................................5-22

$PP_SELE: Select a part program for execution ................................................5-23

$PP_EXEC: Request part program execution up to a defined block ......................5-24

$MDI_CMD: Enter part program blocks from PLUS in the MDI buffer ....................5-25

$PPRESUME: Request process to resume part program execution

after calculation stop request ............................................................................5-27

$PREC_OFF: Disable part program block precalculation .....................................5-28

$PREC_ON: Enable part program block precalculation .......................................5-29

$FEEDBYON: Activate feedrate bypass ............................................................5-30

$FEEDBYOF: Restore the programmed feedrate after feedrate bypass.................5-32

$INTP_ABI: Enables the driver for real time reading of interpolator

parameters. ...............................................................................................5-33

$INTP_DIS: Disables the driver for real time reading of the

interpolator parameters. ...................................................................................5-34

$GET_INTP: Reads in real time a number of interpolator data ..............................5-35

$PP_TSRC: It finds the string inside the active part program................................5-36

$PP_BSRC: It positions the pointer on the active Part Program by n

blocks, onwards or backwards..........................................................................5-37

$RCM_MOD: It defines how the auxiliary functions are sent to the

Plus logic during the search in memory.............................................................5-38

$AXSELFED: It selects one or more axes allowing to change feedrate

override 5-39

$AXMANFED: It sets the feedrate override for one or more axes in

manual movement ...........................................................................................5-40

$INTP_CMD: Send a command to the interpolator..............................................5-41

AXIS MOTION FUNCTIONS

$AX_ENAB: Enable the servo loop of an axis or enable its D/A

converter.........................................................................................................6-2

$AX_DISA: Disable the servo loop of an axis or disable its D/A

converter.........................................................................................................6-3

$SOFTOTL: Enable /disable software overtravel limits.........................................6-4

$SETRIF: Set axes homed flag .........................................................................6-5

10 Series CNC PLUS Library - User Manual (09) iii

Page 18

Index

10 Series CNC PLUS Library - User Manual

$RESRIF: Reset axes homed flag .....................................................................6-6

$STTRAVEL: Set coordinated axes hardware overtravel condition ........................6-7

$SETTEST: Set test mode / Reset test mode....................................................6-8

$HPG_ON: It activates the hand pulse generator (HPG)......................................6-9

$HPG_OFF: It-disables the hand pulse generator (HPG).....................................6-11

$AXTAN_E: Tangent axis algorithm enabling ......................................................6-12

$AXTAN_D: It disables the tangent axis algorithm .............................................6-14

$TCPACT: Enable/disable the Tool Center Point feature ......................................6-15

$TCPWRT: Writes the variables associated to the Tool Center Point....................6-16

$TCPREAD: Reads the variables associated to the Tool Center Point ..................6-18

GENERAL PURPOSE FUNCTIONS

$GSYSDATE: Get system date........................................................................7-2

$GSYSTIME: Get system time .........................................................................7-3

$WARNING: Display user defined error message ...............................................7-4

$232_INIT: Initialize the RS 232 interface ...........................................................7-5

$232_TERM: Set termination characters used in message handling .....................7-6

$232_TXD: Transmit data buffer via the RS 232 interface.....................................7-8

$232_TXS: Transmit an ASCII string via the RS 232 interface...............................7-9

$232_RXD: Receive a data buffer via the RS-232 interface...................................7-10

$232_RXS: Receive an ASCII string via the RS 232 interface...............................7-12

$232_RESE: Reset the RS 232 interface...........................................................7-13

$232_STAT: Get the RS-232 interface status .....................................................7-14

$ANAIN: Read one of the analog input channels of the I/O processor

module...........................................................................................................7-16

$FOUT: Set fast output ....................................................................................7-18

$INWORD: Read an n bit input word from the I/O ring .........................................7-19

$OUTWORD: Write an n bit output word to the I/O ring.......................................7-20

$RQESTOP: Request process E-STOP.............................................................7-21

$SPEPN: Request to energize the E-STOP relay(s)...........................................7-22

$WR_ADA: Writes an ADARING device D/A channel..........................................7-23

$RD_ADA: Reads an ADARING device A/D channel ...........................................7-25

$WARN_HIS: Displays a message defined by the user and stores it

in system history.............................................................................................7-27

