Page 1

10 Series CNC

ASSET

Reference Manual

Code: 45004472R

Rev. 07

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

Tel. +39-0119899711

Web: www.osai.it

e-mail: sales@osai.it

service@osai.it

Copyright 2001-2006 by OSAI

All rights reserved

Edition: May 2006

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of

the product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment

described in this text.

Page 2

abc

abc

Page 3

10 Series CNC ASSET – Reference Manual

SUMMARY OF CHANGES

General

This publication was issued together with the release of version 7.5.

CHAPTER UPDATING TYPE

UPDATE

INDEX

CHAPTER 3

Page 6 Changed description of “SCR - Screen Selection”

CHAPTER 4

Page 6 Changed description of “REA (RED) - Reading a file”

CHAPTER 5

Page 3 Changed description of “RTP – Reading the number of the programmed or

updated

active tool”

10 Series CNC ASSET Reference Manual (07)

Page 4

abc

Page 5

10 Series CNC ASSET – Reference Manual

PREFACE

This manual is intended for 10 Series CNC programmers.

It describes the standard language extensions provided with the ASSET option.

REFERENCES

Preface

This publication constitutes an extension of the 10 Series CNC standard programming language.

Further information may be found in the other manuals of the 10 Series:

• 10 Series CNC Programming Manual

• 10 Series CNC User Manual

• 10 Series CNC AMP - SW Characterisation Manual

• 10 Series CNC PLUS Lybrary - User Manual

• 10 Series CNC PLUS Application Manual

• 10 Series CNC PLUS Language and PLUSEDIT

10 Series CNC ASSET Reference Manual (01) 1

Page 6

Preface

10 Series CNC ASSET – Reference Manual

SUMMARY

1. General

This chapter provides an introduction to the ASSET language and lists the complete set of

ASSET variables.

2. Input commands

This chapter discusses the commands that permit to define and handle manual data entry

windows.

3. Screen management commands

This chapter discusses the commands used for configuring and handling configurable video

screens.

4. File management commands

This chapter describes the ASSET commands used for opening, reading, writing, closing,

deleting and saving ASCII files in the directory of programs.

5. Process management commands

This chapter deals with ASSET commands that permit to read process parameters such as

current and programmed tool number, current and programmed tool offset number, process

state, sub-state and mode, and axes coordinates.

6. Serial line management commands

This chapter describes the commands for management of the serial line: modes of configuration

and operation of the triliteral functions for data reception/transmission.

7. Operating commands

This chapter describes the commands by way of which a process can be issued operating

commands such as CYCLE ON, CYCLE OFF, HOLD, etc.

Appendix A - ASSET error messages

This appendix lists the error messages that may be displayed by the system when executing

ASSET commands.

Appendix B - Error management from part program

This appendix contains information on how to manage certain types of error from the part

program so as not to interrupt execution of the part program itself.

Appendix C - ASSET triliterals table

This appendix provides the complete list of ASSET triliteral functions.

2 10 Series CNC ASSET Reference Manual (01)

Page 7

Preface

10 Series CNC ASSET – Reference Manual

WARNINGS

For correct use of the system, it is important to follow the indications given in the manual, and in

particular those items marked: WARNING, CAUTION or IMPORTANT.

Indicating facts or circumstances that may cause damage to the system,

items of equipment or operators.

Indicating information to be taken into consideration in order to avoid damage

to the equipment in general.

Indicating operations to be carried out with particular care to ensure full

success of the application.

10 Series CNC ASSET Reference Manual (01) 3

Page 8

Preface

10 Series CNC ASSET – Reference Manual

END OF PREFACE

4 10 Series CNC ASSET Reference Manual (01)

Page 9

10 Series CNC ASSET - Reference Manual

INDEX

GENERAL

INTRODUCTION ............................................................................................................. 1-1

VARIABLES .................................................................................................................... 1-3

User Table Variables ............................................................................................. 1-4

PLUS Tables Variables ......................................................................................... 1-5

Axes Table............................................................................................................. 1-6

Tools Table ............................................................................................................ 1-7

Tool Offsets Table ................................................................................................. 1-8

PLUS I/O.......................................................................................................................... 1-9

Inputs (the first 85 arrays)...................................................................................... 1-9

Inputs (after the 85th array) ................................................................................... 1-10

Outputs (the first 85 arrays)................................................................................... 1-11

Outputs (after 85th array) ...................................................................................... 1-12

FILE ................................................................................................................................. 1-13

ASCII files .............................................................................................................. 1-13

Binary files ............................................................................................................. 1-14

COMMANDS ................................................................................................................... 1-15

LCK - Locking/Unlocking PLUS tables .................................................................. 1-16

Index

INPUT COMMANDS

DIF - Definition of a data field ................................................................................ 2-2

INP - Manual data input......................................................................................... 2-7

SCREEN MANAGEMENT COMMANDS

OUT - Screen line parameters............................................................................... 3-3

SCR - Screen selection ......................................................................................... 3-6

FILE MANAGEMENT COMMANDS

OPN - Opening a file.............................................................................................. 4-2

WRT - Writing a file................................................................................................ 4-4

REA (RED) - Reading a file ................................................................................... 4-6

CLO - Closing a channel ....................................................................................... 4-8

DEL (CAN) - Deleting a file.................................................................................... 4-9

10 Series CNC ASSET Reference Manual (07) i

Page 10

Index

10 Series CNC ASSET - Reference Manual

INS - Saving an ASCII file in the directory of programs......................................... 4-11

CPY - Copy a file.................................................................................................... 4-12

PROCESS MANAGEMENT COMMANDS

PRO - Definition of the default process ................................................................. 5-2

RTP -Reading the number of the programmed or active tool................................ 5-3

ROP -Reading the number of the programmed or active tool offset .....................5-4

GPS -Reading the process state, sub-state or mode ............................................5-5

RAP -Reading the axis coordinates ....................................................................... 5-7

PLS -Reading PLUS SW variables ........................................................................ 5-9

SERIAL LINE MANAGEMENT COMMANDS

SOP - Activate and configure the serial port.......................................................... 6-2

GET - Data reception from serial line.................................................................... 6-6

PUT - Data transmission on serial line ................................................................. 6-8

SCL - Close the serial port..................................................................................... 6-10

EPS - Execute part program from serial line ......................................................... 6-11

OPERATING COMMANDS

CON - CYCLE ON command................................................................................. 7-2

COF - CYCLE OFF command ............................................................................... 7-3

HON - HOLD ON command................................................................................... 7-4

HOF - HOLD OFF command ................................................................................. 7-5

RES - RESET command........................................................................................ 7-6

SMD - Set operating mode .................................................................................... 7-7

SAX - Select axis for manual movement ...............................................................7-8

DIR - Direction of manual movements................................................................... 7-9

JOG - Jog step value .............................................................................................7-10

FHO - Enable/Disable FEEDHOLD .......................................................................7-11

ASSET ERROR MESSAGES

Description of messages and remedial action ....................................................... A-1

ERROR MANAGEMENT FROM PART PROGRAM

ERR - Enabling/disabling automatic error management from part program .........B-2

Manual data input errors ........................................................................................B-3

File management errors......................................................................................... B-3

Locked table condition ...........................................................................................B-4

Serial line management errors............................................................................... B-4

ASSET TRILITERALS TABLE

List of the Asset Triliterals...................................................................................... C-1

END OF INDEX

ii 10 Series CNC ASSET Reference Manual (07)

Page 11

Chapter 1

GENERAL

INTRODUCTION

ASSET (Advanced Super Set Extension Tool) is a programming language that enhances

10 Series standard programming capabilities. It provides a set of instructions, variables and

variables handling rules that facilitate customisation of 10 Series functions.

In particular, ASSET permits to:

• create personalised video screens.

• create data entry windows and personalise their size, position, graphic layout, background and

foreground colors, and the number and length of the various data entry fields.

• open, read, write and close ASCII files.

• manage PLUS tables and read and/or write accessible parameters.

• read and/or write PLUS I/O variables.

• handle a series of process commands used for reading the process status, the axes position,

the tool parameters, etc.

• handle the serial line from part programs.

• send out operating commands in emulation of the Front Panel/Teach Pendant.

These operations can be carried out by means of specific 3-letter ASSET codes or by writing in the

program blocks the ASSET variables that provide access to parameters that are normally

inaccessible to the programming environment. These commands can be given by the part program

or entered from keyboard, i.e. written by the operator when the system is in MDI mode.

For example, ASSET can be used for programming a machining operation that needs to be

automatically interrupted and kept on hold by the system until the operator fills in a given data entry

window. Each ASSET command described in the manual is supplied with application examples.

10 Series CNC ASSET Reference Manual (06) 1-1

Page 12

Chapter 1

General

Like all high level languages, ASSET must also be used by adequately trained personnel that are

also well acquainted with the characteristics of the system. If inappropriate alterations are made to

the system and logic parameters accessible via ASSET, serious system errors and malfunctions

may occur.

ASSET instructions can be easily combined with the traditional 10 Series programming language.

Actually, ASSET enhances 10 Series programming capabilities by making it possible for 10 Series

commands to handle ASSET variables.

In addition to standard commands, functions and variables, ASSET uses 10 Series syntactic rules

and conventions. For more information about these programming rules and conventions, please

refer to 10 Series CNC Programming Manual.

1-2 10 Series CNC ASSET Reference Manual (06)

Page 13

Chapter 1

General

VARIABLES

ASSET permits to write, read and alter any system variable, with the exception of those to which

special restrictions apply. In doing so it applies the same syntactic rules and conventions as the

standard 10 Series programming language. For more information about standard programming,

please refer to Chapter 7 of 10 Series Programming Manual.

Here is a list of variables handled by ASSET:

• Local variables: E and H.

• System variables: SN and SC.

• User variables: They are identified by an exclamation mark followed by a name. For example,

!USER1. They can contain long real numerical formats and alphanumeric characters.

• PLUS variables: They are identified by an @ followed by a name. For example, @PROG They

can contain short, long or boolean numerical values.

• User Table variables: They are identified by an L followed by a numerical index from 0 through

399 which indicates the table cell. The index-cell relationship will be discussed in a later

chapter.

• PLUS Table variables: They are identified by the $ character followed by the name given to the

variable in the table and an index enclosed between brackets which provides the axes ID (axes

table), the record number (tools table) or the tool offset number (tool offsets table).

Examples:

$AXORIG(2) Identifies the current origin of the axis whose ID is 2 (read only)

$TSTATUS(25) Identifies the condition of the tool stored in record 25 of the tools table

$TACTL1(125) Identifies the current length of the tool stored in record 125 of the tools offset

table.

User Table and PLUS variables are described later in this chapter. For more information about

local, system user variables, please refer to the following 10 Series documents: Programming

Manual, Characterisation Manual, and PLUS Library Manual.

10 Series CNC ASSET Reference Manual (06) 1-3

Page 14

Chapter 1

General

User Table Variables

The User Table (refer to Chapter 3 in the "PLUS Application Manual") has 100 records, each one

of which is made up of 4 variables, for a total 400 variables. The variable index ranges from 0 to

399.

The records and the variables stored in them are arranged sequentially, as shown in the following

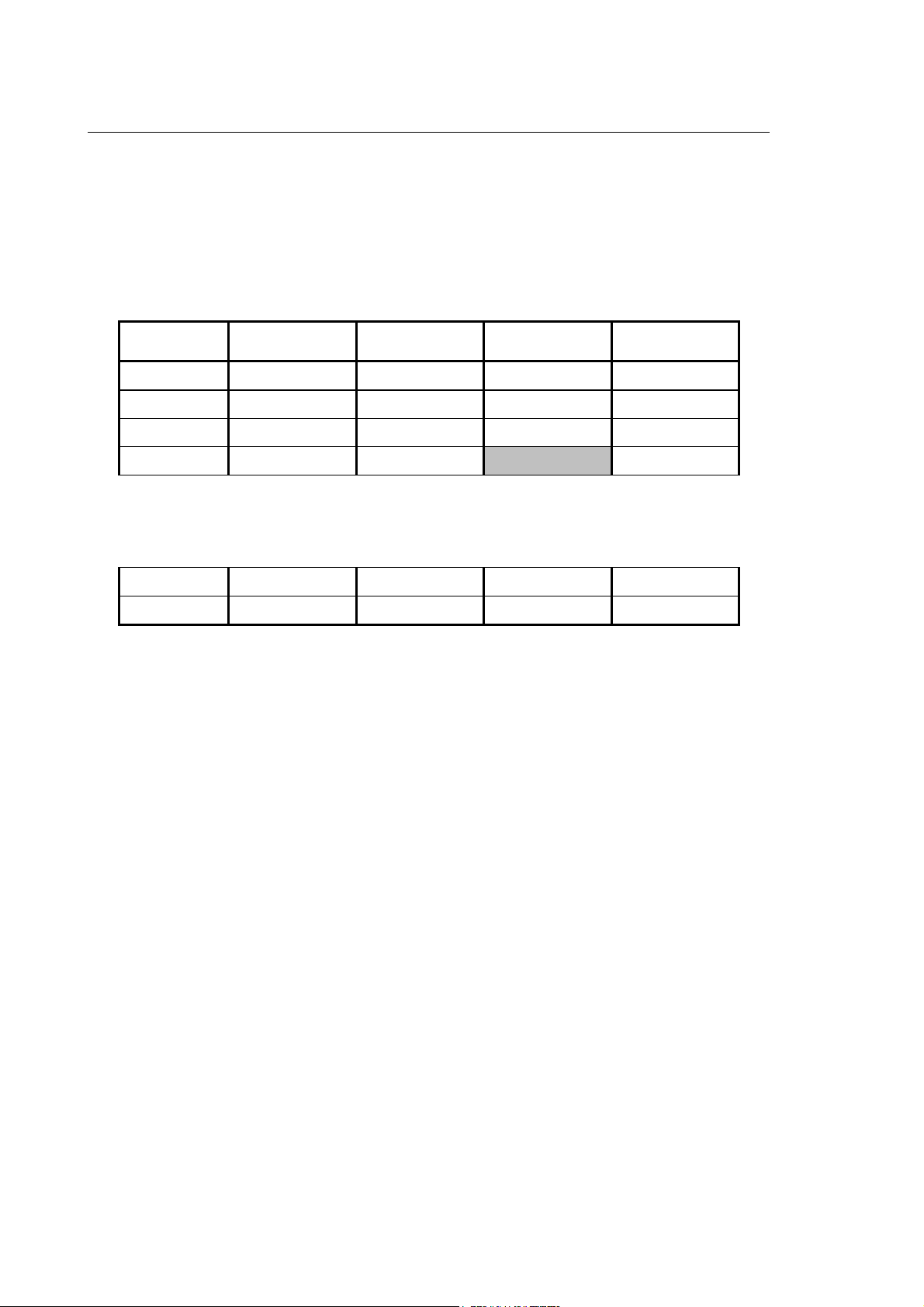

table:

