Page 1

10 Series CNC

AMP

Software Characterization

Manual

Code: 45006667V

Rev. 10

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

e-mail: sales@osai.it

Web: www.osai.it

Copyright 2001-2002 by OSAI

All rights reserved

Edition: July 2001

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of the

product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment described

in this text.

Page 2

abc

Page 3

10 Series CNC - AMP Software Characterization Manual

UPDATES FOR THE PRESENT RELEASE

General

This publication has been issued with the software release 6.1.

This page lists the modifications to the manual in this edition.

PAGE TYPE OF UPDATE

INDEX updated

CHAPTER 1

Pages 26, 27, 28 added: a new paragraph concerning the “Variable Servo Error”

CHAPTER 3

Page 28

Page 31

updated: the description for position errors with/without VFF

changed: axis homing type (admitted values from 0 to 4) in the parameter

configuration

UPDATING

CHAPTER 4

Pages 3, 8

Page 21

CHAPTER 5

Page 27

Page 31

APPENDIX A

Page 20 added: error messages and recovery actions for AM193 and AM194.

added: the field “Alternative Interp. Plane” in the process configuration

added: a usage note in the definition of the G code in the “Interp. Plane” field

updated: the description for position errors with/without VFF

updated: axis homing type (admitted values from 0 to 4) in the axis configuration

10 Series CNC - AMP Software Characterization Manual (10)

Page 4

abc

Page 5

Preface

10 Series CNC - AMP Software Characterization Manual

PREFACE

This manual describes the characterization phase of the 10 Series CNC system through use of the

AMP (Adjustable Machine Parameters) and Servo Monitor utilities. AMP allows the operator to enter

all the necessary parameters and information to configure the system and the various machining

processes. The Servo Monitor allows the operator to perform a tuning of the system in order to

achieve optimum performance.

The manual is intended for the operator that has in charge the system characterization after

installation.

REFERENCES

Read first:

• 10 Series CNC : Product Specification

For further information:

• 10 Series CNC : User Guide

• 10 Series CNC : Programmer Guide

10 Series CNC - AMP Software Characterization Manual (05) 1

Page 6

Preface

10 Series CNC - AMP Software Characterization Manual

SUMMARY

In this guide the operator will find a short description of all the configuration parameters as well as

the procedures for defining them.

1. General Concepts

Contains a description of the numerical control terms used within the manual.

2. AMP

Provides a general description of the AMP configuration procedures.

3. Global Parameters Configuration

Describes the data entries used for configuring the global parameters.

4. Process Configuration

Describes the data entries used for configuring the processes.

5. Axis Configuration

Describes the data entries used for configuring the axes.

6. Human Interface Configuration

Describes the data entries used for configuring the human interface.

7. The Servo Monitor

Describes the Servo Monitor Utility.

8. DSI Service Channel

Describes the DSI Service Channel Utility.

9. Emergency Diagnostic

Describes the Emergency Diagnostic Utility.

A. AMP - Error Messages

Contains the list of error messages completes this guide.

B. Generation of Help Files for OEM Softkeys

Contains instructions to generate help files for OEM defined softkeys.

C. Axis calibration from file

Contains instructions to introduce calibration points of an axis.

2 10 Series CNC - AMP Software Characterization Manual (05)

Page 7

Preface

10 Series CNC - AMP Software Characterization Manual

TERMINOLOGY

Some terms appearing throughout the manual are explained below.

Control Refers to the 10 Series CNC numerical control unit comprising front panel unit and

basic unit.

Front Panel Is the interface module between machine and operator; it has a monitor on which

messages are output and a keyboard to input the data. It is connected to the basic

unit.

Basic Unit Is the hardware-software unit handling all the machine functions. It is connected to

the front panel and to the machine tool.

Is connected to developments or circumstances which can make damages to

the system, to the equipments or to the operators.

Is connected to the information that it is necessary take in consideration in

order to avoid damages to the equipment in general.

Is connected to the operations that it is necessary to execute carefully in order

to assure the full success of the application.

10 Series CNC - AMP Software Characterization Manual (05) 3

Page 8

Preface

10 Series CNC - AMP Software Characterization Manual

END OF PREFACE

4 10 Series CNC - AMP Software Characterization Manual (05)

Page 9

10 Series - AMP CNC Software Characterization Manual

INDEX

GENERAL CONCEPTS

SYSTEM ARCHITECTURE................................................................................... 1-1

CLASSIFICATION OF THE MACHINE AXES .........................................................1-3

SERVO LOOP..................................................................................................... 1-4

Position tolerance....................................................................................... 1-5

Dead zone................................................................................................. 1-6

Travel limits................................................................................................ 1-6

Homing cycle .............................................................................................1-7

Manual/automatic switch search.................................................................. 1-9

Miscellaneous axis parameters ....................................................................1-10

Operating limits ..........................................................................................1-12

Measuring cycle .........................................................................................1-12

Coordinate display modes ........................................................................... 1-12

SPLIT AXES....................................................................................................... 1-13

DUAL AXES ........................................................................................................1-15

AXES WITH ROLLOVER..................................................................................... 1-16

DIAMETER AXES................................................................................................ 1-17

AUXILIARY AXES ............................................................................................... 1-18

SPINDLE AXIS ................................................................................................... 1-19

Spindle axis with gears ............................................................................... 1-19

Spindle axis ramp....................................................................................... 1-20

Spindle with trasducer................................................................................. 1-21

Spindle orientation ......................................................................................1-21

Shared Spindle........................................................................................... 1-22

HANDWHEEL...................................................................................................... 1-23

PART PROGRAM-LOGIC INTERFACE ................................................................. 1-24

Synchronous mode..................................................................................... 1-24

Asynchronous mode ...................................................................................1-24

Language expansion ...................................................................................1-24

PSEUDO AXES................................................................................................... 1-25

VIRTUAL AXES .................................................................................................. 1-25

USER INTERFACE .............................................................................................. 1-25

Logic display ..............................................................................................1-25

OEM softkey ..............................................................................................1-25

VARIABLE SERVO ERROR ................................................................................. 1-26

Index

10 Series CNC - AMP Software Characterization Manual (10) i

Page 10

Index

10 Series CNC - AMP Software Characterization Manual

AMP

SOFTKEY........................................................................................................... 2-1

AMP main menu ........................................................................................ 2-2

Help.......................................................................................................... 2-3

Activate..................................................................................................... 2-4

Select ....................................................................................................... 2-4

Characterization menu softkeys ...................................................................2-5

Operativity notes ........................................................................................ 2-7

Data Entry Storage .....................................................................................2-7

ENTER/EXIT THE CHARACTERIZATION............................................................... 2-8

Edit Comment............................................................................................ 2-10

Backup...................................................................................................... 2-10

Delete....................................................................................................... 2-11

Print.......................................................................................................... 2-11

AMP print utility error messages.................................................................. 2-18

GLOBAL PARAMETERS CONFIGURATION

HARDWARE (10/310, 10/110 AND 10/510 SYSTEM)............................................. 3-2

HARDWARE (10/565 and 10/585 SYSTEMS)........................................................ 3-5

GENERAL INFORMATION................................................................................... 3-8

LOGIC CONFIGURATION ....................................................................................3-10

Boolean Variables ...................................................................................... 3-10

Boolean Var (Variabili boolean).................................................................... 3-10

Short Variables .......................................................................................... 3-12

Double Variables ........................................................................................ 3-14

Auxiliary Axis General Information................................................................ 3-16

Select Auxiliary.......................................................................................... 3-18

Auxiliary Axis Characterization.................................................................. 3-19

Notes on characterization of digital drivers .................................................... 3-31

Physical Conn............................................................................................ 3-32

Axis Calibr .................................................................................................3-34

OPTIONS ........................................................................................................... 3-36

DOS Real-time ...........................................................................................3-37

END User Dos ........................................................................................... 3-38

DOS Graphics............................................................................................ 3-39

PROCESS CONFIGURATION

SELECT PROCESS .............................................................................................4-2

PROCESS CONFIG............................................................................................. 4-3

Proc Char.................................................................................................. 4-3

Proc Variables ........................................................................................... 4-9

Progr Char................................................................................................. 4-13

M Codes ....................................................................................................4-16

G Codes.................................................................................................... 4-20

GTL (Geometrical Technological Language) ................................................. 4-23

Virtual Axes............................................................................................... 4-25

E Parameters .............................................................................................4-27

User Variables ........................................................................................... 4-28

ii 10 Series CNC - AMP Software Characterization Manual (10)

Page 11

10 Series CNC - AMP Software Characterization Manual

AXIS CONFIGURATION

AXIS CONFIGURATION ...................................................................................... 5-1

Axis General Information............................................................................. 5-2

Pseudo Axes ............................................................................................. 5-5

Spindle...................................................................................................... 5-6

Notes on the characterization of digital drivers............................................... 5-14

Probing...................................................................................................... 5-15

Select Axis ................................................................................................5-17

Axis Characterization.................................................................................. 5-18

Notes on the characterization of digital drivers............................................... 5-32

Axis Charact (Slave axis selected with "Select Axis")................................... 5-33

Axis Calibration ..........................................................................................5-34

Physical Connection ...................................................................................5-37

HUMAN INTERFACE CONFIGURATION

HUMAN INTERFACE ........................................................................................... 6-1

H.I. Gen Info............................................................................................... 6-2

Add Scr Config ...........................................................................................6-5

Process Screen ......................................................................................... 6-7

Select Menu .............................................................................................. 6-8

OEM SK Config.......................................................................................... 6-10

Select DE.................................................................................................. 6-13

DE Config.................................................................................................. 6-15

PPDIR Config .............................................................................................6-18

Index

THE SERVO MONITOR

USING THE SERVO MONITOR............................................................................ 7-2

ENABLING THE SERVO MONITOR ......................................................................7-3

CHANGE PARAM................................................................................................ 7-4

DEFAULT VALUES.................................................................................... 7-4

ALTERING A VALUE.................................................................................. 7-4

Null Offset ..................................................................................................7-5

Tolerance................................................................................................... 7-6

Dead Zone................................................................................................. 7-8

Backlash ...................................................................................................7-9

KC KV VFF ............................................................................................... 7-10

Servo Error................................................................................................. 7-12

Feed/Acc/Jrk ............................................................................................. 7-13

Spindle...................................................................................................... 7-15

Operative Limits ......................................................................................... 7-18

Split Param................................................................................................ 7-19

Broken wire................................................................................................ 7-21

CONFIGURING THE OSCILLOSCOPE................................................................. 7-22

Config. oscill.............................................................................................. 7-22

Feedrate on the profile ................................................................................ 7-24

Feed calculated (single axis) .......................................................................7-26

Following error (single axis) .........................................................................7-28

Feed and error on same axis....................................................................... 7-30

10 Series CNC - AMP Software Characterization Manual (10) iii

Page 12

Index

10 Series CNC - AMP Software Characterization Manual

CONTINUOUS MODE.......................................................................................... 7-31

TRIGGER MODE................................................................................................. 7-31

DATA DISPLAY MODES ......................................................................................7-31

ANALYZING THE DATA (EXAME)......................................................................... 7-34

Main menu and graphics............................................................................. 7-34

Zoom......................................................................................................... 7-35

Time Enlarge.............................................................................................. 7-35

Dimension ................................................................................................. 7-35

Check ....................................................................................................... 7-36

Save ASCII ................................................................................................ 7-36

SAVING AND RESTORING DATA........................................................................ 7-37

Save.......................................................................................................... 7-37

Restore ..................................................................................................... 7-38

ERROR MESSAGES ............................................................................................7-39

DSI SERVICE CHANNEL

SETUP ............................................................................................................... 8-2

DESCRIPTION.................................................................................................... 8-3

SAVE ALL.......................................................................................................... 8-4

Format and syntax of the configuration file.................................................... 8-5

LOAD................................................................................................................. 8-8

SELECT AXIS .....................................................................................................8-12

READ BLOCK..................................................................................................... 8-14

WRITE DATA ......................................................................................................8-16

COMMAND......................................................................................................... 8-17

SAVE AX INFO................................................................................................... 8-18

show load log ....................................................................................................8-19