$SEL_SCR: It selects a screen ........................................................................7-28

$WRI_SCR: User-defined (PLUS screen) ...........................................................7-31

$RIO_INP: Reads remote I/O inputs..................................................................7-34

$RIO_OUT: Write the remote I/O outputs ...........................................................7-35

$IBS_INP: Transfer of physical inputs from the INTERBUS modules to

the MW variables ...........................................................................................7-36

$IBS_OUT: Transfer of the MW variables to the physical outputs of

the INTERBUS modules..................................................................................7-37

POINT-TO-POINT-AXES / SPINDLE LIBRARY

$AABORT: Abort a point-to-point-interpolator .....................................................8-3

$ACLOSE: Close channel for point-to-point-interpolator .......................................8-4

$AOPEN: Open channel for point-to-point-interpolator.........................................8-5

$ARESET: Request to reset a point-to-point-interpolator .....................................8-6

$PALMOVE: Move a point-to-point-axis .............................................................8-7

$SCLOSE: Close RTI channel for spindle...........................................................8-9

iv 10 Series CNC PLUS Library - User Manual (09)

Page 19

$SETRANG: Select spindle gear range..............................................................8-10

$SG96RPM: Request G96 constant surface speed spindle control.......................8-11

$SG97RPM: Set spindle speed in RPM.............................................................8-13

$SOPEN: Open a channel for spindle management ............................................8-14

$SORIENT: Request spindle orientation.............................................................8-15

$SRESET: Request to reset a spindle ...............................................................8-16

$RTIRES: Read RTI axes and spindle monitor table ............................................8-17

$AUX_STAT: Read the status of a point-to-point axis and the spindle ...................8-18

$GET_POSD: Read the position and feed rate of a point-to-point axis

interfaced with the DAC drive via a RS-232 serial line..........................................8-21

OFFSET AND TOOLS HANDLING

$TOOLACT: Update axis table with new tool offset .............................................9-2

$ACTOFFS: Request activation of a tool offset ...................................................9-5

$COMPOFF: Compute new axes offset .............................................................9-8

$NAXOFF: Activate new axes offset ..................................................................9-9

$TBLGETW: Read short information from a system or user table.........................9-10

$TBLGETD: Read double information from a system or user table ........................9-11

$TBLPUTW: Write short information to a system or to the user table ...................9-12

$TBLPUTD: Write double information to a system or to the user table..................9-13

$TBLSRCD: Request a table lookup (floating point entry)....................................9-14

$TBLSRCW: It requests a table search (short format field) ..................................9-16

$TOOL_RD: Acquisition of the identifiers of the slave tools involved in

multitool T function programming.......................................................................9-18

Index

10 Series CNC PLUS Library - User Manual

PROCESS/SYSTEM VARIABLES HANDLING

$GBPROVAR: Get Boolean process variable.....................................................10-3

$SBPROVAR: Set Boolean process variable......................................................10-4

$GETEPAR: Get part program E parameter.......................................................10-5

$SETEPAR: Set part program E parameter........................................................10-6

$GETHPAR: Get part program H parameter.......................................................10-7

$SETHPAR: Set part program H parameter........................................................10-8

$GETHFL: Reads part program H parameter flag (HF) .........................................10-9

$SETHFL: Sets part program HF flag ................................................................10-10

$GETSC: Get ASCII global part program variable (SC) ........................................10-11

$SETSC: Set global ASCII part program "SC" variable ........................................10-12

$GETSN: Get numerical global part program variable (SN)...................................10-13

$SETSN: Set global numerical part program "SN" parameter ...............................10-14

$GETUSED: Reads double process user variables .............................................10-15

HUMAN INTERFACE

$HISPROC: Select a process to control ............................................................11-2

$SETCUSK: Set OEM softkey status; ON/OFF type..........................................11-3

$SETCUSL: Set OEM softkey status; Maintained, Data Entry and

Normal ...........................................................................................................11-4

$SETHINT: Set human interface protection bits..................................................11-5

$MTB_ON: Assign an Pilot panel to a process ...................................................11-7

$MTB_OFF: Disconnect an Pilot panel from a process .......................................11-9