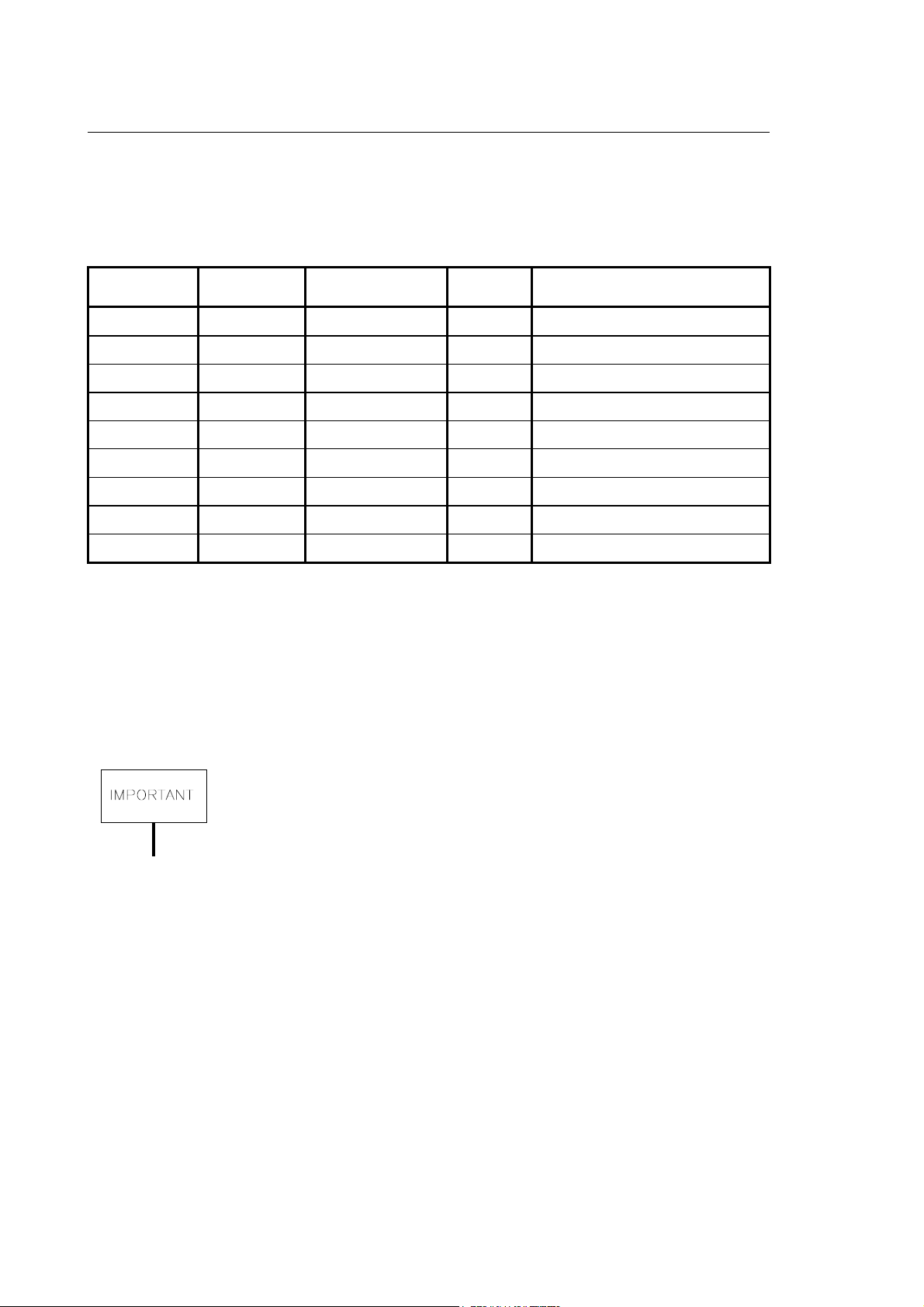

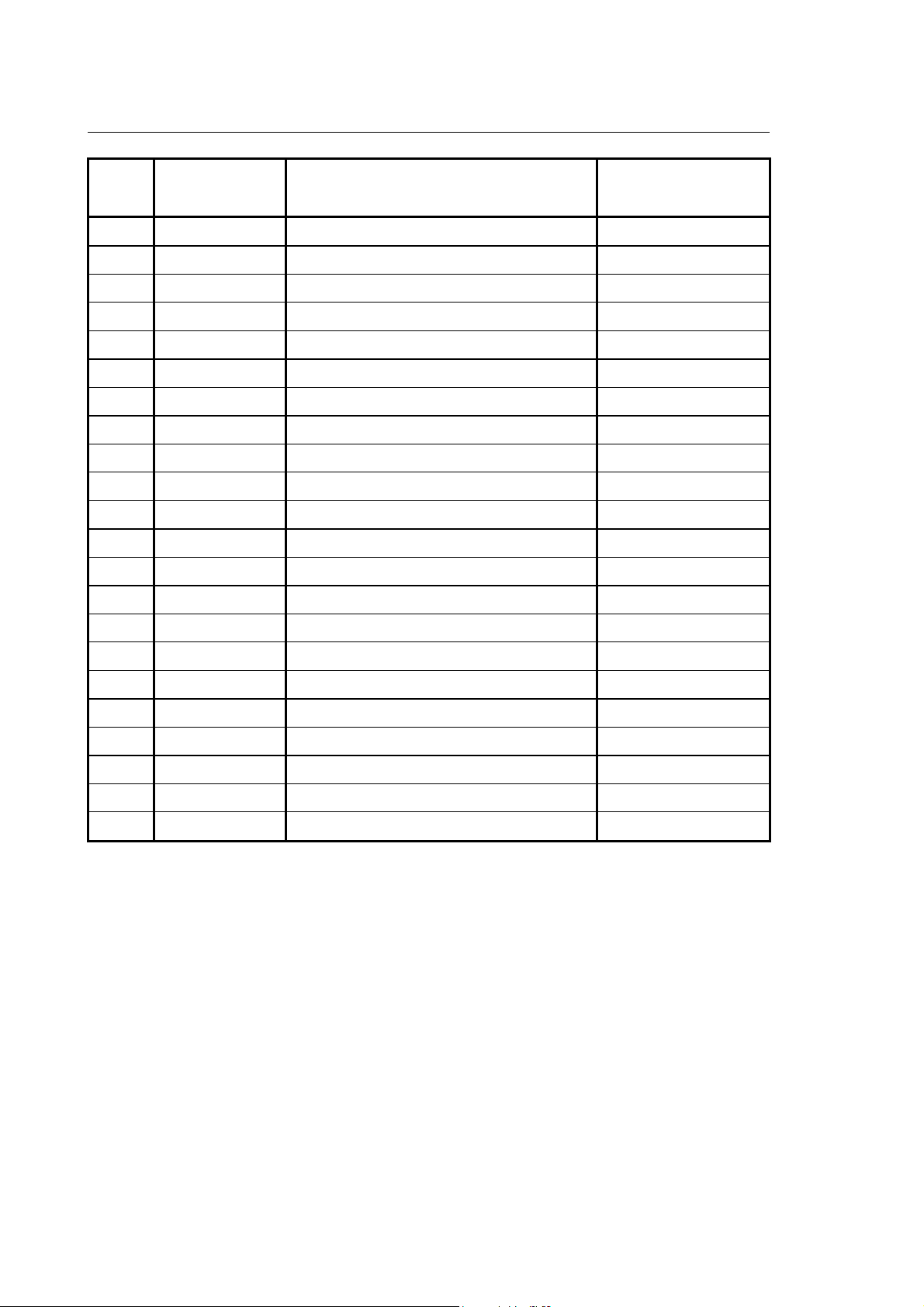

Record N° Variable 1 Variable 2 Variable 3 Variable 4

000001 L0 L1 L2 L3

000002 L4 L5 L6 L7

000003 L8 L9 L10 L11

000004 L12 L13 L14 L15

...............

...............

000099 L392 L393 L394 L395

000100 L396 L397 L398 L399

To calculate the index when the position of the cell in the table and the variable are known, the

following formula can be used:

Index = (Record Number - 1) x 4 + (Number of the variable in the record - 1)

For example, the index of the highlighted cell in the table is as follows:

Index = (4 - 1) x 4 + (3 - 1) = 14

To calculate the record number and the variable when the index is known, the following formula

may be used:

Record = (Index / 4) + 1

Variable = [Remainder of (Index / 4)] + 1

For example, L145 addresses record 37 (145 / 4 + 1) and variable 2 (remainder of the division + 1

= 1 + 1).

1-4 10 Series CNC ASSET Reference Manual (06)

Page 15

Chapter 1

General

PLUS Tables Variables

PLUS Tables include the Axes Tables, the Tools Tables and the Tools Offsets Tables. The

contents of these tables are normally handled by the machine logic. Each PLUS Table is made up

of a given number of pages which contain the parameters that describe the object of the table. The

number of pages in each table is as follows:

Table N° of Pages Contents

Axes table 32 Axes identification

Tools Table 250 Record number in the table

Tool OffsetsTable 300 Tool offsets number

The table page number coincides with the index that follows the variable name.

The type, number and symbol of a parameter vary from table to table. The sections that follow

illustrate a typical page of each table. For further information about these tables, refer to Chapter 3

of the "PLUS Application Manual".

The ASSET instruction LCK permits to write protect PLUS tables. When write protection is active,

PLUS tables may be accessed only via ASSET. More information about the LCK triliteral is

provided in the final section of this chapter.

Values read or written in PLUS tables using ASSET are not affected by the

current unit of measure (G70/G71) but are considered as absolute values. It

should be remembered therefore that any numeric values representing

lengths are with reference to the machine's unit of measure configured in

AMP; it is up to the operator to perform any conversion required.