LOADING DSI DRIVErs PARAMETERS ................................................................ 8-20

Usage Mode .............................................................................................. 8-20

Application notes ........................................................................................8-21

Error messages.................................................................................................. 8-22

EMERGENCY DIAGNOSTIC

EmergenCY START ............................................................................................9-1

EMERGENCY DIAGNOSTIC Screen Softkeys.............................................. 9-2

TABLE RESET UTILITY....................................................................................... 9-4

Reset Request........................................................................................... 9-5

Select Tables............................................................................................. 9-6

Delete Tables............................................................................................. 9-7

LANGUAGE MANAGEMENT UTILITY................................................................... 9-10

Activate..................................................................................................... 9-13

Create....................................................................................................... 9-15

Delete....................................................................................................... 9-17

Text Handler .............................................................................................. 9-18

Text Types .................................................................................................9-19

Compare.................................................................................................... 9-21

Update...................................................................................................... 9-23

Show diff.................................................................................................... 9-24

Modify ....................................................................................................... 9-25

EDITOR FOR MODIFYING TEXT FILES ................................................................9-26

iv 10 Series CNC - AMP Software Characterization Manual (10)

Page 13

10 Series CNC - AMP Software Characterization Manual

SoftkeyS of the editor FOR CONFIGURATION File MODIFICATION .................... 9-29

DELETE .................................................................................................... 9-29

INSERT..................................................................................................... 9-29

MODIFY.................................................................................................... 9-30

SK MODIFY............................................................................................... 9-31

DE MODIFY............................................................................................... 9-33

HELP MODIFY........................................................................................... 9-34

ERR MODIFY ............................................................................................ 9-36

ERROR ATTRIB ......................................................................................... 9-37

VIEW........................................................................................................ 9-38

BACKUP ................................................................................................... 9-39

RESTORE ................................................................................................. 9-40

EXIT.......................................................................................................... 9-41

OFF-LINE version of language utility................................................................. 9-42

GENERAL EXEC FILE COMPILING UTILITY......................................................... 9-44

DSI REBOOT CONFIGURATION.......................................................................... 9-47

CFG DSI Setup.......................................................................................... 9-48

DATA RESTORE................................................................................................. 9-49

error MESSAGES ............................................................................................... 9-50

Reset Tables Utility .................................................................................... 9-50

Utility Languages ........................................................................................9-52

Utility Compiler........................................................................................... 9-58

Utility DSI Reboot Configuration................................................................... 9-60

Index

AMP - ERROR MESSAGES

Message Description And Recovery Action........................................................ A-1

GENERATION OF HELP FILES FOR OEM SOFTKEYS

HELP file - menu association....................................................................... B-1

AXIS CALIBRATION FROM FILE

General ............................................................................................................. C-1

File Format ................................................................................................ C-2

Error conditions and messages ....................................................................C-3

10 Series CNC - AMP Software Characterization Manual (10) v

Page 14

Index

10 Series CNC - AMP Software Characterization Manual

END OF INDEX

vi 10 Series CNC - AMP Software Characterization Manual (10)

Page 15

Chapter

1

GENERAL CONCEPTS

This chapter provides a glossary of the terms used in the present AMP Configuration Guide. For

users who are not familiar with NC technology it may serve as an introduction to the philosophy

underlying system operation. Users with extensive NC experience can use it as a source of lexical

reference. Special attention has been devoted to the classification of the axes and to the description

of the characteristics of the various types.

Users already familiar with numeric control machines may use this chapter as a terminology

reference.

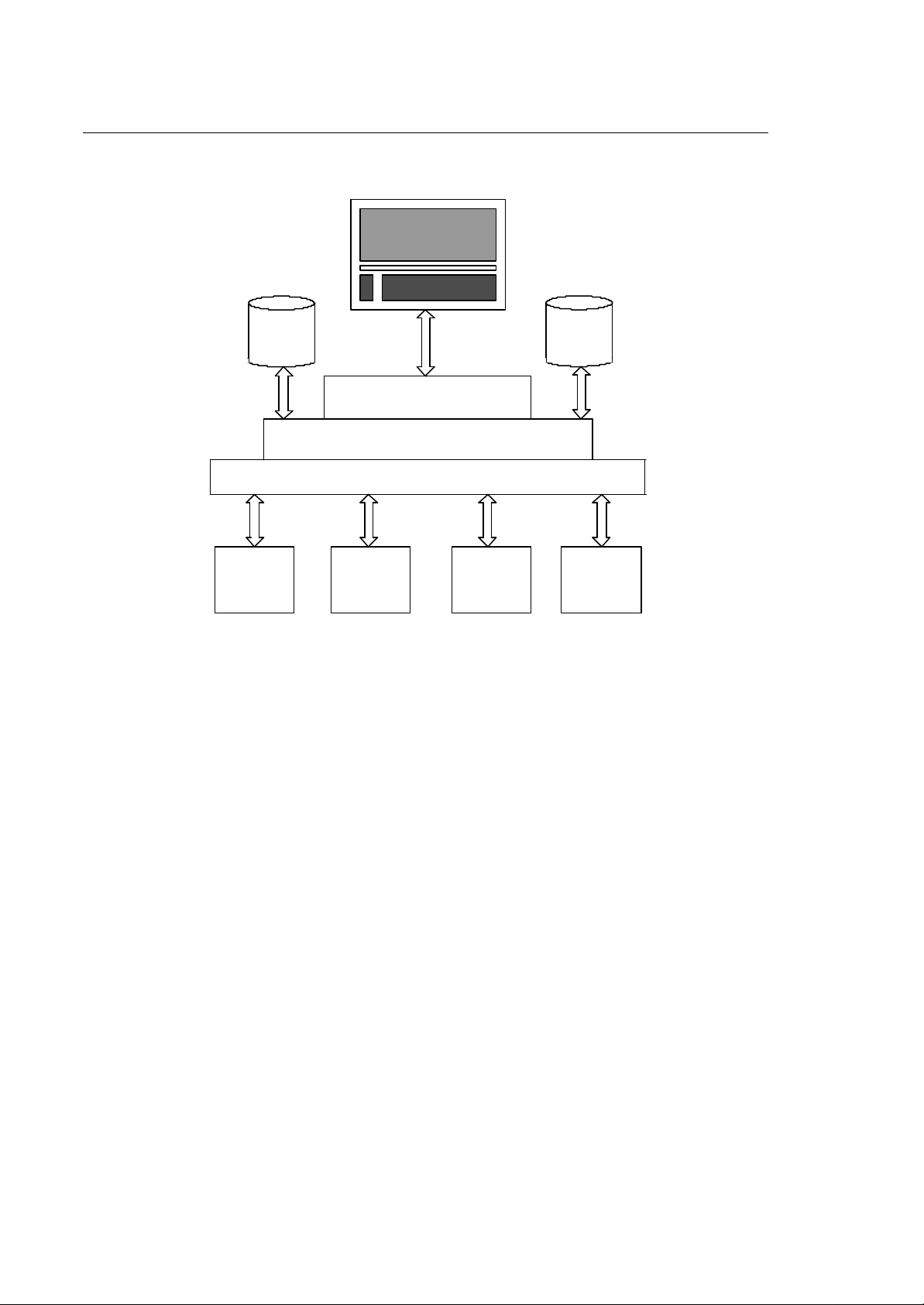

SYSTEM ARCHITECTURE

The architecture of 10 Series CNC can be broken down into four partitions, each of which controls a

specific set of features.

10 Series CNC - AMP Software Characterization Manual (10) 1-1

Page 16

Chapter 1

General Concepts

HARD

DISK

UNIT

UTILITIES

OPERATOR PA NEL

COMMUNICATIONS

OPERATING SY STEM

INTER-PROCESS COMMUNICATIONS

CN

PROCESS

I/O

INTERFACE

FLOPPY

DISK

UNIT

H

HUMAN

INTERFACE

The major function of each partition is as follows:

Numerical Control Includes the part program interpreter, the axes interpolator and the process

manager for machining centers.

Utilities I ncludes a series of text-only and graphics packages that can be used by

the end user, the OEM or the technical assistance.

I/O Interface Controls the execution of the machine tool/control interface code that has

been developed by the OEM.

Human Interface Controls all the data input and display operations and the man/machine

interface.

1-2 10 Series CNC - AMP Software Characterization Manual (10)

Page 17

Chapter 1

General Concepts

CLASSIFICATION OF THE MACHINE AXES

10 Series CNC can control the following types of axes:

Coordinated axes These are physical axes that move in coordination with each other.

Each 10 Series CNC AMP process can move 6 simultaneous axes

and up to 9 coordinated axes.

Auxiliary axes

Spindle axis

The axes can also be classified according to the type of move that they must carry out:

linear axis

rotary axis

split axis

dual axis

diameter axis

These are physical axes that are not requested to move in coordination

with each other.

This is the tool-holder spindle. 10 Series CNC can associate one

spindle with each process.

It is an axis moving on a rectilinear trajectory

It is a coordinated axis programmable in degrees.

It is a physical axis coupled to a pair of motors for synchronized

motion.

It is an axis whose moves are dependent on the moves of the master

axis to which it is coupled.

It is a coordinated axis that must be programmed and displayed with a

2 coefficient.

10 Series CNC - AMP Software Characterization Manual (10) 1-3

Page 18

Chapter 1

General Concepts

SERVO LOOP

10 Series CNC permits to define the algorithms that are used for servo loop control of each axis.

Such algorithms are based on three configurable constants, Kc, Kv and Kcs. 10 Series CNC uses

these constants in the following formula:

V

= (Le * Kv + Vff) * Kc

out

Where:

Vout

Le

Kv

Vff

The units of measure for the constants are: Le [mm], Kv [1/s], Vff [mm/s] (Le * Kv + Vff) represents a

velocity. Therefore, Kc is a velocity-to-voltage conversion factor .

The control applies the following internal formula:

Where:

Le'

Vff

output voltage

lagging error

servo loop gain

velocity feed forward

V

out

is the lagging error expressed in "encoder pulses"

is a function of the interpolation clock

is the voltage output by the Digital/Analog converter

is the variance between the programmed axis

position requested by the control and the actual

position measured by the position transducer

is the position loop gain

is a velocity value that is proportional to the

programmed axis feedrate.

= Le' * K + Vff * Kc

K

K and Kc are calculated using parameters established in the system configuration. The formulas are:

1-4 10 Series CNC - AMP Software Characterization Manual (10)

is the result of multiplying Kc by Kv

Kc =

K =

Vm*60

Fm

Vm*60

Fm

*

*

Pm

Pe

60000

Cki

*

8192

*

10

8192

* (Kv * 16.66666666...)

10

Page 19

For the spindle, the formula is:

Vm

Fm

*

8192

10

Kcs =

Where:

Vm = maximum voltage

Fm = maximum velocity

Pm = mechanical pitch

Pe = electrical pitch

Cki = interpolator clock [ms]

8192 is the number of possible output levels for the D/A converter

10 is the maximum positive or negative voltage output of the D/A converter

60000 is the minute-to-millisecond conversion factor.