10 Series CNC PLUS Library - User Manual (09) v

Page 20

Index

10 Series CNC PLUS Library - User Manual

$HUM_ABI: It enables specified softkeys...........................................................11-10

$HUM_DIS: It disables specified softkeys ..........................................................11-12

$CON_LED: It manages the leds on the OPLink operator panel...........................11-14

AXES RELATED FUNCTIONS

$GETAXINT: Get real axis position ....................................................................12-3

$AX_CHAS: Change the servo mode of an axis..................................................12-4

$AX_PROB: Enable probing signal for one or more axis......................................12-5

$AX_RDPB: Read the probed positions of one or more axis.................................12-6

$AX_RESE: Aborts the actual operation of the addressed axis............................12-8

$AX_ZSH1: Write PLUS zero shift offset #1 .......................................................12-9

$AX_ZSH2: Write PLUS zero shift offset #2 .......................................................12-10

$AX_SELE: Activate axis monitor functions / gear range.....................................12-11

$AX_RPOS: Resets the axis' position ...............................................................12-13

$AX_SETZ: It allows the activation of different functions for the

specified axis ...............................................................................................12-14

$AX_GET1: Get axis (spindle) servo parameters .................................................12-15

$AX_GET2: Get axis (spindle) servo parameters .................................................12-17

$AX_GET3: Get axis (spindle) servo parameters .................................................12-20

$AX_GET4: Get axis (spindle) servo parameters .................................................12-22

$AX_GET5: Get axis (spindle) servo parameters .................................................12-24

$AX_GET6: Get axis (spindle) servo parameters .................................................12-26

$AX_GET7: Get axis (spindle) servo parameters .................................................12-28

$AX_GET8: Get axis (spindle) servo parameters .................................................12-33

$AX_PUT1: Set axis servo parameter................................................................12-35

Notes concerning the “STANDSTILL-GAIN” parameter.........................................12-41

$AX_PUT2: Set axis servo parameter................................................................12-42

$AX_PUT3: Set axis servo parameter................................................................12-44

$AX_GETS: Get axis status .............................................................................12-46

$TC_CONF: It configures the transducer ERDC for read operations ......................12-48

$TC_READ1: It reads the physical position of the transducer...............................12-50

$TC_WRIT: Set D/A Converter output ................................................................12-52

$FAX_WCON: Configures the driver for real time data communication

from PLUS to AXES.........................................................................................12-55

$FAX_RCON: Configures the driver for real time data communication

from AXES to PLUS .........................................................................................12-57

$FAX_PUT: Real time updating of an axis' zero shift value ...................................12-59

$FAX_GET: Reads in real time axis parameters .................................................12-61

$AXD_RDD: It reads a numerical parameter from a digital drive

associated to a D.S.I. axis...............................................................................12-63

$AXD_WRD: It writes a numerical parameter to a digital drive

associated to a D.S.I. axis...............................................................................12-65

$AXD_RDS: It reads a string parameter from a digital drive

associated to a D.S.I. axis...............................................................................12-66

$AXD_WRS: It writes a string parameter to a digital drive associated

to a D.S.I. axis 12-67

$AXD_PUT: Sets Control Word bits of a digital drive associated with

a D.S.I. axis 12-68

vi 10 Series CNC PLUS Library - User Manual (09)

Page 21

SPECIAL FUNCTIONS

$ACTRES: Request an active reset to be executed ............................................13-2

$LOCKTAB: Set table interlock status (inhibit third party access) ........................13-3

$UNLKTAB: Cancel table interlock status (enable third party access)..................13-5

$FAST_WR: Writes data in the DP dedicated area .............................................13-6

$FAST_RD: Reads data from a dedicated DP area.............................................13-8

$DE_ETH: enables or disables communication via Ethernet ................................13-10

PLUS PRE-DEFINED SYMBOLS

Pre-defined logic routine names ........................................................................A-2

Pre-defined logic interface routines....................................................................A-3

Names suggested for global system variables ....................................................A-4

Names suggested for process pre-defined variables ............................................A-6

Names suggested for fields and tables ..............................................................A-9