10 Series CNC ASSET Reference Manual (06) 1-5

Page 16

Chapter 1

General

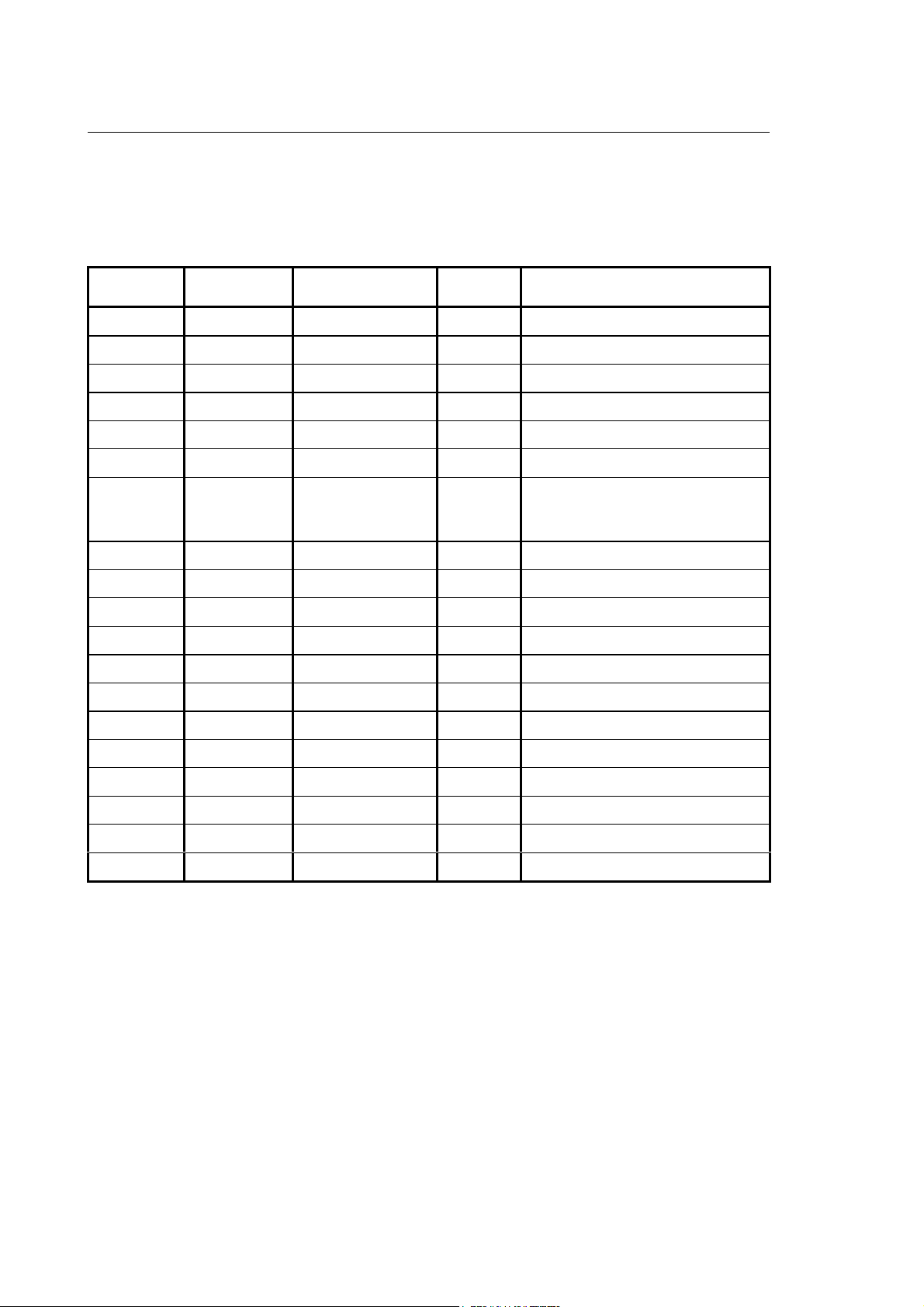

Axes Table

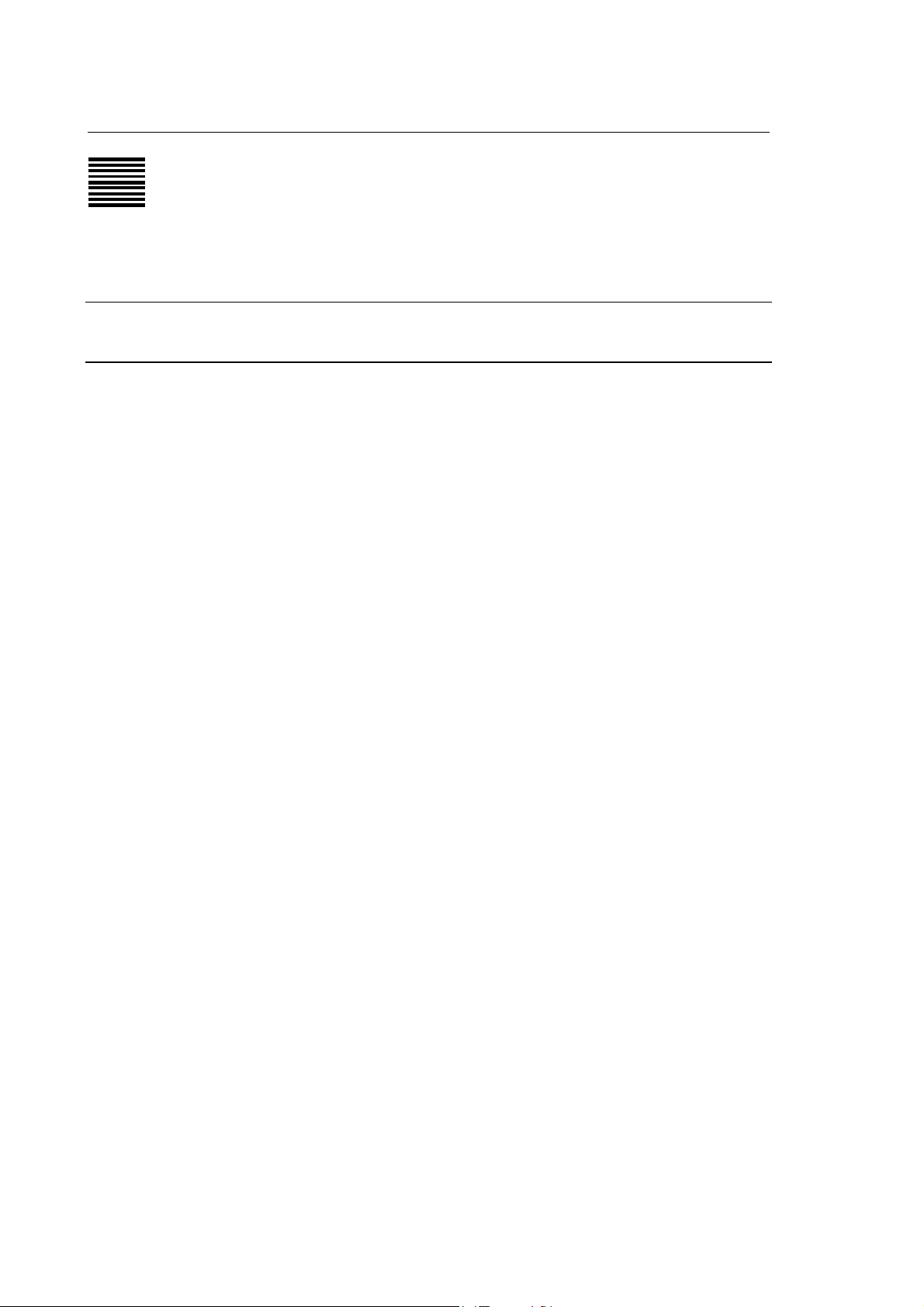

Each of the 32 pages in this table is made up of 19 fields identified by a name, as shown in the

example below. The index of each variable can range from 1 through 32 and corresponds to the

axes ID. The index may be a numerical value or another variable.

Field Type Variable name Format Meaning

reserved reserved --- --- ---

AXNAME read only $AXNAME(x) S axis name in ASCII

AXORIG read only $AXORIG(x) D value of current origin

reserved reserved --- --- ---

AXOFG92 read only $AXOFG92(x) D current G92 offset value

AXTOFF read only $AXTOFF(x) D current tool offset value

PRO_OFFS read only $PRO_OFFS (x) D total current corrector value

applied by the process when an 'h'

is enabled

TOT_OFFS read only $TOT_OFFS(x) D total offset of the current axis

ORIG1 read/write $ORIG1(x) D value of origin # 1

ORIG2 read/write $ORIG2(x) D value of origin # 2

ORIG3 read/write $ORIG3(x) D value of origin # 3

ORIG4 read/write $ORIG4(x) D value of origin # 4

ORIG5 read/write $ORIG5(x) D value of origin # 5

ORIG6 read/write $ORIG6(x) D value of origin # 6

ORIG7 read/write $ORIG7(x) D value of origin # 7

ORIG8 read/write $ORIG8(x) D value of origin # 8

ORIG9 read/write $ORIG9(x) D value of origin # 9

ORIG10 read/write $ORIG10(x) D value of origin # 10

reserved reserved --- ---

x = page number or axis identification number

S = short, D = double

Example:

To write into variable E1 the value of the current total offset of the axis identified by ID4, which is

the sum of the axis origin, the G92 offset and the tool offset, key in the following instruction:

E1 = $TOT_OFFS(4)

To assign to the origin # 1 of the axis identified by ID 5 the numerical value 1.4, key in the

following:

$ORIG1(5) = 1.4

1-6 10 Series CNC ASSET Reference Manual (06)

Page 17

Chapter 1

General

Tools Table

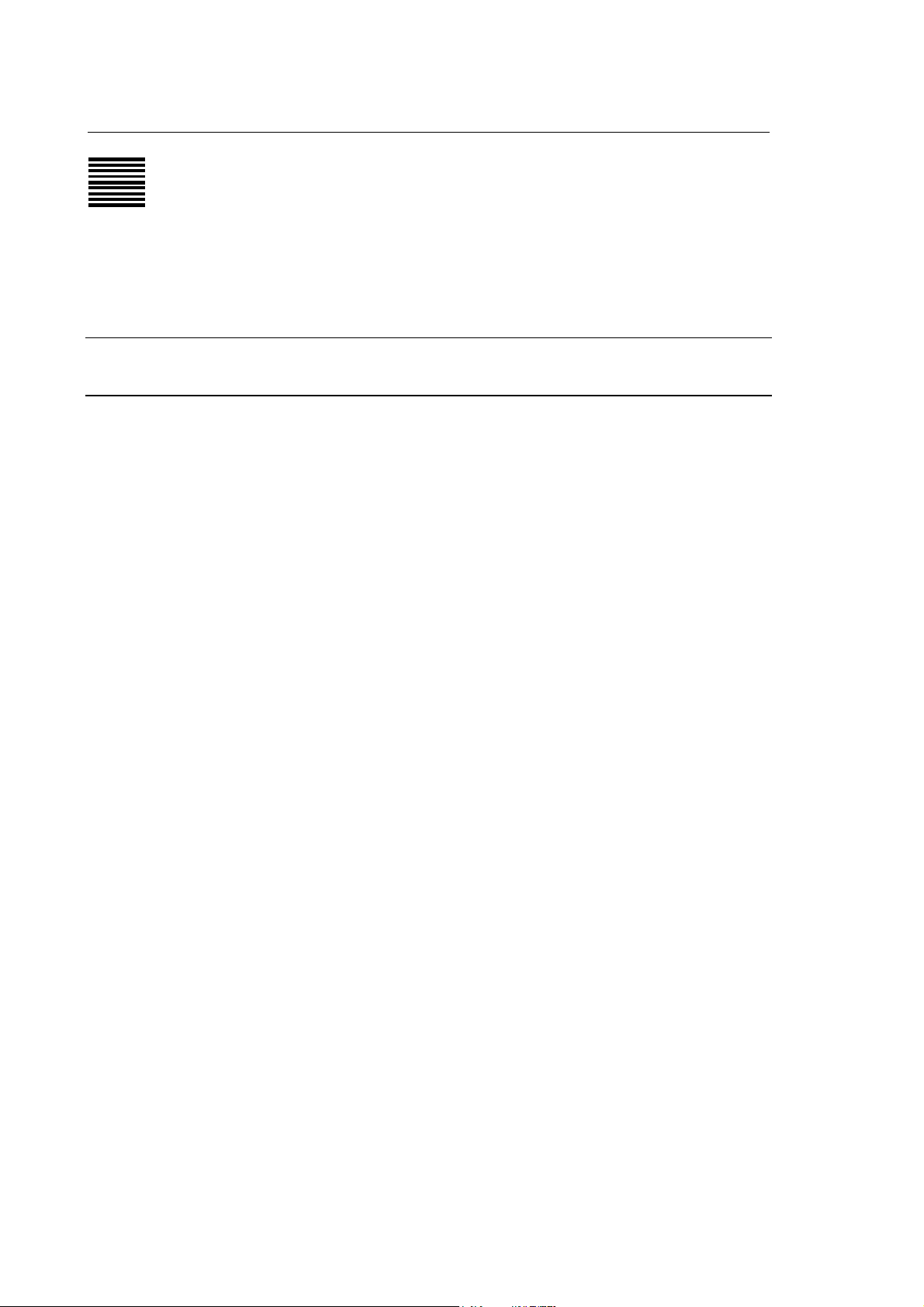

Each of the 250 records of the table has 13 fields whose ID's are shown in the following diagram.

Each variable can take an index from 1 to 250. They can be expressed by a number or an E

parameter.

Field Type Variable name Format Meaning

TCODE read/write $TCODE(x) T** tool code

TOOLPOS* read/write $TOOLPOS(x) S Information regarding the tool position

TFAMCOL read/write $TFAMCOL(x) S reserved

TOOLTYPE* read/write $TOOLTYPE(x) S Information regarding the type of tools

TSTATUS read/write $TSTATUS(x) S tool status

TCNTRL read/write $TCNTRL(x) S tool control word

MAXLIFE read/write $MAXLIFE(x) D Initial life

REMLIFE read/write $REMLIFE(x) D real life

TUSER1 read/write $TUSER1(x) D User variable # 1 for tool

TUSER2 read/write $TUSER2(x) D User variable # 2 for tool

TUSER3 read/write $TUSER3(x) D User variable # 3 for tool

TUSER4 read/write $TUSER4(x) D User variable # 4 for tool

TOLOFNR read/write $TOLOFNR(x) S default tool offset number

x = page number or tool record number

S = short, D = double

* = these fields of the table may have various meanings depending on the configuration and on

how they are used by the machine logic (see the 10 Series User Manual for details).

** = integer number (max. 12 digits)

Example:

To read the code of the tool stored in record 35 key in the following function:

(DIS, $TCODE(35))

To assign to the tool stored in record 42 a life equal to 500 cycles, key in the following:

$LIFETYPE(42) = 3

$MAXLIFE(42) = 500

10 Series CNC ASSET Reference Manual (06) 1-7

Page 18

Chapter 1

General

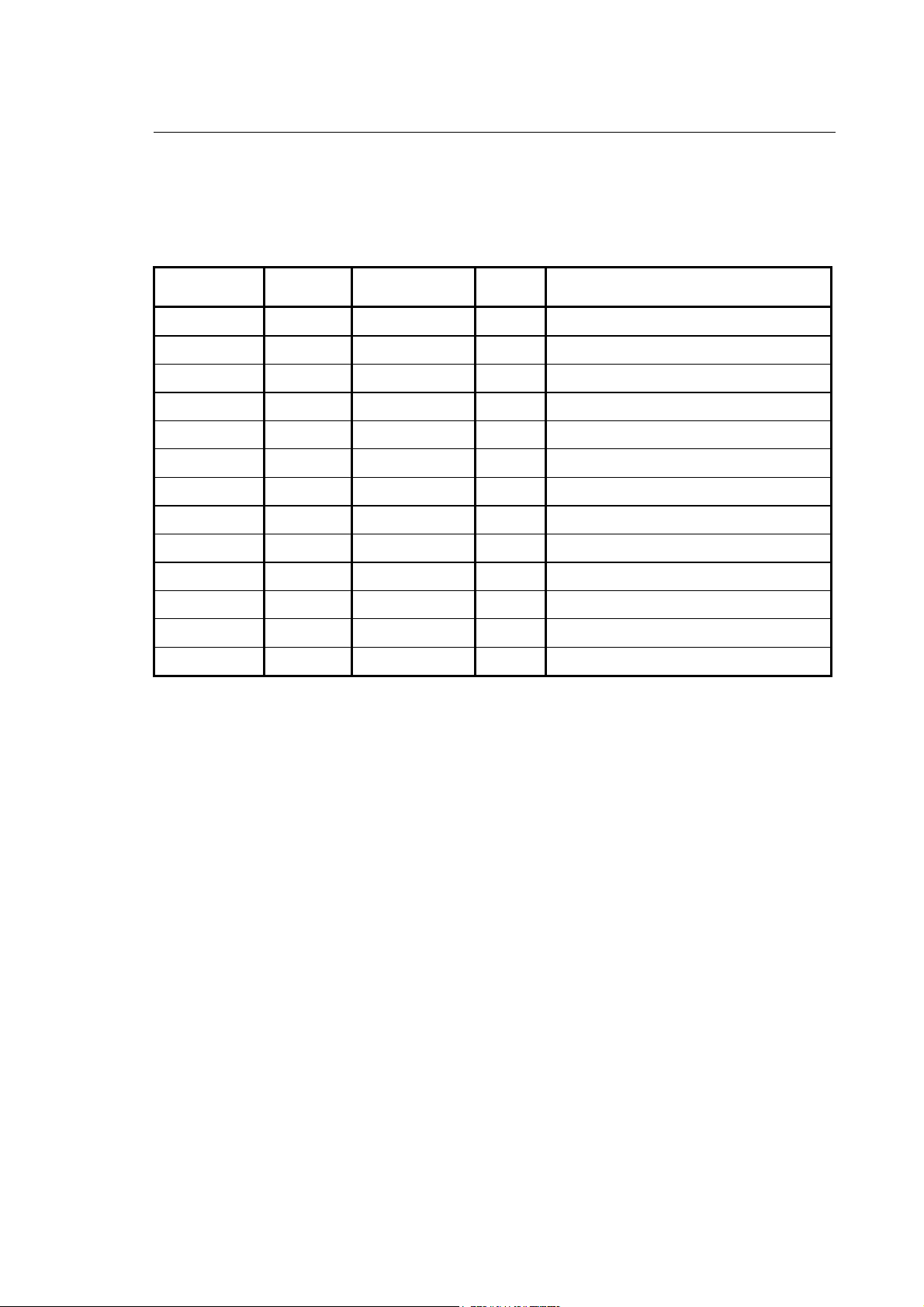

Tool Offsets Table

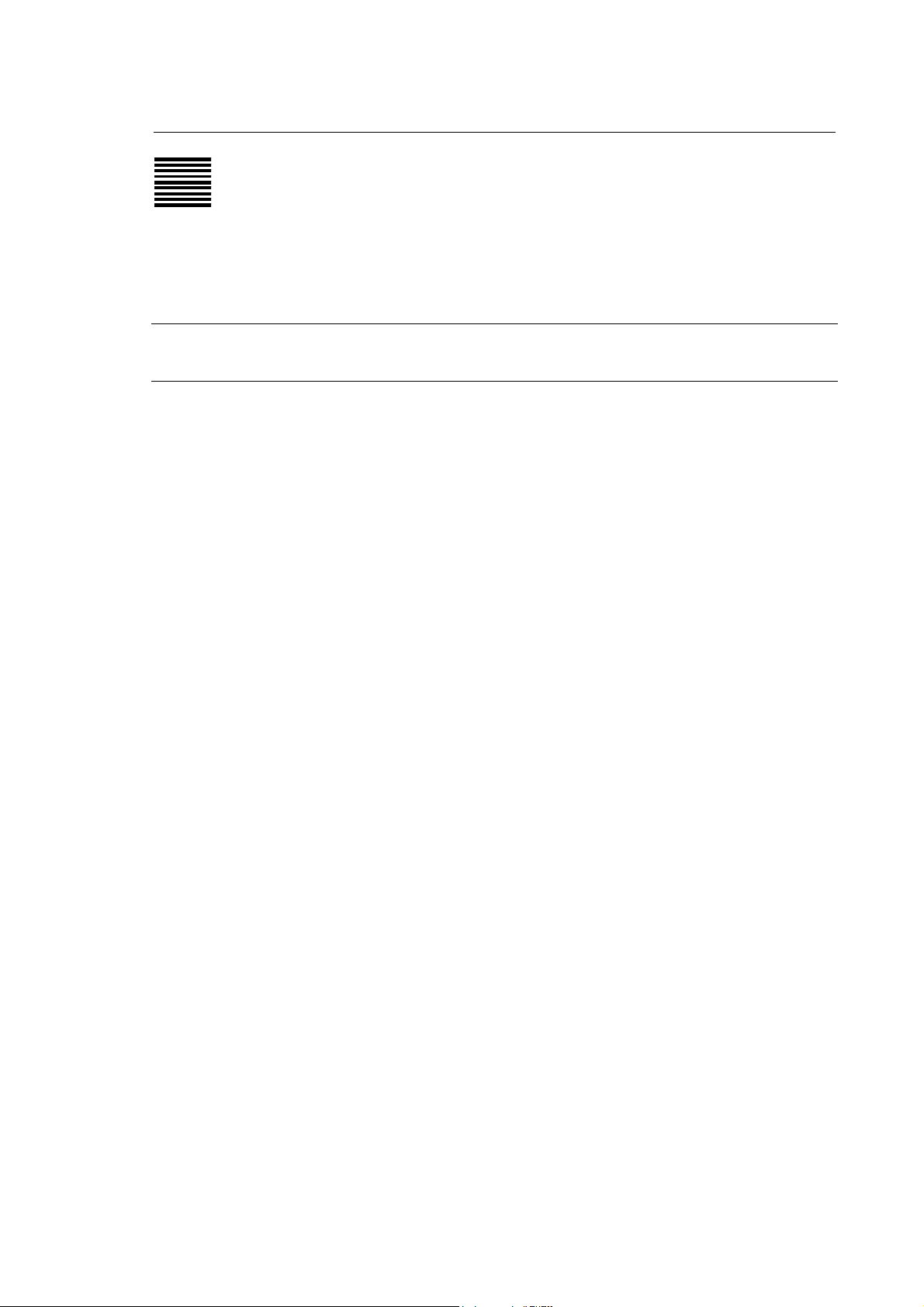

Each of the 300 pages or tool offsets in this table is made up of 9 fields. Each field is identified by a

name which is shown in the table below. Variable indexes range from 1 to 300. An index may be a

numerical value or another variable.

Field Type Variable name Format Meaning

TACTL1 read/write $TACTL1(x) D current tool length # 1

TCMAXL1 read/write $TCMAXL1(x) D maximum offset for length # 1

TCACTL1 read/write $TCACTL1(x) D current offset for length # 1

TACTL2 read/write $TACTL2(x) D current tool length # 2

TCMAXL2 read/write $TCMAXL2(x) D maximum offset for length # 2

TCACTL2 read/write $TCACTL2(x) D current offset for length # 2

TDIAMETER read/write $TDIAMETER(x) D tool diameter

TCACDIAM read/write $TCACDIAM(x) D diameter offset value

TORIENT read/write $TORIENT(x) S tool orientation

x = page number or offset number

S = short, D = double

Example:

If you want to supply the maximum requalification of the length # 1 of the corrector 137 with the

value in the user # 3 variable in the Tool Table at record 35, write:

$TCMAXL1(137) = $TUSER3(35)

If the value of process variable TTR (Thoroidal Tool Radius) has been set or

configured as 1, the fields relating to length # 2 are assumed to coincide with

the size of the tool tip radius (in TCP and HSM applications).

1-8 10 Series CNC ASSET Reference Manual (06)

Page 19

Chapter 1

General

PLUS I/O

PLUS inputs are arranged in 85 11-bit arrays followed by 427 16-bit arrays; outputs are arranged in

85 6-bit arrays followed by 427 16-bit arrays. Accordingly, a total of 7767 inputs and 7342 outputs

has to be managed.

An array and its Input or Output are identified by an I or an O preceded by $ and followed by the bit

index between brackets: $I(index) or $O(index), as in the User Table. For example, $I(35),

$O(812).

The Input/Output arrays can be pictured as tables, as shown in the figures below.

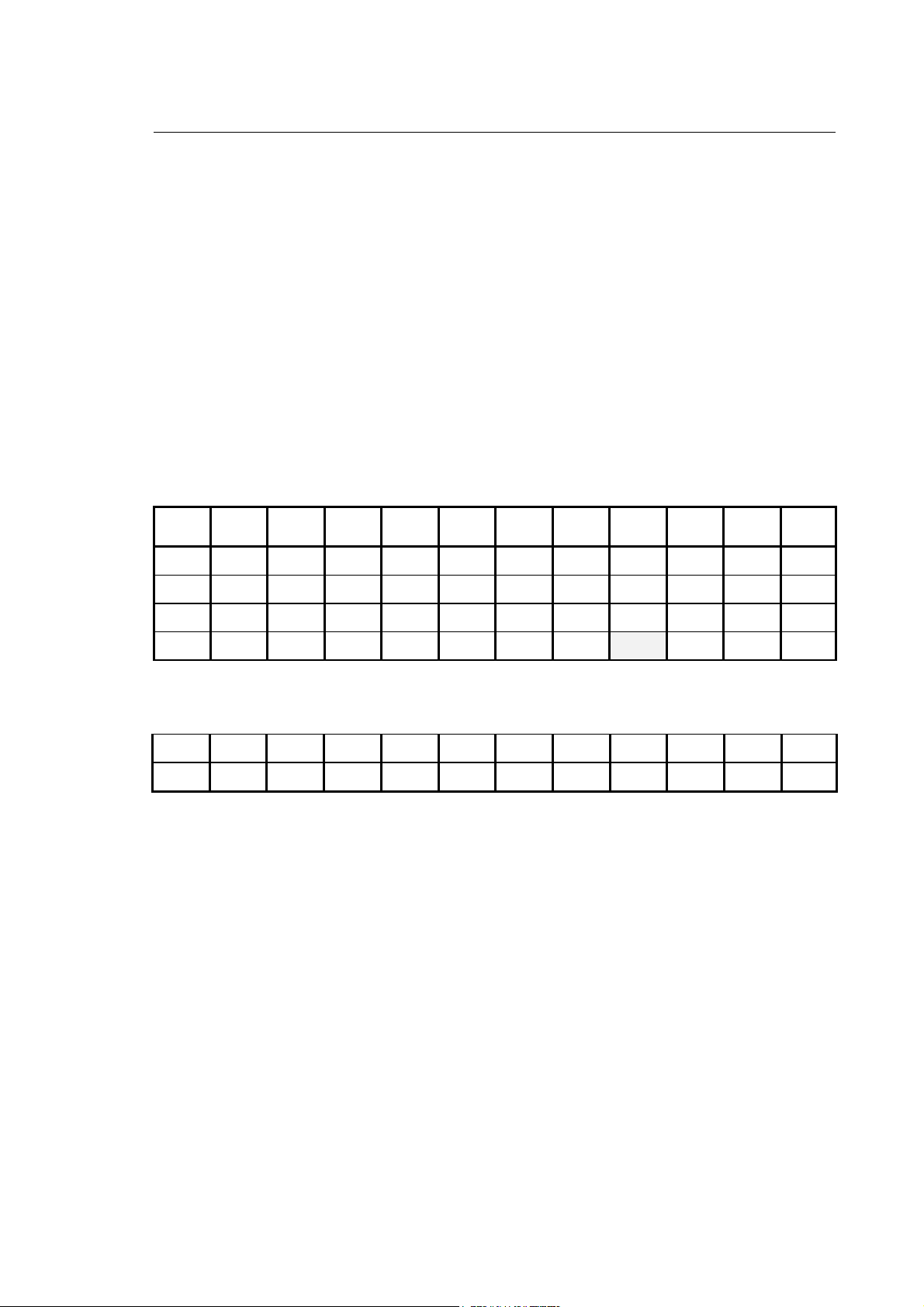

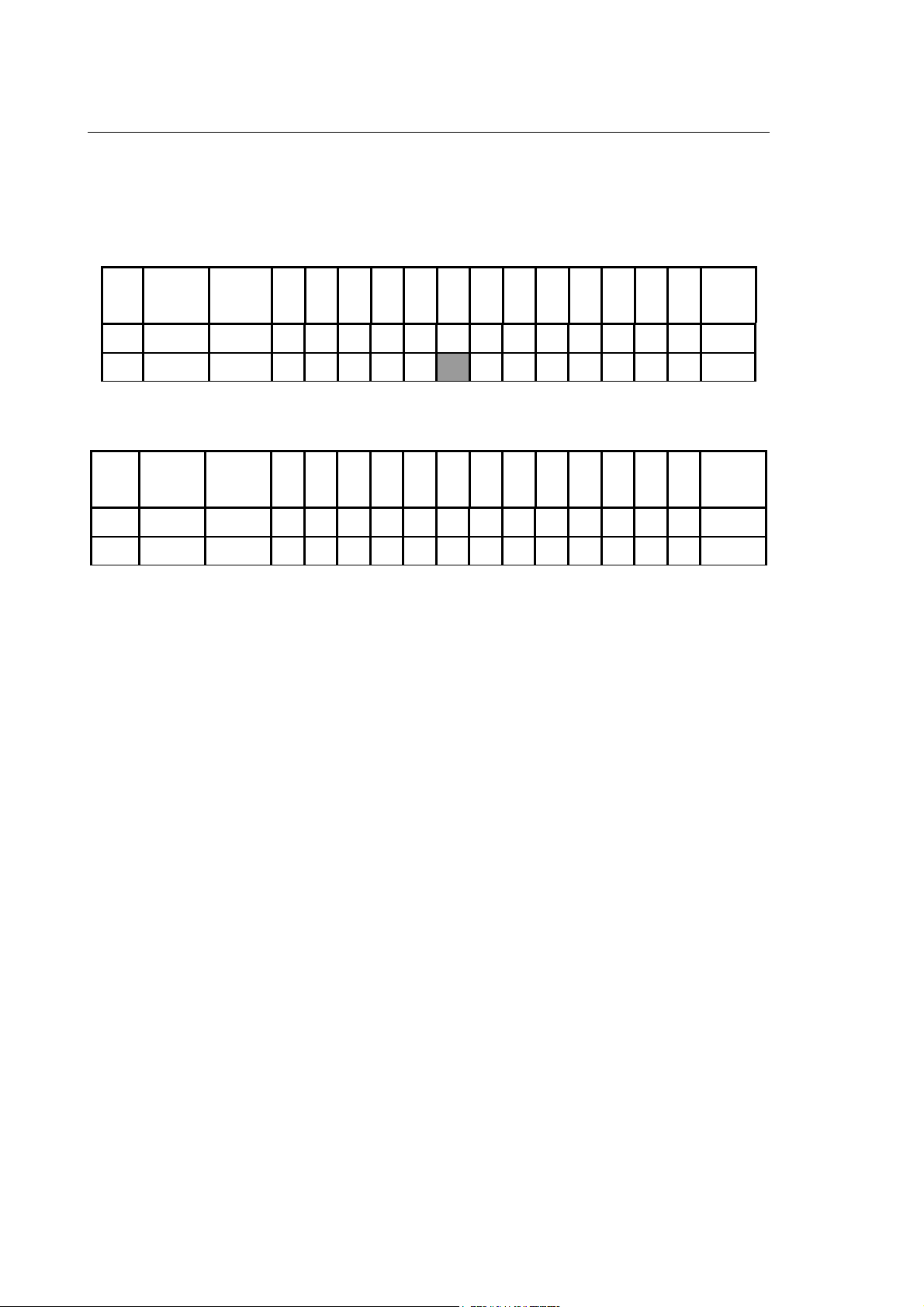

Inputs (the first 85 arrays)