Chapter 1

General Concepts

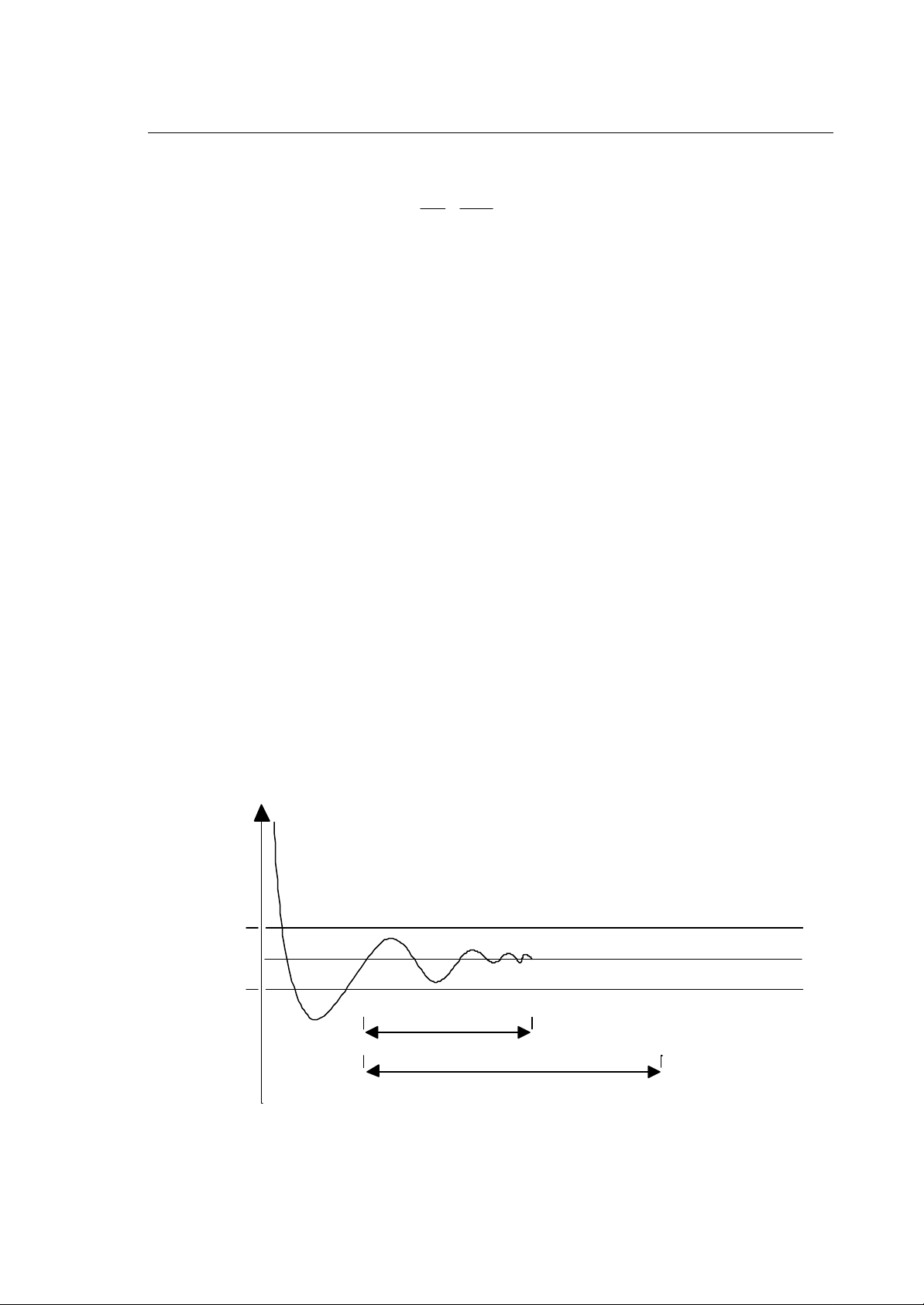

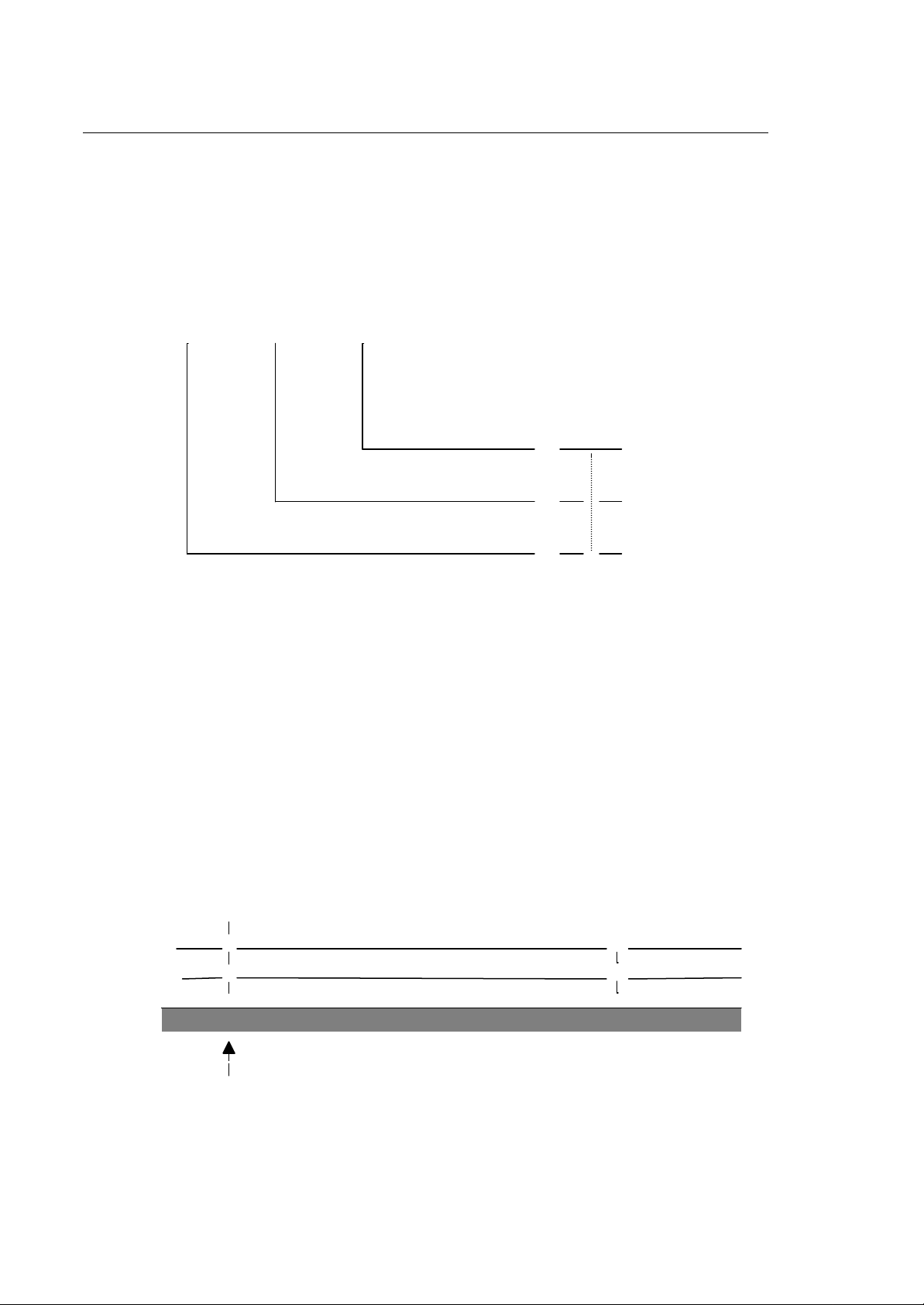

Position tolerance

The position tolerance is the threshold within which the axis must position at motion end. If the axis

is out of tolerance, the move is not considered terminated.

When a move ends, if the position control is active, the system checks that all the axes are in the

programmed position and that their lagging error (Le) is smaller than the threshold configured in the

"in position band" field.

To enhance the positioning accuracy, the "in position band" threshold must remain active during an

interval specified in the "in position window" field. If it does not, or if the positioning error is out of

tolerance after the interval specified in the "in position time-out", the system generates an emergency

condition.

lagging

error

in position

band

t

in position window

in position time-out

10 Series CNC - AMP Software Characterization Manual (10) 1-5

Page 20

Chapter 1

General Concepts

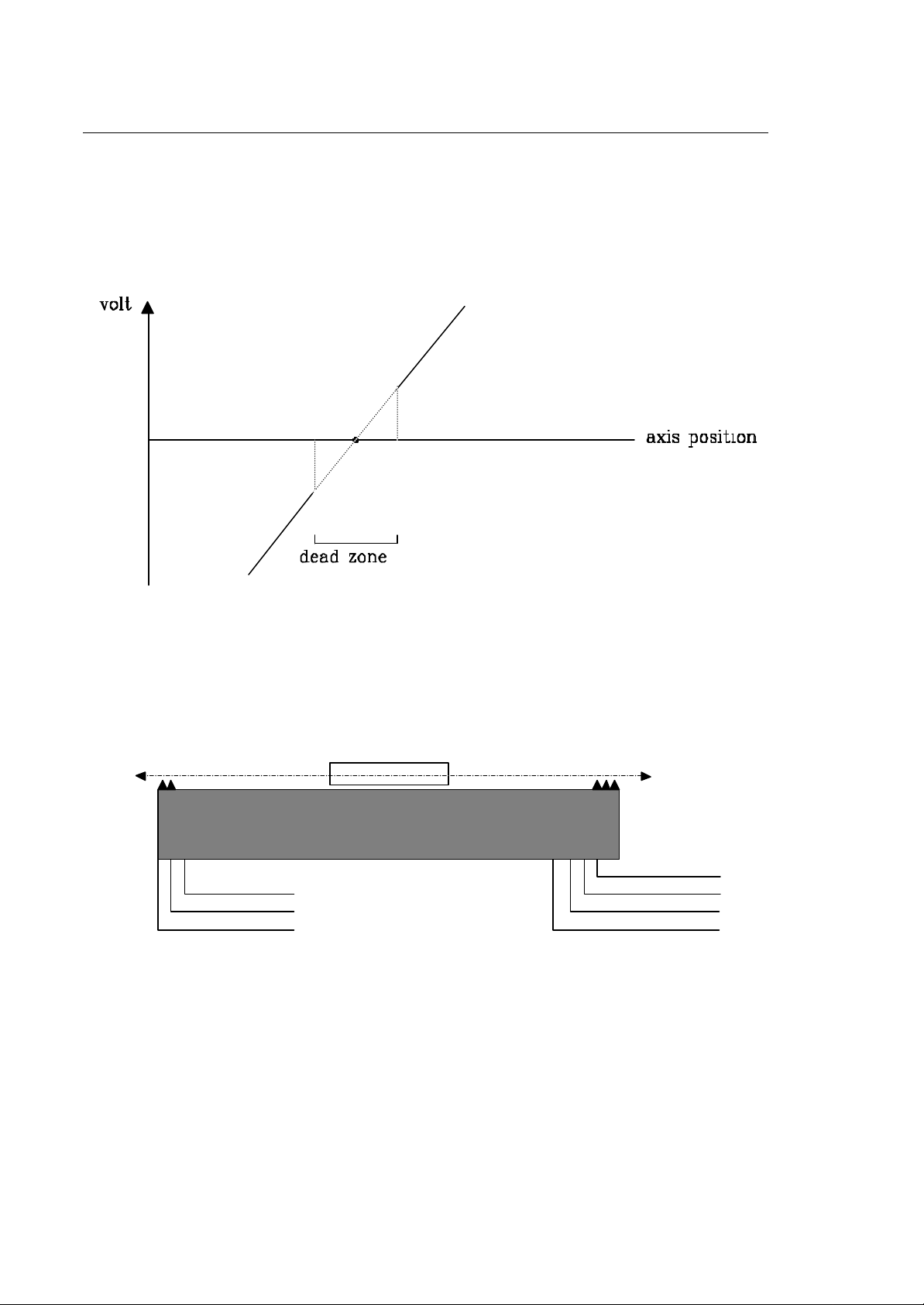

Dead zone

It is the threshold within which the D/A reference voltage output remains to zero irrespective of the

position error.

The dead zone must be smaller than the position tolerance.

Travel limits

Each axis moves within the limits of an operating field, which is a function of the characteristics of the

machine and can be established by means of physical and/or calculation devices which protect the

axis from erroneous operation or loss of control.

+

ov er trave l+

opera tin g lim itend o f tra v e l -

overtrav el -

The axis travel limits may be controlled by:

• positive/negative end of travel microswitches

• positive/negative end of travel microswitches

• positive/negative operating limits

end of travel+

opera ting lim it+

zero microswitch

NOTE:

In many applications zero microswitch can be coincident with end of travel.