Index

10 Series CNC PLUS Library - User Manual

NC MESSAGES

ERROR CODES DISPLAYED IN THE NC ENVIRONMENT ...........................................B-1

POINT-TO-POINT AXES / SPINDLE MESSAGES

POINT-TO-POINT AXES / SPINDLE MESSAGES .......................................................C-1

AVAILABLE TABLES

AVAILABLE TABLES ...............................................................................................D-1

Axes table......................................................................................................D-1

Tool table........................................................................................................D-2

Tool offset table ...............................................................................................D-2

User table .......................................................................................................D-2

HUMAN INTERFACE AND PLUS RELATED MESSAGES

Human Interface Related Messages .................................................................E-1

PLUS Related Messages .................................................................................E-1

ERROR MESSAGES FOR THE D.S.I. INTERFACE

Error List ........................................................................................................F-1

MESSAGES FOR POINT TO POINT AXIS CONTROLLED VIA RS232 SERIAL LINE

Serial Driver ....................................................................................................G-1

DAC/DSC Osai Drive .......................................................................................G-2

10 Series CNC PLUS Library - User Manual (09) vii

Page 22

Index

10 Series CNC PLUS Library - User Manual

END OF INDEX

viii 10 Series CNC PLUS Library - User Manual (09)

Page 23

Chapter

1

BASIC LANGUAGE FUNCTION BLOCKS

The basic language function blocks are the direct equivalents of the corresponding instruction list

elements. Every time you use one of these function blocks, its internal (IL) code will be inserted in

your program. In this sense the basic language function block behave like macros. The function

blocks discussed in this chapter do not call any functions. Each one of the sections in this chapter

covers a group of function blocks which all work on the identical data format.

Those function blocks which internally use a system function call are covered in the other chapters of

this manual. They are called language extensions because they expand the capabilities of the

language beyond the capabilities of the single instructions.