Arrays or groups of inputs may be numbered from 00 to 84, whereas the 11 bits in the array are

numbered from 0 to 10. The index of the first input variable will be 0, whereas the index of the last

input variable will be 934, as shown in the table below:

Array bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7 bit 8 bit 9 bit 10

00

01

02

03

$I(0) $I(1) $I(2) $I(3) $I(4) $I(5) $I(6) $I(7) $I(8) $I(9) $I(10)

$I(11) $I(12) $I(13) $I(14) $I(15) $I(16) $I(17) $I(18) $I(19) $I(20) $I(21)

$I(22) $I(23) $I(24) $I(25) $I(26) $I(27) $I(28) $I(29) $I(30) $I(31) $I(32)

$I(33) $I(34) $I(35) $I(36) $I(37) $I(38) $I(39) $I(40) $I(41) $I(42) $I(43)

.........................

.........................

83

84

$I(913) $I(914) $I(915) $I(916) $I(917) $I(918) $I(919) $I(920) $I(921) $I(922) $I(923)

$I(924) $I(925) $I(926) $I(927) $I(928) $I(929) $I(930) $I(931) $I(932) $I(933) $I(934)

To calculate the index from the cell position, i.e. when the array and bit numbers are known, use

this formula:

Index = array number x 11 + bit number

For example, to address bit 7 from array 03, the $I variable must be assigned the following index:

Index = 3 x 11 + 7 = 40

The resulting variable will be $I(40), as shown in the table.

To calculate the array and bit numbers from the index, divide the index by 11: the ---- will be the

array number and the remainder will indicate the bit number.

For example, the $I(172) variable will address the 15 (172 / 11) array and the 7 (172 - 15 x 11) bit.

10 Series CNC ASSET Reference Manual (06) 1-9

Page 20

Chapter 1

General

Inputs (after the 85th array)

The numbering of the individual input arrays or input groups goes from 85 to 511; the 16 bits within

an array are numbered from 0 to 15. In these conditions the index of the first input variable will be

935, the index of the last variable will be 7766, as can be seen from the table below:

Array bit 0 bit 1 bit2bit3bit4bit5bit6bit7bit8bit9bit10bit11bit12bit13bit14bit 15

85

86

$I(935) $I(936) $I(950)

$I(951) $I(952) $I(966)

..........................

..........................

Array bit 0 bit 1 bit2bit3bit4bit5bit6bit7bit8bit9bit10bit11bit12bit13bit14bit 15

510

511

$I(7735) $I(7736) $I(7750)

$I(7751) $I(7752) $I(7766)

The formula used to define an index starting from the position of the cell (i.e., the array number and

the bit number), is as follows:

index = (array number – 85) X 16 + 935 + bit number

For example, if we want to address bit 13 in array 86 (i.e., the grey-coloured cell), the index of

variable $I must be determined as follows:

Index = (86 – 85) X 16 + 935 +13 = 964

In this case, the variable will therefore turn out to be $I(964), as shown in the table. Conversely, if

we want to determine an array and a bit, knowing the relative index, we must subtract 935 from the

index and then divide the value obtained by 16. By adding 85 to the whole number determined in

this manner, we get the array number, while the difference will identify the bit within the array. For

example: for variable $I (7736) we get array 510 ((7736-935)/16+85) and bit 1 ((7736-935) / 16).

1-10 10 Series CNC ASSET Reference Manual (06)

Page 21

Chapter 1

General

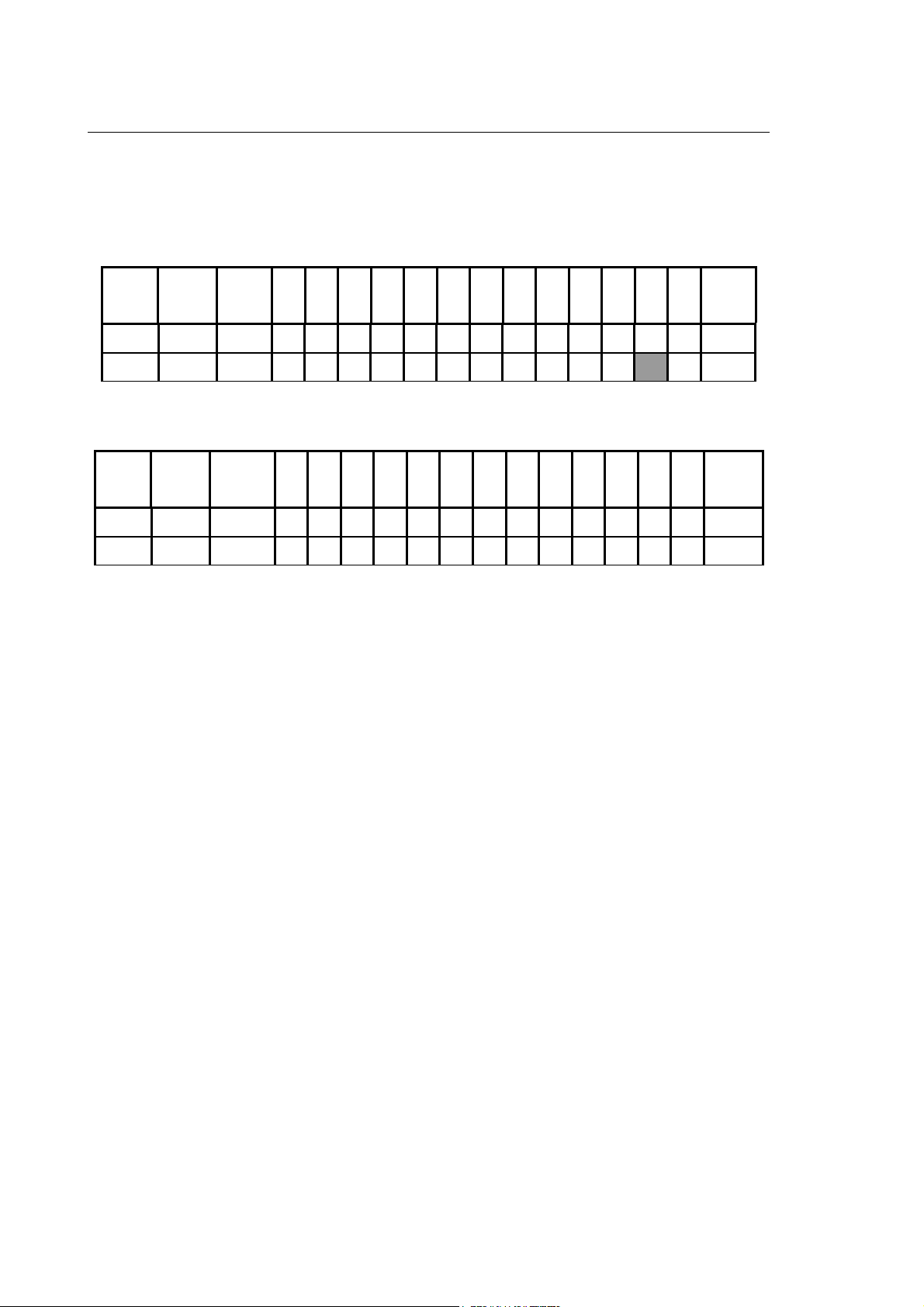

Outputs (the first 85 arrays)

Arrays or groups of outputs may be numbered from 00 to 84, whereas the 6 bits in the array are

numbered from 0 to 5. The index of the first output variable will be 0, whereas the index of the last

output variable will be 509, as shown in the table below:

Array bit 0 bit 1 bit 2 bit 3 bit 4 bit 5

00 $O(0) $O(1) $O(2) $O(3) $O(4) $O(5)

01 $O(6) $O(7) $O(8) $O(9) $O(10) $O(11)

02 $O(12) $O(13) $O(14) $O(15) $O(16) $O(17)

03 $O(18) $O(19) $O(20) $O(21) $O(22) $O(23)

...................

....................

83 $O(498) $O(499) $O(500) $O(501) $O(502) $O(503)

84 $O(504) $O(505) $O(506) $O(507) $O(508) $O(509)

To calculate the index from the cell position, i.e. when the array and bit numbers are known, use

this formula:

Index = array number x 6 + bit number

Examples:

1. To address bit 2 from array 03, the $O variable must be assigned the following index:

Index = 3 x 6 + 2 = 20

The resulting variable will be $O(20), as shown in the table.

2. To calculate the array and bit numbers from the index, divide the index by 16: the integer value

obtained through the division will be the array number and the remainder will indicate the bit

number.

For example, the $O(214) variable will address the 35 (214/6) array and the 4 (214 - 35 x 6) bit.

10 Series CNC ASSET Reference Manual (06) 1-11

Page 22

Chapter 1

General

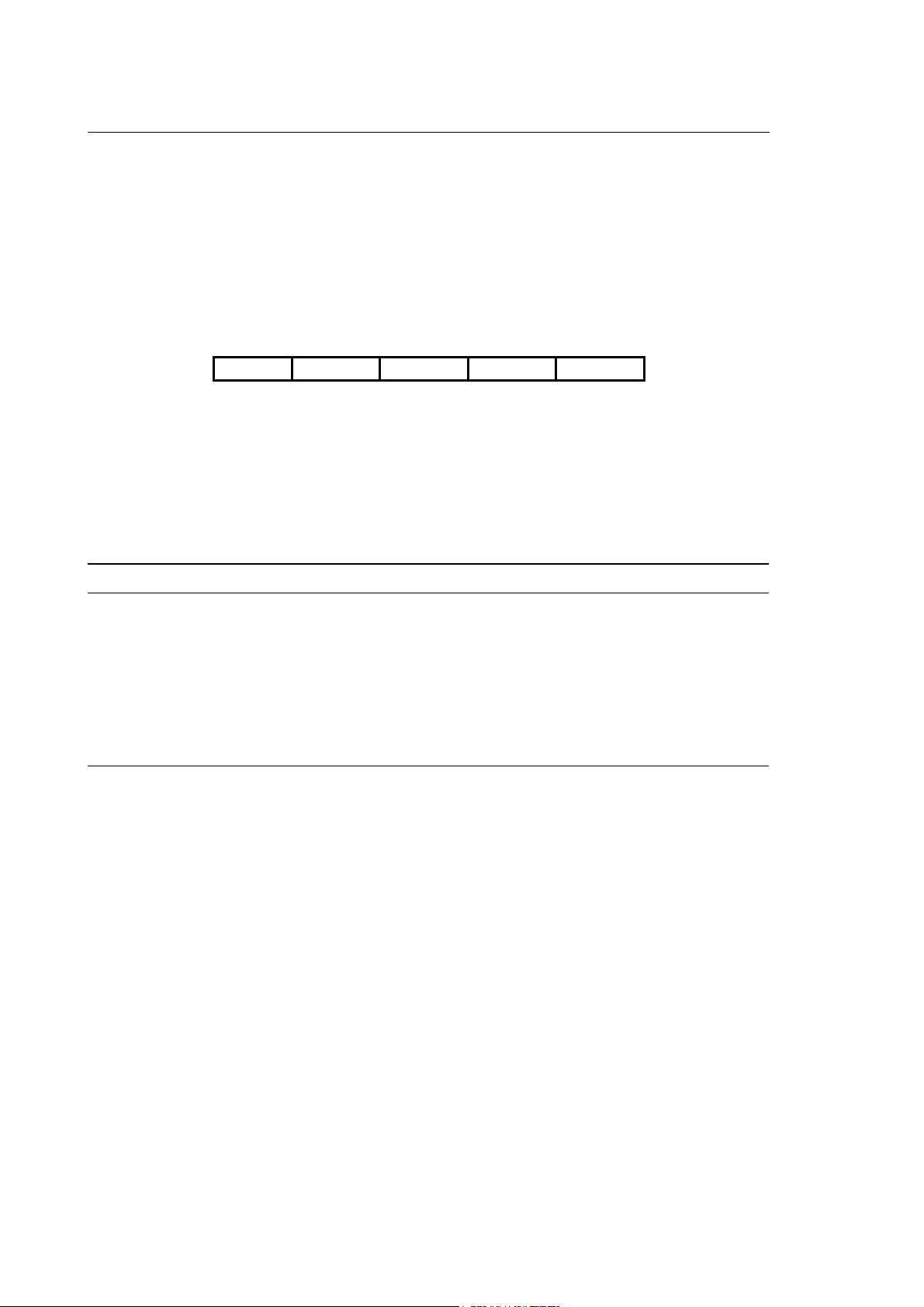

Outputs (after 85th array)

The numbering of the individual output arrays or output groups goes from 85 to 511; the 16 bits

within an array are numbered from 0 to 15. In these conditions the index of the first output variable

will be 510, the index of the last variable will be 7341, as can be seen from the table below:

Ar

bit 0 bit 1 bit2bit3bit4bit5bit6bit7bit8bit9bit10bit11bit12bit13bit14bit 15

ray

$O(510) $O(511) $I(525)

85

$O(526) $I(527) $I(541)

86

..........................