1-6 10 Series CNC - AMP Software Characterization Manual (10)

Page 21

Chapter 1

General Concepts

The microswitches start operating as soon as the machine is switched on whereas the operating

limits, which are based on the axes positions, start operating only after the axes have been homed.

The overtravel microswitches are normally connected directly to the power circuitry of the axes.

In order to enable the travel microswitches that are connected to the I/O board they must be managed

by the logic.

Operating limits are managed directly by the control. While the control executes a special cycle,

such as tool or pallet change, the operating limits can be disabled or modified by the logic to allow

displacements beyond the limits. Operating limits must be disabled/modified with standstill axes.

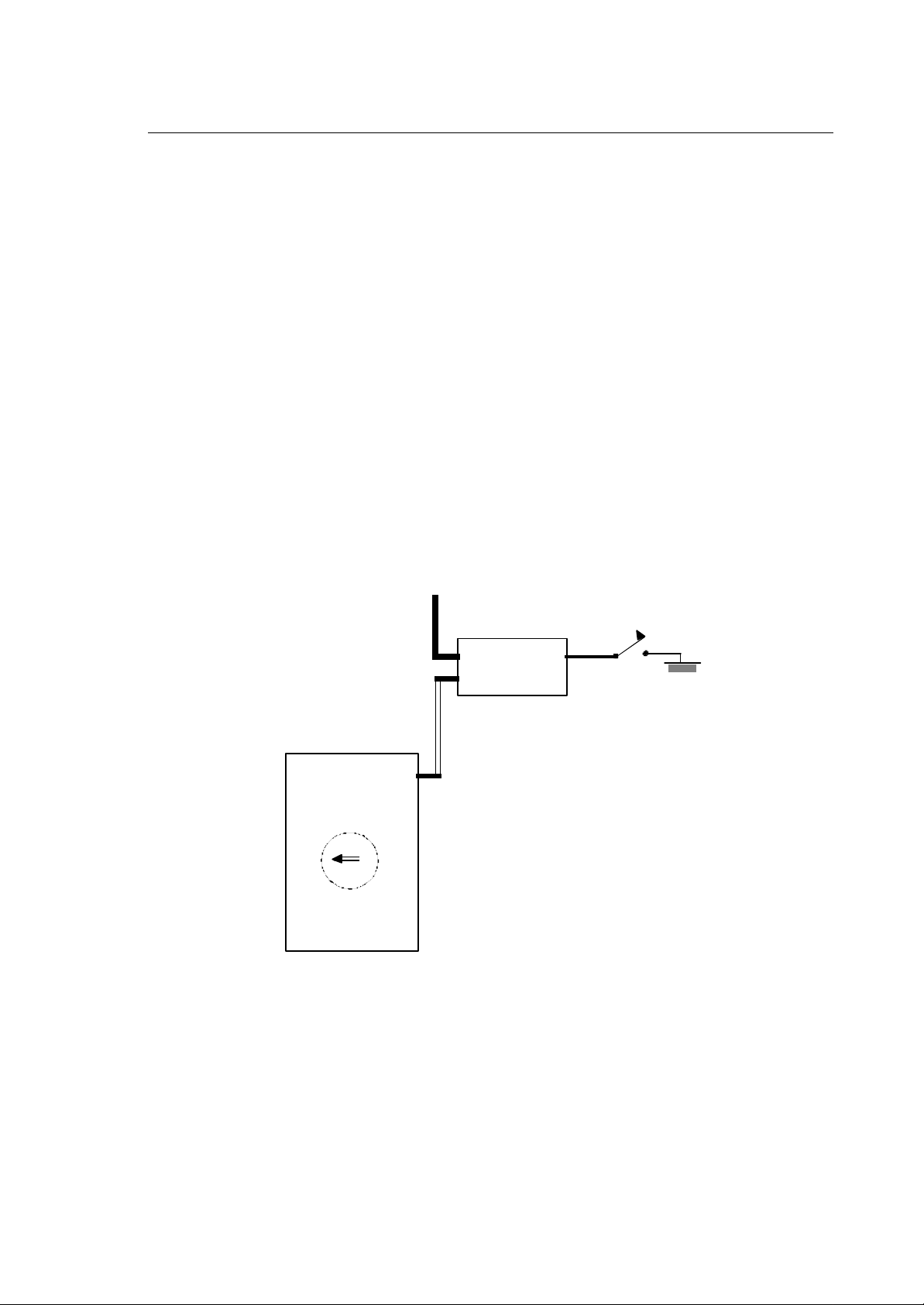

Homing cycle

Each time the system is switched on it is necessary to execute a homing cycle, i.e. to move the

axes to the microswitch that is considered as the machine zero. The aim of this operation is to reset

the internal counters that measure the axes positions. Axes home microswitch inputs are managed

by the foreground logic, whose status can be read in status words SW03 and SW04 (refer to the

"PLUS Application Manual").

This cycle is defined as home cycle.

I/O C AR D

FOREGROUND

SW

I/O RIN G

MODU LE

optical fiber

Ixx

The status of signals SW3 and SW4 must be interpreted as follows:

1= microswitch released

0= microswitch closed

10 Series CNC - AMP Software Characterization Manual (10) 1-7

Page 22

Chapter 1

General Concepts

To invert this operation mode it is necessary to write the NOT operator in the logic equations.

The homing cycle makes all the requests and signal controls that permit to refer the machine zero to

the initial time.

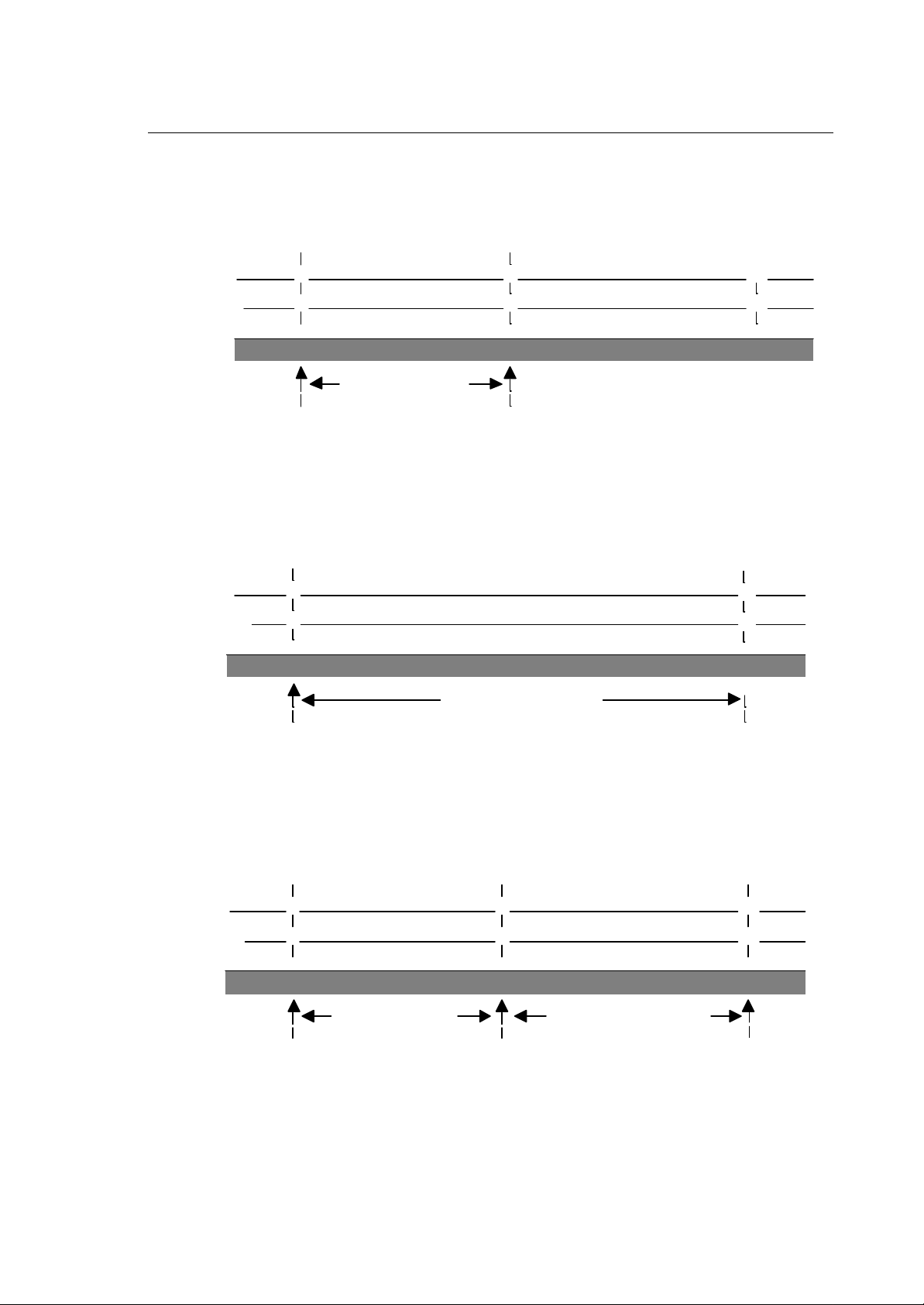

A homing cycle can be broken down into four main steps:

1. Zero switch search

During this step the axis makes a linear displacement in search of the zero microswitch. As the

contact with the microswitch occurs, the axis decelerates until it comes to a complete stop.

2. Zero switch release

n this step the axis reverts the direction of motion and moves until the zero microswitch is released.

The return velocity is equal to the configured "home position feed" and cannot be altered by the "feed

override".

3. Electric zero search

This step starts when the microswitch is released. The system waits for the electrical zero (i.e.

marker ) to be read and then stops the axis.

4. Return to electric zero

After the system has acquired the coordinates in which the electrical zero was read, the axis is

returned to the zero position.

If at cycle start the microswitch is already closed, the system will carry out only the last three steps.

If the axis is configured with an optical linear scale, the microswitch is assumed to be missing and

1only the last two steps will be carried out: in this case the electrical zero switch search speed will

be the one used in manual mode.

The homing cycle will be interrupted if the system is reset or put on hold. To resume the cycle a

CYCLE START command must be given.

1-8 10 Series CNC - AMP Software Characterization Manual (10)

Page 23

F +

" h o m e l i m it s w it c h

r e l e a s e d " d e t e c t e d b y

P .L . U . S . a n d

" h o m e li m i t s w it c h

p r e s s e d " d e t e c t e d b y

P . L .U . S . a n d

n o t i f i e d t o t h e s y s t e m

O

" m a nua l fe ed " - "m anu al" feed

n o ti f i e d t o t h e s y s t e m

m a rk er

"h om e fe ed"

AX IS H O M E D

w /o nu ll offs e t

+ "m anu al" f eed

Chapter 1

General Concepts

t

A X IS H O M E D

w ith nu ll offs e t

F -

Manual/automatic switch search

The switch search can be carried out manually or automatically. The "homing cycle type" field

permits to define the switch search mode to be used in the homing cycle for each process.

Manual switch search

The characteristics of the manual switch search cycle to be carried out by the process axes are as

follows:

1. prior to starting the cycle the operator must check that the selected direction of motion is

compatible with the configured direction.

2. during the first step, i.e. while the axes are moving towards the microswitch, the operator must not

release the CYCLE START pushbutton. If the command is to be sent by the logic, this means that

no CYCLE STOP command must be given.

3. after the microswitch has been found the homing cycle will be completed even if the CYCLE

START pushbutton is released and unless a RESET or HOLD command is given.

Automatic switch search

The characteristics of the automatic switch search cycle are:

1. the direction of motion is automatically selected by the control.

2. after the homing cycle has been launched, the operator can release the CYCLE START

pushbutton. The cycle will be completed unless a RESET or HOLD command is given.

10 Series CNC - AMP Software Characterization Manual (10) 1-9

Page 24

Chapter 1

n

General Concepts

Miscellaneous axis parameters

10 Series CNC also allows characterization of the following axis parameters:

1. null offset

2. home position

corrects the position of the zero microswitch

defines a machine zero that is independent from both the physical

position of the zero microswitch and the actual axes displacement.

c (machine zero)

b (theoretical ho me switch )

a (physical home switch)

The positions shown in the figure are as follows:

a) physical position of the zero microswitch

b) theoretical position of the zero microswitch

home

positio

null

offset

c) machine zero referred to the theoretical machine zero with respect to which all the other axis

position parameters are defined.