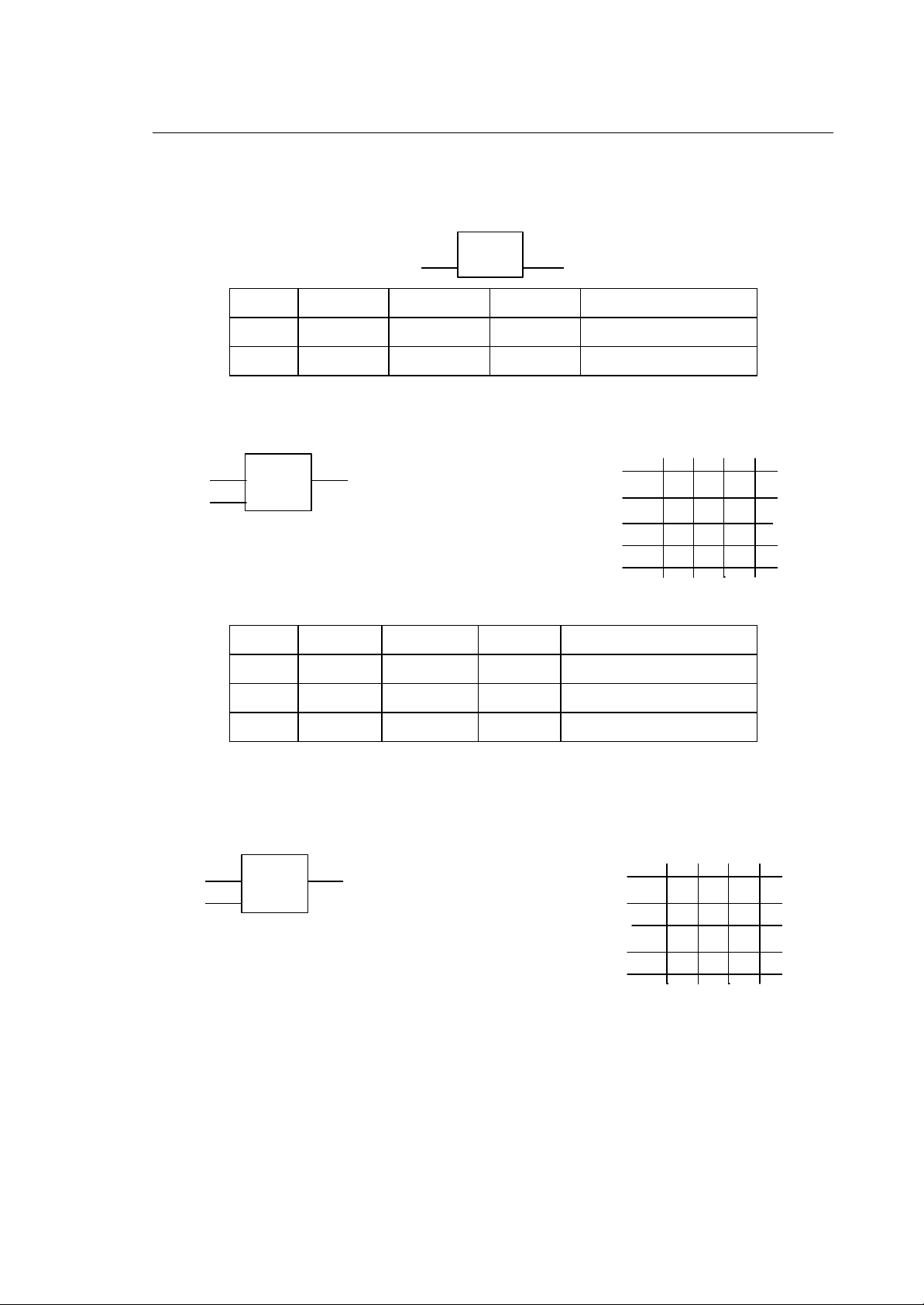

For each of the basic language function blocks you will find a table which contains the attributes of

the inputs and outputs of a function block. The columns in this table are:

NAME : Name of the connection

INVERSION : Indicates whether the input or output can be logically inverted. This attribute

is only available for Boolean connections.

DUPLICATION : If this attribute shows yes, you are allowed to make one or more copies of

this connection. Each one of the copied connections will have the same

attributes as the original and the connected variable will be processed just

like the original variable.

FORMAT : The format of an operand to be connected to an input or an output can be

one of:

Boolean only bits allowed

short 16 bit integer operand

double 64 bit floating point operand

char string or string constant

all no check, all formats possible

special for special operands NAM and LAB only

As you enter an operand for a function block, it will be checked if it

matches the required format.

GROUP : The different types of operands are divided into groups. For certain function

block connections some groups will be excluded (e.g. it is not allowed to

connect an input to a Boolean function block output). The letters in this

column indicate which type of operand may be used:

10 Series CNC PLUS Library - User Manual (08) 1-1

Page 24

Chapter 1

WARNING

Basic Language Function Blocks

M M variables (depending on the format you must select M Boolean

MW -> short MD -> double).

G global retentive G variables (depending on the format you must

select G -> Boolean, GW -> short or GD -> double).

S System flags or S variables. (again, select the S or SW

depending on the format of the connection; S -> Boolean or SW > short)

T Timer variables. T or TW depending on the format (T -> Boolean,

TW -> short).

C Counter variables. C or CW depending on the format (C ->

Boolean, CW short).

K Constants. KB -> Boolean, KW or KH -> short, KD -> double.

X local variables. Select X -> Boolean, XW -> short or XD -> double,

depending on the format of the connection.

Y subroutine parameters. select Y -> Boolean, YW -> short or YD -

> double in accordance with the format of the connection.

A ASCII string variable.

#" Text constants.

NAM subroutine names, PLUS routine names

LAB label names

Double constants (KD) are defined with the following format:

KD ± x.yyyyE ± zzz

The decimal part yyyy must always be written in full (4 figures).

1-2 10 Series CNC PLUS Library - User Manual (08)

Page 25

Chapter 1

IMPORTANT

Basic Language Function Blocks

LINE ELEMENT

The line element can be used to "connect" a variable or a constant (left side) with one or more other

variables (right side). The variables (constants) on both sides must have the same type (i.e. short).

The line element is only available to connect Boolean, short and double variables and constants.

Examples:

short constant c onnected to short variable s

KH00FF

Boolean constant connect ed to boolean variables

KB1 O 24,03

Short constant connected to a timer preset word

KW100 TW 020

MW 200

MW 201

G 010,00

.

Of course you cannot connect inputs and/or constants to the right side of a line element. For an

explanation of how to insert a line element please refer to the Plusedit manual.

When you design a logic program using Function Blocks please consider some