..........................

Ar

bit 0 bit 1 bit2bit3bit4bit5bit6bit7bit8bit9bit10bit11bit12bit13bit14bit 15

ray

510

511

$O(7310) $O(7311) $O(7325)

$O(7326) $O(7327) $0(7341)

The formula used to define an index starting from the position of the cell (i.e., the array number and

the bit number), is as follows:

index = (array number – 85) X 16 + 510 + bit number

For example, if we want to address bit 7 in array 86 (i.e., the grey-coloured cell), variable $O must

be assigned the following index:

Index = (86 – 85) X 16 + 510 + 7 = 533

In this case, the variable will therefore turn out to be $O(533), as shown in the table. Conversely, if

we want to determine an array and a bit, knowing the relative index, we must subtract 510 from the

index and then divide the value obtained by 16. By adding 85 to the whole number determined in

this manner, we get the array number, while the difference will identify the bit within the array. For

example: for variable $O (680) we get array 95 ((680-510)/16+85) and bit 10 ((680-510) / 16).

1-12 10 Series CNC ASSET Reference Manual (06)

Page 23

Chapter 1

General

FILE

10 Series ASSET can manage two types of files:

• ASCII files

• Binary (data) files

Except where otherwise stated, these files are located in default directory E:\FILE or F:\FILE, which

ASSET can access. However it is also possible to read or write with ASSET in files belonging to

other directories. In this case, the full pathname and extension of the file in question must be

specified (e.g. E:\USER\FILE|FILE1.DAT).

These files are located in the E:\FILE or F:\FILE directories, which are accessible to ASSET. Their

main characteristics are discussed in the sections that follow.

ASCII files

ASCII files may contain part programs, messages, etc. They are not formatted and have records of

undefined length that must be written and read sequentially. ASCII files are given the .ASC

extension by the system by default, in cases where the file was opened in read or write mode

without the full pathname and extension being specified.

In an ASCII file it is not possible to read, write or search for a specific record. Maximum record

length is 127 characters.

The system always starts reading an ASCII file from the first record, on which it positions

automatically as it opens the file.

Writing an ASCII file means adding a new record after the last record in the file. To edit an ASCII

file it is necessary to read it sequentially, make the necessary alterations and write a new file that

will replace the old one.

10 Series CNC ASSET Reference Manual (06) 1-13

Page 24

Chapter 1

General

Binary files

Binary files are formatted files that are used for storing the parameters managed by the system, i.e.

variables, numbers, parameters, etc. Records have a fixed length that is declared when the first

record is written. Binary files are given the .DAT extension by the system by default, in cases

where the file was opened in read or write mode without the full pathname and extension being

specified.

For example, to write into a file the tool code with the relevant TUSER1-4 user variables the binary

file record will be as follows:

TCODE TUSER1 TUSER2 TUSER3 TUSER4

When the system writes the first record it automatically creates a header that is invisible to the user

and defines the format of all the file records.

Binary file records can be searched for and addressed for reading and writing operations.

A record can be up to 300 bytes long.

To calculate the record length in bytes it is necessary to know the length of each of the variables

stored in the record. This information is listed in the table below:

Variable Length in bytes

Boolean 1

Byte 1

Short 2

Long 4

Real 4

Long Real (Double) 8

String Number of characters in the string.

For example: SC0.4 --> 4 characters --> 4 bytes

Example:

if you write the following variables into a table:

(WRT,1,E1,E5,L3)

The record will occupy 24 bytes because there are 3 double variables and 3 x 8 = 24

For the following writing command:

(WRT,1,SC0.60,L5,"TEST")

the record length will be 72 bytes (60 + 8 + 4).

Unless otherwise specified in the reading or writing command, access to the file occurs at the first

record for reading and after the last record for writing. After a record has been read or written the

cursor will position to the subsequent record.

When reading or writing commands including ASSET binary files it is possible to declare a

parameter that specifies the number of the target record.

1-14 10 Series CNC ASSET Reference Manual (06)

Page 25

Chapter 1

General

COMMANDS

ASSET ensures full compatibility with the commands and instructions typical of the standard

programming environment. For more information about parametric programming, please refer to

Chapter 7 of the 10 Series Programming Manual.

Here is a list of syntactic and typographical conventions used throughout the manual:

The function name and the mandatory signs will be printed in boldface type. Mandatory parameters

associated to a function will be indicated by an italicised mnemonics. Parameters may be enclosed

between brackets.

[ ] Square brackets enclose optional parameters that may be omitted. Do not write these

brackets into the block.

{ } Graphs enclose parameters that are alternative to one another and are separated by a |. Do

not write graphs into the block.

| The vertical bar is the separator between two alternative parameters. Do not write this bar into

the block.

Parameters may be expressed by letters, alphanumeric characters and numbers. Letters are used

as keys or to identify the characteristic of a command. Alphanumeric characters identify file and

variable names and are used for messages. Numbers identify parameters, multiple elements, etc.

Non significant zeroes can be omitted.

Example:

(OPN, channel, filename, {A|B}, {R|W})

The three-letter code, the commas and the brackets are mandatory. A is alternative to B and R is

alternative to W.

The sections that follow describe ASSET functions. For each function the following information is

provided:

• Function name

• Meaning

• Syntax

• Mandatory and optional parameters

• Other characteristics and notes

• Examples.

10 Series CNC ASSET Reference Manual (06) 1-15

Page 26

Chapter 1

General

LCK - Locking/Unlocking PLUS tables

This instruction permits to inform the logic or other applications that the specified table is being

edited and is not accessible to them. After the table has been edited it is necessary to give another

LCK in order to indicate that the table is available.

Syntax:

(LCK, table number, {0 | 1})

where:

table number Is a number from 1 to 4 that identifies the write protected table. It can be

expressed as a numerical value, a local variable or a system variable with the

following mening:

1 axes table (origins)

2 tools table

3 tool offsets table

4 user table (L variables).

0 | 1 Write 1 to indicate that the specified table is write protected by ASSET. If the

table is already reserved by another user, such as PLUS or Table Editor, an

error message will be displayed:

NC270 PLUS Table already locked

This error can be managed from program by setting ERR = 1. For more

information refer to Appendix B.

Write 0 to indicate that the table is no longer reserved for ASSET and can be

accessed by other users.

Characteristics

$xxxxxx or L variables are always accessible and need not be write protected with ASSET.

However, it is recommended to lock the table to make sure that no other user has access to the

memory area written by ASSET.

Use LCK to unprotect a table only when it has been write protected from part program. Otherwise,

you may unprotect a table that was reserved for other users (such as the machine logic).

1-16 10 Series CNC ASSET Reference Manual (06)

Page 27

Example:

The following example shows how to write variables into the Tools Table:

. . .

. . .

ERR = 1 enables error management from part program

"LOOP"

(LCK,2,1)

(GTO,LOOP,STE=45) 45 = write protected table; waiting for unlocking command

$TCODE(1) = 12

$TUSER1(1) = 3.45

$TCODE(2) = 13

$TUSER1(2) = 6.21

(LCK,2,0) unprotected tools table

ERR = 0 disables error management from part program

. . .

. . .

Chapter 1

General

10 Series CNC ASSET Reference Manual (06) 1-17

Page 28

Chapter 1

General

END OF CHAPTER

1-18 10 Series CNC ASSET Reference Manual (06)

Page 29

Chapter 2

INPUT COMMANDS

Input commands permit to create, customise and manage data entry windows. In particular, they

make it possible to:

• Define the labels of the data entry fields and the destination of input data;

• Define the layout of the data entry window: window size and position, text position, etc.

• Define the background, foreground and text colors.

The three-letter codes that allow to program these features are as follows:

• DIF

• INP

10 Series CNC ASSET Reference Manual (04) 2-1

Page 30

Chapter 2

Input Commands

DIF - Definition of a data field

DIF permits to define the size and color of a data entry window that has been programmed with the

INP command. It must be used when the characteristics to be configured are different from the

default ones.

Syntax

(DIF, window number, first line, first column, first field line, first field column, empty lines, number

of fields [,background color, text color, field color])

where:

window number identifies a predefined window. It is an integer from 1 to 10. DIF,0 invokes the

default window, which cannot be modified.

first line is the screen line where the data entry window starts. It is an integer from 0 to

18.

Line 19 is always reserved for error messages.

first column is the screen column where the border of the window is positioned. It is an

integer from 0 to 79 which must obviously be selected according to the length of

the displayed data.

first field line is the line occupied by the first window field declared in the INP block. This field

may be the name of the window or a data field.

It is a value in the 0 to 18 range which depends on the value of the first line

parameter.

first field column is the screen column occupied by the first INP field and measures the distance

from the screen border to the window border in characters. If programmed with

the INP command the field will be automatically centered.

It is an integer from 0 to 79 which must obviously be selected according to the

length of the displayed data.

empty lines is the number of empty lines that separates two subsequent comment or field

lines.

It is an integer from 0 to 18 which must obviously be selected according to the

available space and the length of the displayed data. If you write 0 there will be

no empty lines.

If INP programs only one data entry field, the empty lines value is use for

positioning the lower border with respect to the last displayed line.

number of fields specifies the number of fields to be displayed on the same line. It ranges from 1

to 4. The distance between two fields is 3 characters.

background color (optional) Defines the color of the data entry window background. If it is omitted,

the default background color is blue. Allowed values are between 0 and 7. The

meaning of these values is shown in the Characteristics section.

2-2 10 Series CNC ASSET Reference Manual (04)

Page 31

Chapter 2

Input Commands

text color (optional) Defines the color of the name and text displayed in the data entry

window. If it is omitted, the default color is yellow. Allowed values are between

0 and 7. The meaning of these values is shown in the Characteristics section.

field color (optional) Defines the color of the characters and markers entered from the

keyboard on the fields programmed with INP. If it is omitted, the default color is

white. Allowed values are between 0 and 7. The meaning of these values is

shown in the Characteristics section.

Characteristics

• The parameters configured in the background color, text color and field color are as follows:

1. black

2. blue

3. green

4. cyan

5. red

6. magenta

7. yellow

8. white

• The window layouts established by DIF are retained in the system memory after a reset.

10 Series CNC ASSET Reference Manual (04) 2-3

Page 32

Chapter 2

Input Commands

• All the fields in the DIF instruction (included the colors) may be programmed directly, i.e., by

writing numerical values, or through local and system variables.

• ASSET includes a default DIF instruction. If no DIF is declared in the INP instruction, the default

DIF displays the following window. This window implies that INP has declared 8 fields plus the

WINDOW NAME. The numbers of lines and columns are in italics. Default window parameters

are as follows:

column 0 column 79

PROCESS CONTROLLED: 1 CAPS ON DATE: 15/12/1993 TIME: 9:35:00

PROC: 1 IDLE AUTO OPT STOP RETRACE

0

1

2

FIELD 1: xxxxxxxxxx

3

4

FIELD 2: xxxxxxxxxx

5

6

FIELD 3: xxxxxxxxxx

7

8

FIELD 4: xxxxxxxxxx

9

10

FIELD 5: xxxxxxxxxx

11

12

FIELD 6: xxxxxxxxxx

13

14

FIELD 7: xxxxxxxxxx

15

16

FIELD 8: xxxxxxxxxx

17

18

(Reserved for error messages)

19

MACHINE SETUP TABLES DIAGNOSTICS PERIPHERALS UTILITY

WINDOW NAME

POS DISPLAY NEXT DISPLAY SELECT PROCESS ENLARGE HELP

AUTO MANUAL PART PROGRAM VARIABLES OEM SOFTKEY

First line: 0

First column: 0

First field line: 1

First field column: 1

Empty lines: 1

Number of fields on a line: 1

Background color: Blue

Label color: Yellow

Field color: White

These parameters are programmed by the following DIF format:

(DIF,1,0,0,1,1,1,1,6,7,4) (the last three digits can be omitted)

2-4 10 Series CNC ASSET Reference Manual (04)

Page 33

Chapter 2

Input Commands

Examples:

Let's assume that you need to program a data entry window (WINDOW #3) that is made up of

three fields and one window name, like the one shown in the figure below:

column 0 column 79

PROCESS CONTROLLED: 1 CAPS ON DATE: 15/12/1993 TIME: 9:35:00

PROC: 1 IDLE AUTO OPT STOP RETRACE

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

POS DISPLAY NEXT DISPLAY SELECT PROCESS ENLARGE HELP

MACHINE SETUP TABLES DIAGNOSTICS PERIPHERALS UTILITY

FIELD 1: xxxxxxxxxx

FIELD 2: xxxxxxxxxx

FIELD 3: xxxxxxxxxx

AUTO MANUAL PART PROGRAM VARIABLES OEM SOFTKEY

WINDOW NAME

The number of fields, the field lengths, the characters in the window name and the fields labels

(FIELD 1 through 3) are specified in the INP file.