The examples that follow show how to use these parameters:

correct microswitch position

machine zero on the zero microswitch

a=b=c

absolute

position

transducer

plane

physical ho me switch

0

0

theoretical

machine zero

null offset = 0

home position = 0

100

100

1-10 10 Series CNC - AMP Software Characterization Manual (10)

Page 25

Chapter 1

General Concepts

microswitch position error

machine zero on the microswitch

absolute

position

transducer

plane

a=c

-5

0

null offset

physical home switch theoretical

b

0

machin e zero

no microswitch position error

offset between machine zero and physical microswitch

a=b

absolute

position

transducer

-100

0

null offset = +5

home position = 0

100

+1055

null offset = 0

home position = +100

c

0

100

plane

home position

physical home switch

theoretical

microswitch position error

offset between the machine zero and the zero microswitch

b

theoretical

absolute

position

transducer

plane

a c

-105 -100

null offset

physical ho me switch

machine ze ro

null offset = +5

home position = +100

0

+10550

home position

machine zero

10 Series CNC - AMP Software Characterization Manual (10) 1-11

Page 26

Chapter 1

General Concepts

Operating limits

The operating limits are defined with respect to the machine zero (c) in the AMP.

Measuring cycle

The coordinates read by the axes boards are referred to the machine zero (c).

Coordinate display modes

10 Series CNC permits the display of the following axis coordinates:

Absolute coordinates

Machine coordinates

Work coordinates

Distance to go

Error

The example that follows illustrates an axes calibration sequence.

1. Set the "null offset" and "home position" fields in the AMP to zero.

2. Key in the corrections to the geometrical errors in the AMP. This corrections are based on the

mecahnical distances to the physical microswitch.

3. Switch off and reboot the control.

4. Home the axis.

5. Move the axis to the position in which the zero microswitch should have been wired.

6. With the axis in this position read the "absolute position" coordinate.

7. Write this value in the "null offset" AMP field for the axis in object.

referred to the machine zero (c)

referred to the machine zero (c) and including the origins

programmed coordinates

difference between programmed and machine coordinates

difference between interpolated and real coordinates

8. If the home position is to be established on a value other than zero, write this value in the "home

position" AMP field for the axis in object.

9. Switch off and reboot the control.

10. From this point, all the machine coordinates are measured with respect to the "machine zero".

11. If necessary, define the operating limits in the AMP. These limits are always referred to the

"machine zero".

1-12 10 Series CNC - AMP Software Characterization Manual (10)

Page 27

Chapter 1

General Concepts

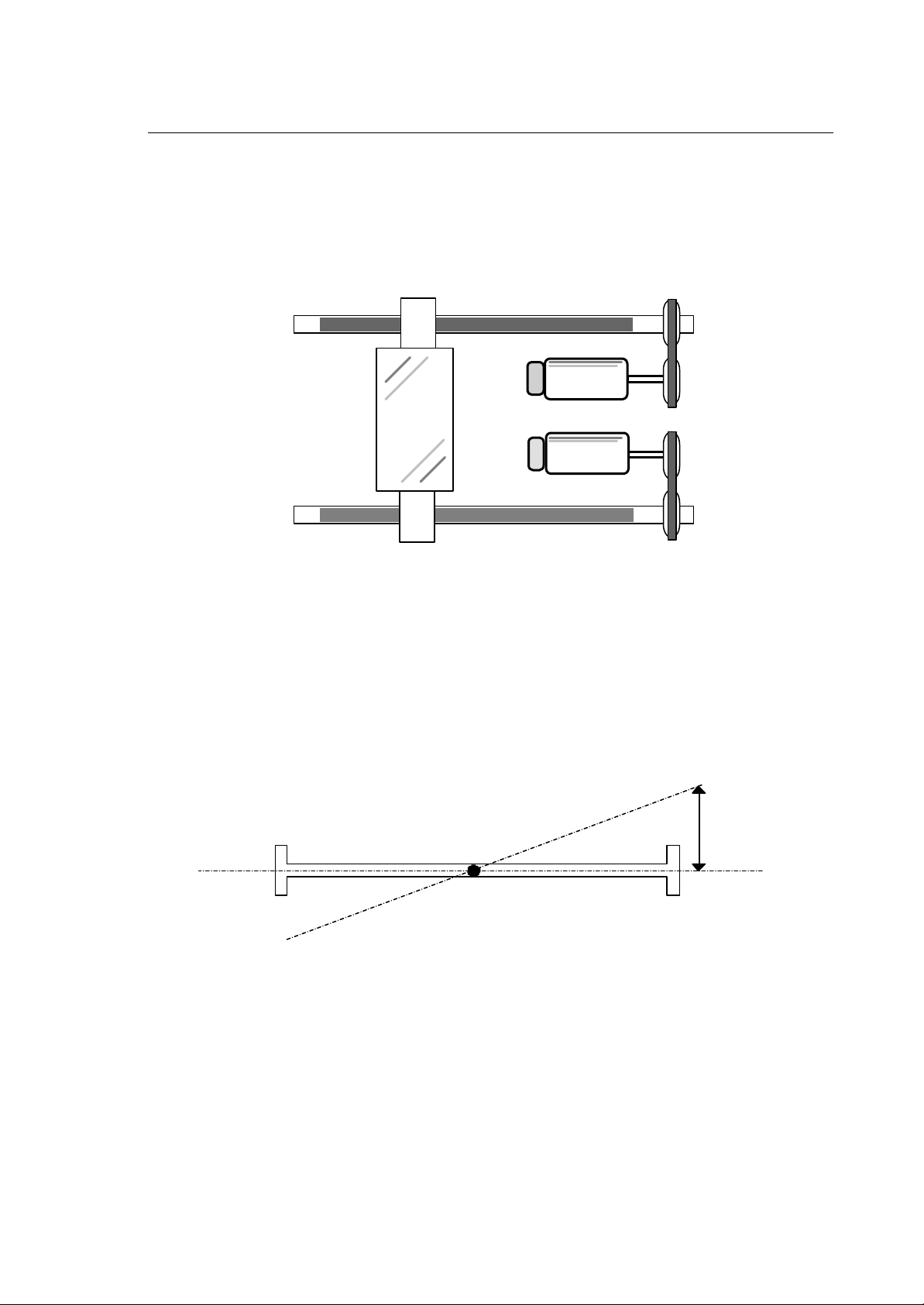

SPLIT AXES

A split axis (gantry) is a physical axis coupled to a pair of motors or drives. Split axes are typical of

large machines and of machines with special mechanical requirements, such as

From the User's standpoint, a split axis is seen as one single axis configured as a Master.

Servo motor 1

Axis

Servo motor 2

The parameters that configure a split axis are:

SKEW It is the maximum acceptable disalignment between two physical axes. Two

maximum values are configured: the first one (Max Skew Error) is used both

during movement for non referred axes and during the marker search; the second

(Skew Error) is used for all other movements for referred axes and after the marker

search.

When the current skew error exceeds the configured value, an emergency

condition (Skew Error) occurs.

SKEW GAIN permits to specify the skew compensation value.

SKEW

When the split axis is enabled, the system calculates at each sampling the lagging errors of the

master (Lem = Lagging Error Master) and the slave (Les = Lagging Error Slave).

The misalignement (SKEW) can be calculated as follows:

SKEW = Lem - Les

10 Series CNC - AMP Software Characterization Manual (10) 1-13

Page 28

Chapter 1

General Concepts

The result of multiplying the SKEW value by the SKEW GAIN can be used for calculating new lagging

errors with the folllowing formulas:

Lem' = Lem + (Skew Gain * (Skew/2 ) )

Les' = Les - (Skew Gain * (Skew/2) )

If these new lagging errors are multiplied by a K constant, the resulting voltages on the D/A converter

represent positive and negative skew compensations to be applied to the master and the slave.

Such compensation tends to re-align the axes correctly.

In case of emergencies (servo, error, skew error ...) and of all operations generating disabling and

abling of a couple of split axes, it is necessary to refer the axes again in order to ensure correct

application of configured null offset and home position parameters and recuperate the misalignment

between the two physical axes that the activation/deactivation condition may have generated.

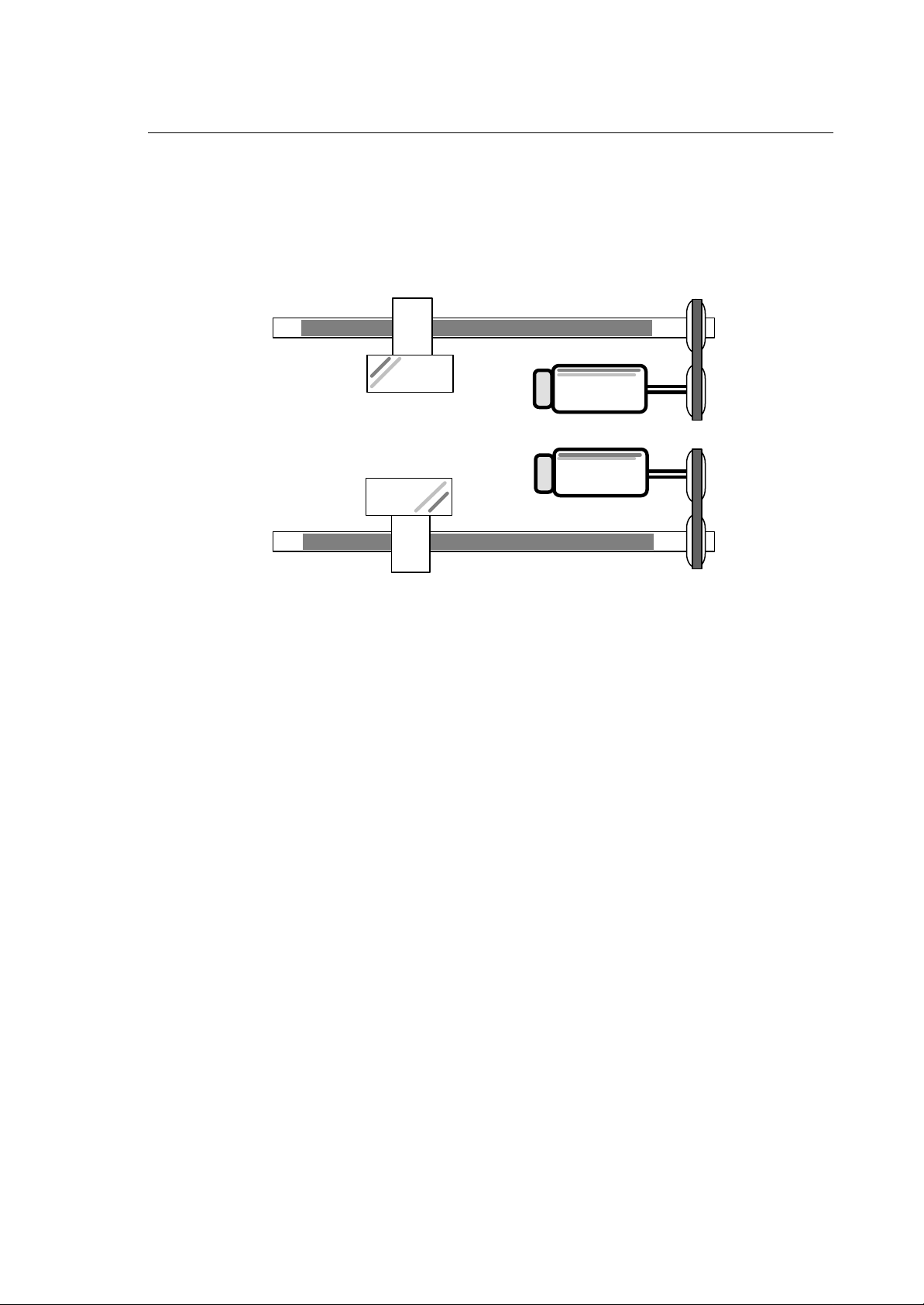

The figure illustrates how the wiring and/or the mechanical orientation permit to shift the counting

direction of the position transducer or the rotation of the motor between the master and the slave.