Let's also assume that the window must be positioned as follows:

distance from the upper border to the status line: 3 lines

distance from the window border to the screen border: 10 characters

distance from the window name to the upper window border: 1 line

distance from the first field to the left window border: 1 character

number of empty lines between fields: 1

number of fields per line: 1

The format of the DIF command will be:

(DIF,3,3,10,1,1,1,1)

10 Series CNC ASSET Reference Manual (04) 2-5

Page 34

Chapter 2

Input Commands

To display blue comments and red inputs on a green background, the format of the DIF command

will be:

(DIF,3,3,10,1,1,1,1, 2,1,4)

These numbers may be partially or totally replaced by local or system variables. For example, if the

contents of the first line, first column, and first field column fields are stored in variables E1, E2 and

E3, the format of the above command must be:

(DIF,3,E1,E2,1,E3,1,1)

If a great many fields must be displayed in one window it is possible to write several fields on the

same line with the following format:

(DIF,5,3,5,1,3,1,3)

The 6 fields programmed with INP will display this window:

WINDOW NAME

FIELD 1: xxxxxxxxxx FIELD 2: xxxxxxxxxx FIELD 3: xxxxxxxxxx

FIELD 4: xxxxxxxxxx FIELD 5: xxxxxxxxxx FIELD 6: xxxxxxxxxx

2-6 10 Series CNC ASSET Reference Manual (04)

Page 35

Chapter 2

Input Commands

INP - Manual data input

This command permits to link manual data inputs to their destination variables. It is used for

programming the name of the data entry window and the field labels. Data will be arranged

according to the window size and layout established with DIF. If the default DIF suits the user

needs the window number may be omitted.

When INP is executed, it enables the MDI mode.

Syntax

(INP, [Nwindow number,] [T WINDOW NAME,] label, label length, variable

[,label, label length, variable]

[,label, label length, variable]

[,label, label length, variable]

[,label, label length, variable]

[,label, label length, variable]

[,label, label length, variable]

[,label, label length, variable])

where:

window number (optional) It is the number of data entry window established with DIF.

It may be a number in the 0 to 10 range written in the command line or read

from a variable.

0 is the default window number, which is associated to the window described by

the DIF command.

window name (optional) It is the label displayed on the first window line. It may be a character

string enclosed between quotes ( ' or " ) or a string variable. For example,

SC0.10.

Its maximum length is 40 characters. The name is automatically centered on the

first window line.

Each data entry window may contain up to 8 fields. Each field is configured by the following

parameters:

label Is the name of the field. For example: tool, feedrate, etc.

It may be a character string enclosed between quotes ( ' or " ) or a string

variable. For example, SC0.10.

The label length may range from 0 and the value specified by the label length

parameter. The maximum label length is 40 characters.

label length Specifies the maximum length of the field label. The programmer may use this

parameter to arrange various fields on one line regardless of the length of the

label string.

It may be a number written in the command line or read from a variable.

variable It is a local or system variable whose current value is displayed on the data

entry window and updated with manual data input.

10 Series CNC ASSET Reference Manual (04) 2-7

Page 36

Chapter 2

Input Commands

Characteristics

When the system reads an INP block it switches to the MDI mode and displays the programmed

data entry window with the current variable values specified in the INP command.

The size, position and colors of the data entry window are programmed by the DIF instruction

whose number is specified in the INP command. If this number is omitted, the data entry window

will have the default characteristics.

Displayed values may be edited with the same procedures described for the other data entry

windows.

To exit from the data entry window and quit the MDI mode, press [ESC], [Enter], [Page Up], [Page

Down], [Home] and [End].

By pressing [ESC], [Page Up], [Page Down], [Home] and [End] the input window is closed but the

values of the programmed variables are not updated with the values you may have entered. In this

case, the STE system variable assumes a value that indicates the type of key with which the input

window has been closed. The possible values are the following:

Type of key STE value with ERR = 0

ESC

PAGE UP

PAGE DOWN

HOME

END

20

22

23

24

25

Press [Enter] to close the window saving the alterations to programmed values. If a format error is

detected in the assignment (for example, if VEF is assigned a value outside the 0.1 - 8.0 range) it

can be managed from program by setting the ERR variable to 1 (refer to Chapter 6, "Error

Management from Part Program").

The system automatically synchronises (#) the INP command to the execution of the program

(refer to Chapter 1 in the Programming Manual).

NOTE:

The label length must be programmed according to the number of fields that need to be displayed

on the same line. To well align fields on the same columns it is advisable to assign the same label

length to all the fields. This value must be equal to or greater than that of the longest label.

The system will not visualise an error message as long as it can display at least

one digit from the current or input data assigned to the right-most fields on the

window.

This should be remembered when programming position of the window on the

screen and the data fields in it and the label length.

It is recommended to display all the digits in the various data entry fields.

2-8 10 Series CNC ASSET Reference Manual (04)

Page 37

Chapter 2

Input Commands

Examples:

E1 = 1000; feedrate

(INP,'FEEDRATE',15,E1)

The above commands permit to visualise a data entry window whose size and colors are specified

by the default parameters in the DIF command. This window will visualise the "FEEDRATE" label

followed by a 7 character space (7 = 15 - the actual label length) and the current value of the E1

variable (1000 in the example). This value may be altered from keyboard or confirmed with [Enter].

(INP,T'INPUT TEST','FIELD 1',20,SC0.20)

This command permits to display a data entry window whose name is "INPUT TEST" and a 20

character field to display the contents of the SC0.20 variable preceded by the "FIELD 1" label.

(INP,N1,'FIELD 1',20,SC0.20,"FIELD 2", 20, E3,'FIELD 3',20,@PLUS)

This command permits to display a data entry window whose characteristics are specified by DIF 1,

without name, and in which the contents of the SC0.20, E3 and @PLUS variables are preceded by

the "FIELD 1", "FIELD 2" and "FIELD 3" labels.

10 Series CNC ASSET Reference Manual (04) 2-9

Page 38

Chapter 2

Input Commands

END OF CHAPTER

2-10 10 Series CNC ASSET Reference Manual (04)

Page 39

Chapter 3

SCREEN MANAGEMENT COMMANDS

10 Series displays all the parameters and data requested for system operation on a screen made

up of 25 lines. Each line has 80 characters. Screen lines are divided as follows.

• 1 status information line

• 21 lines (data area) displaying process and task information.

• 3 softkey lines.

The status line and the softkey lines are managed by the system. The data area may visualise two

screen types:

• Full screens: occupy 21 80-character lines.

• Quadrants: occupy 10 39-character lines.

The screens used on the 10 Series are of two types:

• System screens: the information in these screens is displayed through the system software;

see the user manual for significance of this information.

• User screens: contain information displayed by the user by way of the machine logic functions,

or using the ASSET OUT instruction.

10 Series CNC ASSET Reference manual (07) 3-1

Page 40

Chapter 3

Screen Management Commands

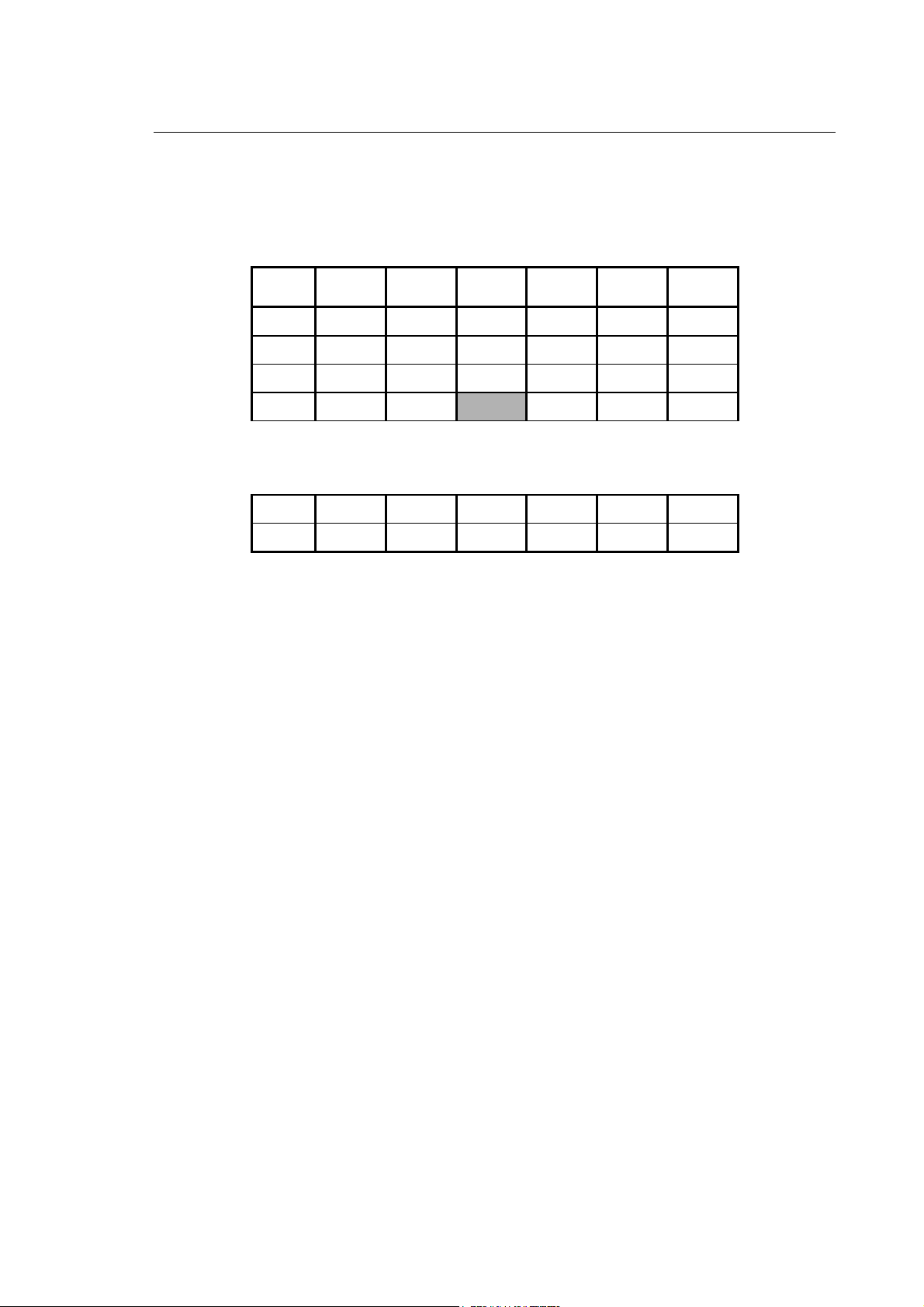

Code Screen

Type

Description Modified with

ASSET?

1 (*) Main process screen No

2 (*) Main logic screen No

3 (*) Axes coordinate in large font No

4 (*) Logic screen 1 Yes

5 (*) Logic screen 2 Yes

6 (*) Logic screen 3 Yes

7 (*) Logic screen 4 Yes

8 (*) Additional screen 1 No

9 (*) Additional screen 2 No

10 (*) Additional screen 3 No

11 (*) Additional screen 4 No

12 (*) Additional screen 5 No

25 (**) Logic quadrant 1 Yes

26 (**) Logic quadrant 2 Yes

27 (**) Logic quadrant 3 Yes

28 (**) Logic quadrant 4 Yes

35 (**) System status quadrant No

36 (**) Axes coordinates quadrant No

37 (**) Part program display quadrant No

38 (**) Process status quadrant No

39 (**) Programmed codes status quadrant No

40 (**) Axes offsets quadrant No

(*) Full screen size

(**) Quadrant

ASSET offers two, three-letter screen management commands:

• OUT for definition of the following line parameters:

− position

− contents (type of data, length, etc.)

− background and foreground colors

− font.

• SCR for selection of the screen associated with a given process.

3-2 10 Series CNC ASSET Reference manual (07)

Page 41

Chapter 3

Screen Management Commands

OUT - Screen line parameters

OUT defines location, length, colors and fonts on a line basis.

Syntax

(OUT,Screen code, line, column, background color, data color, [/length,] variable, ... ,variable)

where:

Screen code Is the screen number provided by the table on page 3-2.

Allowed values are 4, 5, 6, 7, 25, 26, 27, 28, which correspond to the

tables that can be modified with ASSET and described in the previous

table. This parameter can be written with a numerical format or read from

a local or system variable.

line Is the line number. It ranges from 0 to 20 in full size screens or from 0 to

9 in quadrants.

This parameter can be written with a numerical format or read from a

local or system variable.

column Is the number of the column where the line starts. It ranges from 0 to 79

in full size screens or from 0 to 38 in quadrants. If the maximum value is

selected, i.e. 79 or 38, only one character will be displayed.

This parameter can be written with a numerical format or read from a

local or system variable.

background color Is the background color of the selected line. It ranges from 0 to 7 (refer to

the Characteristics paragraph in this section) and may be written with a

numerical format or read from a local or system variable.

data color Is the color of the contents displayed on the selected line. It ranges from

0 to 15 (refer to the Characteristics paragraph in this section) and may be

written with a numerical format or read from a local or system variable.

/length (optional) Is the length of the selected line. It ranges from 1 to the

maximum number of characters displayed between the selected column

number and the last column configured for that screen.

It may be written with a numerical format or read from a local or system

variable. In any case the slash ( / ) is mandatory.

variable,...,variable, Is the list of characters or numerical variables to be displayed on the line.

Up to 8 variables of the same or of different types are allowed. Strings of

characters must be enclosed between quotes ( ' or " ).

10 Series CNC ASSET Reference manual (07) 3-3

Page 42

Chapter 3

Screen Management Commands

Characteristics

• The allowed values for background color and data color and their meaning are shown in the

table below:

Parameter value Background color Data color/display mode

0 Black Black / Normal

1 Blue Blue / Normal

2 Green Green / Normal

3 Cyan Cyan / Normal

4 Red Red / Normal

5 Magenta Magenta / Normal

6 Yellow Yellow / Normal

7 White White / Normal

8 Not allowed Black / Blinking

9 Not allowed Blue / Blinking

10 Not allowed Green / Blinking

11 Not allowed Cyan / Blinking

12 Not allowed Red / Blinking

13 Not allowed Magenta / Blinking

14 Not allowed Yellow / Blinking

15 Not allowed White / Blinking

• If both background color and data color are set to zero, the system will nevertheless default to

a white-on-black screen.

• To program a blank between variables when the line displays several variables, write the blanks

between quotes (for example, " ") or store them in a string variable, which may be repeated

several times in the same command.