(T=transducer, M=motor)

MASTER

T

M

MASTER

T

M

SLAVE

SLAVE

T

M

T

M

1-14 10 Series CNC - AMP Software Characterization Manual (10)

Page 29

Chapter 1

General Concepts

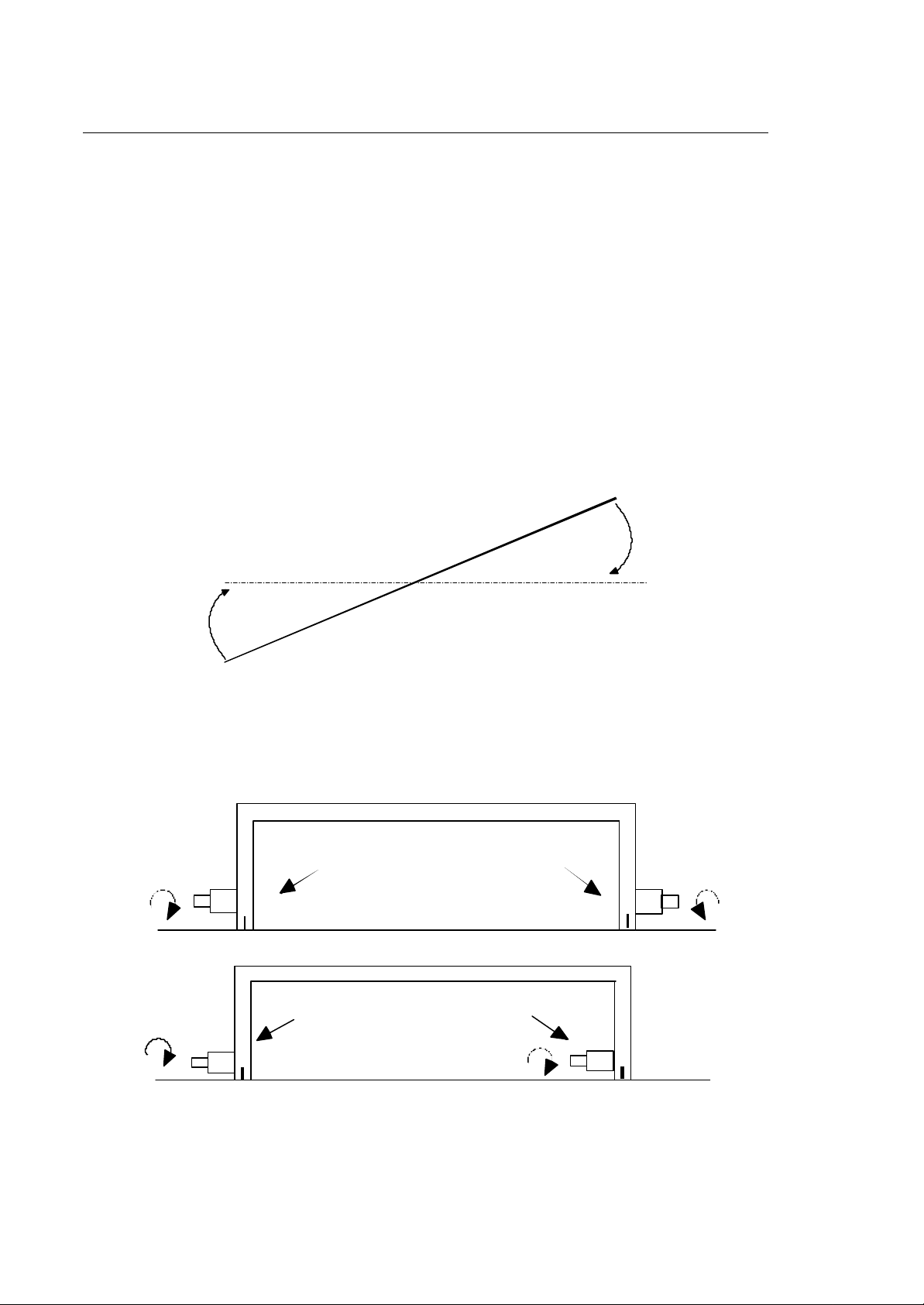

DUAL AXES

Dual axes are two or more axes that follow an identical trajectory. A typical application of this feature

are multiple heads and multi-spindles.

Axis 1

Axis 2

Servo motor 1

Servo motor 2

With dual axes, only the programming of the master axis is mandatory.

The master-slave association must be defined by the program (refer to the UDA instruction in the

Programming Guide).

10 Series CNC - AMP Software Characterization Manual (10) 1-15

Page 30

Chapter 1

General Concepts

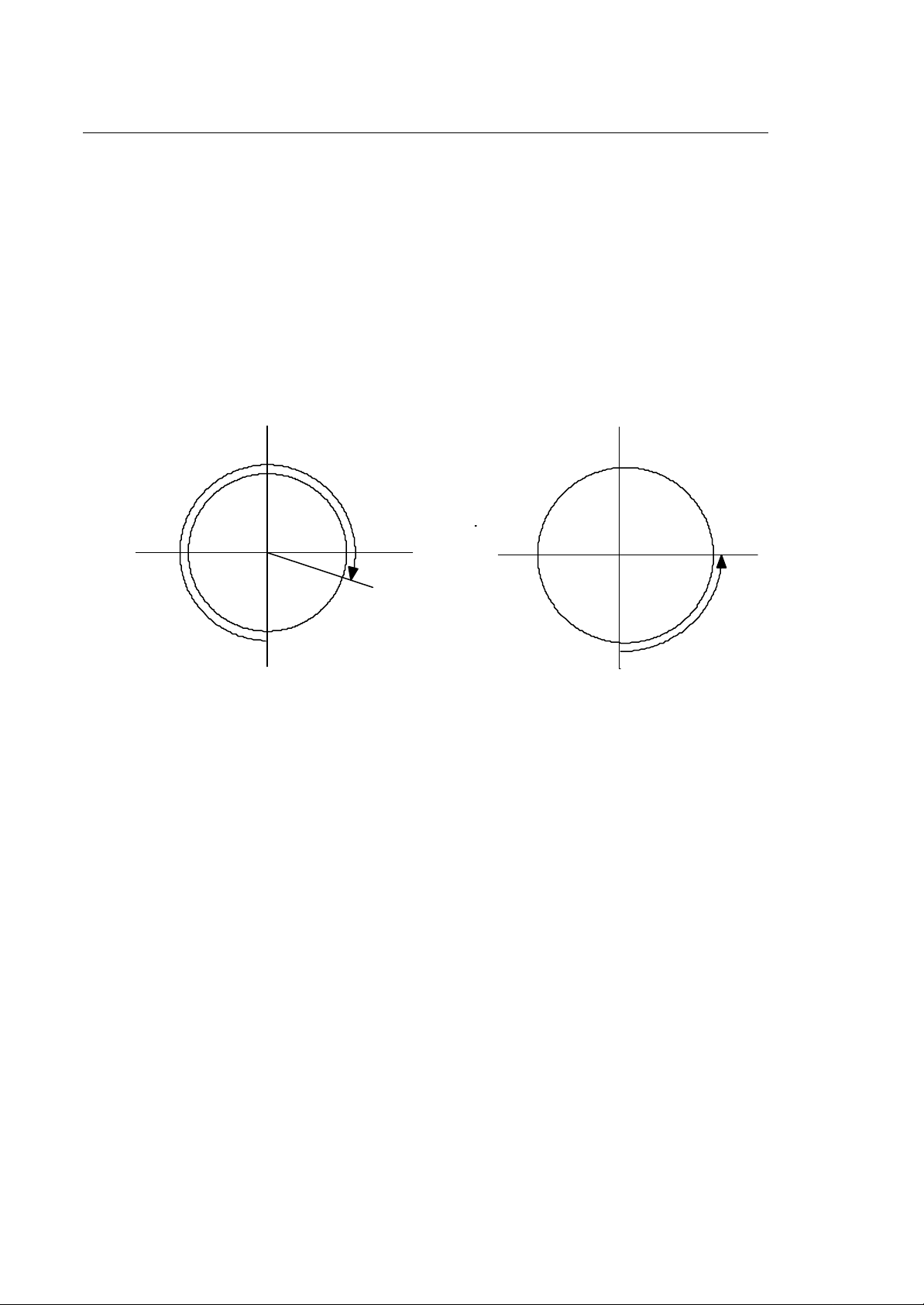

AXES WITH ROLLOVER

The axes with rollover are linear or rotary axes whose position is controlled by the system within a

range from zero to the value configured in the "Rollover pitch" field.

The sign of the quote programmed for the axis with rollover indicates the rotation direction:

• positive, rotation is in a clockwise direction

• negative, rotation is in an anticlockwise direction.

Examples:

270

180

CLOCKWISE

ROTATION

359.999

0

0

90

ANTICLOCKWISE

ROTATION

1-16 10 Series CNC - AMP Software Characterization Manual (10)

Page 31

Chapter 1

General Concepts

DIAMETER AXES

Diameter axes are coordinated axes that must be programmed and displayed with a 2 coefficient.

Example:

10 Series CNC - AMP Software Characterization Manual (10) 1-17

Page 32

Chapter 1

General Concepts

AUXILIARY AXES

Auxiliary axes are interpolated axes that are managed directly by the machine logic.

This feature permits to control those axes that do not take part in the machining process but support

auxiliary functions such as tool change chains, part change gates, etc.

10 Series CNC can control up to 6 simultaneous auxiliary axes coordinated with one another.

Auxiliary axes remain independent from machining axes and work in parallel with the machine tool

activities.

Example:

STEP POCKET

Step = Distance between two pockets

Pocket = Generic position of a tool in the tool magazine.

1-18 10 Series CNC - AMP Software Characterization Manual (10)

Page 33

SPINDLE AXIS

The spindle axis is the axis on which the tool is mounted during the machining cycle.

It may correspond to one of the machine axes.

SPINDLE

Chapter 1

General Concepts

Spindle axis with gears

Gears are speed reduction devices that can be installed between the motor and the spindle.

They enhance the motor performance by allowing to reach a high torque at medium and low speeds.

10 Series CNC MC can control spindles with as many as four different gears.

Prior to enabling a range it is necessary to configure the corresponding conversion factor between the

maximum voltage applied to the servo drive and the spindle velocity in rpm.

It is also possible to configure various "servo loop gain" values for each gear used by the spindle with

transducer during spindle orientation.

The parameters that configure this feature are:

• "Voltage for max RPM gear n"

• "Max speed for gear n".

10 Series CNC - AMP Software Characterization Manual (10) 1-19

Page 34

Chapter 1

General Concepts

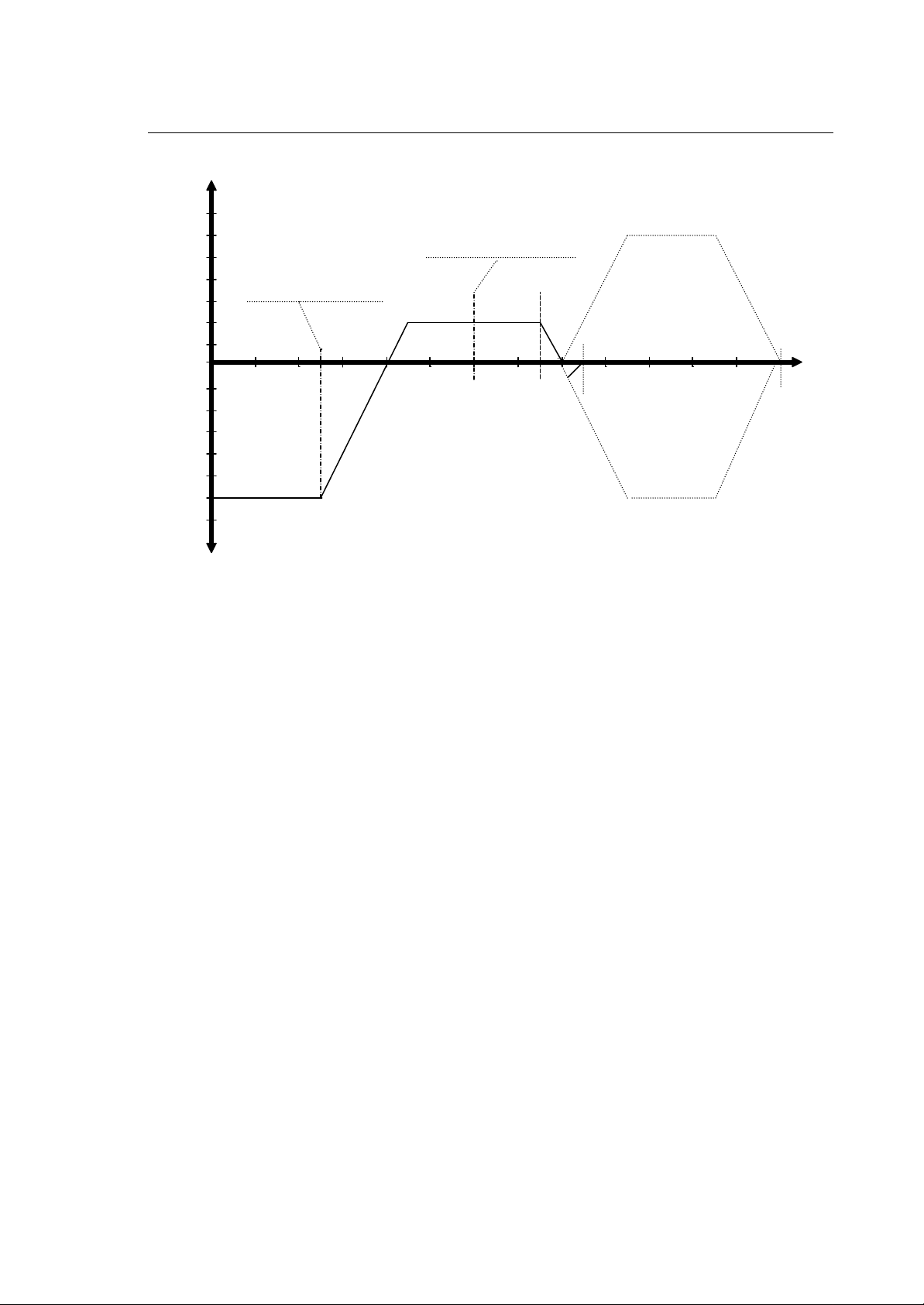

Spindle axis ramp

10 Series CNC permits to configure whether the converter voltage is to vary uniformly (i.e. follow a

variation ramp) or make a step when the programmed rotation speed varies.

In spindle drives this control is carried out by an input compensation net.

By using the potentialities of the control unit and disactivating the compensation network it is

possible to optimize spindle functionality, mainly for threading cycles and orienting.

Examples:

Spindle axis without ramp.

Volt

+7.5

-7.5

Spindle axis with ramp.

Volt

+7.5

-7.5

rt

To establish a ramp it is necessary to configure the "reversal time", i.e. the time employed by the

spindle for switching from the maximum clockwise rotation speed to the maximum counter clockwise

rotation speed with the gear that allows the lowest voltage/speed ratio. Such gear must also be

configured.

If the ramp is not configured, these parameters must nevertheless be specified because they are

used during tapping and boring canned cycles.

1-20 10 Series CNC - AMP Software Characterization Manual (10)

Page 35

Chapter 1

General Concepts

Spindle with trasducer

The position transducer has two basic applications:

1. execution of threading and tapping cycles

2. spindle orientation to a defined position.

Spindle orientation

With 10 Series CNC spindle orientation is made possible by the $SORIENT machine logic function.

To compensate the offset between the transducer electrical zero and the spindle physical zero it is

possible to define an "Offset for spindle orientation" in the AMP.

The orientation cycle is carried out in interpolated mode and requires definition of the following

additional parameters to define the execution type.

Speed for Spindle Orientation

This parameter defines the threshold of speed below that the control enables spindle positioning.

If the orientation request is made when the spindle rotates at a higher speed, the system will take the

spindle to a lower speed before enabling the positioning cycle.

Acceleration for Orientation

This parameter specifies the spindle acceleration during orientation.

Since the gears and the loads affect the spindle response, it is advisable to assign to this parameter

a value smaller than the result of the following calculation:

Vm

60

where:

VM Is the "Voltage for max RPM" defined for the gear used for setting the "Spindle

reversal time".

TR Is the "Spindle reversal time".

*

TR*0.5

1

10 Series CNC - AMP Software Characterization Manual (10) 1-21

Page 36

Chapter 1

General Concepts

Shared Spindle

The spindle can be shared among several processes i.e. it can be declared in a “master” process

(Spindle field = Yes) and can be used by other processes simultaneously or not (Spindle field =

Shared).

The spindle has to be declared with the same identifier in all processes which can use it, whereas the

spindle's characterization parameters (Spindle section) need only be declared for the master

process.

In order to use the functions associated with the Spindle (the S functions) in a process on

programming level, the spindle has to be programmed in the process.

The management of the spindle's sharing among several processes is handled by the machine logic

which has to accept the programming of the spindle in a process if it is already controlled by another

process.

1-22 10 Series CNC - AMP Software Characterization Manual (10)

Page 37

Chapter 1

General Concepts

HANDWHEEL

The handwheel is a position transducer connected to one of the encoder inputs of the axes board. It

permits to move an axis by a distance that is proportional to the angle variation of the transducer

position.

To ensure maximum accuracy, it must comply with the following requirements:

1. The axis to be moved must be a configured axis.

2. The axis and the handwheel must be configured on the same board.

3. The handwheel encoder input must not be associated to any other configured axis.

4. The axis associated to the handwheel must be in idle status, i.e. it cannot be in motion.

5. If the handwheel is active it is not possible to carry out axis motion and axis enable/disable

operations directly on the axis.

6. Scale factor, representing the correspondence between handwheel impulses and distance to be

covered by the axis, must be chosen correctly.

Scale factor in fact, must have a value sufficient to grant the axis a jumpless movement even when

the handwheel is moved very fast.

For ex.: if the scale factor is very high therefore, if each minimum movement of the handwheel

corresponds to a great axis movement, the axis itself could not be able to execute that movement

correctly.

A SERVO ERROR may be generated in this situation.

Modification of the configured servo error value might be necessary in order to

optimize the hamdweel's function (see "POSITION ERROR WITHOUT VFF"

description in chapter 5 of this manual)

ENABLE/DISABLE of handwheel is prompted through logic functions (See PLUS Library Manual)

10 Series CNC - AMP Software Characterization Manual (10) 1-23

Page 38

Chapter 1

General Concepts

PART PROGRAM-LOGIC INTERFACE

The dialogue between the part program and the machine logic can be synchronous or asynchronous.

Synchronous mode

In this mode the part program makes a series of requests that must be acknowledged before

execution. These functions include:

• motion start/end M functions

• spindle S functions

• tool T functions

• pseudo axes

T and S follow predefined rules, whereas M functions are configurable and can be adapted to more

specific requirements (refer to Chapter 4, Section "M Codes").

Asynchronous mode

This mode exploits the possibility to render a series of machine logic variables visible to the part

program.

In the system configuration (see Chapter 3, Section "Logic Configuration") each variable must be

associated to a mnemonics (which will be used by the part program) and to an optional initialization

value.

These variables do not lose their contents when the system is switched off.

Language expansion

Logic global variables make it possible for the part program to acquire information that is not directly

accessible.

For example, the part program can learn the axis position by using an M function in order to

command the PLUS logic to carry out the acquisition, write the result in a shared variable (GW or

GD) and eventually authorize the part program to resume execution.

M100 (M to request the position of the W axis)

@ COORD_W variable shared with PLUS

Part program:

N001 M3 X123.4 Y321.5 M100

N002 E10=@COORDINATE_W

N003 Y(E10/2)

The logic can use global variables also as preset values or as non-volatile memory. To render these

variables inaccessible to the part program they must not be associated to a mnemonics.

1-24 10 Series CNC - AMP Software Characterization Manual (10)

Page 39

Chapter 1

General Concepts

PSEUDO AXES

Pseudo axes are written in the program without being associated to actual system axes. They are

used for requesting the machine logic to execute specific functions. They have the same functionality

of the PRELUDE M function.

Among the typical pseudo axes functions are: regulation of the water jet, management of secondary

spindles, etc.

VIRTUAL AXES

They are used to define some functionalities in AMP like axes virtualization.

The only parameter to be configured is the Axis ID.

They don't have neither name nor characteristics.

USER INTERFACE

10 Series CNC provides a series of predefined video pages that can be enlarged to occupy the full

screen or reduced to quadrants that display information about one topic. The size and contents of the

video pages and the sequence in which they are displayed can be configured in the AMP (refer to the

"Human Interface" chapter in this manual).

Logic display

With the $WSCREEN PLUS function it is possible to write alphanumeric and or semigraphic color

characters in the display areas reserved for the machine logic.

The machine logic can also be used for developing those texts that vary through system operation.

The SYNOPTIC EDITOR utility, that is also available in the PLUS environment (see Plus User

manual), permits the predefinition for each screen of graphics that will be loaded at system bootstrap.

OEM softkey

The dialogue between the operator and the machine can be facilitated by creating a tree of softkey

menus. The meaning of each softkey is application specific and can be established by the machine

logic.

The softkeys are the tools that permit to give a command, i.e. enable a given machine logic area.

Within each area it is therefore necessary to establish the procedures for command recognition and

execution. In some cases, activation of the softkey must be accompanied by a data input.

The interactions between the system and the operator can be developed by composing the video

screens that will be under machine logic control. Such screens prompt the operator to select a

course of action by means of the OEM softkeys and/or to input additional bits of information.

10 Series CNC - AMP Software Characterization Manual (10) 1-25

Page 40

Chapter 1

General Concepts

VARIABLE SERVO ERROR

The “Variable Servo Error” feature consists in a new logic control of the Servo Error during axis moves.

Usually the Servo Error is taken as absolute (i.e. it is directly compared with the axis tracking error).

This new feature allows to consider the Servo Error as an additional element to be added to the

theoretical tracking error, the axis is accumulating during its move based on the programmed

parameters (speed, gain, active or inactive VFF and VFF%).

During the move the algorithm calculates the theoretical axis error (based on its instantaneous speed)

to which it adds the configured delta plus the error accumulated during the delay due to the

positioning loop. Then this sum is compared to the tracking error.

The error accumulated during the feedback delay is calculated on the basis of the rapid acceleration

and is equal to:

Epsi_delay = rapid acc / (kv * 16.6666)²

Here 'rapid acc' and 'kv' are in the measurement units of the AMP.

THIS SUM IS ONLY CALCULATED ONCE AT START-UP AND NOT

CHANGED THEREAFTER.

In order to enable this feature you have to set the value of the movement Servo Error without VFF so

that it is smaller than the theoretical error calculated with maximum speed (the “Maximum Feed” field

in AMP) with VFF at zero. Once enabled, the algorithm becomes active for moves with as well as

without VFF and takes the delta value from the pertinent configured Servo Errors.

The algorithm becomes active at the start of a move if a comparison shows that the Servo Error value

is smaller than the theoretical maximum (which is calculated only once at start-up on the basis of the

data configured in AMP). If this condition is not met, the algorithm does not start and the Servo Error

is taken as an absolute value in the usual manner.

The algorithm does not become active if a VFF% equal to zero has been configured. If you want to

enable it on an axis which moves with the predefined error only, you have to enter a value different

from zero into the VFF% field.

The algorithm does not become active, when a VFF value equal to 100% has been configured on the

axis during a VFF move (the theoretical error is then zero, therefore the value of the configured Servo

Error is directly applied).

For Split axes the feature only works on the master axis.