• The contents specified in the OUT block must belong to the same line and cannot be longer

than the line. To display more data it is necessary to program more OUT's.

In addition, several parameters may be displayed on the same line by programming different

OUT blocks with appropriate line, column and length values so as to prevent overlapping.

3-4 10 Series CNC ASSET Reference manual (07)

Page 43

Screen Management Commands

Example:

The following command:

(OUT,5,3,10,2,8,/60,"TEST VAR E1: ",E1," "TEST VAR SC0.10: ",SC0.10)

allows to display the following screen:

column 0 column 79

PROCESS CONTROLLED: 1 CAPS ON DATE: 15/12/1993 TIME: 9:35:00

PROC: 1 IDLE AUTO OPT STOP RETRACE

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

POS DISPLAY NEXT DISPLAY SELECT PROCESS ENLARGE HELP

MACHINE SETUP TABLES DIAGNOSTICS PERIPHERALS UTILITY

TEST VAR E1: 1254.0 TEST VAR SC0.10: ABCDEFGHIL

AUTO MANUAL PART PROGRAM VARIABLES OEM SOFTKEY

Chapter 3

A 60-character green bar starting on column 10 appears on line 3. Its contents will be displayed in

black and blinking. Note that the strings programmed between quotes end by blanks, which

prevents parameters from being displayed as an uninterrupted line.

This is screen 5 and is associated to logic screen 2.

With the following variables:

SN1 = 5

SN2 = 3

SN3 = 10

SN4 = 2

SN5 = 8

SN6 = 60

SC30.12 = "TEST VAR E1: "

SC5.19 = "TEST VAR SC0.10: "

the OUT command could be rewritten as follows:

(OUT,SN1,SN2,SN3,SN4,SN5,/SN6,SC30.12,E1," ",SC5.19,SC0.10)

10 Series CNC ASSET Reference manual (07) 3-5

Page 44

Chapter 3

Screen Management Commands

SCR - Screen selection

SCR selects the video screen associated to the current process.

Syntax

(SCR,Screen code [, background color for initialization])

where:

Screen code Is the screen number provided by the table on page 3-2. It can be written

with a numerical format or read from a local or system variable.

If this number is > 100, the selected screen belongs to ProcessController

Windows application of WinNBI software.

background colour for

initialization (optional)

This parameter is taken into consideration only if the screen code

represents a screen that can be modified by ASSET. In this case, the

screen will be initialized with the color specified and all data previously on

that screen will be deleted. If this parameter is not specified, the screen

will not be initialized.

If the screen code is > 100 and background colour is > 0, the automatic

change of the screen selection is inhibited, possible on the Windows

application through F4 button.

Characteristics

If the system reads the command but no screen has been configured for the selected process the

visualised screen will not change. On the contrary, if the specified screen has been configured, it

will be immediately visualised.

The background color for initialization is defined by a number from 0 to 7, as illustrated in the table

below:

1. Black

2. Blue

3. Green

4. Cyan

5. Red

6. Magenta

7. Yellow

8. White

Screen change for ProcessController

If you want to select a ProcessController screen from Part Program, it is necessary to specify a

screen code > 100 in the SCR command. The number of the activated screen is “screen code –

100” and it is written into the SW5 variable with 15

th

bit=1 if background colour > 0.

3-6 10 Series CNC ASSET Reference manual (07)

Page 45

Chapter 3

Screen Management Commands

Example 1:

Let's assume that the system controls three processes and that the following screens have been

associated to them:

Process 1: Screens 1, 3, 8

Process 2: Screens 1, 2, 9, 25

Process 3: Screens 1, 3, 8, 9

In addition, let's assume that the (SCR,8) command was programmed in process 2 when process 1

is selected. The system will display screen 8, which is associated to process 1. If the same

command were programmed when process 2 is selected, no changes would be noticed.

Example 2:

Let’s assume that the following screens have been configured in the ProcessController of WinNBI

software:

PROCESS 1: 1,3,8

In addition, let’s assume that the (SCR,108,1) command was programmed in process 1. The

system will display screen 8 which is associated to process 1 and the automatic change of screen

through F4 button will be inhibited.

10 Series CNC ASSET Reference manual (07) 3-7

Page 46

Chapter 3

Screen Management Commands

END OF CHAPTER

3-8 10 Series CNC ASSET Reference manual (07)

Page 47

Chapter 4

FILE MANAGEMENT COMMANDS

The system may control ASCII and binary data files. The characteristics of these files have been

discussed in Chapter 1.

ASSET file management commands make it possible to:

• open a file and link it to a management channel.

• read a binary file or a record sequentially.

• write or edit a binary file or a record sequentially.

• close any file opened by ASSET.

• delete a file.

• copy an ASCII file to the directory of programs.

• allocate and release physical devices for file access.

• copy a file

The functions quoted above are executed by the following three-letter commands, described in this

chapter:

− OPN

− REA

− WRT

− CLO

− DEL

− INS

− GDV

− RDV

− CPY

10 Series CNC ASSET Reference Manual (07) 4-1

Page 48

Chapter 4

File Management Commands

OPN - Opening a file

This instruction permits to open a file and link it to a channel number. It also specifies whether the

file will be opened for reading or writing.

The channel is a marker that facilitates access to the file from other ASSET file management

commands.

Syntax

(OPN, channel, filename, {A | B | P}, {R | W})

where:

channel Is a number from 1 to 5 that identifies the channel. A channel is another file that

will be subsequently used by the REA or WRT commands.

It can be written in the block with a numerical format or read from the specified

variable.

filename Is the name of the file (max. 8 characters) associated to the channel. It may be

an alphanumerical string or the name of the character variable that contains the

file name. When it is a variable it must be preceded by a '?'.

The complete path and extension may be specified in the filename.

{A | B | P} Defines the type of file: ASCII (A), binary (B) or if a file belongs to the system

directory of programs (P).

{R | W} Specifies the type of access:

R: reading

W: writing

Characteristics

In each process it is possible to open 5 simultaneous files (channels).

If neither the path nor extension are specified in filename, the system provides the file extension

.DAT for binary files and .ASC for ASCII files. The file will be read or written in the default directory

(E:\FILE or F:\FILE).

If a file is opened for reading it must have been previously created and saved in the system. If the

file is opened for writing it need not exist in the system already and will be written in the working

directory when the session is closed.

4-2 10 Series CNC ASSET Reference Manual (07)

Page 49

Chapter 4

File Management Commands

Examples:

1. The TEST ASCII file in directory E:\FILE may be opened for reading and associated to channel

1 by the following command:

(OPN,1, TEST,A,R)

2. If the name of the DATAFILE file is written in the SC0.8 variable:

E1=2

SC0.8 = "DATAFILE"

and the channel number is stored in the E1 variable, DATAFILE may be opened for reading and

associated to channel 2 with the following command:

(OPN,E1,?SC0.8,B,W)

The full pathname of the file is E:\FILE\DATAFILE.DAT.

3. With command:

(OPN,1,E:\TEST.KKK,A,R)

File ASCII E:\TEST.KKK is opened for reading.

10 Series CNC ASSET Reference Manual (07) 4-3

Page 50

Chapter 4

File Management Commands

WRT - Writing a file

This command permits to write a record into the file specified and linked by a previous OPN block.

Data will be written sequentially, in the same order in which they are specified in the WRT block.

Syntax

(WRT, channel,[R record,] variable [, ...,variable])

where:

channel Is the channel number linked to the file by the previous OPN command. In

addition, OPN must have opened the file for writing (W).

record (optional) is a number or a variable that identifies the file record in which the

parameters must be written. It is always preceded by an R.

This parameter is accepted only if the file is binary.

If record is omitted, data will be written in the record used for the latest reading

and the system will position at the beginning of the subsequent record. If this is

the first writing instruction after OPN, data will be written on the first file record.

The maximum number of records that can be specified is 65535.

variable Is the variable(s) (max. 30) whose data must be written in the file records.

If the destination file is an ASCII file only character variables will be accepted.

If the destination file is binary, it is necessary to use the same number and type

of variables written in the first file record.

4-4 10 Series CNC ASSET Reference Manual (07)

Page 51

Chapter 4

File Management Commands

Characteristics

If the file is binary (i.e. has been opened with the B marker) and the number of records in the file

has not been specified in WRT, data will be written in the record that follows the record written

during the last writing session. If there have been no previous writing sessions, data will be written

in the first file record.

The first data written on an empty binary file are the record type, the number of variables, the types

of variable and the sequence in which variables must be arranged. This record provides the access

pattern to be followed by subsequent reading or writing operations, in which the same number, type

and sequence of variables must be used.

For example, if the first writing operation was programmed by the following command:

(WRT,1,E1, SC3.4,@PLUS_SHORT(1))

that is, 1 double variable, 4 character variables and 1 short variable, subsequent writing or reading

commands will resemble the following:

(WRT,1,L1,"JOE",@PLUS_SHORT(4))

(REA,1,SN1,!TEST.4CH,@PLUS_SHORT(6))

If other formats, types or numbers of variables are used or if variables are arranged in a different

sequence, an NC248 Data file access error will occur.

In ASCII files data are always written in the last file record. To edit an ASCII file you must open it,

read it sequentially record by record, make the necessary alterations and write the records into a

new file under a new name.

Alterations will become effective only after the file has been closed. To read a just-altered file you

must first close it with CLO and then open it for reading.

Examples:

(WRT,1,SC5.80)

This command writes into the ASCII file associated to channel 1 the first 80 characters stored in the

SC5 variable.

(WRT,3,R12,E7,E8,E9)

This command writes into record 12 of the binary file associated to channel 3 the data stored in

variables E7, E8 and E9. The pointer remains at the beginning of record 13.

10 Series CNC ASSET Reference Manual (07) 4-5

Page 52

Chapter 4

File Management Commands

REA (RED) - Reading a file

This commands reads a record from the file declared by the previous OPN command and specifies

the channel to which the file is associated.

Syntax

(REA, channel,[R record,] variable [, ...,variable])

where:

channel Is the channel number linked to the file by the previous OPN command. In

addition, OPN must have opened the file for reading (R).

record (optional) is a number or a variable that identifies the file record whose

parameters must be read. It is always preceded by an R.

This parameter is accepted only if the file is binary.

If record is omitted, the system will read the record used for the latest reading

and positions the pointer at the beginning of the subsequent record. If this is the

first reading instruction after OPN, data will be read from the first file record.

The maximum number of records that can be specified is 65535.

variable Is the variable(s) (max. 30) where read data must be written.

If the destination file is binary, it is necessary to use the same number and type

of variables written in the first file record. Otherwise, an NC248 error will occur.

If the destination file is an ASCII file, this procedure is not necessary because

the variable format conversion is performed automatically, based on the order of

reading.

Characteristics

The command may be expressed indifferently as REA or RED.

Binary File

If the file is binary (i.e. has been opened with the B marker) and the number of records in the file

has not been specified in REA, data will be read from the record that follows the one used during

the last reading session.

ASCII File

In an ASCII file (i.e. has been opened with the A marker), data will be read from the record on

which the pointer remained positioned since the last reading session.

The conversion of a numerical parameter into the input variable format is automatically performed.

The end of a numerical field is identified by a space, by a sign or by an alphabetical character; if at

least a numerical character has not been read during the reading of a numerical variable, the

system will visualise format error.

The end of a string field is identified by the number of characters specified by the input variable.

4-6 10 Series CNC ASSET Reference Manual (07)

Page 53

Chapter 4

File Management Commands

If the number of variables specified in reading is different from number of fields present in a file

record, the system will not visualise an error message, but, it will write variables in sequence until

the record is completed.

Examples:

(REA,1,SC5.80)

This command reads from the ASCII file associated to channel 1 the first 80 characters stored in

the SC5 variable. (The maximum allowed string length is 80 characters).

(REA,3,R12,E7,E8,E9)

This command reads data from record 12 of the binary file associated to channel 3 and writes them

into variables E7, E8 and E9. The pointer remains at the beginning of record 13. The sample

record of this file is made up of 3 double variables.

Reading examples on ASCII file

Let’s assume that the record to be read from the ASCII file, associated to channel 1, consists of the

following fields:

-5.00 +3400 PLUTO

the commands resulting

(REA,1,E1,E2,E3) Format error because the character “P” is not numerical

(REA,1,SCO.8,E1,SC10.80) SCO=-5.00+3 E1=400; SC10=PLUTO

(REA,1,E1) E1=-5.00

After every reading is completed, the pointer will be positioned to the next record, so in the case of

the last reading example above the fields after –5.00 will be lost.

10 Series CNC ASSET Reference Manual (07) 4-7

Page 54

Chapter 4

File Management Commands

CLO - Closing a channel

This command closes the file associated to the specified file. If the channel is omitted, all the

ASSET files opened by the process will be closed.

Syntax

(CLO [, channel])

where:

channel (optional) Is the channel number linked to the file in the OPN instruction.

Characteristics

If the channel is omitted, CLO will close all the ASSET files that have been opened by the process.

An alternative method for closing all the ASSET files that have been opened by the process is a

system reset.

Examples:

(CLO, 2)

This command closes the file associated to channel 2.

(CLO)

This command closes all the ASSET files that have been opened by the process.

4-8 10 Series CNC ASSET Reference Manual (07)

Page 55

Chapter 4

File Management Commands

DEL (CAN) - Deleting a file

This command permits to delete the specified file from the working directory or the part program

directory.

Syntax

(DEL, filename, A|B|P)

where:

filename Is the name of the file.

Full pathname and extension may be specified in filename. If the path is not

specified, the file indicated present in the ASSET working directory (markers A

or B) or the part program file (marker P, with 48 characters max.) will be

deleted.

If filename is preceded by a ? the name of the file is stored in a local or system

variable.

A|B|P These markers describe the characteristics of the file:

A delete the ASCII file ( .ASC extension) indicated from the working directory,

if the path or extension were not specified

B delete the BINARY (data) file ( .DAT extension) indicated from the working