The feature is not enabled for spindle type axes, axes with digital interface and with the Electronic

Cam feature.

Change of parameters by the Servo Monitor may change the Servo Error application algorithm.

1-26 10 Series CNC - AMP Software Characterization Manual (10)

Page 41

Chapter 1

General Concepts

Example 1 :

maximum feed = 4000 mm/min

acceleration = 300 mm/sec²

Servo Loop gain = 1

Position Error with VFF = 5 mm

Position Error without VFF = 5 mm

VFF% = 100

The theoretical error for comparison at maximum feed without VFF results as 4 mm.

Given that the “Position Error without VFF” is set to 5, the algorithm is not enabled and Servo Error

emergency is triggered, when the error exceeds 5 mm.

Example 2 :

maximum feed = 4000 mm/min

acceleration = 300 mm/sec²

Servo Loop gain = 1

Position Error with VFF = 1.5 mm

Position Error without VFF = 2.5 mm

VFF% = 100

As in the previous example the theoretical error is 4 mm.

For moves with VFF the “Position Error without VFF” is set to 1.5, but the algorithm is not enabled,

because VFF is equal to 100%. Hence Servo Error emergency is triggered when the error exceeds

1.5 mm.

For moves without VFF the “Position Error without VFF” is set to 2.5 (i.e. smaller than 4). Therefore

the algorithm is enabled and the error delta is 2.5 plus the delay equal to 300 / (16.666)² = 3.58. If the

current feed is 2000 mm/min, Servo Error emergency is triggered when the error exceeds 2 + 3.58 =

5.58 mm.

Example 3 :

maximum feed = 4000 mm/min

acceleration = 300 mm/sec²

Servo Loop gain = 1

Position Error with VFF = 1.5

Position Error without VFF = 2.5

VFF% = 50

As before the theoretical error for comparison is 4 mm.

10 Series CNC - AMP Software Characterization Manual (10) 1-27

Page 42

Chapter 1

General Concepts

For moves with VFF the error delta with VFF is 1.5. Assuming a feed of 2000 mm/min is

programmed, the theoretical error is 1 mm (as the current feed will be with VFF at 50%). Therefore

the Servo Error emergency triggers when the error exceeds 1 + 1.5 + 300 / (16.666)² = 3.58 mm.

For moves without VFF the error delta is 2.5. With a feed of 3000 mm/min the Servo Error emergency

triggers when the error exceeds 3 + 2.5 +1.08 = 6.58 mm.

END OF CHAPTER

1-28 10 Series CNC - AMP Software Characterization Manual (10)

Page 43

Chapter

2

AMP

AMP (Adjustable Machine Parameters) is one of the utilities installed in the OEM Utility partition of

the system. AMP allows the user to set the parameters that define the various processes to be run

by the machining centre.

To enter the AMP utility, press the softkey UTILITY in the general 10 Series CNC screen.

HELP

OEM SOFTKEYS

UTILITY

10 Series CNC general screen

AMP utility selection

AMP

Access to the AMP utility is also possible with the system in emergency, i.e. by holding down key

[F1].

SOFTKEY

There are seven softkeys to handle the configuration environment:

by pressing the right most softkey the operator can select the menu line that contains the desired

item with a loop cycle (the selected line is displayed in a different colours)

the middle softkeys correspond to the items of the selected line. By pressing one of these softkeys,

the operator can access the desired data entry

by pressing the left most softkey the operator can always return to the main menu.

10 Series CNC - AMP Software Characterization Manual (06) 2-1

Page 44

Chapter 2

AMP

AMP main menu

When AMP is activated, the first displayed menu is shown in the following picture:

date: dd/mm/yy

ACTIVATED AMP RUNNING AMP

time: hh:mm:ss

COMPILED

Y

N

INFORMATION

BOX

CONFIGURATION

STATUS

Configuration

0 - 3

Adjust Machine Parameters

SELECTED AMP

3 0 0

-- A M P D I R E C T O R Y L I S T --

0 - DEFAULT

1 - DEFAULT

2 -

3 -

CURSOR

ACTIVATE SELECT

BACKUP

EDIT COMMENT

DELETE PRINT

SOFTKEYS

HELP

EXIT

AMP utility allows to manage 4 different configurations; this is very useful to switch from one

configuration to another one.

The configurations are numbered from 0 to 3 and can associate a comment (that is displayed close

the configuration number).

The desired configuration can be selected using the arrows keys:

The blue cursor will highlight the request configuration.

2-2 10 Series CNC - AMP Software Characterization Manual (06)

Page 45

Chapter 2

AMP

INFORMATION BOXES

• Selected AMP

It is the selected configuration to be modified

• Activated AMP

It shows the configuration that will be used on the next power up.

• Running AMP

It shows the configuration that was used during the last (current) power up.

CONFIGURATION STATUS

• Y The AMP configuration has been compiled successfully

• N The AMP configuration has not been compiled or the compilation was not ended

successfully

• (Empty) The AMP directory is void.

CURSOR AND CONFIGURATION

• They highlight one of the 4 possible configurations.

SOFTKEYS

• They allows to activate the possible functions. They will be explained in detail in the following

pages.

Help

At any moment during the AMP configuration, the user can display additional information about a

certain parameter or sub menu by selecting the HELP softkey. This help text is displayed within a

window on the right side of the screen and varies according to the context in which it has been

activated: if the user has selected the HELP softkey when a menu is on the screen, the help text will

contain information about that specific menu (data entries and associated parameters); if Help is

activated when a data entry is on the screen, the help text will contain information about parameter

values (range, restrictions, measuring, unit, etc.).

10 Series CNC - AMP Software Characterization Manual (06) 2-3

Page 46

Chapter 2

HARDWARE

LOGIC CONF

AMP

Activate

Activates the configuration (0-3) selected via the arrow keys and highlighted by the blue bar.

The configuration number is displayed in the central information box.

This configuration will be used by 10 Series CNC on the next power up.

Trying to activate a configuration that was not previously compiled, the error

"AM155 AMP directory can not be activated: binary file does not exist" is

generated.

To get information regarding the compilation, see also the section regarding the

SELECT softkey.

Select

Opens the characterization, this will be ended pushing the EXIT softkey.

See also the "Enter/Exit the characterization" paragraph.

T

SELEC

first line

SELECT PROCESS

BACKUP

PROCESS CONFIG

AXIS CONFIG

AMP main menu

Characterization menu

OPTIONS

HUMAN INTERF

HELP

EXIT

third line

second line

2-4 10 Series CNC - AMP Software Characterization Manual (06)

Page 47

Chapter 2

AMP

Characterization menu softkeys

The first line of the characterization menu included the following softkeys for global parameter

configuration (chapter 3).

• HARDWARE data entry Hardware configuration of the system

• GENERAL INFO data entry General information for configuration

(measuring unit, number of configurable processes, logic

variables)

• LOGIC CONF sub menu (LOGIC CONFIGURATION)

• BOOLEAN VAR (Booleans variables)

• SHORT VAR (Short variables)

• DOUBLE VAR (Double variables)

• AUX GEN INFO (Auxiliary axes general information)

• SELECT AUX (Auxiliary axes selection)

• AUX CHARACT (Auxiliary axes characterization)

• PHYSICAL CONN (Physical connection)

• AXIS CALIBR (Axis calibration)

• Option sub-menu

• DOS REAL-TIME (Real-time DOS Interface)

• UND USER DOS (End User Dos utility)

• DOS GRAPHICS (DOS Graphic Utility Interface)

• HELP Help text

The second line includes the following softkeys associated to process related functions.

• SELECT PROCESS data entry (PROCESS SELECT)

It is meaningful for multi process systems only and allows

to select the process to be configured. All the information

that follows is related to the selected process.

10 Series CNC - AMP Software Characterization Manual (06) 2-5

Page 48

Chapter 2

AMP

• PROCESS CONFIG sub-menu (PROCESS CONFIGURATION)

• GTL (High level geometry)

• VIRTUAL AXES (Virtual axes)

• E PARAMETERS (E variables)

• USER VARIABLES (User variables)

• PRO CHAR (Process characterization)

• PROC VARIABLES (Process variables)

• PROGR CHAR (Program characteristics)

• M CODE (M code)

• G CODE (G code)

• AXIS CONFIG sub-menu (CO-ORDINATE AXES CONFIGURATION)

• AXES GEN INFO (Co-ordinate axes general information)

• PSEUDO AXES (Pseudo axes)

• SPINDLE (Spindle characterization)

• PROBING (Touch probe)

• SELECT AXIS (Axis selection)

• AXIS CHARACT (Axis characterization)

• AXIS CALIBR (Axis calibration)

• PHYSICAL CONN (Physical connection)

• HUMAN INTERF sub-menu (OPERATOR INTERFACE)

• HI GEN INFO (Operator interface general information)

• ADD SCR CONFIG (Additional screen configuration)

• COMMON SCREEN Not available

• PROCESS SCREEN (Process screen cycle)

• SELECT MENU (OEM menu selection)

• OEM SK CONFIG (OEM softkey configuration)

• SELECT DE (OEM data entry selec tion)

• DE CONFIG (OEM data entry configuration)

• PPDIR CONFIG (Part program directory configuration)

The third line of the menu includes the EXIT softkey

• EXIT (Exit for the characterization session).

2-6 10 Series CNC - AMP Software Characterization Manual (06)

Page 49

Chapter 2

AMP

Operativity notes

When the user has selected the desired data entry with the proper softkeys, he can start defining the

associated parameters with the alphanumeric keyboard.

The cursor is automatically positioned on the value field of each parameter. The operator can accept

the displayed value or he can insert a new one. If necessary, the operator can move the cursor by

using the arrow keys.

The correct range of values for each parameter is shown in the Help window that the operator can

display by pressing the HELP softkey.

In some cases the permissible range is displayed as a list (for example, user variable names, coordinate axis names, etc.).

For each entered value, AMP performs range and congruency checks. In case of mistakes, the

relevant error message is displayed (see Appendix A) and the cursor remains on the wrong

parameter.

Some data entries can be listed on more than one screen page. The user can display the various

pages by using [Pg Dn] and [Pg Up] keys.

Data Entry Storage

Once the data entry has been completed, the user can confirm and store it in the AMP files, by

pressing the [Enter] key.

To abort a data entry it is possible to press the [Esc] key.

10 Series CNC - AMP Software Characterization Manual (06) 2-7

Page 50

Chapter 2

AMP

ENTER/EXIT THE CHARACTERIZATION

10 Series CNC manages up to 4 "on line" configurations.

When the SELECT softkey is used to modify the selected configuration (0, 1, 2 or 3), this is copied in

a work directory.

All the changes will be made in the work directory.

Following configuration (press EXIT), there are 3 alternatives:

1. Perform the secondary calculations transforming the information entered (source files) into a

configuration that may be used by the bootstrap (binary files).

2. Save the data entered without performing the secondary calculations (this may also be useful in

cases where errors that cannot be eliminated at the time are signalled during the secondary

calculations but you want to save the changes made in any case). In this case, any binary files

generated previously are lost and care must be taken because, if the AMP directory was the

active one, on rebooting the system will not find the binary configuration files and the control will

have to be started in emergency mode to generate and activate an AMP configuration.

3. Do not save the new configuration. In this case any changes made are lost. If there were binary

files for the previous configuration, these will be maintained as the source files from which they

were generated have not been changed. You are advised to use this exit mode when entering the

configuration for consultation to avoid losing the binary files.

Remember the meaning of the terms Source and Binary for the AMP utility:

SOURCE FILES contain the information entered with the data entry.

BINARY FILES files generated by the secondary calculations and actually used by 10

Series CNC to configure the machine on starting (BOOTSTRAP).

Examples:

• If you press SELECT (see figure) configuration no. 1 becomes the working configuration.

AMP directory Working directory

AMP0

Select

AMP1

AMP2

EXIT

AMP3

2-8 10 Series CNC - AMP Software Characterization Manual (06)

Page 51

Chapter 2

HELP

EXIT

-- EXIT --

Translate new parameters? (Y/N)

Y

HELP

EXIT

-- EXIT --